Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

107 results about "Vacuum arc remelting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vacuum arc remelting (VAR) is a secondary melting process for production of metal ingots with elevated chemical and mechanical homogeneity for highly demanding applications. The VAR process has revolutionized the specialty traditional metallurgical techniques industry, and has made possible incredibly controlled materials used in the biomedical, aviation, and aerospace fields.

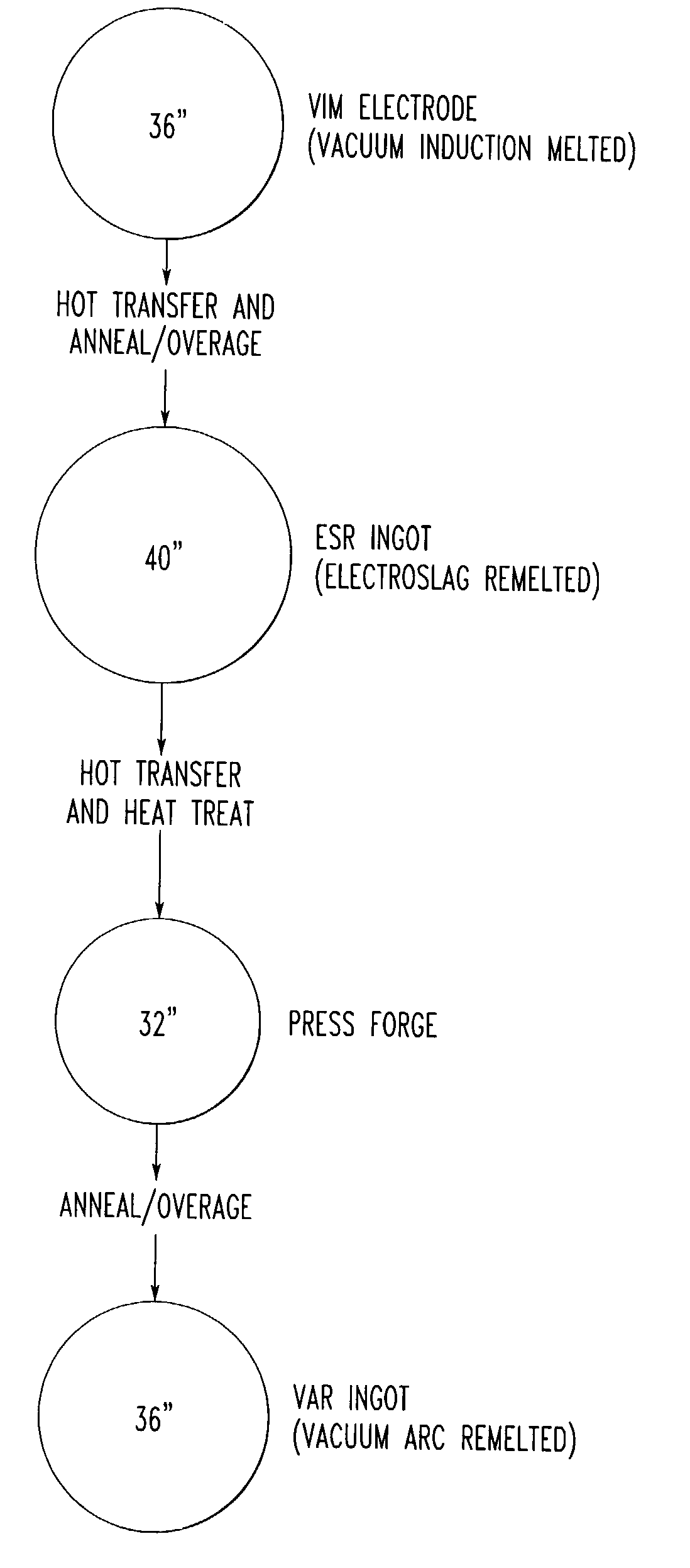

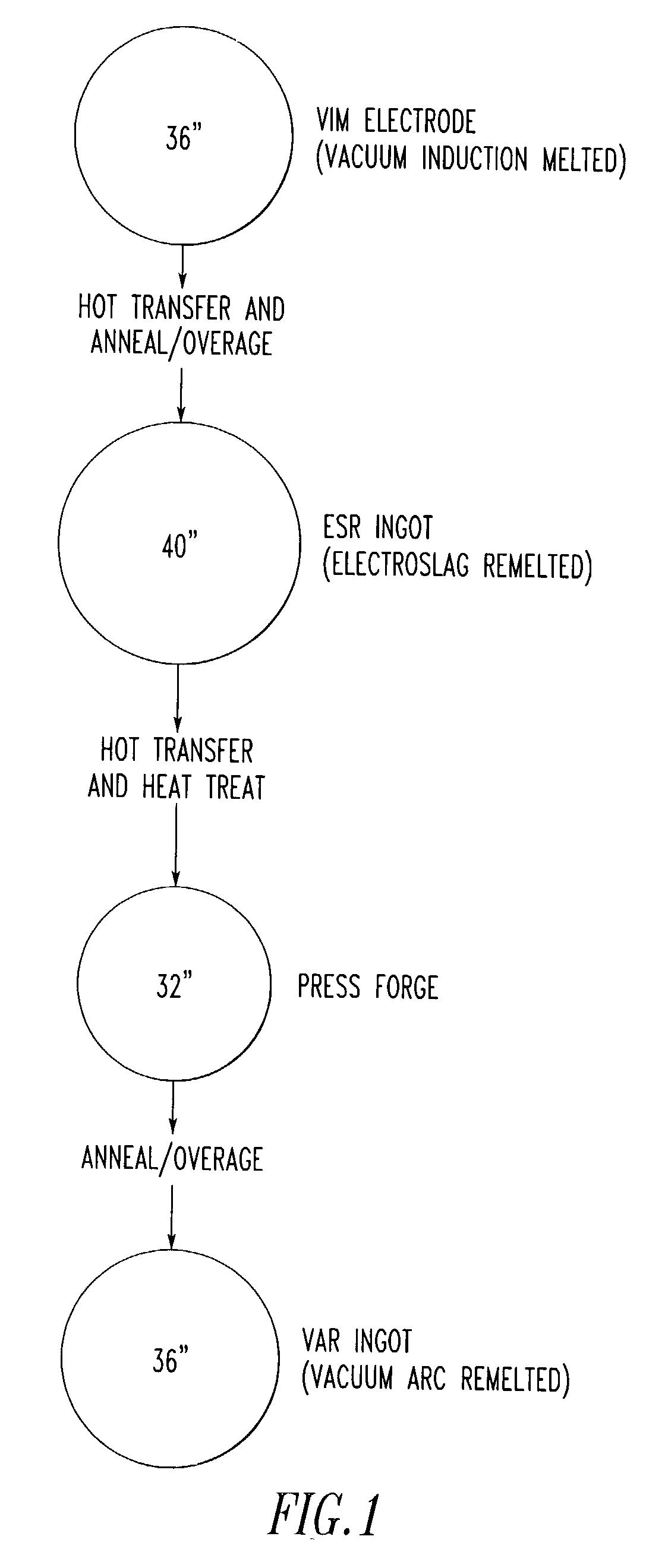

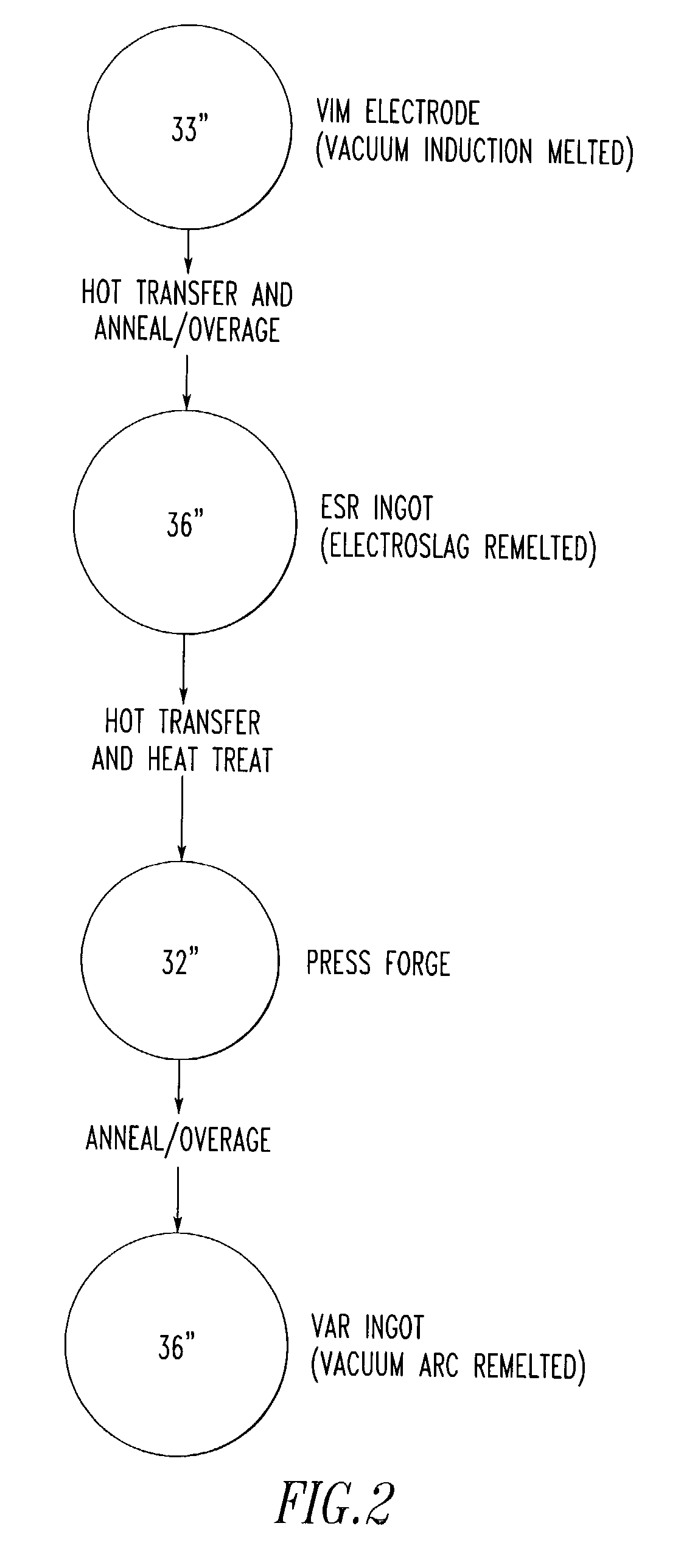

Method for producing large diameter ingots of nickel base alloys

InactiveUS6416564B1Inhibit thermal stressLarge caliberWelding/cutting media/materialsElectric furnaceCasting moldHeating furnace

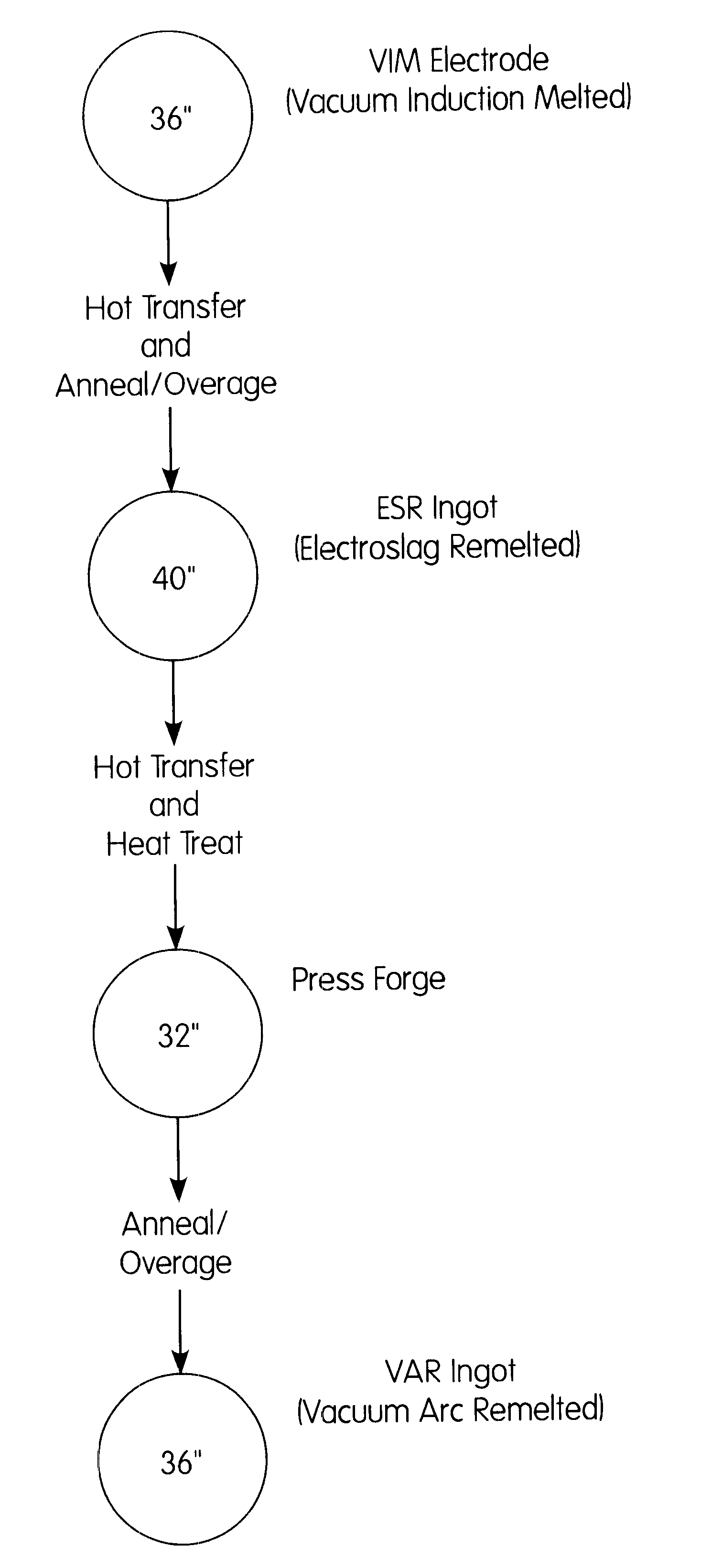

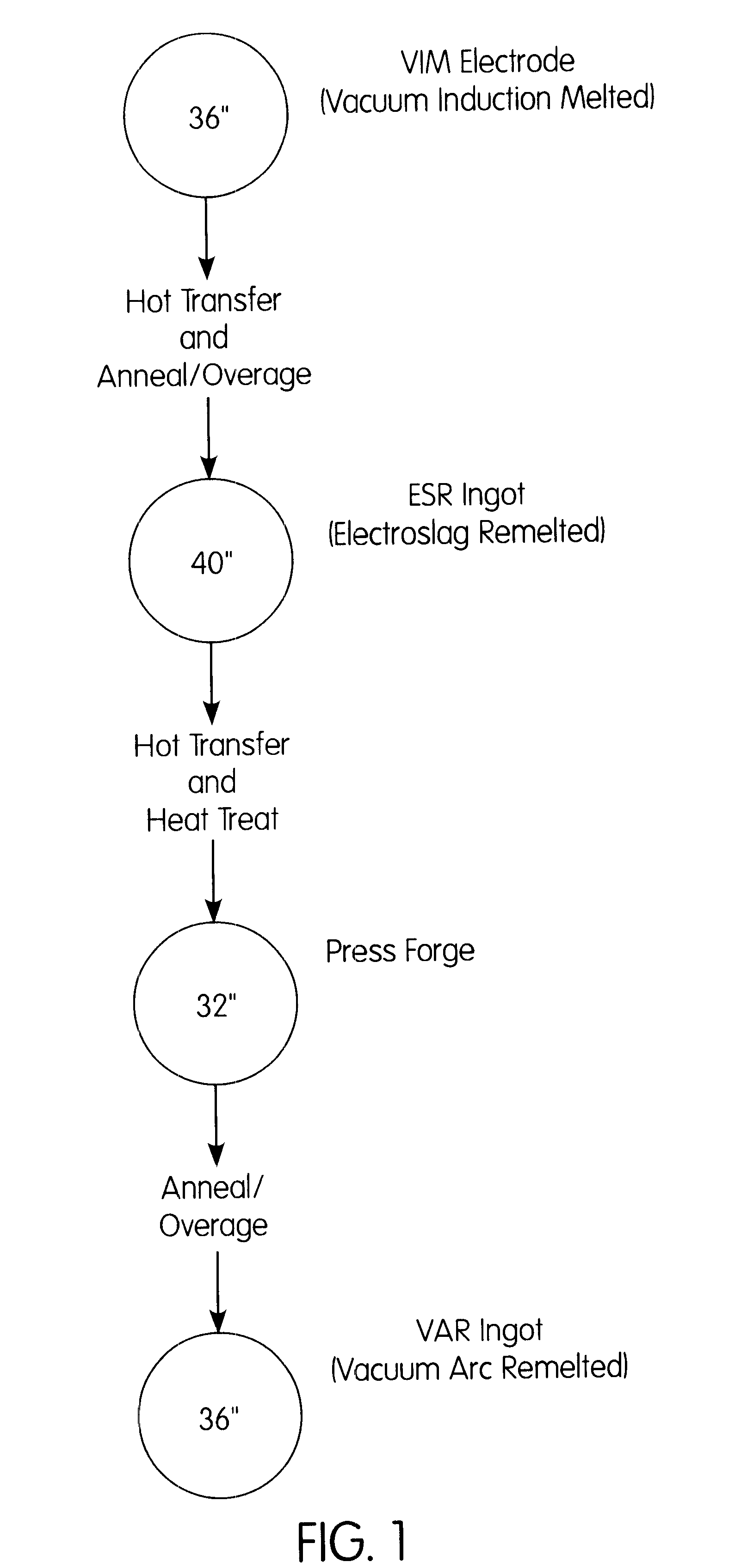

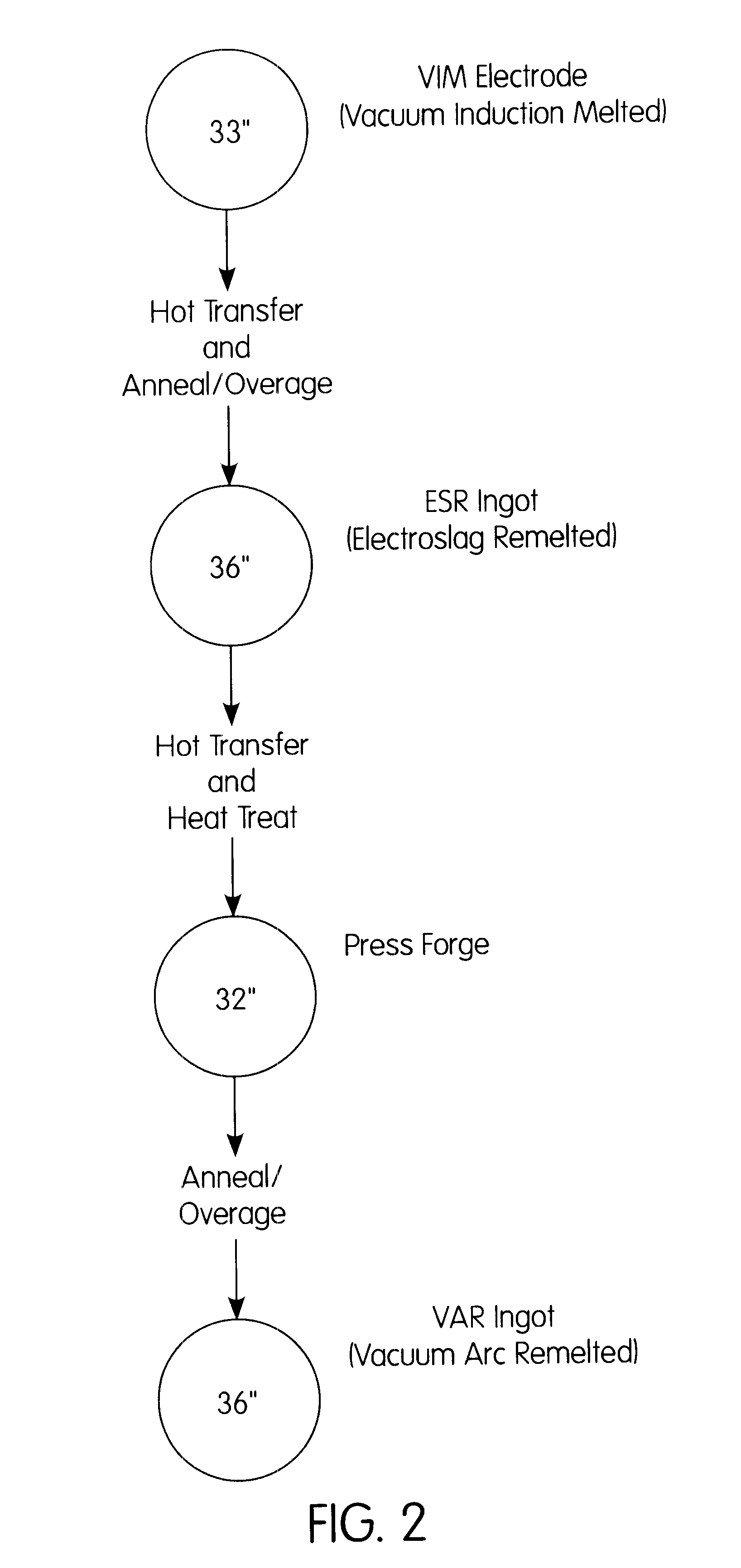

A method of producing a nickel base alloy includes casting the alloy within a casting mold and subsequently annealing and overaging the ingot at at least 1200° F. (649° C.) for at least 10 hours. The ingot is electroslag remeelted at a melt rate of at least 8 lbs / min (3.63 kg / mm.), and the ESR ingot is then transferred to a heating furnace within 4 hours of complete solidification and is subjected to a novel post-ESR heat treatment. A suitable VAR electrode is provided form the ESR ingot, and the electrode is vacuum arc remelted at a melt rate of 8 to 11 lbs / minute (3.63 to 5.00 kg / minute) to provide a VAR ingot. The method allows premium quality VAR ingots having diameters greater than 30 inches (762 mm) to be prepared from Alloy 718 and other nickel base superalloys subject to significant segregation on casting.

