Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

602results about "Fluid pressure measurement using piezo-electric devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

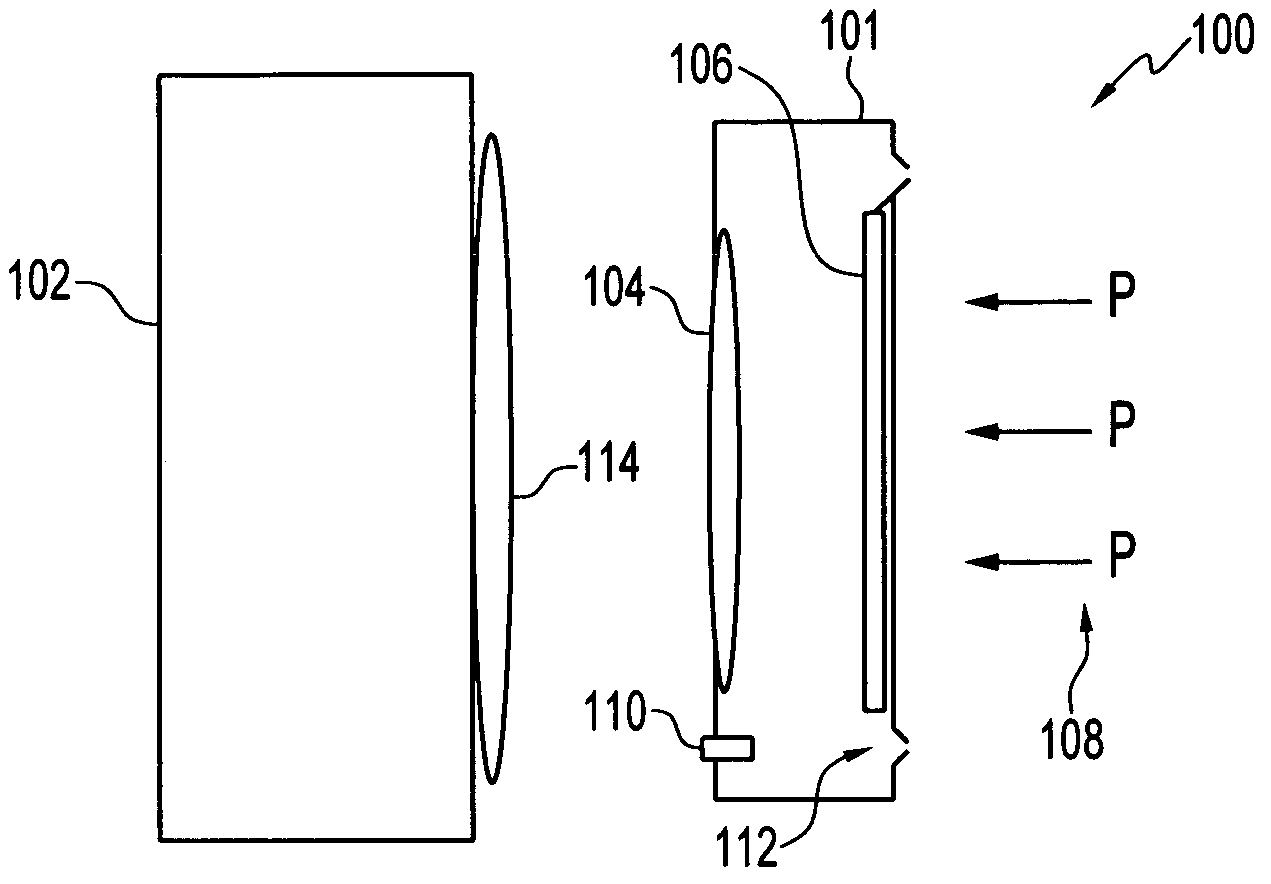

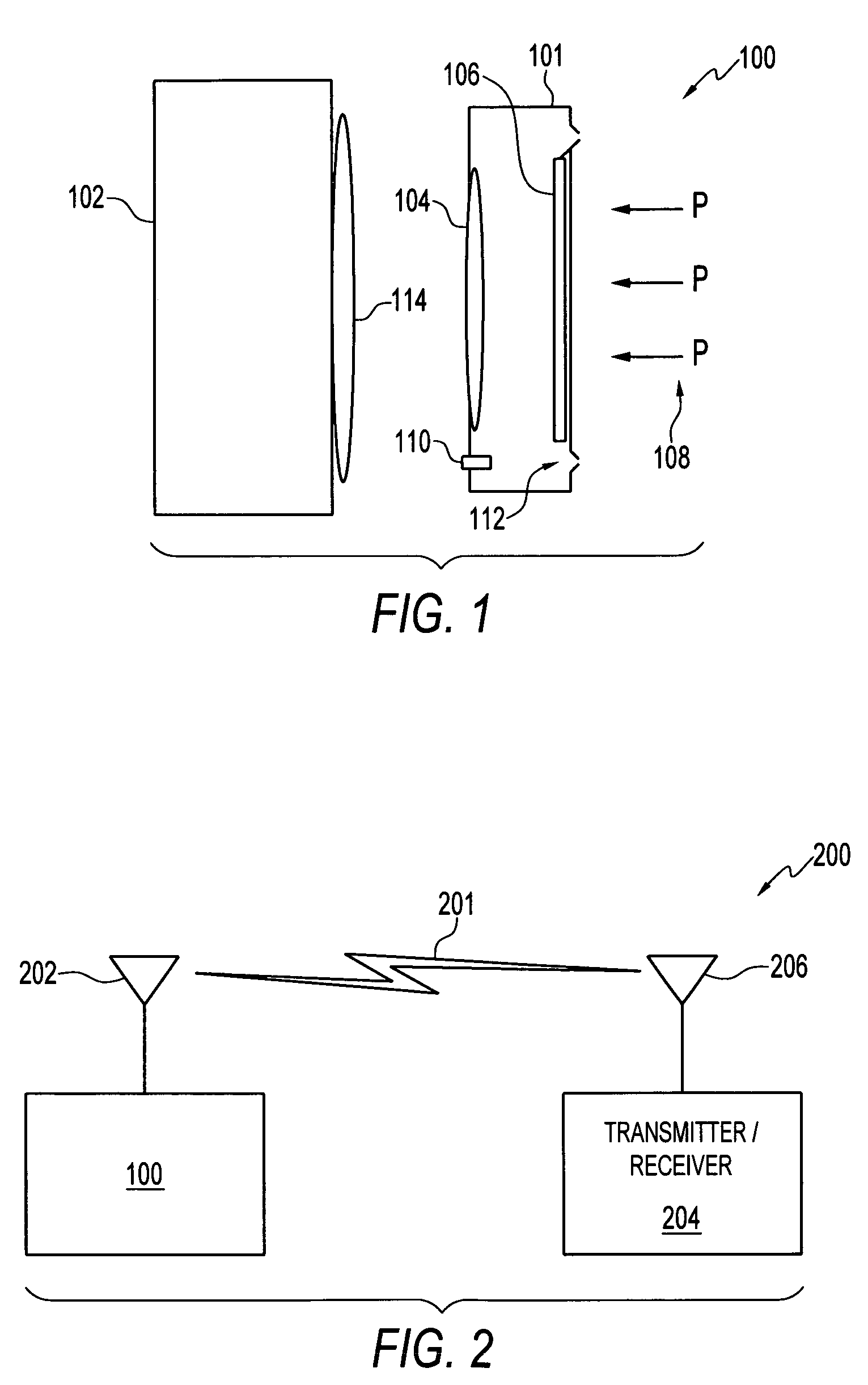

