Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

277 results about "Melting heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

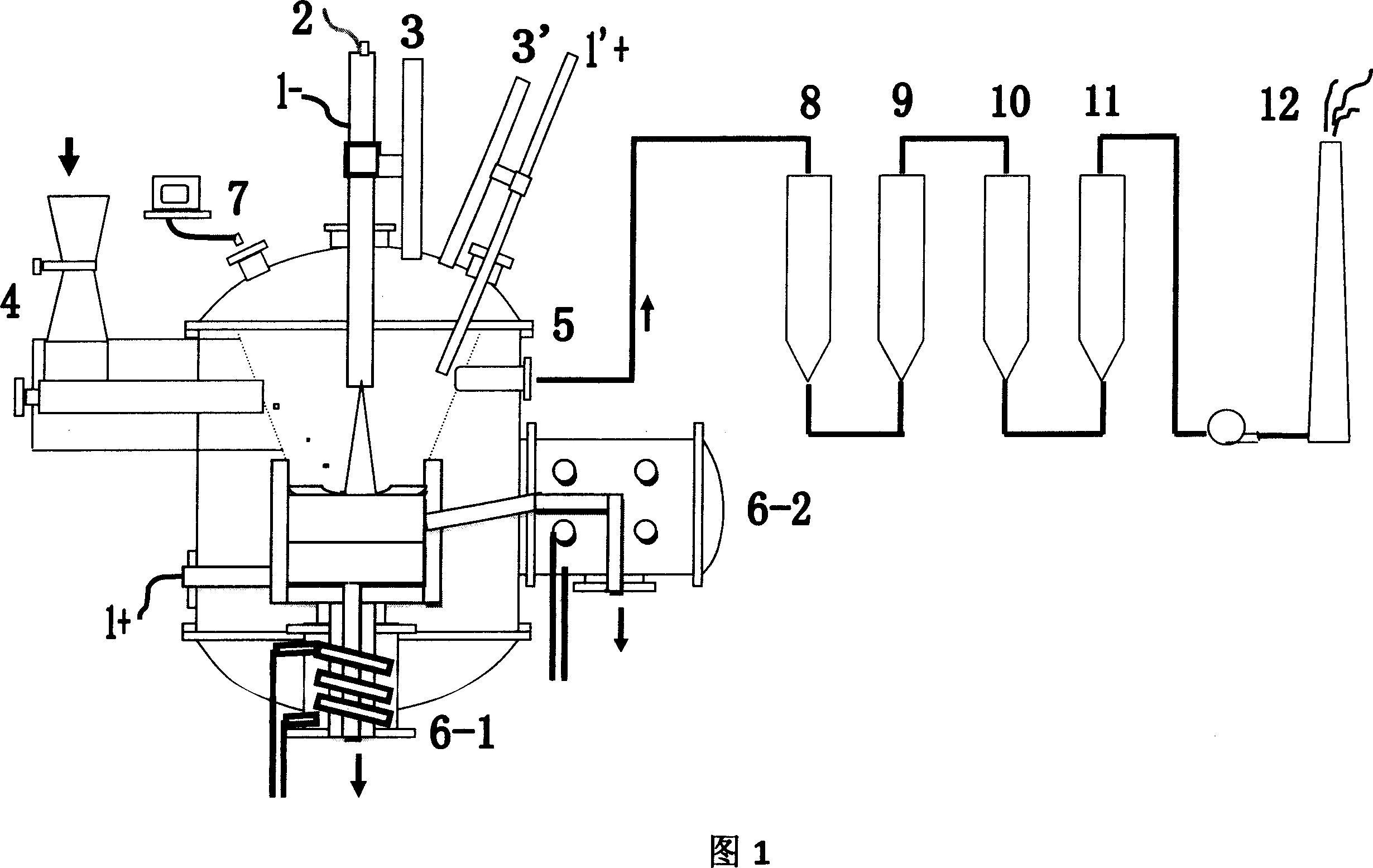

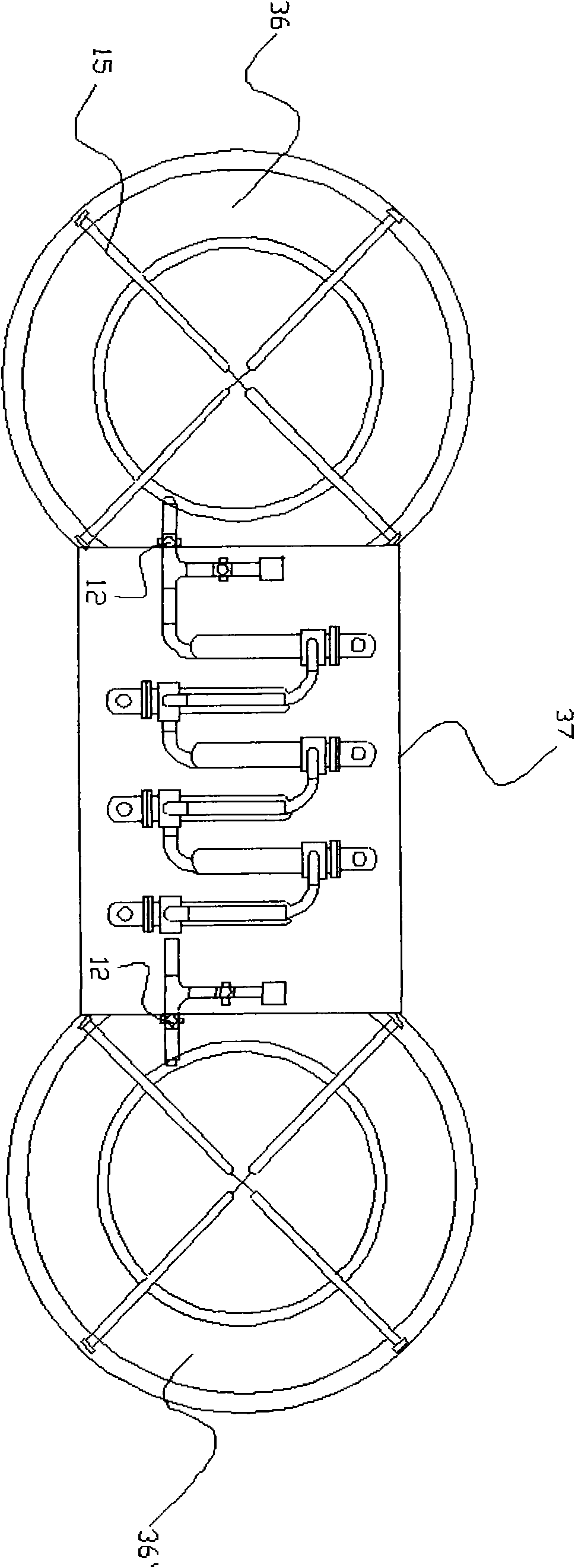

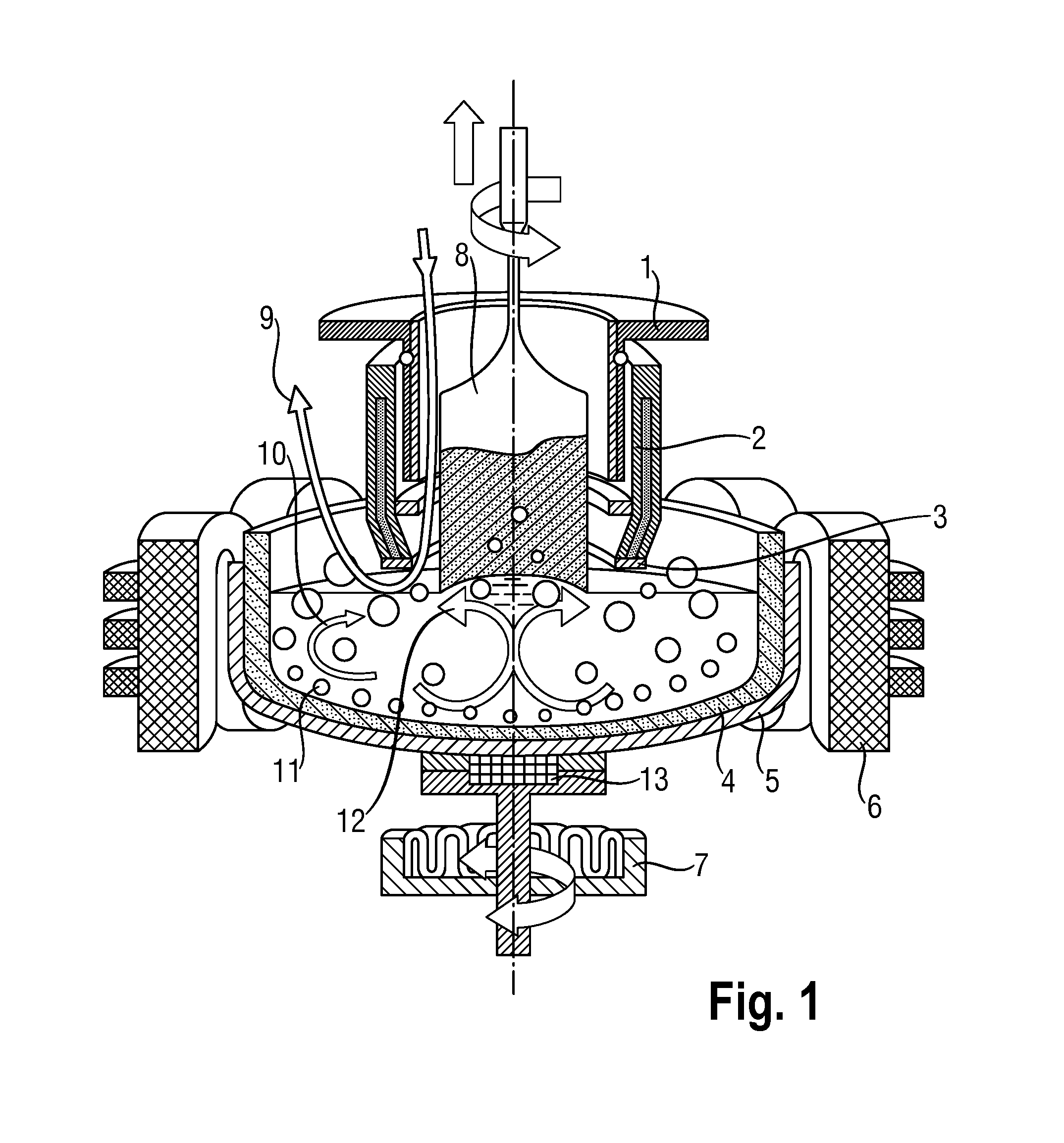

Poisonous waste treating method and special apparatus

InactiveCN101088581AAvoid secondary pollutionReduce processingDispersed particle separationCombined combustion mitigationHigh energyPolychlorinated biphenyl

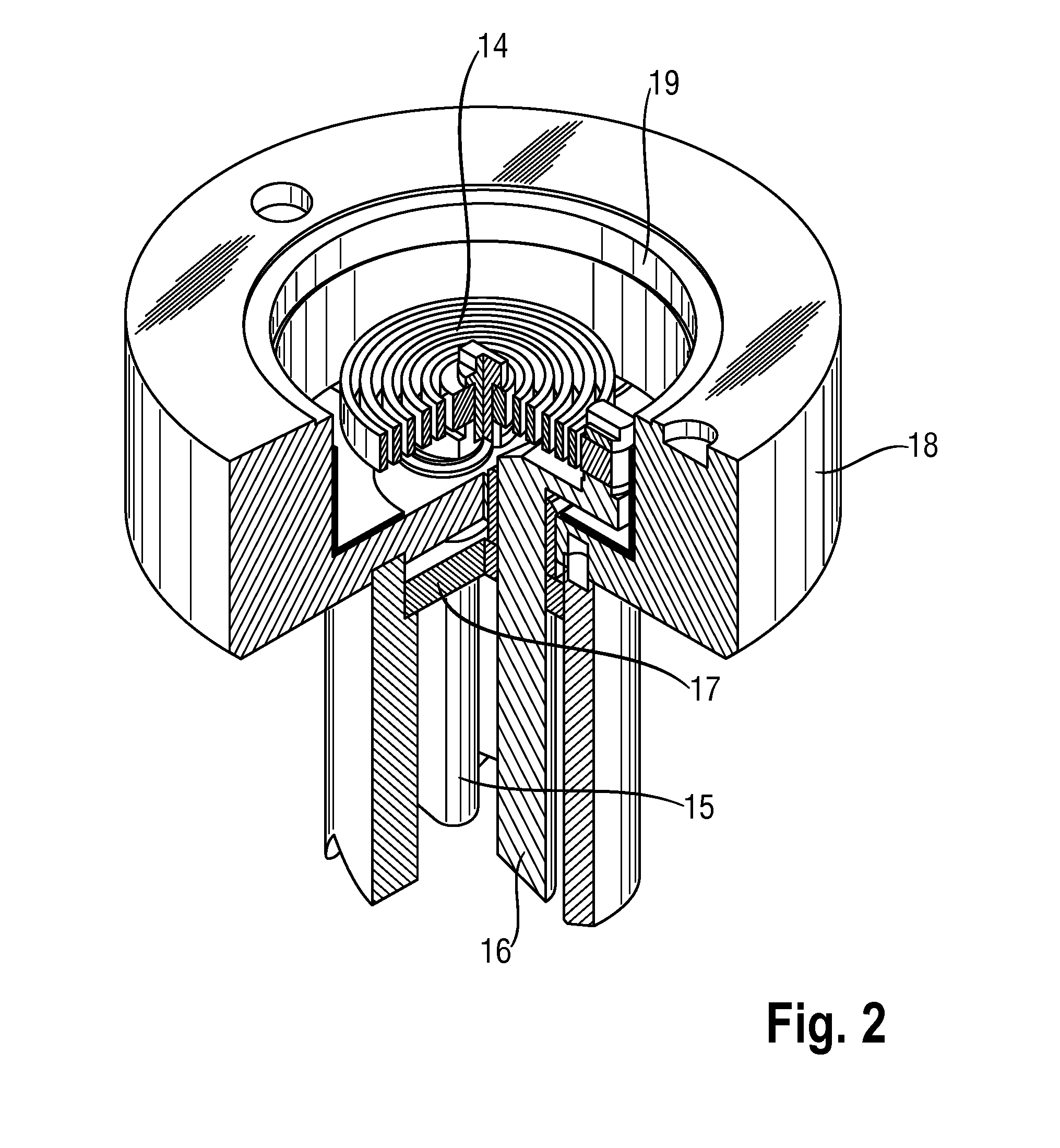

The present invention relates to poisonous waste treating method and apparatus, and belongs to the field of waste treating technology. The poisonous waste treating apparatus is plasma apparatus comprising a furnace body, a main graphite electrode and an auxiliary graphite electrode connected to the cover of the furnace body, carrier gas supplier connected to the main graphite electrode, a feeder, a vitreous body exhausting heat pump, a metal melt heat pump, a crucible inside the furnace body, a lower electrode in the bottom of the furnace body, a liquid level sensor connected to the sensor controller, and a tail gas exhausting system connected to the furnace body. It is used in treating polychlorinated biphenyl and other high dangerous waste through instantaneous high temperature, and has no secondary pollution, capacity of recovering high energy gas, and capacity of recovering metals.

Owner:HOOTECH

Toner binder and toner

A toner excellent in low temperature fixability and blocking resistance, and a toner binder are provided. The present invention is a toner binder containing a crystalline resin (A) having a maximum peak temperature of heat of fusion (Ta) of 40 to 100° C., a ratio between the softening point and Ta (softening point / Ta) ranging from 0.8 to 1.55, and a melting start temperature (X) within a temperature range of (Ta±30)° C., and satisfying the following requirements; and a toner containing the toner binder and a coloring agent:[Requirement 1] G′(Ta+20)=50 to 1×106 [Pa][Requirement 2] |log G″(X+20)−log G″(X)|>2.0[G′: storage elastic modulus [Pa], G″: loss elastic modulus [Pa]].

Owner:SANYO CHEM IND LTD

Method for detecting high-temperature mineralization characteristic of sintered iron ores

InactiveCN102809579AScientificPracticalInvestigating phase/state changeAbsorption capacityReaction temperature

The invention discloses a method for detecting the high-temperature mineralization characteristic of sintered iron ores. The quality and performance of iron ores which are applied to the sintering are evaluated by detecting indexes of iron ore powder / CaO reaction of the iron ores such as initial temperature, reaction rate, post-reaction strength and reaction melting heat in the high-temperature mineralization process. By the method, multiple characteristics such as initial reaction temperature, maximum reaction rate, reaction heat absorption capacity, liquid-phase flowability and binding-phase strength can be detected in the same equipment in the same test, so the invention is characterized in that the measurement method is simple and high in detection speed and detection results are accurate. By the method for detecting the high-temperature mineralization characteristic of the sintered iron ores, the corresponding relation between maximum reaction rate, reaction heat absorption capacity and binding-phase strength properties and yield, quality and energy consumption indexes of sintered ore is established, so the method is scientific and practical.