Owner:ATI PROPERTIES

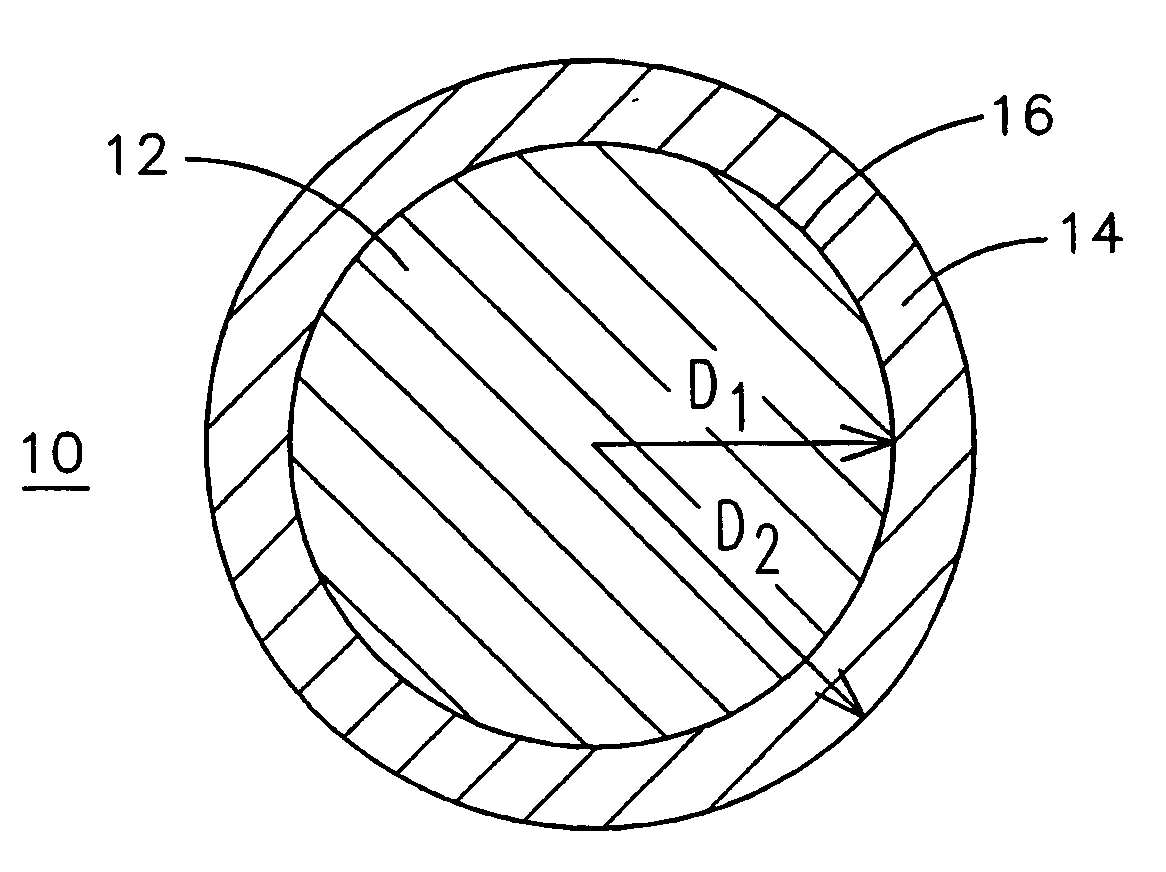

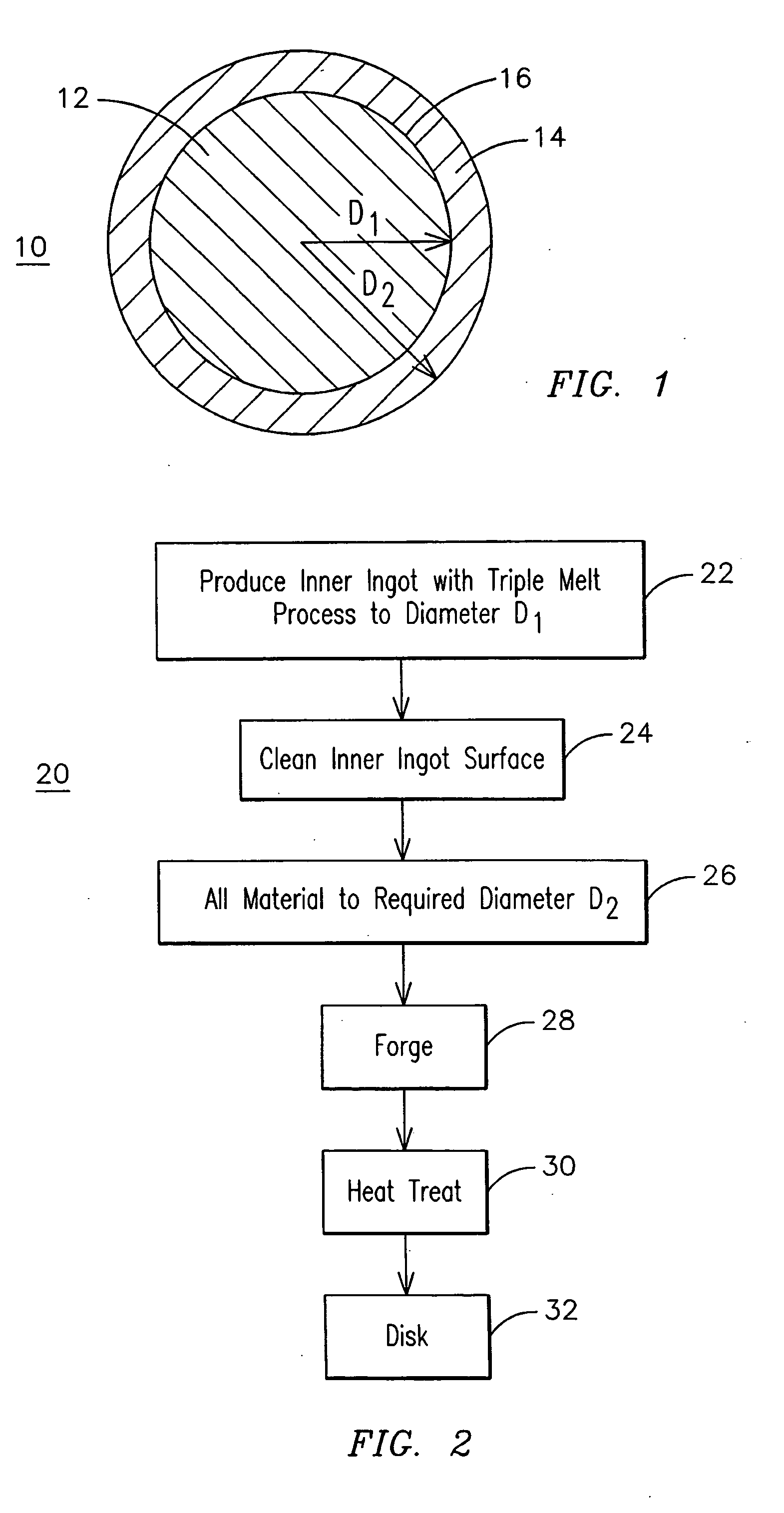

Method of manufacturing a rotating apparatus disk

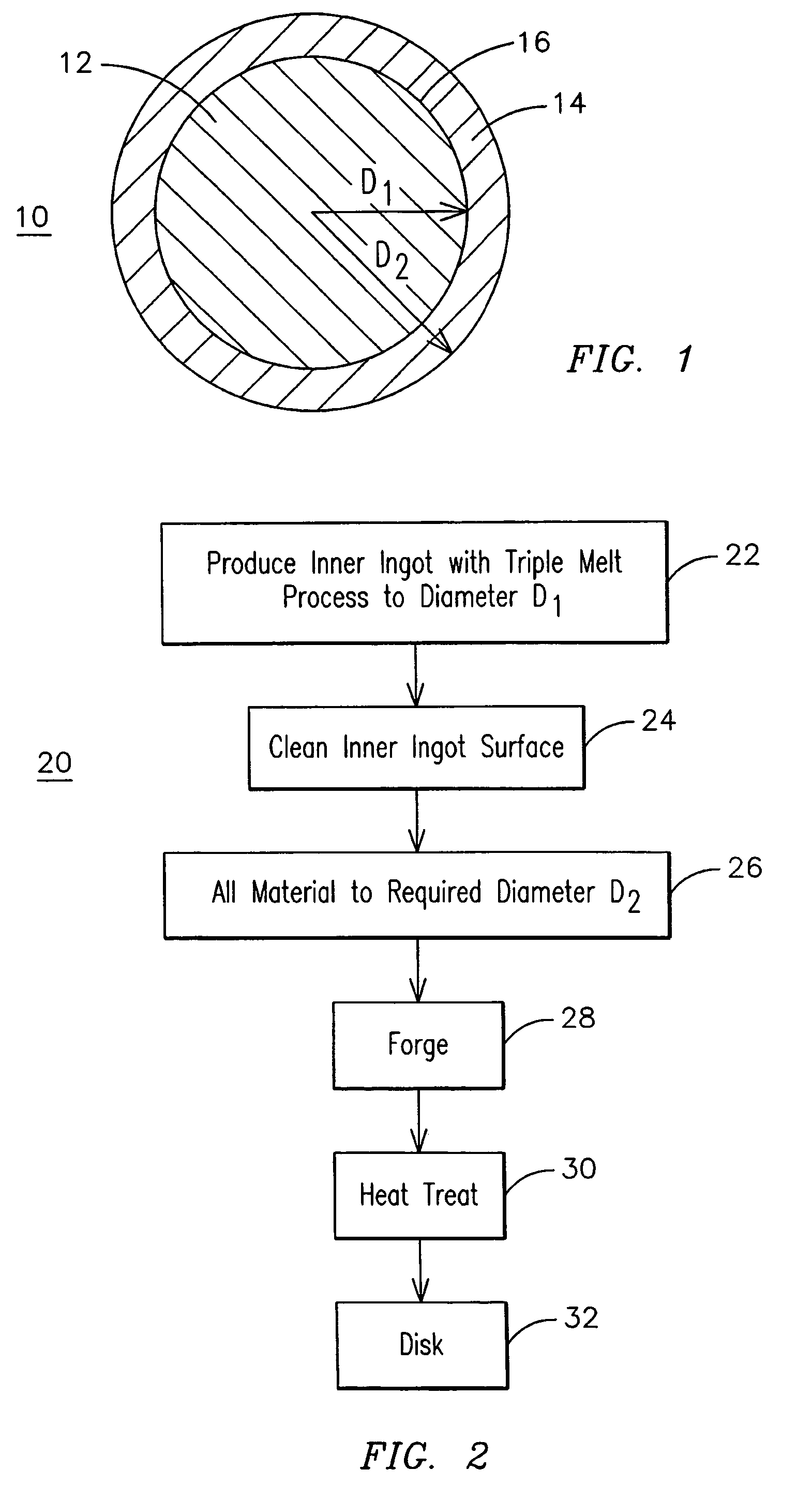

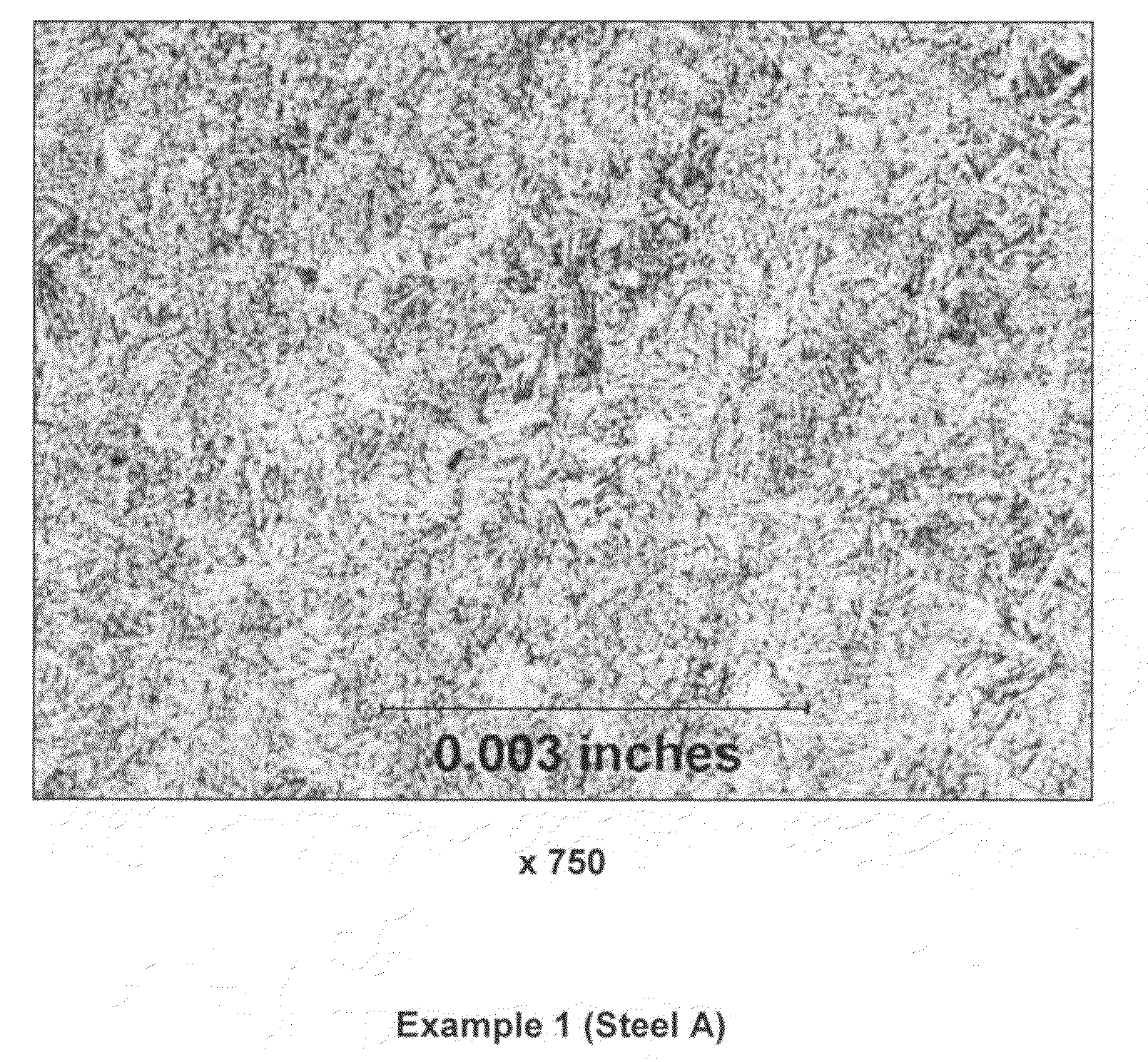

InactiveUS7316057B2Semiconductor/solid-state device detailsSolid-state devicesDeposition processVacuum arc remelting

