Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

76 results about "Y alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Y alloy is a nickel-containing aluminium alloy. It was developed by the British National Physical Laboratory during World War I, in an attempt to find an aluminium alloy that would retain its strength at high temperatures.

A1-N1-Y alloy films for electrodes of semiconductor devices and sputtering targets for depositing the A1-N1-Y alloy films

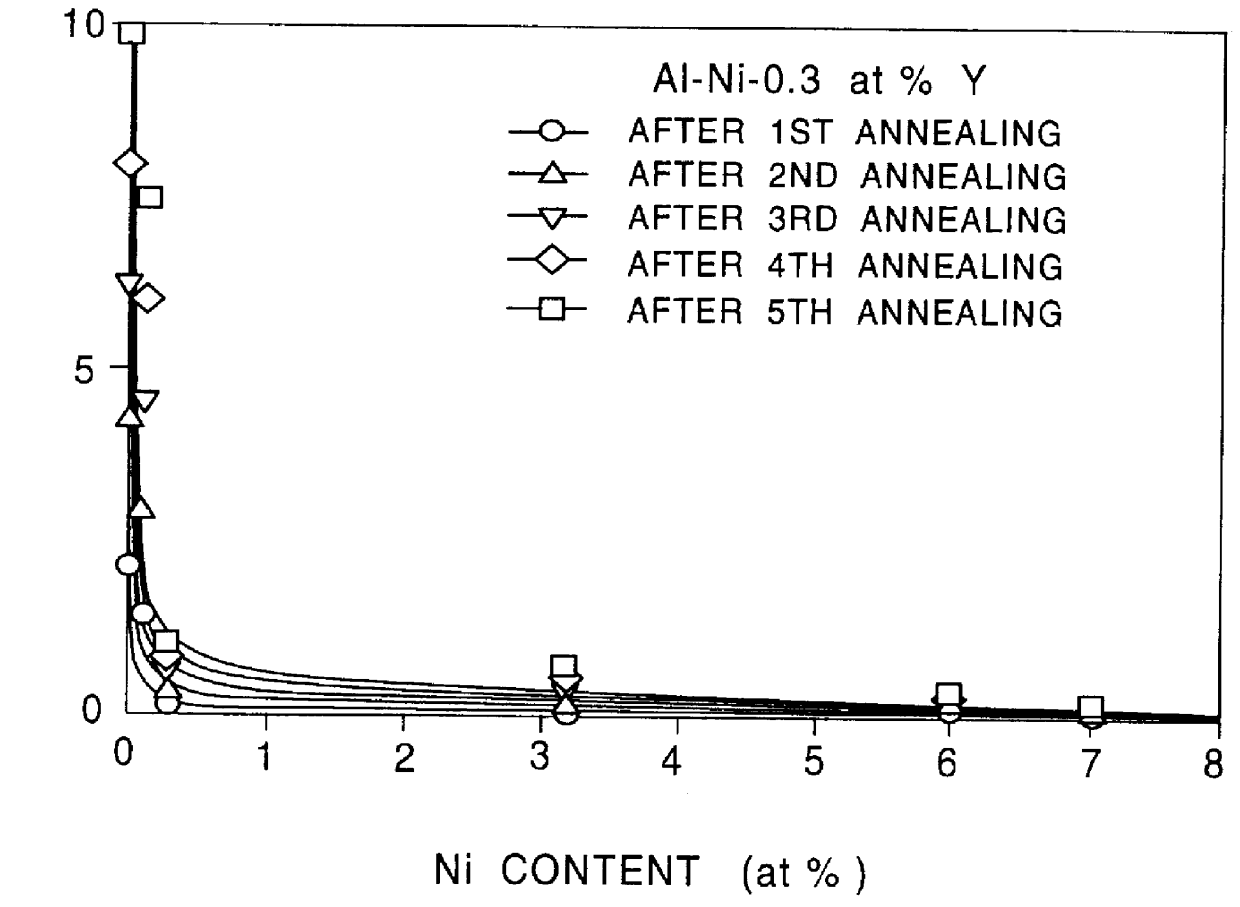

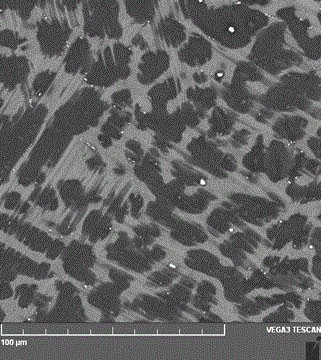

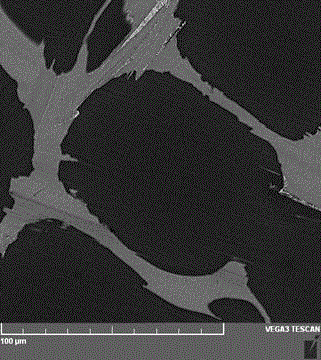

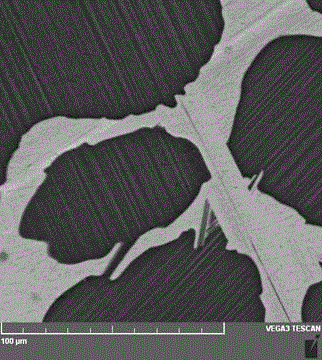

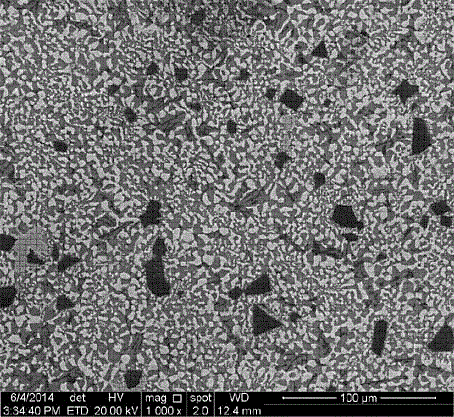

The invention provides an Al alloy film for use as an electrode of a semiconductor device and also provides an Al alloy sputtering target used to produce such an Al alloy film wherein the Al alloy film has not only a low resistivity equal to or less than 5 mu OMEGA cm and a high hillock resistance (property of hillock suppression) but also a high dielectric strength when it is anodized into an anodic oxide film and wherein the Al alloy film has a composition such that the Ni content is equal to or greater than 0.3 at % and the Y content is equal to or greater than 0.3 at % and such that 0.22 CNi+0.74 CY<1.6 at % where CNi denotes the Ni content (at %) and CY denotes the Y content (at %) and further wherein, in order to deposit the Al alloy film by sputtering, a spray forming Al alloy target containing Ni and Y is used.

Owner:KOBE STEEL LTD

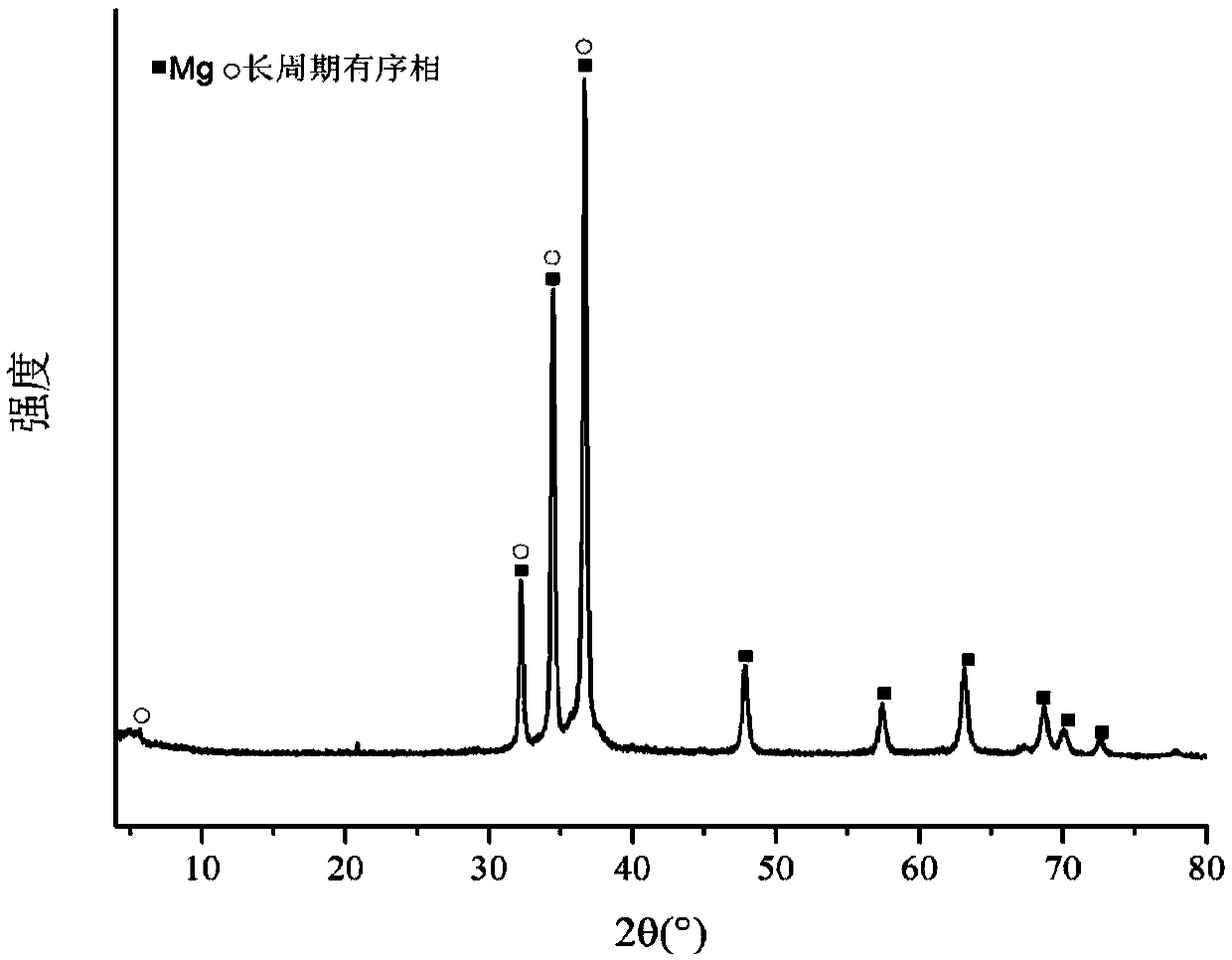

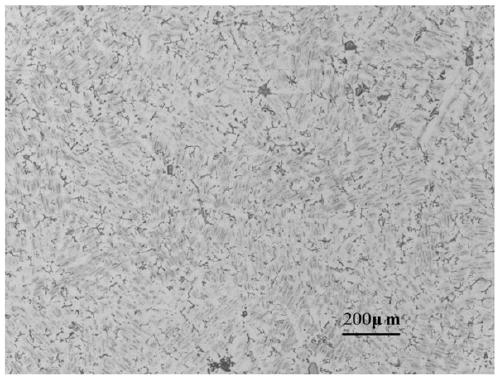

High-damping Mg-Zn-Y alloy and preparation technique thereof

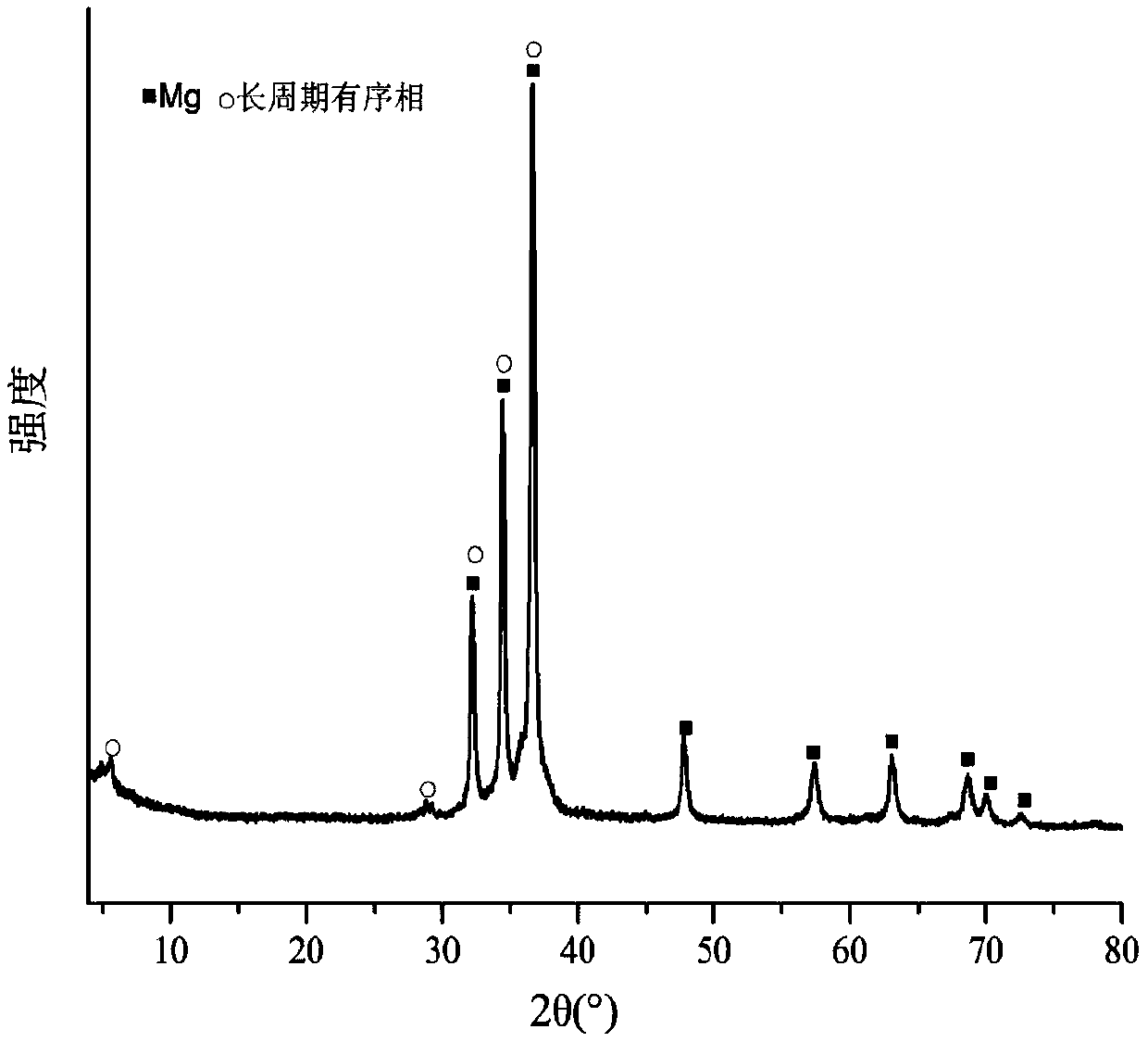

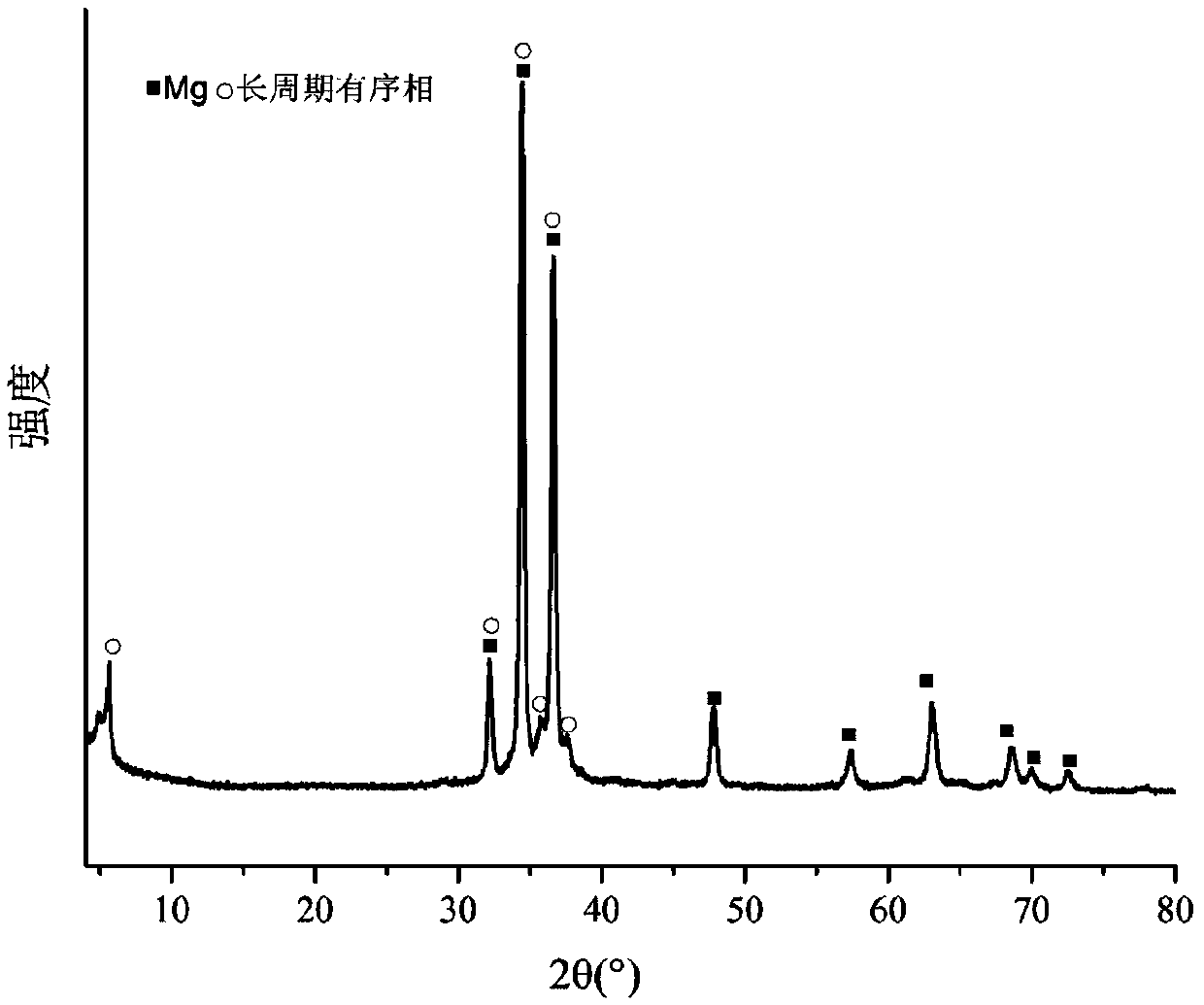

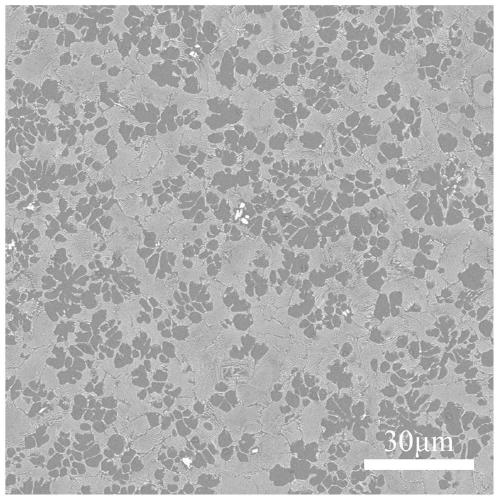

The invention discloses a high-damping Mg-Zn-Y alloy containing rare-earth yttrium and a manufacturing method thereof. The magnesium alloy is composed of the following components in percentage by weight: 4.0-4.8% of Y, 6.6-8.9% of Zn, and the balance of magnesium and inevitable impurities. By designing the Zn and Y contents according to the synthesis components, the alloy is mainly a two-phase alloy composed of a magnesium phase and a long-period phase, wherein the long-period phase is an effective strengthening phase in the magnesium alloy and is beneficial to the damping capacity of the alloy. The alloy composition control and smelting techniques are adopted to control the grain size and long-period phase (LPSO) distribution in the alloy, thereby greatly enhancing the damping capacity of the alloy, ensuring the alloy strength and implementing the balanced optimization of damping and mechanical properties of the magnesium alloy. The technique is simple and easy to operate, has the advantages of high transferability and lower cost, and can be used for aerospace, track traffic and textile technology to achieve the effects of damping and noise reduction.

