Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

105 results about "Dynamic strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

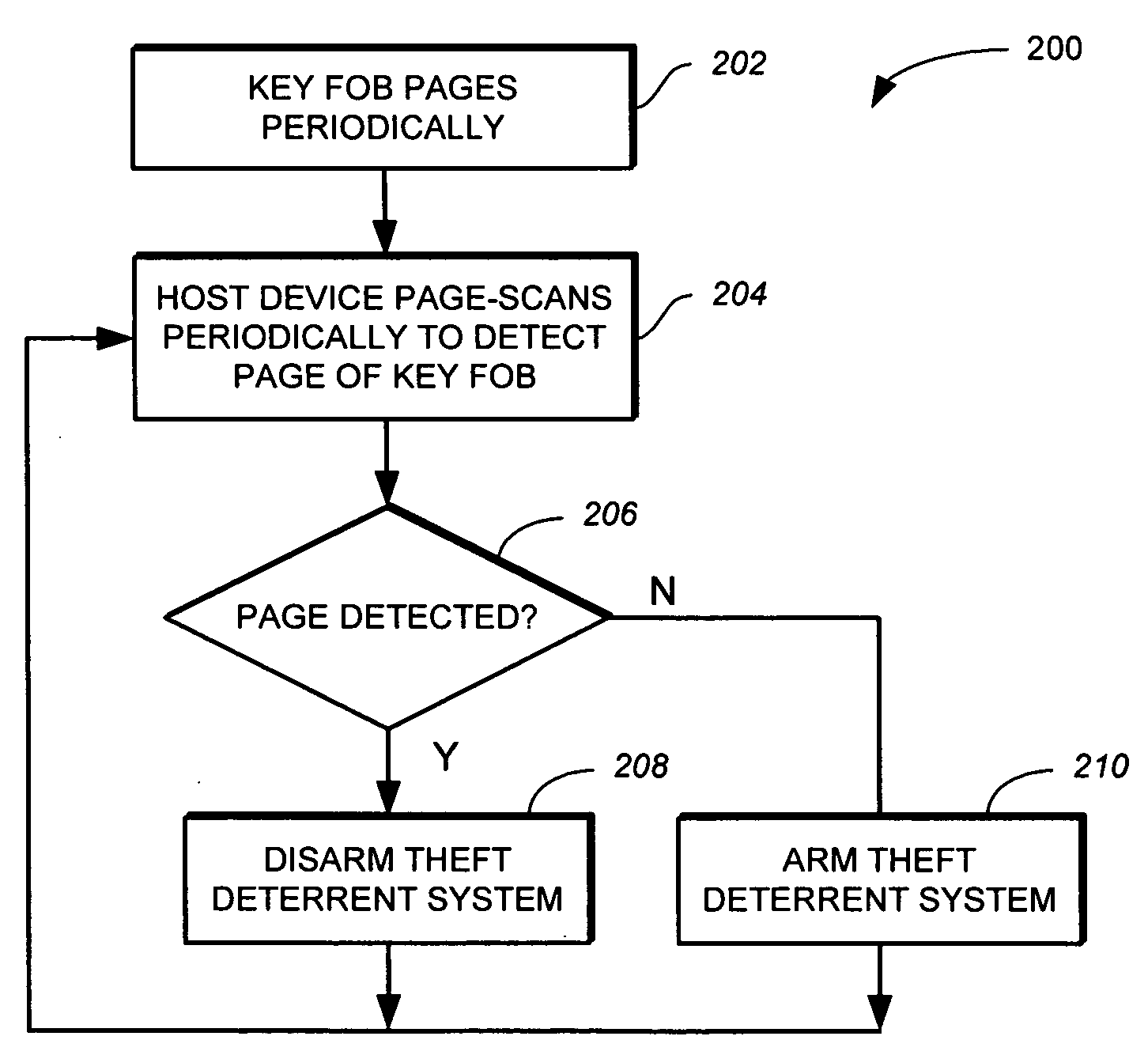

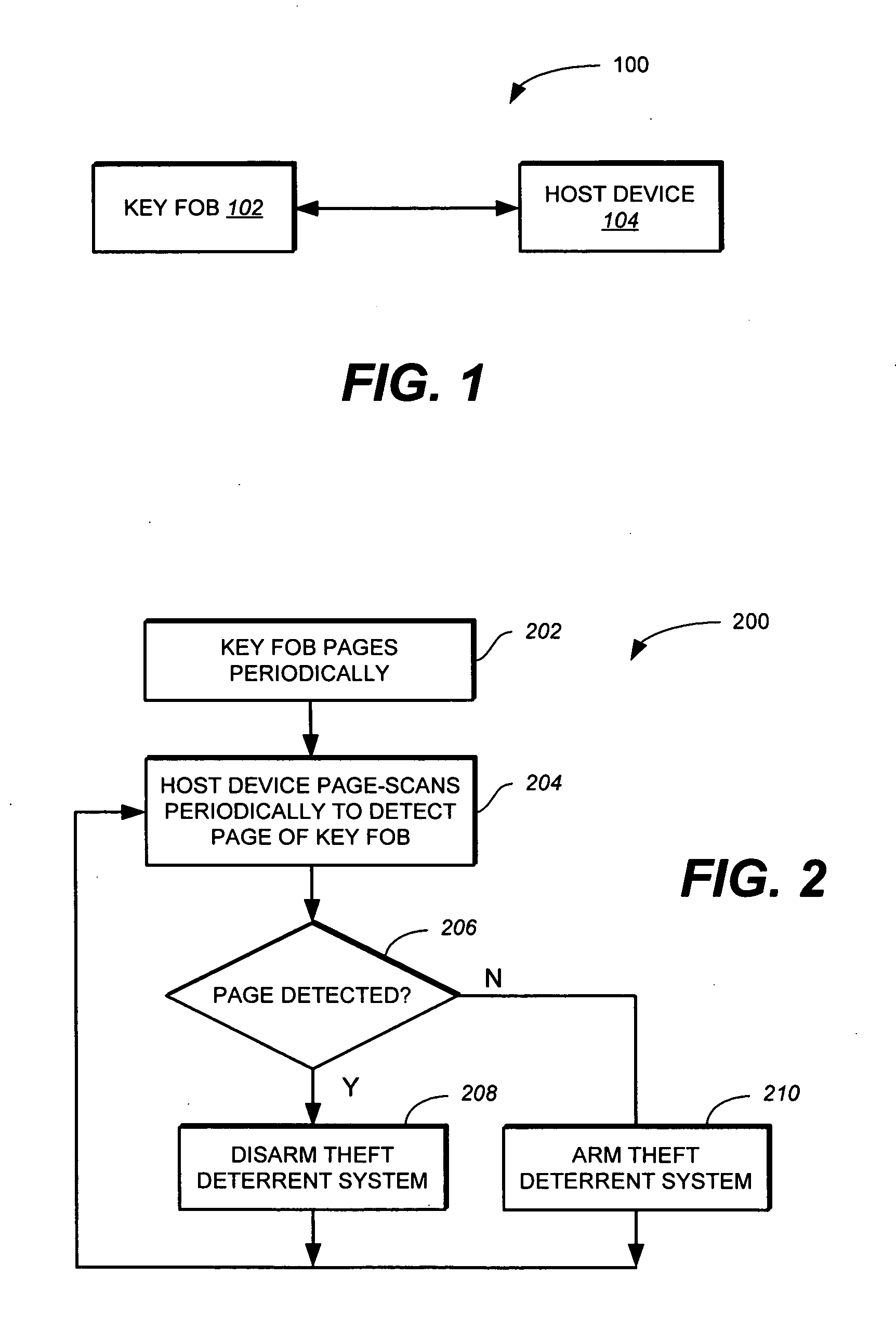

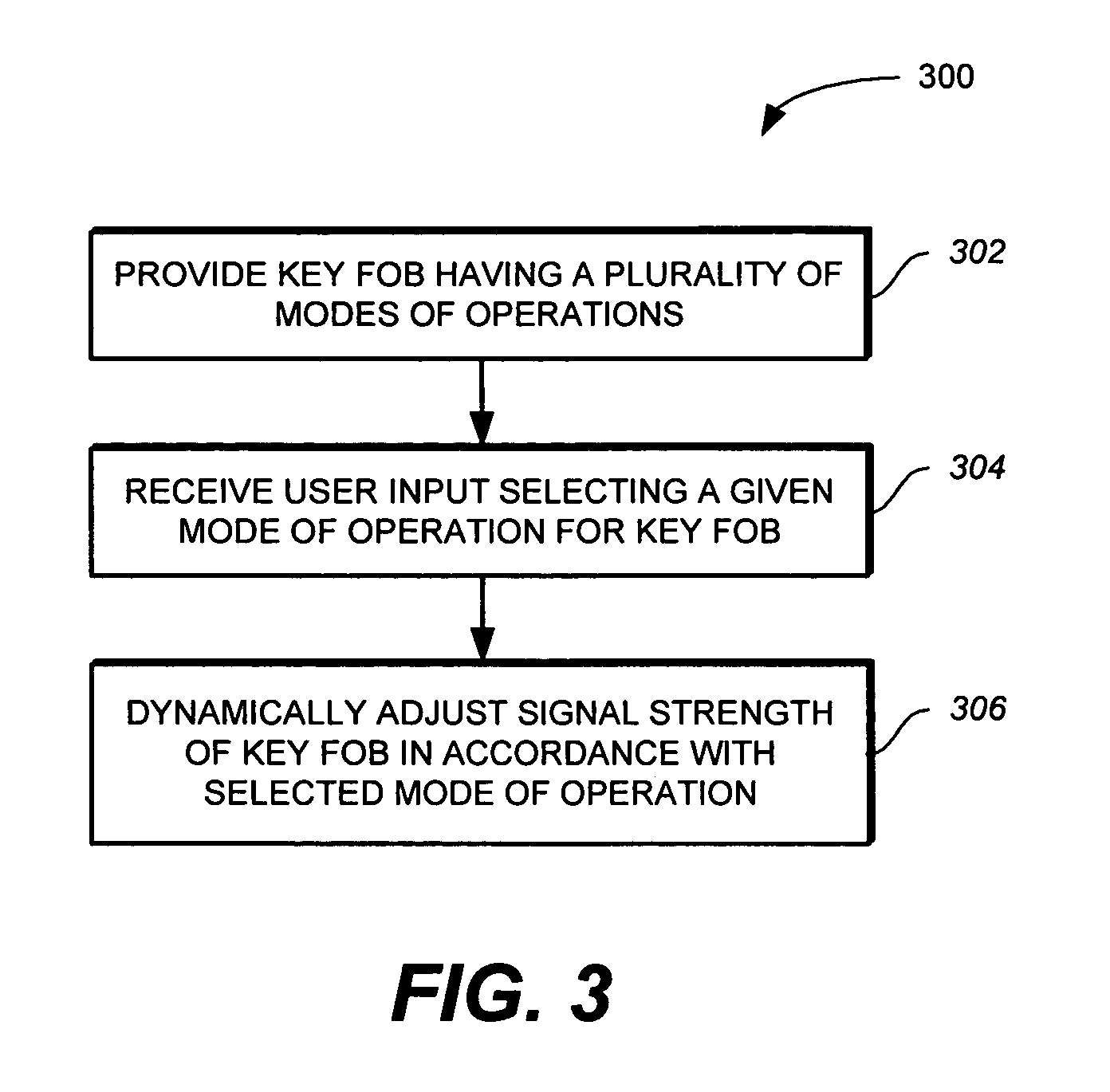

Method and system for transmit scheduling and dynamic strength adjustment of a security fob signal

InactiveUS20080061929A1Extend battery lifeImprove securityElectric signal transmission systemsDigital data processing detailsComputer hardwareDynamic strength

Methods and systems for managing communication between a key fob and a host device are provided. In one implementation, the system includes a key fob configured to operate in accordance with one of a plurality of modes, including an automatic mode and a manual mode. The system further includes a host device associated with the key fob, wherein responsive to the key fob operating in accordance with the automatic mode, the key fob is configured to page periodically, and the host device is configured to page-scan periodically to detect a page from the key fob. In one implementation, the key fob further includes a controller configured to dynamically adjust a signal strength of a communication signal between the key fob and the host device in accordance with a mode of operation selected (or desired) by the user.

Owner:LENOVO (SINGAPORE) PTE LTD

Preparation method of Al/W/PTFE energetic material

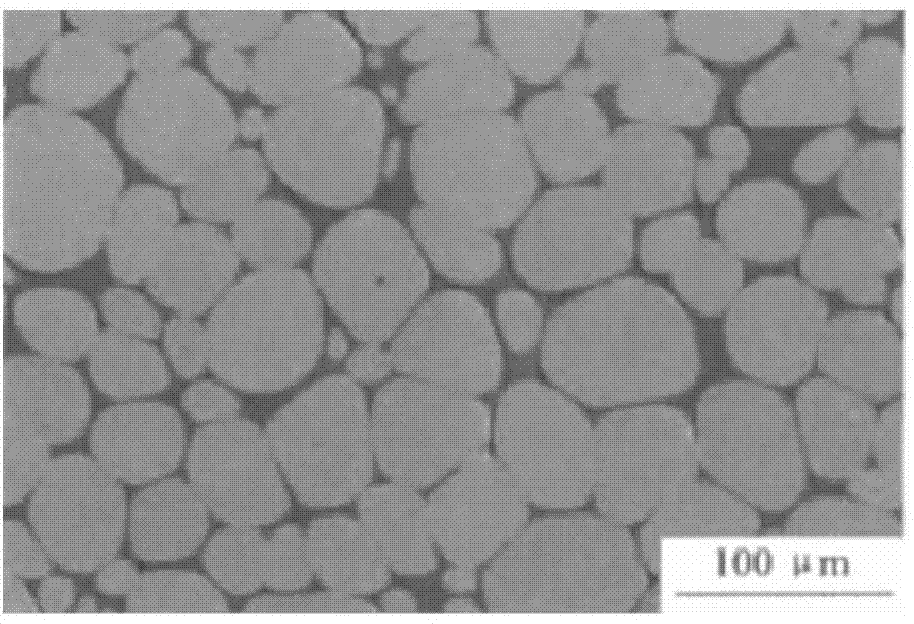

The invention relates to a preparation method of an Al / W / PTFE energetic material and belongs to the field of energetic materials. The preparation method orderly comprises raw material powder preparation, surface modification, mixed powder drying, compression molding and sintering molding. The preparation method utilizes conventional Al, W and PTFE powder as raw materials which are easily purchased and have a low cost. The preparation method has simple processes and a low cost and is suitable for batch production. Compared with the traditional Al / PTFE energetic material (Al: 26.4wt% and PTFE: 73.6wt%), the Al / W / PTFE energetic material obtained by the preparation method has higher compressive strength, density and reaction threshold. When a mass fraction of W of the energetic material is 60%, compared with the traditional Al / PTFE energetic material, the Al / W / PTFE energetic material improves density by 88%, dynamic strength limit by 21% and a reaction threshold by 24%.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

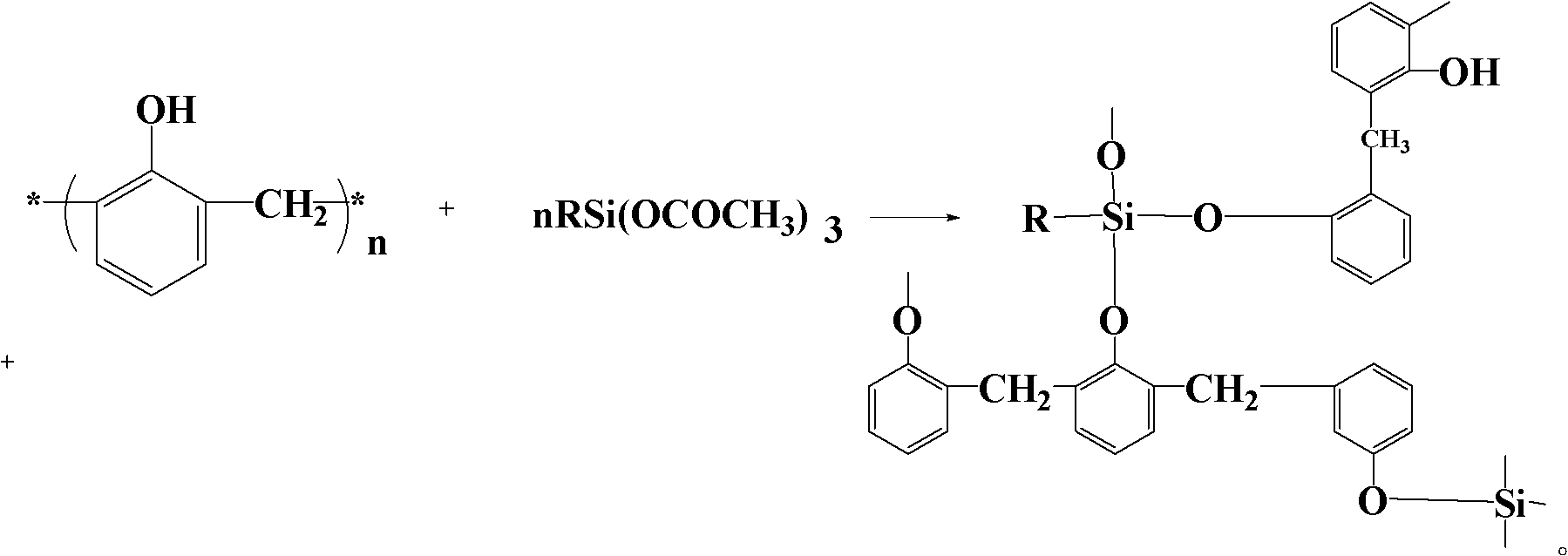

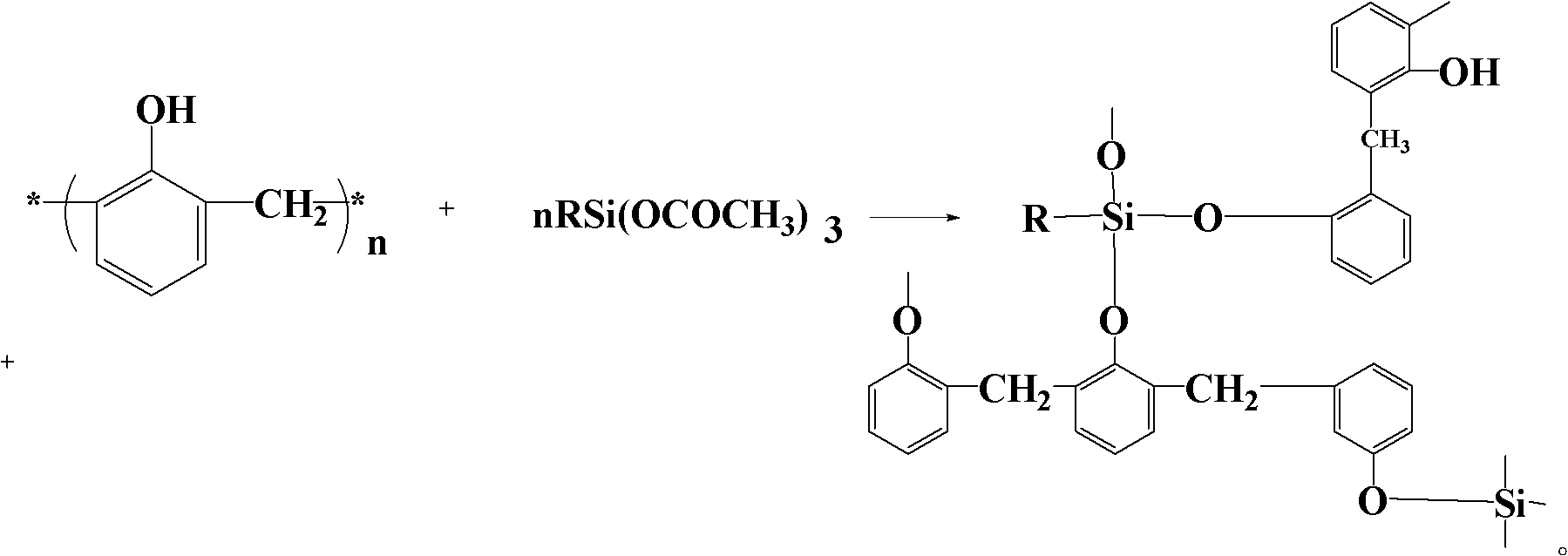

Adhesive for automobile disc brake pad and preparation method thereof

InactiveCN101824295AImprove stabilityImprove bindingAldehyde/ketone condensation polymer adhesivesFriction liningDynamic strengthAdhesive

The invention discloses an adhesive for an automobile disc brake pad and a preparation method thereof, which have stable system, heat resistance and high dynamic strength. The adhesive for the automobile disc brake pad consists of 100 parts of silicone modified phenolic resin, 5-10 parts of toughened material, 1-7 parts of curing agent, 2-5 parts of auxiliary agents and 100-300 parts of solvent. The invention solves the problems of unstable system, bad high-temperature stability, short retention time and bad use technological property of the existing brake pad. The adhesive for the automobiledisc brake pad of the invention is obtained by placing phenol, formaldehyde and organic organoacetoxysilane together to carry out polymerization reaction, dehydrating, adding organic solvent and toughened system and stirring. The adhesive for the automobile disc brake pad of the invention is prepared according to the following steps of: 1, polymerization reacting; 2, cooling and dehydrating; and 3, adding the toughened system and other auxiliary agents, and stirring to prepare the adhesive for the automobile disc brake pad, which has good high-temperature stability and uniform distribution.

Owner:HUNAN BOYUN AUTOMOBILE BRAKE MATERIALS +1

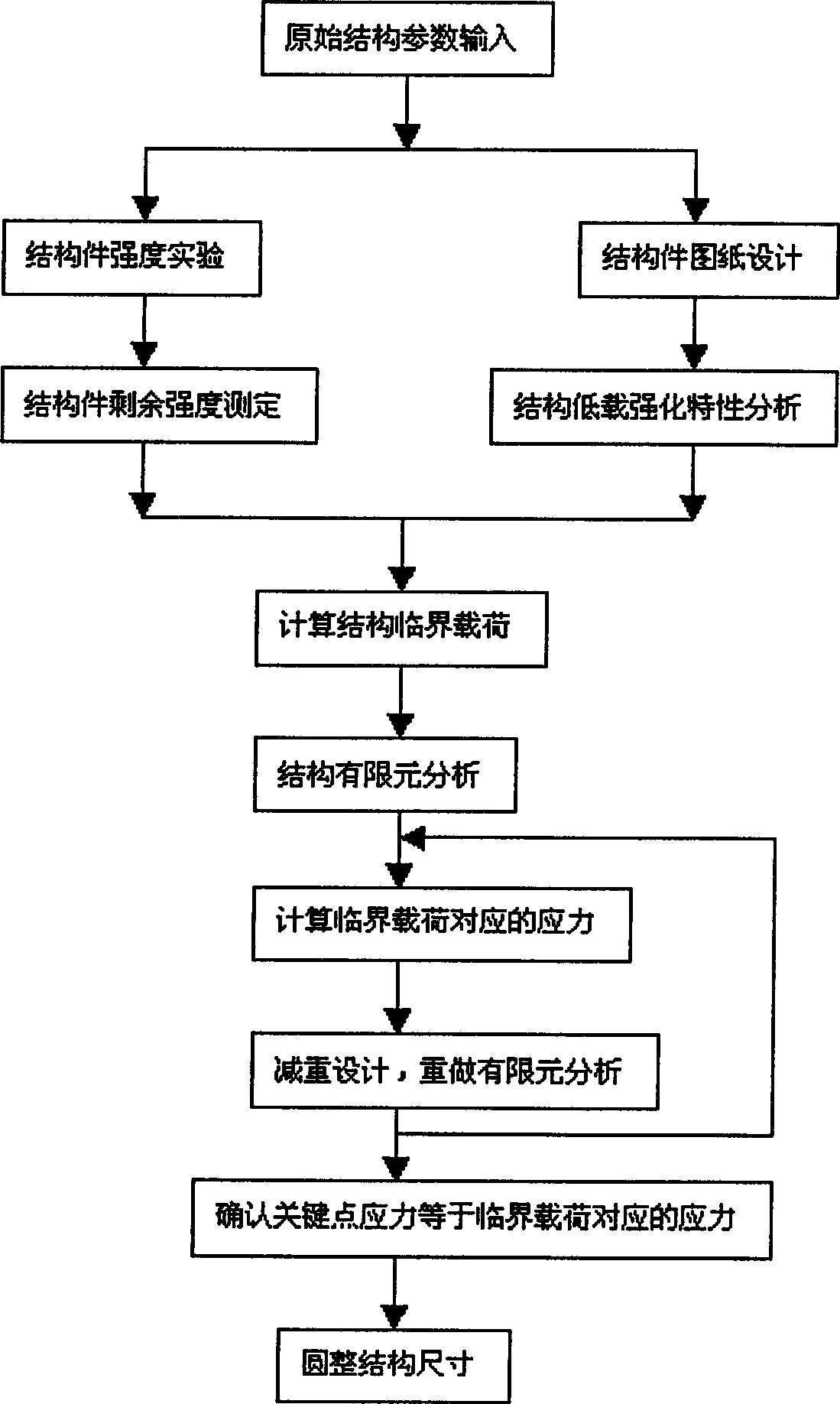

Automobile structure lightweighting design method based on structure intensity variation characteristic

InactiveCN1843829AFull strengthAchieve lightweight designSpecial data processing applicationsVehiclesConstant loadDynamic strength

The invention discloses a method for reducing the weight of vehicle, based on the structural strength variable character. It comprises: 1, via strength calculation or test to get the strength change in constant load; 2, via the dynamic strength increase matrix of structure, attaining the critical load; 3, processing structure finite analysis on the structure, calculating the stress in critical load; 4, fixing the stress of weight reduced structure and designing relative structure. With said invention, the structure can attain longer service life and reduce weight. Said invention has high reliability and operational property. Since, there is not strength test on the sample; the user can calculate the strength increase in the sample load according to the lower-load strength character of structure, to calculate the critical load, to realize weight-reduced structure.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

