Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Act as a reducing agent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

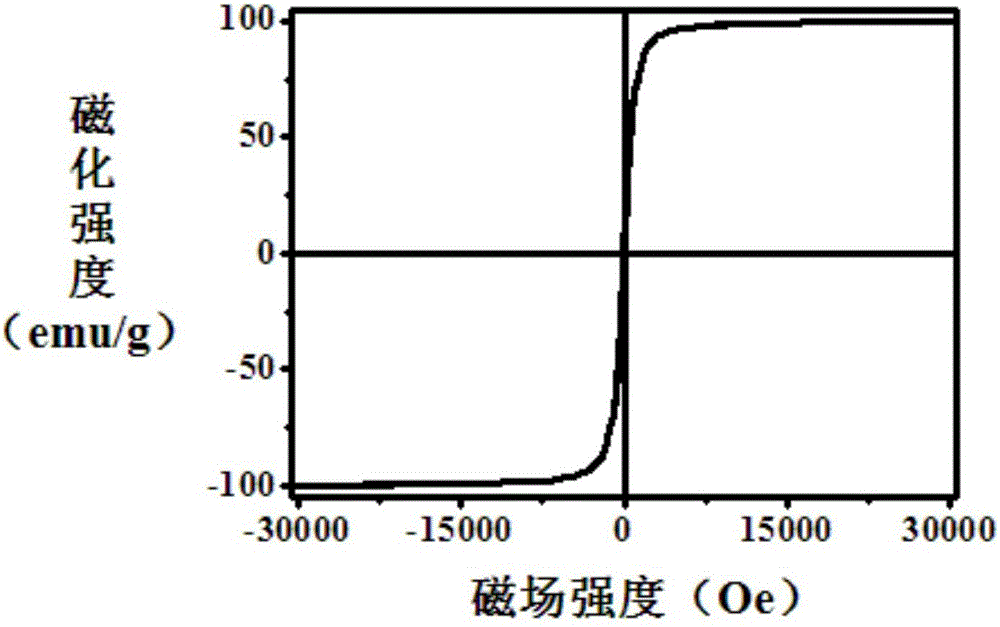

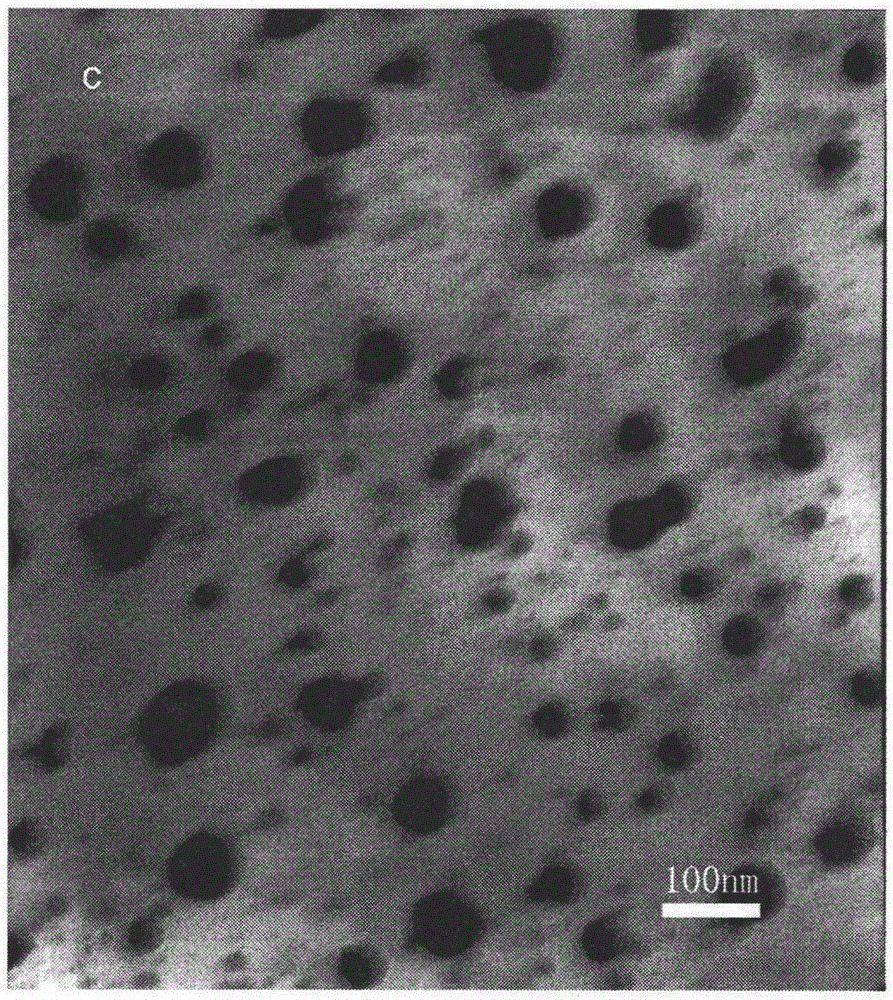

Preparation method of core-shell magnetic/gold nano particles

ActiveCN102861921AGood dispersionStrong magnetic responseMaterial nanotechnologyControlled releaseSuperparamagnetism

