Heat resistant magnesium alloy and preparation method thereof

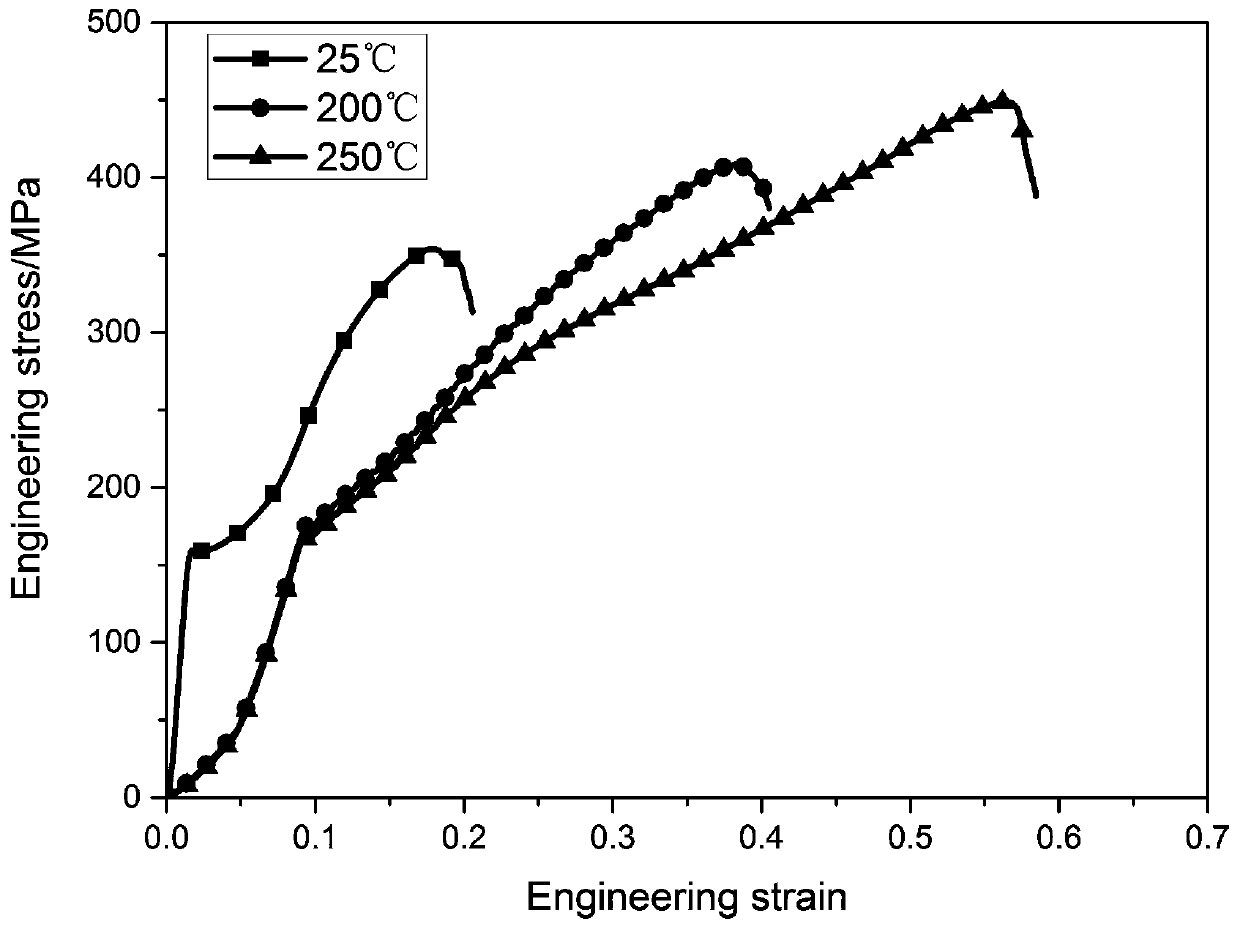

A magnesium alloy, heat-resistant technology, applied in the field of magnesium alloy materials, can solve the problems of low thermal stability, poor high-temperature performance of the alloy, and limit the practical application of magnesium alloys, etc., and achieve the effect of good high-temperature strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

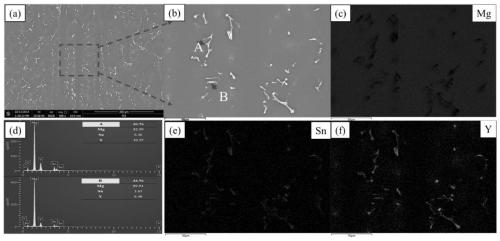

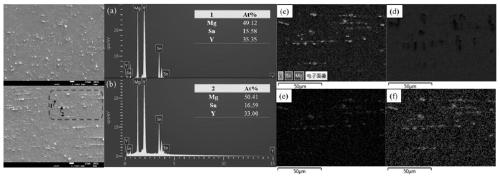

[0023] The components and mass percentages of the heat-resistant magnesium alloy provided in this example are: tin Sn 0.3wt.%, rare earth yttrium Y2wt.%, and the balance is magnesium Mg. It should be noted that due to the limitation of process conditions, there may still be some unavoidable impurities in the alloy.

Embodiment 2

[0025] The components and mass percentages of the heat-resistant magnesium alloy provided in this example are: tin Sn 0.4wt.%, rare earth yttrium Y 3wt.%, and the balance is magnesium Mg.

Embodiment 3

[0027] The components and mass percentages of the heat-resistant magnesium alloy provided in this embodiment are: tin Sn 0.5wt.%, rare earth yttrium Y 3wt.%, and the balance is magnesium Mg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com