Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

508 results about "Ag alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

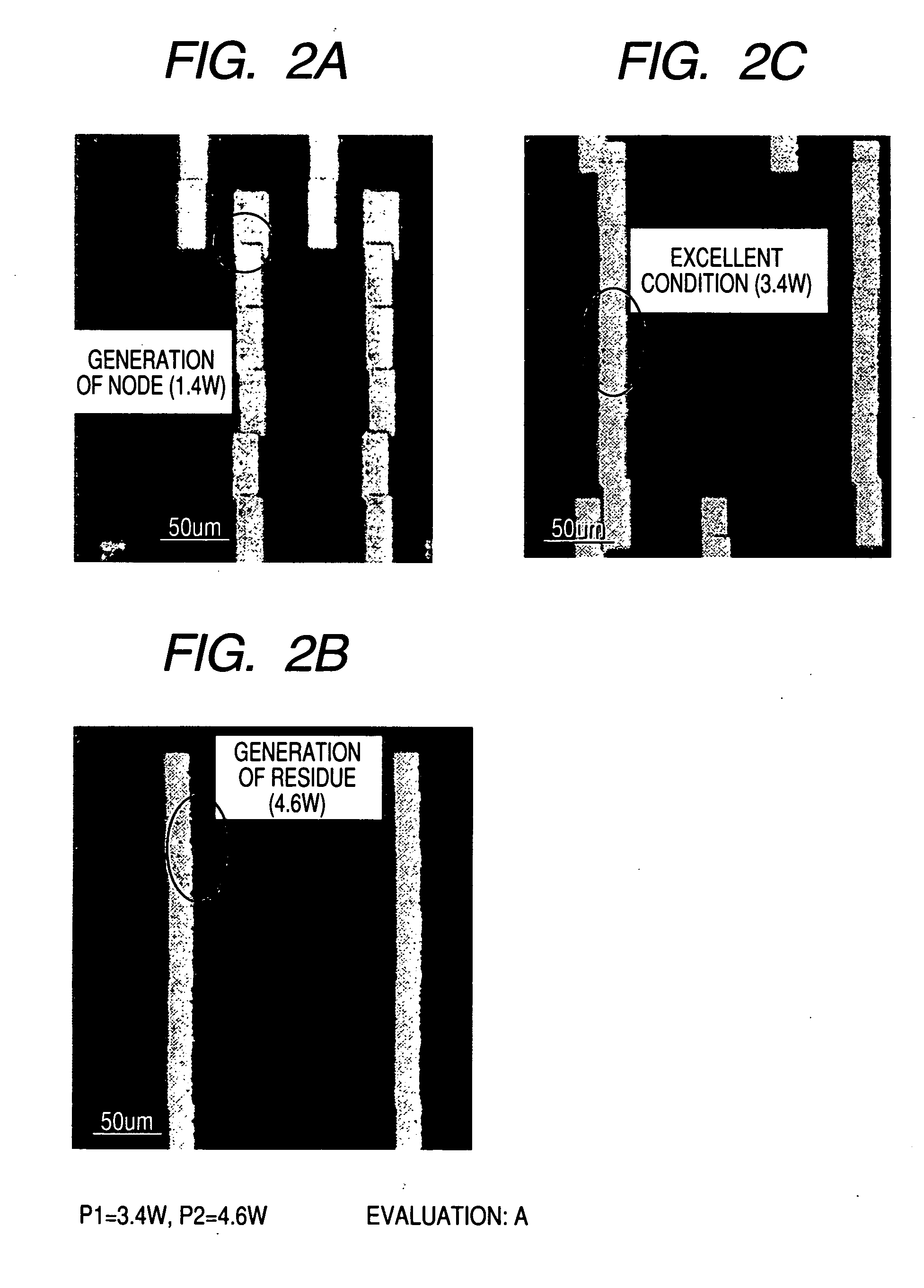

Etching solution composition

InactiveUS20100320457A1High selectivityImprove uniformity and stabilitySemiconductor/solid-state device manufacturingNon-linear opticsMetallurgyAlloy

Provided is an etching solution composition for selectively etching a metal film, which is composed of Al, Al alloy or the like and is arranged on an amorphous oxide film, from a laminated film including the metal film and an amorphous oxide film of various types. The etching solution composition is used for selectively etching the metal film from the laminated film which includes the amorphous oxide film and the metal film composed of Al, Al alloy, Cu, Cu alloy, Ag or Ag alloy, and is composed of an aqueous solution containing an alkali.

Owner:IDEMITSU KOSAN CO LTD +1

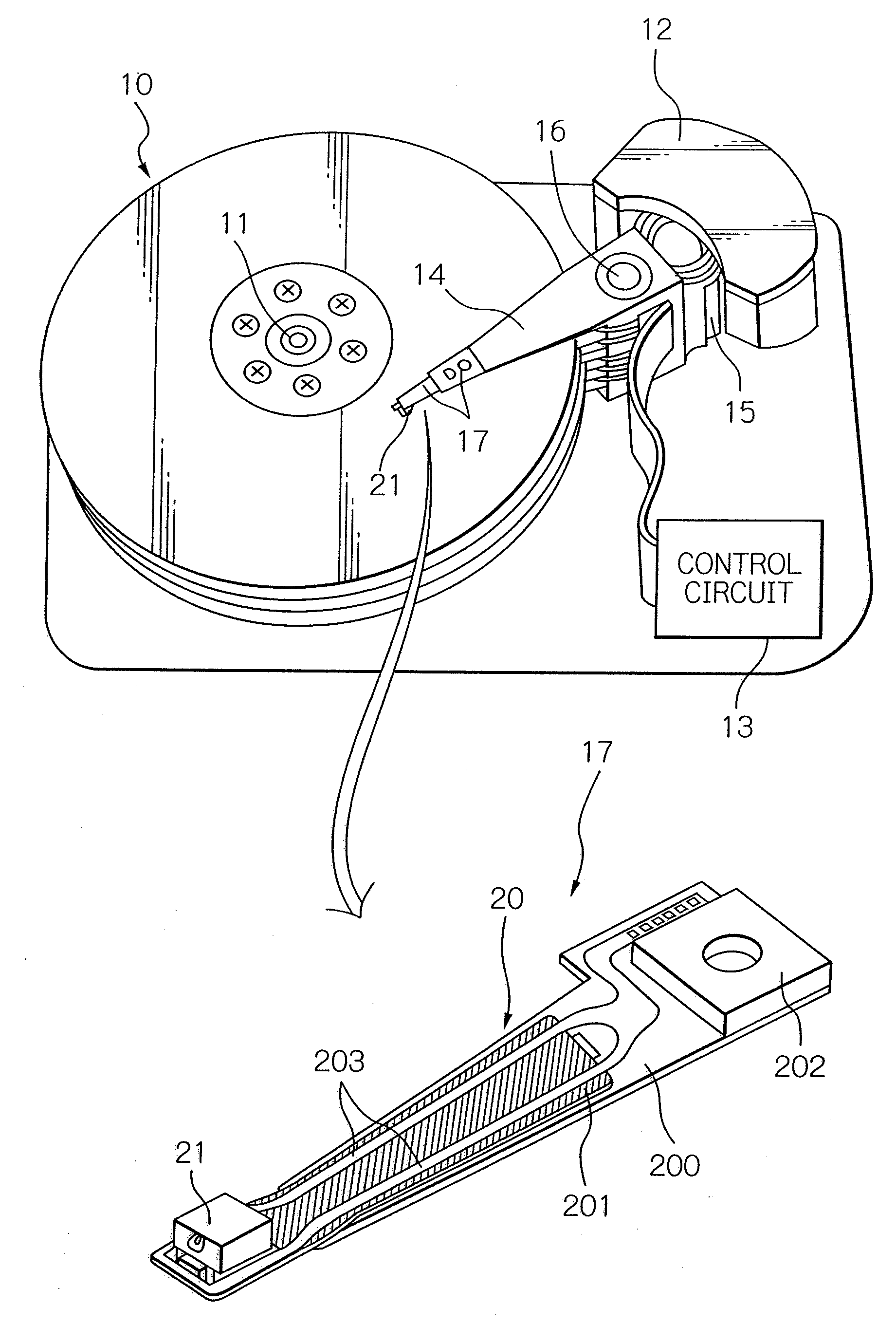

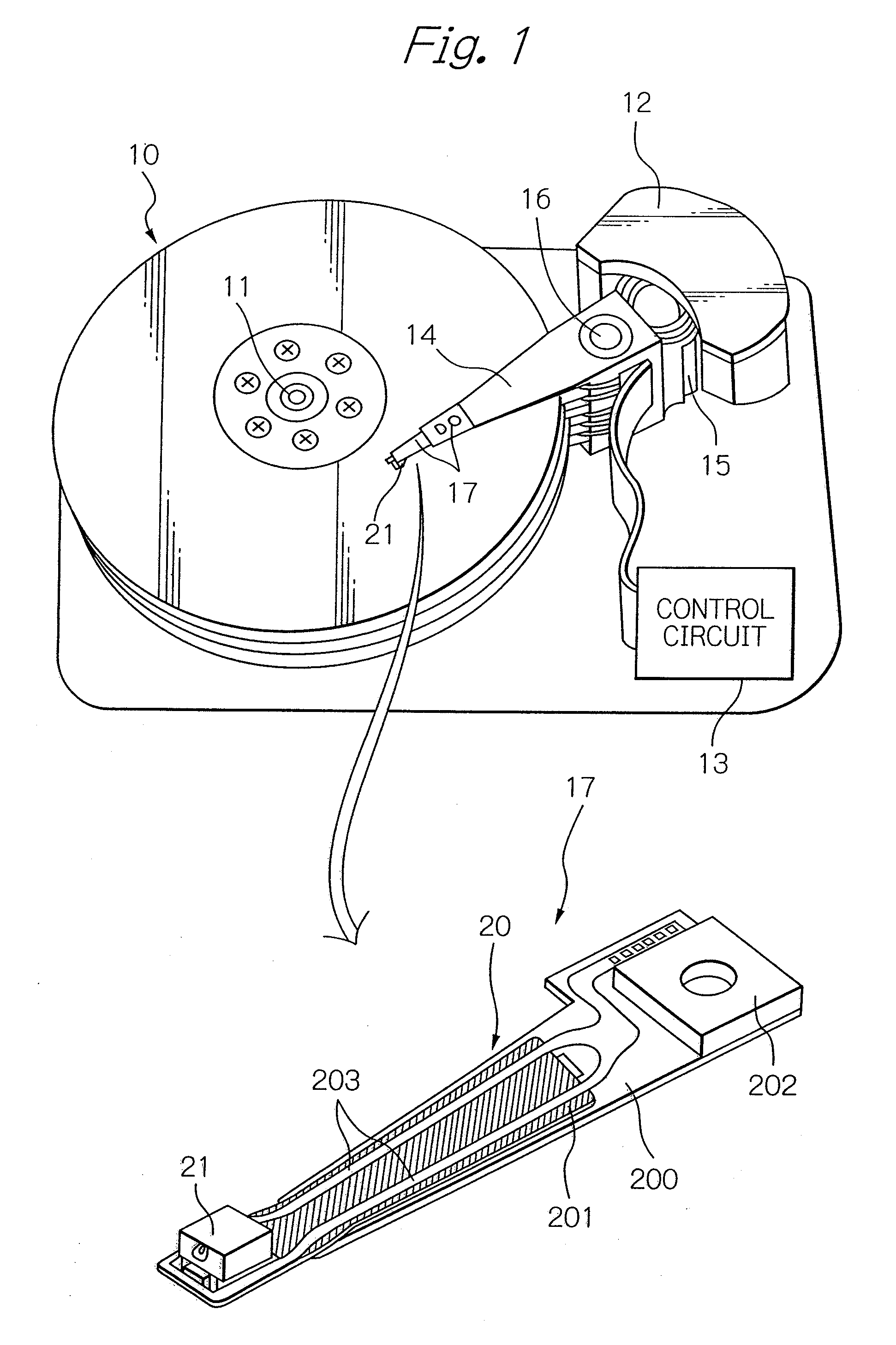

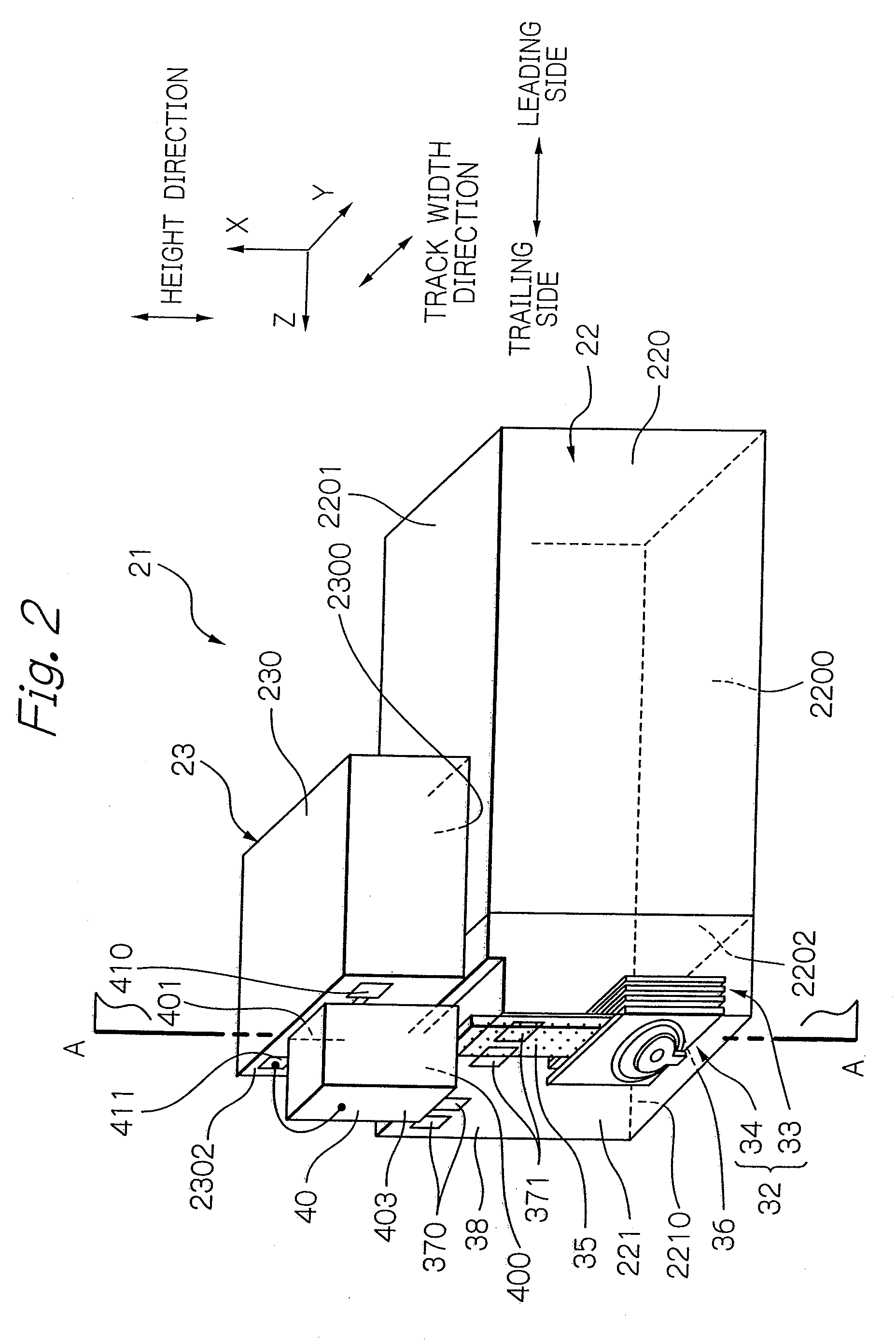

Near-Field Light Transducer Comprising Propagation Edge With Predetermined Curvature Radius

ActiveUS20110038236A1Satisfactory thermally-assisted magnetic recordingImprove light utilization efficiencyCombination recordingRecord information storageSurface plasmonTransducer

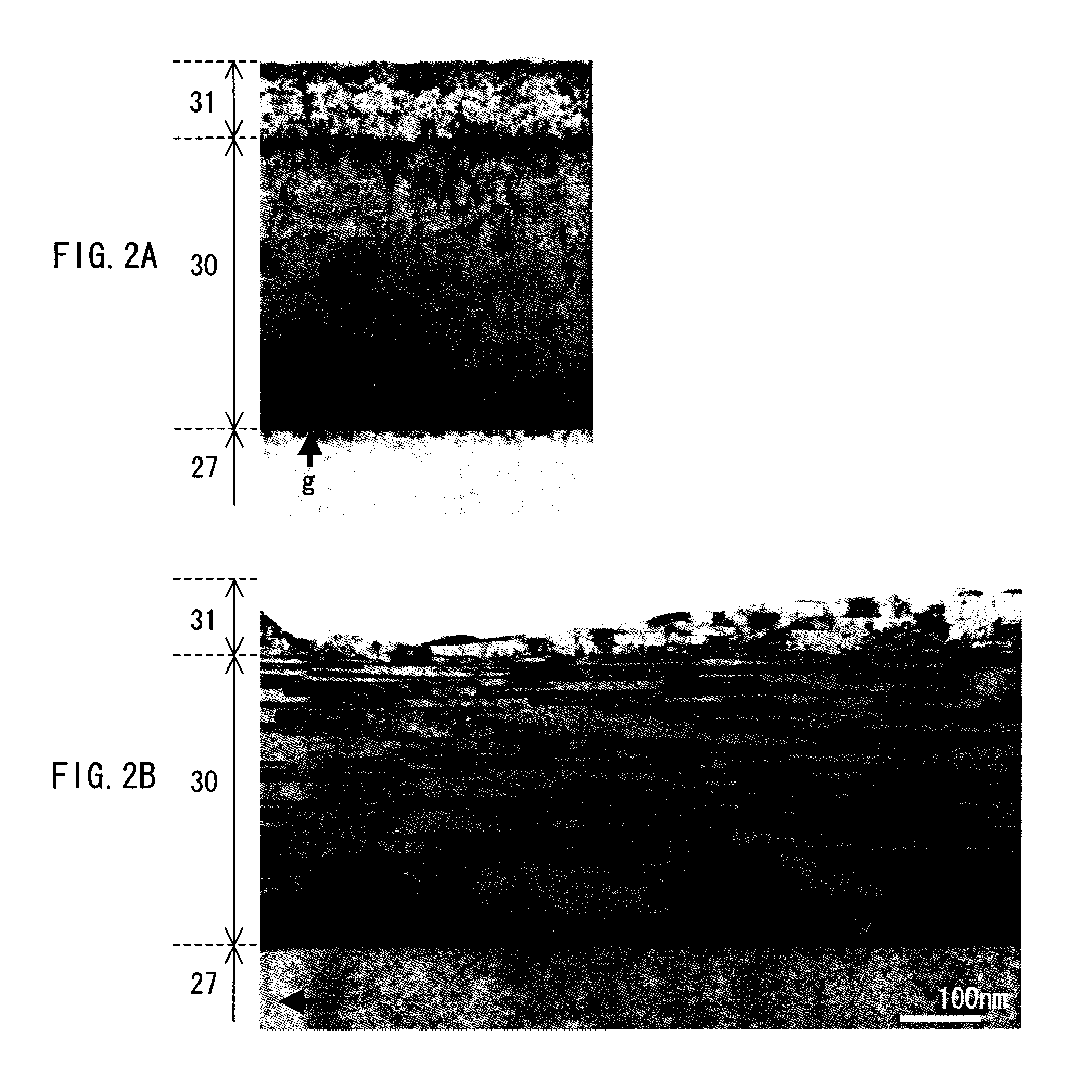

Provided is a near-field light transducer with a propagation edge in which the generation of defects is suppressed. The transducer is formed of a Ag alloy and comprises an edge, the edge comprising a portion to be coupled with a light in a surface plasmon mode, the edge extending from the portion to a near-field light generating end surface, and the edge being configured to propagate surface plasmon excited by the light. Further, a curvature radius of the rounded edge is set in the range from 6.25 nm to 20 nm. In the edge and its vicinity, the generation of defects such as cracking and chipping is suppressed. Thereby improved are a propagation efficiency of surface plasmon and a light use efficiency of the transducer. The Ag alloy preferably contains at least one element selected from a group of Pd, Au, Cu, Ru, Rh and Ir.

Owner:TDK CORPARATION

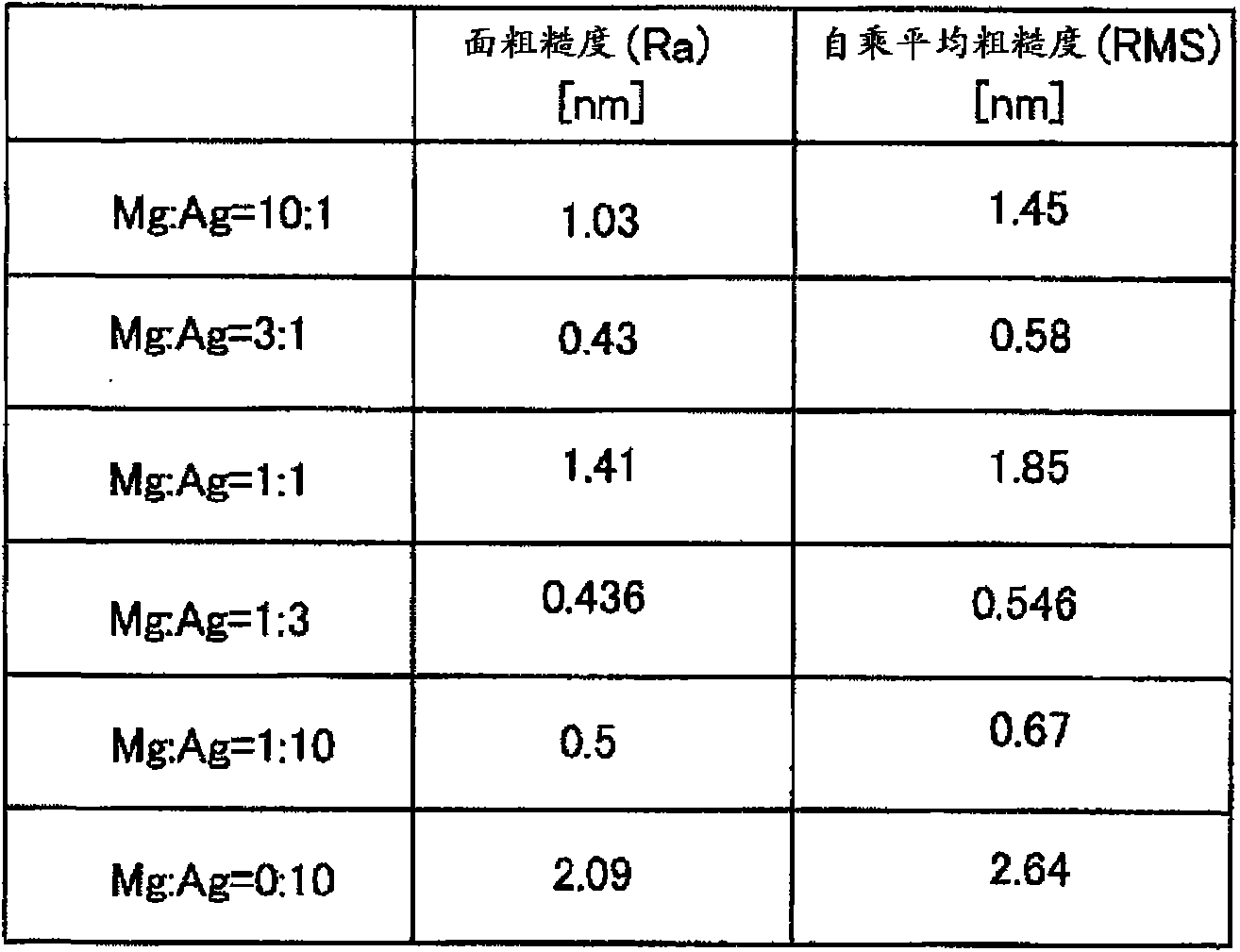

Reflective Ag alloy film for reflectors and reflector provided with the same

ActiveUS20050008883A1Improve reflectivityProductivity is deterioratedMirrorsVacuum evaporation coatingRare-earth elementSurface roughness

A reflective Ag alloy film for reflectors, which has excellent surface flatness and shows high reflectivity even under a heating environment and a reflector. The reflective Ag alloy film for reflectors has an average surface roughness of 2.0 nm or less and contains a rare earth element (such as Nd) in a content in the range of 0.1 to 3.0 at %, or further at least one selected from Au, Pd, Cu and Pt in a content in the range of 0.5 to 5.0 at %. The reflector comprises the above reflective Ag alloy film formed on a substrate.

Owner:KOBE STEEL LTD

Tin-silver solder bumping in electronics manufacture

ActiveUS20070037377A1Improve stabilityReduced and entirely eliminated voidingCellsSemiconductor/solid-state device detailsElectrolysisThiourea

A process for forming a solder bump on an under bump metal structure in the manufacture of a microelectronic device comprising exposing the under bump metal structure to an electrolytic bath comprising a source of Sn2+ ions, a source of Ag+ ions, a thiourea compound and / or a quaternary ammonium surfactant; and supplying an external source of electrons to the electrolytic bath to deposit a Sn—Ag alloy onto the under bump metal structure.

