Polytetrafluoroethylene (PTFE) base electrothermal thick film and manufacturing method thereof

A polytetrafluoroethylene and polytetrafluoroethylene technology, which is used in the field of polytetrafluoroethylene based electric heating thick film, can solve the problems of thin carbon film electric heating film not being able to withstand high pressure, unable to make thick electric heating film, rapid aging and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

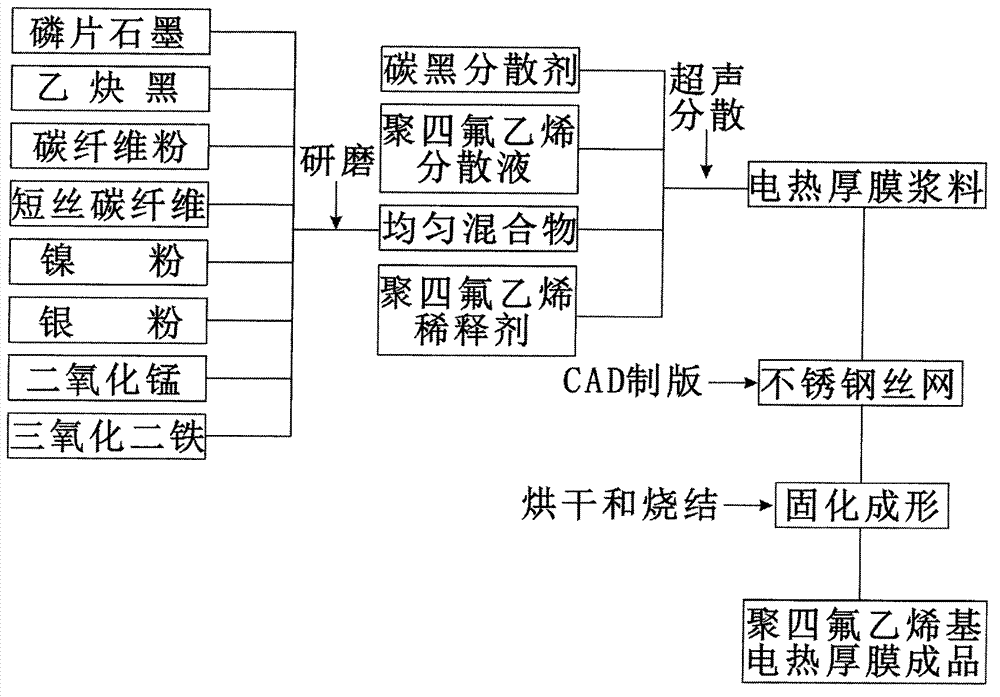

Method used

Image

Examples

Embodiment 1

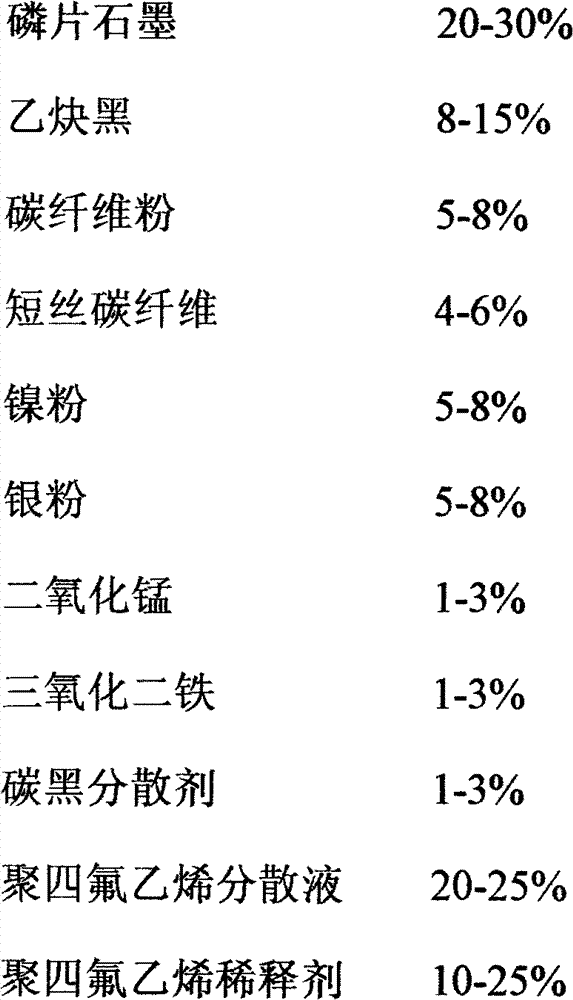

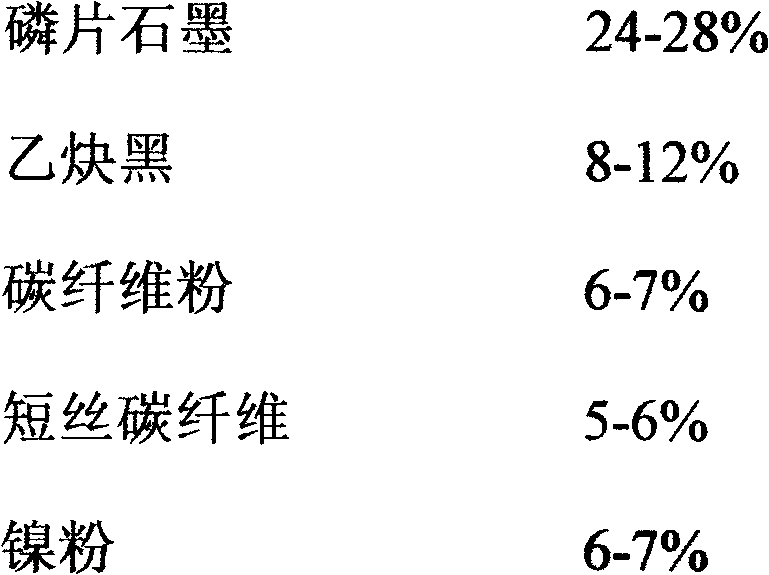

[0021] Get 24 grams of phosphorus flake graphite, 8 grams of acetylene black, 6 grams of carbon fiber powder, 5 grams of short carbon fiber, 6 grams of nickel powder, 6 grams of silver powder, 2 grams of manganese dioxide, and 2 grams of ferric oxide to prepare materials, put them in the grinding Machine mill for 1 hour to make a homogeneous mixture.

[0022] After grinding, the homogeneous mixture is mixed with 2 grams of the carbon black dispersant, 22 grams of polytetrafluoroethylene dispersion, and 15 grams of polytetrafluoroethylene diluent by weight percentage, and is dispersed by ultrasonic wave for 2 hours to prepare polytetrafluoroethylene Paste for vinyl heating thick film.

[0023] The components of the PTFE-based electric heating thick film in Example 1 are calculated based on the optimal weight ratio of its internal structure.

Embodiment 2

[0025] Get 26 grams of phosphorus flake graphite, 10 grams of acetylene black, 6 grams of carbon fiber powder, 6 grams of short carbon fiber, 7 grams of nickel powder, 7 grams of silver powder, 3 grams of manganese dioxide, and 3 grams of ferric oxide to prepare materials, put them in the grinding Machine mill for 1 hour to make a homogeneous mixture.

