Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

146results about How to "Improve conductivity stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

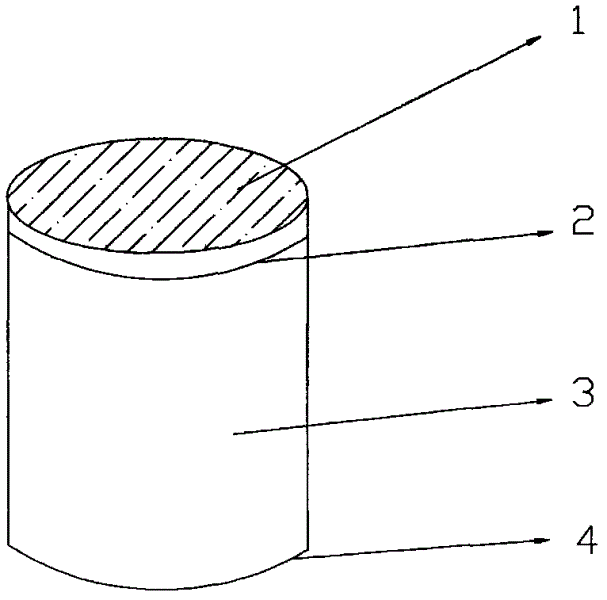

Rubber conductive particle and preparation method thereof

ActiveCN102623196AImprove conductivity and stabilityEasy thicknessContact materialsMetal layered productsTotal thicknessLaser cutting

The invention provides a rubber conductive particle, comprising a rubber base material and metal plated film on the surface of the particle. The metal plated film can comprise one layer or a plurality of layers, and has a total thickness of 0.05mum to 1mm. The rubber conductive particle has a cylindrical shape or a platform shape, has a cross section of a circular shape, an elliptical shape, or a polygon shape, and has a cross section diameter of 1mm to 10mm. The preparation method of the rubber conductive particle comprises: first preparing a rubber sheet material with moulding, injecting, extruding, or calendering methods; then plating the metal plated film on the surface of the rubber sheet material by employing plating technique; and carrying out punching, shearing or laser cutting on the sheet material to obtain the rubber conductive particle. The rubber conductive particle of the invention is characterized by good conductivity of metal coating, thin thickness of the coating, reduction of raw material consumption, low manufacturing cost, and no pollution basically, and can be used as a conduction contact component of a push-button circuit board.

Owner:NANTONG MEMTECH TECH

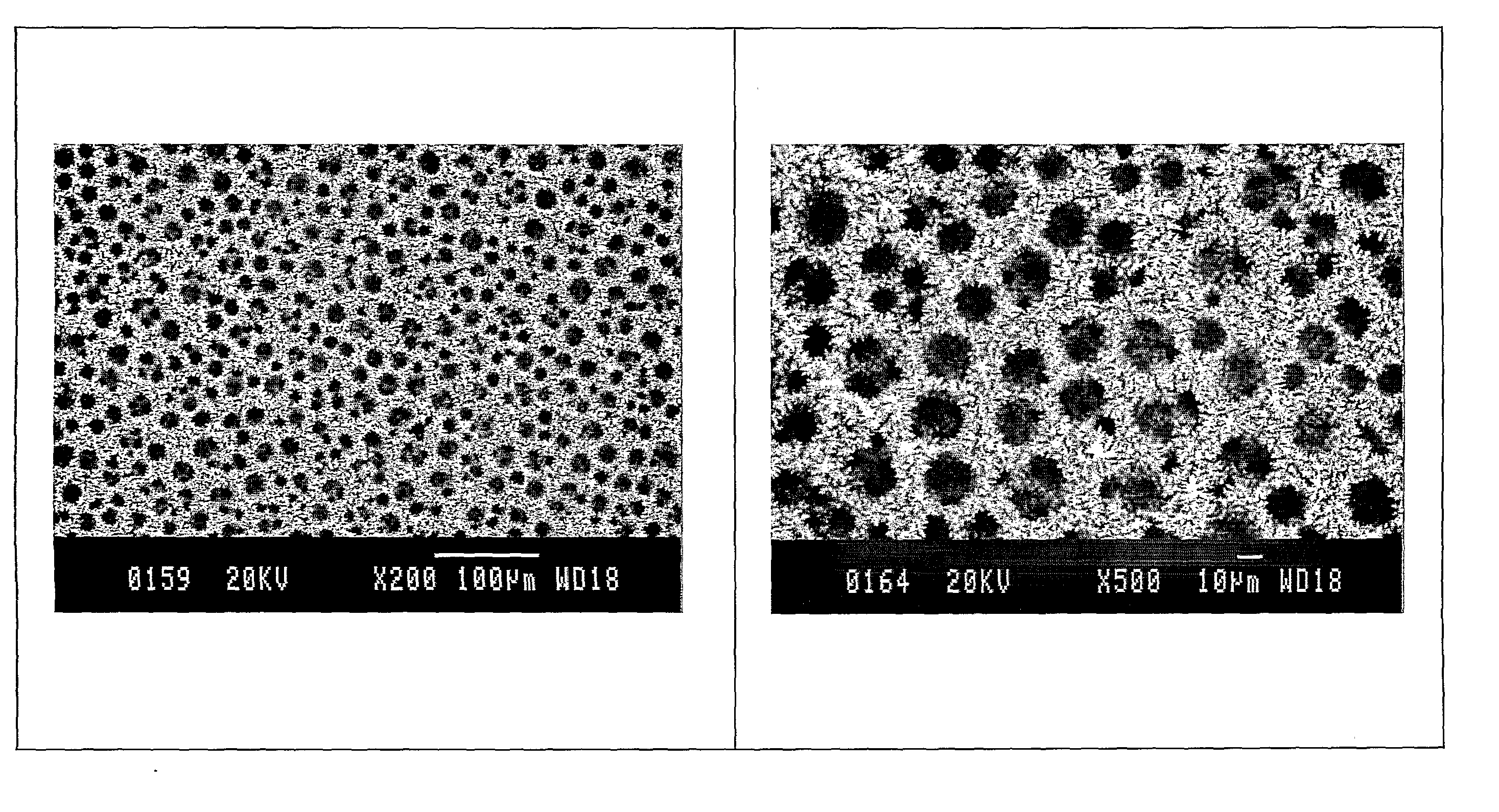

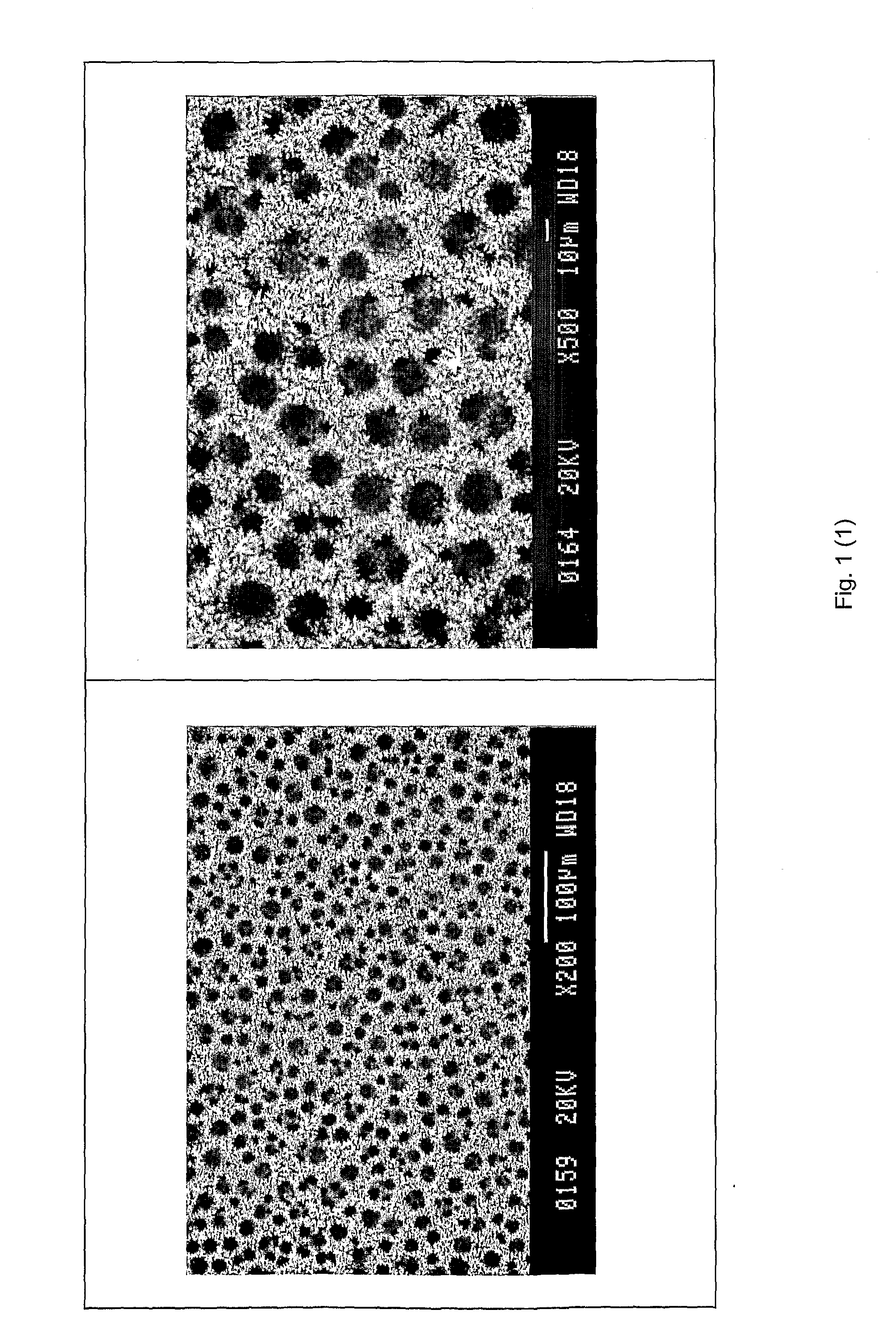

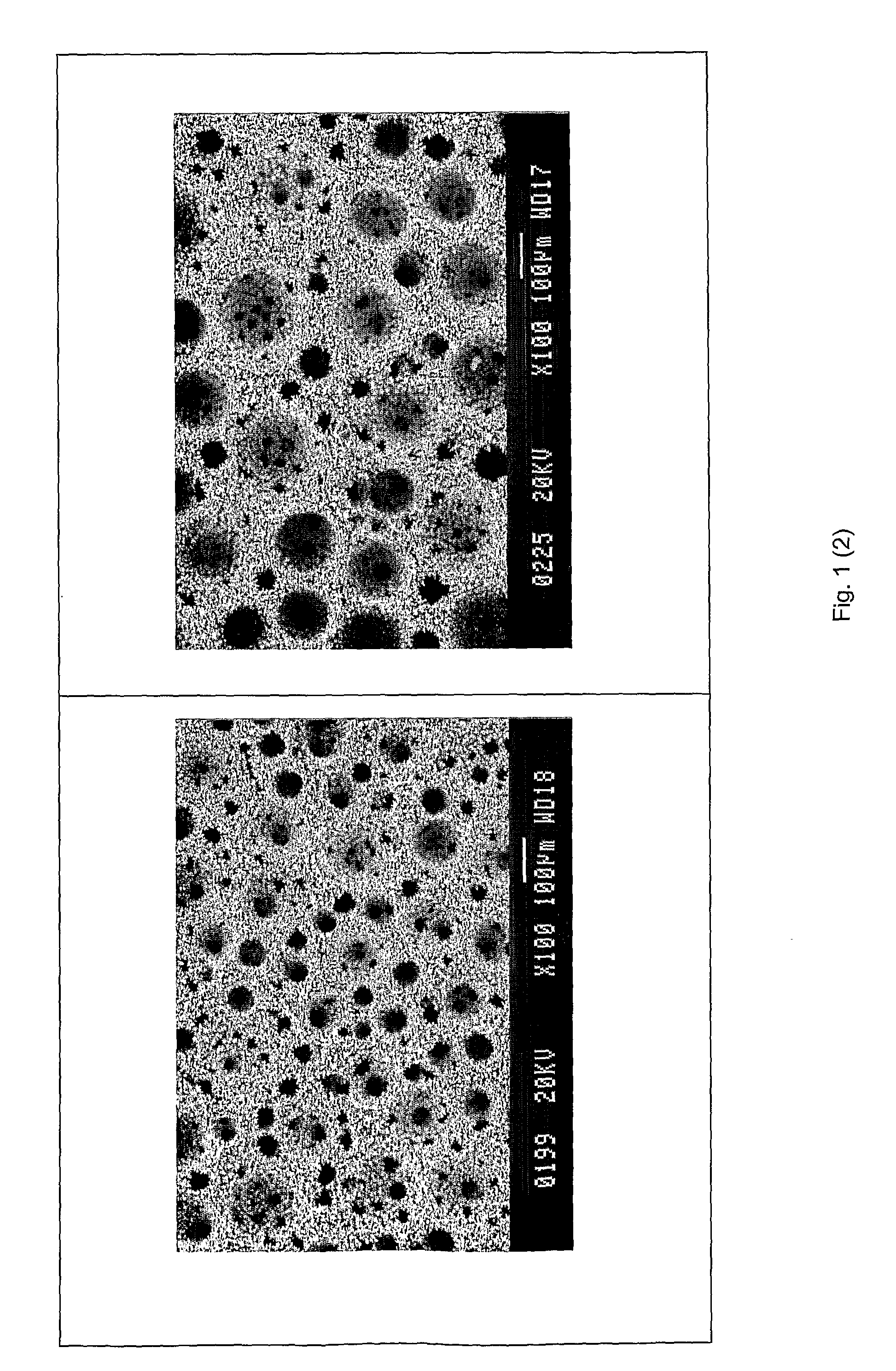

Porous Layer

InactiveUS20100044018A1Improve conductivity stabilityImprove mechanical stabilityLayered productsPretreated surfacesSurface layerPorous layer

Heat exchange device with a boiling surface comprising porous surface layer arranged on a solid substrate, the porous surface layer comprises a porous wall structure defining and separating macro-pores that are interconnected in the general direction normal to the surface of the substrate and have a diameter greater than 5 μm and less than 1000 μm wherein the diameter of the pores gradually increases with distance from the substrate wherein the porous wall structure is a continuous branched structure.