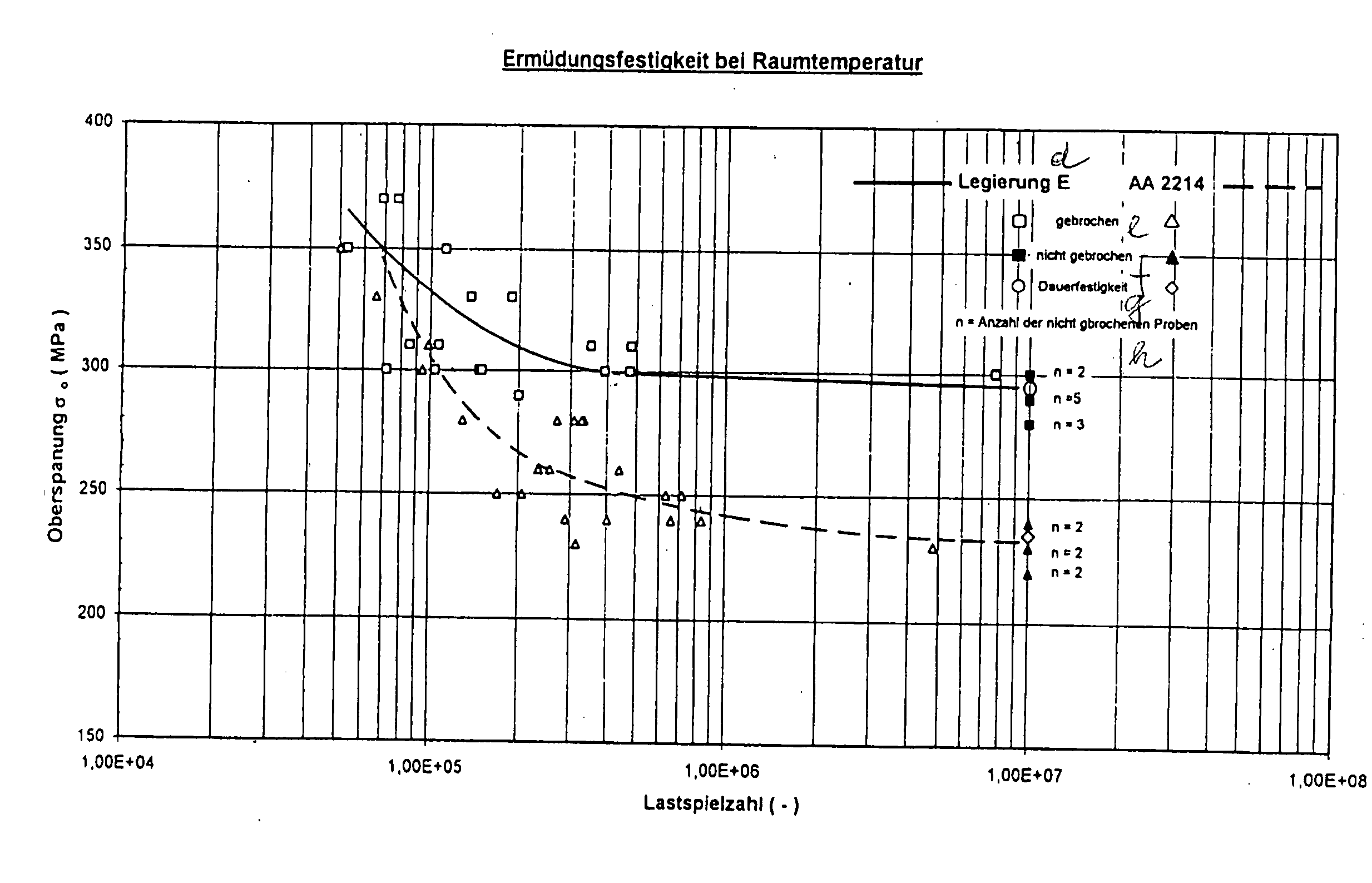

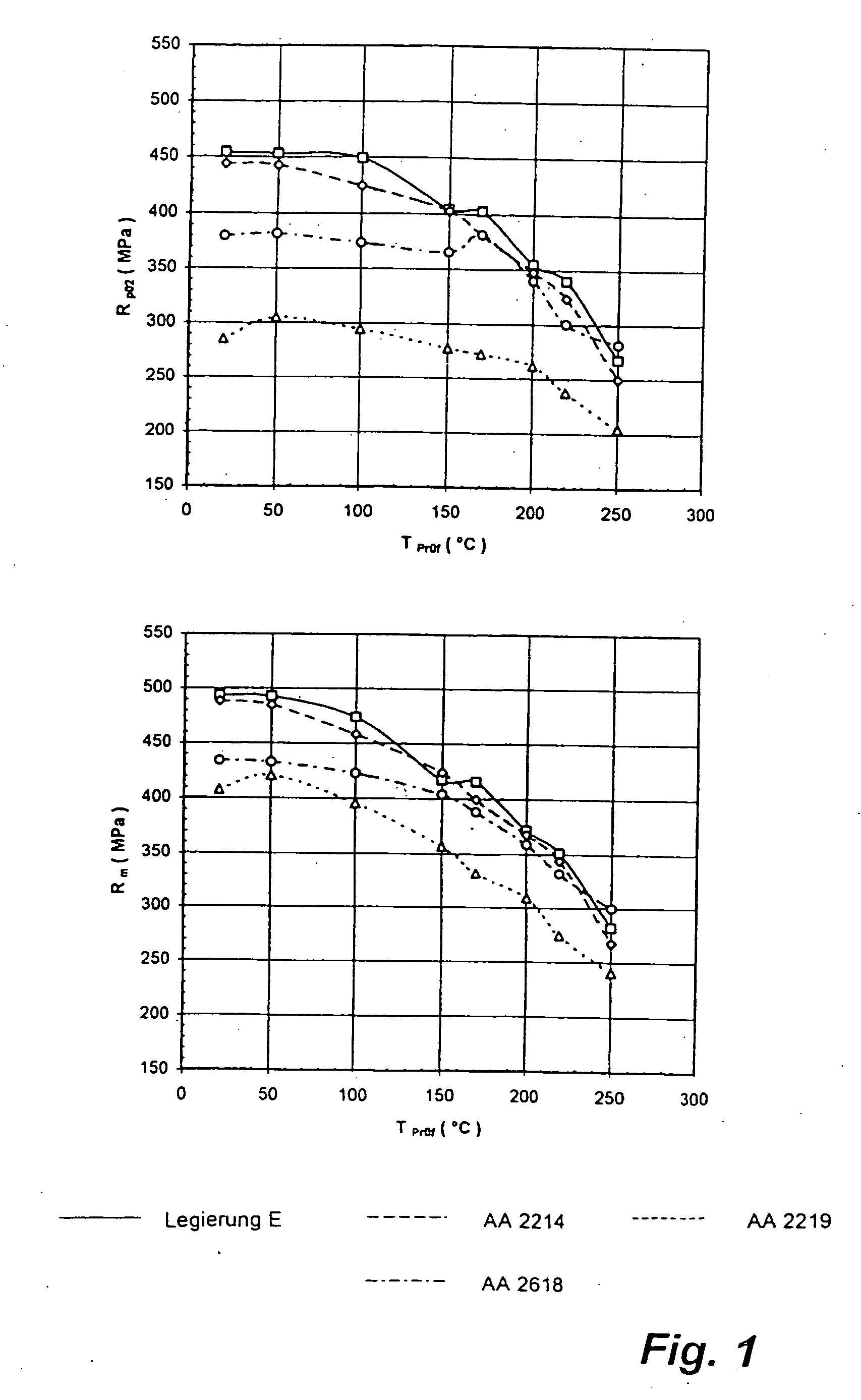

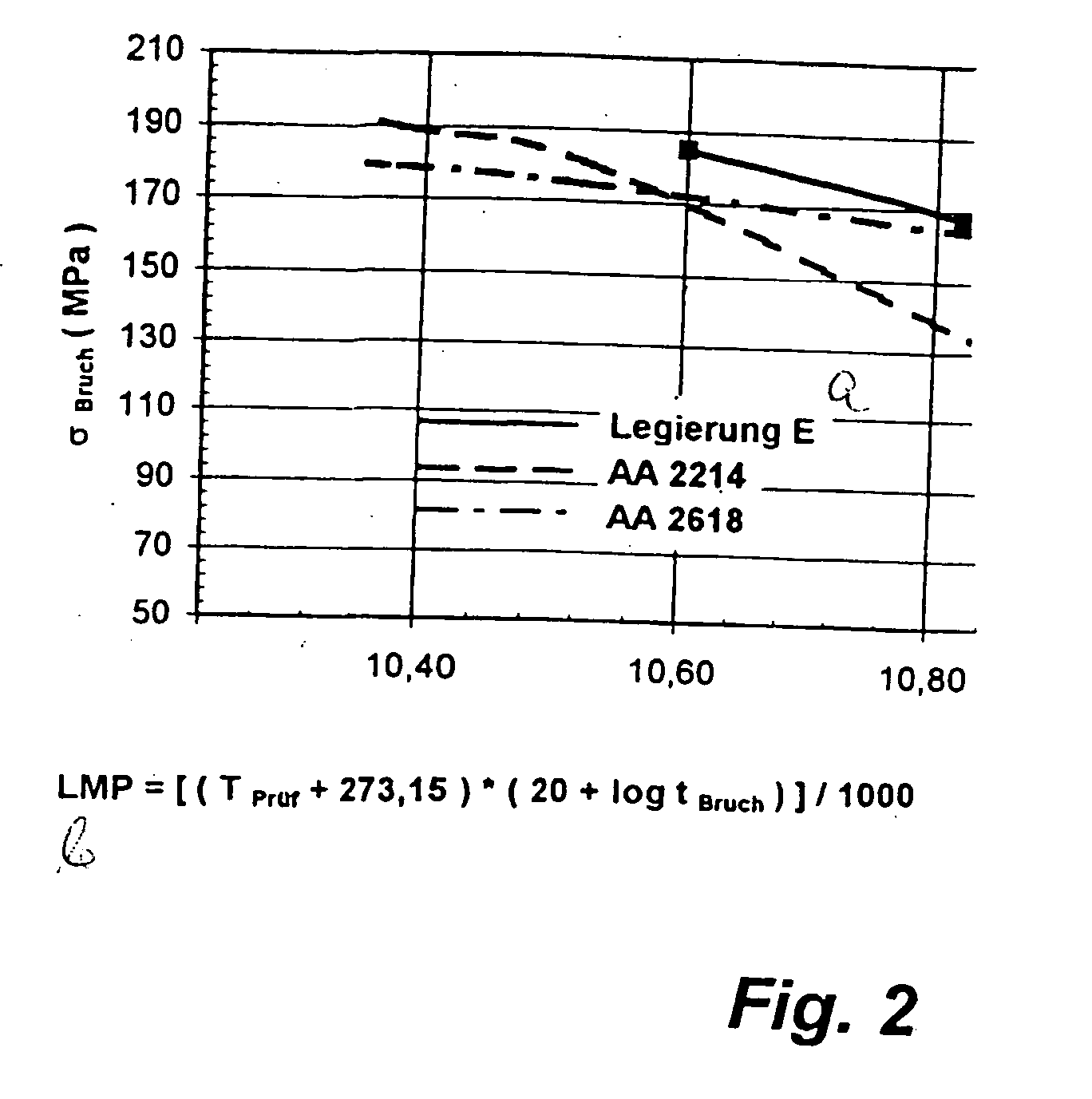

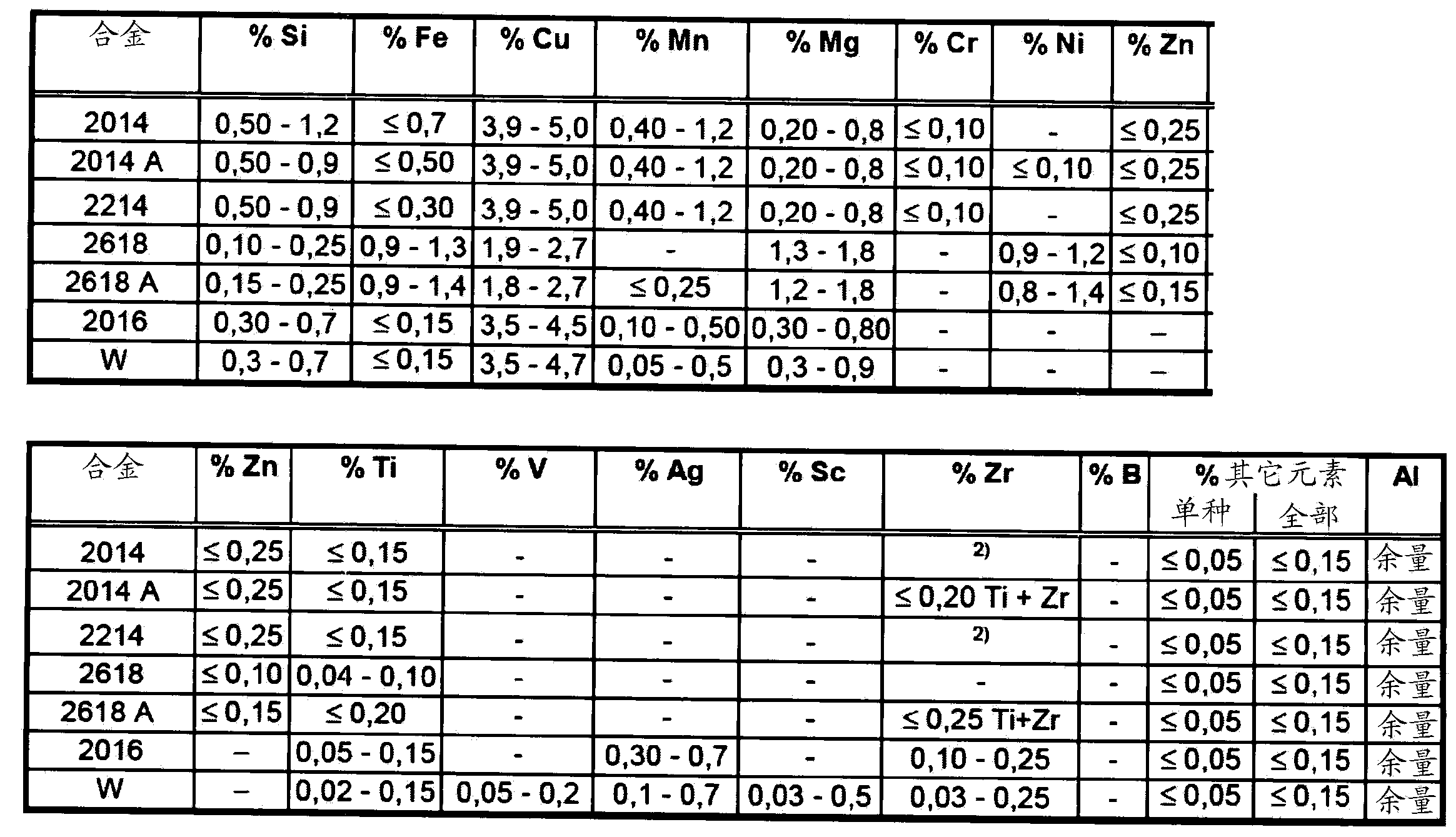

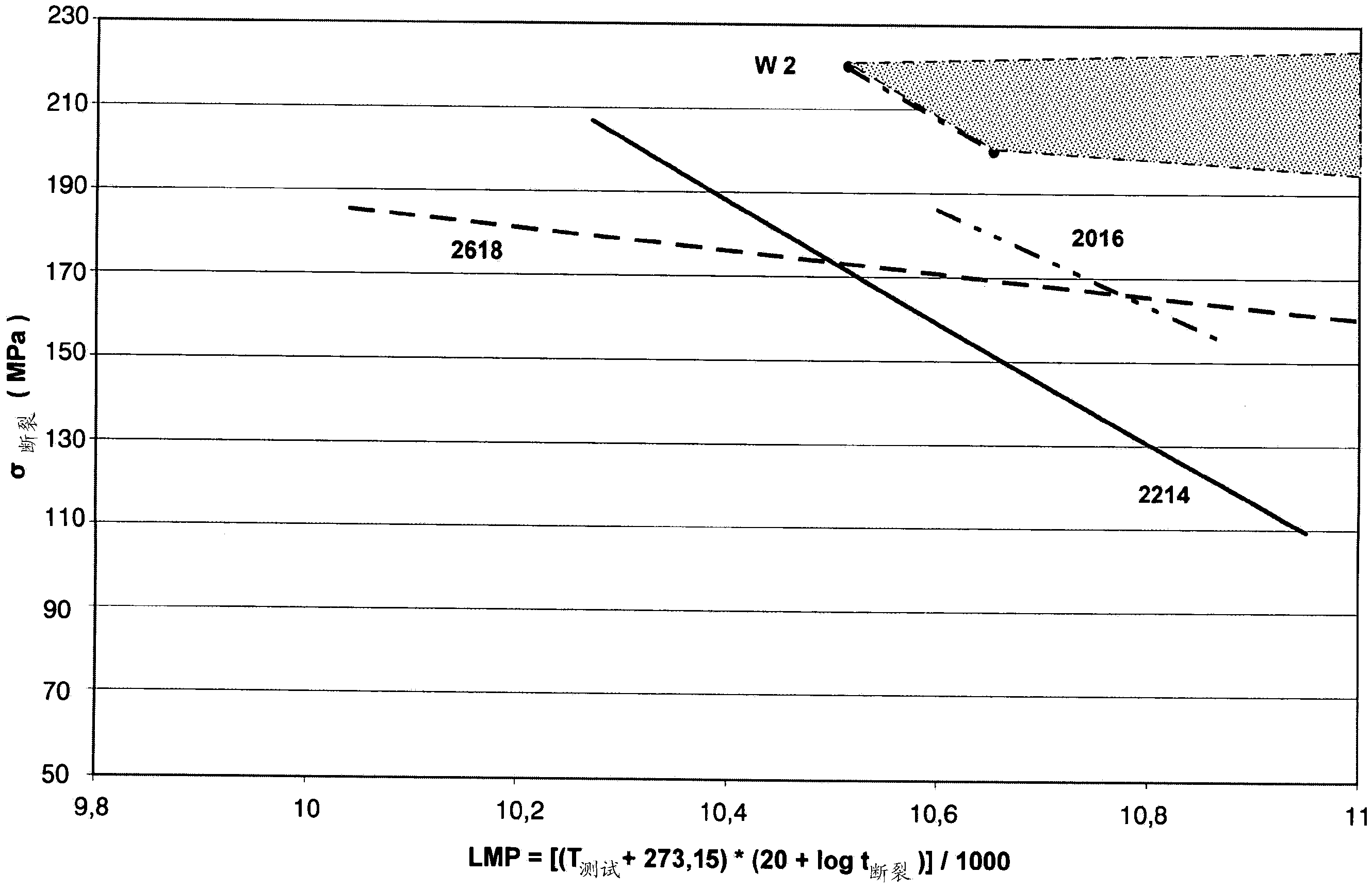

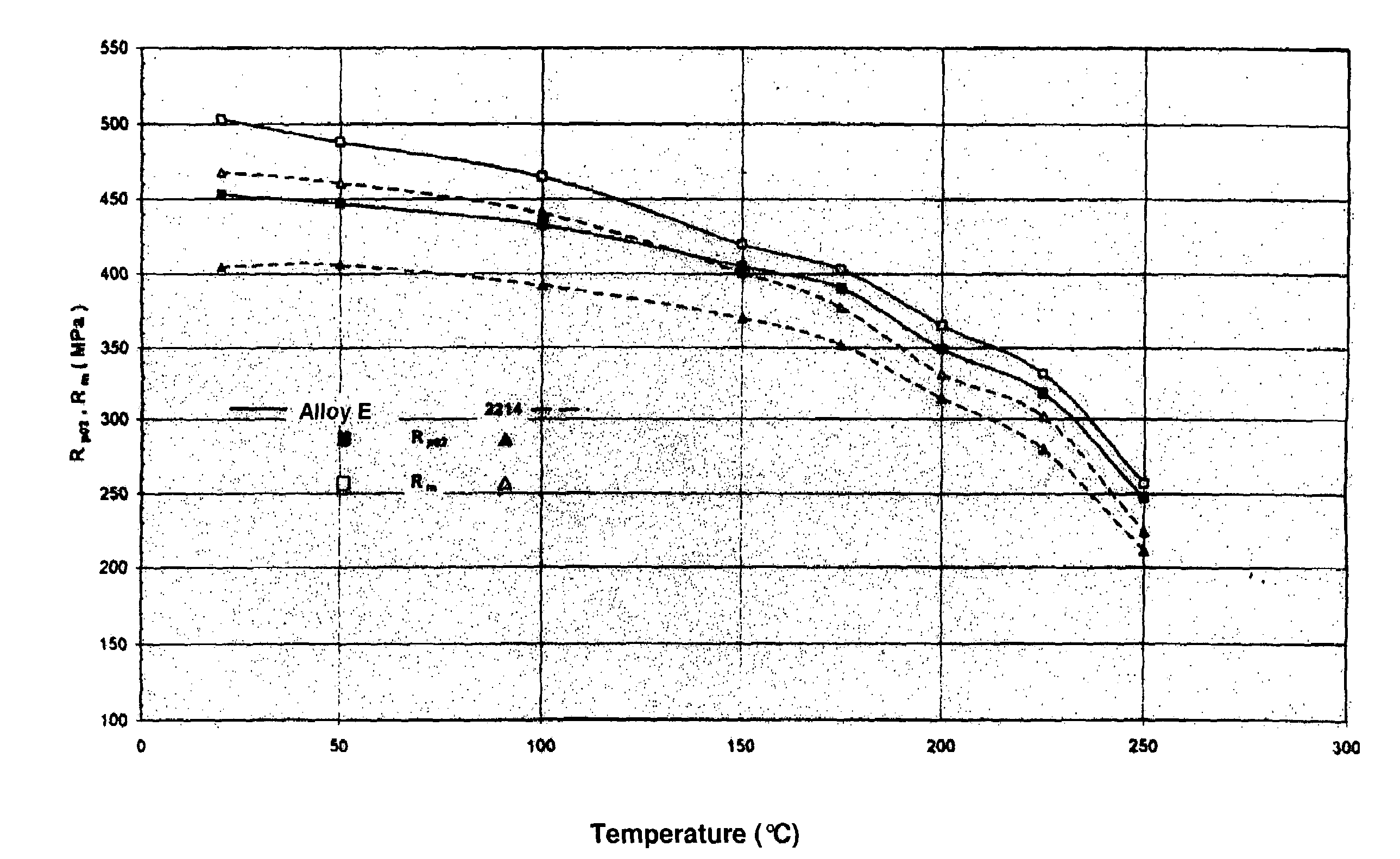

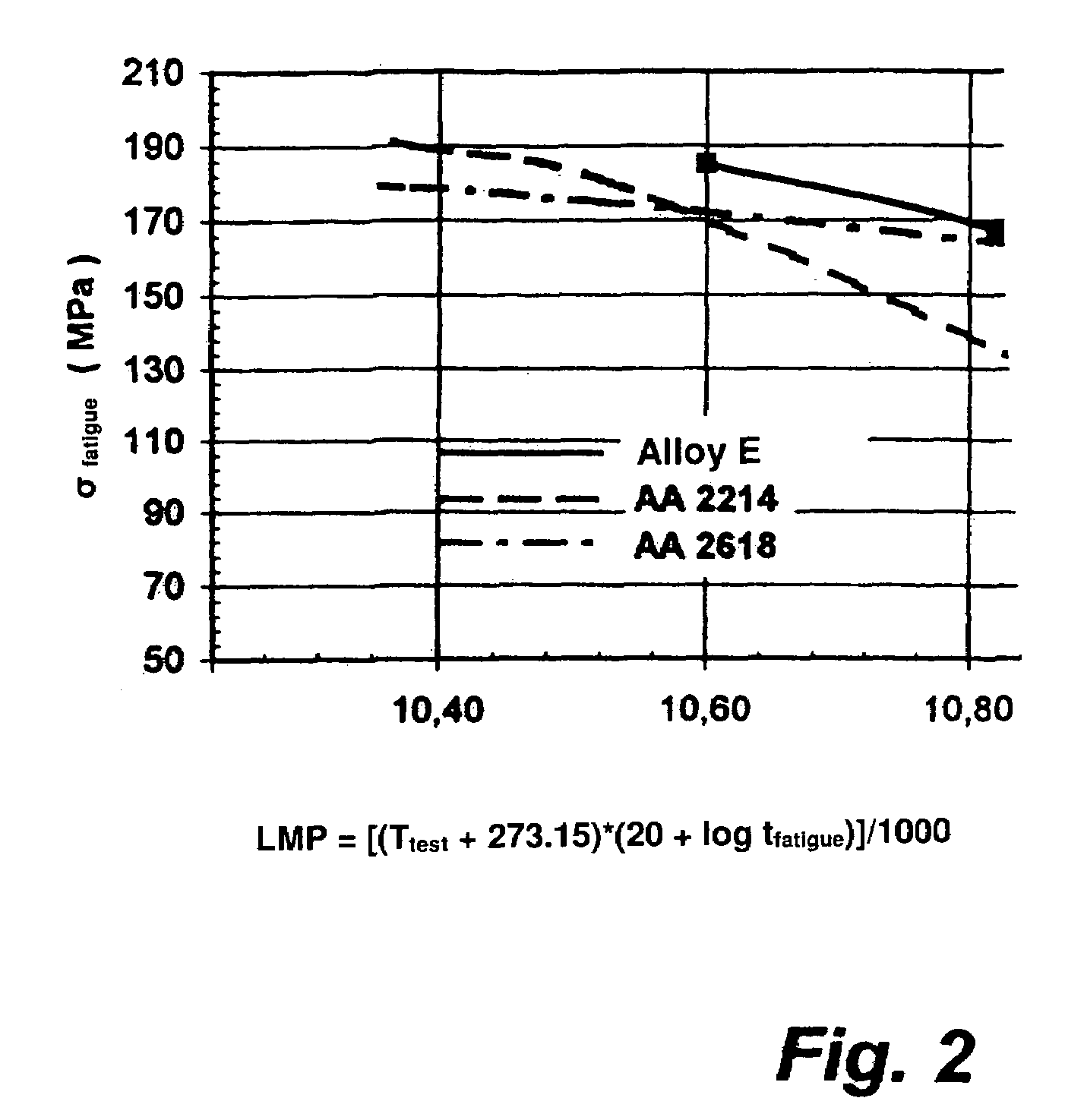

Al/cu/mg/ag alloy with si, semi-finished product made from such an alloy and method for production of such a semi-finished product

An Al / Cu / Mg / Mn alloy for the production of semi-finished products with high static and dynamic strength properties has the following composition: 0.3-0.7 wt % silicon (Si), max. 0.15 wt. % iron (Fe), 3.5-4.5 wt % copper (Cu), 0.1-0.5 wt. % manganese (Mn), 0.3-0.8 wt. % magnesium (Mg), 0.5-0.15 wt % titanium (Ti), 0.1-0.25 wt % zirconium (Zr), 0.3-0.7 wt. % silver (Ag), max. 0.05 wt. % others individually, max 0.15 wt. % others globally, the remaining wt. % aluminum (Al). The invention further relates to a semi-finished product made for such an alloy and a method of production of a semi-finished product made for such an alloy.

Owner:FA OTTO FUCHS

Method for preparing soft magnetic composite material through hot pressing

InactiveCN103862048AEasy and efficient to prepareControl mechanical strengthInorganic material magnetismInductances/transformers/magnets manufactureEpoxyDispersed media

A method for preparing a soft magnetic composite material through hot pressing includes the following steps: dispersing particle soft magnetic powder into a dispersing medium, adding a coupling agent to conduct surface processing, conducting separation to obtain magnetic powder wrapping the coupling agent, conducting washing and drying through absolute ethyl alcohol to obtain the coupling agent modified magnetic powder, mixing the epoxy resin and an epoxy hardener to obtain an epoxy resin system mixture, mixing the coupling agent modified magnetic powder and the epoxy resin system mixture according to the proportion to obtain mixed slurry containing the magnetic powder and the epoxy resin system mixture, pouring the mixed slurry into a container, conducting vacuumizing, arranging the container into a constant temperature oven to conduct procuring to obtain composite slurry obtained through procuring, transferring the procured composite slurry into a mould, and conducting solidification and die pressing through a hog pressing machine to obtain the soft magnetic composite material. The method is simple in process, low in cost, favorable for operation and capable of achieving good magnetic performance and dynamic strength of the composite material by adjusting the content of the magnetic powder. The shape is controllable, and the mechanical performance is good.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

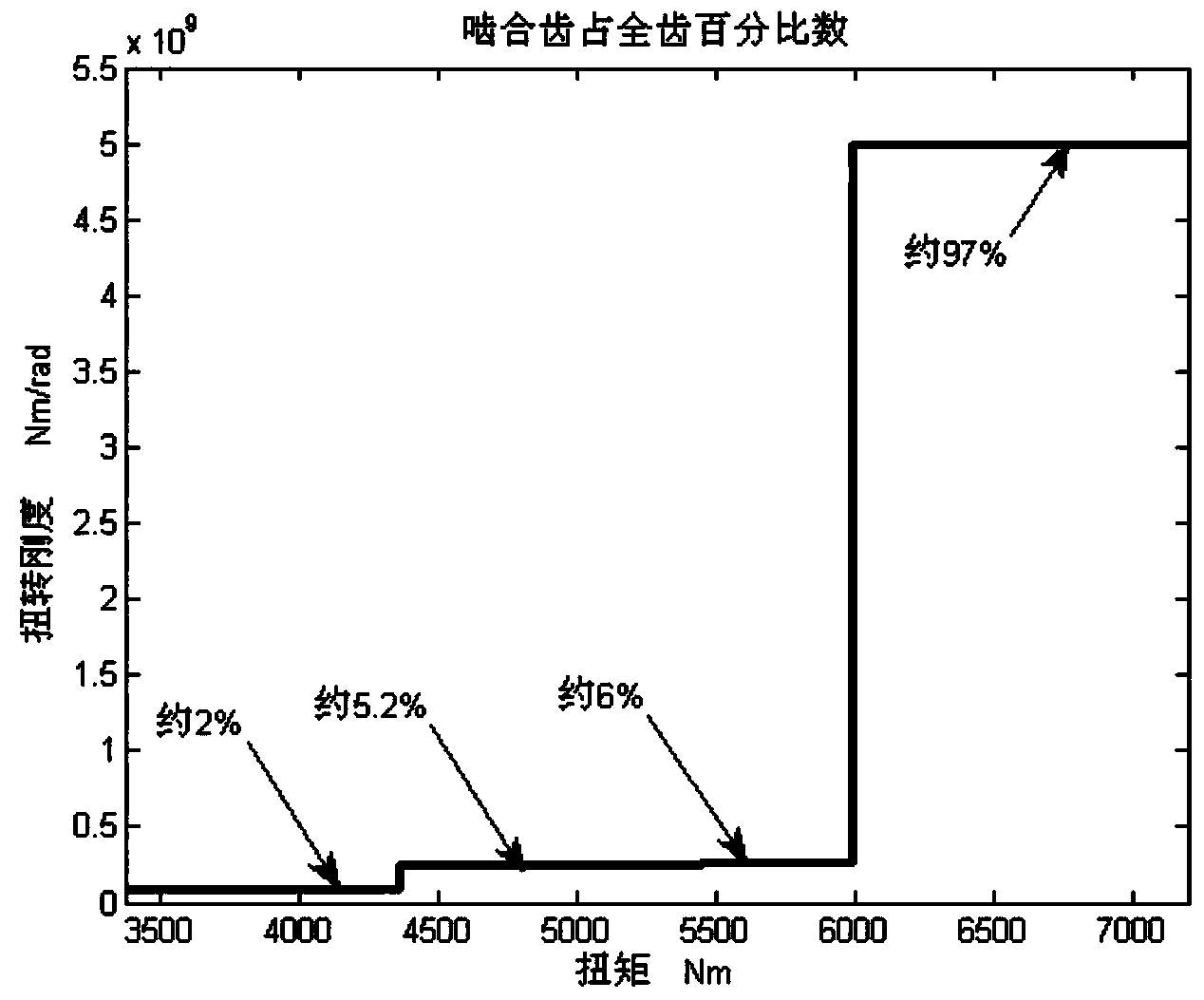

Method for obtaining circumferential load distribution of friction plate tooth part through variable-contact-rigidity testing

InactiveCN103837341AHigh precisionAvoid the problem of synchronously collecting large amounts of dataMachine gearing/transmission testingDynamic strengthDistribution characteristic

The invention belongs to the technical field of testing simulation, and provides a method for obtaining circumferential load distribution of a friction plate tooth part through variable-contact-rigidity testing. The method aims at carrying out testing on static stress on the friction element tooth part, accordingly achieving mutual verification of two distribution rule testing results, and providing theoretical supports for dynamic strength simulation and design of a friction element. According to the method, the mass data synchronous collecting problem difficult to solve can be solved, middle testing links and a data processing link are omitted, the distribution characteristics of circumferential loads of the friction plate tooth part can be directly obtained through a variable-contact-rigidity curve obtained through the testing, and the accuracy of the testing results is improved; the testing method is simple, practical and high in testing result accuracy.

