Wet type copper base friction material and its preparation method

A friction material, copper-based technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problem of difficulty in adapting to high power, miniaturization of high-speed friction transmission and braking devices, low mechanical strength, and unsatisfactory thermophysical properties, etc. problems, to achieve good processability, high mechanical strength, and stable wet friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

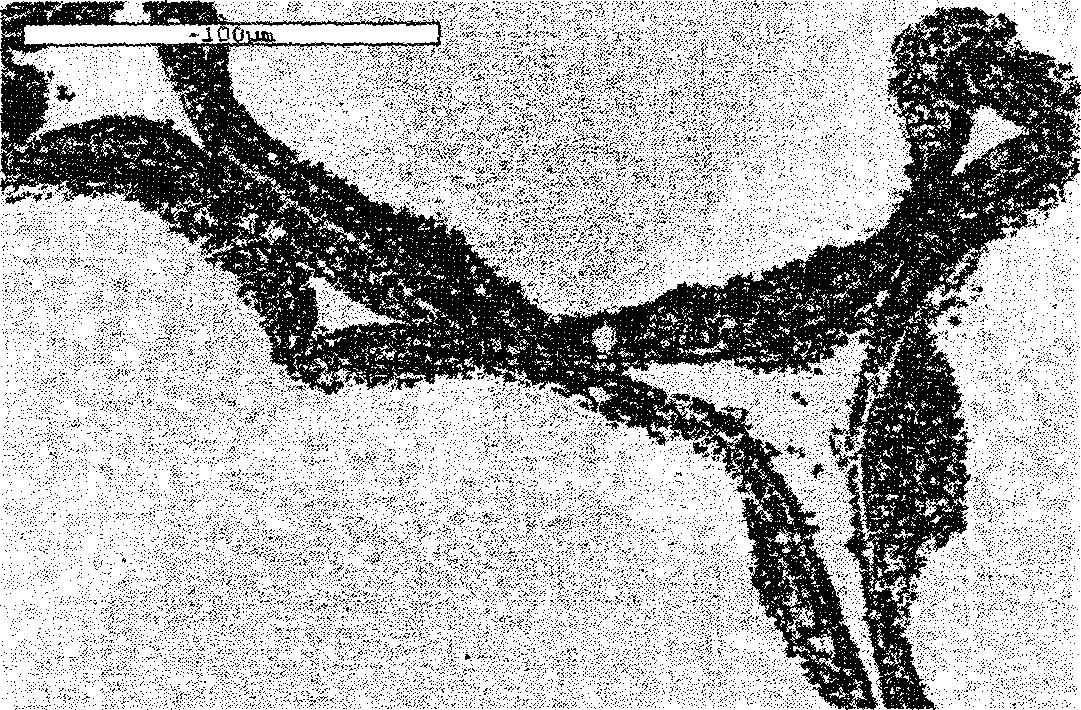

[0035] In the present invention, the preparation process of the three-dimensional connected network-like dense silicon carbide ceramic skeleton can adopt the Chinese invention patent (invention name: a high-strength and dense foamed silicon carbide ceramic material and its preparation method, application number: 03134039.3, application date: 030922 ), the basic steps are as follows: (see the description of the patent application for details)

[0036] Using silicon carbide powder and high-yield carbon-rate resin as the basic raw materials and foam plastic as the template, the preparation process is as follows:

[0037] 1) Slurry preparation

[0038] Mix silicon carbide powder, high carbon yield resin, curing agent and ethanol in proportion, and the weight percentage between silicon carbide powder, high carbon yield resin and curing agent is 80wt.%~30wt.%: 19wt.%~50wt.% : 1wt.%~20wt.%, after mechanical stirring, the ball milling time is 0.5~2h, filtered through 35~140 mesh siev...

