Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

200results about How to "Reduced diffusion rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

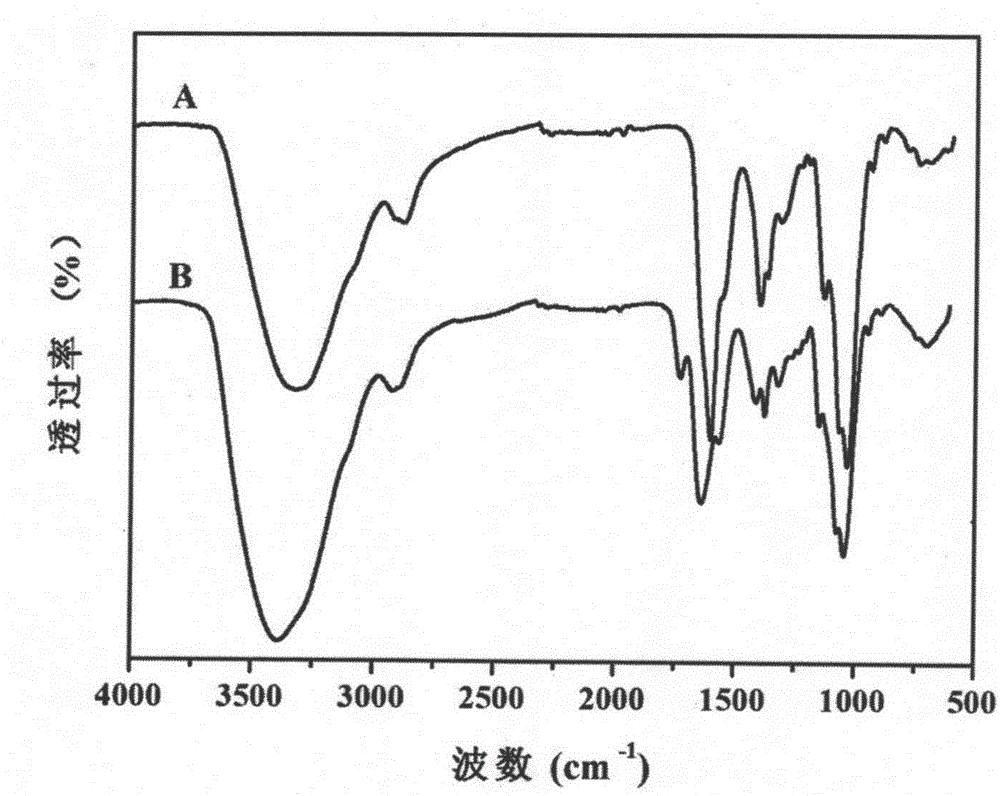

Preparation method of nano meso-porous silicon composite hydrogel with controlled release function

InactiveCN106492220AHigh activityKeep aliveAerosol deliveryInorganic non-active ingredientsControl releaseBiocompatibility Testing

The invention discloses a preparation method of nano meso-porous silicon composite hydrogel with a controlled release function. The preparation method includes the steps that micromolecular medicine is loaded in meso-porous silicon nano-particles; an oxidized hyaluronic acid and carboxymethyl chitosan solution is prepared, and the medicine-carrying nano-particles are added into the hyaluronic acid solution to be ultrasonically treated and then stirred to be uniform; a medicine-carrying nano composite hydrogel carrier is prepared. The prepared nano composite hydrogel has good mechanical performance, biocompatibility, biodegradability and medicine slow release effects, and has potential of being applied to the fields of tissue engineering and biological medicine treatment. In addition, the preparation method of the nano composite hydrogel is simple, cost is low, and large-scale production can be achieved.

Owner:DONGHUA UNIV

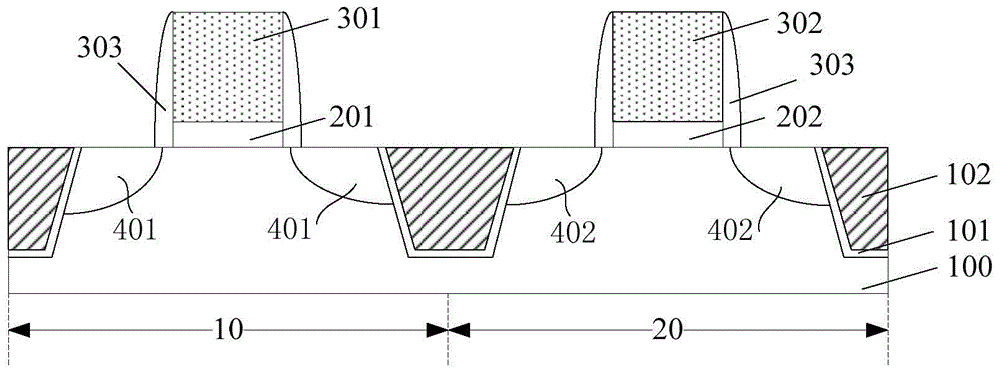

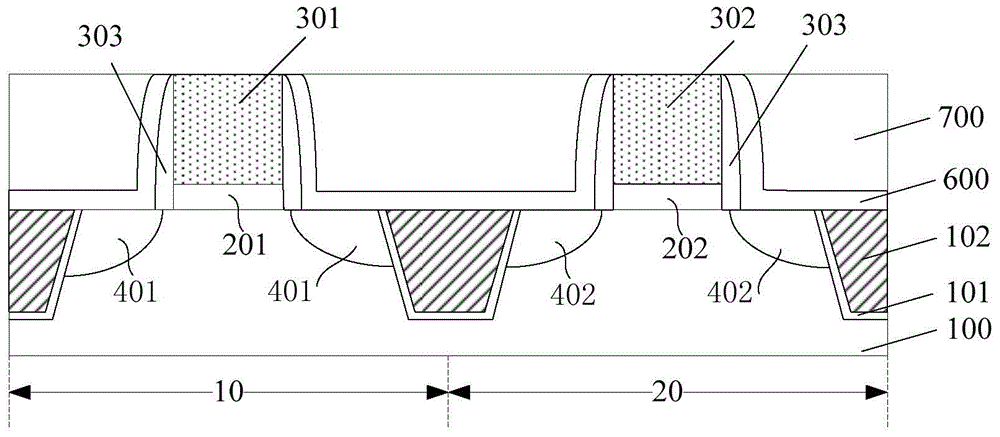

CMOS transistor and forming method thereof

ActiveCN104810368AInhibited DiffusionAffects issues such as gate leakage currentTransistorSemiconductor/solid-state device manufacturingCMOSGate dielectric

Disclosed are a CMOS transistor and a forming method thereof. The method includes the following steps: providing a semiconductor substrate which includes an NMOS area and a PMOS area, wherein a dielectric layer is formed on the surface of the semiconductor substrate, a first grove is arranged in the dielectric layer on the NMOS area, a second groove is arranged in the dielectric layer on the PMOS area and both of the first groove and the second groove are exposed out of the part of the semiconductor substrate; forming a gate dielectric layer on the inner surfaces of the first groove and the second groove and a coverage layer on the surface of the gate dielectric layer, wherein the coverage layer is doped with non-proliferation ions; forming a barrier layer on the surface of the coverage layer; forming a first work function layer on the surface of the barrier layer in the second groove; forming a second work function layer on the surface of the barrier layer in the first groove and on the surface of the first work function layer in the second groove; and forming a grid electrode layer, which fills fully the first groove and the second groove, on the surface of the second work function layer.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

SiC particle-enhanced aluminum based composite with high-temperature wear resistance and preparation method of SiC particle-enhanced aluminum based composite

The invention provides a SiC particle-enhanced aluminum based composite with high-temperature wear resistance and a preparation method of the SiC particle-enhanced aluminum based composite and belongsto the field of aluminum alloy materials. The preparation method comprises the following steps of smelting industrial pure aluminum, aluminum-silicon alloy, aluminum-copper alloy, pure magnesium, thealuminum-copper alloy, aluminum-nickel alloy, aluminum-zinc alloy, aluminum-titanium alloy and aluminum-magnesium alloy at 700-800 DEG C according to a mass ratio; performing degassing refining; performing casting at 700-750 DEG C; using vacuum smelting, stirring and casting equipment to smelt a substrate at 700-800 DEG C; adding micron-size SiC particles; performing semi-solid state stirring at550-570 DEG C; performing casting at 700-750 DEG C; and performing T6 heat treatment. For the SiC particle-enhanced aluminum based composite with the high-temperature wear resistance and the preparation method, the substrate alloy components are designed self according to an alloy phase diagram, and a proper element content is selected, so that a high temperature resistant hard phase occurs aftersubstrate alloy heat treatment, and the substrate hardness at high temperature is ensured; and meanwhile, by adding an SiC-enhanced phase, the high temperature resistance of the composite is further improved.

Owner:TONGJI UNIV

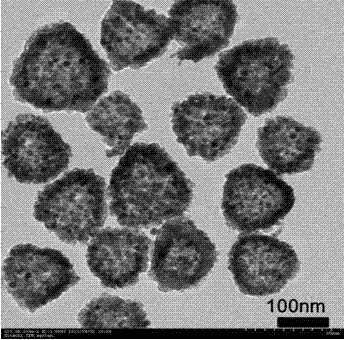

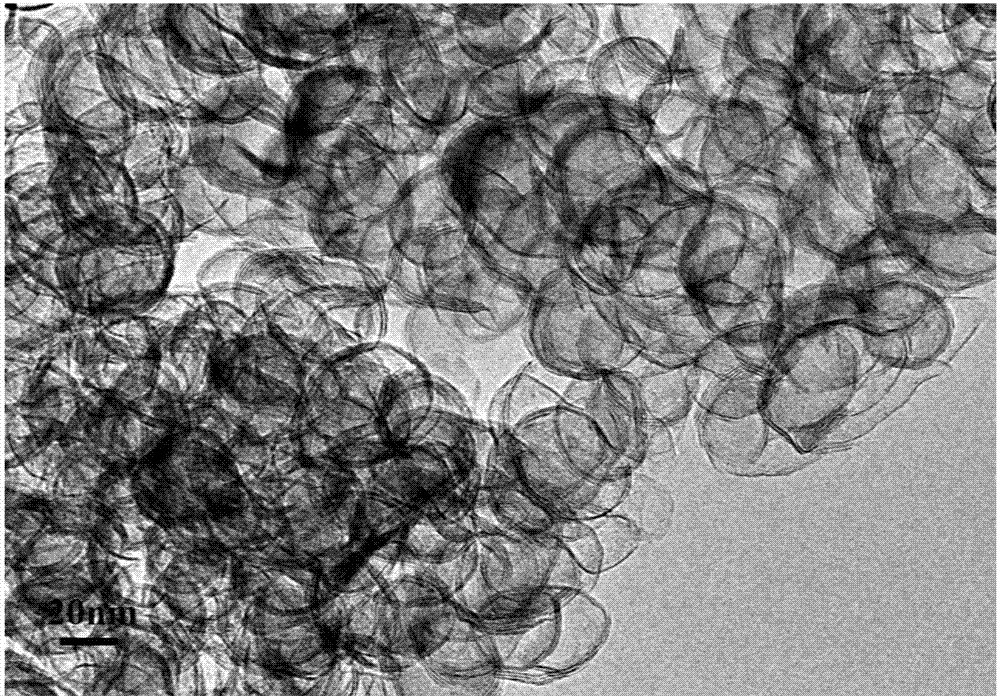

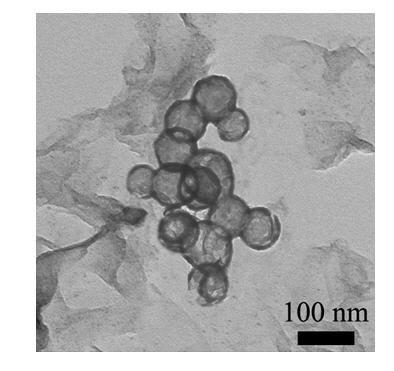

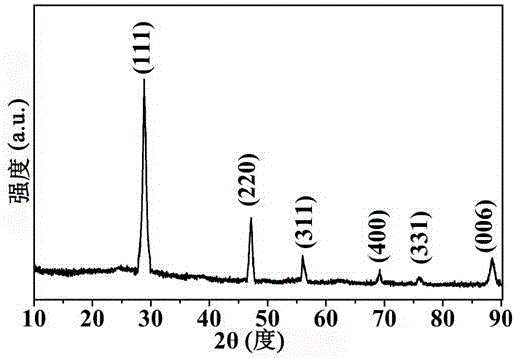

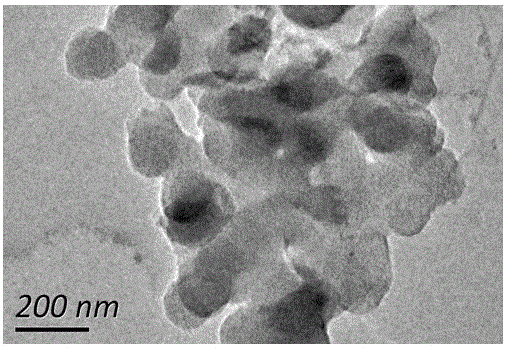

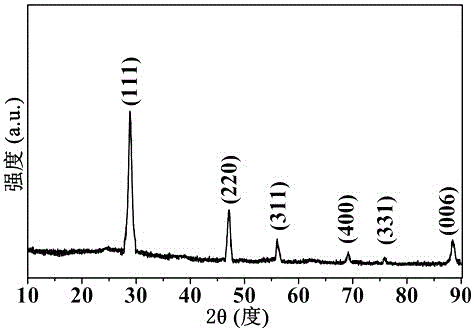

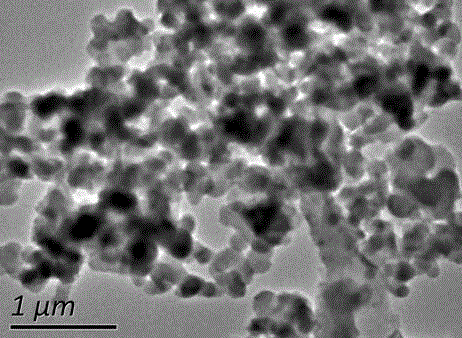

Lithium ion battery made of hollow porous nickel oxide composite material on basis of coating of N-doped carbon layer, and preparation method thereof

InactiveCN103682327AHigh discharge specific capacityImprove cycle stabilityFinal product manufactureCell electrodesCarbon layerDispersity

The invention relates to a lithium ion battery made of a hollow porous nickel oxide composite material, and the negative electrode material of the lithium ion battery is wrapped by an N-doped carbon layer. The lithium ion battery comprises a negative electrode plate, a positive electrode plate, a bath solution and a membrane, and is characterized in that the active material of the negative electrode plate is the hollow porous nickel oxide composite material coated by an N-doped carbon layer and formed by taking an ionic liquid as a coating agent, the grain diameter of the hollow porous nickel oxide composite material is 200 to 300 nm, and the surface of the hollow porous nickel oxide composite material is coated with the N-doped carbon layer thin film distributed evenly. According to the lithium ion battery provided by the invention, the negative electrode material has a hollow porous structure coated by the unique N-doped carbon layer, the grain diameter is small, the dispersity is good, the conductivity performance of the material is good, lithium-ion and electron have a fast diffusion rate and transmission rate in the material, the lithium ion battery constructed on the basis of the material has the characteristics of good discharging performance, high cyclic stability and high capability. The invention further provides a preparation method of the lithium ion battery.

