Program control system and method for testing heat storage and release cycling performances of phase change material

A phase change material and cycle performance technology, applied in the direction of material thermal development, material thermal analysis, and material analysis, can solve the problems of narrowing the temperature range of phase change material storage and release heat test, complicated operation, low test efficiency, etc., to improve Test efficiency and accuracy, extend temperature range, avoid effects of residual heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

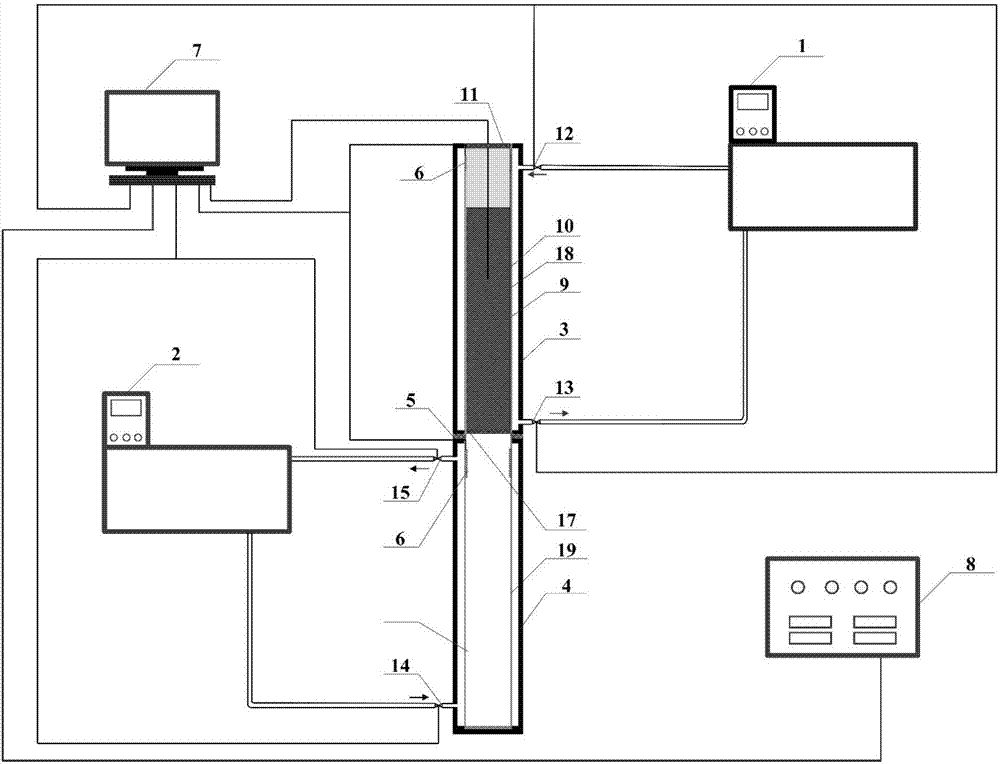

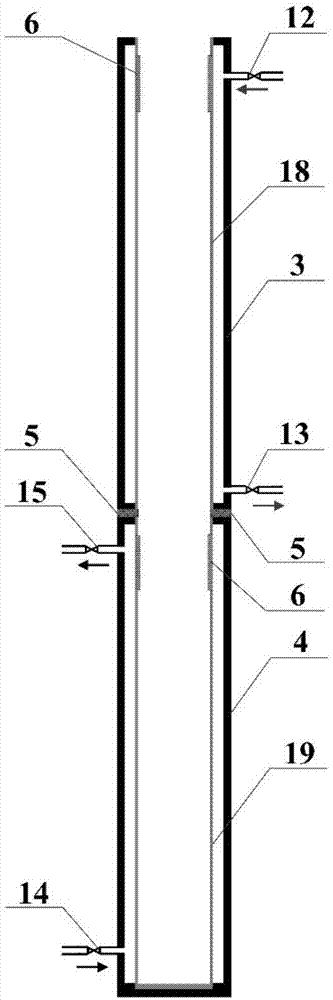

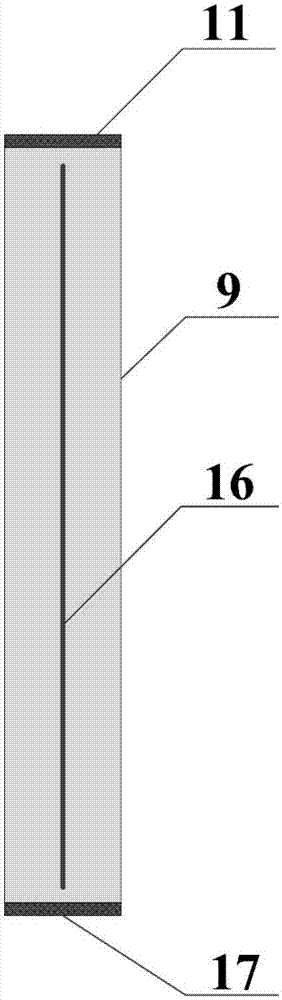

[0038] In order to make the object, technical solution and advantages of the present invention clearer, the following will further describe the embodiments of the present invention in detail in conjunction with the accompanying drawings.

[0039] like figure 1As shown, the program control system for testing the heat storage and release cycle performance of phase change materials includes a high-temperature constant temperature bath 1, a low-temperature constant temperature bath 2, a high-temperature fluid circulation jacket 3, a low-temperature fluid circulation jacket 4, an insulating partition 5, and an automatic lifting rod 6 , program controller 7, data acquisition instrument 8, phase change material sample tube 9. First put a certain mass of phase change material 10 into the phase change material sample tube 9 and cover it with a heat-insulating sealing cover 11, then put the phase change material sample tube 9 into the high temperature fluid circulation jacket 3 and fix ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com