Owner:DANFOSS AS

Copper-silver alloy conductor size and its preparing method

InactiveCN1783355ALower sintering temperatureImprove conductivity stabilityNanostructure manufactureLuminescent paintsSupersonic wavesAlloy nanoparticle

This invention provides Cu-Ag alloy conductor slurry and its manufacturing method including: preparing nm particles of Cu-Ag alloy, matching conductor slurry and sintering the slurry, in which, the nm particles are prepared under the mixed atmosphere of H and Ar with the DC arc plasma method and the preparation for the slurry includes: fully mixing terpinyl, EC and absolute alcohol then adding nm particles and fully beating them up to be vibrated by supersonic waves then to be added with glass power to beat them up again and vibrate them with supersonic waves to get the conductor slurry. The sinter temperature is bellow 220deg.C under 1.33Pa. Advantage: the sinter temperature is low not needing protection gas while sintering, the conductive stability is higher than Cu power slurry and ití»s possible to replace Au, Ag and Pd slurry.

Owner:SHENYANG POLYTECHNIC UNIV

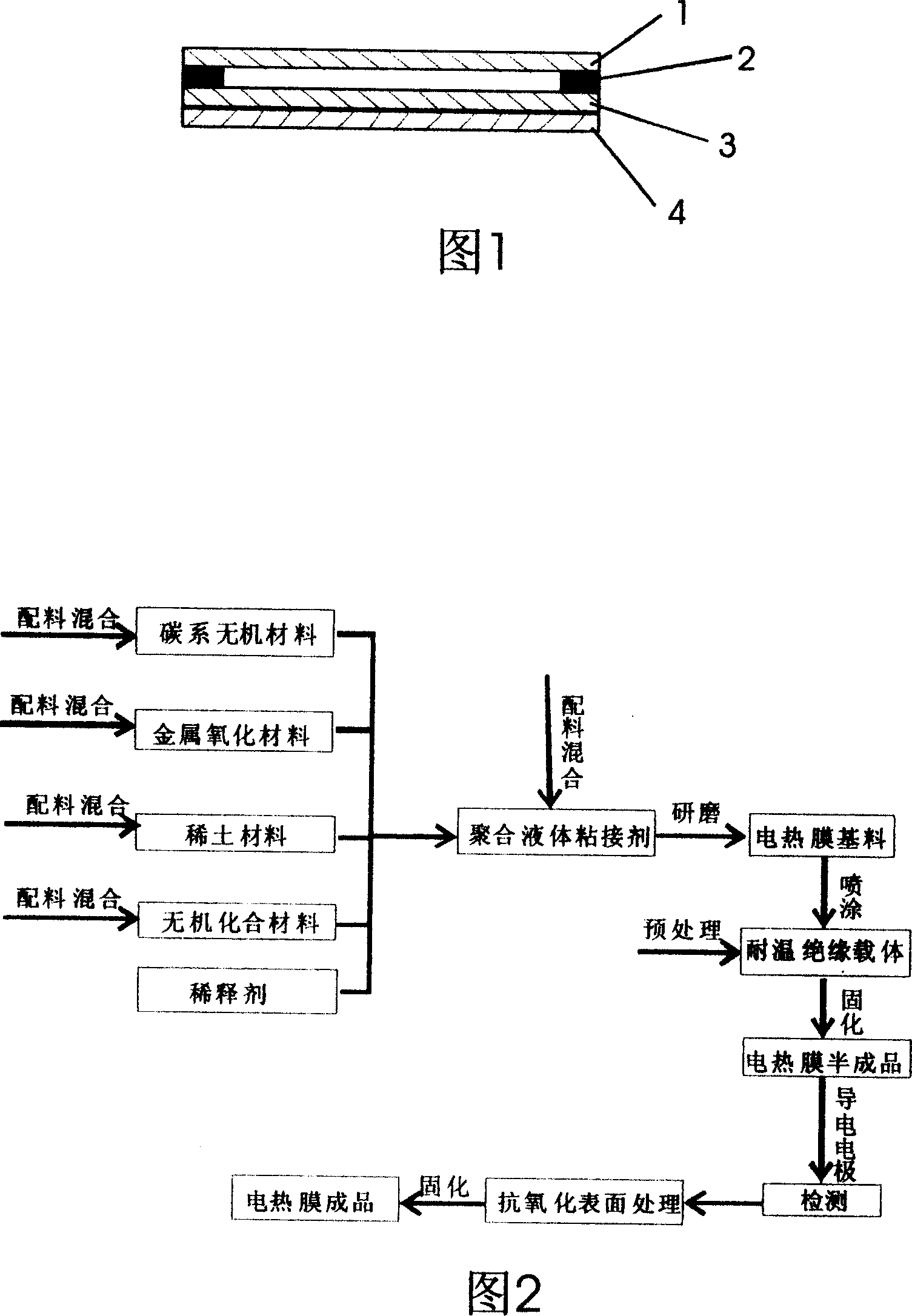

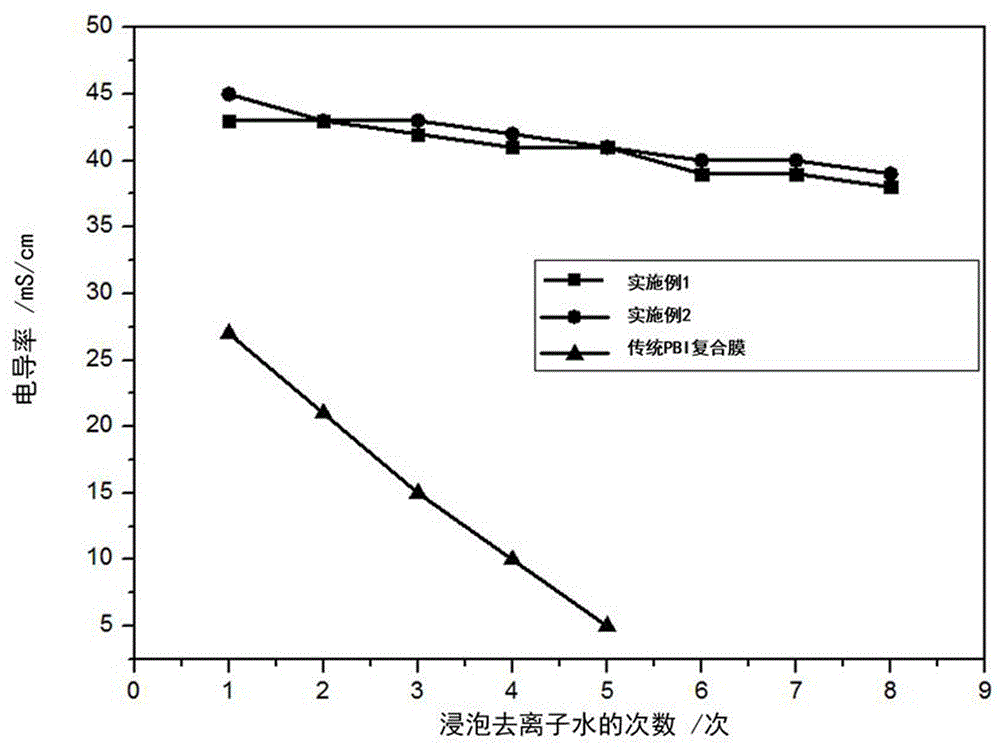

Composite low-voltage electrothermal film and making method

InactiveCN1980494AWide variation in geometryImprove conductivityHeating element materialsManufacturing technologyLiquid medium

The structure of the complex low-voltage electric heating film (CLEHF) consists of the electric heating inorganic compound (EHIC), the hi-temperature durable (HTD) isolator, the electrodes and the anti-oxidation HTD isolation layer. The EHIC consists of the carbon system inorganic material, the rare-earth material, the metal oxide, the inorganic compound and the polymerization liquid medium adhesive. The manufacture technology of CLEHF includes: ingredient configuring, mixing, skiving, spraying, solidifying and forming. With a low work voltage of 12 volts, CLEHF heats up to 100 degrees centigrade in only 50 seconds. This invention possesses advantages of fast response time, high heating efficiency and wide application range. Depending on different features and usages of various heater bodies, different materials are selected to form different shapes of heating films. Therefore, this heating film adapts to all handy low voltage electric heating apparatuses.

Owner:周挺

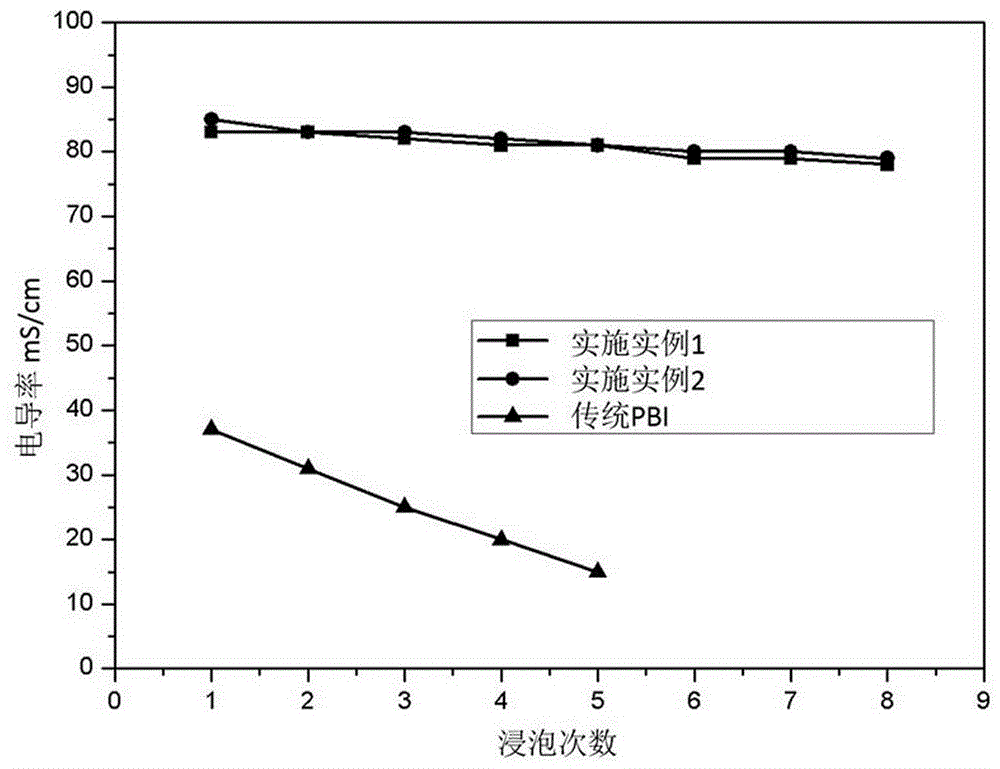

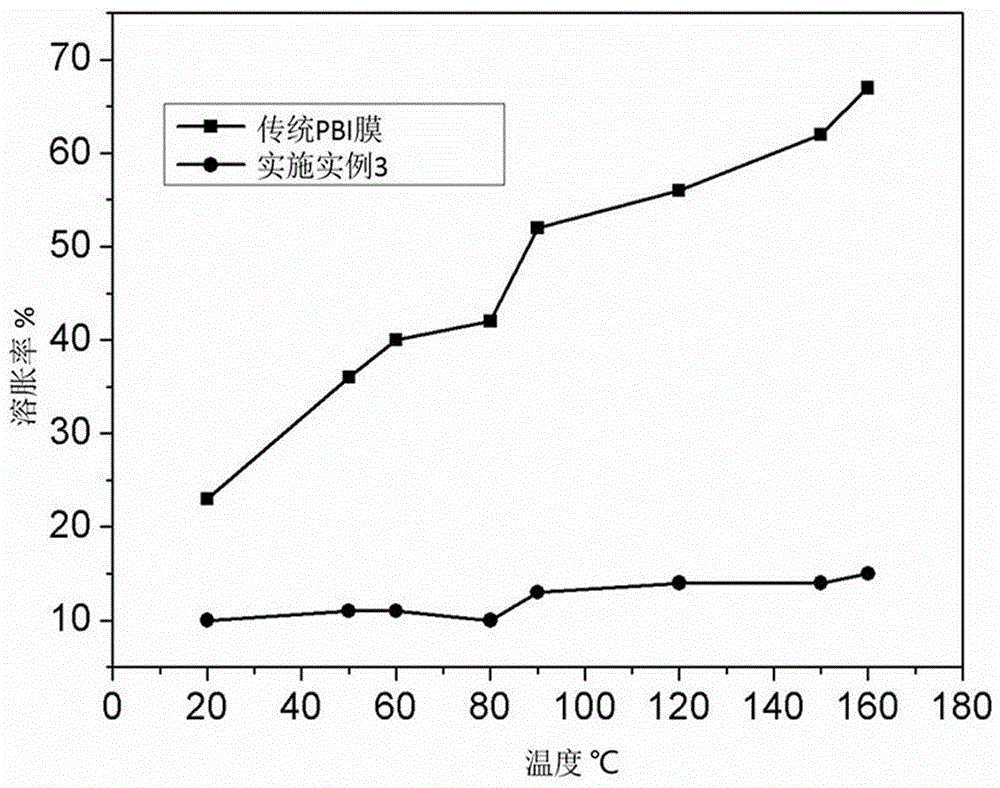

High conductivity cross-linked organic phosphate polybenzoimidazole high temperature proton exchange membrane and preparation method thereof

The invention discloses a high conductivity cross-linked organic phosphate polybenzoimidazole high temperature proton exchange membrane and preparation method thereof. The polybenzoimidazole is adopted as the polymer substrate. Through polymerization reaction and the adoption of vinyl benzyl chloride as the cross-linking agent, the self-cross-linking of polybenzoimidazole and Vinyl phosphate is conducted to form the membrane, which can be adopted for the preparation of homogeneous phase high temperature proton exchange membrane. The membrane not only can enhance the adsorption site of phosphoric acid, thus enhancing the conductivity of the membrane, but also can hugely reduce the phosphoric acid loss of polybenzoimidazole / phosphoric acid film, effectively enhance the conductivity stability of the membrane. Under non-wetting condition the membrane has the advantages of excellent proton conductive capability, and low air permeability. The membrane can be adopted for the high temperature proton exchange membrane fuel cell, direct alcohol fuel cell, electrochemical sensor and other electrochemical devices.

