Silver base rare earth alloy contact material for low-voltage switch electric appliance and method for preparing same

A low-voltage switch, rare earth alloy technology, applied in contact materials, electrical switches, circuits, etc., can solve problems such as poor switch operating characteristics, and achieve the effects of low contact temperature rise, strong anti-welding ability, and extended service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

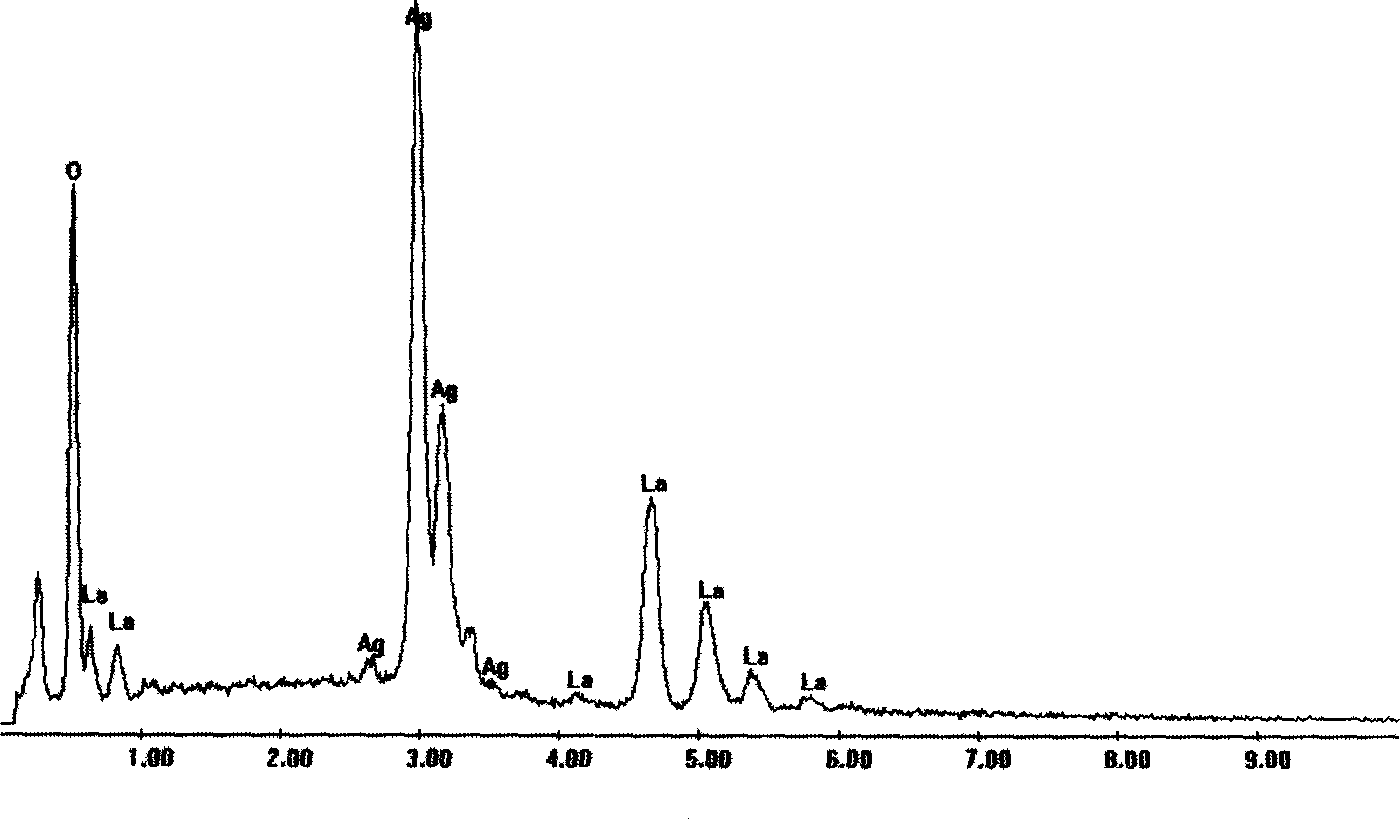

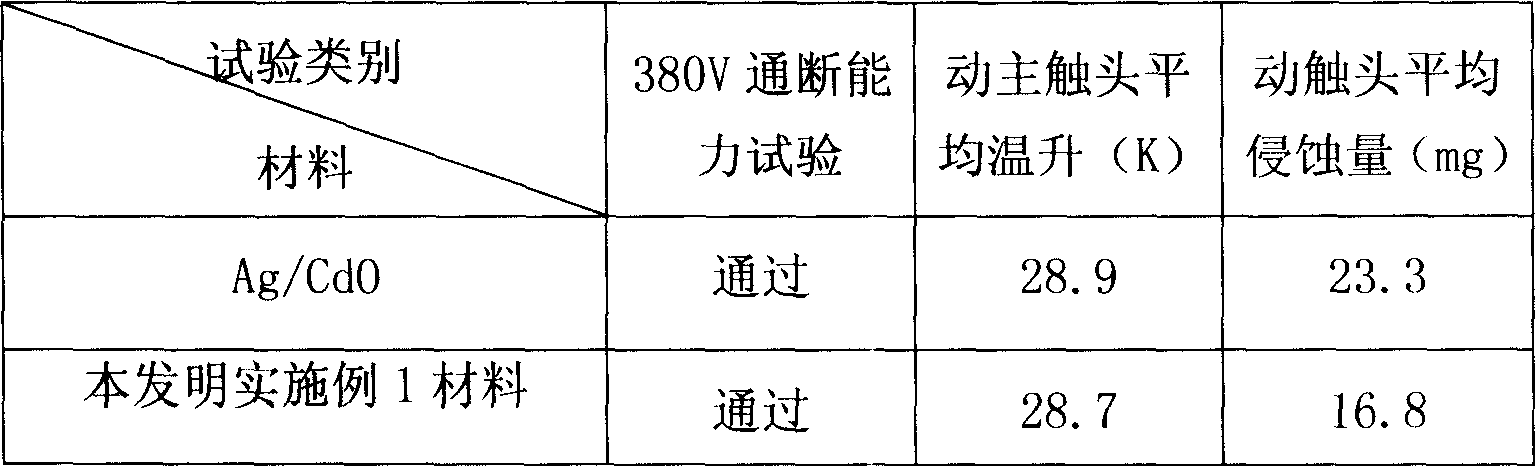

Embodiment 1

[0021] First, the Ag chips, La chips, Sn chips and Bi chips are mixed according to the proportion of ingredients, and then HNO is added after mixing them evenly. 3 until all dissolved to obtain a mixed solution, and then add solid Na as a coprecipitant 2 CO 3 , control PH=8~9, make the mixed solution with SnO 2 Co-precipitation occurs with particles as the core until SnO is obtained. 2 Uniformly dispersed Ag with particle as the core 2 CO 3 , La 2 (CO 3 ) 3 and Bi 2 (CO 3 ) 3 Until the coprecipitate was completely precipitated, the coprecipitate was filtered with deionized water, washed, dried, and then calcined at 420 °C to obtain Ag / La 2 O 3 +SnO 2 +Bi 2 O 3 the composite powder, and then the obtained Ag / La 2 O 3 +SnO 2 +Bi 2 O 3 The composite powder is processed into a compact with the required shape and size by ordinary molding method. At this time, the total pressing pressure is 30 tons, and then the compact is solid-phase sintered at a sintering temper...

Embodiment 2