Owner:CHINA NORTH VEHICLE RES INST

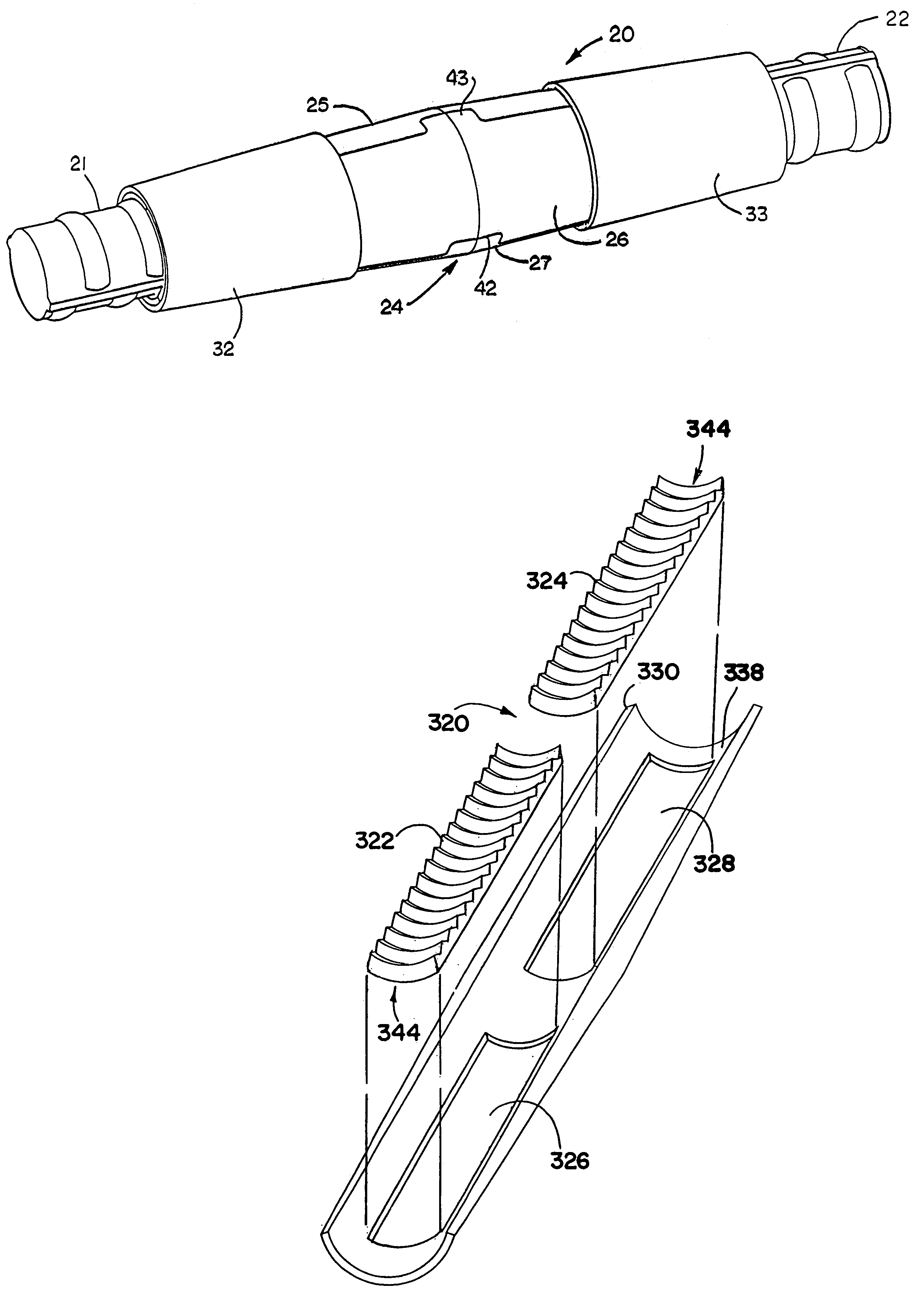

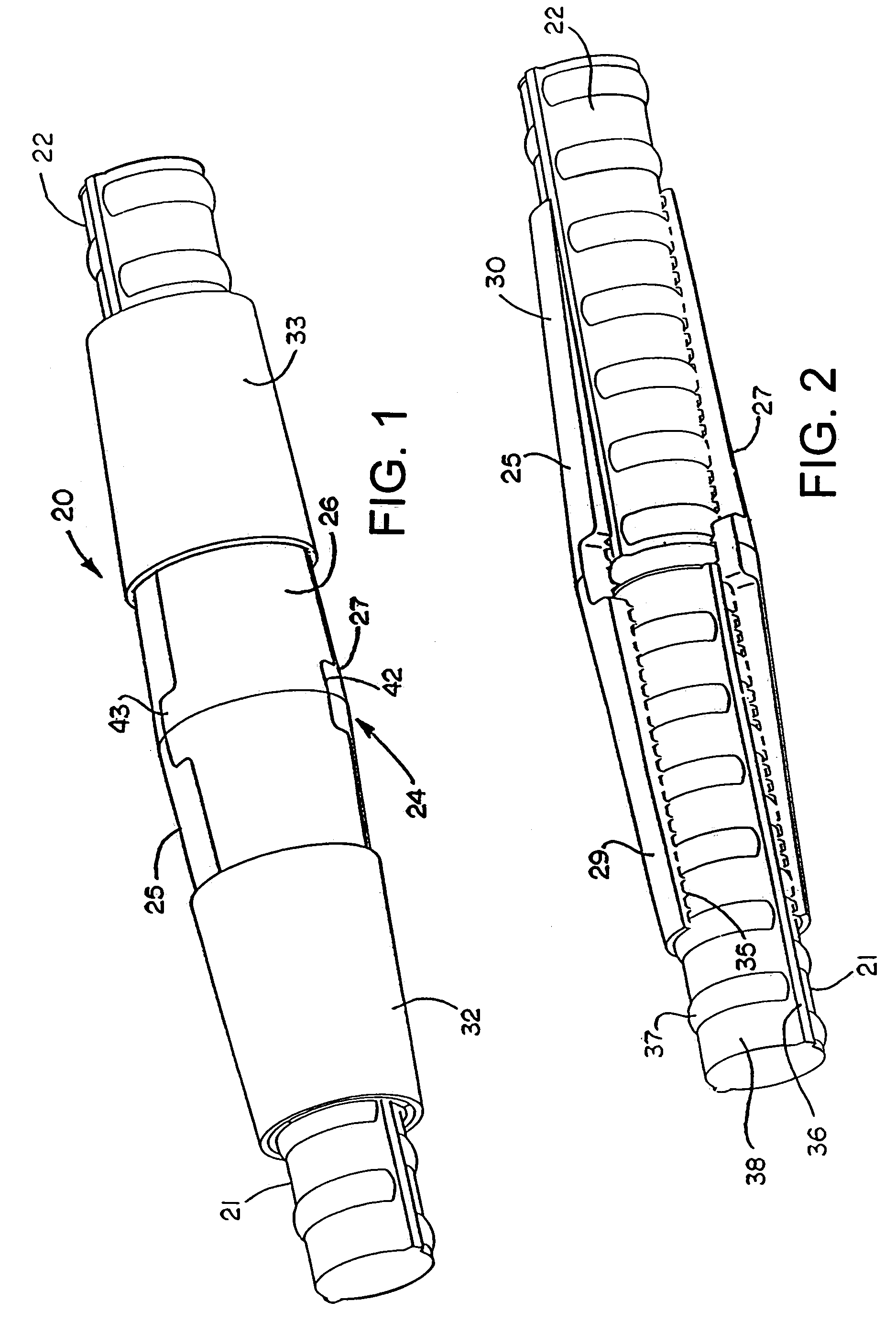

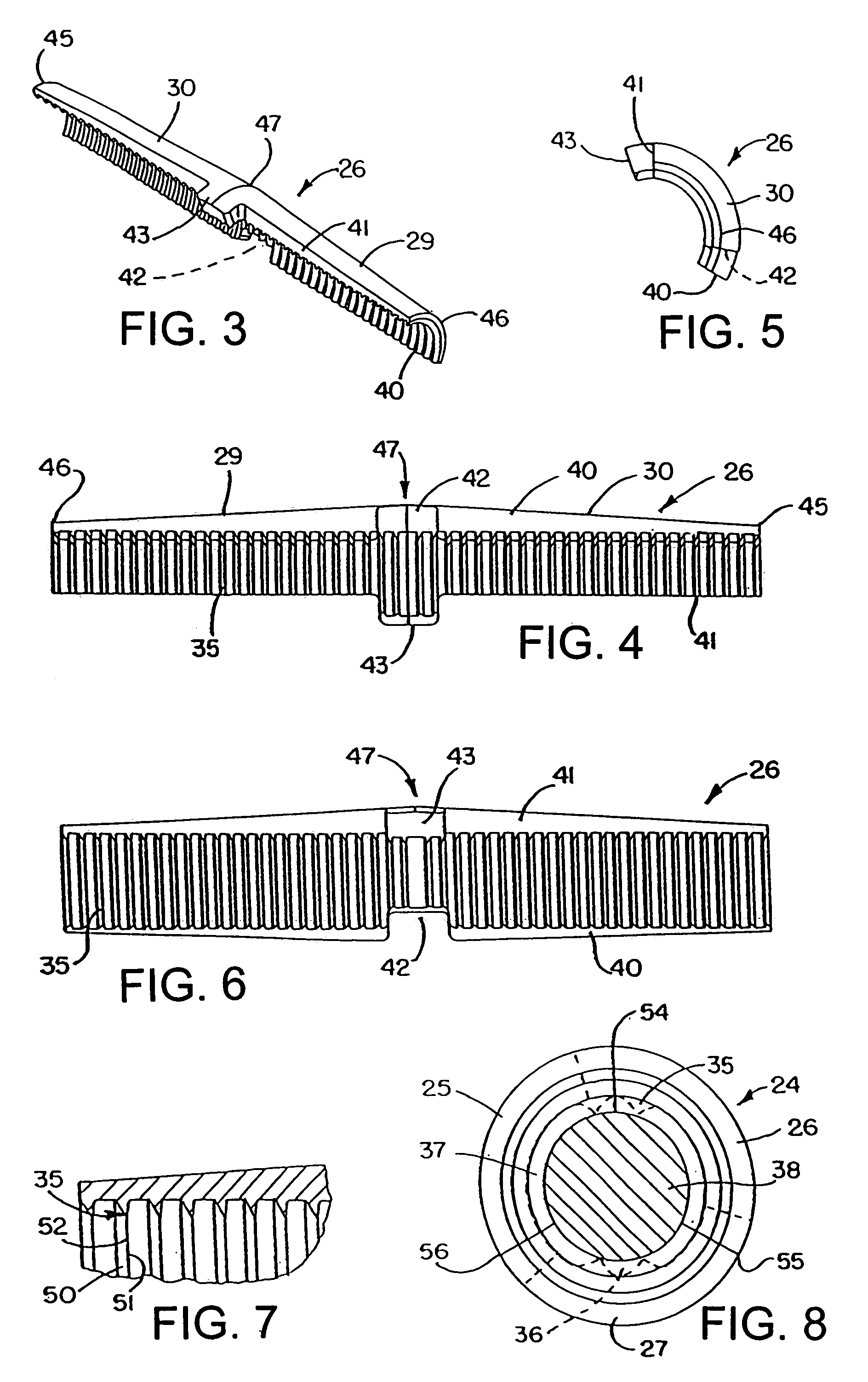

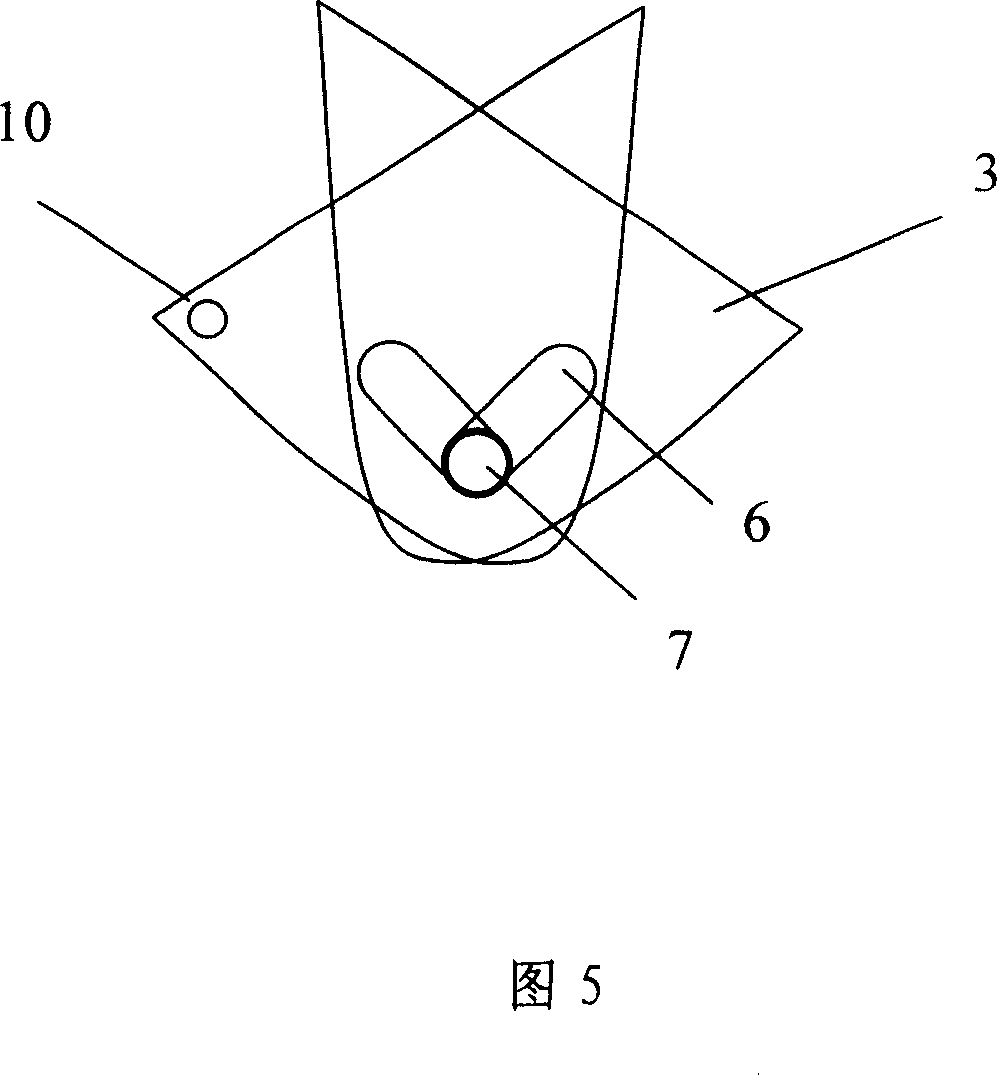

Reinforcing bar connection and method

InactiveUS7118299B2Affect fatigueAffect ultimate strength propertyRopes and cables for vehicles/pulleyRod connectionsDynamic strengthEngineering

A high strength reinforcing bar splice uses a contractible jaw assembly bridging the bar ends to be joined. The jaw assembly includes interior teeth designed to bite into the projecting ribs or deformations on the outside of the bar ends which form the overall diameter of the bar but not the core or nominal diameter of the bar. The jaw assembly is constricted from both axial ends by driving tapered locking collars on each end of the jaw assembly with a tool while concurrently causing the jaw assembly to constrict and bite into the bar ends. When the tool is removed, the collars remain in place locking the jaw assembly closed. The splice provides not only high tensile and compressive strengths but also has good fatigue and dynamic strength to qualify as a Type 2 coupler.

Owner:ERICO INT

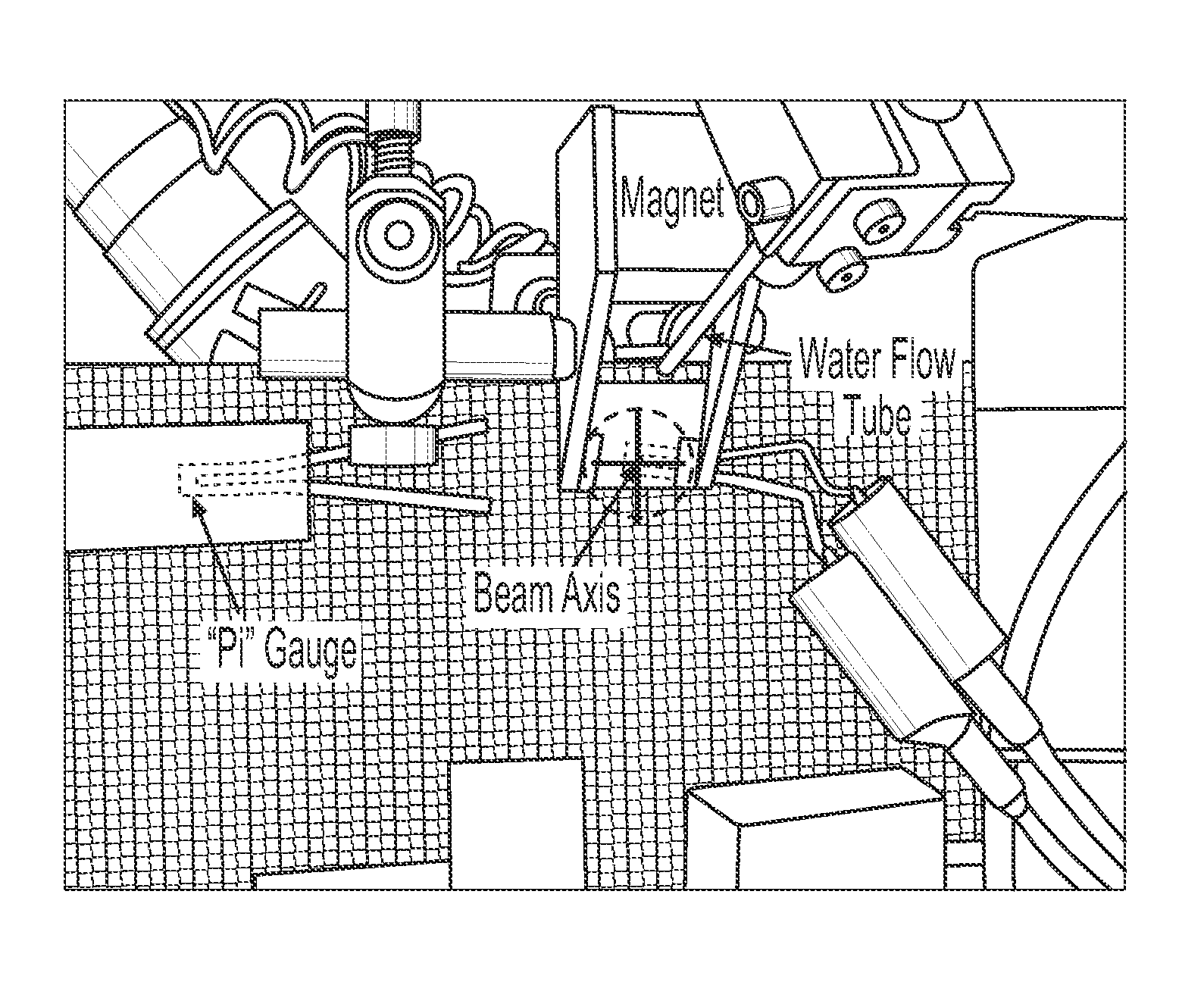

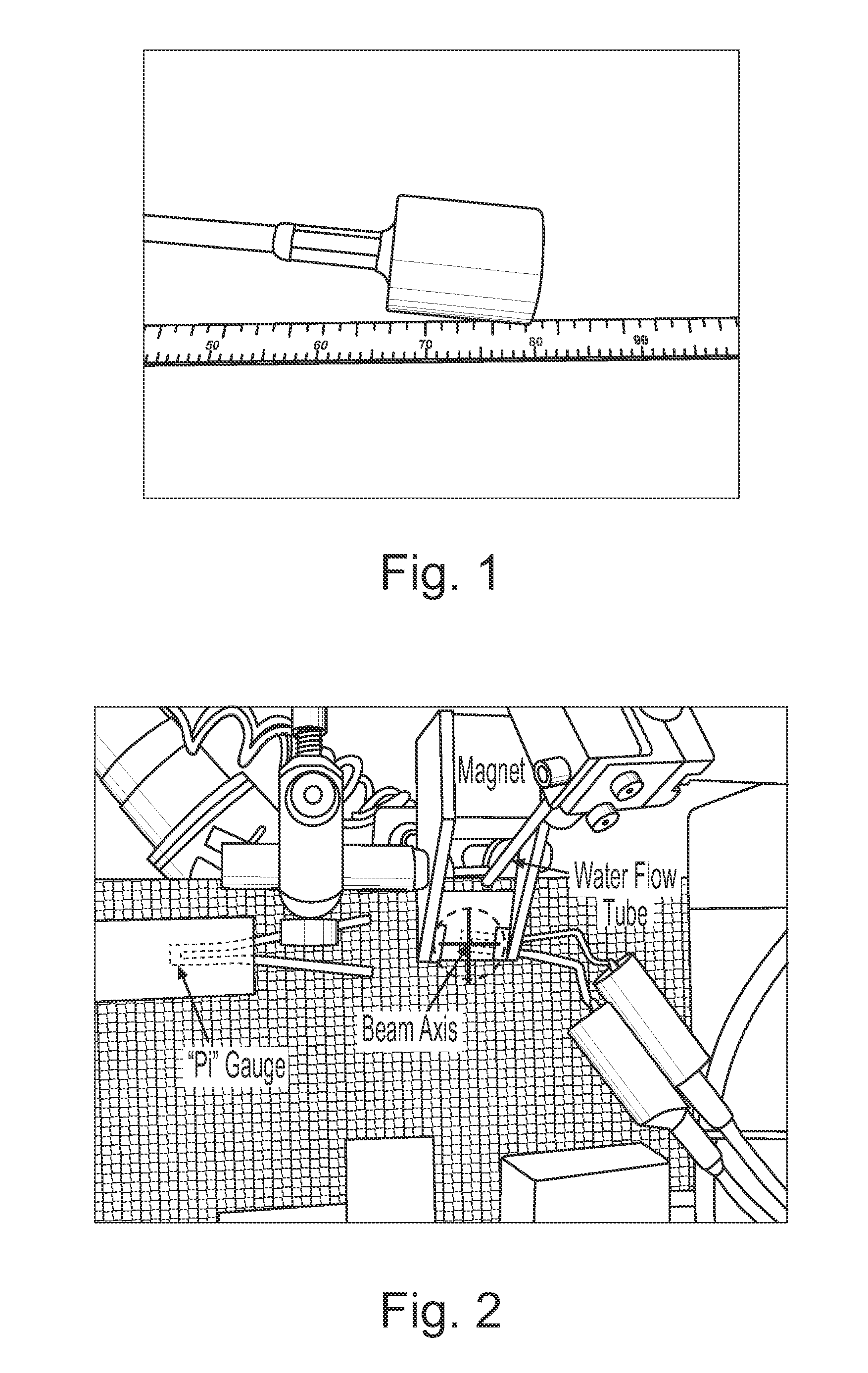

Apparatus and method for non-destructive testing

ActiveUS8156811B2Material analysis using wave/particle radiationAnalysing solids using sonic/ultrasonic/infrasonic wavesNon destructiveDynamic strength

A diagnostic means to enable real-time inspection of bonded structures. The disclosed apparatus detects bond failure stress waves on-axis from the front side (beam application side). Pi-box and pi-rail EMAT gauges can be used with the disclosed apparatus. An inductively coupled EMAT may also be employed. An improved means to remotely deliver an interrogating laser beam to a surface is provided. The process head may utilize a water column or a water film. The water film process head may include the use of either a single water film or two spaced apart water films. The disclosed apparatus can be used with bonded composite structures, bonded structures using various materials, and to determine the dynamic strength of unbonded solid materials. The apparatus may also be used in other applications that require remote flexible delivery of a localized stress wave to a material and / or diagnosis of the resultant stress waves.