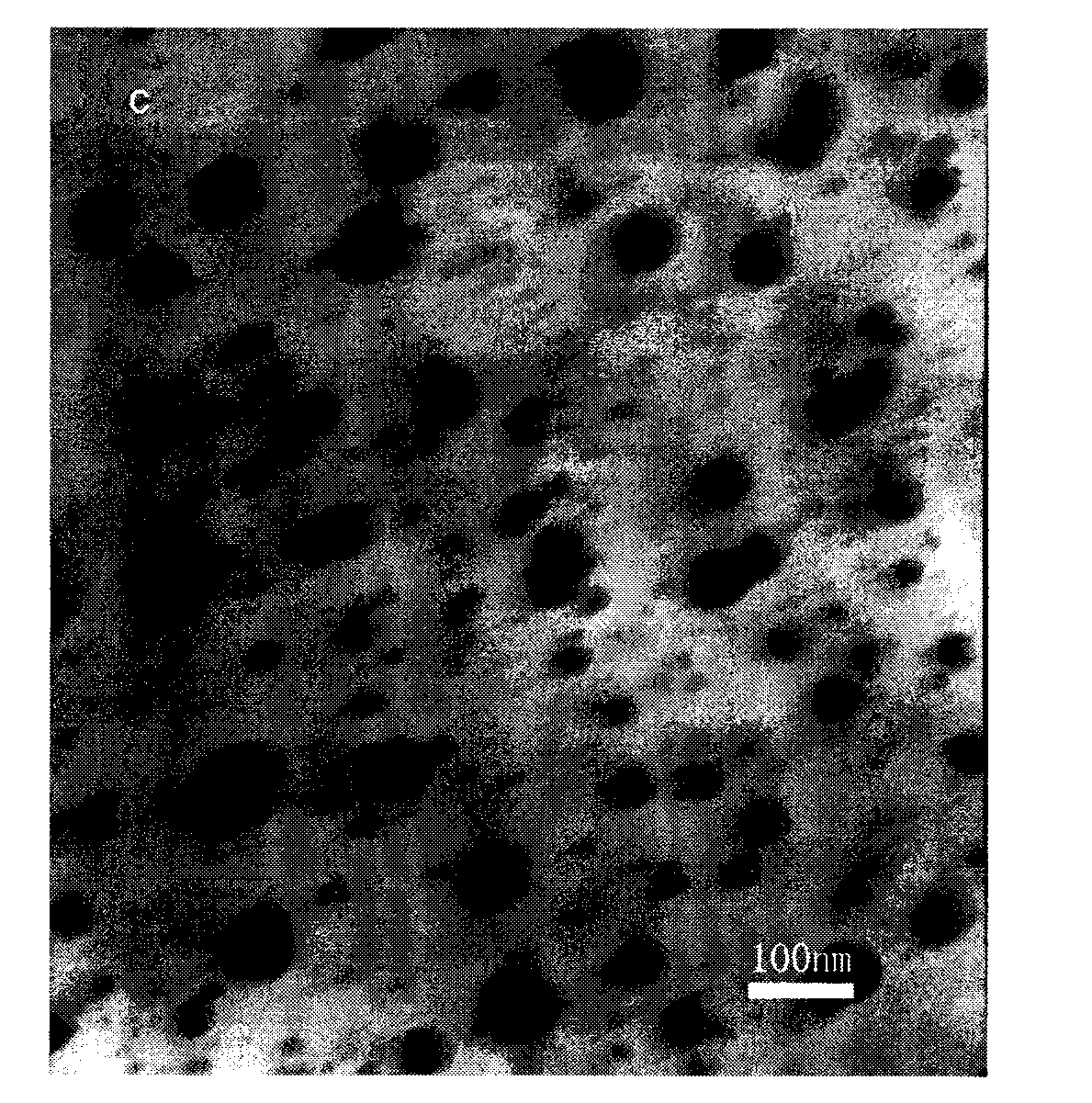

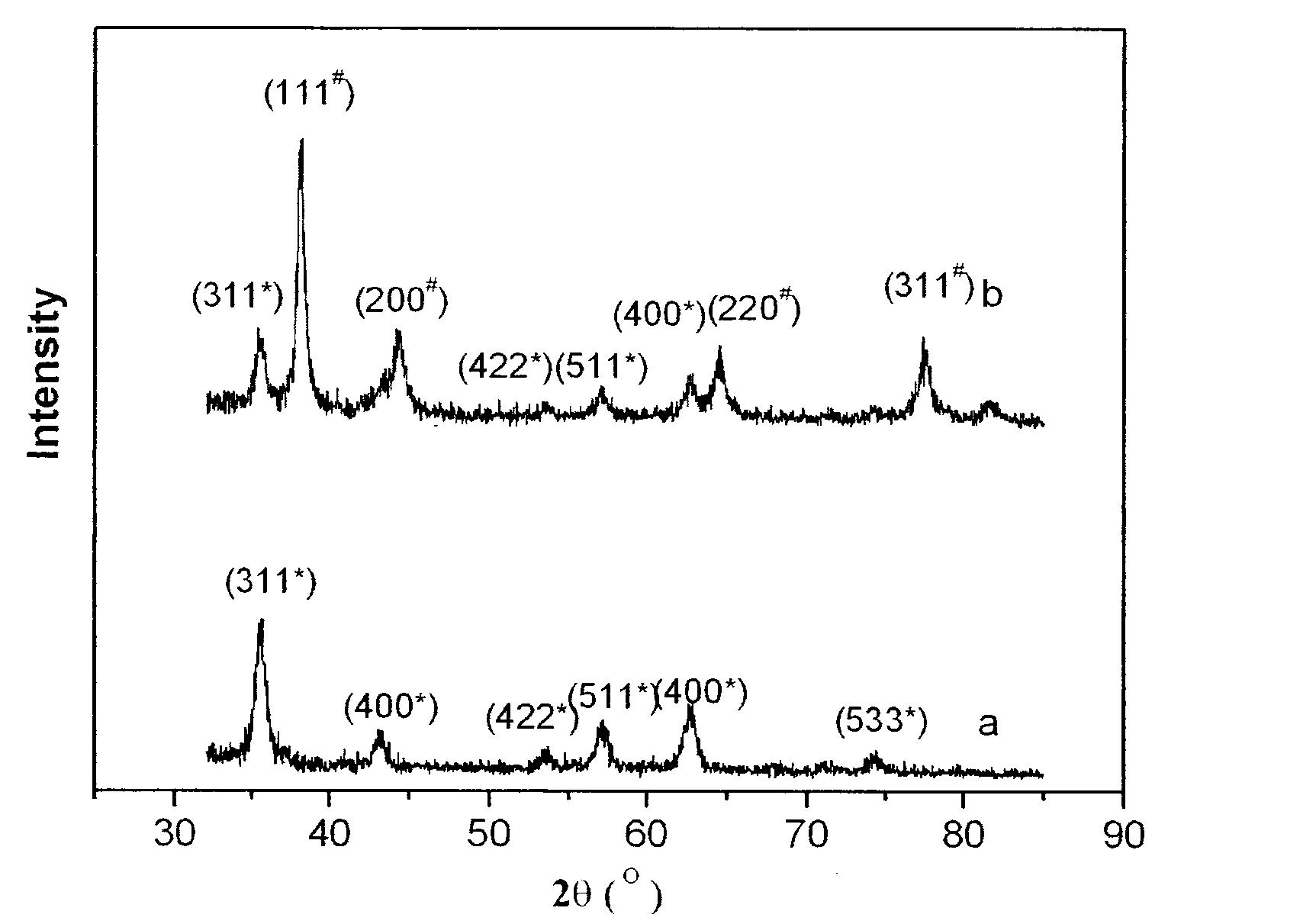

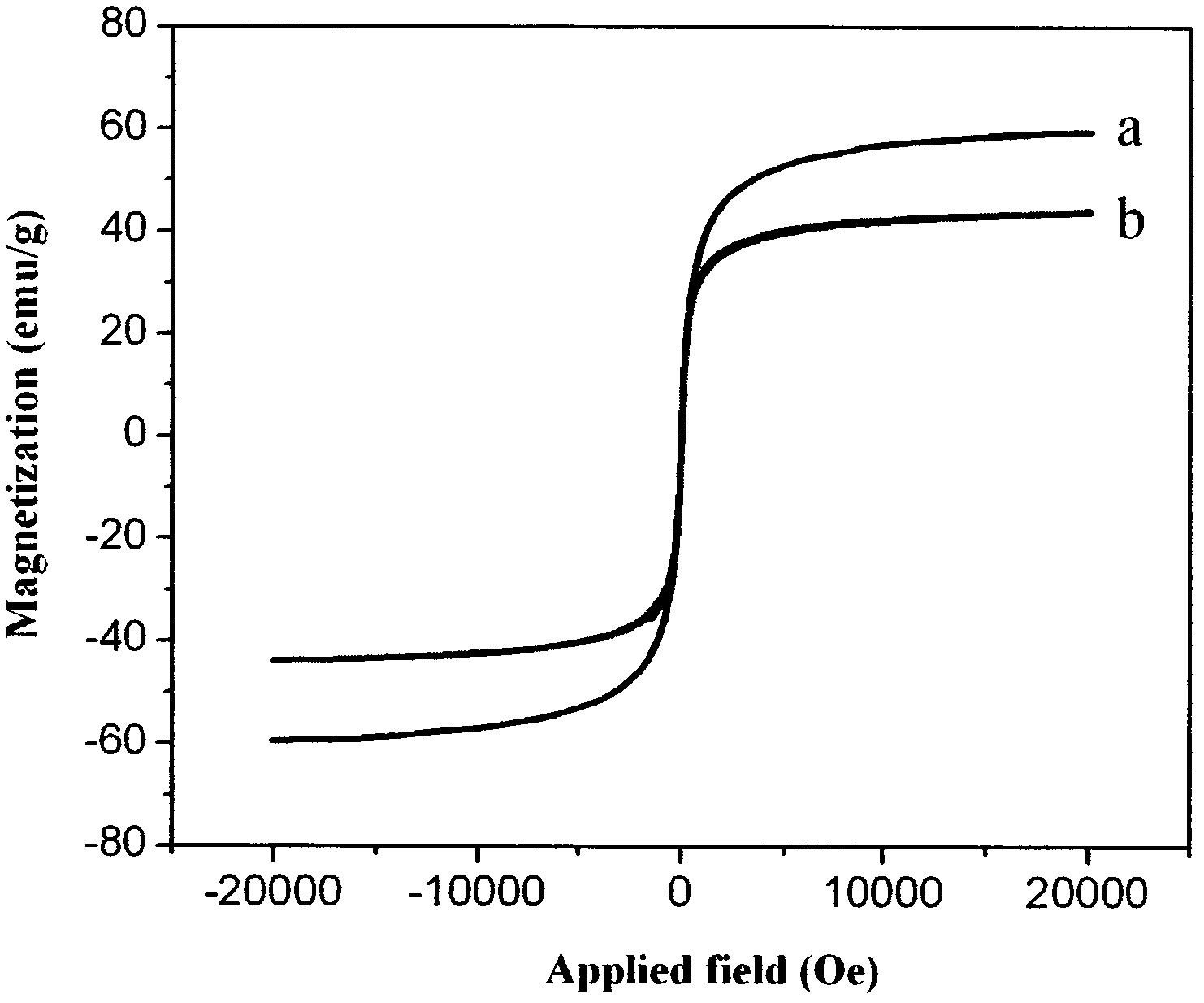

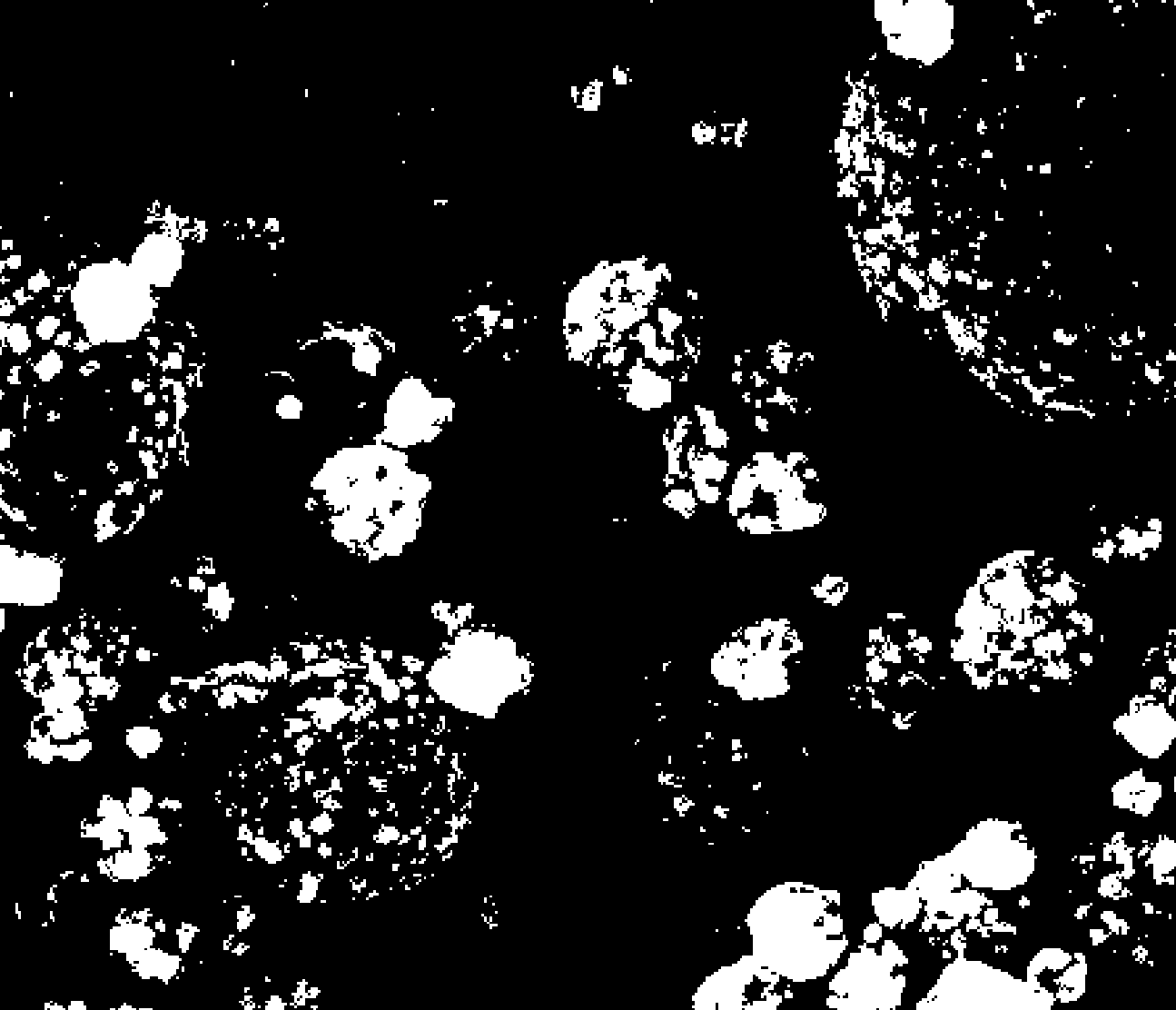

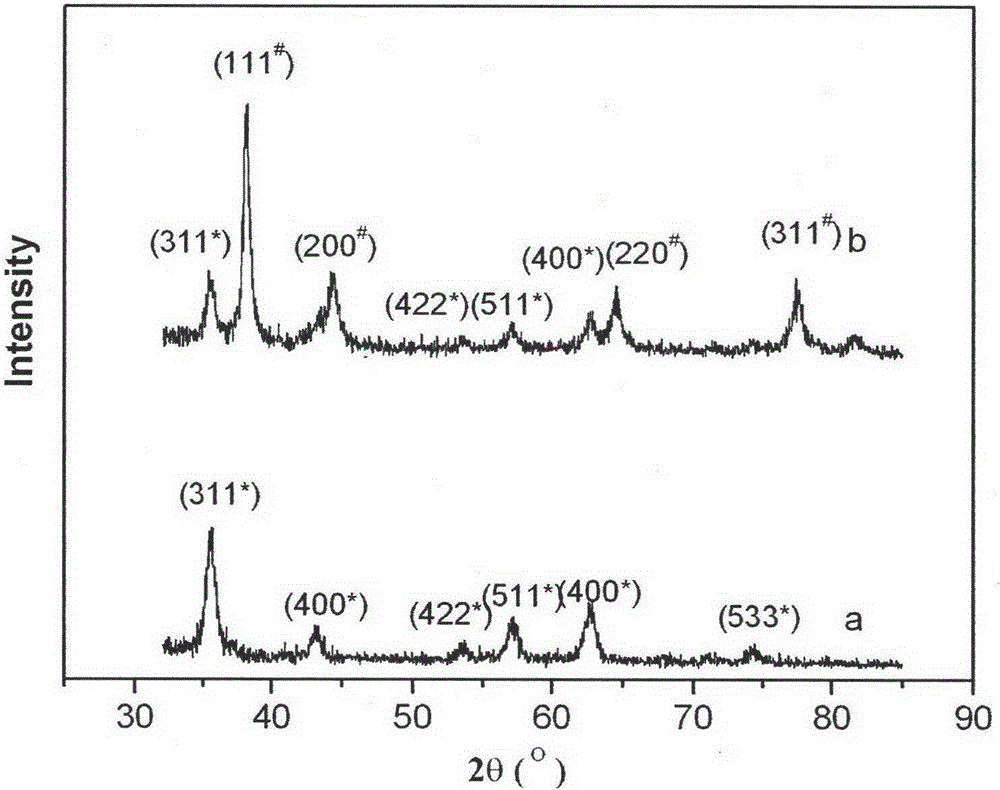

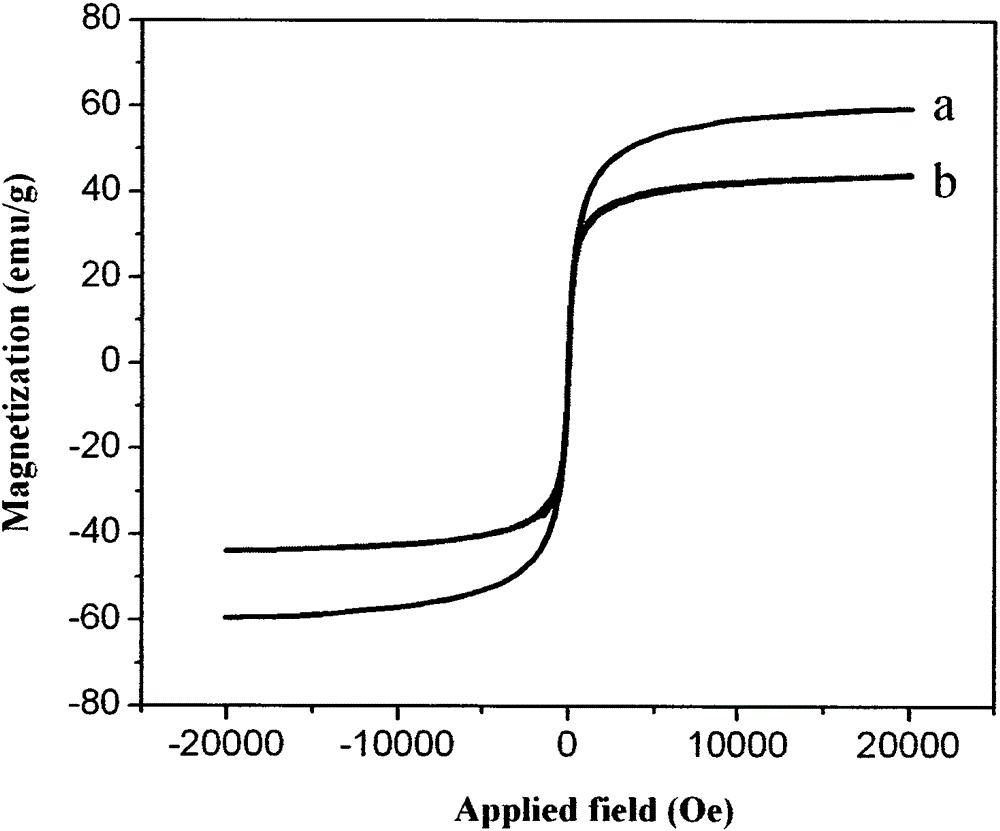

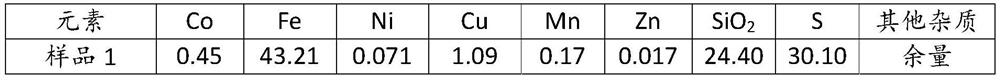

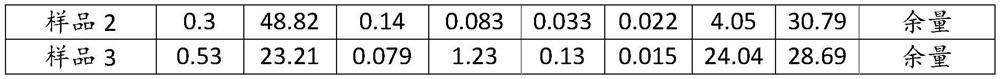

The invention discloses a preparation method of magnetic / gold nano particles. The preparation method comprises the following steps: firstly adopting a co-precipitation method to prepare the magnetic Fe3O4 nano particles; polymerizing the dopamine in-situ on the surfaces of the magnetic particles to obtain Fe3O4 nano particles modified by the poly dopamine; introducing polyphenol and amino groups to the surfaces of the Fe3O4 nano particles; absorbing the nano gold seeds on the surfaces of the modified magnetic particles through the static action; adopting the nano gold which is absorbed on the surfaces of the magnetic particles as the seed, adopting the polyphenol on the surfaces of the magnetic particles as a reducing agent, gradually adding the chloroauric acid liquid to gradually produce the gold layers on the surfaces of the magnetic particles to obtain the core-shell magnetic / gold nano particles. The nano particles have good water dispersion and strong magnetic respond performance. The diameters of the nano particles are 30-100 nanometers, the saturation magnetization is 30.1-38.7emu / g, and the nano particles are superparamagnetic. The nano particles have wide application prospect on the fields of targeted drug controlled release, thermal therapy, separation of protein and enzyme, etc.

Owner:SOUTHWEST UNIVERSITY FOR NATIONALITIES

Carbon coated granularity controllable spherical lithium ferric phosphate composite positive pole material and preparation thereof

InactiveCN101420034AWide variety of sourcesThe synthesis process is simpleElectrode manufacturing processesChemical/physical/physico-chemical processesLithium iron phosphateGranularity

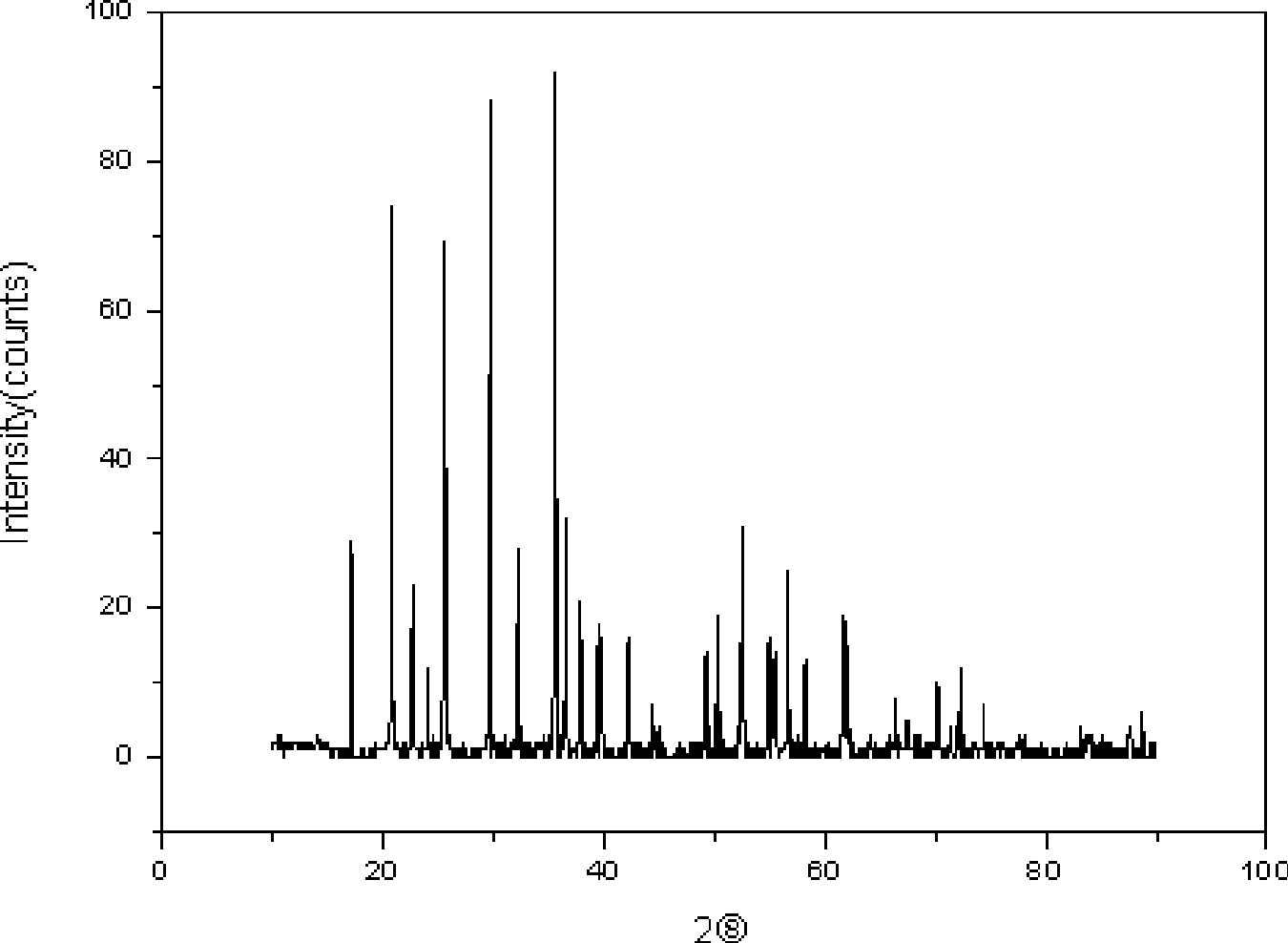

The invention discloses a carbon-coated granularity controllable sphere lithium iron phosphate compound anode material and a preparation method thereof, the steps of the preparation method is as follows: 1) the Fe<3> compound is weighted according to mol ratios as below: 1.95-2.05 of the Fe<3> compound, 1.95-2.05 of lithium source compound, 0.01-0.2 of phosphorus source compound and 2 of carbon source; 2) defined amount water is added into the Fe<3> compound, the lithium source compound, the phosphorus source compound and the carbon source, and is mixed and placed into a stirring grinder for grinding, thus obtaining precursor solution; 3) a precursor solution is granulated by spraying and drying for obtaining yellow precursor solution powder; 4) the precursor solution powder is calcined under the condition of atmosphere protection and is cooled. By adopting the spraying and drying, the obtained sphere powder granularity is evenly distributed and the size of the granularity can be adjustable; glucide is taken as the carbon source, thus achieving the purpose of thinning the particles and improving the product purity and performance; and the synthesis technique is simple, the source of the raw material is wide, thus greatly reducing the manufacturing cost.

Owner:李庆余 +2

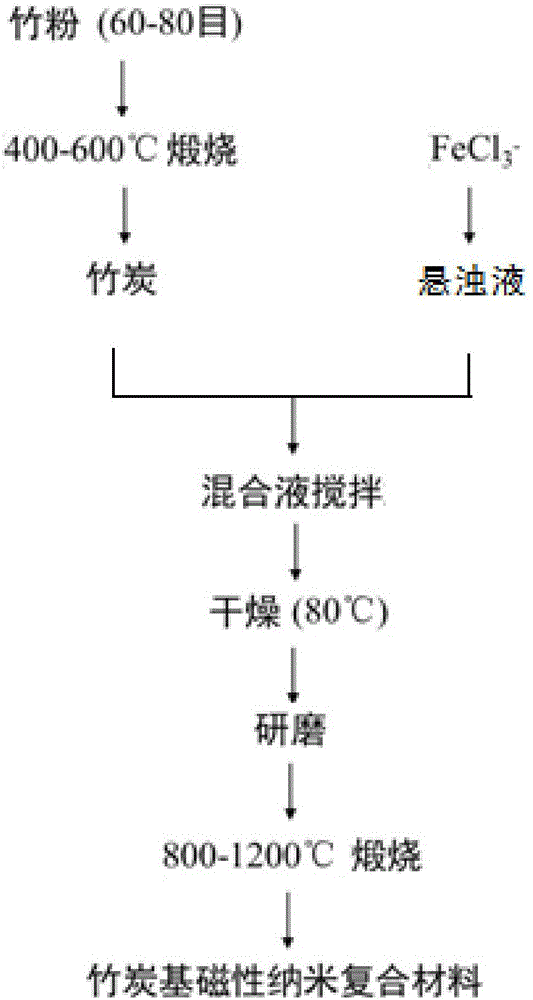

Bamboo charcoal-based magnetic composite material and preparation method

InactiveCN105817203AHigh yieldSimple manufacturing processOther chemical processesAlkali metal oxides/hydroxidesIron saltsMagnetic media

The invention belongs to the technical field of materials, particularly relates to a bamboo charcoal-based magnetic composite material, and further discloses a preparation method of the material .The method comprises the steps that bamboo charcoal is utilized as a carrier, a chlorine-containing iron salt serves as the raw material, and the composite material is prepared through a high-temperature thermal cracking reaction .According to the bamboo charcoal-based magnetic composite material, moso bamboo powder with a rich natural pore structure serves as the raw material to prepare biochar to serve as a metal carrier and a carbon source, magnetic media are introduced into the biochar through the high-temperature thermal cracking reaction, composite iron oxide or zero-valent iron biochar can be orientedly synthesized by controlling the reaction temperature, the preparation process is simple and easy to operate, operation is convenient, the process conditions are easy to control, the time is saved, the raw materials are cheap, the product yield is high, complex and expensive equipment is not needed, the cost is reduced, the problems that the cost is high, and the preparation process is complex in the traditional method of introducing the magnetic media are solved, and the bamboo charcoal-based magnetic composite material and the preparation method are particularly suitable for industrial production and popularization.

