Method for detecting high-temperature mineralization characteristic of sintered iron ores

A detection method and technology for iron ore, applied in the field of iron ore sintering, can solve problems such as complex detection and detection process, and achieve the effects of simple measurement method, fast detection speed and accurate detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in more detail below with examples.

[0034] The process steps of a method for detecting the high-temperature mineralization characteristics of sintered iron ore are:

[0035] (1) The iron ore powder is made into a powder with a particle size of less than 0.074mm in the grinding equipment, and then according to the ratio of 2.0 alkalinity, the iron ore powder and the CaO reagent with a purity greater than 99.9% are mixed evenly in the sample mixer to prepare Iron ore powder mixture;

[0036] (2) Make the mixture of CaO reagent and iron ore powder into a small cylindrical cake of Φ3mm×5mm in the sample preparation equipment;

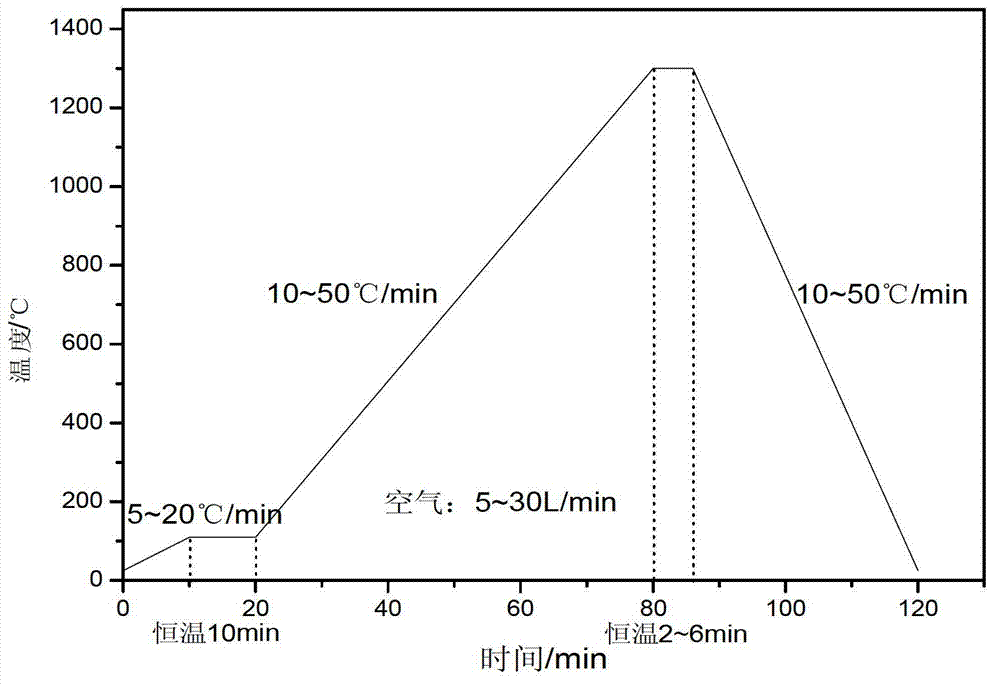

[0037] (3) Place the sample in a diameter of Φ5mmAl 2 o 3 crucible, and then Al 2 o 3 The crucible was placed in a comprehensive thermal analyzer, raised from room temperature to 110°C at a heating rate of 10°C / min, kept at 110°C for 10 minutes, and then raised from 110°C to 1300°C at a heating rate of 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com