Fe-based amorphous/nanocrystalline soft magnetic alloy thin belt and preparation method thereof

A nanocrystalline soft magnetic, iron-based amorphous technology, applied in the field of alloys, can solve problems such as less research on alloys, and achieve the effects of improving saturation magnetic induction, high thermal stability, and increasing nucleation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) Use pure iron, pure boron, and pure silicon as raw materials, and each component element is based on atomic percentage Fe 78 Si 13 B 9 Add to the arc melting furnace after batching;

[0049] (2) Vacuum the arc melting furnace to 5×10 -3 After Pa is filled with argon gas, the raw materials prepared in step (1) are heated to 1200-1400°C in an arc melting furnace to melt them, and the melting is repeated 5 times;

[0050] (3) Use argon gas to spray the molten liquid alloy onto a high-speed rotating copper roller at 1200~1400℃, and the surface linear speed of the copper roller is 40m / s, so as to prepare iron-based amorphous / nanocrystalline soft magnetic alloy thin band.

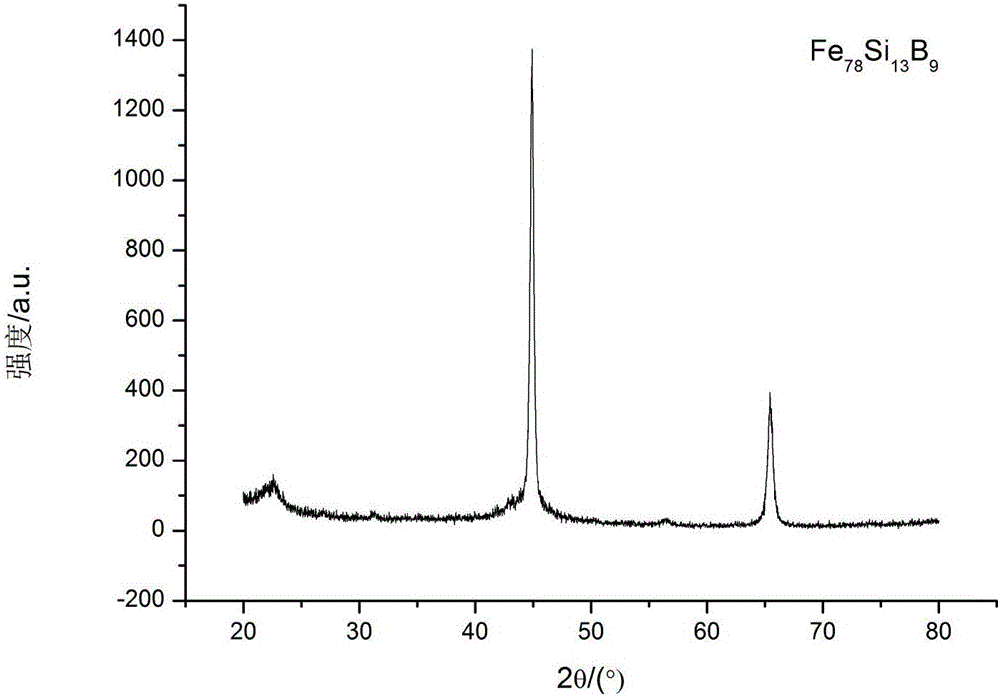

[0051] The crystal structure of the prepared Fe-based amorphous / nanocrystalline soft magnetic alloy ribbon was tested by XRD. The original alloy Fe 78 Si 9 B 13 The XRD diffraction pattern has sharp diffraction peaks at 2θ=45° and 2θ=60°, see image 3 , The saturation magnetization Ms is 157.79emu / g and the c...

Embodiment 2

[0053] (1) Use pure iron, pure boron, pure silicon, and pure copper as raw materials, and each component element is based on atomic percentage Fe 77 Cu 1 Si 13 B 9 Add to the arc melting furnace after batching;

[0054] (2) Vacuum the arc melting furnace to 5×10 -3 After Pa is filled with argon, the raw materials prepared in step (1) are heated to 1200-1400°C in an arc melting furnace to melt them, and the melting is repeated 5 times;

[0055] (3) Use argon gas to spray the molten liquid alloy onto a high-speed rotating copper roller at 1200~1400℃, and the surface linear speed of the copper roller is 40m / s, so as to prepare iron-based amorphous / nanocrystalline soft magnetic alloy thin band.