Owner:INT CENT FOR BAMBOO & RATTAN

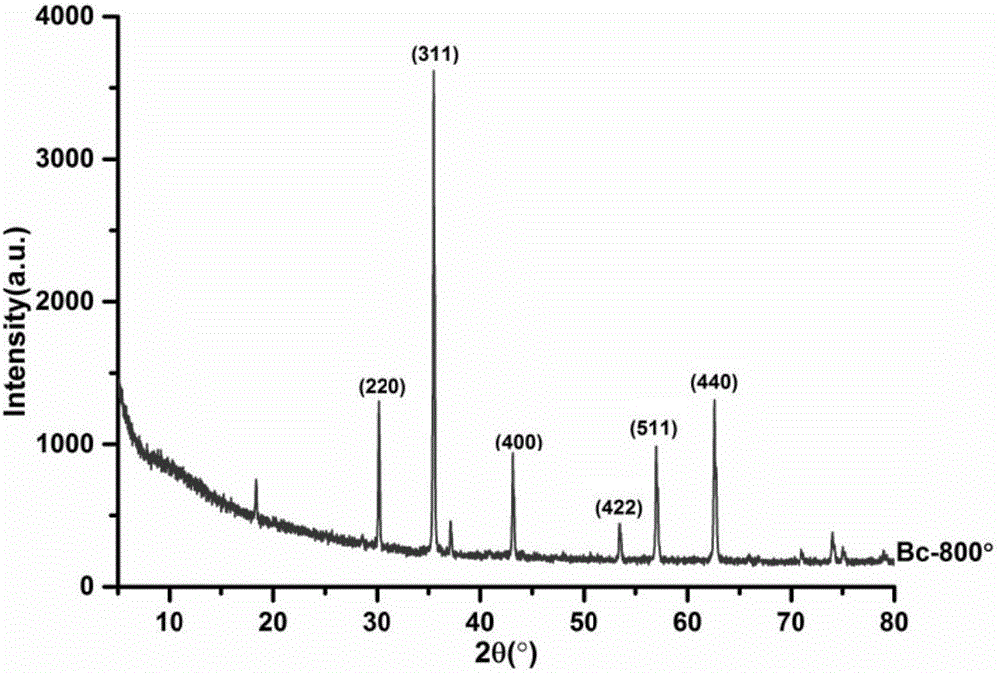

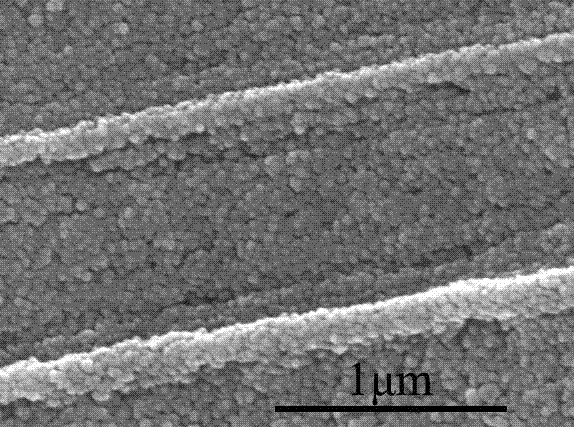

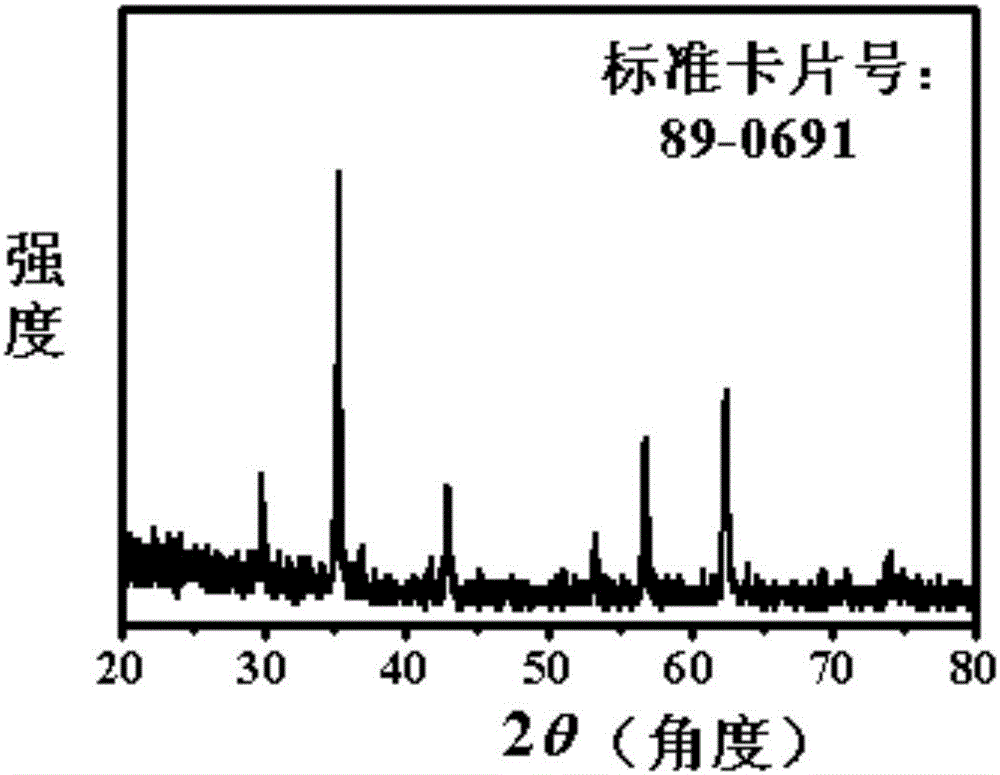

Ferrum oxidate nano magnetic material and method for preparing the same

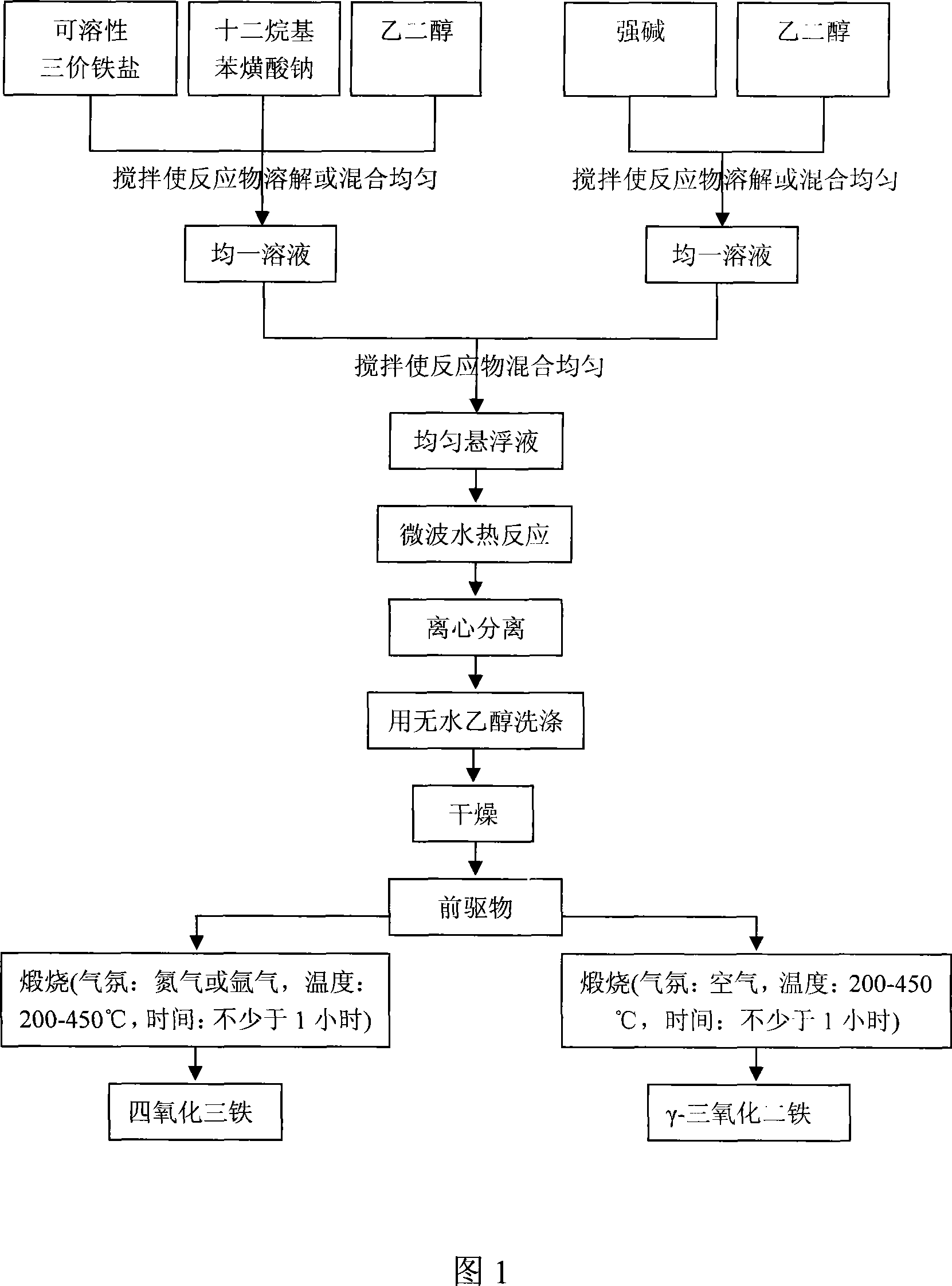

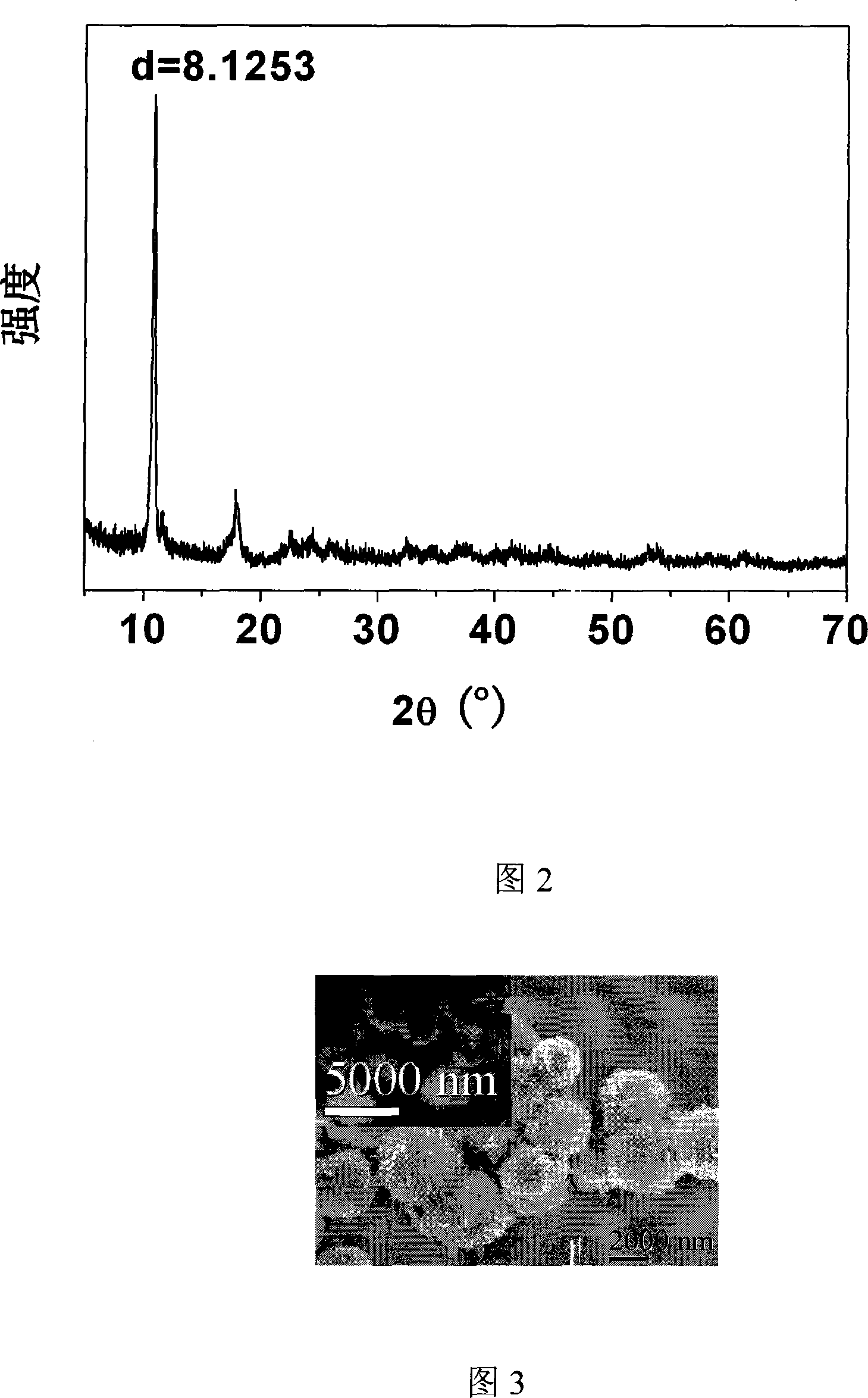

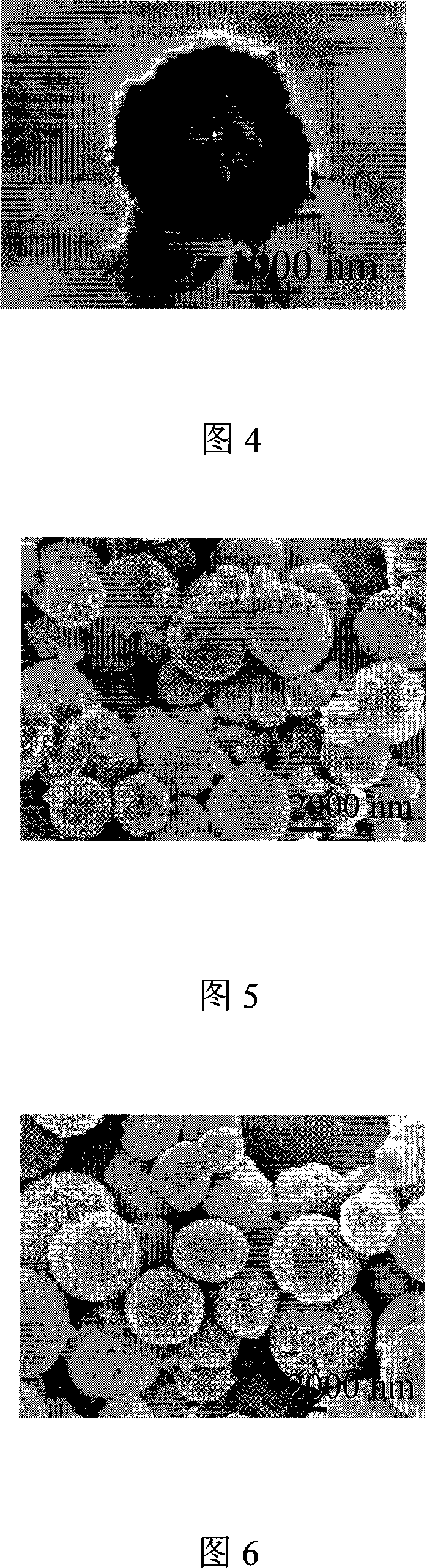

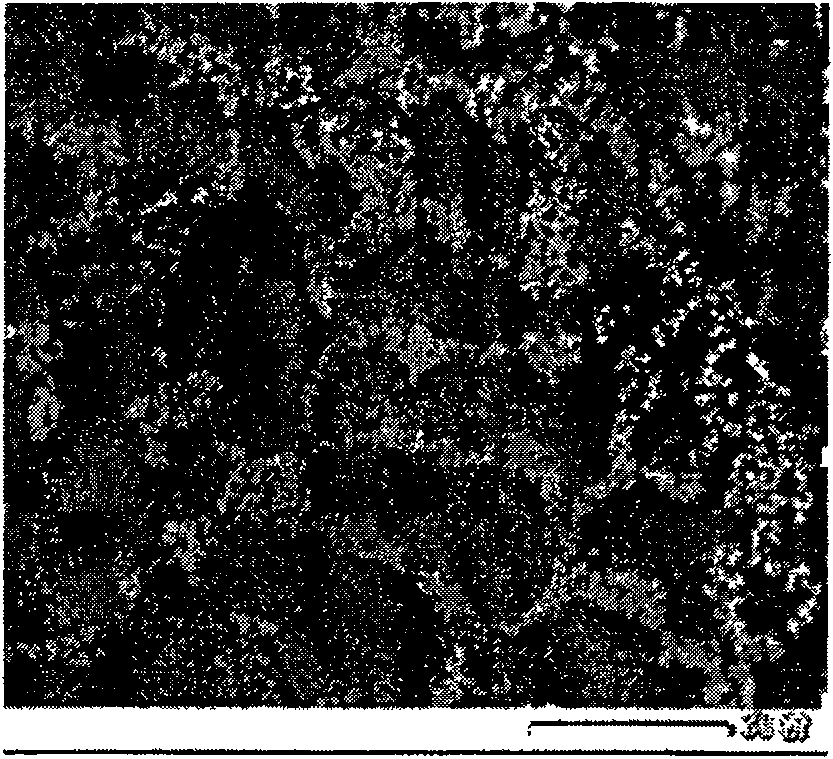

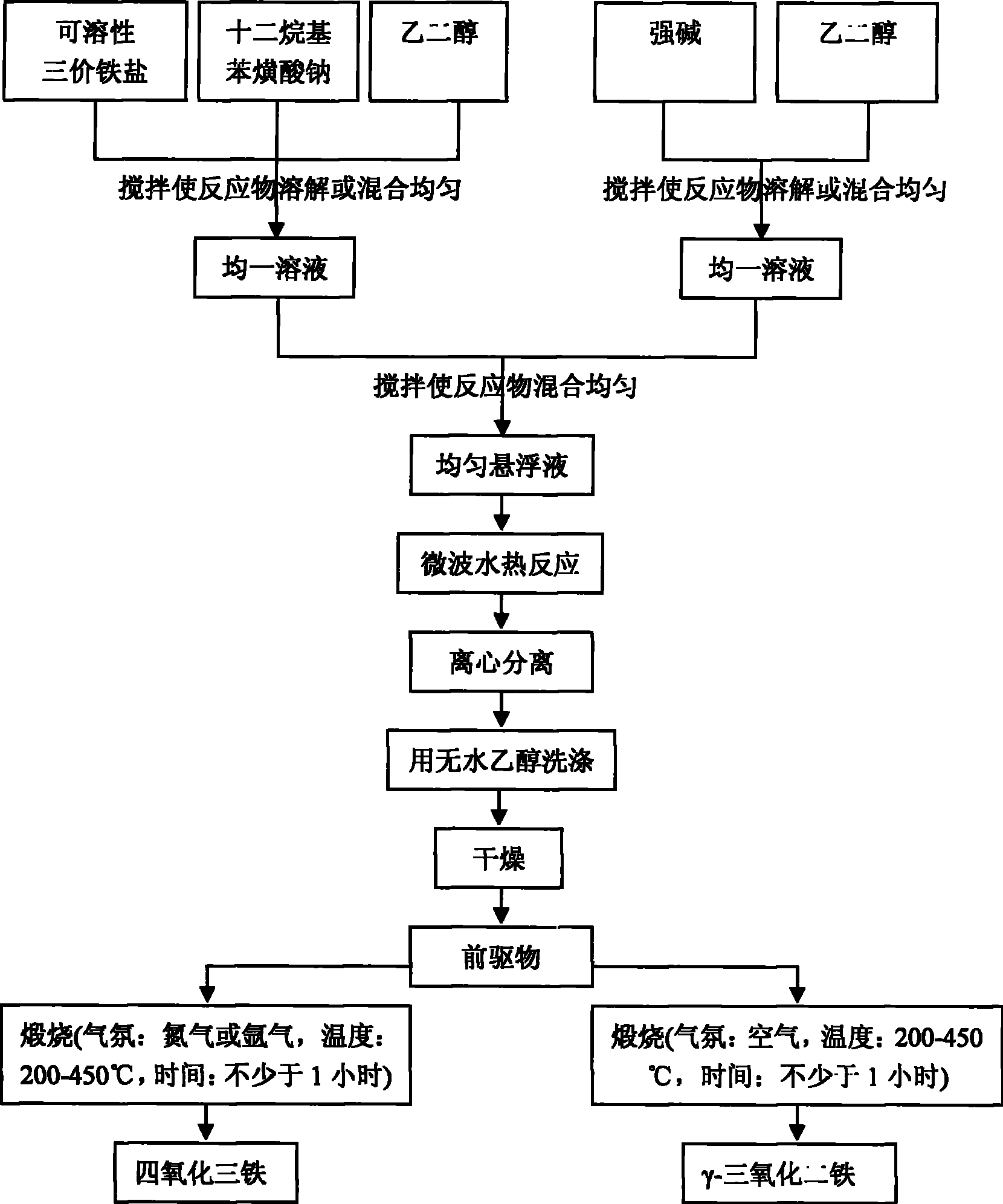

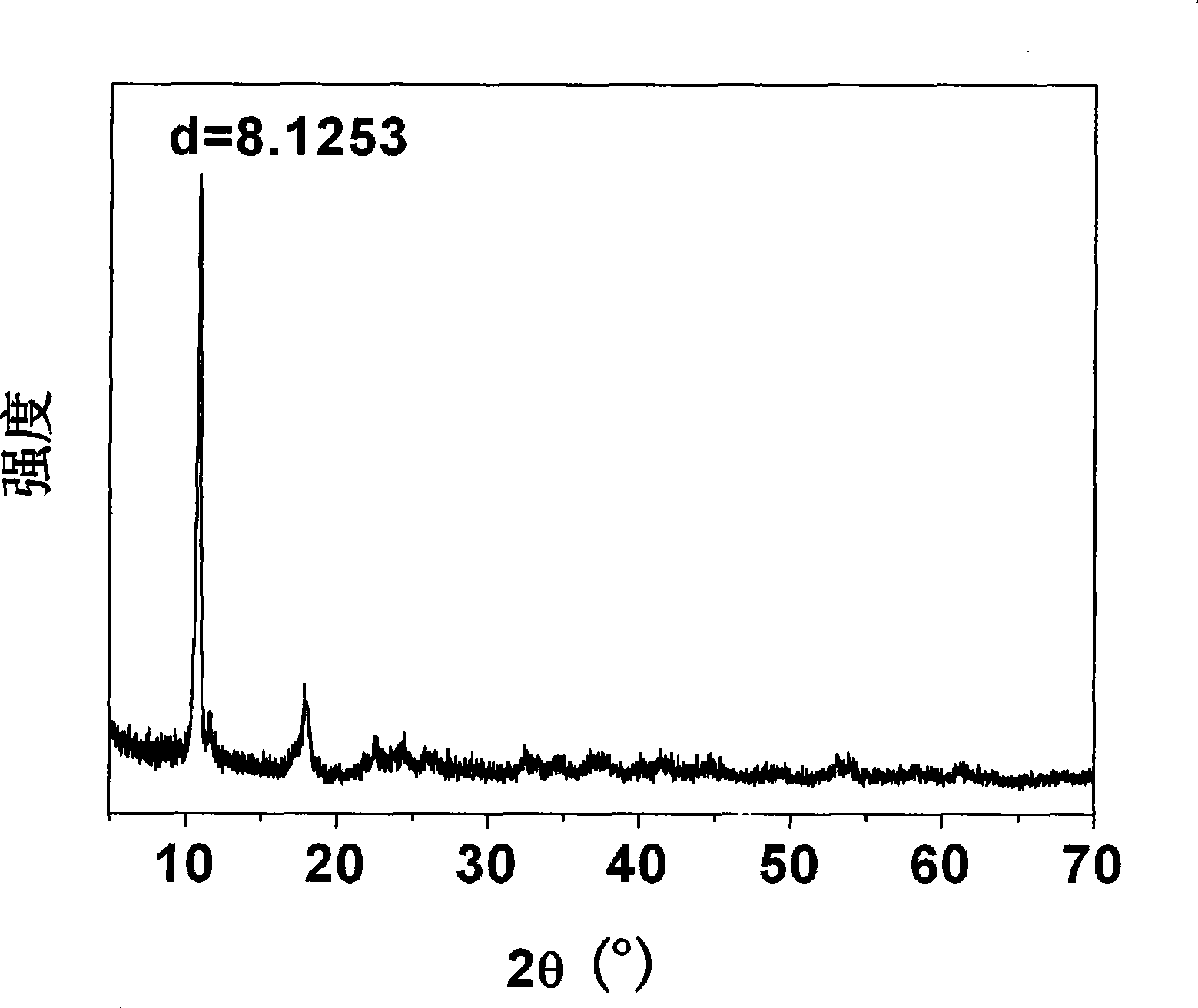

InactiveCN101117241AAct as a reducing agentEasy to manufactureInorganic material magnetismFerroso-ferric oxidesSolventPolytetrafluoroethylene

The invention relates to a nanomagnetic material of iron oxide and the fabrication method, and belongs to the nano-material fabrication field; the invention adopts glycol as a solvent and a reducing agent, and adopts sodium dodecyl benzene sulfonate as a surfactant, and adopts dissoluble trivalent iron sodium and alkali as a raw material, a mixing process under a room temperature is conducted to make a homogeneous suspension; the mixed liquid is turned into a polytetrafluoroethene lining to conduct a microwave water thermal reaction, after the reaction is over, the product from the reaction is separated, washed and dried to make a precursor nano-powder which is calcined to make a ferroferric oxide nano-powder or gamma ferric oxide nano-powder; the nano-powder body has a hollow ball structure assembled by a nano-piece, the hollow ball dimension is two to four micron while the inner hollow dimension of the hollow ball is one to three micron; the invention is characterized in low raw material cost, easy process, easy operation, controllable profile and so forth; the specific surface area is high, the magnetic performance is favorable.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

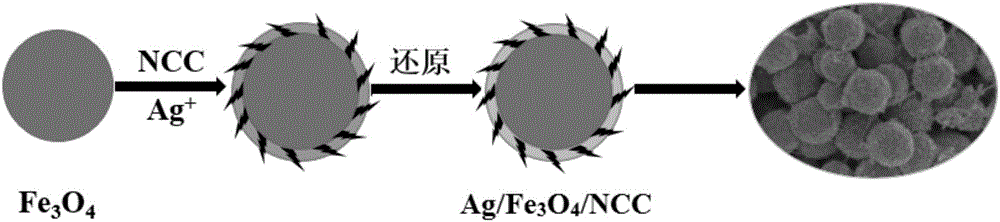

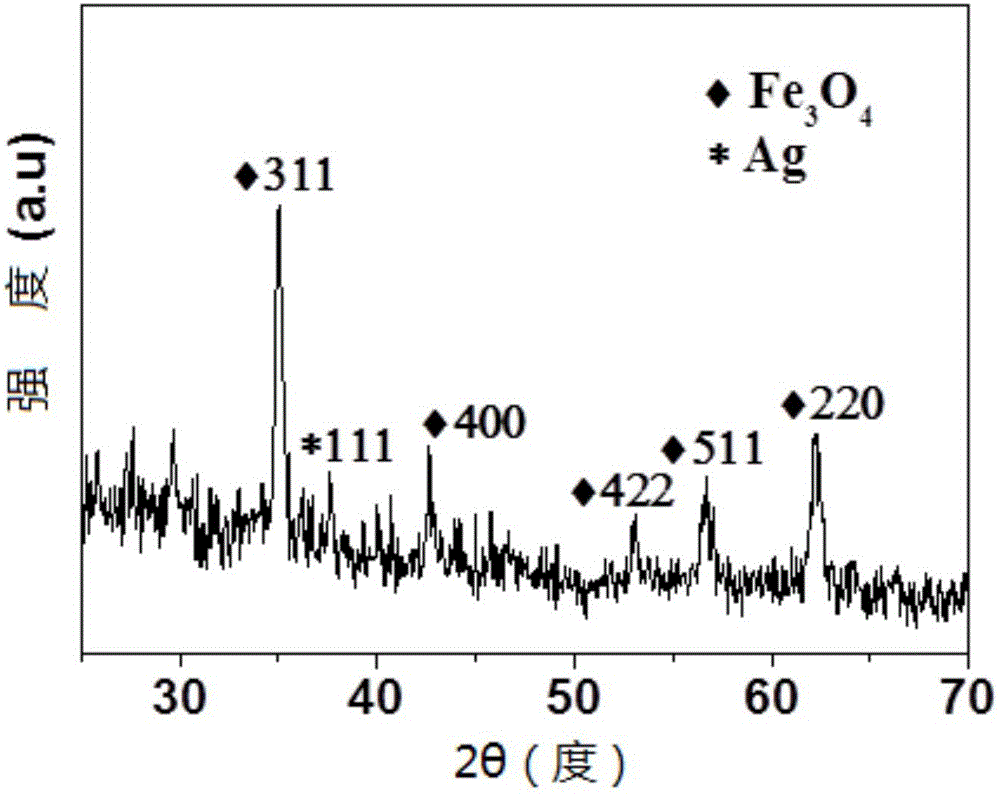

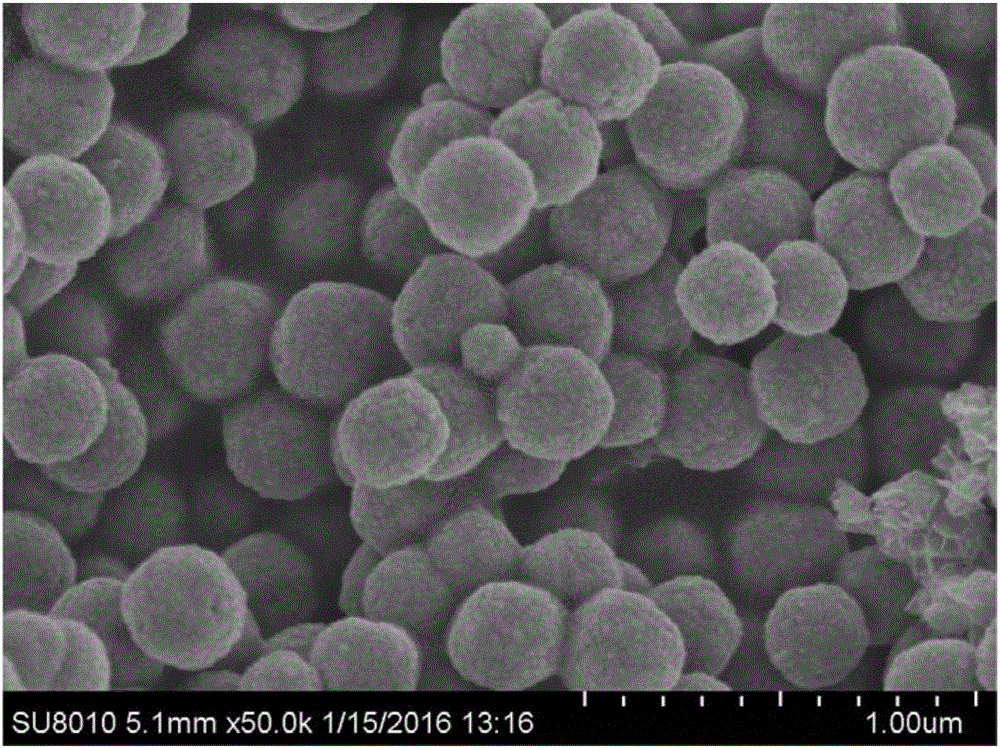

Ag/Fe3O4/nano-cellulose tri-element composite material and preparation method thereof

InactiveCN105688992AHigh bonding strengthGood monodispersityBiocideWater/sewage treatment by irradiationMicrowaveSolvent

The invention discloses a preparation method of a Ag / Fe3O4 / nano-cellulose tri-element composite material. Nano-cellulose is used in the preparation method and plays a role as a reducing agent, and improving of binding strength between Ag and Fe3O4 nanoparticles is facilitated. The preparation method is environment-friendly, pollution-free and high in reaction selectivity and reaction efficiency; water is used as a solvent, so that the preparation method is wide in raw material source and low in cost, and production cost is lowered. The Ag / Fe3O4 / nano-cellulose tri-element composite material can be prepared through a hydrothermal method and a microwave hydrothermal method, so that industrialization is facilitated.

Owner:BEIJING FORESTRY UNIVERSITY

Preparation method of porous ZnO and ZnO/Ag nanometer free-standing film

InactiveCN103204538ASimple stepsUnlimited volumeMaterial nanotechnologyZinc oxides/hydroxidesFiltrationOrganic dye

