Continuous casting machine for stainless compound steel plate strip blank

A composite strip and stainless steel technology is applied to near-net shape continuous casting equipment and continuous casting of stainless steel composite strip blanks. It can solve the deformation and wear of the cooling steel belt, limit the casting speed of the casting slab, and affect the service life of the cooling steel belt, and achieve the effect of increasing the casting speed of the casting slab, improving the service life, and eliminating the dummy mechanism and vibration device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

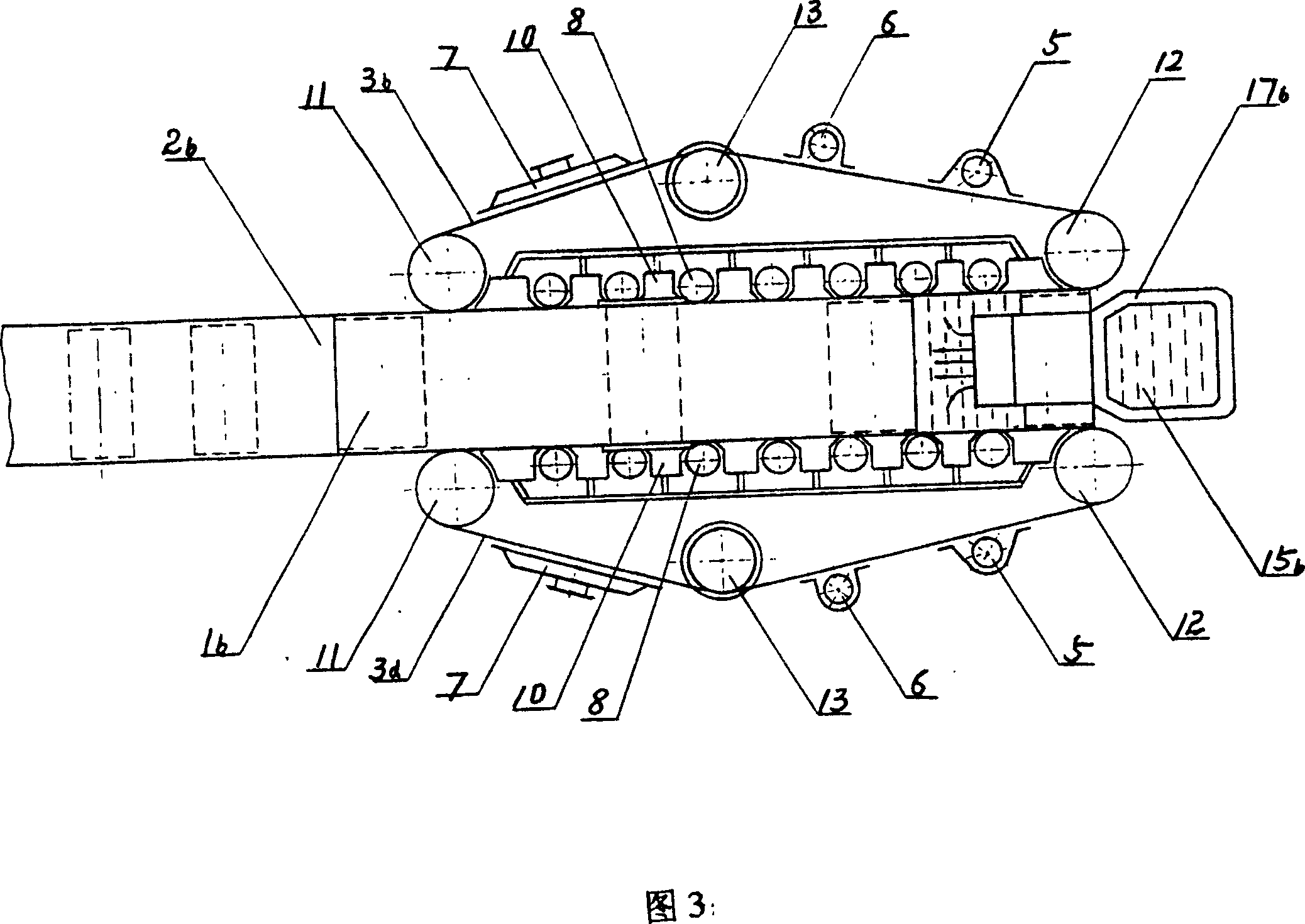

[0041] 1. (See Figure 1) When producing stainless steel double-sided composite slab blanks, stainless steel water 15 is poured into crystallizer A through stainless steel water tundish 16 and stainless steel water casting tank 17; stainless steel water 15b is cast through stainless steel water tundish 16b and stainless steel water The tank 17b is injected into the crystallizer B, moves downward synchronously with the crystallizers A and B, and gradually cools and crystallizes into a stainless steel strip blank, and enters the crystallization together with the lower cooling steel strips 2 and 2b of the crystallizers A and B when cooled to an appropriate temperature At this time, the low-carbon molten steel 18 is injected into the gap reserved between the two stainless steel strip blanks of the crystallizer C through the low-carbon molten steel tundish 19 and the low-carbon molten steel casting tank 20. Device C continues to move downward synchronously. At this time, the inner si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com