Owner:UNIV OF SCI & TECH LIAONING

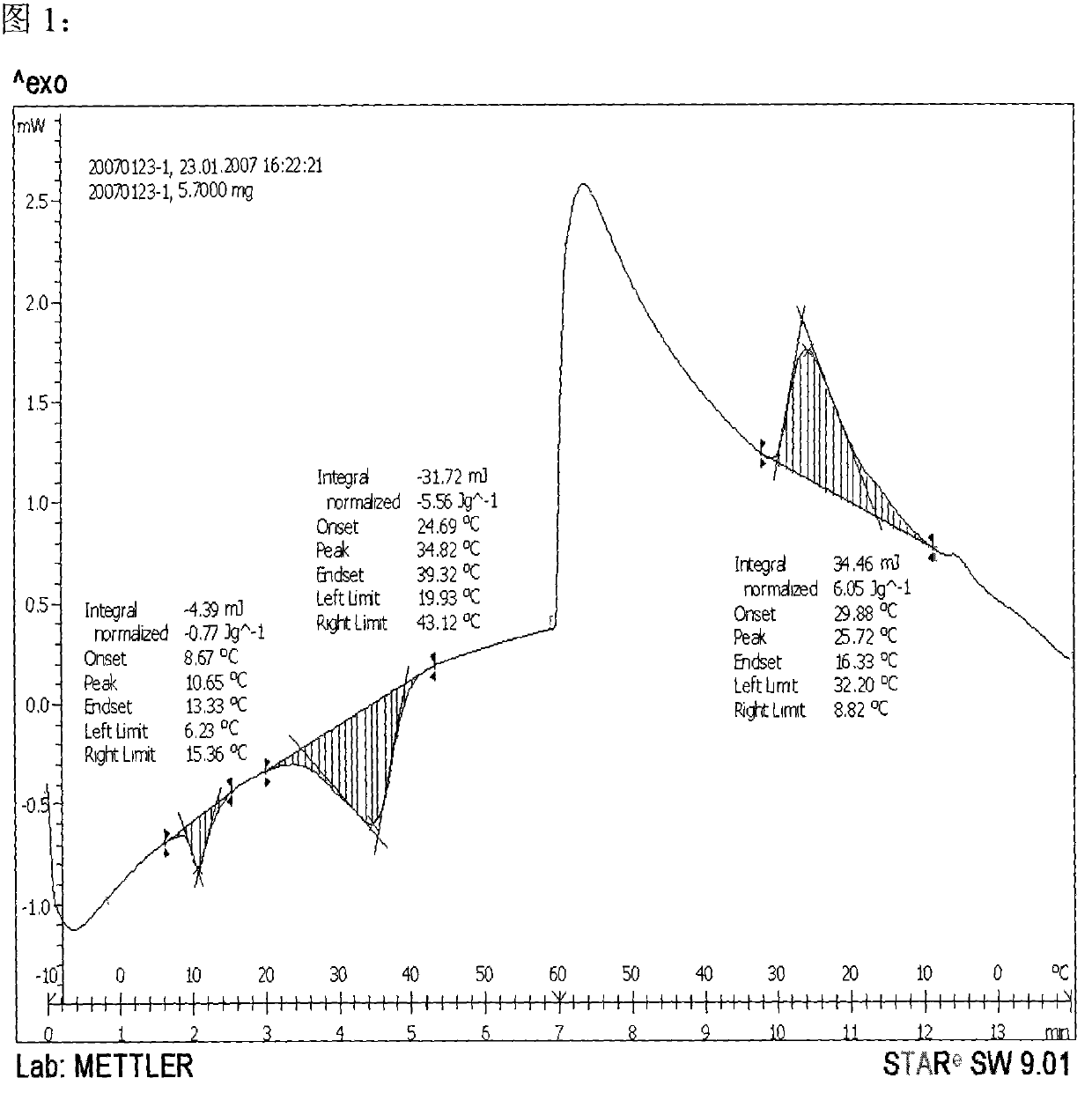

Intelligent temperature-adjusting viscose fibre and its production

InactiveCN101029421AGood textile propertiesArtificial filaments from viscoseCelluloseBreakdown strength

A phase-variable material micro-capsule as temperature-adjusting functional material, an intelligent temperature-adjusting viscose fiber and its production are disclosed. Dry breakdown strength is >=1.42CN / dtex, wet breakdown strength is>=0.64CN / dtex; It consists of cellulose 84.7-92.75wt%, micro-capsule 5-30wt% and water-content 7-15wt% and oil solution 0.15-0.30wt%. The fiber coagulation heat-liberation enthalpy valueDeltaH>=1.0J / g, melt heat-adsorption enthalpy value DeltaH>=1.0J / g. It is non-toxic, has better adaptability and no harm.