Owner:ZHANGJIAGANG IND TECH RES INST CO LTD DALIAN INST OF CHEM PHYSICS CHINESE ACADEMY OF SCI

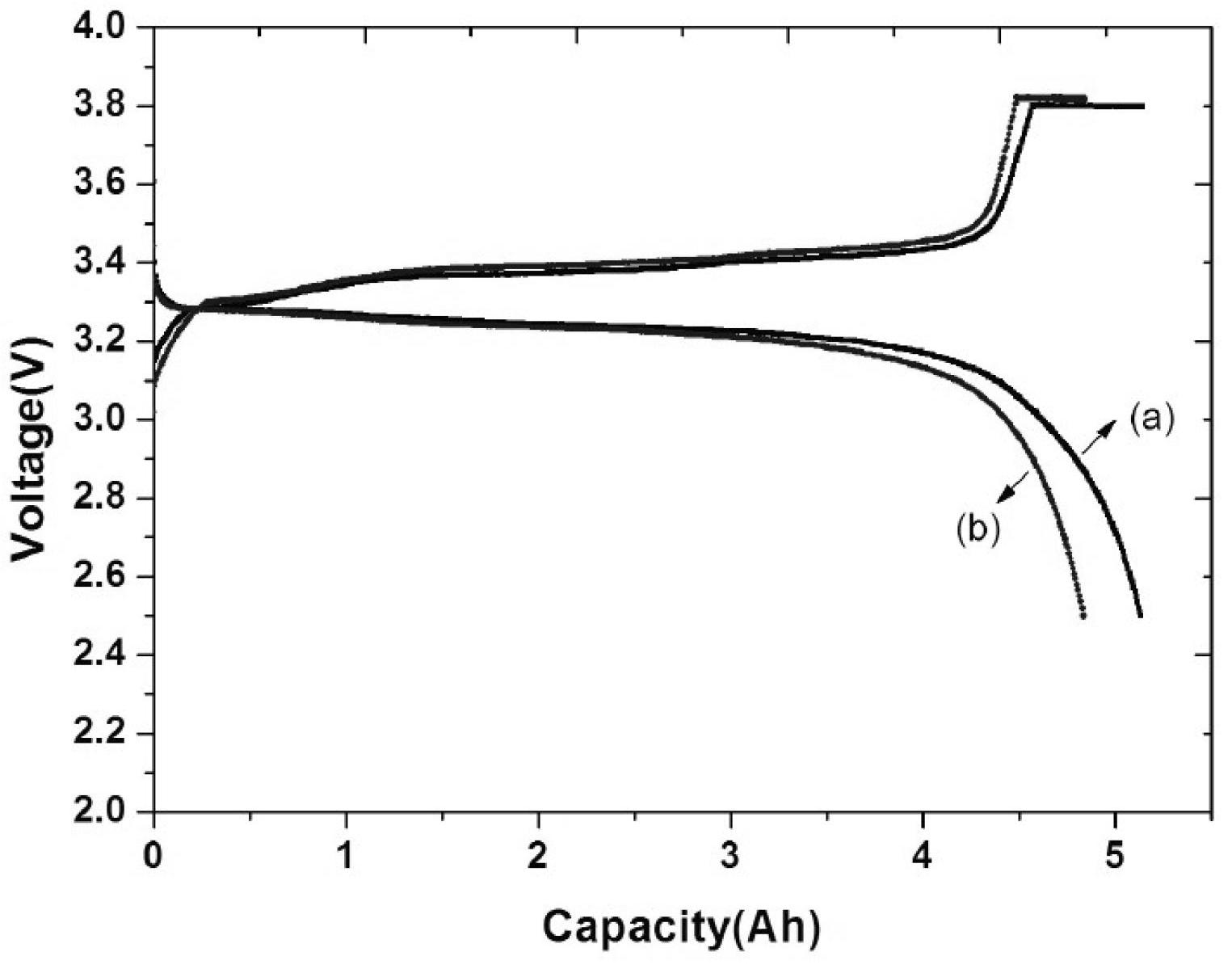

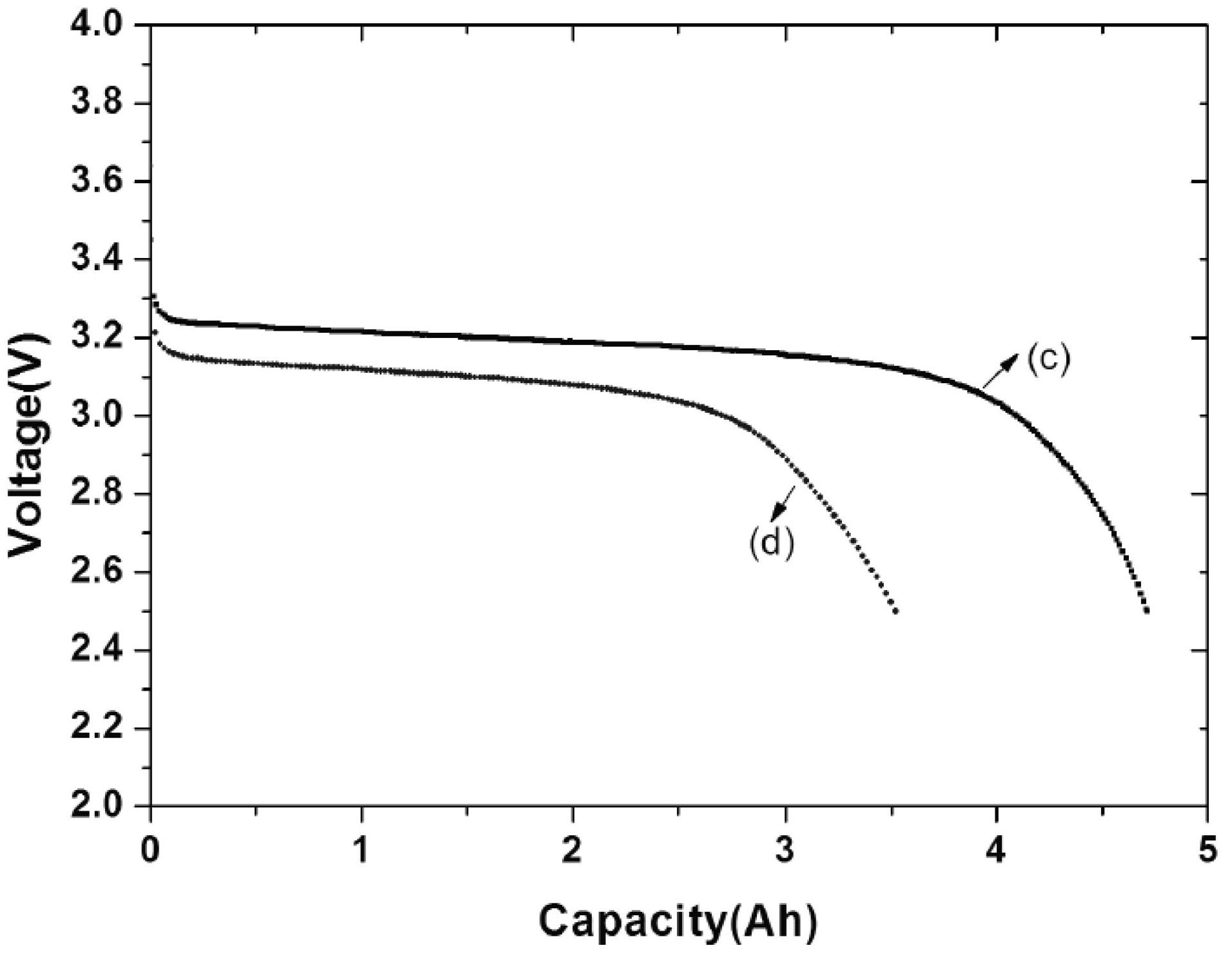

Lithium ferric phosphate battery adopting compound conductive agent and manufacturing method thereof

InactiveCN102683712AIncreased capacity and magnificationImprove conductivity stabilityFinal product manufactureCell electrodesIonPolyvinylidene fluoride

The invention discloses a manufacturing method for a lithium ferric phosphate battery adopting a compound conductive agent. The manufacturing method comprises the following steps of: dissolving anode binder polyvinylidene fluoride in N-methyl pyrrolidone and stirring, thereby obtaining anode glue; adding a carbon nano-tube / conductive polymer compound material into the anode glue and scattering; adding anode active matter LiFePO4 and stirring, thereby obtaining anode slurry; uniformly coating the anode slurry on two surfaces of an aluminum foil, drying, and then rolling and slicing, thereby obtaining anode plates; uniformly mixing cathode active matter graphite, the carbon nano-tube / conductive polymer compound material, a cathode binder and de-ionized water, thereby obtaining cathode slurry; uniformly coating the cathode slurry on two surfaces of a copper foil, drying, and then rolling and slicing, thereby obtaining cathode slices; coiling, flatly pressing and banding, and then drying for 8 hours in vacuum at 65 DEG C; filling electrolyte into a dried battery; and forming an end product of the lithium ferric phosphate battery after filling the electrolyte. According to the manufacturing method provided by the invention, the capacity, multiplying power, circulation and safety property of the battery are greatly improved.

