Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

102results about How to "Low electronegativity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

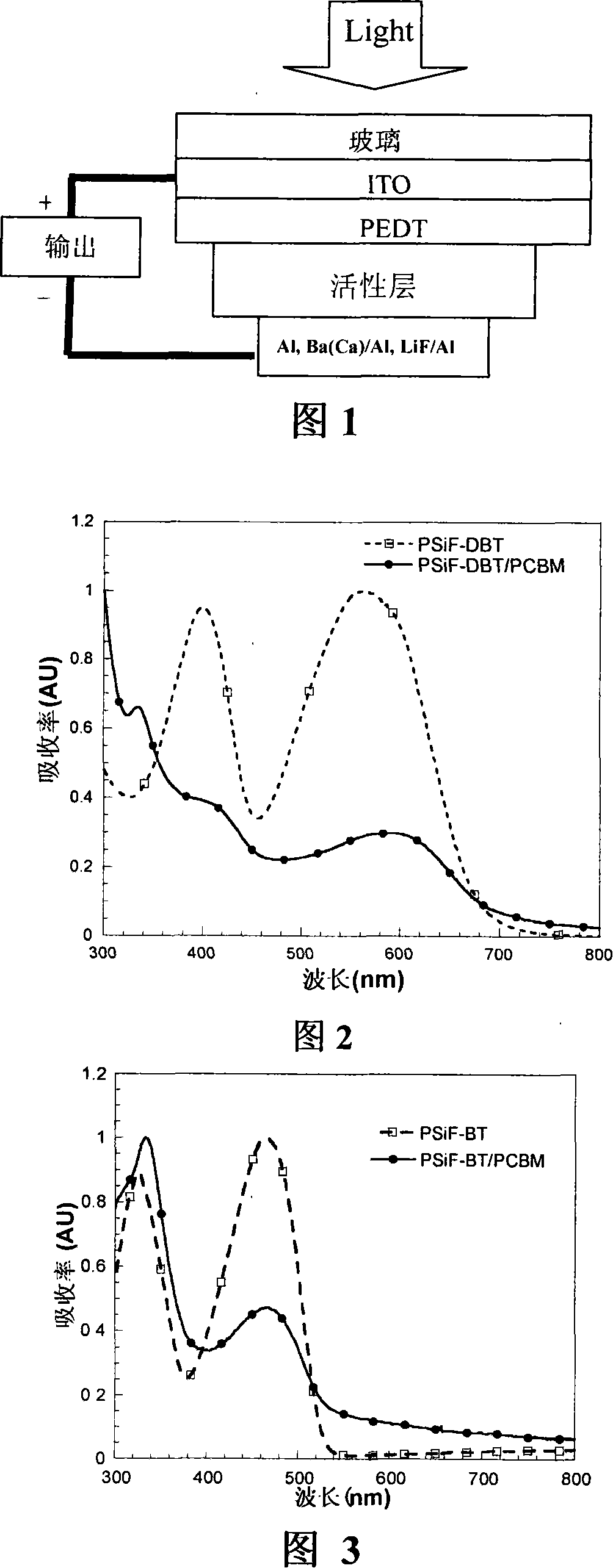

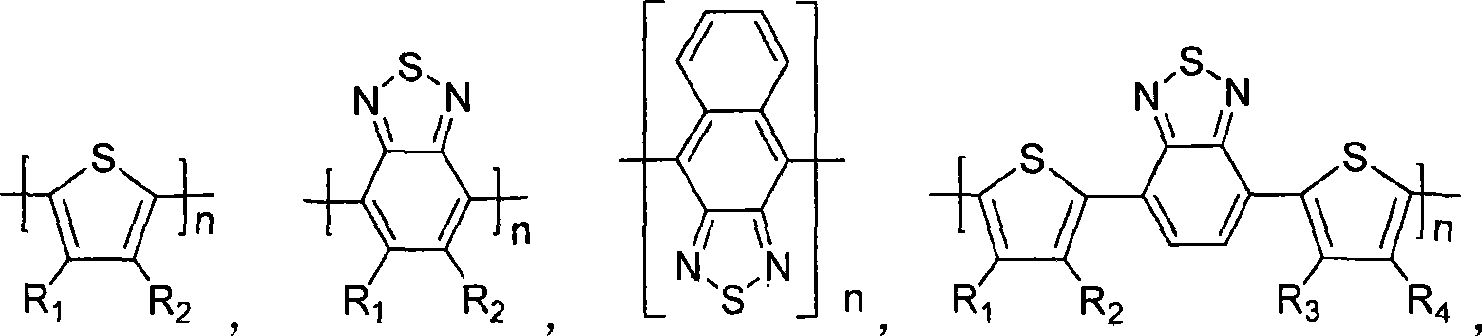

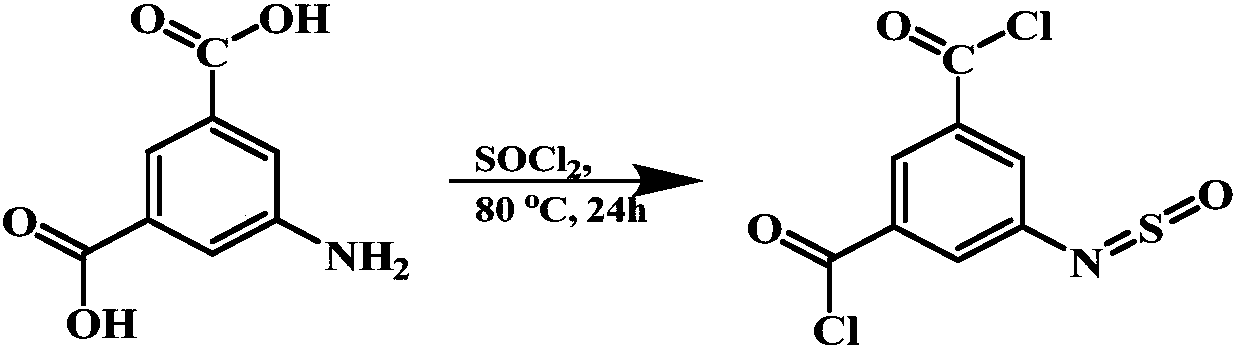

Silicon-containing fluorine conjugated polymer and its preparing process and application

ActiveCN101148495AHigh electron mobilityHigh photothermal oxidation stabilityFinal product manufactureSolid-state devicesHigh energyField-effect transistor

The present invention relates to silico fluorene copolymer and its application. The silico fluorene copolymer is copolymer of 2, 7-silico fluorine and narrow band gap monomer, and has absorption spectrum with absorption side band greater than 500 nm and absorption band side expanded to red light and near infrared region. It is prepared through copolymerizing 2, 7-silico fluorine and narrow band gap monomer containing hetero N and / or S atoms. It may be applied in making polymer solar cell, FET, etc. It has high mobility, high long-term stability and high energy converting efficiency.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of hydrogenation catalyst containing silicon and zirconium

ActiveCN101491768AEnhanced interactionLow electronegativityMetal/metal-oxides/metal-hydroxide catalystsNitrogenAluminium oxide

The invention discloses a method for preparing a hydrogenation catalyst. The catalyst contains auxiliary agents of silicon and zirconium, and carries at least one metal element of VIB family and at least one metal element of VIII family. The assistant silicon and the zirconium are added during gelling of aluminum oxide, so that the silicon and the zirconium are evenly dispersed on the surface of the aluminum oxide, and can give full play to the auxiliary agent. Simultaneously, the catalyst has proper acidic property, so the catalyst shows higher activities of hydrodenitrification and hydrodesulphurization, and has higher activity and stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing aluminum oxide dry glue powder containing silicon and zirconium

The invention discloses a method for preparing aluminum oxide dry glue powder containing silicon and zirconium. The method comprises the following steps: after an solution containing an aluminum compound and precipitating agent are subjected to gel forming reaction, adding a compound solution containing zirconium into the mixture under the condition of controlling proper pH value and the like, adding a compound containing silicon into the mixture before, after or at the same time of adding the compound containing zirconium, and then washing, filtering and drying the mixture to obtain the dry glue containing the silicon and the zirconium. Through optimizing process and condition of adding the silicon and the zirconium as assistant into the aluminum oxide dry glue, the silicon and the zirconium are evenly dispersed on the surface of aluminum oxide, and can give full play of the assistant.

Owner:CHINA PETROLEUM & CHEM CORP +1

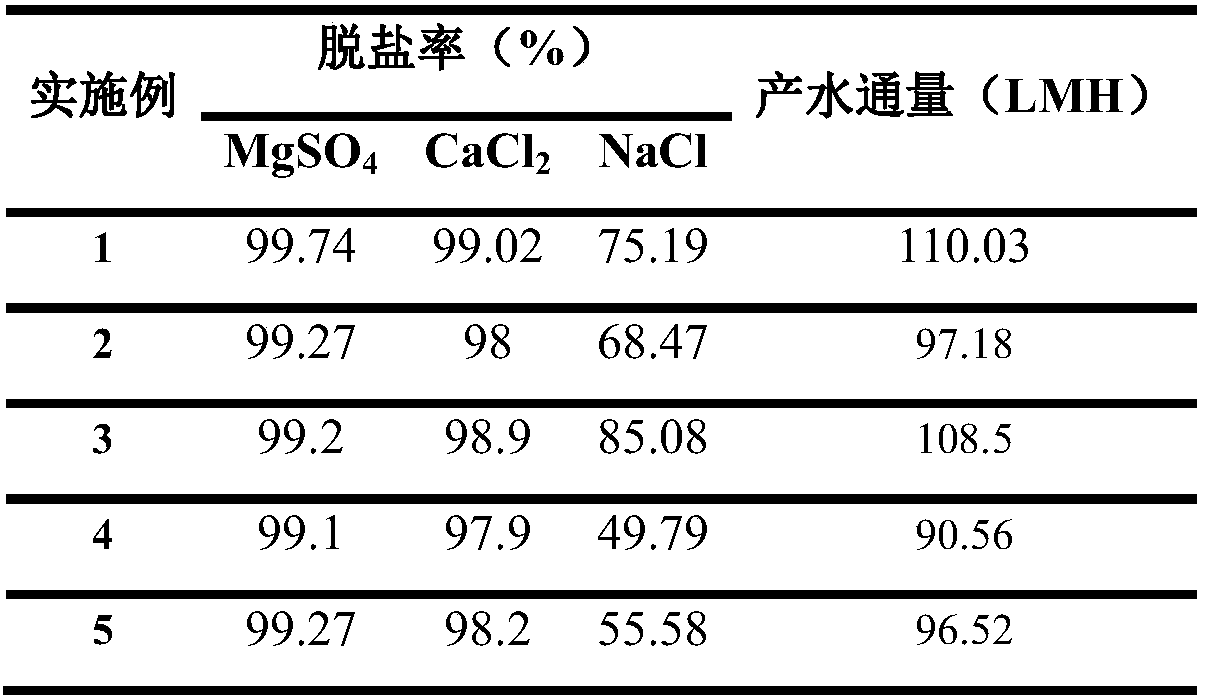

High-throughput polyamide nanofiltration composite membrane and preparation method thereof

InactiveCN108187512ALow operating pressureImprove throughputSemi-permeable membranesWater desalinationChemical oxygen demand

The invention discloses a high-throughput polyamide nanofiltration composite membrane and a preparation method thereof, which belong to the field of polymeric membrane materials. The composite membrane is prepared by the interfacial polymerization reaction between 5-(N-sulfonamido)isophthaloyl dichloride or a mixture of 5-(N-sulfonamido)isophthaloyl dichloride and 1,3,5-trimesoyl chloride and piperazine monomer, and can be widely used in a water softening process for removing bivalent cations such as Ca<2+> and Mg<2+>. The high-throughput polyamide nanofiltration composite membrane is structurally provided with an ultrathin (10nm) release layer, surface charge are low in electronegativity, the membrane surface property is smooth and hydrophilic, high throughput is shown in terms of properties, the high-throughput polyamide nanofiltration composite membrane has an excellent trapping effect on bivalent and polyvalent cations and good pollution resistance, and the high-throughput polyamide nanofiltration composite membrane can be widely applied in high-throughput domestic water purifiers, sea water desalination, brackish water pretreatment, removal of COD (chemical oxygen demand) suchas dye molecules and phenol molecules in wastewater, separation of dye / salt and material separation and concentration processes in pharmaceutical and food industries.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Room-temperature liquid metal battery

ActiveCN106025249ASmall electromotive forceLow densityCell electrodesSecondary cellsLiquid metalLiquid alloy

The invention provides a room-temperature liquid metal battery which comprises an anode, a cathode, an interlayer and a battery shell. The anode is made of a gallium-based or mercury-based liquid alloy, the cathode is made of an alkali metal liquid alloy, the interlayer is ionic liquid, and the anode, the interlayer and the cathode are arranged in the battery shell from bottom to top. The cathode is made of the alkali metal liquid alloy, the anode is made of the gallium-based or mercury-based liquid alloy, electrolyte is the ionic liquid, and the three materials are liquid at room temperature, so that heating and heat insulating devices are not needed, and the room-temperature liquid metal battery can be realized really.

Owner:YUNNAN KEWEI LIQUID METAL VALLEY R & D CO LTD

Rare-earth plating aid for hot dip tinning and preparation method thereof

InactiveCN102660724AImprove thermal stabilityGood removal effectHot-dipping/immersion processesTinningCopper plating

The invention discloses a rare-earth plating aid for hot dip tinning and a preparation method thereof. 1 liter of rare-earth plating aid comprises the following raw materials by weight: 80 to 150 grams of inorganic salt, 50 to 100 grams of organic acid, 15 to 25 grams of organic amine salt, 2 to 12 grams of rare-earth compounds and a solvent, wherein the raw materials are mixed, and the solvent is added to 1 liter of constant volume. According to the rare-earth plating aid, the heat stability and the capacity of removing an oxidation film of the plating aid are improved, the corrosivity is reduced, and the capacity of molten tin liquor to the adsorption, moistening and spreading of copper matrixes (copper plating layers) is improved obviously under the modified action of the rare-earth compounds; and a tinning layer of which the thickness is 6 to 9 micrometers can be obtained by one-time dip plating, and powerful guarantee is provided for the weldability and oxidation resistance of products such as electronic leads.