Owner:HEBEI JIGAO CHEM FIBER +1

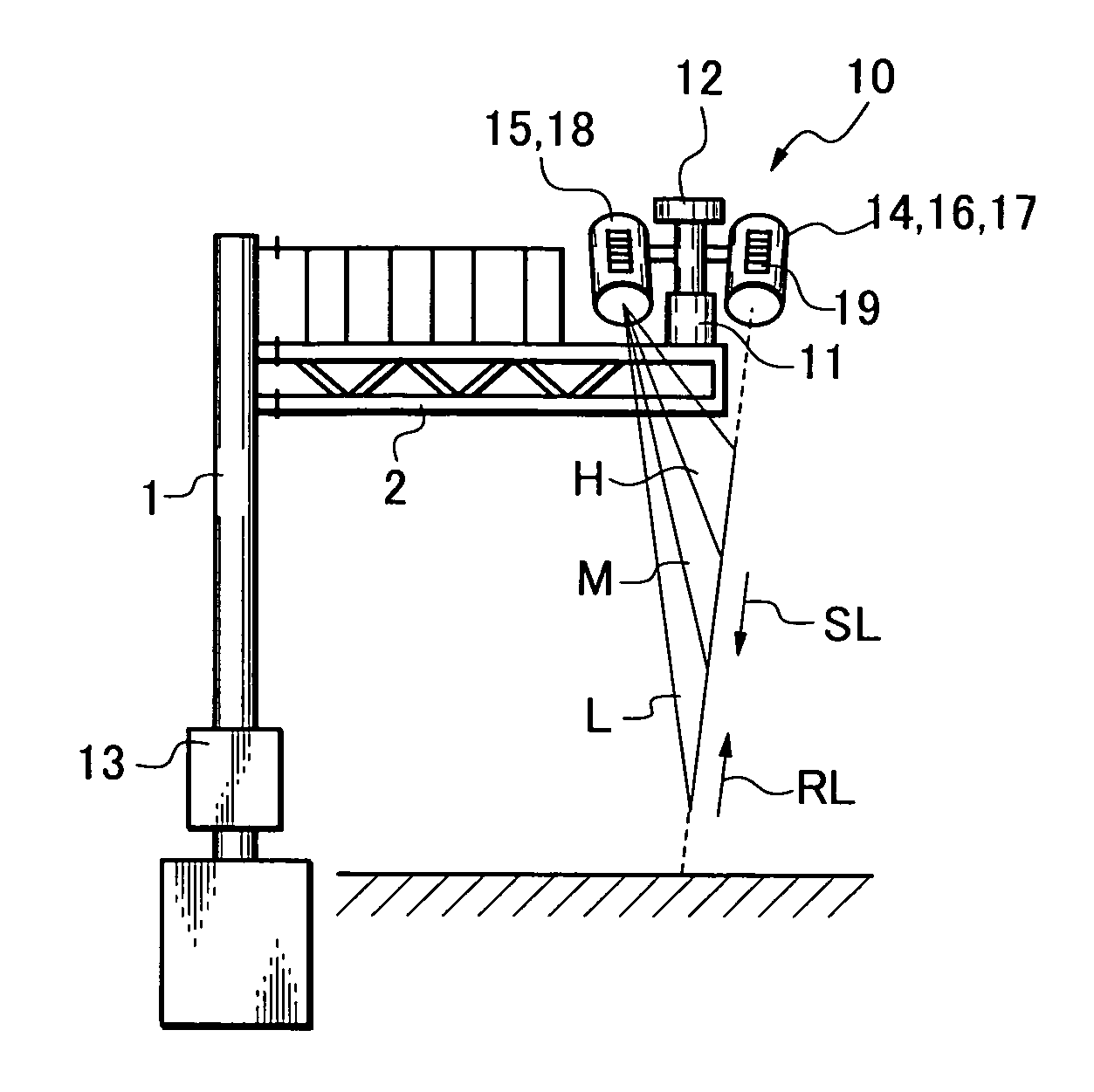

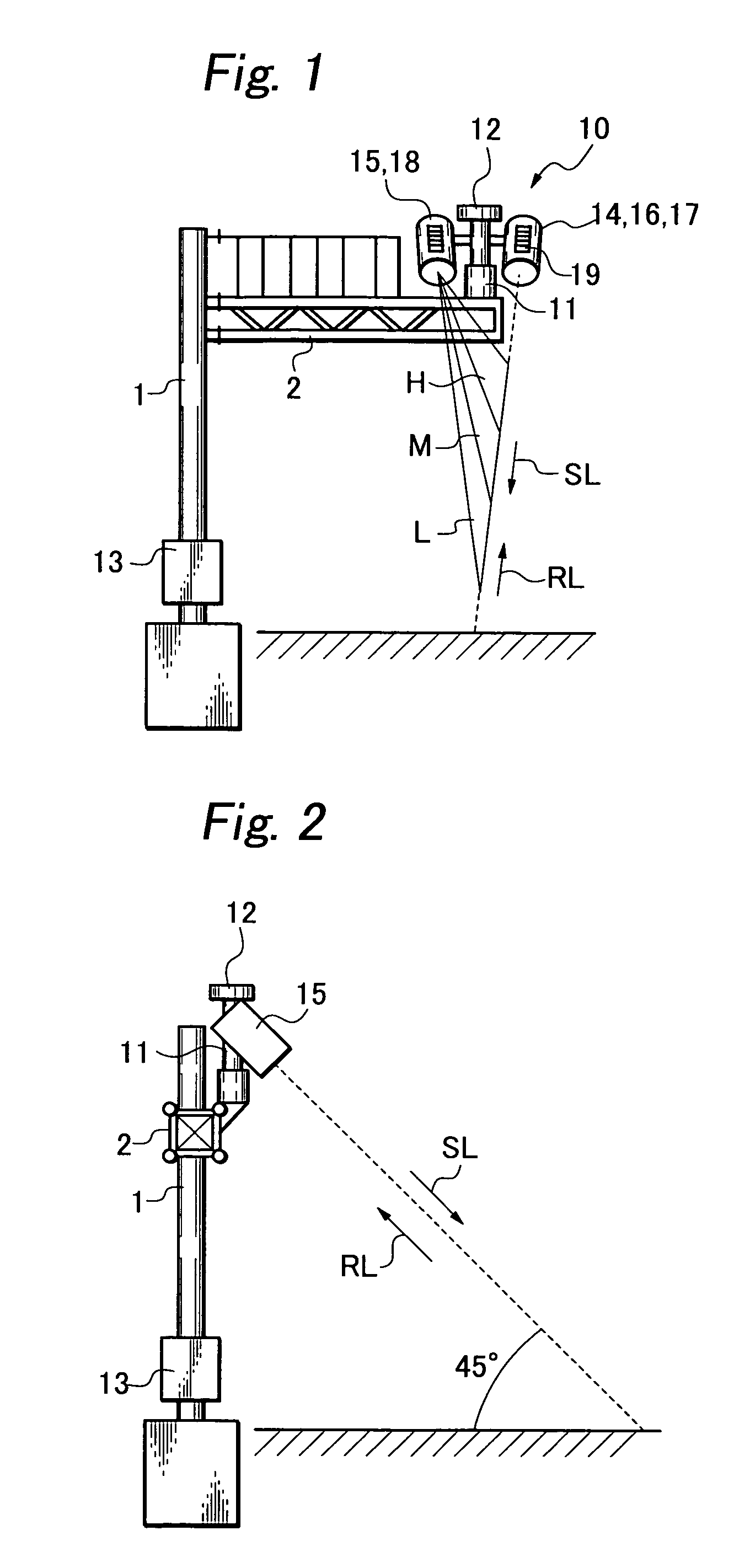

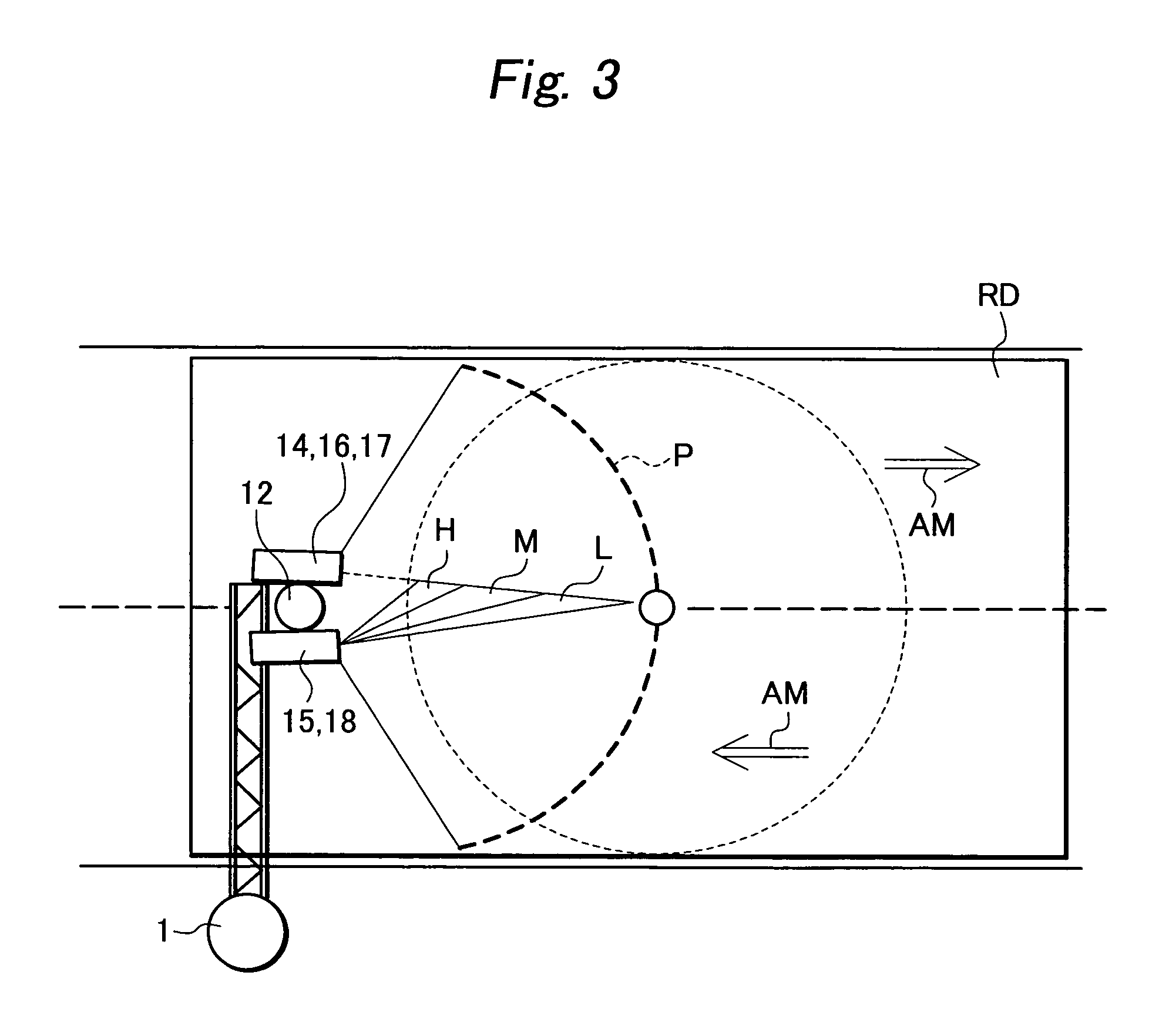

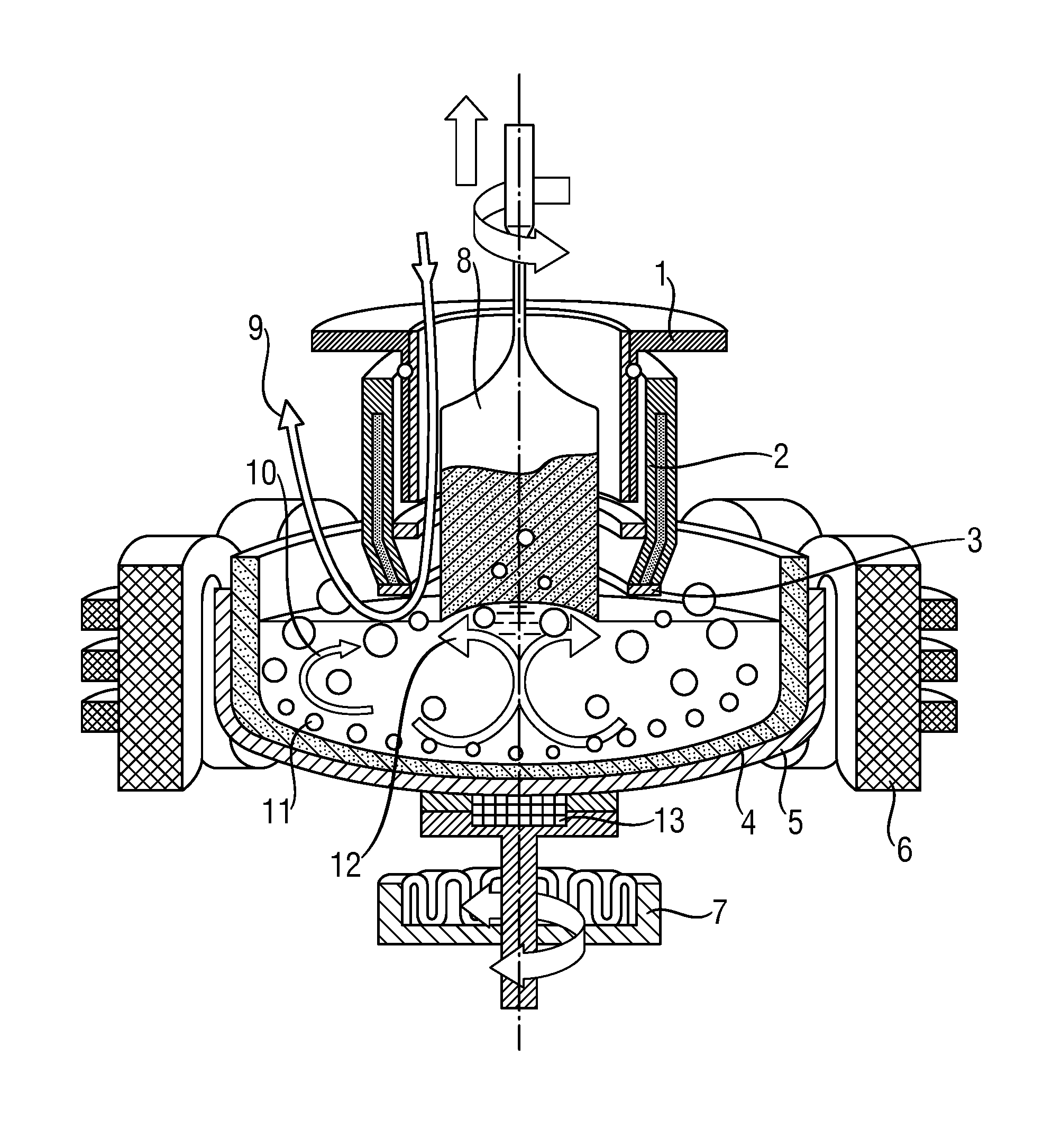

Road surface sensor and monitoring control method for road surface

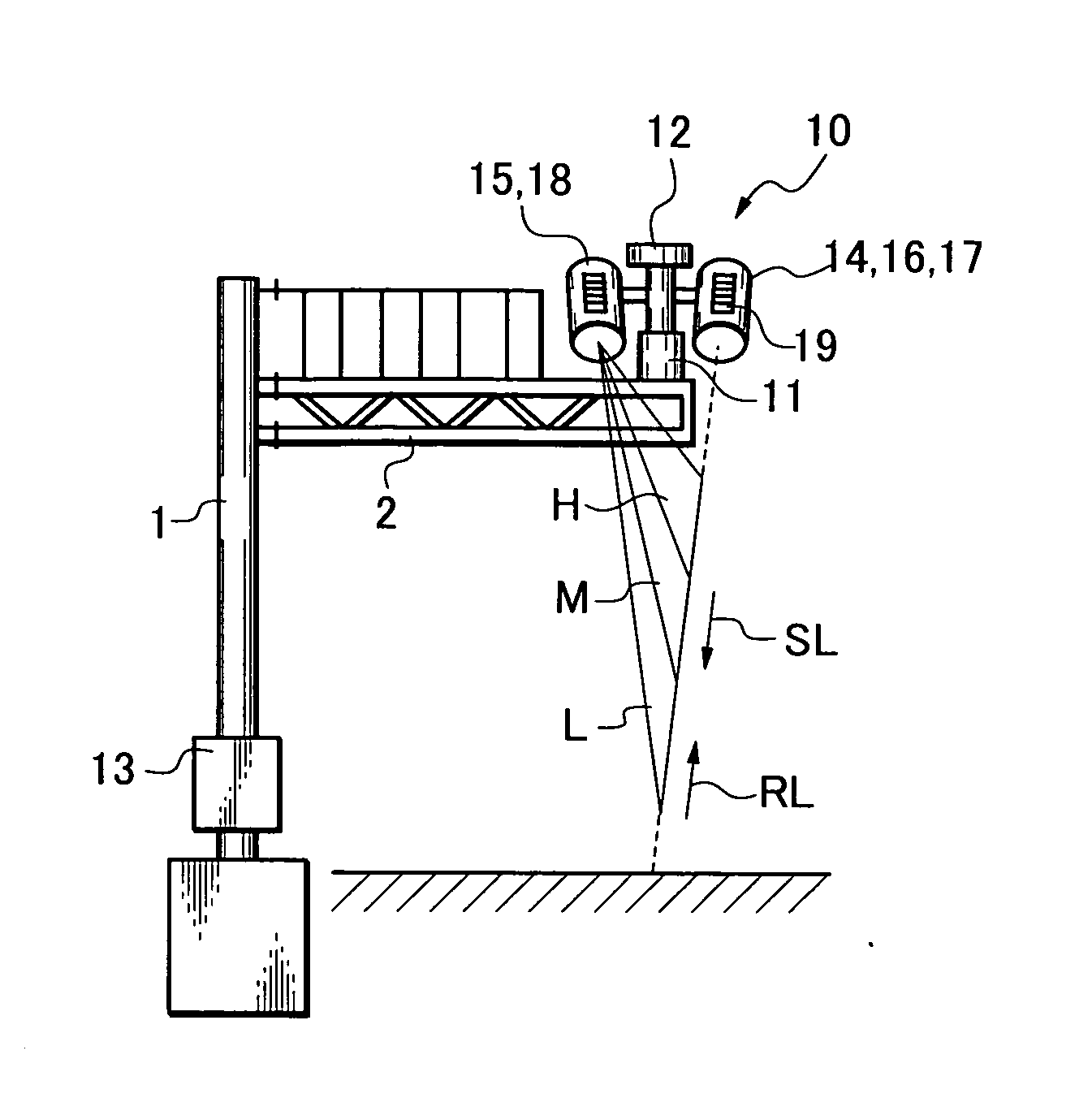

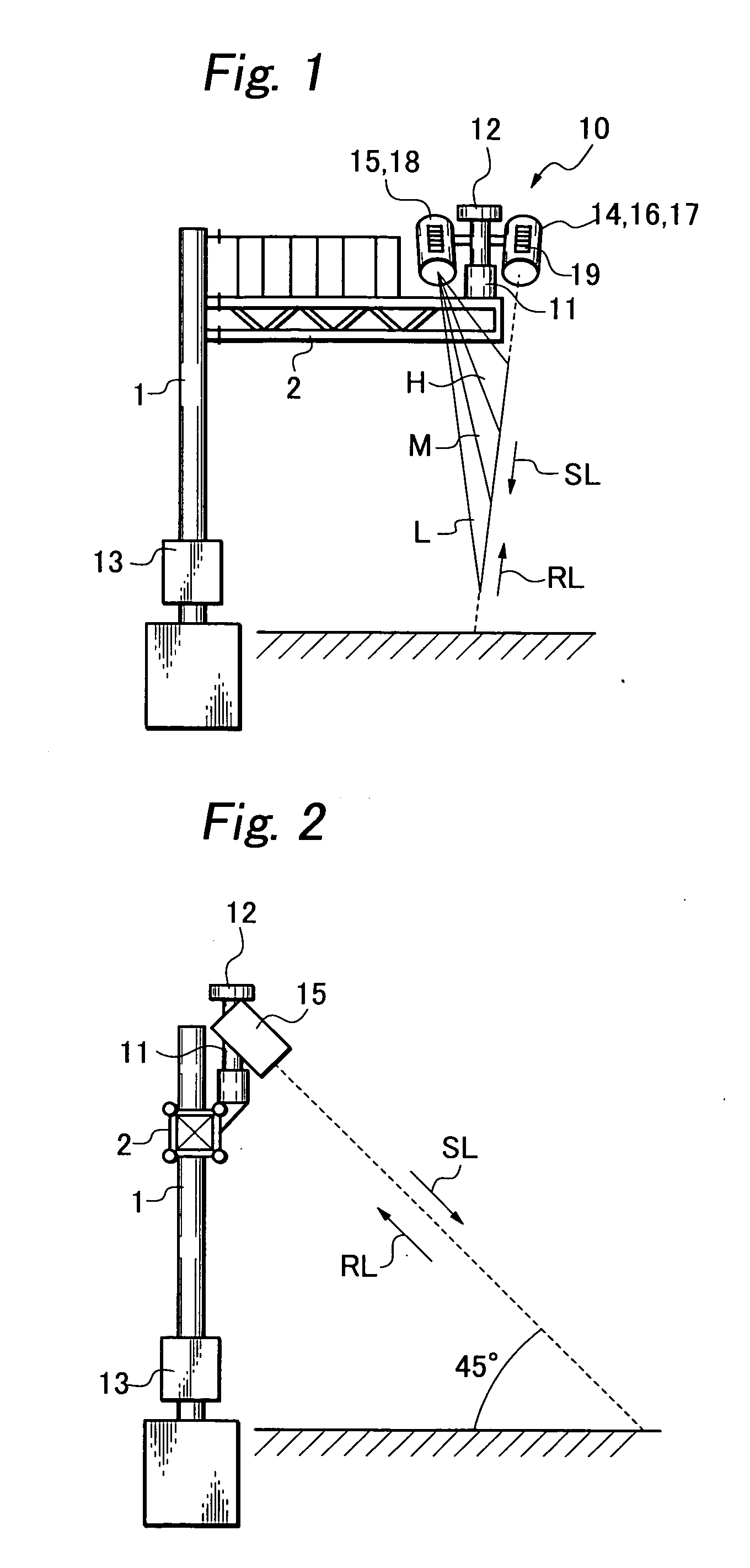

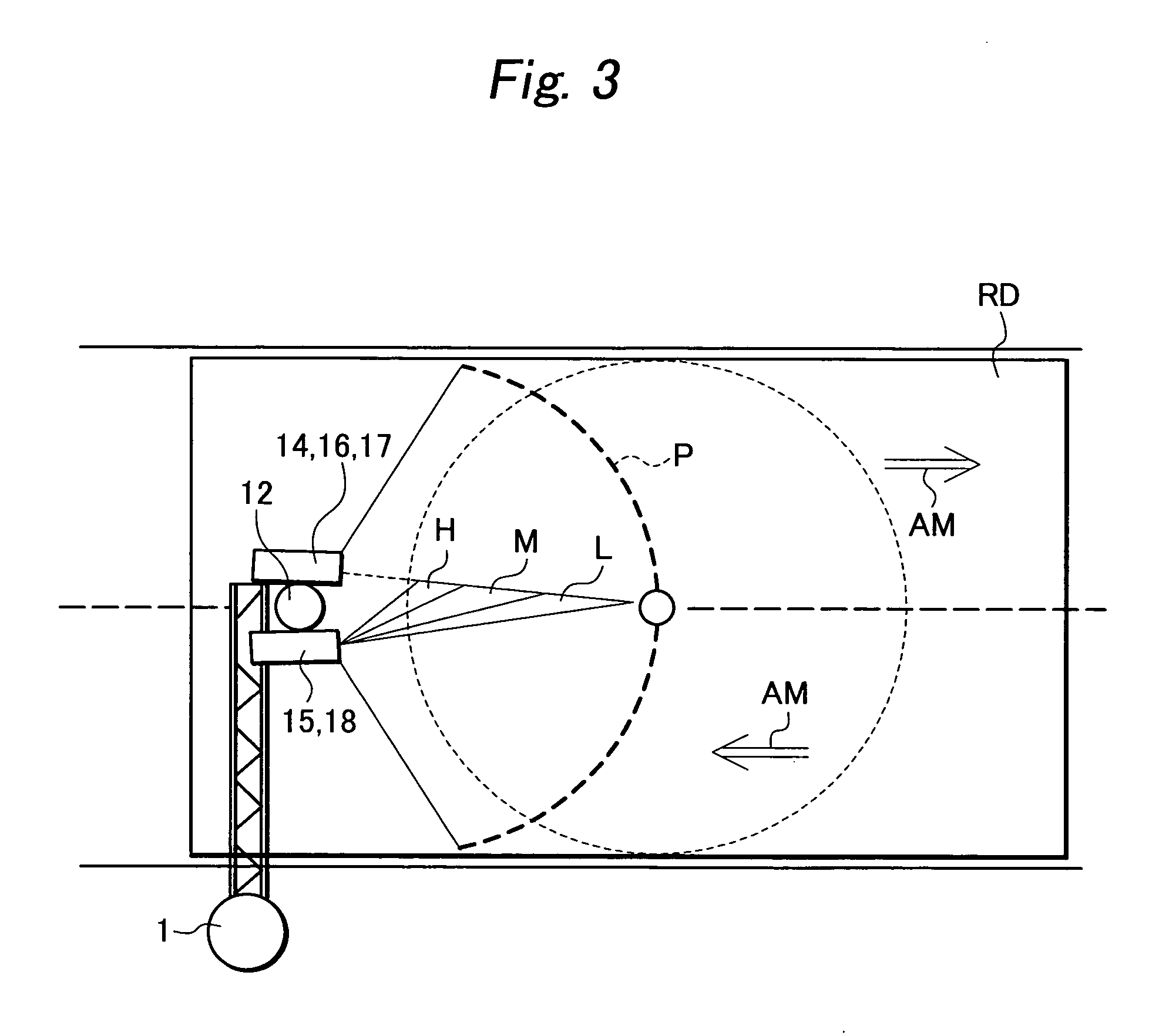

InactiveUS20050047864A1Don't waste energyRainfall/precipitation gaugesIn situ pavingsSnow meltingEngineering

In order to melt snow and prevent freezing without consuming energy wastefully and to monitor a road surface state remotely, a road surface sensor includes: a rotating stand provided so as to be reciprocatingly rotatable upward on the road surface; a snow-melting / freezing heat quantity measurement dummy road surface having an electric heater buried therein and to use as a reference road surface for heat quantity measurement to derive a melting heat quantity for snow falling on the surface and a heat quantity required for freezing prevention; a reference light irradiating / reflected light receiving device that is attached so as to be rotatable with the rotating stand; a space reflected light receiving device; a non-contact road temperature measuring device; a non-contact snow cover depth measuring device; a road surface image pickup device; and a moisture sensor. The reference light irradiating / reflected light receiving device includes a reference light irradiating device for irradiating reference light and a reflected light receiving device for receiving reflected light of the reference light from the road surface, and the reflected light receiving device separates and receives only reflected light of the reference light out of the reflected light from the road surface.

Owner:YAMADA TECH CORP +1

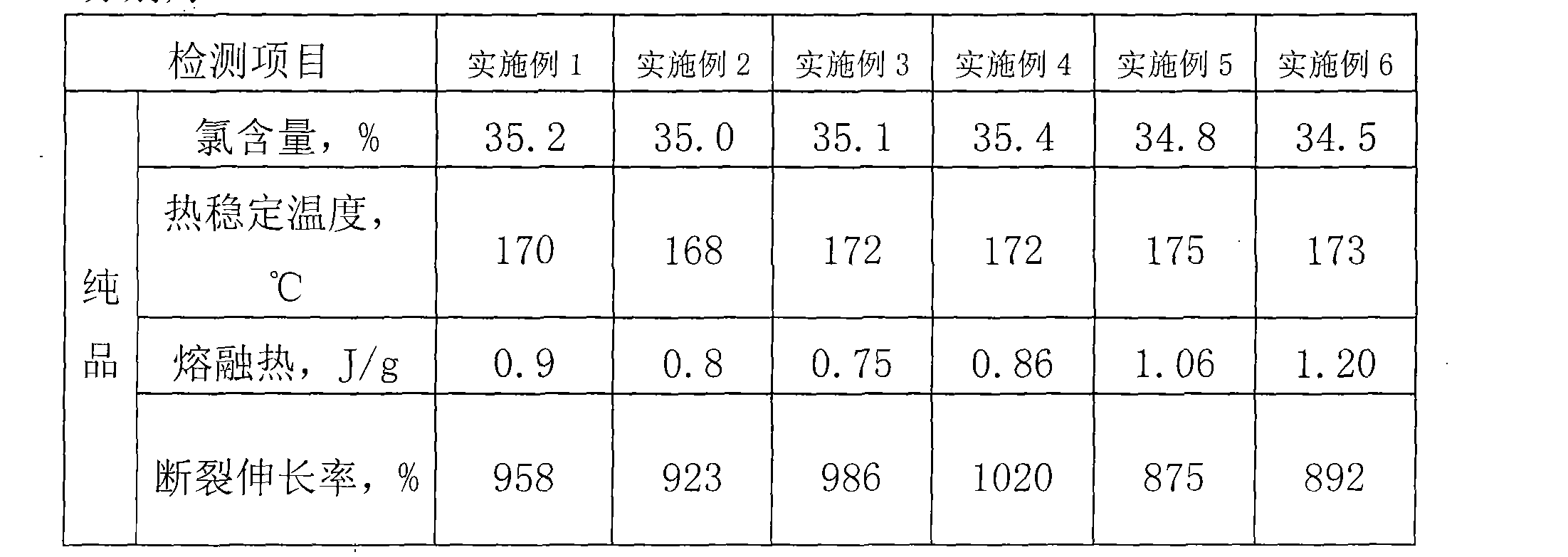

Preparation of chlorinated polythylene

InactiveCN101280030AReduce chlorination timeThe degree of chlorination in depthPolymer scienceChlorinated polyethylene

The invention belongs to plastic profile product modifier technical field and discloses a preparation method for a PVC anti-impact modifier chlorinated polyethylene. The invention is mainly technically characterized in that after dispersant, emulsifier, initiator and powdery high-density polyethylene resin are added into a chlorinating reactor with water inside in a stirring state, then the mixture is heated and processed through three chlorine reactions at different temperature ranges; after the reaction, the enwrapped HCl formed in the reactor is discharged; after repeated hot water washing, centrifugal dehydration and drying, calcium stearate, calcium carbonate and lanthanum carbonate are added to obtain the finished product through stirring, mixing and screening. As the high-density polyethylene resin in the preparation technology is high-mesh powdery material and three chlorine reactions are needed in the process, the chlorinated polyethylene prepared by the technology has higher thermal stable temperature and lower melting heat; if the chlorinated polyethylene serves as the anti-impact modifier of PVC products, the PVC product produced thereby has strong impact strength and tensile strength.