The invention belongs to the technical field of nanometer material preparation and performance research and in particular relates to a preparation method of a porous ZnO and ZnO / Ag nanometer free-standing film and a method of using the porous ZnO and ZnO / Ag nanometer free-standing film for organic dye photo-catalytic degradation treatment. The preparation method comprises the following steps of: preparing a basic zinc carbonate nanometer precursor in an aqueous solution containing zinc acetate and hexamine; removing a reaction mother solution by carrying out vacuum filtration on the prepared precursor and forming a uniform film layer on the surface of filter paper; and drying for peeling off the filter paper and the precursor to obtain the basic zinc carbonate nanometer precursor free-standing film; roasting the free-standing film to obtain the porous ZnO nanometer free-standing film; adding a proper amount of silver nitrate in the precursor preparation process, generating Ag nanometer particles in situ on the surface of the nanoribbon and finally forming the ZnO / Ag nanometer composite free-standing film. The preparation method of the porous ZnO and ZnO / Ag nanometer free-standing film is low in consumption, environmentally-friendly and easy for realization of expansion, and has prospect in large-scale industrial production.

Owner:TONGHUA NORMAL UNIV

Method for preparing foam aluminium sandwich structure

The invention relates to a method for preparing a foam aluminium sandwich structure. Foam aluminium is processed into samples of any required size by using wire cutting or other machining methods. The method comprises the following steps: performing derusting and deoiling treatment on the surface of the foam aluminium; mixing k3AlF6 and KAlF4 in a ratio of 1:1-2, heating the mixture till the mixture is in a molten state, cooling the mixture for crystallization, grinding crystals into powder, adding water into the powder to prepare a suspension in a ratio of 1:2 to 4, and spreading the suspension on the surface of a foam aluminum work piece uniformly; and putting the treated foam aluminum work piece in a mold, placing the mold in a furnace at the temperature of between 520 and 585 DEG C, keeping the temperature for 2 minutes, taking the mold out, injecting molten alloy melt heated to 500 to 580 DEG C into the mold, and cooling the melt to obtain the foam aluminum sandwich structure. The method for preparing the foam aluminum sandwich structure has the characteristics of high preparation efficiency, simple process, low cost and easy realization of line production.

Owner:GUANGDONG OCEAN UNIVERSITY

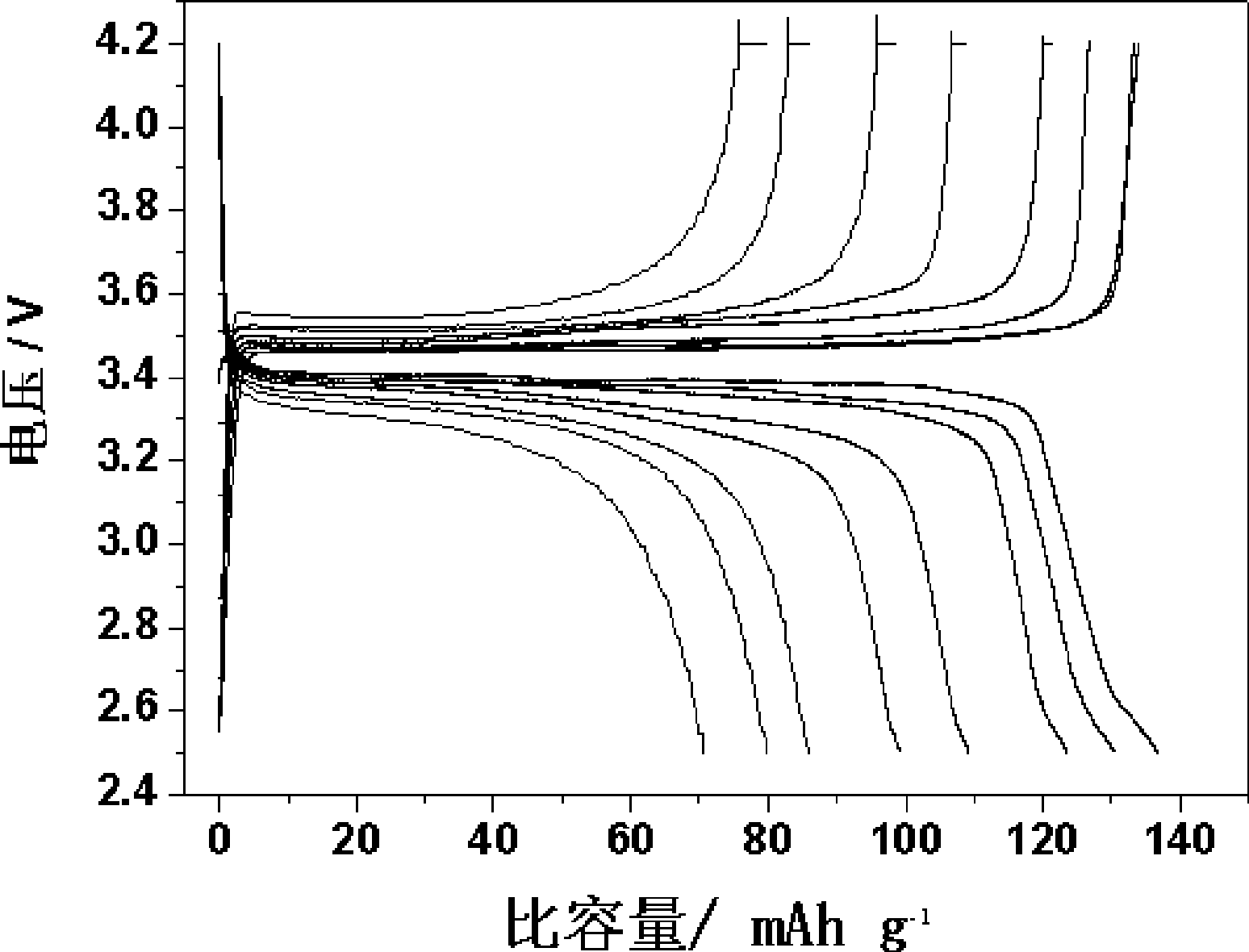

Making method of anode material Li3V2(PO4)3 of high performance/price ration lithium ion battery

InactiveCN101101986AImprove conductivityImprove electrochemical performanceElectrode manufacturing processesPhosphorus compoundsLithium hydroxidePhosphoric acid

The invention is concerned with a kind of preparation method of anode material Li3V2(PO4)3 to lithium ion cell with sol-gel and carbothermal reduction; combine technology. It takes lithium hydroxide or lithium carbonate, ammonium vanadate and phosphoric acid as raw material, citric acid as complexing agent with 3 to 3.05 :2 Li / V mol ratio and 2 to 4 : 3 to 3.05 citric acid / Li mol ratio. Put into water to get sol, vaporize the solvent to get gel, dry to get disaggrega-tire organic matter in advance in 300 to 400 degree air, then bake for 8 to 16 hours in Ar or N2 atmosphere containing H24-8 percent during 700 to 900 degree, cool and grind to get Li3V2(PO4)3 / C. This anode material has 132 mAh / g specific votume and 3.6 to 4.15 V work pressure with the range of 3 to 4.2 V pressure. Compared with LiCoO2, Li3V2(PO4)3 is advanced ion cell with high capability anode.