Owner:HEFEI UNIV OF TECH

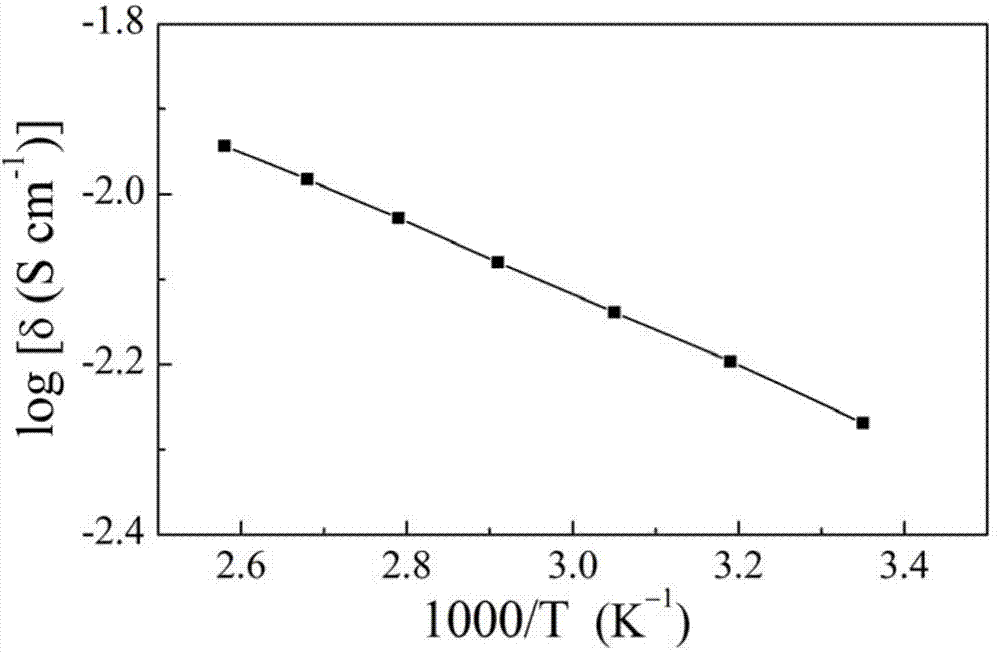

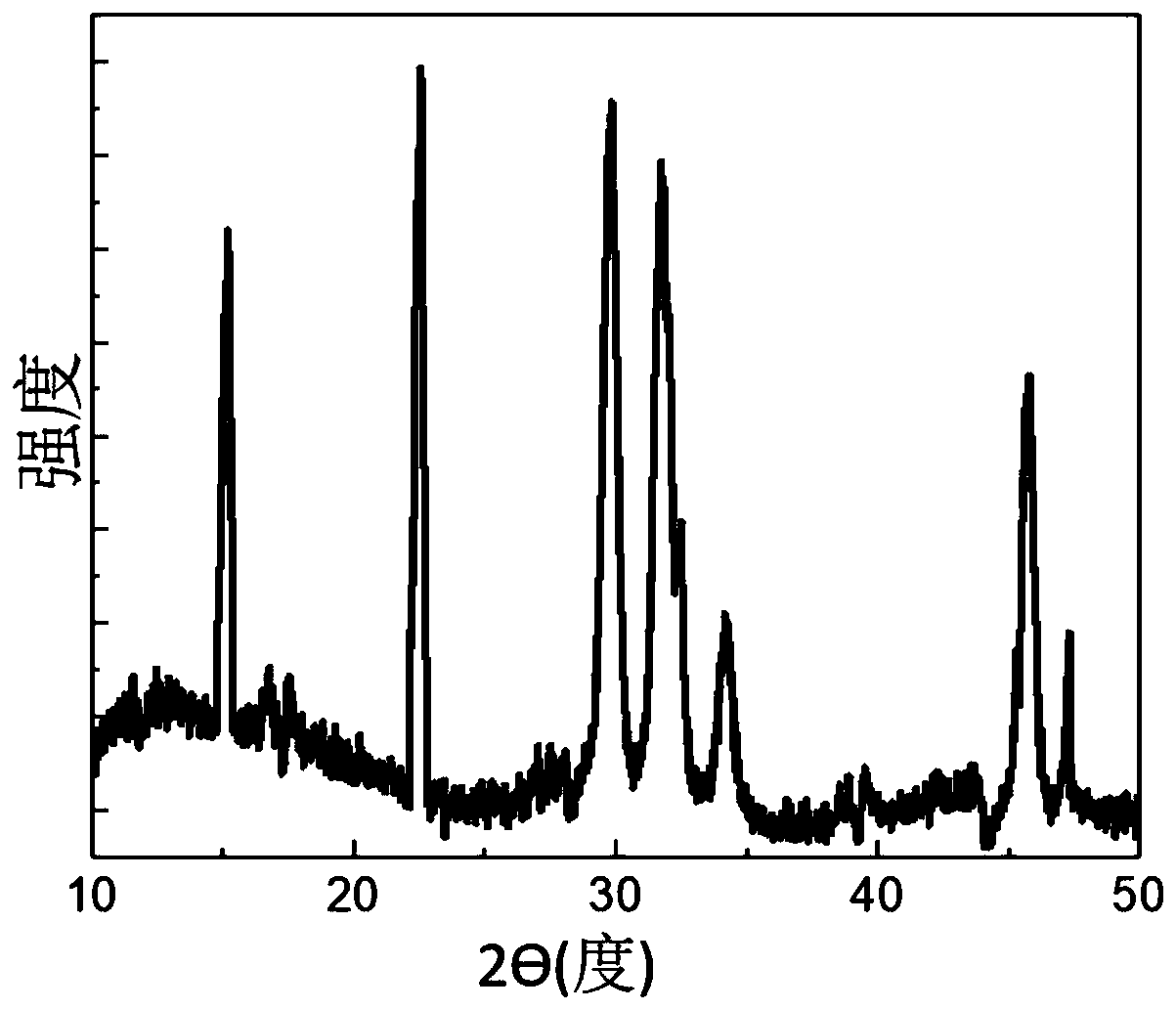

Sulfide electrolyte materials, preparation method thereof and all-solid lithium secondary battery

ActiveCN103531849AImprove ionic conductivityHigh Li-ion conductivityFinal product manufactureElectrolytesElectrolyteLITHIUM PHOSPHATE

The invention provides sulfide electrolyte materials shown by a formula (I) and sulfide electrolyte materials shown by a formula (II). The invention further provides a design thought and a preparation method of the sulfide electrolyte materials. A certain amount of lithium phosphate is doped and added to or compounded to sulfide solid electrolytes, and the ionic conductivity of the sulfide electrolyte materials is improved.

Owner:STATE GRID CORP OF CHINA +3

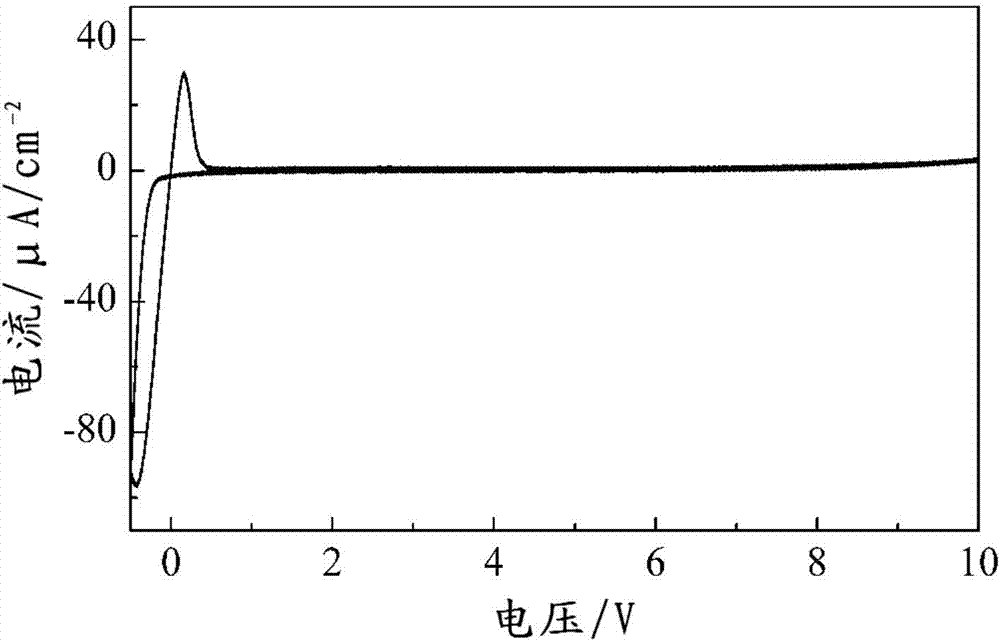

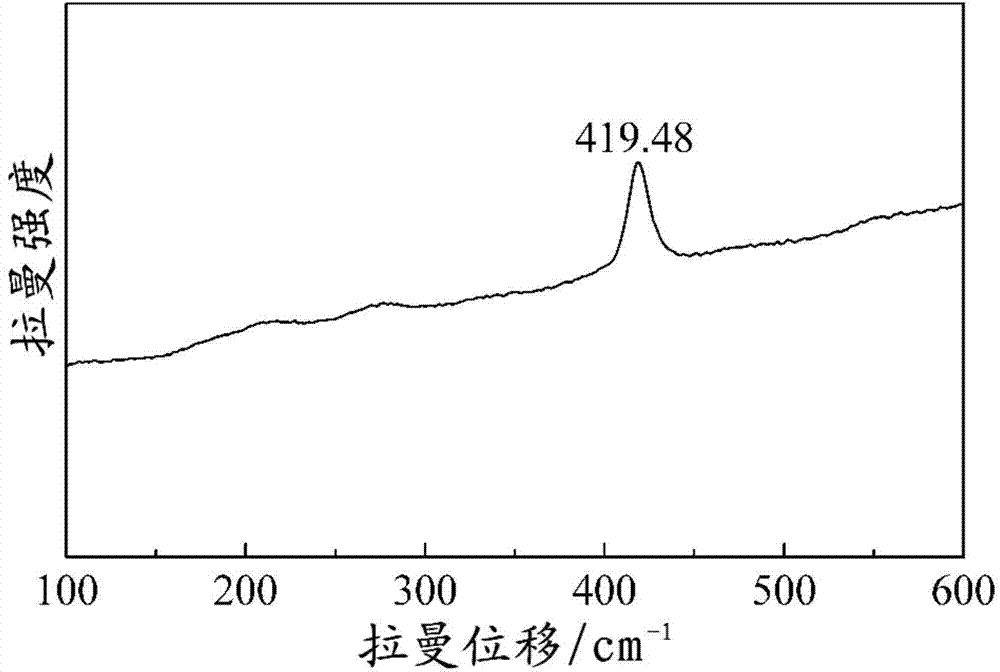

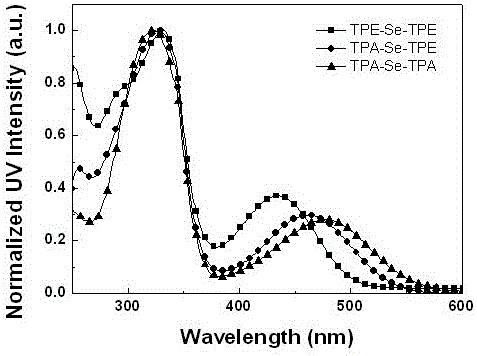

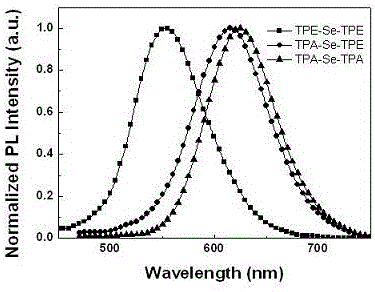

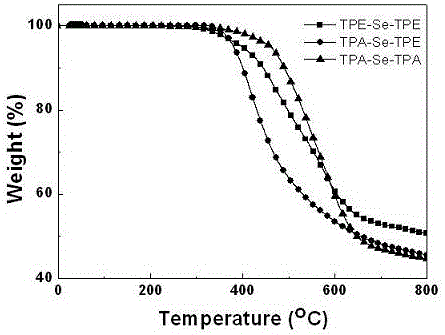

Preparation method and application of 2,1,3-benzoselenadiazole derivative

InactiveCN106831650AAtomic radius is largeLow electronegativityOrganic chemistrySolid-state devicesOrganic electroluminescenceQuenching

The invention discloses a preparation method and application of 2,1,3-benzoselenadiazole derivative. The derivative is TPE-Se-TPE, TPA-Se-TPE or TPA-Se-TPA, i.e., tetraphenyl ethylene (TPE) and / or triphenylamine group (TPA) are respectively introduced on a 4 position and a 7 position of the 2,1,3-benzoselenadiazole derivative. The prepared 2,1,3-benzoselenadiazole derivative has the advantages that the phenomena of aggregation and quenching can be effectively avoided, the properties of aggregation, induction and luminescence are achieved, and the luminescence efficiency of the material can be obviously enhanced, so that the 2,1,3-benzoselenadiazole derivative can be applied to an organic electroluminescence device as a luminescent layer.