Owner:HEBEI JINGXIN CHEM GRP CO LTD

1-Butene polymer and molded product consisting of the polymer

1-butene based polymer satisfying following requirements (1″) to (4″) provides formed product having low stickiness, superior flexibility and transparency.(1″) Crystalline resin having melting point (Tm−P), not observed or in the range of 0 to 100° C., wherein said melting point defined as the peak top of the peak observed in the highest temperature zone of the melting heat absorption curve obtained by heating a sample of said polymer at a rate of 10° C. / minute using Differential Scanning Calorimeter (DSC), after melting said sample in advance at 190° for 5 minutes under nitrogen atmosphere, followed by cooling it to −10° C. at a rate of 5° C. / minutes, and keeping it at −10° C. for 5 minutes.(2″) Stereoregularity index {(mmmm) / (mmrr+rmmr)} is at most 20.(3″) Molecular weight distribution (Mw / Mn) measured by Gel Permeation Chromatography (GPC) method is at most 4.0.(4″) Weight average molecular weight (Mw) measured by GPC method is in the range of 10,000 to 1,000,000.

Owner:IDEMITSU KOSAN CO LTD

Salt-melting heat-storing warehouse

The invention provides a salt-melting heat-storing warehouse, relating to a solar heat power-generation and heat-storage system. A closed system consists of low-temperature storage tank equipment, high-temperature storage tank equipment, a heat exchanging system, a nitrogen pipeline system and a liquid salt-melting pipeline. The salt-melting heat-storing warehouse is characterized in that the nitrogen pipeline system comprises a nitrogen pipeline and a nitrogen storage tank; the nitrogen pipeline is communicated with the low-temperature storage tank equipment, the high-temperature storage tank equipment and the liquid salt-melting pipeline; the heat exchanging system is connected with the low-temperature storage tank equipment and the high-temperature storage tank equipment respectively by the liquid salt-melting pipeline; the low-temperature storage tank equipment comprises a low-temperature storage tank; the high-temperature storage tank equipment comprises a high-temperature storage tank; one end of the liquid salt-melting pipeline is arranged in the low-temperature storage tank and the other end of the liquid salt-melting pipeline is arranged in the high-temperature storage tank. When the salt-melting heat-storing warehouse is used for storing heat, the temperature of the melted salt is heated to 386 DEG C; during the heat discharging, the melted salt of the system is cooled to the temperature of about 292 DEG C; under both the heat-storing condition and the heat-discharging condition, the melted salt is in liquid state; the cold salt and the hot salt are stored in independent tanks respectively; and the heat storage system with the independent cold tank and heat tank has the advantages that both the heat storage and the heat discharging can occur at constant temperature.

Owner:HUAINAN CHINA SCI ENERGY STORAGE SCI & TECH

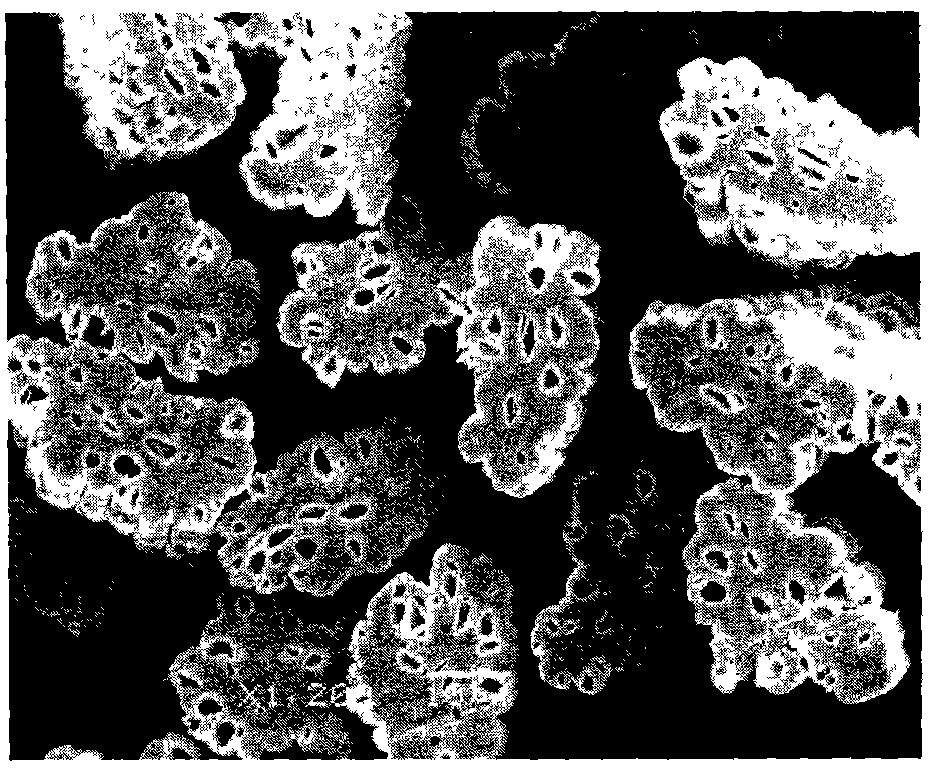

Preparation method of high-purity superfine alumina powder body

InactiveCN1394807ALower activation energyNo passivationAluminium oxide/hydroxide preparationAluminium oxides/hydroxidesPhase conversionAluminium hydroxide

The preparation method of high-purity superfine aluminium oxide powder body includes the following steps: melting aluminium in aluminium alloy melting heat-insulating furnace, using compressed air as atomization medium, and using deionized water as cooling medium to atomize aluminium liquor to obtain active aluminium powder paste body, concentrating to obtain concentrated aluminium powder paste body, adding aluminium hydroxide crystal seed whose concentration is 30-50% and grain size is 10-30 nm, making hydrolysis and reaction to produce aluminium hydroxide sol, drying at 110 deg.C to obtain aluminium hydroxide powder body, placing the power body in furnace, making phase conversion treatment for 2-4 hr. at 650-850 deg.c to obtain gamma-Al2O3 powder body, then making phase conversion treatment at 1100-1250 deg.c for 3-5 hr.

Owner:刘明

Polyester film for sealant use, laminate, and packaging bag

ActiveUS20160108171A1High heat sealing strengthNot easily adsorbedOther chemical processesSynthetic resin layered productsPolyethylene terephthalatePolyester resin

The invention provides a polyester film for sealant use. The polyester film contains a polyester resin having ethylene terephthalate as a main structural component and including one or more monomer components that may serve as amorphous components so that the total amount of the monomer components are not less than 12 mol % and not more than 30 mol % among total monomer components. The polyester film is uniaxially or biaxially stretched, and has a particular heat-sealing strength and crystal melting heat capacity. The invention also provides a laminate including as at least one layer of the polyester film for sealant use, as well as a packaging bag that utilizes the laminate.

Owner:TOYO TOYOBO CO LTD

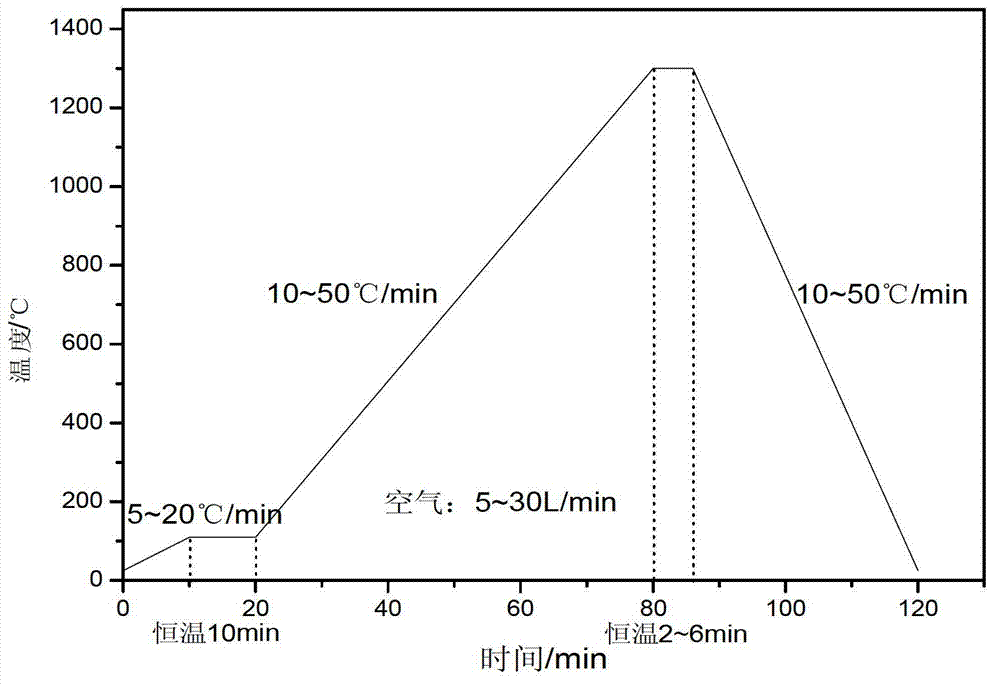

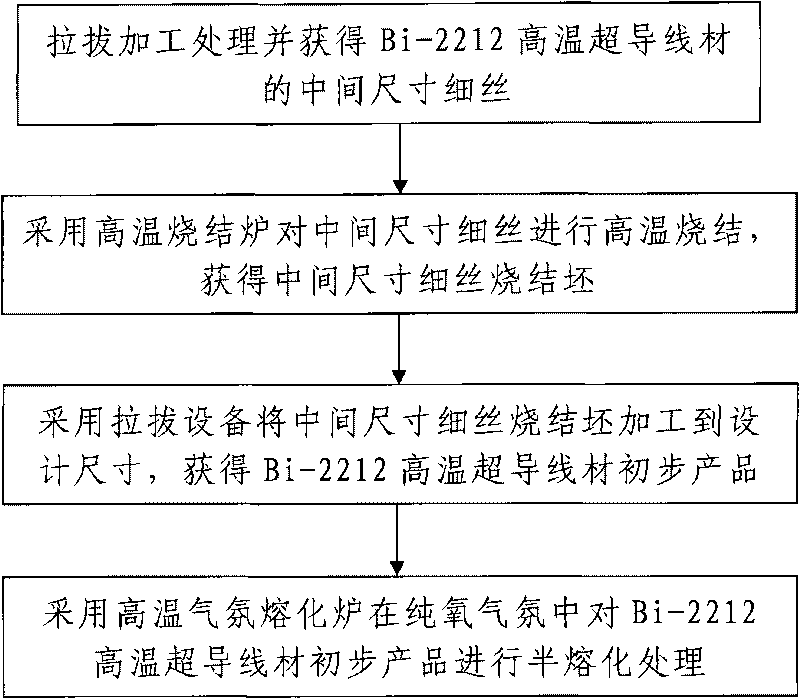

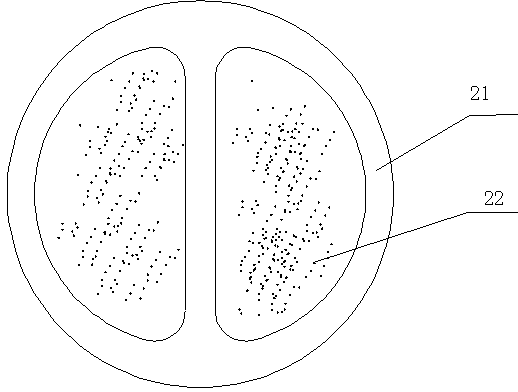

Preparation method for Bi-2212 high-temperature superconducting wires

ActiveCN101714429ASimple preparation processReasonable designSuperconductors/hyperconductorsSuperconductor devicesHigh temperature superconductingAtmosphere

The invention discloses a preparation method for Bi-2212 high-temperature superconducting wires. The preparation method for Bi-2212 high-temperature superconducting wires comprises the following steps of: 1, drawing and machining raw materials to obtain intermediate size filaments of Bi-2212 high-temperature superconducting wires; 2, performing high temperature sintering on the intermediate size filaments at the temperature of between 800 and 880 DEG C by using a high temperature sintering furnace to obtain intermediate size filament sintered blanks, and then machining intermediate size filament sintered blanks into a design size by using a drawing apparatus to obtain initial products of the Bi-2212 high-temperature superconducting wires; and 3, performing semi-molting treatment on the initial products of the Bi-2212 high-temperature superconducting wires in the atmosphere of pure oxygen by using a high temperature atmosphere melting furnace. The method has simple, easy and practical steps; the prepared Bi-2212 high-temperature superconducting wires have excellent performance; and bubbling phenomenon of the wires in the process of semi-melting heat treatment is avoided, and meanwhile crystal grain arrangement of the Bi-2212in the wires is also improved and current-carrying performance and uniformity of the wires are also improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

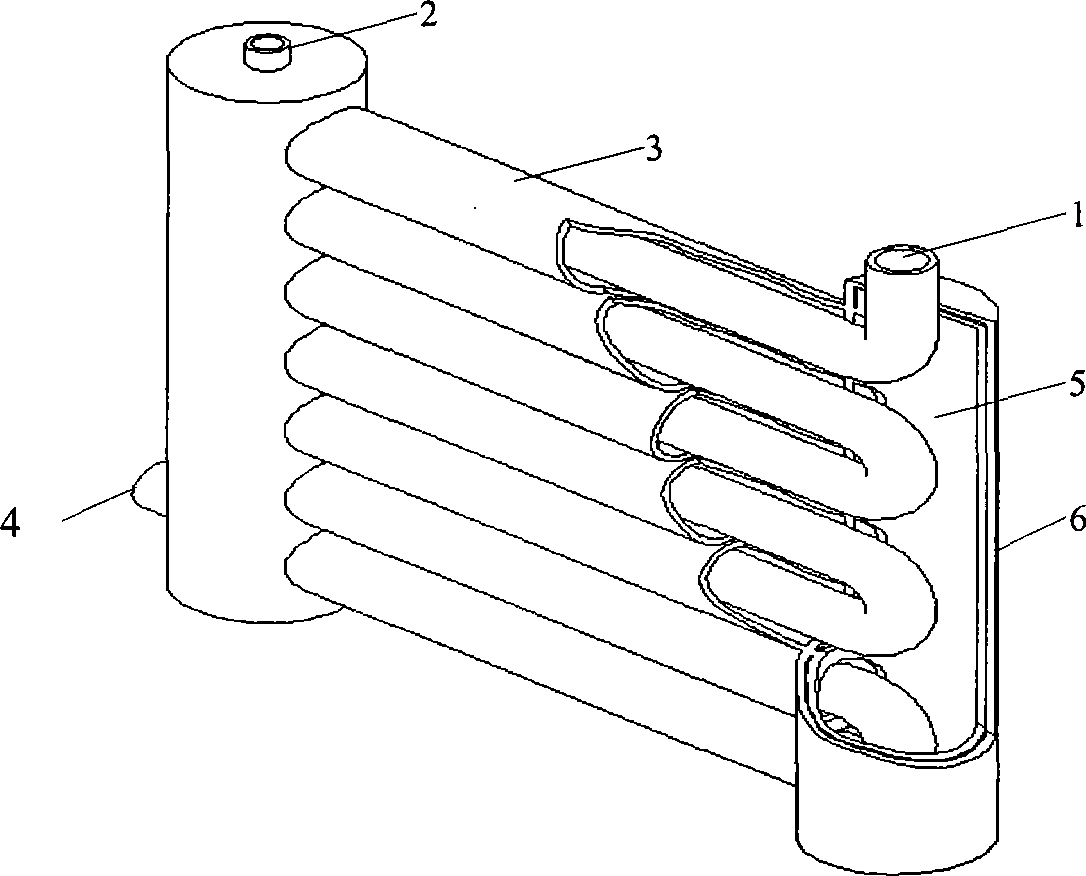

Solar molten salt sleeve pipe type steam generation method and device thereof

ActiveCN101382277ASmall temperature changeStable outputSolar heat devicesSteam generation using hot heat carriersStable stateHeat flow

The invention provides a solar molten salt cannula-typed vapor generating method and a device thereof. The generating method comprises the following steps: a refractory selective absorbing coat layer of a jacket outer wall is used for absorbing and irradiating solar energy in real time and transmitting heat to molten salt medium inside a molten salt cannula, and then to water or vapor inside a snakelike inside tube until the vapor is stably generated by the whole device; the irradiation intensity of solar energy is adjusted through the melting heat absorption or the solidifying heat discharging of the molten salt medium inside the molten salt cannula or a salt collecting slot when exceeding a designed intensity range, thus maintaining the stable vapor generation of the whole device. The generating device is an integral structure that is formed by arranging the salt collecting slot at the left and right sides of the molten salt cannula, the molten salt cannula consists of a jacket and a snakelike inner pipe, the jacket is communicated with the salt collecting slot, a vapor outlet is arranged at an upper end of the snakelike inner pipe, and a water flow inlet is arranged at a lower end of the snakelike inner pipe; an air vent is arranged at an upper end of the whole device. The generating device has simple structure and stable state of exported vapor, can bear larger heat flow density and frequent thermal shock, and has greater temperature range.