Owner:LSP TECH INC

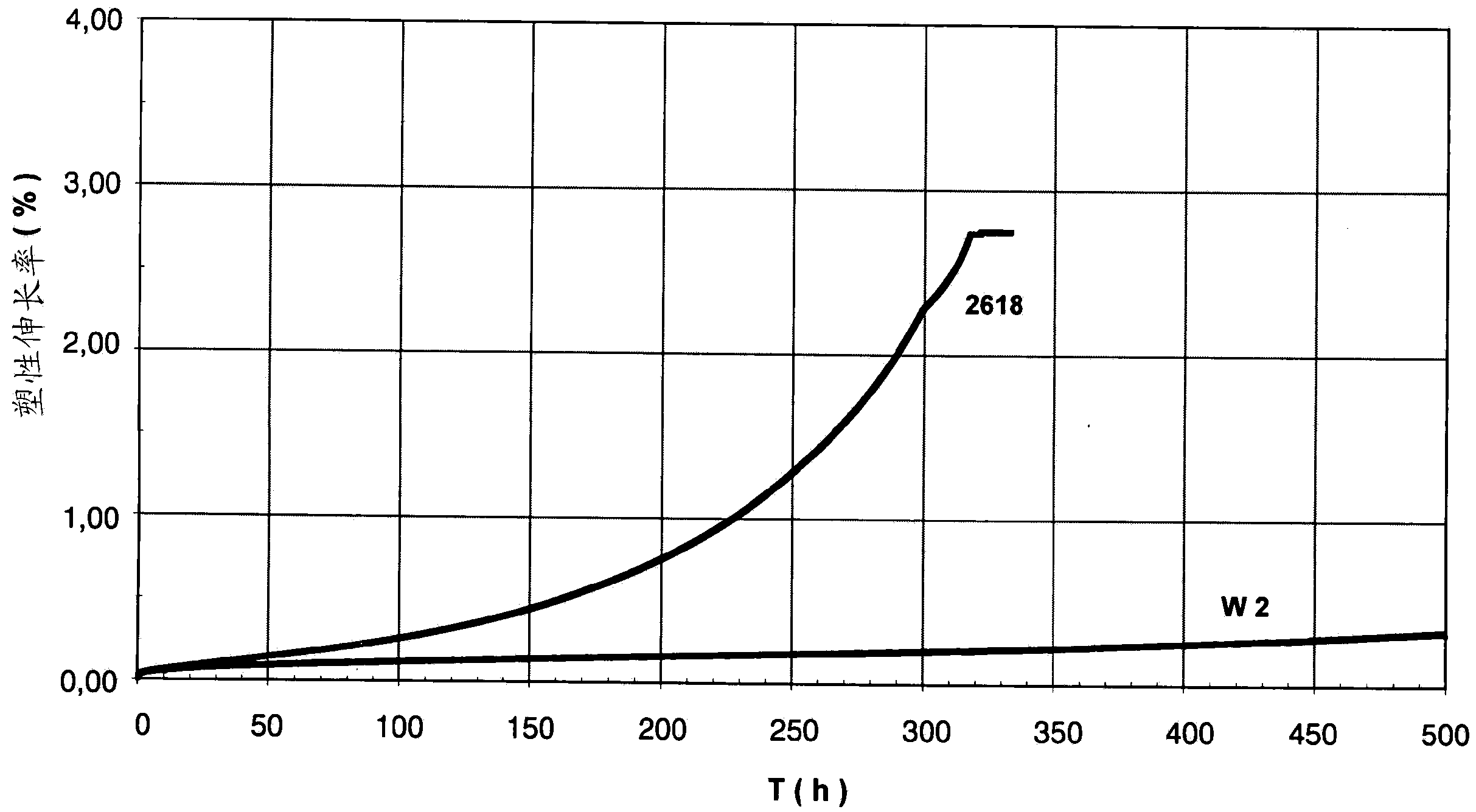

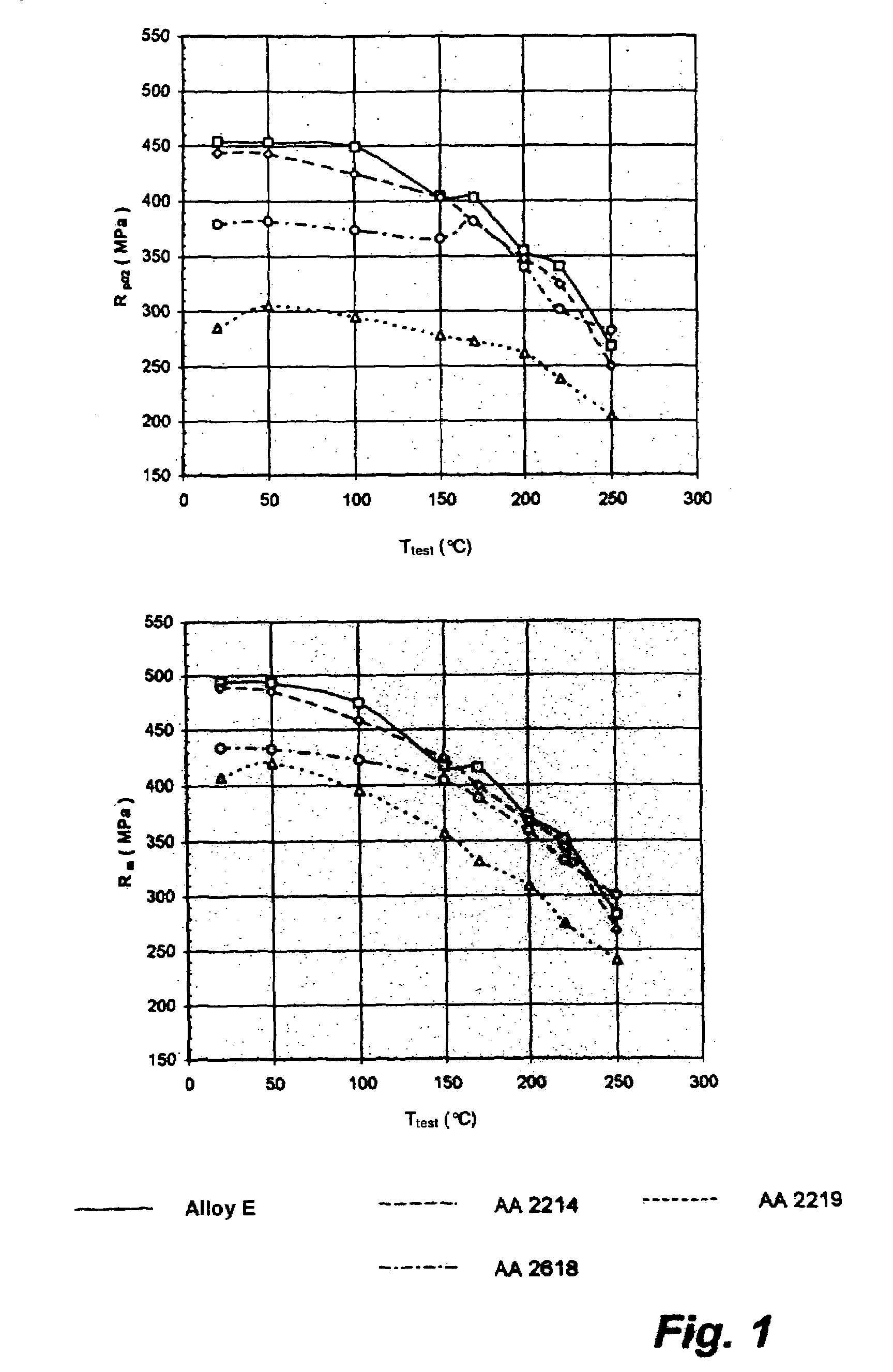

Heat-resistant Al-Cu-Mg-Ag alloy and process for producing a semifinished part or product composed of such an aluminium alloy

A heat-resistant Al-Cu-Mg-Ag alloy for producing semifinished parts or products, which is suitable for use at elevated temperatures and has good static and dynamic strength properties combined with an improved creep resistance and comprises: 0.3-0.7% by weight of silicon (Si), not more than 0.15% by weight of iron (Fe), 3.5-4.7% by weight of copper (Cu), 0.05-0.5% by weight of manganese (Mn), 0.3-0.9% by weight of magnesium (Mg), 0.02-0.15% by weight of titanium (Ti), 0.03-0.25% by weight of zirconium (Zr), 0.1-0.7% by weight of silver (Ag), 0.03-0.5% by weight of scandium (Sc), 0.03-0.2% by weight of vanadium (V), not more than 0.05% by weight of others, individually, not more than 0.15% by weight of others, total, balance aluminium, is described. A process for producing a semifinished part or product composed of the abovementioned aluminium alloy is also described.

Owner:OTTO FUCHS

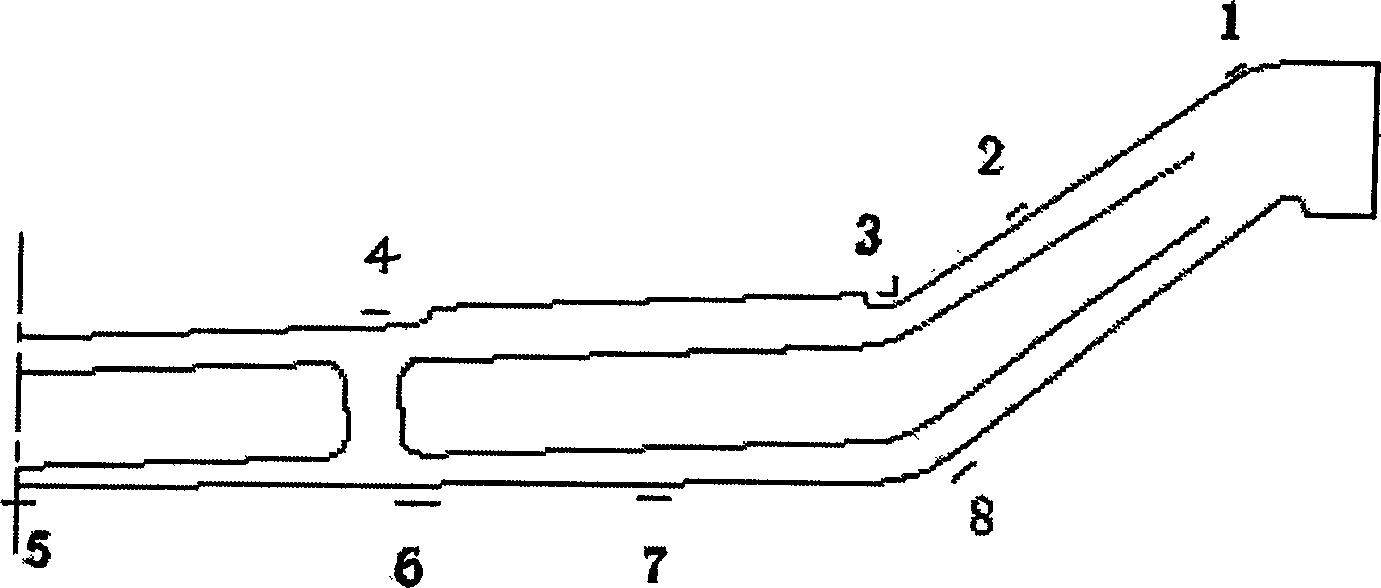

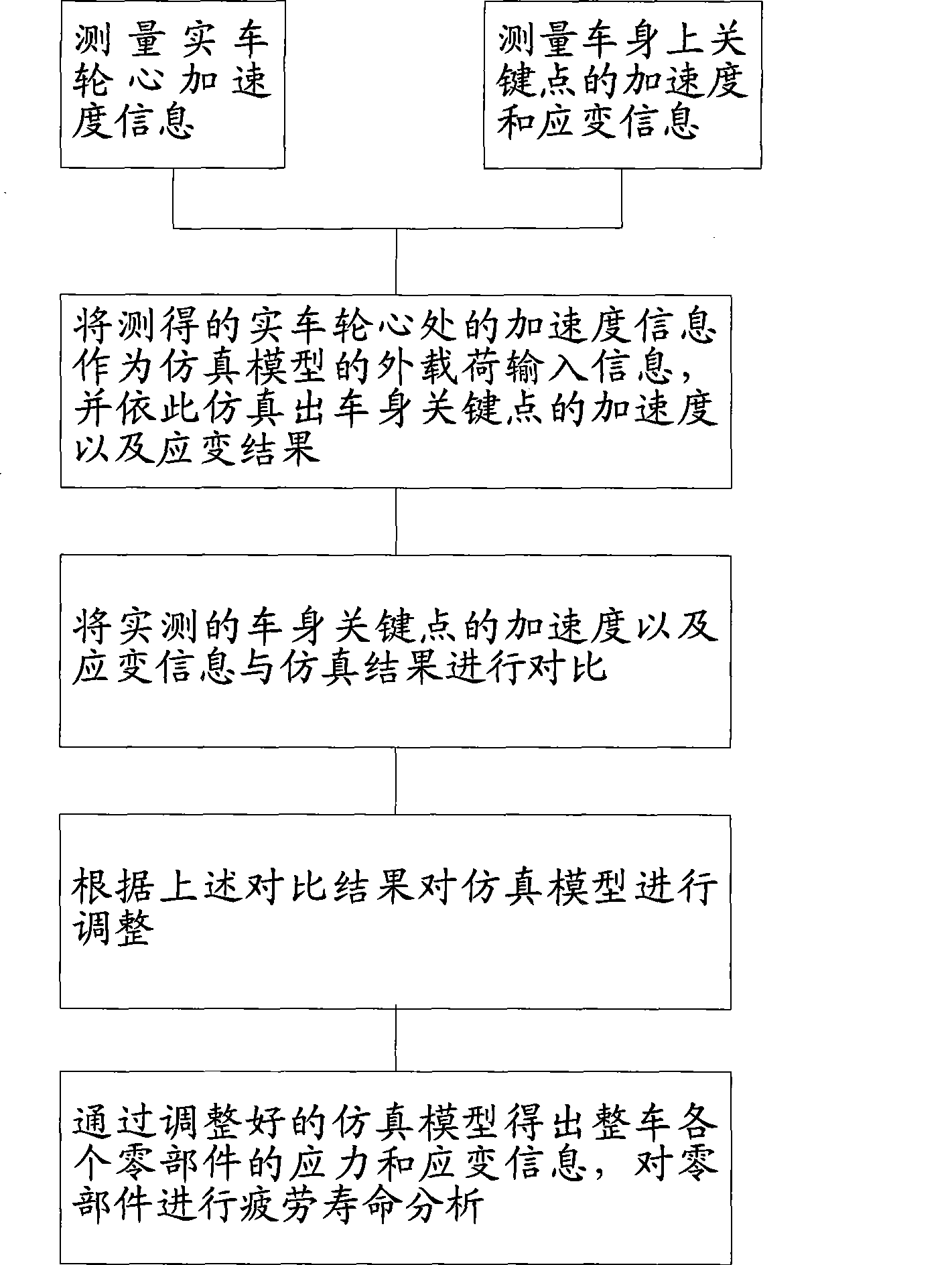

Car body dynamic intensity analysis method

InactiveCN101368882AShorten the test cycleReduce testing costsVehicle testingMachine part testingDynamic strengthBody dynamics

The invention provides a vehicle body dynamic strength analysis method, comprising the following steps: a, simultaneously measure the acceleration information of a solid wheel center and the acceleration and strain information at key points on the vehicle body; b, taking the acceleration information at the solid wheel center as the external load input information of a simulation model, and then simulating the acceleration and strain results of the key points on the vehicle body based on the external load input information; c, comparing the actually measured acceleration and strain information of the key points on the vehicle body with the simulation result; d, adjusting the simulation model based on the comparison result; and e, through the adjusted simulation model, obtaining the stress and strain information of each component of the complete vehicle and carrying out fatigue life analysis on the components.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD +1

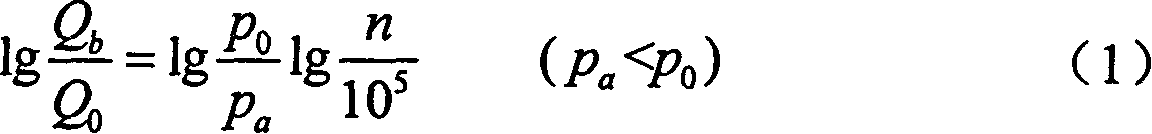

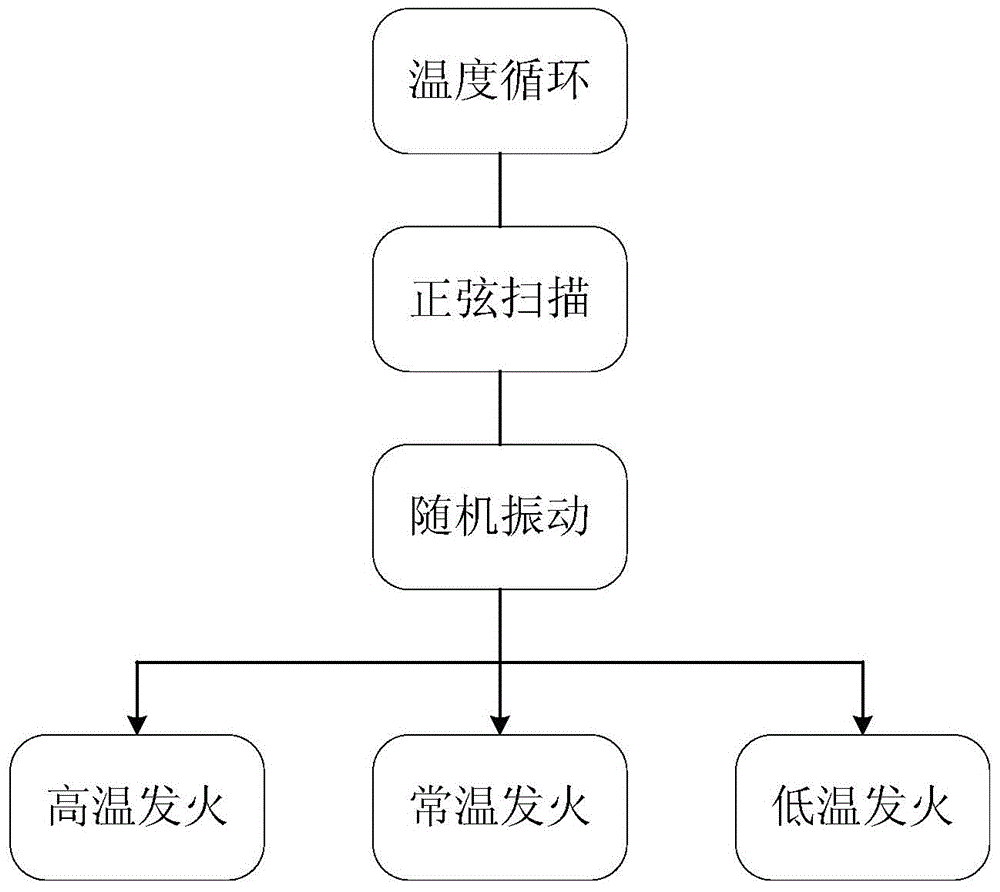

Allowance test assessment method for mild detonation fuse separation device

ActiveCN105486523AComprehensive assessment of separationComprehensive assessment strengthStructural/machines measurementDetonationDynamic strength

Owner:BEIJING INST OF ASTRONAUTICAL SYST ENG +1

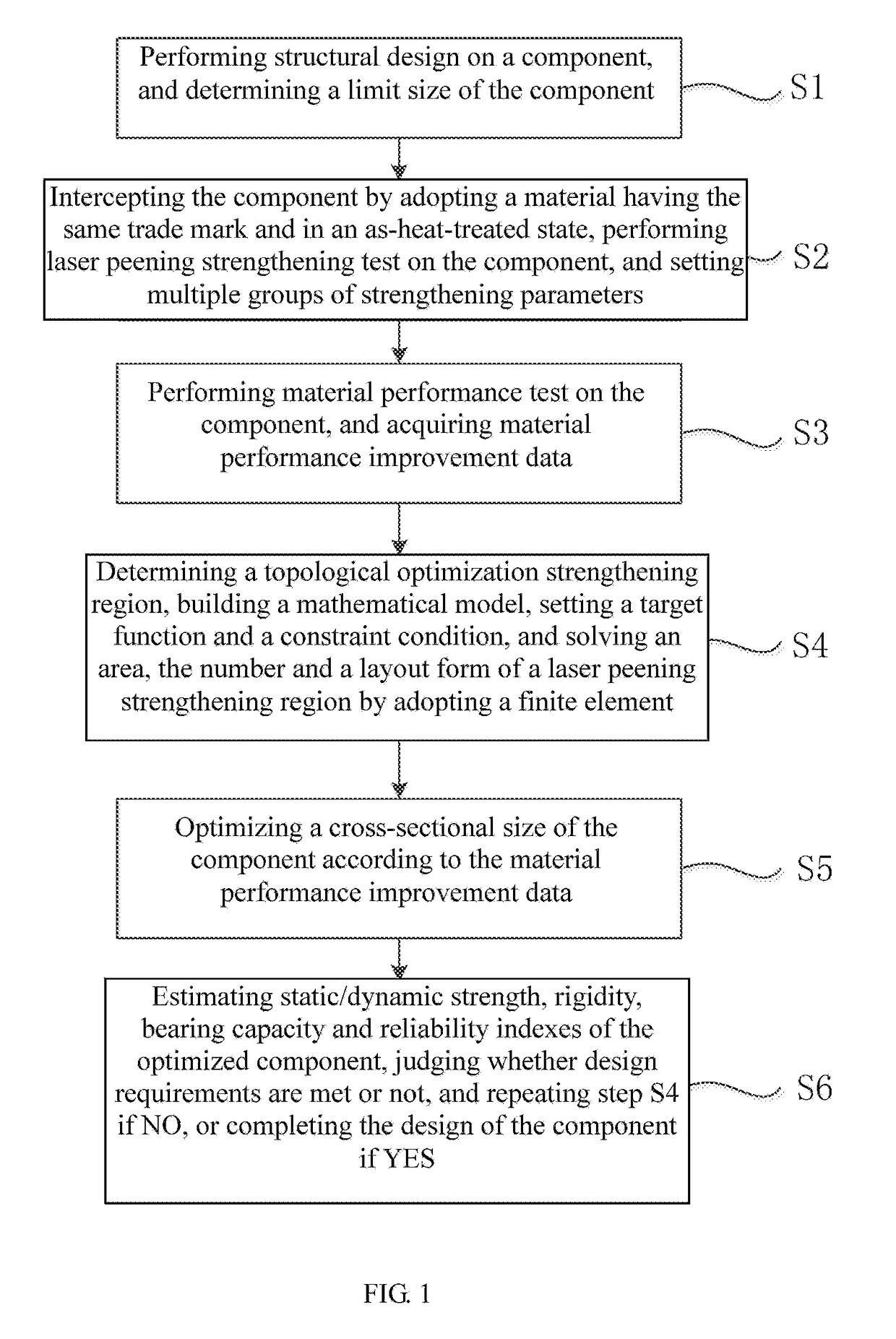

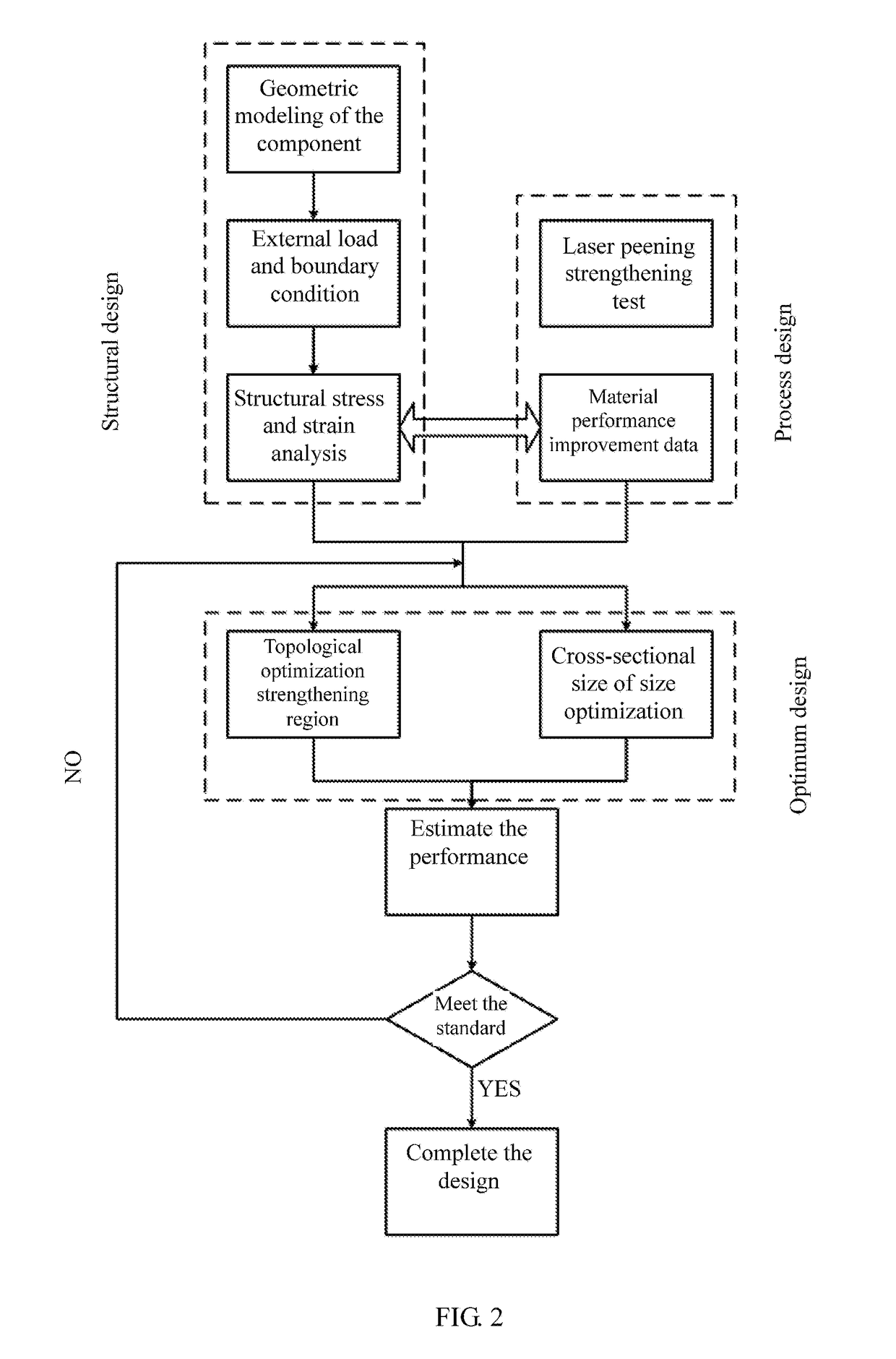

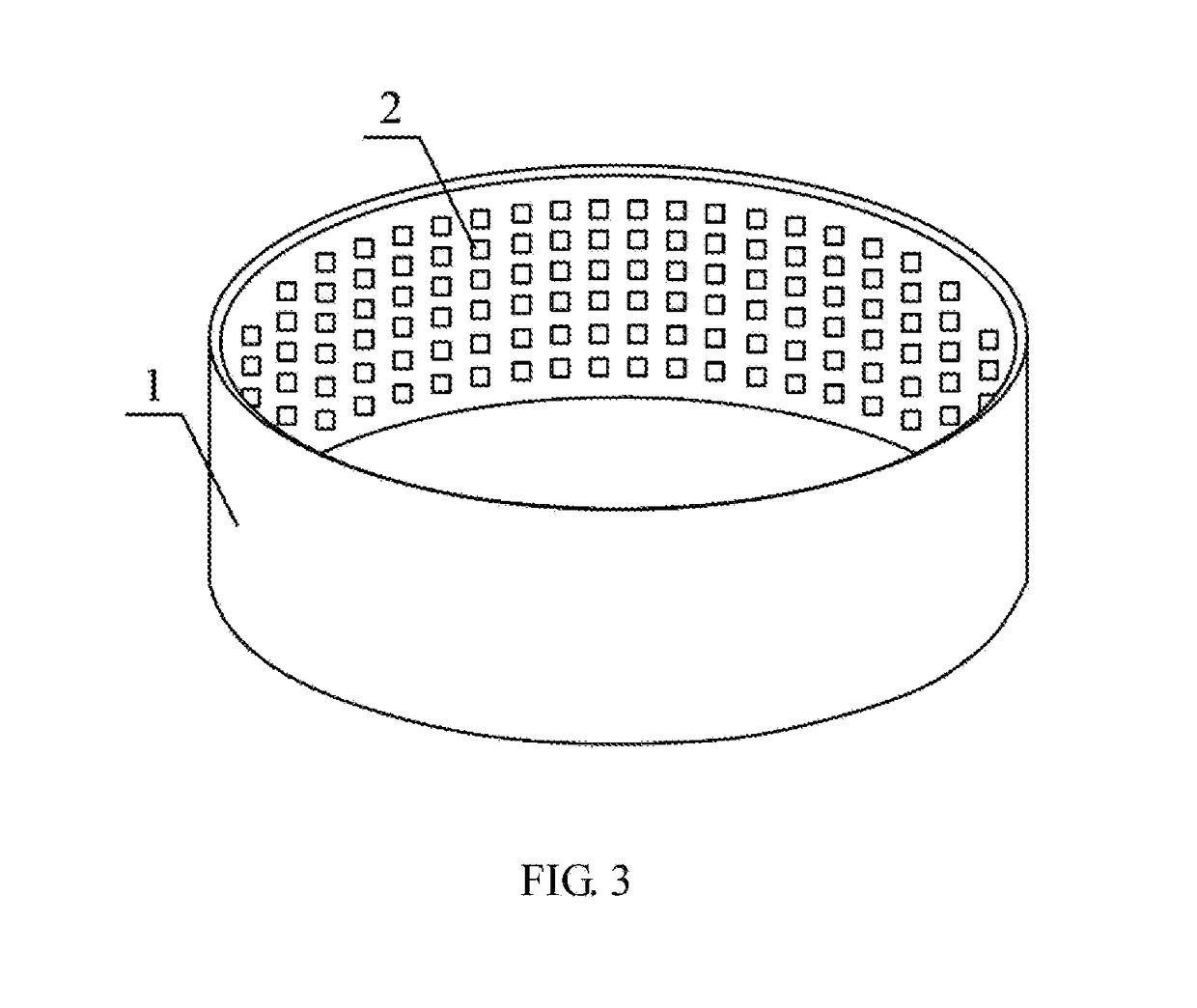

Method for rigidity enhancement and weight reduction using laser peening

ActiveUS20190042680A1High in component treatment reliabilityReduce weightGeometric CADConfiguration CADDynamic strengthTopology optimization

A method for rigidity enhancement and weight reduction using laser peening, includes the following steps: determining a limit size of a component; performing laser peening strengthening test on the component, and setting multiple groups of strengthening parameters; performing material performance test on the component, and acquiring material performance improvement data; determining a topological optimization strengthening region; optimizing the cross-sectional size of the component according to the material performance improvement data; and estimating static / dynamic strength, rigidity, bearing capacity and reliability indexes of the optimized component, judging whether design requirements are met or not, and repeating the step of determining the topological optimization strengthening region if NO, or completing the design of the component if YES.