Owner:CHONGQING UNIV

Multielement-enhanced heat-resistant corrosion-resistant magnesium alloy and manufacturing method thereof

ActiveCN107083508AImprove room temperature and high temperature mechanical propertiesImproves strength and hardnessRare-earth elementCorrosion resistant

The invention discloses a multielement-enhanced heat-resistant corrosion-resistant magnesium alloy and a manufacturing method of the multielement-enhanced heat-resistant corrosion-resistant magnesium alloy. The ingredients of the multielement-enhanced heat-resistant corrosion-resistant magnesium alloy comprise pure magnesium ingots, pure zinc ingots, Mg-Gd alloy, Mg-Y alloy, Mg-Nd alloy, Mg-Ca alloy, Mg-Zr alloy and nanometer-scale NdN particles. The elements in the raw materials comprise, by mass, 3.5-5.0% of Gd, 1.0%-3.0% of Y, 0.5%-0.8% of Nd, 0.8%-1.5% of Zn, 0.3%-0.8% of Ca, 0.3%-0.6% of Zr, 0.5%-1.5% of nanometer-scale NdN particles and the balance Mg. The sequence of the mass percentage contents of the three rare earth elements of the Gd, the Y and the Nd from large to small is Gd>Y>Nd, and the mass percentage of the total addition amount of the three rare earth elements of the Gd, the Y and the Nd does not exceed 10%. The particle size of the nanometer-scale NdN particles is 80-150 nm. The steps of pretreatment and cladding of the NdN particles, preheating of the ingredients, smelting, refining, doping, pouring, sectioned solution treatment and artificial aging treatment are sequentially conducted, and then the fine, dispersive nanometer-precipitated-phase microscopic-structure heat-resistant corrosion-resistant magnesium alloy product is obtained. By the adoption of the multielement-enhanced heat-resistant corrosion-resistant magnesium alloy and the manufacturing method of the multielement-enhanced heat-resistant corrosion-resistant magnesium alloy, the manufacturing cost is low, and the heat resistance and corrosion resistance of the magnesium alloy are excellent.

Owner:YANGZHOU FENG MING METAL PROD +1

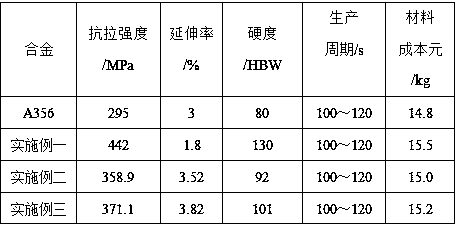

Rare earth aluminum alloy material and preparation method thereof

ActiveCN110885940AGood casting performanceReduce dendrite spacingCastabilityUltimate tensile strength

On one hand, the invention provides a rare earth aluminum alloy material comprising the following components by mass: 6%-8% of Si, 1.5%-4.5% of Cu, 0.2%-0.5% of Mg, 0.3%-0.8% of Mn, 0.2%-0.5% of Re, 0.1%-0.2% of Ti, 0.01%-0.05% of Sr and 80%-89% of Al; the Re is mischmetal containing Ce and La, and the Ti, Si, Ce and La rare earth elements are introduced into aluminum alloy; the castability of thealuminum alloy is improved effectively, and the freezing range and dendrite arm spacing of the alloy are reduced; the rare earth aluminum alloy material is higher in strength and plasticity; the component requirements of the rare earth aluminum alloy material are lower, and high purity Al ingots and expensive Zr, V and Y alloys are not required; the production cost is low, and the rare earth aluminum alloy material is high in industrial value. On the other hand, the invention provides a preparation method of the rare earth aluminum alloy material, and an indirect extrusion casting process isadopted; and the industrial production is achieved, and the preparation method has huge development potential in the fields of lightweight automobiles, intelligent robots, aerospace and the like.

Owner:KA FUNG IND TECH HUIZHOU CO LTD

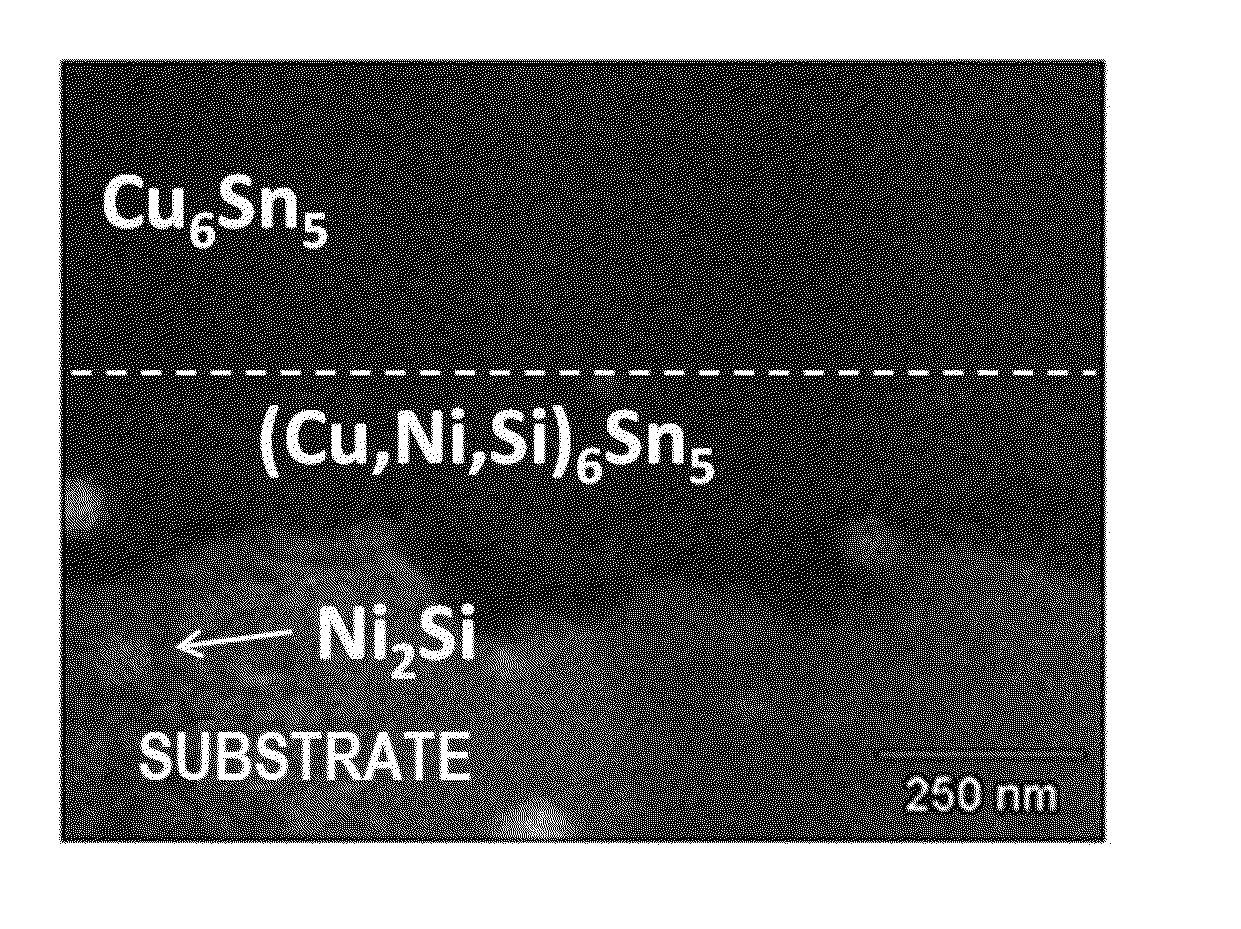

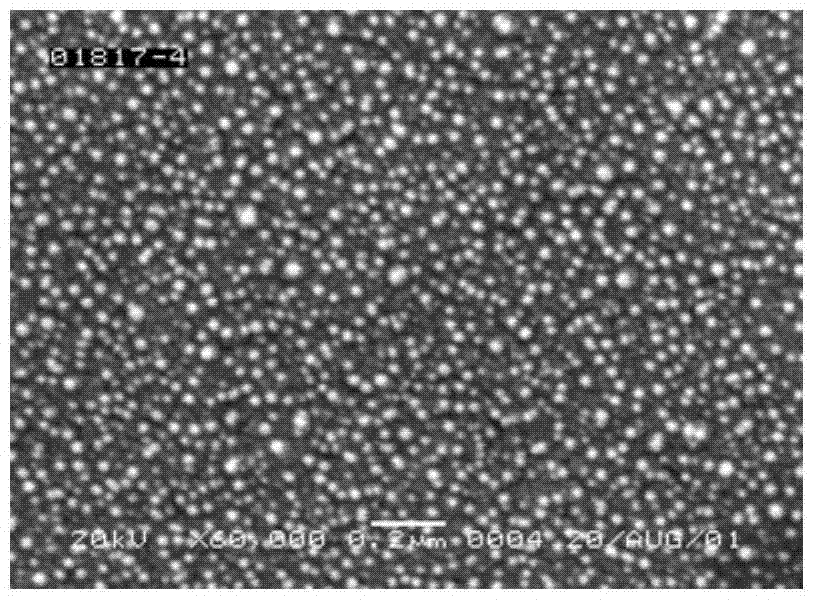

Tin-plated copper-alloy material for terminal having excellent insertion/extraction performance

InactiveUS20140287262A1Reduce coefficient of frictionReduce contact resistanceConductive materialCoupling contact membersTinningSurface layer

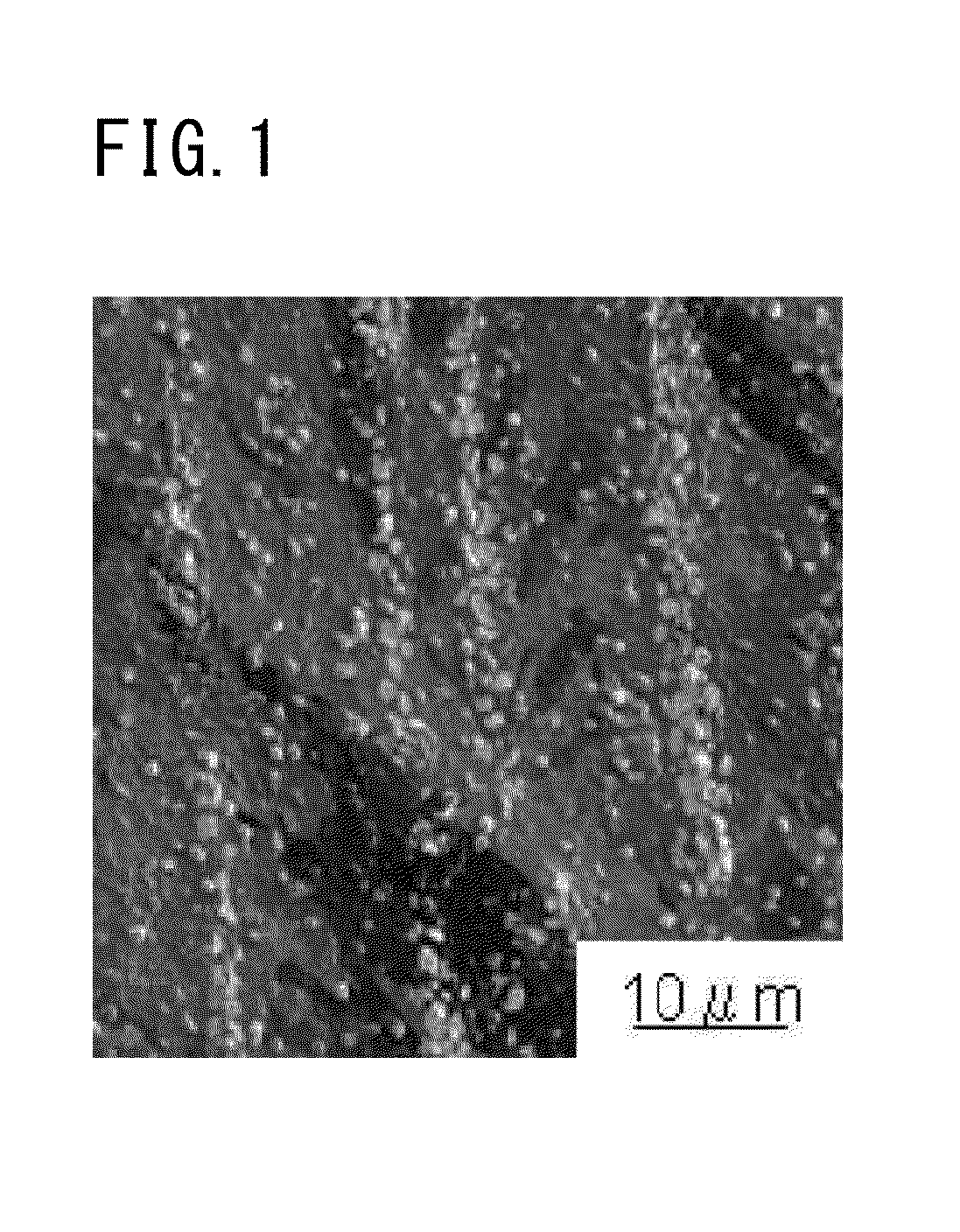

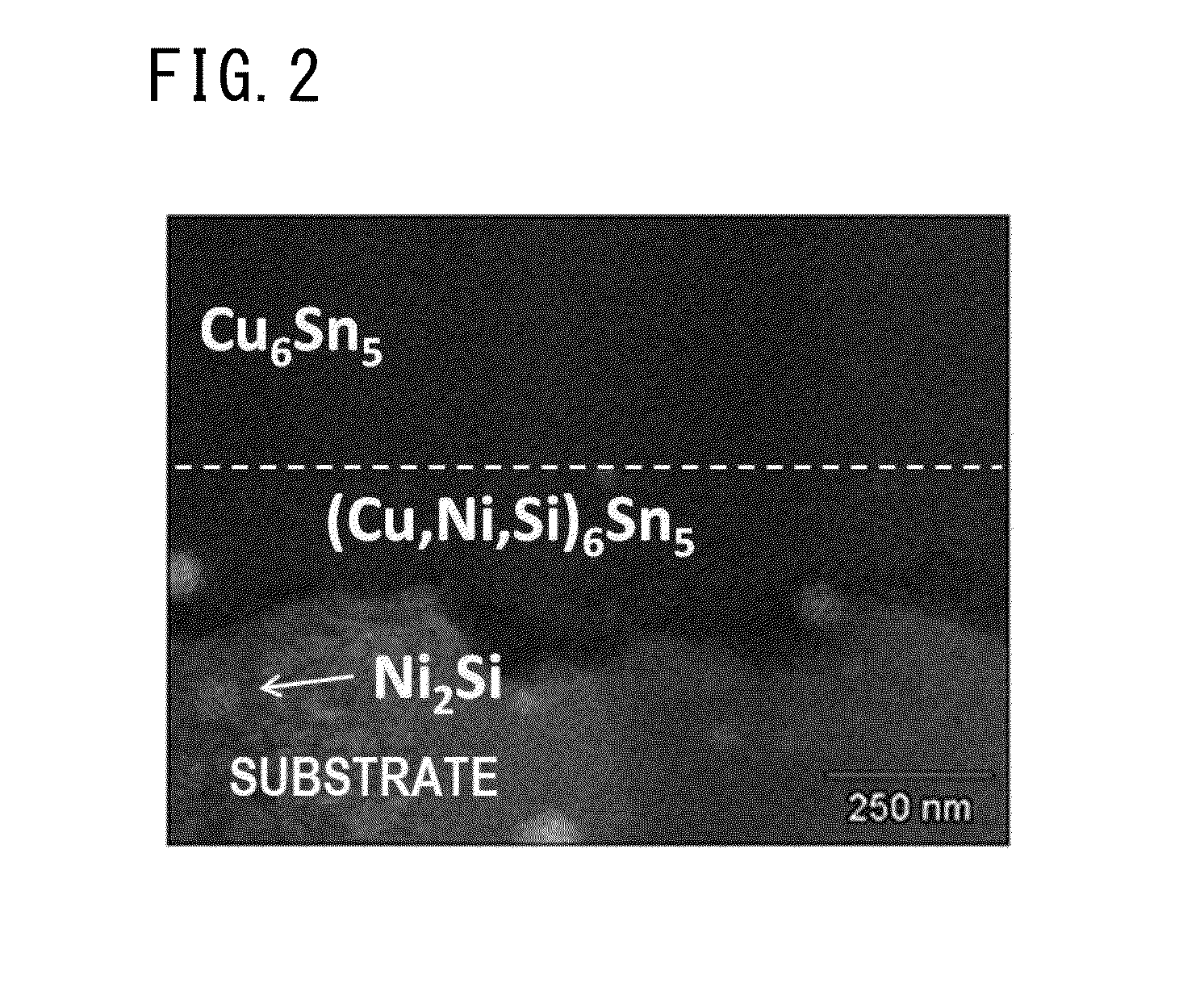

Tin-plated copper-alloy terminal material in which Sn-based surface layer is formed on a surface of a substrate made of Cu alloy, and a Cu—Sn alloy layer is formed between the Sn-based surface layer and the substrate; the Cu—Sn alloy layer contains Cu6Sn5 as major proportion and has a compound in which a part of Cu in the Cu6Sn5 is substituted by Ni and Si in the vicinity of a boundary face at the substrate side; an arithmetic average roughness Ra of the Cu—Sn alloy layer is 0.3 μm or more in at least one direction and an arithmetic average roughness Ra in all direction is 1.0 μm or less; an oil-sump depth Rvk of the Cu—Sn alloy layer is 0.5 μm or more; and an average thickness of the Sn-based surface layer is 0.4 μm or more and 1.0 μm or less and dynamic friction coefficient is 0.3 or less.