Owner:NANJING NORMAL UNIVERSITY

Radial truck tire air-tight layer component and preparation process thereof

InactiveCN102604243AImprove stabilityImprove thickness uniformityTyresPneumatic tyre reinforcementsVulcanizationEngineering

The invention belongs to the technical field of processing of rubber tires, and particularly relates to a radial truck tire air-tight layer component and a preparation process thereof. The radial truck tire air-tight layer component comprises the following substances in parts by mass: 100 parts of rubber substrate, 40-100 parts of reinforcing system, 1-10 parts of anti-aging system, 4.7-15 parts of vulcanization system, 0-20 parts of radiation crosslinking sensitizer and 0-50 parts of additive aid. The method comprises the following steps of: mixing other substances except a vulcanizing agent, discharging glue, and adding the vulcanizing agent for preparing a rubber compound; and rolling the prepared rubber compound to obtain an air-tight layer sheet of 3-5 millimeters in thickness, performing cobalt source radiation treatment in the air to obtain the radial truck tire air-tight layer component, wherein the radiation dosage of the air-tight layer sheet is 5-50 kGy. The air-tight layer component which is subjected to radiation pretreatment has the advantages of high Green strength, high structural size stability, high air tightness, and capability of improving the tire quality at a lower radiation dosage.

Owner:河南省科学院同位素研究所有限责任公司 +1

High-temperature protective coating for nickel base alloy steel

ActiveCN104017397ASolve the problem of difficult descalingReduced diffusion rateCoatingsSodium carboxymethylcelluloseAluminium

The invention relates to a high-temperature protective coating for a hot-rolling heat pretreatment process of nickel base alloy steel. The coating powder comprises the following components: 20%-40% of Al2O3, 10%-30% of SiO2, 10%-20% of MgO, 10%-20% of TiO2, 5%-15% of CuO, 5%-15% of Y2O3, 0%-1% of Na2O and 0%-1% of K2O, wherein Al2O3 and SiO2 are from one or two of Kyanite and aluminum ash, and TiO2 is from rutile ore. A binder in the coating is mixed from one or more selected from sodium silicate, potassium silicate and silica sol, and a dispersant is carboxymethyl cellulose. For usage, the powder and water are mixed and milled into a slurry according to the weight ratio of 2:1; the slurry is added with the binder accounting for 5-10 wt.% of the slurry, and the dispersant accounting 1-2 wt.% of the slurry; the mixture is well mixed and milled to size of 200-600 mesh to obtain the coating. The coating can be directly sprayed on billet below 800 DEG C, and can effectively solve the problem of hard descaling in heat treatment of nickel base alloy at 1200-1350 DEG C.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

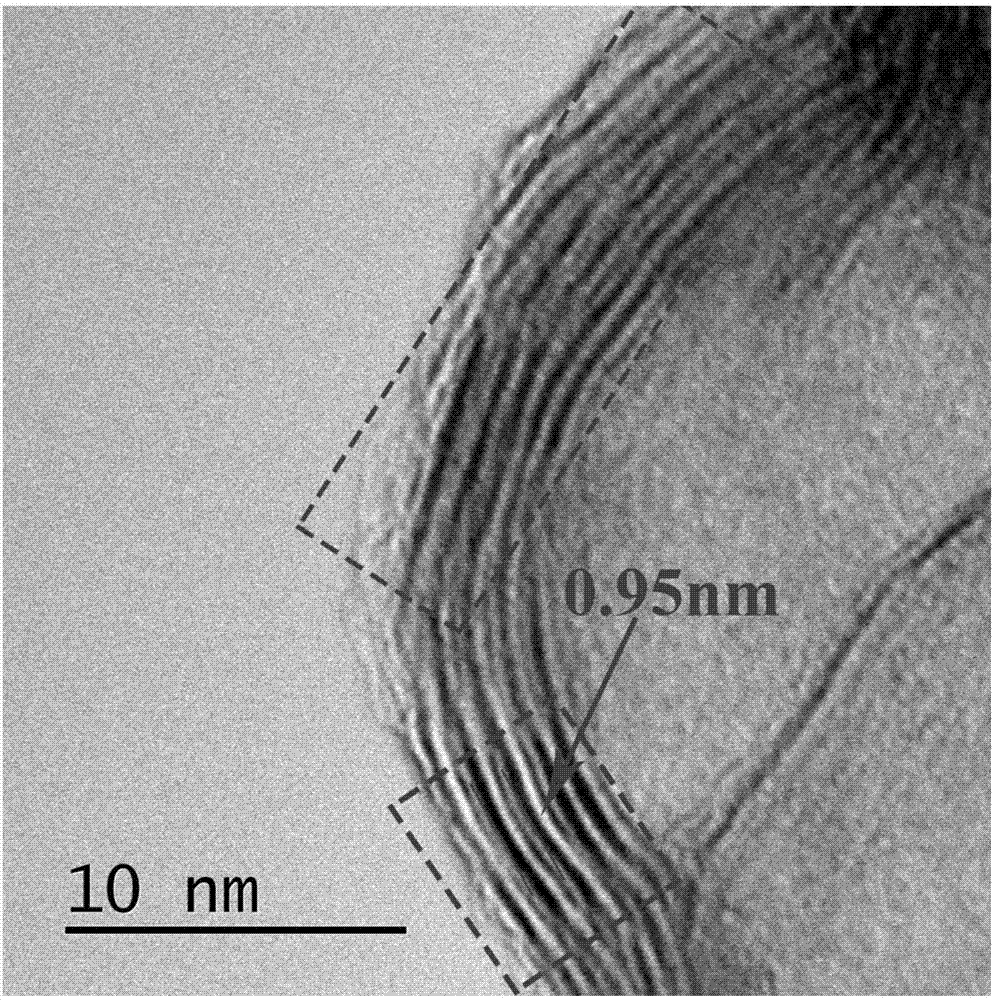

Method for preparing molybdenum disulfide/graphene alternate intercalation structure material

ActiveCN107540019AHigh crystallinityReduced diffusion rateGrapheneMolybdenum sulfidesNew energySulfur

The invention relates to a method for preparing a molybdenum disulfide / graphene alternate intercalation structure material. The method includes the following steps that a moderate molybdenum source and a moderate sulfur source are dissolved in water respectively, and are fully stirred to obtain even solutions; a surfactant is added into the sulfur source, then the obtained molybdenum-source solution is slowly dropped into a solution formed by the sulfur source and the surfactant, a uniform solution or colloid is formed, the uniform solution or colloid is heated to 100 DEG C to 300 DEG C at thepressure of 10 MPa to 300 MPa, and is reacted for 3 hours to 48 hours at the constant temperature, and after the reaction is end, a reaction system is naturally cooled to be the indoor temperature, and pressure is released; the obtained powder is washed, dried and calcined, and the molybdenum disulfide / graphene alternate intercalation structure material is obtained. The method is simple in preparing process and environmentally friendly, an intercalation structure of molybdenum disulfide and graphene can be obtained, the interlayer spacing of the molybdenum disulfide is amplified accordingly,and the method has the important application value in the research aspects of a high-efficiency photocatalyst and a new energy material.

