Nickel-tungsten-based alloy coating screen pipe for high-salinity oil-gas well containing hydrogen sulfide and carbon dioxide

A technology with carbon dioxide and high salinity, which is applied in wellbore/well components, mining fluids, earthwork drilling and mining, etc. It can solve problems that have not been reported in research and application, and achieve excellent anti-corrosion performance, low material cost, easy loading and unloading easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

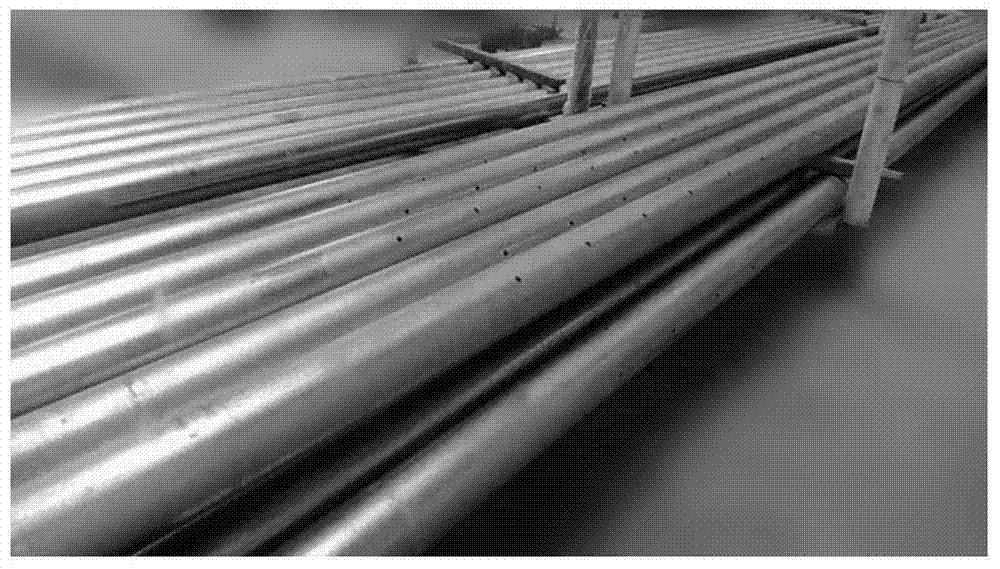

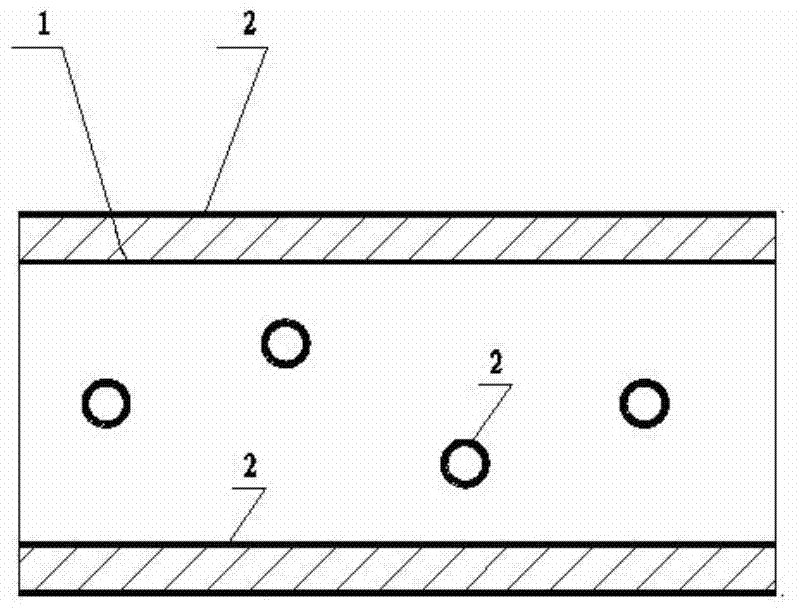

[0041] like figure 1 , figure 2 As shown, a tungsten alloy screen tube, its structure includes a base tube (110ss material Ф127 × 9.19mm type casing, the surface through holes are evenly arranged in a spiral shape) and a nickel-tungsten-based alloy coating.

[0042] Its preparation process is:

[0043] The casing of Ф127×9.19mm made of 110ss material is used as the base pipe. After the thread is machined on the base pipe, surface treatment and activation are carried out, and then nickel-tungsten alloy is electroplated on the inner surface and the thread of the base pipe, taken out and cleaned. Then, sieve holes are punched on the base pipe according to the designed shape and size. After the sieve holes are punched, nickel-tungsten alloy is electroplated on the outer surface of the base pipe and in the sieve holes. After the electroplating is completed, it is cleaned and then heat-treated at 180-550 ℃, and the finished product is packaged.

[0044] The appearance of the obtai...

Embodiment 2

[0046] The base tube is a Ф127×9.19mm sleeve made of 110ss material. The through holes on the surface are evenly arranged in a spiral shape, and the Ni-W-Co ternary alloy is electroplated.

[0047] The preparation process is the same as in Example 1.

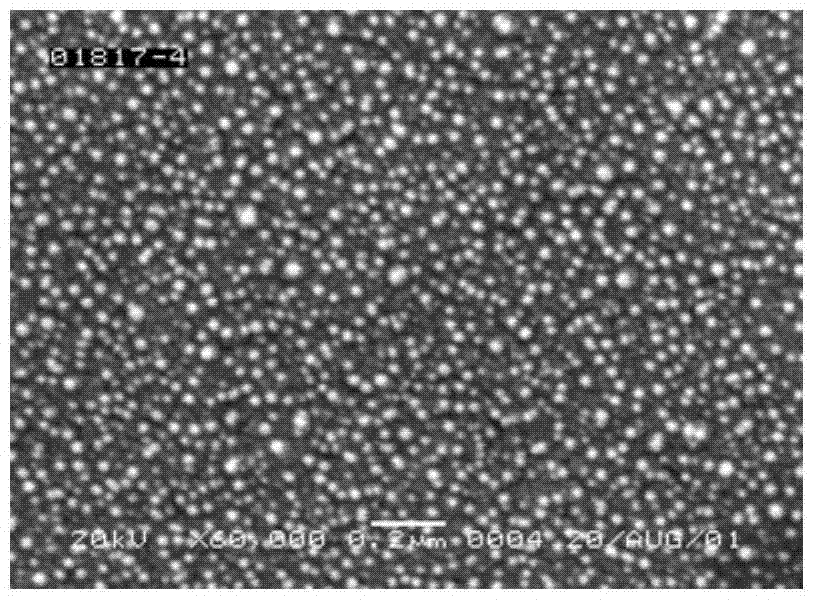

[0048] The appearance of the obtained product is uniform and fine, and the composition of the alloy coating is Ni65%, W30%, Co5%; the thickness of the coating is 60-90 μm; and the hardness is 920Hv. The sample is tested according to GB / T17897-1999 stainless steel ferric chloride pitting corrosion test method (6% FeCl3, 24h), and the test results are shown in Figure 9 ,as the picture shows, Figure 9 Picture a in the picture shows the appearance of the tungsten alloy sample after the test, and it can be seen that there is no obvious corrosion on the surface of the sample; Figure 9 Picture b in the middle is the topography of the tungsten alloy coating surface magnified by 200 times after the test. The coating surface is flat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com