Embodiment 1

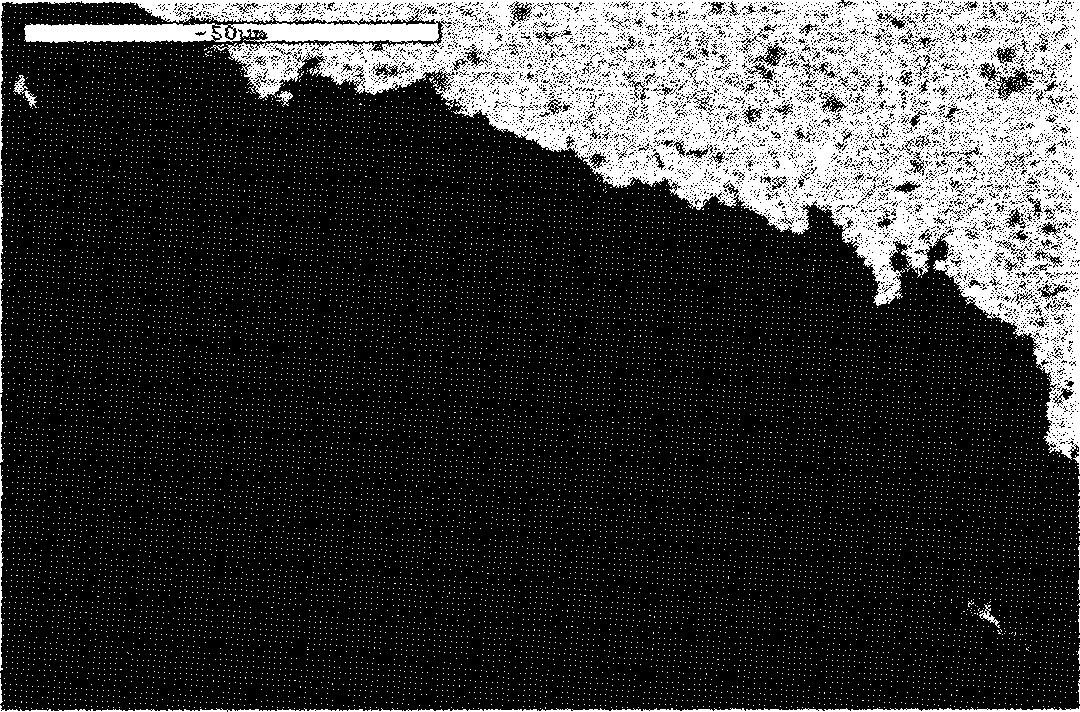

[0061] 1. The ribs are loose and porous three-dimensional connected network silicon carbide ceramic skeleton (the density of ribs is 80%)

[0062] The preparation of a three-dimensional connected network silicon carbide ceramic skeleton with loose and porous ribs is completed through the steps of slurry preparation→dipping→pyrolysis→filling the central hole of the carbon skeleton→siliconization;

[0063] 2. Add filler to the mesh of silicon carbide ceramic skeleton

[0064] Mix graphite with a particle size of 10 μm and iron with a particle size of 74 μm (the weight ratio of iron to graphite is 5 / 4), then add an appropriate amount of phenolic resin diluted with absolute ethanol, curing agent (p-toluenesulfonic acid), and mix again 1. After granulation, pass through 80-120 mesh (180-125 μm) sieves, and the under-sieves are dried and solidified at 100° C.; The acid addition accounts for 6wt.%-8wt.% of the resin weight, and the phenolic resin is diluted with absolute ethanol to ...

Embodiment 2

[0076] The difference from Example 1 is:

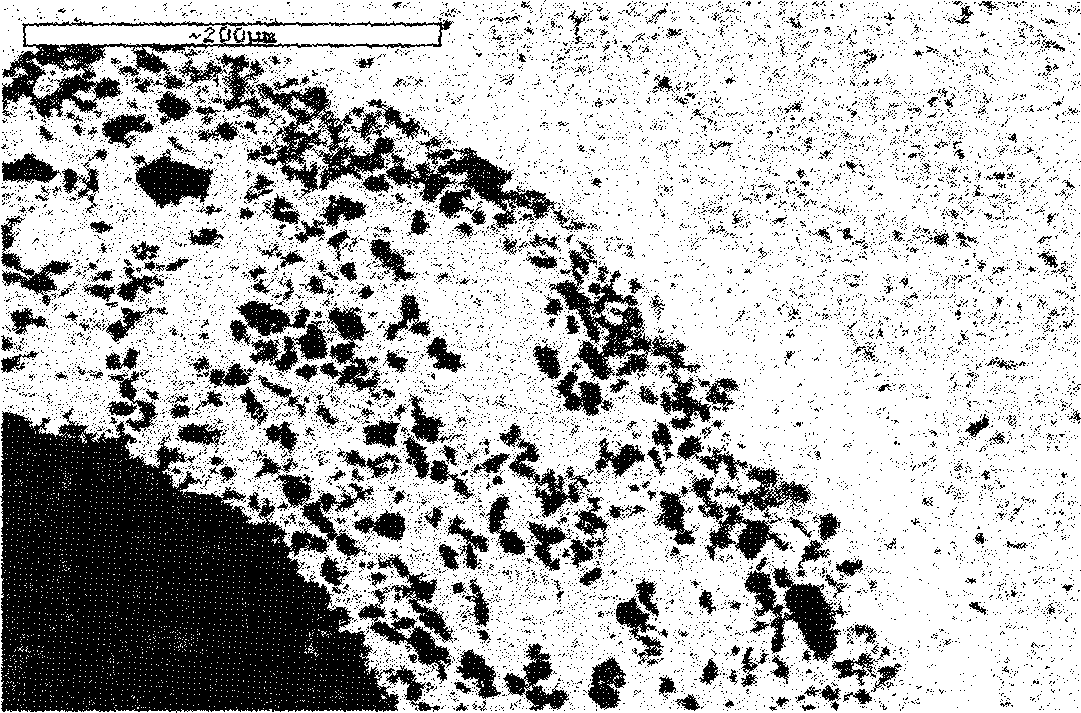

[0077] 1. Choose a dense three-dimensional connected network silicon carbide ceramic framework with ribs (the density of ribs is 99%)

[0078] The preparation of a three-dimensional interconnected network silicon carbide ceramic skeleton with dense ribs is completed through the steps of slurry preparation → dipping → hot pressing densification → pyrolysis → filling the central hole of the carbon skeleton → siliconizing;

[0079] 2. Add filler to the mesh of silicon carbide ceramic skeleton

[0080] Mix graphite with a particle size of 30 μm and iron with a particle size of 100 μm (the weight ratio of iron to graphite is 5 / 3) and a small amount of nickel powder with a particle size of 80 μm, and then add an appropriate amount of phenolic resin and curing agent diluted with absolute ethanol (for toluenesulfonic acid), mixed again, granulated and passed through an 80-mesh (180 μm) sieve, and the under-sieve was dried and solidified at 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com