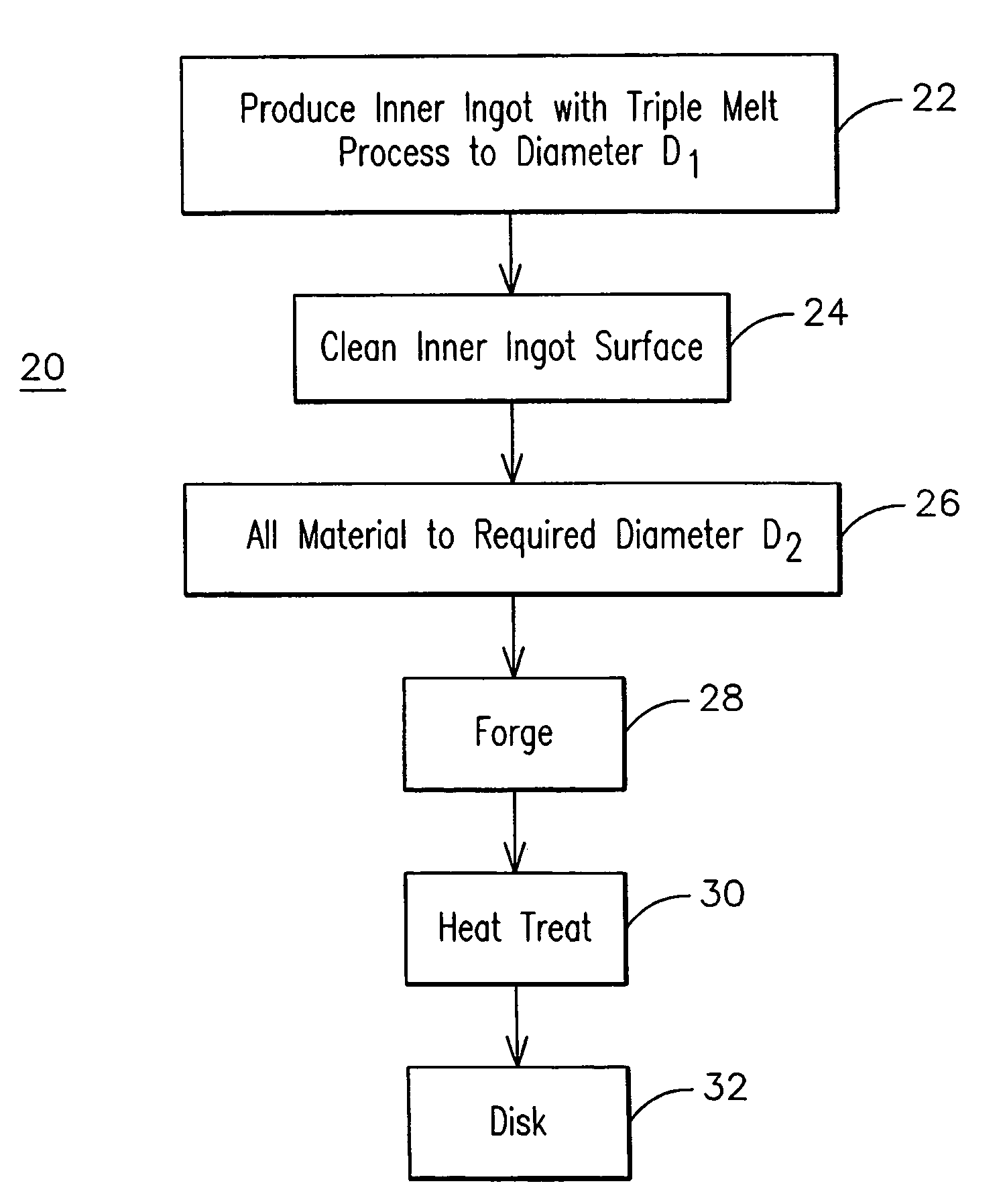

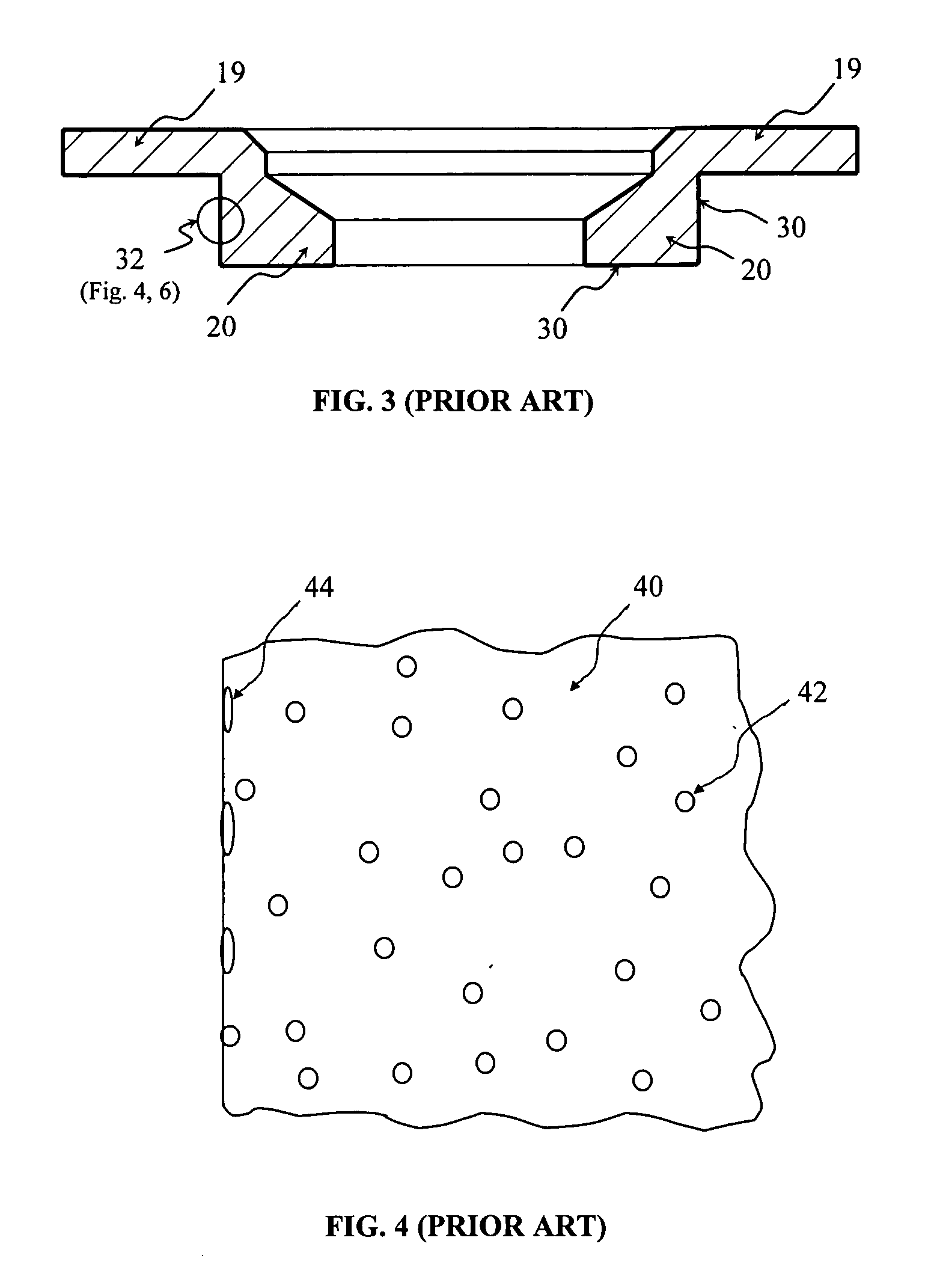

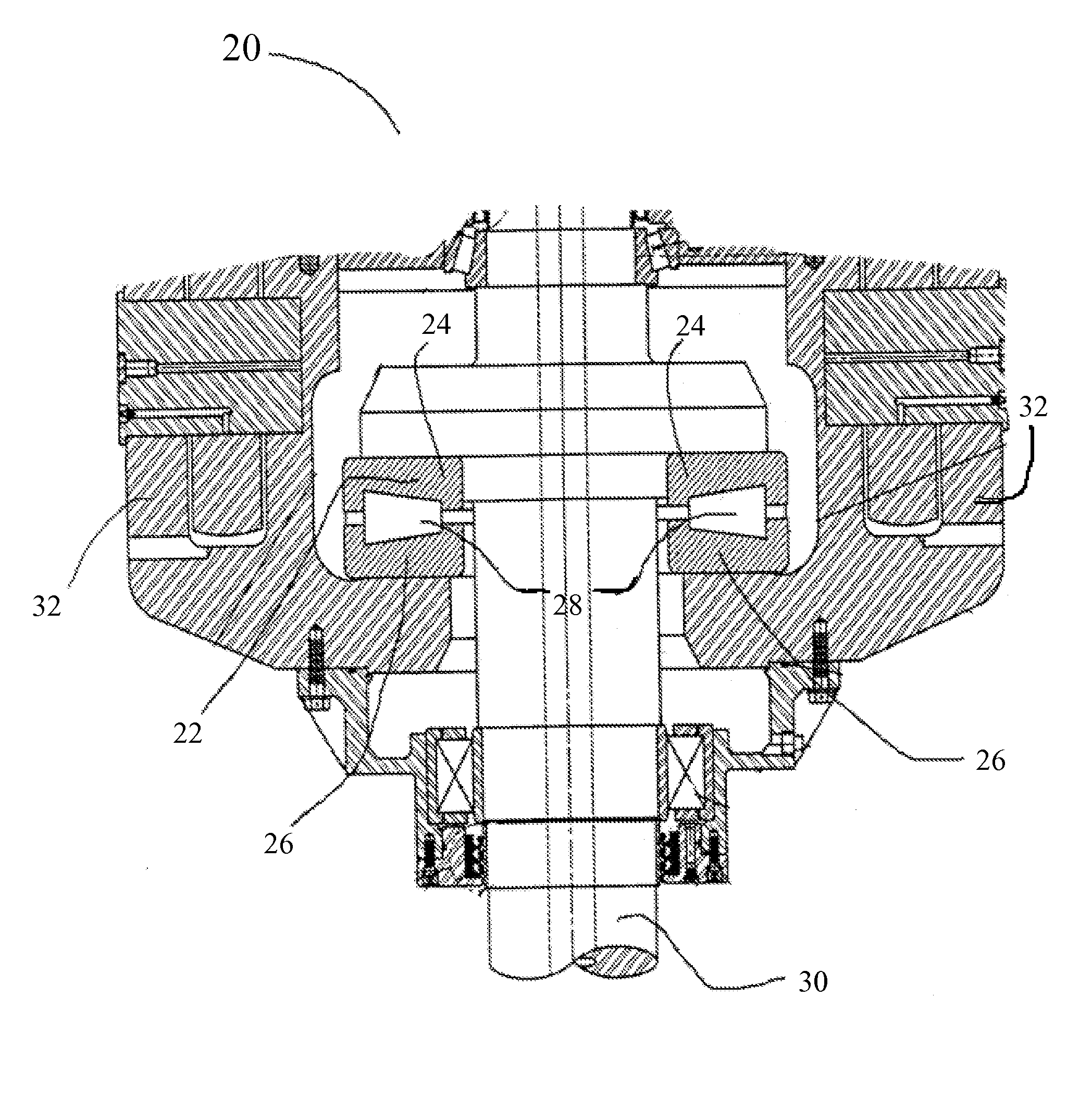

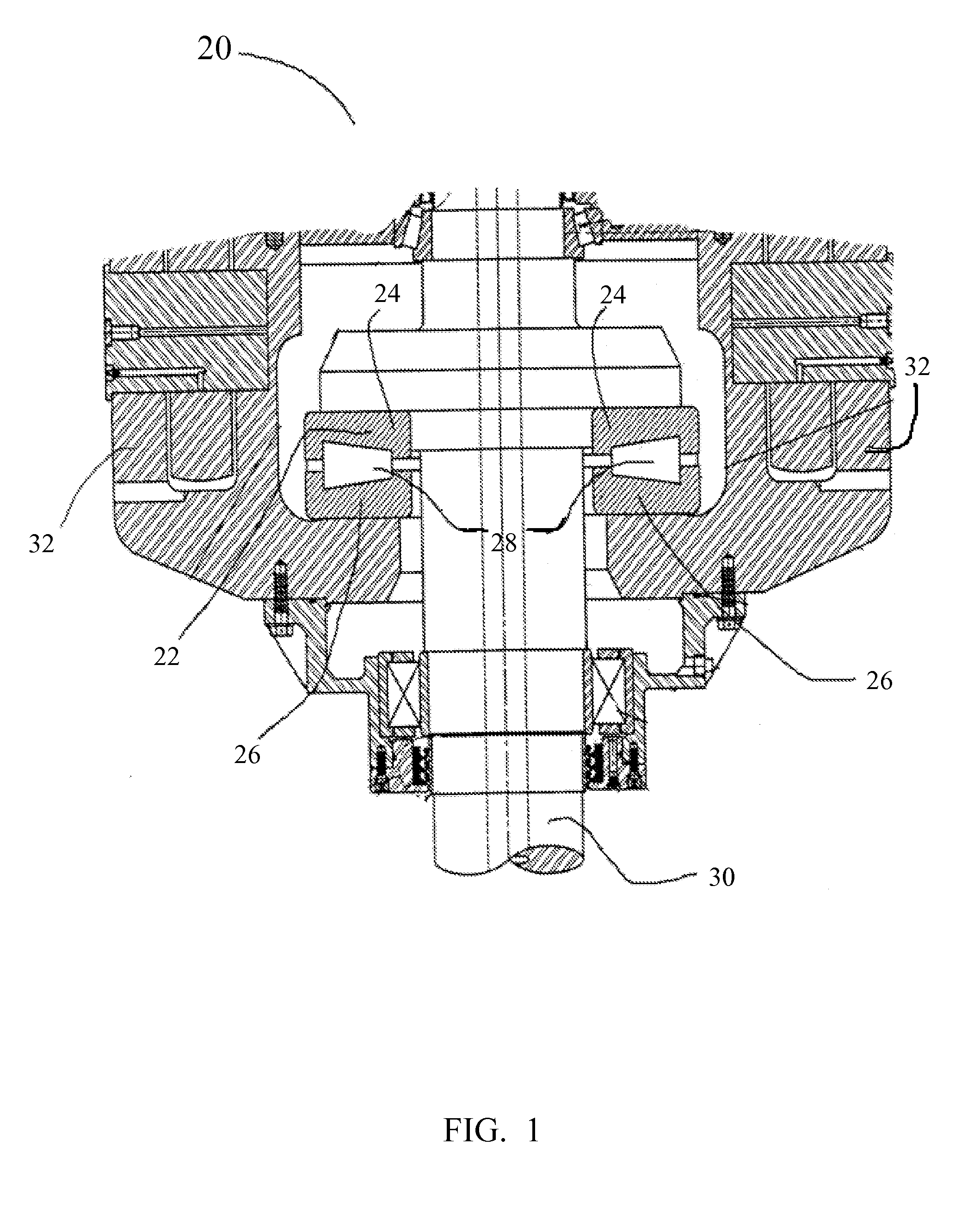

A method (20) of fabricating a large component such as a gas turbine or compressor disk (32) from segregation-prone materials such as Alloy 706 or Alloy 718 when the size of the ingot required is larger than the size that can be predictably formed without segregations using known triple melt processes. A sound inner core ingot (12) is formed (22) to a first diameter (D1), such as by using a triple melt process including vacuum induction melting (VIM), electroslag remelting (ESR), and vacuum arc remelting (VAR). Material is than added (26) to the outer surface (16) of the core ingot to increase its size to a dimension (D2) required for the forging operation (28). A powder metallurgy or spray deposition process may be used to apply the added material. The added material may have properties that are different than those of the core ingot and may be of graded composition across its depth. This process overcomes ingot size limitations for segregation-prone materials.