Owner:JIANGXI NORMAL UNIVERSITY

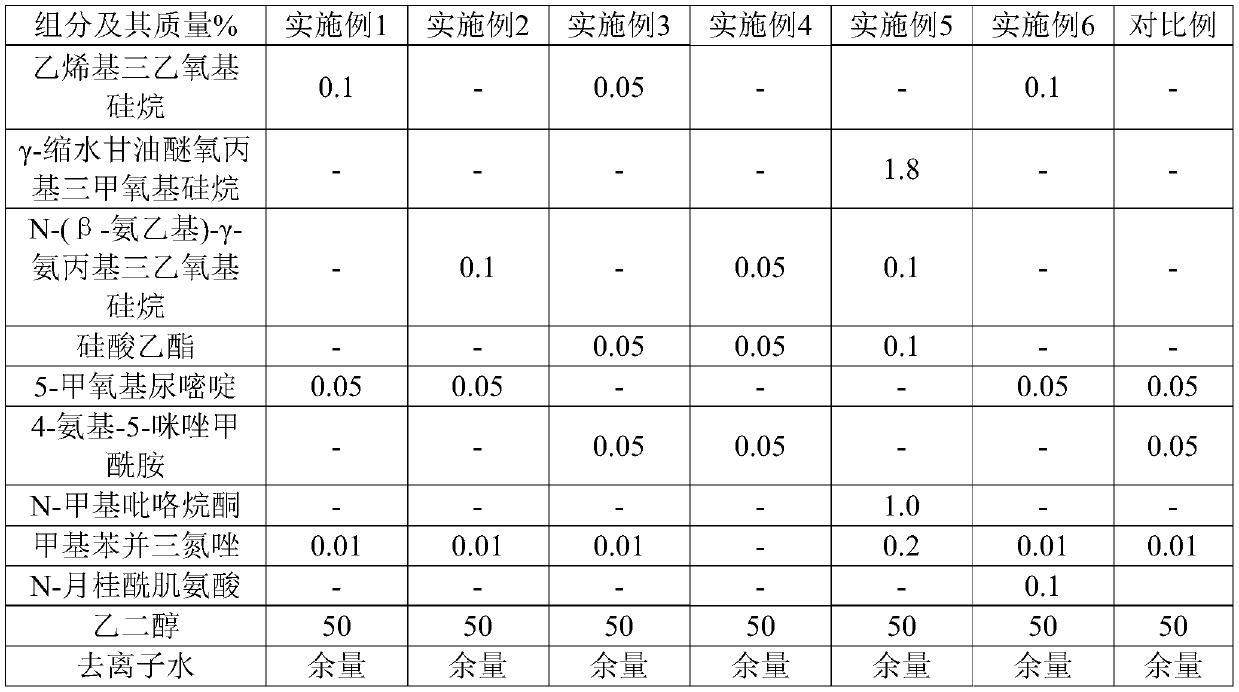

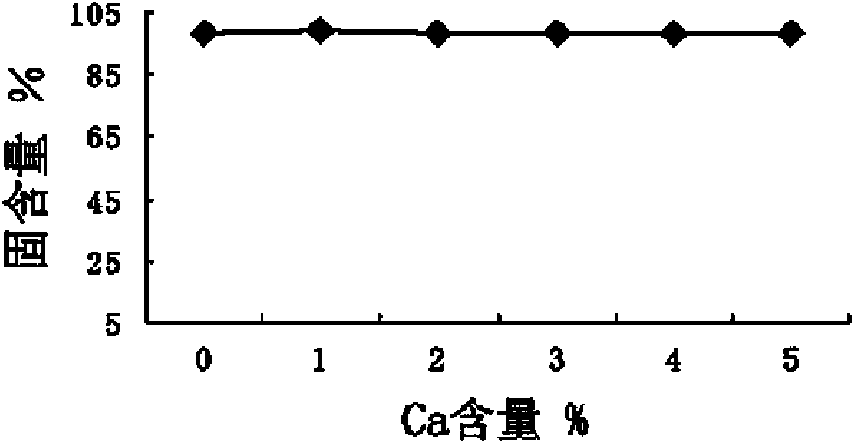

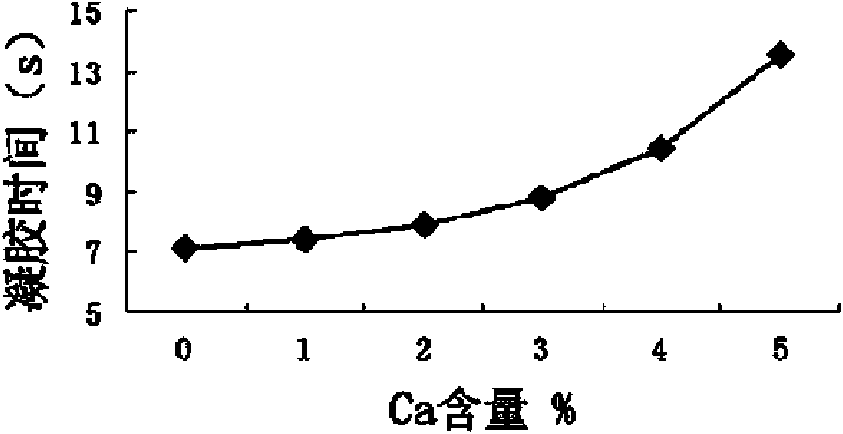

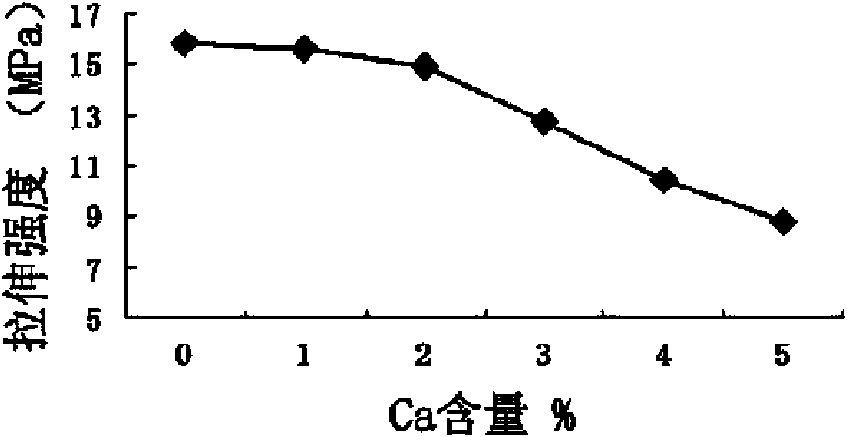

Low-conductivity cooling liquid and preparation method thereof

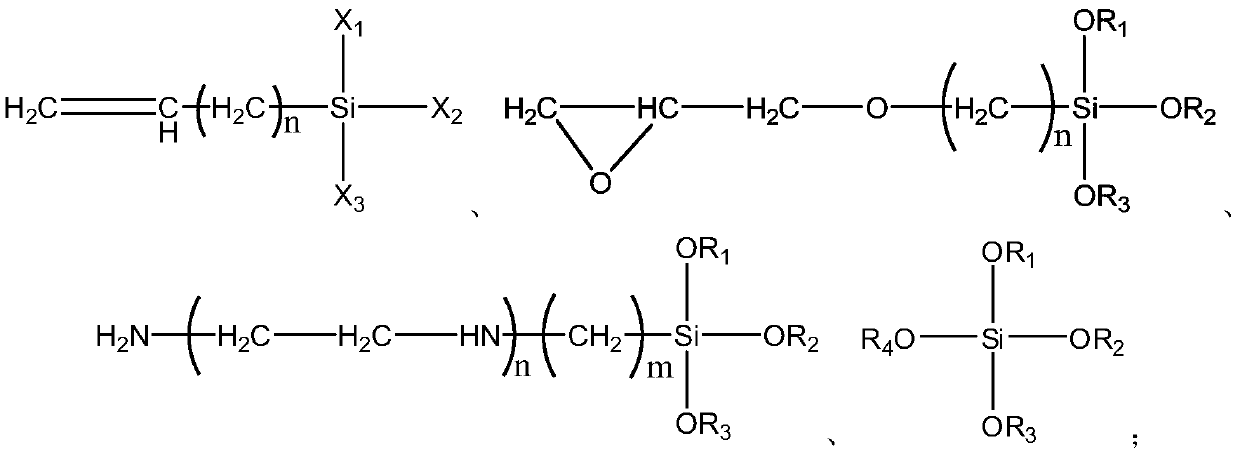

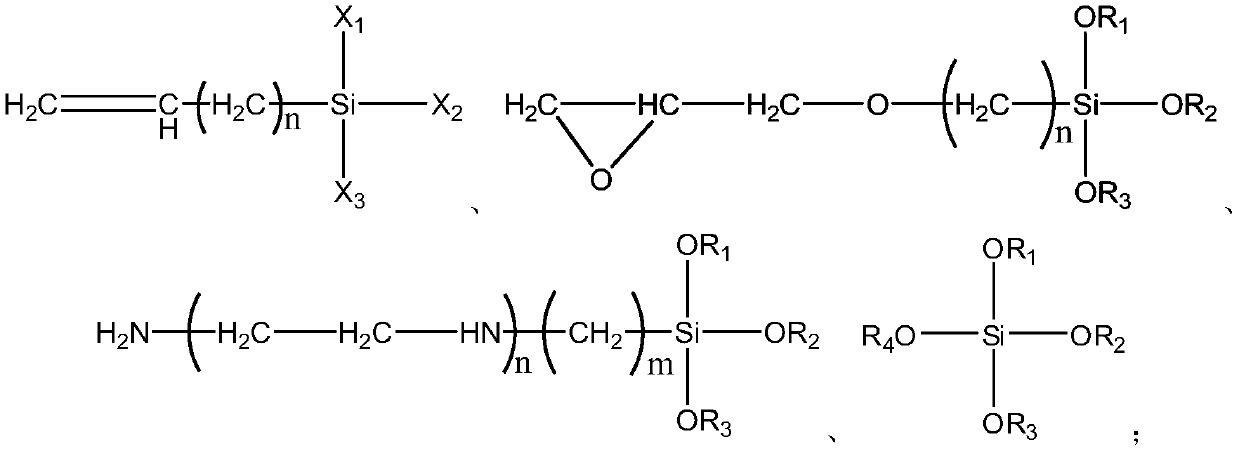

ActiveCN109762642AGuaranteed storage stabilityAvoid hydrolysisLubricant compositionCorrosionOrganosilicon

The invention relates to a low-conductivity cooling liquid and a preparation method thereof, and belongs to the field of chemical engineering. The total mass of each component in a cooling liquid formula is 100%, and the low-conductivity cooling liquid is prepared from the components in percentage by mass: 30-80% of dihydric alcohol, 0.05-5.0% of organosilicon compound, 0.01-2.0% of nitrogen-containing compound, 0-1.0% of azole-based compound and the balance of deionized water. The organosilicon compound, the nitrogen-containing compound and the azole-based compound are uniformly mixed and then added into the dihydric alcohol for normal temperature stirring for more than 20min, and finally the deionized water is added for uniform mixing to obtain the low-conductivity cooling liquid. The low-conductivity cooling liquid has good effect of corrosion inhibition on a multi-metal system, has better storage and using stability, and can be used for cooling and heat exchanging of fuel cells, electric automobile motors and wind power generators.

Owner:中国船舶集团有限公司第七一八研究所

Low molecular weight amino latent crosslinker and spray polyurea elastomer thereof

InactiveCN101608025AReduce crosslinkingReduced activityPolyurea/polyurethane coatingsElastomerElectronegativity

The invention relates to a low molecular weight amino latent crosslinker, which is formed by urea or mixture of urea and low molecular weight polyamine. The low molecular weight polyamine is aliphatic or aromatic diamine or triamine. The diamine is dicyandiamide and the triamine is melamine; and the urea and the melamine are mixed according to a weight ratio of 2:1. A spray polyurea elastomer is generated by reaction of an isocyanate component (A component) and an amino compound (B component); the amino compound of the B component comprises amine-terminated resin, an amine-terminated chain extender and a low molecular weight amino latent crosslinker accounting for 0.1% to 5% of the B component. The low molecular weight amino latent crosslinker has easily-obtained materials, convenient processing and relative cheap price, and can reduce the cost of SPUA. As the low molecular weight polymer amine is influenced by ortho-atoms or atom groups, electronegativity of nitrogen atoms in the amino group is reduced, thus utilizing the electron effect to reduce the reactivity of the amino groups and isocyanate.

Owner:北京立高科技股份有限公司 +1

Mg<2+>, Al<3+>, Zr<4+> and S<2-> ion co-doped garnet type solid electrolyte

The invention discloses an Mg<2+>, Al<3+>, Zr<4+> and S<2-> ion co-doped garnet type solid electrolyte Li5La3Nb2O12 which is characterized by comprising the stoichiometric equation: Li[5+x+2y+z]La[3-x]MgxAlyZrzNb[2-y-z]O[12-m]Sm, wherein x is equal to 0.1-0.5, y is equal to 0.1-0.2, z is equal to 0.1-0.2, and m is equal to 0.1-0.3; and the solid electrolyte is formed by uniformly mixing Li2CO3, La2O3, MgO, Al2O3, ZrO2, Nb2O5 and thiourea in the molar ratio of (2.7-3.05):(1.25-1.45):(0.1-0.5):(0.05-0.1):(0.1-0.2):(0.8-0.9):(0.1-0.3), and ball milling, pressing and sintering. According to the invention, the lithium-ion conductivity greater than 10<-4>S / cm can be obtained at room temperature.

Owner:NINGBO UNIV

Surface-treating method for PTFE/aramid fiber woven pad

ActiveCN104294578AGood adhesionGood flexibilityPhysical treatmentAdhesive processes with surface pretreatmentRare-earth elementFree energies

The invention discloses a surface-treating method for a PTFE / aramid fiber woven pad. The surface-treating method comprises the following steps of (1) immersing the PTFE / aramid fiber woven pad in a rare earth solution, and carrying out ultrasonic treatment; and (2) washing the pad after ultrasonic treatment with water, and drying to obtain a surface-treated pad. According to the surface-treating method for the PTFE / aramid fiber woven pad, the rare earth solution is used as an ultrasonic treatment medium to carry out ultrasonic modification on the pad; by virtue of intense cavitation effect produced by ultrasonic waves, free energy on surfaces of aramid fibers is reduced and the rare earth solution can infiltrate the surfaces of the fibers rapidly and thoroughly; due to a special 4f electronic shell structure, the rare earth element has the characteristics of relatively small electronegativity and prominent chemical activity, so that oxygen-containing active groups in the modifier can be introduced to the surfaces of the fibers; concentration of the active groups on the surfaces of the fibers is increased; and adhesion properties of the pad is greatly increased.