Owner:MACDERMID ENTHONE INC

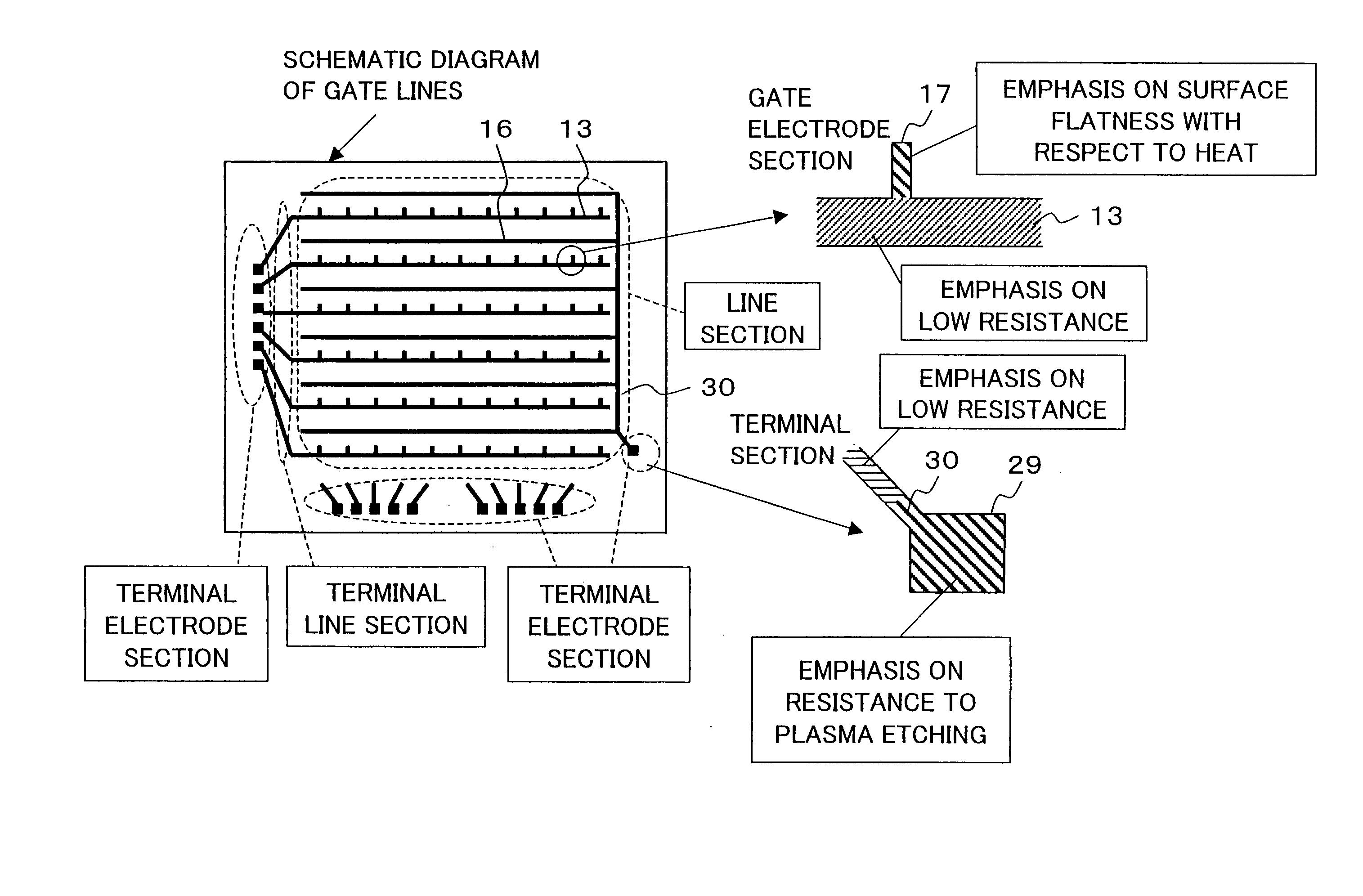

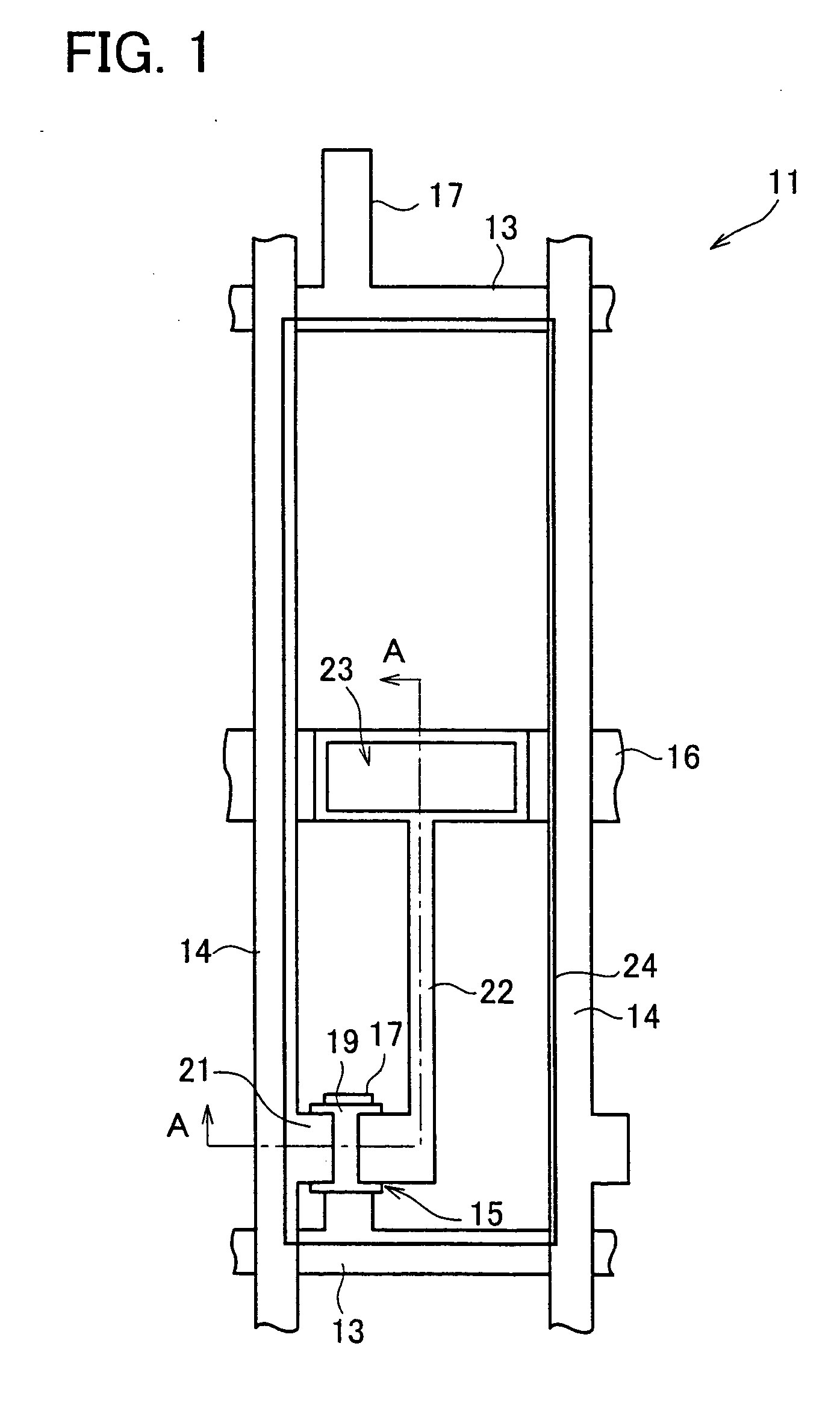

Silver alloy material, circuit substrate, electronic device, and method for manufacturing circuit substrate

InactiveUS20050019203A1Strong adhesionHigh plasma resistanceSemiconductor/solid-state device detailsPrinted circuit aspectsIndiumHemt circuits

A circuit substrate of the present invention uses as component materials for gate lines and gate electrodes, silver alloy material containing silver as a main component, and at least one element selected from the group consisting of tin, zinc, lead, bismuth, indium, and gallium. It is especially preferable that the silver alloy material mainly consisting of silver and containing indium is used for the gate lines and the gate electrodes. With this, it is possible to provide silver alloy material whose resistance value, adhesion, plasma resistance, and reflection characteristics can be appropriately adjusted by the adjustment of the content of indium. Further, it is also possible to apply the alloy in accordance with the characteristic required for each part of the circuit substrate.

Owner:SHARP KK

Semiconductor light emitting device and method of manufacturing the same

InactiveUS20070145396A1Improve reflectivityImprove linearitySemiconductor/solid-state device manufacturingSemiconductor devicesLight reflectionContact layer

A semiconductor light emitting device having high reflectivity and a high electrical contact property between a light reflection layer and a semiconductor layer is provided. The semiconductor light emitting device is formed by laminating a semiconductor layer, a light reflection layer and a protective layer on a substrate in this order. The semiconductor layer is formed by laminating a buffer layer, a GaN layer, an n-type contact layer, an n-type cladding layer, an active layer, a p-type cladding layer and a p-type contact layer in this order. The light reflection layer is formed by depositing an Ag alloy on a surface of the p-type contact layer while heating the substrate at, for example, a temperature from 100° C. to less than 400° C. After the semiconductor layer, the light reflection layer and the protective layer are formed, the semiconductor layer, the light reflection layer and the protective layer are heated in a predetermined time range at an ambient temperature within a higher temperature range than a temperature range at the time of heating the substrate.

Owner:SONY CORP

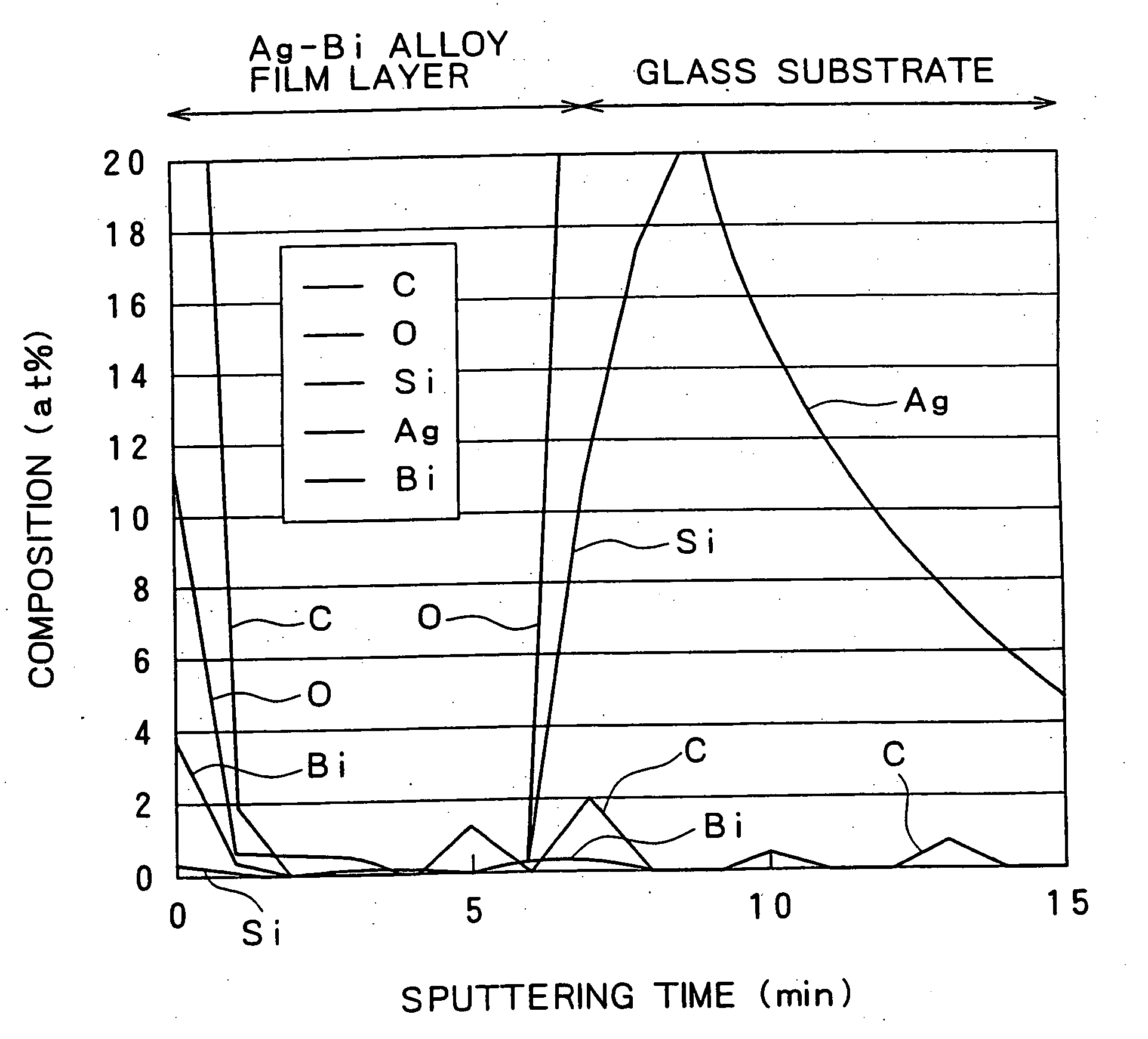

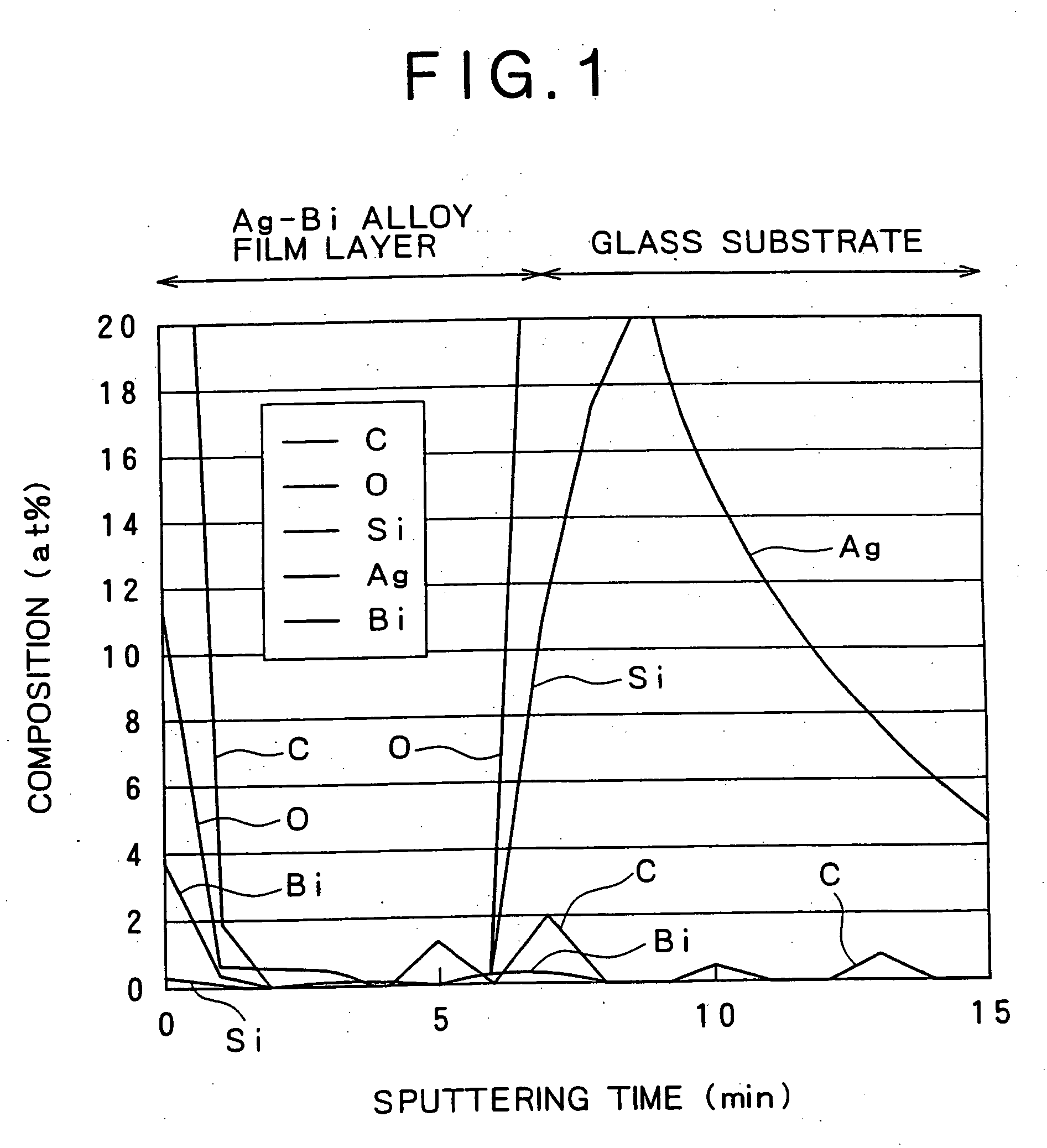

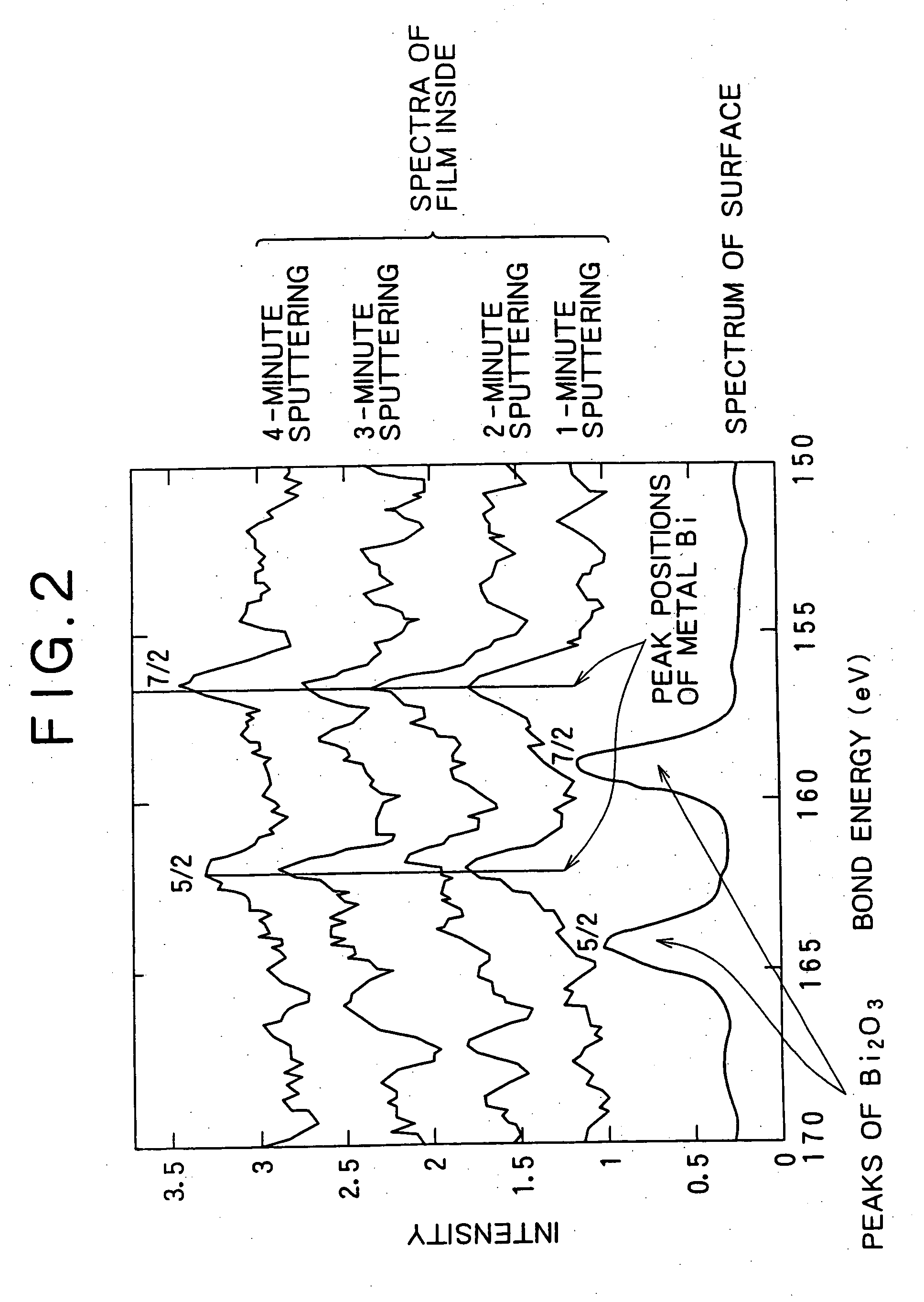

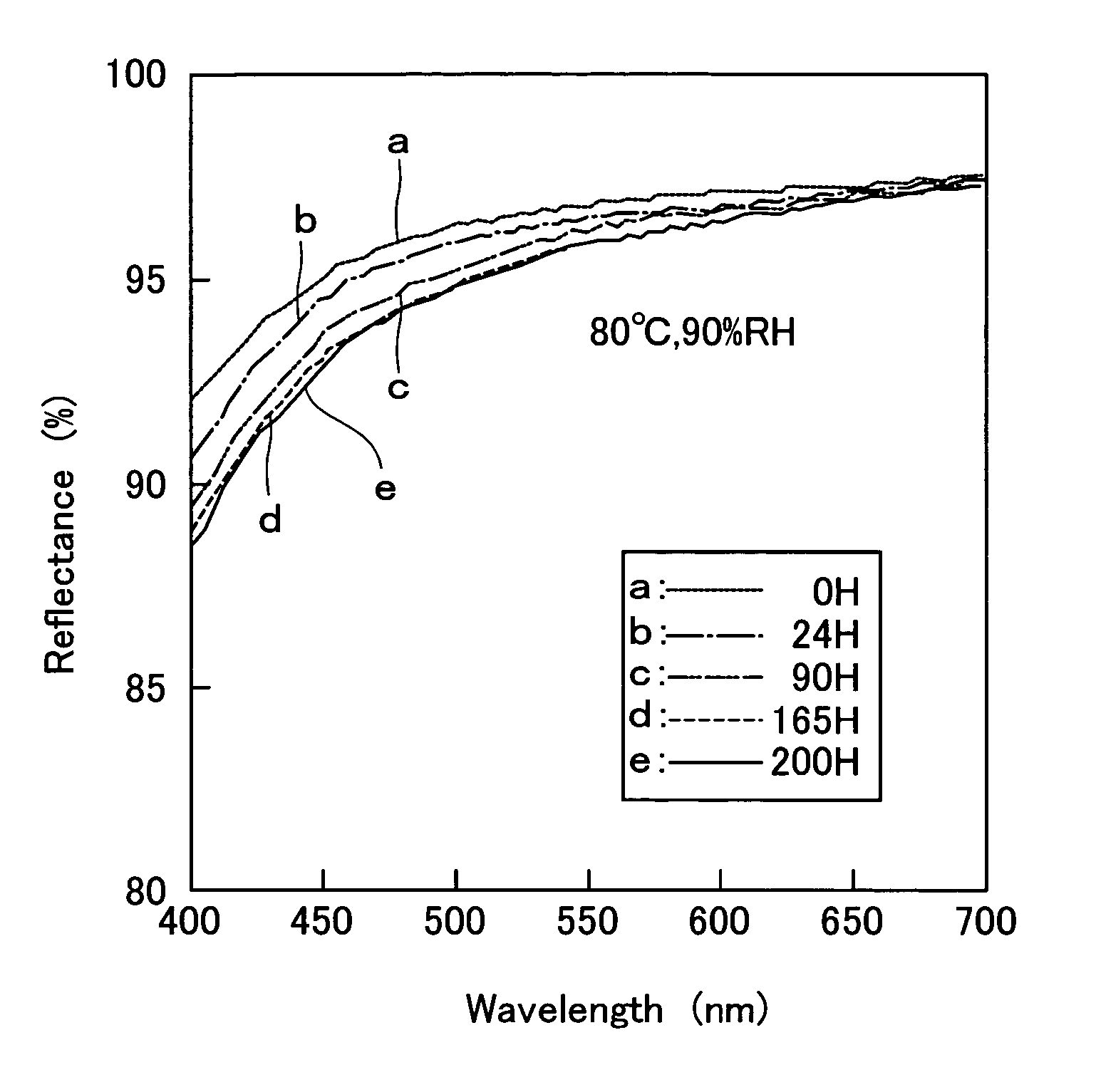

Ag base alloy thin film and sputtering target for forming Ag base alloy thin film