Owner:MITSUBISHI MATERIALS CORP

FeCoCrNi series high-entropy alloy selective laser melting in-situ additive manufacturing method and product

ActiveCN111085689AReduce manufacturing costReduce R&D costsAdditive manufacturing apparatusTransportation and packagingSelective laser meltingHigh entropy alloys

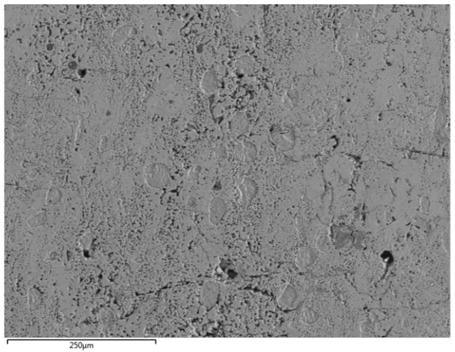

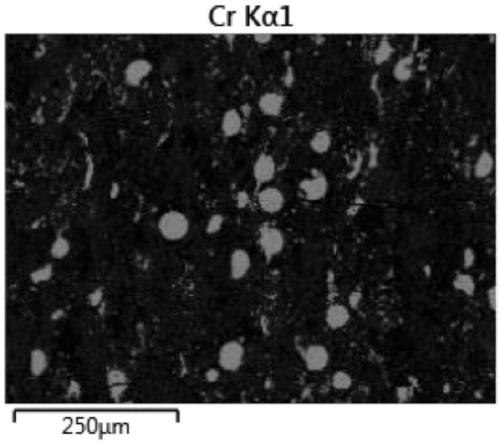

The invention provides a FeCoCrNi series high-entropy alloy selective laser melting in-situ additive manufacturing method. The method comprises the following steps: step 1, mixing mixed elemental metal powder with M-X alloy powder and / or N-Y alloy powder, wherein the mixed elemental metal powder at least comprises two of Fe, Co and Ni metal elemental powder, the M element in the M-X alloy powder is the metal element with the highest melting point in a high-entropy alloy, the N metal element in the N-Y alloy powder is the metal element with the lowest melting point in the high-entropy alloy, Xand Y are at least one metal element in the mixed elemental metal powder, and the molar number of each metal element in the mixed metal powder is the same; and step 2, carrying out laser additive manufacturing through laser 3D printing equipment to obtain the FeCoCrNi series high-entropy alloy. The product is good in forming effect and free of air holes and macroscopic cracks.

Owner:TIANJIN UNIV

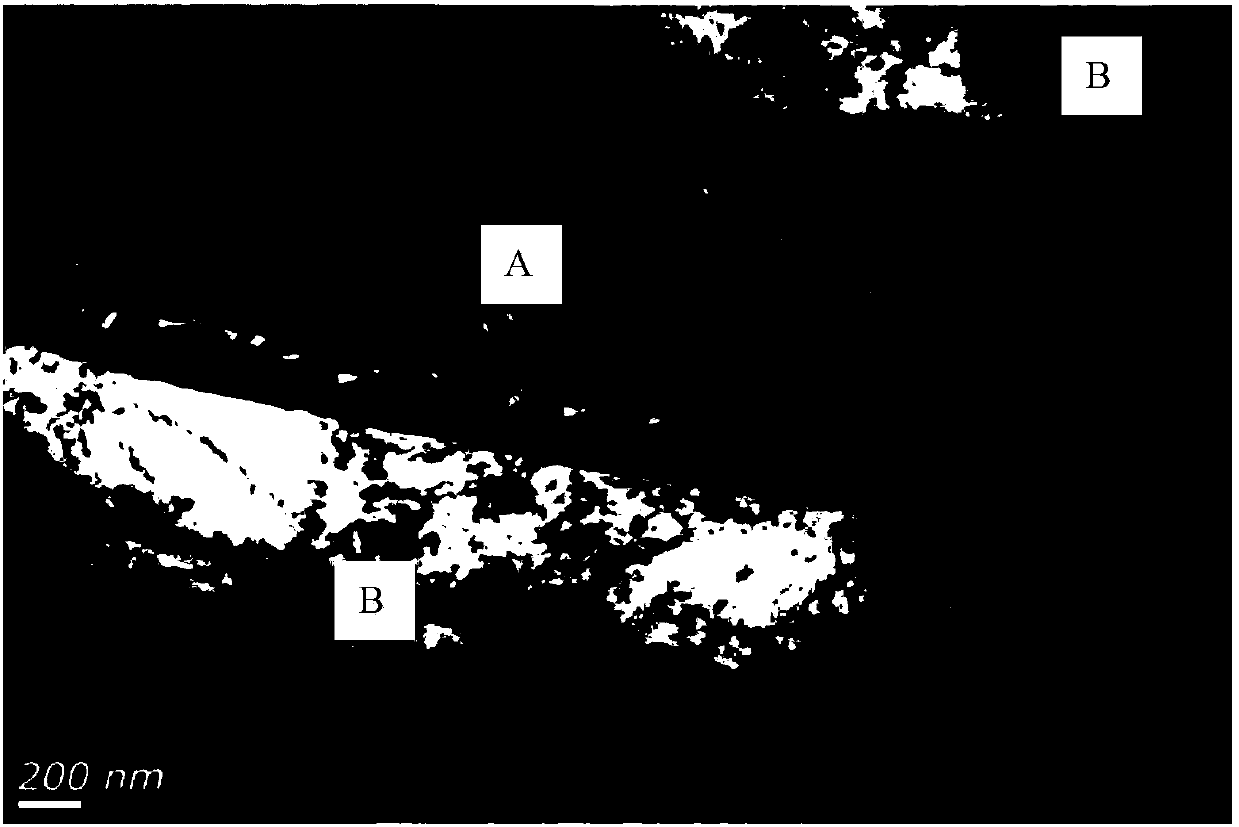

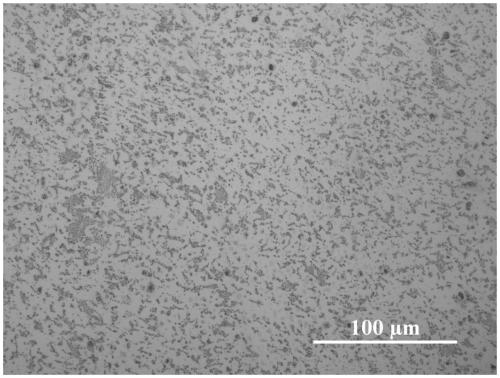

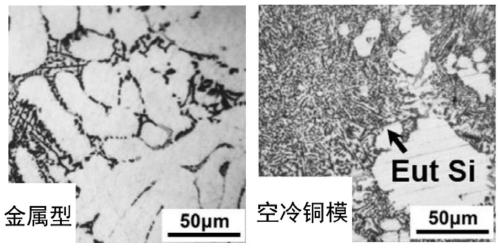

Method for preparing dual special structure combined reinforced Mg-Zn-Y alloy

The invention relates to a method for preparing an icosahedral quasicrystalline phase and long-period stacking ordered structure combined reinforced Mg-Zn-Y alloy. The alloy prepared by the method contains the chemical elements in percentage by mass: 10wt% of Zn and Y and the balance of Mg, wherein Zn is added in the form of pure Zn, Y is added in the form of Mg-25wt%Y intermediate alloy, and Mg is industrial pure magnesium. According to the method, alloy structures, obtained after magnesium alloy is subjected to smelting, metal type molding and solid solution and grading aging treatment, are an alpha-Mg solid solution, an icosahedral quasicrystalline phase and a long-period stacking ordered structure phase; a quasi-crystal, which is formed through dispersion precipitation, depends on strong pinning on dislocation and forms a firm interface with a matrix, so that the magnesium alloy can be remarkably reinforced; a long-period structure and a matrix interface are in coherency, so that the thermal stability is very high, the coarsening is not easy, the dislocation motion and the extension of deformation twin crystals can be remarkably hindered, the mechanical properties of the alloy are improved obviously, the tensile strength can reach 352MPa to the maximum, and the elongation percentage can reach 7.5%. The method is beneficial to the promotion of the extensive application of high-strength magnesium alloy in many fields, such as automobiles, aviation and electronic communication.

Owner:EAST CHINA JIAOTONG UNIVERSITY

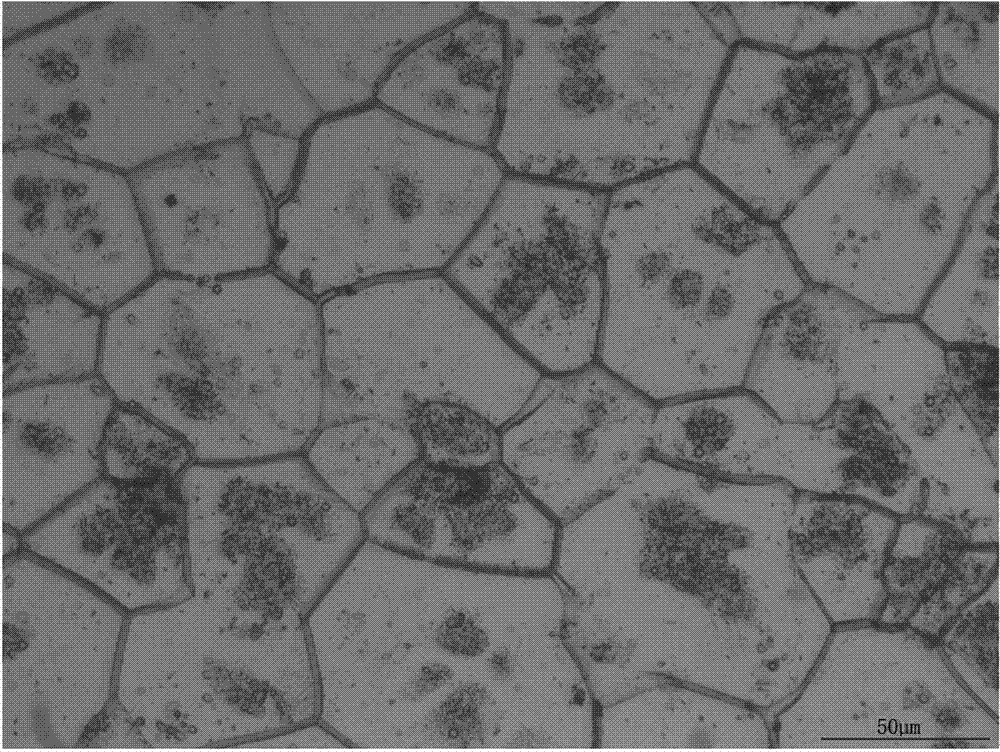

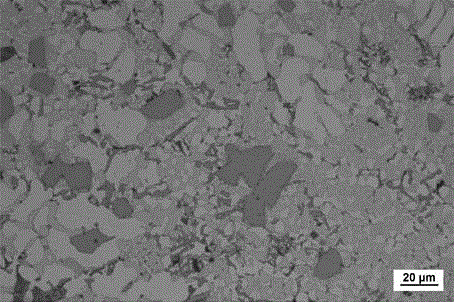

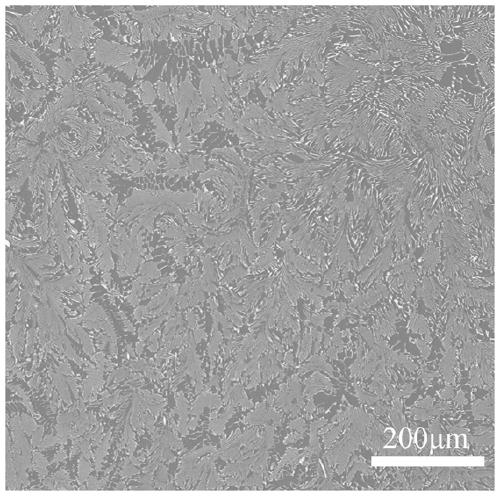

Mg-Gd-Y rare earth magnesium alloy cast ingot homogenization heat treatment method

InactiveCN111560550AEliminate composition segregationEliminate internal stressRail transitMaterials science

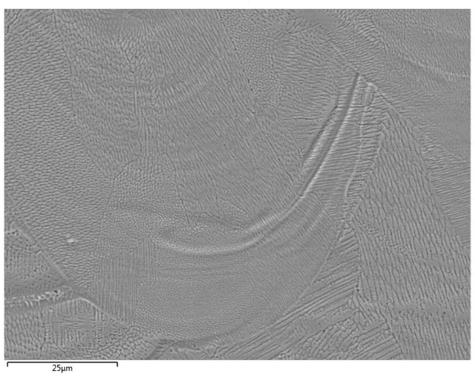

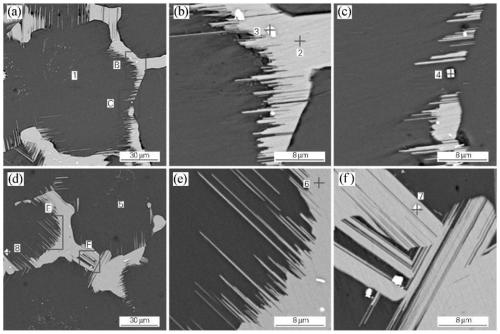

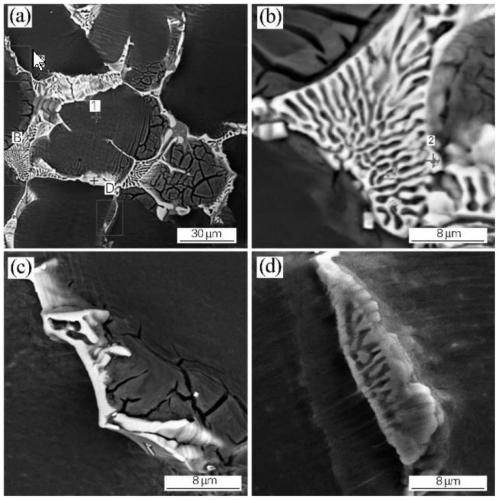

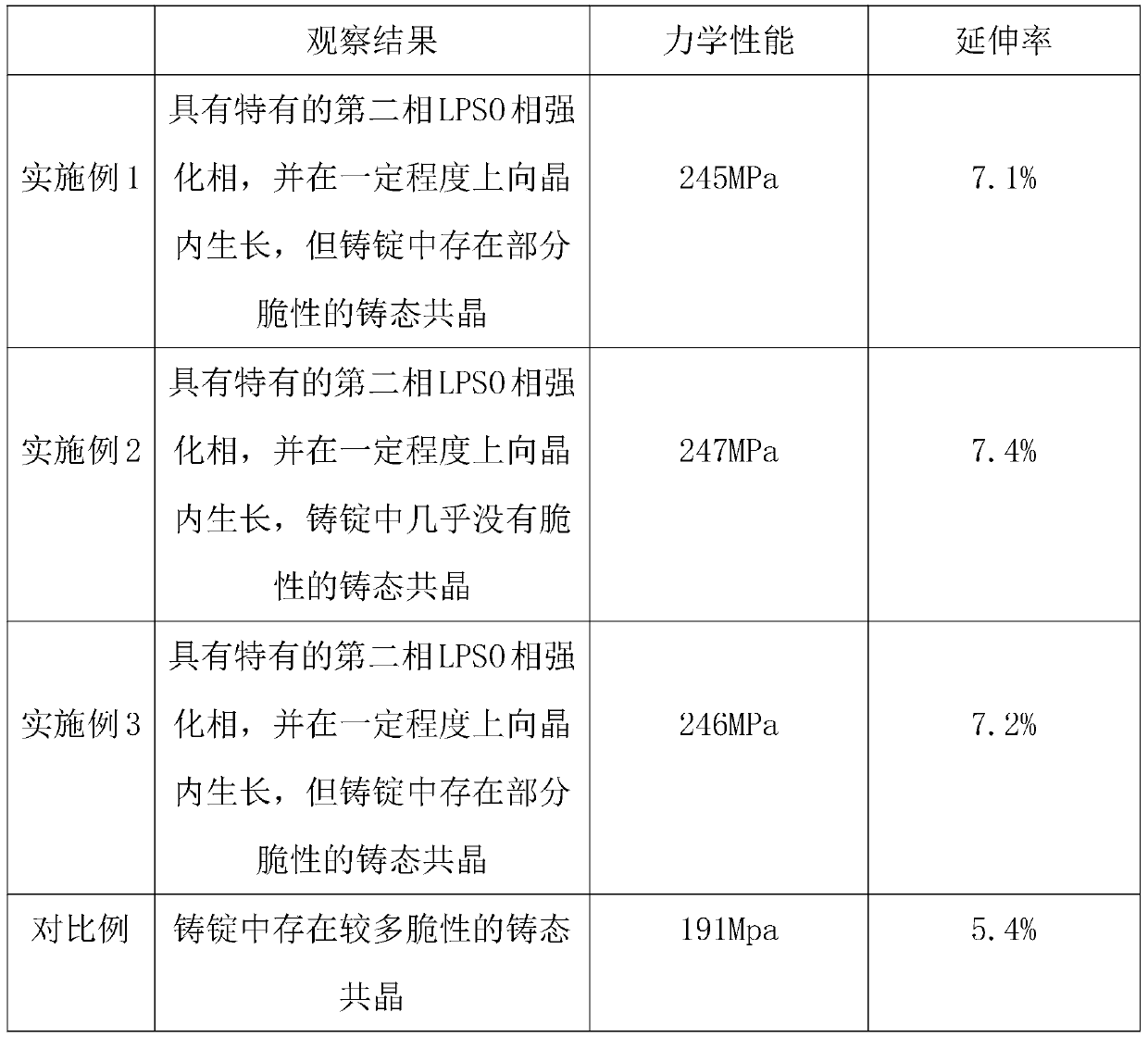

The invention discloses a Mg-Gd-Y rare earth magnesium alloy cast ingot homogenization heat treatment method, and particularly relates to the technical field of magnesium alloy material preparation. The homogenization heat treatment method comprises the following steps that a magnesium alloy cast ingot is placed in a homogenization heat treatment furnace, the temperature is increased to be 520-525DEG C and kept for at least 10-12 hours, air cooling is carried out at the speed of 60-80 DEG C / h, then cooling is carried out until the room temperature is achieved, and a finished product is obtained. According to the method, a reasonable homogenization annealing system is adopted, so that the component segregation and internal stress of a Mg-Gd-Y rare earth magnesium alloy are eliminated, andparticularly, the growth of strengthening phase LPSO phases of the Mg-Gd-Y alloy in a matrix and crystal grains can be effectively promoted, the strength and heat resistance of the alloy are effectively improved, and the preparation is provided for subsequent plastic forming processing process; and moreover, the method is suitable for rare earth magnesium alloy castings of various sizes, and the performance of rare earth magnesium alloy casting material for aerospace and rail transit is improved.