Owner:SHANDONG UNIV

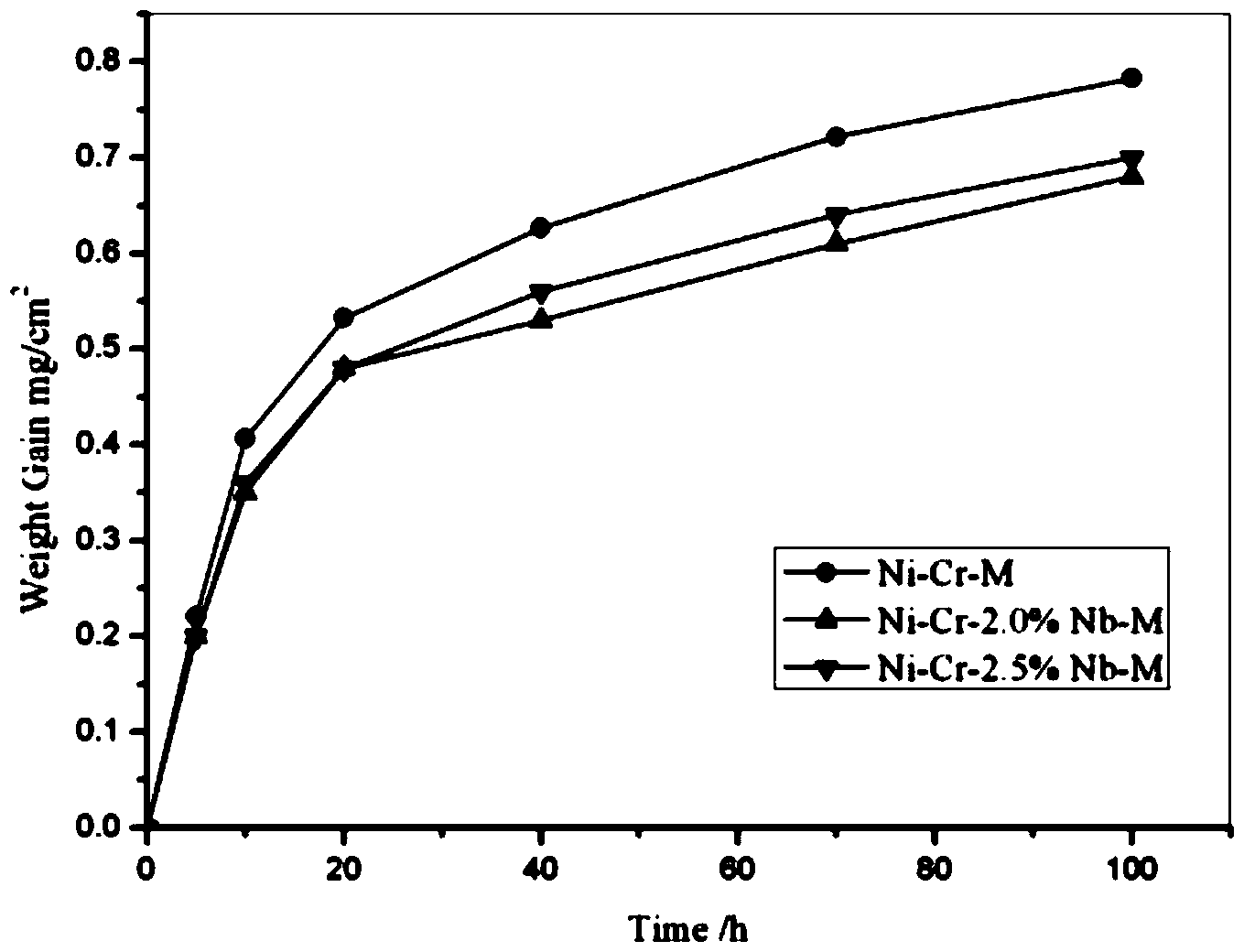

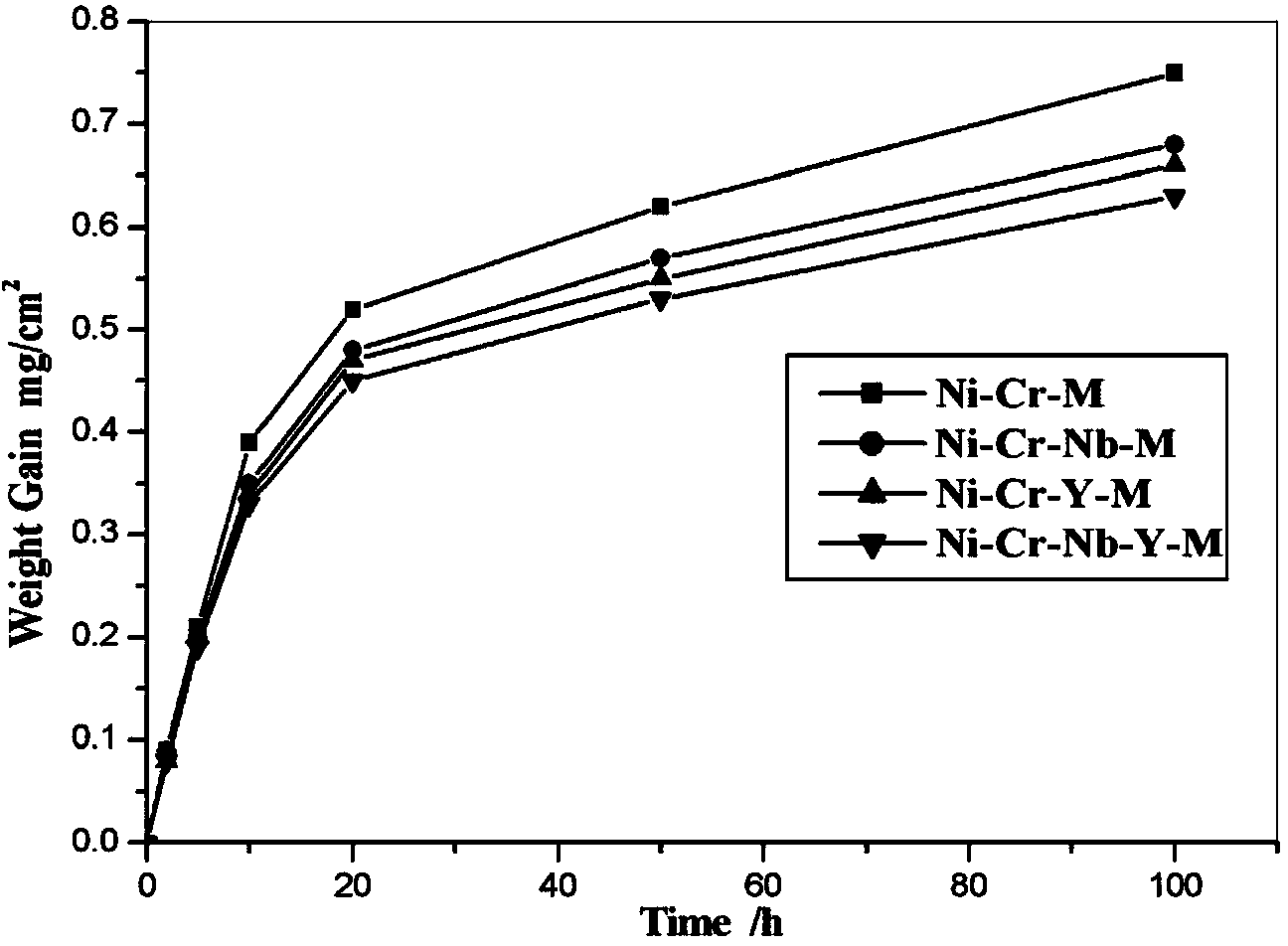

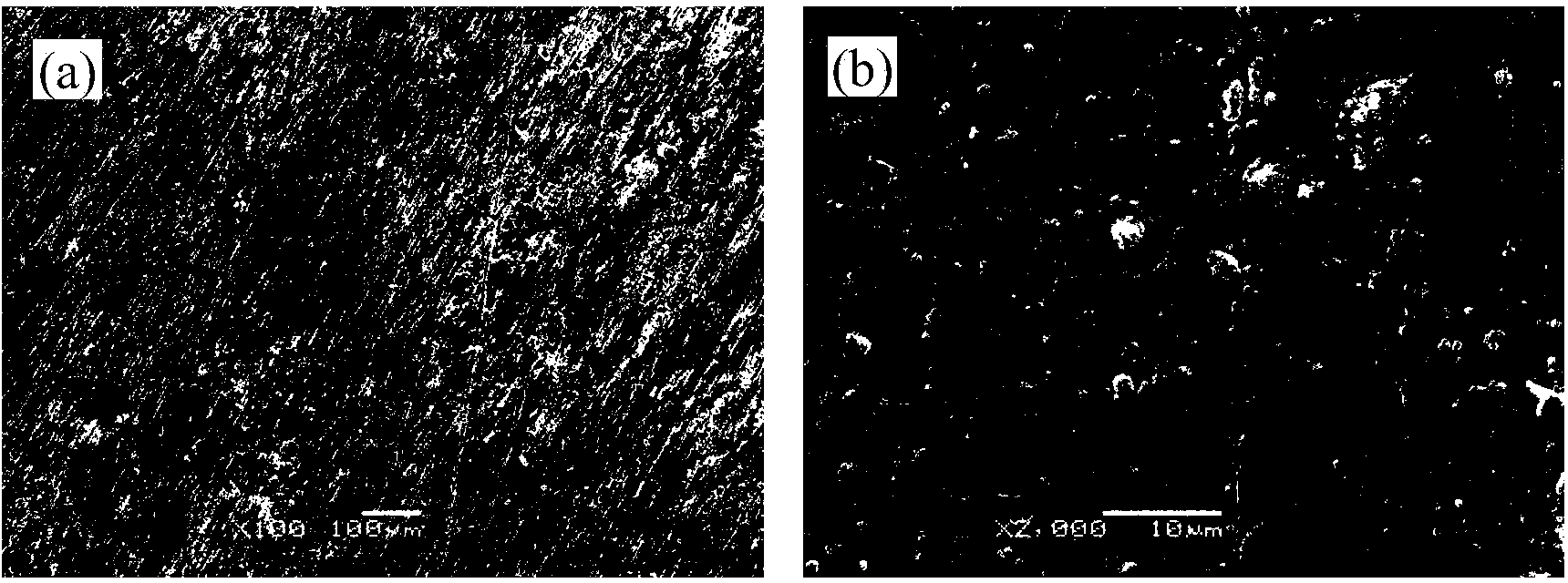

Nickel-based high temperature alloy, preparation method thereof as well as application thereof in spark plug electrode

The invention relates to a nickel-based high temperature alloy, a preparation method thereof as well as application thereof in a spark plug electrode. The nickel-based high temperature alloy contains the following components in percent by weight: 0.04%-0.06% of C, 19%-21% of Cr, 7%-9% of W, 5%-7% of Mo, 1%-2% of Ti, 0.5%-2% of Al, 0.004%-0.006% of B, 0.03%-0.05% of Zr, 0.7%-0.9% of Fe, 0-3% of Nb, 0-1% of Y, and the balance of Ni and inevitable impurities. The preparation method of the nickel-based high temperature alloy comprises the following steps of: mixing the components in a vacuum electric-arc melting furnace according to a proportion, smelting, getting out and forming; heating up to 1200 DEG C in a heating furnace, carrying out thermal-insulation solid-solution treatment for 4 hours, and carrying out air-cooling; and carrying out thermal-insulation aging treatment for 10 hours at 800 DEG C, and carrying out air-cooling to prepare the nickel-based high temperature alloy. The nickel-based high temperature alloy disclosed by the invention has good high-temperature oxidation resistance and corrosion resistance, and can be applied to the spark plug electrode material so as to prolong the service life of an electrode and the service life of a spark plug.

Owner:SHANDONG UNIV

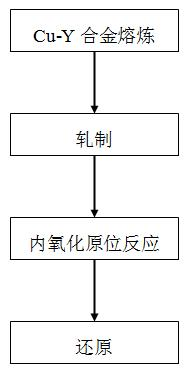

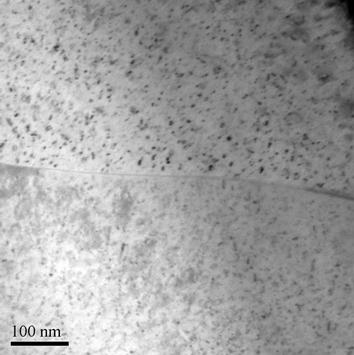

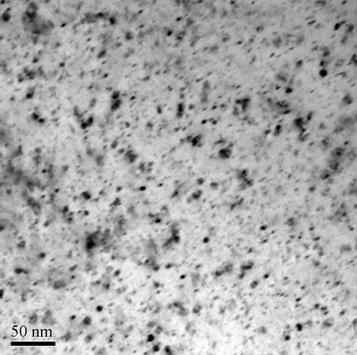

Dispersion strengthening copper-based composite material and preparation method thereof

The invention relates to a dispersion strengthening copper-based composite material and a preparation method thereof. The dispersion strengthening copper-based composite material and the preparation method thereof are characterized in that A dispersion strengthening phase is yttrium oxide, and the content of yttrium oxide in copper is 1-2.5 percent by weight, and the preparation method comprises the processes of alloy smelting, rolling, internal oxidation, reduction and the like. The preparation method has the advantages of short process and low production cost. The tensile strength of the product is greater than 550 MPa, the conductivity exceeds 90 percent IACS (international annealed copper standard), and the softening temperature is higher than 900 DEG C. The dispersion strengthening copper-based composite material has higher mechanical property, excellent electrical conductivity and high-temperature softening resistance. The Y2O3 granulate dispersion strengthening copper-based composite material prepared in the invention can be applied to computer integrated circuit lead frames, resistance welding electrodes for automobile industry, linings of crystallizers of continuous casting machines for metallurgical industry, equipment and carrier rockets, electric car and electric power train aerial conductor and the like, and the character of service and the service life can be obviously improved.

Owner:NANCHANG UNIV

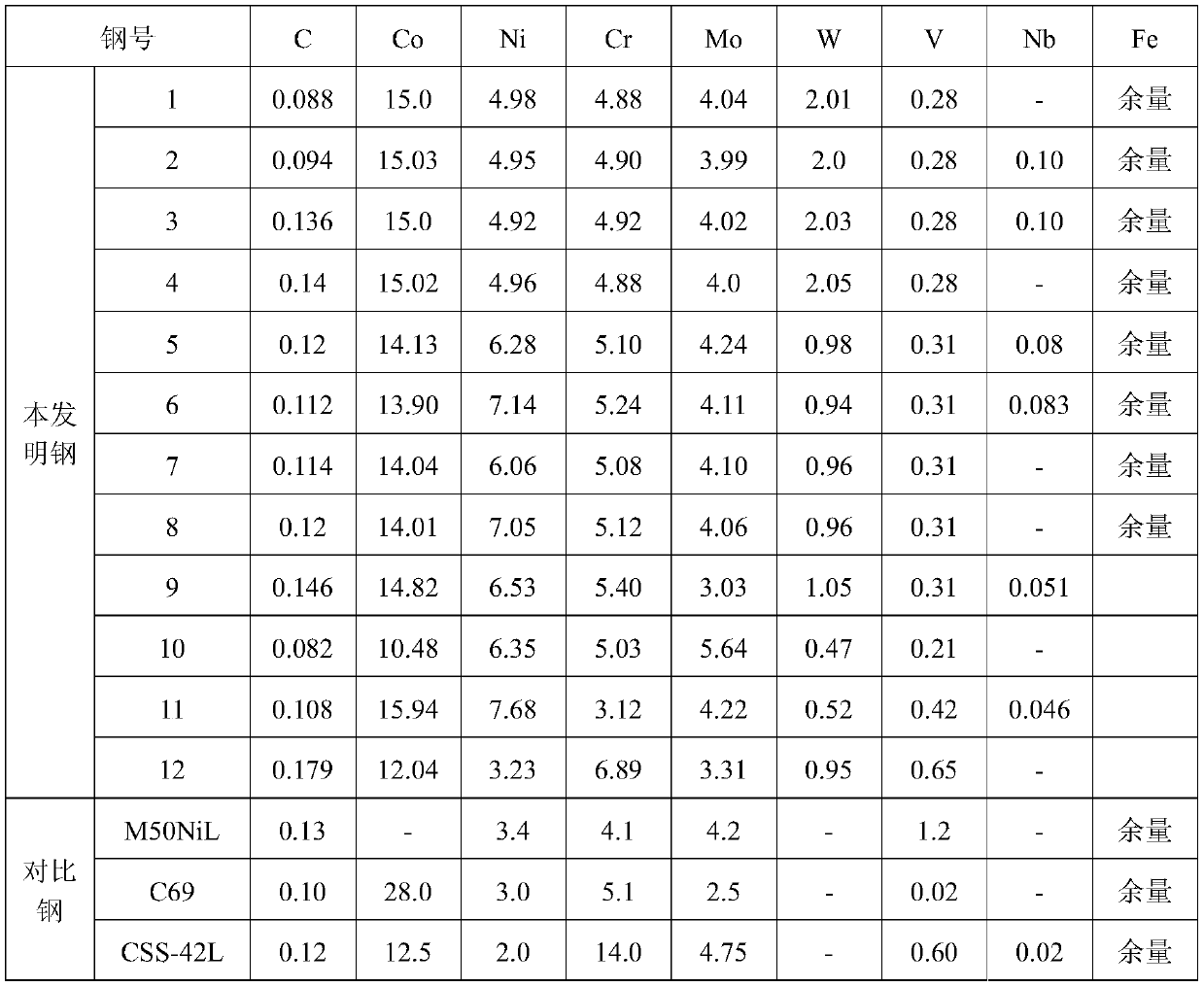

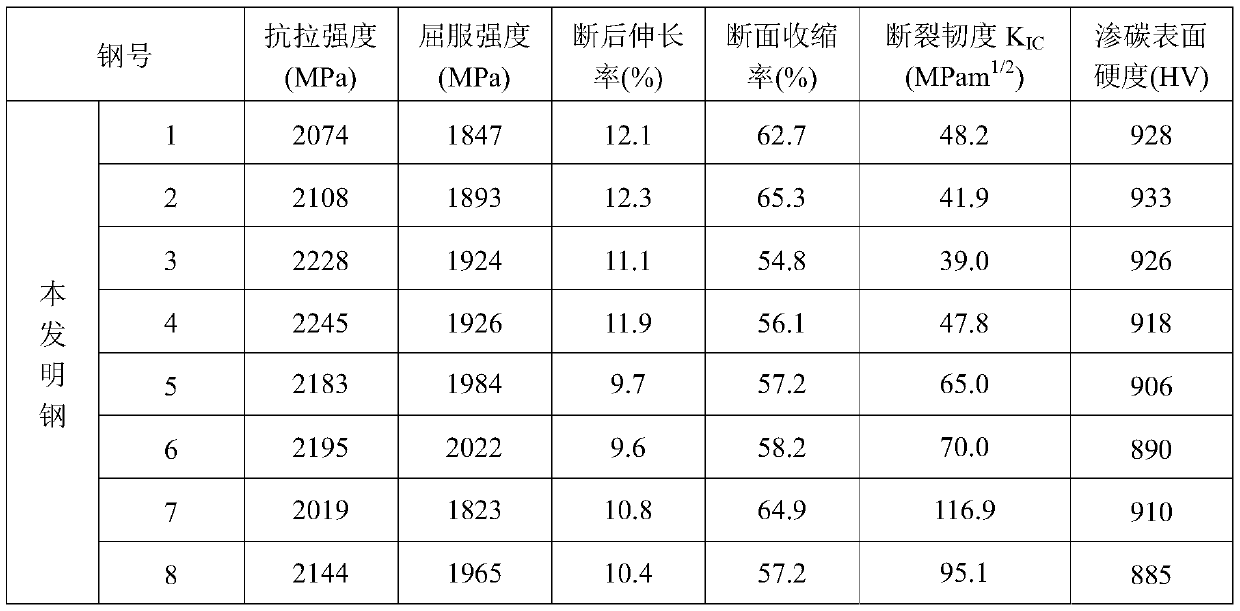

Ultra-high-strength heat-resistant gear bearing steel with ultra-hardened surface layer and preparation method thereof