Owner:ZHEJIANG ZHENLONG BATTERY

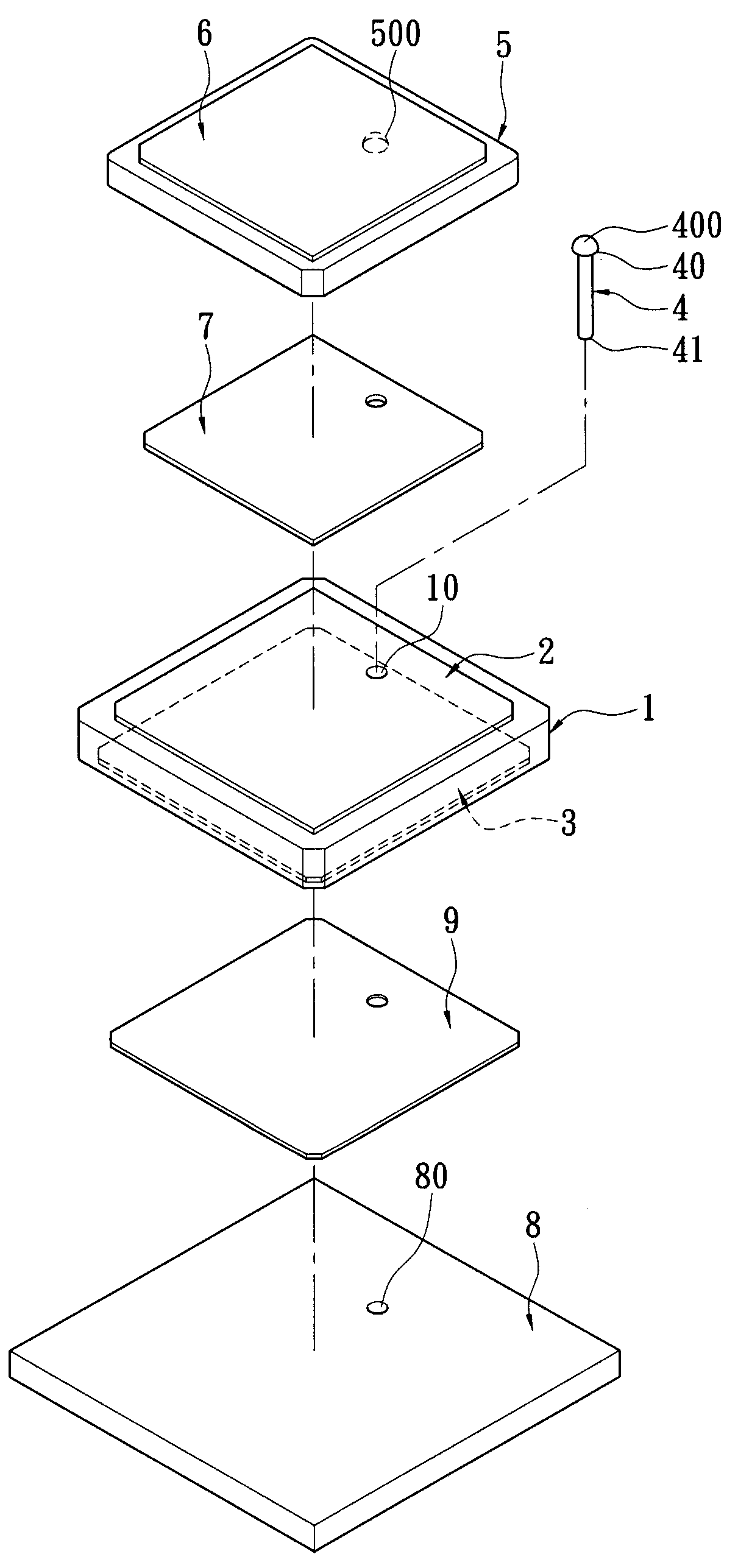

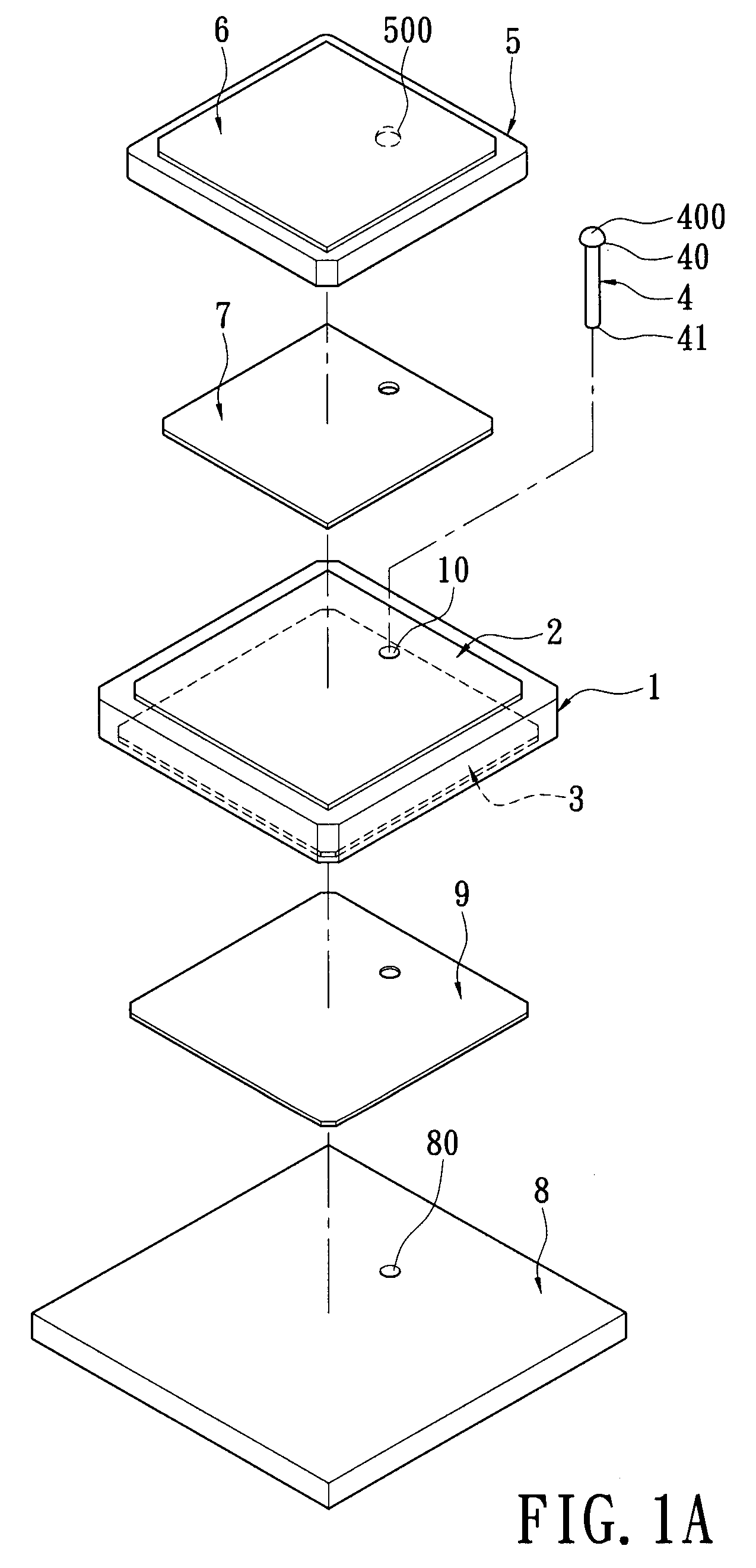

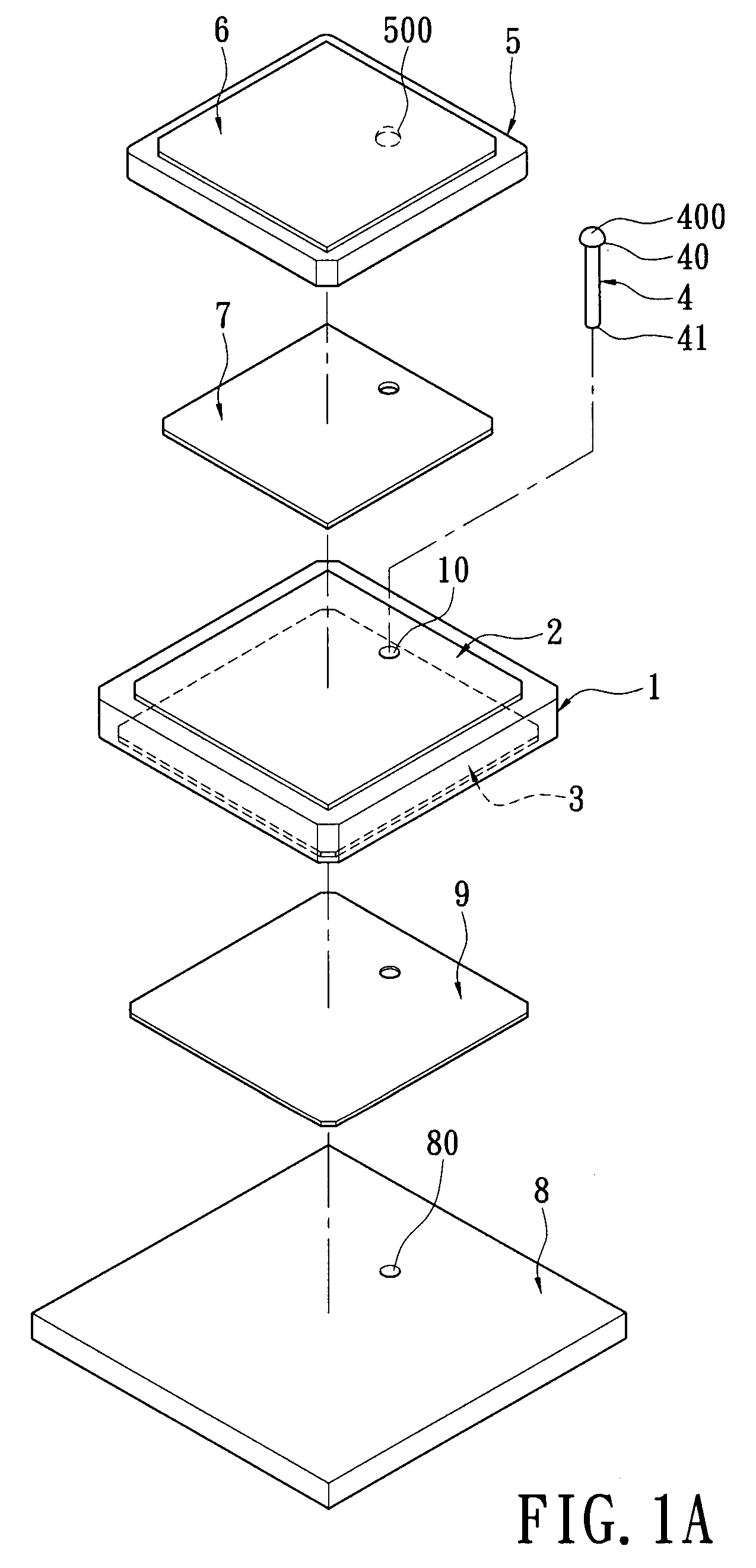

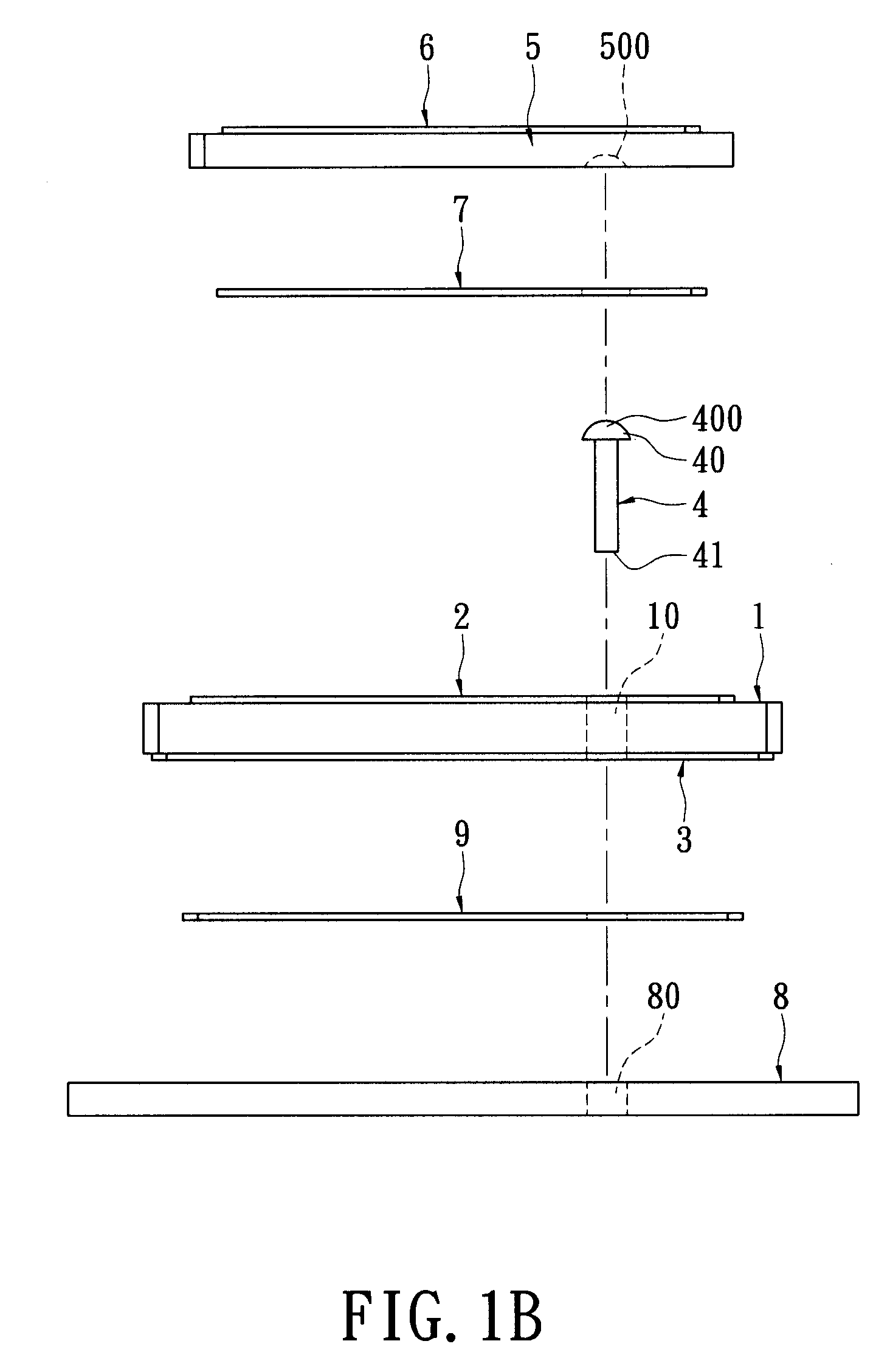

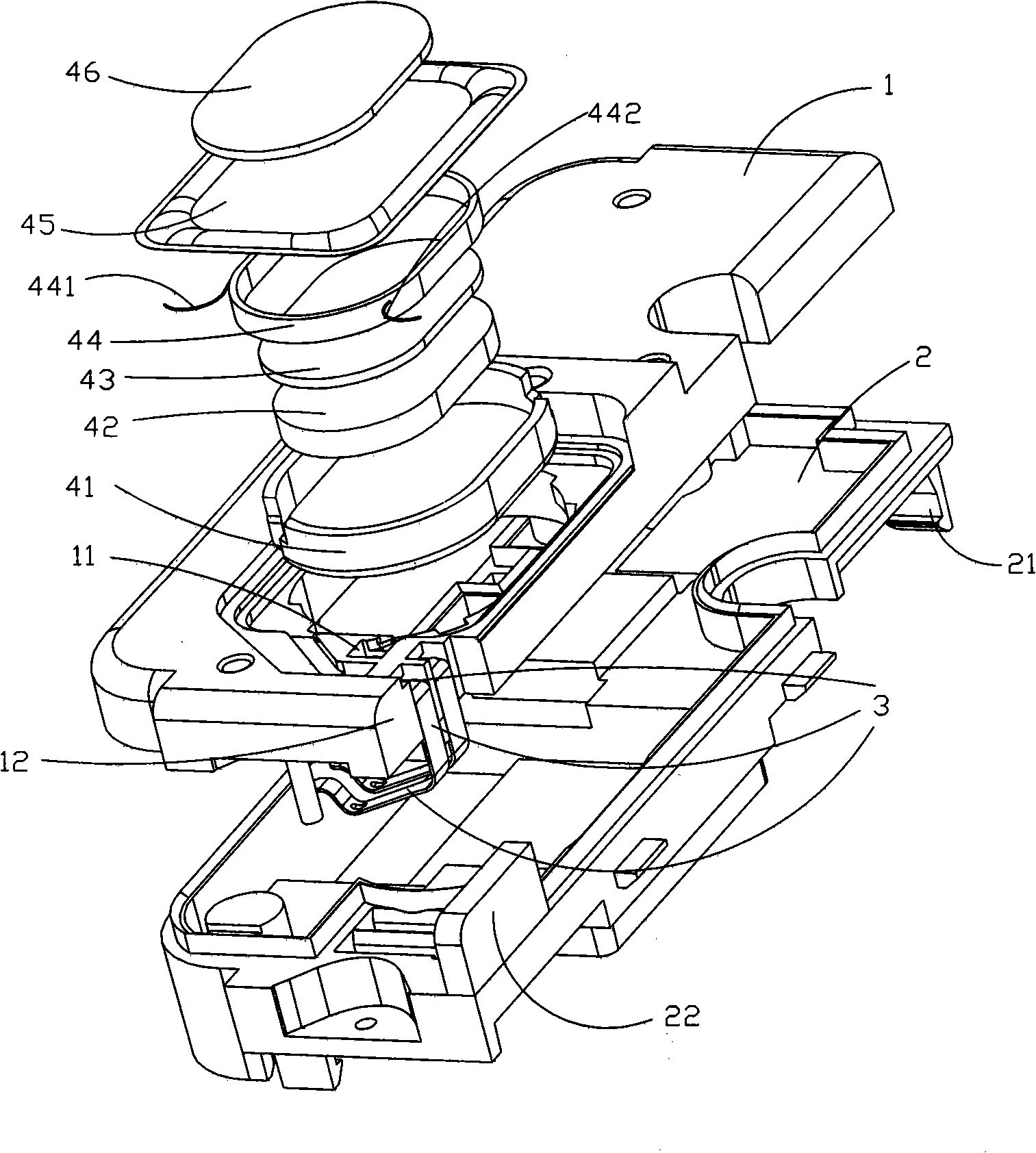

Circular polarization antenna structure with a dual-layer ceramic and method for manufacturing the same

ActiveUS20100164809A1Improve structural stabilityImprove electrical stabilitySimultaneous aerial operationsRadiating elements structural formsCircularly polarized antennaAntenna feed

A circular polarization antenna structure with a dual-layer ceramic includes a first hard dielectric body, a first metal layer, a grounding layer, an antenna feed pin, a second hard dielectric body, a second metal layer and an adhesive element. The first metal layer and the grounding layer dispose on a top surface and a bottom surface of the first hard dielectric body. The antenna feed pin passes through the through hole of the first hard dielectric body, the top side of the antenna feed pin is fixed on the top surface of the first hard dielectric body, and the bottom side of the antenna feed pin extends outwards from the bottom surface of the first hard dielectric body. The second hard dielectric body disposes above the top side of the first hard dielectric body. The second metal layer disposes on the top surface of the second hard dielectric body.