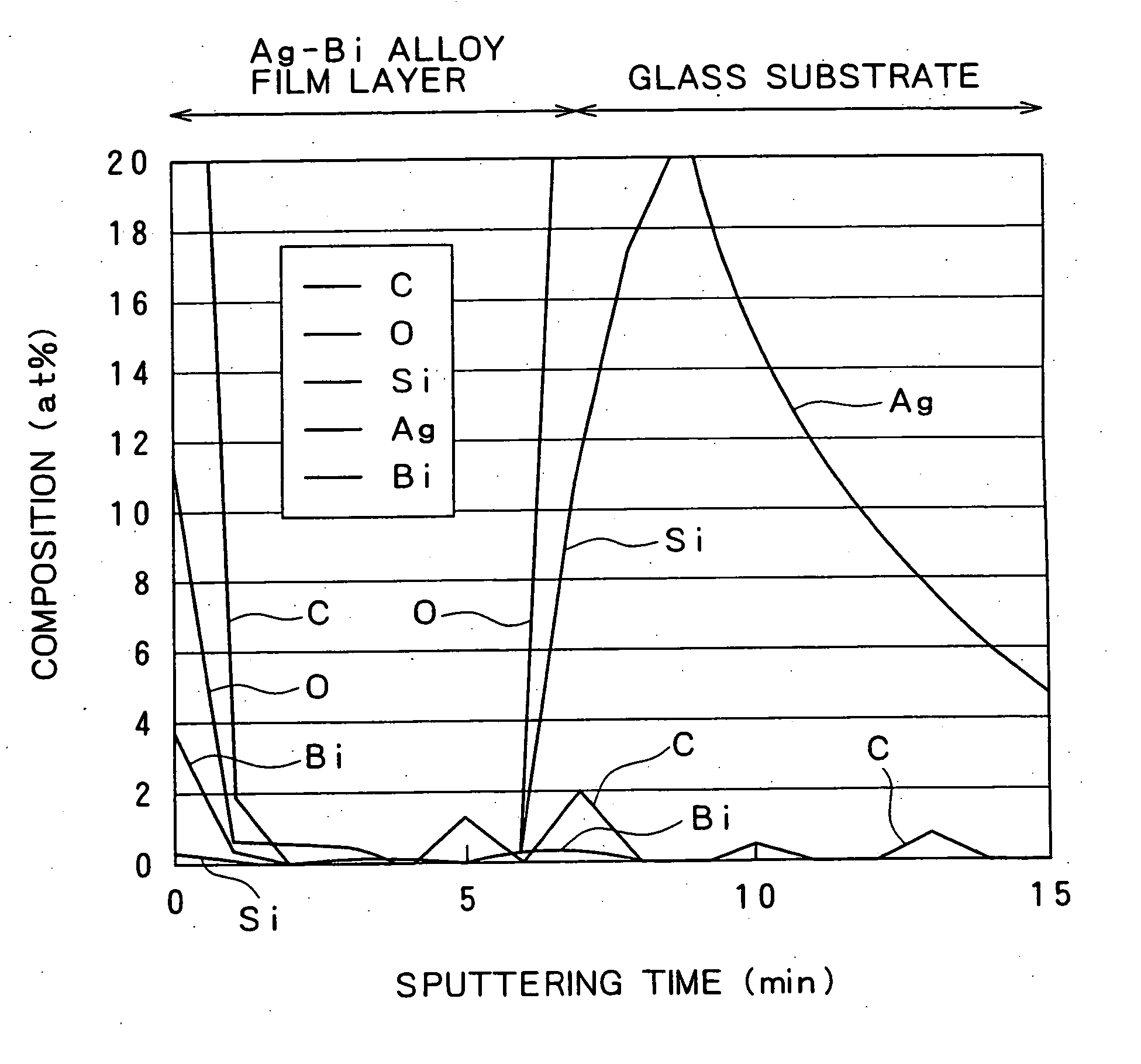

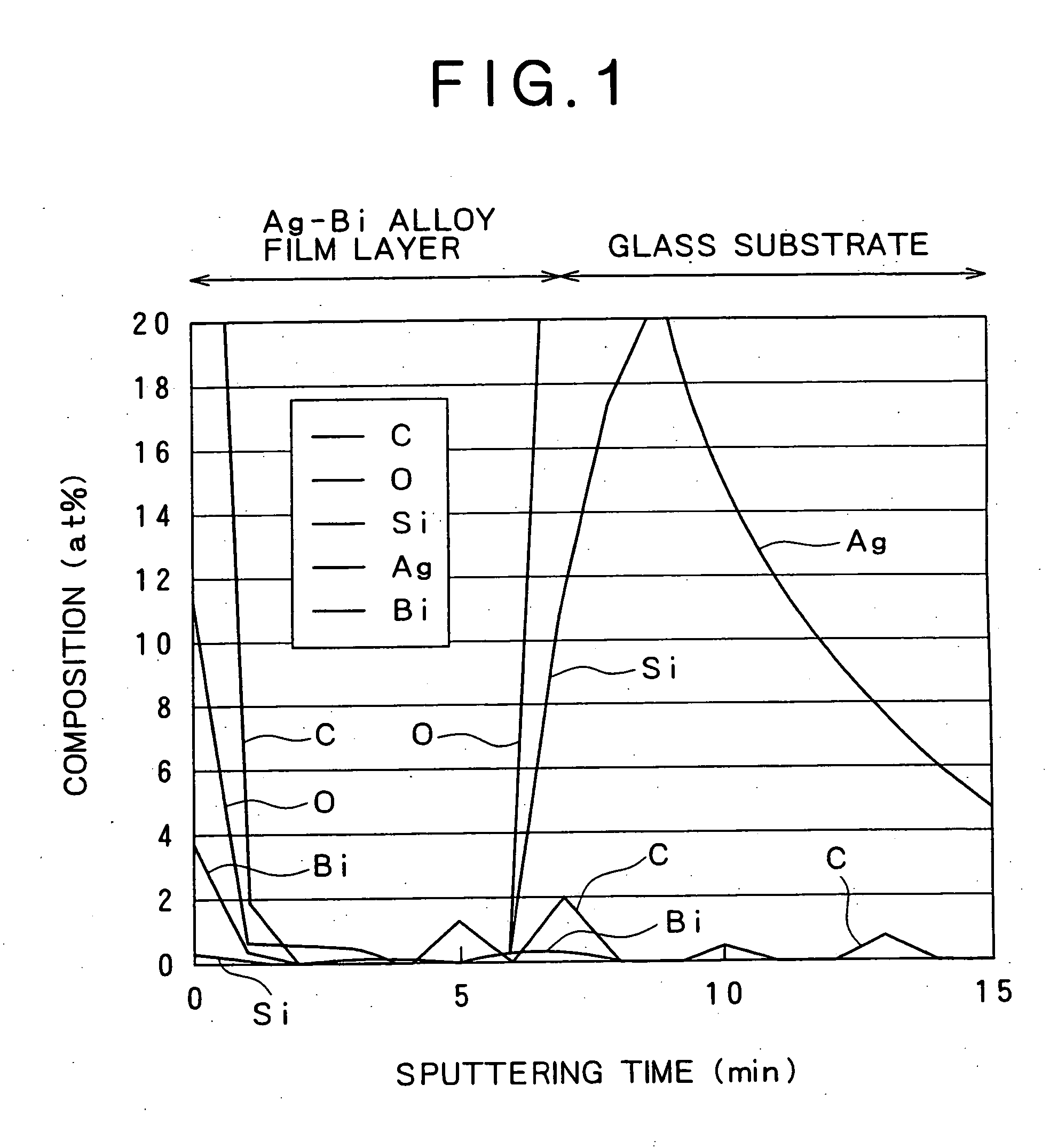

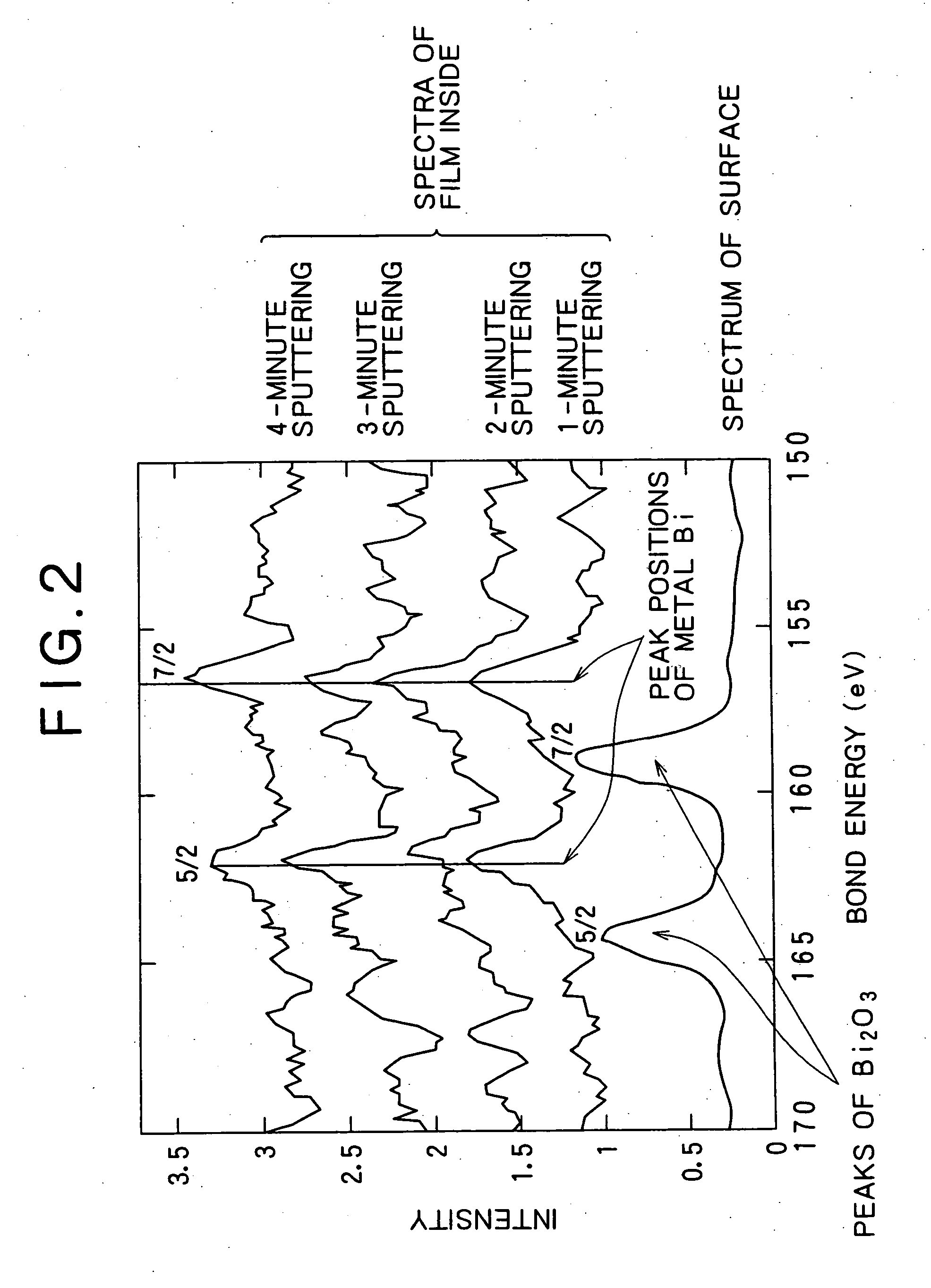

ActiveUS20060104853A1Improve recordEnhance reproduction characteristicSteering ruddersVacuum evaporation coatingOptical reflectionElectrical resistance and conductance

The present invention relates to an Ag alloy film. Particularly, it is preferably used as a reflective film or semi-transmissive reflective film for an optical information recording medium having high thermal conductivity / high reflectance / high durability in the field of optical information recording media, an electromagnetic-shielding film excellent in Ag aggregation resistance, and an optical reflective film on the back of a reflection type liquid crystal display device, or the like. The Ag alloy film of the present invention comprises an Ag base alloy containing Bi and / or Sb in a total amount of 0.005 to 10% (in terms of at %). Further, the present invention relates to a sputtering target used for the deposition of such an Ag alloy film.

Owner:KOBE STEEL LTD

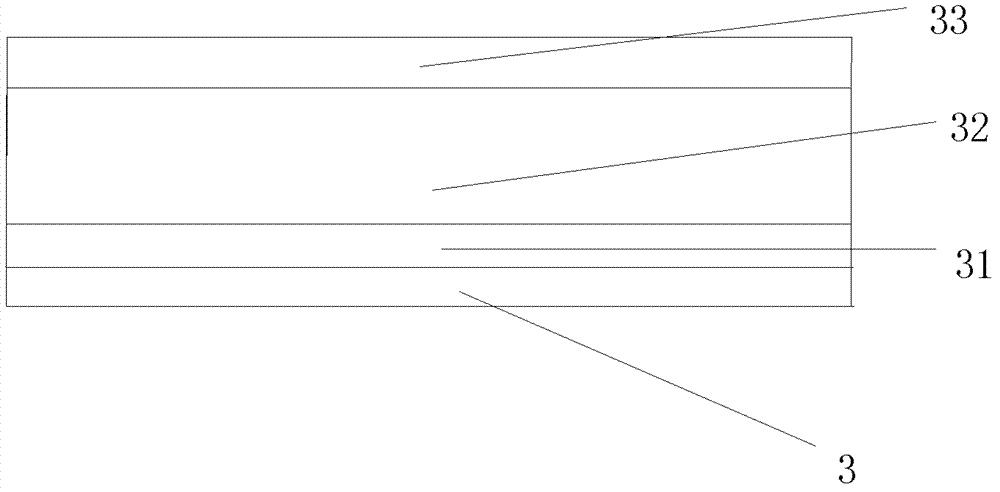

Power module metalized ceramic substrate and metallization method thereof

InactiveCN102896832AImprove bindingImprove antioxidant capacityVacuum evaporation coatingSputtering coatingChemical platingCeramic substrate

The invention, relating to the field of ceramic surface modification, discloses a power module metalized ceramic substrate and a metallization method thereof. The method disclosed herein comprises the following steps: firstly depositing copper or silver with a thickness of 0.1-5 mum on the surface of a power module ceramic substrate by magnetron sputtering or arc ion plating; then depositing copper, silver, copper alloy or silver alloy with a thickness of 50-1000 mum by chemical plating or electroplating; and finally depositing silver, gold, tin or nickel with a thickness of 0.1-5 mum by magnetron sputtering or arc ion plating, or depositing a tin or nickel layer with a thickness of 2-5mum by chemical plating or electroplating. According to the invention, the metalized ceramic component obtained by the method disclosed herein has large current-carrying capacity, strong thermal conductivity and heat dissipation capability, good gas tightness, reliable and stable quality, etc., is easily welded with other metals or ceramics and composite materials, and can be used in the fields of vacuum devices, aerospace, aviation, radio and television, communication, metallurgy, medicine, high-energy physics, etc.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

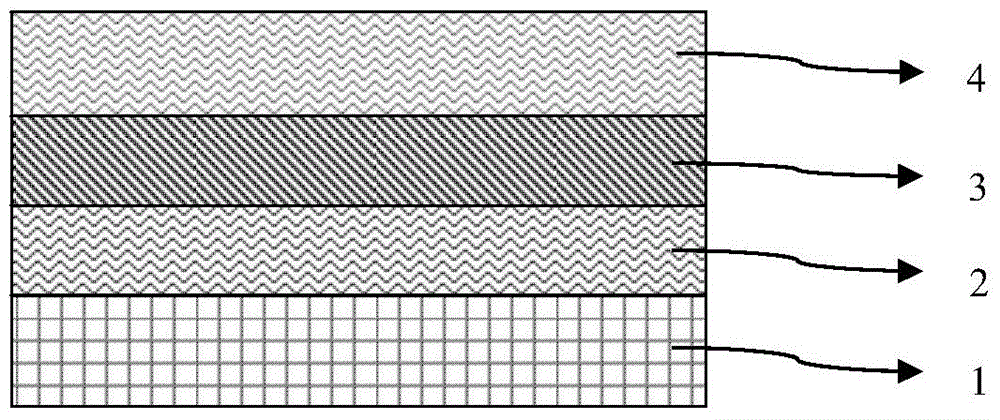

Transparent conducting thin film with enhanced thermal stability and preparation method and application thereof

ActiveCN104979037ASuppresses the weak point that is easy to condense when heatedGood energy level matchingConductive layers on insulating-supportsSolid-state devicesOrganic solar cellRare-earth element

The invention relates to a transparent conducting thin film with enhanced thermal stability and a preparation method and application thereof. The transparent conducting thin film consists of a substrate, a first semiconductor layer, a silver alloy layer and a second semiconductor layer sequentially from bottom to top; according to the silver alloy layer, metal silver is combined with aluminum, zinc, titanium, copper, magnesium, nickel, rare earth elements or chromium to form a bi-element silver alloy layer or a multi-element silver alloy layer. The transparent conducting thin film provided by the invention can be used for photoelectric devices, such as organic light-emitting devices (OLEDs), organic solar cells and perovskite batteries; furthermore, on the basis of improving the thermal stability of the photoelectric devices, the dose of the photoelectric devices on a silver material per unit area can be reduced, device cost can be beneficially controlled, resources are saved; and the transparent conducting thin film also can be applied to magnetic shielding, special functional window coatings, transparent heat preservation building glass and the like.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

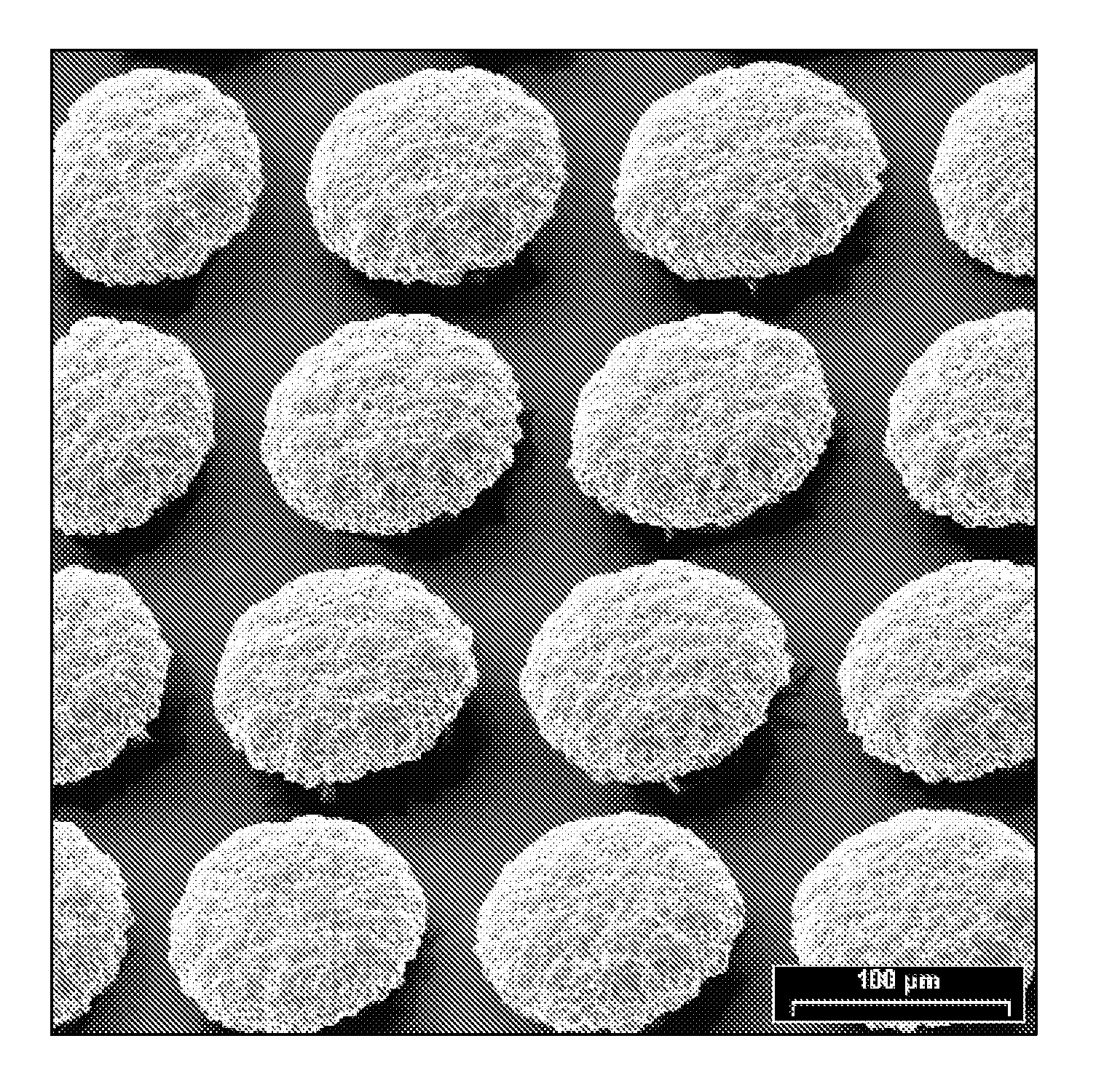

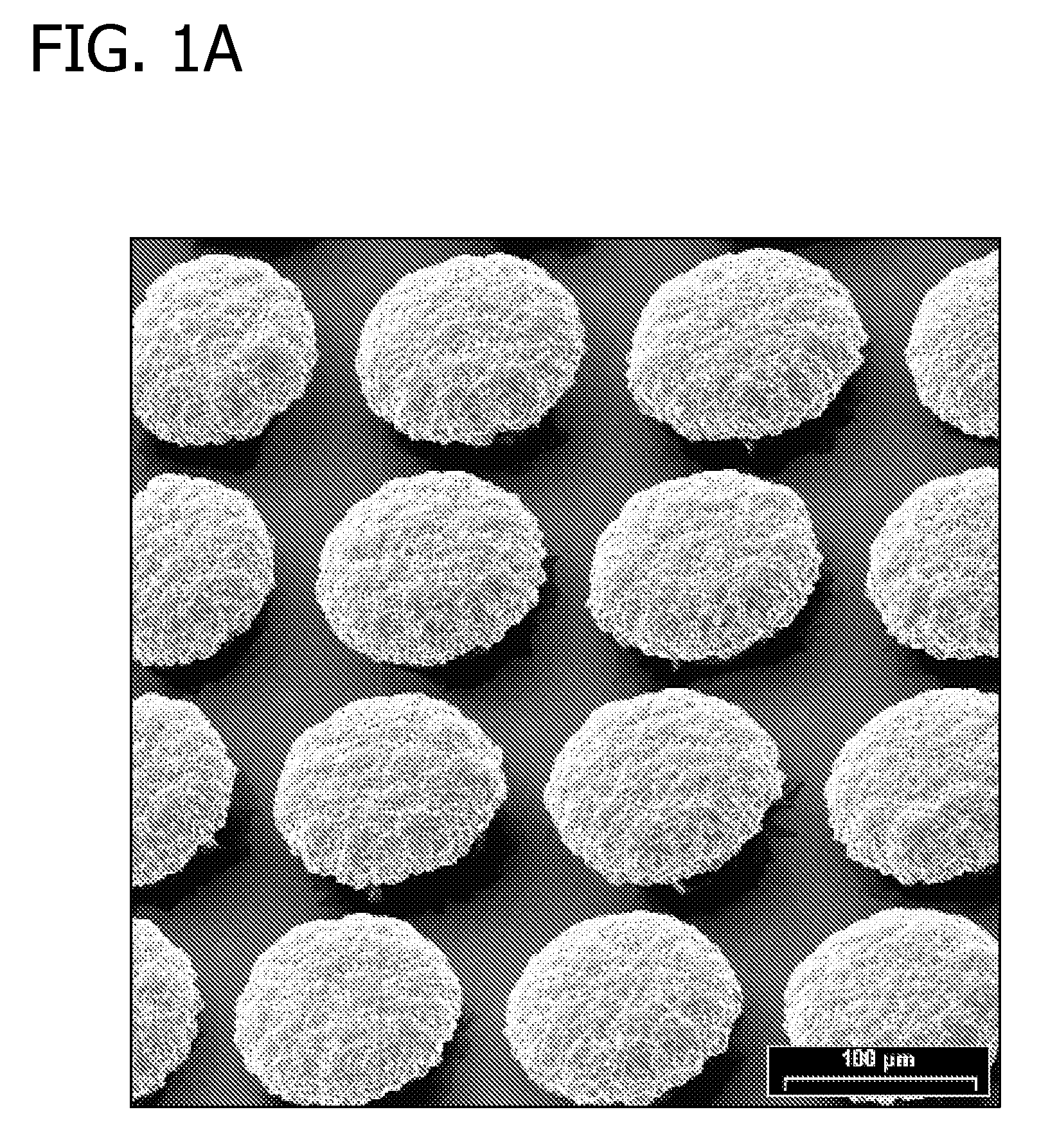

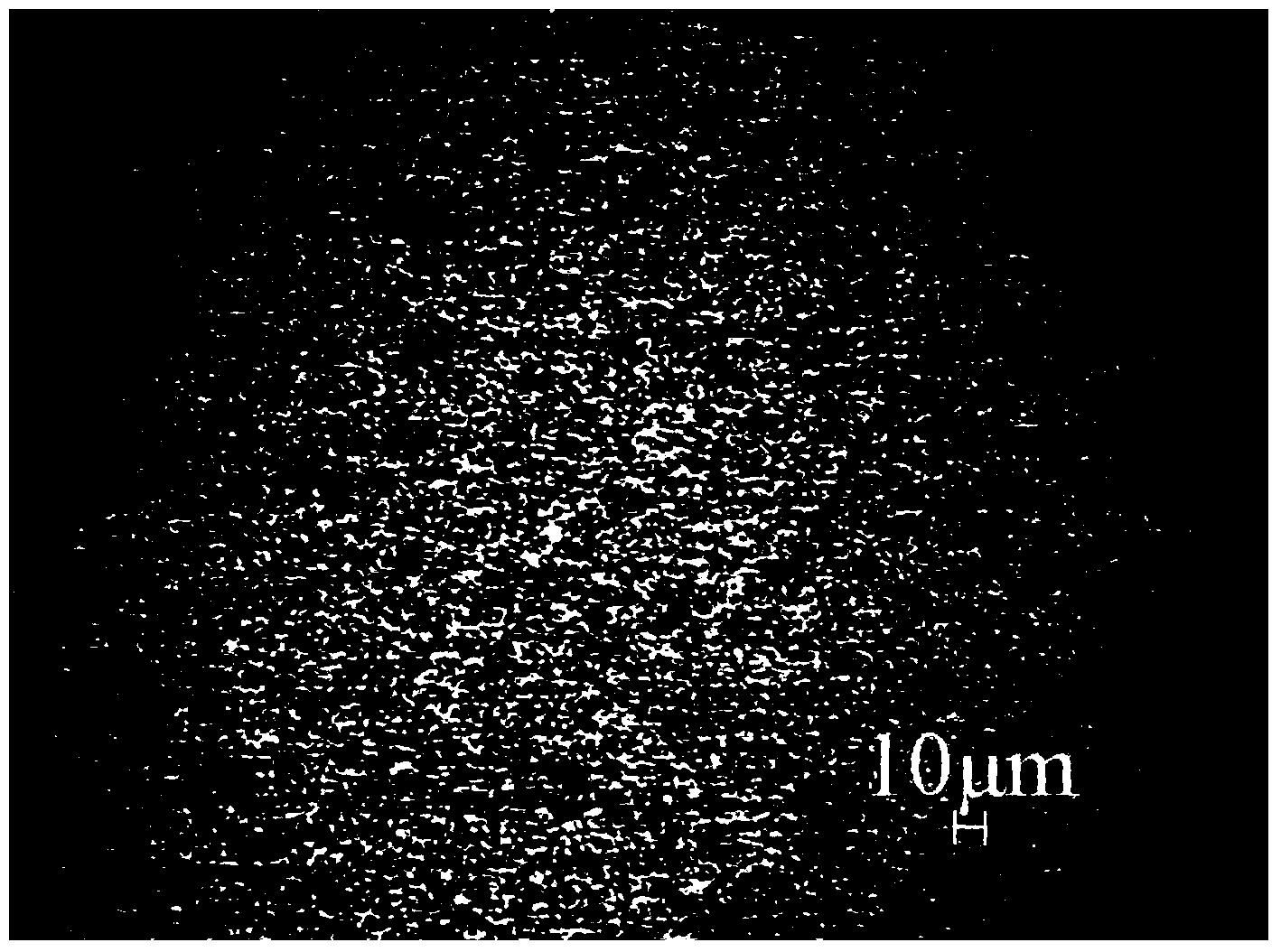

Surface-enhanced Raman scattering active substrate and preparation method thereof

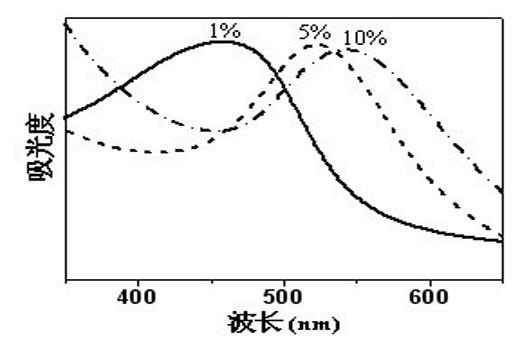

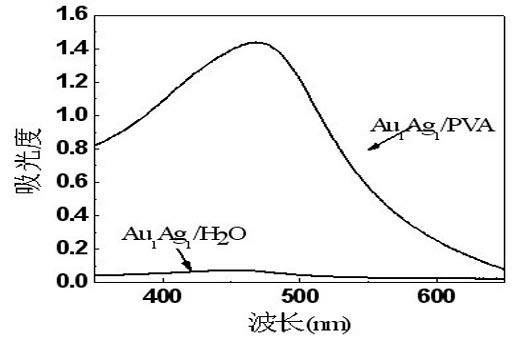

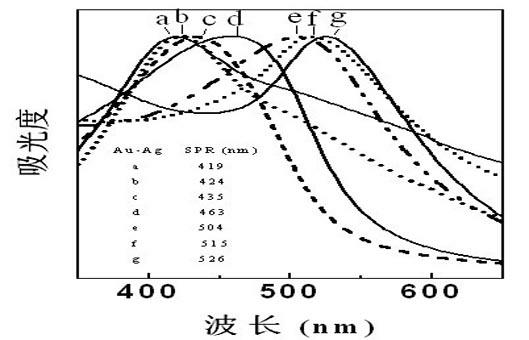

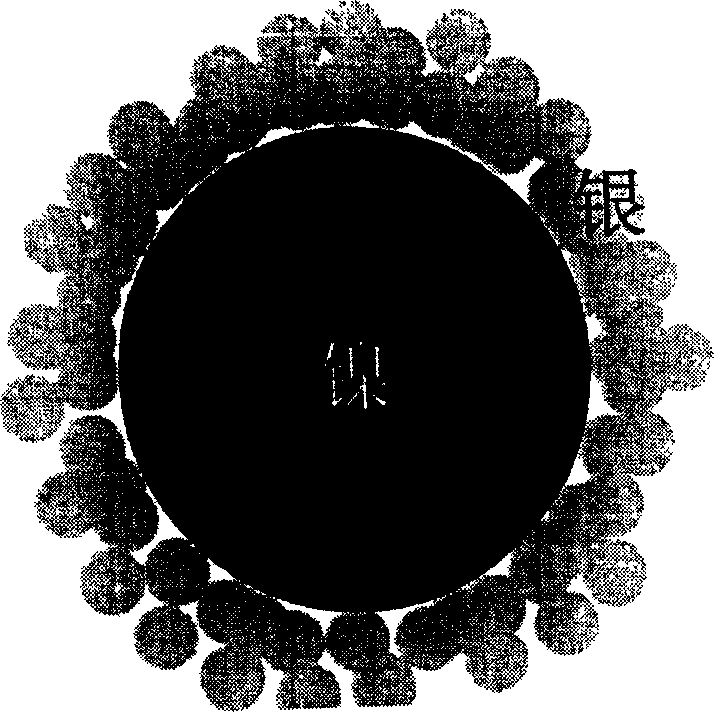

InactiveCN102677212AWide wavelength rangeIncrease concentrationFilament/thread formingRaman scatteringAlloy nanoparticlePolyvinyl alcohol

The invention relates to a surface-enhanced Raman scattering active substrate and a preparation method thereof. A HAuCl4 solution and a AgNO3 solution are added in a polyvinyl alcohol aqueous solution with a certain mass concentration, then sodium citrate is added to prepare a polyvinyl alcohol / Au-Ag alloy nanoparticle spinning solution after sufficient reaction, and a parallel type electrostatic spinning technology is adopted to obtain the surface-enhanced Raman scattering active substrate with a polyvinyl alcohol / Au-Ag alloy nanoparticle composite nanofiber structure, wherein the content of Au-Ag alloy nanoparticles is 2*10<-4> to 2*10<-2> mol / g, and the molar ratio of Au:Ag is (1:2)-(1:3). As gold-silver alloy nanoparticles can absorb light from blue to green and the plasma resonance wavelength can be controlled and adjusted between silver and gold, the applicable wavelength range of the surface-enhanced Raman scattering active substrate material provided by the invention is wider than that of a gold or silver single-component substrate.