ActiveCN110423955AHigh tensile strengthImprove plasticitySolid state diffusion coatingCarburizingVacuum arc remelting

The invention belongs to the technical field of materials, and relates to an ultra-high-strength heat-resistant gear bearing steel with ultra-hardened surface layer and a preparation method thereof. The chemical composition of the steel comprises the following chemical components of, in percentage by mass, 0.08-0.18% of C, 10.0-16.0% of Co, 3.0-8.0% of Ni, 3.0-7.0% of Cr, 3.0-6.0% of Mo, 0.5-2.0%of W, 0.2-1.0% of V, 0-0.1% of Nb, and the balance Fe and impurity elements. According to the method, vacuum induction melting, vacuum induction melting and vacuum arc remelting or vacuum induction melting and electroslag remelting are adopted for smelting. Steel ingots are diffusion annealed and forged into steel products. Steel samples are subjected to preliminary heat treatment, carburization and final heat treatment, the tensile strength of the steel is not less than 1900 MP a, the yield strength is not less than 1600 MP a, and the carburized surface hardness is not less than 850 HV (equivalent to 66 HRC). The method has the advantages that compared with the prior art, the method has higher tensile strength, yield strength and relatively good plasticity, toughness and heat resistance,has excellent surface carburization super-hardening performance and fatigue performance, and achieves good matching of the core super-toughening and surface super-hardening.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

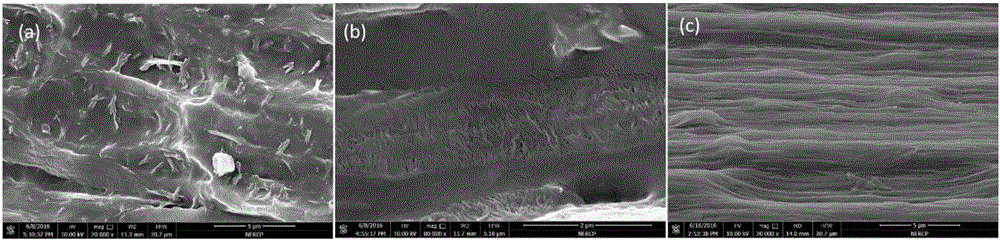

High-barrier antistatic graphene/polymer nanocomposite sheet/film and preparation method thereof

The invention relates to a high-barrier antistatic graphene / polymer nanocomposite sheet / film. Through an incomplete nanosphere crystal or shish-kebab structure of the high-barrier antistatic graphene / polymer nanocomposite sheet / film, the interfacial gap between spherulites in a large spherulite system is eliminated, amorphous area molecular chain movement is limited, a diffusion rate of gas molecules in the structure is reduced and material barrier properties are improved. The high-barrier antistatic graphene / polymer nanocomposite sheet / film comprises, by mass, 100 parts of polymer base resin, 0.005 to 1 part of graphene and 0 to 1.5 parts of a compatibilizer. Through the compatibilizer and a special flow channel structure of the multi-stage drawing extrusion system, graphene dispersion and orientation distribution are adjusted and controlled. The heterogeneous nucleation and space limitation effects of the graphene sheet induce formation of an orientation molecular chain and restricted nanosphere crystal and shish-kebab structures so that amorphous area density can be significantly increased, the interfacial gap between spherulites is reduced, amorphous area molecular chain movement is limited, a diffusion rate of gas molecules in a polymer matrix is reduced, a gas small molecule passing path is extended and the barrier properties of the nanocomposite sheet / film are improved.

Owner:GUIZHOU MATERIAL IND TECH INSTITUE

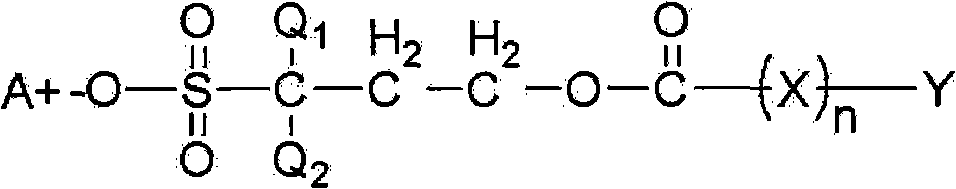

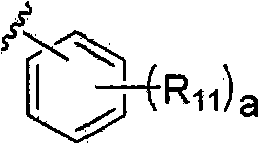

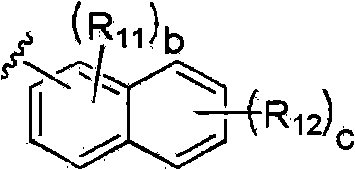

Photoacid generator, its preparation method and resist composition containing the photoacid generator

ActiveCN102289149AReduced diffusion rateDiffusion distance is shortSulfonic acids salts preparationPhotosensitive materials for photomechanical apparatusAlkaneResist

There are provided a photoacid generator, a method for manufacturing the same, and a resist composition comprising the same. The photoacid generator is a compound represented by the following formula 1, wherein Y represents any one selected from the group consisting of analkyl group substituted with an aryl group, and an aromatic hydrocarbon group; Q1 and Q2 each independently represent a halogenatom; X represents any one selected from the group consisting of an alkanediyl, an alkenediyl, NR', S, O, CO and combinations thereof; R' represents any one selected from the group consisting of a hydrogen atom and an alkylgroup; n represents an integer from 0 to 5; and A+ represents an organic counterion. The photoacid generator can produce, at the time of exposure, an acid which has a low diffusion rate, has a short diffusion distance, and exhibits an appropriate of degree of acidity so that the line width roughness (LWR) characteristics can be improved, and elution of which in a solvent such as pure water that is used in the process can be controlled.

Owner:SK MATERIALS PERFORMANCE CO LTD

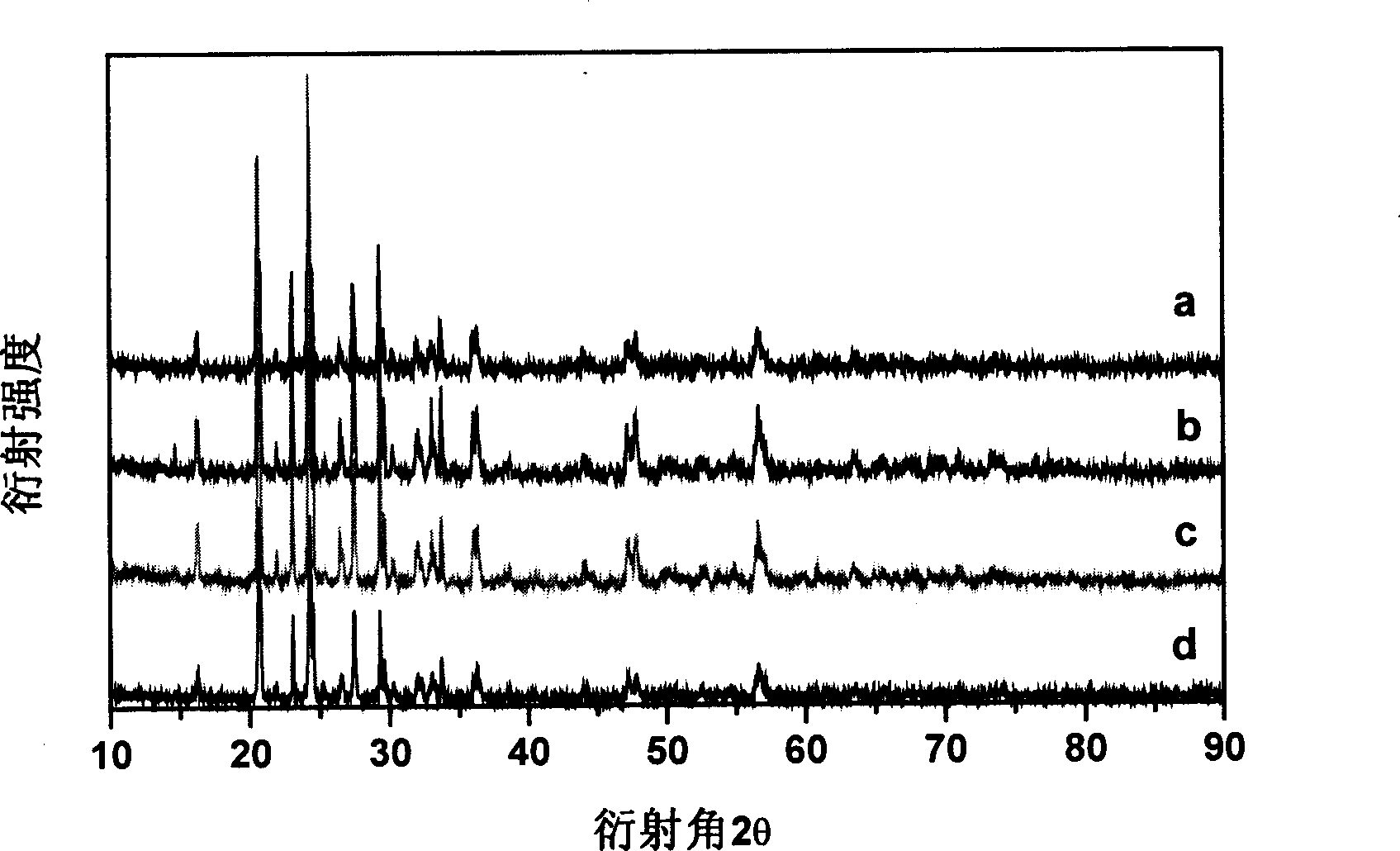

Method for preparing lithium vanadium phosphoric acid of anode material of lithium ion battery under high pressure

InactiveCN1872671ASimple processAvoid cumbersome preprocessing stepsCell electrodesEnergy inputAluminium-ion batteryReaction temperature

This invention relates to a high-pressure method for preparing vanadium lithium phosphate used as the anode material for lithium ion batteries. The method comprises: (1) mixing lithium salt, vanadium salt and phosphate uniformly, and ball-milling for 7-24 h; (2) preheating in the air at 200-500 deg.C for 2-12 h to obtain vanadium lithium phosphate. The method has such advantages of simple process, abundant raw materials, no need for reductive gas protection during reaction, short reaction time and low reaction temperature. The product has high capacity and good recycling property, and can be used as the anode material for lithium ion batteries.

Owner:广州鸿森材料有限公司

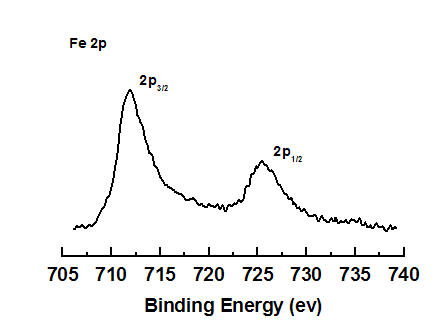

Nano iron phosphate hollow sphere/graphene composite material and preparation method thereof

InactiveCN102185147AGood electrical conductivityGood discharge stabilityCell electrodesCvd grapheneUrea

The invention relates to a nano iron phosphate hollow sphere / graphene composite material with graphene as a carrier, and the nano iron phosphate of a hollow spherical structure with the particle size 50-100nm grows on the graphene. The preparation method of the composite material provided by the invention comprises the following steps: carrying out a hydro-thermal reaction on a mixed liquid containing oxidized graphene, hexahydrate ammonium ferrous sulfate and phosphoric acid at 60-120 DEG C by using urea as a precipitator and adding a surfactant (lauryl sodium sulfate); washing the products;and carrying out vacuum drying, obtaining the nano iron phosphate hollow sphere / graphene composite material. The nano iron phosphate hollow sphere / graphene composite material provided by the invention has the advantages of unique nano hollow structure, excellent electrical conductivity and discharge stability, small particle size, good dispersity and suitability for the anode material of a lithium ion secondary electrode; and the preparation method based on a low-temperature hydro-thermal method is simple and economic, thereby being suitable for realization of industrial large-scale production.