Owner:HENAN UNIV OF SCI & TECH

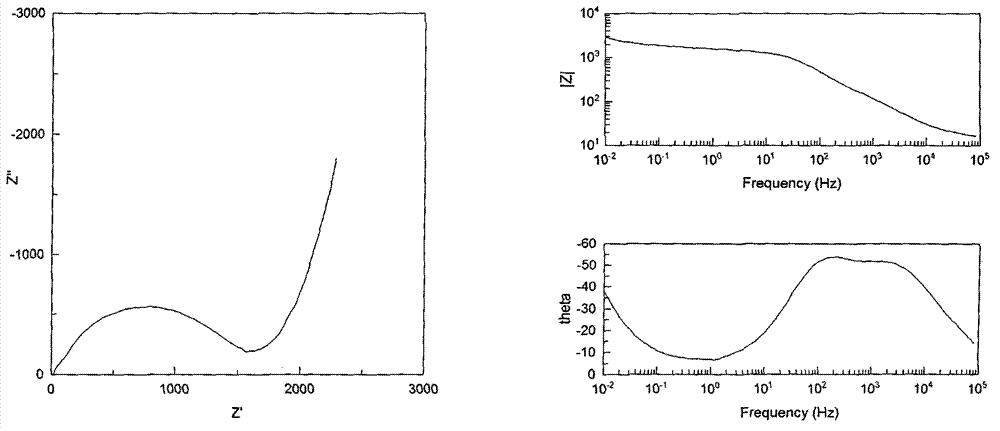

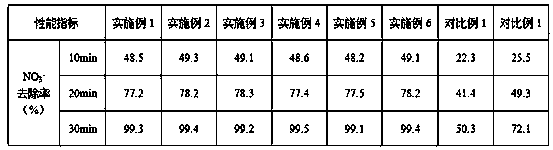

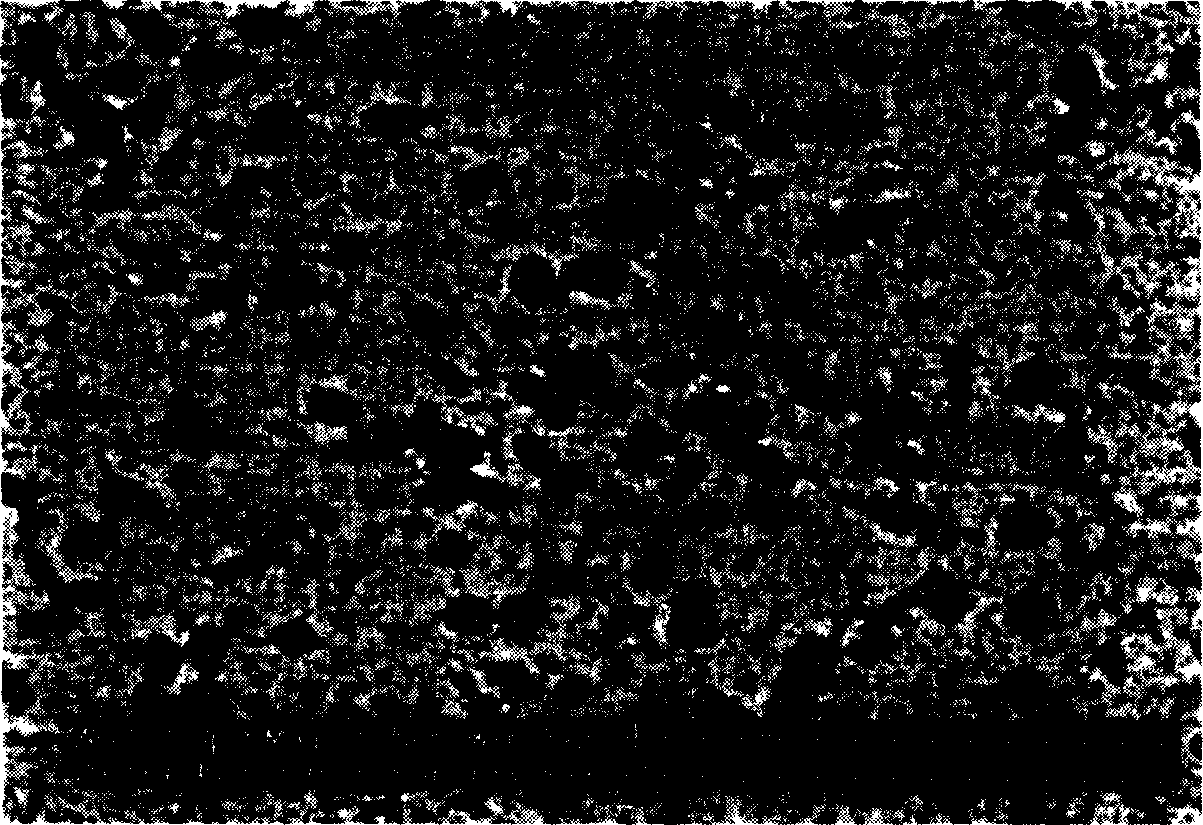

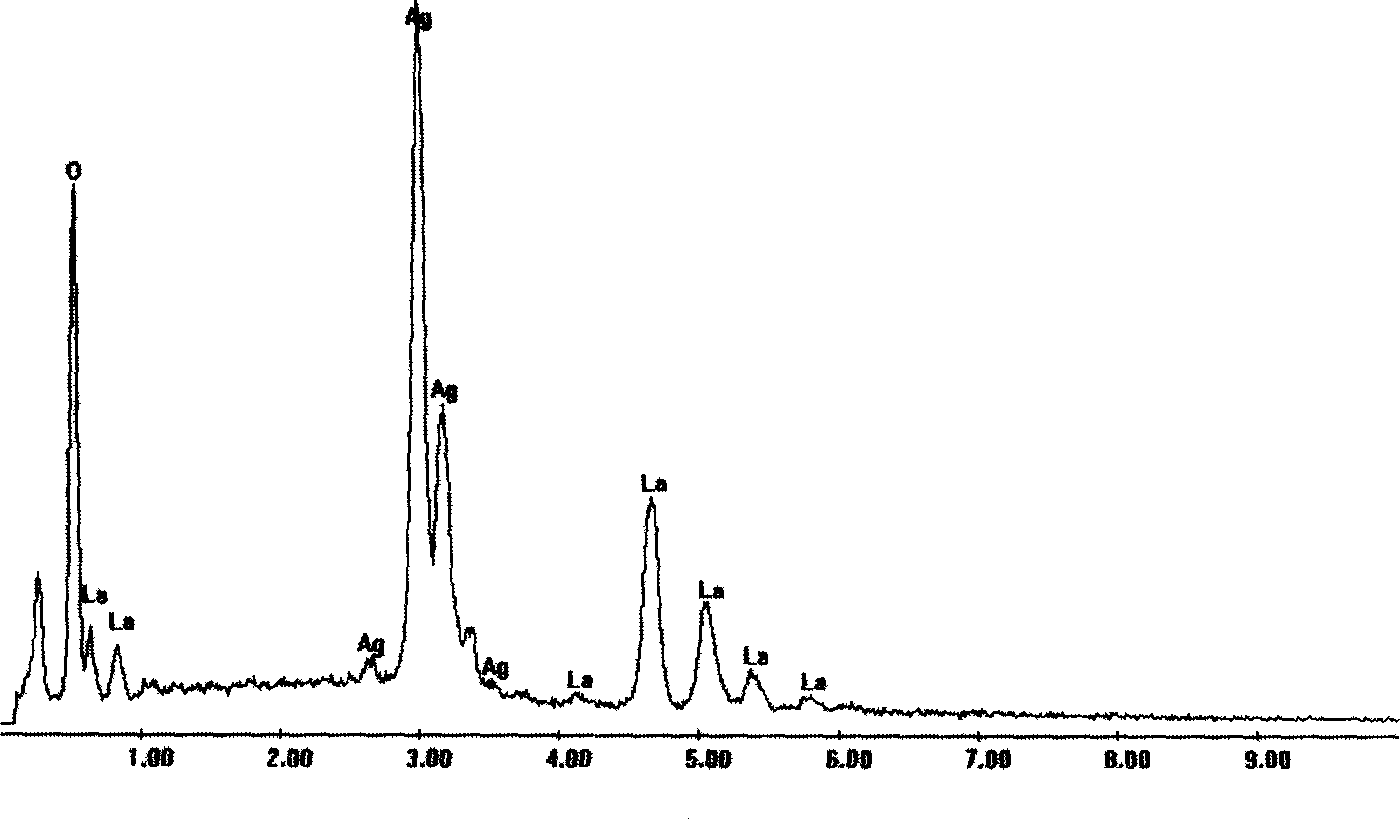

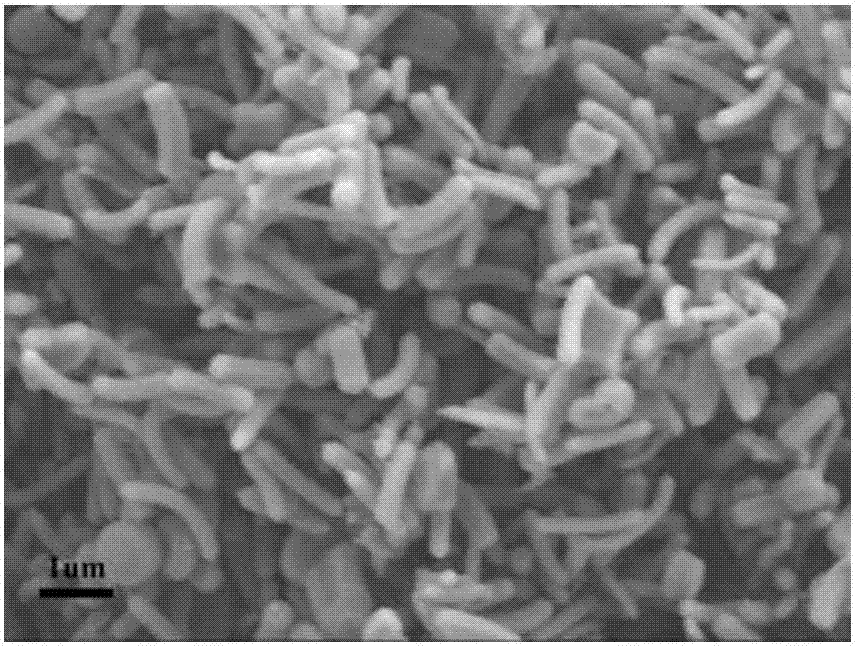

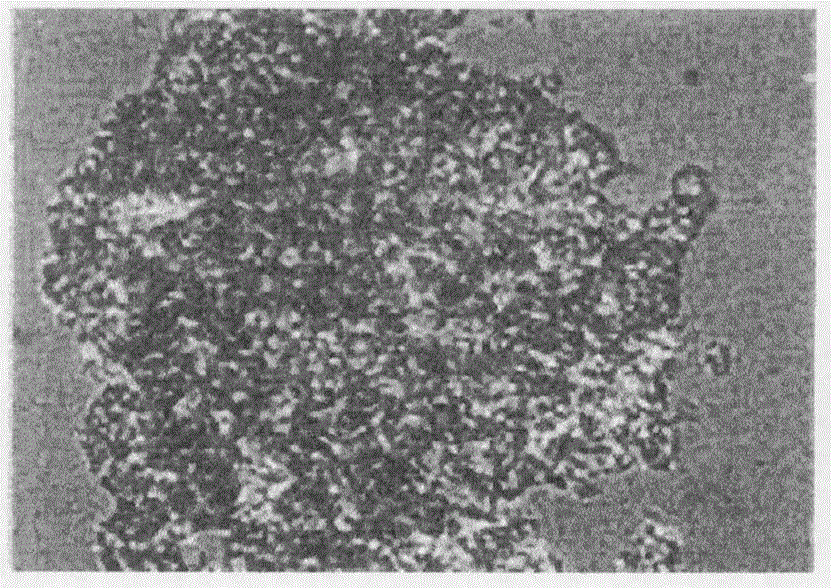

Carbon nanotube/hydrotalcite material for removal of nitrate nitrogen from water and preparation method

ActiveCN109289772AGood effectLarge specific surface areaOther chemical processesWater contaminantsRare earthElectronegativity

Relating to the technical field of nitrogen-containing sewage treatment, the invention provides a carbon nanotube / hydrotalcite material for removal of nitrate nitrogen from water and a preparation method. The method includes: conducting in-situ generation of a lanthanum-doped hydrotalcite layer on the pipe wall of a multiwalled carbon nanotube by coprecipitation, and employing a cationic surfactant cetylpyridine bromide for surface modification of the hydrotalcite layer, thus obtaining the carbon nanotube / hydrotalcite material for removal of nitrate nitrogen from water. According to the preparation method provided by the invention, hydrotalcite is loaded on the pipe wall of the multiwalled carbon nanotube, thus increasing the specific surface area of hydrotalcite and exposing more active sites, and rare earth metal lanthanum is also employed for doping, lanthanum undergoes complexing with NO3<-> to form a stable polyamine complex. Further, cetylpyridine bromide is employed for surfacemodification, thus reducing the electronegativity of the hydrotalcite surface, and providing more active sites for adsorption of NO3<->. Therefore, the carbon nanotube / hydrotalcite material has a goodremoval effect on nitrate nitrogen in water.

Owner:成都硕特科技股份有限公司

Method for preparing silicon and zirconium containing aluminum oxide carrier

ActiveCN101618346ALow electronegativityStrong property modulationCatalyst carriersRefining to eliminate hetero atomsHigh activitySilicon

The invention discloses a method for preparing a silicon and zirconium containing aluminum oxide carrier. The silicon and zirconium in the carrier are added in the glue forming process of the aluminum oxide; and by optimizing process and conditions under which the auxiliary agents of silicon and zirconium are added in the dry glue of the aluminum oxide, the silicon and zirconium are evenly dispersed on the surface of the aluminum oxide, so that the actions of the auxiliary agents can be fully utilized. The silicon and zirconium containing aluminum oxide carrier prepared by the method has the advantages of larger pore volume and reference area and proper surface acidity, and can achieve higher activity and more ideal active stability when the carrier is used for the hydrogenation treatment of heavy mass raw materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

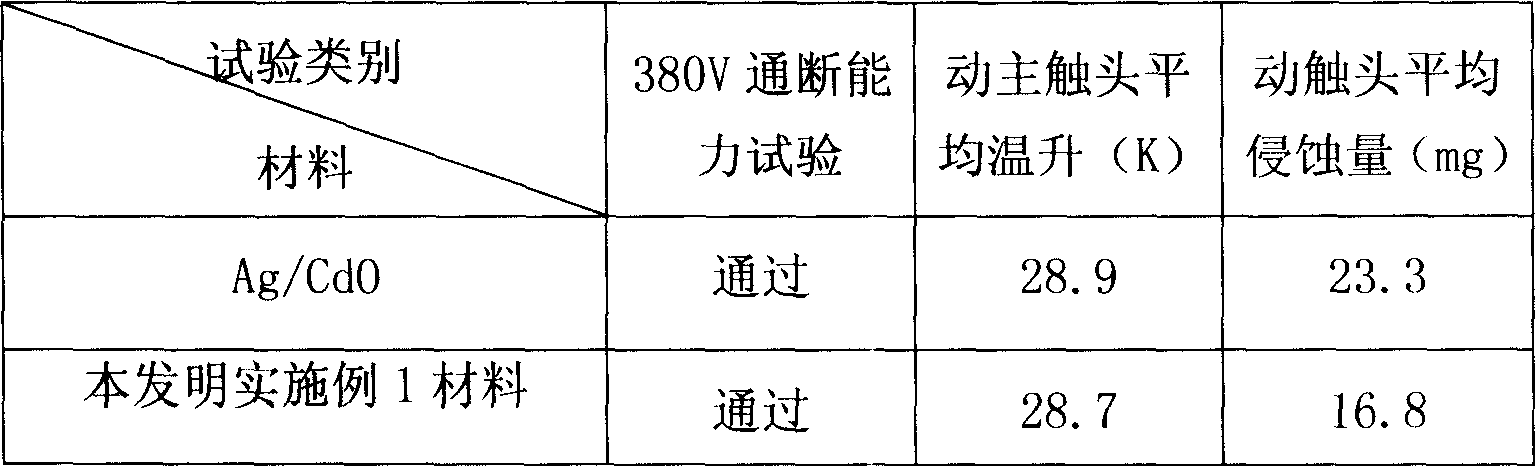

Silver base rare earth alloy contact material for low-voltage switch electric appliance and method for preparing same

InactiveCN1632894AExtended service lifeReduce temperature riseContact materialsLow voltageRare earth

This invention relates to a silver-based rare earth alloy touch material used in low voltage switch appliance and its process method. Its chemical components are the following: rare earth metal oxide xú¢1í½7 úÑ; Me oxide yú¢1í½3 úÑ; SnO#-[2] zú¢(12-x-y)úÑ; the rest is metal silver, wherein the rare earth metals are LaíóCeíóPr or Nd and Me as BiíóIníóSb or T1. Its process method is as following: to use chemical co-precipitation to make powder and to shape and sinter the deposited powder.

Owner:HEBEI UNIV OF TECH

Preparation method for anticorrosion steel used for water-cooling spray nozzle

ActiveCN106119724AImprove impact resistanceReduced diffusion rateSolid state diffusion coatingMolten stateBoriding

The invention discloses a preparation method for anticorrosion steel used for a water-cooling spray nozzle. The method comprises the following steps that raw materials are heated into a molten state to obtain a liquid alloy, wherein the liquid alloy comprises, by weight, 0.1-0.25% of C, 1.2-1.5% of Cr, 0.3-0.6% of Al, 1.2-1.6% of Mg, 0.2-0.3% of Zr, 0.4-0.6% of Ni, 1.2-1.3% of Mn, 0.08-0.12% of Mo, 0.1-0.13% of V, 0.03-0.06% of Co, 0.02-0.05% of Ga, 1.5-1.6% of T, 0.6-0.8% of Si and the balance Fe; a steel billet is obtained through casting; heat treatment is conducted; boriding is conducted; and the steel billet subjected to heat treatment and boriding is coated with a conversion film.

Owner:滁州帝邦科技股份有限公司

B<3+>, Al<3+>, Mg<2+>, Y<3+> and S<2-> co-doped solid electrolyte Li7La3Zr2O12

The invention discloses a B<3+>, Al<3+>, Mg<2+>, Y<3+> and S<2-> co-doped solid electrolyte Li7La3Zr2O12 which is characterized in that a chemometry formula is Li7+y1+y2+2y3YxLa3-xBy1Aly2Mgy3Zr2-y1-y2-y3O12-mSm, wherein x=0.1-0.3; y1=0.1-0.2; y2=0.1-0.2; y3=0.1-0.3; m=0.1-0.3; and the B<3+>, Al<3+>, Mg<2+>, Y<3+> and S<2-> co-doped solid electrolyte Li7La3Zr2O12 is prepared by the steps of uniformly mixing Li2CO3, Y2O3, La2O3, Al2O3, MgO, ZrO2 and thiourea according to a mole ratio of (3.7-4.0):(0.05-0.15):(1.35-1.45):(0.05-0.1):(0.05-0.1):(0.1-0.3):(1.3-1.7):(0.1-0.3), ball-grinding, pressing and sintering. A room-temperature lithium ion conductivity of more than 5*10<-4>S / cm can be obtained.

Owner:NINGBO UNIV

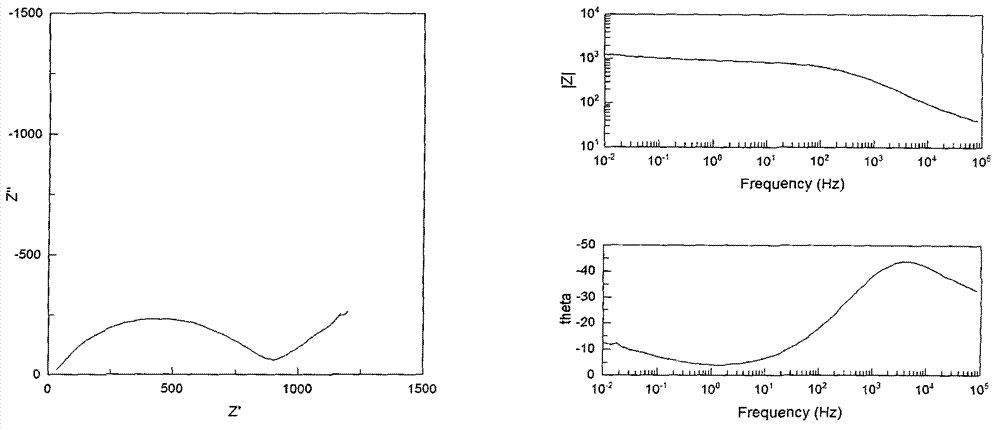

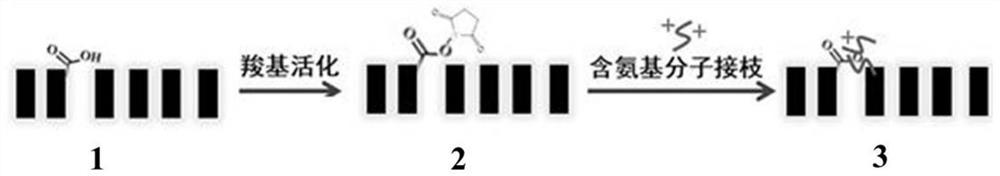

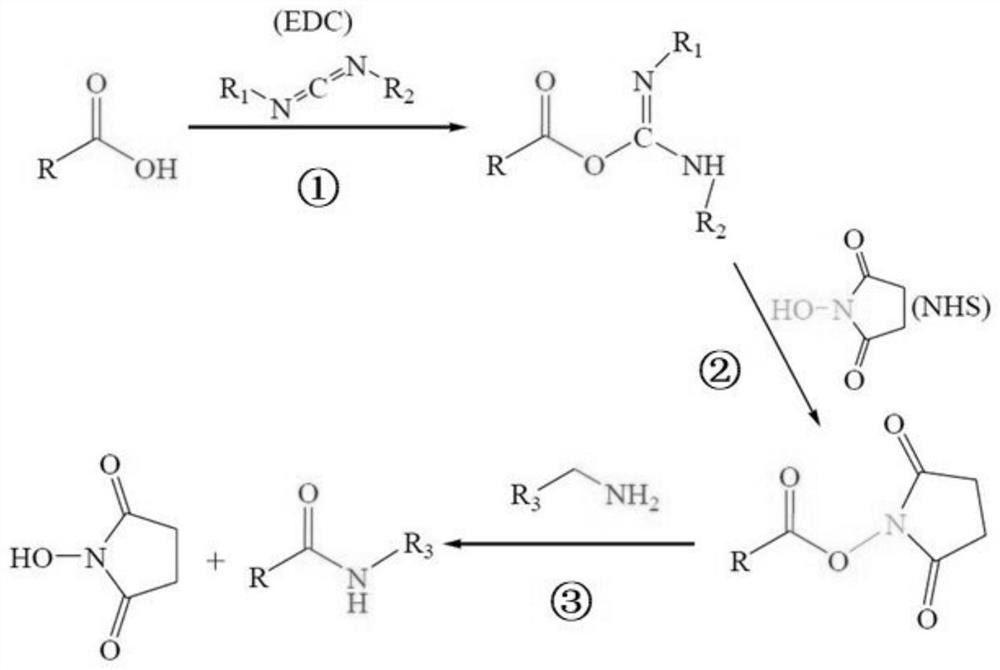

Polyamide nanofiltration membrane as well as preparation method and application thereof