Owner:GUANGDONG UNIV OF TECH

High-density kinetic energy ultra-high-strength tungsten-nickel heat-resisting alloy and preparation method thereof

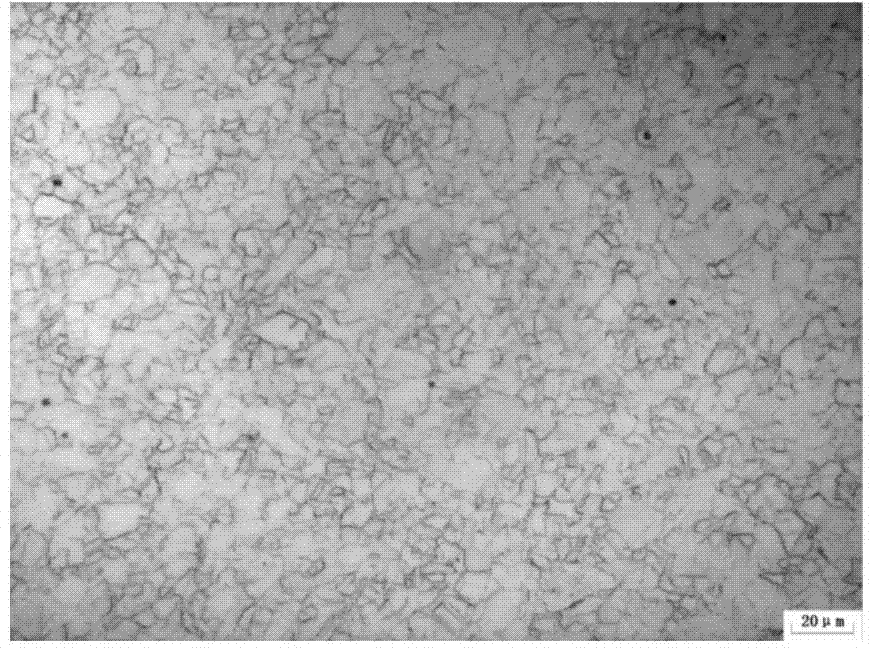

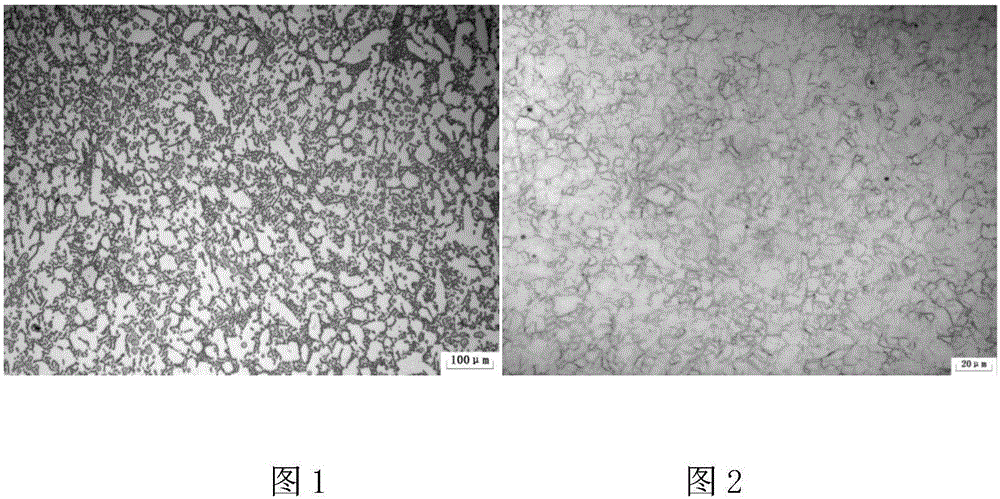

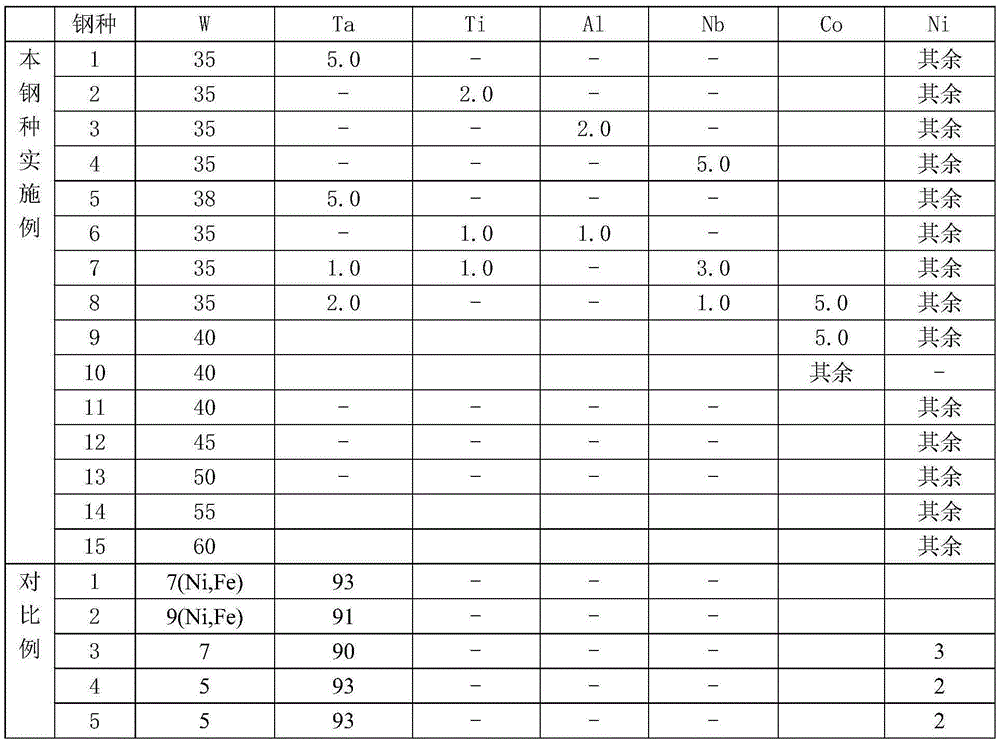

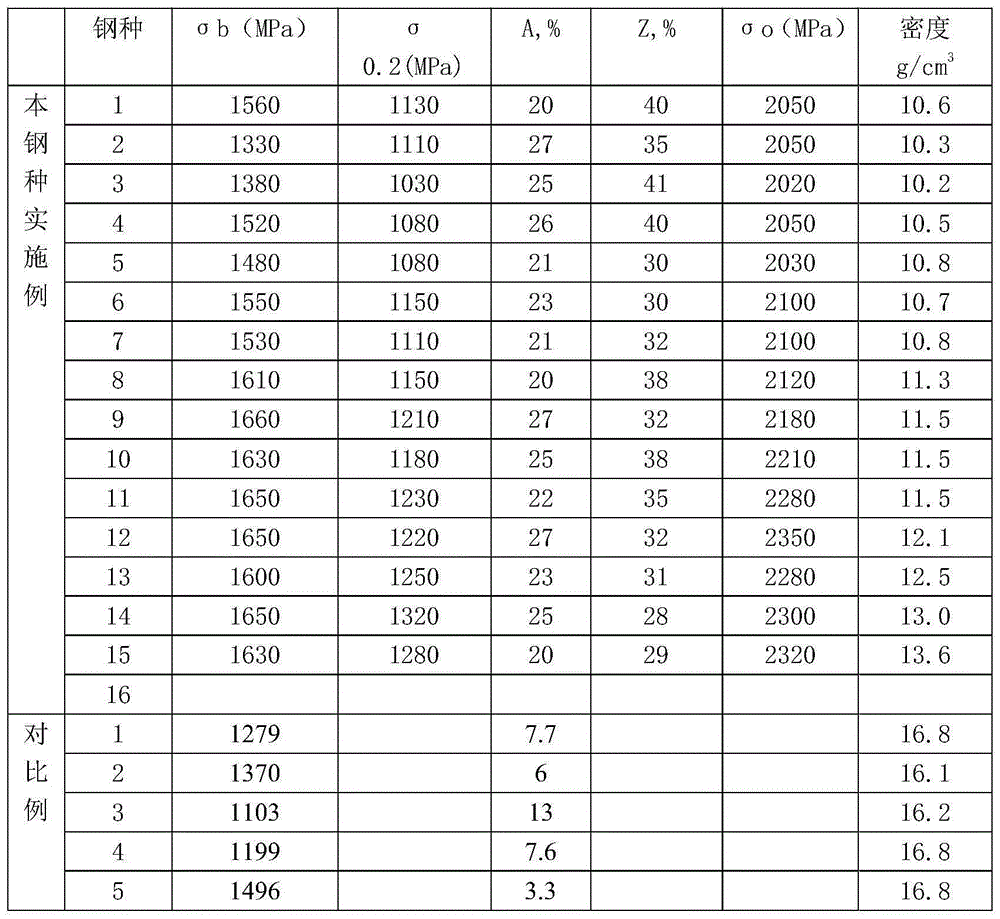

The invention discloses a high-density high-toughness kinetic energy ultra-high-strength tungsten-nickel alloy, belongs to the field of heat-resisting alloys, and in particular relates to a high-density kinetic energy ultra-high-strength tungsten-nickel heat-resisting alloy. The high-density kinetic energy ultra-high-strength tungsten-nickel heat-resisting alloy comprises the following chemical compositions in percentage by weight: 50-80% of Ni, 20-40% of W, 0-3% of Ti, 0-3% of Al, 0-8% of Nb and the balance of other inevitable impurity elements and micro elements such as rare earth. A preparation method of the high-density kinetic energy ultra-high-strength tungsten-nickel heat-resisting alloy adopts the following processes: vacuum induction and vacuum self-consuming remelting or electro-slag remelting. Compared with the prior art, the high-density kinetic energy ultra-high-strength tungsten-nickel heat-resisting alloy disclosed by the invention has excellent comprehensive performance and excellent properties such as high density, high toughness, ultra-high strength and ultra-high dynamic strength, and ensures that the density can reach 9.0-13.0g / cm<3>, the impact toughness can reach more than 100J / cm<2>, the static tensile strength can reach more than 1350MPa, and the dynamic compressive strength can reach more than 1900MPa.

Owner:CENT IRON & STEEL RES INST

In-trench water-stone separation siphoning-drainage debris flow control method

ActiveCN102535384AAddress governance issuesIncreased durabilityHydraulic engineering apparatusStream regulationSiphonDynamic strength

The invention discloses an in-trench water-stone separation siphoning-drainage debris flow control method. A series of permeable pipes are disposed in a trench in an area for formation or passage of debris flow, and drain siphons are connected to downstream ends of the permeable pipes. When the water level of rain flood reaches the siphoning level, water permeating into the permeable pipes is drained to the downstream safety trench through the drain siphons so that dynamic strength of the water in the trench is reduced. Using the method can effectively control formation and passage of debris flow and solve treatment methods for debris flow trenches on different scales, and control engineering is simple in construction and high in adaptability. Gravity flow is converted into full in-pipe flow under the action of siphoning drainage, and drainage efficiency is improved. Pipe sedimentation can be prevented under the suction action of siphoning. Diverted drainage in the case of high water level has low impact on the hydrological environment of the trench.

Owner:ZHEJIANG UNIV

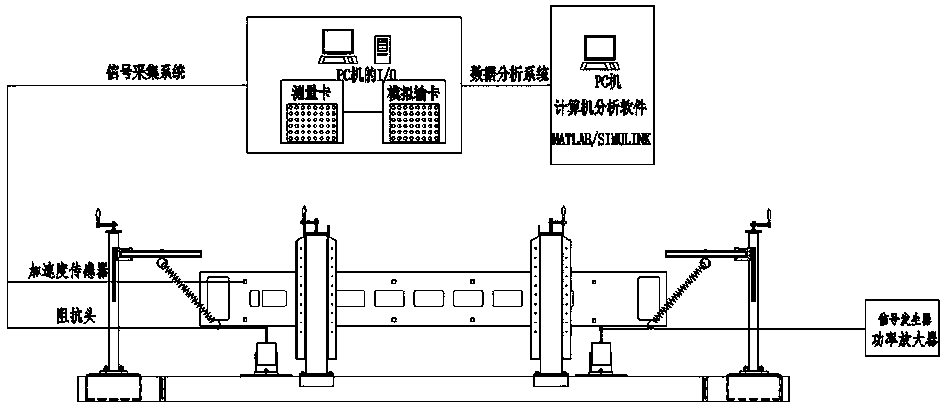

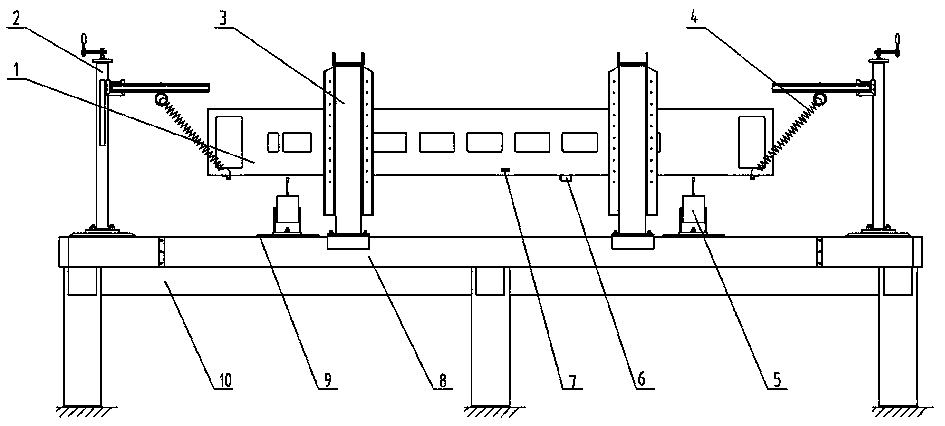

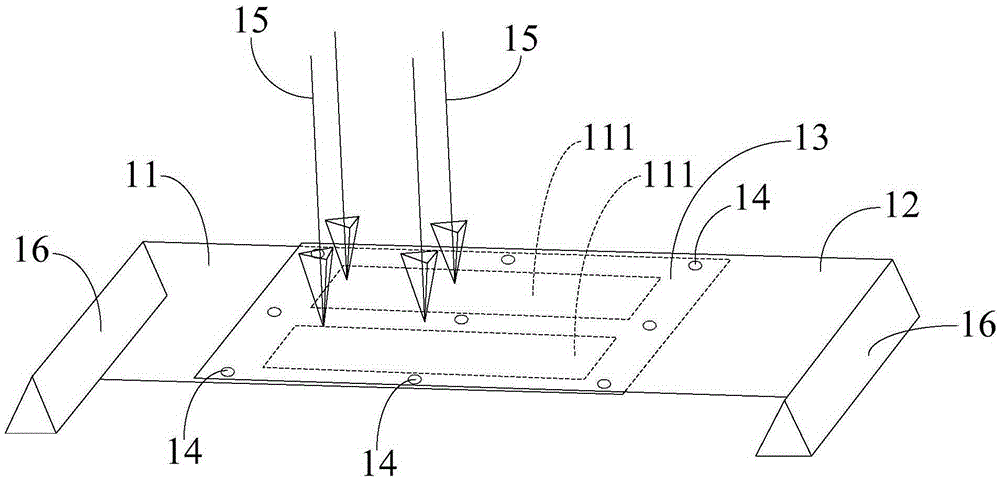

Multi-target-proportion vehicle body vibration characteristic comprehensive test platform

InactiveCN103528831AOvercoming trial costsEnable optimization analysisRailway vehicle testingDigital signal processingDynamic strength

The present invention discloses a multi-target-proportion vehicle body vibration characteristic comprehensive test platform which comprises the following components: a proportion vehicle body, a computer, a data acquisition device, a power amplifier, various kinds of sensors, a test platform underframe, etc. Two ends of the test platform underframe are provided with a hoisting frame which facilitates proportion vehicle height adjustment, a middle hoisting frame which can move bidirectionally, and a plurality of vibration exciter mounting frames, thereby realizing single / multiple point excited modal test and analysis. The multi-target-proportion vehicle body vibration characteristic comprehensive test platform can realize equivalent research for dynamic strength and dynamic stiffness of proportion vehicle body structures of different rail vehicles. Furthermore through modal parameter identification technique and acquired excited and responded load time history, a structure frequency response function is acquired by means of modern digital signal processing technique, and a physical parameter model of the structure system is acquired. Furthermore load identification and sensitivity analysis are performed on the structure physical parameter for realizing identification and optimization for the structure parameter. Furthermore the test platform underframe of the invention has a small structure size and greatly reduces cost of the structure modal test.

Owner:SOUTHWEST JIAOTONG UNIV

Al/Cu/Mg/Ag alloy with Si, semi-finished product made from such an alloy and method for production of such a semi-finished product

An Al / Cu / Mg / Mn alloy for the production of semi-finished products with high static and dynamic strength properties has the following composition: 0.3–0.7 wt % silicon (Si), max. 0.15 wt. % iron (Fe), 3.5–4.5 wt % copper (Cu), 0.1–0.5 wt. % manganese (Mn), 0.3–0.8 wt. % magnesium (Mg), 0.5–0.15 wt % titanium (Ti), 0.1–0.25 wt % zirconium (Zr), 0.3–0.7 wt. % silver (Ag), max. 0.05 wt. % others individually, max 0.15 wt. % others globally, the remaining wt. % aluminum (Al). The invention further relates to a semi-finished product made for such an alloy and a method of production of a semi-finished product made for such an alloy.

Owner:FA OTTO FUCHS

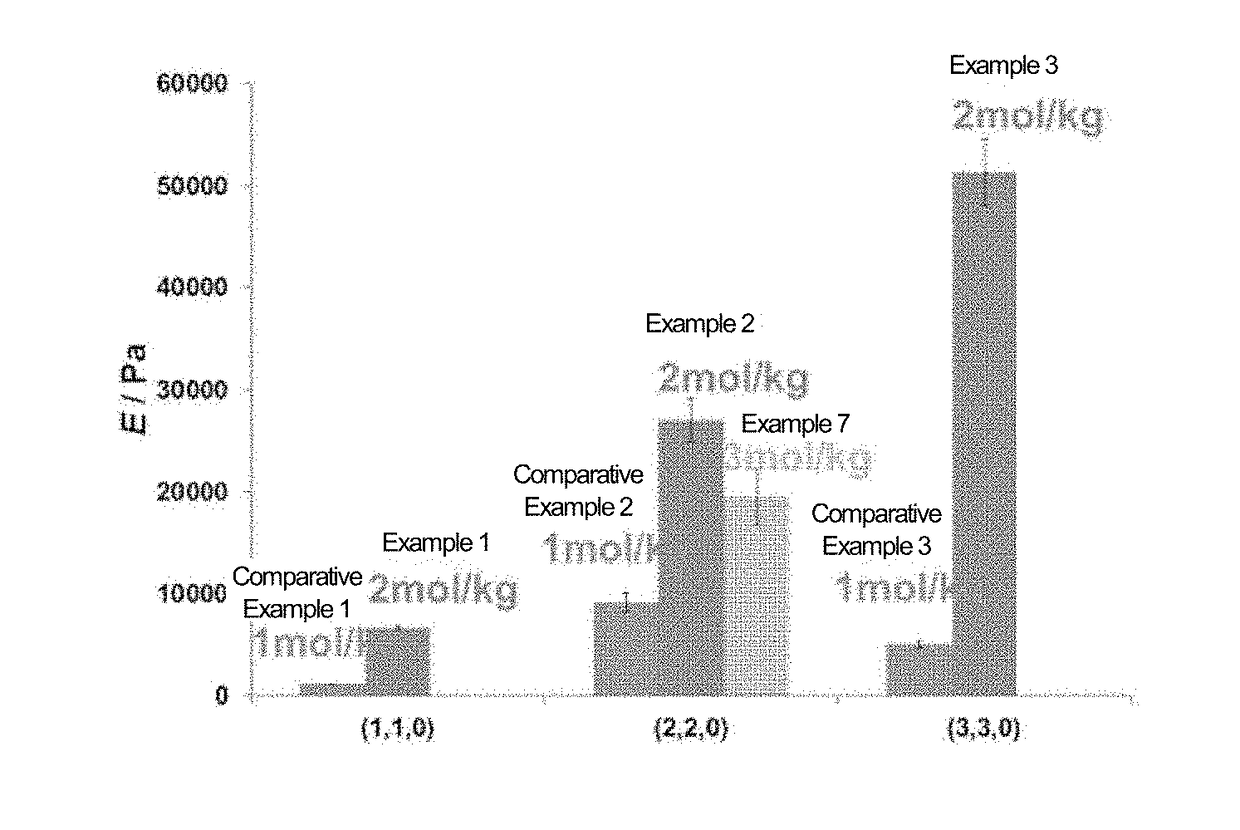

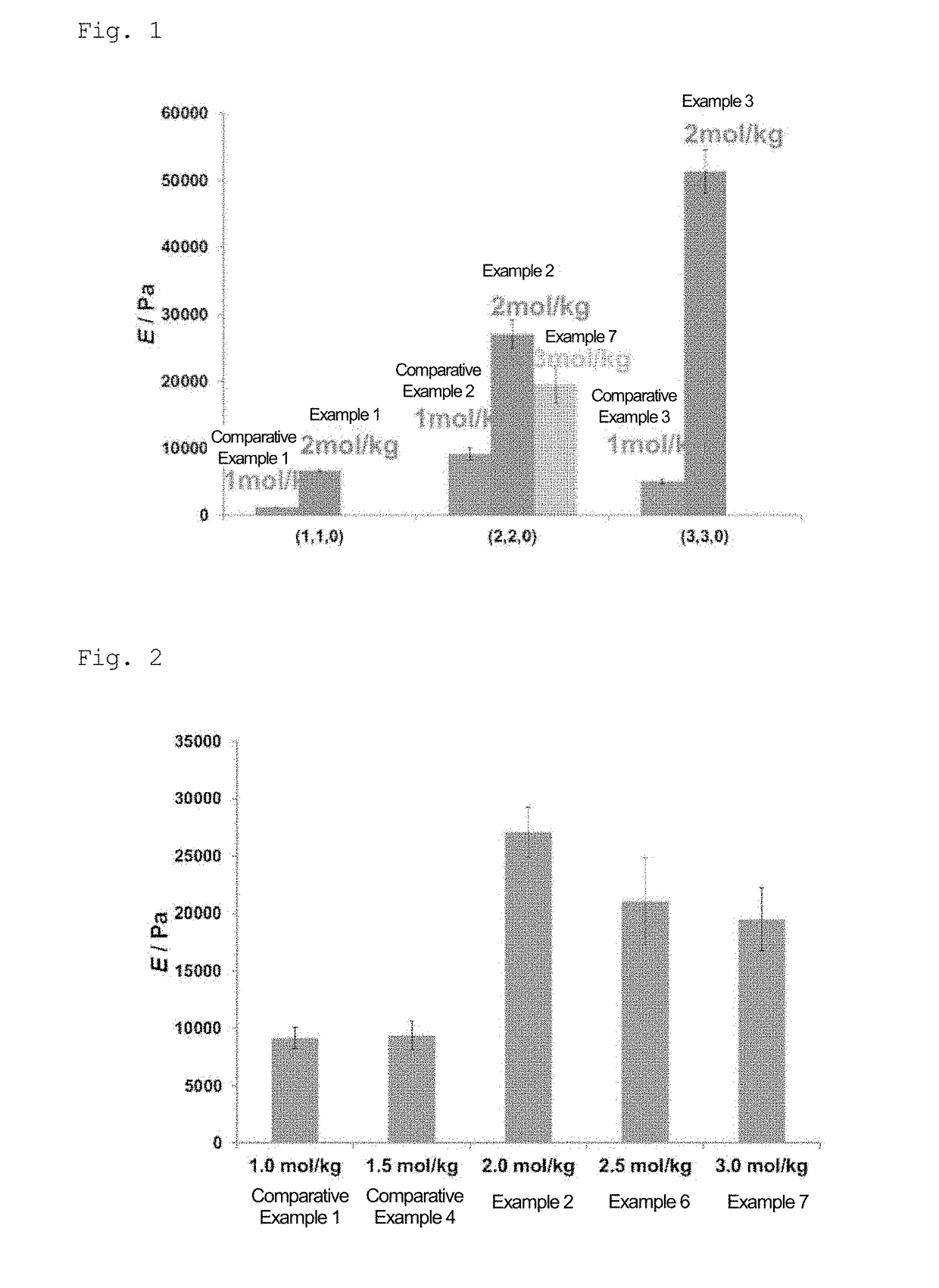

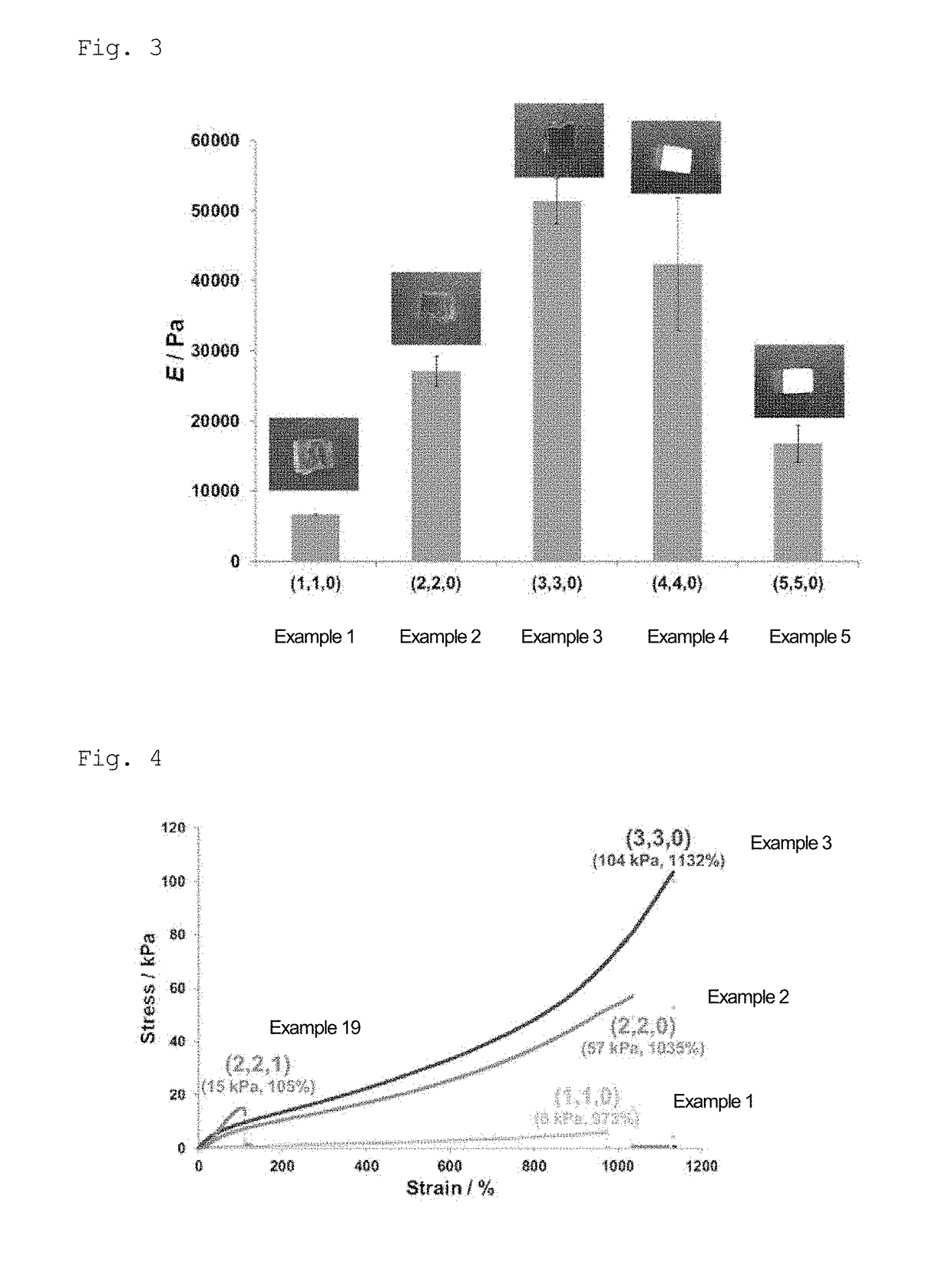

Self-repairing material and manufacturing method therefor

The present invention provides a self-repairing material having self-repairing properties and shape memory properties, as well as high dynamic strength, and also provides a method for manufacturing the same. The self-repairing material of the present invention comprises a polymer comprising specific monomer units in specific ratios, and the concentration of the monomer units is within a specific range.