[0026] After grinding, the homogeneous mixture is mixed with 3 grams of the carbon black dispersant, 24 grams of polytetrafluoroethylene dispersion, and 18 grams of polytetrafluoroethylene diluent by weight percentage, and ultrasonic dispersion is used for 2 hours to prepare polytetrafluoroethylene Paste for vinyl heating thick film.

[0027] The components of the PTFE-based electric heating thick film in Example 2 are calculated based on the optimal weight ratio of its internal structure.

Embodiment 3

[0029] Get 28 grams of phosphorus flake graphite, 12 grams of acetylene black, 7 grams of carbon fiber powder, 6 grams of short carbon fiber, 7 grams of nickel powder, 7 grams of silver powder, 3 grams of manganese dioxide, and 3 grams of ferric oxide to prepare materials, put them in the grinding Machine mill for 1 hour to make a homogeneous mixture.

[0030] After grinding, the homogeneous mixture is mixed with 3 grams of carbon black dispersant, 24 grams of polytetrafluoroethylene dispersion, and 20 grams of polytetrafluoroethylene diluent by weight percentage, and is dispersed by ultrasonic wave for 2 hours to prepare polytetrafluoroethylene Paste for vinyl heating thick film.

[0031] The components of the polytetrafluoroethylene-based electric heating thick film in Example 3 are calculated based on the optimal weight ratio of its internal structure.

[0032] The process steps for manufacturing the above-mentioned polytetrafluoroethylene-based electric heating thick film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com