Owner:SIEMENS ENERGY INC

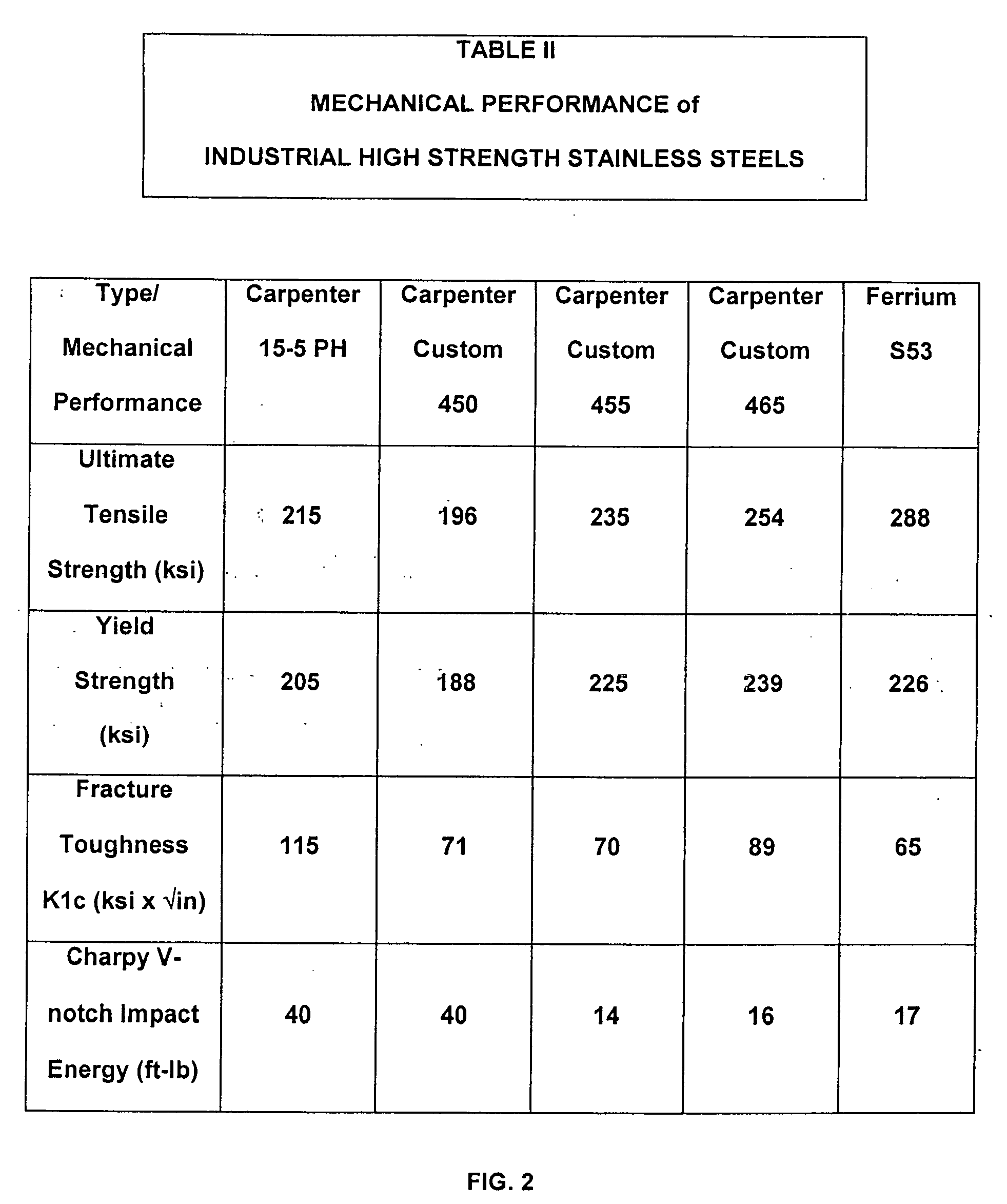

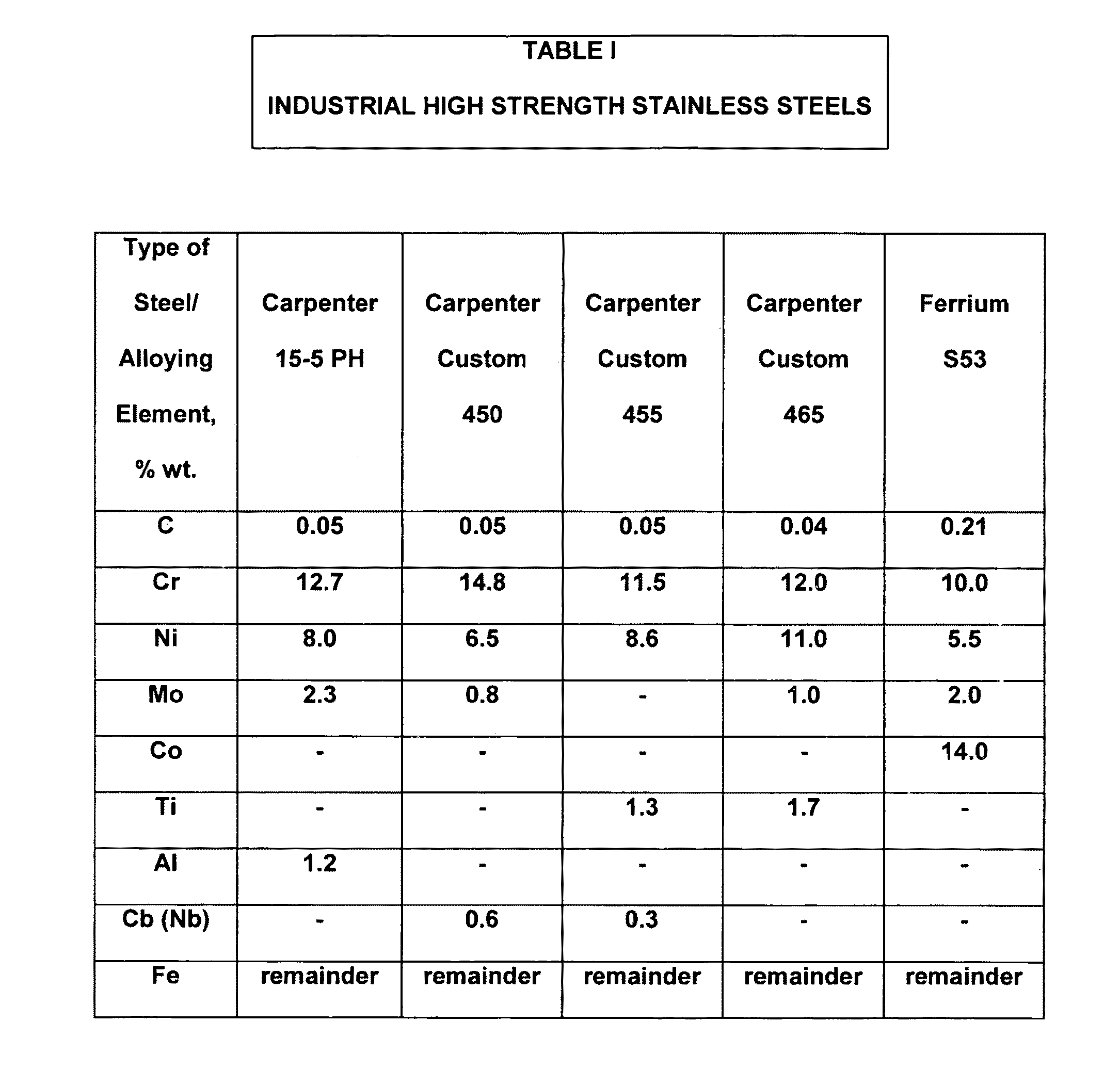

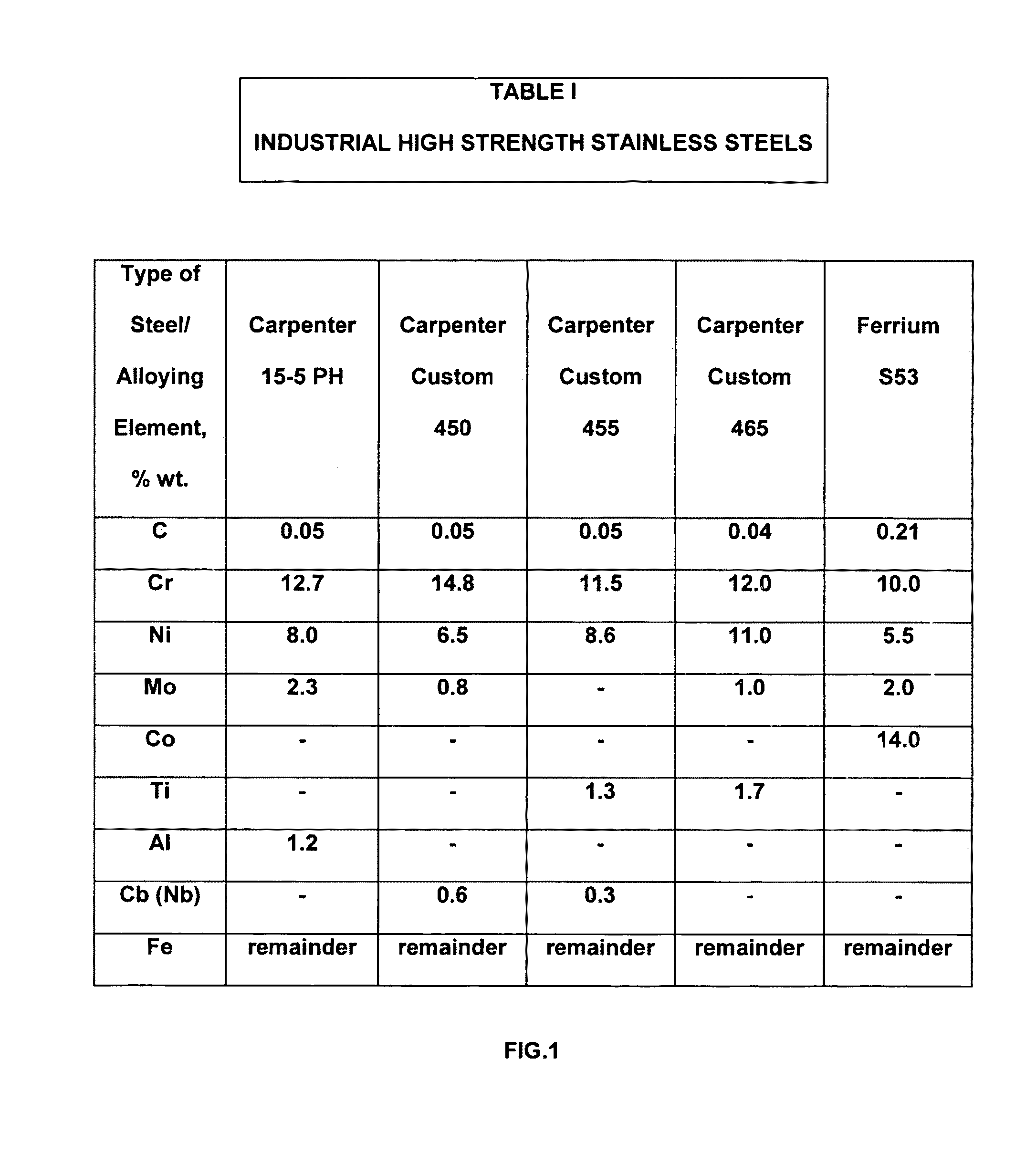

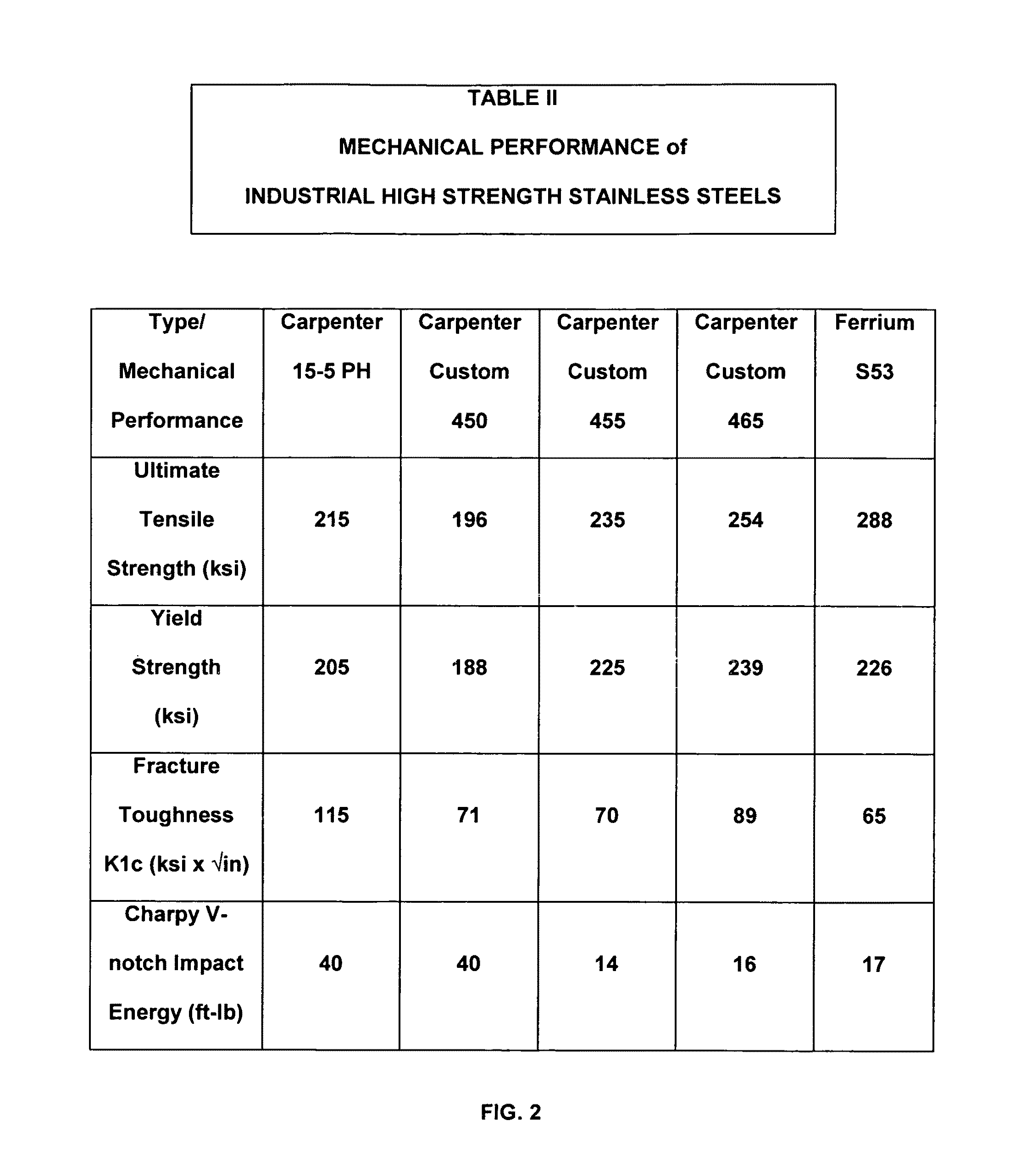

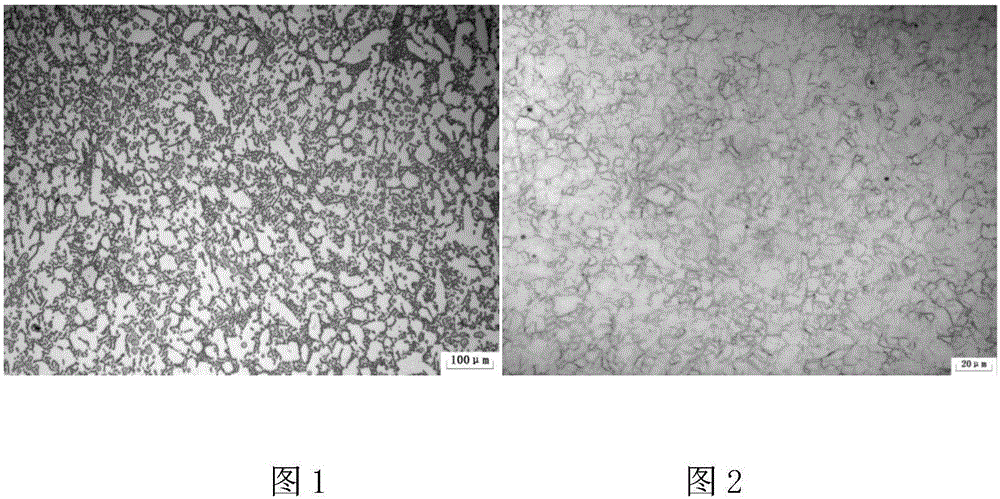

Low cost high strength martensitic stainless steel

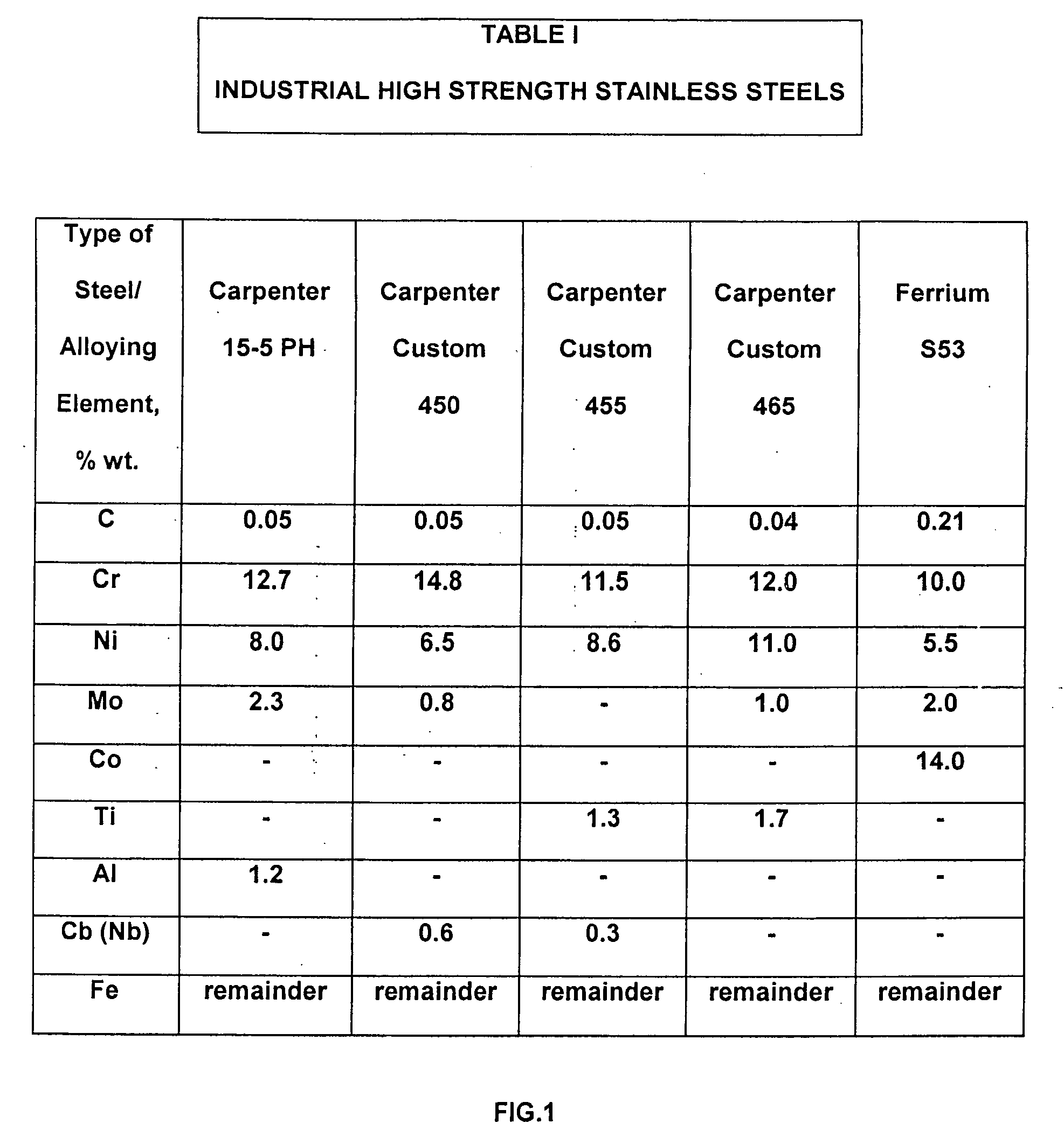

A cobalt-free low cost high strength martensitic stainless steel, with concentration of Ni up to 3.0% and Mo up to 1.0% of weight, has HRC of 53, UTS of 297 ksi, YS of 220 ksi, Charpy V-notch impact energy of 17.8 ft-lb, corrosion resistance in salt spray test ASTM 117. The steel was melted in an open induction furnace and vacuum arc remelting (VAR) and / or electroslag remelting (ESR) were not used to refine the steel. Further processing included homogenized annealing, hot rolling, and recrystallization annealing. The steel was heat treated by oil quenching, refrigeration, and low tempering. The steel has a microstructure consisting essentially of small packets of fine martensite laths, retained austenite, and carbides as centers of growth of the martensite laths. The cost and energy in making the steel are substantially reduced.

Owner:FEDCHUN VLADIMIR A +1

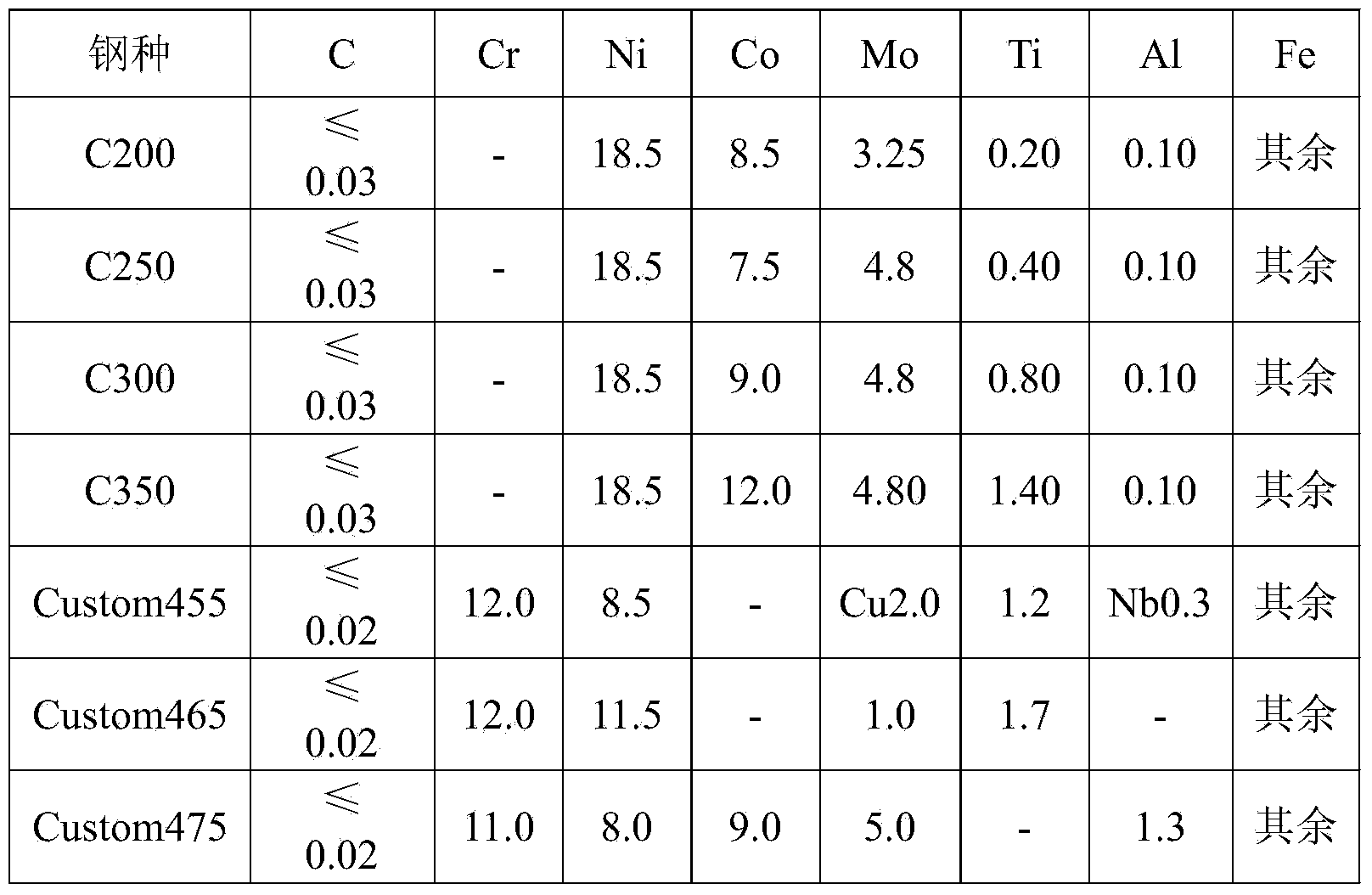

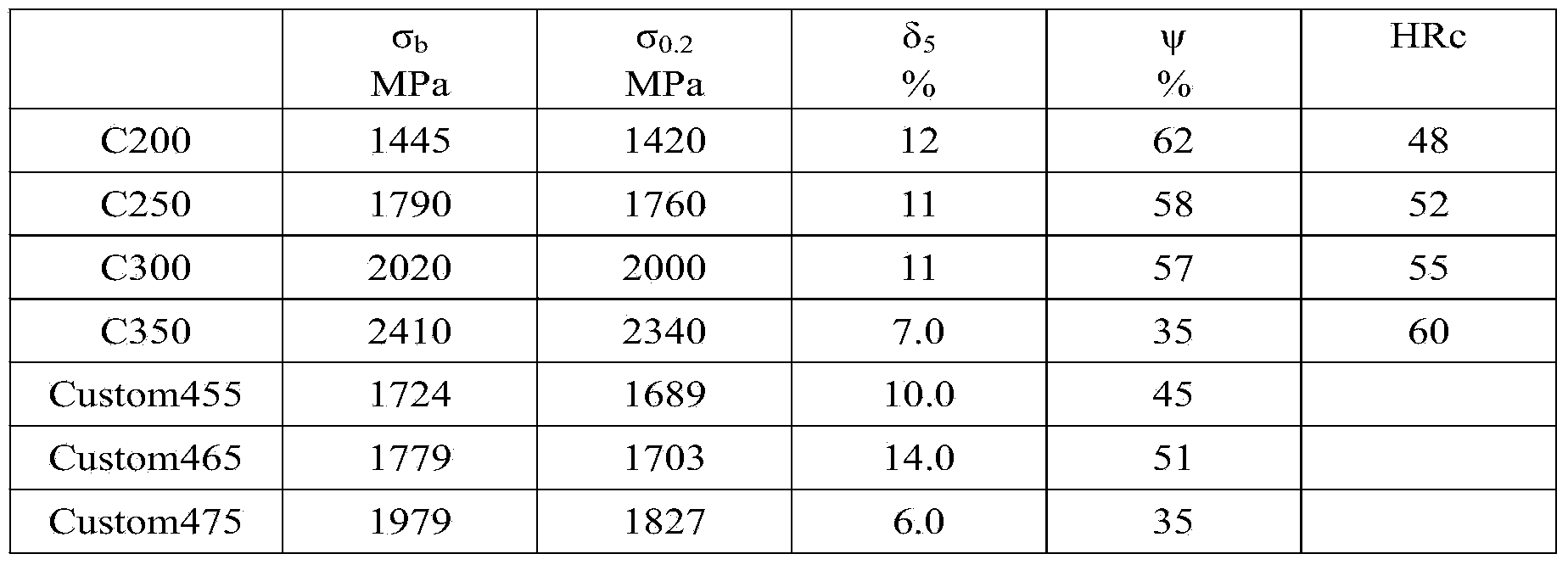

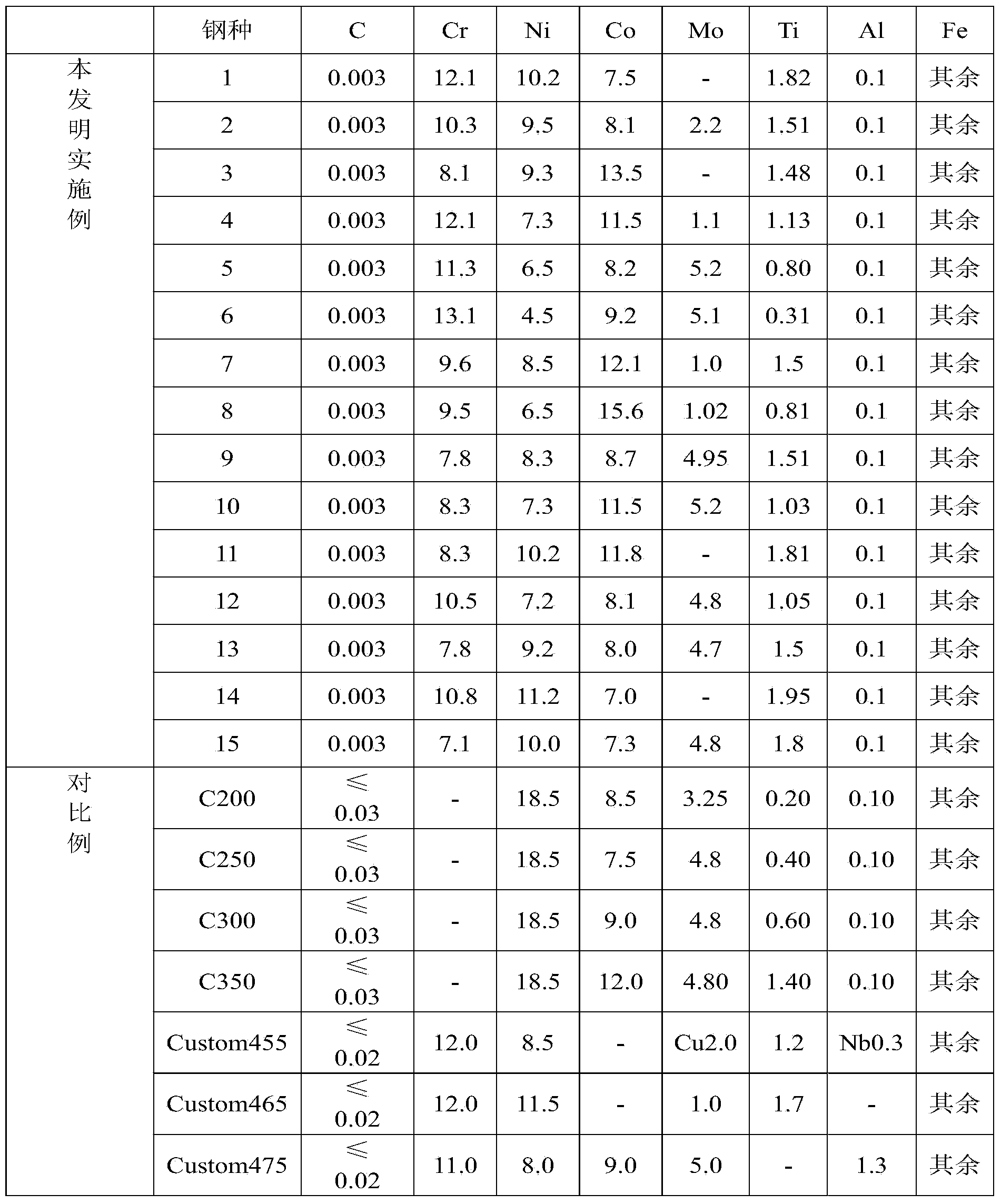

Titanium reinforced high-cobalt martensitic aged anti-corrosion ultrahigh-strength steel and preparation method

The invention discloses titanium reinforced high-cobalt martensitic aged anti-corrosion ultrahigh-strength steel and a preparation method, belonging to the technical field of alloy steel. The steel comprises the following chemical components in percentage by weight: less than or equal to 0.01% of C, 7.0 to 14.0% of Cr, 3.0 to 11.0% of Ni, 5.0 to 17.0% of Co, 0 to 6.0% of Mo, 0.3 to 2.0% of Ti, less than or equal to 0.3% of Al, and the balance of Fe and inevitable impurity elements. The preparation method preferably adopts smelting processes of vacuum induction, vacuum arc remelting or vacuum induction, electroslag remelting and the like. Compared with the prior art, the steel has the advantages that the comprehensive performance is good under the co-action of high Ti and Co content in the alloy, and the steel has strong toughness matching, higher strength and better stress corrosion resistance at the same time due to the corresponding Cr.