ActiveCN112108020AExcellent alkali swelling resistanceImprove stabilityReverse osmosisInorganic saltsPolyamide

The invention provides a polyamide nanofiltration membrane as well as a preparation method and application thereof. The preparation method comprises the following steps: (1) activating a polyamide base membrane by using an activating agent to obtain an activated polyamide base membrane; and (2) grafting the activated polyamide base membrane obtained in the step (1) with an amino compound to obtainthe polyamide nanofiltration membrane. The preparation method has the advantages of simple process, convenience in operation and the like; on one hand, the prepared polyamide nanofiltration membranehas the advantages of small surface macropore number, small average pore size and high rejection rate for organic micromolecules; on the other hand, the electronegativity is low, and the rejection rate of monovalent inorganic salt is low; and the polyamide nanofiltration membrane also has excellent alkali-resistant swelling performance and chemical stability, and has a wide industrial applicationprospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparing method for wear-resisting steel used for water-cooling nozzle

InactiveCN106048514AImprove impact resistanceReduced diffusion rateSolid state diffusion coatingSodium bicarbonateBoron carbide

The invention discloses a preparing method for wear-resisting steel used for a water-cooling nozzle. The preparing method includes the following steps that smelting and pouring are conducted; heat treatment is conducted; a steel billet obtained after heat treatment is subjected to pretreatment and then put into a boriding agent, the temperature is increased to 910 DEG C to 930 DEG C, heat insulation is conducted for 6 h to 7 h, and then a steel billet generated after boriding is obtained; and covering of a conversion film is conducted. The use amount of the boriding agent ranges from 1.3 g / cm<2> to 1.6 g / cm<2>, and the boriding agent includes, by weight, 4-6 parts of boron carbide, 10-15 parts of borax, 3-4 parts of potassium fluoborate, 0.5-1 part of sodium fluosilicate, 5-7 parts of sodium bicarbonate, 40-50 parts of silicon carbide and 30-35 parts of activated carbon. Covering of the conversion film includes the specific steps that the steel billet generated after boriding is cleaned and then put into a conversion solution, the temperature is increased to 40 DEG C to 50 DEG C, heat insulation is conducted for 18 min to 22 min, and the wear-resisting steel used for the water-cooling nozzle is obtained through drying. The wear-resisting steel has good wear-resisting performance and is good in corrosion resistance performance and high temperature resistance performance.

Owner:CHUZHOU DIBANG TECH

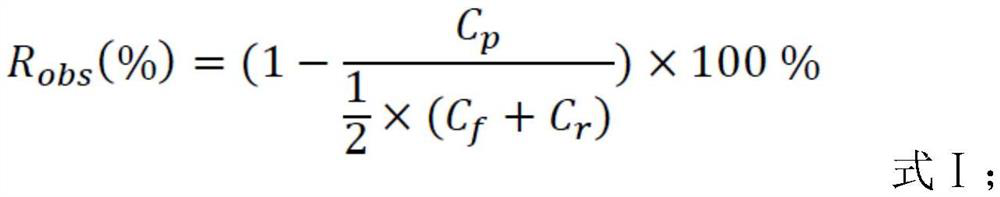

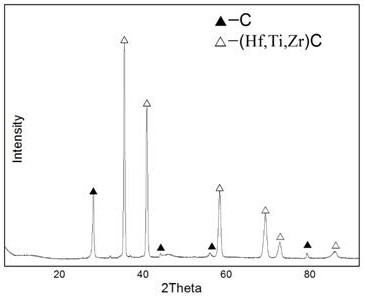

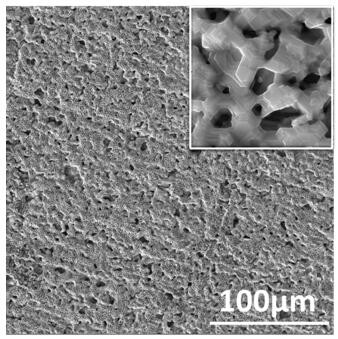

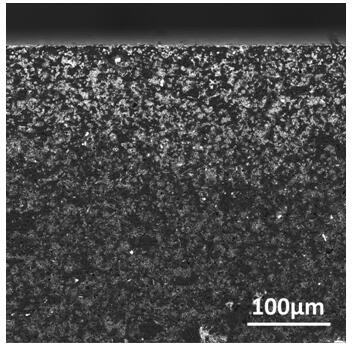

Multi-metal carbide modified carbon-based material and preparation method thereof

The invention discloses a multi-metal carbide modified carbon-based material and a preparation method thereof. The method comprises the steps that metal elementary substance Hf serves as a reaction source, a metal fluoride acid salt mixture serves as an active agent, a mixed salt of NaCl and KCl serves as a molten salt medium, graphite serves as a matrix, the mixed salt of the KCl and the NaCl is heated to be in a molten state; the metal elementary substance Hf and the metal fluoride are subjected to a combination reaction in a molten salt medium in a molten state to generate active metal atoms, and when the active metal atoms make contact with a carbon material, the combination reaction is carried out to form multi-element metal carbide. The number of the coatings is gradually reduced from the surface of the substrate to the interior of the substrate, so that the matching of thermal expansion coefficients between the coatings and the substrate is favorably improved, and a good binding force and thermal shock resistance between the coatings and the substrate are ensured; in addition, the method is simple in process, low in cost and high in operability, raw materials are easy to obtain, the shape of the graphite matrix in the method is not limited, and the application range is wide.

Owner:NAT UNIV OF DEFENSE TECH

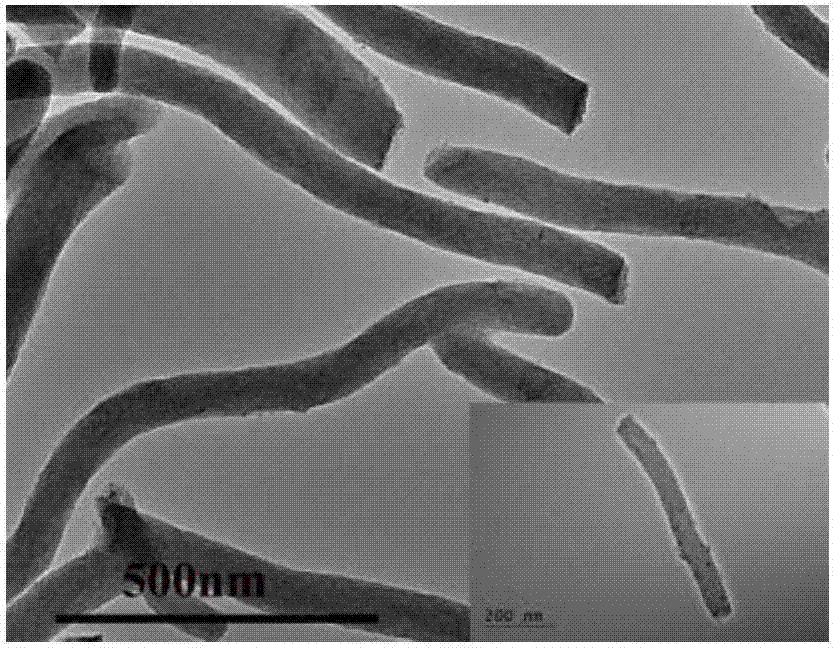

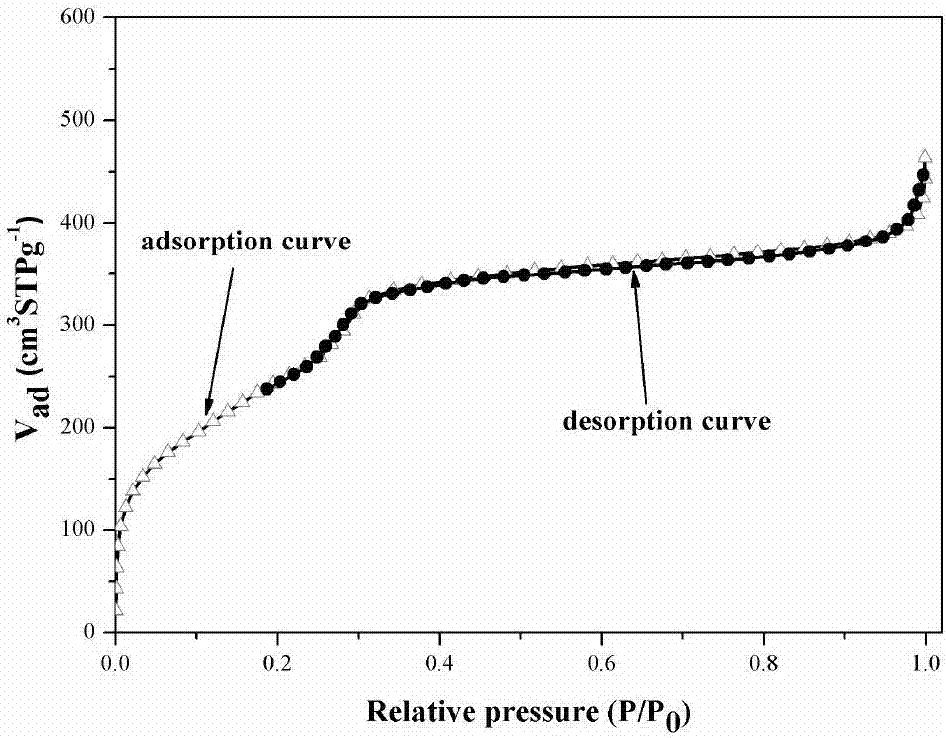

Aluminiferous SiO2 loaded high-dispersion Pt catalyst, and preparation method and application thereof

The invention relates to an aluminiferous SiO2 loaded high-dispersion Pt catalyst, and a preparation method and application thereof. The method comprises the following steps: uniformly mixing a PVP-Pt ethyl alcohol solution with absolute ethyl alcohol, and then adding K modified rod-shaped aluminiferous SiO2 and uniformly mixing, thereby acquiring a mixed solution; filtering the acquired mixed solution, washing and drying, and then roasting for 4-7h under the air atmosphere at 400-600 DEG C; roasting for 4-7h under the hydrogen atmosphere at 400-600 DEG C, thereby acquiring the aluminiferous SiO2 loaded high-dispersion Pt catalyst. The aluminiferous SiO2 loaded high-dispersion Pt catalyst is prepared according to a double-surfactant method, a hydrothermal synthesis method, a post-modification aluminizing method, an ion exchange method, a glycol reduction method, a colloid impregnation method, and the like, has Pt nano-particles with high specific surface area, large micropore volume and high dispersing degree, has an excellent low-temperature catalytic oxidation property to OVOCs and has ultrahigh reaction stability.

Owner:XI AN JIAOTONG UNIV

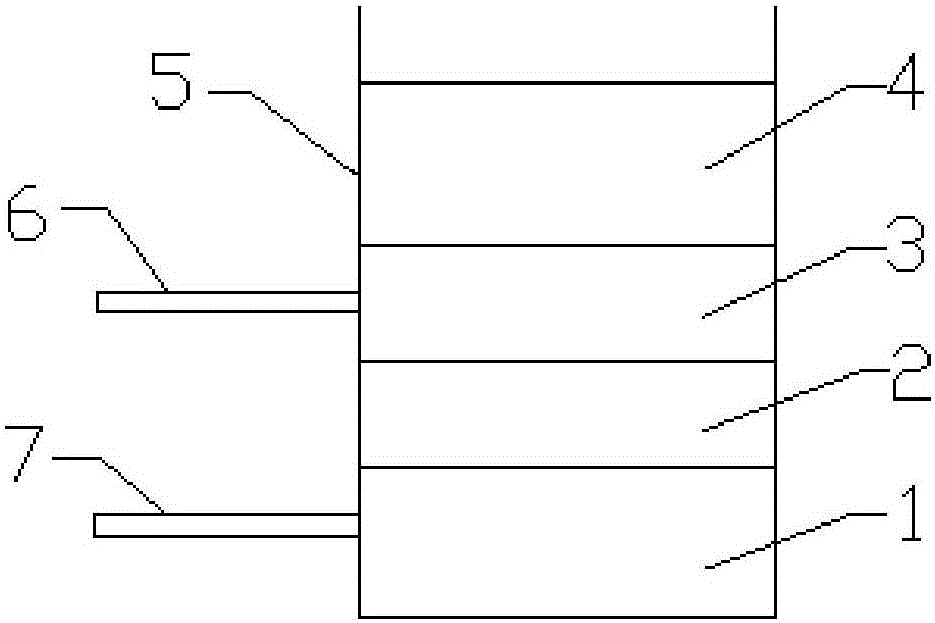

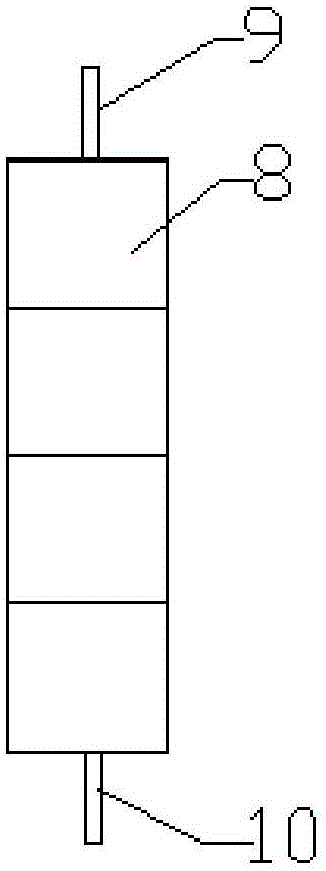

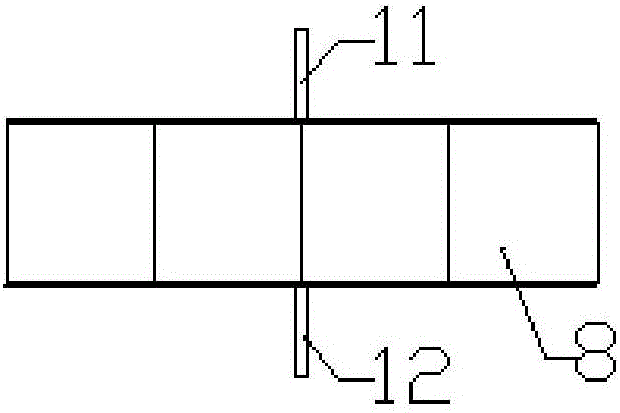

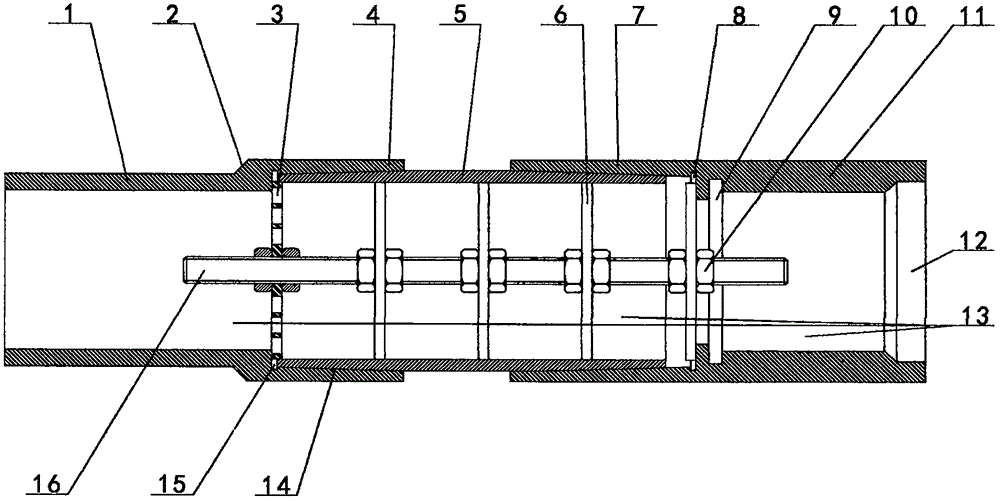

Universal type scale preventing device

The invention relates to a scale preventing device, in particular to a universal type scale preventing device. Each scale preventing piece (6) is provided with a plurality of holes (3) penetrating through two side faces. The scale preventing pieces (6) are fixed to a spindle at intervals to form a scale preventing string and sleeved with a connecting pipe (5). One end of the connecting pipe (5) is sleeved with one end of a reducing connecting pipe (1), and the other end of the connecting pipe (5) is sleeved with one end of a connecting sleeve (11). The spindle comprises the chemical components of Ni(+Co), S, Al, Fe, Mn, Ti, C, Si and Cu. The electronegativity of alloy materials of the spindle is lower than that of ions in the liquid phase, so that the polarization effect of fluid is generated, and wax and colloidal substances in raw oil are in a suspended state and not prone to being adsorbed on the pipe wall in a gathered mode; and the purpose of preventing scales is achieved.