Owner:朱先军

Method for electroplating metal on surface of insulating base material

ActiveCN108977862AImprove surface propertiesImprove bindingPrinted circuit manufactureConductive polymerWater soluble

The invention relates to a method for electroplating metal on the surface of an insulating base material. The method comprises the following steps that the surface of the insulating base material makes contact with a water-soluble anionic compound, so that a modified surface is produced; the modified surface makes contact with an aqueous solution containing permanganate ions, so that a manganese dioxide adsorption layer is formed on the modified surface; a conducting polymer layer is formed on the surface of the manganese dioxide adsorption layer; and electroplating is carried out on the surface of the conducting polymer layer, and thus a metal layer is formed. According to the method, the anionic compound is deposited on the surface of the insulating base material so as to form a coatinglayer tightly combined with the surface of the base material, after the modification and adsorption, an even film with a certain thickness is formed on the surface, thus, under the metal electroplating liquid and electroplating condition are the same, the deep plating capacity and dispersing capacity of the electroplating liquid can be greatly improved, the obtained metal plating layer has the characteristics of being flat, even and good in backlighting effect, and the hole breakout phenomenon and the phenomenon that certain parts of the electroplating metal layer in holes are too thin are avoided.

Owner:GUANGDONG TONESET SCI & TECH

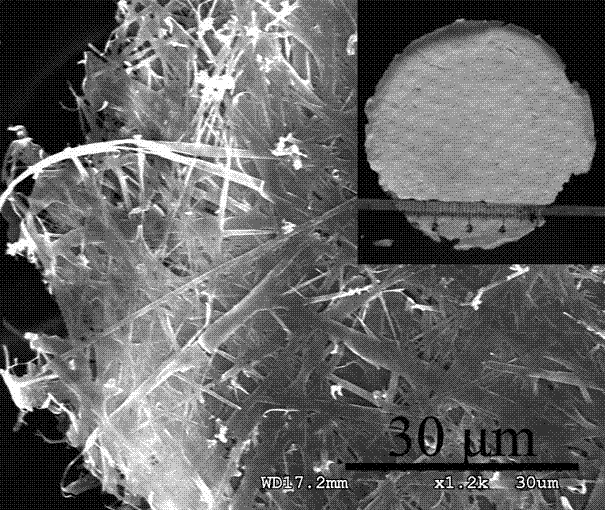

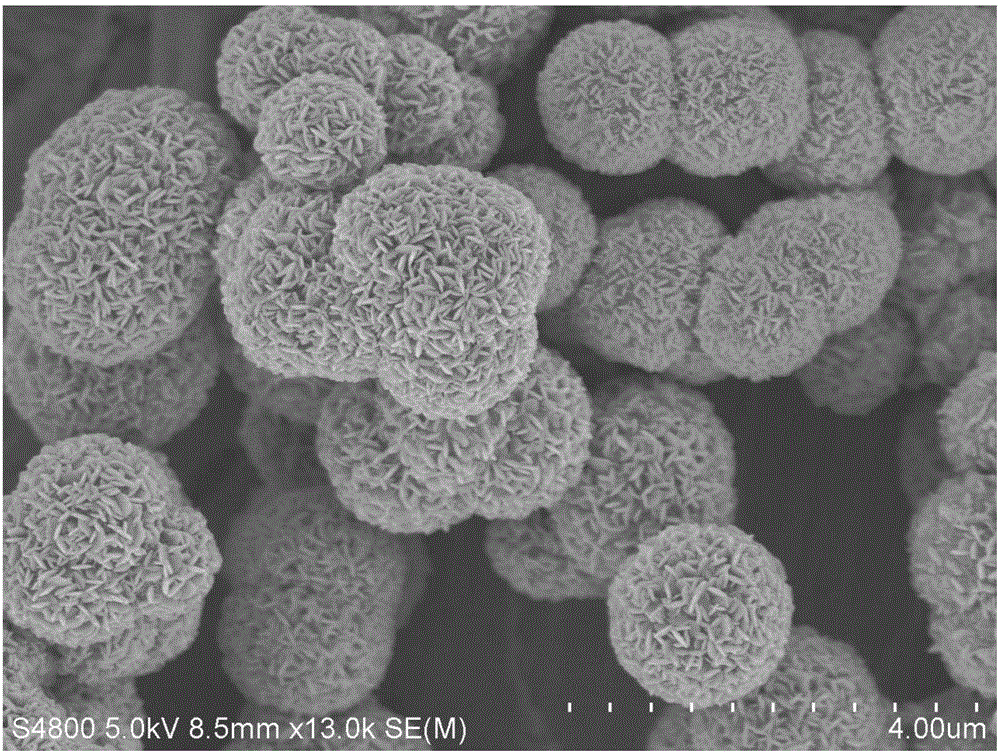

Ferroferric oxide micro-nano material as well as preparation method and application thereof

ActiveCN106745319AIncrease the number ofPrevent precipitationCell electrodesSecondary cellsMicro nanoPotassium ferricyanide

The invention provides a ferroferric oxide micro-nano material as well as a preparation method and application thereof. The preparation method comprises the steps of dissolving potassium ferricyanide into a mixed solvent of water and glycerin, and preparing a three-dimensional self-assembling spherical structure based on ferroferric oxide by virtue of a one-time solvothermal method, wherein the core of the spherical structure is formed by nanoparticles, the surface of an outer layer of a sphere is formed by polyhedral nanosheets through embedding and interweaving, and the diameter of the sphere is 1-3 microns. Compared with the prior art, the preparation method has the advantages that a synthetic method is extremely simple, the cost is low, the preparation is finished by one step, the operation is simple, the reproducibility is high, and the three-dimensional self-assembling spherical structure can be obtained under the action of glycerin. The ferroferric oxide micro-nano material has the characteristics of uniform size, high purity, low cost, easiness in industrial production and the like. The ferroferric oxide micro-nano material prepared by virtue of the preparation method presents excellent performance in the aspect of energy storage of lithium ion batteries and has potential practical application values.

Owner:ANHUI NORMAL UNIV

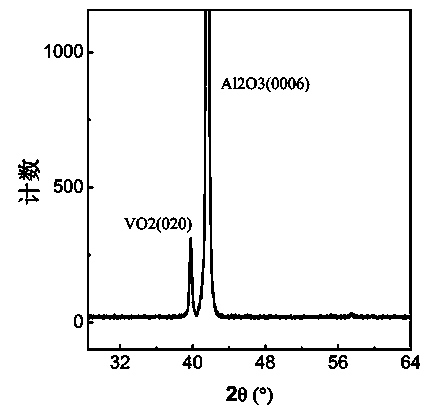

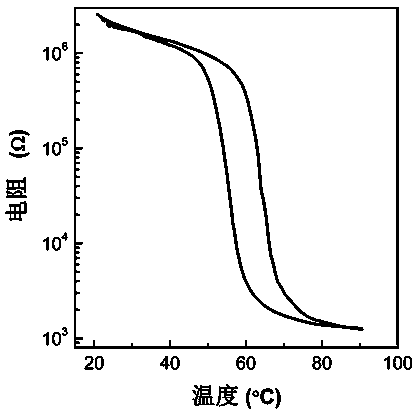

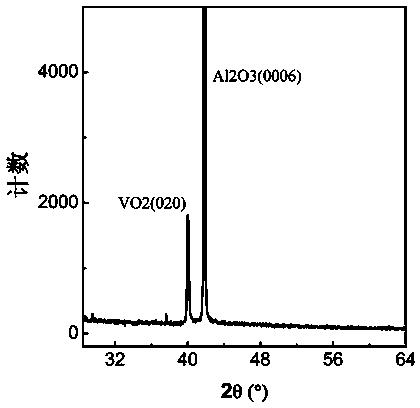

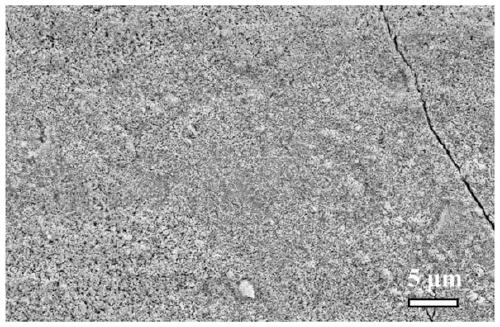

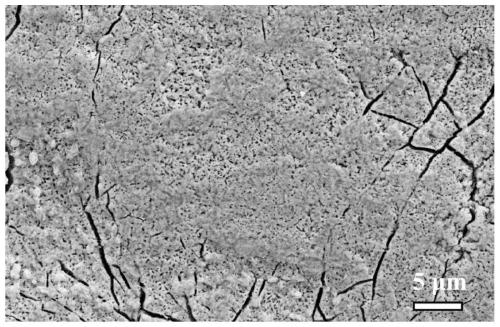

Liquid-phase preparation method of high-oriented vanadium dioxide film

ActiveCN104060241AAct as a reducing agentRestore evenlyLiquid/solution decomposition chemical coatingVanadium dioxidePhase change

The invention discloses a liquid-phase preparation method of a high-oriented vanadium dioxide film, belonging to the field of chemical function materials. The preparation method comprises the following steps: preparing precursor liquid by taking triisopropoxyvanadium oxide as solute, coating a sapphire substrate with the obtained precursor liquid to prepare a precursor film, and finally sintering the precursor film in a vacuum environment. According to the preparation method, the vanadium dioxide film is prepared by controlling vacuum sintering conditions on the basis of a liquid-phase method, the obtained film is good in growth orientation, the phase change temperature of the film is about 60 DEG C, and the change of electrical resistivity before and after the phase change is more than three orders of magnitude; in addition, the preparation process is simple and suitable for large-range popularization.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

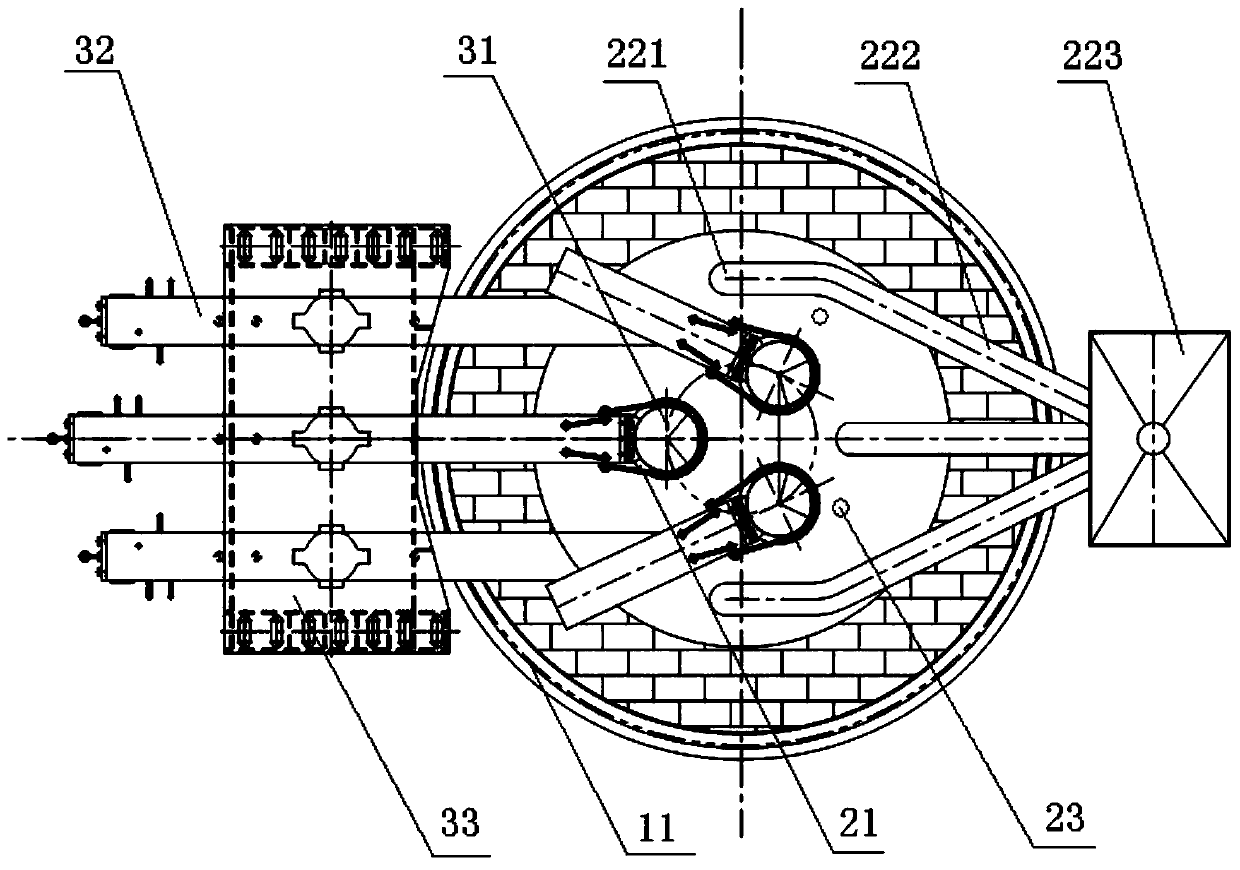

Electric melting furnace, electric melting method and method for producing rock wool by using electric smelting red mud

PendingCN110342782AArc stabilizationNo pollution in the processGlass furnace apparatusElectric furnaceWoolPower grid

The invention provides an electric melting furnace, an electric melting method and a method for producing rock wool by using electric smelting red mud, and relates to the field of high-temperature melting. An electric melting furnace body is in structure matching with an ignition device, and electric discharging points of graphite electrodes of the ignition device are respectively and electricallyconnected with resistance wires; an electrode automatic adjusting mechanism comprises an electrode lifting mechanism, the electrode lifting mechanism is electrically connected with the three-phase graphite electrodes, and the electrode lifting mechanism drives the three-phase graphite electrode to ascend and descend; and the electric melting furnace body is provided with channels for moving the graphite electrodes. According to the technical scheme, the contact area between the three-phase graphite electrodes and a molten liquid can be adjusted, and the voltage can be converted under an on-load condition, so that electric arc heat is concentrated, the electric arc is stable, and the phenomena of large fluctuation of voltage and current, unstable arc burning, short circuit and arc breakingare avoided. Impact on the power grid in an implementation process is avoided, and no harmonic pollution is caused.

Owner:北京金亚润环保科技有限公司

Method for using grapefruit juice to restore silver ions in silver nitrate solution

InactiveCN103706803AImprove stabilitySimple and fast operationNanotechnologyWater bathsAnhydrous ethanol

The invention discloses a method for using grapefruit juice to restore silver ions in silver nitrate solution. The method includes: well mixing about 20mL of freshly squeezed grapefruit juice with about 20mL of 0.01-0.1mol / L silver nitrate solution under the constant-temperature water bath at about 30 DEG C, allowing the two to react in a 50mL small beaker, standing the reaction liquid for 48 hours, using a high-speed centrifuge to separate sedimentation, washing the sedimentation with anhydrous ethanol, and centrifuging the washed sedimentation with the high-speed centrifuge to obtain the products.