Owner:CENT IRON & STEEL RES INST

Method of manufacturing a rotating apparatus disk

InactiveUS20060075624A1Semiconductor/solid-state device detailsExtrusion containersDeposition processVacuum arc remelting

A method (20) of fabricating a large component such as a gas turbine or compressor disk (32) from segregation-prone materials such as Alloy 706 or Alloy 718 when the size of the ingot required is larger than the size that can be predictably formed without segregations using known triple melt processes. A sound inner core ingot (12) is formed (22) to a first diameter (D1), such as by using a triple melt process including vacuum induction melting (VIM), electroslag remelting (ESR), and vacuum arc remelting (VAR). Material is than added (26) to the outer surface (16) of the core ingot to increase its size to a dimension (D2) required for the forging operation (28). A powder metallurgy or spray deposition process may be used to apply the added material. The added material may have properties that are different than those of the core ingot and may be of graded composition across its depth. This process overcomes ingot size limitations for segregation-prone materials.

Owner:SIEMENS ENERGY INC

Large diameter ingots of nickel base alloys

InactiveUS20020170386A1Difficult to extractIncrease the diameterWelding/cutting media/materialsElectric furnaceCasting moldHeating furnace

A method of producing a nickel base alloy includes casting the alloy within a casting mold and subsequently annealing and overaging the ingot at at least 1200° F. (649° C.) for at least 10 hours. The ingot is electroslag remelted at a melt rate of at least 8 lbs / min. (3.63 kg / min.), and the ESR ingot is then transferred to a heating furnace within 4 hours of complete solidification and is subjected to a novel post-ESR heat treatment. A suitable VAR electrode is provided form the ESR ingot, and the electrode is vacuum arc remelted at a melt rate of 8 to 11 lbs / minute (3.63 to 5.00 kg / minute) to provide a VAR ingot. The method allows premium quality VAR ingots having diameters greater than 30 inches (762 mm) to be prepared from Alloy 718 and other nickel base superalloys subject to significant segregation on casting.

Owner:ATI PROPERTIES

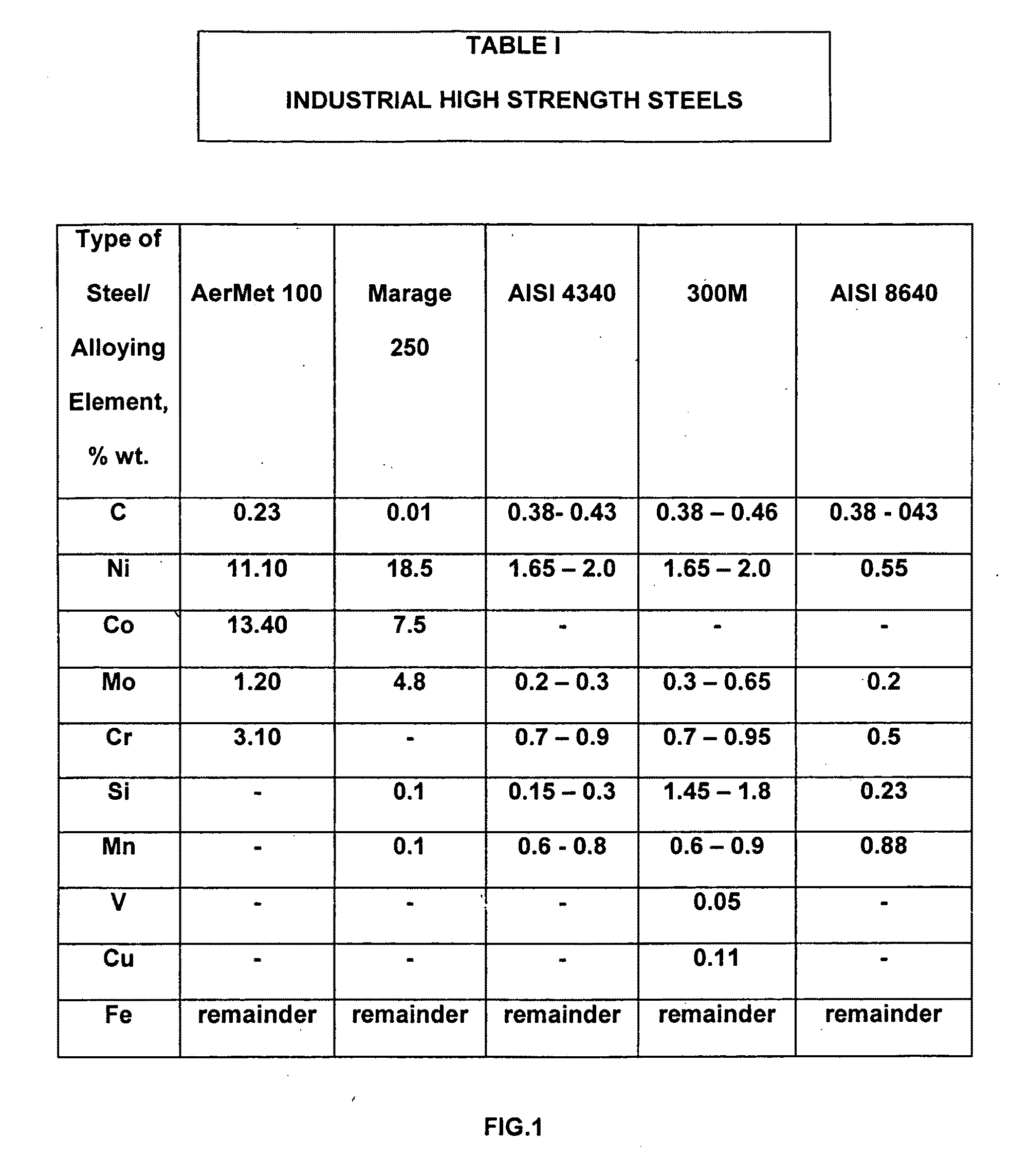

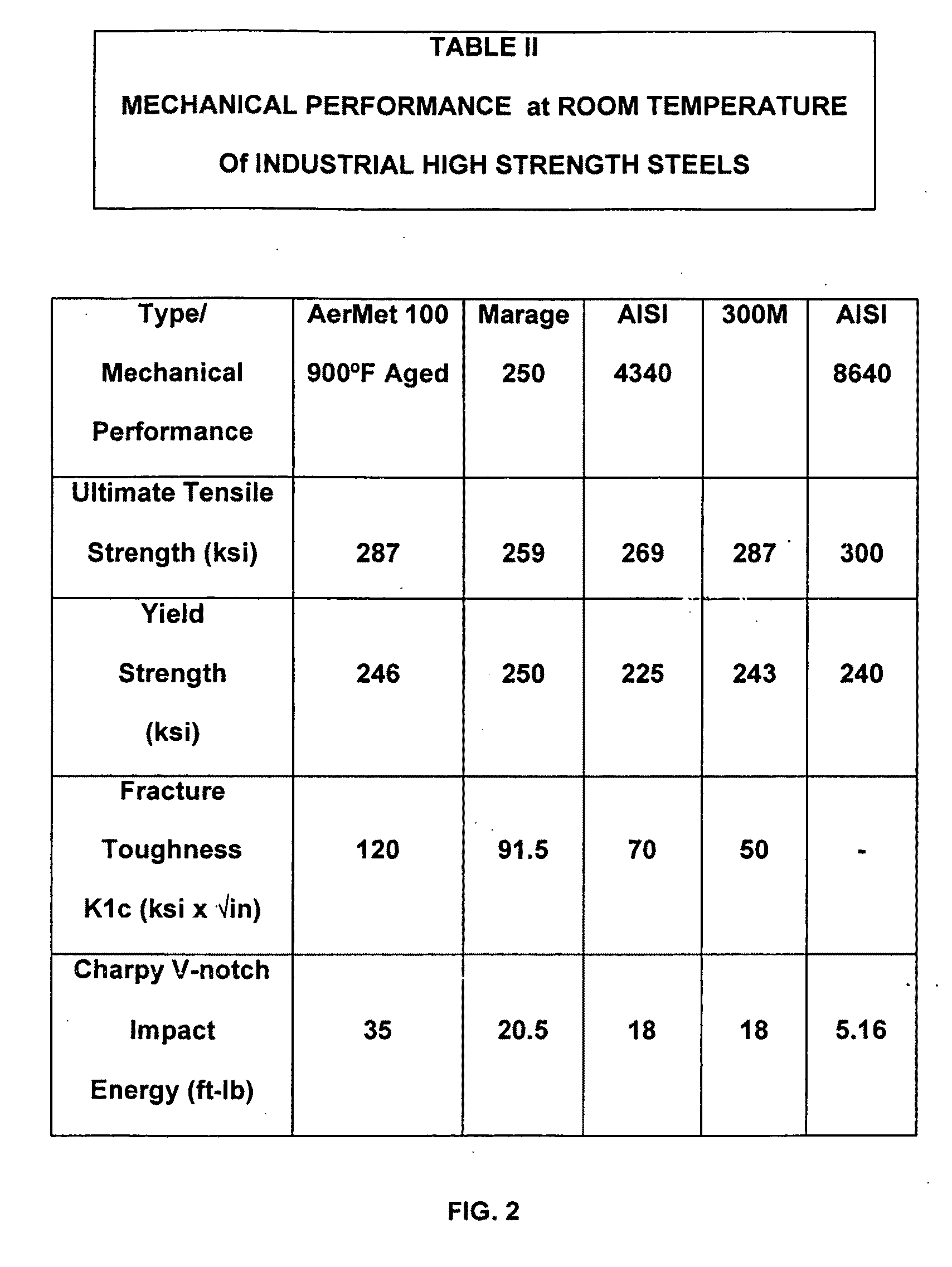

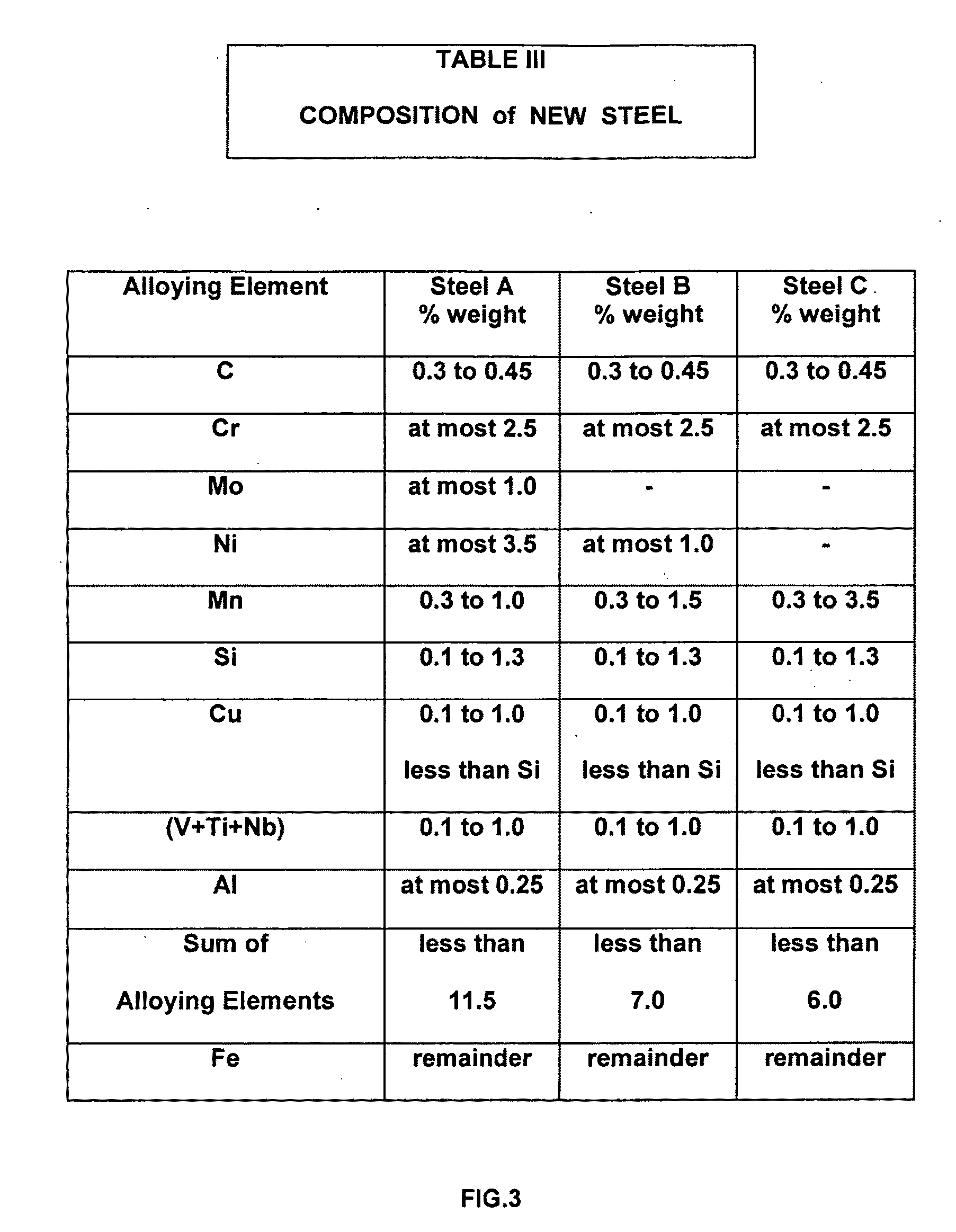

Method of designing a low cost, high strength, high toughness, martensitic steel and an article made thereof

InactiveUS20090291013A1Low costImprove toughnessHeat treatment process controlMathematical modelLaboratory scale

A method for designing a low cost, high strength, high toughness martensitic steel in which a mathematical model is used to establish an optimum low cost alloying concentration that provides specified levels of strength toughness. The model also predicts critical temperatures and the amount of retained austenite. Laboratory scale ingots of the optimum alloying composition were produced comprising by % wt. of about: 0.37 of C; 1.22 of Ni; 0.68 of Mn; 0.86 of Si; 0.51 of Cu; 1.77 of Cr; and 0.24 of V; and the balance Fe and incidental impurities were melted in an open induction furnace. After homogenized annealing, hot rolling, recrystallization annealing, and further oil quenching, refrigerating, and low tempering, a tempered martensite microstructure was produced consisting of small packets of martensitic laths, fine vanadium carbide, as centers of growth of the martensitic lathes, and retained austenite. Mechanical tests showed the following results: HRC of 52; UTS of 282 ksi; YS of 226 ksi; Charpy V-notch impact toughness energy of 31 ft-lbs. Energy consumption vacuum arc remelting (VAR) and electroslag remelting (ESR) were not required for improving strength and toughness.

Owner:FEDCHUN VLADIMIR A +1

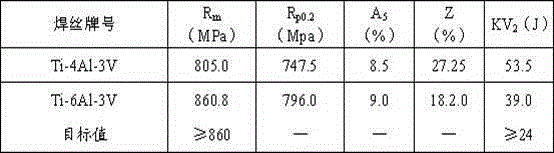

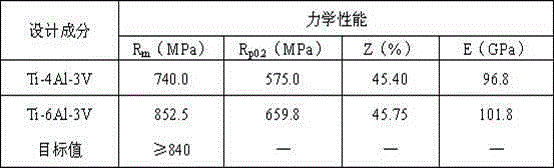

Special Ti-6Al-3V welding wire for Ti-6Al-4V ELI titanium alloy and machining process of special Ti-6Al-3V welding wire

InactiveCN104923968AImprovement and improvement of mechanical propertiesHigh tensile strengthWelding/cutting media/materialsWelding/soldering/cutting articlesMetallic aluminumTitanium alloy

The invention provides a special Ti-6Al-3V welding wire for Ti-6Al-4V ELI titanium alloy and a machining process of the special Ti-6Al-3V welding wire. The special Ti-6Al-3V welding wire includes the alloy components of, by weight, 5.5-6.75% of Al, 2.5-4.5% of V, smaller than 0.20% of Fe, smaller than 0.13% of O and the balance Ti. The machining process of the special Ti-6Al-3V welding wire includes the following steps that a, the raw material weight ratio of Al-V intermediate alloy to pure metal aluminum to titanium sponge is calculated according to the design components of the welding wire, and the raw materials are smelted into ingots through vacuum arc remelting; b, the ingots are forged into bar billets; c, the bar billets are rolled into bars; d, the bars are rolled into wire billets; e, the wire billets are stretched; f, the wire billets are straightened, descaled, polished and ground; g, the wire billets are thermally treated and then stretched into wires; h, vacuum annealing is conducted on the wires after alkaline washing and acid washing are conducted on the wires; i, the wires are straightened and then cut into straight wires; j, the straight wires are ground into finished products. Through the adjustment of the content of main alloy elements and impurity elements and the reasonable production process, the titanium welding wire with better mechanical performance matching performance with the Ti-6Al-4V ELI titanium alloy is produced, and the performance of a weld joint of the welding wire can meet the index requirements of a manned cabin.

Owner:BAOJI TITANIUM IND CO LTD

Method for smelting and producing TA10 hot continuous rolling square billet by adopting electron beam cooling bed furnace

InactiveCN104212989AImprove ingot qualityThe melting process is simpleElectric arc furnaceIngot casting

The invention discloses a method for smelting and producing a TA10 hot continuous rolling square billet by adopting an electron beam cooling bed furnace. The production process comprises the following steps that firstly, titanium sponge with the granularity of 6 mm to 10 mm and molybdenum particles with the granularity of 6 mm to 8 mm are mixed, after being evenly mixed, the titanium sponge and the molybdenum particles are pressed into an electrode block, in-furnace welding is adopted to enable the electrode block to be welded into an electrode, a vacuum arc remelting furnace is used for one-time smelting to obtain Ti-Mo intermediate alloy, and the content of Mo in the Ti-Mo intermediate alloy is 15 percent to 25 percent; secondly, the Ti-Mo intermediate alloy manufactured in the first step is broken in an ingot mode to form Ti-Mo intermediate alloy particles with the granularity smaller than or equal to 3 mm; and the like. The method for smelting and producing the TA10 hot continuous rolling square billet by adopting the electron beam cooling bed furnace is simple in process and convenient to operate, the ingot casting quality is improved, meanwhile, the production process is greatly shortened, the yield is improved, the production cost is greatly reduced, and the billet has the good market competition capability.