Owner:NANJING NORMAL UNIVERSITY

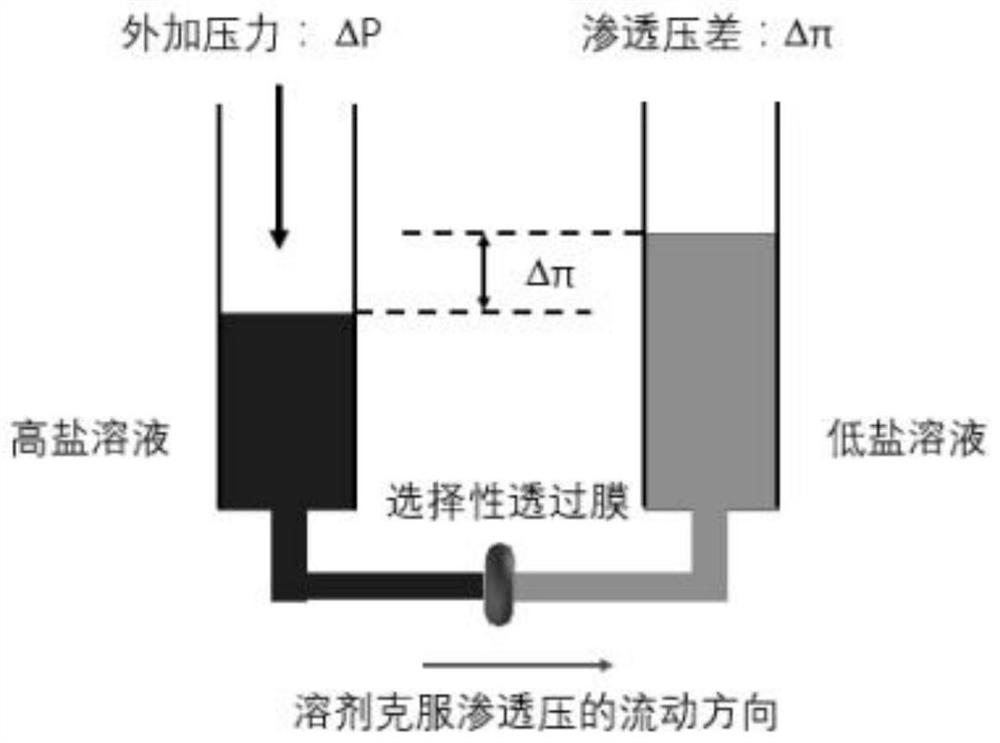

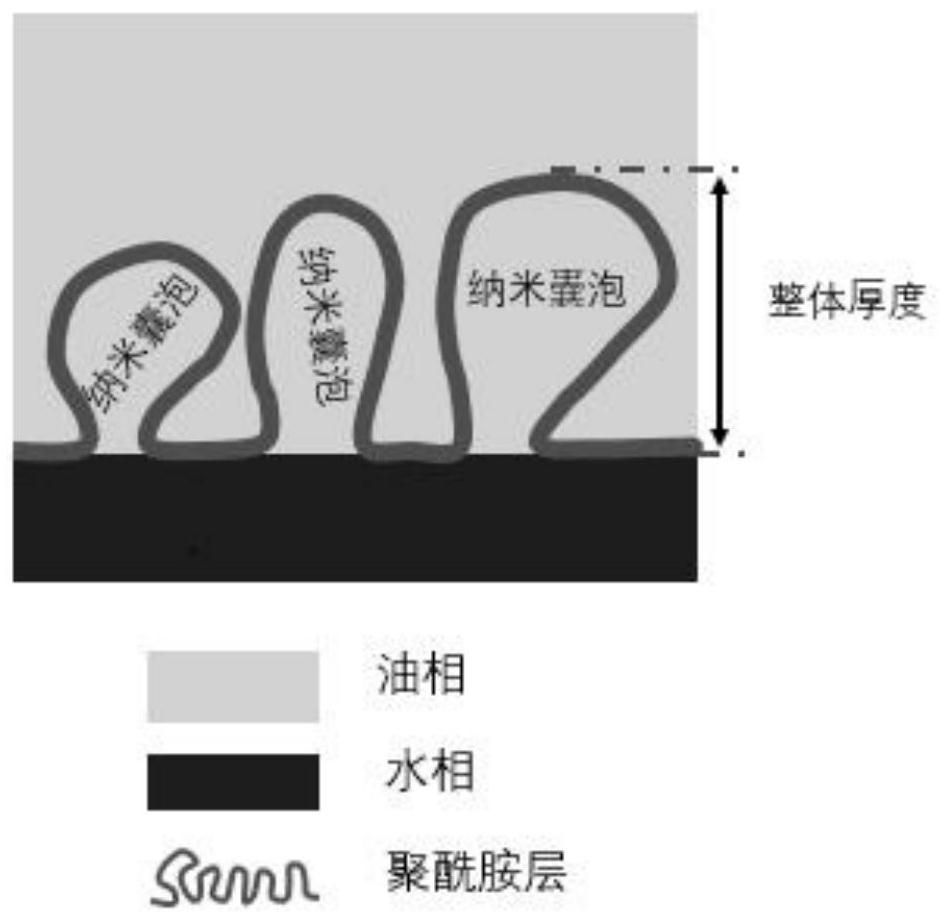

Preparation method of high-performance reverse osmosis membrane for promoting growth of polyamide nano vesicles

ActiveCN111790277AWeakened permeabilityAvoid situations prone to shrinkageMembranesReverse osmosisSulfonateReverse osmosis

The invention discloses a preparation method of a high-performance reverse osmosis membrane for promoting the growth of polyamide nano vesicles. A polysulfone ultrafiltration membrane is selected as asupport bottom membrane, and interfacial polymerization reaction of a water-phase amine monomer and an oil-phase polybasic acyl chloride monomer is carried on the surface of the support bottom membrane to compound with a polyamide ultrathin layer, thereby forming a reverse osmosis membrane; and the permeation selectivity of the reverse osmosis membrane is optimized by regulating and controlling parameter conditions in the interfacial polymerization process. On the basis, potassium perfluorobutyl sulfonate is introduced into an aqueous phase solution to promote the growth of polyamide nano vesicles supporting the surface of the bottom membrane and increase the surface roughness of the membrane, so that the permeation flux of the membrane is improved, and the performance of the reverse osmosis membrane is further optimized. According to the reverse osmosis membrane prepared by the method, the permeation flux of the membrane can be remarkably improved while the salt rejection rate is notlost. The invention provides a new reference way for development of a polyamide reverse osmosis membrane with high rejection rate and high flux.

Owner:ZHEJIANG UNIV OF TECH

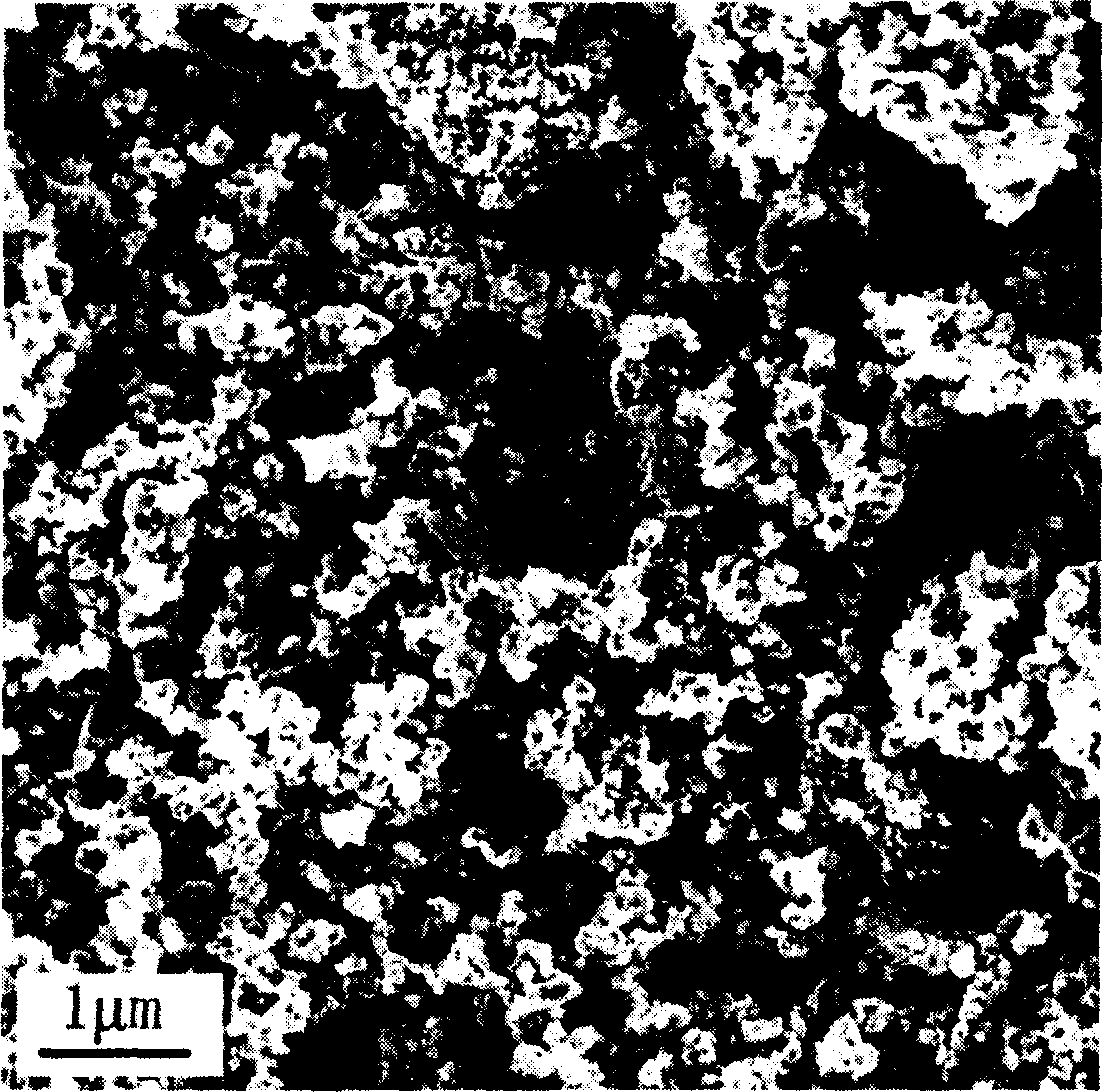

N-doped carbon layer wrapped hollow-porous nickel oxide composite material and preparation method thereof

InactiveCN103682277AUniform particle sizeWell dispersedMaterial nanotechnologyCell electrodesSolventNickel oxides

The invention discloses an N-doped carbon layer wrapped hollow-porous nickel oxide composite material, which adopts an ionic liquid as a coating agent to form an N-doped carbon layer after carbonization coated upon a nano nickel oxide surface of a hollow-porous structure with a particle size of 200-300 nm. The preparation method for the composite material comprises the steps as follows: dispersing carbamide, nickel chloride hexahydrate and sodium acetate into ethylene-glycol, conducting a solvothermal reaction and obtaining a precursor body of a spherical carbonic acid hydrogen nickel; dispersing the precursor body into a 1-butyl-3-methylimidazole tetrafluoroborate ionic liquid, treating through adopting a solvothermal method, conducting a thermal treatment with argon gas to the product and obtaining the composite material. The N-doped carbon layer wrapped hollow-porous nickel oxide composite material provided by the invention adopts the unique nano hollow and porous structure, and is small in particle size and good in dispersity, excellent in electric conductivity and electric discharge stability, is applicable to anode materials of lithium ion secondary electrodes; the adopted solvothermal preparation method is simple, economical, and suitable for industrialized mass production.

Owner:NANJING NORMAL UNIVERSITY

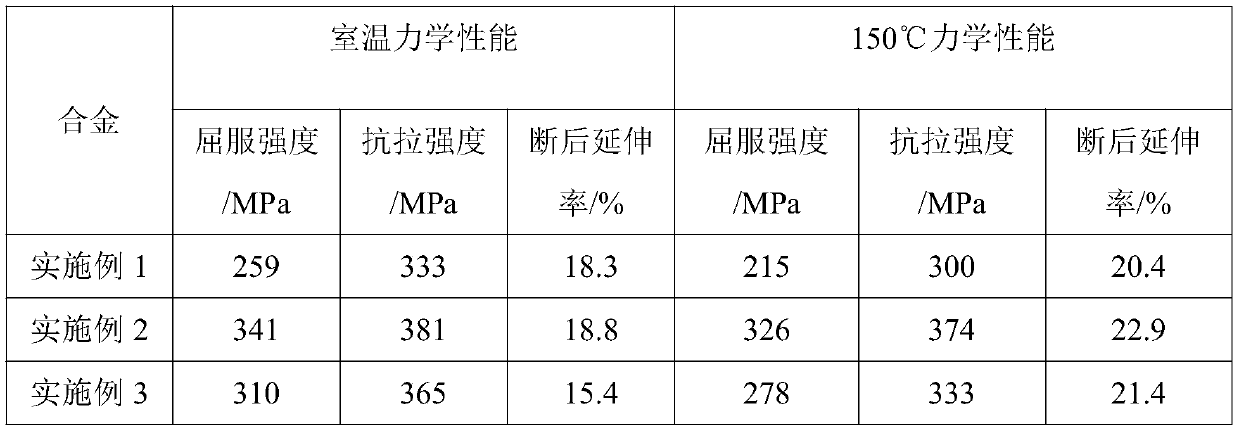

LPSO-phase strengthened degradable high-temperature magnesium alloy and preparation method thereof

ActiveCN111235450AHigh strengthImprove plasticitySealing/packingDynamic recrystallizationContinuous casting

The invention discloses an LPSO-phase strengthened degradable high-temperature magnesium alloy and a preparation method thereof. The magnesium alloy comprises components in percentage by weight as follows: 12%-18% of rare earth elements (Gd and Ho), 1.5%-6% of transitional elements (Cu, Ni and Zn), 0.2%-0.8% of Zr and the balance Mg. The LPSO phase of the magnesium alloy has a special long-periodstructure, and according to dislocation and grain boundary hindrance effects, dynamic recrystallization promoting effect, grain size refining effect and coordination deformation of the LPSO phase, comprehensive mechanical properties of the alloy can be improved. The preparation method of the magnesium alloy adopts a semi-continuous casting process and a homogenizing treatment and extrusion process, the magnesium alloy with room-temperature tensile strength of 330 MPa or higher, room-temperature elongation of 15% or higher, 150-DEG C tensile strength of 300 MPa or higher, 150-DEG C elongation of 20% or higher, high mechanical properties and good degradation rate is obtained. The LPSO-phase strengthened degradable high-temperature magnesium alloy can be widely applied to a packer tool bridgeplug for fracturing construction of oil and gas fields.