Owner:SUZHOU UNIV

High temperature antioxidant base metal composition and its production process

InactiveCN1416986ALow costReduce manufacturing costAlkaline accumulator electrodesLiquid/solution decomposition chemical coatingOxidation resistantAmmonium hydroxide

The present invention relates to a high temperature antioxidant base metal composition and its production process. The composition includes Ni in 30-54 pts.wt. and Ag in 46-70 pts.wt, and the Ag alloy forms thin antioxidant layer on the surface of Ni grains. The production process includes preparing sensitizing liquid, activating liquid, ammonia solution of silver and reductant; dipping, stirring, pickling, sensitizing, cleaning, activating, reduction, heating, and other steps. The said process can produce electrode with the conducting performance similar to that of noble metal but only one tench in cost. The application of the present invention can reduce the cost of MPT, MLCC and other electronic elements and product. The present invention has the features of simple process, low production cost and capacity of co-sintering with ceramic in atmosphere.

Owner:XIAN UNIV OF TECH

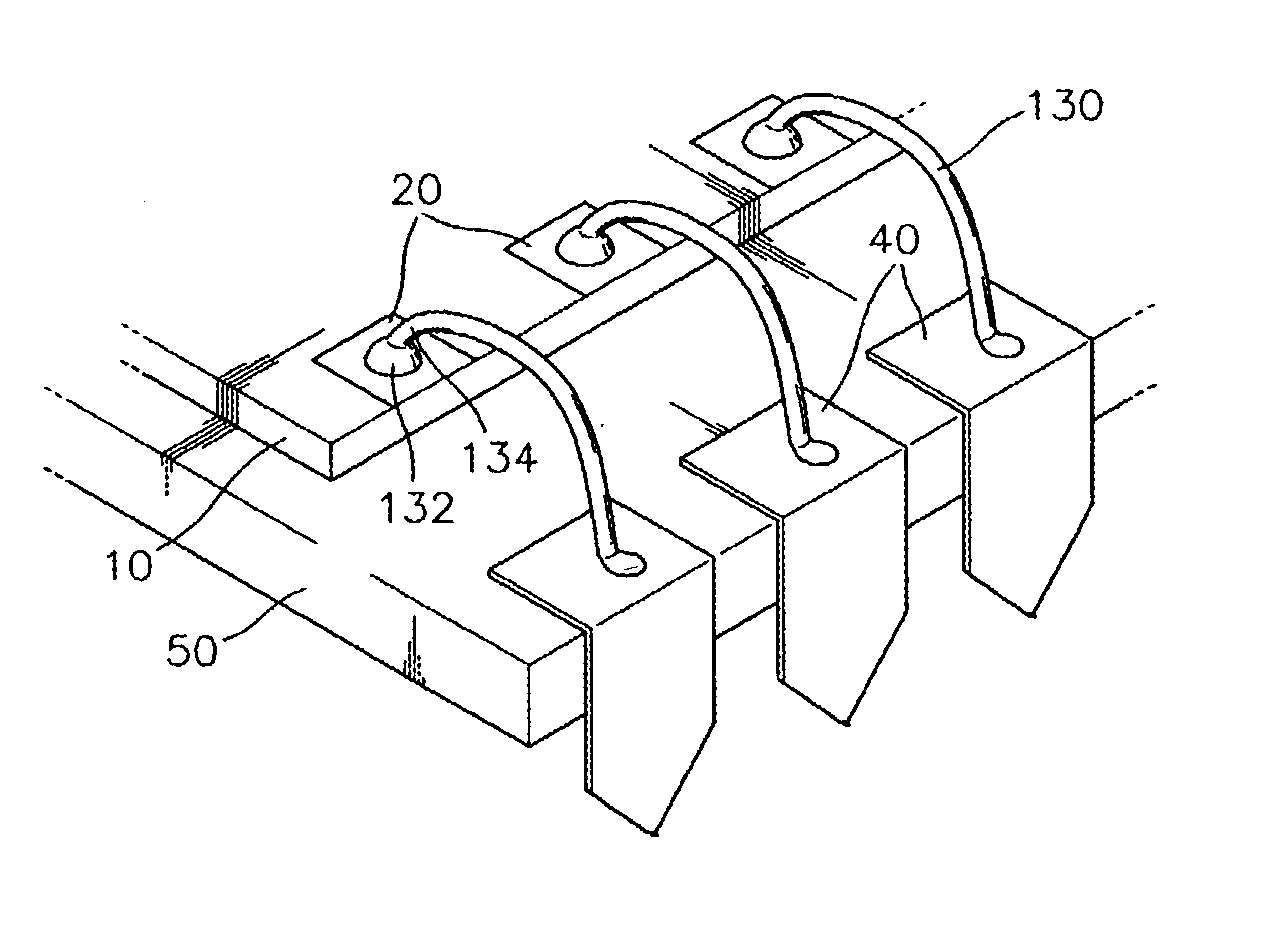

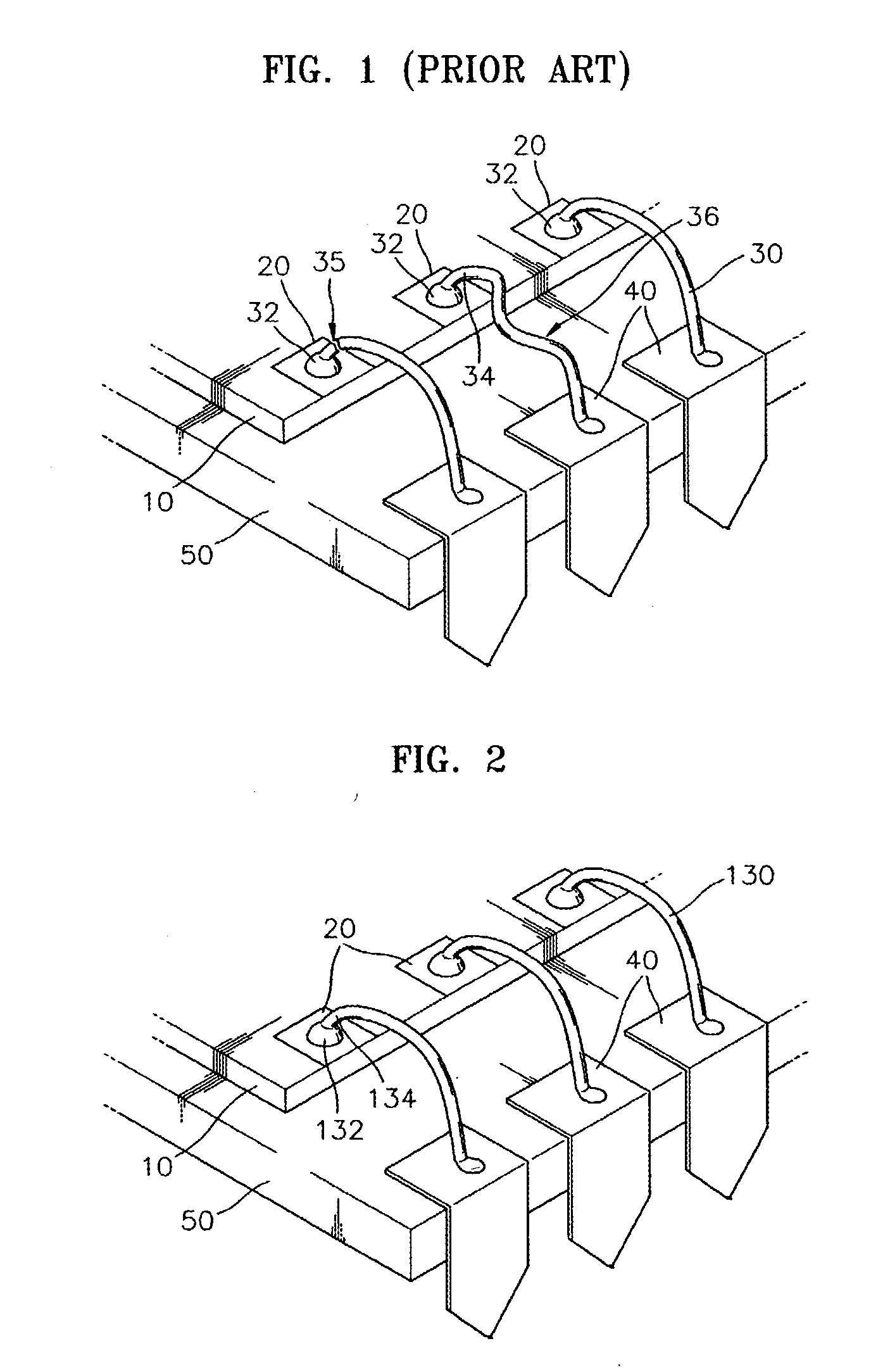

Gold-silver bonding wire for semiconductor device

InactiveUS20030209810A1Avoid cleaningImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesDevice materialRoom temperature

A gold-silver alloy bonding wire for a semiconductor device is provided. The bonding wire contains: a Au-Ag alloy including 5-40% Ag by weight in Au having a purity of 99.999% or greater; at least one element of a first group consisting of Pd, Rh, Pt, and Ir in an amount of about 50-10,000 ppm by weight; at least one element of a second group consisting of B, Be, and Ca in an amount of about 1-50 ppm by weight; at least one element of a third group consisting of P, Sb, and Bi in an amount-of about 1-50 ppm by weight; and at least one element of a fourth group consisting of Mg, TI, Zn, and Sn in an amount of about 5-50 ppm by weight. The bonding wire is highly reliable with a strong tensile strength at room temperature and high temperature and favourable bondability. When the bonding wire is looped, no rupture occurs in a ball neck region. Also, no chip cracking occurs since the ball is soft.

Owner:MK ELECTRON

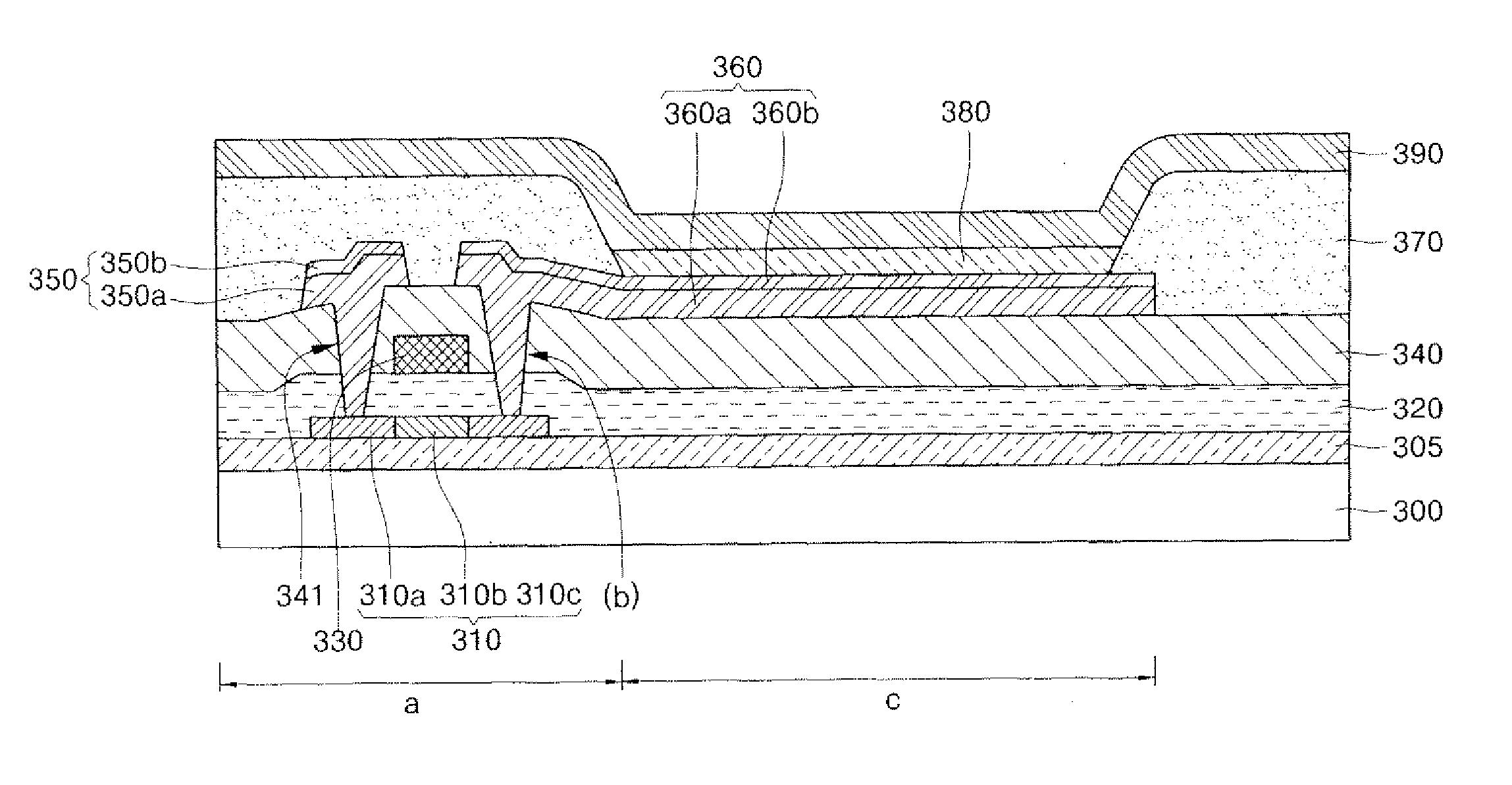

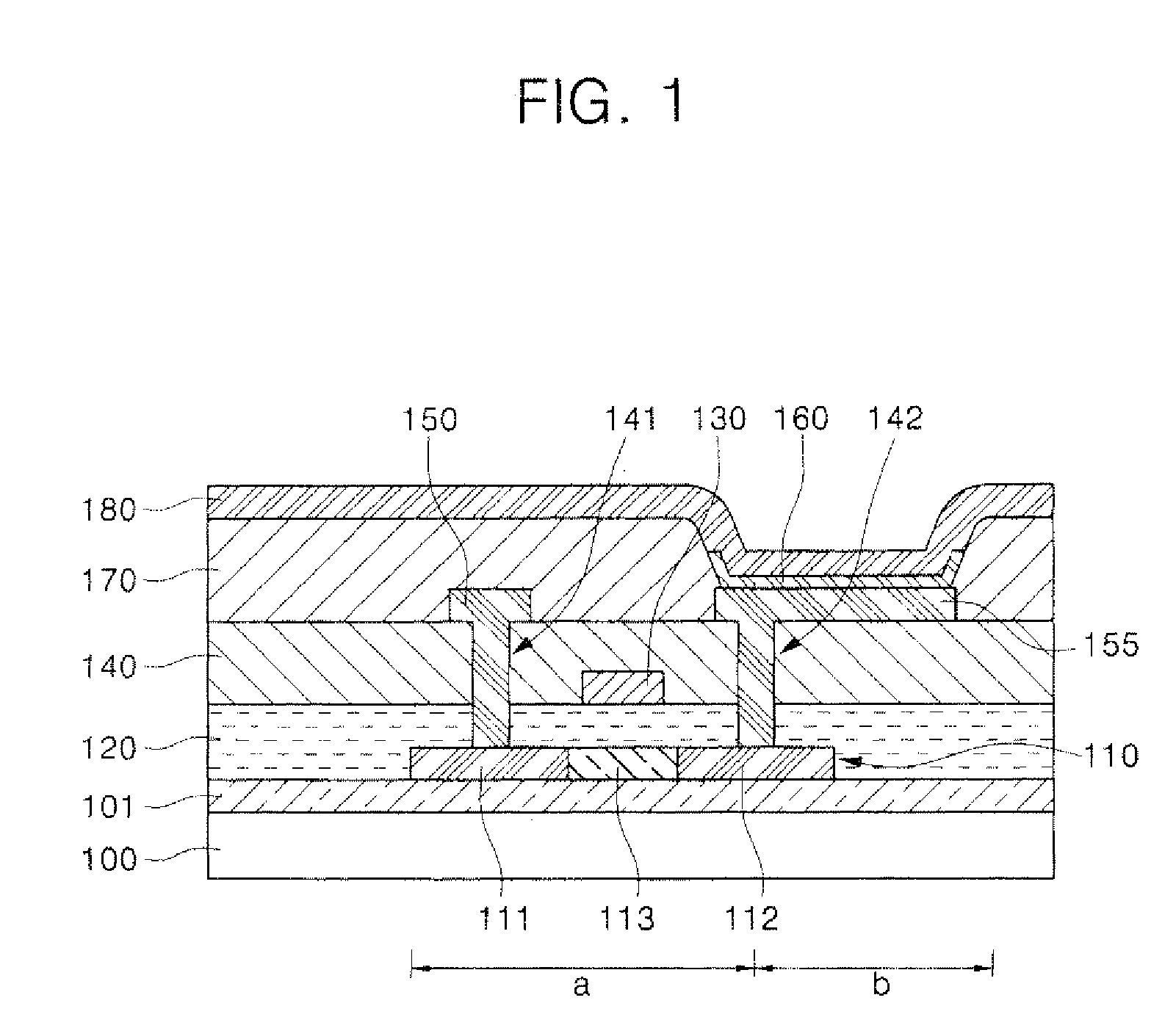

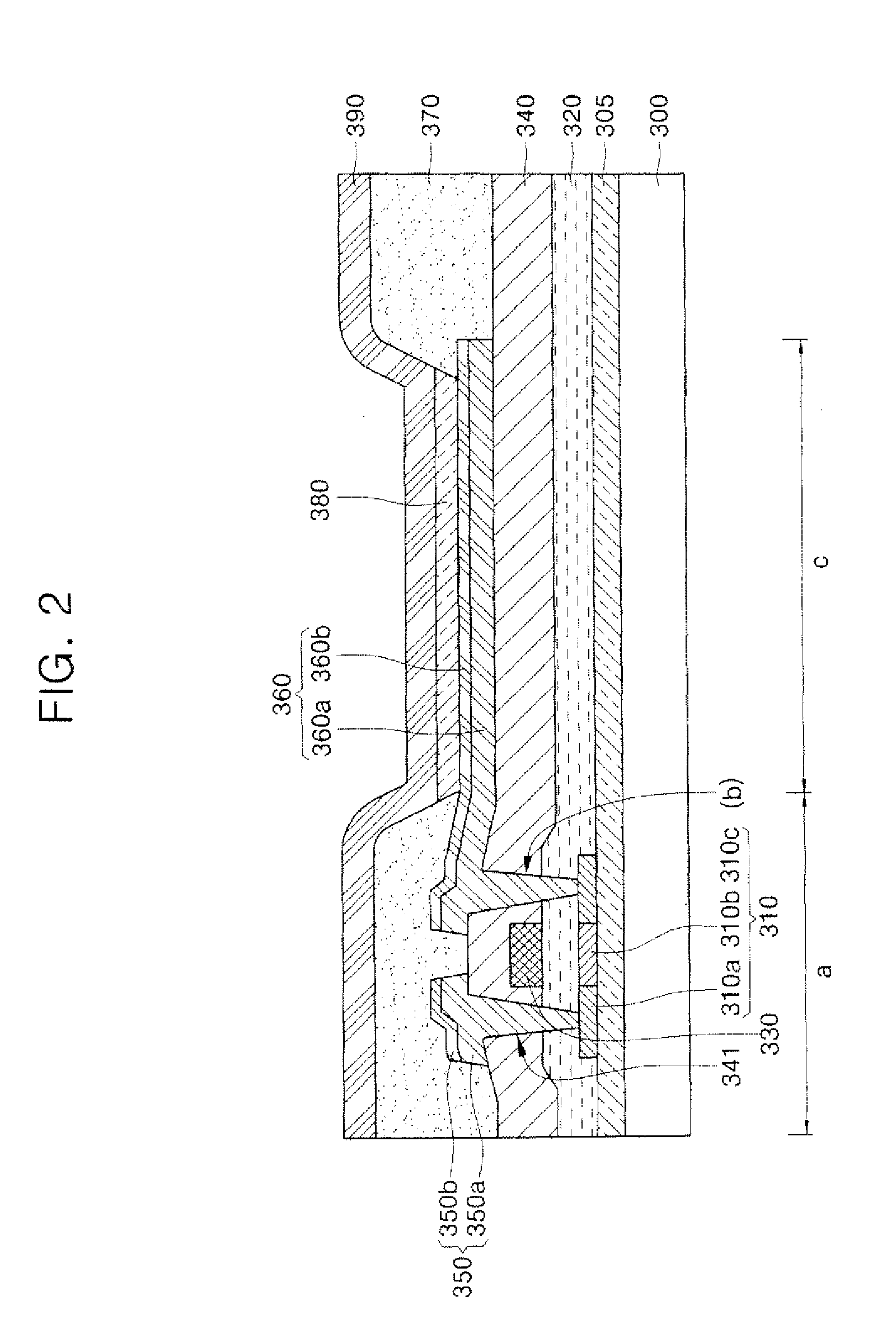

Organic light emitting display device and method of fabricating the same

ActiveUS20060243976A1Increasing reflectivity and efficiencyReducing the organic light emitting display device panel sizeElectroluminescent light sourcesSolid-state devicesLine widthDisplay device

An organic light emitting display device and a method of fabricating the same are provided, which employ an Ag alloy containing Sm, Tb, Au, and Cu to simultaneously form a source electrode, a drain electrode, and a first electrode of the organic light emitting display device for increasing the reflectivity and efficiency of the organic light emitting display device and reducing the organic light emitting display device panel size by reducing a line width of the source and drain electrodes due to the low resistance of the source and drain electrodes.

Owner:SAMSUNG DISPLAY CO LTD

Ag base alloy thin film and sputtering target for forming Ag base alloy thin film

InactiveUS20060154104A1Increased durabilityImprove reliabilitySteering ruddersVacuum evaporation coatingOptical reflectionElectrical resistance and conductance

The present invention relates to an Ag alloy film. Particularly, it is preferably used as a reflective film or semi-transmissive reflective film for an optical information recording medium having high thermal conductivity / high reflectance / high durability in the field of optical information recording media, an electromagnetic-shielding film excellent in Ag aggregation resistance, and an optical reflective film on the back of a reflection type liquid crystal display device, or the like. The Ag alloy film of the present invention comprises an Ag base alloy containing Bi and / or Sb in a total amount of 0.005 to 10% (in terms of at %). Further, the present invention relates to a sputtering target used for the deposition of such an Ag alloy film.

Owner:KOBE STEEL LTD

Copper-silver alloy conductor size and its preparing method

InactiveCN1783355ALower sintering temperatureImprove conductivity stabilityNanostructure manufactureLuminescent paintsSupersonic wavesAlloy nanoparticle

This invention provides Cu-Ag alloy conductor slurry and its manufacturing method including: preparing nm particles of Cu-Ag alloy, matching conductor slurry and sintering the slurry, in which, the nm particles are prepared under the mixed atmosphere of H and Ar with the DC arc plasma method and the preparation for the slurry includes: fully mixing terpinyl, EC and absolute alcohol then adding nm particles and fully beating them up to be vibrated by supersonic waves then to be added with glass power to beat them up again and vibrate them with supersonic waves to get the conductor slurry. The sinter temperature is bellow 220deg.C under 1.33Pa. Advantage: the sinter temperature is low not needing protection gas while sintering, the conductive stability is higher than Cu power slurry and ití»s possible to replace Au, Ag and Pd slurry.

Owner:SHENYANG POLYTECHNIC UNIV

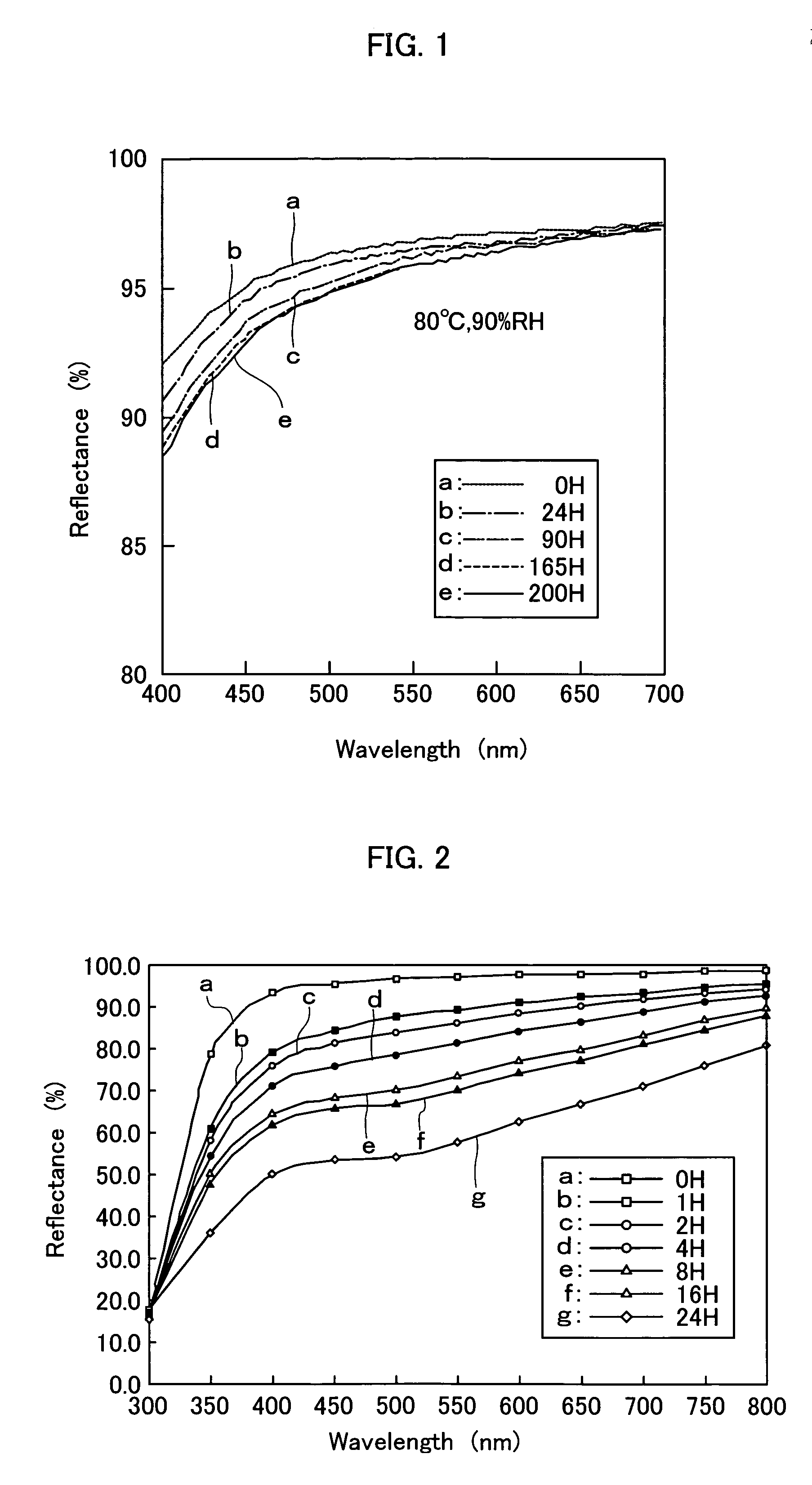

Ag-based reflection film and method for preparing the same

InactiveUS20060068227A1High light transmittanceConsiderably stabilizedVacuum evaporation coatingSputtering coatingSputteringDisplay device

An Ag-based reflection film consists of a laminate film comprising an Ag or Ag-alloy film provided thereon with a quite thin capping layer. The Ag-based reflection film can be prepared by, for instance, forming, on a substrate, an Ag or Ag-alloy film according to the sputtering technique, while using a sputtering target, for instance, having a composition corresponding to that of the pure Ag film, and Ar gas as a sputtering gas, while adding an additional gas such as O2, only at the initial stage of the Ag or Ag-alloy film-forming step; and then forming a quite thin capping layer, on the Ag or Ag-alloy film, according to the sputtering technique, while using a sputtering target having a composition corresponding to that of the capping layer, and Ar gas as a sputtering gas, while if necessary adding an additional gas such as O2. The Ag-based reflection film can maintain a high reflectance without causing any deterioration thereof even under the severe conditions such as those for the hydrogen sulfide-exposure test because of the presence of a quite thin capping layer. The reflection film may be applied to, for instance, those used for display devices and optics-relating ones.