Owner:盘锦福瑞电子科技有限公司

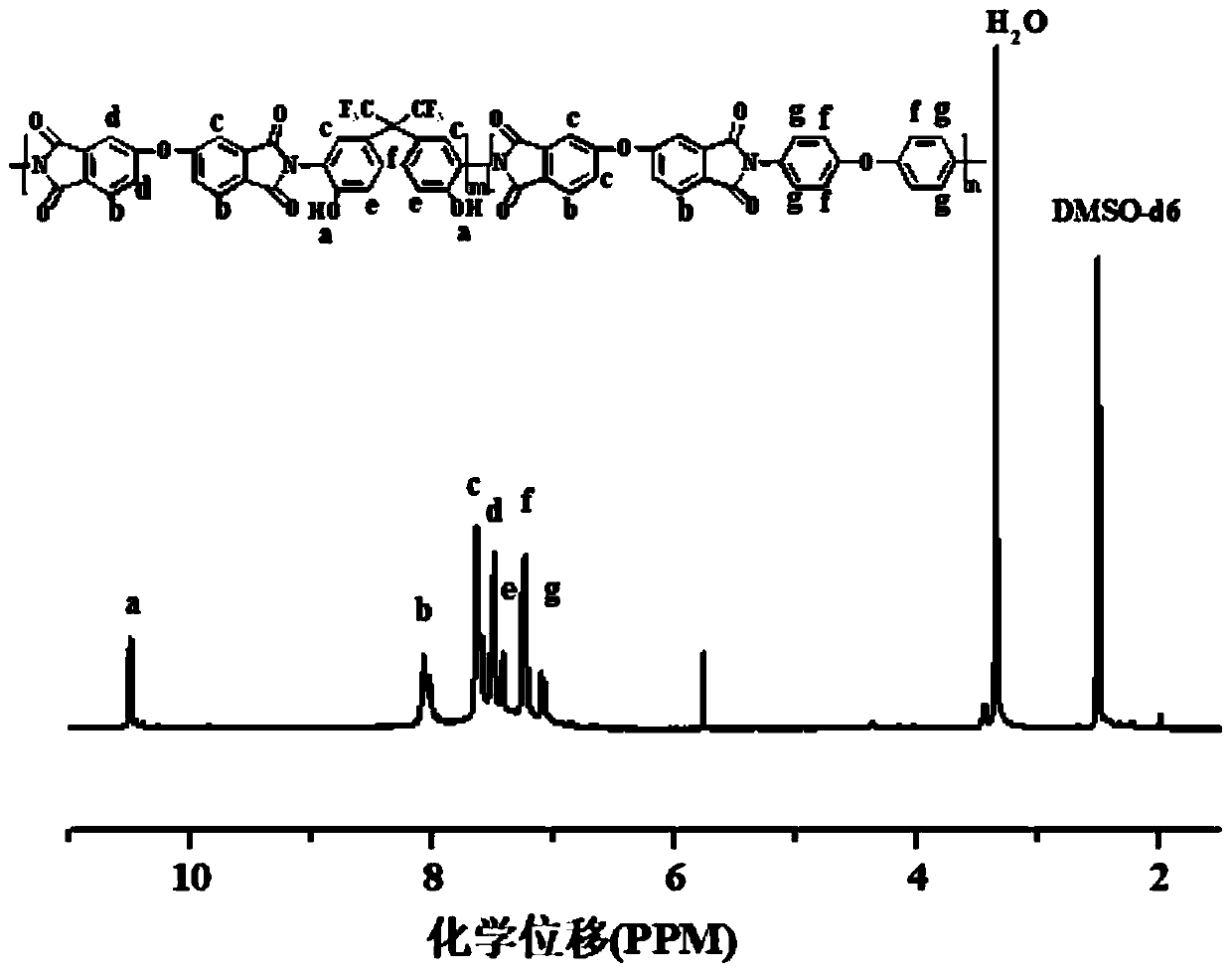

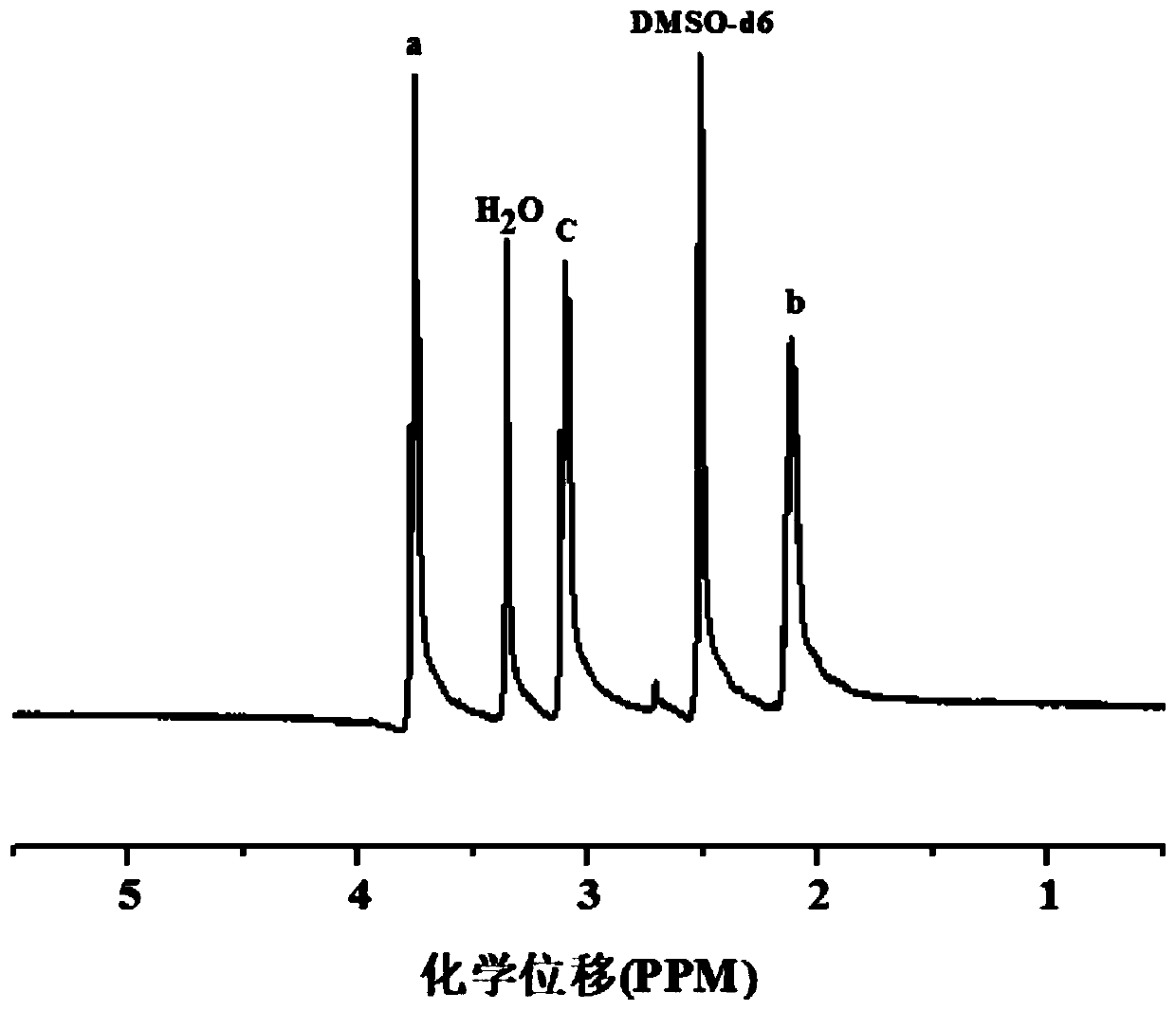

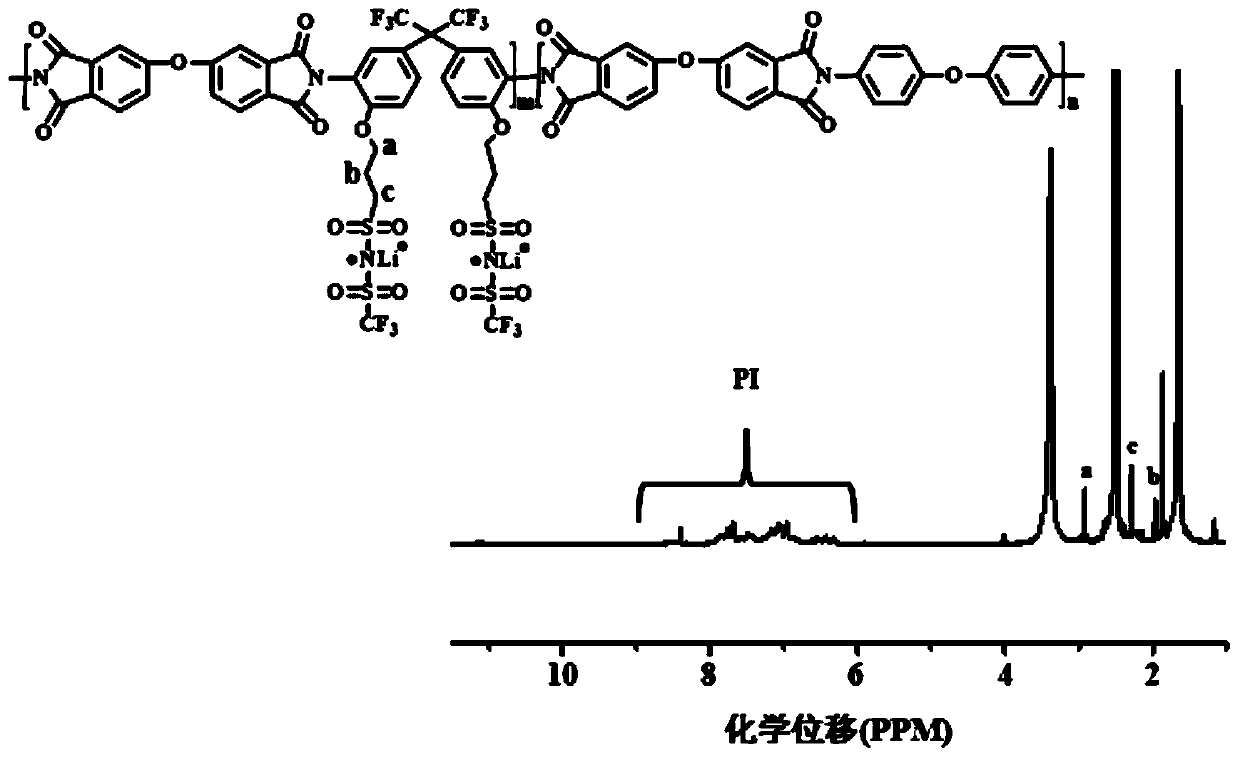

Polyimide single-ion polymer, preparation method thereof and solid polymer electrolyte membrane

ActiveCN111548490AEasy thermal stabilityImprove transmission performanceSecondary cellsLithium-ion batteryElectronic conductivity

The invention provides a polyimide single-ion polymer, a preparation method thereof and a solid polymer electrolyte membrane. The chemical structure of the polyimide single-ion polymer is shown as a formula (I). The good thermal stability of polyimide is utilized; in addition, each repeating unit of the obtained polyimide skeleton contains two trifluoromethyl groups (-CF3), so that the polymer hasgood solubility; 3-chloropropane sulfonyl lithium (trifluoromethanesulfonyl) imide lithium salt is fixed on the polymer through a grafting reaction; low lithium ion dissociation domain energy existing in a lithium bis(sulfonyl) imide part can promote dissociation and transmission of lithium ions in grafted 3-chloropropanesulfonyl lithium (trifluoromethanesulfonyl) imide lithium salt, high lithiumion conductivity of the polymer electrolyte is ensured, more lithium sources are provided, the migration number of Li<+> of the electrolyte membrane is increased; therefore, the thermal stability andelectrochemical stability of the polymer electrolyte membrane and the cycling stability of a battery are ensured, and the use safety of a lithium ion battery is ensured.

Owner:NORTHEAST NORMAL UNIVERSITY

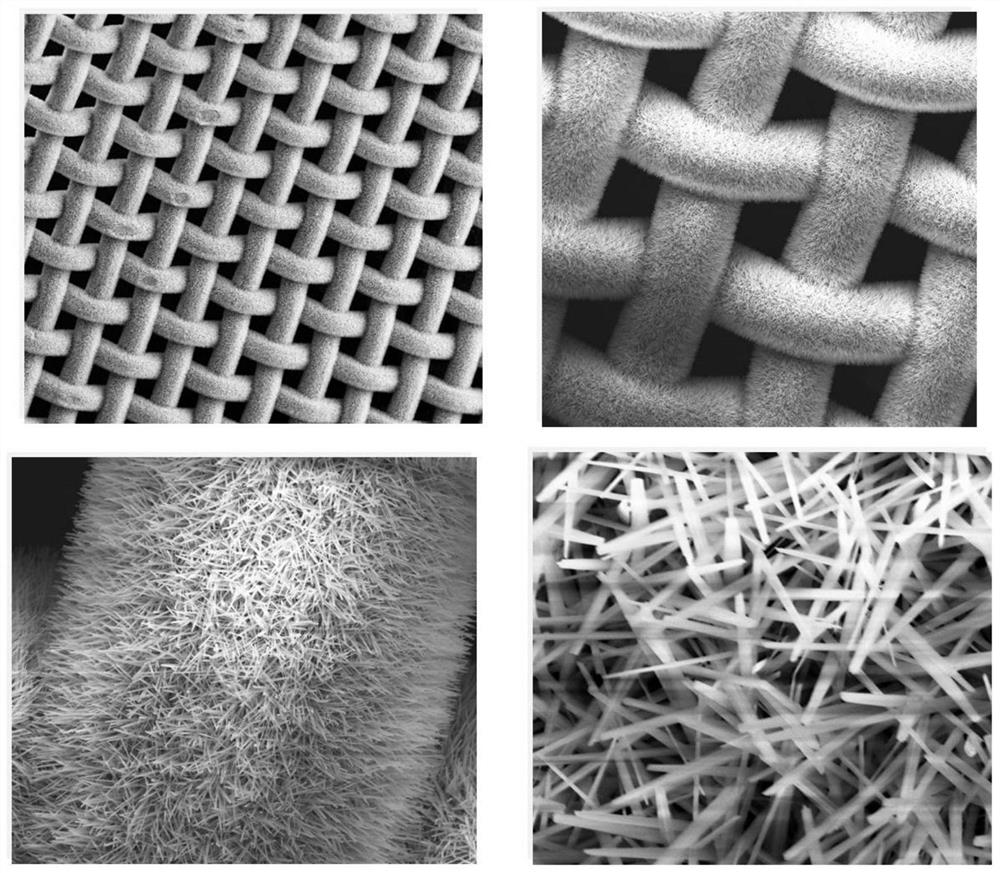

Array type metal sulfide composite electrode material and preparation method thereof

ActiveCN111900334AHigh specific surface areaImprove conductivityCell electrodesElectrolytic agentConductive polymer

The preparation method of the array type metal sulfide composite electrode material comprises the following steps: step 1, taking a copper mesh substrate, slicing, ultrasonically cleaning, and dryingfor later use; 2, adopting an electrochemical workstation, adopting a constant current mode, taking foamy copper as a working electrode, taking mercury oxide as a reference electrode, taking a platinum sheet as a counter electrode and taking NaOH as an electrolyte, and electroplating to prepare a Cu(OH)2 nano array; 3, putting the prepared Cu(OH)2 nano array into a tubular furnace for annealing treatment to prepare a copper peroxide CuO2 nano array; 4, carrying out vulcanization treatment on the annealed copper peroxide CuO2 nano array sample to prepare a Cu9S5 nano array; and 5, coating a layer of conductive polymer ppy outside the Cu9S5 nano array by adopting an electroplating method to prepare a Cu9S5@ppy nano array. Therefore, the vertical Cu9S5 nanosheet is prepared on the surface ofthe foamy copper, and a layer of polypyrrole is coated outside the Cu9S5 nanosheet, so that the stability of the electrode material is improved, and the obtained electrode material has excellent electrochemical performance.

