Heat-resistant Al-Cu-Mg-Ag alloy and process for producing a semifinished part or product composed of such an aluminium alloy

An al-cu-mg-ag, semi-finished product technology, used in heat treatment equipment, quenching agents, manufacturing tools, etc., can solve problems such as low static strength and dynamic strength values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

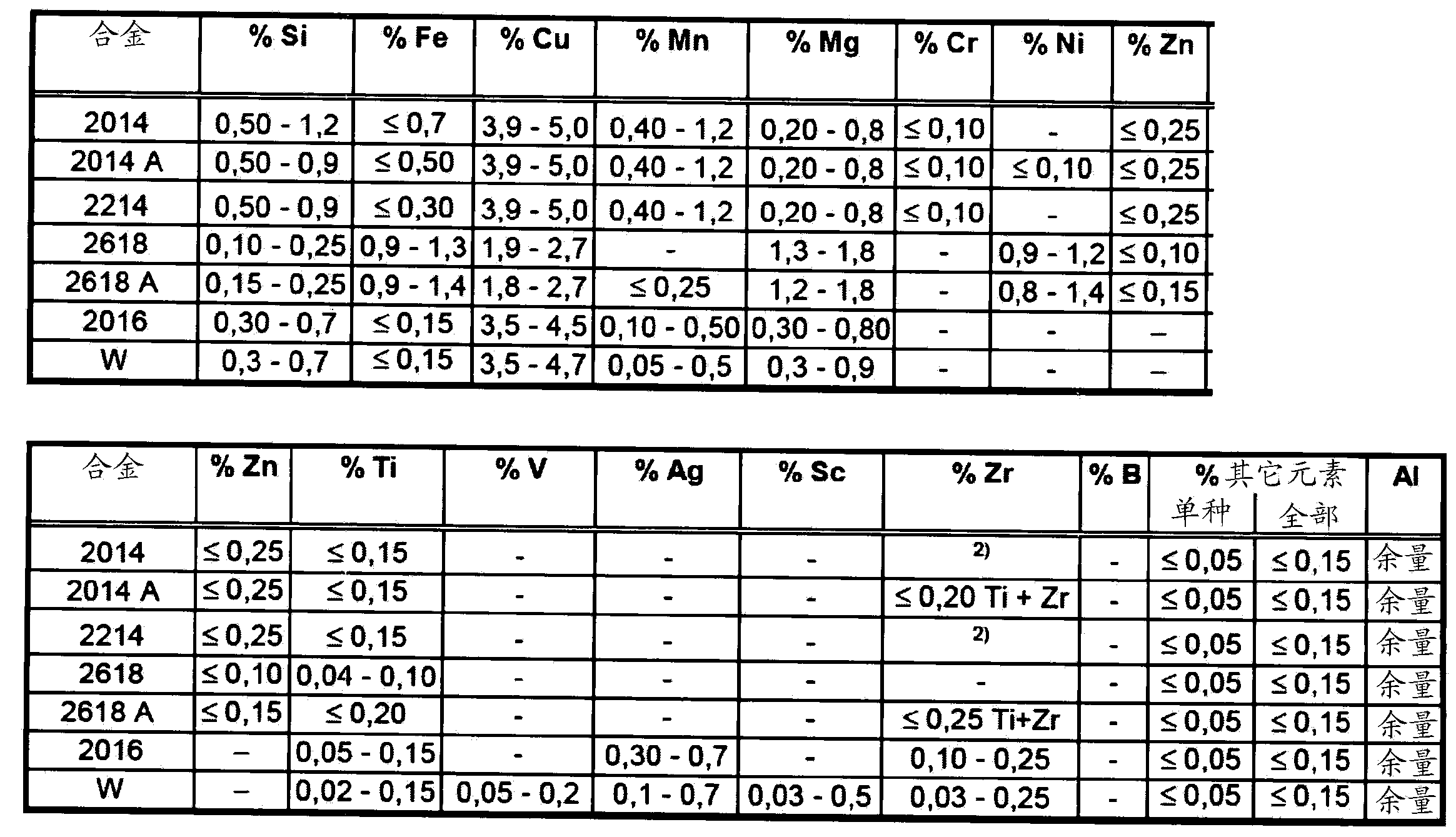

[0062] figure 1 The chemical composition of the alloys of the present invention is shown in comparison to previously known aluminum alloys. On the one hand, those alloys are compared which are capable of producing semi-finished or finished products with high static and dynamic strength properties in a known manner. This concerns alloys AA2014, AA2014A and AA2214. Furthermore, two previously known alloys are compared in relation to particularly good long-term stability under thermal influence. This concerns alloys AA2618 and AA2618A. The previously known alloy AA2016 is also given. The data for the amount of specific alloying elements given in the table is taken from International Alloy Designations and Chemical Composition Limits for Wrought Aluminum and Wrought Aluminum Alloys, The Aluminum Association Inc., 1525 Wilson Boulevard, Arlington, April 2006.

[0063] figure 1 The table with "W" designates alloys according to the invention. The comparison of the alloy composi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com