Double-phase high-density kinetic energy tungsten-nickel-cobalt alloy capable of being cast and forged and preparation method

A high-density, cobalt alloy technology, which is applied in the field of dual-phase high-density castable and forgeable kinetic energy tungsten-nickel-cobalt alloys and its preparation, can solve the problems of difficulty in increasing the density and the decline in the performance of dual-phase tungsten-nickel alloy casting and forging processes. Good dynamic strength, good organizational consistency and uniformity, and excellent overall performance

Active Publication Date: 2015-11-25

CENT IRON & STEEL RES INST

View PDF5 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, strengthening elements such as Ti, Al, Nb, etc. are added to the tungsten-nickel solid solution or tungsten-cobalt solid solution to form a strengthening phase γ', etc., and the strength is improved through aging precipitation, such as the invention patent DT730, etc., but limited by the γ' phase forming elements Generally, when the tungsten element content in such alloys is less than 40%, it is difficult to increase the density to 12g / cm 3 Above, it is true that when the tungsten element content is less than 40%, the melting point drops below 1500°C and the solid solution temperature drops below 1050°C, which can have better casting and forging process performance, but in order to further increase the density and kinetic energy, it must be further improved. The content of tungsten element, when the tungsten element exceeds 38%, the alloy is a dual-phase structure. Usually, the casting and forging process performance of the dual-phase tungsten-nickel alloy drops sharply. The conventional process cannot be easily applied and requires precise control of the process.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