Owner:YUNNAN TITANIUM IND

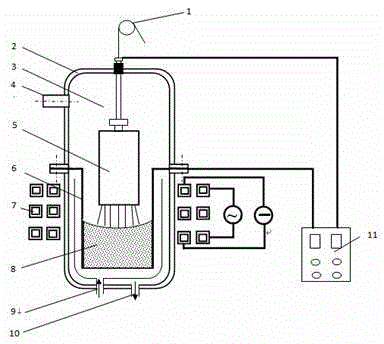

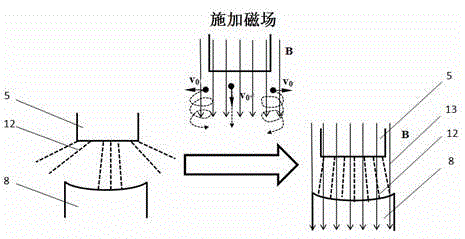

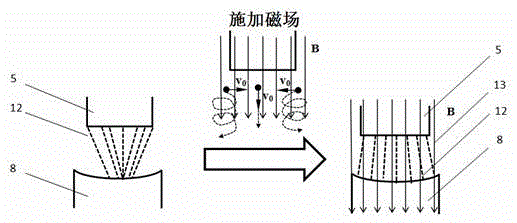

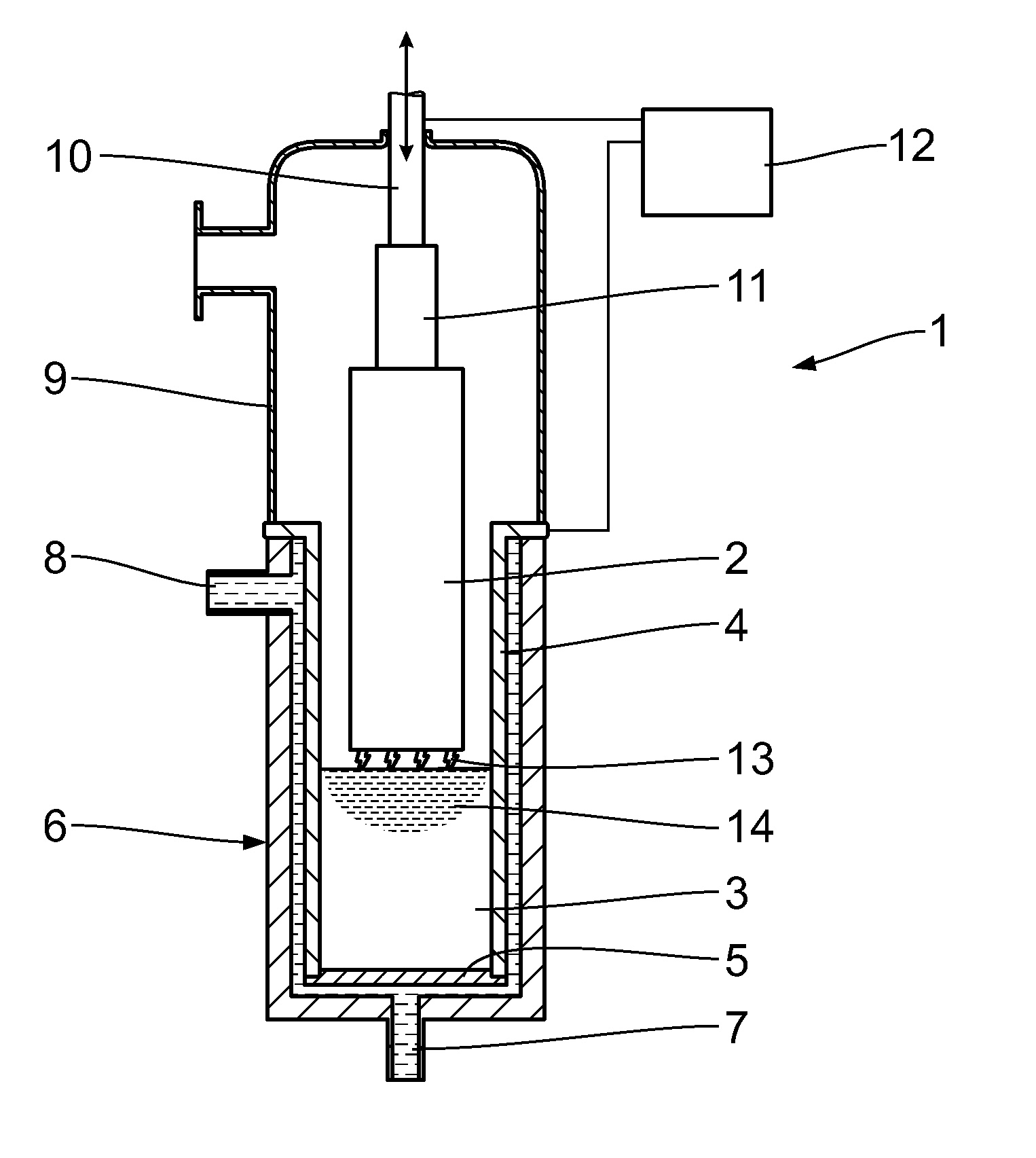

Method and device for remelting and refining metals by vacuum magnetic-control arc

The invention discloses a method and a device for remelting and refining metals by a vacuum magnetic-control arc. According to the method and the device, a magnetic field generator is applied on the tail end of a vacuum arc remelting electrode and the periphery of a metal melting pool; the magnetic field generator is composed of two groups of concentric coils; a direct current and an alternating current are charged respectively; and a static magnetic field component generated by charging the direct current forms an inhibition effect on charged particles which radially move, thus delaying generations of an inter-electrode ion-lacking phenomenon and anode spots, reducing the voltage and the energy of the arc, and preventing that an agglomerated arc is formed to remelt so that the local temperature of the electrode is too high to generate serious fusion and vaporization to influence metallurgical quality; meanwhile, the alternating magnetic field component generated by charging the alternating current is capable of forming a certain pressure gradient in the metal melting pool, and generating pressure wave broken dendrites; in additional, a certain included angle always exists between the alternating magnetic field and the current of the direct-current arc, so that a certain oscillation Lorentz force is formed, thus contributing to break dendrites, refine solidification structures and reduce cast ingot segregations.

Owner:SHANGHAI UNIV

Manufacturing method for tube blank made of high-silicon titanium-contained austenitic stainless steel

ActiveCN108866271AGuaranteed Chemical CompositionAssurance Control RequirementsIncreasing energy efficiencyFurnace typesVacuum arc remeltingAustenite

The invention belongs to the technical field of metallurgical materials, and relates to a manufacturing method for a tube blank made of high-silicon titanium-contained austenitic stainless steel. Themanufacturing method sequentially comprises the following steps that (1) ingredients of the high-silicon titanium-contained austenitic stainless steel are smelted in a vacuum induction furnace; (2) vacuum arc remelting is carried out; and (3) homogenization and forging are carried out, specifically, forging in a rapid forging machine and forging in a precision forging machine are carried out in sequence, wherein in the forging process of the rapid forging machine, the tong handle forging process, the pre-deformation process, the homogenization heat treatment process, the rapid forging processand the cutting process are carried out in sequence, and in the forging sequence of the precision forging machine, the heat preservation process and the precision forging process are carried out in sequence. The manufacturing method for the tube blank made of the high-silicon titanium-contained austenitic stainless steel has the advantage that the produced tube blank can meet the uniformity control requirements of a fast reactor core cladding material on the content of harmful elements O and S, the inclusion level and the tissues in the tube blank.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

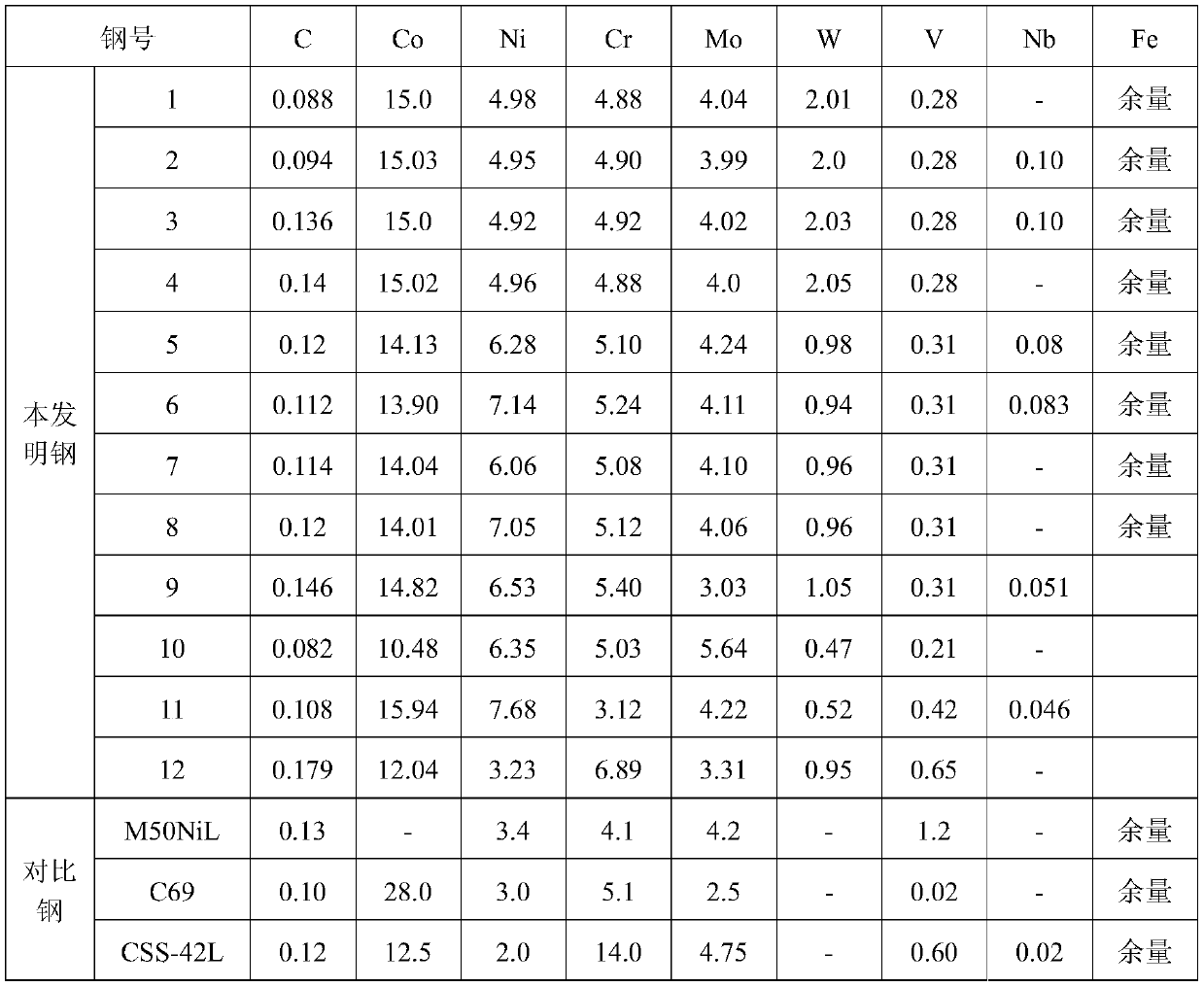

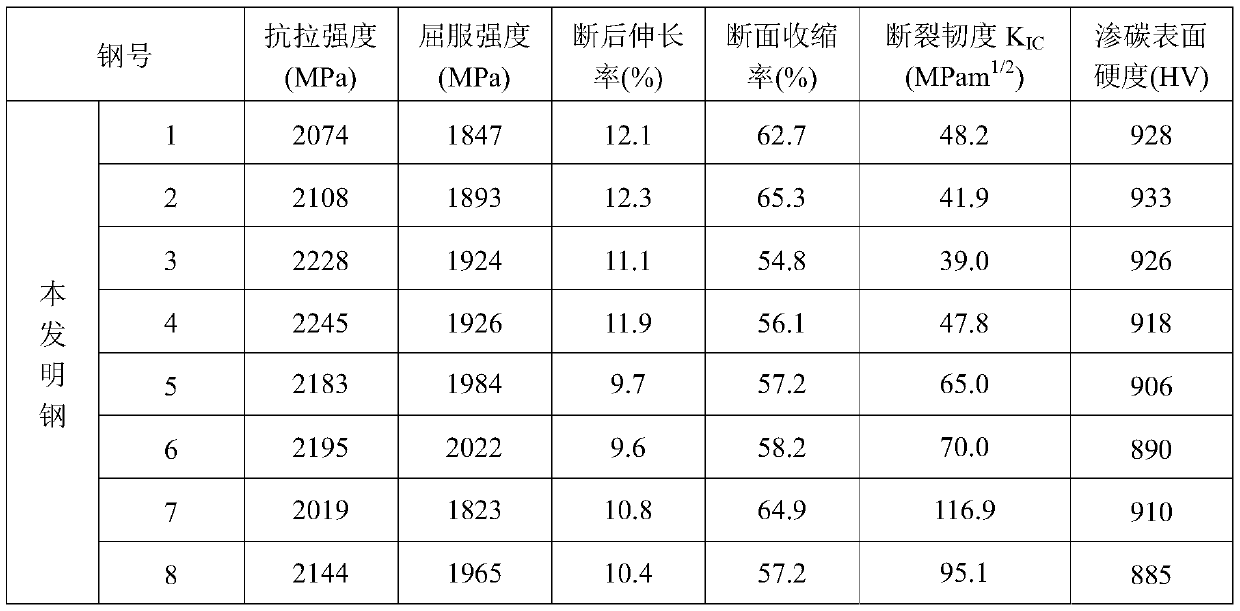

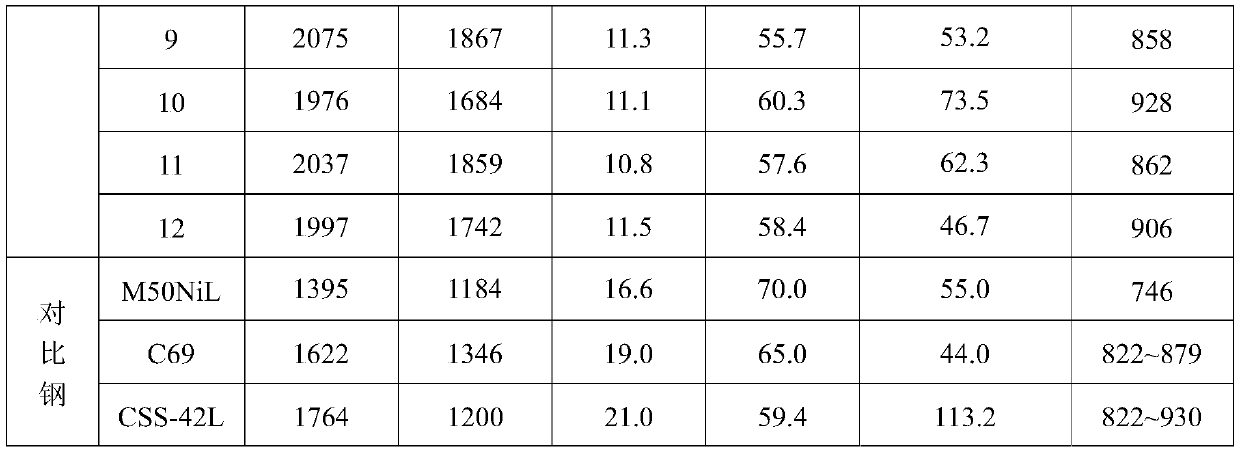

Ultra-high-strength heat-resistant gear bearing steel with ultra-hardened surface layer and preparation method thereof

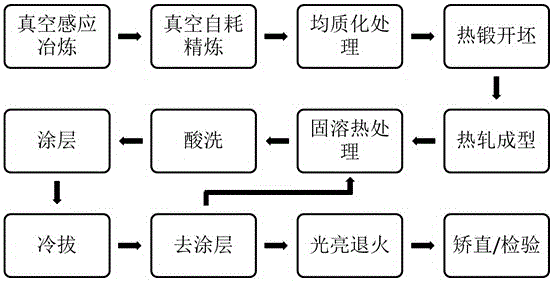

ActiveCN110423955AHigh tensile strengthImprove plasticitySolid state diffusion coatingCarburizingVacuum arc remelting

The invention belongs to the technical field of materials, and relates to an ultra-high-strength heat-resistant gear bearing steel with ultra-hardened surface layer and a preparation method thereof. The chemical composition of the steel comprises the following chemical components of, in percentage by mass, 0.08-0.18% of C, 10.0-16.0% of Co, 3.0-8.0% of Ni, 3.0-7.0% of Cr, 3.0-6.0% of Mo, 0.5-2.0%of W, 0.2-1.0% of V, 0-0.1% of Nb, and the balance Fe and impurity elements. According to the method, vacuum induction melting, vacuum induction melting and vacuum arc remelting or vacuum induction melting and electroslag remelting are adopted for smelting. Steel ingots are diffusion annealed and forged into steel products. Steel samples are subjected to preliminary heat treatment, carburization and final heat treatment, the tensile strength of the steel is not less than 1900 MP a, the yield strength is not less than 1600 MP a, and the carburized surface hardness is not less than 850 HV (equivalent to 66 HRC). The method has the advantages that compared with the prior art, the method has higher tensile strength, yield strength and relatively good plasticity, toughness and heat resistance,has excellent surface carburization super-hardening performance and fatigue performance, and achieves good matching of the core super-toughening and surface super-hardening.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Preparation method of solid cored welding wire for molten-salt corrosion resistance nickel-base superalloy welding

ActiveCN106181131APrecise content controlReduce lossWelding/cutting media/materialsSoldering mediaSolution treatmentVacuum arc remelting

The invention discloses a preparation method of a solid cored welding wire for molten-salt corrosion resistance nickel-base superalloy welding, and belongs to the technical field of metal welding. The method includes the technological processes of vacuum smelting, vacuum arc remelting, homogenization, hot forging cogging, hot rolling, solution treatment, acid pickling, coating, cold drawing, coating removal and bright annealing. The invention further discloses the solid cored welding wire for molten-salt corrosion resistance nickel-base superalloy welding. The solid cored welding wire is prepared through the method. Compared with the prior art, by the adoption of the method, high-quality solid cored welding wires of various diameters for molten-salt corrosion resistance nickel-base superalloy welding can be produced with the extremely-high rolling yield in a batch mode, and the prepared solid cored welding wire can meet the requirement for welding molten-salt reactor structural materials.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Method for preparing copper and chromium 50 electric contact material by utilizing vacuum arc remelting furnace

ActiveCN108441670ASmall particle sizeEvenly distributedTransportation and packagingMetal-working apparatusVacuum arc remeltingImpurity

The invention relates to a method for preparing a copper and chromium 50 electric contact material by utilizing a vacuum arc remelting furnace. Copper powder with particle diameter ranging from 0.01 micron to 1 micro, and chromium powder with particle diameter ranging from 0.01 micron to 1 micro are prepared with a new method, and are smaller in particle diameter compared with the copper powder and the chromium powder used in the prior art. The prepared copper powder and chromium powder are chosen to be mixed according to certain proportion, the mixer is pressed into material bars by using cold isostatic pressing, and the material bars carry out consumable electrode arc melting after being sintered to form alloy ingots. Under the action of a high-temperature electric arc, a consumable electrode carries out layered melting quickly and evenly and drops to the bottom of a water cooling crystallizer, and because of the large cooling rate on the periphery of the crystallizer furthermore, itis realized that Cu and Cr alloy ingots solidify, and then uniform and fine Cu and Cr alloy structures are obtained, wherein the content of Cr in Cu and Cr alloy ranges from 45% to 55%. According tothe method for preparing the copper chromium 50 electric contact material by utilizing the vacuum arc remelting furnace, a vacuum consumable electrode arc melting method is used for preparing a Cu andCr electric contact material with the content of Cr ranging from 45% to 55% (wt), the material is free of pores, loose, less in impurities, free of macro and micro defects such as Cu and Cr enrichment, and both the microstructure of Cu and the microstructure of Cr are smaller than 20 micrometers.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

Titanium alloy preparation technology

The invention discloses an efficient energy-saving short-process technology for preparing high-quality titanium alloy Ti-Ni-Nb, and provides a titanium alloy preparation technology. The novel technical process is mainly composed of a titanium and titanium alloy crucible-type vacuum induction melting (VIM) technology and a titanium and titanium alloy cold-hearth melting (CHM) technology. The VIM technology is used for primary ingot casting of titanium and titanium alloy preparation, and the electrode preparation of vacuum arc remelting (VAR) electrode arc melting alloy and primary alloy melting of a traditional preparation technology are replaced. The CHM technology is used for secondary refining of the primary titanium and titanium alloy ingot, and then the titanium and titanium alloy ingot in a required shape is prepared. By means of the efficient energy-saving titanium alloy Ti-Ni-Nb preparation technology, the alloy preparation process can be simplified, and high quality alloy ingots in various shapes can be produced.

Owner:匡永刚

Low cost high strength martensitic stainless steel

A cobalt-free low cost high strength martensitic stainless steel, with concentration of Ni up to 3.0% and Mo up to 1.0% of weight, has HRC of 53, UTS of 297 ksi, YS of 220 ksi, Charpy V-notch impact energy of 17.8 ft-lb, corrosion resistance in salt spray test ASTM 117. The steel was melted in an open induction furnace and vacuum arc remelting (VAR) and / or electroslag remelting (ESR) were not used to refine the steel. Further processing included homogenized annealing, hot rolling, and recrystallization annealing. The steel was heat treated by oil quenching, refrigeration, and low tempering. The steel has a microstructure consisting essentially of small packets of fine martensite laths, retained austenite, and carbides as centers of growth of the martensite laths. The cost and energy in making the steel are substantially reduced.

Owner:FEDCHUN VLADIMIR A +1

Vacuum arc remelting method for inhibiting macrosegregation of high-temperature alloy with high content of Nb

The invention discloses a vacuum arc remelting method for inhibiting the macrosegregation of high-temperature alloy with high content of Nb, comprising the following steps: subjecting the high-temperature alloy with high content of Nb to vacuum arc remelting, wherein in the normal remelting process, the melting pressure is controlled at 22-30V, the melting current is controlled at 5,000-7,000A, and the molten drip rate is controlled at 6-8 drops per second; and cooling by water and helium filling, wherein the pressure of the helium is controlled at 300-500Pa. The invention further discloses the high-temperature alloy with high content of Nb, which is obtained by melting by adopting the method. According to the characteristics of a vacuum arc furnace and the characteristic that the high-temperature alloy with high content of Nb is easy to be subjected to macrosegregation in the process remelting by using the vacuum arc furnace, the vacuum arc remelting process parameters can be formulated reasonably, the macro component segregation is prevented and inhibited effectively. The product obtained by melting has good quality, high production efficiency and significant economic benefit.