Owner:OSAKA UNIV

Double-phase high-density kinetic energy tungsten-nickel-cobalt alloy capable of being cast and forged and preparation method

The invention discloses double-phase high-density kinetic energy tungsten-nickel-cobalt alloy capable of being cast and forged and a preparation method, and belongs to the field of kinetic energy alloy. The double-phase high-density kinetic energy tungsten-nickel-cobalt alloy comprises, by weight, 35-65% of W, 0-3% of Ti, 0-3% of Al, 0-8% of Nb, 0-10% of Ta and the balance Ni or Co or NiCo, unavoidable impurity elements and micro elements like rare earth. The preparation method adopts vacuum induction plus vacuum arc remelting. Compared with the prior art, the double-phase high-density kinetic energy tungsten-nickel-cobalt alloy capable of being cast and forged is good in comprehensive performance, has high density, high rigidity, super high strength, super high dynamic strength and other excellent properties, the density can reach 11.0-15.0 g / cm<3>, the impact rigidity can reach 80 J / cm<2> or higher, the static tensile strength can reach 1300 MPa or higher, and the dynamic compression strength can reach 1800 MPa or higher.

Owner:CENT IRON & STEEL RES INST

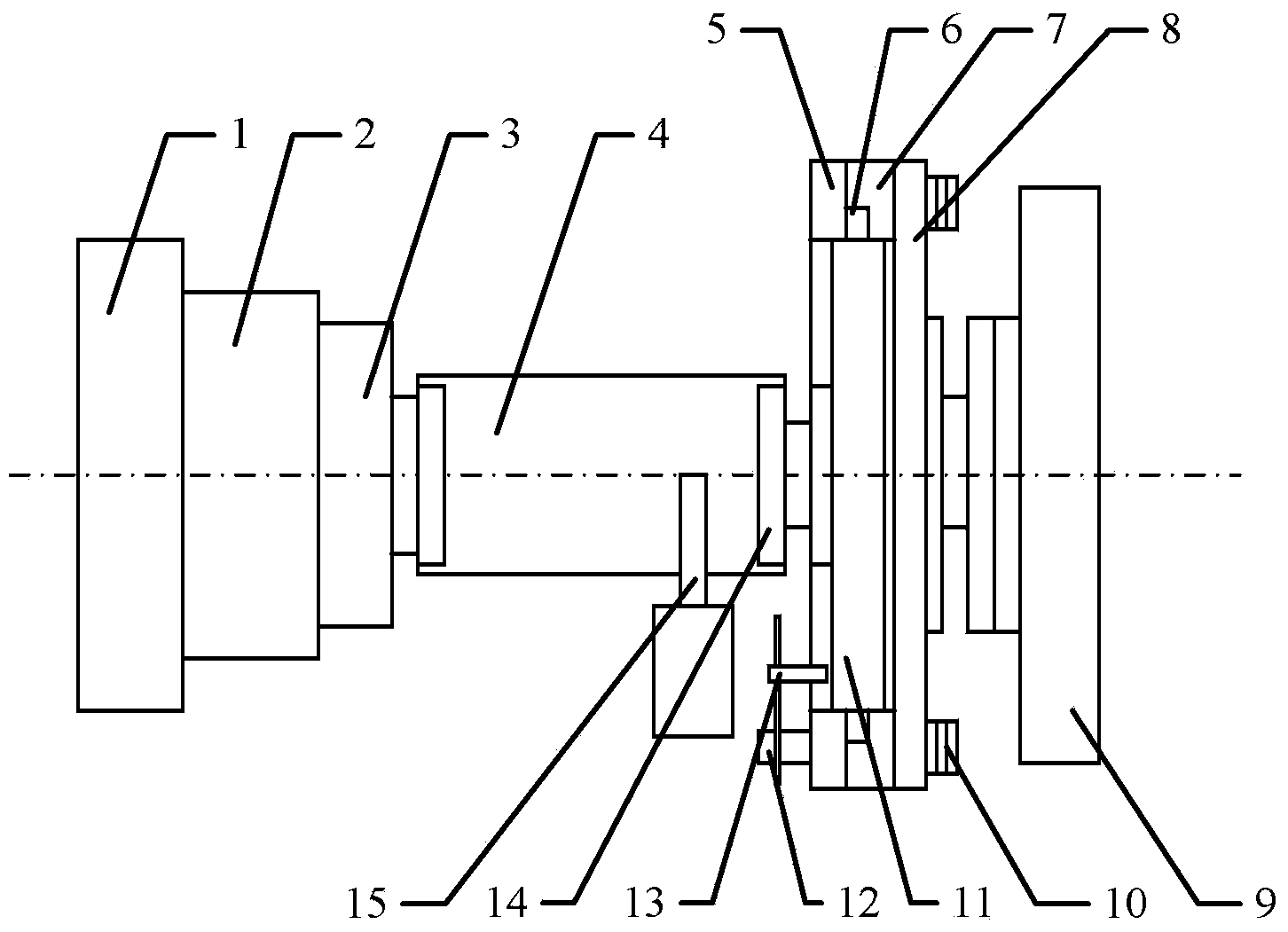

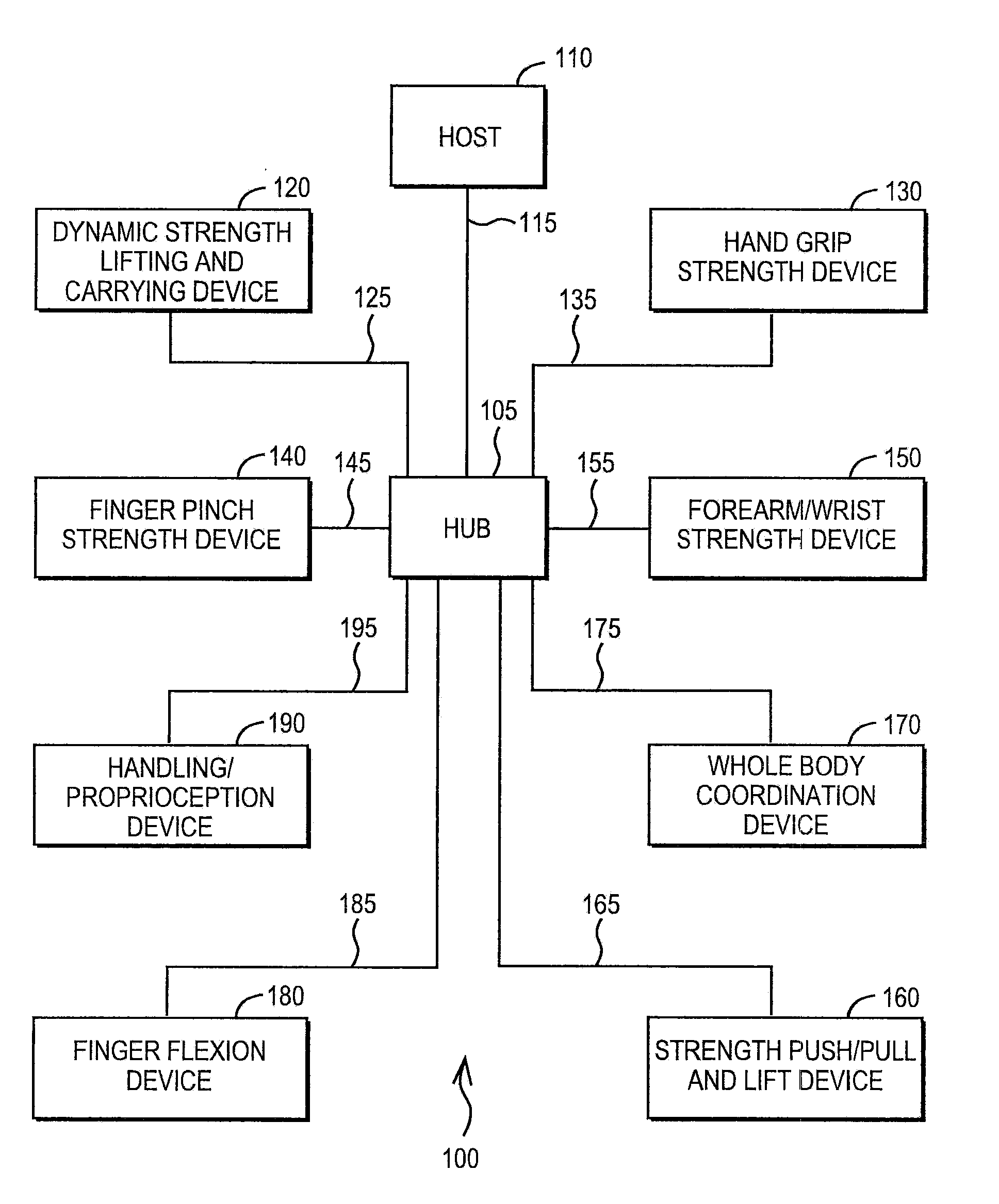

Work capacities testing apparatus and method

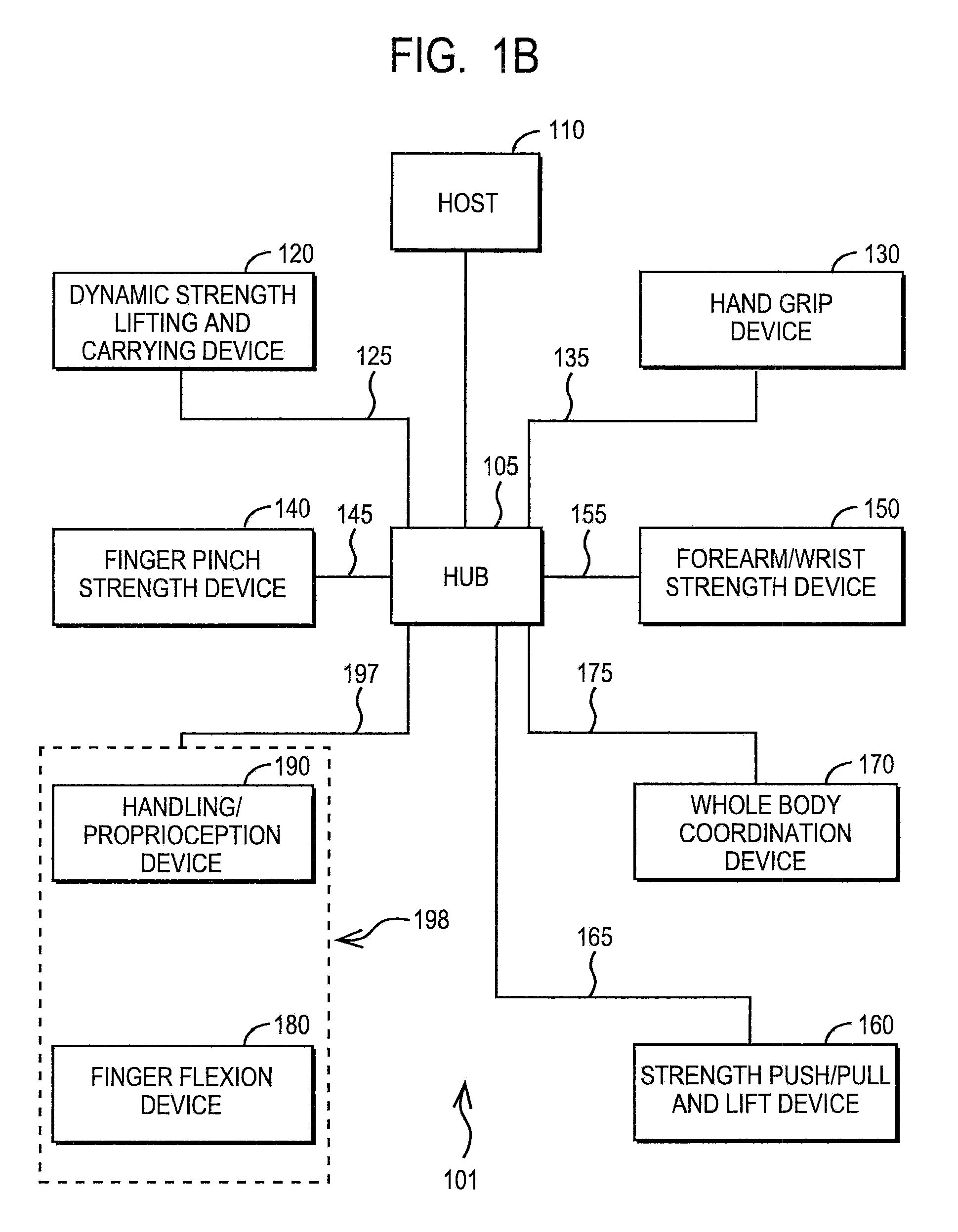

A portable work capacities testing apparatus, and a method using that portable apparatus, are disclosed. The apparatus comprises a host computer 110, a dynamic strength and lifting device 120 releaseably interconnected with the host computer, a hand grip strength device 130 releaseably interconnected with the host computer, a finger pinch strength device 140 releaseably interconnected with the host computer, a forearm / wrist strength device 150 releaseably interconnected with the host computer, a handling / proprioception device 190 releaseably interconnected with the host computer, a finger flexion device 180 releaseably interconnected with the host computer, a whole body coordination device 170 releaseably interconnected with the host computer, and a strength push / pull / lift device 160 releaseably interconnected with the host computer.

Owner:AKINS ROBERT +2

Method for casting and producing glass mould roughcast by V-process molding process

InactiveCN104985118AGood staticHigh strengthFoundry mouldsFoundry coresDynamic strengthOxidation resistant

The invention discloses a method for casting and producing glass mould roughcast by a V-process molding process. The method comprises the following processes: casting glass mould roughcast by adopting a heat-resistant alloy cast iron material; assembling aluminum alloy mould cores on replaceable mould board cores and finishing the cores; respectively placing replaceable mould board cores in an upper sand box and a lower sand box of a vacuum sand box; carrying out film laminating; carrying out film roasting; carrying out vacuum pouring; carrying out thermal treatment, and the like. According to the method, the mould roughcast, with a D-type graphite form in a roughcast inner cavity part and A-type graphite forms in other roughcast outer parts, is obtained by methods of carrying out process control and boiler-front inoculation treatment, adding alloy elements such as Mo, V, Ti, Cr, Cu and Al, adopting chilled iron cores and the like. The A-type graphite form structure has good static and dynamic strength, higher thermal conductivity and stable processing performances; the D-type graphite form structure has better compactness and higher tensile strength, and is remarkably improved in wear resistance, heat resistance, oxidization resistance and thermal fatigue resistance; and the mould roughcast with different graphite-form structures on key parts is glass mould roughcast which is most suitable for a glass bottle tank forming process.

Owner:HEBEI ANDY MOULD CO LTD

Wet type copper base friction material and its preparation method

InactiveCN1865388AHigh mechanical strengthImprove thermophysical propertiesOther chemical processesDynamic strengthUltimate tensile strength

The invention discloses a wet copper base friction material and preparing method, which is composed of three-dimensional, interconnect network carborundum ceramic skeleton, copper alloy and other inorganic fillers, wherein the bulk percentage of copper alloy is 60-70 vol. percent; the bulk percentage of network carborundum ceramic skeleton and inorganic filler is 40-30 vol. percent. The fusing high-temperature liquid alloy is squeezed in the three-dimensional network carborundum ceramic skeleton of inorganic filler under pressure, which possesses high dynamic strength. The invention can be applied in large power; high speed wet friction driving and braking device.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

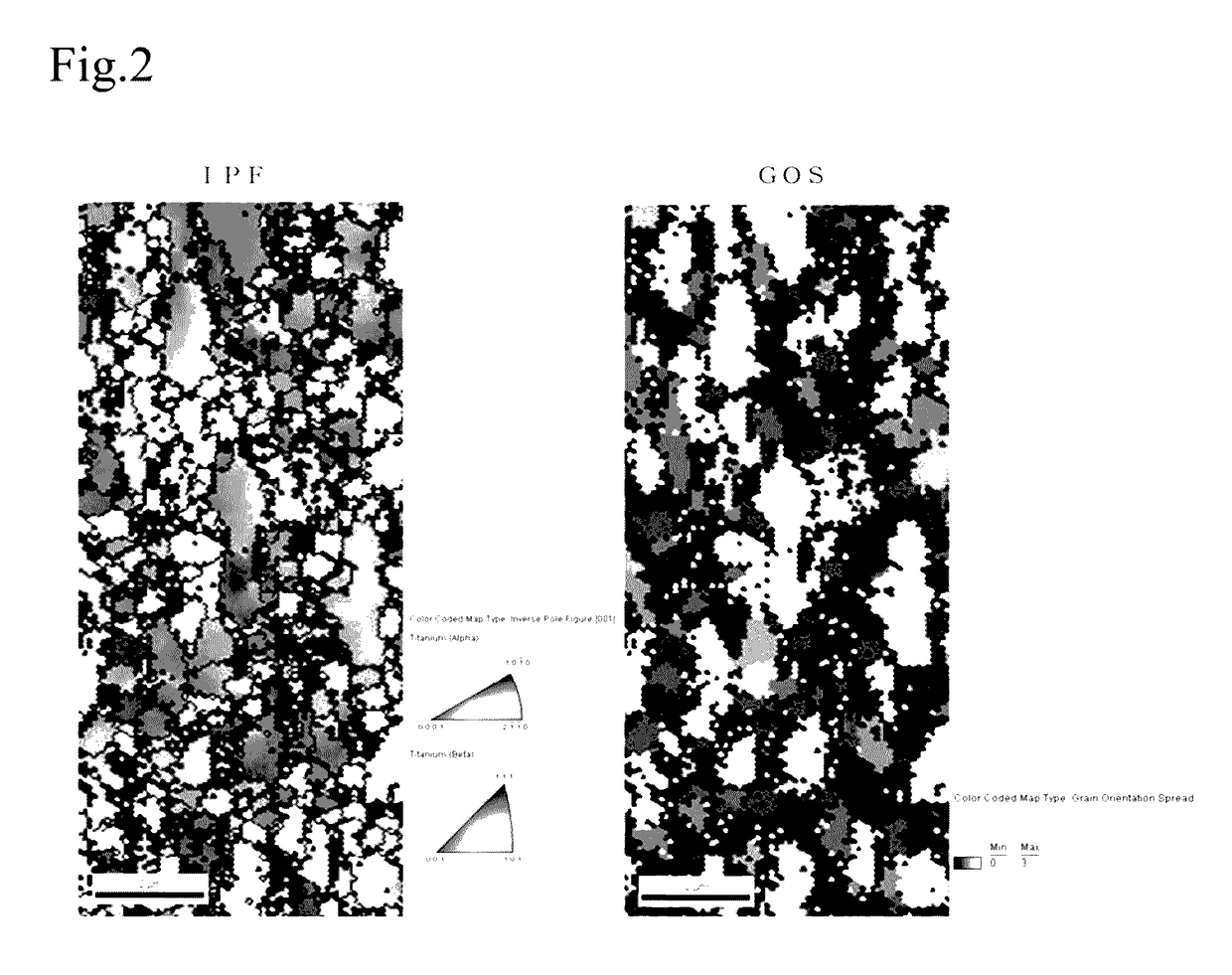

Nanocrystal-containing titanium alloy and production method therefor

An alloy having an α′ martensite which is a processing starting structure is hot worked. The alloy is heated at a temperature increase rate of 50 to 800° C. / sec, and strain is given at not less than 0.5 by a processing strain rate of from 0.01 to 10 / sec in a case of a temperature range of 700 to 800° C., or by a processing strain rate of 0.1 to 10 / sec in a case of a temperature range of 800° C. to 1000° C. By generating equiaxial crystals having average crystal particle diameters of less than 1000 nm through the above processes, a titanium alloy having high strength and high fatigue resistant property can be obtained, in which hardness is less than 400 HV, tensile strength is not less than 1200 MPa, and static strength and dynamic strength are superior.

Owner:NHK SPRING CO LTD +1

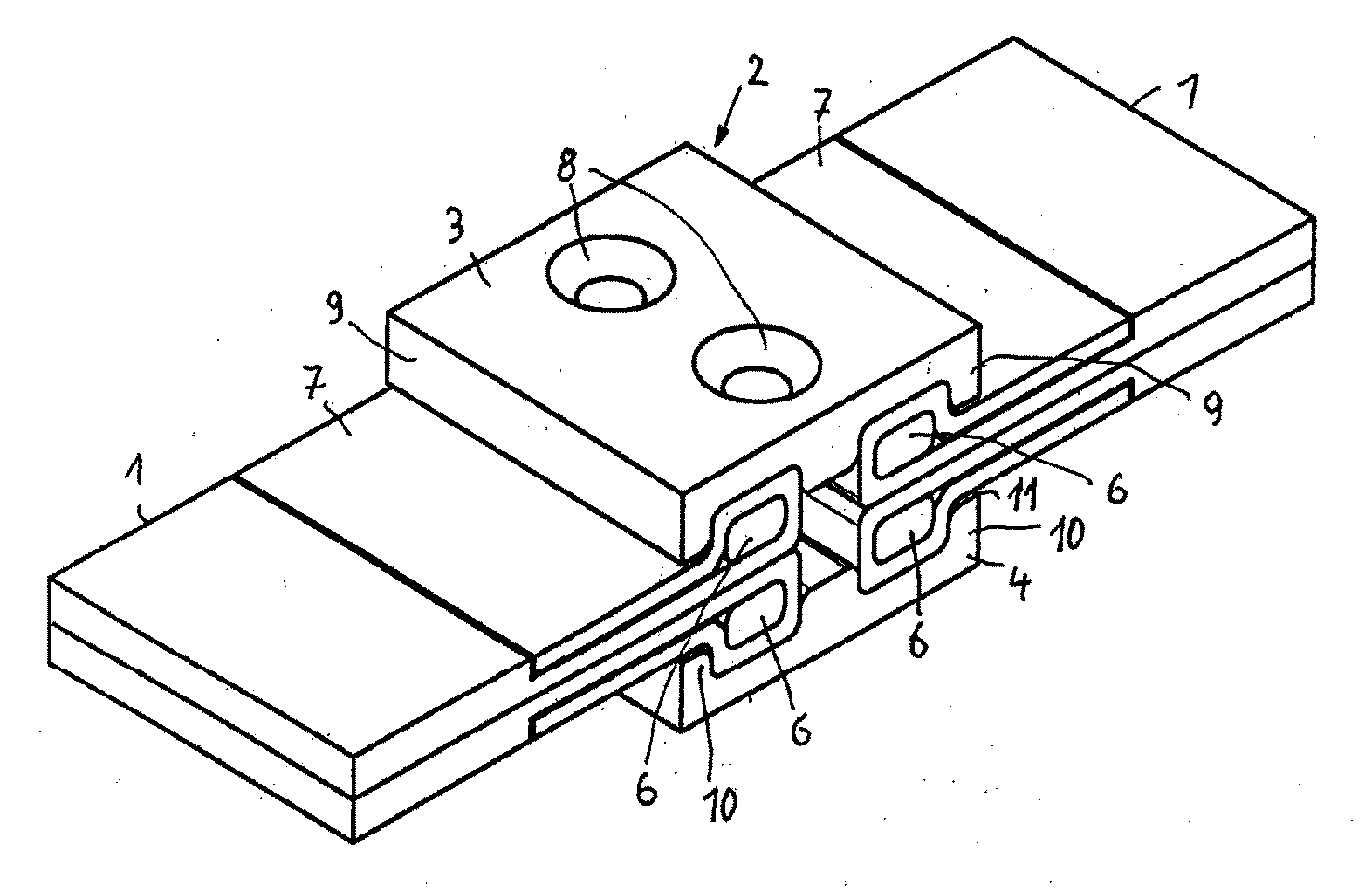

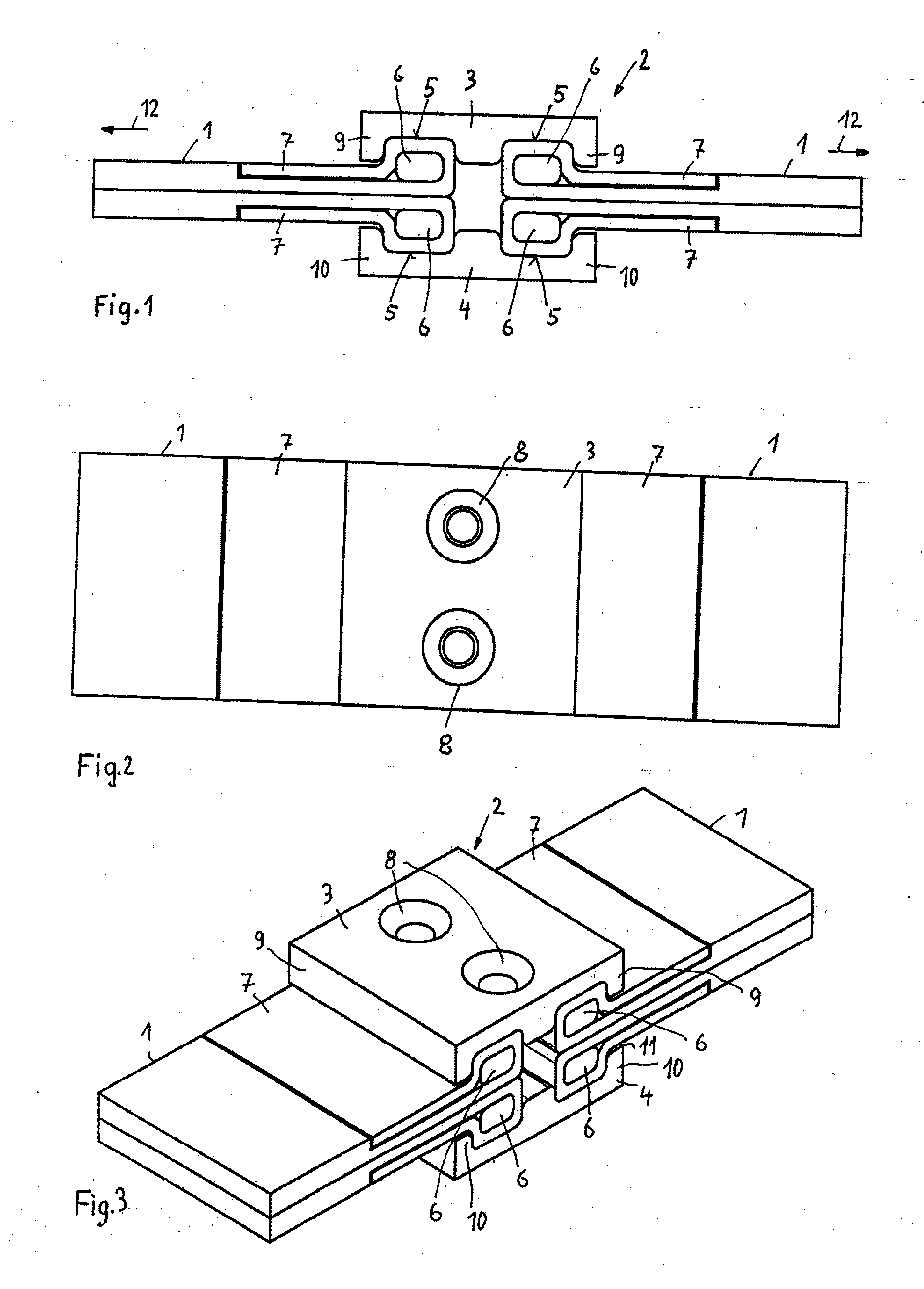

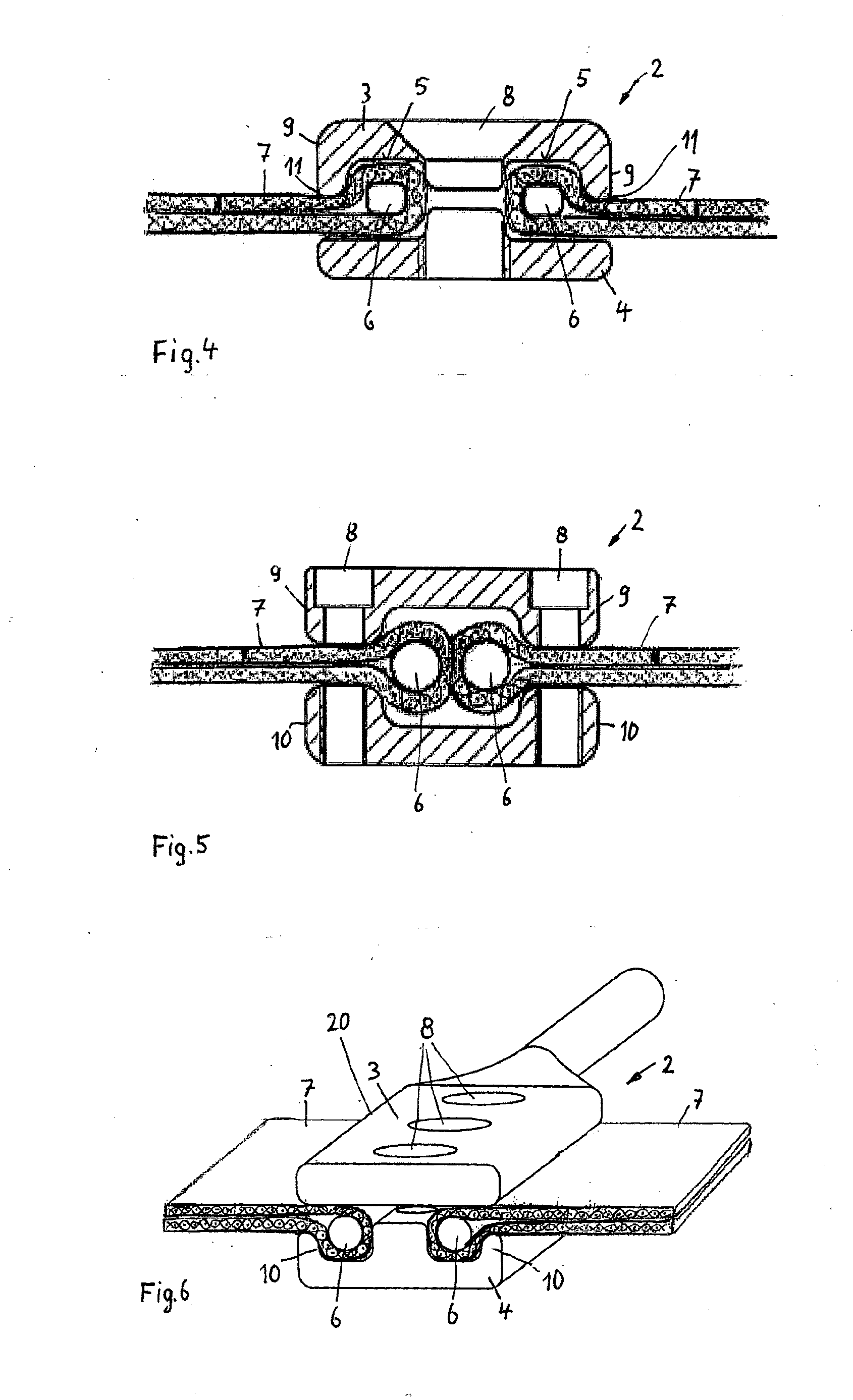

Endless belt for conveyor belts of agricultural machines

InactiveUS20170023101A1High dynamic strengthImprove static strengthBelt fasteningsDynamic strengthEngineering