Owner:东营睿港招商服务有限责任公司

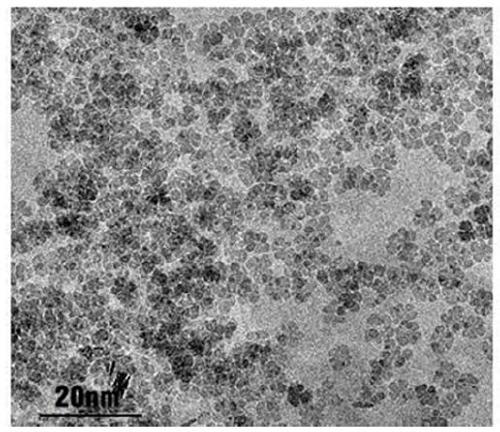

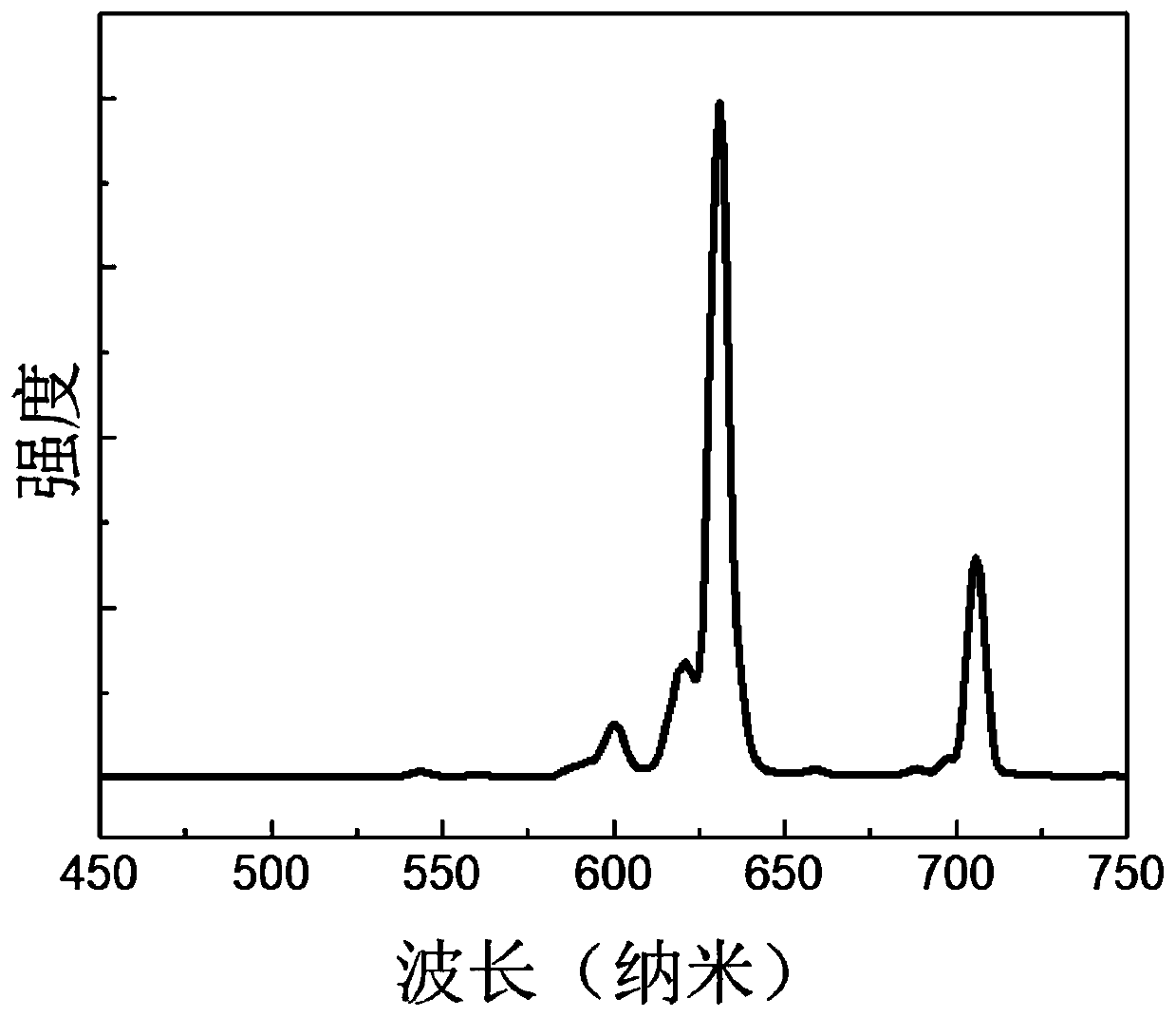

Quantum dot fluorescent probe for pH detection as well as preparation method and application of quantum dot fluorescent probe

InactiveCN111286327ALower the nucleation barrierDecreased fluorescence intensityMaterial nanotechnologyNanoopticsCarboxylic groupQuantum dot

The invention belongs to the field of inorganic luminescent materials. The invention relates to preparation of a calcium ion and europium ion co-doped bismuth oxysulfide nanocrystal and an applicationof the nanocrystal in pH detection. A quantum dot fluorescent probe for pH detection is formed by modifying the surface of a citric acid ligand with 10Ca / 6Eu: Bi2O2S nanocrystals, and the molar ratioof the citric acid ligand to the 10Ca / 6Eu: Bi2O2S nanocrystals is (2-10): 1. In the process of preparing the nanocrystal, alkaline earth calcium ions are added, so that the nucleation energy barrierof the bismuth oxysulfide nanocrystal is reduced, and the growth of the bismuth oxysulfide nanocrystal is further promoted. On the basis, through surface ligand exchange, the surface of the nanocrystalline is provided with the citric acid ligand. Along with the increase of the pH value, carboxyl in citric acid is gradually ionized, and the electronegativity of the surface of the nanocrystal is gradually reduced, so that the electronic layout on a charge migration band is inhibited, and the fluorescence intensity of Eu<3+> ions is further reduced. The simple fluorescence pH detection method provides a new idea for exploring a novel pH probe.

Owner:杭州众道光电科技有限公司

Fast preparation method of high-transmittance silica aerogel film

InactiveCN104609430APromote polymerizationIncrease electropositivitySilicon compoundsSilicon oxygenAmbient pressure

The invention discloses a fast preparation method of a high-transmittance silica aerogel film, and belongs to the technical field of function materials. After tetraethoxysilane and ethylene glycol monomethyl ether, ethanol or methanol are uniformly mixed, deionized water and a dryness control chemical additive are added, the mixture is stirred uniformly, ammonium fluoride is added, and silica sol is obtained; a cleaned and dried glass substrate is immersed in the silica sol, constant-speed pulling and film coating are performed, and a wet gel film is obtained; the wet gel film is subjected to ambient pressure drying in the atmosphere of ethylene glycol monomethyl ether, and the silica aerogel film is obtained. The preparation period is greatly shortened, nucleophilic attack can be performed to form an intermediate state of a high coordination state, fluorine has lower electronegativity compared with oxygen, central silicon ions have higher electropositivity, a silicon oxygen bond is weakened, a gel polymerization reaction is facilitated, and the high-transmittance silica aerogel film with excellent mechanical property is formed.

Owner:YANGZHOU TIANCHEN FINE CHEM +2

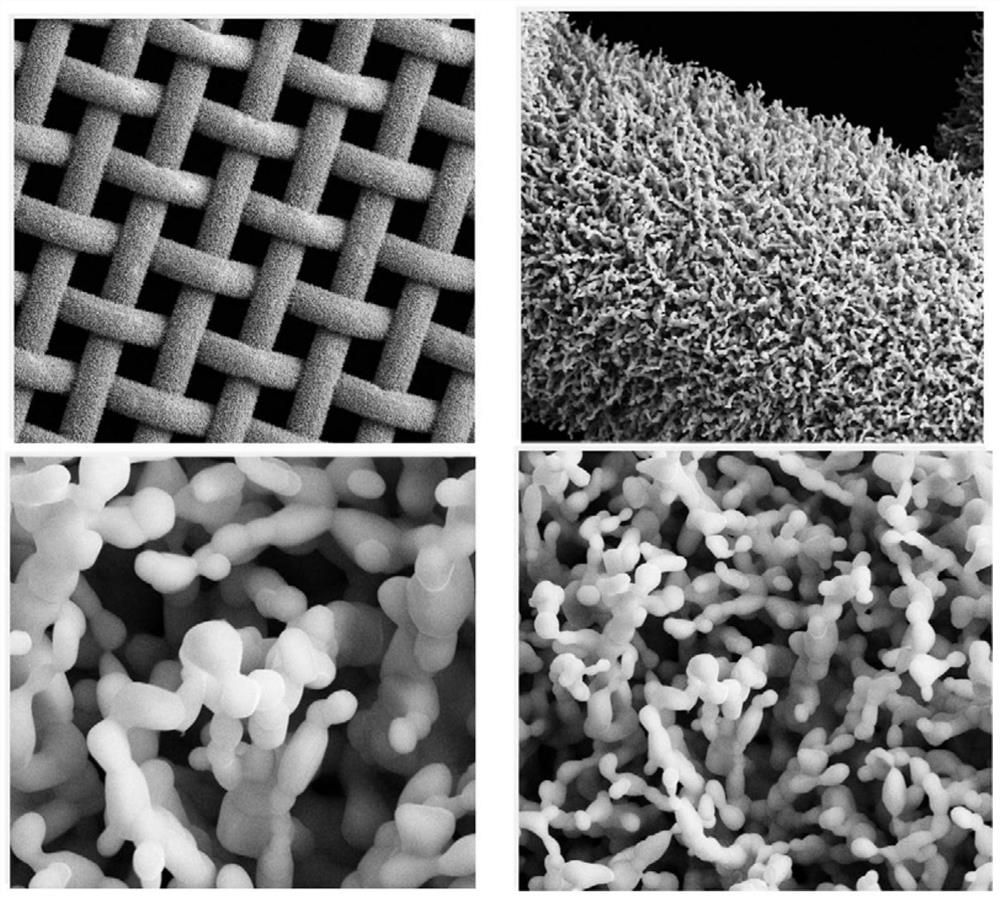

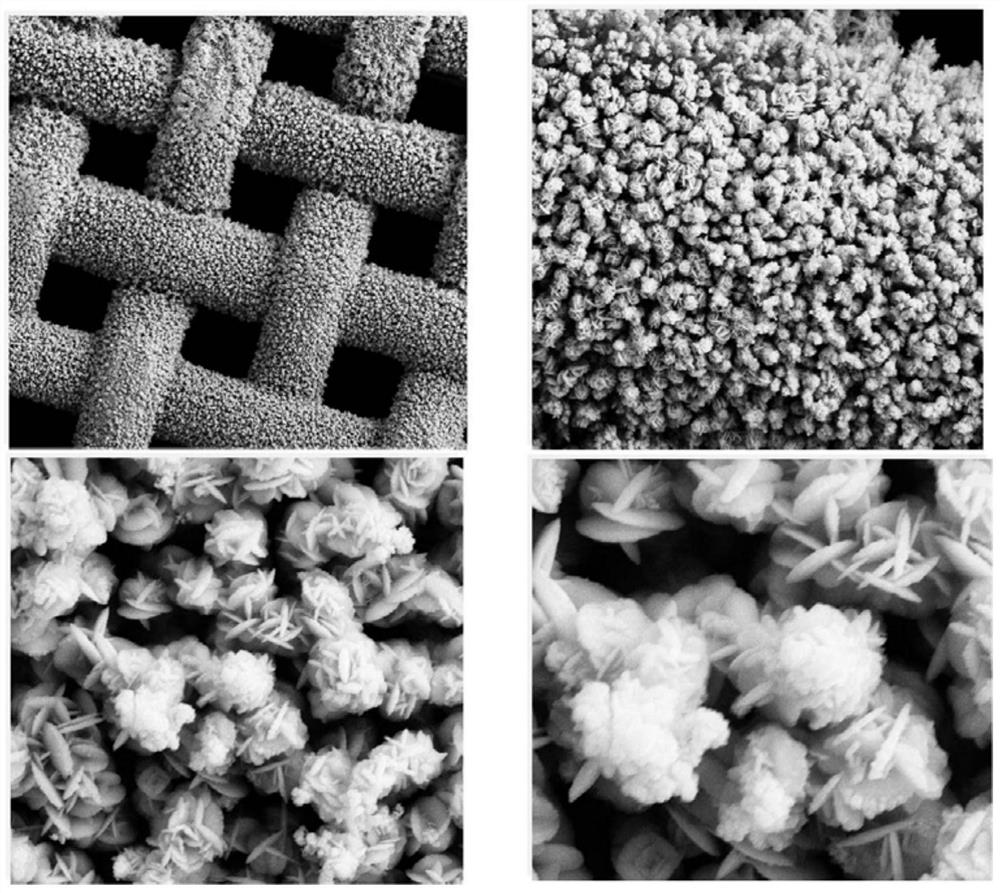

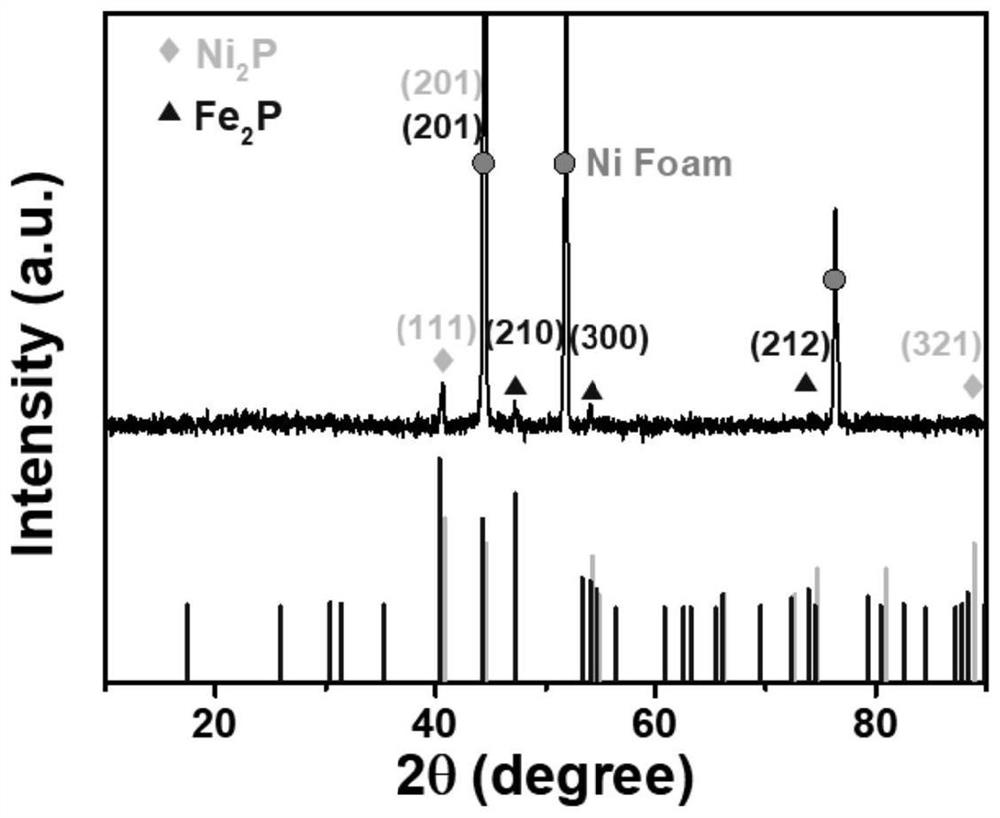

Preparation method and application of iron nickel phosphide nanosheet forming capacitor material

PendingCN114804045AExcellent electrochemical performanceNot easy to fall offHybrid capacitor electrodesHybrid/EDL manufactureIron phosphideElectrically conductive