Owner:ULVAC INC +1

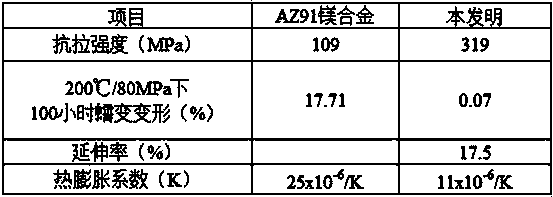

Multielement-reinforced heat-resistant magnesium alloy and manufacturing method thereof

The invention discloses a multielement-reinforced heat-resistant magnesium alloy and a manufacturing method thereof. The multielement-reinforced heat-resistant magnesium alloy is prepared from the following raw materials in parts by weight: 1000 parts of magnesium, 65-85 parts of aluminum, 5-8 parts of zinc, 10-30 parts of yttrium, 1.5-5 parts of manganese, 5-15 parts of neodymium, 3-4 parts of cerium, 1-4 parts of calcium, 0.4-1 part of strontium, 0.1-0.5 part of silicon, 3-6 parts of silver and 10-40 parts of boron carbide. The manufacturing method comprises the following steps: carrying out acid washing, drying and preoxidation on the boron carbide, preheating the materials, smelting the magnesium and aluminum while introducing protective gas, adding an aluminum-manganese alloy and a pure zinc ingot to carry out alloying, adding an aluminum-silver alloy, a magnesium-silicon alloy, a magnesium-yttrium alloy, a magnesium-cerium alloy, a magnesium-neodymium alloy, a magnesium-calcium alloy and a magnesium-strontium alloy, smelting, adding the boron carbide particles for reinforcement, carrying out gas refinement on the melt by using argon, carrying out extrusion casting, and finally, carrying out solid solution aging treatment to obtain the heat-resistant magnesium alloy finished product. The magnesium alloy has excellent comprehensive properties under high-temperature conditions.

Owner:YANGZHOU FENG MING METAL PROD

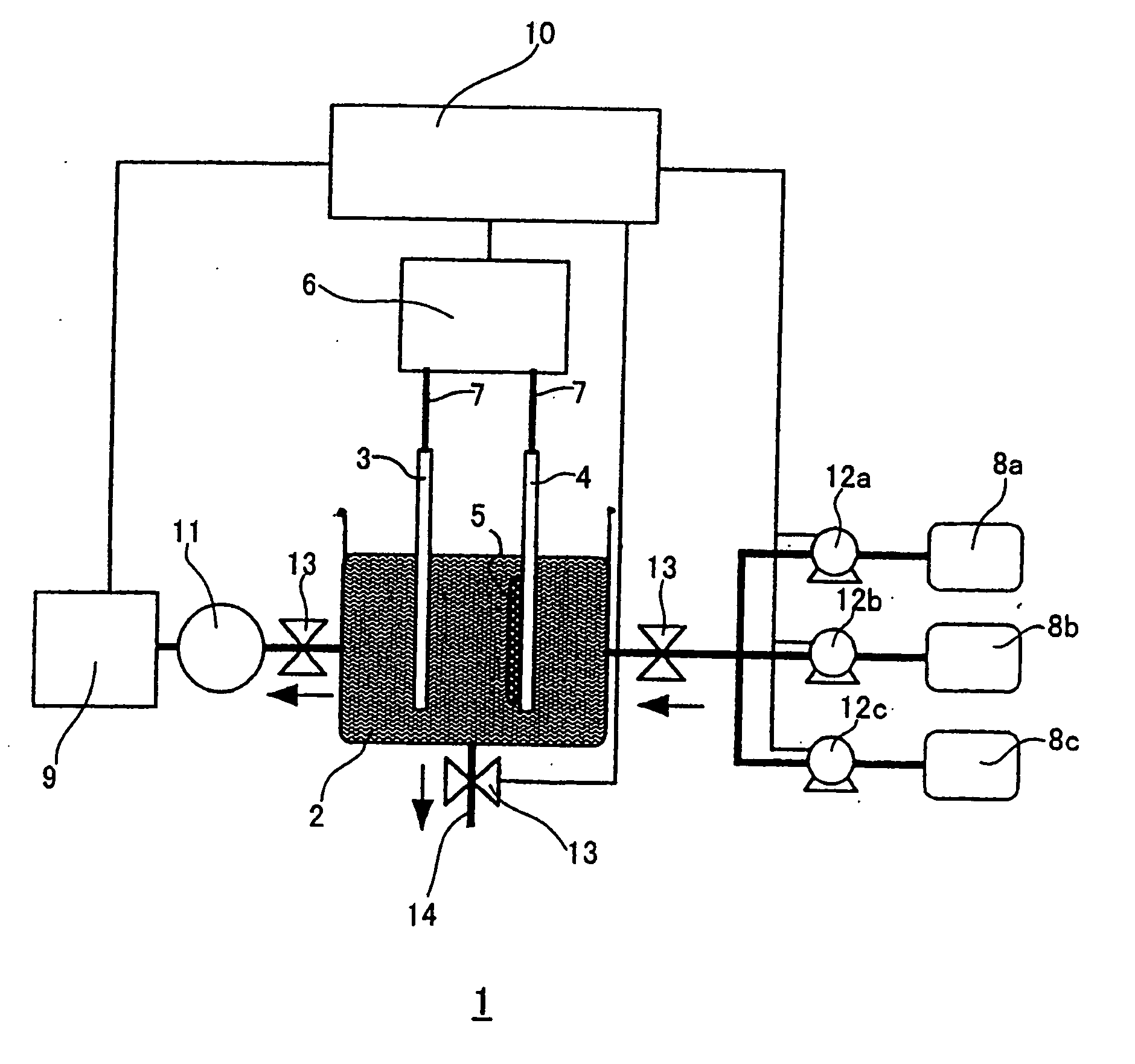

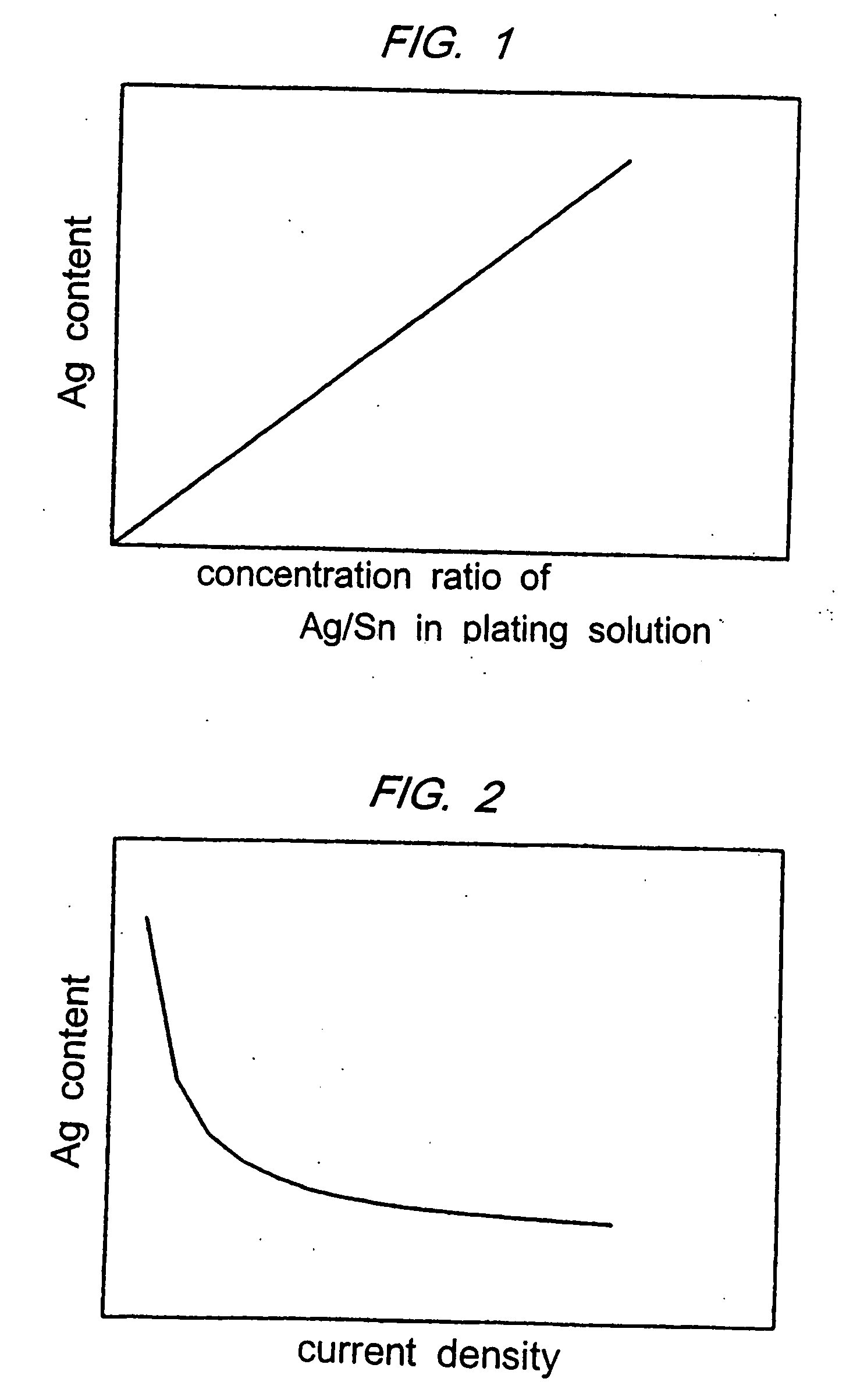

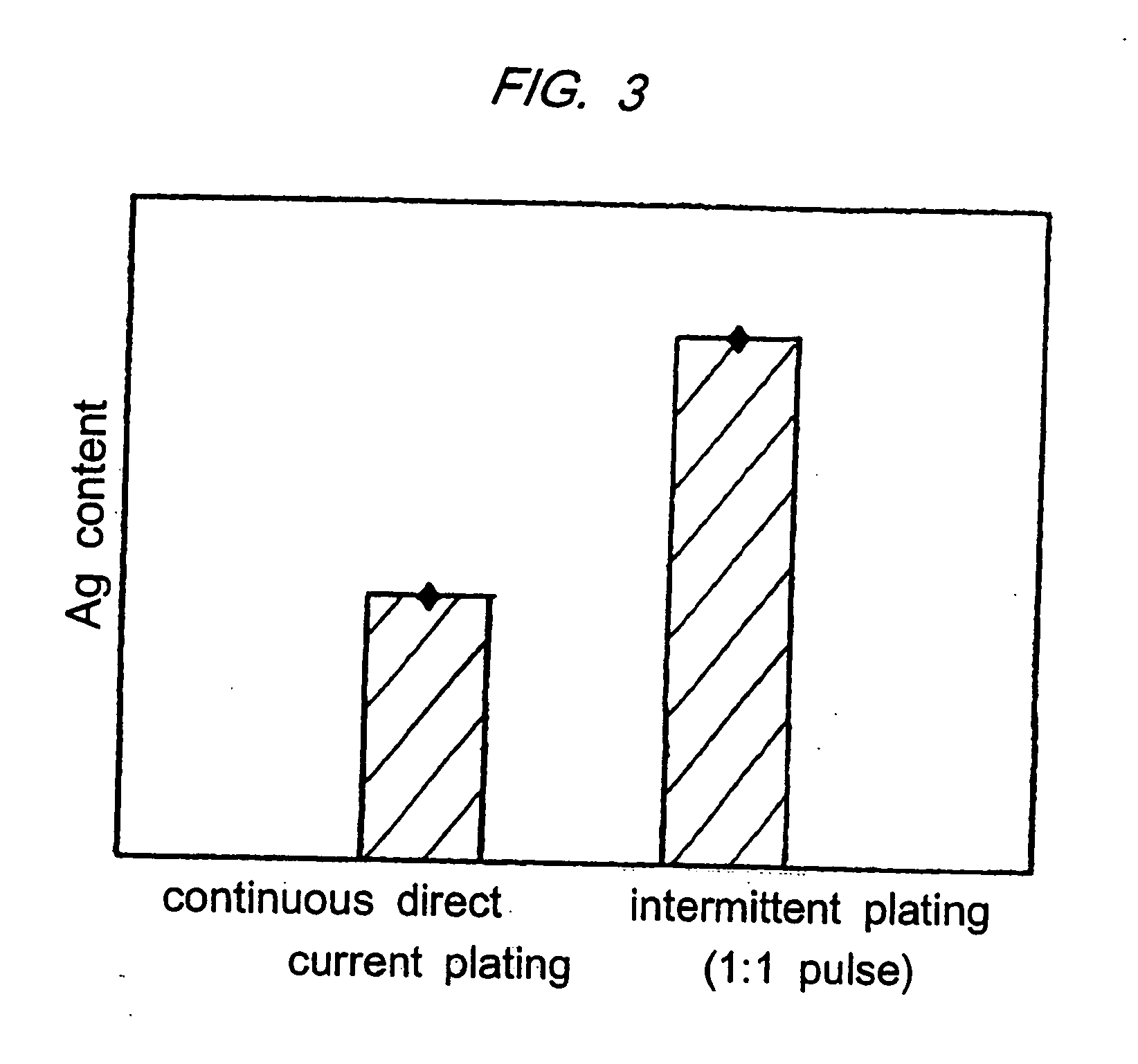

Method of forming a lead-free bump and a plating apparatus therefor

InactiveUS20050279640A1Raise the reflow temperatureCellsPrinted circuit assemblingElectroplatingAg alloy

The present invention relates to a lead-free bump with suppressed formation of voids, obtained by reflowing a plated film of Sn—Ag solder alloy having an adjusted Ag content, and a method of forming the lead-free bump. The lead-free bump of the present invention is obtained by forming an Sn—Ag alloy film having a lower Ag content than that of an Sn—Ag eutectic composition by plating and reflowing the plated alloy film.

Owner:SHIMOYAMA MASASHI +4

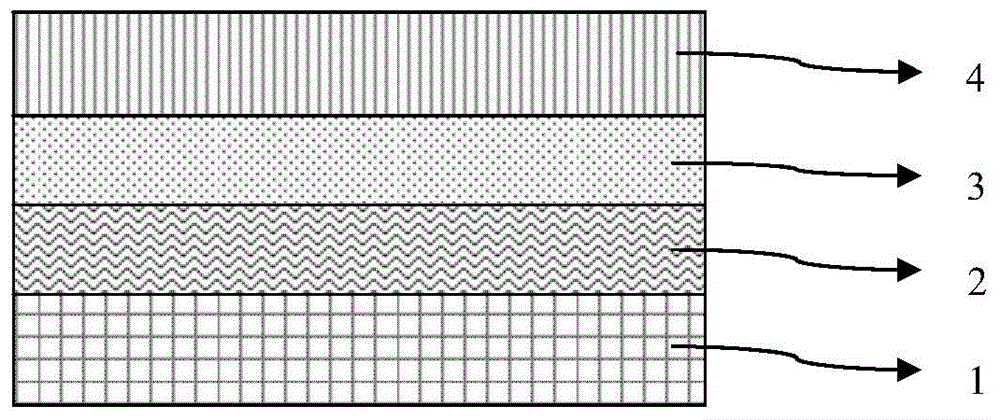

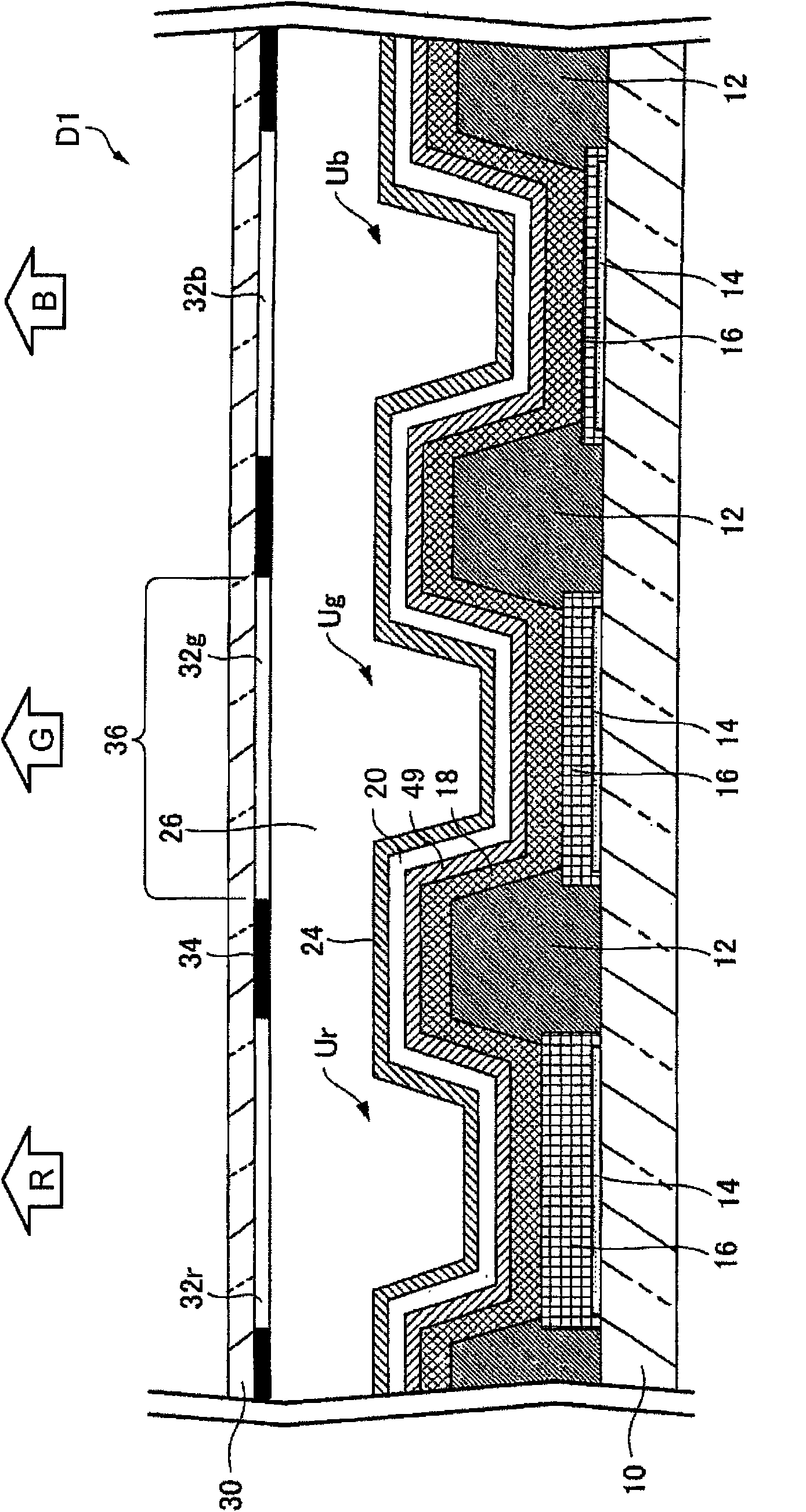

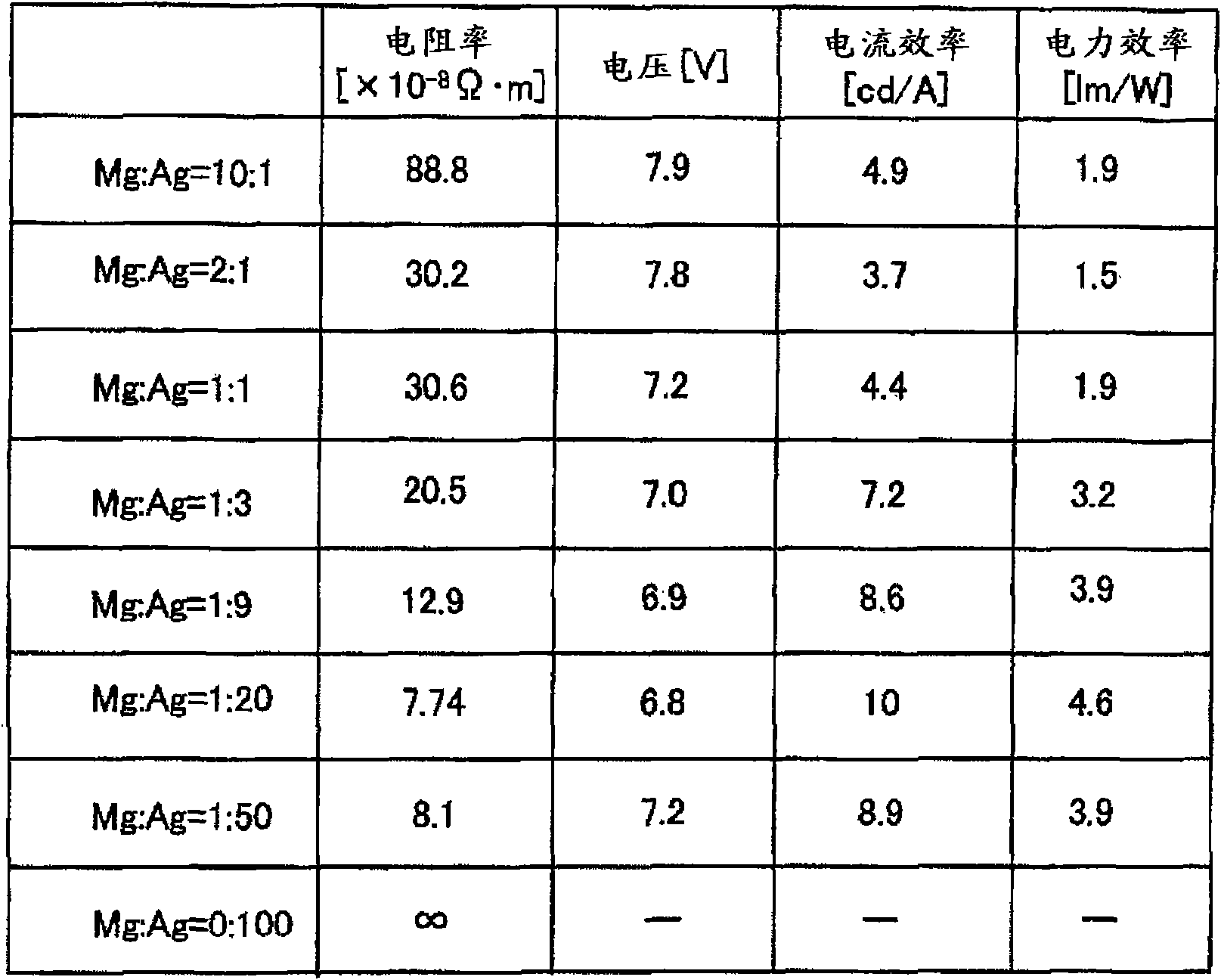

Light-emitting device, electronic equipment, and process of producing light-emitting device

ActiveCN101661997AAvoid time costReduce manufacturing costSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringLight emitting device