Owner:DONGGUAN UNIV OF TECH +1

Toner, development agent, and image forming apparatus

Toner contains a binder resin containing one or more kinds of crystalline resin and one or more kinds of non-crystalline resin. The non-crystalline resin located at the surface portion of the toner forms a shell structure of a continuous phase of the non-crystalline resin and the toner has an amount of melting heat of 30 J / g or more in a second temperature rising as measured by differential scanning calorimetry (DSC).

Owner:RICOH KK

Film and method of manufacturing the same, laminated film or sheet, and laminated body

ActiveUS8642159B2Increase resistanceHigh transparencySynthetic resin layered productsRecord information storageAcrylic resinFluoride

Owner:MITSUBISHI CHEM CORP

Polypropylene copolymer, composition containing the same, and process for producing the same

ActiveUS20060025535A1Satisfactory propertyImprove solubilityGraft polymer adhesivesSolubilityPolymer science

A problem of the invention is to provide a propylene copolymer which is excellent in adhesion to crystalline propylene-based polymers and which is excellent in solubility and compatibility with polar resins, a process for producing the same, and a composition containing the subject polypropylene copolymer. The invention is concerned with a polypropylene copolymer, which is characterized by having a polymer principal chain (A) derived from a propylene-based polymer having (1) a prescribed requirement as defined by the 13C-NMR spectral measurement and having (2) a melting point [Tm] by a differential scanning calorimeter of not higher than 100° C., or a crystal melting heat of less than 5 J / g; and a side chain containing a polymer chain (B) which is different from the principal chain, with a weight ratio of (A) / (B) being in the range of from 20 / 1 to 1 / 20, a composition containing the subject copolymer, and a process for producing the subject copolymer.

Owner:MITSUBISHI CHEM CORP

Low void solder joint for multiple reflow applications

ActiveUS20140193658A1Quickly dissolves the silverLow melting pointSemiconductor/solid-state device detailsSolid-state devicesEngineeringSacrificial metal

Methods and apparatus are provided for attaching a heat spreader to a die and includes disposing a solder thermal interface material between a first surface of a die and a first surface of a heat spreader without disposing a liquid flux between the die and the heat spreader to form an assembly, wherein at least one of the first surface of the die and a first surface of the heat spreader have disposed thereon a metallization structure comprising a transition layer and a sacrificial metallization layer, the sacrificial metallization layer disposed as an outer layer to the metallization structure adjacent the solder thermal interface material; and heating the assembly to melt the thermal interface and attach the die to the heat spreader.

Owner:INDIUM CORP

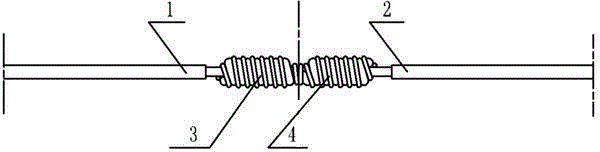

Production method of copper core cable soldered and sealed intermediate joint

The invention relates to a production method of a copper core cable soldered and sealed intermediate joint. The production method comprises the following steps that: 1) a cable, a wire 1 and a wire 2 are skinned, and the wires are made into a fixedly-connected bare joint 3; 2) the bare joint is wound with a solder wire 4; 3) the solder wire 4 is wrapped in aluminum foil paper 5; 4) a heat gun 6 is turned on to uniformly heat the aluminum foil paper, so that the solder wire can be indirectly heated to be soldered on the bare joint; 5) the joint is sleeved with a heat shrinkable sleeve 7, and the heat shrinkable sleeve 7 is uniformly heated with the heat gun; 6) the heat shrinkable sleeve shrinks and attaches to the bare joint; 7) the production of other wire joints of the cable is completed at a place where the above wire joint is not located according the step 1 to step 6; 8) cable sheaths at two ends of the joints are wrapped in hot-melt adhesive tapes 9 by one to two laps; and 9) the hot-melt adhesive tapes are sleeved with a large heat shrinkable sleeve 10, and the large heat shrinkable sleeve is uniformly heated with the heat gun, and therefore, the large heat shrinkable sleeve can shrink, and the hot-melt adhesive tapes in the large heat shrinkable sleeve can be melt, and the heat shrinkable sleeve can be bonded with the cable sheaths by the hot-melt adhesive, so that sealing and waterproof performance can be realized.

Owner:LEYARD LIGHTING CO LTD

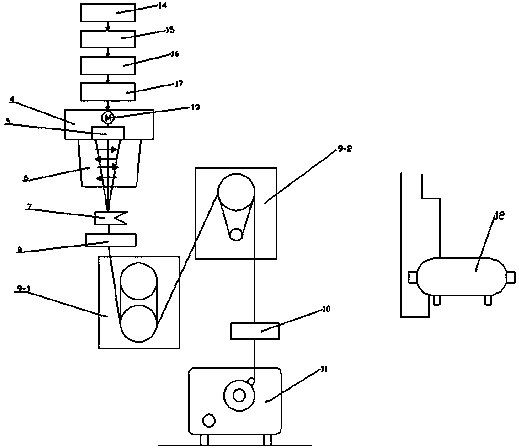

Super-fine denier FDY (fully drawn yarn) spinning equipment and spinning process

ActiveCN104141175AIncrease success rateSame dwell timeSpinnerette packsArtificial thread manufacturing machinesYarnProcess engineering

The invention relates to spinning equipment and a spinning process, in particular to super-fine denier FDY (fully drawn yarn) spinning equipment and process and belongs to the field of textile. The super-fine denier FDY spinning equipment mainly comprises a melt-delivering device and a spinning equipment body, the melt-delivering device mainly comprises a melt filter, a booster pump and a melt heat exchanger, and the spinning equipment body mainly comprises a spinning manifold, a metering pump, a spinning component, a ring blower unit and a biphenyl evaporator. The process includes the steps of 1), melt delivering; 2), metering, filtering and extruding; 3), cooling and curing; 4), clustering and oiling; 5), netting and winding. The equipment and the process are improved at the same time, so that the aspects of high success rate of loading the components on the equipment, normal section of finished yarns, less wool, indicators and the like are remarkably improved, and product quality can be improved.

Owner:JIANGSU DELI CHEM FIBER CO LTD

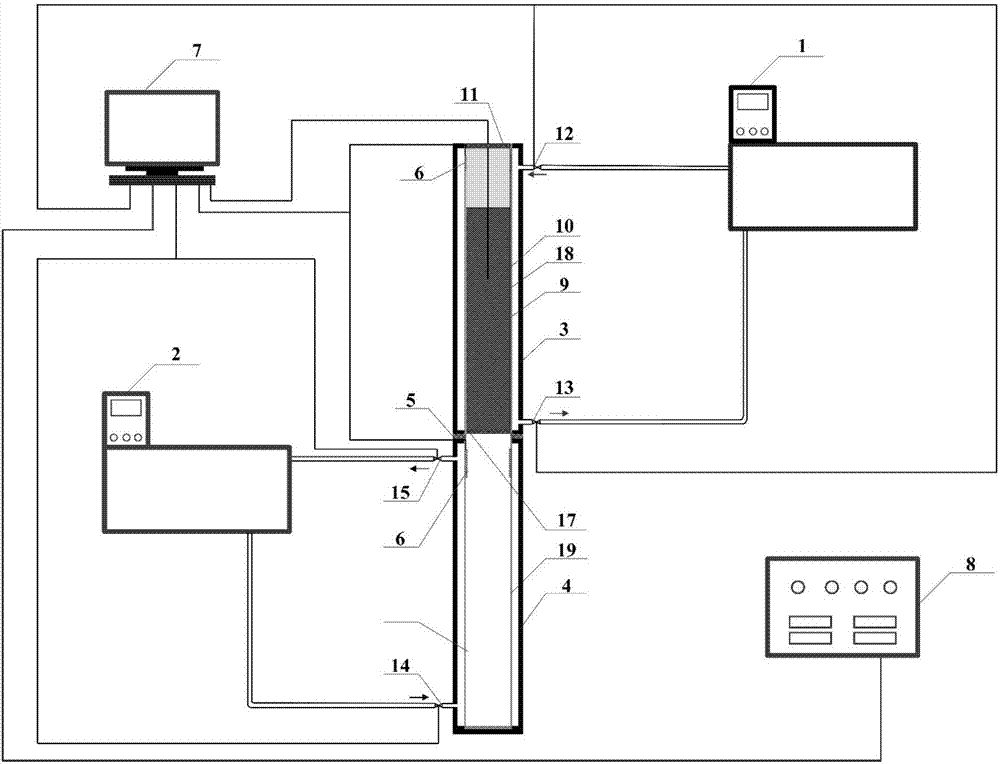

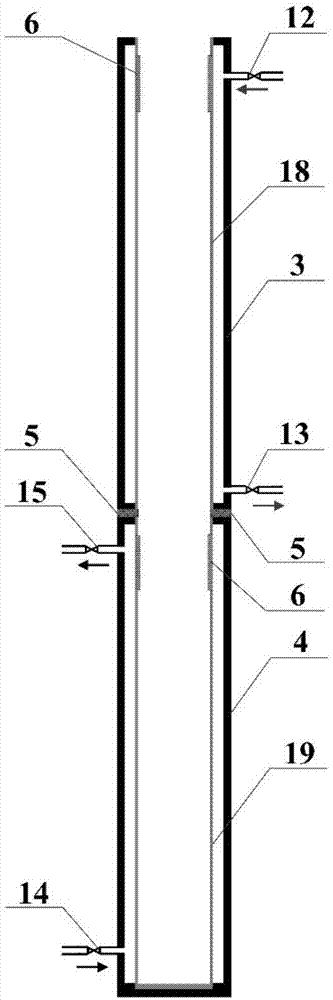

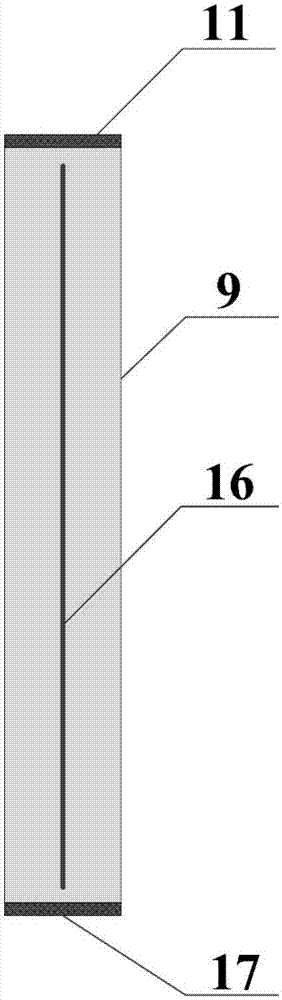

Program control system and method for testing heat storage and release cycling performances of phase change material

InactiveCN107228880ARealize heat storage and discharge cycle performance testRealize multiple heat storage and discharge cycle performance testsMaterial heat developmentInvestigating phase/state changeAutomatic controlData acquisition

The invention discloses a program control system and method for testing the heat storage and release cycling performances of a phase change material. The system is used in the field of the phase change material heat storage and release cycling performance test. The system comprises a high temperature constant temperature bath, a low temperature constant temperature bath, a high temperature fluid circulation jacket, a low temperature fluid circulation jacket, a heat insulation diaphragm plate, an automatic lifting bar, a program controller, a data acquisition instrument and a phase-change material sample tube. Through the high temperature fluid circulation jacket and the low temperature fluid circulation jacket, phase change material melting heat storage and solidification heat release are realized so that the high temperature constant temperature fluid and the low temperature constant temperature fluid are completely separated. Through the heat insulation diaphragm plate, heat exchange between the high temperature fluid circulation jacket and the low temperature fluid circulation jacket is avoided. The automatic lifting bar realizes automatic switching of heat storage and heat release of the phase change material. The program controller realizes automatic control of the phase change material heat storage and release cycling performance test. Through the parameters recorded by the data acquisition instrument, the test on multiple-step heat storage and release cycling performances of the phase change materials is realized.

Owner:ZHEJIANG UNIV

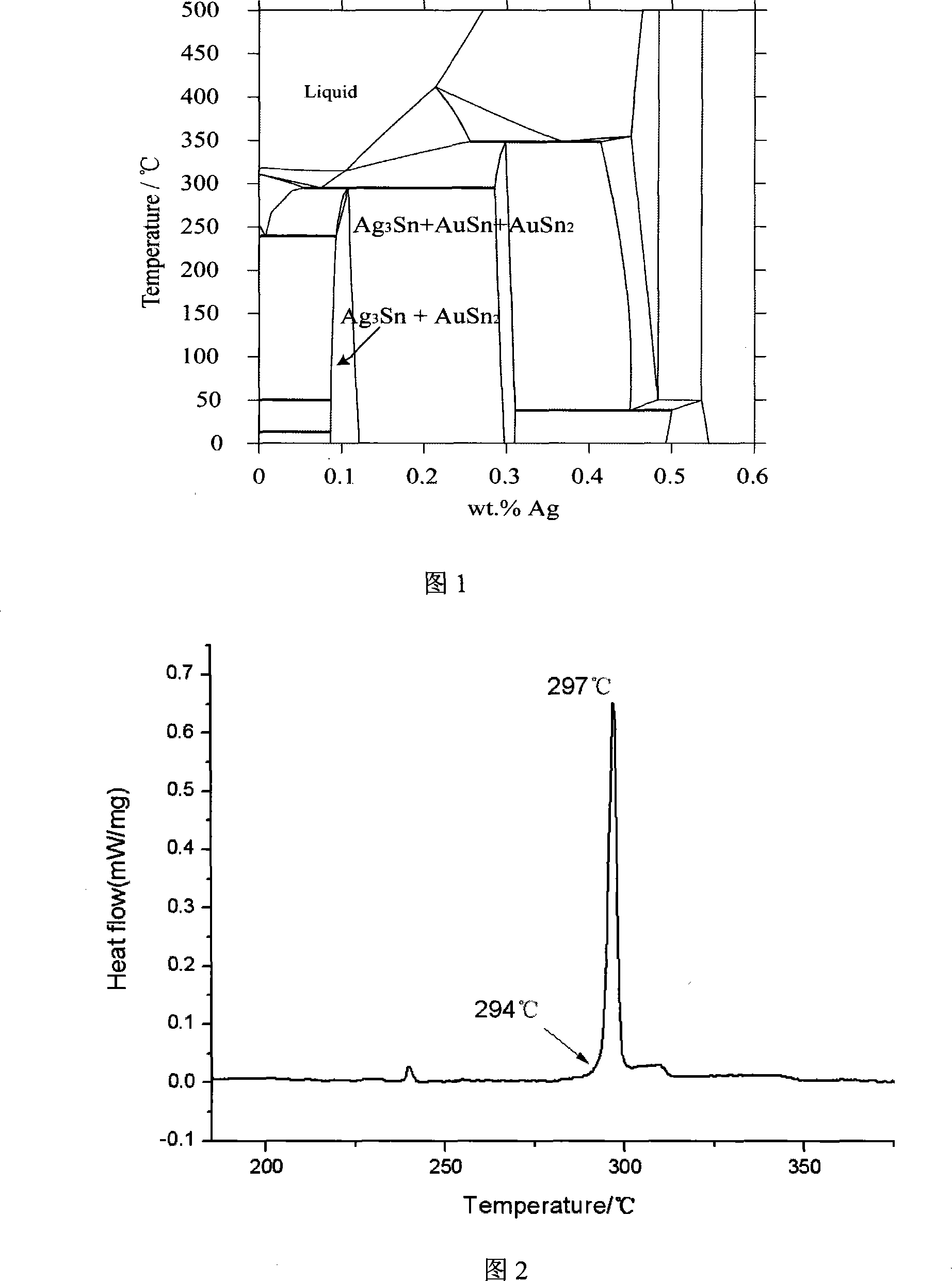

Tin silver gold leadless welding material and preparation thereof

InactiveCN101234456AImprove wettabilitySimple preparation processWelding/cutting media/materialsSoldering mediaIce waterMetal alloy

The invention discloses a tin-silver-gold lead free solder and a preparation method thereof. The invention relates to a metal alloy, in particular to a high temperature lead free solder used in grading package and the preparation method thereof. The invention provides a novel high temperature tin-silver-gold lead free solder, the melting temperature of which can reach about 300 DEG C and which has good wettability, electrical property and welding effect and can replace the traditional Pb solder alloy of Sn-95wt percent (the melting point is 300 DEG C) and the preparation method thereof. The components and the content according to the weight percentage are as follows: 8 to 13 percent of silver, 35 to 45 percent of gold and the rest of tin. Silver, gold and tin materials are vacuum packaged in a quartz tube; and the vacuum degree in the quartz tube is ensured to be 5Pa below; then high purity argon is filled in the tube to (0.7 to 0.8) multiplied by 10<5>Pa; then the materials are put into a reaction furnace to go through melting heat treatment, then quenched in ice water after being taken out, and then vacuum packaged and annealed for at least 24 hours.