Owner:CENT SOUTH UNIV

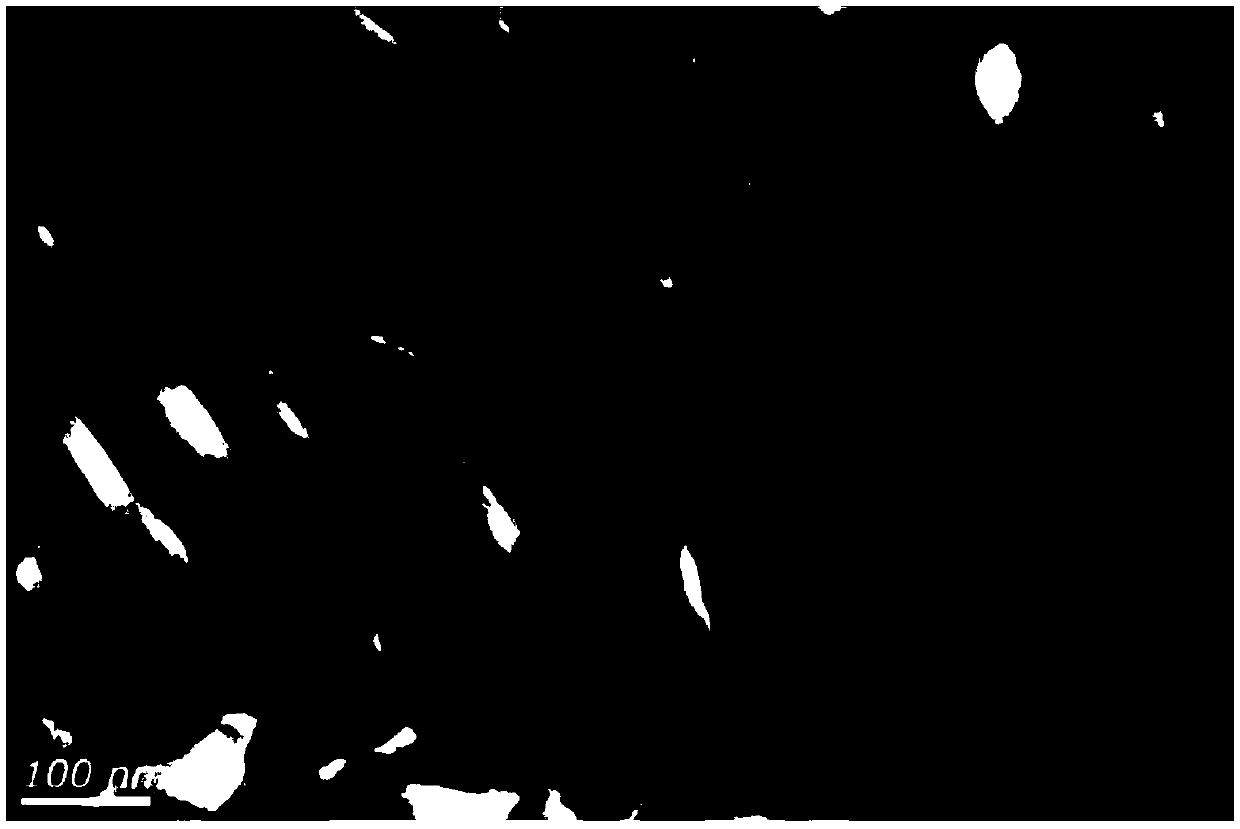

Method for preparing nano quasi-crystal reinforced Mg-Zn-Y alloy by means of equal channel angular pressing

ActiveCN107815579AImprove mechanical propertiesExpand the range of industrial applicationsFurnace temperatureThermal treatment

The invention discloses a method for preparing nano quasi-crystal reinforced Mg-Zn-Y alloy by means of equal channel angular pressing. The method includes the following steps that A, cast-state Mg-Zn-Y alloy is prepared according to the set atomic percentage composition ratio of all components and comprises 0.5%-6% of Zn, 0.08%-1.2% of Y and the balance Mg based on the set atomic percentage composition of all the components, and the atomic percentage composition specific value of the Zn to the Y is 5-7:1; B, the cast-state Mg-Zn-Y alloy is annealed for 8-20h at the temperature of 380-420 DEG C, and furnace cooling is conducted; C, the annealed Mg-Zn-Y alloy is subjected to hot extrusion after heat preservation lasts for 2-4h at the temperature of 300-400 DEG C, the extrusion temperature is300-400 DEG C, and the extrusion ratio is 9-60:1; D, the Mg-Zn-Y alloy processed through hot extrusion in the step C is put into a thermal treatment furnace, the furnace temperature rises to 540-600DEG C, heat preservation lasts for 5-20min, and quenching is performed; and E, the Mg-Zn-Y alloy obtained in the step D is subjected to equal channel angular pressing after heat preservation lasts for2-4h at the temperature of 180-330 DEG C, and accordingly the nano quasi-crystal reinforced Mg-Zn-Y alloy can be obtained. By adoption of the method, the high-performance magnesium alloy with good yield strength, tensile strength and ductility can be prepared.

Owner:SOUTHWEST JIAOTONG UNIV

Surface treatment method for improving corrosion resistance and anti-icing performance of titanium alloy surface

ActiveCN110983257ALower surface energyImprove hydrophobicityVacuum evaporation coatingSputtering coatingMicro nanoBi layer

The invention discloses a surface treatment method for improving corrosion resistance and anti-icing performance of a titanium alloy surface. The method comprises the following steps that S1, surfacepretreatment is performed on the titanium alloy surface by plasma etching; S2, double-layer glow plasma Ni-Cu-Y alloying is carried out on the surface of the titanium alloy, and a Ni-Cu-Y alloy layeris prepared; and S3, construction of micro / nano scale rough structure is preformed on the prepared Ni-Cu-Y alloy layer by plasma etching. According to the method, the plasma etching technology and thedouble glow plasma surface metallurgy method are combined and used for anti-icing and corrosion resistance performance of the titanium alloy surface, and the corrosion resistance and the anti-icing performance of the titanium alloy surface are greatly improved after the surface treatment of the method.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Magnesium-aluminum-zinc-cerium-yttrium alloy and preparation method and application thereof

InactiveCN107150188ALower requirementExtended service lifeWelding/cutting media/materialsSoldering mediaWear resistantMetallic materials

The invention relates to magnesium-aluminum-zinc-cerium-yttrium alloy and a preparation method and application thereof, particularly relates to the wear-resistant magnesium-aluminum-zinc-cerium-yttrium alloy, a bead weld wire of the magnesium-aluminum-zinc-cerium-yttrium alloy and the preparation method of the magnesium-aluminum-zinc-cerium-yttrium alloy and belongs to the field of metal material technologies and metallurgy technologies. The magnesium-aluminum-zinc-cerium-yttrium alloy comprises the chemical ingredients of, in percentage by mass, 5.52-6.55% of Al, 0.43-1.52% of Zn, 0.32-0.65% of Mn, 1.01-2.54% of Ce, 0.24-2.07% of Y and the balance Mg. In the condition of a room-temperature dry friction wear test, after the welding wire of the Mg-Al-Zn-Ce-Y alloy is subjected to bead weld, the relative wear resistance of the welding wire can reach 2.96.

Owner:NORTHEASTERN UNIV

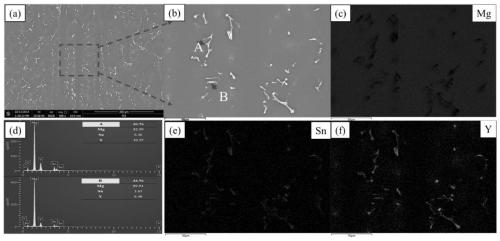

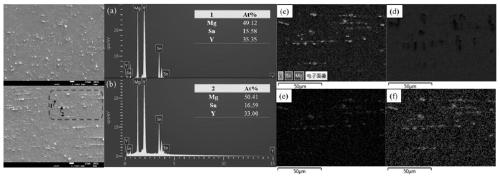

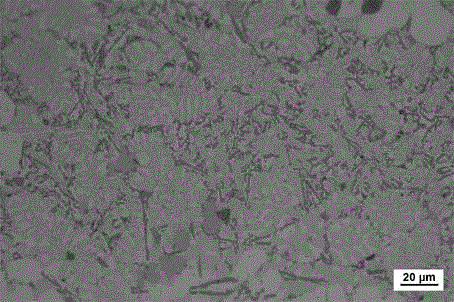

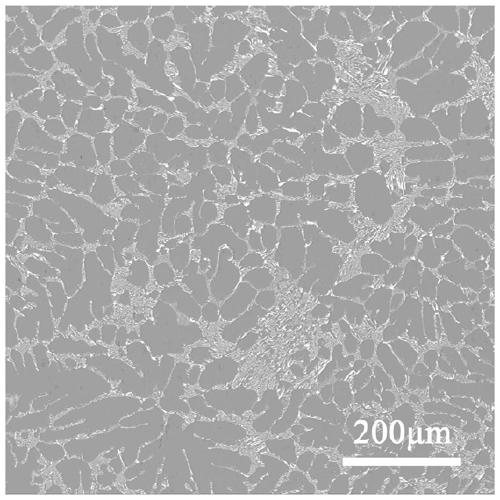

High-strength and high-plasticity cast Mg-Ni-Y alloy and preparation method thereof

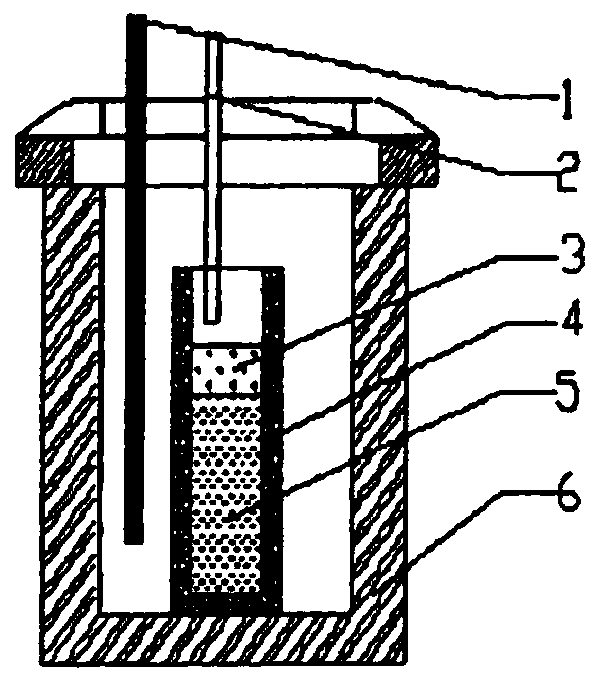

The invention discloses a high-strength and high-plasticity cast Mg-Ni-Y alloy and a preparation method thereof. The high-strength and high-plasticity cast Mg-Ni-Y alloy is prepared from the followingcomponents in percentage by mass: 1-5% of Ni, 1-10% of Y and the balance of Mg. According to the high-strength and high-plasticity cast Mg-Ni-Y alloy and the preparation method thereof, a magnesium alloy is strengthened through long-period ordered phases, and the mechanical properties of the prepared as-cast state Mg-Ni-Y alloy at the room temperature can be achieved, specifically, the compressive strength is 430-490 MPa, and the elongation rate is 26-34%; and the alloy is smelted through a vacuum suspension smelting furnace, direct casting forming is conducted, inclusions in the smelting process can be reduced, the uniformity of the alloy components is improved, the subsequent homogenization treatment process is reduced, energy sources are saved, and the production efficiency is improved. Compared with the prior art, a preparation technology of the high-strength and high-plasticity cast Mg-Ni-Y alloy is simpler, the strength of the alloy is improved, the elongation rate of the alloyis increased, and the application range of the magnesium alloy in the field of cars is expanded.

Owner:SHANGHAI UNIV

Heat resistant magnesium alloy and preparation method thereof

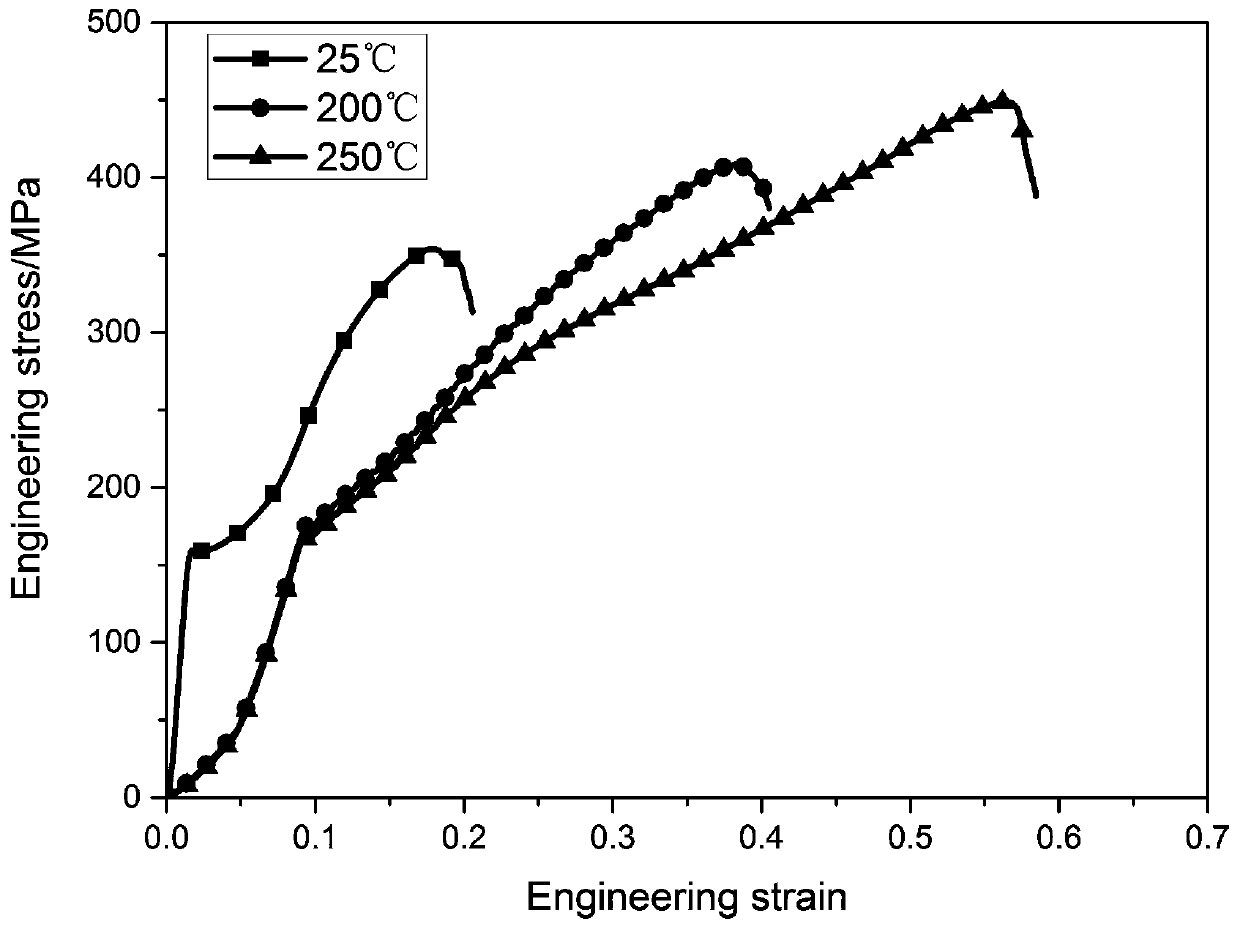

The invention relates to a heat resistant magnesium alloy and a preparation method thereof. The heat resistant magnesium alloy is a Sn3Y5 phase-containing Mg-Sn-Y alloy. The Sn3Y5 phase-containing Mg-Sn-Y alloy is prepared from the following components in percentage by weight: 0.3 to 0.7 percent of Sn, 2 to 5 percent of rare-earth yttrium and the balance of Mg. The preparation method comprises thefollowing steps of preparing materials, smelting, casting, homogenizing and performing hot extrusion. The heat resistant magnesium alloy is a deformed magnesium alloy which contains a nano-scale precipitated phase and a high-thermal stability enhanced phase (Sn3Y5). The alloy shows an abnormal temperature effect of compressive strength at the temperature below 200 and 250 DEG C; the compressive strengths are respectively 408 MPa and 448 MPa, which are far higher than the room temperature compressive strength 353 MPa; and meanwhile, excellent plasticity is maintained. Compared with other heatresistant magnesium alloy, the alloying element content is low, so that the heat resistant magnesium alloy has the advantage of low cost.