Owner:XI AN JIAOTONG UNIV

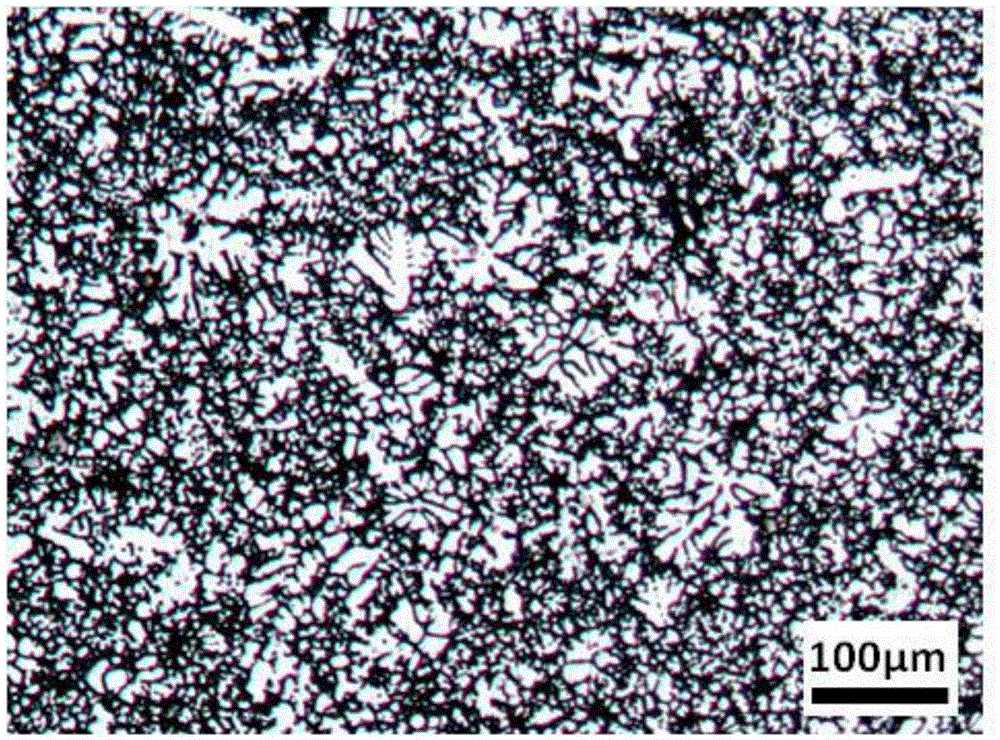

Corrosion-resistant and high-temperature creep-resistant die-cast magnesium alloy and prep ration method thereof

The invention provides a corrosion-resistant and high-temperature creep-resistant die-cast magnesium alloy and a prep ration method thereof and belongs to the technical field of light metal materials. The die-cast magnesium alloy comprises the following components in percentages by mass: 7.0-11.5wt.% of Al, 0.5-2.0wt.% of Zn, 0.3-0.4wt.% of Mn, 0.2-2.5wt.% of RE, 0.1-3.3wt.% of Yb, 0.1-5.8wt.% of Sm, 0.1-2.0wt.% of Sr and the balance of Mg and inevitable impure elements, wherein RE is mixed rare earth. The invention also provides a preparation method of the corrosion-resistant and high-temperature creep-resistant die-cast magnesium alloy. A test verifies that in a condition of the applied stress is 50MPa and the testing temperature is 150 DEG C, the 100h steady state creep rate of the magnesium alloy is 1.81*10<9> / s and 100h creep strain is 0.18%; through a neutral salt spray test by 5% NaCl for 100h at 35 DEG C, the corrosion rate is 0.055mg / cm<2>day.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Clay inhibitor capable of improving clay resistance of polycarboxylate superplasticizer and use method of clay inhibitor

The invention provides a clay inhibitor capable of improving clay resistance of a polycarboxylate superplasticizer. The inhibitor comprises a component A and a component B in a mass ratio being (1.5-3.0):1; the component A is pure slaked lime; the component B is prepared from raw materials in percentage by mass as follows: 5%-25% of a micromolecular polymer, 5%-25% of an organic cationic polymer, 0.02%-0.1% of a macromolecular polymer and 55%-85% of water. The invention further provides a use method of the clay inhibitor. Under the synergistic effect of a pretreatment modification function of the component A on clay in a cement-based material and a shielding function of the component B on the adoption of the superplasticizer by the clay, the inhibitor effectively reduces the adoption effect of the clay on the polycarboxylate superplasticizer, that is, the synergistic effect effectively inhibits the adverse effect of the clay on the polycarboxylate superplasticizer, and the working performance of the cement-based material is remarkably improved.

Owner:安徽瑞和新材料有限公司

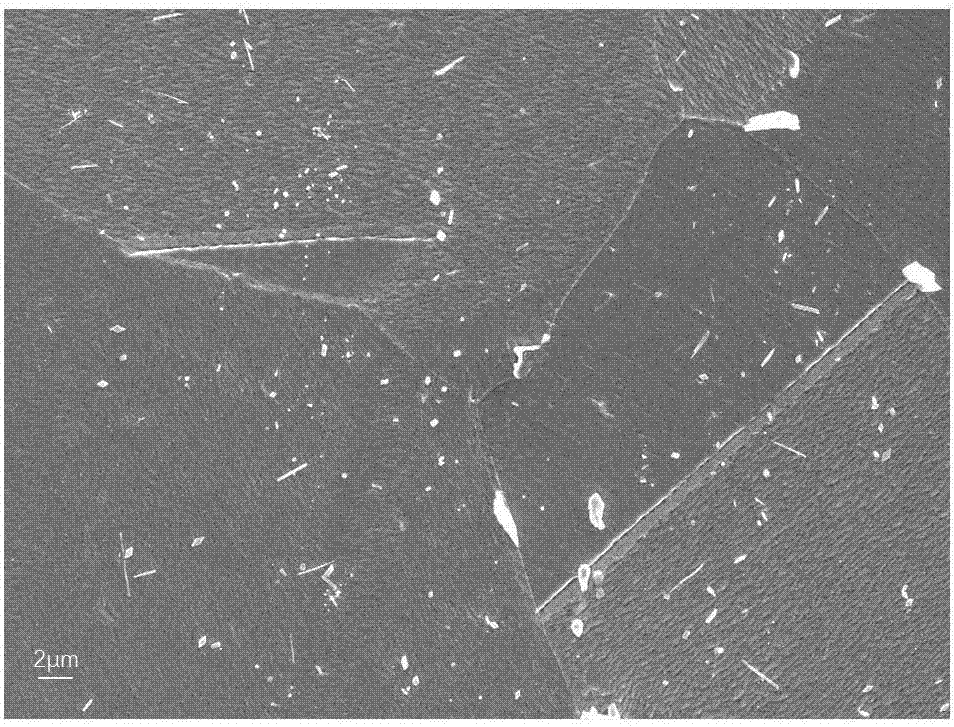

Heat treatment method capable of improving room-temperature impact toughness of austenitic heat-resistant steel after aging

ActiveCN107058702AThe process steps are simpleImproved impact toughness dropGrain boundaryImpact toughness

The invention provides a heat treatment method capable of improving the room-temperature impact toughness of austenitic heat-resistant steel after aging. The heat treatment method is capable of effectively reducing the declining amplitude of the impact toughness after the aging, improving the impact toughness of the heat-resistant steel after the aging, and providing guarantee on the safe running of a power plant unit. The heat treatment method comprises the following steps: step 1, heating the austenitic heat-resistant steel to 1220-1240 DEG C; step 2, insulating the heat of the heated austenitic heat-resistant steel for 15-25min at 1220-1240 DEG C; step 3, cooling the heat-insulated austenitic heat-resistant steel to 1060-1100 DEG C at a cooling speed of 3-5 DEG C / min; and step 4, water-cooling the austenitic heat-resistant steel cooled to 1060-1100 DEG C to room temperature. The heat treatment method provided by the invention achieves the purposes of separating out a second phase and generating a certain amount of serrated grain boundaries through controlling a heat treatment temperature, a heat-insulation time and a cooling speed, so that performance optimization is realized.

Owner:HUANENG POWER INTERNATIONAL +1

High-temperature anti-oxidation layer on metal tungsten surface and manufacturing method of high-temperature anti-oxidation layer

ActiveCN105385987AOptimal Control StructureControllable phaseSolid state diffusion coatingTungsten nitrideNitrogen atmosphere

The invention discloses a manufacturing method of a high-temperature anti-oxidation layer on the metal tungsten surface. The manufacturing method includes the steps that a metal tungsten base material is polished till the surface is smooth and level, and deoiling and degreasing treatment is conducted on the polished surface; the treated metal tungsten base material is soaked into a molybdenum seeping agent and then subjected to heat treatment in the inertia atmosphere, impurities are removed after cooling, and a semi-finished product with a tungsten and molybdenum solid solution layer on the metal tungsten surface is obtained; the semi-finished product is placed in the nitrogen atmosphere to be subjected to heat treatment, impurities are removed after cooling, and a prefabricated body with a molybdenum nitride and tungsten nitride coating on the metal tungsten surface is obtained; the prefabricated body is soaked into a silicification seeping agent to be subjected to heat treatment in the inertia atmosphere, impurities are removed after cooling, and a finished product with W-Mo-N-Si high-temperature anti-oxidation layer on the metal tungsten base material surface is obtained. The invention further relates to the high-temperature anti-oxidation layer obtained through the method and used on the metal tungsten surface.

Owner:XIAMEN UNIV OF TECH

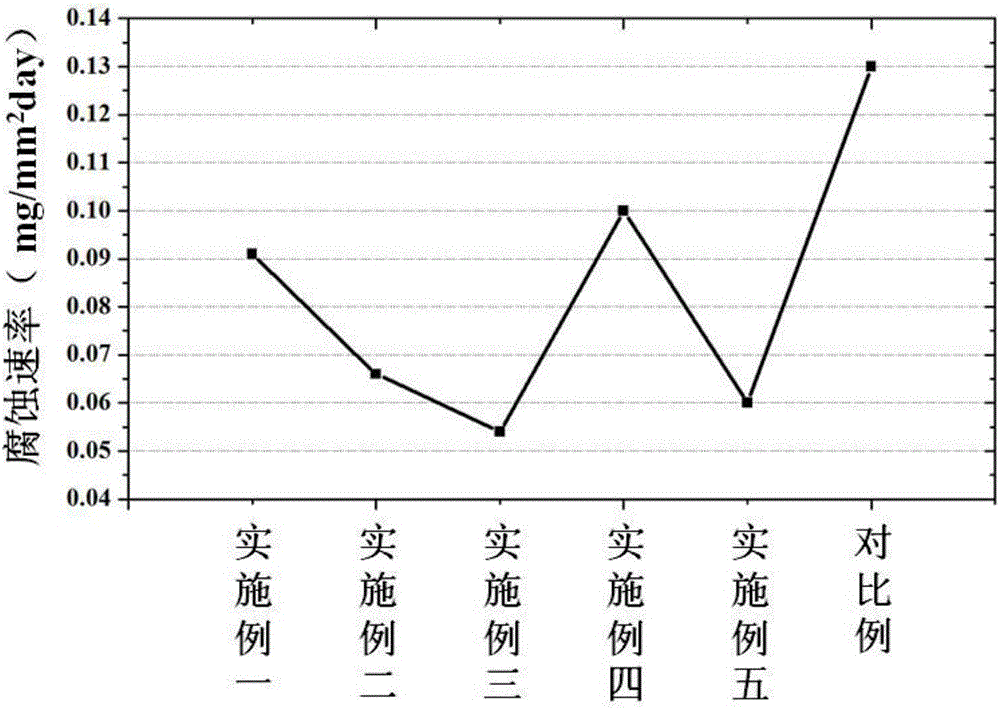

Preparation method for anticorrosion steel used for water-cooling spray nozzle

ActiveCN106119724AImprove impact resistanceReduced diffusion rateSolid state diffusion coatingMolten stateBoriding

The invention discloses a preparation method for anticorrosion steel used for a water-cooling spray nozzle. The method comprises the following steps that raw materials are heated into a molten state to obtain a liquid alloy, wherein the liquid alloy comprises, by weight, 0.1-0.25% of C, 1.2-1.5% of Cr, 0.3-0.6% of Al, 1.2-1.6% of Mg, 0.2-0.3% of Zr, 0.4-0.6% of Ni, 1.2-1.3% of Mn, 0.08-0.12% of Mo, 0.1-0.13% of V, 0.03-0.06% of Co, 0.02-0.05% of Ga, 1.5-1.6% of T, 0.6-0.8% of Si and the balance Fe; a steel billet is obtained through casting; heat treatment is conducted; boriding is conducted; and the steel billet subjected to heat treatment and boriding is coated with a conversion film.