Owner:XIAMEN UNIV

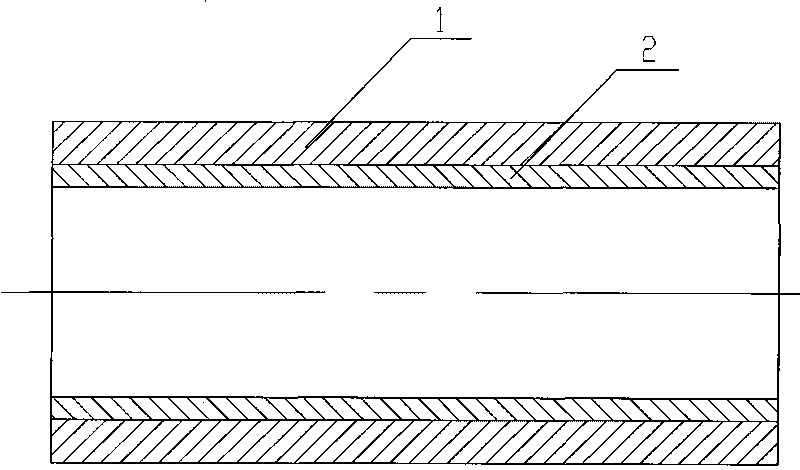

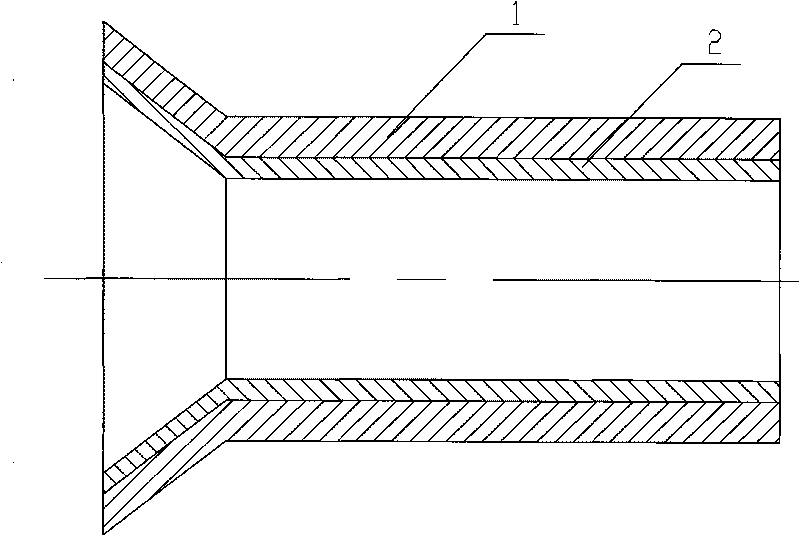

Centrifugal cast tube die and manufacturing technique thereof

ActiveCN101704084AExtended service lifeExcellent thermal fatigue resistance of the surface layerMetal layered productsMelting heatChemical change

The invention discloses a centrifugal cast tube die and manufacturing technique thereof. The centrifugal cast tube die is made of metal material, and the alloy of the inner layer of the tube wall is a composite heat-resisting die steel layer. The matched technique method comprises: adopting centrifugal casting technique to finish shaping the outer layer of the tube wall of the centrifugal cast tube die by using the metal shaping cavity; when the outer layer metal of the tube wall of the centrifugal cast tube die cools to a temperature 20-100 DEG C lower than liquidus temperature, casting melt heat-resisting die steel on the inner surface for forming composite layer, and utilizing high speed rotation of the metal shaping cavity and the physical and chemical change between the metals of the inner layer and outer layer to realize centrifugal shaping of the composite tube blank; ejecting the tube after the alloy is completely solidified to form a blank of the composite cast tube die having complete metallurgy combination layer; trimming the inner surface and outer surface of the blank of the cast tube die and testing performance thereof, and carrying out periodical rolling and deforming by hot flaring technique to finally process into the cast tube die. For the cast tube die manufactured by the invention, heat and fatigue resisting performance is obviously improved, cracking on inner surface is remarkably delayed and service life is greatly prolonged.

Owner:XINXING DUCTILE IRON PIPES CO LTD

Method for preparing foam aluminium sandwich structure

The invention relates to a method for preparing a foam aluminium sandwich structure. Foam aluminium is processed into samples of any required size by using wire cutting or other machining methods. The method comprises the following steps: performing derusting and deoiling treatment on the surface of the foam aluminium; mixing k3AlF6 and KAlF4 in a ratio of 1:1-2, heating the mixture till the mixture is in a molten state, cooling the mixture for crystallization, grinding crystals into powder, adding water into the powder to prepare a suspension in a ratio of 1:2 to 4, and spreading the suspension on the surface of a foam aluminum work piece uniformly; and putting the treated foam aluminum work piece in a mold, placing the mold in a furnace at the temperature of between 520 and 585 DEG C, keeping the temperature for 2 minutes, taking the mold out, injecting molten alloy melt heated to 500 to 580 DEG C into the mold, and cooling the melt to obtain the foam aluminum sandwich structure. The method for preparing the foam aluminum sandwich structure has the characteristics of high preparation efficiency, simple process, low cost and easy realization of line production.

Owner:GUANGDONG OCEAN UNIVERSITY

Road surface sensor and monitoring control method for road surface

InactiveUS6979146B2Don't waste energyRainfall/precipitation gaugesIn situ pavingsSnow meltingEngineering

In order to melt snow and prevent freezing without consuming energy wastefully and to monitor a road surface state remotely, a road surface sensor includes: a rotating stand provided so as to be reciprocatingly rotatable upward on the road surface; a snow-melting / freezing heat quantity measurement dummy road surface having an electric heater buried therein and to use as a reference road surface for heat quantity measurement to derive a melting heat quantity for snow falling on the surface and a heat quantity required for freezing prevention; a reference light irradiating / reflected light receiving device that is attached so as to be rotatable with the rotating stand; a space reflected light receiving device; a non-contact road temperature measuring device; a non-contact snow cover depth measuring device; a road surface image pickup device; and a moisture sensor. The reference light irradiating / reflected light receiving device includes a reference light irradiating device for irradiating reference light and a reflected light receiving device for receiving reflected light of the reference light from the road surface, and the reflected light receiving device separates and receives only reflected light of the reference light out of the reflected light from the road surface.

Owner:YAMADA TECH CORP +1

Method For Producing Semiconductor Wafers Composed Of Silicon

ActiveUS20110304081A1Efficient processingPolycrystalline material growthSemiconductor/solid-state device manufacturingWaferingCrucible

Silicon semiconductor wafers are produced by pulling a single crystal at a seed crystal from a melt heated in a crucible; supplying heat to the center of the crucible bottom with a heating power which, in the course of the growth of a cylindrical section of the single crystal, is increased at least once to not less than 2 kW and is then decreased again; and slicing semiconductor wafers from the pulled single crystal.

Owner:SILTRONIC AG

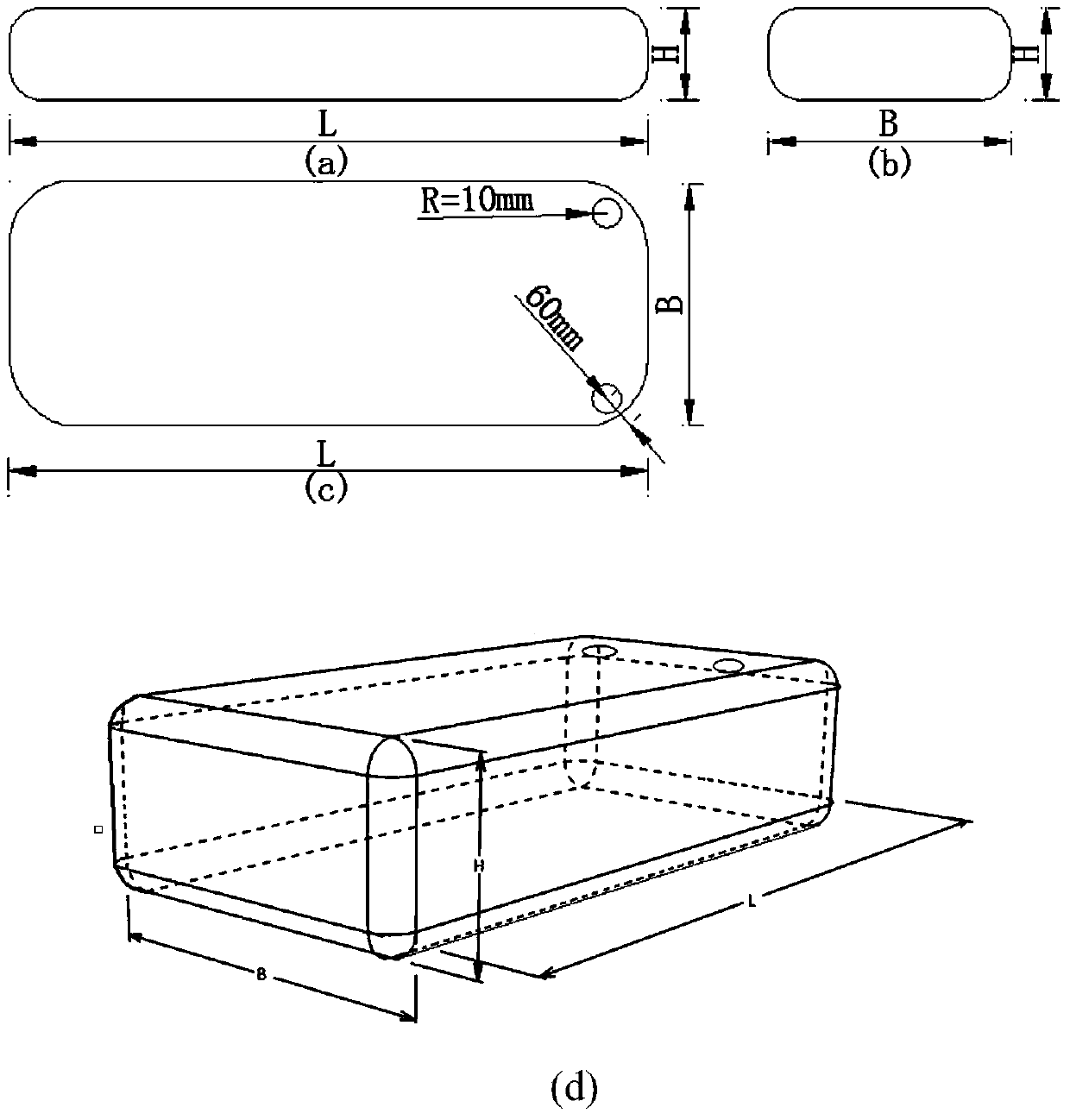

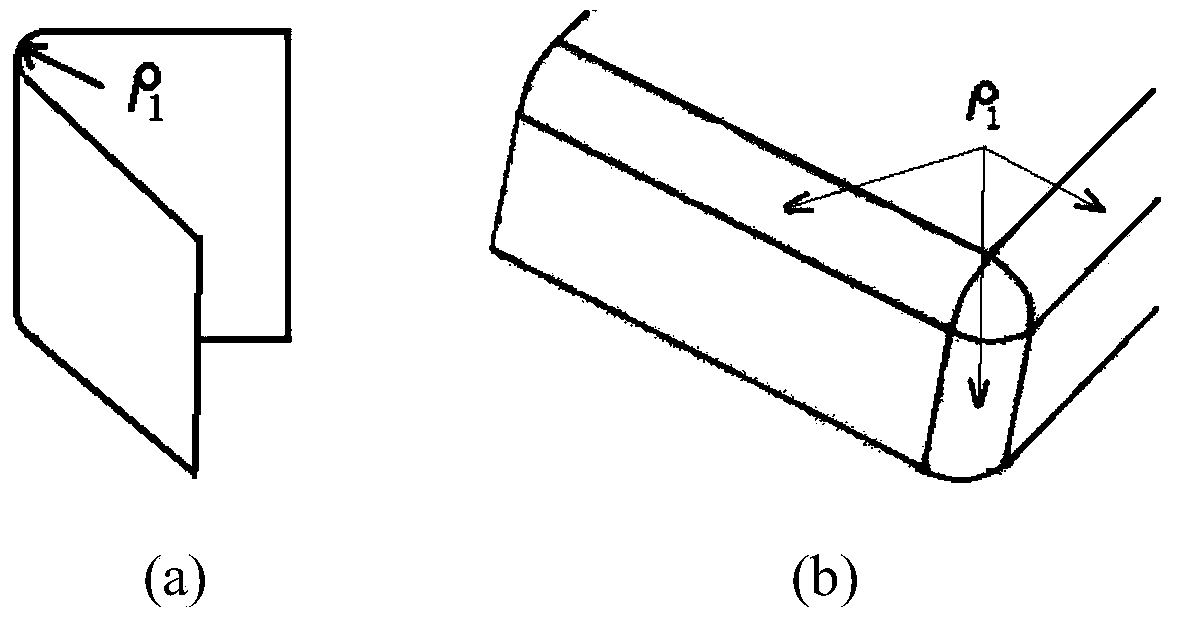

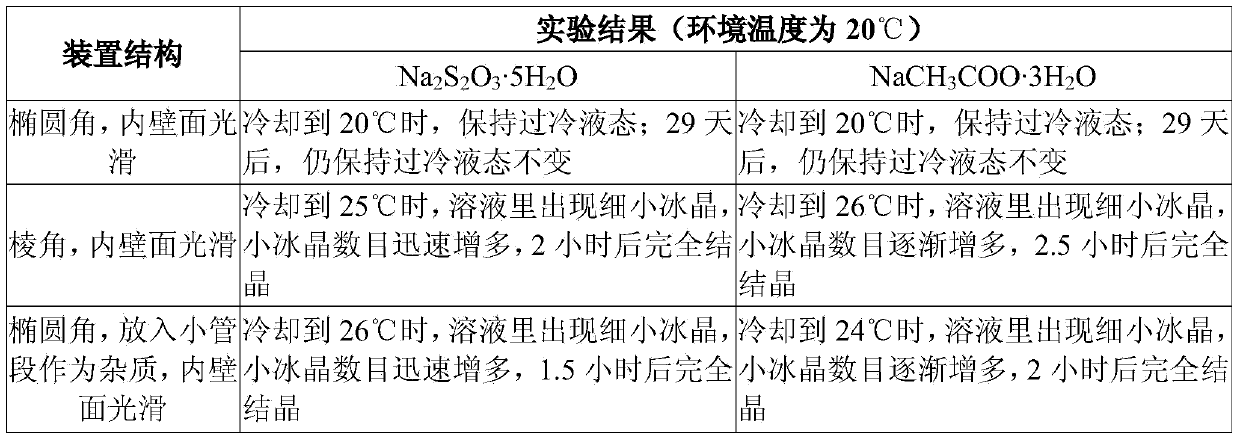

Device and method for utilizing hydrated salt phase-change material to stabilize supercooling energy storage device and application

The invention belongs to the field of application of novel environment-friendly high-efficiency energy storage technology, and particularly relates to a device and a method for utilizing a hydrated salt phase-change material to stabilize a supercooling energy storage device and application. The method includes heating hydrated salt crystals in summer until being completely melted and having a certain superheat degree, and injecting superheat liquid into a circular-arc chamfering or oval-arc chamfering flat cuboid container with a smooth inner wall for sealing; standing in an indoor environment, stably storing the phase-change material in the container in a supercooling liquid form for a long time, storing most of melting heat, and applying mechanical vibration, an electric field, a magnetic field, ultrasonic waves or local low temperature on the device to trigger the device for crystallization energy releasing when heat supply is needed in winter. Compared with conventional cross-season energy storage systems, the energy storage device has the advantages being smaller in heat-radiating loss and higher in energy storage efficiency in the process of energy storage, and being simple to manufacture and low in cost; the used phase-change material is large in energy storage density, and is applied in a cross-season energy storage system, size of the energy storage device is greatly reduced, initial cost is saved, and convenience in control is realized.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