Owner:SOUTHWEST JIAOTONG UNIV

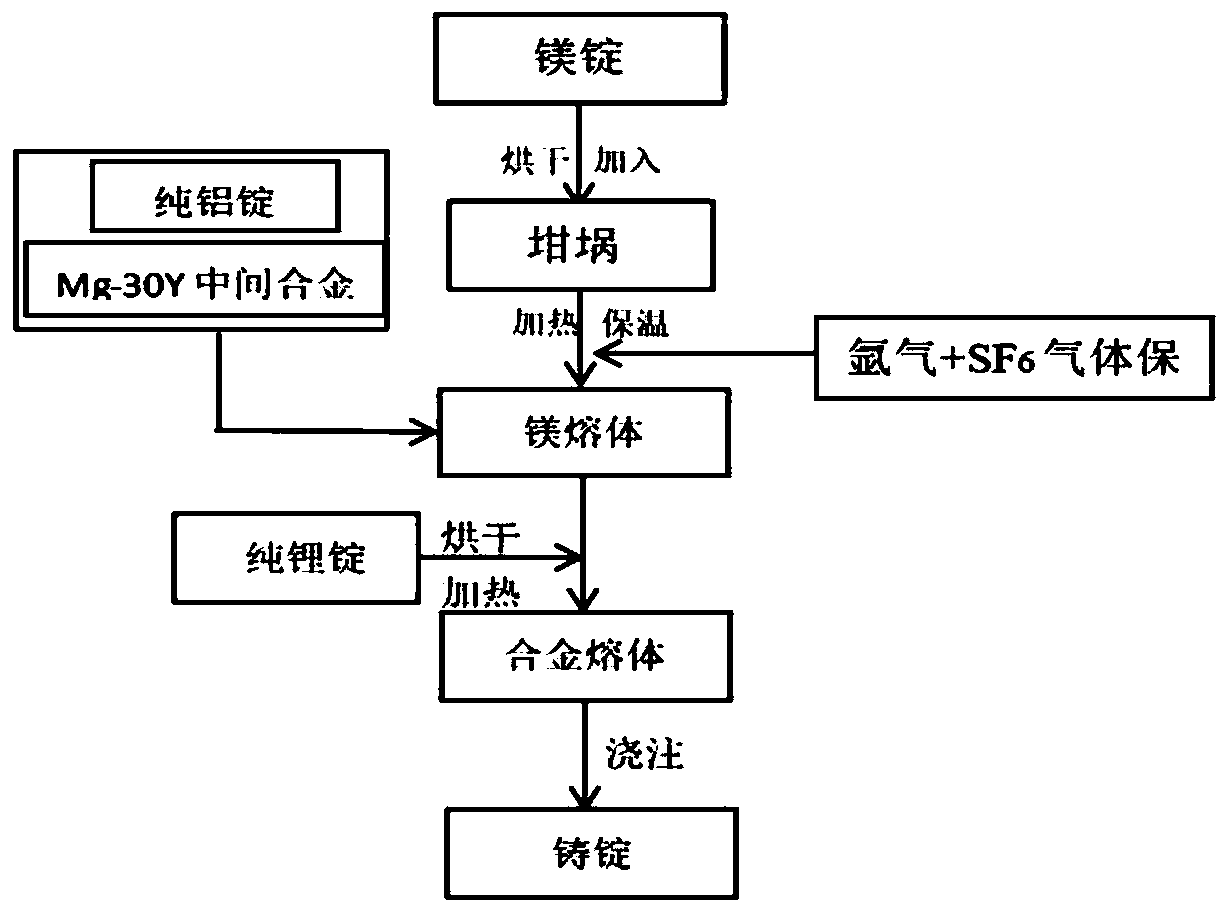

Rare earth yttrium doped magnesium-lithium alloy and preparation method thereof

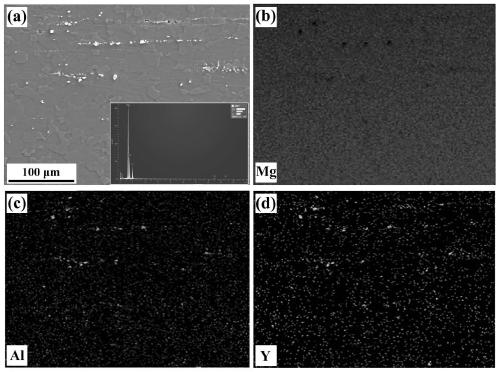

The invention discloses a rare earth yttrium doped magnesium-lithium alloy and a preparation method thereof, and belongs to the technical field of alloy smelting. The rare earth yttrium doped magnesium-lithium alloy is mainly composed of, by mass percent, 3.8%-4.2% of Li, 0.5%-1.0% of Al, 0.2%-1.0% of Y and the balance Mg and impurities. According to the rare earth yttrium doped magnesium-lithiumalloy and the preparation method thereof, the relation between the chemical ingredients, structure and performance of the prepared Mg-Al-Y alloy is studied, and the strengthening and toughening mechanism of the alloy is disclosed. By means of changing the crystal structure of the alloy, refining grains, generating high-melting-point hard phases and the like, the strength of an Mg-Li alloy is improved on the premise of guaranteeing the plasticity, and certain reference bases are provided for actual application of the Mg-Li-Al alloy.

Owner:QINGHAI UNIVERSITY

Nanometer quasi-eutectic enhanced Mg-Zn-Y alloy preparation method

The invention discloses a nanometer quasi-eutectic enhanced Mg-Zn-Y alloy preparation method, which comprises the following steps: A, preparing a cast Mg-Zn-Y alloy according to set atom percentage proportions of each component, i.e., 0.5 to 3 percent of Zn, 0.08 to 0.6 percent of Y and the balance of Mg, the atom percentage ratio of Zn and Y being (5-7):1; B, annealing the cast Mg-Zn-Y alloy for8 to 20h at 380 to 420 DEG C, and performing furnace cooling; C, preserving head of the annealed cast Mg-Zn-Y alloy for 2 to 4h at 300 to 400 DEG C, and performing hot extrusion treatment; D, heatingthe Mg-Zn-Y alloy subjected to hot extrusion processing in step C to 550 to 600 DEG C in a heat treatment furnace along with the furnace, preserving the heat for 5 to 20min, and then performing quenching treatment, so as to obtain a nanometer quasi-eutectic enhanced Mg-Zn-Y alloy. According to the preparation method, an (alpha-Mg+I-phase) quasi-eutectic enhanced Mg-Zn-Y alloy with a lamellar spacing of smaller than 50nm can be obtained.

Owner:SOUTHWEST JIAOTONG UNIV

Aluminum-silicon-copper-yttrium solder for silicon carbide particle reinforced aluminum matrix composite soldering and preparation method for aluminum-silicon-copper-yttrium solder

InactiveCN105479032ALow melting pointImprove ductilityWelding/cutting media/materialsSoldering mediaMaterials scienceAluminum matrix composites

The invention discloses aluminum-silicon-copper-yttrium solder for SiC particle reinforced aluminum matrix composite soldering and a preparation method for the aluminum-silicon-copper-yttrium solder, and belongs to the technical field of welding solder. The solder comprises, by mass, 20.0%-28.0% of Cu, 6.5%-10.0% of Si, 0.05%-0.5% of Y, and the balance Al. The preparation method includes the following steps that A, Al and Al-Si alloy are placed in a crucible of a vacuum induction melting furnace, and high-purity argon is introduced after vacuumizing; B, the temperature is increased to 700 DEG C-800 DEG C through heating, and Al-Si-Cu alloy is formed; C, at the temperature of about 700 DEG C, Al-Y alloy is added, and after heat preservation is conducted at the temperature of 600 DEG C and standing is conducted, casting is conducted through a forming mold; and D, solder alloy is taken out, and after surface oxide skin is removed, remelting is conducted twice according to the same method. The solder is low in preparation temperature, good in wettability, capable of being well combined with a matrix and easy to control.

Owner:HENAN POLYTECHNIC UNIV

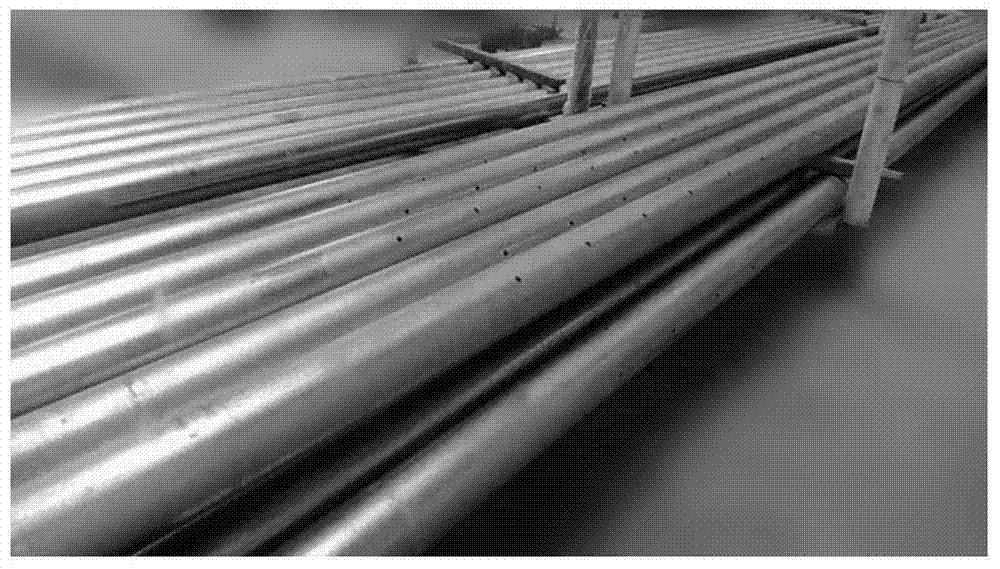

Nickel-tungsten-based alloy coating screen pipe for high-salinity oil-gas well containing hydrogen sulfide and carbon dioxide

ActiveCN103527158AImprove corrosion resistanceEffective protectionFluid removalAlloy coatingMaterials science

The invention relates to a sand prevention filtering screen pipe for a high-salinity oil-gas well containing hydrogen sulfide and carbon dioxide in oil and gas production operation. A preparation method includes uniformly plating a nickel-tungsten-based alloy coating with high abrasion resistance and resistance to the hydrogen sulfide, the carbon dioxide and saturated brine corrosion on the outer surface of a common sulfur-resistant screen pipe, and the nickel-tungsten-based alloy coating comprises external threads at two ends and uniformly distributed through holes. The nickel-tungsten-based alloy coating is a Ni-W-X alloy coating or Ni-W-Y alloy coating or Ni-W-X-Y alloy coating, wherein X refers to Co and / or Fe, and Y refers to P and / or B. The screen pipe simultaneously has the advantages of high strength of the common screen pipe, high corrosion prevention and high abrasion resistance of tungsten alloy and the like, can effectively replace a stainless steel screen pipe, a high-chrome screen pipe and a nickel-based alloy screen pipe and is used for the oil-gas well containing the hydrogen sulfide, the carbon dioxide and saturated brine, and the manufacturing cost of the screen pipe is greatly saved. The screen pipe further has the advantages that base pipe models and drilling types can be randomly selected by customers, and the screen pipe is high in adaptability, wide in application range and the like.