Owner:HUANGSHAN UNIV

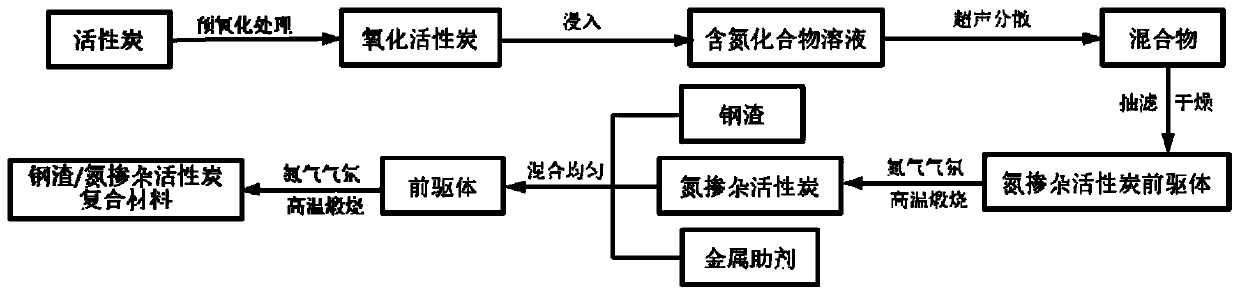

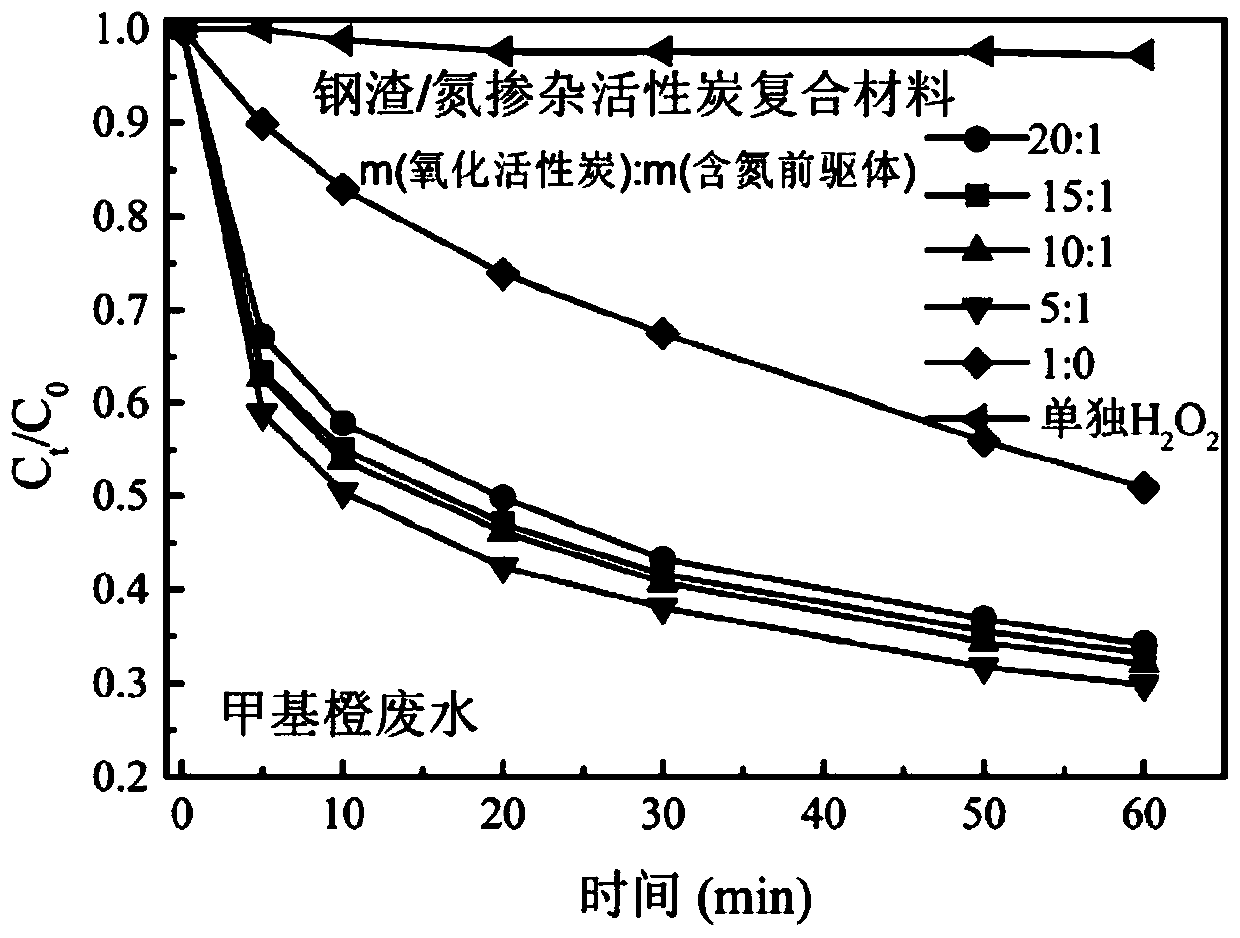

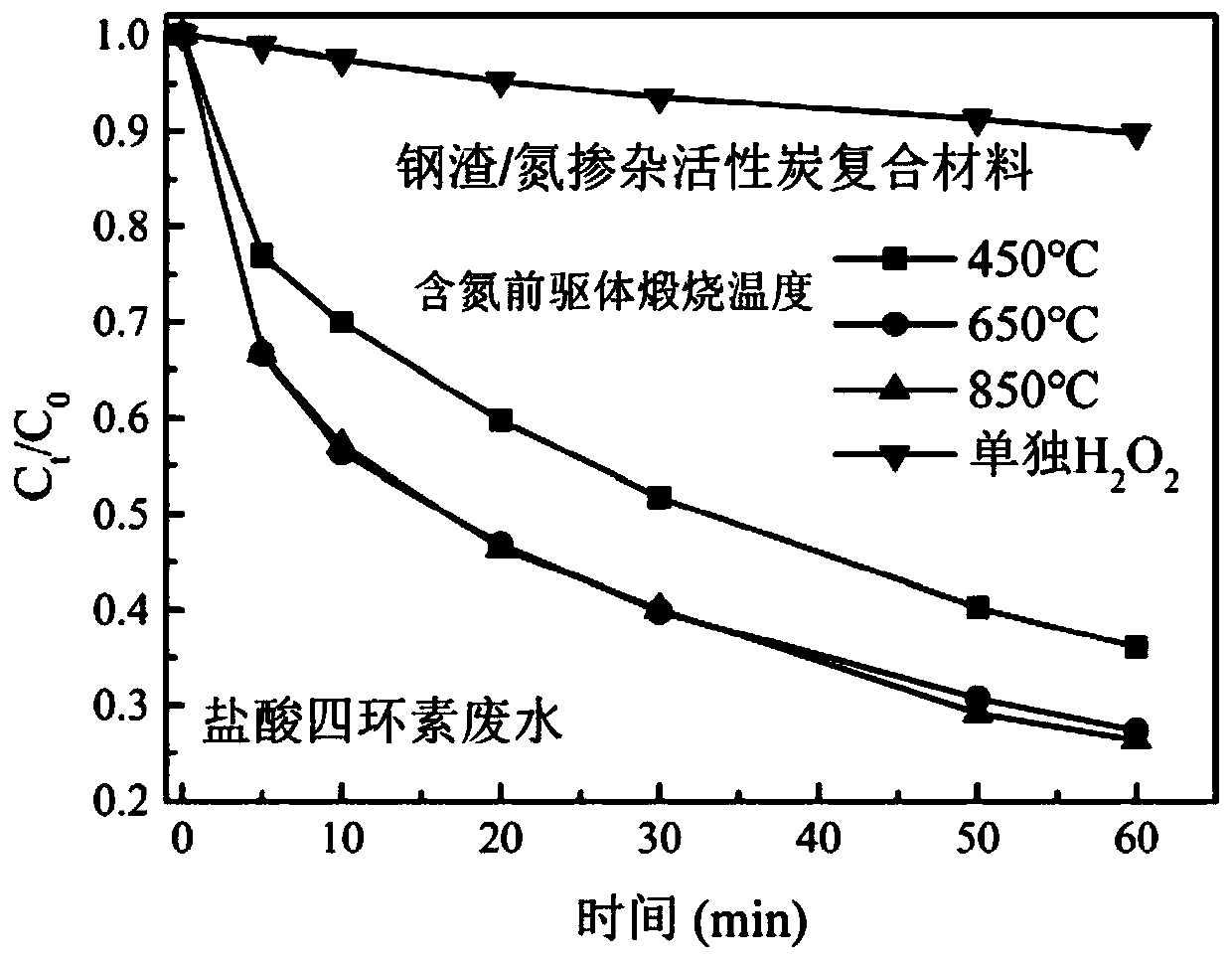

Steel slag/nitrogen-doped activated carbon composite material, and preparation method and application thereof

ActiveCN110465322ALarge specific surface areaWell-developed pore structureWater contaminantsCatalyst activation/preparationActivated carbonSlag

The invention discloses a steel slag / nitrogen-doped activated carbon composite material, and a preparation method and application thereof. The preparation method for the composite material comprises the following steps: pre-oxidizing activated carbon; then putting the pre-oxidized activated carbon into a nitrogen-containing compound solution for ultrasonic treatment, and then carrying out suctionfiltration and drying so as to obtain a nitrogen-doped activated carbon precursor; then calcining the nitrogen-doped activated carbon precursor under a nitrogen atmosphere to obtain nitrogen-doped activated carbon; and finally, mixing steel slag, a metal additive and the nitrogen-doped activated carbon, and carrying out calcining in a nitrogen atmosphere to obtain the steel slag / nitrogen-doped activated carbon composite material. The composite material prepared by the invention retains the rich pore structure of the activated carbon, introduces nitrogen-containing functional groups, contains various active metals in the steel slag, and is a highly efficient catalytic material for catalytic oxidation and removal of organic pollutants in water bodies.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

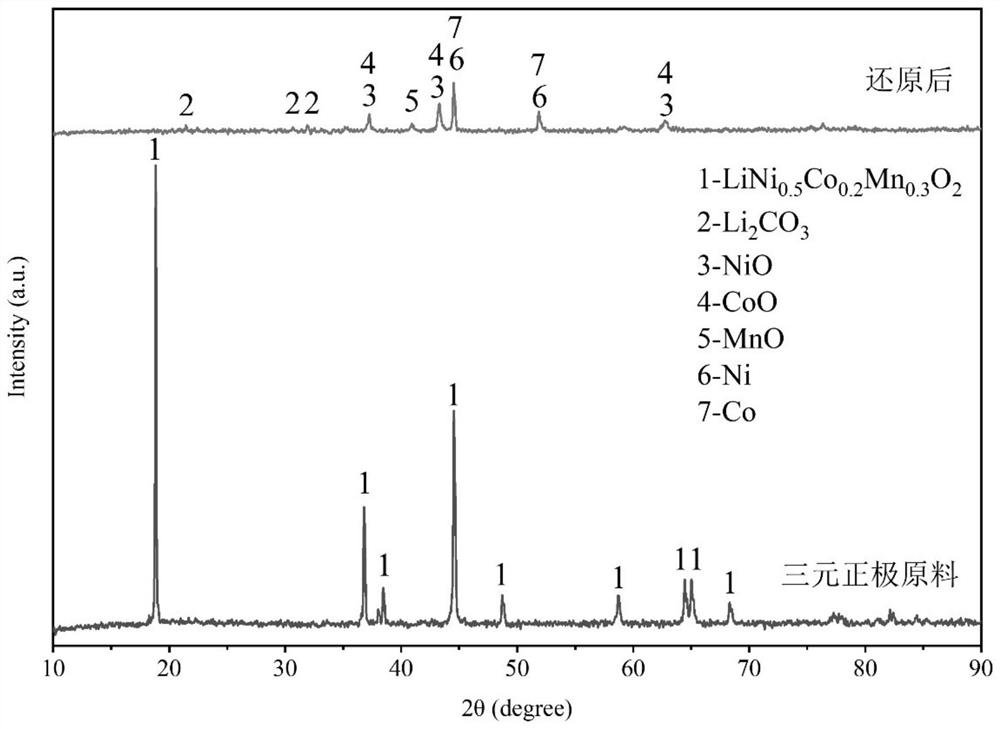

Diaphragm pyrolysis assisted recovery method for valuable metals in waste lithium battery material

ActiveCN114752769AImprove recycling efficiencyEfficient use ofWaste accumulators reclaimingLithium carbonates/bicarbonatesManganeseProcess engineering

The invention discloses a method for recycling valuable metals in a waste lithium battery material assisted by diaphragm pyrolysis, which comprises the following steps of: performing thermal reduction on high-valence transition metals in a waste ternary positive electrode material by using a diaphragm in a waste lithium battery, reducing nickel and cobalt into simple substances or divalent oxides, reducing manganese into low-valence divalent manganese, and forming lithium carbonate by a lithium element. And the reduced waste ternary positive electrode powder is leached in a hot sulfuric acid solution, and finally the leaching efficiency of lithium, nickel, cobalt and manganese is larger than 99%. Meanwhile, pyrolysis oil and pyrolysis gas generated by diaphragm pyrolysis in the thermal reduction process can be recycled as fuel. According to the technical scheme, the purposes of efficient recycling of valuable metal and efficient utilization and resource recycling of the waste diaphragm are synchronously achieved, the technological process is simple, the efficiency is high, and the transportation, storage and management cost is effectively reduced.

Owner:CHINA UNIV OF MINING & TECH

Crude copper blowing process

ActiveCN110923455ALow melting pointSpeed up meltingCombination devicesProcess efficiency improvementCopper oxideWaste treatment

The invention relates to a crude copper blowing process in the technical field of crude copper smelting. The process comprises the following steps of mixing copper-containing waste materials and copper-containing waste treatment tailings, then adding into a side blowing melting furnace, adding a co-solvent, a reducing agent and fuel, simultaneously blowing oxygen into the furnace, and carrying outmixing and blowing at 1200 to 1250 DEG C; and separately discharging blowing tailings, the crude copper and flue gas, and carrying out discharging after the flue gas is treated. The melting point oflimestone is low, so that melting of quartz stone and iron oxide can be promoted, and the fluidity can be improved. Iron, molybdenum, magnesium, calcium, silicon and the like in the furnace charge areoxidized to form oxide in an oxygen-rich environment, and the oxide is combined with the quartz stone to form tailings, so that the non-copper metal elements are separated from copper, copper in copper oxide and copper sulfide can be reduced through the iron oxide, and the copper content is improved; semi coke is used as fuel, and the content of fixed carbon is high, so that sufficient energy isprovided for combustion, the chemical activity is high, and the effect of a reducing agent can also be achieved; and the reduction rate of the copper can be improved through the cooperation of the several chemical meterials.

Owner:洛南环亚源铜业有限公司

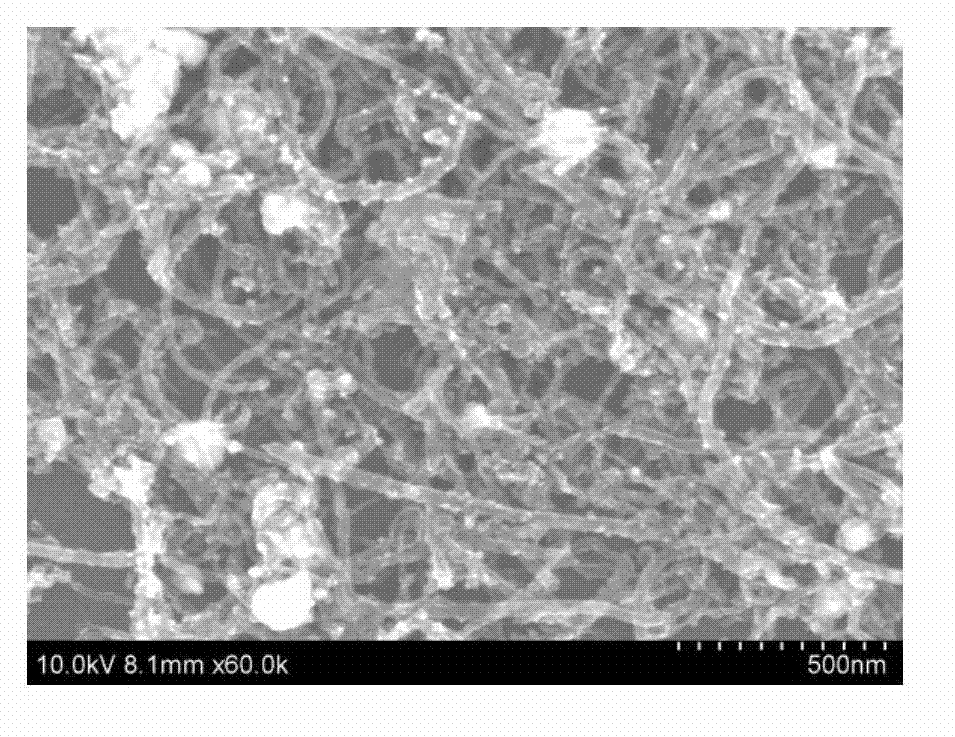

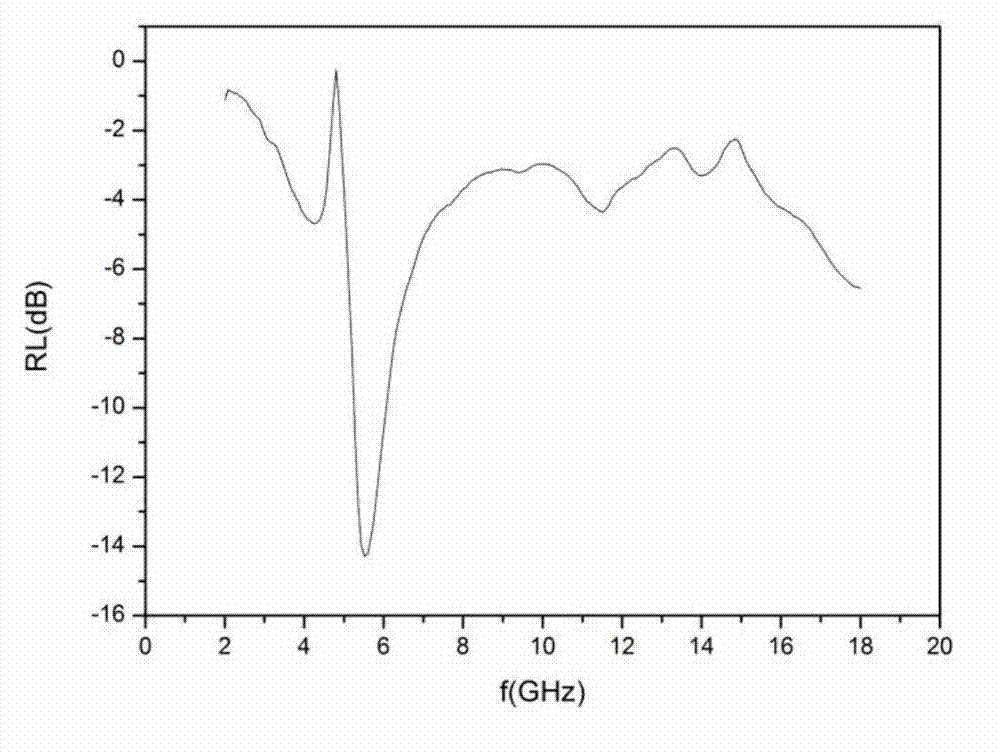

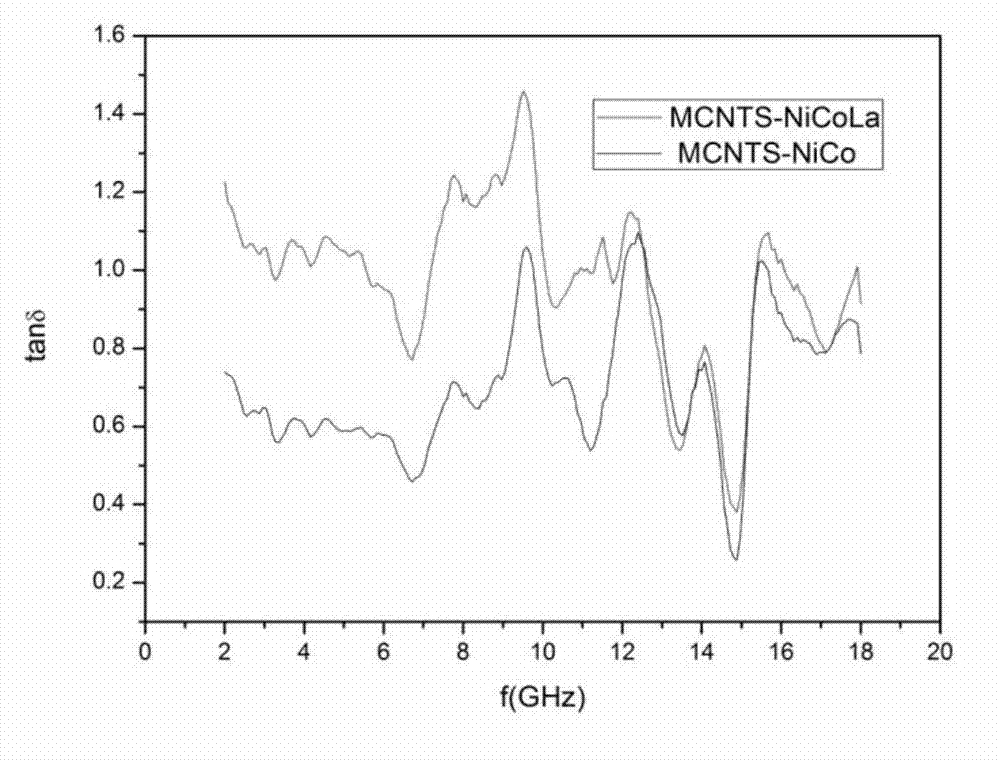

Chemical nickel-cobalt-lanthanum ternary alloy plating solution for carbon nano tube, and chemical plating method

InactiveCN102877048APromote reductionCo-depositionLiquid/solution decomposition chemical coatingIonRare-earth element

The invention relates to a wave-absorbing material and a preparation method thereof, in particular to a chemical nickel-cobalt-lanthanum ternary alloy plating solution for a carbon nano tube, and a preparation method and a chemical plating method thereof. According to the method, a hydrochloric acid solution of lanthanum oxide is added into a chemical plating solution for the carbon nano tube, and the electrode potentials of rare-earth elements La move positively by adjusting the concentration of all components in the plating solution, so that deposition potentials of the rare-earth elements L are close to those of metal Ni and Co; and therefore, alloy co-deposition is realized. One part of the rare-earth elements L in the chemical plating solution exist in the form of positive ions to exert the function of a reducing agent, so that the reduction of metal ions in an alloy plating layer is accelerated, and the phosphorus content in the plating layer is reduced. The chemical plating method has the advantages that according to a chemical nickel-cobalt-lanthanum ternary alloy plating material prepared by the chemical plating method, the lanthanum atom content in the alloy plating layer can reach 4.16 percent.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