A belt as an endless traction device for conveyor belts of agricultural machines, the belt being made of a polymer that is reinforced by fabric plies. Endless belt provides a conveyor belt of this type which has high static and dynamic strength at the connecting point, combined with great bending flexibility. This is achieved in that at least one fabric ply of each belt end, folded back on itself, wraps around a thickened area and extends between the thickened area and a stop, which forms an abutment with respect to the thickened area, in such a way that the fabric ply is jammed between the thickened area and the stop when tension acts on the belt in the reverse direction.

Owner:ARTEMIS KAUTSCHUK UND KUNST & CIE

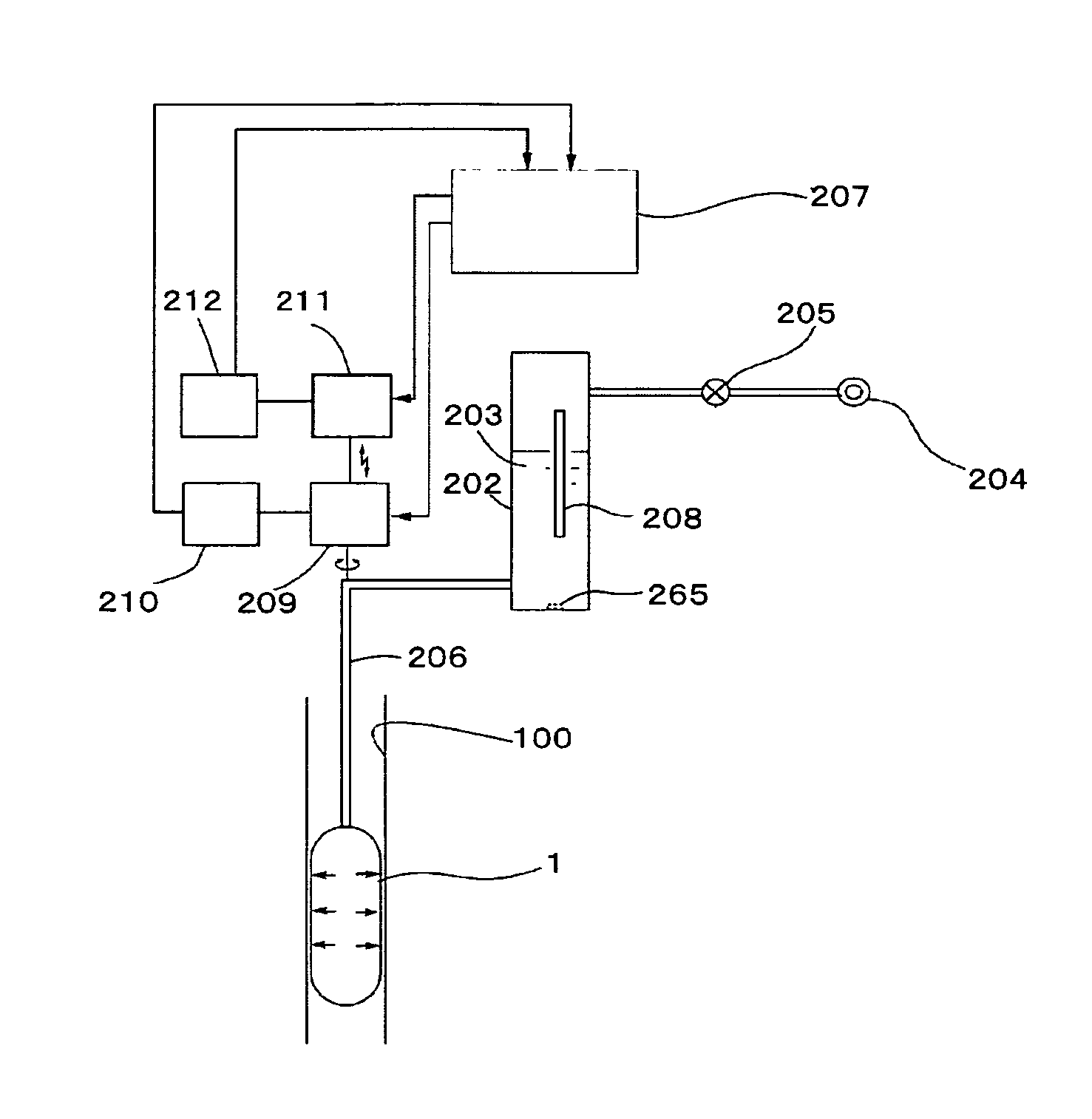

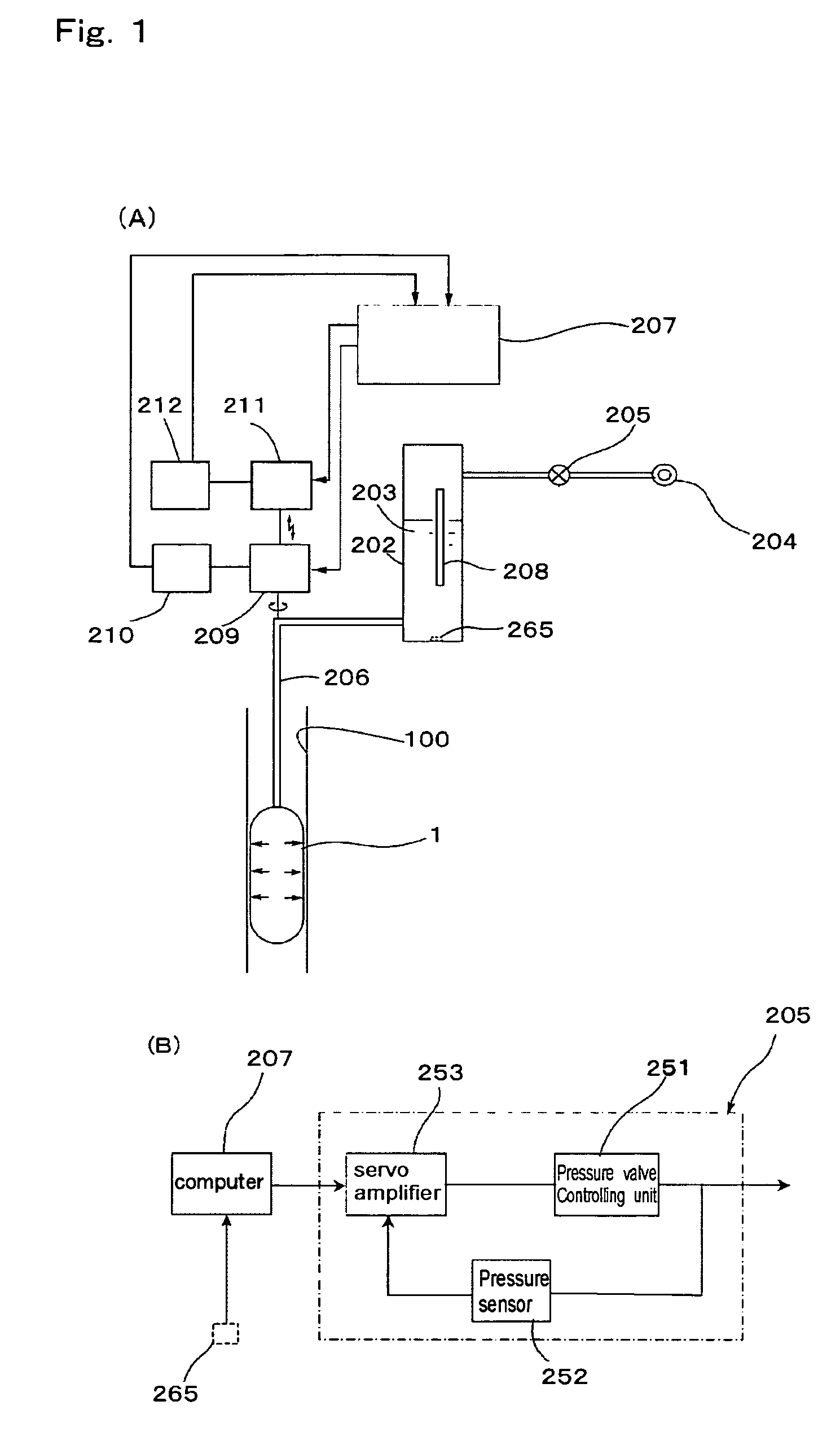

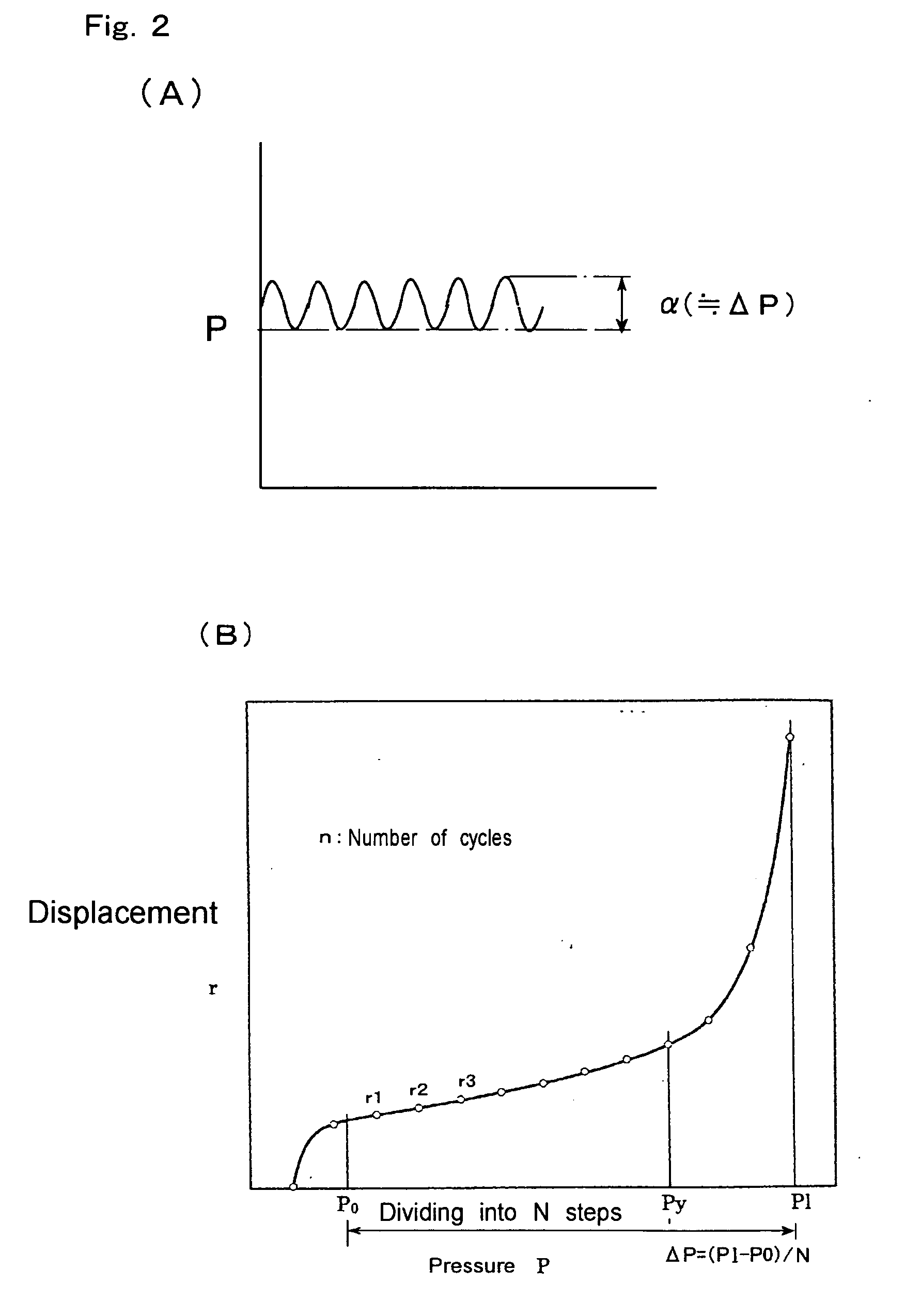

Testing method and apparatus ground liquefaction and dynamic characteristics in original position utilizing boring hole

InactiveUS20070144249A1Time and cost-savingEfficient inductionSurveySurface/boundary effectDynamic strengthEngineering

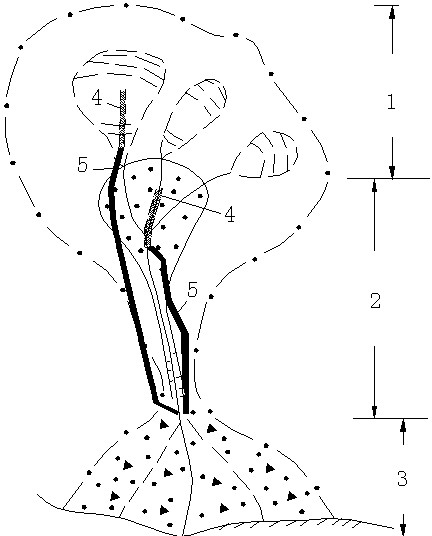

A testing method and apparatus for ground liquefaction and dynamic characteristics in the original position utilizing a boring hole, wherein the dynamic strength and deformation characteristics of a soil layer against a dynamic repetitive load, in an optional position in the ground can be obtained by a simple method. A measuring cell based on a three-chamber construction is used, and upper and lower soil layers (J1, J3) with an intermediate soil layer (J2) therebetween are alternately subjected to a dynamic repetitive load, and what influence there is on the intermediate soil layer (J2) is investigated from the relation between pressure and displacement.

Owner:MASUDA GIKEN

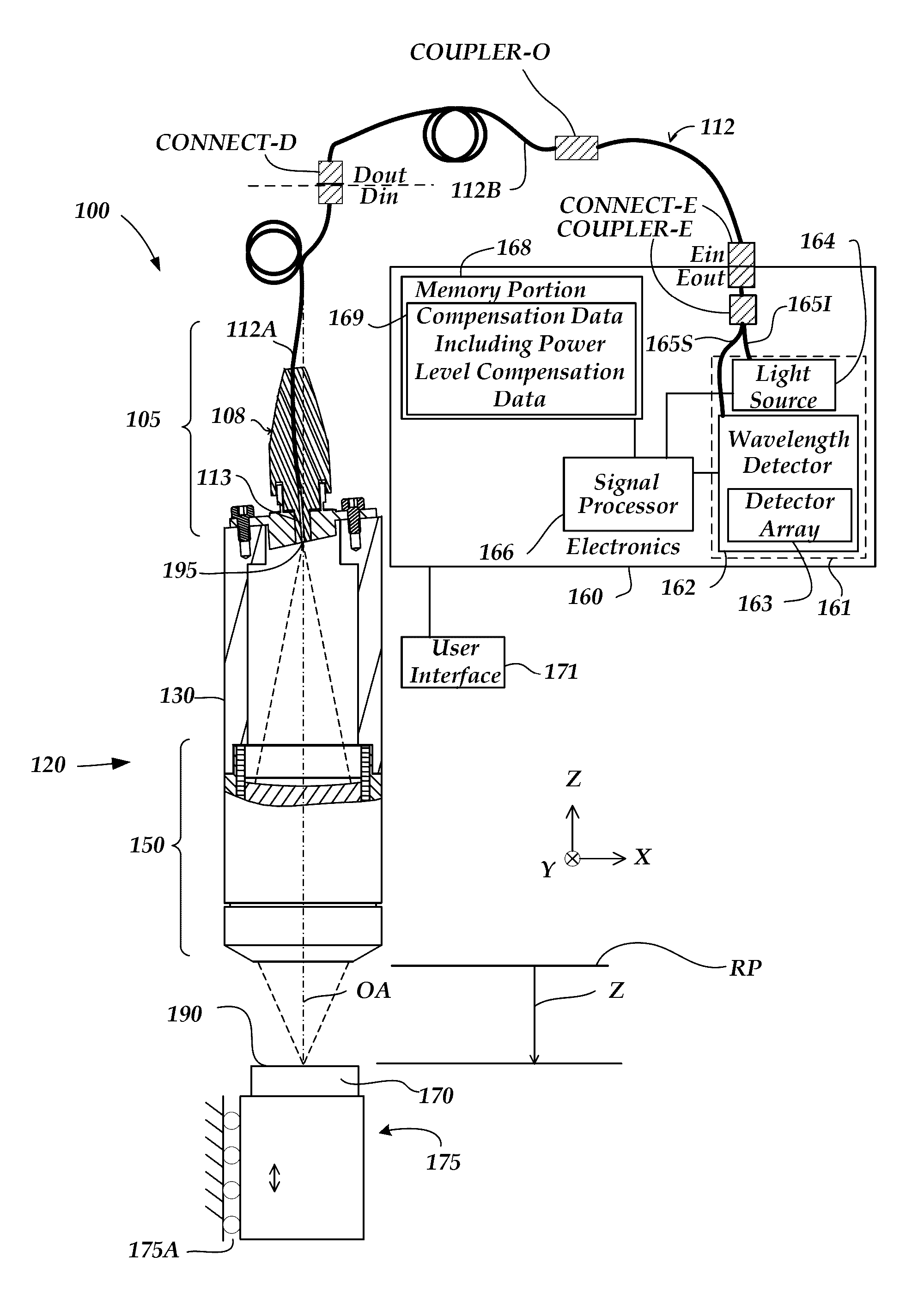

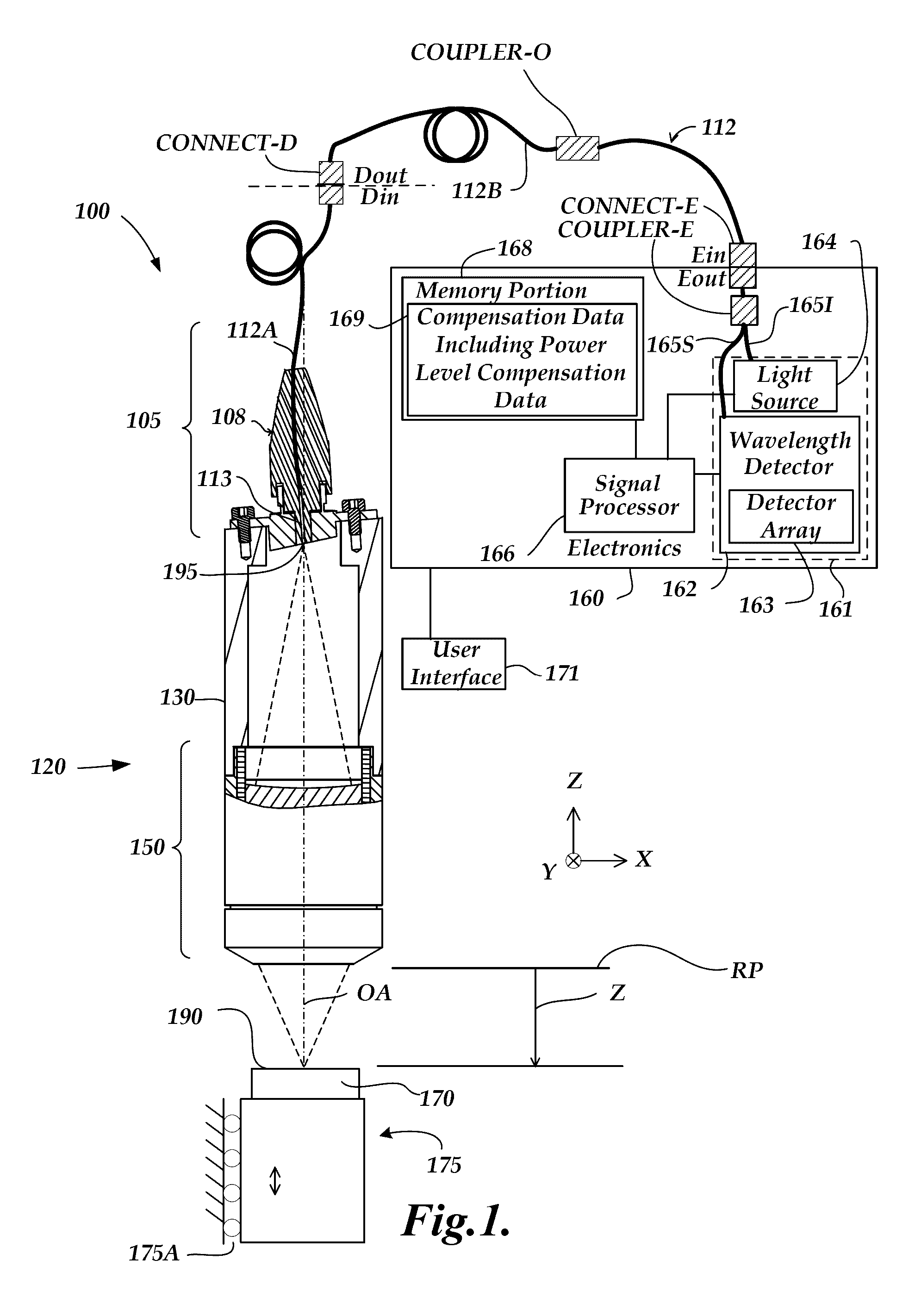

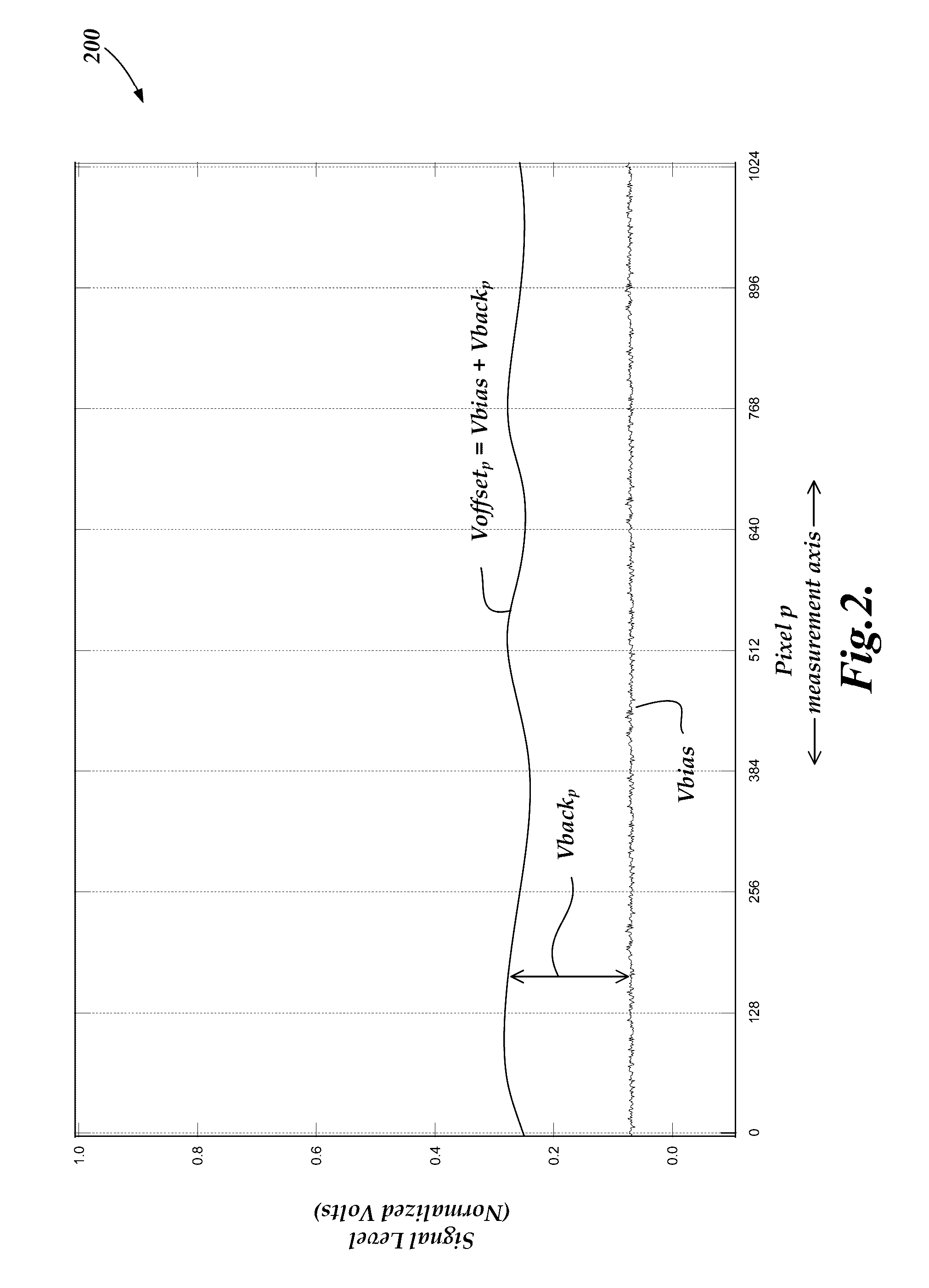

Chromatic range sensor including dynamic intensity compensation function

A chromatic point sensor (CPS) system is provided, which compensates for potential errors due to input spectral profile intensity inconsistencies that arise when driving a CPS illumination source using different power levels. The CPS system includes an optical pen comprising a confocal optical path including a chromatically dispersive element and configured to focus different wavelengths at different distances proximate to a workpiece surface to be measured, an illumination source, and CPS electronics. The CPS electronics include: an illumination source control portion configured to drive the illumination source using different power levels; a CPS wavelength detector comprising a plurality of pixels distributed along a measurement axis of the CPS wavelength detector to provide output spectral profile data; and a power level spectral compensation portion configured to compensate the output spectral profile data to remove or reduce potential errors due to input spectral profile intensity inconsistencies that arise when driving the CPS illumination source using the different power levels.