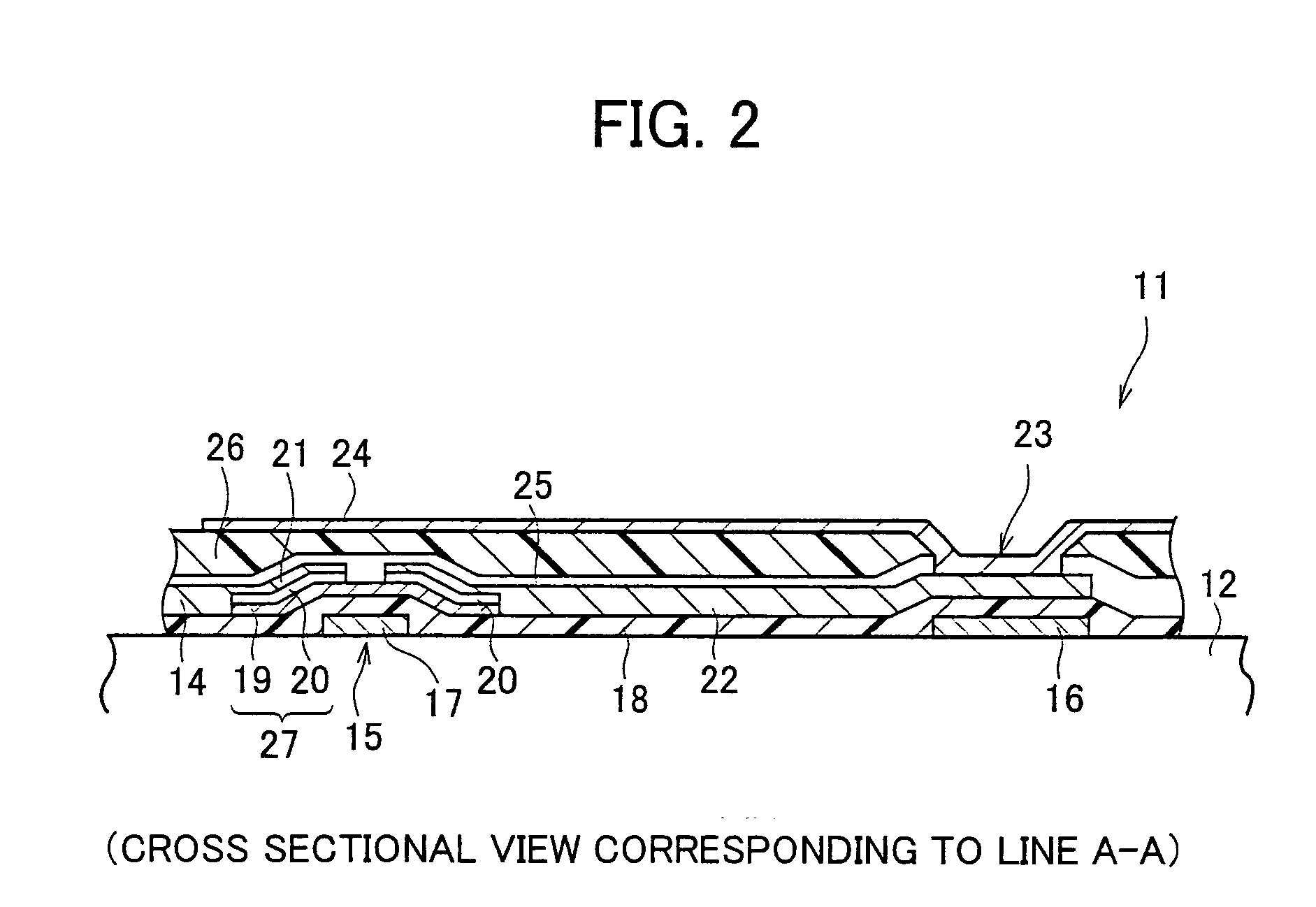

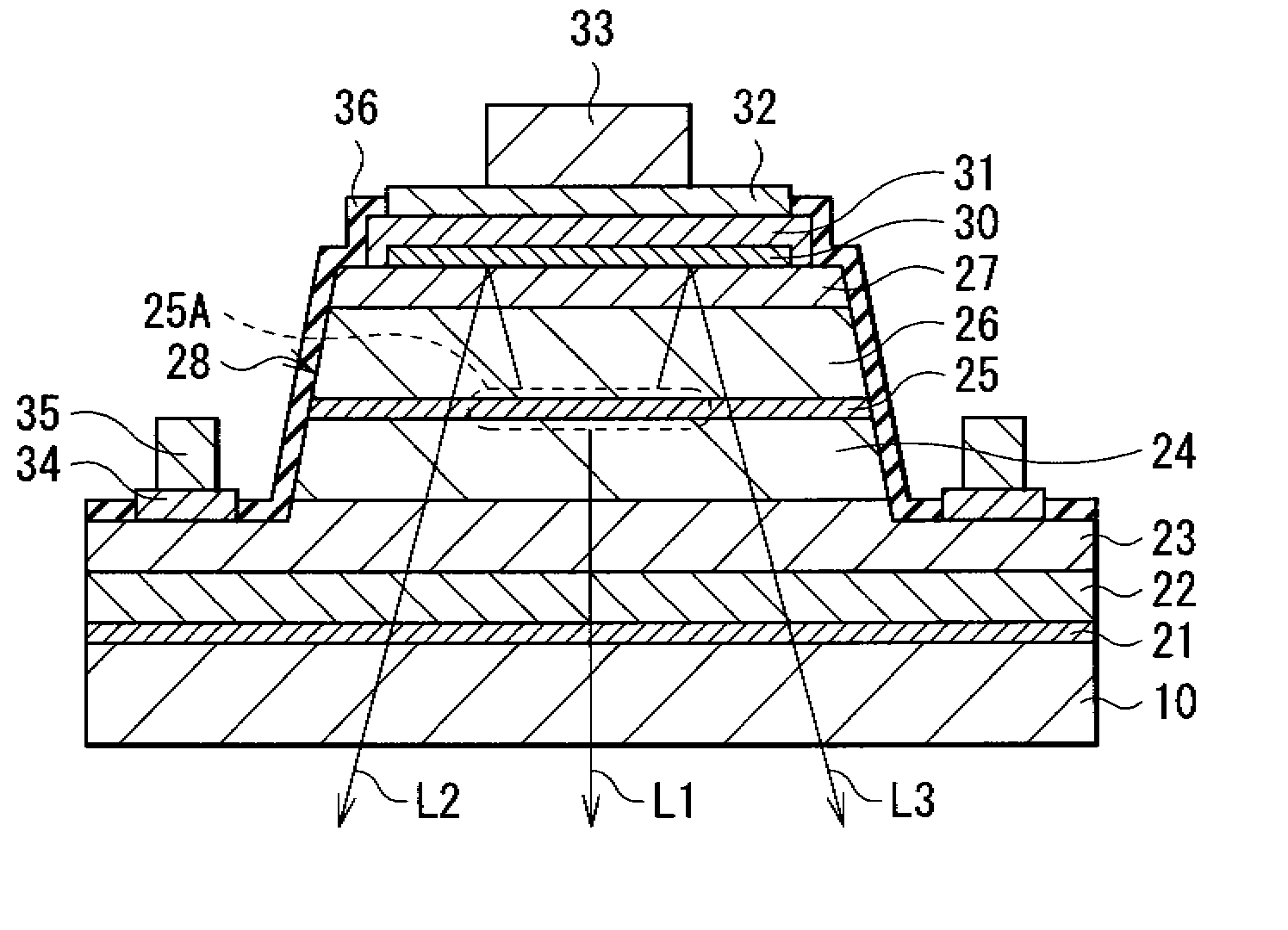

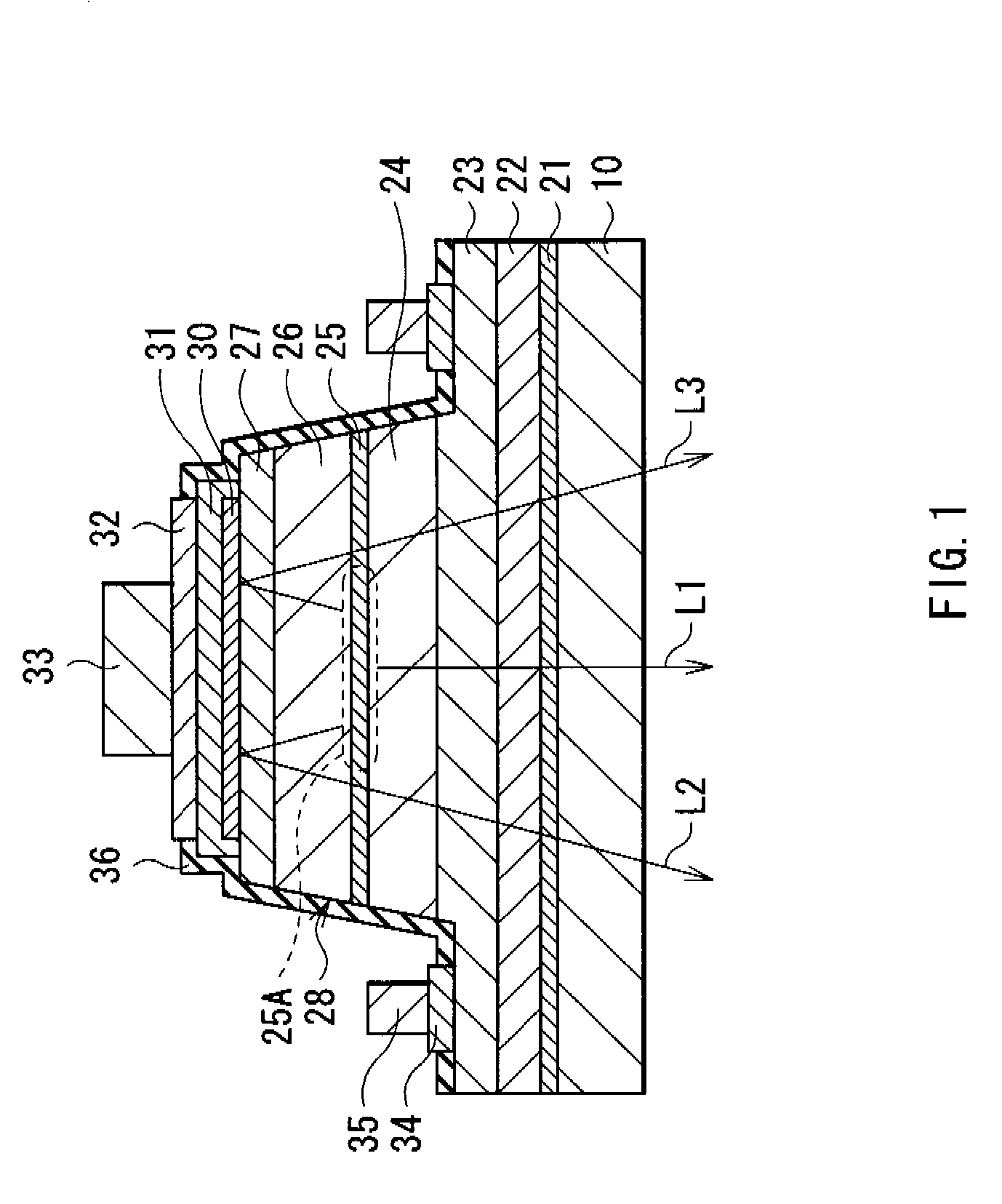

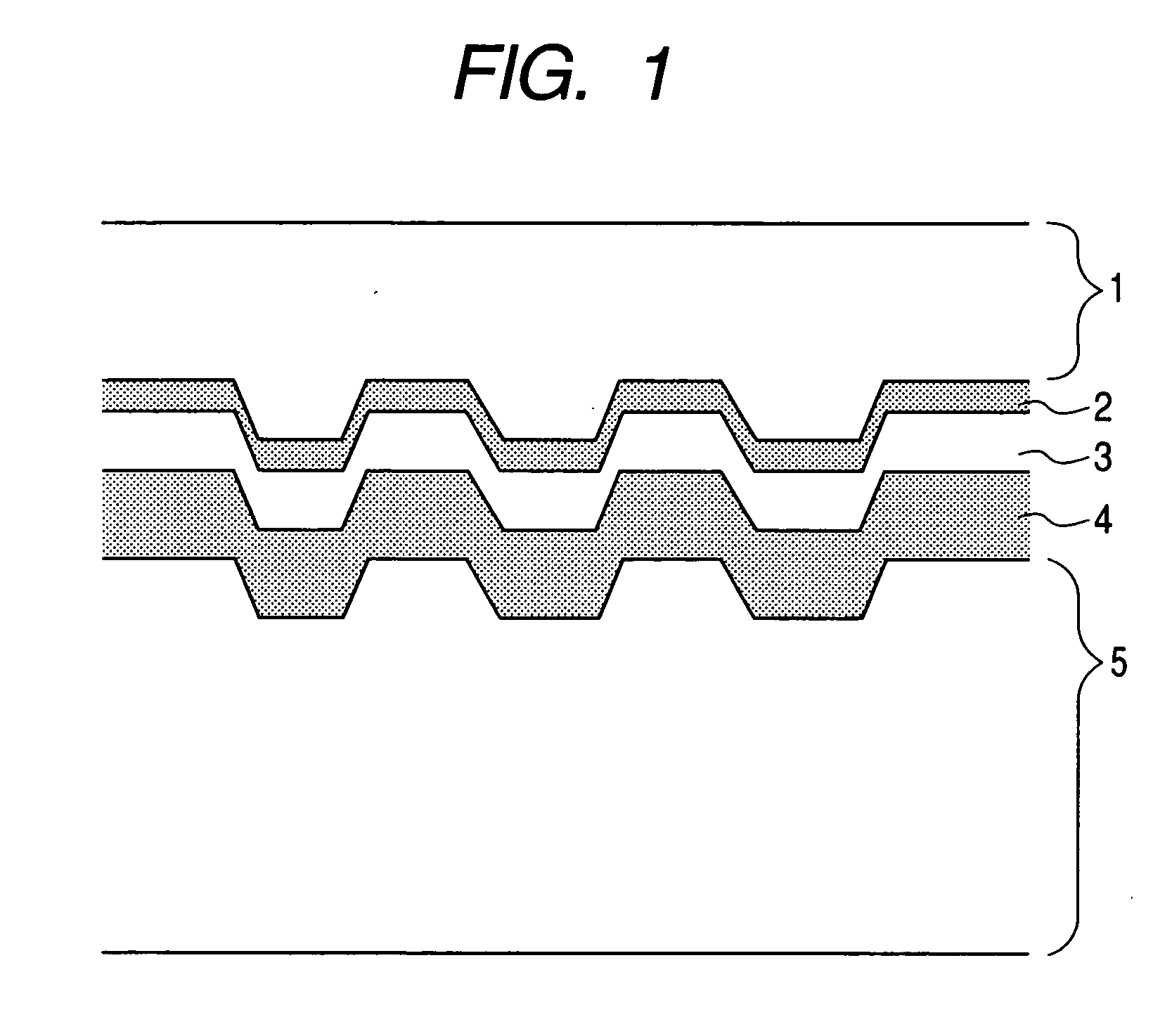

The invention relates to a light-emitting device, an electronic equipment and a process of producing the light-emitting device. The invention is to provide a cathode having both a high electrical conductivity and a high transparency and the light-emitting device having the cathode. The light-emitting device (D1) includes a substrate, a light-reflecting layer (14) formed on the substrate (10), a first electrode (16) disposed on or above the light-reflecting layer (14), a light-emitting function layer (18) disposed on the first electrode (16), and an electron-injection layer (49) disposed on the light-emitting function layer (18) and a second electrode (20) formed on the electron-injection layer (49) having a second electrode (20) with a semi-transparent reflectivity. The second electrode is made of an Ag alloy having an Ag content of from 50% by atoms to 98% by atoms.

Owner:SEIKO EPSON CORP

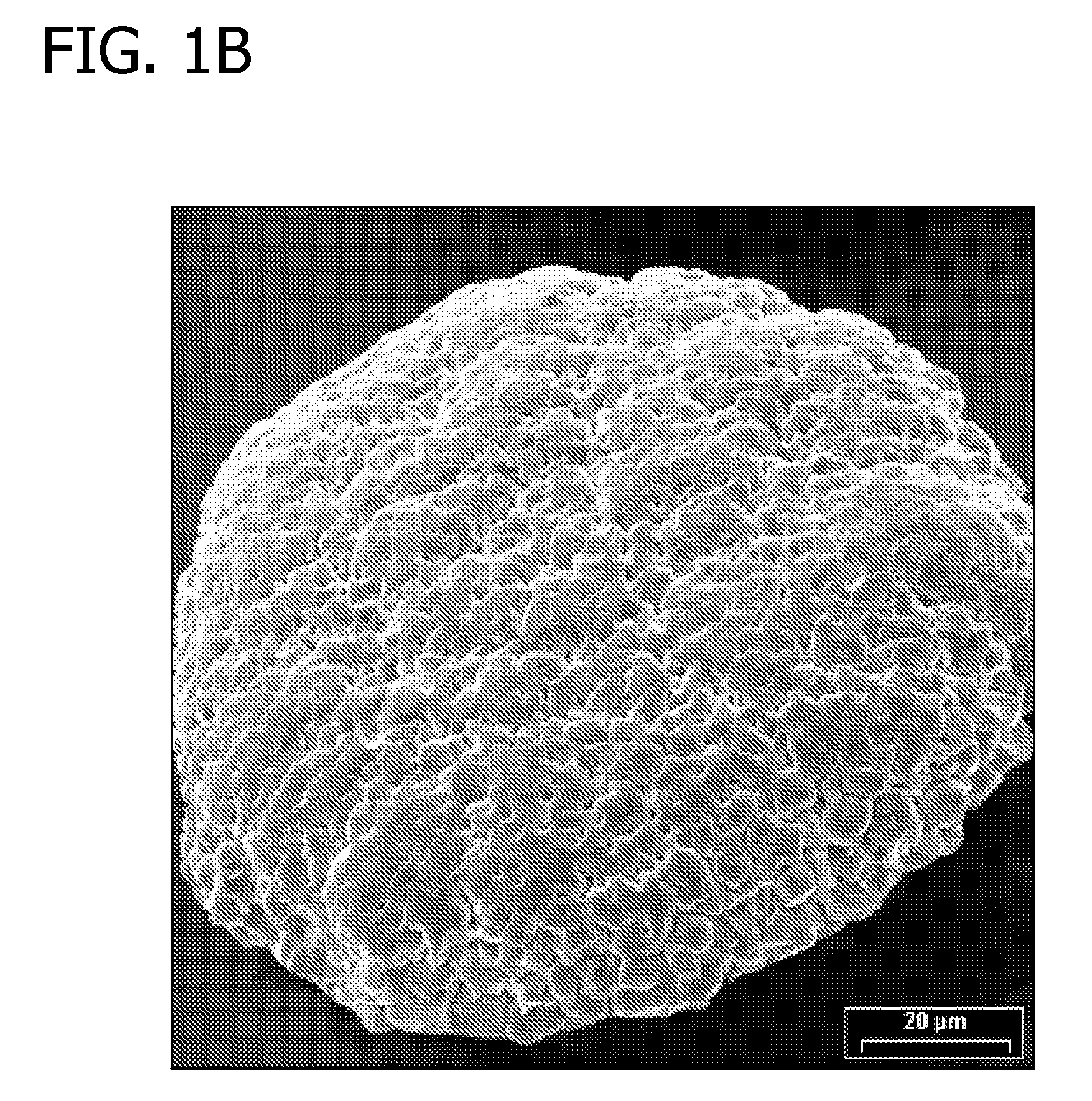

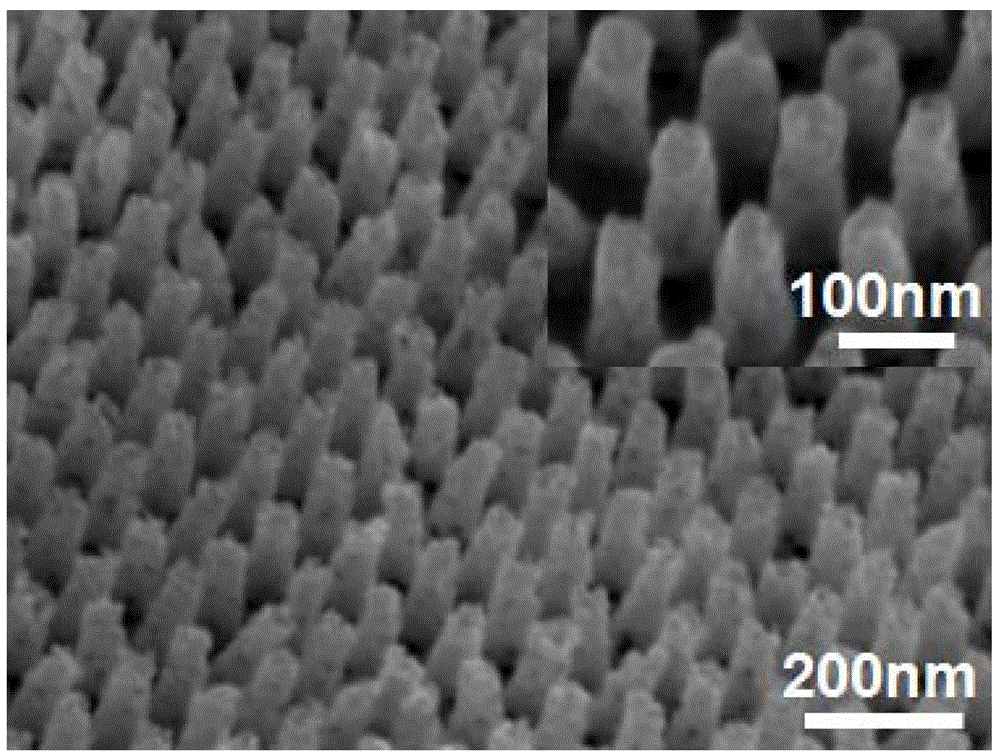

Silver-gold porous nanorod array, preparation method and purpose of silver-gold porous nanorod array

InactiveCN103331440AHigh SERS activityPrevent lodgingMaterial nanotechnologyVacuum evaporation coatingGold nanorodAlloy

The invention discloses a silver-gold porous nanorod array, a preparation method and a purpose of the silver-gold porous nanorod array. The array comprises porous gold nanorods coated with 3-15nm silver films and arranged on a methyl methacrylate substrate coated with a gold film, wherein the nanorods are 150-250nm in length, and 50-70nm in diameter; and holes are 5-20nm in diameter. The method comprises the steps of placing an aluminum oxide template coated with a gold film in a mixed electrolytic solution for electro-deposition, obtaining an aluminum oxide template coated with the gold film and provided with a gold-silver alloy nanorod array deposited in holes, placing the aluminum oxide template in a nitric acid solution for reaction to obtain an aluminum oxide template coated with the gold film and provided with a porous gold nanorod array in holes, coating the other side of the gold film with liquid methyl methacrylate, solidifying, then sequentially placing the aluminum oxide template in a silver nitrate electrolytic solution for the electro-deposition and aqueous alkali for removing the aluminum oxide template, or sequentially placing the aluminum oxide template in aqueous alkali for removing the aluminum oxide template, coating a silver film by an ion sputtering method, and obtaining the objective product. The array can serve as an SERS (Surface Enhanced Raman Scattering) activity substrate for detecting trace organic matters.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Bonding wire and process for manufacturing a bonding wire

InactiveUS20150322586A1Improve consistencyAvoid large deviationMolten spray coatingSingle bars/rods/wires/strips conductorsIridiumPlatinum

A bonding wire comprises a core wire generally made of silver or a silver alloy, and the coating material is selected from one or more of: gold, palladium, platinum, rhodium. Alternatively, the core wire is generally made of copper or a copper alloy, and the coating material is selected from one or more of: palladium, platinum, rhodium, iridium, ruthenium. For both core wires, the coating material can be selected from a group of materials with the following characteristics: (1) the materials' melting temperature is higher than the melting temperature of the core wire material, respectively; (2) the materials' molten surface tension is higher than that of the core wire material, respectively; (3) the materials show a high resistance to oxide formation between the melting temperature of the core wire material and the melting temperature of the respective material itself; and (4) the coating material has the additional characteristic that the material's melting temperature is lower than the boiling temperature of the core wire material.

Owner:MICROBONDS INC

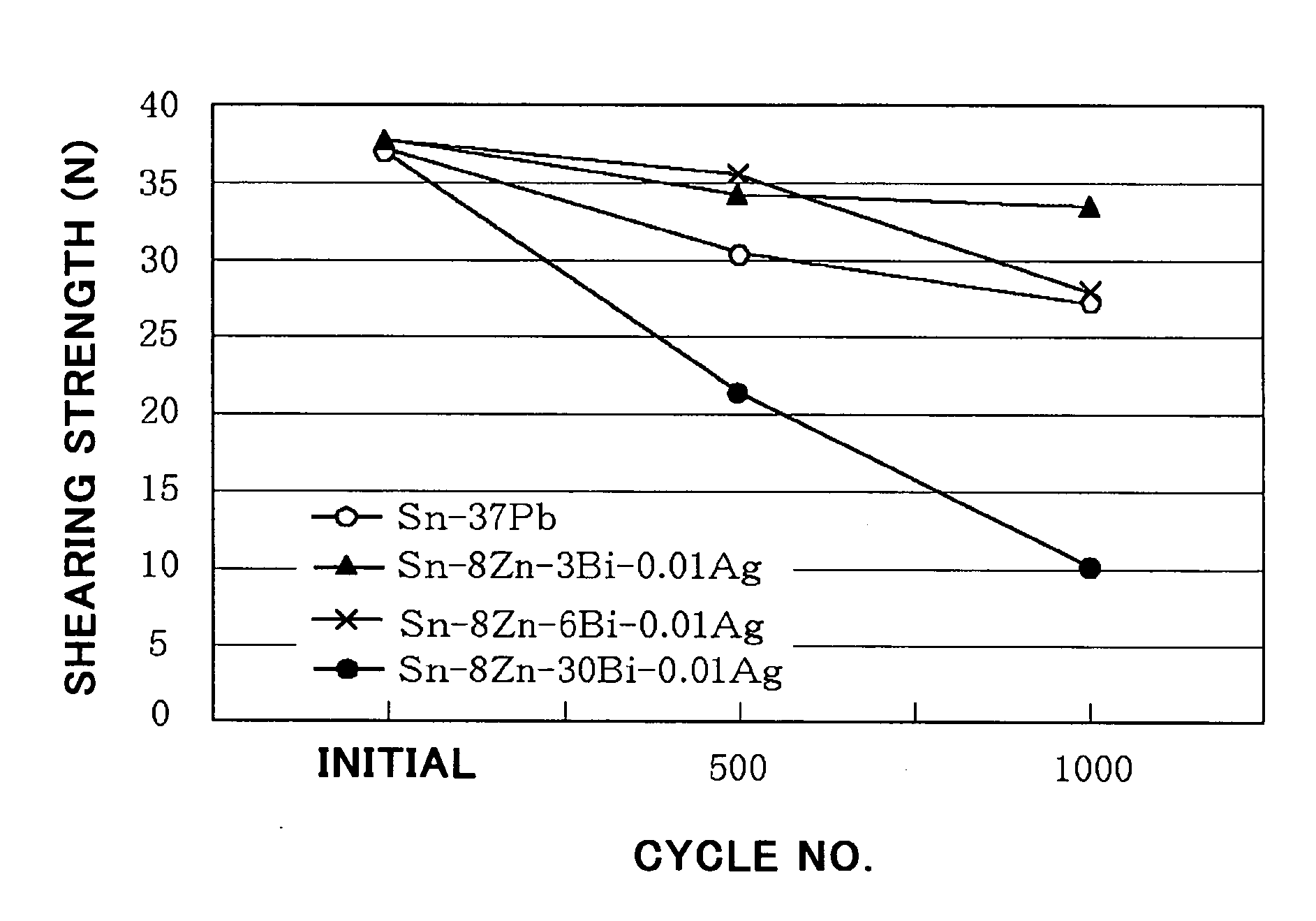

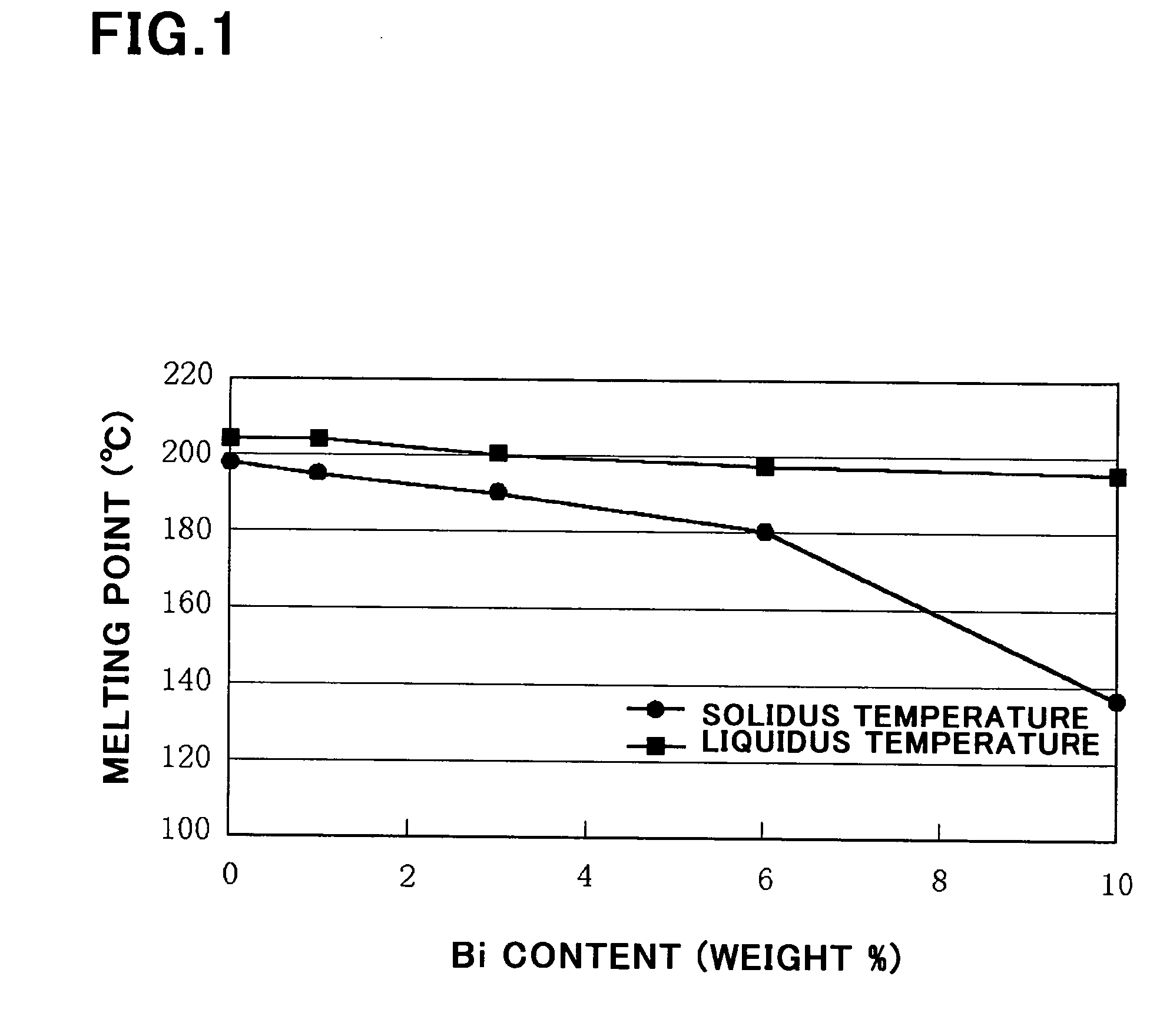

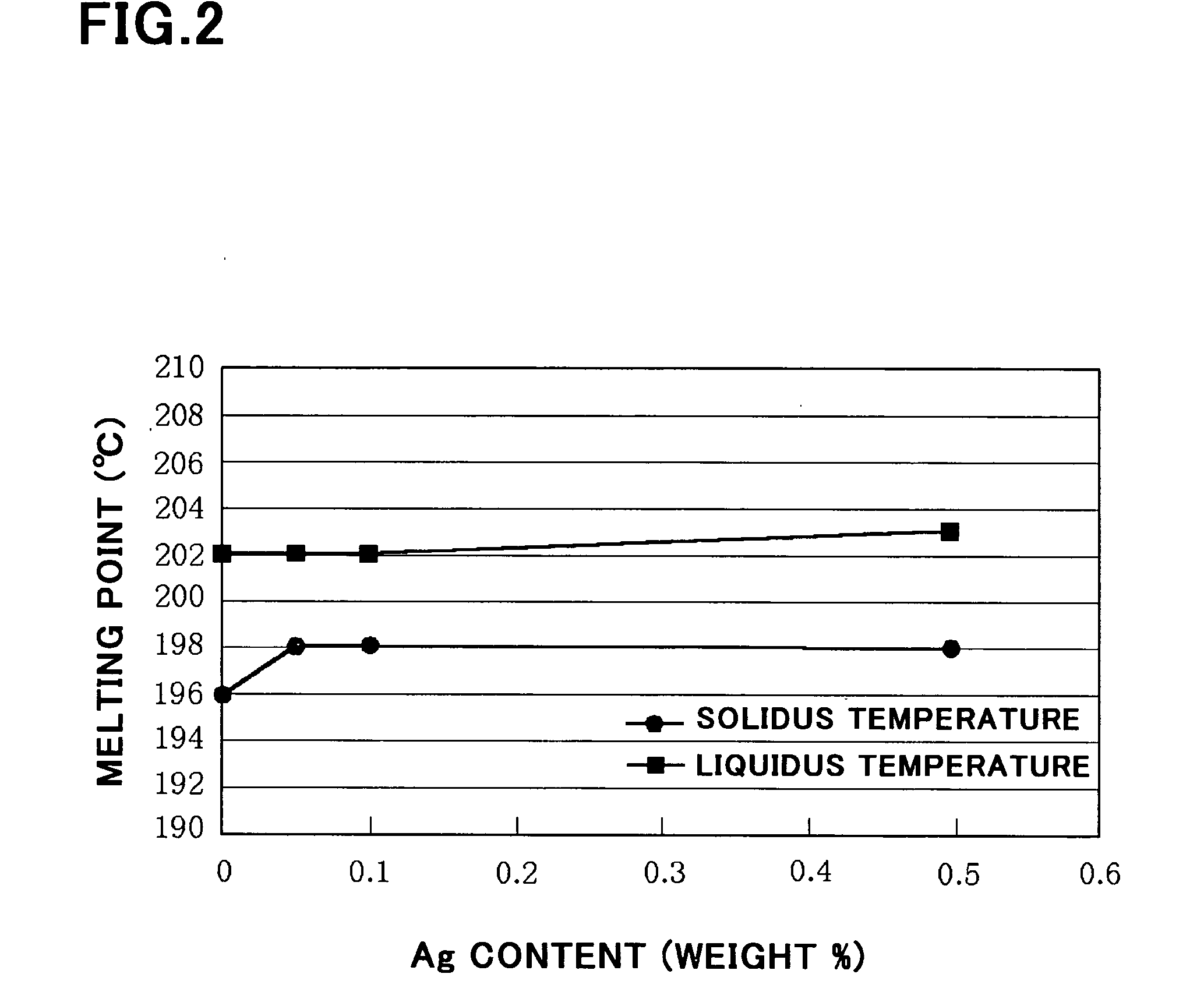

Solder and packaging therefrom

InactiveUS20060011702A1Not to damageLow liquidus temperaturePrinted circuit assemblingWelding/cutting media/materialsZincBismuth

The solder contains Sn—Zn alloy(s) having a single composition ratio or a plurality of composition ratios, and Sn—Bi—Ag alloy(s) having a single composition ratio or a plurality of composition ratios. The solder includes zinc at 7 to 10 weight % both inclusive, bismuth at 0.001 to 6 weight % both inclusive, silver at 0.001 to 0.1 weight % both inclusive, and the remainder of tin when the alloys are melted in mixture.