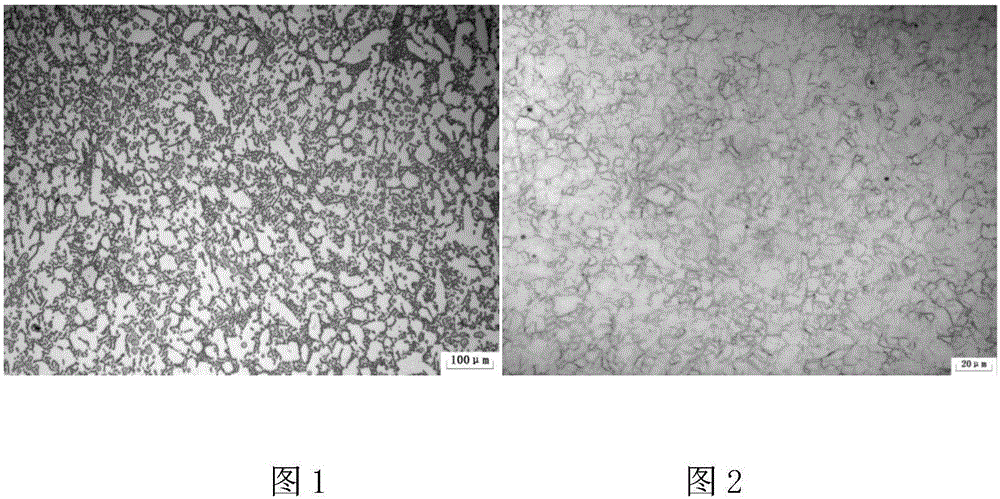

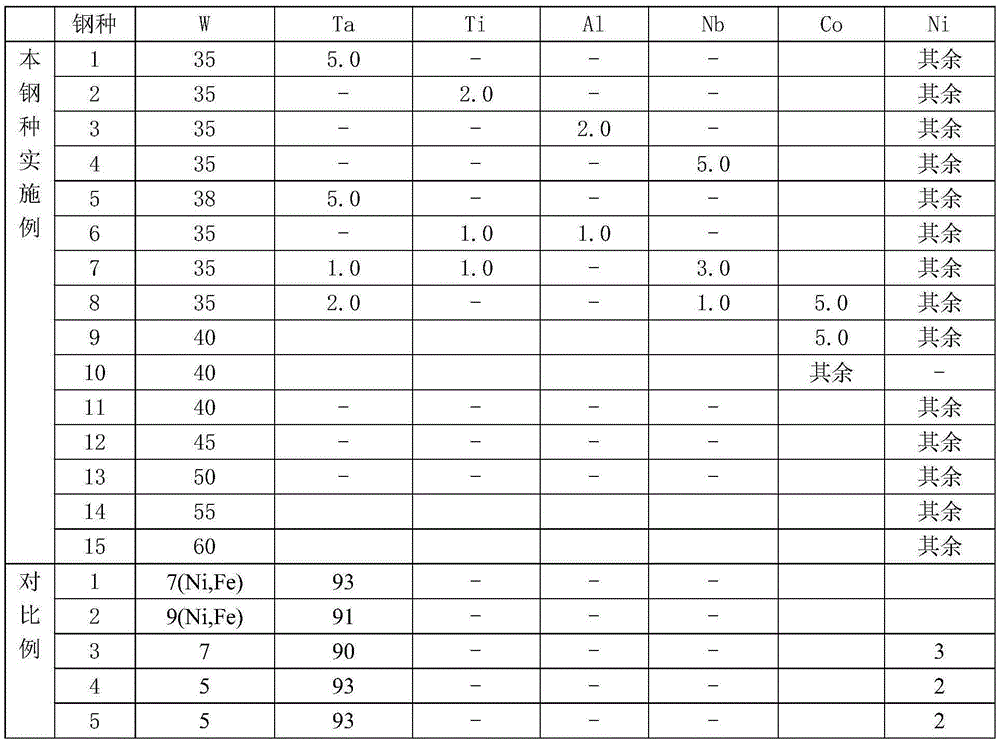

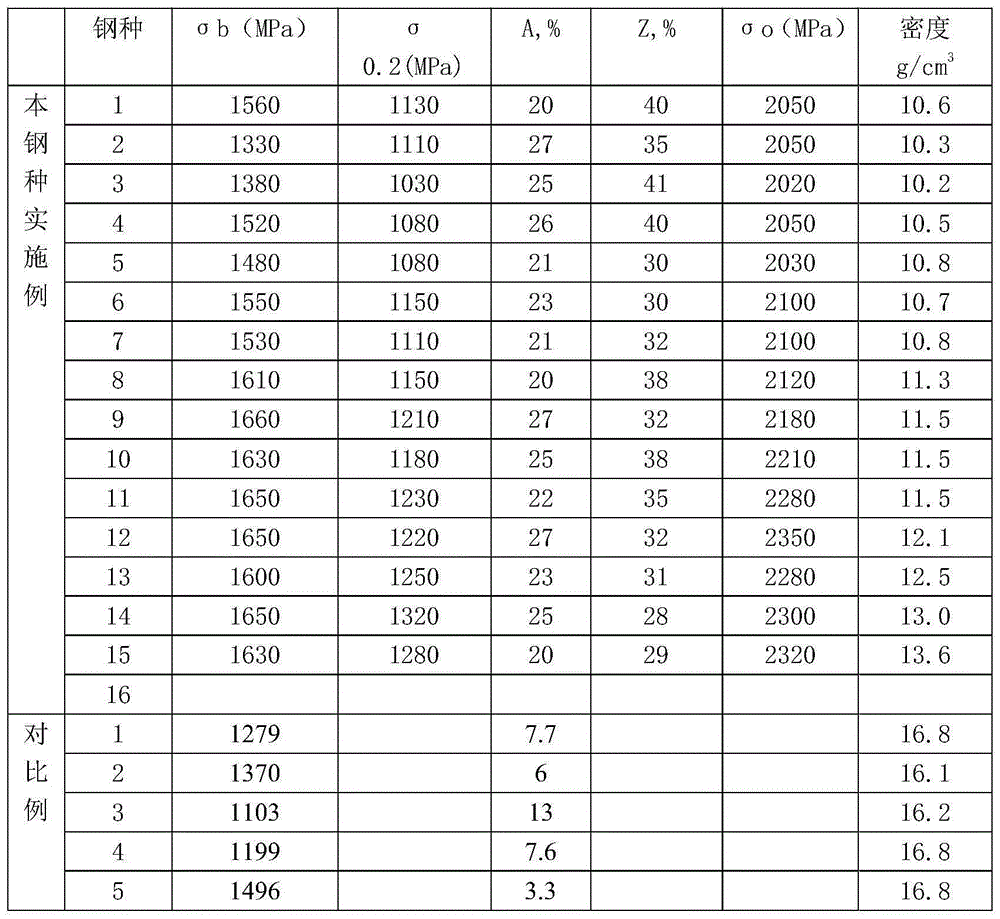

[0028] According to the chemical composition range of the dual-phase high-density castable kinetic energy tungsten-nickel-cobalt alloy of the present invention, a 25 kg vacuum induction furnace is used to prepare a 20 kg alloy ingot 15 furnace. The specific chemical composition is shown in Table 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses double-phase high-density kinetic energy tungsten-nickel-cobalt alloy capable of being cast and forged and a preparation method, and belongs to the field of kinetic energy alloy. The double-phase high-density kinetic energy tungsten-nickel-cobalt alloy comprises, by weight, 35-65% of W, 0-3% of Ti, 0-3% of Al, 0-8% of Nb, 0-10% of Ta and the balance Ni or Co or NiCo, unavoidable impurity elements and micro elements like rare earth. The preparation method adopts vacuum induction plus vacuum arc remelting. Compared with the prior art, the double-phase high-density kinetic energy tungsten-nickel-cobalt alloy capable of being cast and forged is good in comprehensive performance, has high density, high rigidity, super high strength, super high dynamic strength and other excellent properties, the density can reach 11.0-15.0 g / cm<3>, the impact rigidity can reach 80 J / cm<2> or higher, the static tensile strength can reach 1300 MPa or higher, and the dynamic compression strength can reach 1800 MPa or higher.

Description

Technical field [0001] The invention belongs to the technical field of kinetic energy alloys, and particularly relates to a dual-phase high-density castable and forgeable kinetic energy tungsten-nickel-cobalt alloy (DT790) and a preparation method. The alloy has high density, high toughness, ultra-high strength, high dynamic strength and other excellent properties, density Reach 11.0-15.0g / cm 3 , Impact toughness reaches 80J / cm 2 Above, the static tensile strength is above 1300MPa, and the dynamic compressive strength is above 1800MPa. Background technique [0002] Prior to this, the most commonly used high-density materials in the world were tungsten alloys. Due to the high melting point of tungsten, such materials are usually sintered by powder metallurgy. At present, tungsten alloys widely used in the world are W90, W93, W95 and W97, etc., the density of such materials is very high, which can reach 15-18g / cm 3 , But the strength is lower and the toughness is poor. The tensile ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C19/03C22C19/07C22C27/04C22C1/02C22F1/18C22F1/10

Inventor 王春旭厉勇谭成文刘少尊于晓东王富耻黄顺喆韩顺刘宪民李建新庞学东

Owner CENT IRON & STEEL RES INST

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com