Owner:RRT TECH LTD

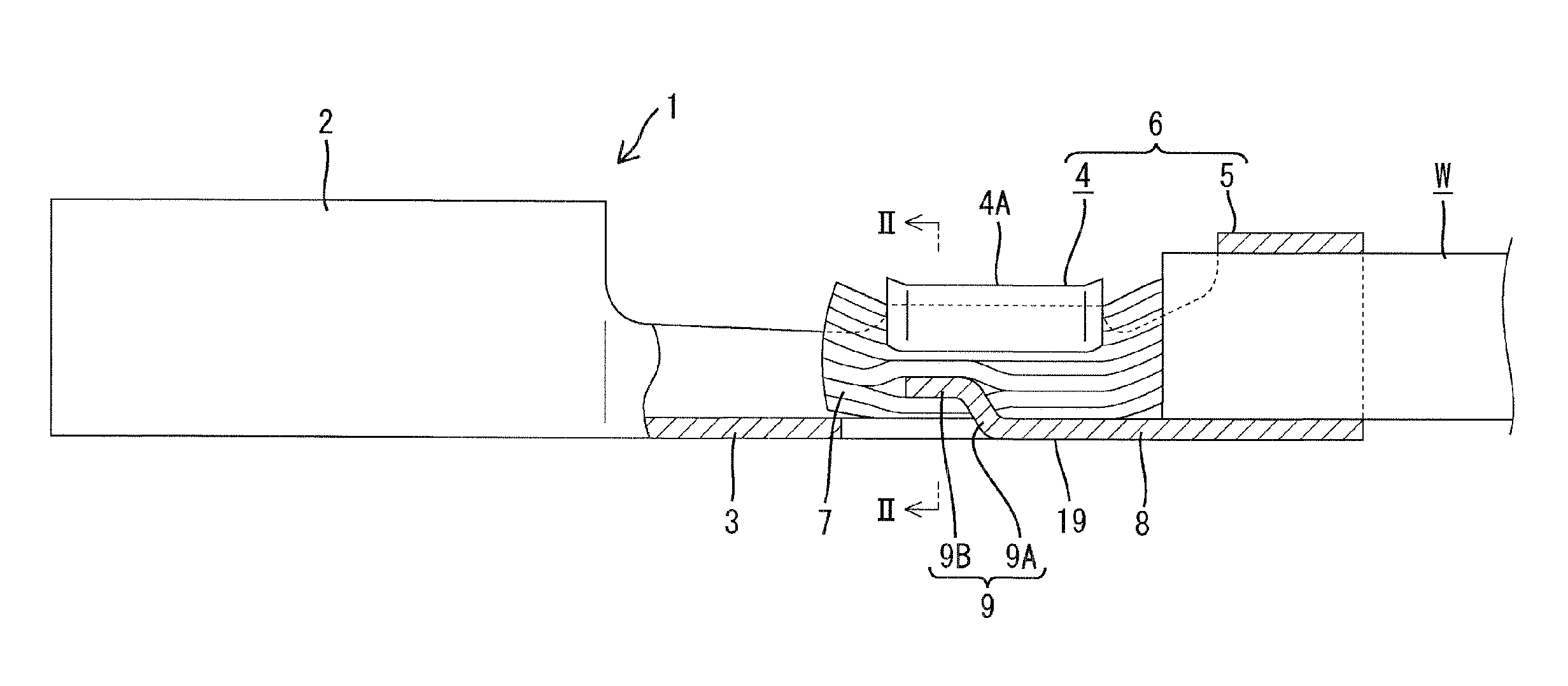

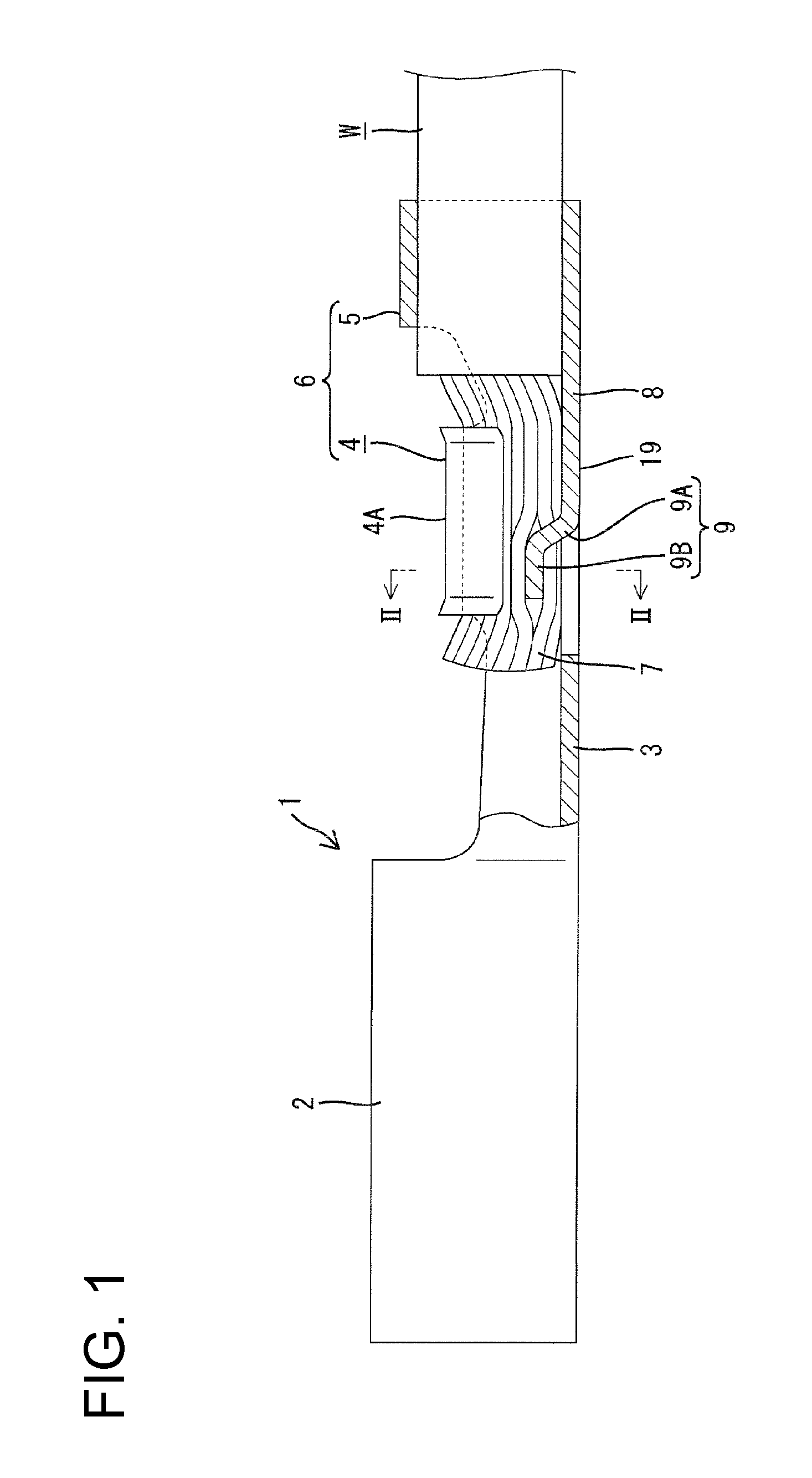

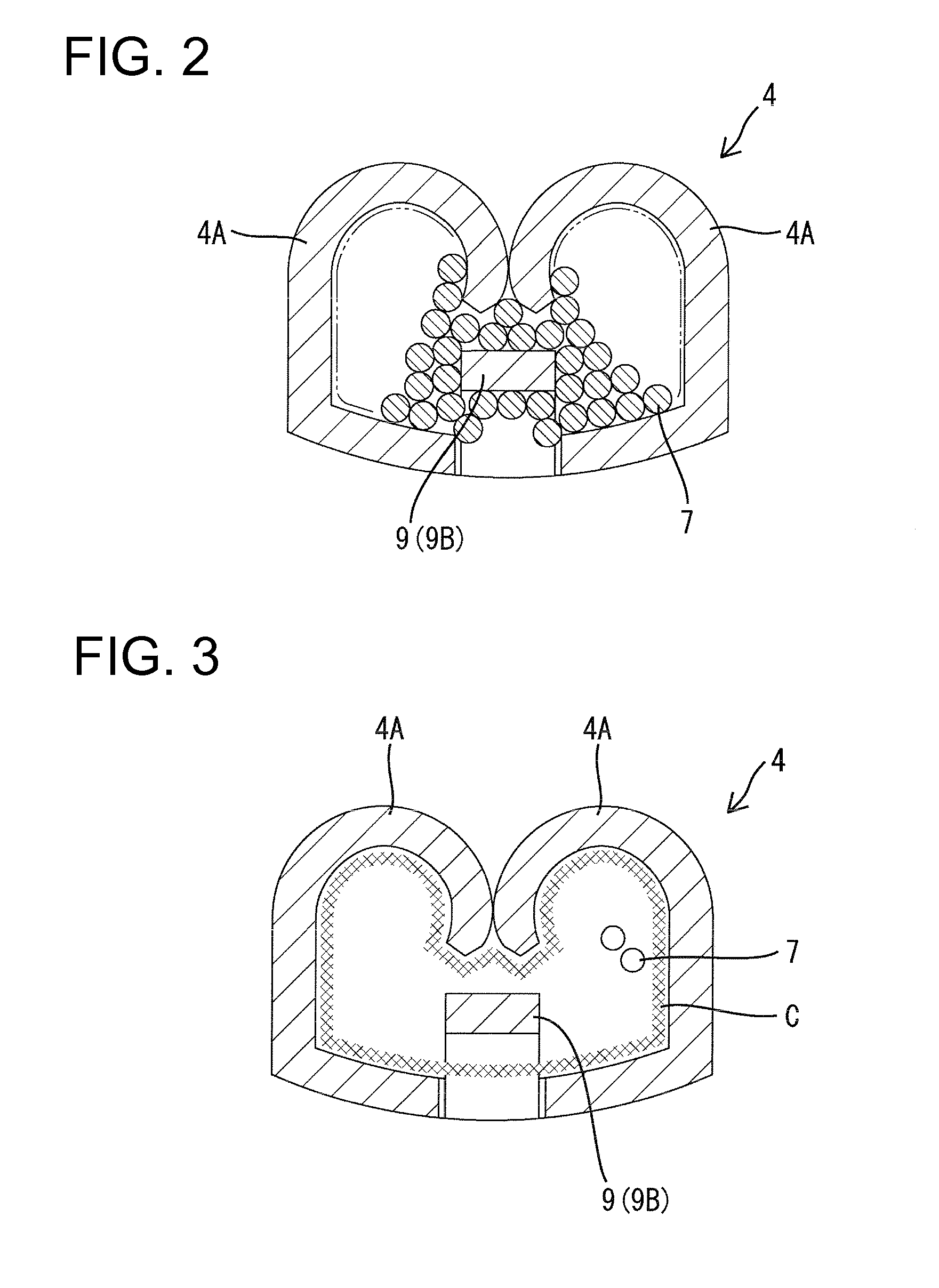

Terminal fitting and a wire connected with a terminal fitting

InactiveUS20100035487A1Increase lengthLong creepage distanceContact member manufacturingConnections effected by permanent deformationEngineeringMetal

A terminal fitting (1, 110, 111, 210) is provided with a wire barrel (4, 131, 231) to be crimped into connection with a core (7, 142, 242) made of a plurality of metal strands and exposed at a leading end portion of a wire (W, 140, 240), and an inner conductive portion (9-12, 134, 135, 235) connected with a wall surface of the terminal fitting (1, 110, 111, 210) and to be held in electrical contact with the metal strands by extending into the inside of the core (7, 142, 242) at an inner side of the wire barrel (4, 131, 231) crimped into connection with the core (7, 142, 242).

Owner:SUMITOMO WIRING SYST LTD

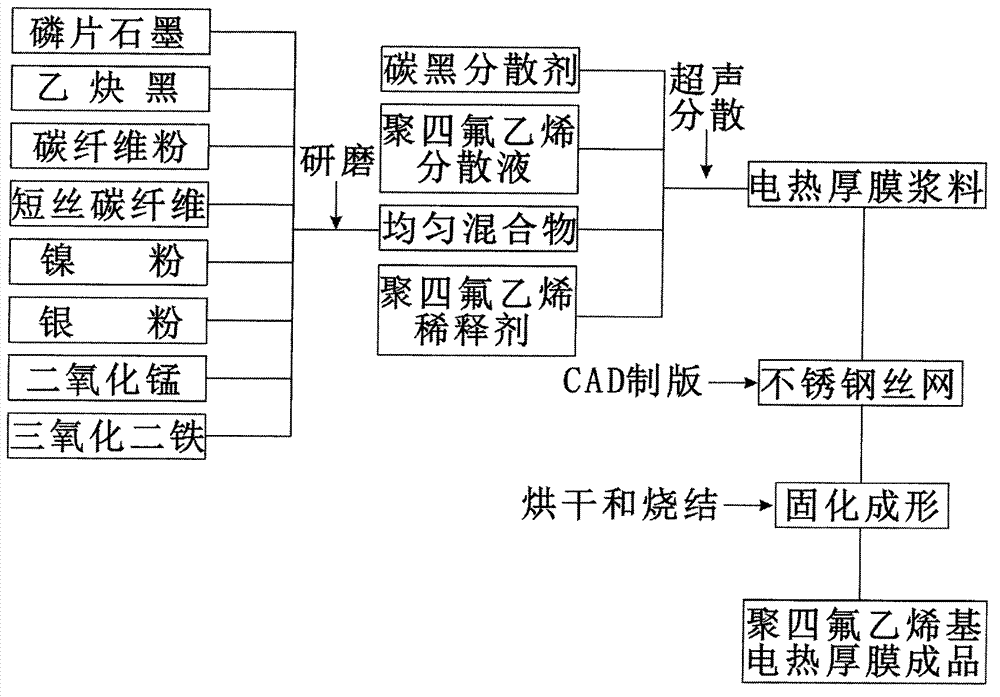

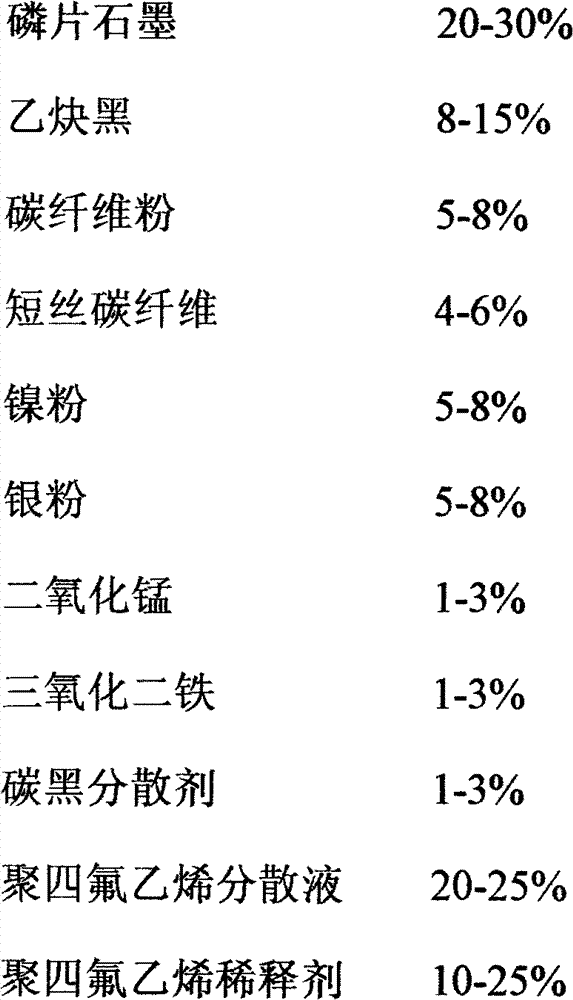

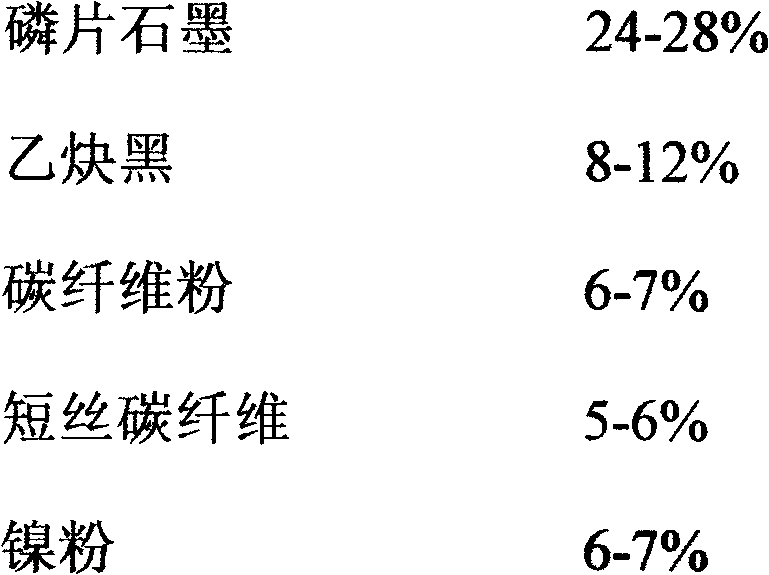

Polytetrafluoroethylene (PTFE) base electrothermal thick film and manufacturing method thereof

