Preparation method for high-thermal-stability NdFeB magnet

A high thermal stability, neodymium iron boron technology, applied in the direction of magnetic objects, inductors/transformers/magnet manufacturing, magnetic materials, etc., can solve the problems of low utilization rate, hindered improvement of coercive force, expensive diffusing agent, etc., to achieve Increase the Curie temperature, increase the coercive force, and improve the effect of the temperature coefficient of magnetic induction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

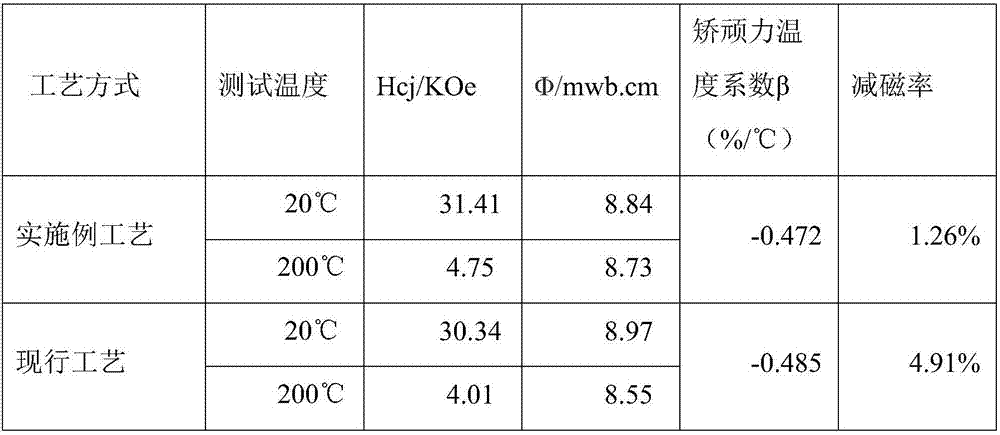

Embodiment 1

[0026] The preparation method of high thermal stability NdFeB magnet of the present invention, it comprises the following steps:

[0027] (1) The X alloy raw material and the Y alloy raw material are respectively smelted by using a vacuum induction quick solidification casting furnace. X alloy composition is Nd 3.5 Dy 30 Fe 65 Nb 0.4 B 1.1 , Y alloy composition is Nd 33.5 Fe 35 co 30 Nb 0.4 B 1.1 , are made into alloy flakes with a thickness of 0.15-0.45mm;

[0028] (2) The X alloy and Y alloy flakes are subjected to hydrogen explosion treatment respectively, the hydrogen absorption pressure is 0.098Mpa, and the dehydrogenation is carried out after the hydrogen absorption is saturated. The dehydrogenation temperature is 580°C, and the dehydrogenation time is 6h to make 300-500μm neodymium Iron-boron alloy particles.

[0029] (3) The X and Y alloy particles obtained above are further passed through jet mill equipment to make powders with an average particle size of 2...

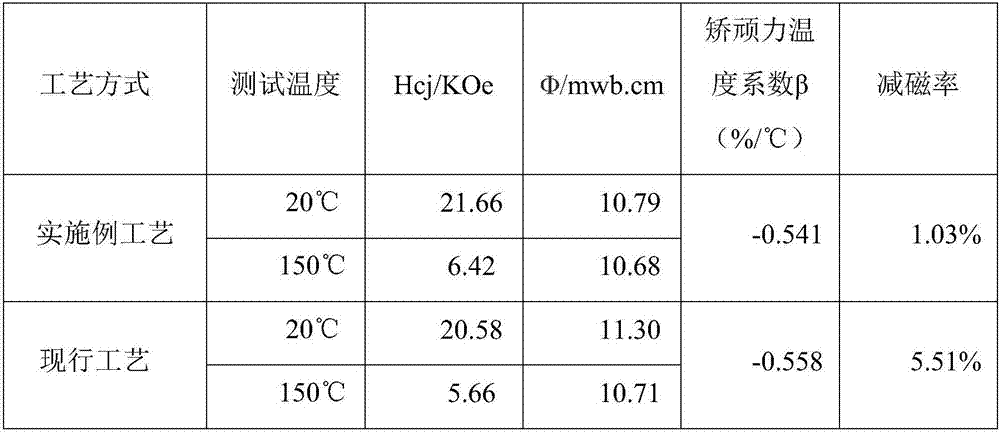

Embodiment 2

[0041] The preparation method of high thermal stability NdFeB magnet of the present invention, it comprises the following steps:

[0042] (1) The X alloy raw material and the Y alloy raw material are respectively smelted by using a vacuum induction quick solidification casting furnace. X alloy composition is Nd 3.5 Dy 30 Fe 65 Nb 0.4 B 1.1 , Y alloy composition is Nd 33.5 Fe 35 co 30 Nb 0.4 B 1.1 , are made into alloy flakes with a thickness of 0.15-0.45mm;

[0043] (2) The X alloy and Y alloy flakes are subjected to hydrogen explosion treatment respectively, the hydrogen absorption pressure is 0.098Mpa, and the dehydrogenation is carried out after the hydrogen absorption is saturated. The dehydrogenation temperature is 560°C, and the dehydrogenation time is 5.8h to make 300-500μm NdFeB alloy particles.

[0044] (3) The X and Y alloy particles obtained above are further passed through jet milling equipment to make powders with an average particle size of 2 to 4 μm; ...

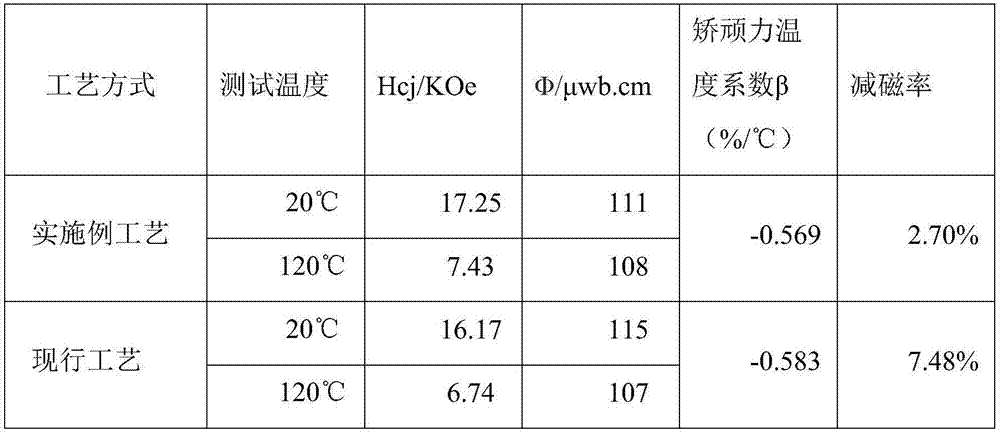

Embodiment 3

[0056] The preparation method of high thermal stability NdFeB magnet of the present invention, it comprises the following steps:

[0057] (1) The X alloy raw material and the Y alloy raw material are respectively smelted by using a vacuum induction quick solidification casting furnace. X alloy composition is Nd 3.5 Dy 30 Fe 65 Nb 0.4 B 1.1 , Y alloy composition is Nd 33.5 Fe 35 co 30 Nb 0.4 B 1.1 , are made into alloy flakes with a thickness of 0.15-0.45mm;

[0058] (2) The X alloy and Y alloy flakes are subjected to hydrogen explosion treatment respectively, the hydrogen absorption pressure is 0.098Mpa, and the dehydrogenation is carried out after the hydrogen absorption is saturated. The dehydrogenation temperature is 530°C, and the dehydrogenation time is 5.5h to make 300-500μm NdFeB alloy particles.

[0059] (3) The X and Y alloy particles obtained above are further passed through jet milling equipment to make powders with an average particle size of 2 to 4 μm; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com