[0029] First, the Ag shavings, Ce shavings, Sn shavings and Bi shavings are prepared according to the composition ratio, and then HNO is added after mixing evenly. 3 until all dissolved to obtain a mixed solution, and then add solid Na as a coprecipitant 2 CO 3 , control PH=8~9, make the mixed solution with SnO 2 The particles are the core and co-precipitation occurs until a uniformly dispersed Ag is obtained 2 CO 3 , Ce 2 (CO 3 ) 3 and Bi 2 (CO 3 ) 3 Until the coprecipitate was completely precipitated, the coprecipitate was filtered with deionized water, washed, dried, and then calcined at 420 ° C to obtain Ag / Ce 2 O 3 +SnO 2 +Bi 2 O 3 the composite powder, and then the obtained Ag / Ce 2 O 3 +SnO 2 +Bi 2 O 3 The composite powder is processed into a compact with the required shape and size by ordinary molding method. At this time, the total pressing pressure is 30 tons, and then the compact is solid-phase sintered at a sintering temperature of 920 ℃, and final...

Embodiment 3

[0032] First, the Ag scraps, Pr scraps, Sn scraps and In scraps are proportioned according to the composition ratio, and then HNO is added after mixing evenly. 3 until all dissolved to obtain a mixed solution, and then add solid Na as a coprecipitant 2 CO 3 , control PH=8~9, make the mixed solution with SnO 2 Co-precipitation occurs with particles as the core until SnO is obtained. 2 Uniformly dispersed Ag with particle as the core 2 CO 3 , Pr 2 (CO 3 ) 3 and In 2 (CO 3 ) 3 Until the coprecipitate was completely precipitated, the coprecipitate was filtered with deionized water, washed, dried, and then calcined at 420 °C to obtain Ag / Pr 2 O 3 +SnO 2 +In 2 O 3 The composite powder of , and then the obtained Ag / Pr 2 O 3 +SnO 2 +In 2 O 3 The composite powder is processed into a compact with the required shape and size by ordinary molding method. At this time, the total pressing pressure is 30 tons, and then the compact is solid-phase sintered at a sintering temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com