High-damping Mg-Zn-Y alloy and preparation technique thereof

A preparation process and high damping technology, applied in the field of metal materials, can solve the problem of small crystal grains, achieve the effect of low cost, simple process, and favorable alloy damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

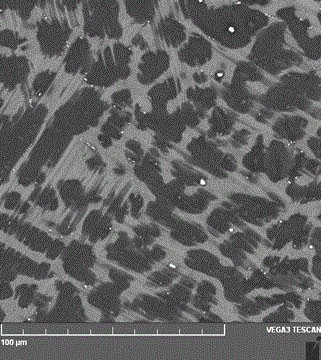

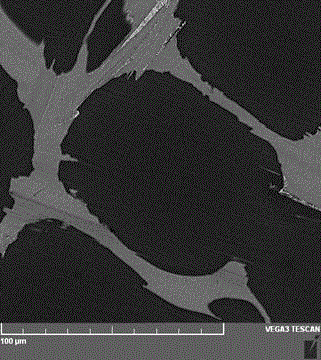

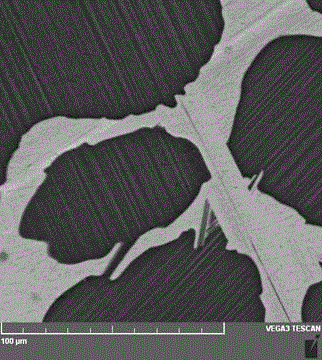

Image

Examples

Embodiment 1

[0027] Embodiment 1: A high-damping Mg-Zn-Y two-phase alloy and its preparation process, the alloy composition (weight percentage): Y-6.6%, Zn-4.2%, less than 0.1% of impurity elements, and the rest is Mg.

[0028] The manufacture method of this high damping Mg-Zn-Y alloy is carried out as follows:

[0029] Step 1: In the vacuum melting furnace, and pass through argon gas for protection, add alloying elements according to weight percentage Y=6.6%, Zn=4.2%. Among them, Y and Zn are added in the form of Mg-30Y master alloy and pure Zn respectively. Heat preservation at 820°C and electromagnetic induction stirring to fully melt the raw materials. After the alloy is completely melted, continue to stand at 780°C for 15 minutes, and then cast.

[0030] Step 2: Grind and polish the ingot, carry out secondary melting on the alloy ingot, heat it up to 820°C for 3 hours; after it is completely melted, keep it at a temperature gradient of 650°C for 1 hour; finally, place the sample in...

Embodiment 2

[0032] Embodiment 2: A kind of high damping Mg-Zn-Y alloy and its preparation process, alloy composition (weight percent):

[0033] Y-7.5%, Zn-4.6% impurity elements are less than 0.1%, and the rest is Mg.

[0034] The manufacture method of this high damping Mg-Zn-Y alloy is carried out as follows:

[0035] Step 1: In the vacuum melting furnace, and pass through argon gas for protection, add alloying elements according to weight percentage Y=6.6%, Zn=4.2%. Among them, Y and Zn are added in the form of Mg-30Y master alloy and pure Zn respectively. Heat preservation at 820°C and electromagnetic induction stirring to fully melt the raw materials. After the alloy is completely melted, continue to stand at 780°C for 15 minutes, and then cast.

[0036] Step 2: Grind and polish the ingot, carry out secondary melting on the alloy ingot, heat it up to 820°C for 3 hours; after it is completely melted, keep it at 650°C for 1 hour; then keep it at 400°C 10h; then place the sample at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com