Stepped cooling and continuous casting method of massive amorphous alloy

An amorphous alloy, step-by-step cooling technology, which is used in the continuous casting of amorphous alloys and the continuous casting of zirconium-based bulk amorphous alloys by step cooling , to achieve the effect of shortening the production cycle, saving mold manufacturing costs, and simple process methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

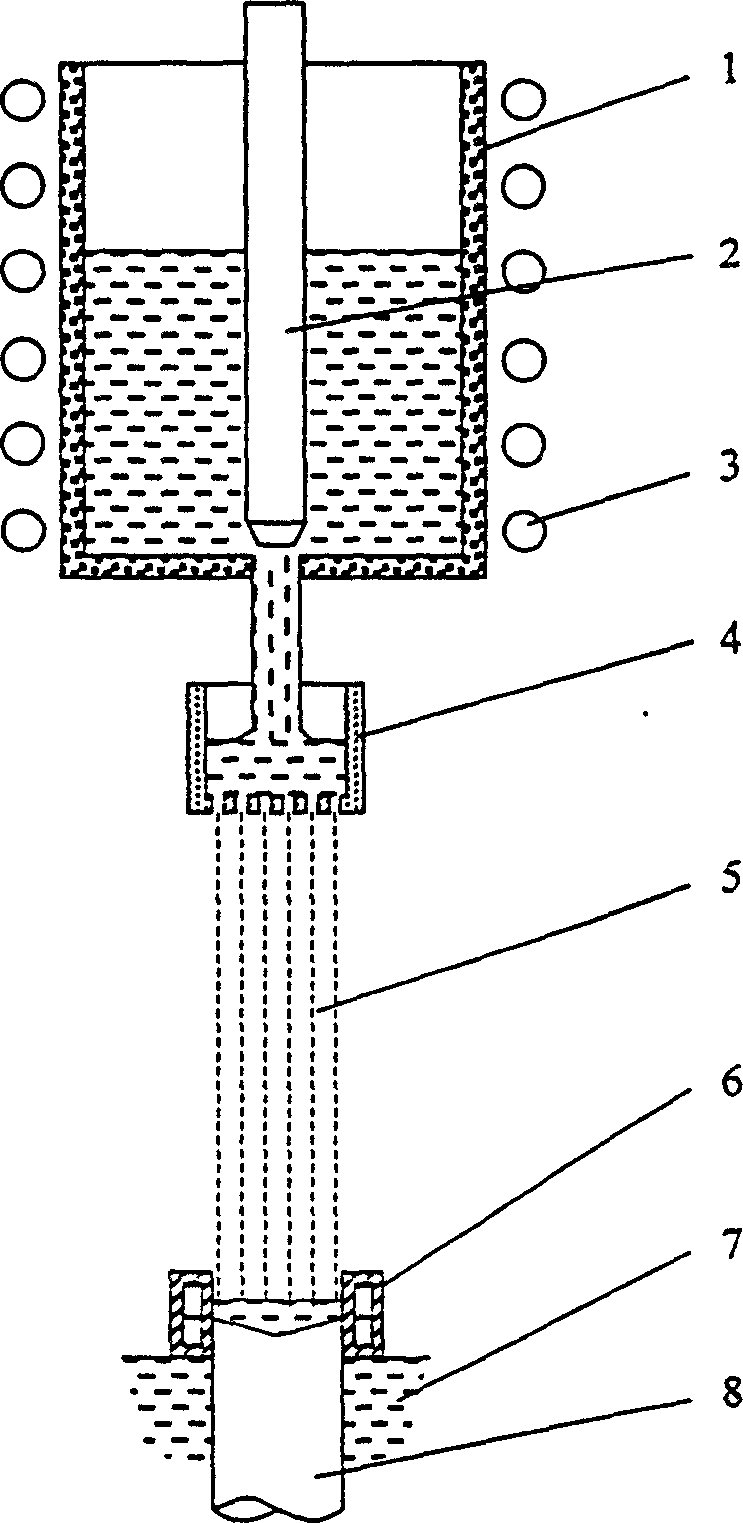

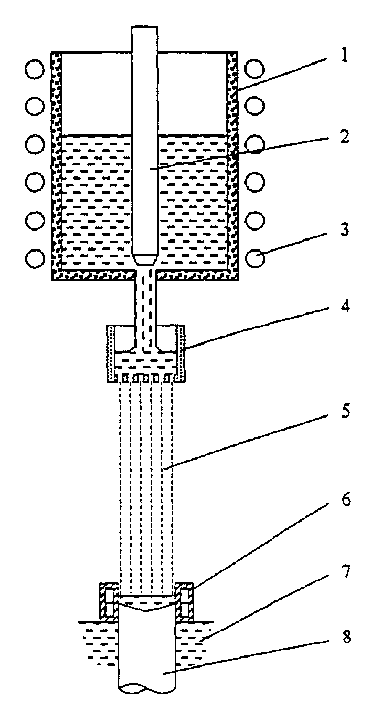

[0022] As shown in the figure, the continuous casting device of the present invention adds a liquid flow disperser 4 on the basis of the existing device. There is a heating element 3 on the outside of the crucible 1, and a column with an adjustable flow rate is placed in the middle of the crucible 1. There is a liquid flow diffuser 4 under the plug 2 and the crucible 1, and a condenser 6 filled with cooling liquid 7 is arranged under the liquid flow diffuser 4.

[0023] The alloy is melted and overheated in the crucible 1 (resistance heating, induction heating or other heating methods are acceptable), and poured into the liquid flow distributor 4 made of refractory material, and its flow rate can be controlled by adjusting the lifting height of the plunger 2 . The alloy liquid is divided into many fine streams after passing through the liquid flow disperser 4, and such streams are cooled in the process of free fall, and the cooling intensity is controlled by adjusting the type,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com