Chemical nickel-cobalt-lanthanum ternary alloy plating solution for carbon nano tube, and chemical plating method

A carbon nanotube and ternary alloy technology, which is applied in the fields of carbon nanotube electroless nickel-cobalt-lanthanum ternary alloy plating solution and its preparation and electroless plating, can solve the problem of not very strong wave absorbing performance, and achieve accelerated Restoration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The first step: selection of base material

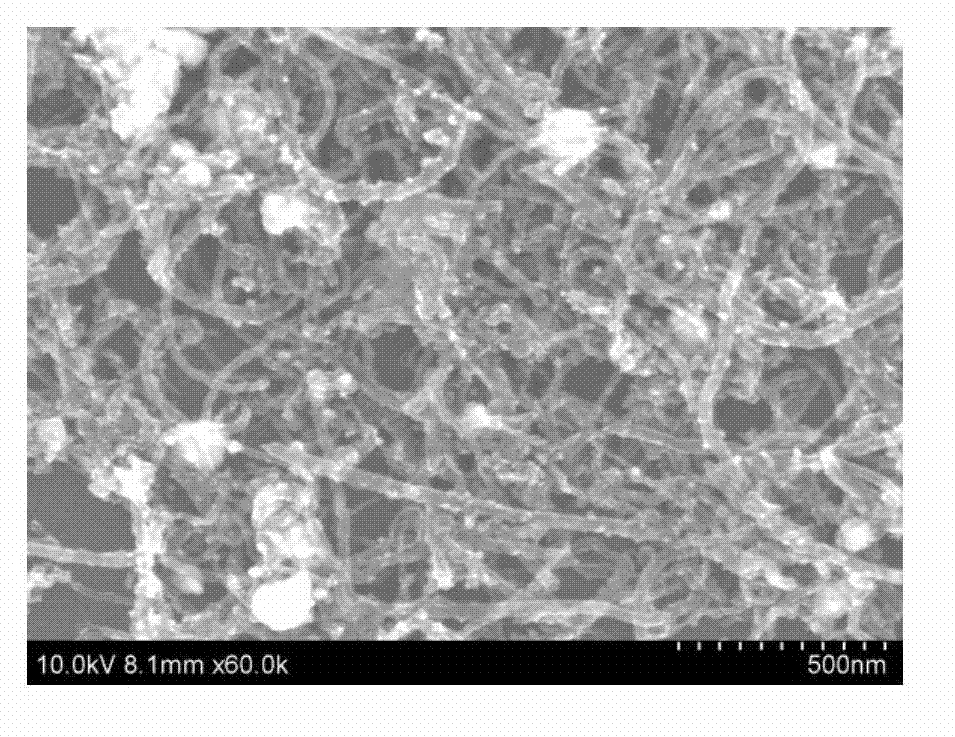

[0027] The matrix material is a multi-walled carbon nanotube: the multi-walled carbon nanotube has a diameter of 50-80 nm and a length of 1-2 μm.

[0028] The second step: the pretreatment of the substrate

[0029] (a) Mixed acid oxidation treatment of carbon nanotubes

[0030] Weigh 2.0g of MWNTs and dissolve in 160ml of mixed acid (the volume ratio of concentrated nitric acid to concentrated sulfuric acid is 1:3), heat and reflux at 70°C for 12h, after cooling, dilute three times, filter, and wash the filter cake with distilled water until neutral. It was then baked at 80°C to constant weight.

[0031] (b) Sensitization, activation

[0032] Add 100ml of sensitizing solution to 1g of carbon nanotubes, ultrasonically disperse at 45°C for 1h, filter, wash with distilled water until neutral; then add carbon nanotubes to 100ml of activation solution, ultrasonically disperse at 45°C for 1h, filter, and wash with distilled wate...

Embodiment 2

[0045] The first step: selection of base material

[0046]The matrix material is a multi-walled carbon nanotube: the multi-walled carbon nanotube has a diameter of 50-80 nm and a length of 1-2 μm.

[0047] The second step: the pretreatment of the substrate

[0048] (a) Mixed acid oxidation treatment of carbon nanotubes

[0049] Weigh 2.0g of MWNTs and dissolve in 160ml of mixed acid (the volume ratio of concentrated nitric acid to concentrated sulfuric acid is 1:3), heat and reflux at 70°C for 12h, after cooling, dilute three times, filter, and wash the filter cake with distilled water until neutral. It was then baked at 80°C to constant weight.

[0050] (b) Sensitization, activation

[0051] Add 100ml of sensitizing solution to 1g of carbon nanotubes, ultrasonically disperse at 45°C for 1h, filter, wash with distilled water until neutral; then add carbon nanotubes to 100ml of activation solution, ultrasonically disperse at 45°C for 1h, filter, and wash with distilled water...

Embodiment 3

[0064] The first step: selection of base material

[0065] The matrix material is a multi-walled carbon nanotube: the multi-walled carbon nanotube has a diameter of 50-80 nm and a length of 1-2 μm.

[0066] The second step: the pretreatment of the substrate

[0067] (a) Mixed acid oxidation treatment of carbon nanotubes

[0068] Weigh 2.0g of MWNTs and dissolve in 160ml of mixed acid (the volume ratio of concentrated nitric acid to concentrated sulfuric acid is 1:3), heat and reflux at 70°C for 12h, after cooling, dilute three times, filter, and wash the filter cake with distilled water until neutral. It was then baked at 80°C to constant weight.

[0069] (b) Sensitization, activation

[0070] Add 100ml of sensitizing solution to 1g of carbon nanotubes, ultrasonically disperse at 45°C for 1h, filter, wash with distilled water until neutral; then add carbon nanotubes to 100ml of activation solution, ultrasonically disperse at 45°C for 1h, filter, and wash with distilled wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com