Owner:湖南常德纳菲尔新材料科技有限公司

Mg-Li-Al-Zn-Y cast magnesium lithium alloy and preparation method thereof

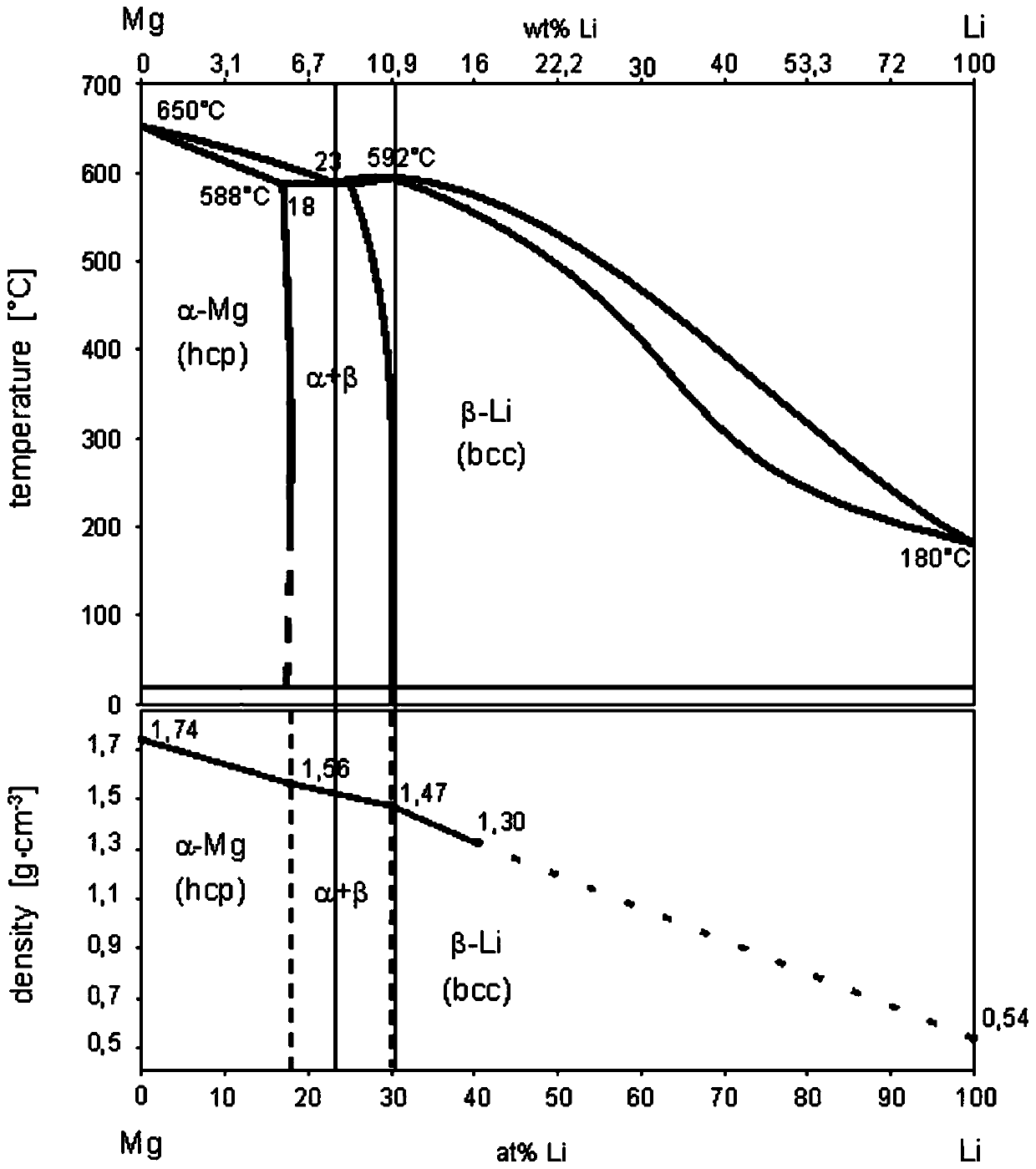

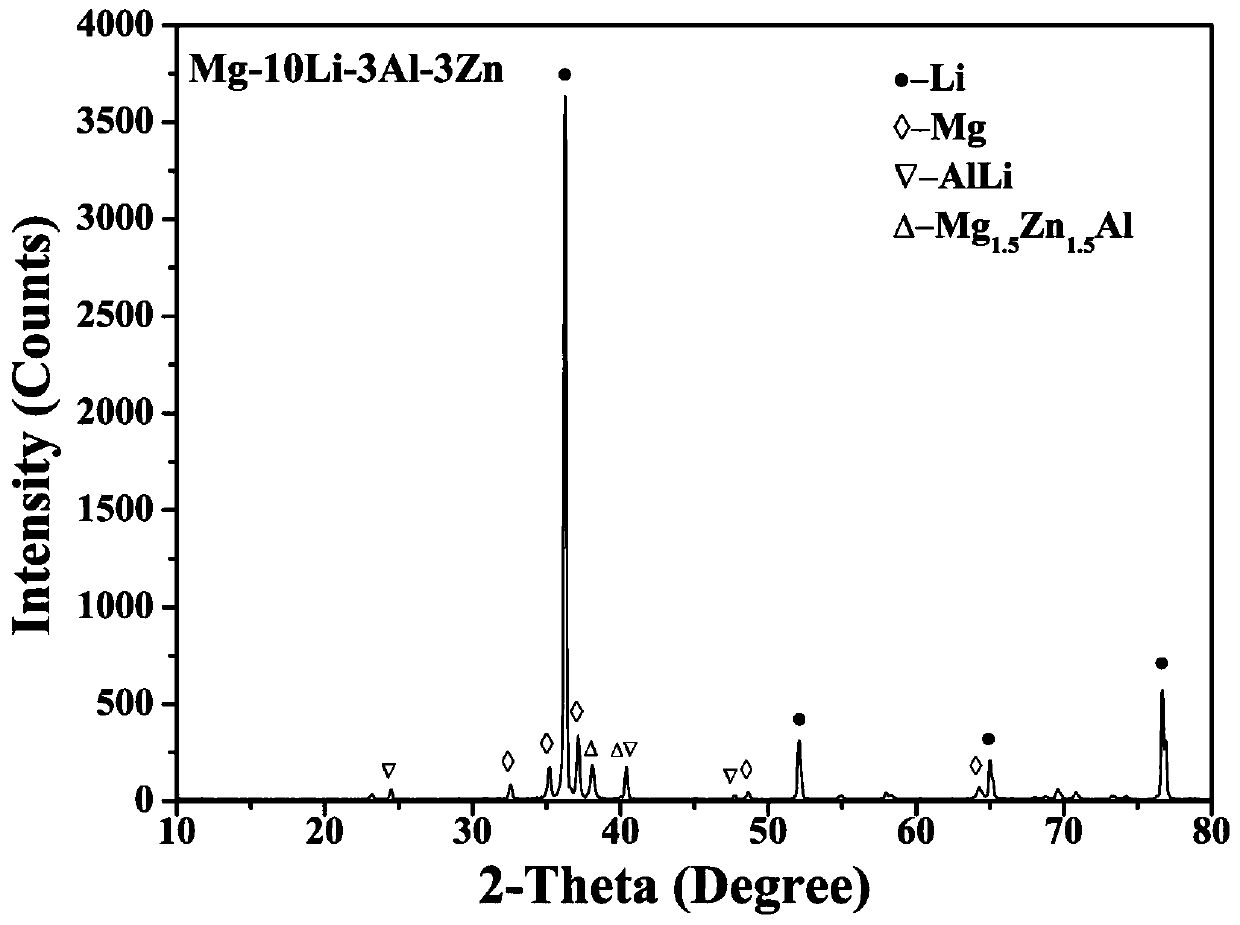

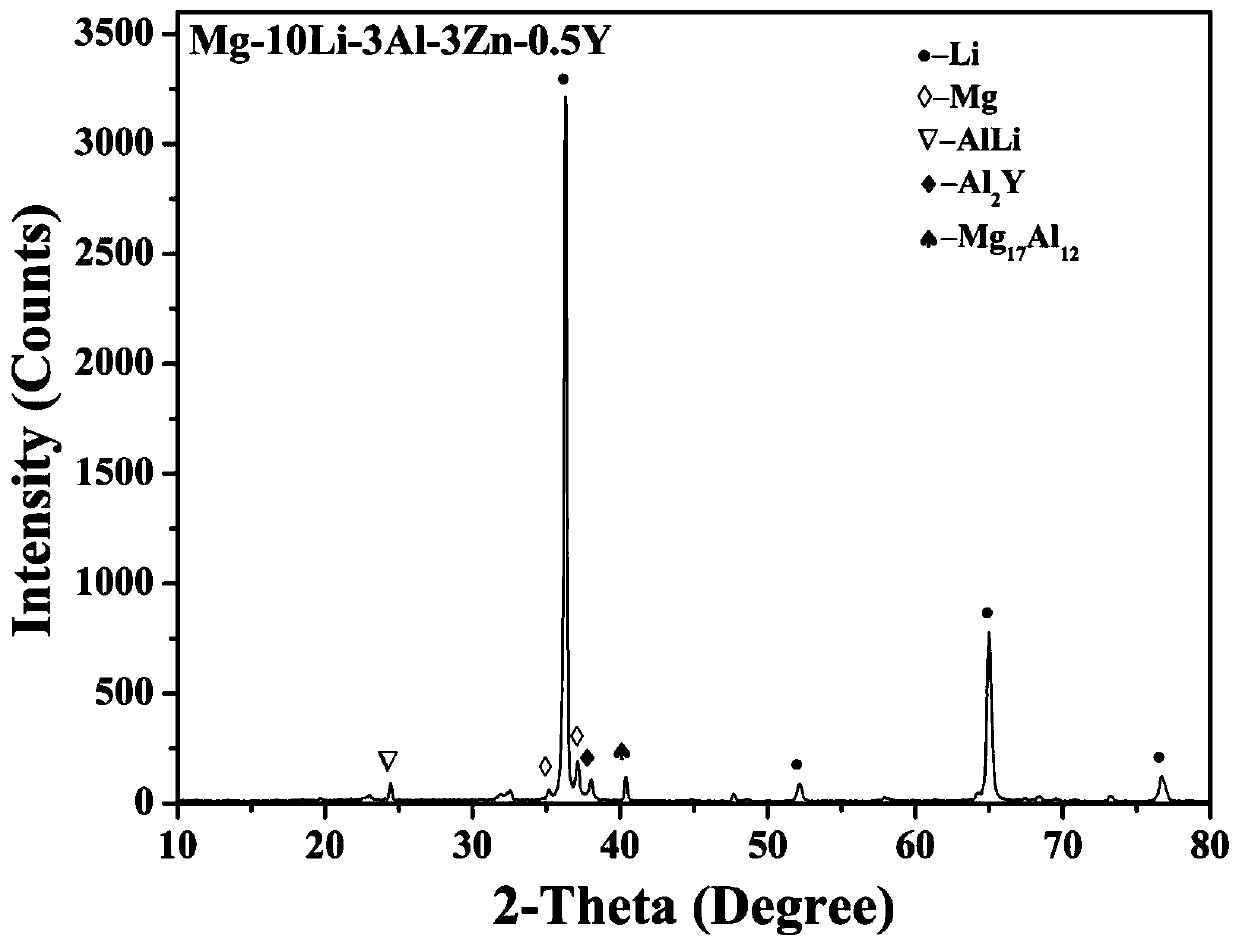

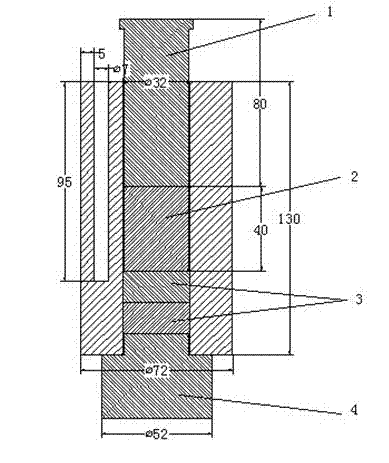

The present invention provides an Mg-Li-Al-Zn-Y cast magnesium lithium alloy and a preparation method thereof. Alloy elements are located in an alpha+beta biphasic region and a beta single-phase region of an Mg-Li binary phase diagram, and an alloy system is Mg-Li-Al-Zn-Y. The alloy comprises, by mass, 8%-11% of Li, 3%-4% of Al, 2.5%-3.5% of Zn, 0.5%-1.2% of Y, the balance Mg and unavoidable impurities, and the cast Mg-Li-Al-Zn-Y alloy is light and high in intensity. According to the preparation of the alloy, Mg, Li, Al, Zn and Mg are used as raw materials, an iron crucible is used in magnesium alloy induction melting and casting equipment to be protected by vacuum melting argon, and after casting cooling, the Mg-Li-Al-Zn-Y alloy is obtained. The Mg-Li-Al-Zn-Y cast magnesium lithium alloyhas low density, the density scope is 1.52g / cm<3>-1.56g / cm<3>, the addition of the alloy element improves the tensile strength of the magnesium lithium alloy, and the tensile strength range is 180-244MPa. The prepared Mg-Li- Al-Zn-Y alloy contains reinforcing phases such as AILi, Al2Y and Mg17Al12. According to the preparation method, the preparation process is simple, and the prepared Mg-Li-Al-Zn-Y alloy has good mechanical properties and is suitable for industrial production.

Owner:SHAANXI UNIV OF SCI & TECH

Solid treatment method for improving strength performance of Mg-Zn-Y alloy

The invention discloses a solid treatment method for improving the strength performance of an Mg-Zn-Y alloy. The method comprises shred preparation of Mg97ZnY2 alloy blank ingots, chipped shred cold pressing, hot pressing consolidating, and extrusion molding. Compared with casting state alloys, an Mg97ZnY2 alloy prepared through the method disclosed in the invention has the advantages of obviously refined structure and substantially improved strength performance, wherein the compressive strength of the Mg97ZnY2 alloy is improved to 487-534MPa from 346MPa, so the increase rate is about 40-50%; the tensile strength is improved to 321-397MPa from 157MPa, so the increase rate is about 104-152%; and the tensile strain at break is improved to 12.7-17.4% from 10.3%, so the increase rate is about 23-71%.

Owner:东莞市镁皓镁合金科技有限公司

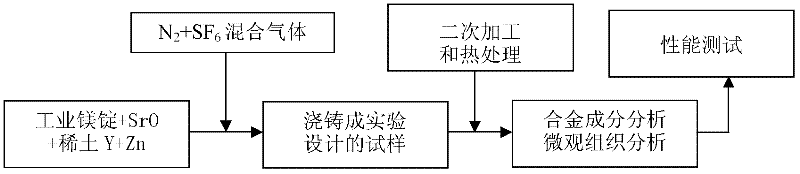

A kind of preparation technology of heat-resistant mg-sr-zn-y alloy

The invention provides a preparation process of a heat-resistant Mg-Sr-Zn-Y alloy. In the preparation process, an industrial pure magnesium ingot and strontium carbonate are used as raw materials, small amounts of rare earth Y and metal Zn are added, and the Mg-Sr-Zn-Y alloy is prepared by using a melting-dipping thermal reduction method. The preparation process provided by the invention has the beneficial effects that inexpensive metal Zn particles are used for substituting for part of expensive rare earth Y, thereby realizing the development on the low-cost and high-heat-resistance Mg-Sr-Zn-Y alloy.

Owner:JIAMUSI UNIVERSITY

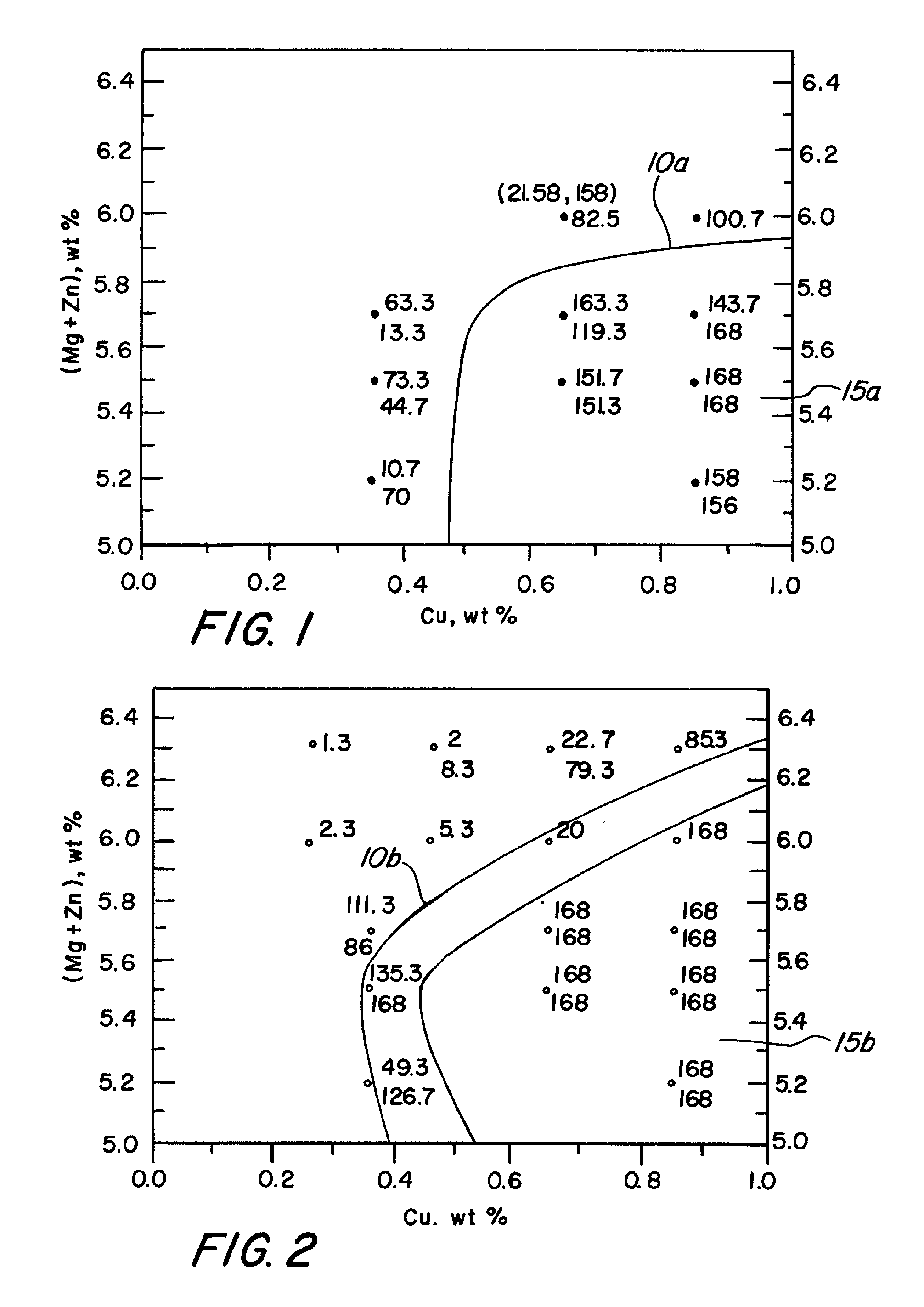

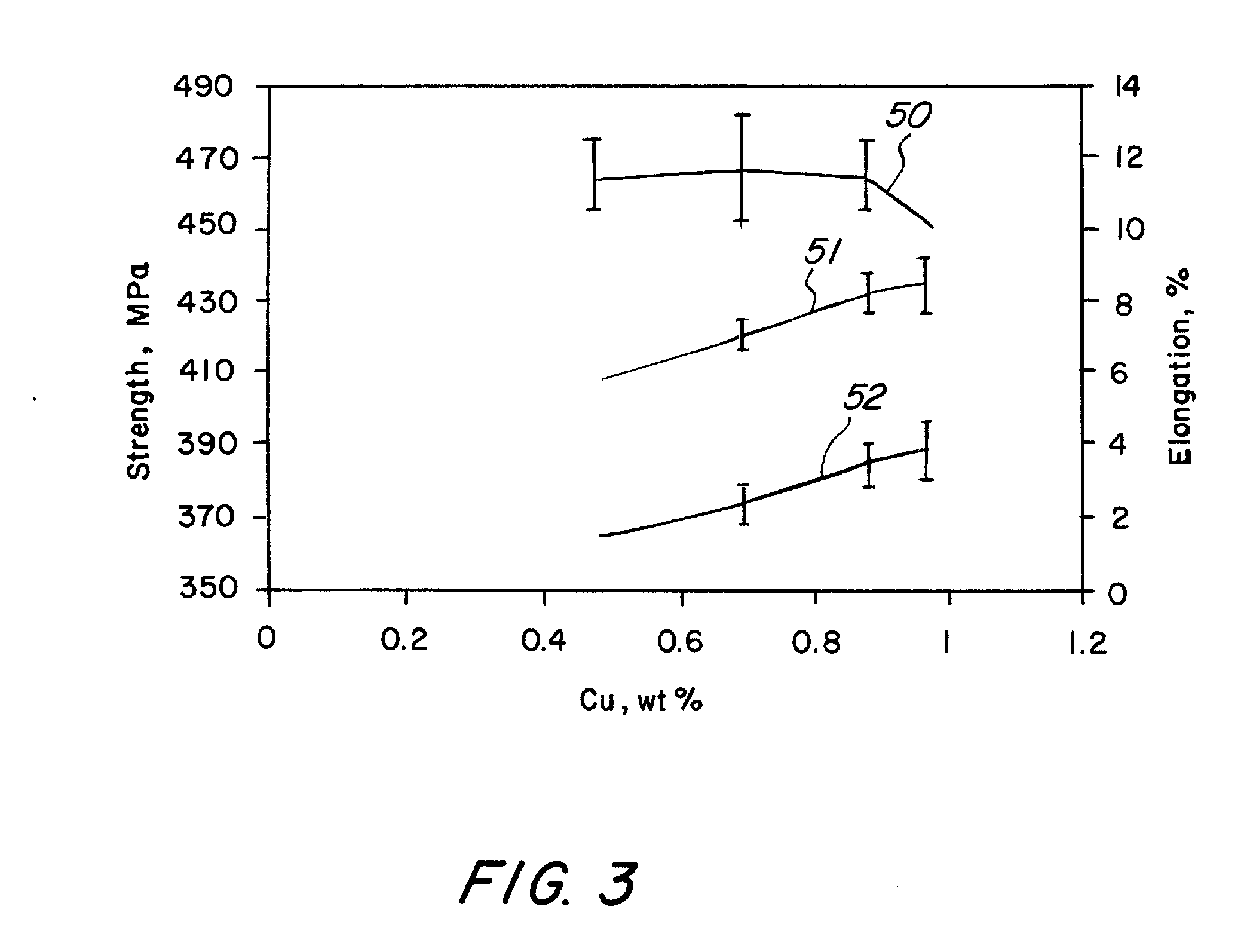

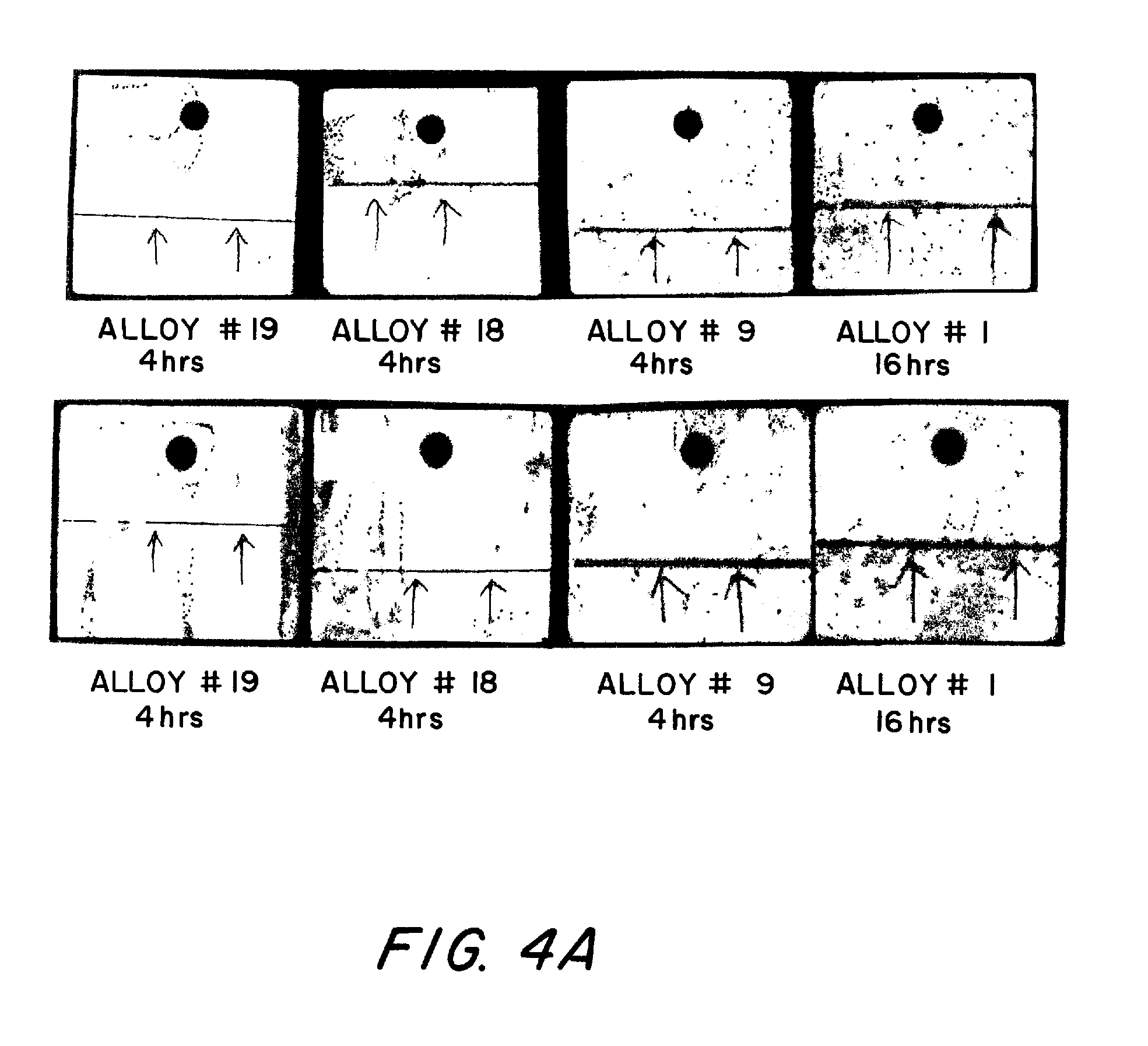

HIGH STRENGTH, HIGH STRESS CORROSION CRACKING RESISTANT AND CASTABLE Al-Zn-Mg-Cu-Zr ALLOY FOR SHAPE CAST PRODUCTS

The present invention provides an Al—Zn—Mg—Cu casting alloy that provides high strength for automotive and aerospace applications and optimized stress corrosion cracking resistance in highly corrosive and tensile environments. The inventive alloy composition includes about 3.5 wt. % to about 5.5 wt. % Zn; about 1.0 wt. % to about 3.0 wt. % Mg; about 0.5 wt. % to about 1.2 wt. % Cu; less than about 1.0 wt. % Si; less than about 0.30 wt. % Mn; less than about 0.30 wt. % Fe; and a balance of Al and incidental impurities.