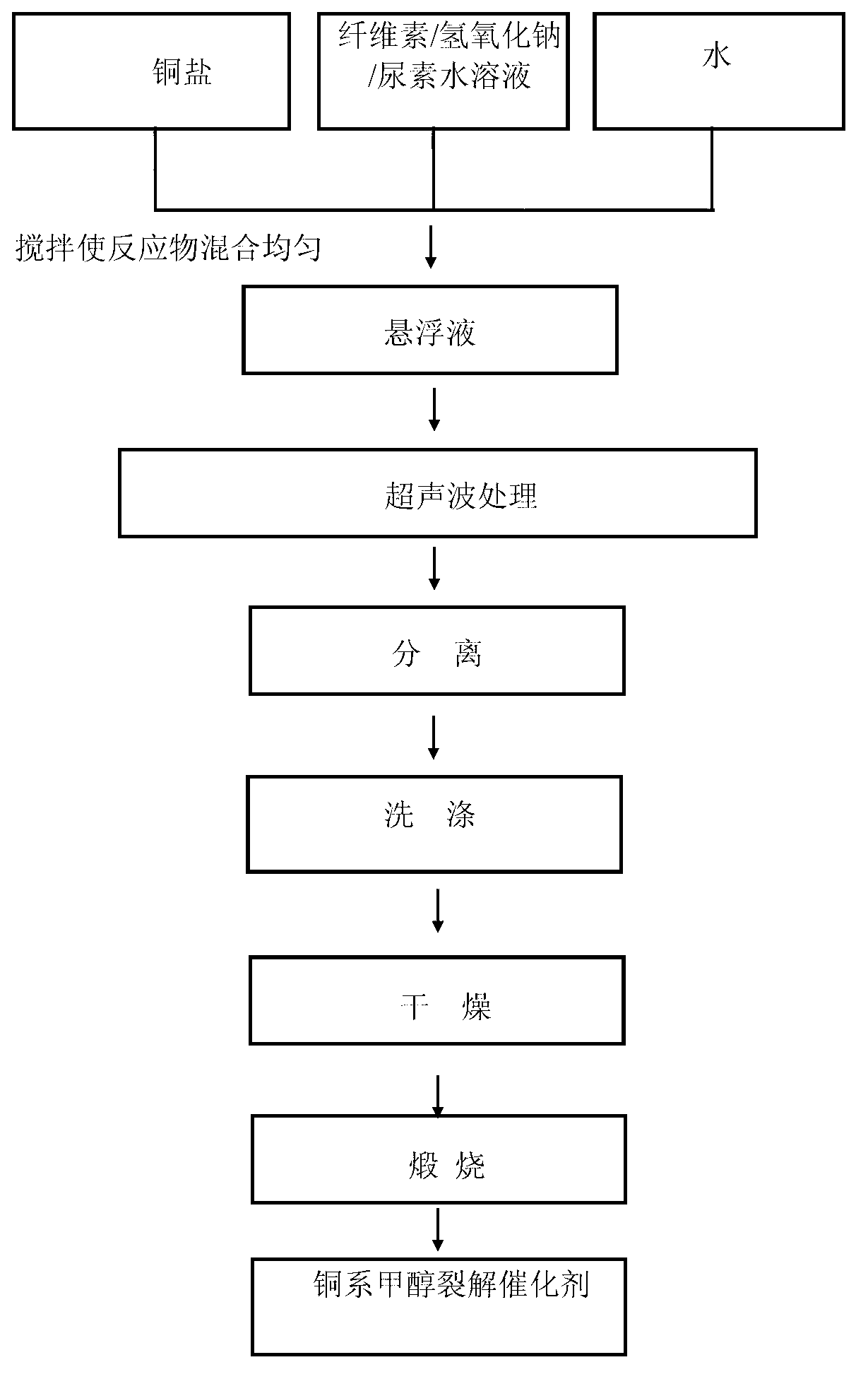

Methanol cracking catalyst and preparation method thereof

InactiveCN103157473ASimple ingredientsWide variety of sourcesHydrogenMetal/metal-oxides/metal-hydroxide catalystsSolventAqueous solution

The invention provides a methanol cracking catalyst and a preparation method thereof. The preparation method comprises the steps of: by taking copper salt and cellulose as raw materials and sodium hydroxide / urea water solution as a solvent, and carrying out fast preparing by adopting an ultrasonic treatment method; and preparing the methanol cracking catalyst by carrying out forging in inert atmosphere. The methanol cracking catalyst prepared by utilizing the preparation method has the advantages that the catalytic activity is strong, the selectivity and the stability are high, the methanol conversion rate is high, the selectivity of H2+CO in products is high, and the application prospect in the field of methanol catalytic cracking is wide.

Owner:BEIJING FORESTRY UNIVERSITY

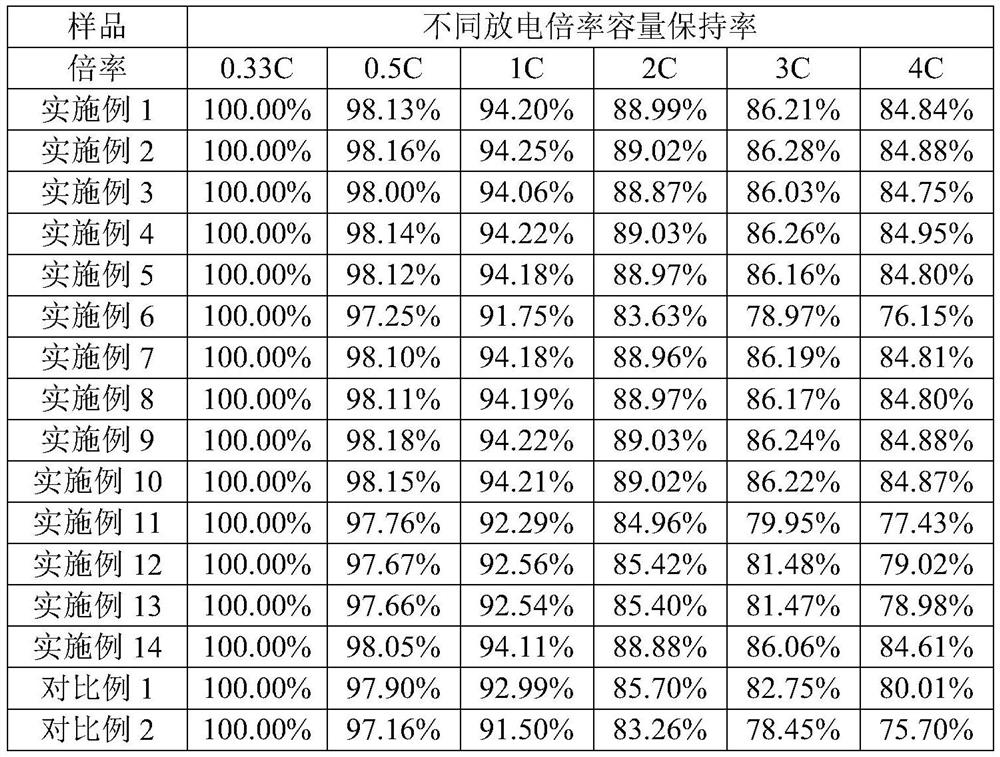

Carbon-coated lithium iron phosphate positive electrode material, preparation method thereof and lithium ion battery

PendingCN114335479AReduce the formation of impuritiesHigh purityCell electrodesSecondary cellsCarbon coatingLithium electrode

The invention provides a carbon-coated lithium iron phosphate positive electrode material, a preparation method thereof and a lithium ion battery. The preparation method of the carbon-coated lithium iron phosphate positive electrode material comprises the following steps: in a first inert atmosphere, mixing a lithium source, a ferrous source and a first solvent for the first time to obtain a first raw material solution; under a second inert atmosphere, the phosphorus source, an auxiliary agent and a second solvent are mixed for the second time, a second raw material solution is obtained, and the auxiliary agent is selected from gentiobiose and / or gentiobiose; carrying out hydrothermal synthesis reaction on the first raw material solution and the second raw material solution to obtain lithium iron phosphate containing a carbon amorphous coating layer; and sintering the lithium iron phosphate containing the carbon amorphous coating layer in a third inert atmosphere to obtain the carbon-coated lithium iron phosphate positive electrode material. By adopting the method, the uniformity of the carbon coating layer in the positive electrode material can be greatly improved, so that the conductivity and the energy density of the positive electrode material can be greatly improved.

Owner:SUNWODA ELECTRIC VEHICLE BATTERY CO LTD

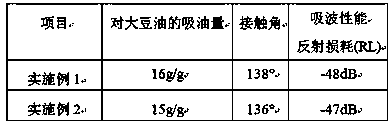

Method for preparing oil-absorbing wave-absorbing composite material from wood fiber powder

InactiveCN110713731AImprove adsorption capacityPromote circulationOther chemical processesMagnetic/electric field screeningFiberSodium acetate

The invention discloses a method for preparing an oil-absorbing wave-absorbing composite material from wood fiber powder, which comprises the following steps: adding deionized water into hydrophobic wood fiber powder, sealing in a reaction kettle, heating, carrying out a hydrothermal treatment reaction, cooling, performing filtration, washing with water, and carrying out freeze drying to obtain oil-absorbing wood fiber powder subjected to hydrothermal treatment; adding pretreated carbon nanotubes and graphene oxide into ethanol, ultrasonically stirring, adding ferrous chloride and ferric chloride, heating and stirring in an oil bath, dropwise adding ammonia water to adjust the pH value, continuously stirring and reacting at a constant temperature, performing suction filtration, washing with water to be neutral, and drying to obtain a magnetic modified carbon nanotube-graphene composite material; and adding an ethylene glycol solution into the oil-absorbing wood fiber powder subjected to hydrothermal treatment, stirring and dispersing, adding ferric chloride, stirring to dissolve the ferric chloride, adding sodium acetate and polyethylene glycol, stirring, reacting in a high-pressure reaction kettle, cooling, performing magnetical separation, respectively washing a product with distilled water and an ethanol solution, and carrying out vacuum drying to obtain the oil-absorbing wave-absorbing composite material.

Owner:刘丹丹

A kind of preparation method of core-shell magnetic/gold nanoparticles

ActiveCN102861921BGood dispersionStrong magnetic responseMaterial nanotechnologySuperparamagnetismPolyphenol

The invention discloses a preparation method of magnetic / gold nano particles. The preparation method comprises the following steps: firstly adopting a co-precipitation method to prepare the magnetic Fe3O4 nano particles; polymerizing the dopamine in-situ on the surfaces of the magnetic particles to obtain Fe3O4 nano particles modified by the poly dopamine; introducing polyphenol and amino groups to the surfaces of the Fe3O4 nano particles; absorbing the nano gold seeds on the surfaces of the modified magnetic particles through the static action; adopting the nano gold which is absorbed on the surfaces of the magnetic particles as the seed, adopting the polyphenol on the surfaces of the magnetic particles as a reducing agent, gradually adding the chloroauric acid liquid to gradually produce the gold layers on the surfaces of the magnetic particles to obtain the core-shell magnetic / gold nano particles. The nano particles have good water dispersion and strong magnetic respond performance. The diameters of the nano particles are 30-100 nanometers, the saturation magnetization is 30.1-38.7emu / g, and the nano particles are superparamagnetic. The nano particles have wide application prospect on the fields of targeted drug controlled release, thermal therapy, separation of protein and enzyme, etc.

Owner:SOUTHWEST UNIVERSITY FOR NATIONALITIES

Combined leaching process of cobalt-sulfur concentrate and cobalt hydroxide ore

ActiveCN113789441AHigh recovery rateAchieve removalProcess efficiency improvementPregnant leach solutionSulfate radicals

The invention discloses a combined leaching process of cobalt-sulfur concentrate and cobalt hydroxide ore. The process comprises the following steps that after the cobalt-sulfur concentrate and the cobalt hydroxide ore are pulped to obtain pulped liquid; reaction is carried out on on the pulped liquid under the pressure of 0.6 MPa to 1.25 MPa and the temperature of 150 DEG C to 180 DEG C, and solid-liquid separation is carried out to obtain a solid phase and a liquid phase; and the liquid phase is the leachate. According to the process, the cobalt-sulfur concentrate and the cobalt hydroxide ore are subjected to high-pressure combined leaching, high-valence cobalt is reduced into low-valence cobalt by the cobalt-sulfur concentrate, and in the high-pressure oxidation leaching process, sulfur ions are oxidized into sulfate radicals, and ferrous ions are oxidized into iron ions; meanwhile, in the environment, the iron ions are hydrolyzed to finally form ferric oxide (Fe<2>O<3>) and hydrogen ions, cobalt hydroxide is leached out by utilizing the generated hydrogen ions, and meanwhile cobalt, copper and nickel in the cobalt-sulfur concentrate are leached into the solution; and the process for utilizing the cobalt-sulfur concentrate is simplified, and the leaching efficiency is improved.

Owner:湖南德景源科技有限公司

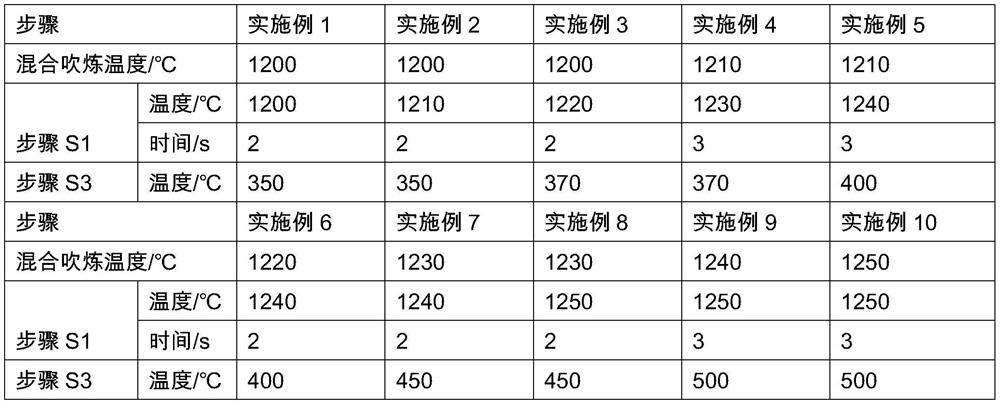

A method for reducing iron scale of hot-rolled strip steel based on reduction pretreatment process

ActiveCN109554529BImprove the efficiency of the reduction reactionControl dew pointFurnace typesProcess efficiency improvementStrip steelContinuous annealing

Owner:NORTHEASTERN UNIV LIAONING

A kind of methanol cracking catalyst and preparation method thereof

InactiveCN103157473BSimple ingredientsWide variety of sourcesHydrogenMetal/metal-oxides/metal-hydroxide catalystsSolventAqueous solution

The invention provides a methanol cracking catalyst and a preparation method thereof. The preparation method comprises the steps of: by taking copper salt and cellulose as raw materials and sodium hydroxide / urea water solution as a solvent, and carrying out fast preparing by adopting an ultrasonic treatment method; and preparing the methanol cracking catalyst by carrying out forging in inert atmosphere. The methanol cracking catalyst prepared by utilizing the preparation method has the advantages that the catalytic activity is strong, the selectivity and the stability are high, the methanol conversion rate is high, the selectivity of H2+CO in products is high, and the application prospect in the field of methanol catalytic cracking is wide.

Owner:BEIJING FORESTRY UNIVERSITY

Blister blowing process

ActiveCN110923455BLow melting pointSpeed up meltingCombination devicesProcess efficiency improvementCopper oxideCopper sulfide

The invention relates to a blister copper blowing process in the technical field of blister copper smelting, which comprises mixing copper-containing waste and copper-containing waste treatment tailings, adding them to a side-blowing melting and incinerator, and adding a cosolvent, a reducing agent, and a fuel, At the same time, oxygen is blown in, and mixed blowing is carried out at 1200-1250°C; finally, blowing tailings, blister copper and flue gas are discharged separately, and the flue gas is discharged after treatment. Limestone has a low melting point, which can promote the melting of quartz stone and iron oxide and improve fluidity. Iron, molybdenum, magnesium, calcium, silicon, etc. in the furnace charge are oxidized in an oxygen-rich environment to form oxides, which combine with quartz stone to form tailings, and realize the separation of non-copper metal elements from copper. Iron oxide can convert copper oxide and copper in copper sulfide Reduction, increase copper content, semi-coke as fuel, high fixed carbon, sufficient energy for combustion, high chemical activity, and can also function as a reducing agent; the combination of these can increase the reduction rate of copper.