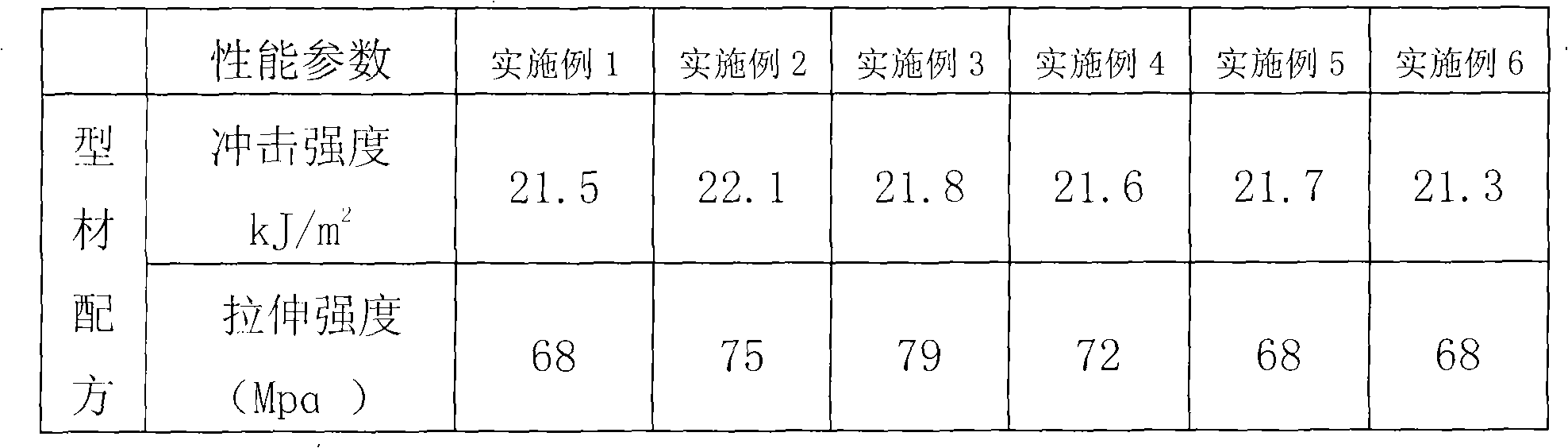

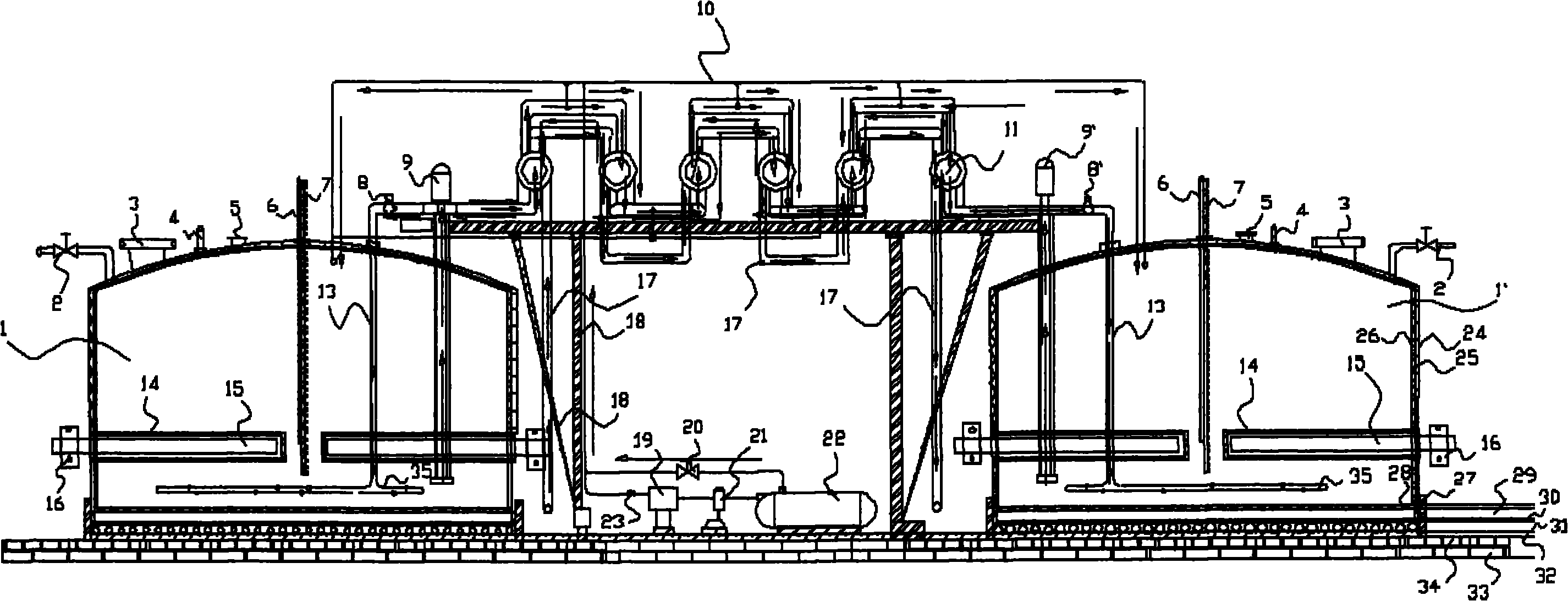

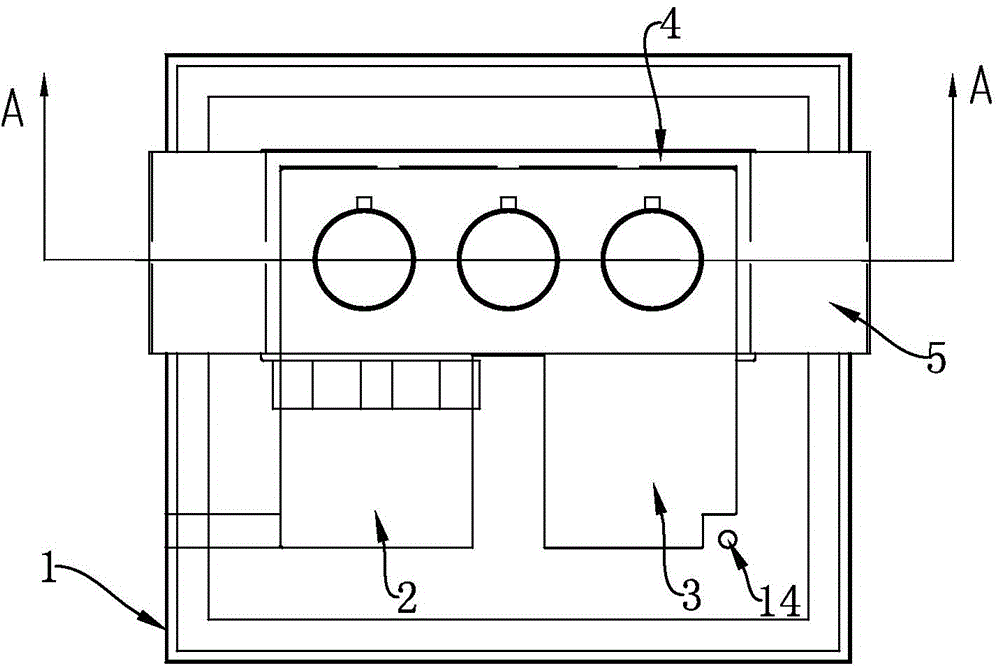

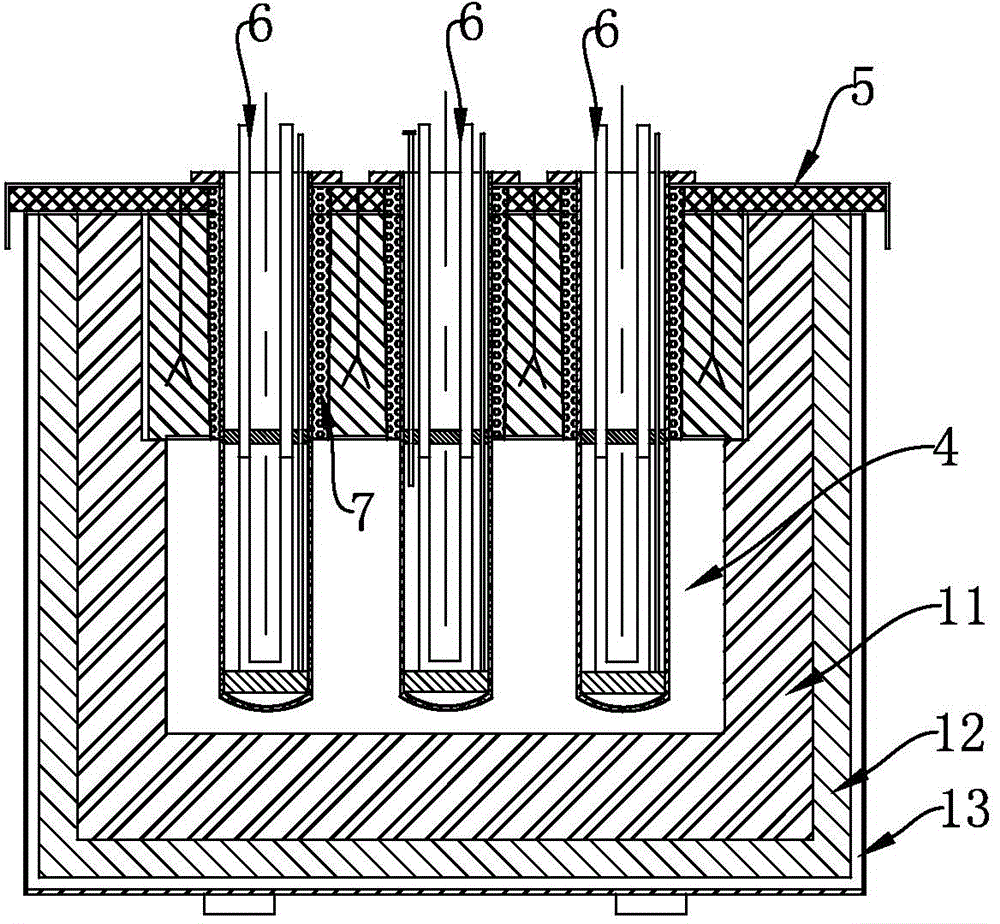

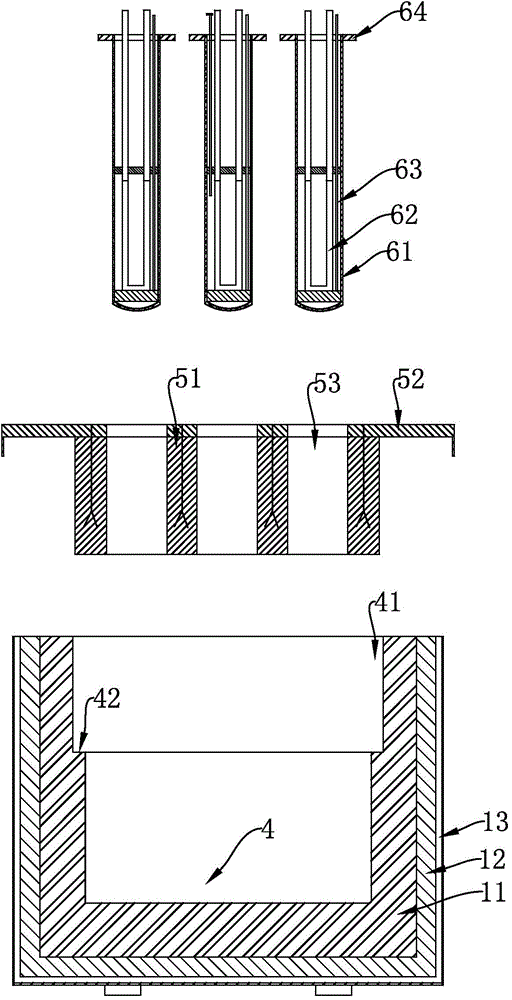

Upper part immersed heating and melting heat-preserving furnace

The invention discloses an upper part immersed heating and melting heat-preserving furnace, relates to a heating and melting heat-preserving furnace, and aims to provide an upper part immersed heating and melting heat-preserving furnace, which has the advantages of low energy consumption, high thermal conversion rate, safety and convenience in use and low failure rate. The upper part immersed heating and melting heat-preserving furnace comprises a furnace body, a furnace cover and a heater, wherein the inner cavity of the furnace body comprises a heating area, a feeding area and a discharging area; the feeding area and the discharging area are communicated with the heating area respectively; the furnace cover is embedded into the opening of the heating area; the top of the furnace cover is further provided with vertical through holes; the heater is embedded into the vertical through holes; the heating position of the heater extends into the inner cavity of the heating area.

Owner:宋振亚

1-butene polymer and molded product consisting of the polymer

1-butene based polymer satisfying following requirements (1″) to (4″) provides formed product having low stickiness, superior flexibility and transparency.(1″) Crystalline resin having melting point (Tm−P), not observed or in the range of 0 to 100° C., wherein said melting point defined as the peak top of the peak observed in the highest temperature zone of the melting heat absorption curve obtained by heating a sample of said polymer at a rate of 10° C. / minute using Differential Scanning Calorimeter (DSC), after melting said sample in advance at 190° for 5 minutes under nitrogen atmosphere, followed by cooling it to −10° C. at a rate of 5° C. / minutes, and keeping it at −10° C. for 5 minutes.(2″) Stereoregularity index {(mmmm) / (mmrr+rmmr)} is at most 20.(3″) Molecular weight distribution (Mw / Mn) measured by Gel Permeation Chromatography (GPC) method is at most 4.0.(4″) Weight average molecular weight (Mw) measured by GPC method is in the range of 10,000 to 1,000,000.

Owner:IDEMITSU KOSAN CO LTD

Cooling process for producing high-magnesium-aluminum alloy welding wire blank through continuous casting and rolling method

ActiveCN108311551AAddresses adverse effects of higher temperaturesGuaranteed work efficiencyWork cooling devicesMetal rolling arrangementsHigh magnesiumEmulsion

The invention relates to a cooling process for producing a high-magnesium-aluminum alloy welding wire blank through a continuous casting and rolling method. The process comprises the following steps:(1) raw material selection and weighing; (2) refining: adding an aluminum ingot in a melting heat-insulation furnace and melting, and then refining; (3) degassing and deslagging: carrying out degassing and deslagging through online refining and filter equipment; and (4) casting and cast-rolling: casting to obtain an ingot, and then conveying the ingot in a twelve-rack two-roll continuous rolling unit and carrying out cast-rolling; and carrying out online cooling on the alloy rod obtained through the cast-rolling through an emulsion. According to the process disclosed by the invention, the adverse influence of high temperature of the alloy rod in a winding process for the high-magnesium-aluminum alloy welding wire blank (alloy rod) is solved, the working efficiency and the stability of thesubsequent winding working are ensured, and the high-temperature damage of the high-temperature aluminum alloy rod to equipment is reduced; and the surface of the aluminum alloy rod can be cleaned toimprove the surface quality while the aluminum alloy rod is cooled to improve the performance stability, so that further improvement for the machining quality is promoted.