The invention discloses a polytetrafluoroethylene (PTFE) base electrothermal thick film, comprising the following materials according to percentage by weight: 20-30% of flake graphite, 8-15% of acetylene black, 5-8% of carbon fiber powder, 4-6% of short carbon fiber, 5-8% of nickel powder, 5-8% of silver powder, 1-3% of manganese dioxide, 1-3% of iron sesquioxide, 1-3% of carbon black dispersant, 20-25% of PTFE dispersion liquid and 10-25% of PTFE diluent. The invention also discloses a manufacturing method of the PTFE base thick film, comprising the steps of grinding and uniformly mixing the flake graphite, the acetylene black, the carbon fiber powder, the short carbon fiber, the nickel powder, the silver powder, the manganese dioxide and the iron sesquioxide according to the proportion, mixing and ultrasonically dispersing the mixture, the carbon black dispersant, the PTFE dispersion liquid and the PTFE diluent according to the proportion to prepare a electrothermal thick film paste, and drying and sintering the electrothermal thick film paste, after a through printing process so as to manufacture the PTFE base electrothermal thick film. The manufacturing method provided by the invention is applicable to high-voltage electrothermal equipment, good in stability and using effect, and is not demoulded.

Owner:CIXI SOVONO ELECTRIC APPLIANCE

High-conduction-stability superelastic yarn, and preparation method and application thereof

The invention discloses a high-conduction-stability superelastic yarn, and a preparation method and application thereof. The preparation method comprises the following steps of (1) preparing a spinning solution, namely dissolving a thermoplastic elastomer material TPE in an organic solvent to obtain the spinning solution; (2) preparation TPE fiber: preparing TPE micro-nano fiber from the spinningsolution obtained in the step (1) through electrostatic spinning, collecting the TPE fiber by using a metal wire in the spinning process, and coating the TPE fiber onto the surface of the metal wire;(3) peeling the TPE fiber coating the surface of the metal wire from the surface of the metal wire, and performing drying to obtain a TPE yarn; and (4) coating liquid metal onto the surface of the dried TPE yarn to obtain an elastic conductive yarn. The preparation method provided by the invention has the advantages that the method is simple; the efficiency is high; the cost is low; and the methodis applicable to mass production. The high-conductivity and high-conduction-stability superelastic yarn can be used for wearable optoelectronic equipment and all other equipment needing to use stretchable conductor materials.

Owner:SOUTH CHINA UNIV OF TECH

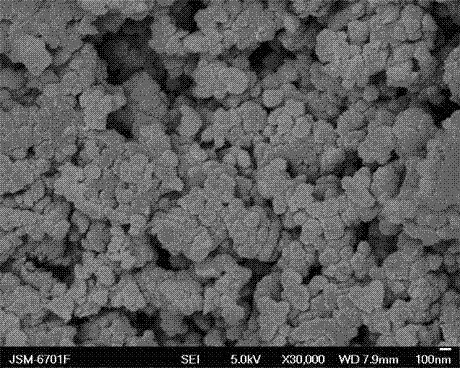

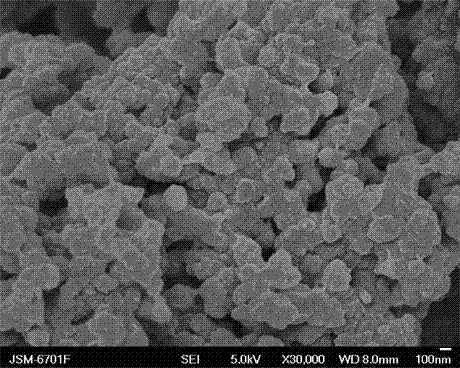

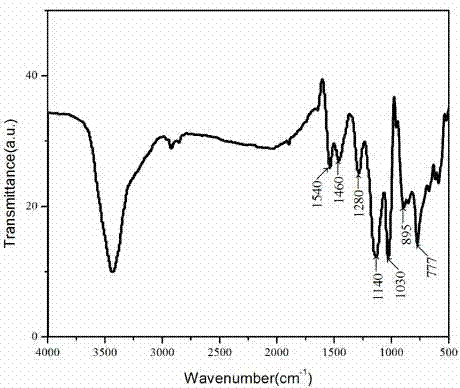

Preparation method of polyaniline@polypyrrole conductive composite material

InactiveCN102964831AImprove conductivity stabilityImprove conductivityPolypyrroleIn situ polymerization

The invention discloses a preparation method of a polyaniline@polypyrrole conductive composite material, which comprises the following steps of: firstly synthesizing PAn by a chemical oxidation method, and performing leaching, cleaning and drying to obtain deep green powder of PAn; then mixing a certain amount of polyaniline with a certain amount of water by an in-situ polymerization method, adding doping agent sulfamic acid and pyrrole monomer respectively, uniformly stirring the mixed liquid, and adding an oxidant ferric trichloride; then filtering the reaction liquid, and washing until the filtrate is neutral; and finally drying the filter cake and grinding to obtain black polyaniline@polypyrrole conductive powder.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

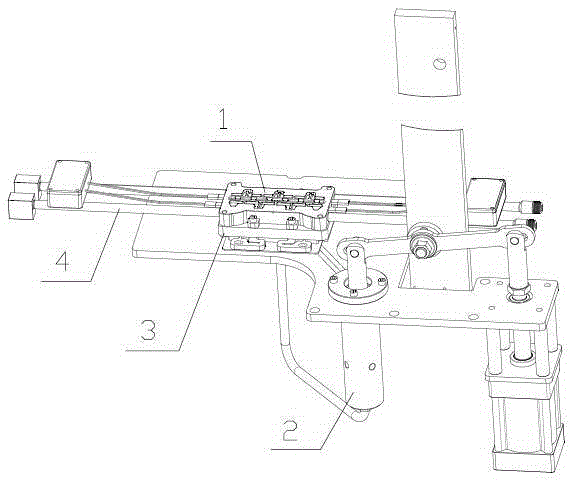

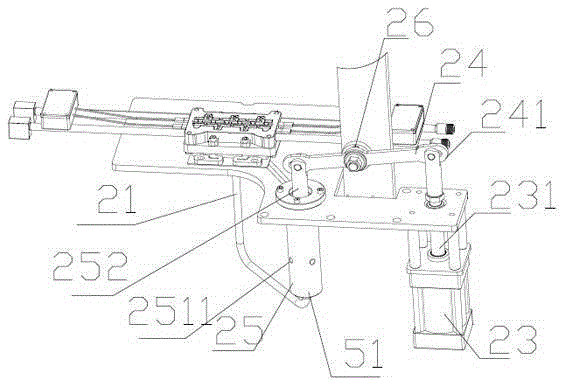

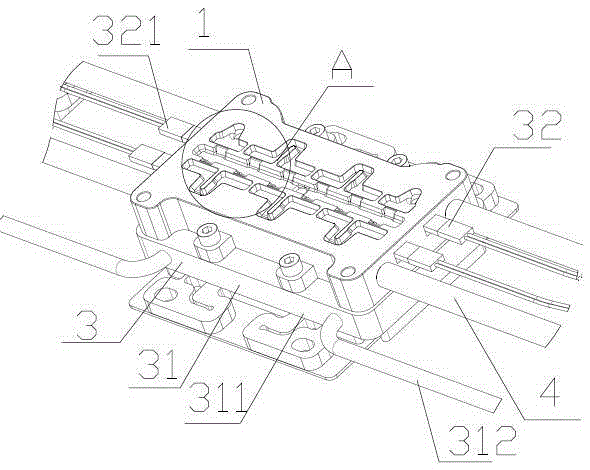

Manufacturing device suitable for busbar

The invention relates to the field of battery manufacturing, in particular to a manufacturing device suitable for a busbar. The manufacturing device suitable for the busbar is characterized by comprising a lead pan and a mold, and further comprises a quantitative lead replenishing device, a heating device for heating the mold and a cooling device for cooling the mold, wherein the mold is positioned above a molten lead level of the lead pan, and comprises a basal way and a liquid inlet formed in the basal way and downwards inserted into the mold; a cover plate is arranged above the mold; and a molding groove is formed in the side end of the basal way. The invention aims to provide the manufacturing device suitable for the busbar; the manufacturing device is simple in structure, and facilitates to actuate; molten lead entering the mold each time is constant; and the mold has no need to enter the lead pan, so that the residue of the molten lead and the generation of lead slag are reduced; and the mold keeps integral molding of the busbar, so that additional cutting and welding are not needed.

Owner:湖州海悦智能科技有限公司

Polypyrrole conduction fiber

InactiveCN108193314AImprove conductivity stabilityImprove mechanical stabilityElectroconductive/antistatic filament manufactureConjugated synthetic polymer artificial filamentsPolypyrroleDissolution

The invention discloses a polypyrrole conduction fiber, which is prepared from the following raw materials in parts by weight: 2 to 4 parts of oleic acid, 1 to 2 parts of ammonium molybdate, 0.7 to 1part of aminopropyltriethoxysilane, 20 to 30 parts of triazole monomers, 0.7 to 1 part of dibenzoyl peroxide, 0.6 to 1 part of 2,6-di-tert-butyl paracresol, 4 to 6 parts of blanc fixe, 70 to 80 partsof polyacrylonitrile and 5 to 7 parts of isopropanol. The triazole monomers are polymerized in an alkamine solution; the obtained aminopyrrole solution is mixed with oleic acid treated filling materials; through the reaction between amino groups and oleic acid, the effective dissolution of the polypyrrole and the filling materials can be realized, so that the mechanical stability and the conduction stability of a finished product material are improved.

Owner:王家浩

Graphene conducting material and preparation method thereof

The invention discloses a graphene conducting material. The graphene conducting material is prepared from the following raw materials in parts by weight: 30 to 41 parts of graphene oxide, 20 to 30 parts of a conducting dispersion solution, 35 to 40 parts of aniline, 1 to 2 parts of ammonium persulfate, 0.4 to 1 part of melamine, 0.1 to 0.2 part of tert-butyl p-diphenol, 4 to 5 parts of diphenyl silanediol and 2 to 3 parts of calcium propionate. According to the graphene conducting material disclosed by the invention, various conducting substances, such as polyaniline, acetylene carbon black and graphene, are added; all the raw materials are blended and the graphene conducting material has very strong cooperatively enhanced conductivity; after the raw materials are treated by a method disclosed by the invention, the effects of stable finished products and efficient electric conduction are realized.

Owner:温州市赢创新材料技术有限公司

Copper-silver alloy conductor size and its preparing method

InactiveCN100429727CLower sintering temperatureImprove conductivity stabilityNanostructure manufactureLuminescent paintsElectrical conductorShielding gas