Owner:洛南环亚源铜业有限公司

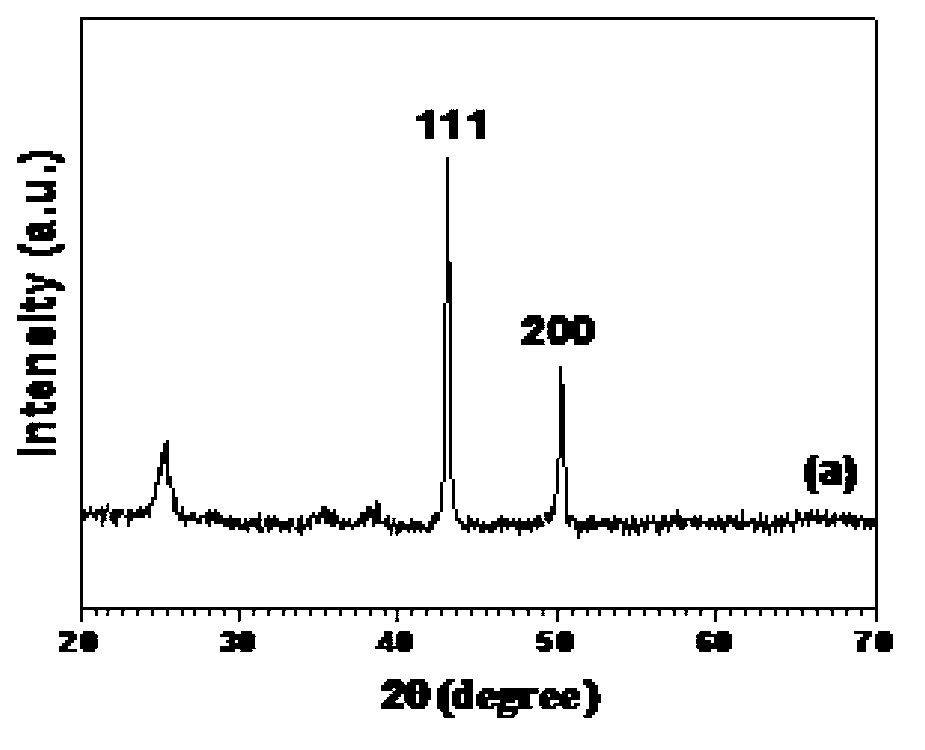

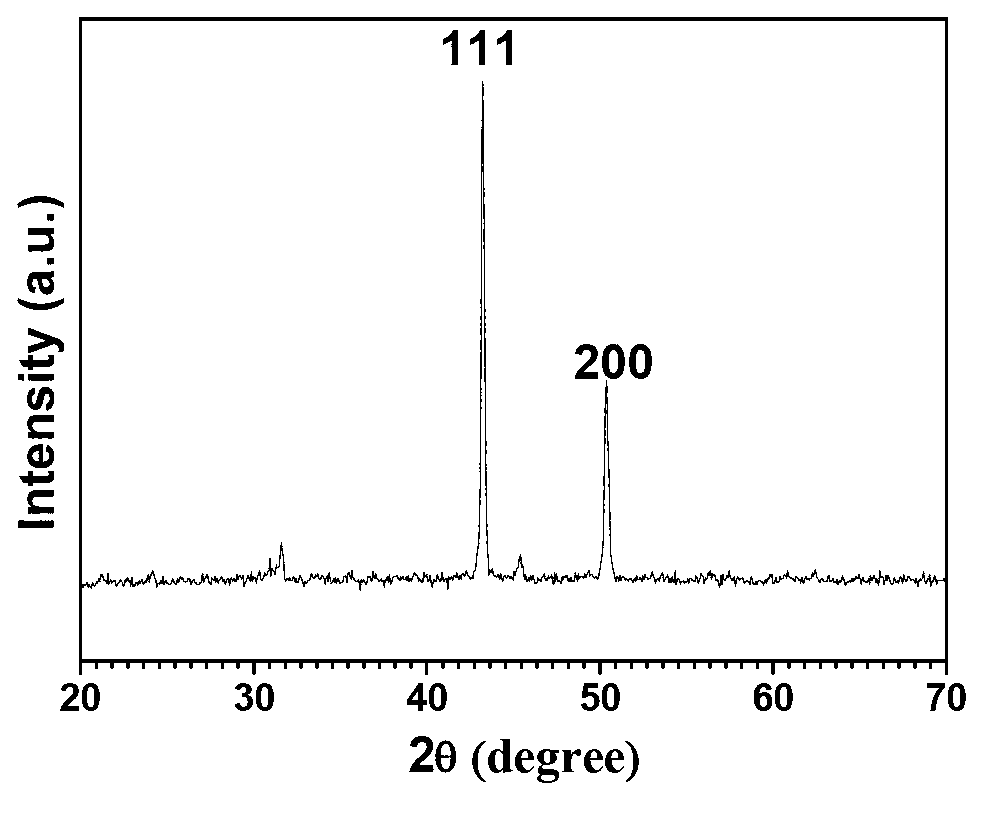

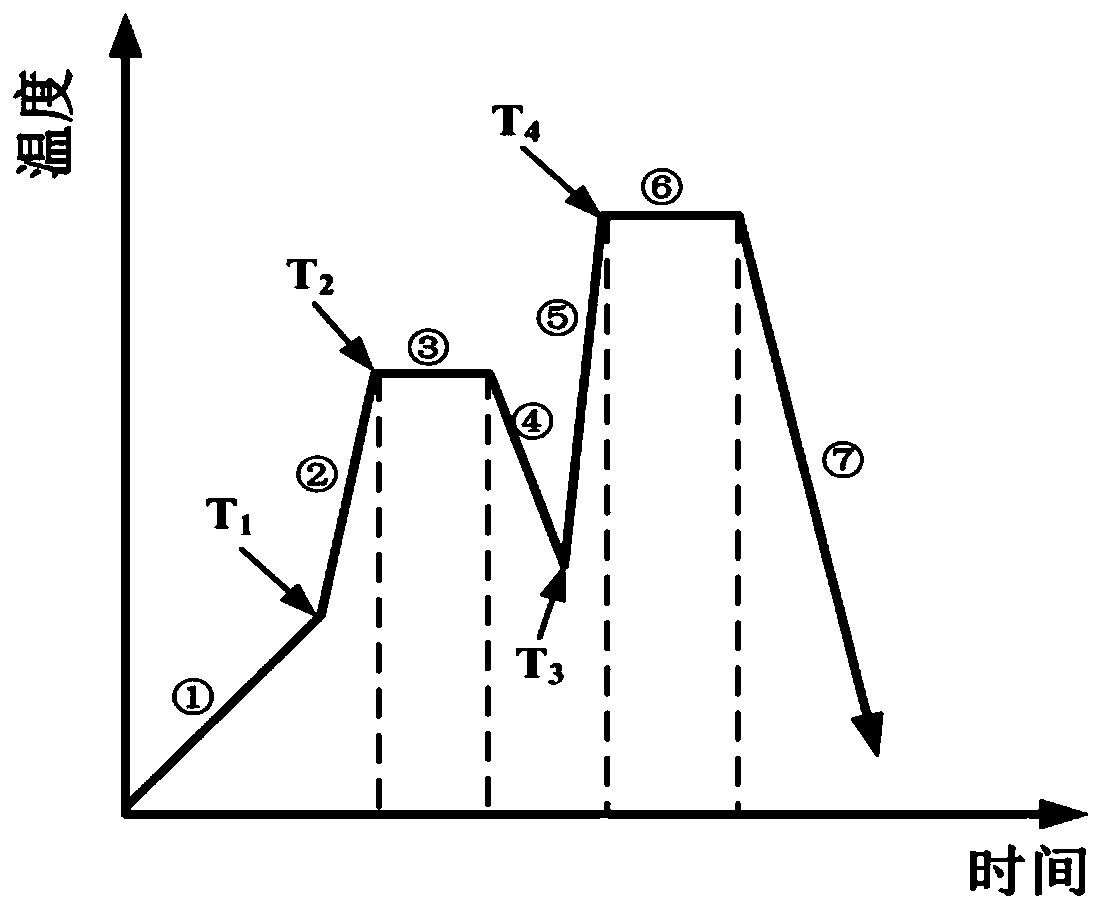

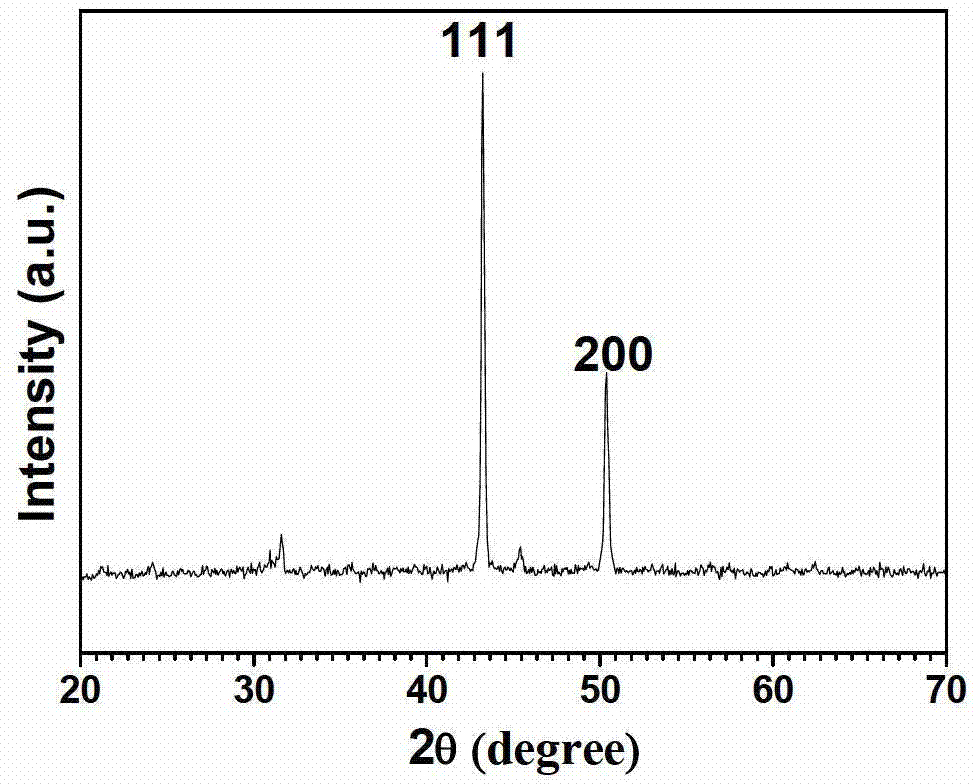

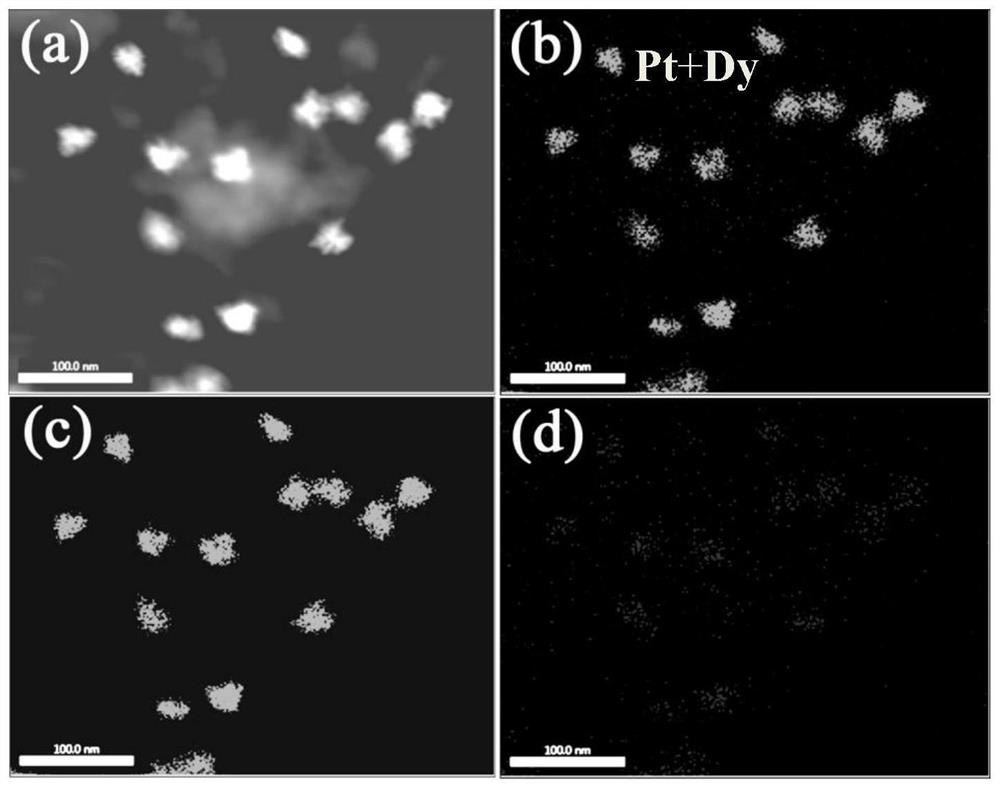

A kind of pt-rare earth alloy material and its preparation method and application

ActiveCN110600754BGood dispersionImprove uniformityMaterial nanotechnologyCell electrodesFuel cellsActive component

The invention proposes a Pt-rare earth alloy material and its preparation method and application, belonging to the technical field of fuel cell material preparation, which is composed of small particles with an average particle diameter of 5-7nm and has a face-centered cubic structure. The average particle size of the flower-shaped particles is 23-26nm. The Pt-rare earth alloy material is a single alloy phase and the Pt-rare earth alloy material is surrounded by {111} crystal planes. The Pt-rare earth alloy material of the present invention has a definite morphology and structure, and presents a single alloy phase, has good dispersion and uniformity, and has superior performance when it is used as an active component in the fuel cell cathode oxygen reduction reaction. Catalytic activity and stability.

Owner:SHAANXI NORMAL UNIV

Nano protection process for textiles

InactiveCN109837736AGood anti-corrosion and anti-mildew effectFunction increaseFibre treatmentHeating/cooling textile fabricsIonLong lasting

The invention relates to a nano protection process for textiles, comprising the steps of processing a textile semi-finished gray fabric, softening for setting, and drying for setting. The nano protection process is characterized in that in the step of softening for setting, the gray fabric is soaked with a nano sodium ion liquid for 1-120 min, the fabric is washed and aired after being taken out to obtain a nano sodium anticorrosion textile; the nano sodium ion liquid is made by mixing, by mass, 0.01-5% of an aminosilane hyperbranched compound, a thickener solution, and copper carbonate solution having the mass molar concentration of 0.01-0.5 mol / L. In the step of softening for setting to treat the textile gray fabric, the textile gray fabric is soaked with the nano sodium ion liquid and is dried; the produced textile has evident anticorrosion and mildew-proof effects, long-lasting functions, has the health functions, such as deodorizing, is tolerant to multiple washing and repeated dry washing.

Owner:贾龙平

Method for preparing foam aluminium sandwich structure

The invention relates to a method for preparing a foam aluminium sandwich structure. Foam aluminium is processed into samples of any required size by using wire cutting or other machining methods. The method comprises the following steps: performing derusting and deoiling treatment on the surface of the foam aluminium; mixing k3AlF6 and KAlF4 in a ratio of 1:1-2, heating the mixture till the mixture is in a molten state, cooling the mixture for crystallization, grinding crystals into powder, adding water into the powder to prepare a suspension in a ratio of 1:2 to 4, and spreading the suspension on the surface of a foam aluminum work piece uniformly; and putting the treated foam aluminum work piece in a mold, placing the mold in a furnace at the temperature of between 520 and 585 DEG C, keeping the temperature for 2 minutes, taking the mold out, injecting molten alloy melt heated to 500 to 580 DEG C into the mold, and cooling the melt to obtain the foam aluminum sandwich structure. The method for preparing the foam aluminum sandwich structure has the characteristics of high preparation efficiency, simple process, low cost and easy realization of line production.

Owner:GUANGDONG OCEAN UNIVERSITY

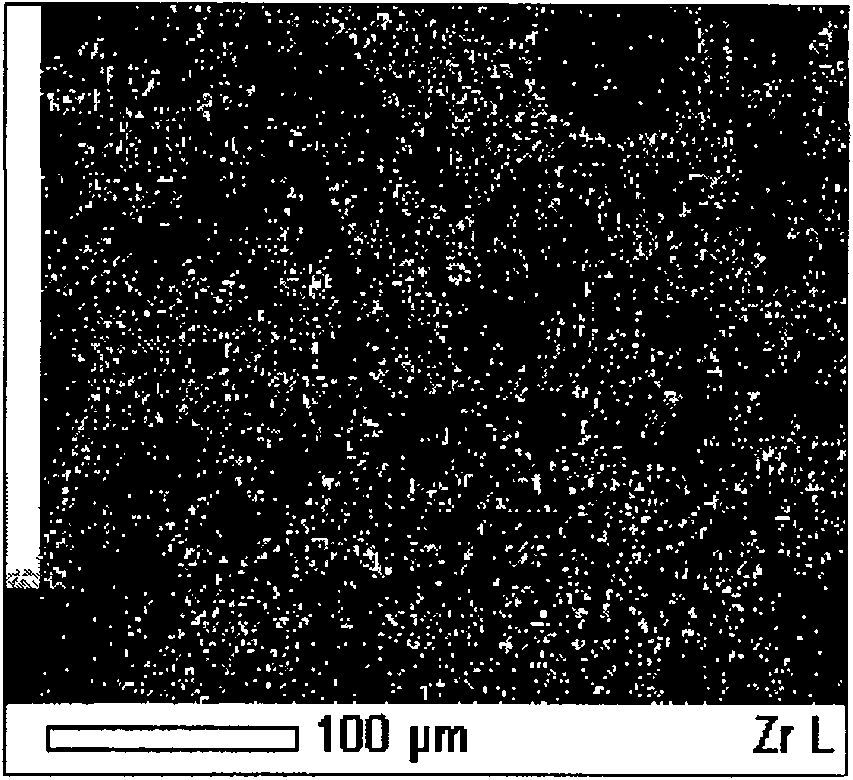

Method for directly preparing Mg-Zr alloy by MgCl2, K2ZrF6 and ZrO2 electrolysis

The invention provides a method for directly preparing Mg-Zr alloy by electrolyzing MgCl2, K2ZrF6 and ZrO2. KCl and K2ZrF6 are dried under 600 DEG C, and anhydrous MgCl2 and KF are dried at 130 DEG C under the vacuum condition; KCl, K2ZrF6, anhydrous MgCl2, KF and ZrO2 are ground and mixed evenly in the ratio of 35 percent to 45 percent : 5.3 percent to 15 percent:35 percent to 45 percent:0.1 percent to 4.5 percent:2 percent to 4 percent, and then heated and melted in an electrobath; a metal molybdenum wire is taken as the cathode, a cathode product collecting sleeve is arranged on the cathode, a graphite rod is taken as the anode, the electrobath temperature is between 650 DEG C and 800 DEG C, the cathode current density is 6A / cm<2> to 13A / cm<2> and the electrobath voltage is 5V to 9V; the temperature is preserved for 10min to 40min after one hour of electrolysis, and the Mg-Zr alloy is deposited near the cathode in the molten salt electrobath; the whole process is carried out underthe protection of argon. With the method, even alloy components can be obtained; and the method solves the technical difficulty of component segregation of the Mg-Zr intermediate alloy, and is characterized by greatly shortened technological process, low operation temperature and low production cost.

Owner:HARBIN ENG UNIV

Ferrum oxidate nano magnetic material and method for preparing the same

InactiveCN101117241BAct as a reducing agentEasy to manufactureInorganic material magnetismFerroso-ferric oxidesSolventPolytetrafluoroethylene

The invention relates to a nanomagnetic material of iron oxide and the fabrication method, and belongs to the nano-material fabrication field; the invention adopts glycol as a solvent and a reducing agent, and adopts sodium dodecyl benzene sulfonate as a surfactant, and adopts dissoluble trivalent iron sodium and alkali as a raw material, a mixing process under a room temperature is conducted to make a homogeneous suspension; the mixed liquid is turned into a polytetrafluoroethene lining to conduct a microwave water thermal reaction, after the reaction is over, the product from the reaction is separated, washed and dried to make a precursor nano-powder which is calcined to make a ferroferric oxide nano-powder or gamma ferric oxide nano-powder; the nano-powder body has a hollow ball structure assembled by a nano-piece, the hollow ball dimension is two to four micron while the inner hollow dimension of the hollow ball is one to three micron; the invention is characterized in low raw material cost, easy process, easy operation, controllable profile and so forth; the specific surface area is high, the magnetic performance is favorable.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com