Owner:PANGANG GROUP JIANGYOU CHANGCHENG SPECIAL STEEL

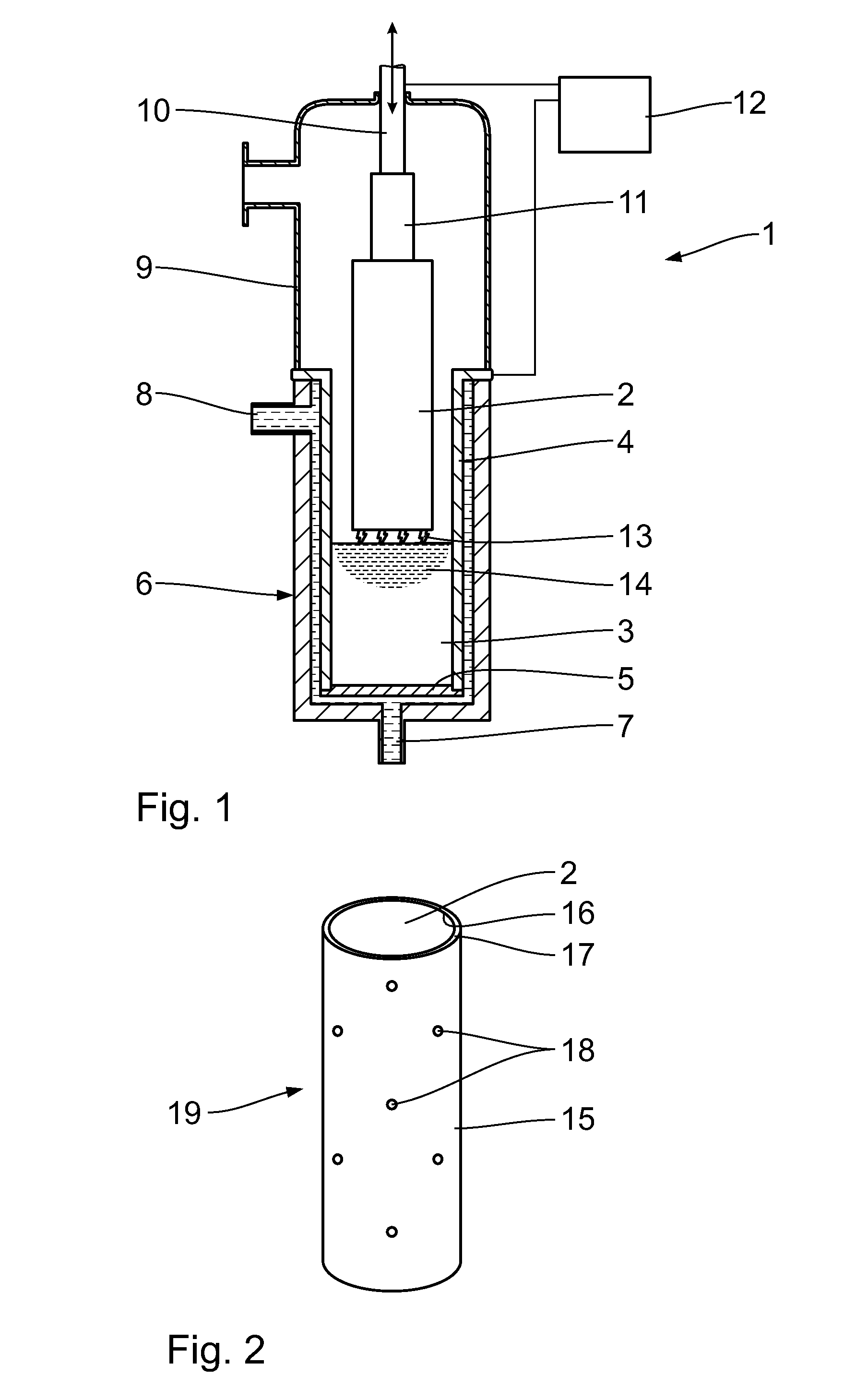

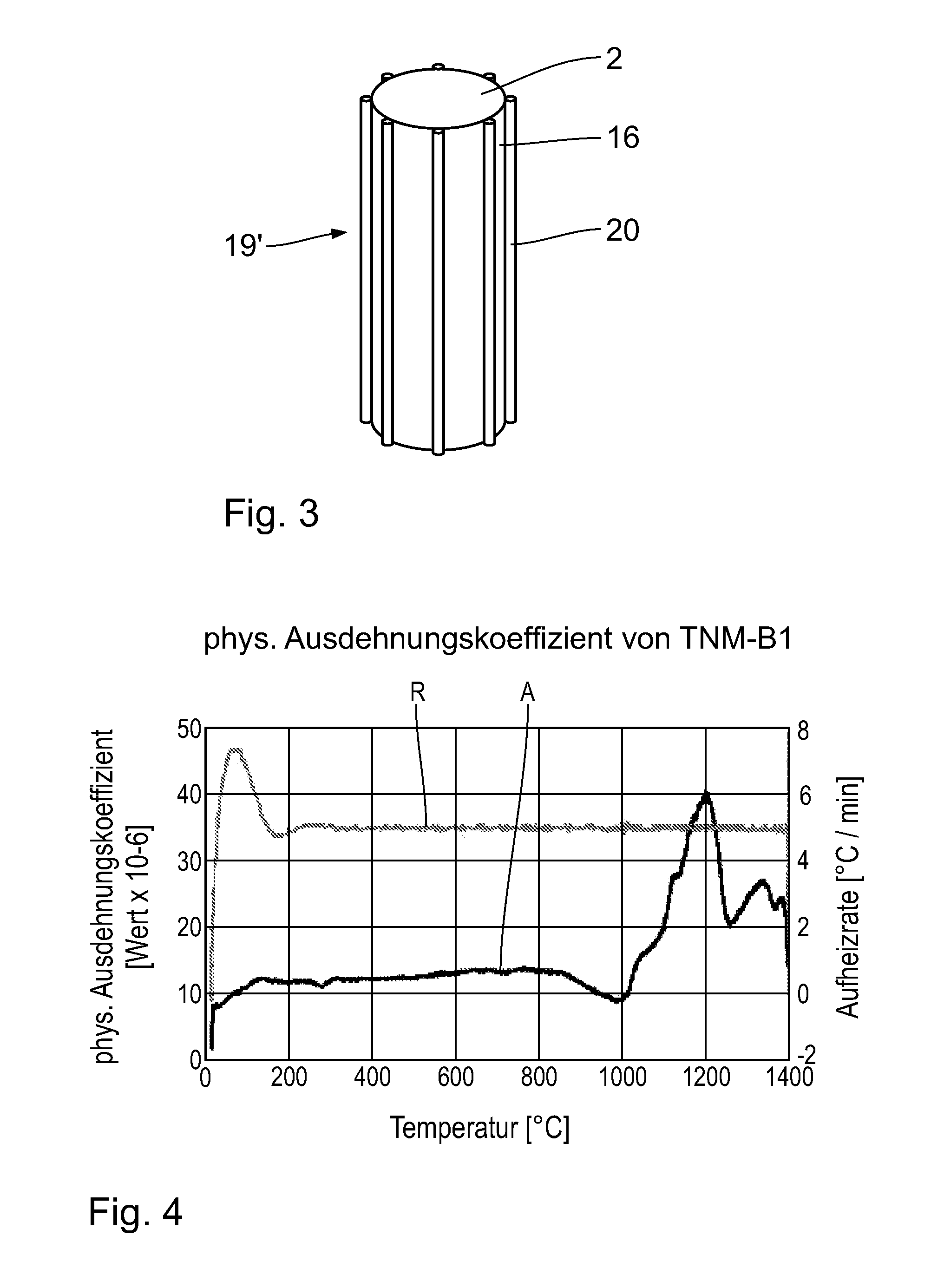

METHOD FOR THE PRODUCTION OF A Ãβ-y-TiAL BASE ALLOY

A method for the production of a γ-TiAl base alloy by vacuum arc remelting, which γ-TiAl base alloy solidifies via the (β-phase (β-γ-TiAl base alloy), comprises the following method steps:forming a basic melting electrode by melting, in at least one vacuum arc remelting step, of a conventional γ-TiAl primary alloy containing a lack of titanium and / or of at least one (β-stabilising element compared to the (β-γ-TiAl base alloy to be produced;allocating an amount of titanium and / or (β-stabilising element to the basic melting electrode, which amount corresponds to the reduced amount of titanium and / or (β-stabilising element, in an even distribution across the length and periphery of the basic melting electrode;adding the allocated amount of titanium and / or (β-stabilising element to the basic melting electrode so as to form the homogeneous (β-γ-TiAl base alloy in a final vacuum arc remelting step.

Owner:GFE METALLE & MATERIALIEN GMBH +1

Tungsten-containing titanium alloy smelting method

The invention discloses a tungsten-containing titanium alloy smelting method. Based on weight percent, 0.1 to 10 percent of tungsten powder is added when granular or chip titanium alloy raw material is mixed, and a tungsten-containing titanium alloy ingot with uniform components is obtained through multiple vacuum arc remelting. The tungsten powder is used as a raw material to be added into the tungsten-containing titanium alloy; because middle processes of preparing a tungsten rod from the tungsten powder by powder metallurgy and subsequent deformation processing technology and performing vacuum arc remelting on the tungsten rod and titanium sponge to form titanium tungsten intermediate alloy are saved, the production cost of the tungsten-containing titanium alloy is greatly reduced, the tungsten-containing titanium alloy ingot with uniform components and no segregation or inclusion can be obtained, and obvious economic benefit can be achieved.

Owner:XIAN SUPERCRYSYAL SCI TECH DEV CO LTD

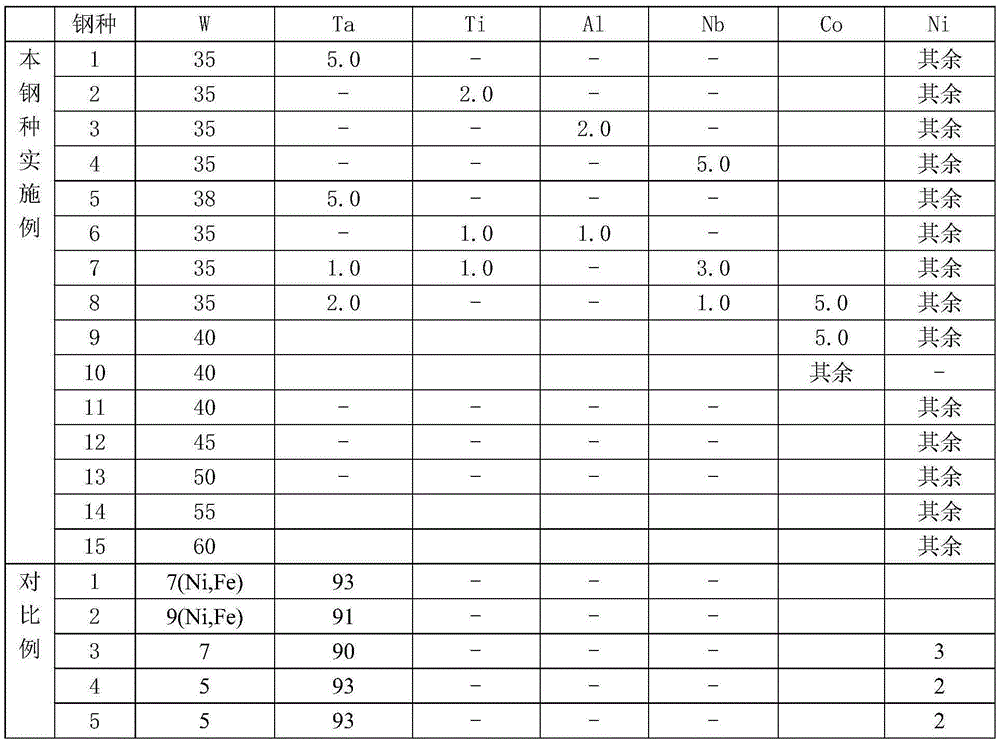

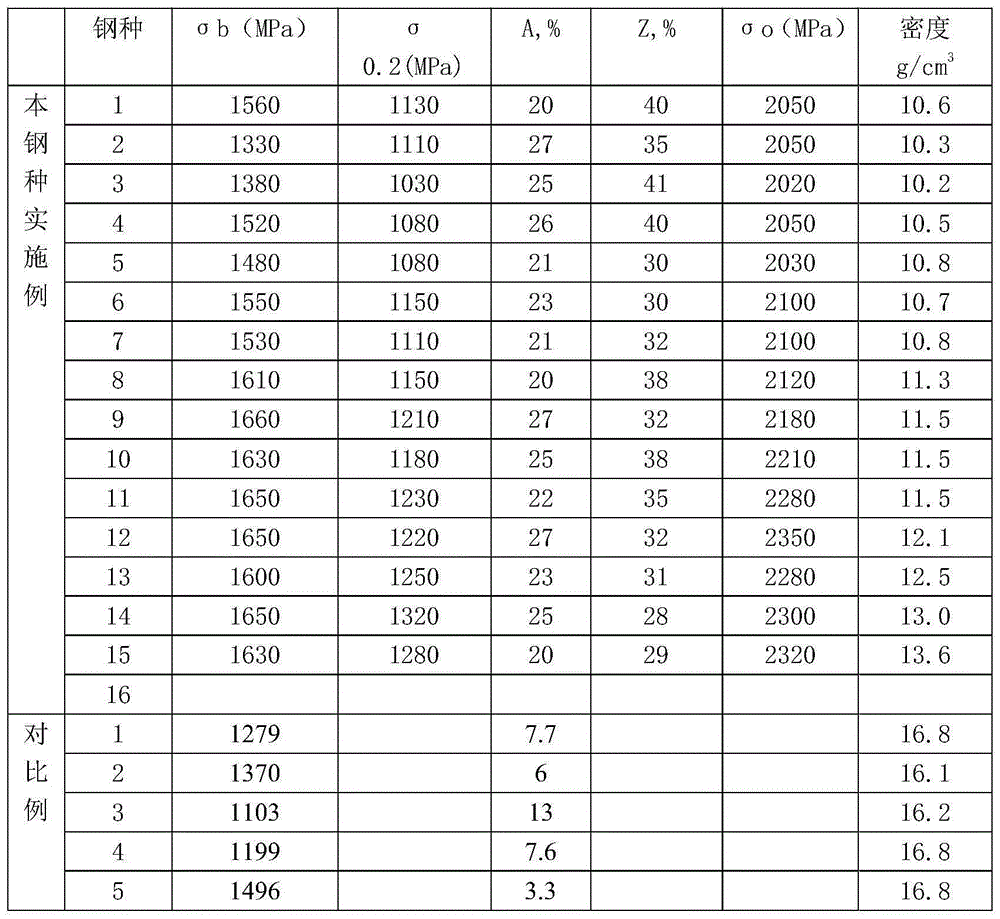

Double-phase high-density kinetic energy tungsten-nickel-cobalt alloy capable of being cast and forged and preparation method

The invention discloses double-phase high-density kinetic energy tungsten-nickel-cobalt alloy capable of being cast and forged and a preparation method, and belongs to the field of kinetic energy alloy. The double-phase high-density kinetic energy tungsten-nickel-cobalt alloy comprises, by weight, 35-65% of W, 0-3% of Ti, 0-3% of Al, 0-8% of Nb, 0-10% of Ta and the balance Ni or Co or NiCo, unavoidable impurity elements and micro elements like rare earth. The preparation method adopts vacuum induction plus vacuum arc remelting. Compared with the prior art, the double-phase high-density kinetic energy tungsten-nickel-cobalt alloy capable of being cast and forged is good in comprehensive performance, has high density, high rigidity, super high strength, super high dynamic strength and other excellent properties, the density can reach 11.0-15.0 g / cm<3>, the impact rigidity can reach 80 J / cm<2> or higher, the static tensile strength can reach 1300 MPa or higher, and the dynamic compression strength can reach 1800 MPa or higher.

Owner:CENT IRON & STEEL RES INST

Light-weight, high-strength, and high-elasticity titanium alloy and implementation method thereof

A light-weight, high-strength, and high-elasticity titanium alloy and an implementation method thereof. The titanium alloy is specifically Ti-8Al-2V-1Cr-0.75Zr, wherein the content of Al is 7.0% to 9.5%, the content of V is 0.5% to 4.0%, the content of Cr is 0.5% to 3.5%, the content of Zr is 0.5% to 2.0%, and the balance is Ti. The titanium alloy is obtained by vacuum arc remelting(VAR), after mold pressing through the adoption of sponge titanium, vanadium, chromium, aluminum zirconium pure, pure aluminum, aluminum vanadium alloy mixed consumable electrode. The titanium alloy is simple in preparation processing steps, low in processing cost, easy in production, and is applicable to various application fields with a requirement for a low-density and high-strength titanium alloy.

Owner:ZHEJIANG SHENJI TITANIUM IND

Metal-mold precision casting method for zirconium and zirconium alloy

ActiveCN103317114ALow thermal conductivityWide variety of sourcesFoundry mouldsFoundry coresSurface-active agentsVacuum arc remelting

The invention provides a metal-mold precision casting method for zirconium and zirconium alloy. The metal-mold precision casting method includes processing a metal mold, painting a high-temperature resistant coating on the inner surface of a mold cavity of the metal mold, and pouring zirconium alloy liquid into the metal mold by a vacuum-arc-remelting kish smelting method. The high-temperature resistant coating comprises, by weight, 55-70% of fire-proof powder, 30-45% of binder, 0.1-1% of surface active agent and 0.1-1% of antifoaming agent. The fire-proof powder is composed of one of Y2O3 (yttrium oxide) powder and ZrO2 (zirconium oxide) powder. The metal mold is simple in technique and convenient to process, and has wide material sources and service life of 10-50 times; for small-batch zirconium and zirconium alloy, production cycle is short and production efficiency is high.