Owner:LIN JEN C +10

Biodegradable zinc alloy anastomotic apparatus and preparation method thereof

InactiveCN111803721AAnastomosis is firmSimple and fast operationSuture equipmentsTissue CompatibilityAbsorbable suture

The invention discloses a degradable zinc alloy anastomotic apparatus and a preparation method thereof. The degradable zinc alloy anastomotic apparatus uses a degradable Zn-Li-Mn-Y alloy as a material, and the degradable Zn-Li-Mn-Y alloy includes the following components: 0-1 wt.% of Li, 0-1 wt.% of Mn and 0-1 wt.% of Y, without including 0, and the rest are Zn and unavoidable impurities. The degradable zinc alloy anastomotic apparatus includes any one of absorbable suture, medical zipper, anastomotic nail, anastomotic ring, anastomotic clip, anastomotic cannula or vascular clamp. The degradable zinc alloy anastomotic apparatus of the invention is excellent in mechanical properties, simple and convenient in operation, firm in anastomosis, capable of being decomposed in tissues or organs, capable of being fully absorbed by tissues and high in tissue compatibility.

Owner:GUANGDONG GENERAL HOSPITAL

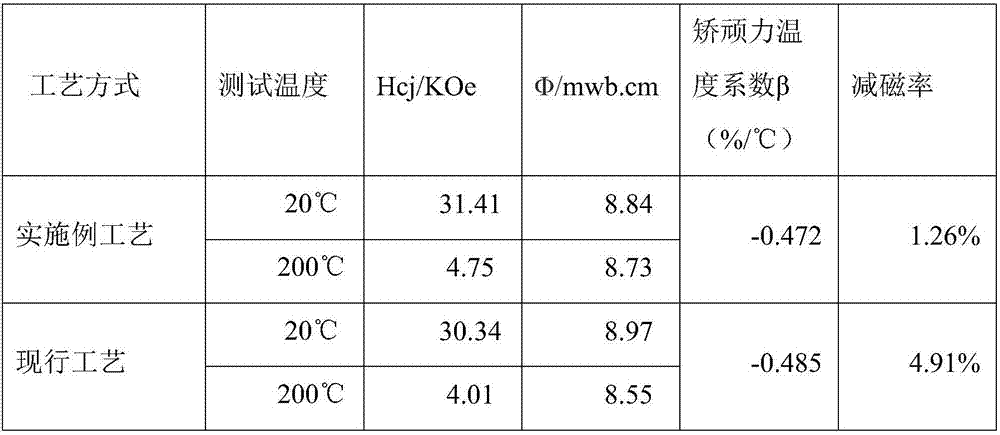

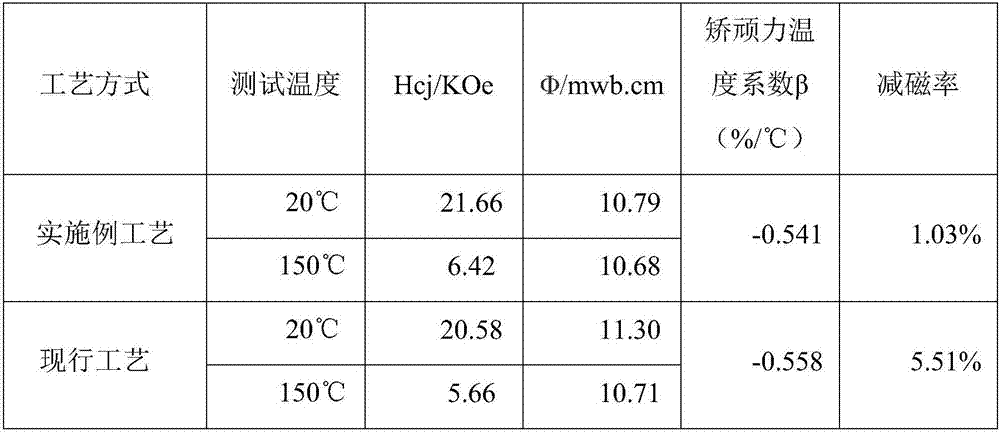

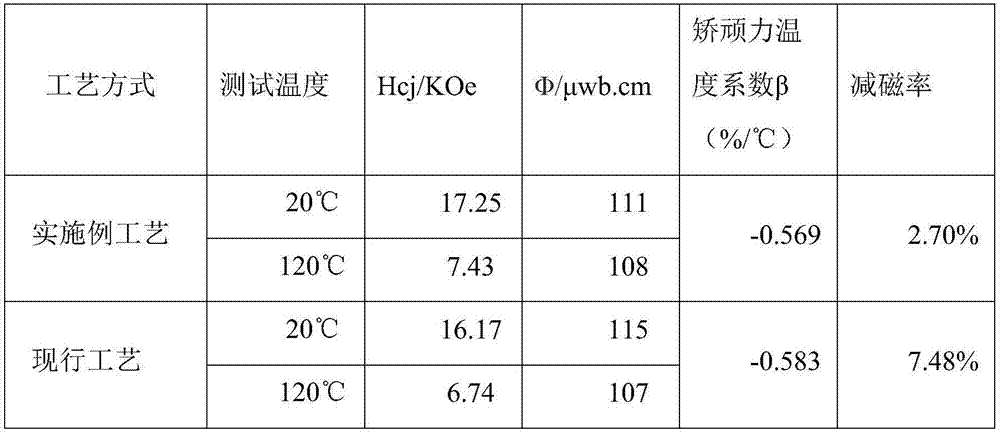

Preparation method for high-thermal-stability NdFeB magnet

ActiveCN107403675AHigh Curie temperatureImprove the temperature coefficient of magnetic inductionInductances/transformers/magnets manufactureMagnetic materialsY alloyMelt spinning

The invention relates to a preparation method for a high-thermal-stability NdFeB magnet. The preparation method comprises the steps of taking X alloy Nd3.5Dy30Fe65Nb0.4B1.1 and Y alloy Nd33.5Fe35Co30Nb0.4B1.1 as raw materials; uniformly mixing X alloy powder and Y alloy powder according to a mass ratio of 1 : 3 to 1 : 28 to prepare mixed powder; and performing pressing forming on the mixed powder in a magnetic field to prepare an NdFeB green body. By controlling a ratio of the two initial alloys, the composition and performance of the magnet are controlled; the NdFeB green body is subjected to vacuum sintering and aging treatment to obtain the high-performance and high-thermal-stability NdFeB magnet with the practical value; and the preparation process comprises the following steps of smelting or melt-spinning, hydrogen explosion, powder preparation, pressing, vacuum sintering and aging treatment.

Owner:廊坊京磁精密材料有限公司

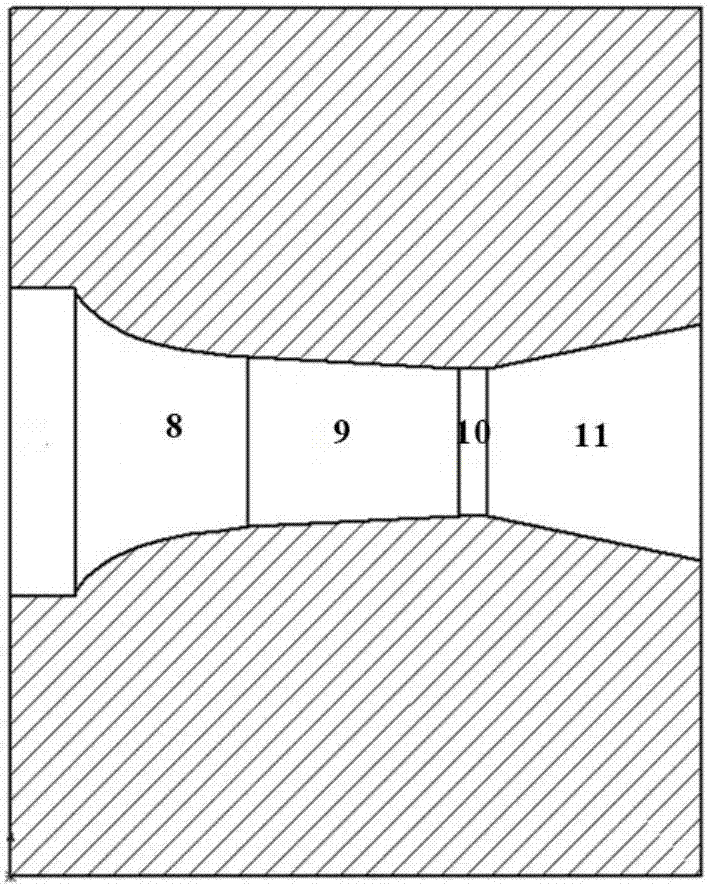

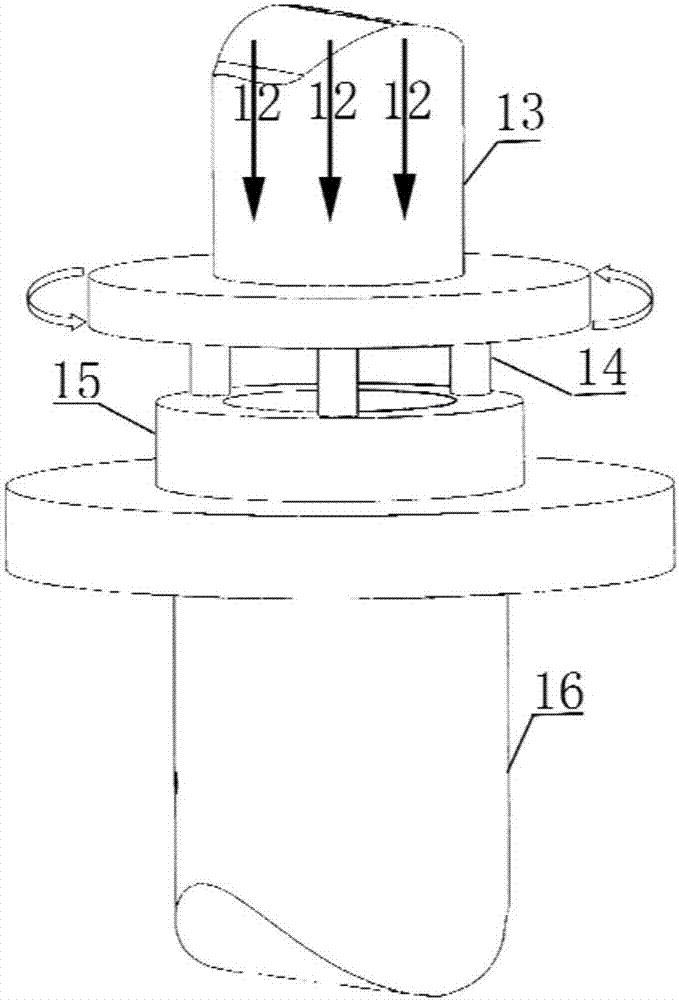

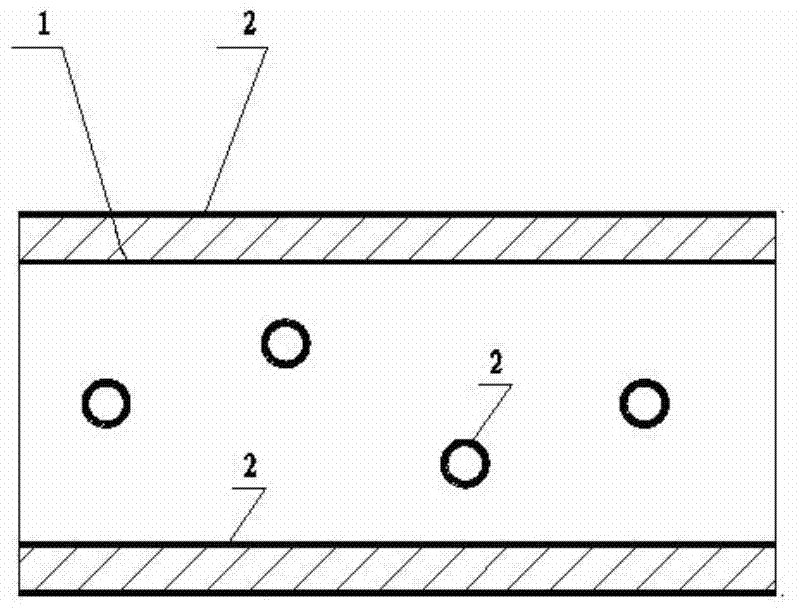

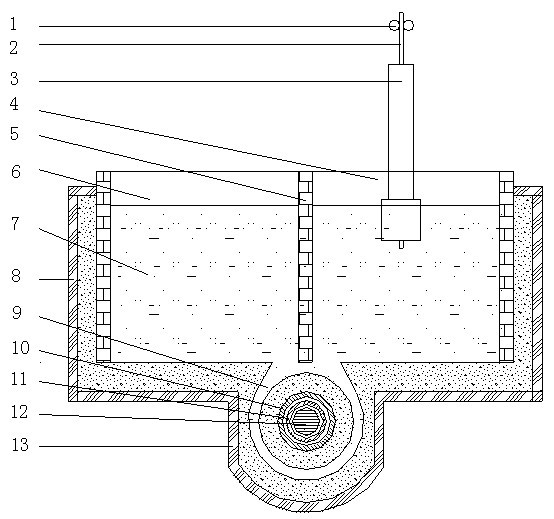

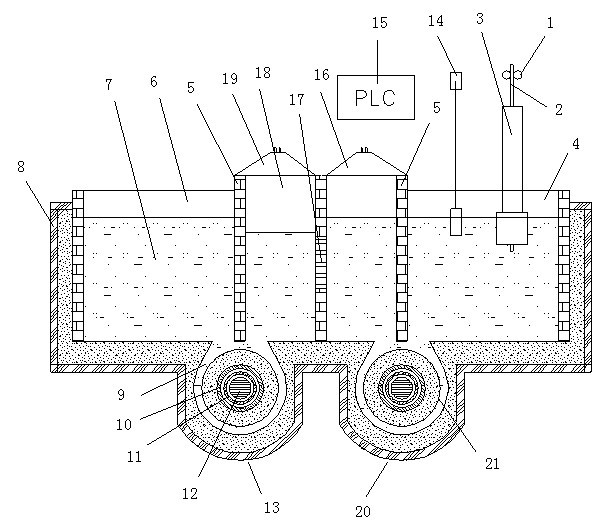

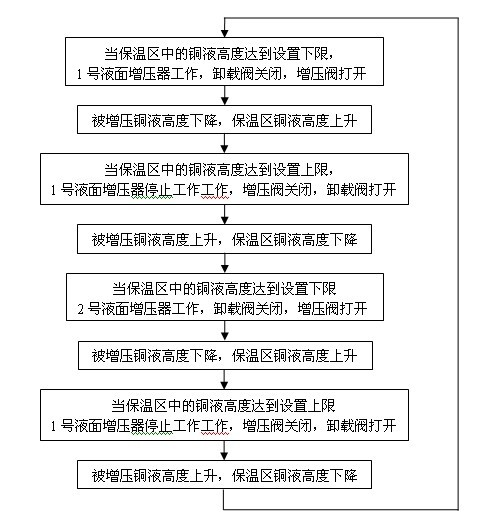

Double-molten channel three-body alloy smelting furnace with boosted stirring of liquid level

ActiveCN102022911AIncreased diffusion areaSpread evenlyCrucible furnacesEndless core furnacesDiffusionAlloy element

The invention relates to a double-molten-channel three-body alloy smelting furnace with boosted stirring of liquid level, comprising a furnace body (8). The three-body alloy smelting furnace is characterized in that the furnace body (8) is divided into three zones in total from front to back, namely, a smelting zone (6), a diffusion zone (18) and an insulating zone (4), wherein the smelting zone (6) and the diffusion zone (18) are connected by a molten channel I (9) arranged in a sensing chamber 1 (13) at the bottom of the furnace body (8), and the diffusion zone (18) and the insulating zone (4) are connected by a melting channel II (21) arranged in a sensing chamber 2 (13) at the bottom of the furnace body (8); the diffusion zone (18) is divided into a front zone and a rear zone by a partitioning plate (17) with a intercommunicating pore in the middle, the tops of the front zone and the back zone are respectively provided with a liquid level booster 1 (16) and a liquid level booster 2 (19); and the top of the insulating zone (4) is provided with a crystallizer (3), and also is provided with a liquid level control device (14) with a floating block. By utilizing the double-molten-channel three-body alloy smelting furnace, the blocking of the molten channels can be prevented, and alloy elements are uniformly diffused.