Owner:NEC CORP

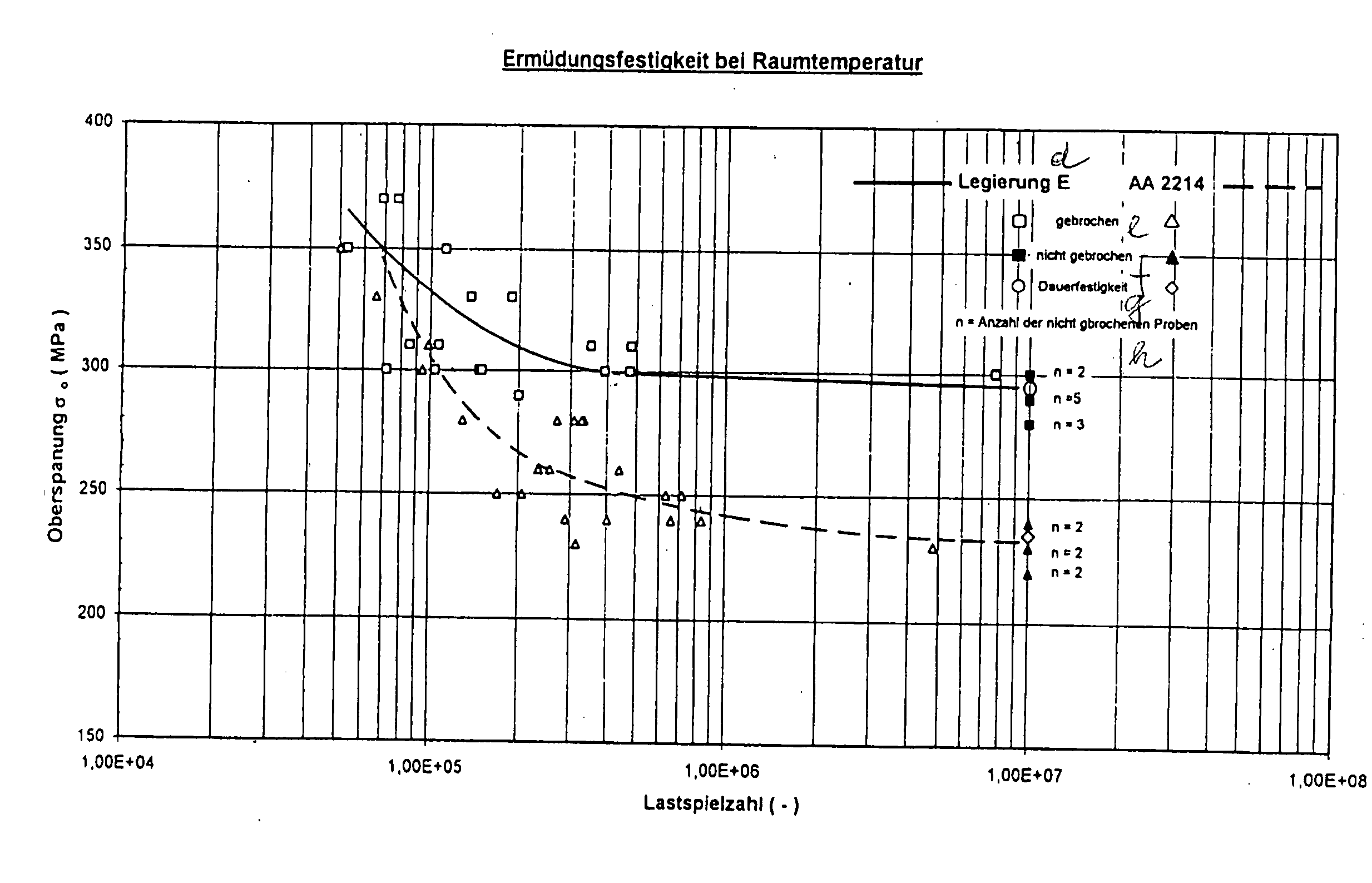

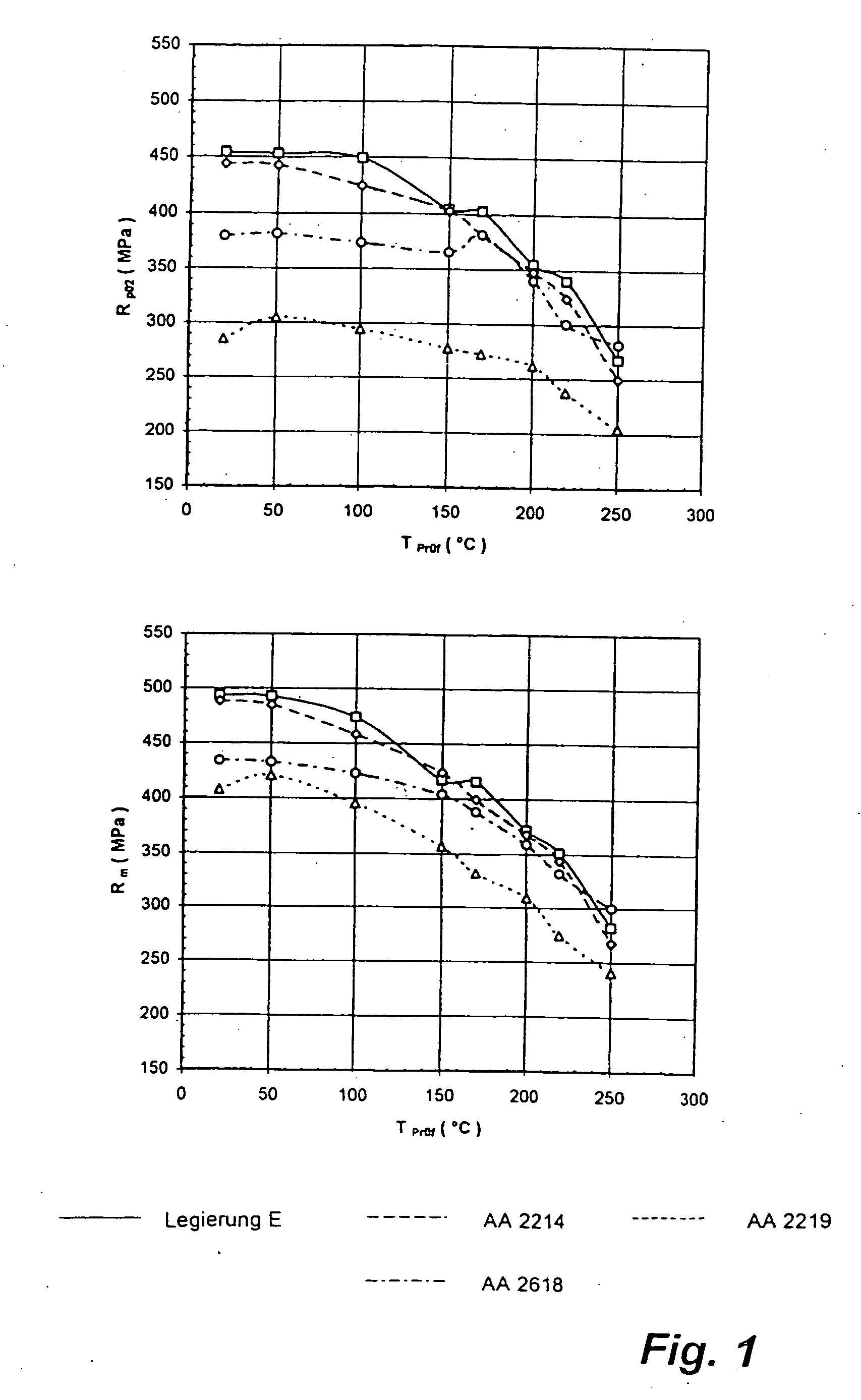

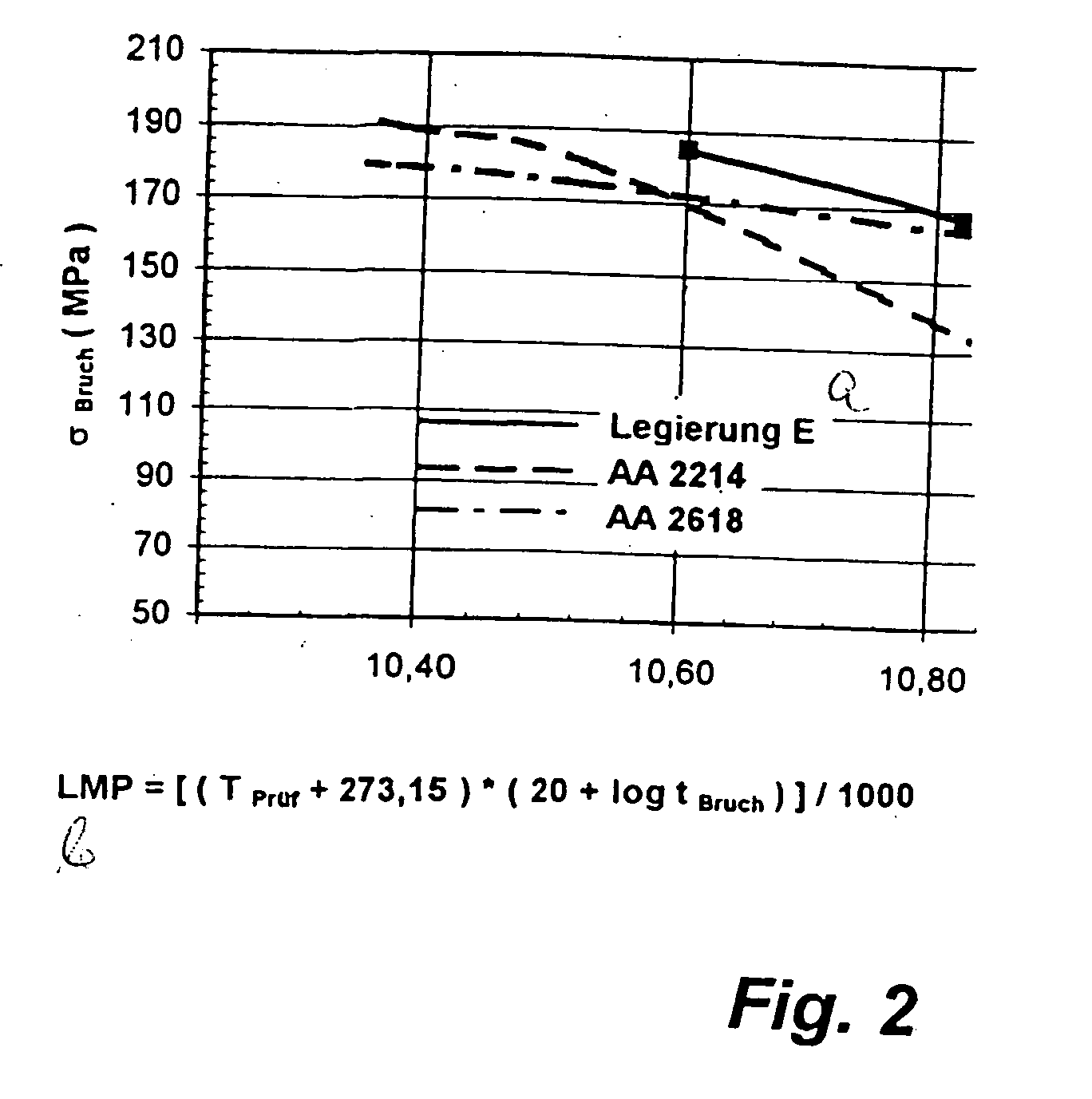

Al/cu/mg/ag alloy with si, semi-finished product made from such an alloy and method for production of such a semi-finished product

An Al / Cu / Mg / Mn alloy for the production of semi-finished products with high static and dynamic strength properties has the following composition: 0.3-0.7 wt % silicon (Si), max. 0.15 wt. % iron (Fe), 3.5-4.5 wt % copper (Cu), 0.1-0.5 wt. % manganese (Mn), 0.3-0.8 wt. % magnesium (Mg), 0.5-0.15 wt % titanium (Ti), 0.1-0.25 wt % zirconium (Zr), 0.3-0.7 wt. % silver (Ag), max. 0.05 wt. % others individually, max 0.15 wt. % others globally, the remaining wt. % aluminum (Al). The invention further relates to a semi-finished product made for such an alloy and a method of production of a semi-finished product made for such an alloy.

Owner:FA OTTO FUCHS

Method for manufacturing cu-ag alloy wire and cu-ag alloy wire

InactiveCN101791638AExcellent productivityImprove productivityCoaxial cables/analogue cablesConcentric cablesProduction rateCoaxial cable

Owner:SUMITOMO ELECTRIC IND LTD

Ag ALLOY REFLECTIVE FILM FOR OPTICAL INFORMATION RECORDING MEDIUM, OPTICAL INFORMATION RECORDING MEDIUM AND Ag ALLOY SPUTTERING TARGET FOR FORMING Ag ALLOY REFLECTIVE FILM FOR OPTICAL INFORMATION RECORDING MEDIUM

InactiveUS20070141296A1Low powerExcellent in mark shapeRecord carriersSynthetic resin layered productsRecording mediaAg alloy

The invention relates to an Ag alloy reflective film for an optical information recording medium, including Ag as a main component, at least one kind of Nd, Gd, Y and Sm in a total amount of more than 0.1 atomic percent and not more than 3.0 atomic percent and at least one kind of W, Mo, V, Zr, Nb and Cr in a total amount of 3.0 to 10.0 atomic percent; an Ag alloy reflective film for an optical information recording medium, including Ag as a main component, at least one kind of Nd, Gd, Y and Sm in a total amount of more than 0.1 atomic percent and not more than 3.0 atomic percent and at least one kind of Ti and Ta in a total amount of 5.0 to 10.0 atomic percent; an optical information recording medium including the Ag alloy reflective film; and an Ag alloy sputtering target having a composition same as that of the Ag alloy reflective film.

Owner:KOBE STEEL LTD +1

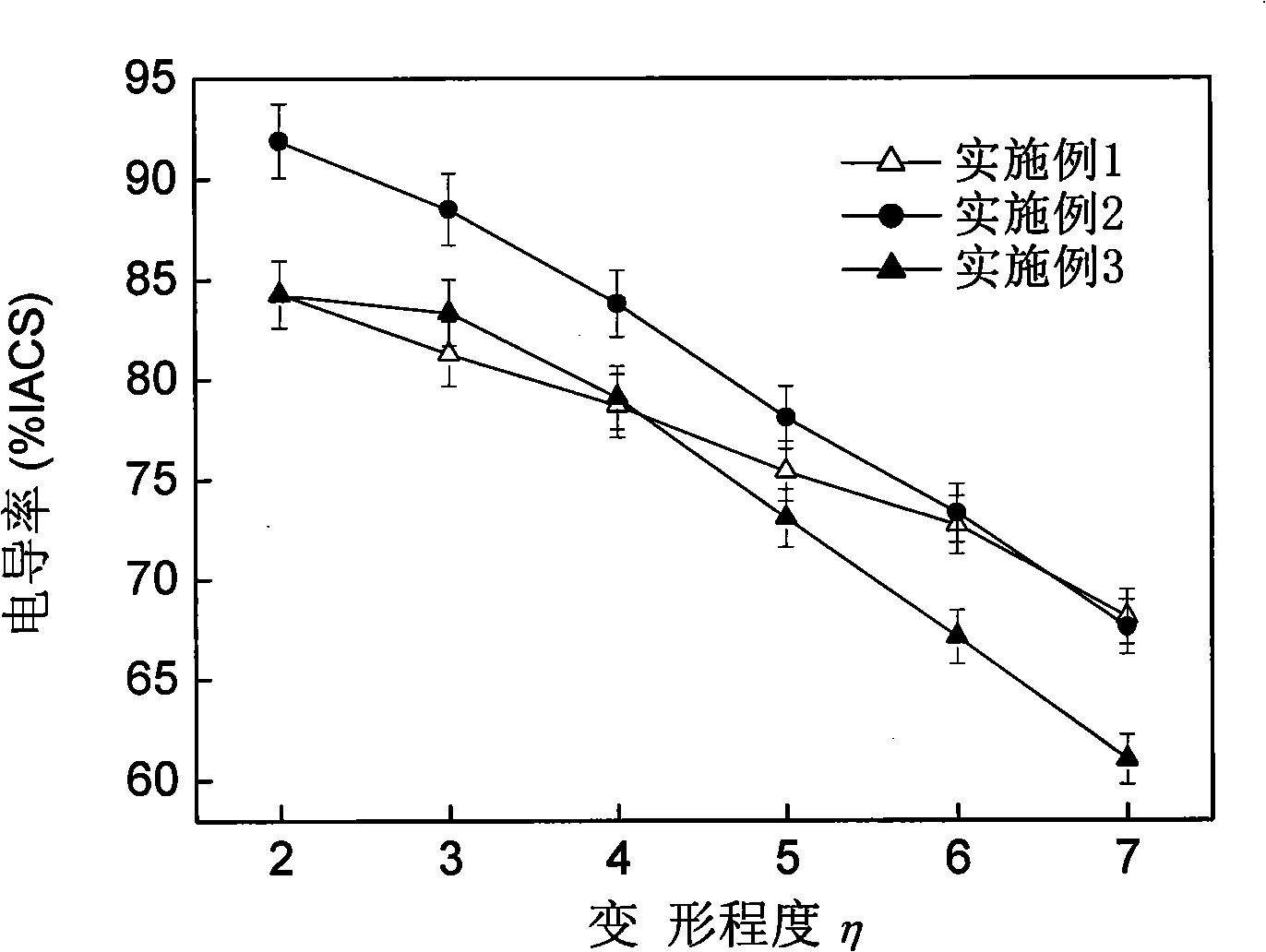

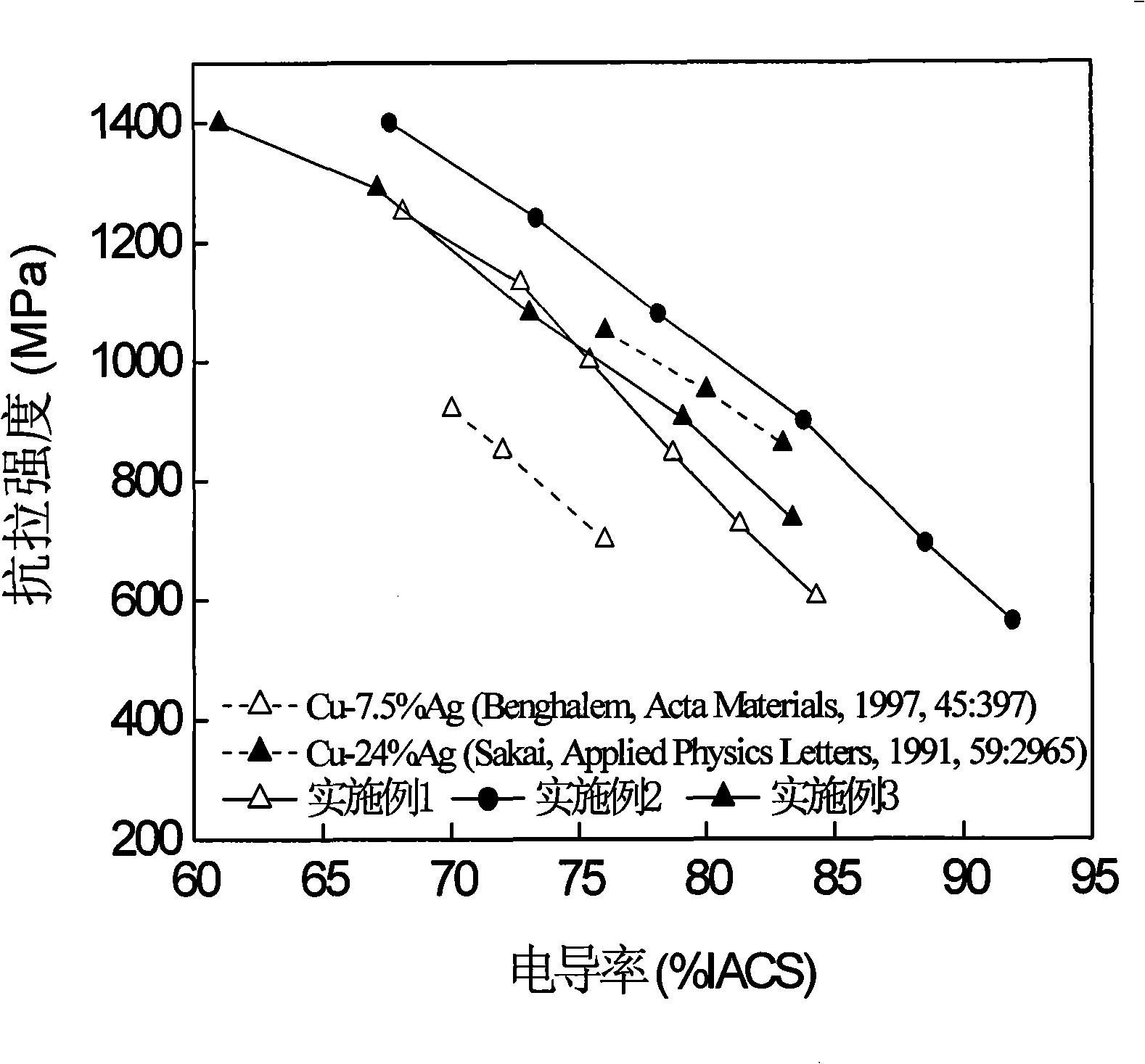

Solid solution and aging treatment method for cooperating Cu-Ag alloy cold drawing processing

The invention discloses a method for solution treatment and aging treatment which are matched with the processing of Cu-Ag alloy cold-finish drawing. A mixture with 7%-12% of Ag by weight and the rest of electrolytic Cu is melted in a vacuum induction furnace and carries out ingoting under the protection of Ar gas, the solution treatment and the aging treatment are carried out to the ingot, and the drawing deformation is carried out several times at the normal temperature. The fiber-phase composite strengthened Cu-(7-12)% Ag alloy obtained by matching the solution treatment and the aging treatment with the deformation processing has the strength of 380-1400MPa and the relative conductivity of (60-92)% IACS. The method simplified the technological process and the combination property of the alloy is close to or even exceeds the alloy with high Ag-content.

Owner:ZHEJIANG UNIV

Fastness and hard silver alloy

The invention discloses a fastness and hard silver alloy comprising 92.5-98.0% metal silver by weight and 2.0-7.5% other components by weight, the other components contain 0.02-7.5% germanium by weight, 0.1-7.5% copper by weight, 0.2-4.0% tin by weight, 0.01-0.5% samarium by weight, 0-5.0% indium by weight, 0-0.05% boron by weight, 0-5.0% zinc by weight, 0-1.0% manganese by weight, 0-1.5% nickel by weight, 0-0.1% silicon by weight, and 0-0.09% zirconium by weight. The silver alloy of the invention has a high rigidity and a fastness performance, can be used for producing jewelry, coins, silver dishwares, medals, etc.