Owner:滁州帝邦科技股份有限公司

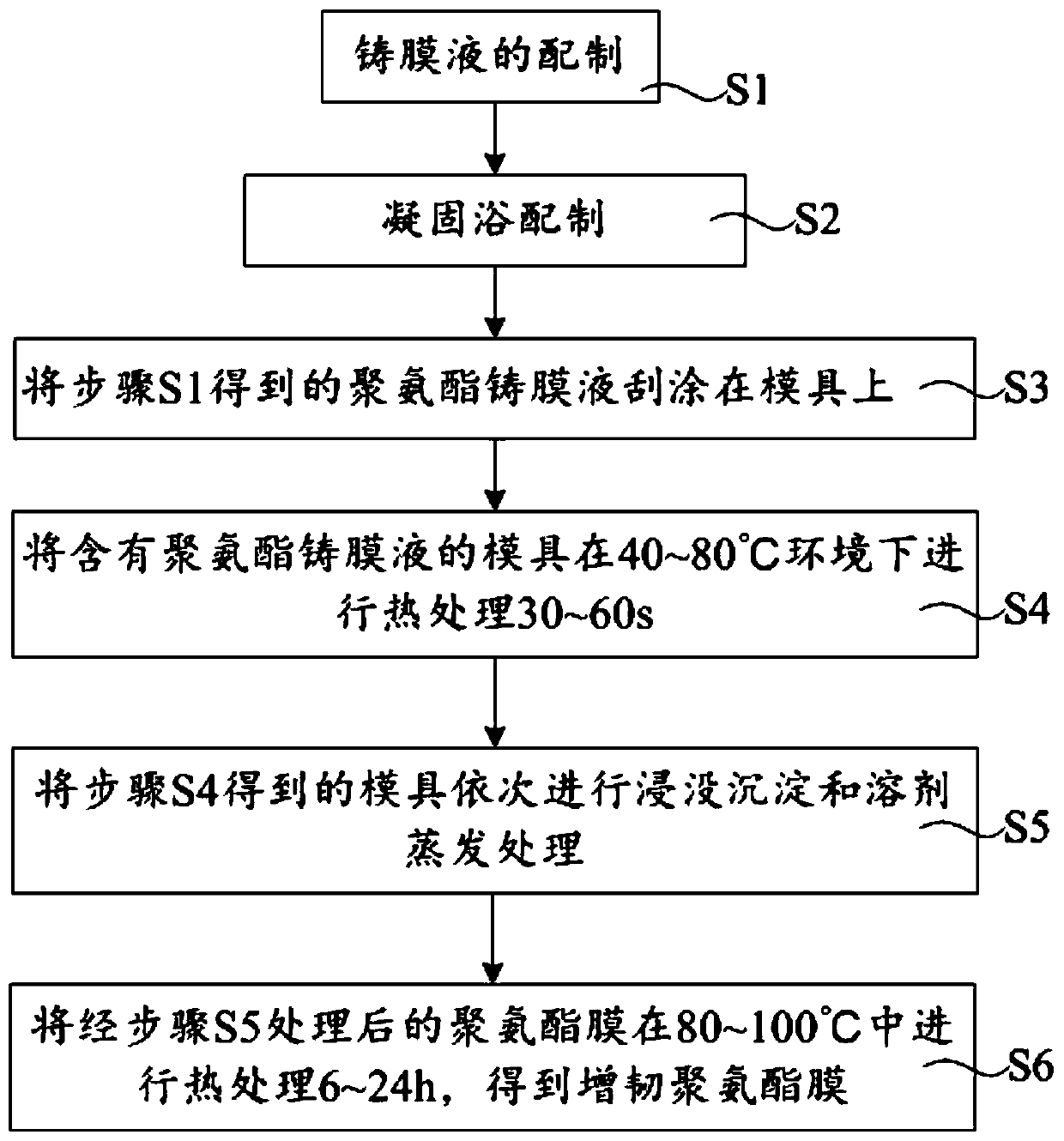

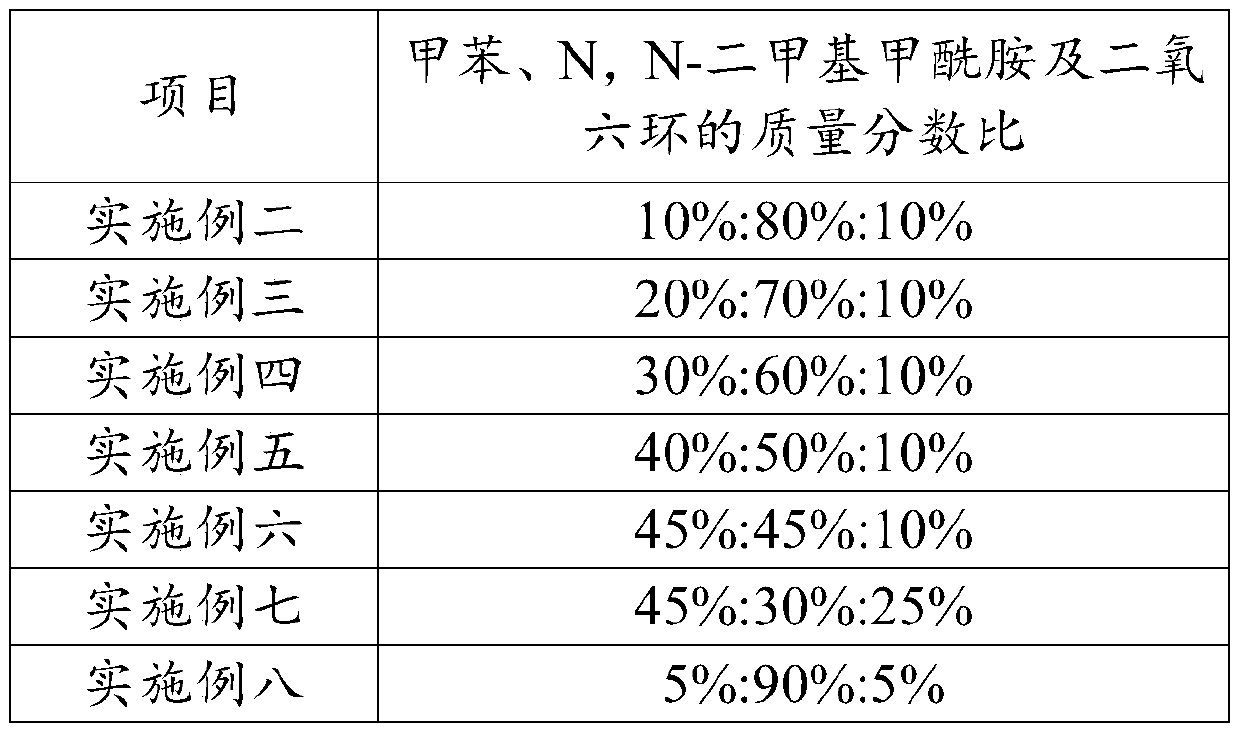

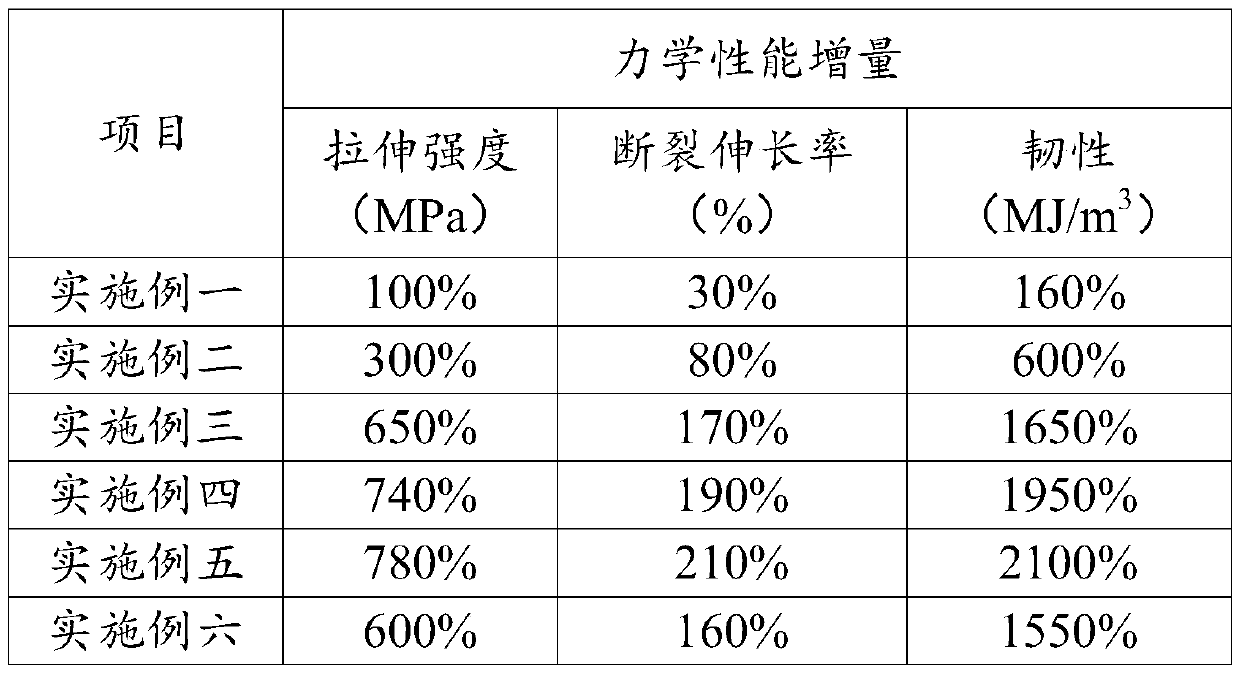

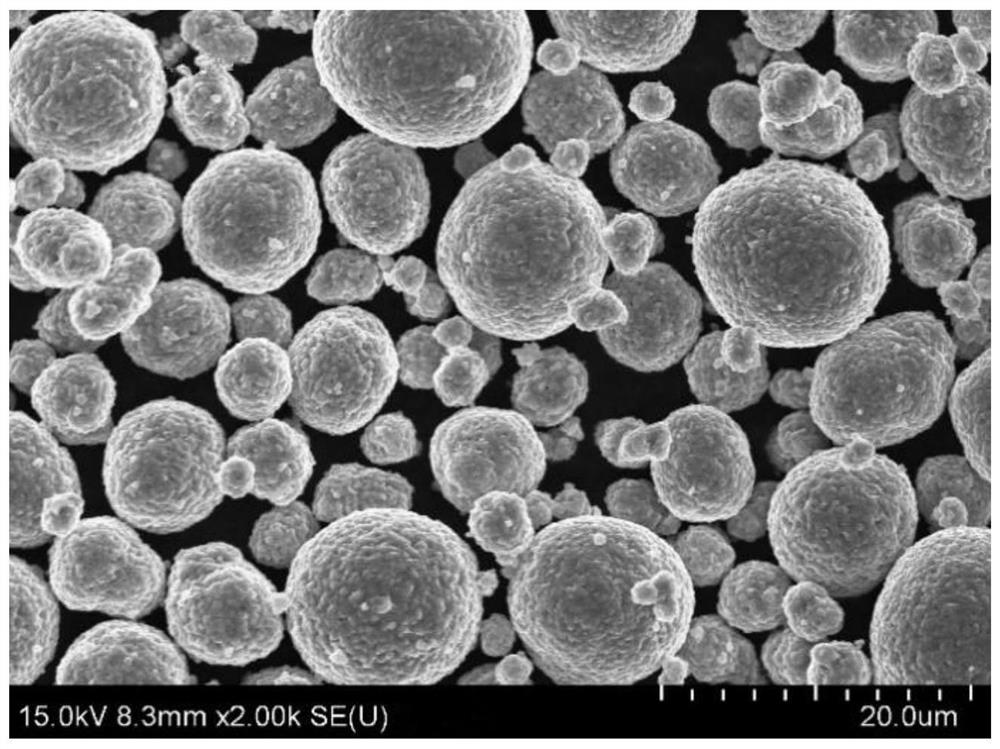

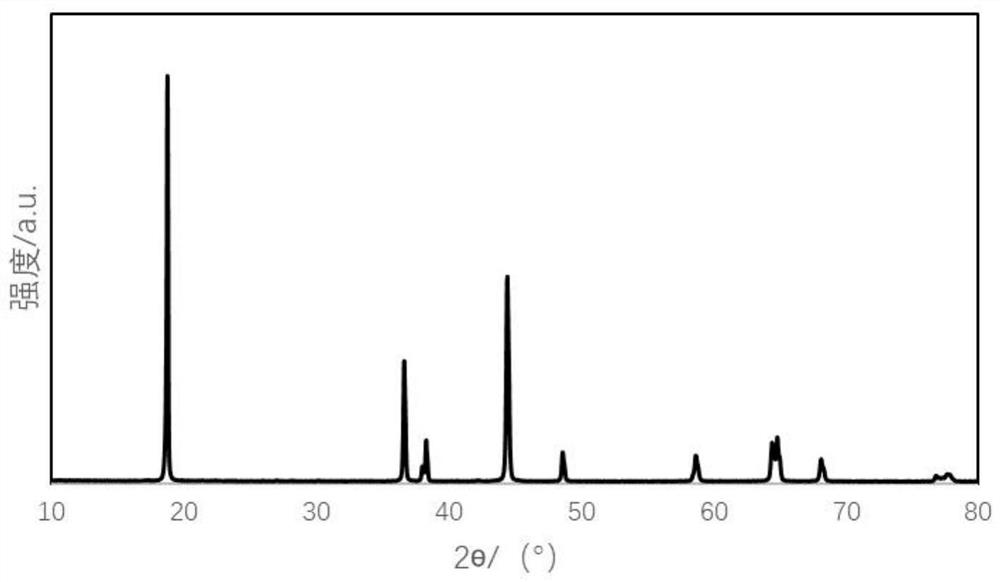

Production method of toughened polyurethane film

The invention provides a production method of a toughened polyurethane film. The production method of the toughened polyurethane film comprises the following steps of (1) producing a casting solution,wherein a poor solvent of polyurethane, N,N-dimethylformamide and a solvent with polarity lower than that of the N,N-dimethylformamide are mixed to form a ternary mixed solvent, and then vacuum defoamation is conducted after a polyurethane prepolymer and the ternary mixed solvent are stirred evenly by a machine so as to produce the polyurethane casting solution; (2) producing a coagulation bath;(3) conducting blade coating on the polyurethane casting solution to coat a mold with the polyurethane casting solution; (4) conducting thermal treatment on the mold in an environment at 40-80 DEG C for 30-60 s; (5) sequentially conducting immersion precipitation and solvent evaporation treatment on the mold; and (6) conducting thermal treatment on a polyurethane film at 80-100 DEG C to obtain thetoughened polyurethane film. According to the production method of the toughened polyurethane film, the poor solvent of the polyurethane, the N,N-dimethylformamide and the solvent with polarity lowerthan that of the N,N-dimethylformamide are adopted, and are mixed to form the ternary mixed solvent system, and the polyurethane film formation speed and a distribution mode of polyurethane moleculechains are improved, so that the polyurethane film excellent in mechanical performance is obtained.

Owner:WUHAN TEXTILE UNIV

Preparation method of high-nickel positive electrode material of composite coating layer

ActiveCN112310376AEffective protectionGuaranteed stabilityCell electrodesSecondary cellsElectrical batteryLithium-ion battery

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a preparation method of a high-nickel positive electrode material of a composite coating layer. The method comprises the following steps: (1) adding the high-nickel positive electrode material and soluble aluminum salt into deionized water, and stirring; (2) adding an alkaline solution of lithium salt into the solution in the step (1), stirring, and enabling the pH value to be 8-14; (3) carrying out suction filtration and washing on the mixed solution obtained in the step (2), and drying in a drying oven; and (4) uniformly mixing the positive electrode material dried in the step (3) with a nano coating agent, then putting the mixture into a preheated box-type furnace filled with oxygen for sintering, and sieving to obtain the high-nickel positive electrode material with the composite coating layer. Compared with a pure dry coating method, the wet precipitation coating method has the advantages that the coating uniformity and an acting force on the surface of the high-nickel positive electrode material are stronger, the coating is uniform, the thickness of the coating layer is controllable, and the comprehensive electrochemical performance of the positive electrode material is improved.

