Carbon nanotube transparent conductive film and preparation method thereof

A technology of transparent conductive film and carbon nanotubes, which is applied in the direction of nanotechnology, nanotechnology, and equipment for manufacturing conductive/semiconductive layers, etc., can solve the problems that it is difficult to realize conductivity and transparency at the same time, and achieve stable conductivity. Effect of high transparency and improved usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

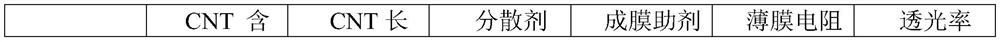

[0063] In view of this, the first aspect of the embodiment of the present application provides a method for preparing a carbon nanotube transparent conductive film, comprising the following steps:

[0064] S01. Dispersing carbon nanotubes in a solvent containing a dispersant to prepare a carbon nanotube dispersion;

[0065] S02. Centrifuge the carbon nanotube dispersion and take the supernatant; add a film-forming aid to the supernatant and mix it to obtain a carbon nanotube solution, wherein the film-forming aid is selected from transparent and conductive film-forming aids;

[0066] S03. Depositing the carbon nanotube solution on the substrate, drying, and cleaning to prepare a carbon nanotube transparent conductive film.

[0067] In the preparation method of the carbon nanotube transparent conductive film provided in the embodiment of the present application, after the carbon nanotube dispersion is centrifuged, a film-forming aid is added to the collected supernatant. On t...

Embodiment 1

[0127] A method for preparing a carbon nanotube transparent conductive film, comprising the following steps:

[0128] S11. Add 2 g of polyacrylic acid to 97.9 mL of water, mix well, add 100 mg of acidified carbon nanotubes (CNTs), and disperse them ultrasonically for 12 hours to obtain a carbon nanotube dispersion; wherein, the length of the CNTs is 100 μm;

[0129] S12. Centrifuge the above-mentioned carbon nanotube dispersion for 90 minutes at a rotational speed of 12000r / min to obtain a layered carbon nanotube dispersion, take the supernatant to obtain a clarified carbon nanotube dispersion; the clarified carbon nanotube 100 mg of polyurethane was added to the dispersion liquid under low-speed stirring to obtain a pre-film-forming solution of carbon nanotubes.

[0130] S13. Take a piece of PET substrate, set the distance between the scraper and the substrate to 20 μm, scrape the above-mentioned carbon nanotube film-forming solution on the surface of the substrate, dry it at...

Embodiment 2

[0132] A method for preparing a carbon nanotube transparent conductive film, comprising the following steps:

[0133] S21. Add 2 g of polyacrylic acid to 97.95 mL of water, mix well, add 50 mg of acidified CNT, and ultrasonically disperse for 12 hours to obtain a carbon nanotube dispersion; wherein, the length of the CNT is 100 μm;

[0134] S22. Centrifuge the above-mentioned carbon nanotube dispersion for 90 minutes at a rotational speed of 12000r / min to obtain a layered carbon nanotube dispersion, take the supernatant to obtain a clarified carbon nanotube dispersion; the clarified carbon nanotube 100 mg of polyurethane was added to the tube dispersion liquid under low-speed stirring to obtain a pre-film-forming solution of carbon nanotubes.

[0135] S23. Take a piece of PET substrate, set the distance between the scraper and the substrate to be 20 μm, scrape and coat the above-mentioned carbon nanotube film-forming solution on the surface of the substrate, dry it at 80° C., ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com