Owner:CHINA RAILWAY CONSTR ELECTRIFICATION BUREAU GRP KANG YUAN NEW MATERIALS CO LTD

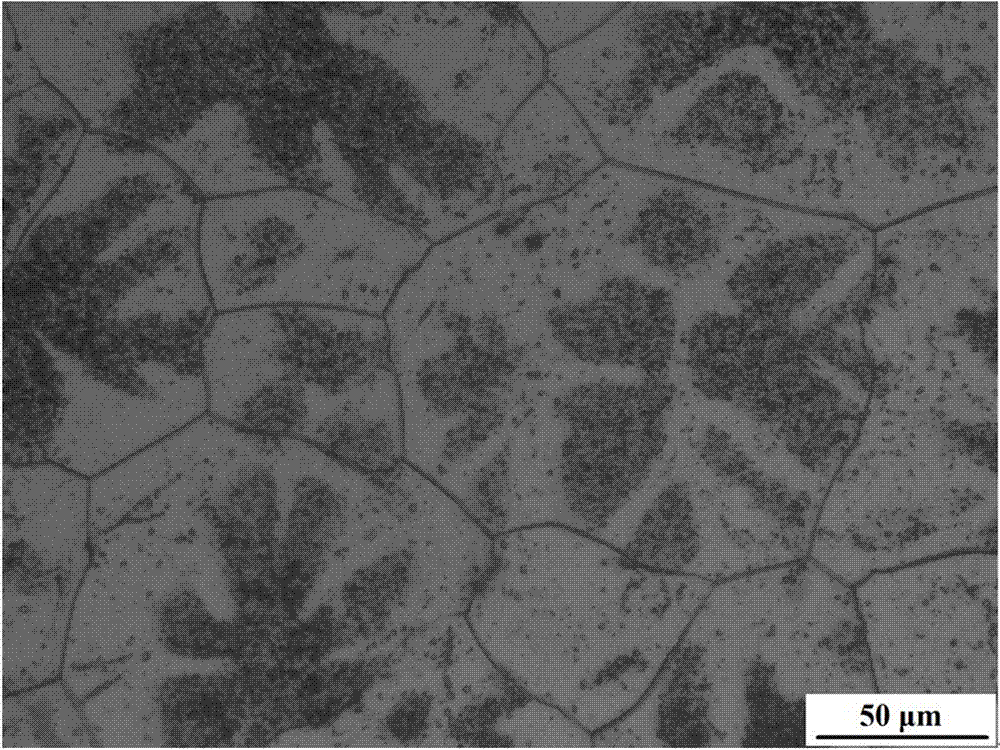

Mg-Gd-Y alloy with high strength and ductility and heat resistance and suitable for low pressure casting and preparation method thereof

The invention provides an Mg-Gd-Y alloy with high strength and ductility and heat resistance and suitable for low pressure casting and a preparation method thereof. The Mg-Gd-Y alloy is prepared fromthe chemical components in percentage by mass: 3.0% to 7.0% of RE, 1.2% to 4.2% of Zn, 0.5% to 1.2% of Al, 0.1% to 0.3% of Mn, 0.01% to 0.08% of M, and the balance of Mg; and M is one or two elementsin Ti and B. The prepared method includes the steps that (1) a material is prepared according to Mg-Gd-Y alloy components; (2) an industrial pure magnesium ingot is melted; (3) a temperature rises to700 DEG C, and industrial pure zinc, and Mg-Gd, Mg-Y and Mg-Mn intermediate alloys are melted; (4) the temperature rises to 730 DEG C, an industrial pure aluminium ingot, and Al-Ti, Al-Ti-B, and Al-Bintermediate alloys are added and all melted, and then magnesium alloy fondant is obtained though refining; (5) low pressure casting is conducted; and (6) second-level solution treatment and artificial aging treatment are conducted. After the Mg-Gd-Y alloy with the high strength and ductility and heat resistance and suitable for low pressure casting is subjected to low pressure casting, second-level solution treatment and artificial aging treatment, indoor temperature extension strength reaches 307 Mpa, and ductility is 17%; and high temperature tensile extension strength at 200 DEG C reaches216 Mpa, ductility is 23%, and the high-end needs of industries of aerospace, automobiles and the like for light weight development are met.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Pt ALLOY FOR JEWELRY

Because high quality alloys are preferred in jewelry items made of a Pt alloy, alloys containing 95 mass% of Pt (Pt950) are required, but Pt950 alloys exhibit low hardness, and therefore suffer from problems such as being easily damaged or deformed during use. Such problems can be solved by using a Pt alloy for jewelry which contains 0.5-4.5 mass% of Ga and 0.5-3.5 mass% of In, with the remaindercomprising 95 mass% of Pt.

Owner:KOBO GLEAM CO LTD +1

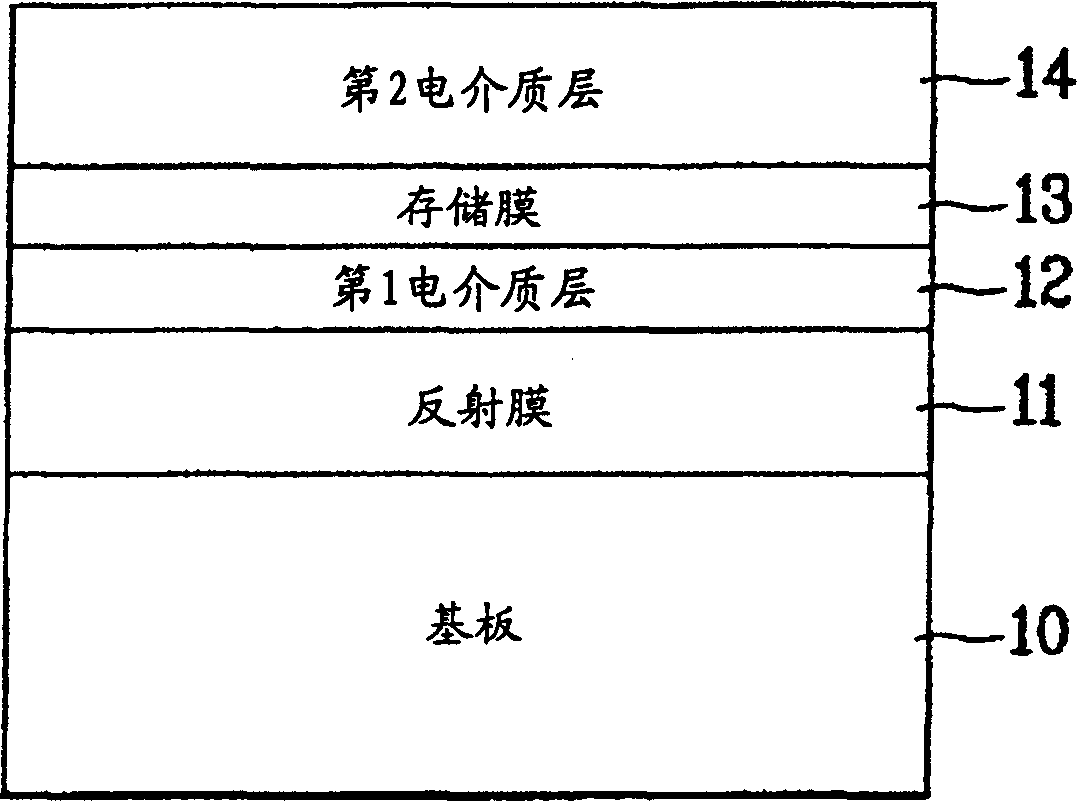

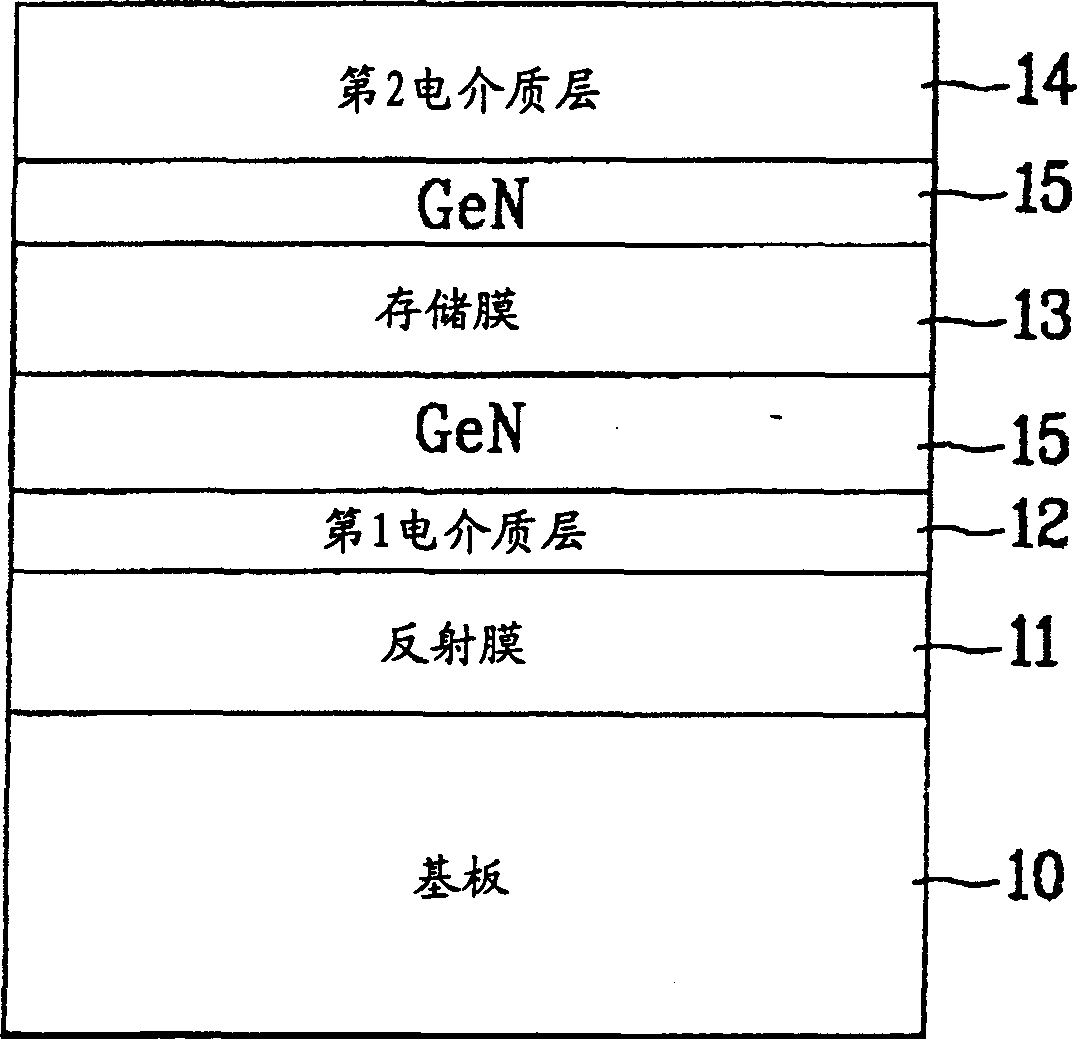

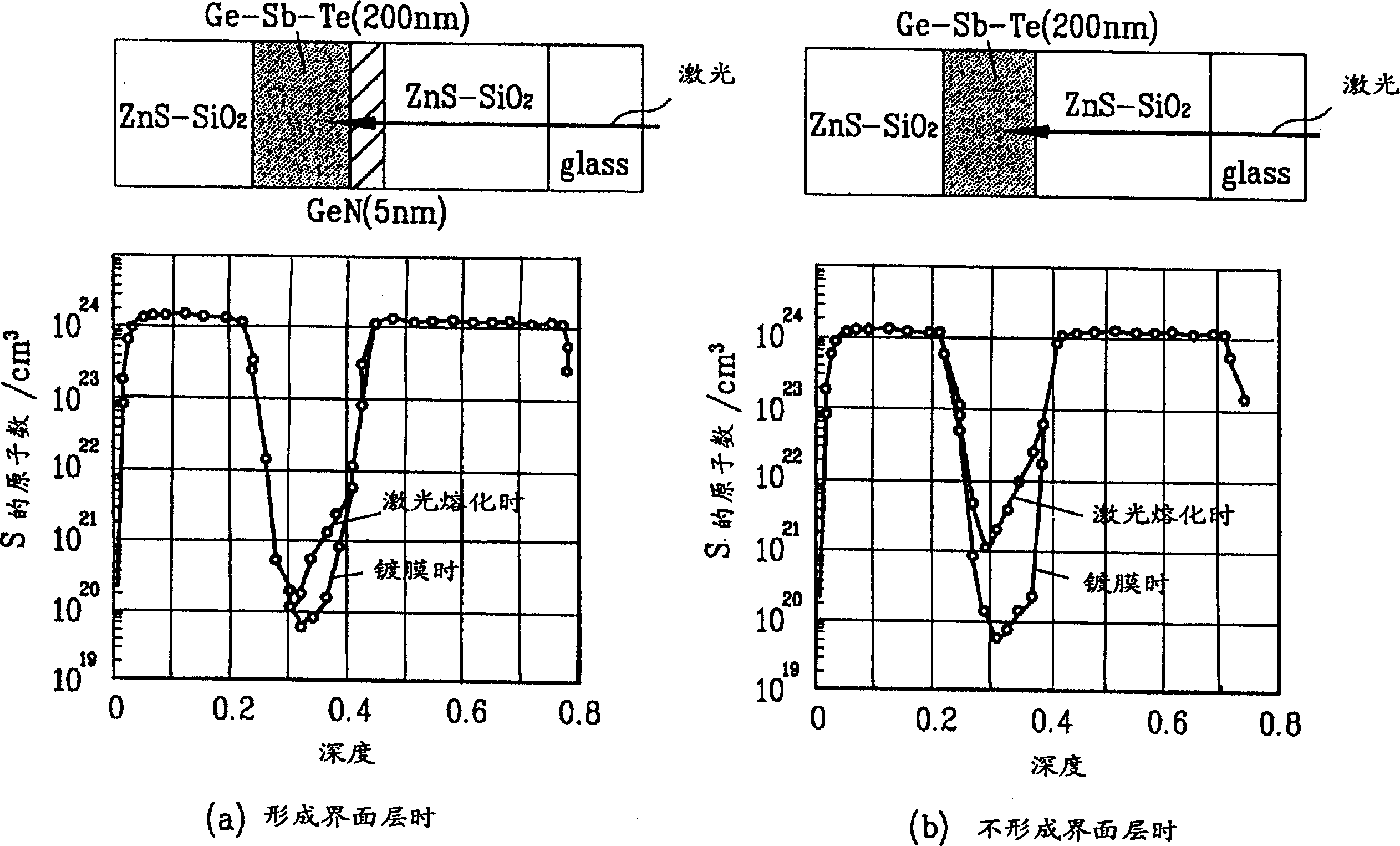

Phase-variable disk

InactiveCN1779820AStop the spreadImprove adhesionRecord information storageOptical recording/reproducingDiffusionOptoelectronics

An optical disc of phase change type is prepared as setting optical disc boundary layer between top storage film and bottom storage film and forming said boundary layer normally by AI ¿C Y or Gee ¿C Y alloy film to prevent sculpture and oxygen generated from dielectric layer from diffusion into storage film when repeated shine of laser is carried out in data storing course.

Owner:LEJIN GUANGDIAN ELECTRONIC CO LTD SHANGHAI

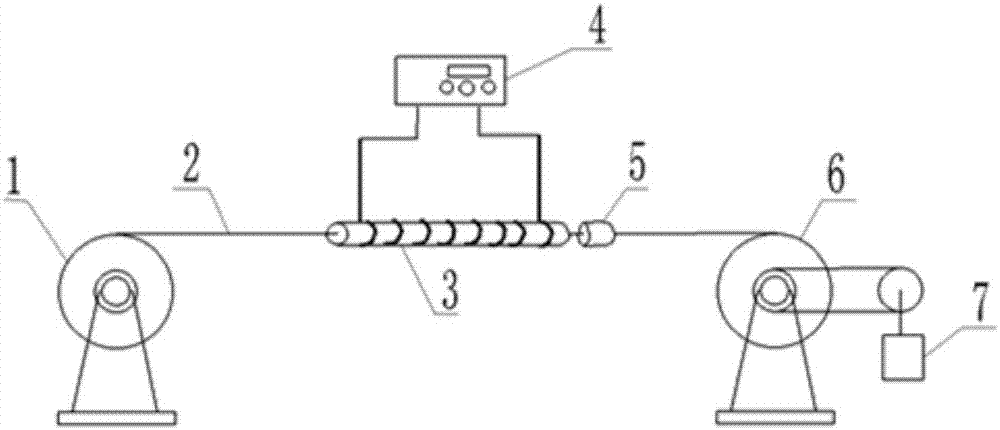

Al-RE-Y alloy refiner and continuous casting and rolling preparation method thereof

ActiveCN111485130AImprove refinementGrain refinementMetal rolling arrangementsContinuous castingAluminium alloy

The invention provides an Al-RE-Y alloy refiner and a continuous casting and rolling preparation method thereof. The alloy refiner is prepared from the following elements in percentage by mass: 3.2-8%of RE, 0.8-4% of Y, and the balance of Al and other unavoidable impurities; the RE / Y mass ratio is 2-4, and RE is at least one element in La and Ce. After the Al-RE-Y alloy refiner is prepared by continuous casting and rolling, the rolled alloy indoor temperature tensile strength exceeds 120MPa, the elongation reaches 30%, and the comprehensive performance is excellent; and the preparation methodhas the advantages of green technology, simplicity, high efficiency, and suitable for large-scale production and the like, and the Al-RE-Y alloy refiner of continuous casting and rolling preparationhas obvious effect on grain refinement of aluminum and aluminum alloy.

Owner:JIANGSU HUAQI ALUMINUM SCI & TECH

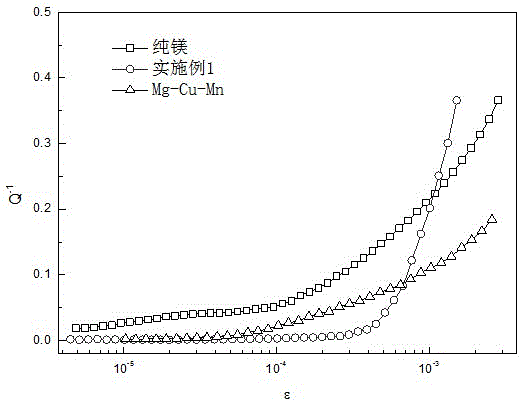

High-damping Mg-Mn-Ce-Al-Zn-Y magnesium alloy and preparation method thereof

The invention relates to a high-damping Mg-Mn-Ce-Al-Zn-Y alloy which comprises the following alloying element components, distributed in an alloy, in percentage by weight: 1.3-2.2% of Mn, 0.15-0.35% of Ce, 0.1-0.3% of Al, 0.25-0.55% of Zn, 0.5-1.5% of Y and the balance magnesium and inevitable impurities. The high-damping Mg-Mn-Ce-Al-Zn-Y magnesium alloy is prepared by the following process: adding the alloy elements in proportion, smelting and ingoting the alloy elements in vacuum, and carrying out water quenching on the smelted alloy to the room temperature, thereby obtaining the high-damping magnesium alloy. According to the process, by virtue of the synergistic effect in many ways, the alloy has relatively high damping capacity and very good plasticity. The damping capacity (Q<-1>) of the material prepared by the alloy can reach 0.2 at a room temperature when strain is 10<-3>. The preparation method is simple in process, is strong in transportability, is easy to operate, and is low in cost, so that the room-temperature damping capacity of the alloy is remarkably improved, and the applied range of the magnesium alloy is expanded.

Owner:CHONGQING UNIV

Al-RE-Y alloy and preparation method thereof

The invention provides an Al-RE-Y alloy and a preparation method thereof. The Al-RE-Y alloy comprises the following chemical components of, in percentage by mass, 3% - 11% of RE, 0.1% - 5% of Y and the balance Al and other inevitable impurities, wherein the RE is at least one element of La and Ce. After the Al-RE-Y alloy is subjected to pressure casting, the room-temperature tensile strength of the die-cast alloy reaches 235 MPa, and the elongation is 11%; the high-temperature tensile strength at 250 DEG C reaches 120MPa, and the elongation is 19%; after gravity casting, the room-temperature tensile strength reaches 140 MPa, the elongation is 14%, and the heat conductivity coefficient is 175 W / (m.K); and the alloy can be used without subsequent heat treatment, and the high-end requirementsof aerospace, military industry, automobiles and other industries for lightweight development are met.

Owner:JIANGSU HUAQI ALUMINUM SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com