Owner:XINJIANG JOINWORLD CO LTD

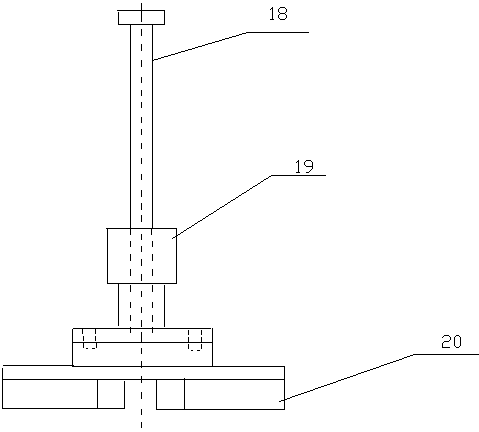

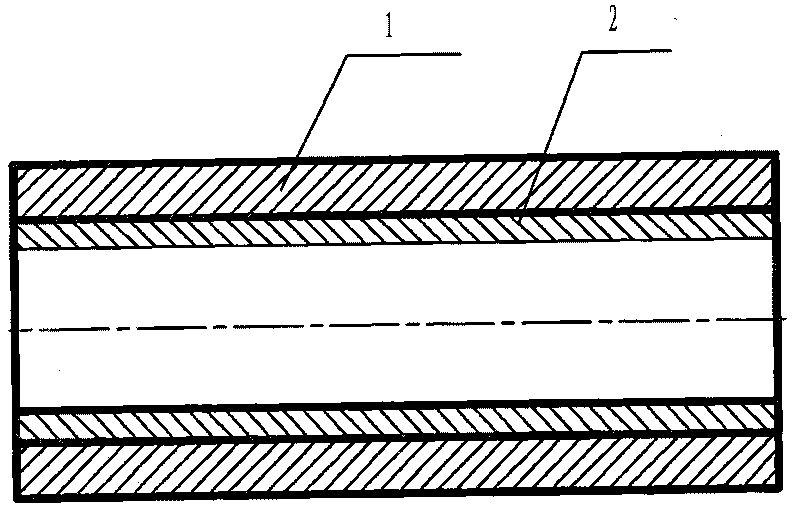

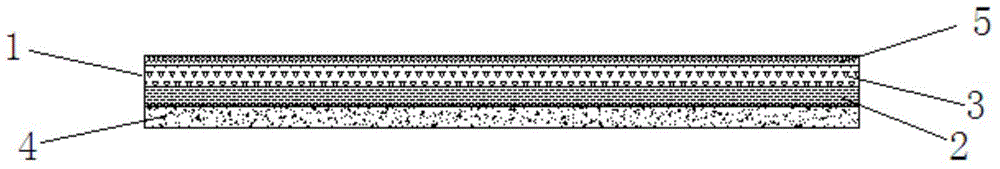

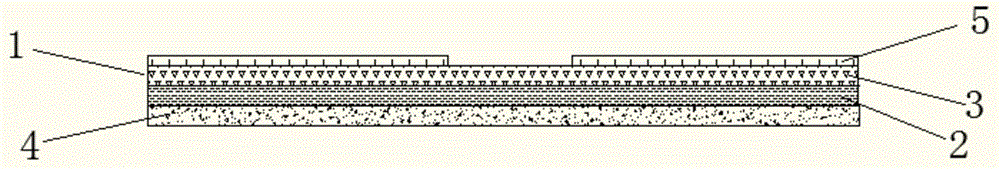

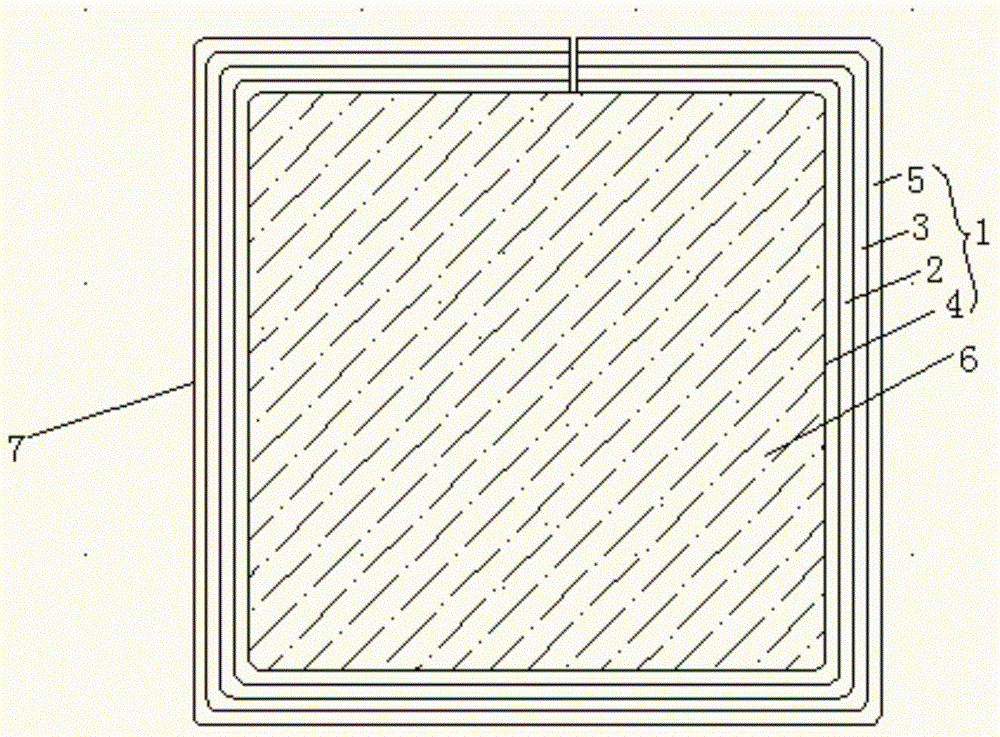

Holt-melting heat-conducting film, heat-conducting liner including hot-melting heat-conducting film and preparation method and preparation device thereof

ActiveCN104320954AWith insulationConductiveLaminationLamination apparatusPolymer scienceHeat conducting

The invention relates to the technical field of heat conducting and heat dissipating devices and preparation methods and preparation devices thereof, and in particular relates to a holt-melting heat-conducting film, a heat-conducting liner including the hot-melting heat-conducting film and a preparation method and a preparation device thereof. The hot-melting heat-conducting film includes a heat conducting layer, wherein an adhesive layer is arranged on one surface of the heat conducting layer while a hot melt adhesive layer is arranged on the other surface of the heat conducting layer, a thin film layer is arranged on the adhesive layer, thus being simple in structure and good in heat conducting and heat dissipating effect; the heat conducting liner includes a hot-melting heat-conducting film and a support substrate, and contact point heat sources with a heat dissipating surface, thus improving heat dissipation efficiency; the preparation method comprises primarily forming, thermoforming, cooling for shaping and pulling and cutting to obtain finished products, so that the method is simple, production efficiency is improved, and production cost is reduced; the preparation device includes a control box, and a material rack, a primary forming mold, a thermoforming mold, a cooling shaping mold, an automatic puller, a counter and a cutting device sequentially arranged on an assembly line, one people can operated the whole assembly line, thus being saving in human and material resources.

Owner:东莞市黄江金杰工程技术工作室

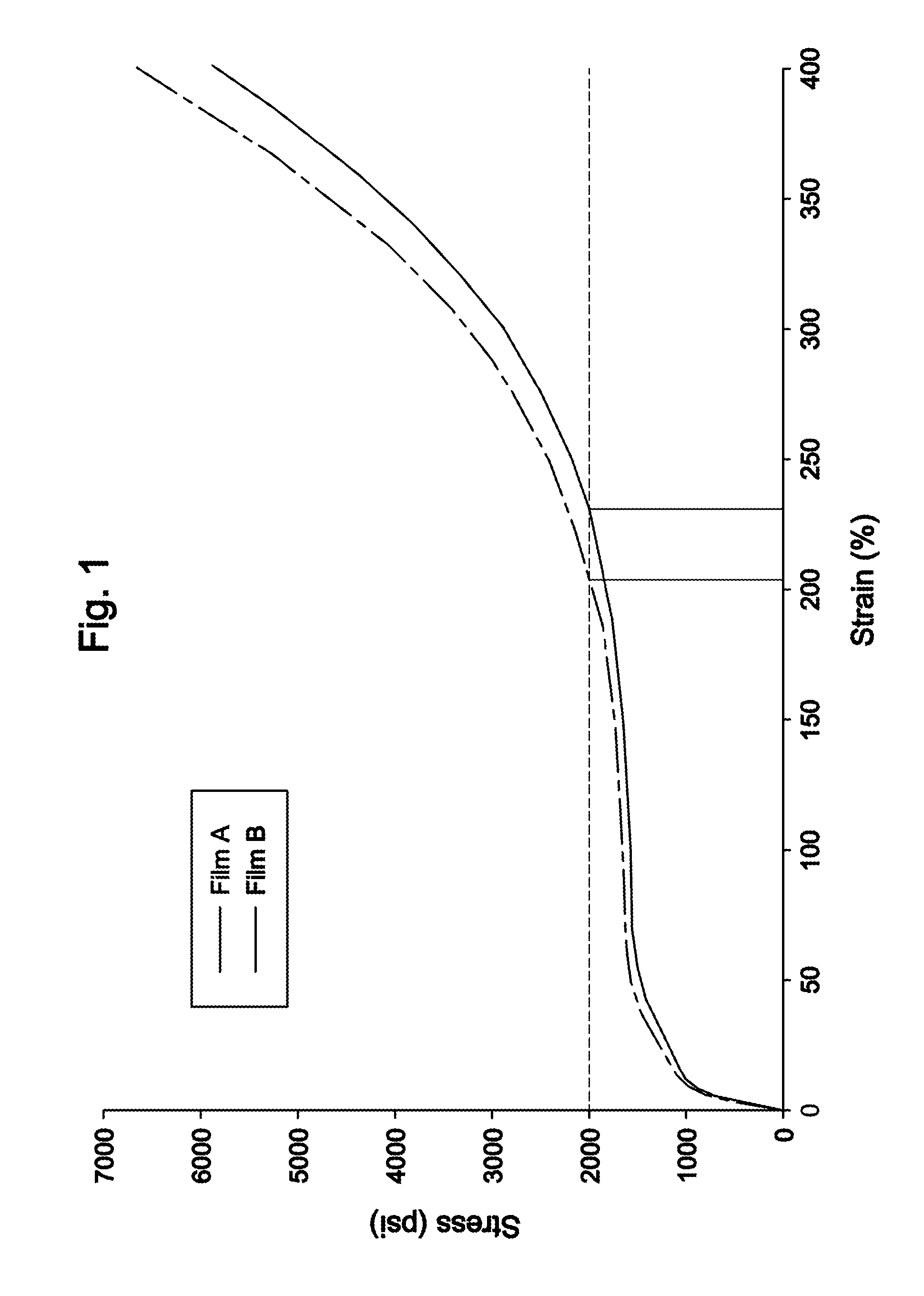

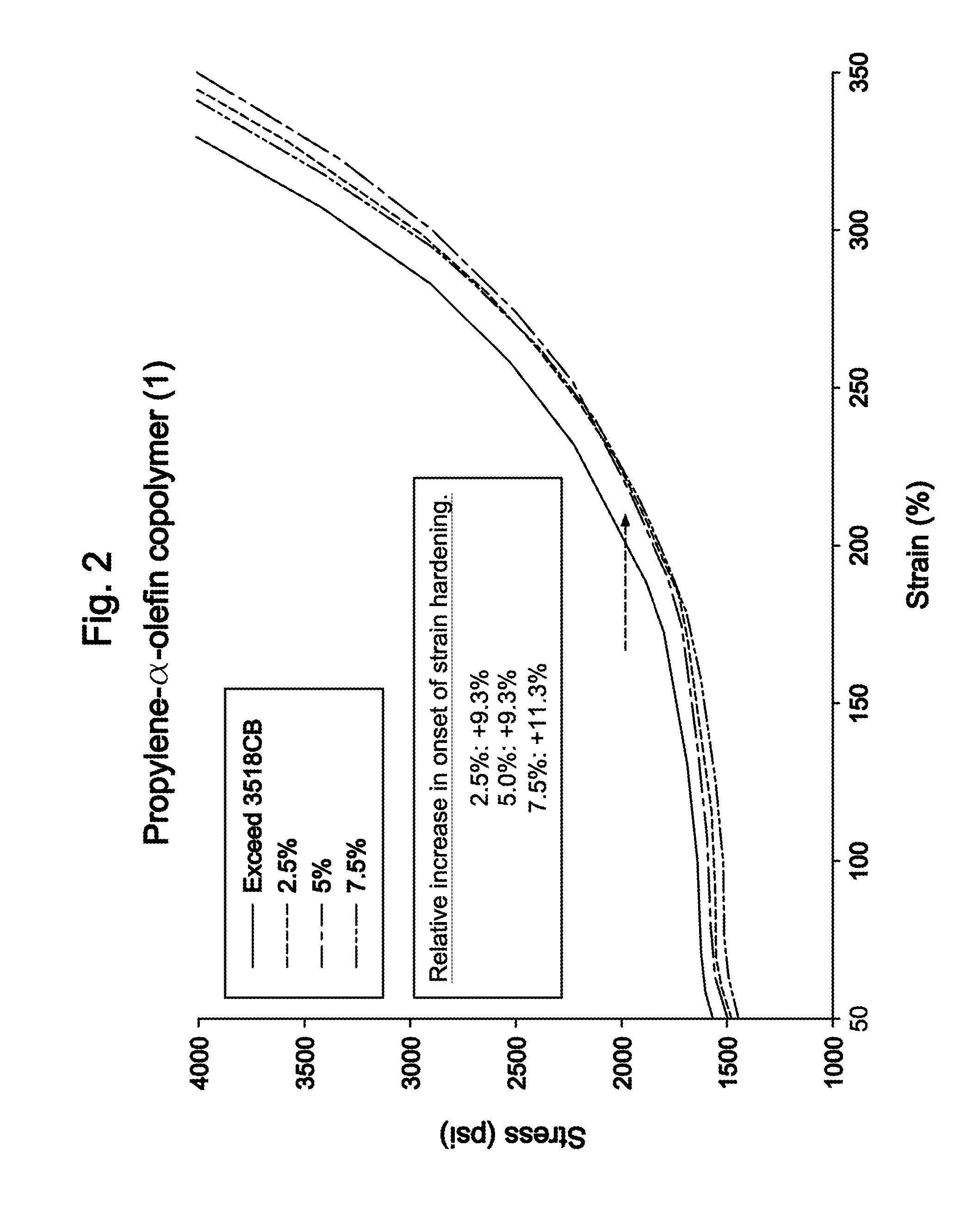

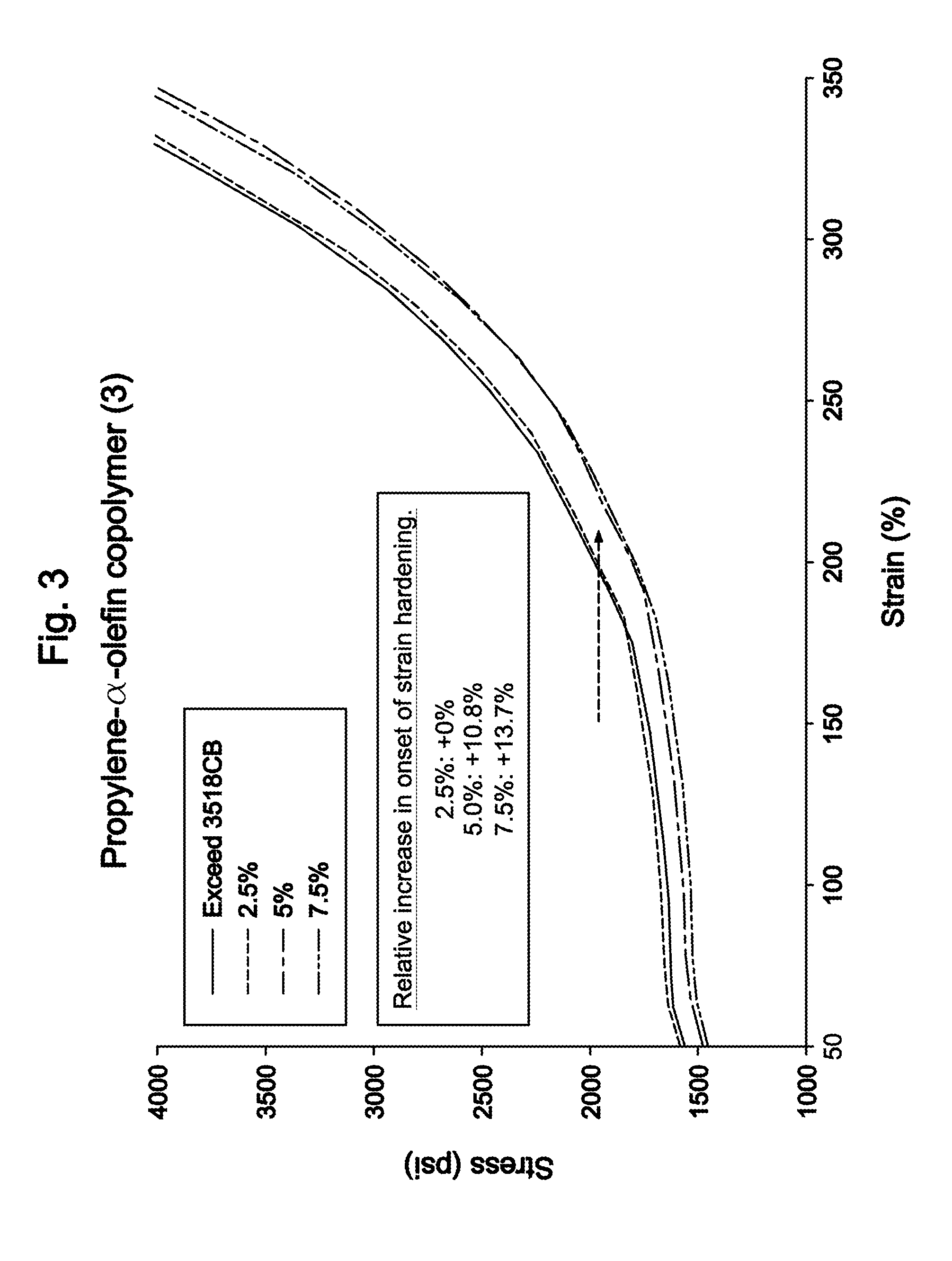

Polyethylene Stretch Film

ActiveUS20100310892A1Strain hardening improvesImproved onsetSynthetic resin layered productsDomestic articlesLinear low-density polyethyleneStretch wrap

In one aspect is a film comprising: (a) within the range of from 50 to 99 wt % linear low density polyethylene based on the weight of the core composition; and (b) within the range of from 1 to 50 wt % propylene-α-olefin copolymer based on the weight of the core composition, wherein the propylene-α-olefin copolymer possesses: (i) a melting temperature (Tm) of less than 105° C., and (ii) a heat of fusion (Hf) of less than 75 J / g; wherein the film is a cast or blown film. The films have excellent strength and elasticity and are ideal for such applications as stretch wrap.

Owner:EXXONMOBIL CHEM PAT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com