Owner:SHENYANG RES INST OF FOUNDRY

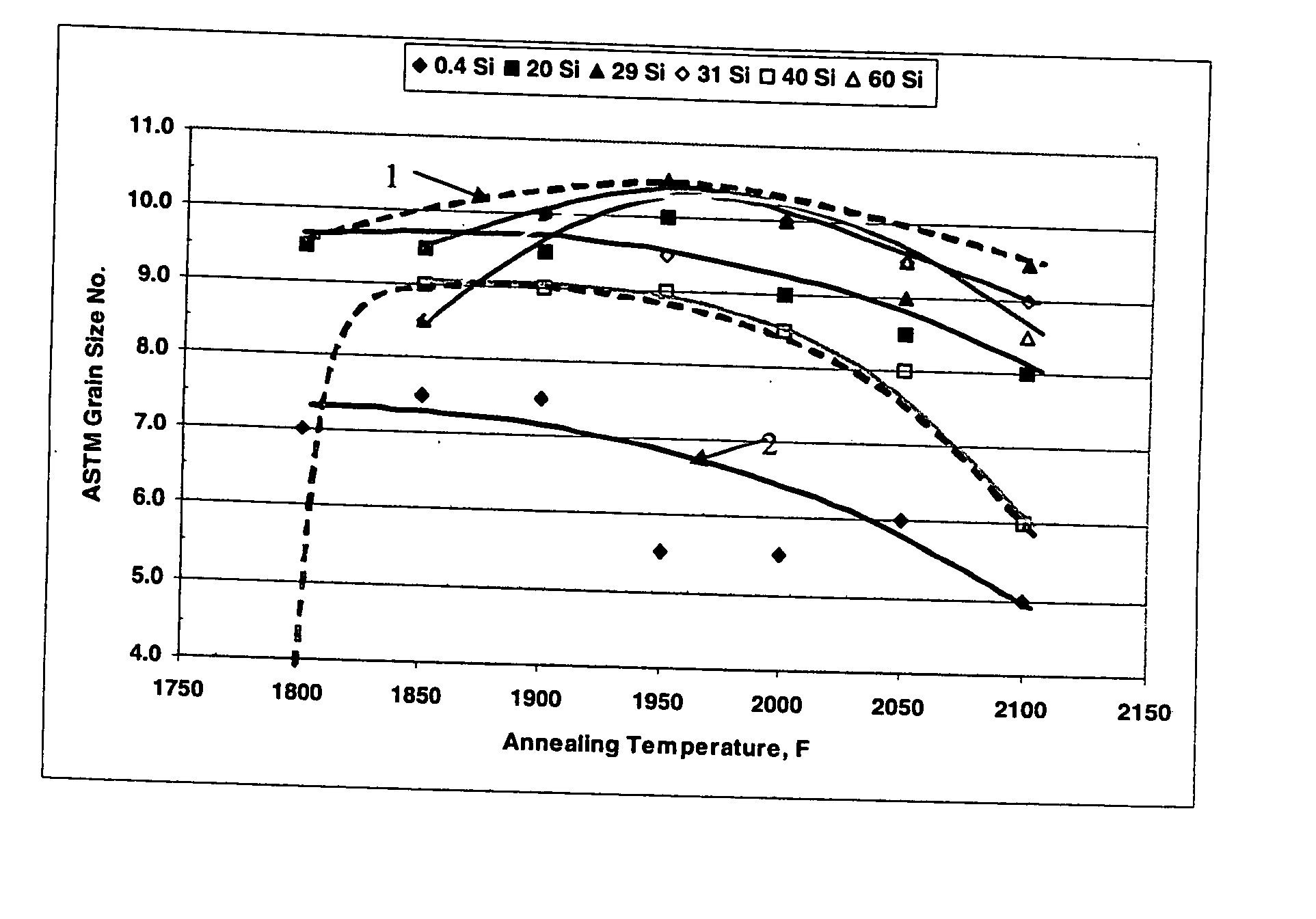

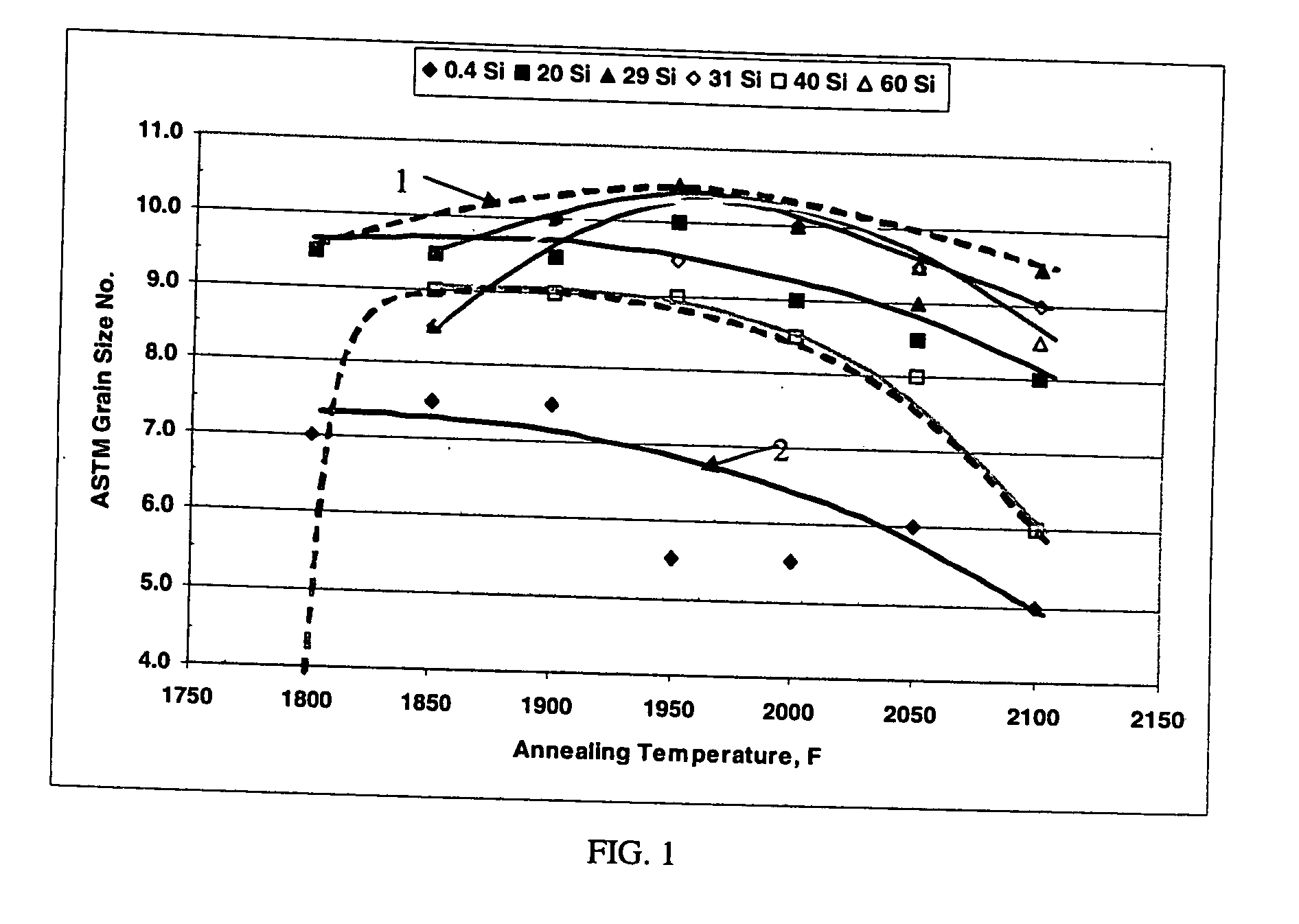

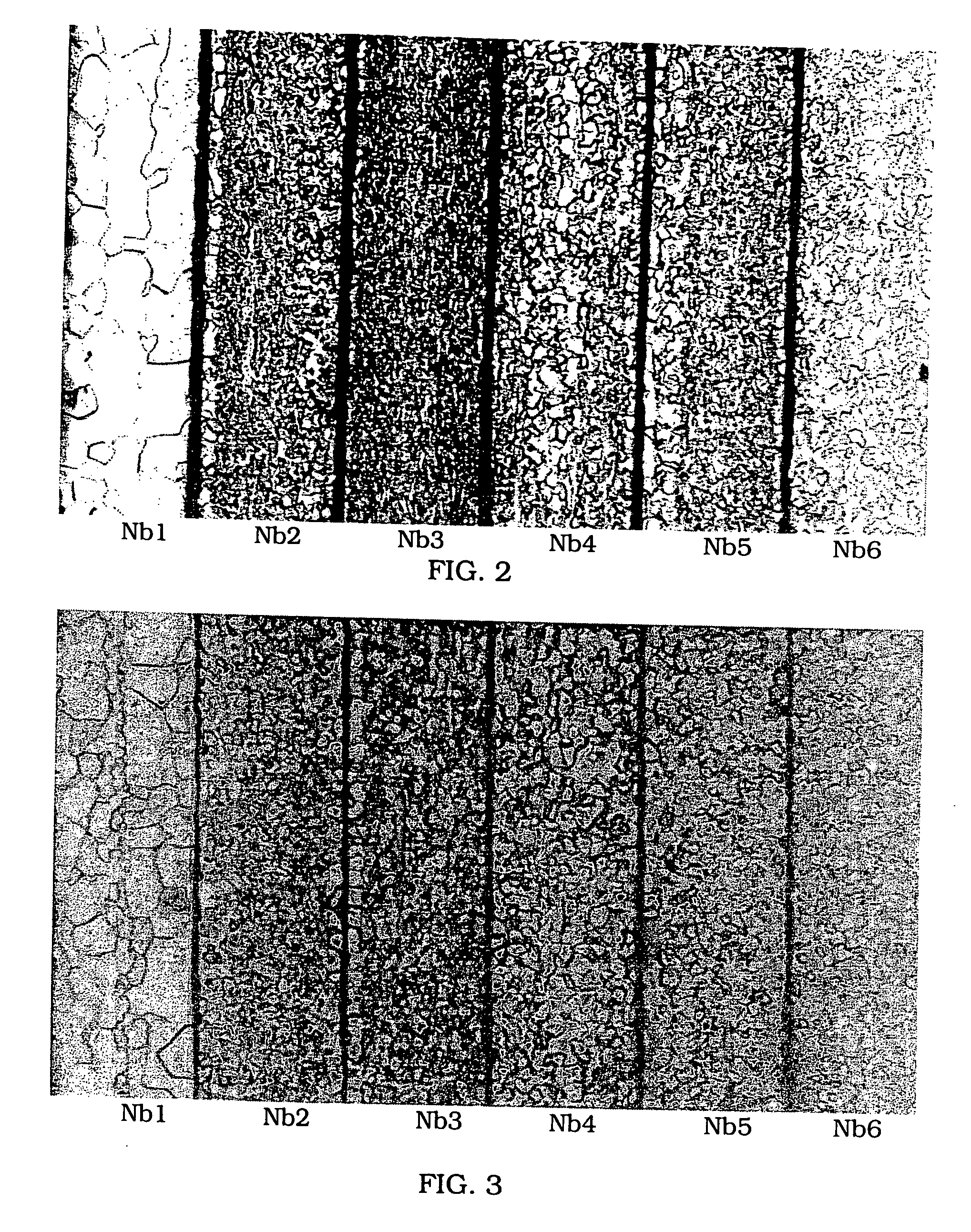

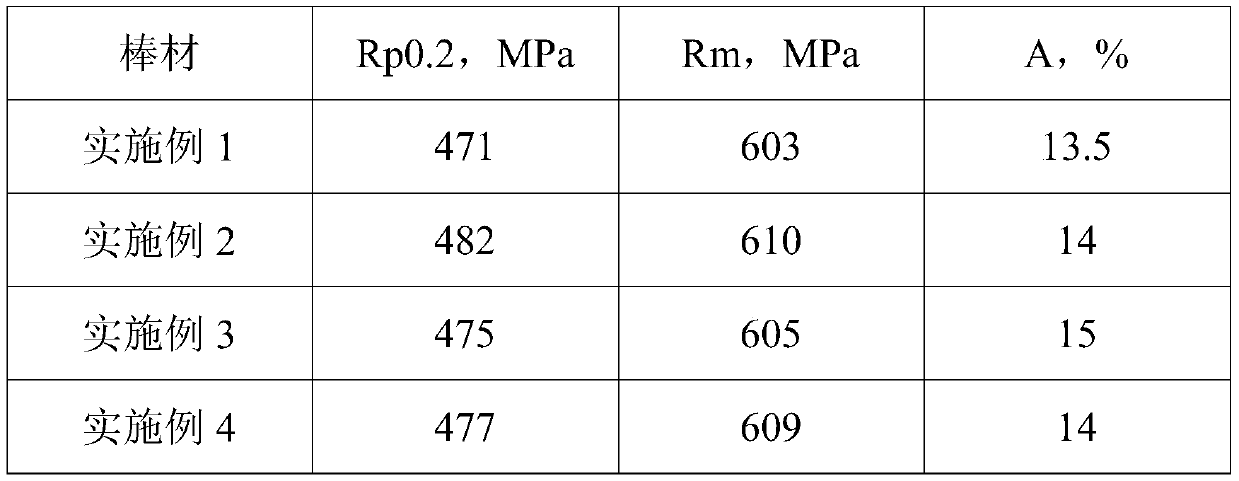

Fine grain niobium sheet via ingot metallurgy

A method of making a silicon-containing alloy of niobium or tantalum that includes: A) forming a blend comprising niobium or tantalum powder and silicon powder and pressing the blend to form pressed blend; B) attaching the pressed blend to an electrode comprising niobium or tantalum; C) melting the electrode and pressed blend under vacuum arc remelting conditions, such that the blend mixes with the melted electrode; D) cooling the melted electrode to form an alloy ingot; and E) applying thermo-mechanical processing steps to the alloy ingot to form a wrought product. The method provides a fully recrystalized niobium or tantalum wrought product with a grain size finer that ASTM 5, that can be used to make deep drawn cups and sputtering targets.

Owner:MATERION NEWTON INC

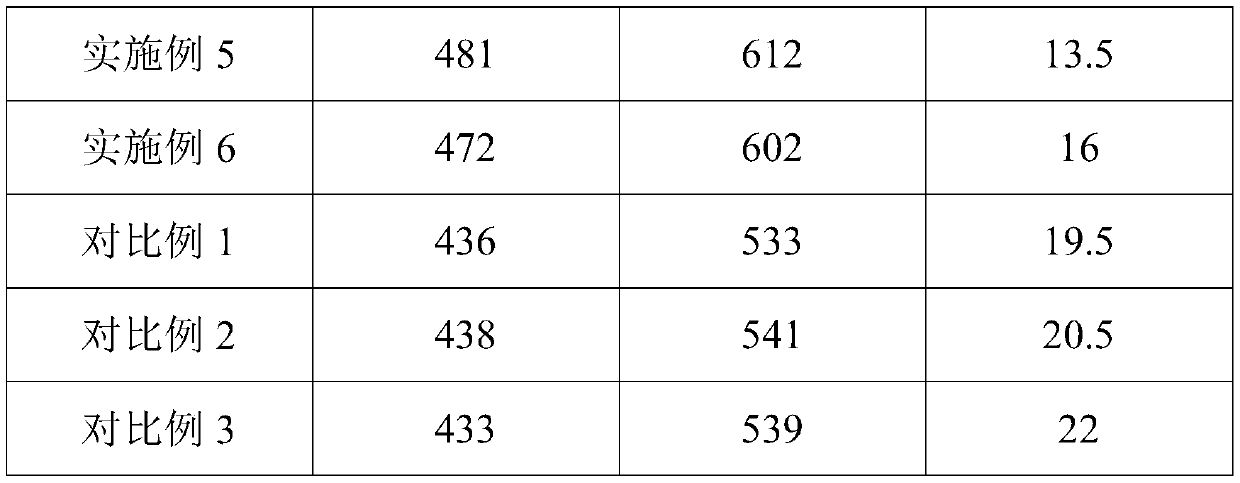

Multi-component alloy composite reinforced high-strength titanium alloy and preparation method thereof

The invention relates to a multi-component alloy composite reinforced high-strength titanium alloy and preparation thereof. The alloy comprises the following components in percentage by weight: 7-9% of vanadium, 3-5% of molybdenum, 2.5-3.5% of aluminum, 1.5-4.5% of chromium, 0.5-4.5% of zirconium, 0.5-3.5% of niobium and the balance of titanium and inevitable impurities. The preparation method comprises the following steps: melting in a vacuum arc remelting furnace; and peeling a melted titanium alloy ingot blank, performing hot forging, performing hot rolling, performing solution treatment, and aging to obtain the high-strength titanium alloy material. The titanium alloy prepared by the invention has excellent strength and plasticity matching; and the tensile properties at room temperature are as follows: sigma b is no less than 1300MPa, delta is no less than 10%, and psi is no less than 30%. The alloy material provided by the invention can be prepared into rods and plates, is applicable to high-strength fasteners, high-strength load-carrying structural parts, high-elasticity springs and the like, and has wide application prospects.

Owner:BAOJI TITANIUM IND +1

Treatment technology of anti-ash-deposition and anti-wear alloy material of waste heat recovery pipeline

InactiveCN105755316AImprove wear resistanceImprove corrosion resistancePressure inorganic powder coatingRare-earth elementAlloy

The invention discloses a treatment technology of an anti-ash-deposition and anti-wear alloy material of a waste heat recovery pipeline.An alloy blank is selected, vacuum arc remelting or electro slag remelting is adopted, the smelting temperature ranges from 3,050 DEG C to 3,100 DGE C, the alloy blank is prepared from, by mass, 11.3%-14.4% of Al, 14.6%-17.5% of Mg, 1.25%-1.5% of Fe, 0.40%-0.7% of Si, 0.01%-0.10% of Cu, 1.5%-1.7% of Mn, 1.4%-2.0% of Zn, 0.10%-0.25% of Zr, 1.10%-3.12% of rare earth elements, smaller than 0.015% of impurity content and the balance Ti; the rare earth elements comprise, by weight, 15%-18% of Gd, 3%-5% of Pr, 7%-9% of Dy, 12.5%-12.8% of Ac, 15%-20% of Nd, 11%-13% of Sm and the balance La.According to the treatment technology of the anti-ash-deposition and anti-wear alloy material of the waste heat recovery pipeline, wear resistance and corrosion resistance of tubing can be greatly improved, the tubing adapts to the severe environment, the service life of the tubing is prolonged, a large amount of ash deposits is prevented from splashing, a large number of resources are saved, and the cost is reduced.

Owner:JIANGSU JINYUAN TENGFENG HEAT EXCHANGE EQUIP CO LTD

Preparation method of short fiber reinforced high-temperature titanium alloy bar for 700-750 DEG C

ActiveCN111020414AEasy to operateStrong process controllabilityMetal-working apparatusFurnace typesSolid solutionTitanium alloy

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

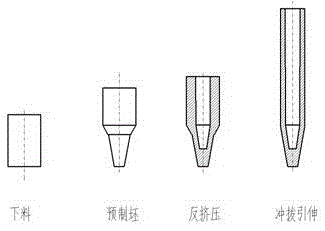

Integrated manufacturing method of ultrahigh-strength alloy steel blind hole component

The invention discloses an integrated manufacturing method of an ultrahigh-strength alloy steel blind hole component. The method includes the steps of steel ingot preparation, heading and drawing cogging, integrated hot forming, heat treatment and other process steps. According to steel ingot preparation, a steel ingot casting blank is prepared through a method of refining outside an electric arc furnace and a vacuum furnace and vacuum arc remelting; according to the heading and drawing cogging, a steel ingot is heated to the initial forging temperature ranging from 1100 DEG C to 1200 DEG C, upsetting and drawing out are performed, the final forging temperature ranges from 800 DEG C to 900 DEG C, and circulation is performed in this way 2-4 times; and according to the heat treatment, oil quenching is performed after heat preservation is performed for 0.5-1 min at the temperature ranging from 860 DEG C to 900 DEG C, and then tempering is performed for 2-3 h at 260 DEG C to 300 DEG C. By means of the integrated manufacturing method, the overall strength and toughness performance of the ultrahigh-strength alloy steel blind hole component can be improved, the breakage toughness of the ultrahigh-strength alloy steel blind hole component can be improved, the smelting cost of an ultrahigh-strength alloy is reduced, and material waste is reduced.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Fine grain niobium sheet via ingot metallurgy

A method of making an alloy of niobium that includes: A) forming a blend comprising niobium powder and a powder of a metal selected from the group consisting of yttrium, aluminum, hafnium, titanium, zirconium, thorium, lanthanum and cerium and pressing the blend to form pressed blend; B) attaching the pressed blend to an electrode comprising niobium; C) melting the electrode and pressed blend under vacuum arc remelting conditions, such that the blend mixes with the melted electrode; D) cooling the melted electrode to form an alloy ingot; and E) applying thermo-mechanical processing steps to the alloy ingot to form a wrought product. The method provides a fully recrystallized niobium wrought product with a grain size finer that ASTM 5, that can be used to make deep drawn cups and sputtering targets.

Owner:H C STARCK INC

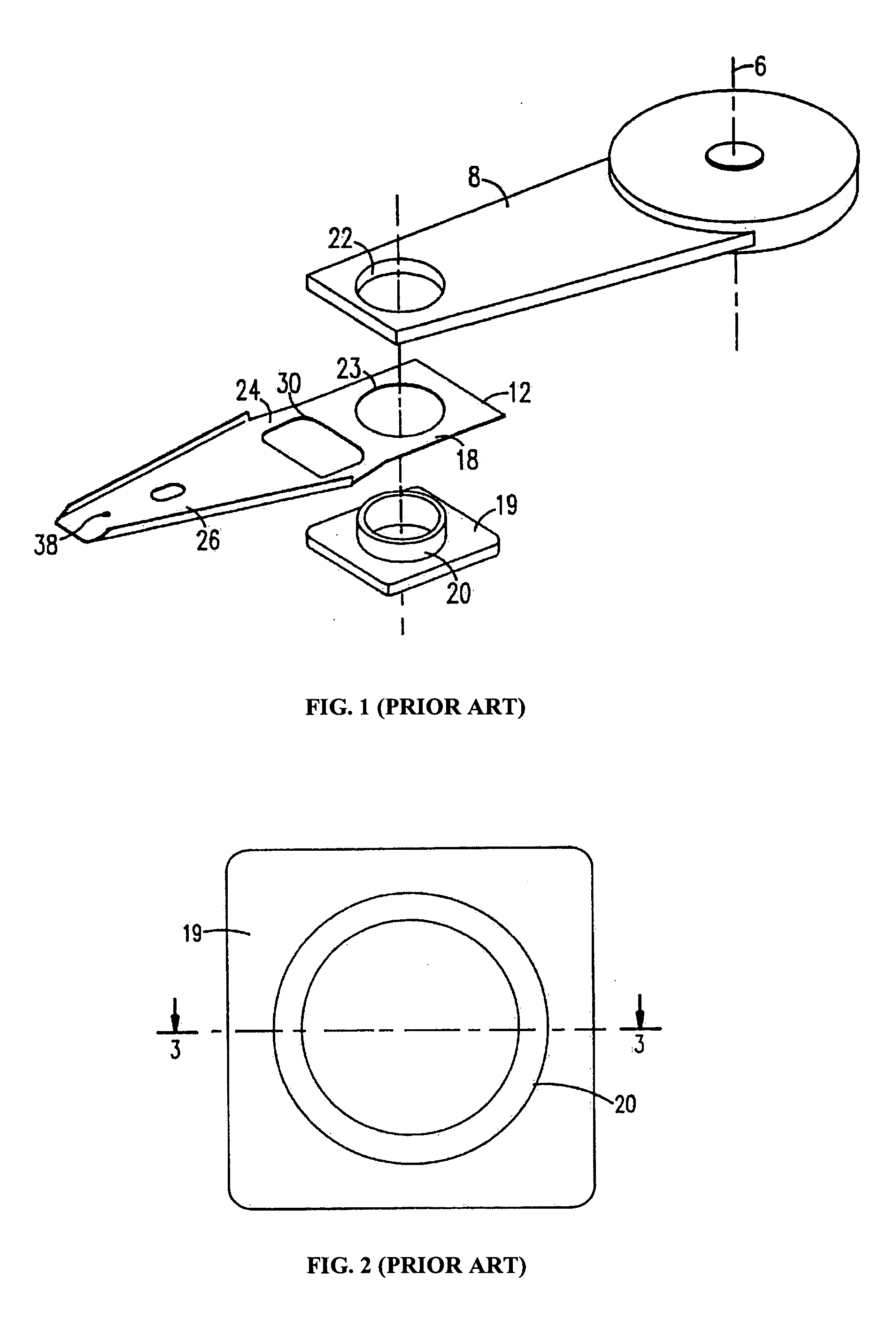

Remelted magnetic head support structure in a disk drive

ActiveUS20050099731A1Record information storageStructure of arm assemblyEngineeringElectro-slag remelting

A magnetic head supporting structure comprises a metal purified by vacuum arc remelting, vacuum induction melting, electroslag remelting, or electroslag remelting under vacuum, in at least one of the regions that undergo plastic deformation during disk drive manufacture, to reduce small hard inclusions that might be released into the disk drive interior environment.

Owner:INTRL PLEX TECH INC

Top drive bearing for use in a top drive system, and made of non-vacuum arc remelted steel configured to achieve an extended life cycle at least equivalent to a life factor of three for a vacuum arc remelted steel

A top drive thrust bearing configured for use in a heavy loaded top drive system. The top drive thrust bearing includes an upper plate; a lower plate; and a plurality of rollers disposed between the upper plate and the lower plate. The composition of the top drive thrust bearing comprising a non-vacuum arc remelted steel including, in weight percent (%), about 0.15% to about 0.18% carbon (C), about 0.15% to about 0.4% silicon (Si), about 0.4% to about 0.7% manganese (Mn), 0% to about 0.025% phosphorus (P), about 0.0005% to about 0.002% sulfur (S), about 0.0002% to about 0.0007% oxygen (O), about 0.001% to about 0.003% titanium (Ti), about 1.3% to about 1.6% chromium (Cr), about 3.25% to about 3.75% nickel (Ni), about 0.0005% to about 0.003% calcium (Ca), about 0.15% to about 0.25% molybdenum (Mo), balance iron (Fe). The top drive thrust bearing of the top drive system is configured to achieve an extended life cycle at least about equivalent to a life factor of three for a vacuum arc remelted steel.

Owner:ROLLER BEARING OF AMERICA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com