Owner:HONG KONG PRODUCTIVITY COUNCIL

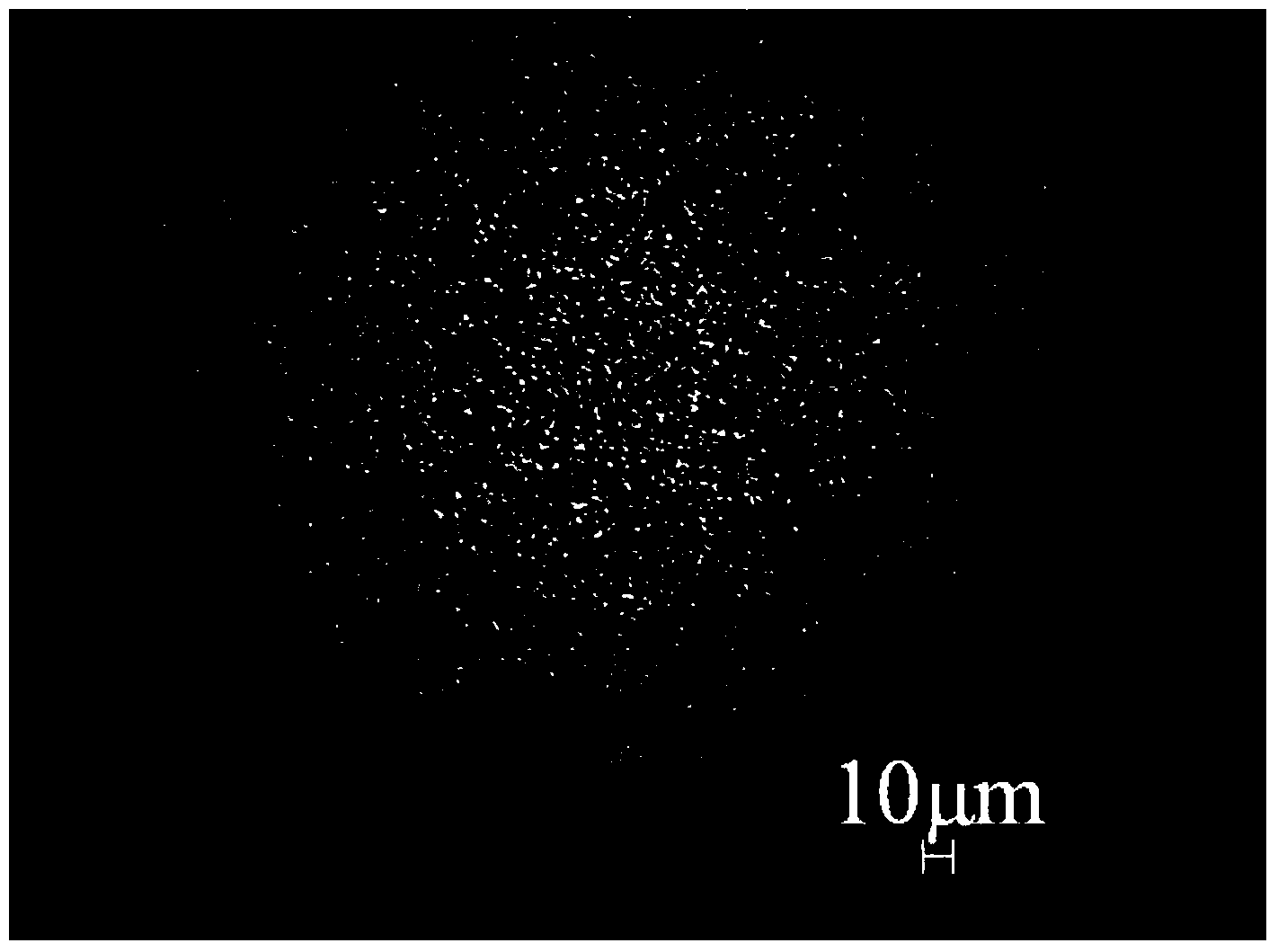

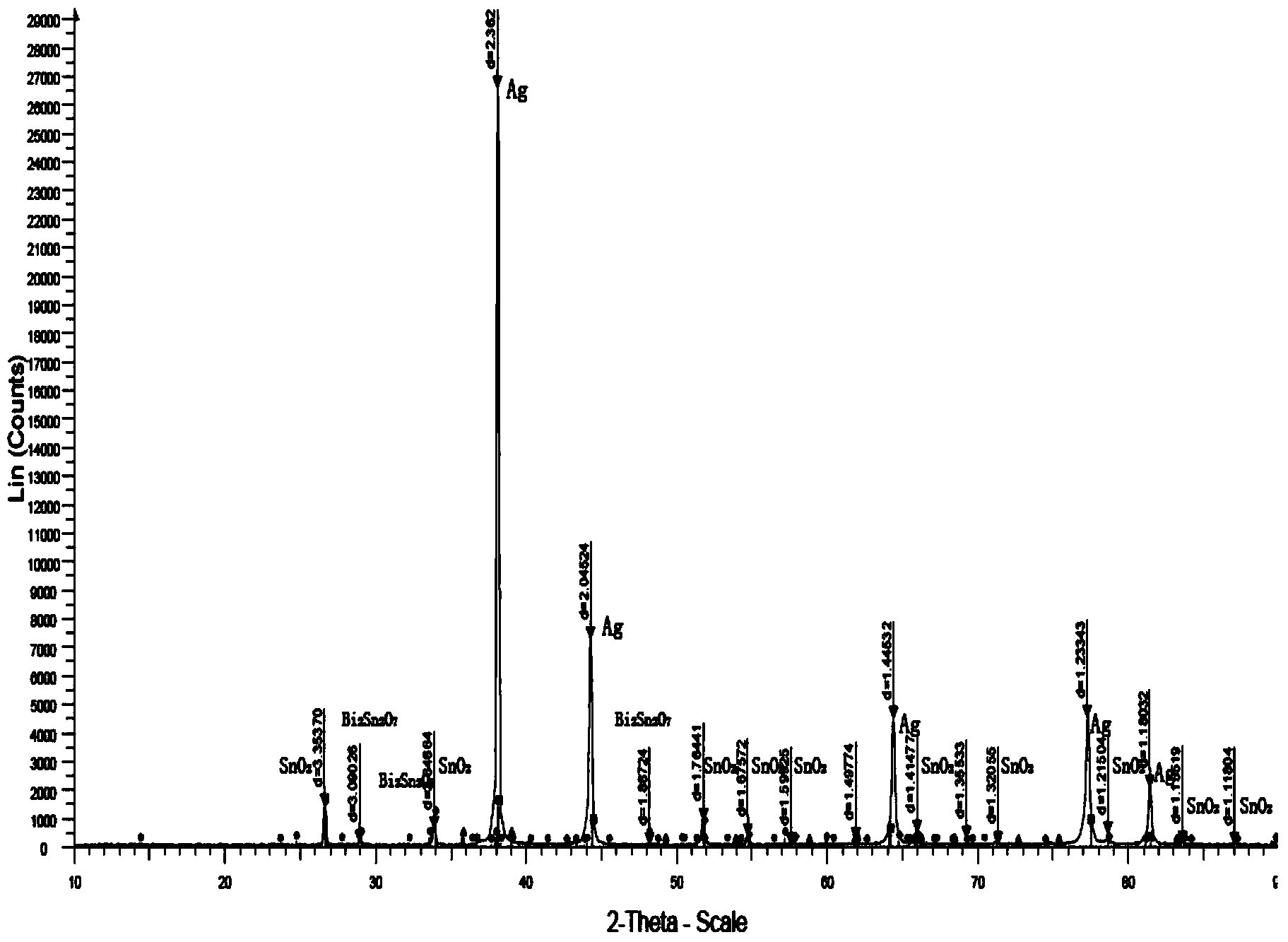

Preparation method for flaky AgSnO2 contact

ActiveCN103643074AGuaranteed uniformity of distributionGuaranteed uniformityCable/conductor manufactureIngotMetal

The invention discloses a preparation method for a flaky AgSnO2 contact. The method comprises the following steps of smelting 0.2 to 2 mass percent of metal additive and the balance of Ag in an intermediate-frequency smelting furnace to form a molten alloy, and performing atomization to prepare Ag alloy powder; mixing the Ag alloy powder with SnO2 powder in a three-dimensional mixer, and mixing the mixture in a V-shaped mixer to obtain mixed AgSnO2 powder; preparing an ingot blank from the mixed AgSnO2 powder according to a conventional method, sintering the ingot blank at high temperature in an oxygen-containing atmosphere, and performing hot extrusion and hot-rolling bonding to obtain a composite AgSnO2 / Ag strip; performing cold rolling, finish rolling and press forming on the composite AgSnO2 / Ag strip to obtain the required flaky AgSnO2 contact. The flaky AgSnO2 contact prepared by the method has the advantages of uniform distribution of SnO2 particles and a trace of additive, stable electrical properties and the like, and a process is simple and suitable for batch production.

Owner:桂林金格电工电子材料科技有限公司

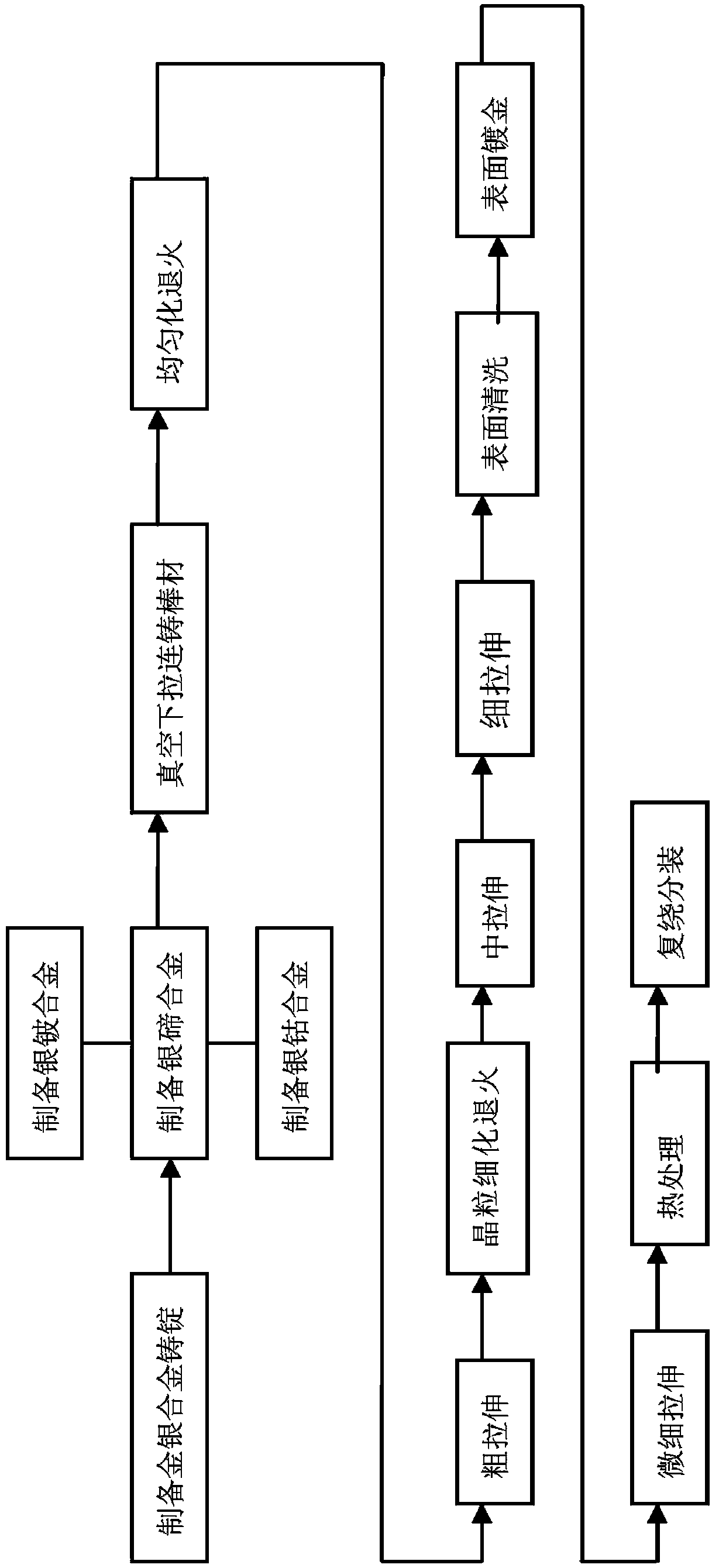

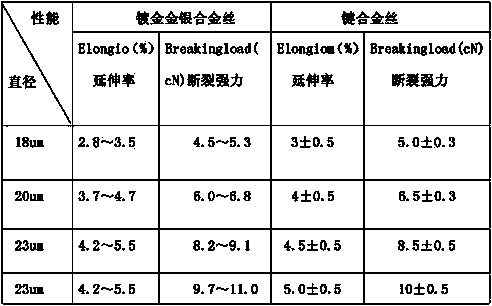

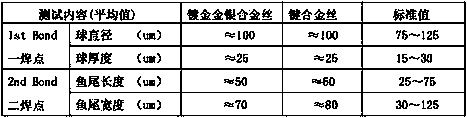

Gold and silver alloy bonding wire with gold-plated layer on surface and preparation method thereof

ActiveCN103474408AReduce packaging costsDense materialSemiconductor/solid-state device detailsSolid-state devicesOxidation resistantElectronic packaging

The invention belongs to the technical field of metal bonding wires used for microelectronic packaging, and particularly relates to a gold and silver alloy bonding wire with a gold-plated layer on the surface and a preparation method of the gold and silver alloy bonding wire. The gold and silver alloy bonding wire is good in push-pull effort, oxidation resistance and bonding performance and low in cost, and the gold-plated layer is arranged on the surface of the gold and silver alloy bonding wire. The gold and silver alloy bonding wire with the gold-plated layer on the surface comprises a gold and silver alloy wire and is structurally characterized in that a gold protective layer is arranged on the surface of the gold and silver alloy wire.

Owner:辽宁凯立尔电子科技有限公司

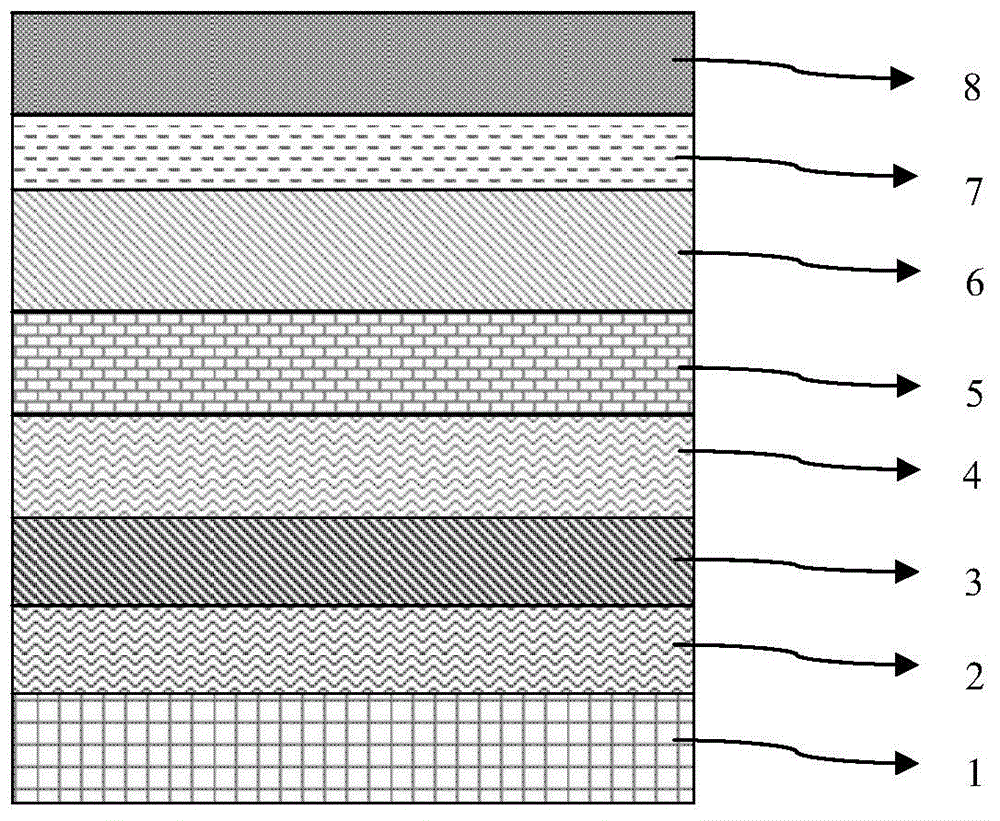

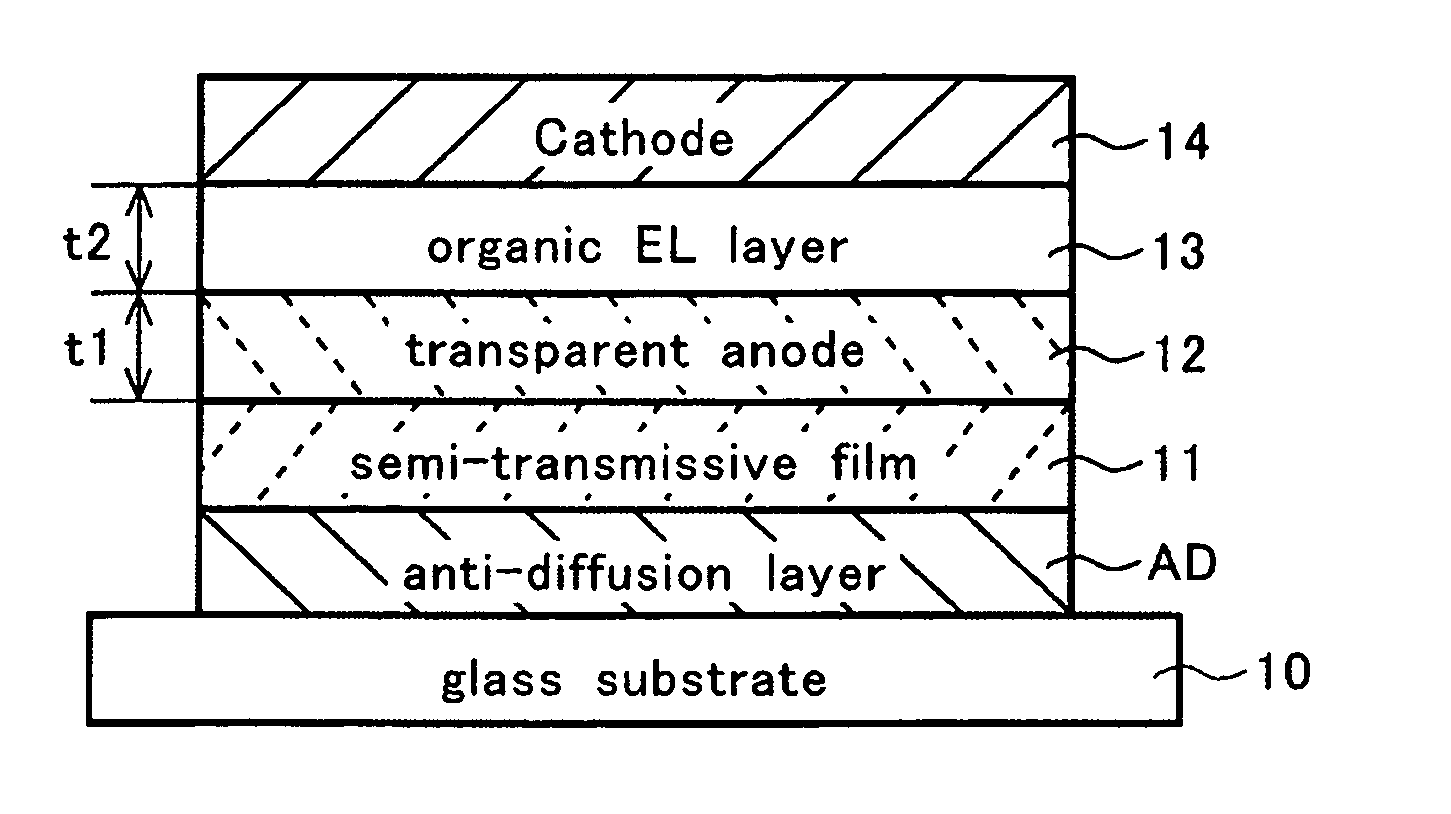

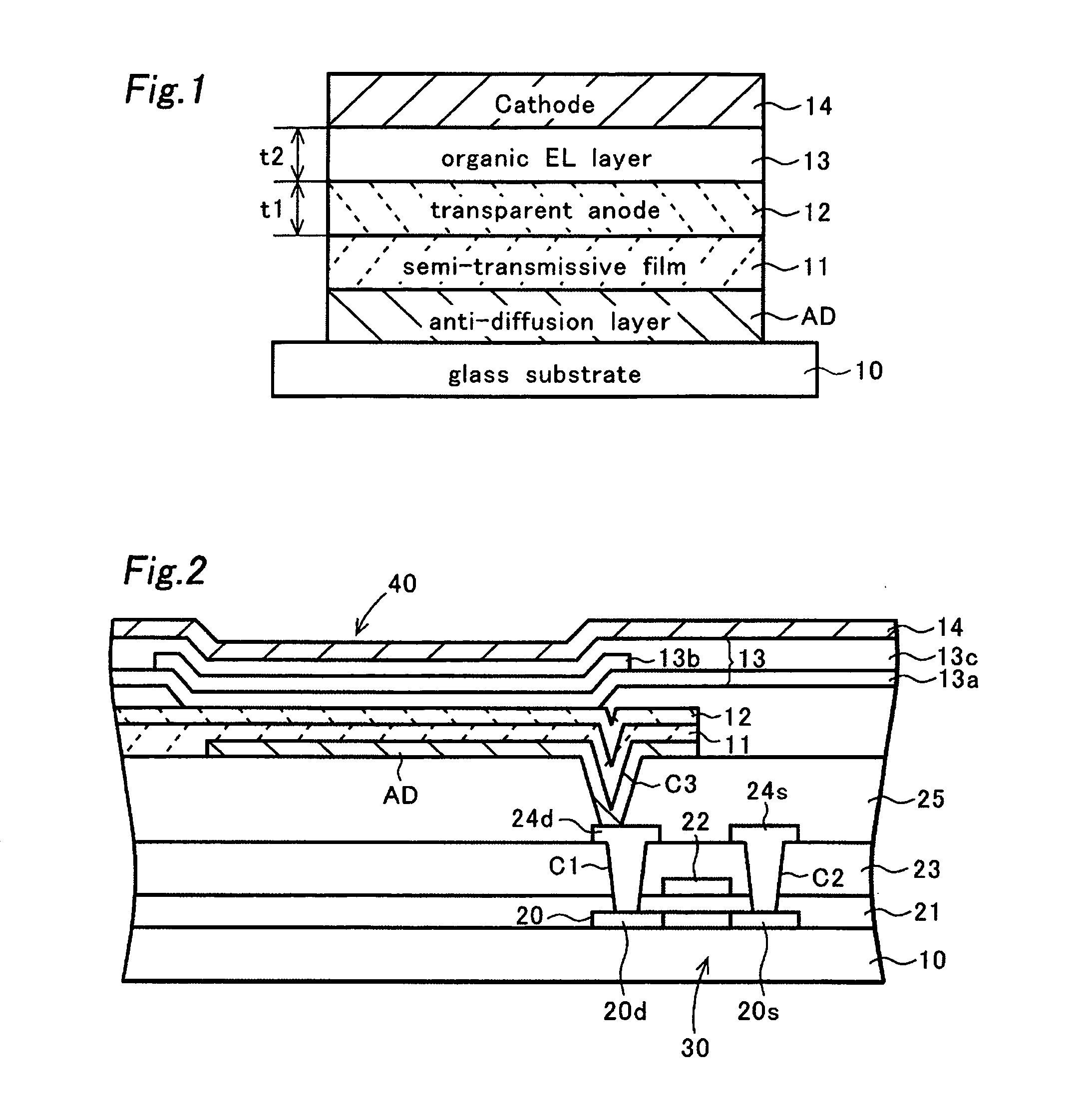

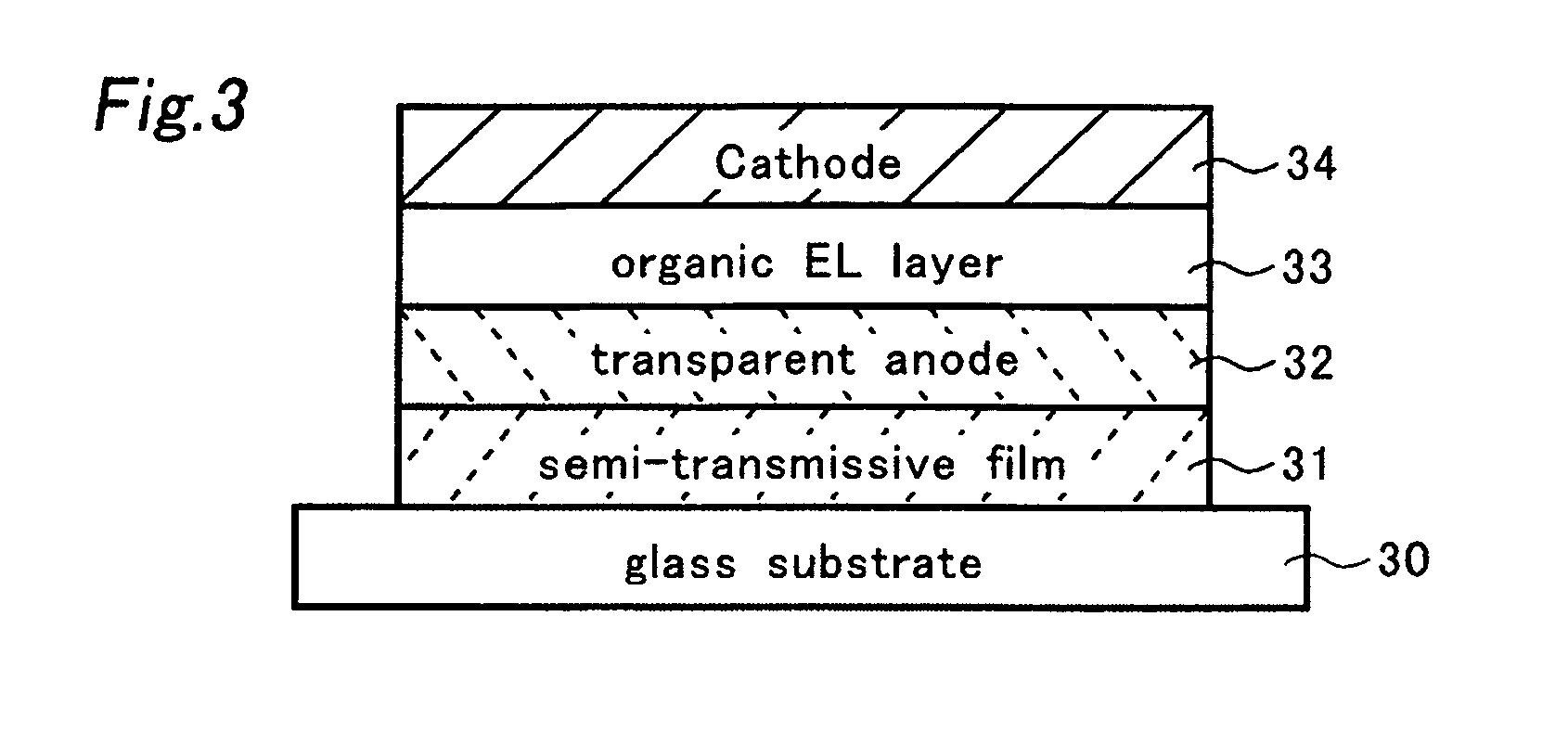

Organic electroluminescent device

InactiveUS20050088081A1Minimize diffusionDischarge tube luminescnet screensElectroluminescent light sourcesOrganic electroluminescenceHole transport layer

This invention provides an organic EL device of optical resonator type where diffusion of an Ag material caused by heat generated in a manufacturing process and while light is being emitted is minimized so as to stabilize characteristics of a driving TFT. In the organic EL device of optical resonator type of the invention, an anti-diffusion layer (made of ITO or IZO) connected with the driving TFT (not shown) is formed on a glass substrate, and a semi-transmissive film (made of an Ag alloy layer) having a predetermined film thickness enabling semi-transmission of light, a transparent anode (an electrode made of ITO or IZO), an organic EL layer (e.g. made of a hole transport layer, an emissive layer, and an electron transport layer), and a cathode (made of an Ag alloy layer) serving as a reflection film having a predetermined film thickness enabling reflection of light are formed on the anti-diffusion layer in this order. The anti-diffusion layer inhibits thermal diffusion of the Ag material of the semi-transmissive film.

Owner:SANYO ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com