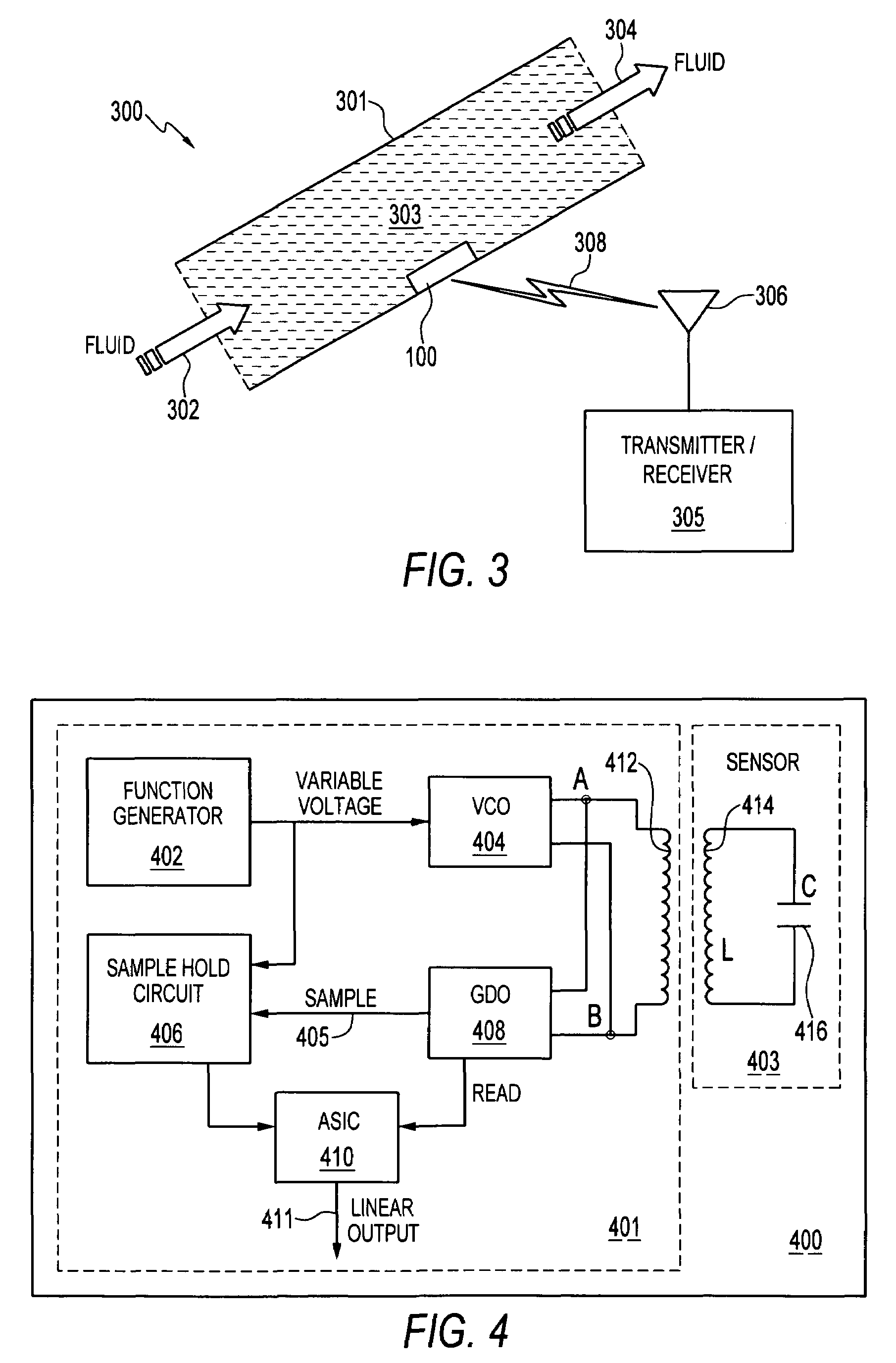

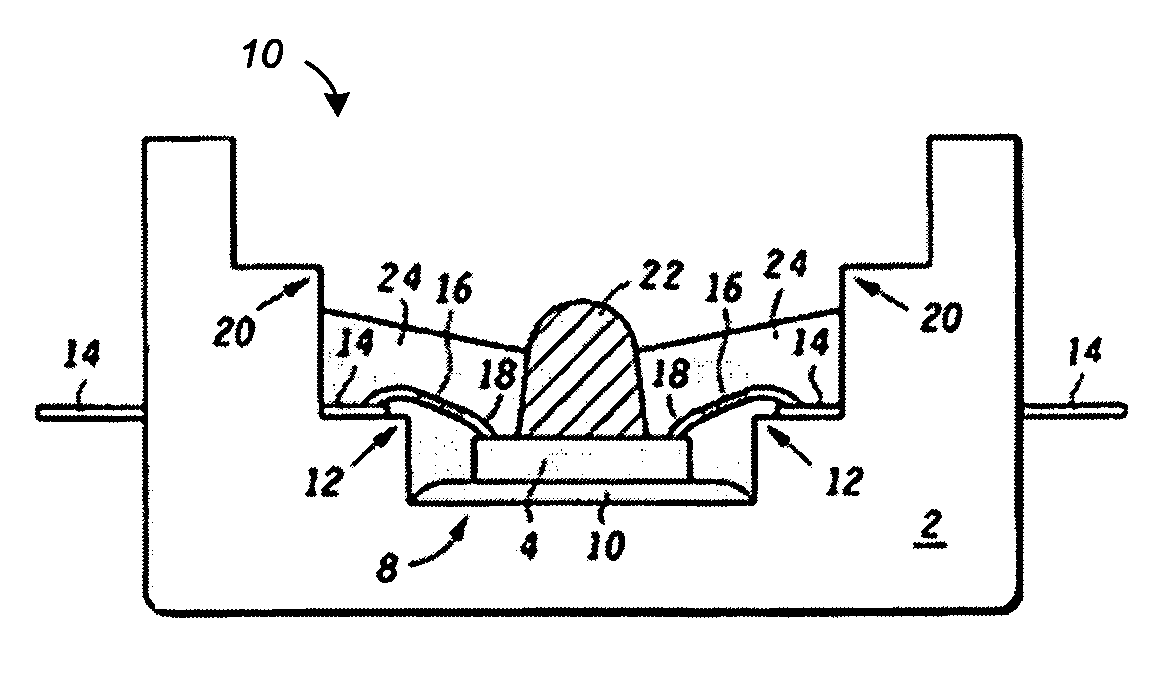

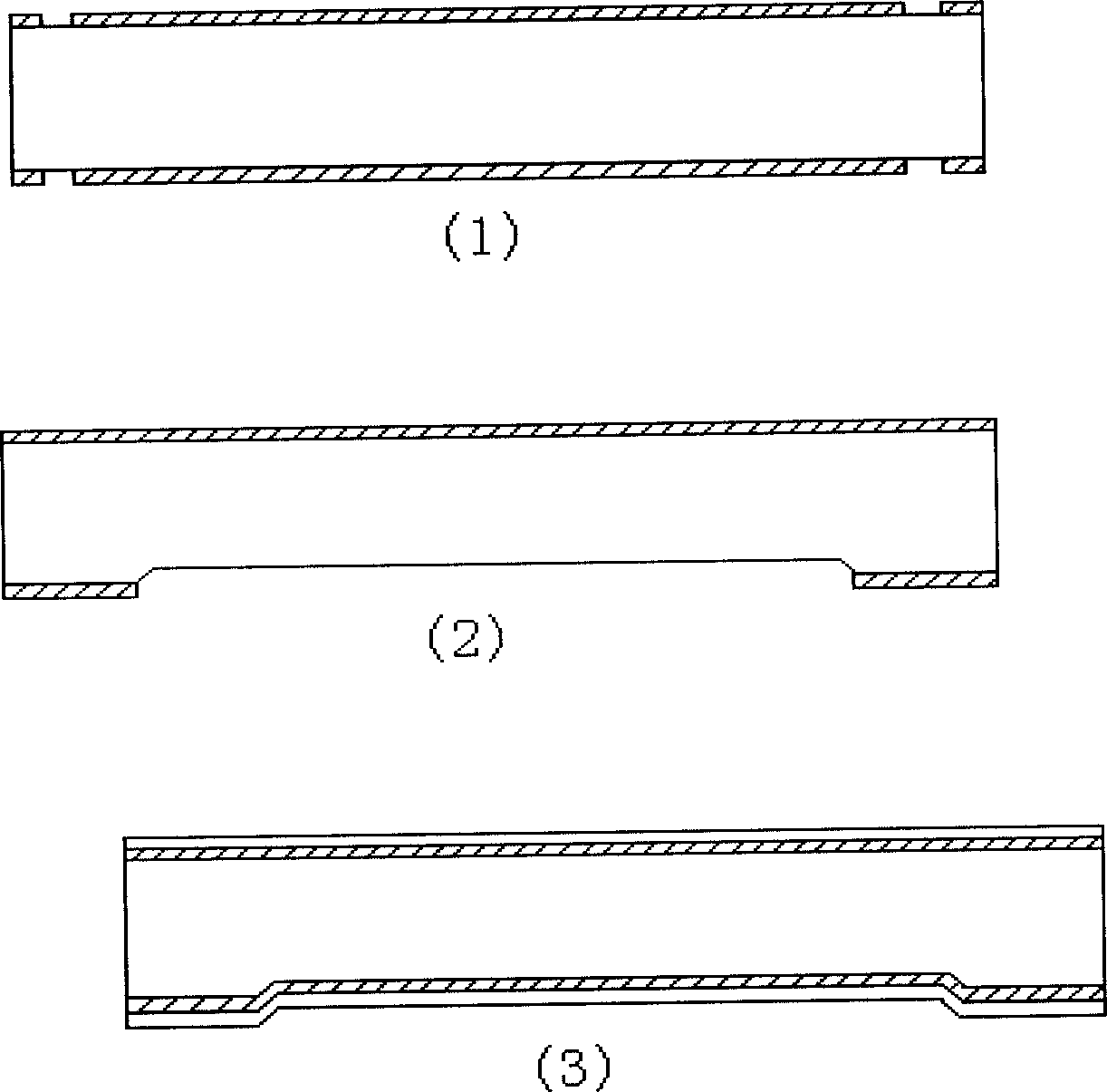