Owner:SHENYANG POLYTECHNIC UNIV

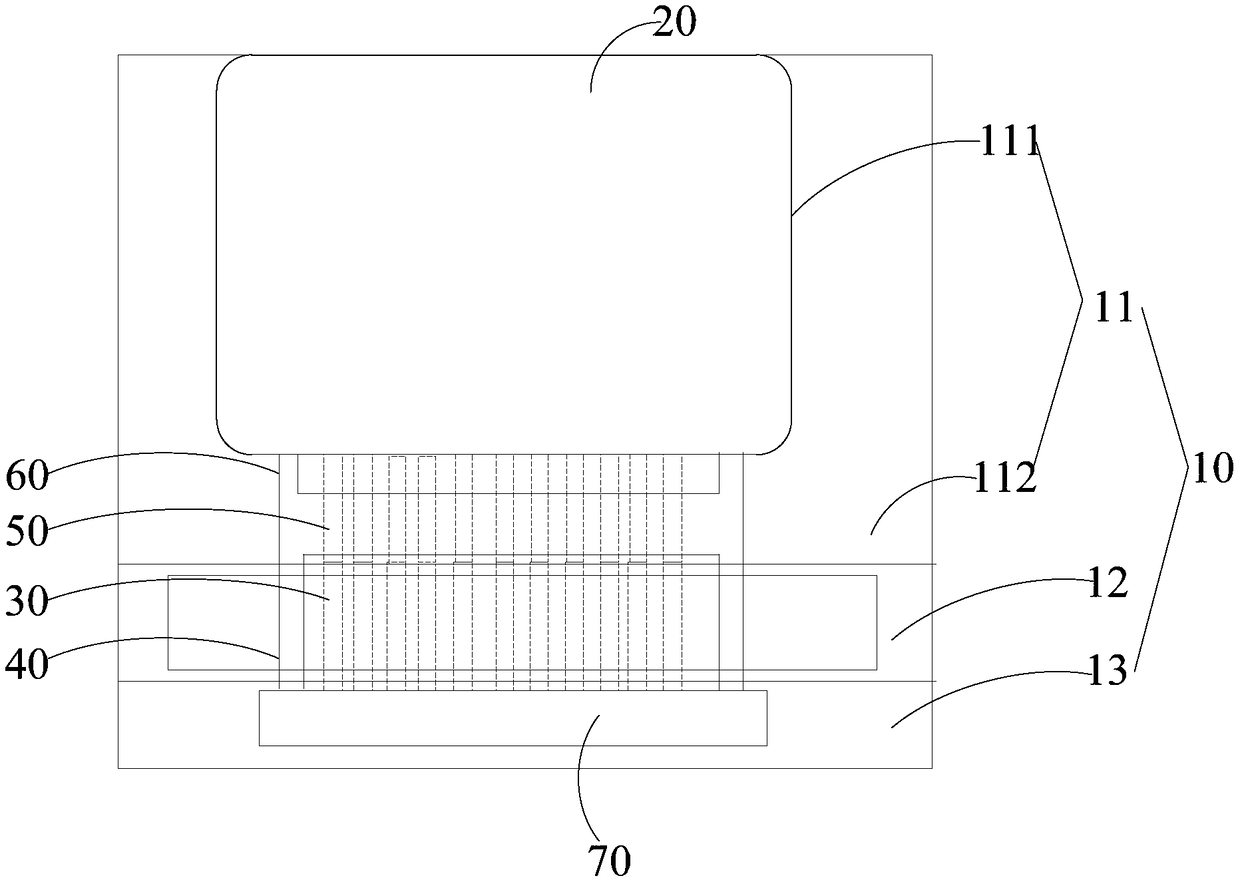

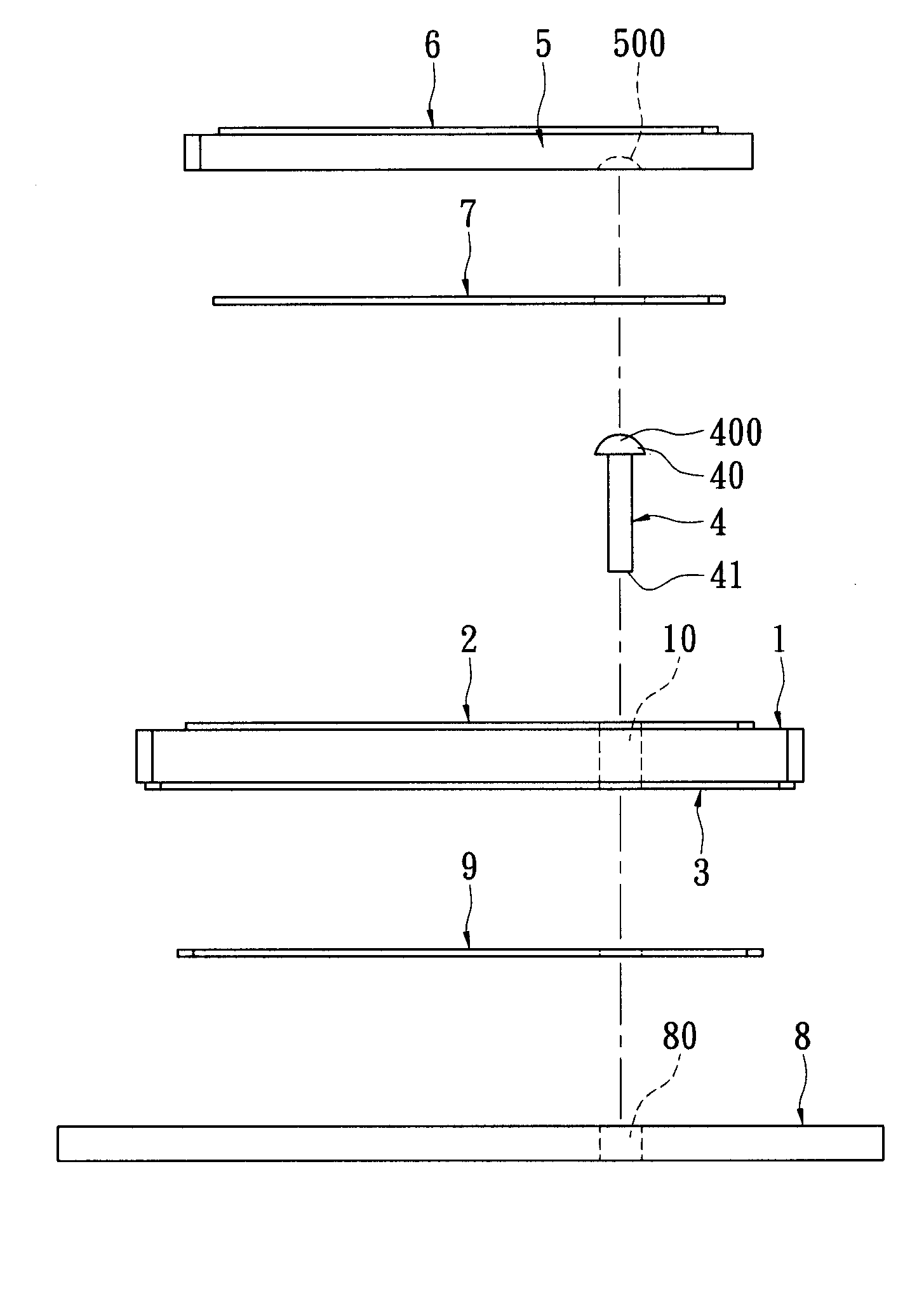

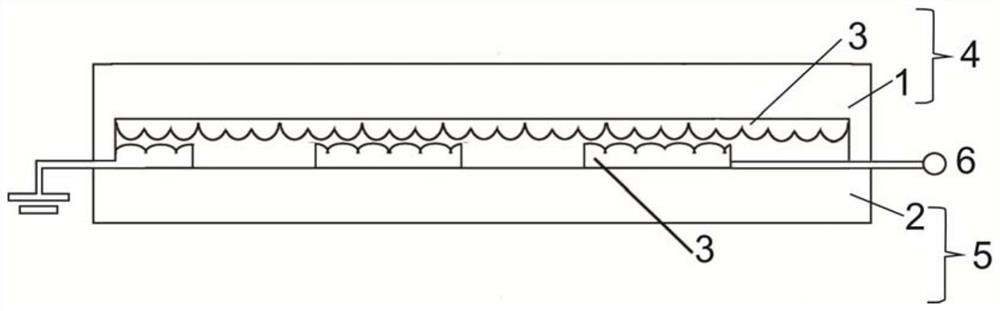

Display panel and electronic equipment

InactiveCN108831306AReduced risk of ruptureImprove conductivity stabilityIdentification meansElectricityFiber

The invention provides a display panel. The display panel comprises a flexible substrate, an illumination functional layer and multiple metal wires, wherein the flexible substrate is provided with a first region, a flexible region and a second region, the second region is bent to the back side of the first region through the flexible region, the illumination functional layer is arranged on the substrate and comprises a first illumination region located on the first region, the metal wires are arranged in the flexible region and electrically connect the first region and the second region, partof or all of the metal wires are flexible conductive fiber wires, and the flexible conductive fiber wires are embedded in the flexible substrate.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Circular polarization antenna structure with a dual-layer ceramic and method for manufacturing the same

ActiveUS8094075B2Improve conductivity stabilityImprove conductivitySimultaneous aerial operationsRadiating elements structural formsCircularly polarized antennaAntenna feed

A circular polarization antenna structure with a dual-layer ceramic includes a first hard dielectric body, a first metal layer, a grounding layer, an antenna feed pin, a second hard dielectric body, a second metal layer and an adhesive element. The first metal layer and the grounding layer dispose on a top surface and a bottom surface of the first hard dielectric body. The antenna feed pin passes through the through hole of the first hard dielectric body, the top side of the antenna feed pin is fixed on the top surface of the first hard dielectric body, and the bottom side of the antenna feed pin extends outwards from the bottom surface of the first hard dielectric body. The second hard dielectric body disposes above the top side of the first hard dielectric body. The second metal layer disposes on the top surface of the second hard dielectric body.

Owner:RRT TECH LTD

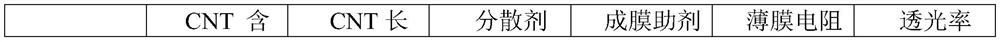

Carbon nanotube transparent conductive film and preparation method thereof

InactiveCN111710472AEvenly dispersedGood dispersionMaterial nanotechnologyConductive layers on insulating-supportsDisplay deviceSolar battery

The invention relates to the technical field of conductive films, and provides a preparation method of a carbon nanotube transparent conductive film. The method comprises the following steps of dispersing carbon nanotubes in a solvent containing a dispersing agent to prepare a carbon nanotube dispersion liquid; carrying out centrifugal treatment on the carbon nanotube dispersion liquid, and takinga supernatant, wherein a coalescing agent is selected from a transparent and conductive coalescing agent; adding a coalescing agent into the supernatant and carrying out mixing treatment to obtain acarbon nanotube solution; and depositing the carbon nanotube solution on a substrate, drying, and cleaning to prepare the carbon nanotube transparent conductive film. The carbon nanotube transparent conductive film prepared by the method provided by the invention has lower resistance and higher transparency, and is suitable for being applied to the fields of touch screens, displays, solar cells and the like.

Owner:SHENZHEN XIWAN TECH CO LTD

Preparation method of polyaniline/attapulgite conductive composite material

The invention provides a preparation method of a polyaniline / attapulgite conductive composite material. The preparation method comprises the following steps of: firstly mixing a certain amount of ionic liquid, a small amount of attapulgite, a certain amount of aniline monomer, a certain amount of dopant amino sulfonic acid and HCl solution with the concentration of 1 mol / l, and intensely agitating for 0.5h under the condition of 0-40 DEG C; then slowly dripping a certain amount of oxidant ammonium persulfate solution into the mixture to enable the solution to turn into dark green, and reacting for 30min-4h under the condition of 0-40 DEG C; and finally carrying out suction filtration on the mixed solution and washing with distilled water until filtrate is neutral in sequence, drying a filter cake in a vacuum drying oven at 40 DEG C, and grinding the filter cake to obtain polyaniline / attapulgite conductive composite material powder.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

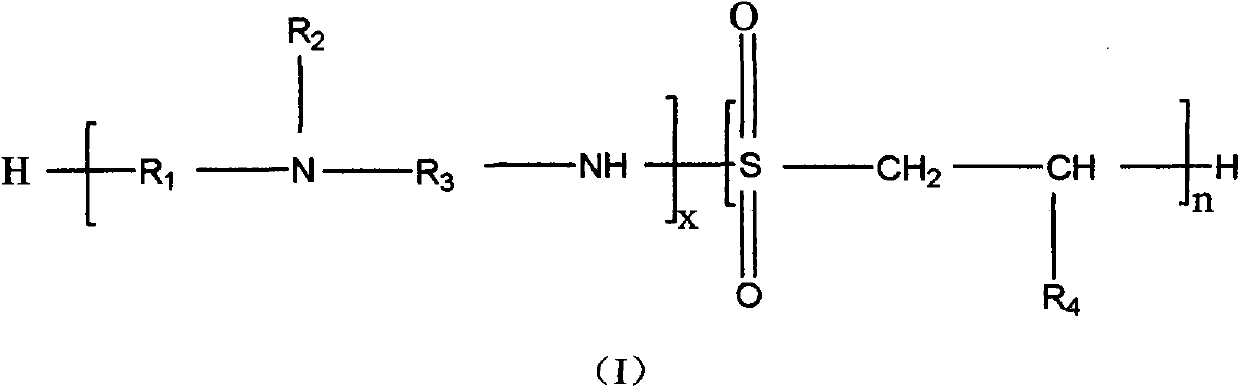

Anti-static fuel additive and preparation method thereof

InactiveCN103275771AReduce the external electric field strengthImprove conductivityLiquid carbonaceous fuelsFuel additivesChemistrySulfone

The invention relates to a fuel additive and in particular relates to an anti-static fuel additive and a preparation method thereof. The anti-static fuel additive comprises polyamino sulfone shown in a formula (I). Amino and sulfonyl in the anti-static additive are in a same molecule, and the ratio of amino to sulfonyl is fixed, so that the anti-static additive can be also kept in gasoline or diesel in the absence of a stabilizer, the electrical conductivity of an oil product is stable, the production program of the anti-static additive is simplified, and the cost is lowered; and the anti-static additive is not easily adsorbed by metallic media, the electric conductivity of gasoline or diesel is not easily attenuated during transportation and usage processes, and the stability of the electrical conductivity is high.

Owner:PLA AIR FORCE OIL MATERIAL RES INST

Flexible conductive fiber based on silver nanowires and preparation method of flexible conductive fiber

ActiveCN109338717AImprove conductivity stabilityIncreased durabilityFibre typesHydrofluoric acidMiniaturization

The invention discloses a flexible conductive fiber based on silver nanowires. The conductive fiber is characterized in that the surface of a polyurethane fiber is wrapped with a plurality of layers of silver nanowires. The invention further discloses a preparation method of the conductive fiber. The preparation method comprises the steps of transferring a silver nanowire conductive network absorbed on an inner wall of a capillary glass tube to the surface of polyurethane, and then dissolving the capillary glass tube through hydrofluoric acid to form the conductive fiber. The conductive fiberuses the silver nanowires as a material of a conductive functional layer and transparent polyurethane as a fiber matrix material; the prepared conductive fiber has excellent conductivity and good acid-base corrosion resistance; the material of conductive layer is only retained on the surface of a fiber matrix; the fiber matrix is not damaged; and compared with a conductive fiber prepared by a mixed conductive filling method, the prepared conductive fiber has better flexibility and elasticity and can be bent, wound, stretched and cut. The conductive fiber meets miniaturization, flexibility andwearability development requirements of electronic equipment in the future.

Owner:XIAN UNIV OF TECH

Making method of graphene electrocardioelectrode

InactiveCN107913061AEnhanced Raman ScatteringImprove conduction efficiencyDiagnostic recording/measuringSensorsGrapheneSilver ion

The invention discloses a making method of a graphene electrocardioelectrode. The making method includes: mixing a solution containing silver ions with graphene; irradiating by an ultraviolet lamp forreduction to obtain the electrocardioelectrode. The defect that silver and graphene are incompatible is overcome, and Raman scattering of graphene is enhanced. The electrocardioelectrode made by themethod overcomes the defect that silver and graphene are incompatible, Raman scattering of graphene is enhanced, electroconductive efficiency and stability of the electrocardioelectrode are improved,and service life of the electrocardioelectrode is prolonged.

Owner:湖南豌豆医疗用品有限公司

Metal conductive ink and preparation method thereof

The invention discloses metal conductive ink and a preparation method thereof, and belongs to the technical field of ink preparation. The metal conductive ink comprises, by mass, 20-50% of metal nanoconductive particles, 20-30% of a binder, 20-40% of a solvent and 10-15% of a pigment; wherein the conductive filler comprises silver-coated nano particles, and the silver-coated nano particles comprise silver-coated copper nano particles and silver-coated silicon dioxide nano powder. The preparation method comprises the following steps: preparing a first dispersion mixture; preparing a second dispersion mixture; preparing a third dispersed mixture; and mixing and grinding the components. On one hand, through the selection design of the metal nano conductive particles and the selection of themixed solvent, the agglomeration of the nano conductive particles can be prevented; on the other hand, through the preparation method of gradually dispersing and mixing the metal nano conductive particles, the dispersing performance of the metal nano conductive particles in the whole ink material is improved, so that the conductive ink has beneficial conductivity.

