Dispersion strengthening copper-based composite material and preparation method thereof

A technology of dispersion strengthening copper and composite materials, which is applied in the field of composite materials and preparation, can solve problems such as difficulty in reinforcement, and achieve high mechanical properties, cost savings, and excellent high temperature softening resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

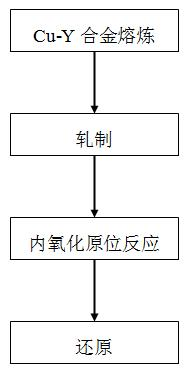

[0024] see figure 1 , smelting Cu-0.4wt.%Y alloy ingots with a vacuum intermediate frequency induction furnace, and rolling the alloy ingots into plates with a thickness of 0.5mm, at 800 o C Insulate in an industrial nitrogen atmosphere for 2 hours, carry out internal oxidation treatment on the sample, so that Y is completely oxidized into Y 2 o 3 , after the 600 o C hydrogen atmosphere reduction for 1 hour.

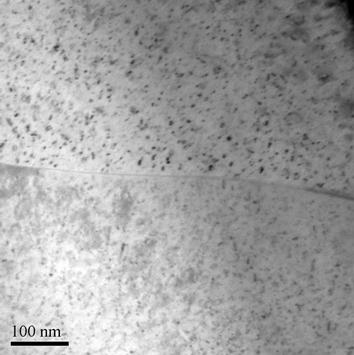

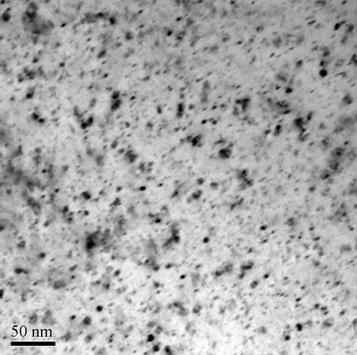

[0025] Yttrium oxide dispersion strengthened copper matrix composite material was prepared through the above process, Y 2 o 3 The particles are evenly distributed on the copper substrate, the average particle size is 7nm, and the average particle distance is 25nm, see figure 2 . The properties are: tensile strength 584MPa, electrical conductivity 94%IACS, softening temperature 900 o c.

Embodiment 2

[0027] see figure 1 , smelting Cu-0.4wt.%Y alloy ingots with a vacuum intermediate frequency induction furnace, and rolling the alloy ingots into plates with a thickness of 1mm, at 900 o C Insulate in an industrial nitrogen atmosphere for 3 hours, and perform internal oxidation treatment on the sample, so that Y is completely oxidized into Y 2 o 3 , after the 600 o C hydrogen atmosphere reduction for 1 hour.

[0028] The properties of the copper-based composite material prepared by the above process are: tensile strength 587MPa, electrical conductivity 94%IACS, softening temperature 900 o c.

Embodiment 3

[0030] see figure 1 , smelting Cu-0.4wt.%Y alloy ingots with a vacuum intermediate frequency induction furnace, and rolling the alloy ingots into plates with a thickness of 5mm, at 1000 o C Insulate in an industrial nitrogen atmosphere for 5 hours, and perform internal oxidation treatment on the sample, so that Y is completely oxidized into Y 2 o 3 , after the 600 o C hydrogen atmosphere reduction for 1 hour.

[0031] The properties of the copper-based composite material prepared by the above process are: tensile strength 580MPa, electrical conductivity 92%IACS, softening temperature 900 o c.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com