Owner:江西普瑞美新材料科技有限公司

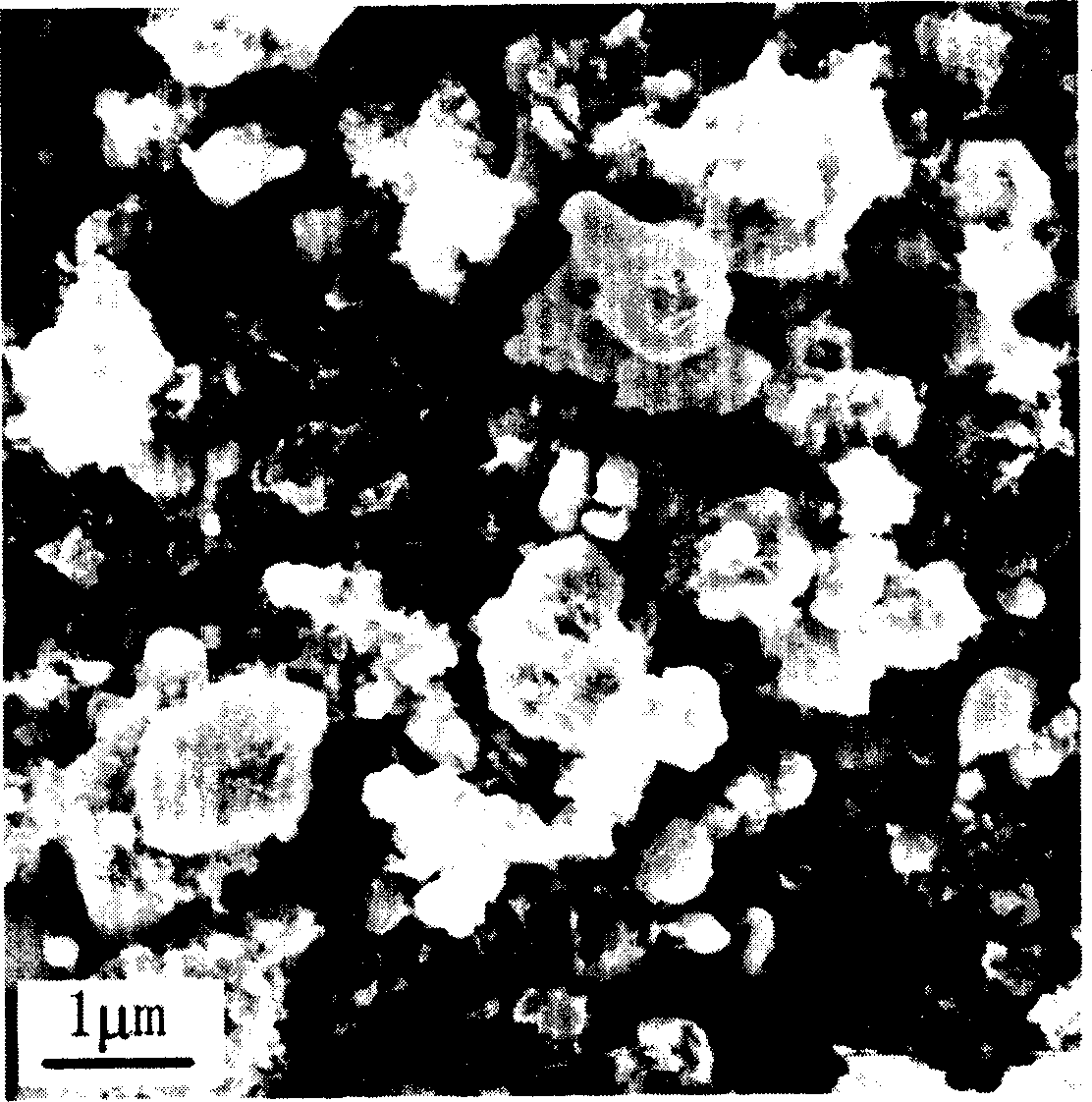

Low-temperature preparation method of rice-hull-based porous silicon material

InactiveCN106430213ASimple processLow priceMaterial nanotechnologyCell electrodesPorous siliconMaterials science

The invention discloses a low-temperature preparation method of a rice-hull-based porous silicon material and belongs to the technical field of nanoelectrode material preparation. The method comprises the steps that first, washed and dried rice hulls are heated and oxidized in air to obtain rice hull ash, then the rich hull ash is soaked with diluted hydrochloric acid, washed with distilled water and dried, and the dried rich hull ash is obtained; the dried rich hull ash, aluminum powder or a mixture of aluminum powder and magnesium powder and a chloride mixture are mixed and then subjected to a sealed heating reaction, the temperature is kept till the reaction is over, then the mixture is cooled to room temperature, the product obtained after the reaction is collected, soaked with diluted hydrochloric acid and washed with distilled water, and the rice-hull-based porous silicon material is obtained. The method has the advantages that the process is simple, the raw materials are low in price, the reaction process has a low requirement for temperature, and the yield is high; the prepared rice-hull-based porous silicon material has excellent electrochemical performance and can be used as a lithium ion battery cathode material, thereby providing a new way for high-value-added utilization of the rice hulls.

Owner:YANGZHOU UNIV

Hyperbranched polymer-SiO2 modified epoxy resin insulating material and preparation method thereof

InactiveCN110776806APolymer branching degreeReduced effectivenessNon-macromolecular adhesive additivesEpoxy resin adhesivesPolymer sciencePolymer modified

The invention relates to the technical field of epoxy resin adhesives, and discloses a hyperbranched polymer-SiO2 modified epoxy resin insulating material and a preparation method thereof. The hyperbranched polymer-SiO2 modified epoxy resin insulating material is prepared from the following formula materials: hyperbranched polymer, nanosilicon dioxide, a silane coupling agent, a catalyst, dodecylsuccinic anhydride and epoxy resin. A three-dimensional net-like spherical structure of the hyperbranched polymer has a high degree of molecular branching, so that nano-SiO2 is uniformly dispersed on the huge specific surface of the hyperbranched polymer, nano-SiO2 agglomeration is reduced, nano-SiO2 reduces the effective charge and charge accumulation in a coating interface area, the diffusion rate of a carrier is reduced, the formation of conductive paths is suppressed, the breakdown characteristics of epoxy resin coatings are improved, the hyperbranched polymer has excellent elastic expansion structure and good structural stability, the crosslinking density of the epoxy resin is increased, the mobility of a molecular segment of the epoxy resin is suppressed, and the impact cross sectioncaused by the stress expansion of the resin is reduced.

Owner:王利玲

Modified magnesium phosphate cement and preparing method thereof

ActiveCN105731991AControllable clotting timeGood strength developmentMagnesium phosphateReaction rate

The invention discloses modified magnesium phosphate cement and a preparing method thereof and relates to the field of building materials. The modified magnesium phosphate cement comprises main components and auxiliary components. The main components are 70-85% of magnesium phosphate cement, 5-10% of gypsum and 10-20% of coal ash. The auxiliary components are etherification alcohol modifier, retarder and water-retaining agent, wherein the ratio of the mass of the etherification alcohol modifier to the sum of mass of the main components is 1-5%, the ratio of the mass of the retarder to the sum of mass of the main components is 2-5%, and the ratio of the mass of the water-retaining agent to the sum of mass of the main components is 1-3%. The preparing method comprises the steps of weighing, grinding and mixing. Through surface modification conducted by means of the etherification alcohol modifier, the number of active sites on the surfaces of magnesium phosphate particles is increased, adsorbability of the retarder is improved, interdiffusion of effective ions is slowed, and reaction rate is reduced; meanwhile, under the combined action of the retarder and the water-retaining agent, the performance of the magnesium phosphate cement is well improved. The setting time of the obtained cement is prolonged greatly, the defects of magnesium phosphate cement that early strength enhance rate is high and long-term strength enhance rate is low are overcome, and delayed coagulation time and strength development are both considered fundamentally.

Owner:BEIJING UNIV OF TECH

Ball milling preparation method of rice hull-based porous silicon nanomaterial

The present invention provides a ball milling preparation method of a rice hull-based porous silicon nanomaterial, belonging to the technical field of preparation of nano-electrode materials. The method comprises the steps of heating to oxidize or incompletely oxidize water-washed and dried rice hull in air, so as to obtain rice hull ash, then soaking by using dilute hydrochloric acid, washing with distilled water and then drying, and obtaining the dried rice hull ash; and mixing the dried rice hull ash with aluminum powder, or aluminum powder, magnesium powder and a corresponding chloride so as to obtain a mixed material, then putting the mixed material in a ball milling machine to grind and cool to room temperature, collecting the product, soaking with dilute hydrochloric acid, then washing with distilled water so as to obtain the rice hull-based porous silicon nanomaterial. The preparation method is simple, the cost of the raw material is low, the yield is high, solid phase reaction is good for industrial production, and the prepared rice hull-based porous silicon nanomaterial has excellent electrochemical performance.

Owner:YANGZHOU UNIV

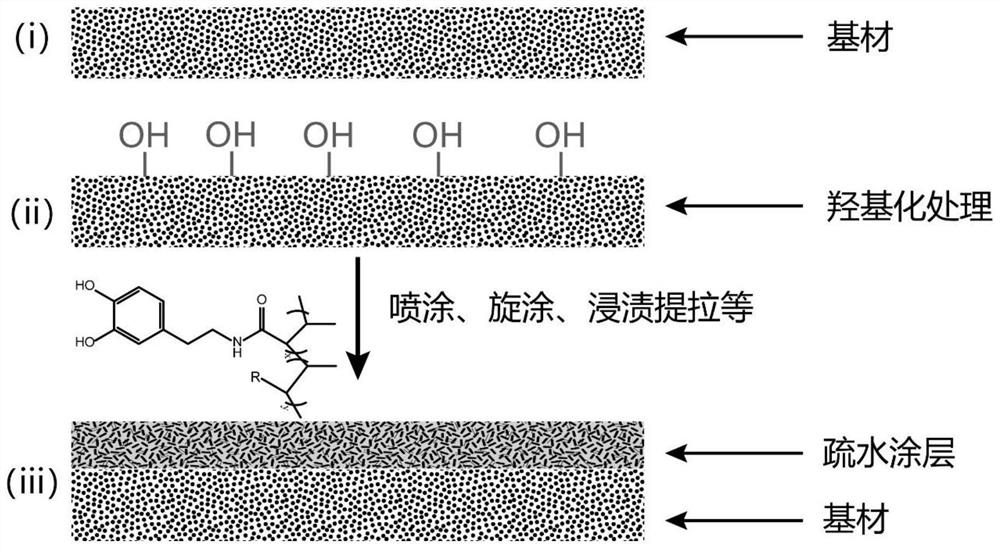

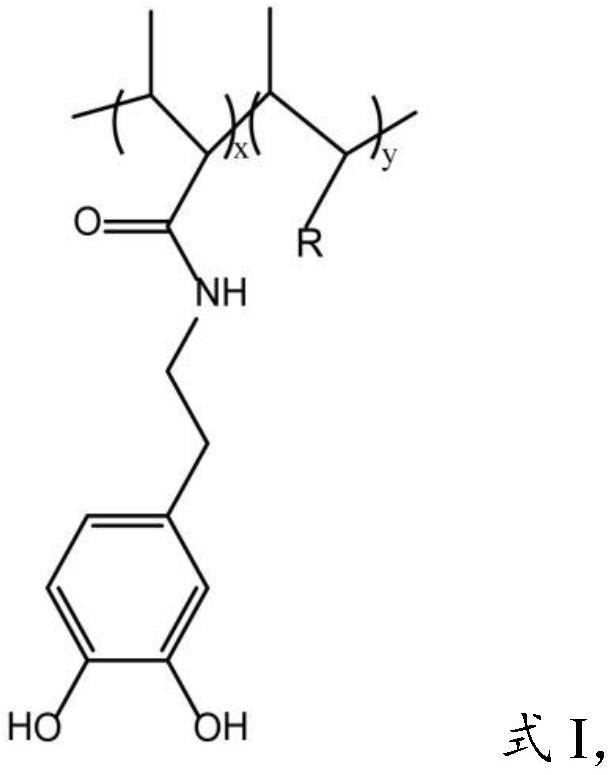

Hydrophobic moisture-resistant coating as well as preparation method and application thereof

The invention provides a hydrophobic moisture-resistant coating as well as a preparation method and application thereof, and belongs to the technical field of coatings. The prepared dopamine copolymer has an excellent adhesion characteristic, the coating and the surface of a pretreated base material are combined together through chemical covalent bonds, excellent bonding performance is given to the hydrophobic moisture-resistant coating and a substrate, and the bonding strength of the coating and the substrate is greatly enhanced; by adding the filler, the diffusion path of water molecules is increased, the diffusion rate of the water molecules is effectively reduced, meanwhile, the interaction between the hydrophobic moisture-resistant coating and the water molecules is weak, the moisture adsorption capacity is low, and therefore the function of blocking moisture for a long time is achieved. The hydrophobic moisture-resistant coating provided by the invention can be applied to the surface and interface fields of building external wall thermal insulation, roof waterproof and thermal insulation integration, building boards, thermal insulation and moisture-resistant materials of refrigerator cars and refrigeration houses, external protective layers of precise instruments and the like, and can effectively avoid oxidation and swelling deformation of wrapped materials due to moisture absorption of the materials, and influences on the dimensional precision of precision parts.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

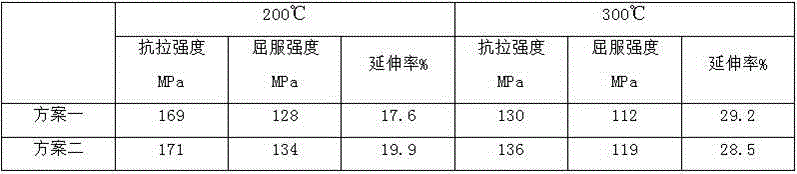

High-strength and high-temperature-resistant magnesium alloy

The invention discloses a high-strength and high-temperature-resistant magnesium alloy, and belongs to the field of metallic materials. The magnesium alloy mainly comprises elements of magnesium, aluminum, zinc, manganese, erbium, yttrium, zirconium and the like, the magnesium alloy is composed, by weight percentage, of 1-2% of the aluminum, 2-3% of the zinc, 0.5-1% of the manganese, 2-3.5% of the erbium, 1.5-2% of the yttrium, 0.02-0.05% of the zirconium, less than 0.02% of silicon, less than 0.002% of copper, less than 0.002% of iron, less than 0.005% of other impurities and the balance magnesium. According to high-strength and high-temperature-resistant magnesium alloy, the elements such as the magnesium, the aluminum, the zinc, the manganese, the erbium, the yttrium and the zirconium are added into the magnesium alloy, room-temperature strength and corrosion resistance of materials are improved, tensile strength, elongation and high-temperature strength of the magnesium alloy are greatly improved, and the magnesium alloy can work under the temperature ranging from 200 DEG C to 300 EDG C for a long time.

Owner:HEBEI GANGYAN DEKAI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com