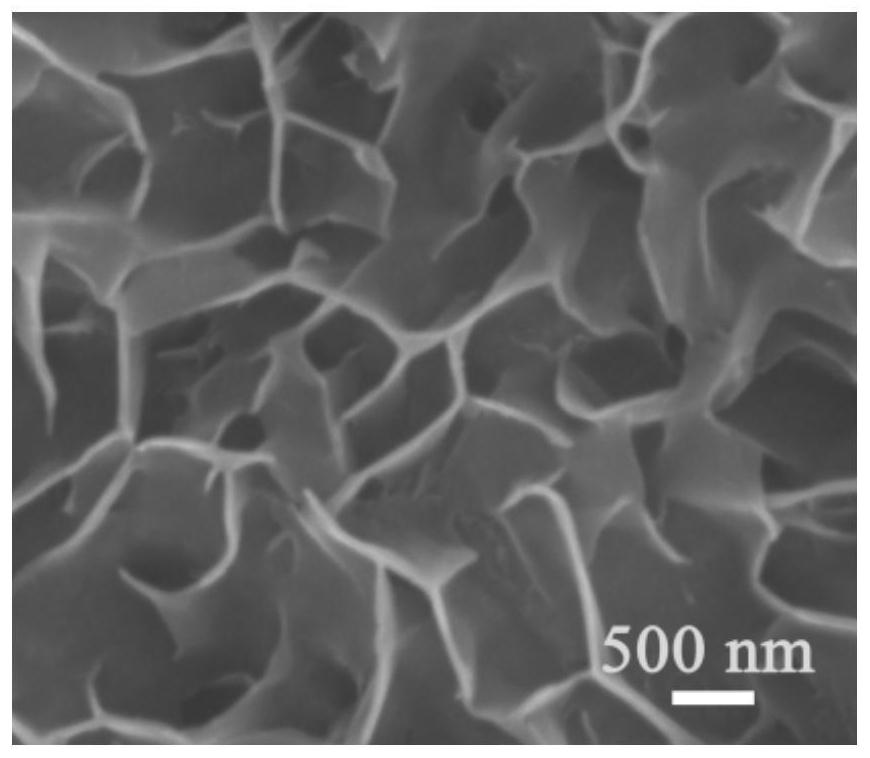

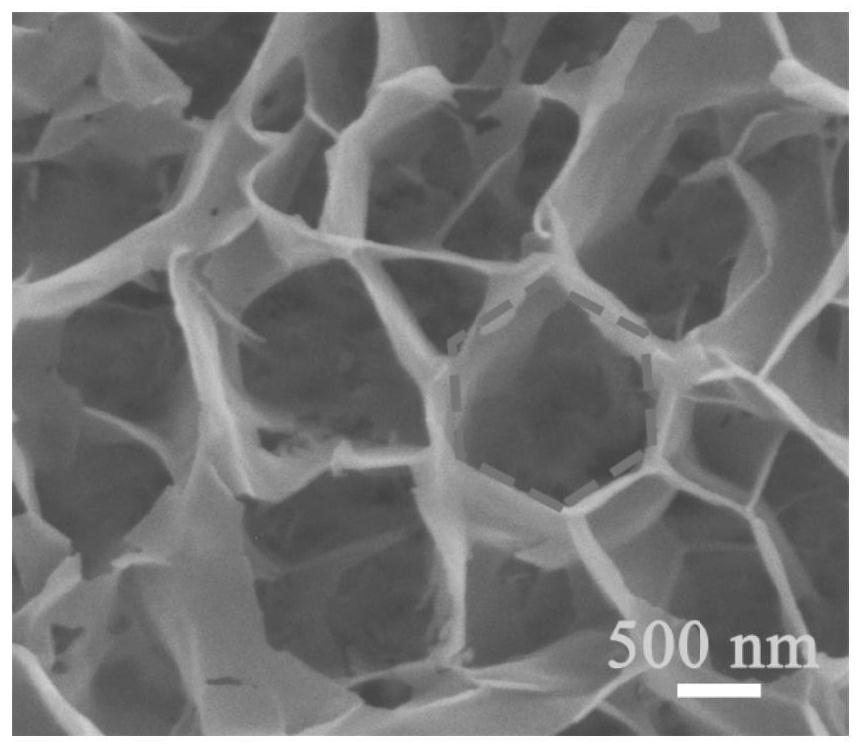

The invention belongs to the field of supercapacitors, and particularly relates to a preparation method and application of an iron nickel phosphide nanosheet forming a capacitor material. According to the technical scheme, a conductive support material is adopted as an electrode current collector and a support, an iron-nickel double-metal hydroxide nanosheet precursor grows on the surface of the conductive support material in situ by adopting a solvothermal method, and then the supercapacitor electrode material with the honeycomb-shaped iron-nickel phosphide nanosheet array structure is formed through heat treatment and phosphorization. The method is simple to operate, low in cost, environment-friendly and green, and the size and morphology of the material are easy to regulate and control. The iron nickel phosphide nanosheet disclosed by the invention is an excellent supercapacitor electrode material, and has high specific capacity and excellent long-acting circulation capability.

Owner:WUHAN UNIV OF SCI & TECH

Preparation method of adhesive for making board from straws

InactiveCN103435755AGood stabilityGood water resistance and mechanical propertiesWood working apparatusFlat articlesRADIUSDibutyl tin dilaurate

The invention belongs to the technical field of preparation of adhesives, and relates to a preparation method of an adhesive for making a board from crop straws, which comprises the following steps: dissolving diphenylmethane diisocyanate and polyether glycol NJ-330 in acetone; and by using dibutyltin dilaurate as a catalyst, adding hydroxypropyl methacrylate to perform termination, and adding fluorine-containing acrylate monomer to react by using azodiisobutyronitrile as an initiator, thereby obtaining the adhesive. The adhesive prepared by the method provided by the invention is free of free formaldehyde monomer. The fluorine element is introduced into an isocyanate adhesive system; fluorine atoms with lower polarizability, strong electronegativity and small Van der Waals radius can be combined with carbon atoms to form a high-bond-energy C-F bond, and the main group -CF3 of the fluorocarbon compounds has extremely low surface energy, so that the adhesive has high stability; after the adhesive forms the film, the film has favorable water resistance and mechanical properties, has strong bonding action with the straws subjected to surface treatment; and the adhesive can be used for preparing an artificial straw board according to a common artificial fiber board production technique.

Owner:JIANGSU UNIV

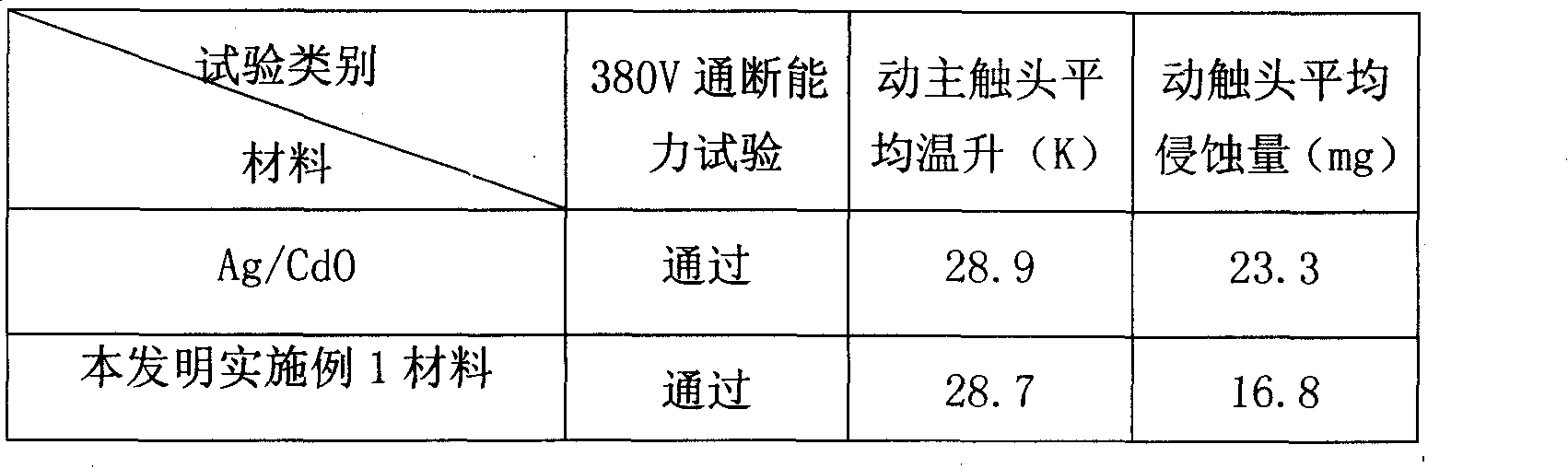

Silver base rare earth alloy contact material for low-voltage switch electric appliance and method for preparing same

InactiveCN100369171CExtended service lifeReduce temperature riseContact materialsLow voltageRare earth

Owner:HEBEI UNIV OF TECH

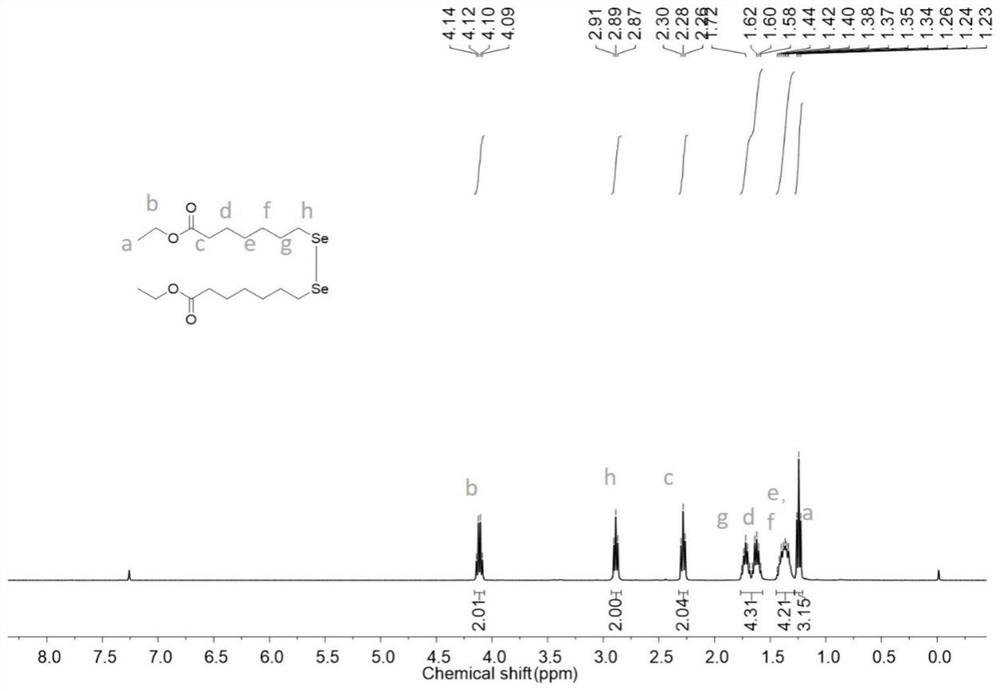

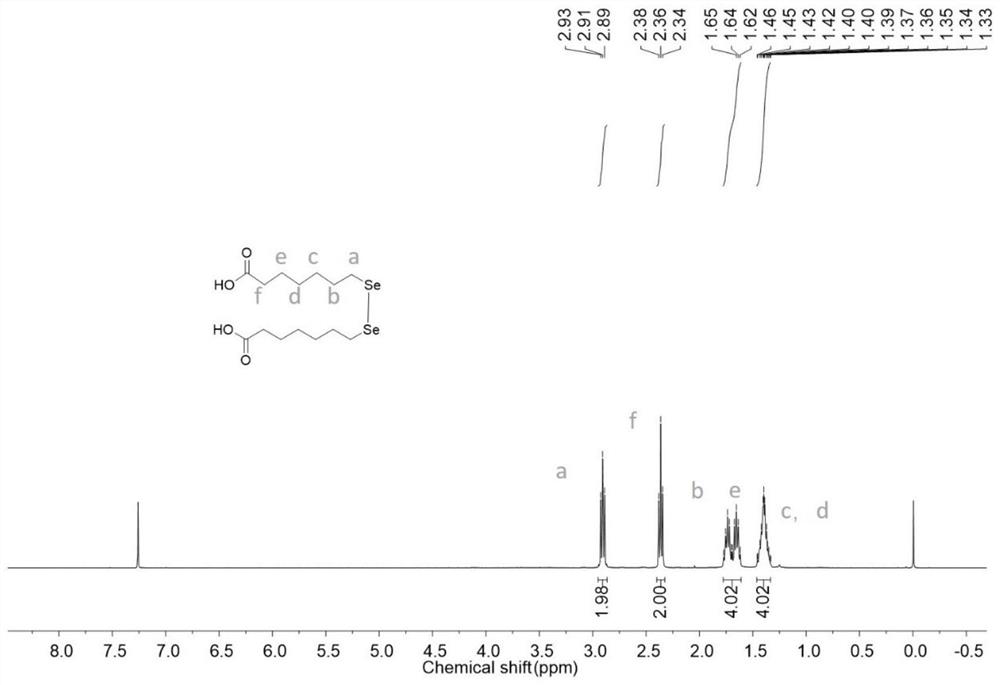

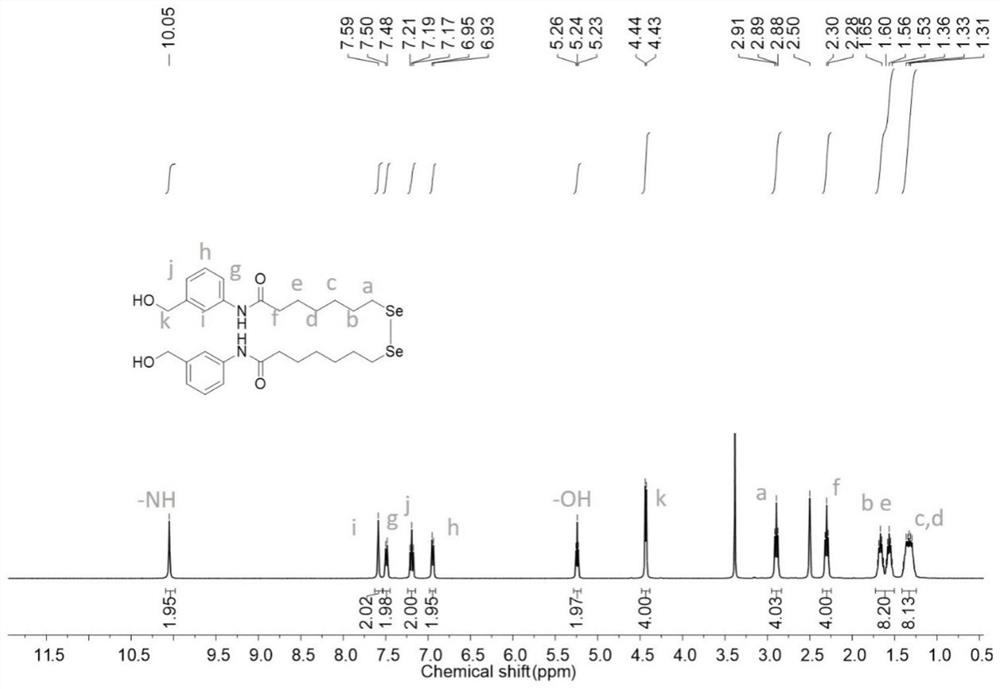

Selenium polymer prodrug micelle with reduction responsiveness, preparation method and application

ActiveCN111789964ASimple structureImprove in vivo stabilityOrganic active ingredientsPharmaceutical non-active ingredientsPolyethylene glycolPerylene derivatives

The invention discloses a selenium polymer prodrug micelle with reduction responsiveness, a preparation method and application, and belongs to the technical field of biological medicine. The micelle is prepared by applying the following selenium prodrug polymer; the selenium prodrug polymer has a structure as shown in a formula (I); according to the invention, by using vorinostat as a model, firstly, a vorinostat derivative containing a di-selenium bond is synthesized, then hydrophilic fragments polyethylene glycol are connected to both ends of the derivative, and then the obtained product isprepared into the nano micelle, so that a drug is stable in a body, and a histone deacetylase inhibiting effect is obviously improved; and the preparation method is simple, convenient, green and environmental-friendly, and has the potential of mass production.

Owner:NANKAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com