Owner:MITUTOYO CORP

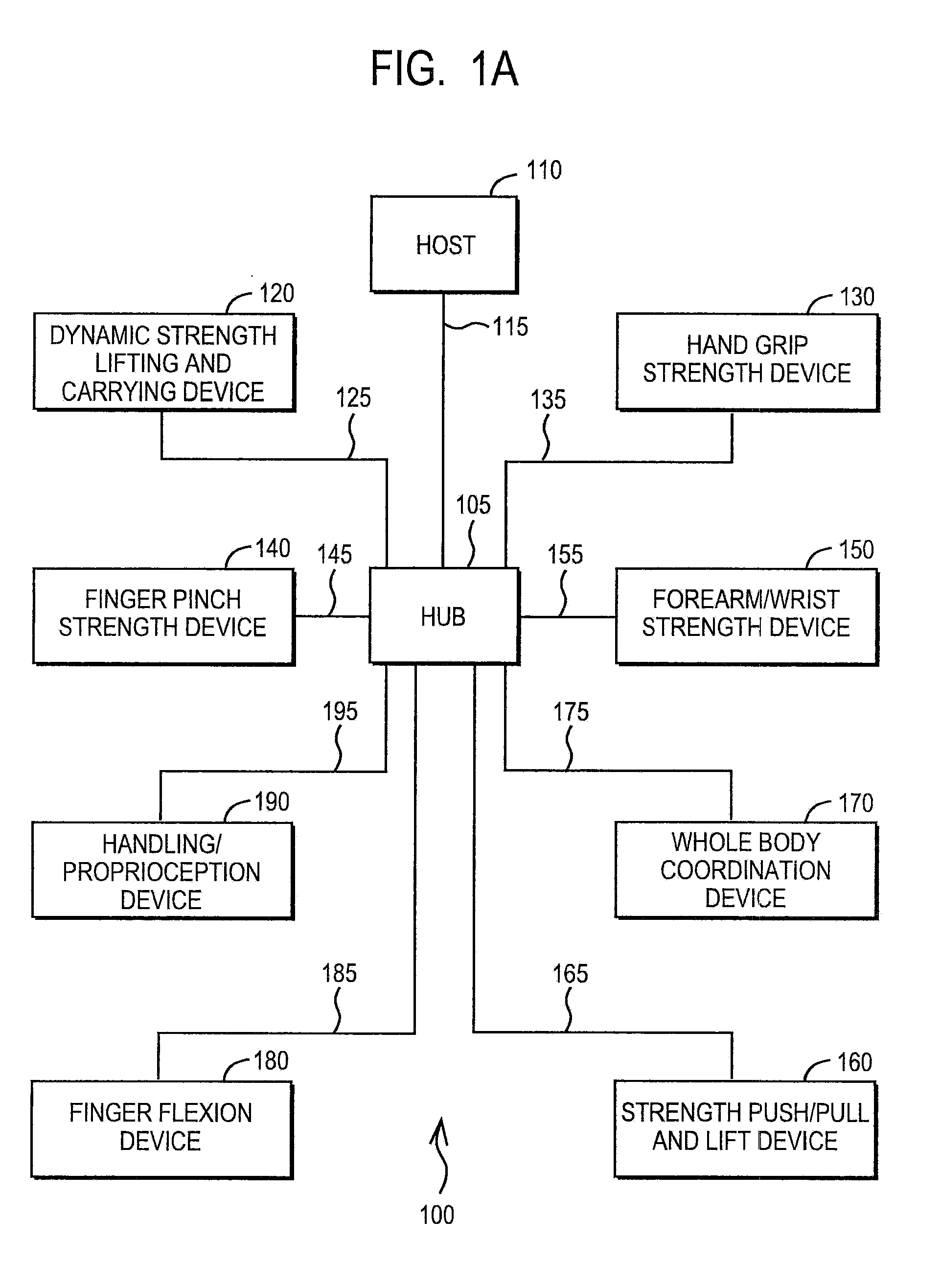

Work Capacities Testing Apparatus and Method

A portable work capacities testing apparatus comprising a portable computer, a hub releaseably interconnected with the portable computer, a dynamic strength and lifting device releaseably interconnected with the hub, a hand grip strength device releaseably interconnected with the hub, a finger pinch strength device releaseably interconnected with the hub, a forearm / wrist strength device releaseably interconnected with the hub, a handling / proprioception device releaseably interconnected with the hub, a finger flexion device releaseably interconnected with the hub, a whole body coordination device releaseably interconnected with the hub, and a strength push / pull / lift device releaseably interconnected with the hub.

Owner:AKINS ROBERT +2

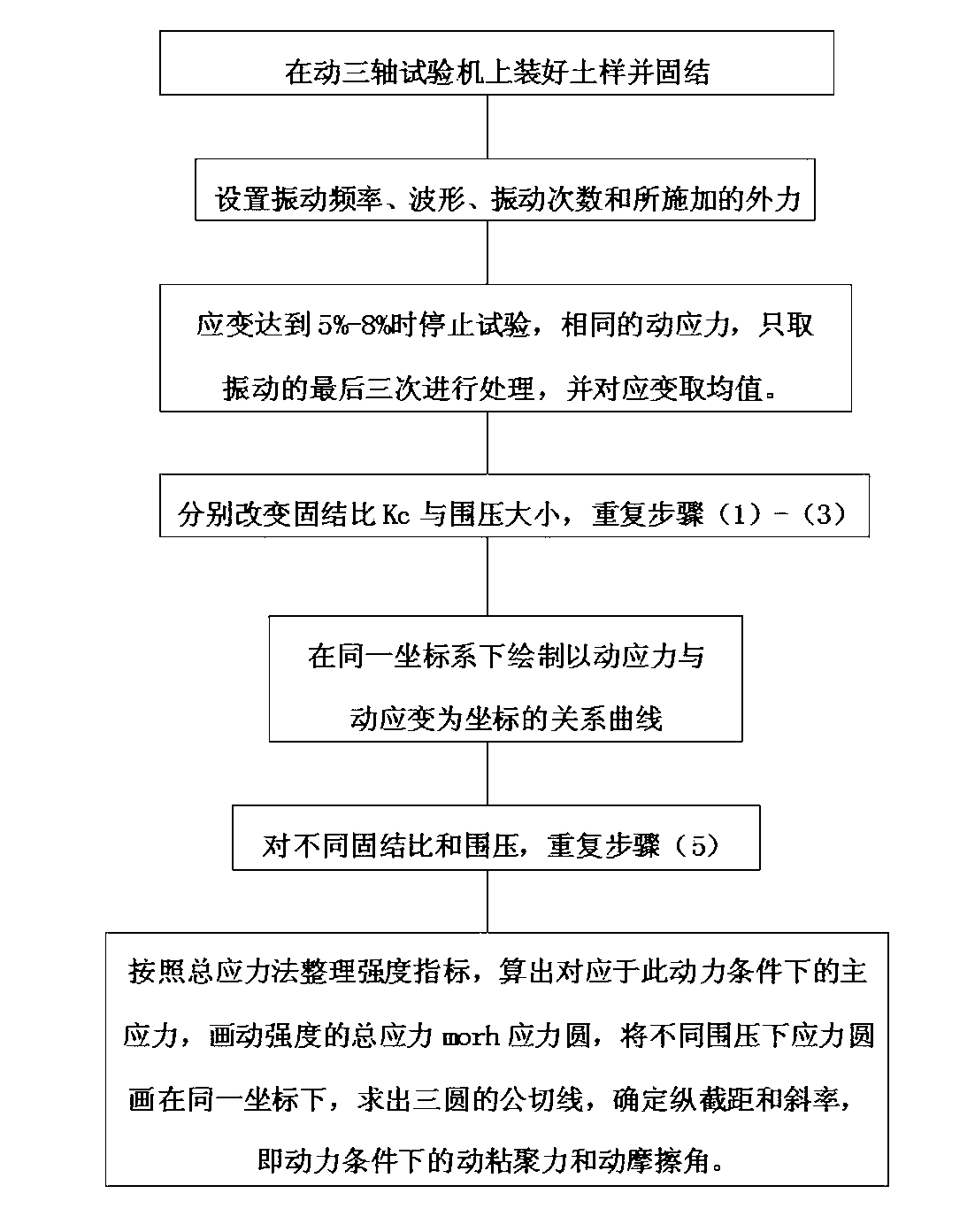

Method for testing soil constitutive relation and dynamic strength parameter

ActiveCN103308386ASimplify workloadSimple methodMaterial strength using tensile/compressive forcesTriaxial shear testDynamic strength

The invention relates to a method for testing a soil constitutive relation and a dynamic strength parameter. The method comprises the following steps of: placing a soil sample in a dynamic triaxial test machine and consolidating; determining vibration frequency, vibration wave type, vibration times and applied external force; applying continuously-increased external force for vibrating; keeping in the same vibration times; stopping testing while straining to reach some degree (5 to 8% in general); processing the last three vibrations under the same dynamic stress; averaging the strains; drawing a relation curve with the dynamic stress and dynamic strain serving as the coordinates under the same coordinate system; arranging strength indexes according to a total stress way; calculating the corresponding main stress under such power condition; drawing a total stress morh stress circle for the dynamic strength; drawing the stress circles under different confining pressures in the same coordinate; calculating a common tangent of the three circles; and determining a vertical intercept and a gradient which are respectively the dynamic cohesive force and dynamic friction angle under a power condition. The method is simple and accurate in result, greatly simplifies the workload of the test, and is the best choice for the engineering test with requirement on time.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

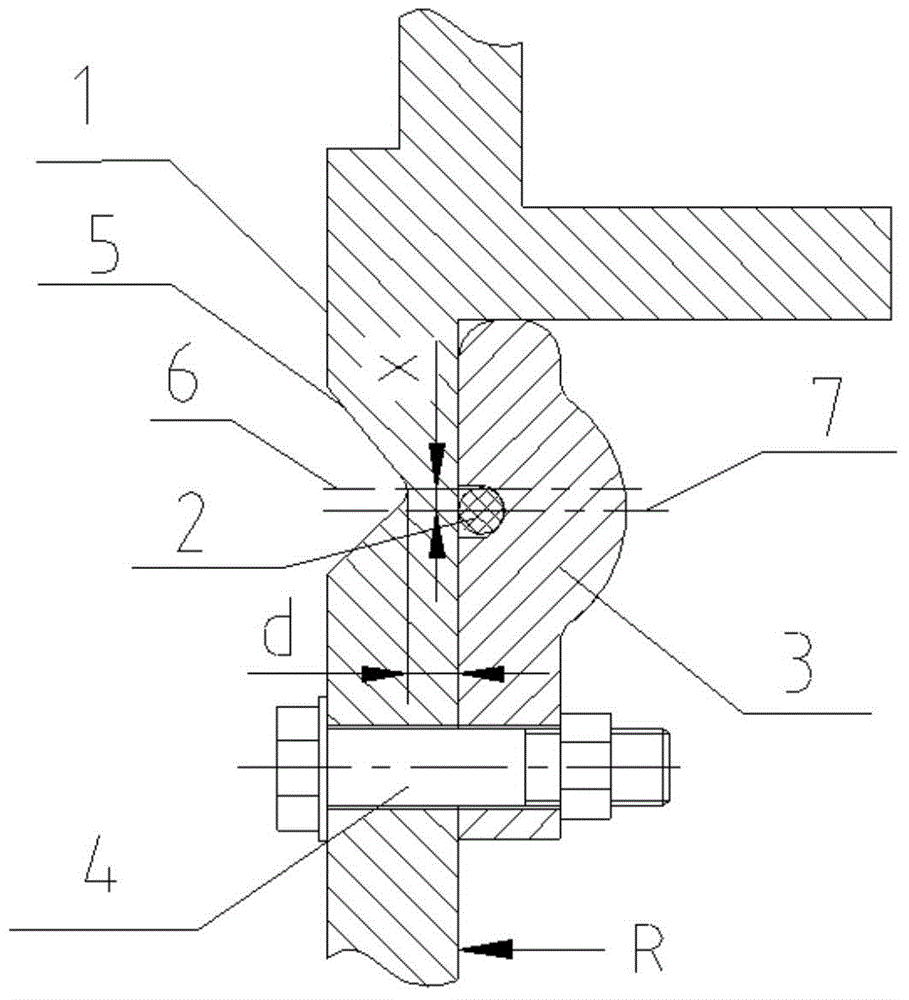

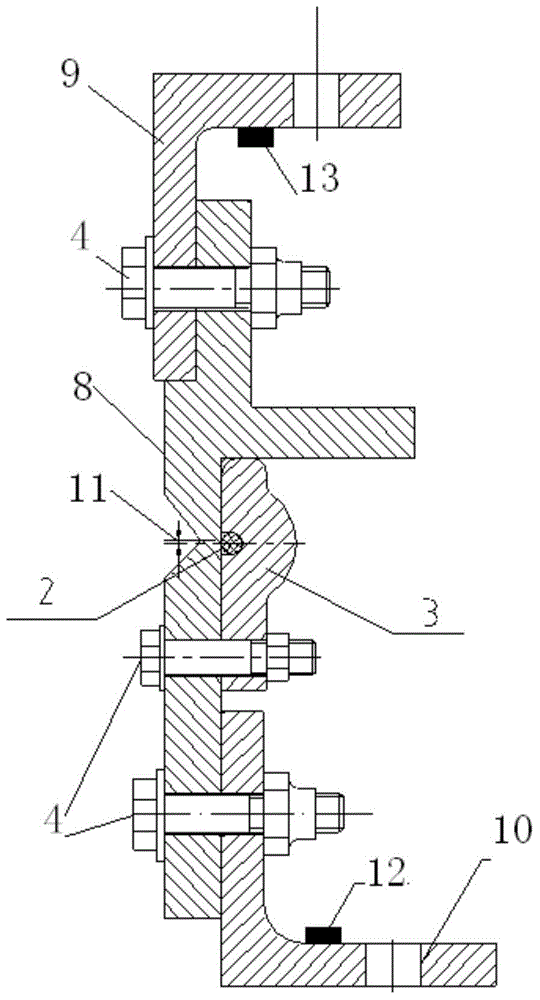

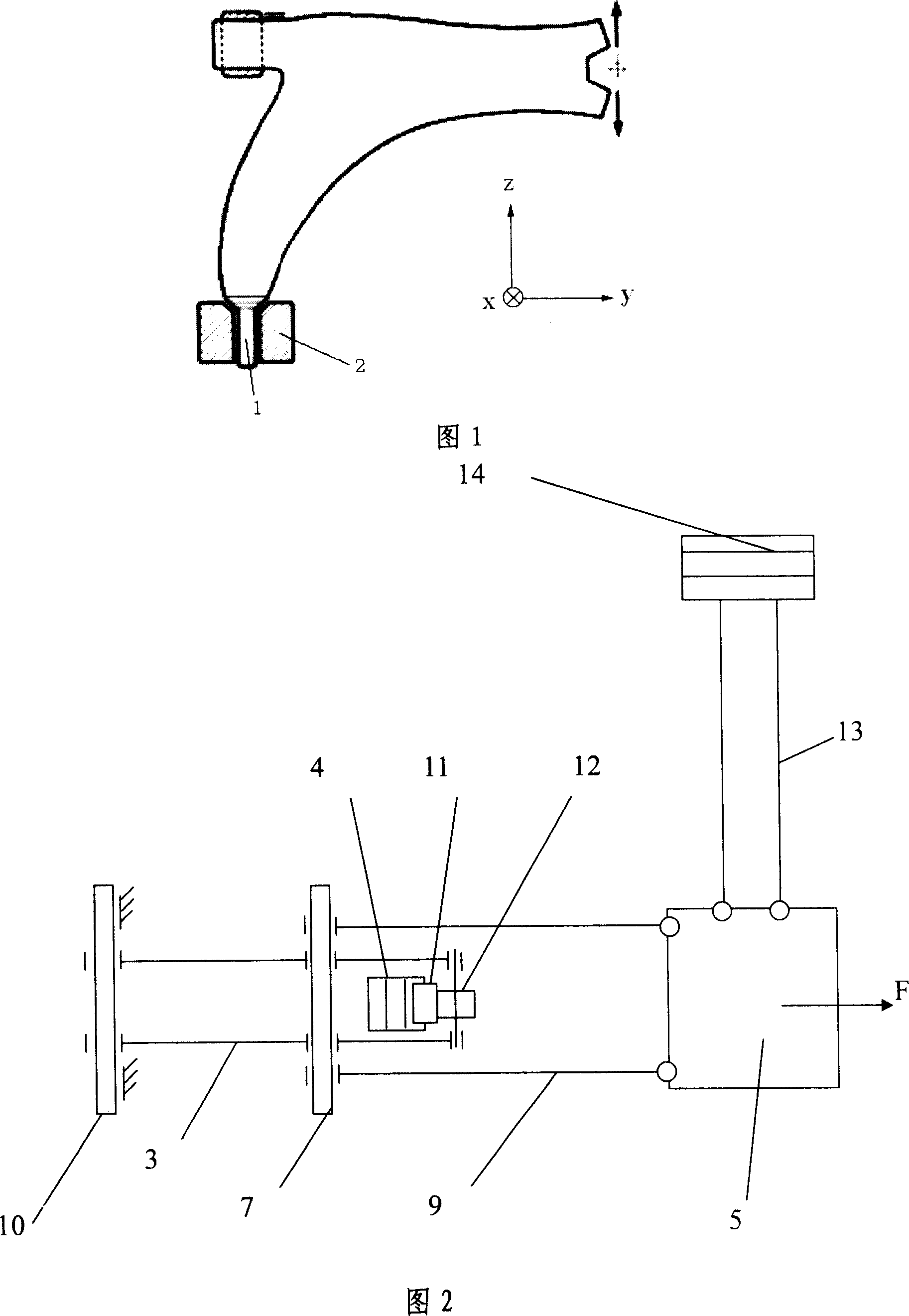

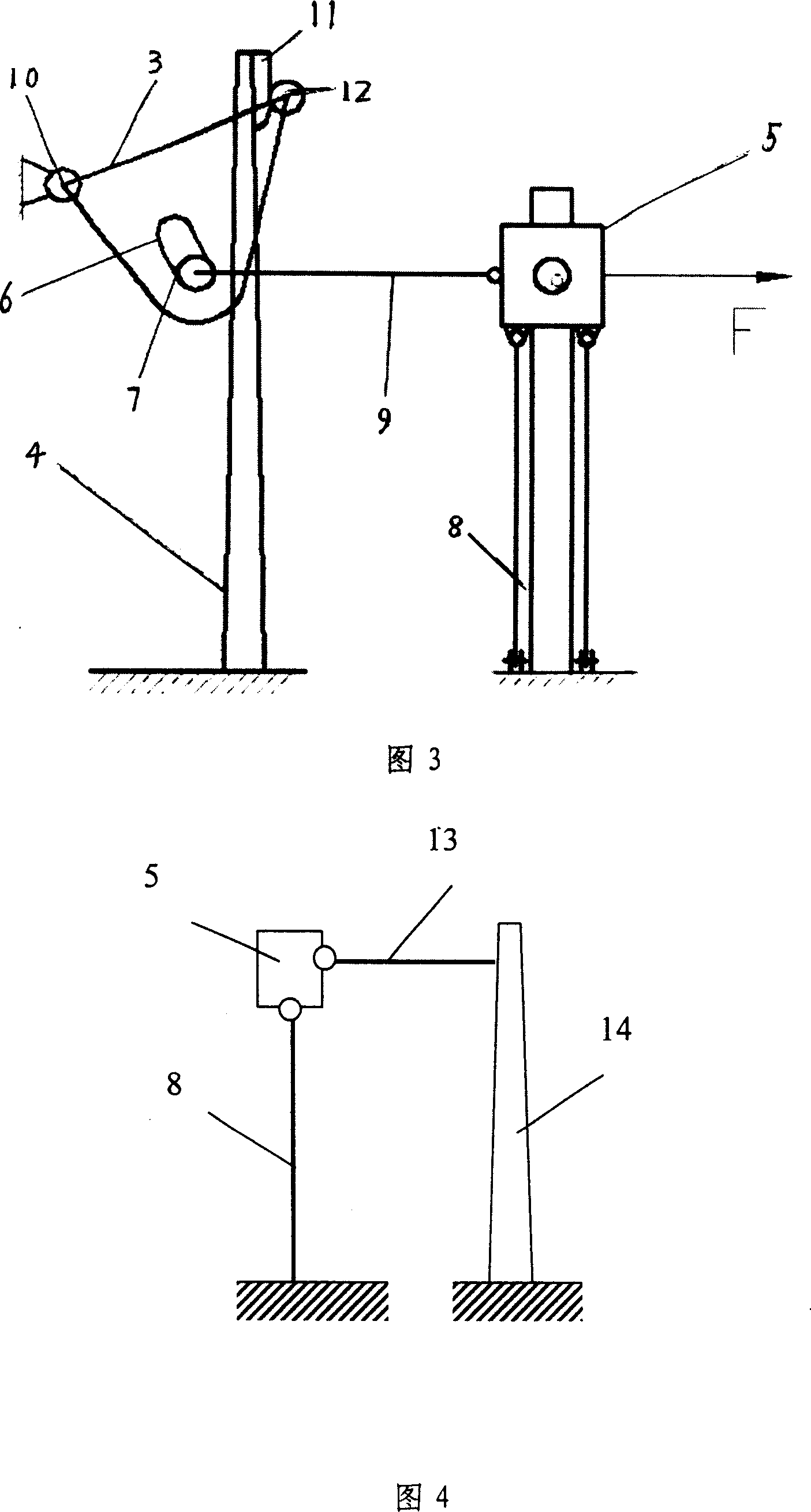

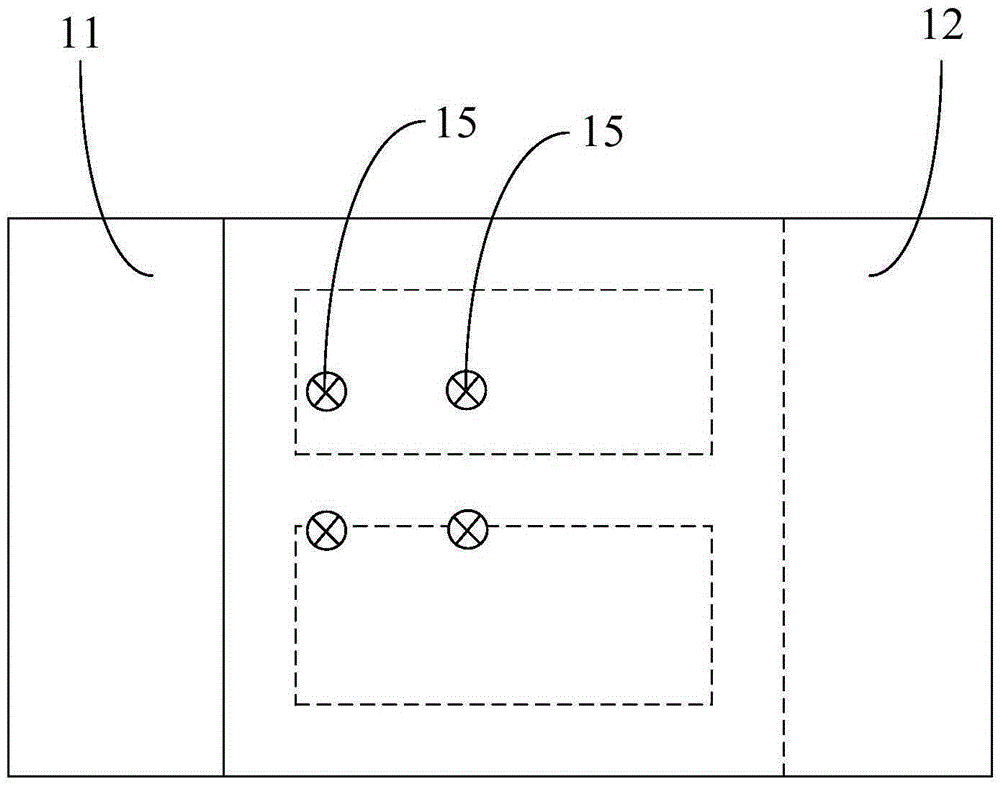

Mechanism for measuring dynamic strength of automobile front axle rocker arm

InactiveCN101071090ARealistically reproduce the working stateIncrease credibilityVehicle testingElasticity measurementDynamic strengthPull force

A structure used to test dynamic intensity of protocerebral rocker of a car can at the same time imitate the rigidity restriction of axial direction linearity and radial nonlinearity. One side of anti-yaw fastening device imitate rigidity restriction of axial direction linearity, the other side is separately linked to two triangle crank-spring armor plate agency, anti-yaw fastening device drives one triangle crank agency to do rotary motion clockwise or drives the other one to do rotary motion counterclockwise. The rolling axletree in a climax of the triangle crank component does vertical motion along the top bump of spring panel on the taper, so it produces different acting force and actuating arm acting on spring panel on the taper to result the anti-yaw fastening device to produce nonlinearity rigidity restriction counterforce consisting with rocker radial rigidity property, the back shaft supporting restriction of protocerebral rocker is in the anti-yaw fastening device, so it really re-creates the working state of protocerebral rocker of a car and promote the reliability of simulation test.

Owner:SHANGHAI UNIV OF ENG SCI

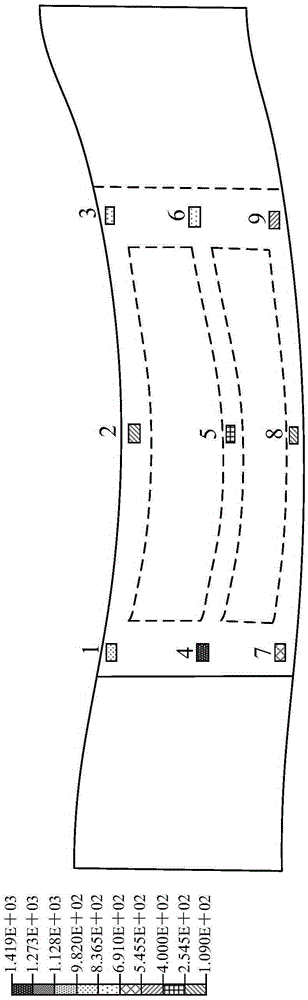

Welding spot arrangement optimization method based on welding spot force-bearing homogenization

ActiveCN105279343AOptimize force distributionUniform force distributionForecastingSpecial data processing applicationsDynamic strengthElement model

The invention discloses a welding spot arrangement optimization method based on welding spot force-bearing homogenization. The welding spot arrangement optimization method comprises the steps of establishing a finite element model of an original welding structure which comprises a plurality of welding spots; applying a restriction and a load on the original welding structure in the finite element model, and obtaining force bearing condition of each welding spot; establishing a welding spot arrangement optimizing mathematical model for minimizing summation of stresses which are bear by all welding spots as an optimizing target in a manner that the contribution value of each welding spot is used as a design variable; determining whether a corresponding welding spot is reserved according to the contribution value of each welding spot, and obtaining optimized welding spot distribution. The welding spot arrangement optimization method is based on structure topology optimization design technology, so that uniform force bearing distribution of each welding spot after optimization is realized. On condition that dynamic strength, static strength and rigidity of a welded structure are ensured, the number of failed welding spot in the bearing process is effectively reduced and furthermore the number of the welding spots is reduced.

Owner:YANFENG ADIENT SEATING CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com