Preparation method and product of high-stability flexible transparent conductive cellulose film

ActiveCN109081932ATo achieve an organic combinationImprove conductivity stabilityStarch coatingsBulk chemical productionTransparent conducting filmCellulose pulp

The invention provides a preparation method and a product of a high-stability flexible transparent conductive cellulose film. The method includes the steps: dissolving cellulose pulp in a cellulose solvent and preparing a regenerated cellulose film by regeneration treatment; preparing starch solution; dispersing silver nanowires in the starch solution to form silver nanowire and starch solution and covering the cellulose film with the silver nanowire and starch solution to obtain a sample; drying the prepared sample in a drying box to obtain the high-stability flexible transparent conductive cellulose film. In introducing a starch buffer layer, the silver nanowires are effectively attached to a cellulose film substrate, so that the conductive stability and the abrasion resistance of the conductive film are greatly increased, and the high-end quality of the flexible transparent conductive film is improved.

Owner:FUJIAN AGRI & FORESTRY UNIV

Method for preparing Ag-coating-Ni composite nano powder conductive slurries

InactiveCN102969082ALower sintering temperatureImprove conductivity stabilityNon-conductive material with dispersed conductive materialCable/conductor manufactureElectrically conductiveTungsten

The invention relates to a method for preparing Ag-coating-Ni composite nano powder conductive slurries. A direct-current arc plasma method is used, a mixture of block Ag and block Ni serves as a positive electrode, and metal tungsten serves as a negative electrode to prepare Ag-coating-Ni composite nano powder and conductive slurries. The prepared conductive slurries are low in sintering temperature, in no need of protection gas during sintering, higher than nano Ni powder, Cu powder and Ag-Cu alloy powder slurries in conductive stability, hopeful for replacing expensive gold, silver and palladium conductive slurries and suitable for industrial application.

Owner:SHENYANG POLYTECHNIC UNIV

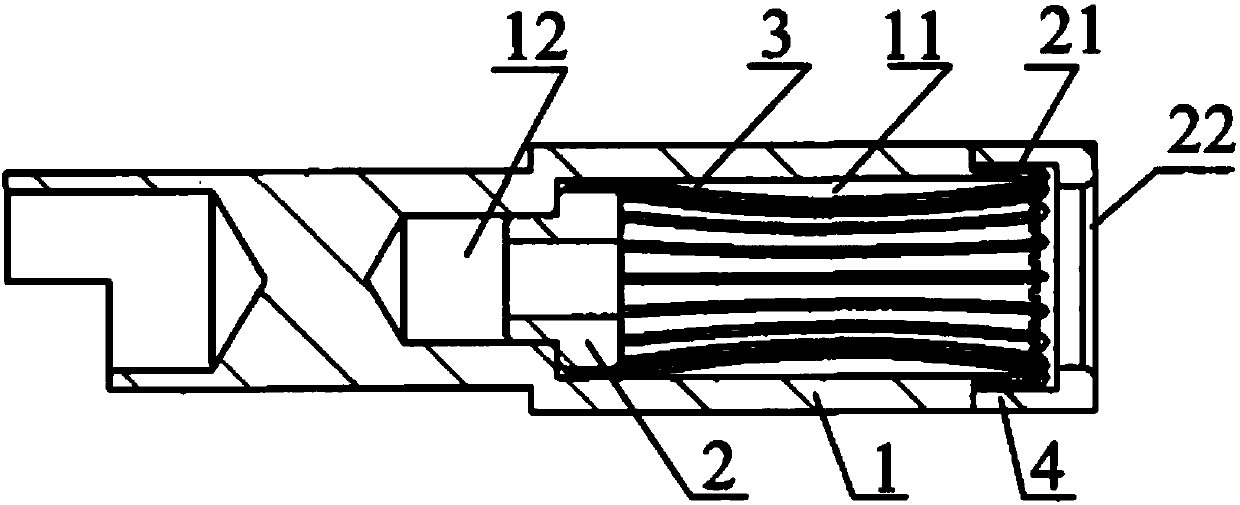

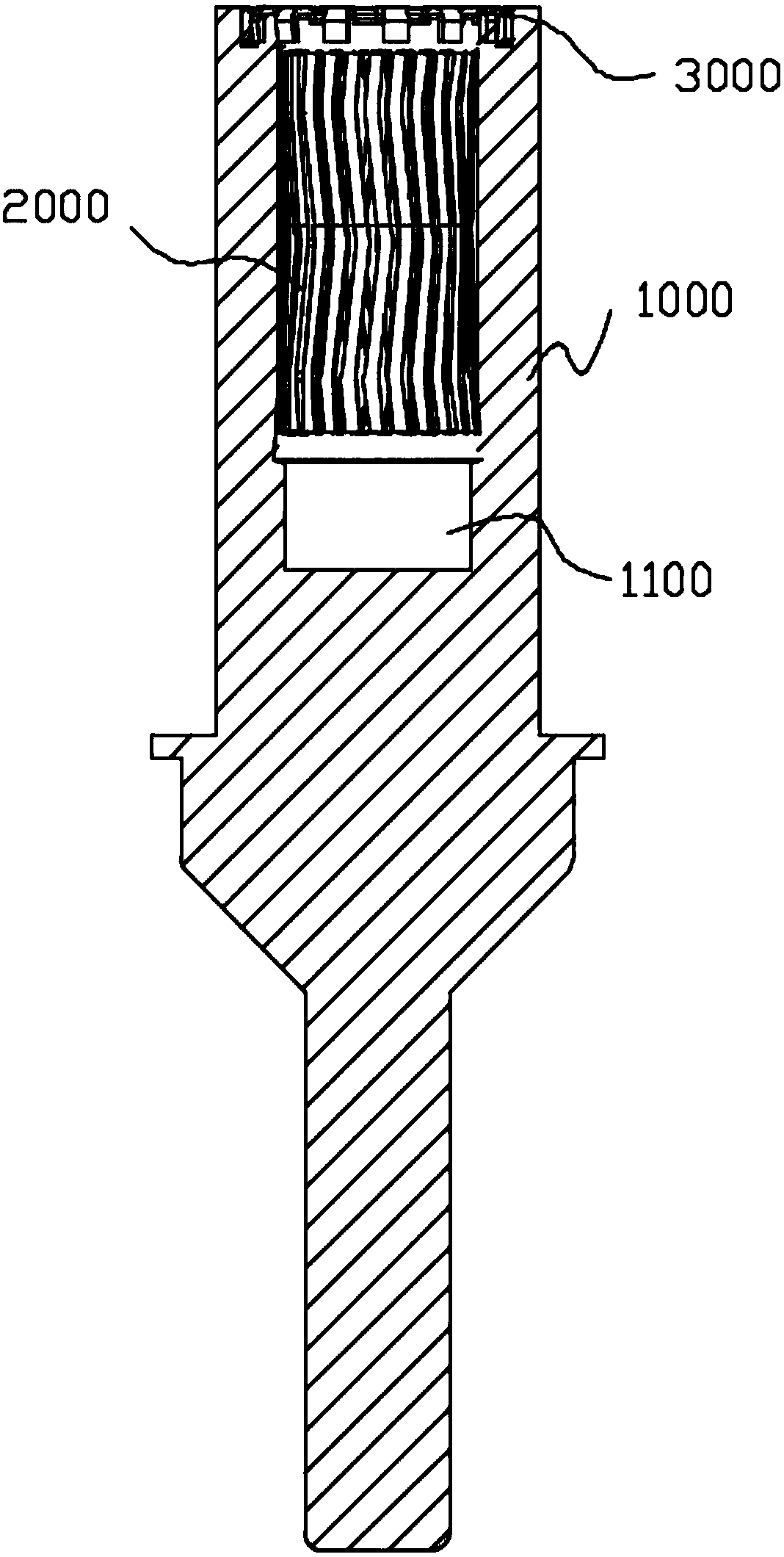

Wire spring plug bush

PendingCN107732510AIncrease the effective contact areaEasy to fixCoupling device detailsEngineeringMechanical engineering

The invention provides a wire spring plug bush. The wire spring plug bush comprises an outer sleeve, a wire spring and a claming ring, wherein the outer sleeve has an inserting hole; the inserting hole adopts a blind hole structure and extends in the axial direction of the outer sleeve; a stage is arranged on the inner side of the inserting hole; an annular groove is formed in the end plane of theouter sleeve; the annular groove is close to the outer side edge of the inserting hole; multiple claws are arranged at the first end of the wire spring; the claws are mounted on the wall, positionedbetween the inserting hole and the annular groove, of the outer sleeve; the second end of the wire spring is mounted on the stage; and the clamping ring is clamped in the annular groove and used for fixing the claws. According to the wire spring plug bush provided by the invention, on one hand, the wire spring plug bush is more compact in structure, the effective contact area of the wire spring isenlarged, and conductive stability is reinforced; on the other hand, by virtue of structural change, the wire spring can be fixed on the outer sleeve more easily and firmly; and in addition, the structure is simplified and the mounting efficiency is higher.

Owner:深圳市华南汇机科技有限公司

Method of preparation of conductive polymer/carbon nanotube composite nanofiltration membrane and the use thereof

ActiveUS20210008503A1Need of expensiveImproved ion separation performanceMaterial nanotechnologyMembranesPolymer scienceConductive polymer

A method for preparation of conductive polymer / carbon nanotube (CNT) composite nanofiltration (NF) membrane and the use thereof. This conductive polymer / CNT composite NF membrane is obtained by polymerizing conductive polymer into a CNT membrane and then in-situ cross-linking with glutaraldehyde under acidic condition. The synthetic method for the conductive polymer / CNT composite NF membrane is simple and has no need of expensive equipment. The prepared membrane has controllable membrane structure and possesses superior electrical conductivity and electrochemical stability. The membrane can couple with electrochemistry for electrically assisted filtration. With the electrical assistance, the membrane can achieve improved ion rejection performance while retaining high permeability by enhancement of membrane surface charge density, which alleviates the permeability-selectivity trade-off. Furthermore, the electrically assisted NF membrane filtration can also enhance the removal for small molecular organic pollutants.

Owner:DALIAN UNIV OF TECH

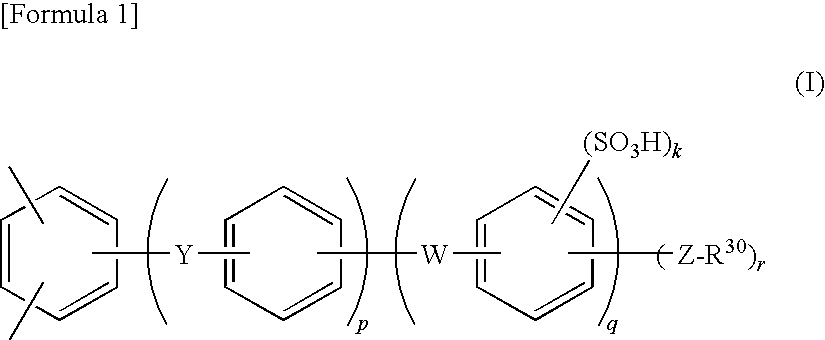

Electrode electrolyte for polymer-type fuel cell, and use thereof

InactiveUS20100167161A1Improve proton conductivityHigh mechanical strengthSolid electrolytesOrganic chemistryPolymer electrolytesFuel cells

Disclosed is an electrode electrolyte for solid polymer fuel cells, which uses a polymer electrolyte containing a polyarylene copolymer containing a nitrogen-containing aromatic ring having a substituent represented by —SO3H, —(O(CH2)hSO3H or —O(CF2)hSO3H (wherein h represents an integer of 1-12). By having such a constitution, the electrode electrolyte for solid polymer fuel cells can be produced at a low cost, while being excellent in proton conductivity, dimensional stability, hydrothermal resistance and mechanical strength. In addition, this electrode electrolyte for solid polymer fuel cells enables to recover a catalyst metal.

Owner:JSR CORPORATIOON +1

Transducer and assembly method thereof

InactiveCN101351057AGood electrical connectionSimplify the assembly processTransducer casings/cabinets/supportsEngineeringRetaining wall

The invention discloses a transducer, which comprises a conductive terminal, a first shell and a second shell and is characterized in that the conductive terminal comprises a first conductive part, a second conductive part which is connected with the first conductive part and a third conductive part which is connected with the second conductive part; the first shell is provided with a channel and a retaining wall; the second shell is provided with a baffle plate; the first conductive part of the conductive terminal goes through the channel; the second conductive part of the conductive terminal is hung at a through groove between the baffle plate and the retaining wall; the third conductive part of the conductive terminal is exposed outside the first shell and the second shell, which realizes good electric link. The invention also discloses an assembly method of the transducer and is characterized in that the first conductive part of the conductive terminal is inserted into the channel of the first shell; the second conductive part of the conductive terminal is parallel with the retaining wall; the third conductive part of the conductive terminal is exposed outside the first shell and the second shell; therefore, the process is simplified and the cost is saved.

Owner:AAC ACOUSTIC TECH (SHENZHEN) CO LTD

Conductive resin for 3D printing technology, and preparation method and application thereof

ActiveCN113956409AImprove conductivity stabilityHigh tensile strengthFluid pressure measurement using piezo-electric devicesAdditive manufacturing apparatusPolymer sciencePolyvinyl alcohol

The invention discloses a conductive resin for a 3D printing technology, and a preparation method and application thereof, and belongs to the technical field of 3D printing materials. The conductive resin comprises, by weight, 70-95 parts of a polymerization reaction material, 20-35 parts of a conductive material and 0.5-3 parts of a photoinitiator, and the polymerization reaction material comprises hydroxyethyl acrylate, polyethylene glycol diacrylate, polyvinyl alcohol, acrylamide and modified polydimethylsiloxane. According to the polymerization reaction material disclosed by the invention, the components are mutually cooperated, and a stable three-dimensional network structure is formed through physical crosslinking and chemical crosslinking, so that the mechanical property of the resin can be effectively improved, and the problem that the conductive material dispersed in water is uniformly dispersed in the resin is solved; therefore, the conductive stability of the conductive resin is improved, and the problem that the mechanical property of conductive hydrogel with similar components becomes poor due to water loss is solved. The resin is simple in preparation method, is manufactured through a photocuring 3D printing technology, and has a huge application prospect in the fields of flexible sensing and the like.

Owner:SOUTHWEST MEDICAL UNIVERISTY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com