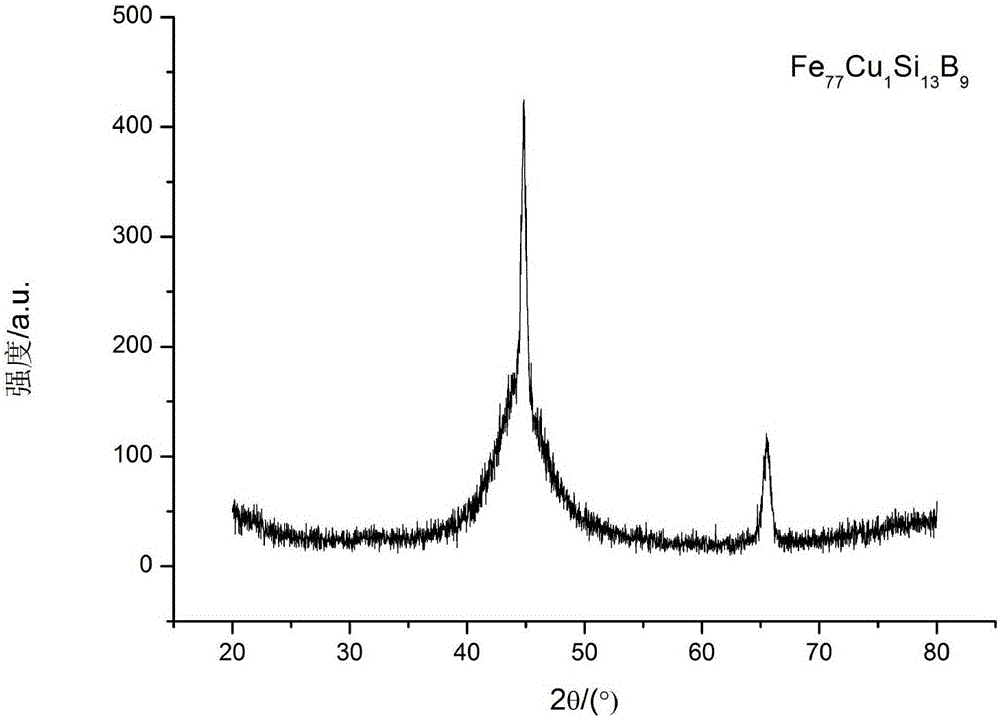

[0056] The crystal structure of the prepared iron-based amorphous / nanocrystalline soft magnetic alloy ribbon was examined by XRD. The XRD spectrum has a significantly broadened α-Fe diffraction peak, and there is a diffuse scattering packet under the diffraction peak, indicating the ribbon The ...

Embodiment 3

[0058] (1) Selecting 99.5% Fe pure iron and 99.9% Cu, Zr, Si, B as raw materials, according to the atomic percentage of Fe 74 Cu 1 Zr 3 Si 13 B 9 Add to the arc melting furnace after batching;

[0059] (2) Vacuum the arc melting furnace to 5×10 -3 After Pa is filled with argon, the raw materials prepared in step (1) are heated to 1200-1400°C in an arc melting furnace to melt them, and the melting is repeated 5 times;

[0060] (3) Spray the molten liquid alloy on a high-speed rotating copper roller at 1200°C with argon gas, and the surface linear velocity of the copper roller is 40m / s, thereby preparing an iron-based amorphous / nanocrystalline soft magnetic alloy ribbon. The thickness of the iron-based amorphous alloy strip is 15-40 μm, and the width is 1-5 mm.

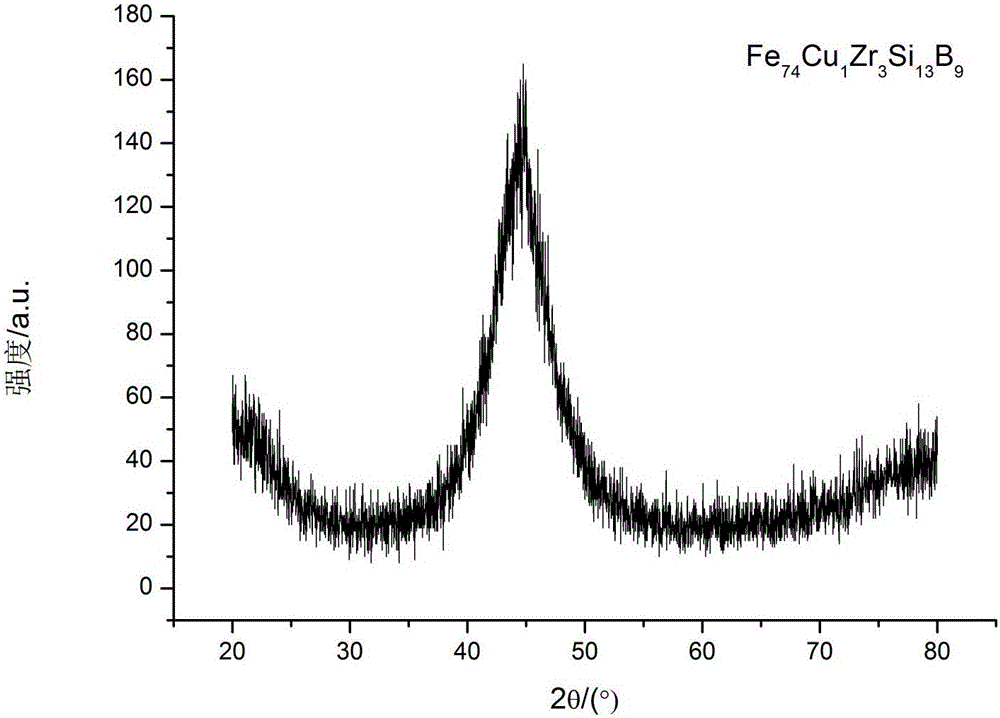

[0061] The crystal structure of the prepared iron-based amorphous nanocrystalline soft magnetic alloy ribbon was tested by XRD. The XRD spectrum only has diffuse scattering peaks unique to amorphous, and there is no sharp diff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com