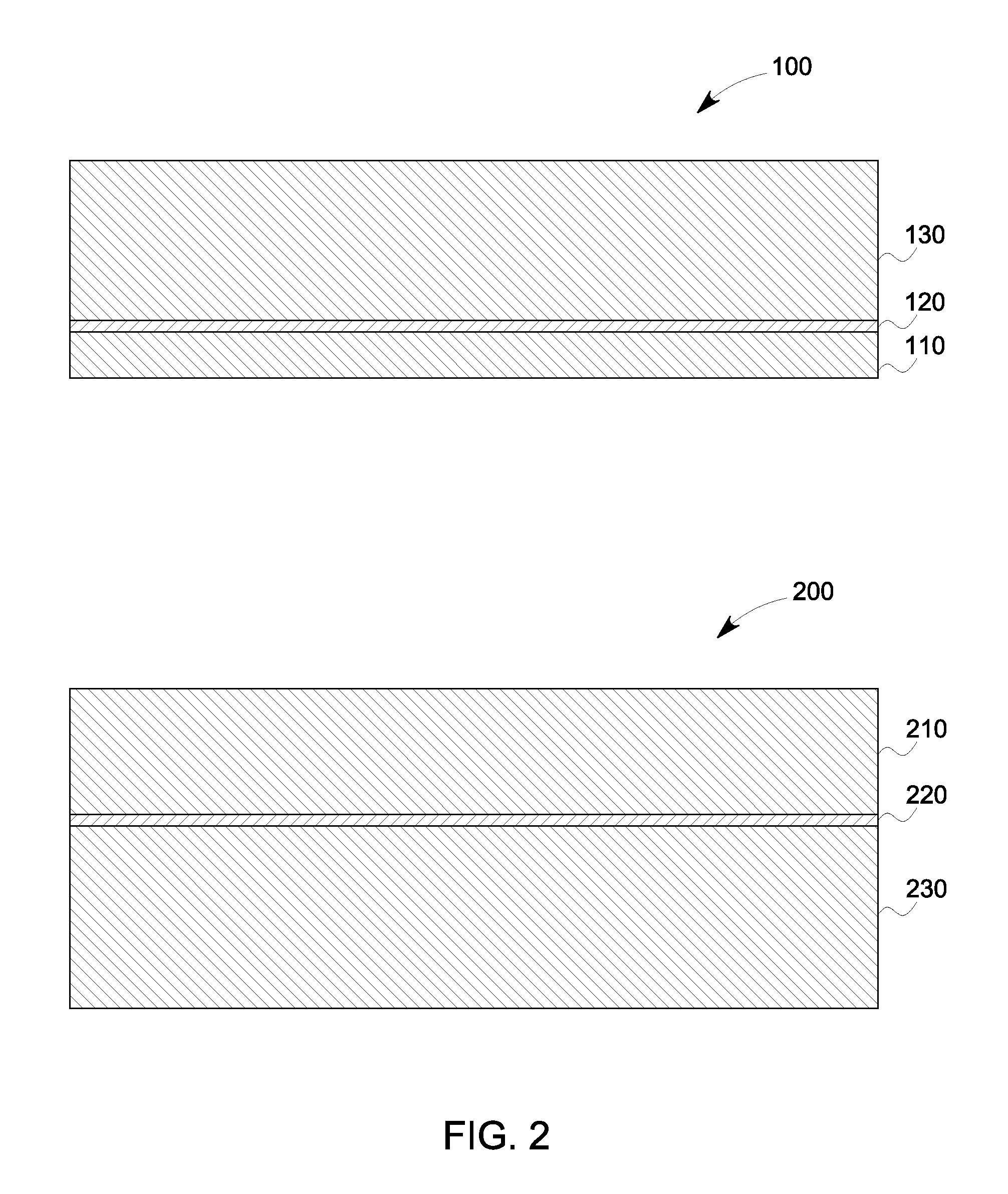

Disposable and trimmable wireless pressure sensor

InactiveUS7146861B1Easy to understandFluid pressure measurement using piezo-electric devicesFluid pressure measurement using inductance variationEngineeringInductor

A disposable pressure sensor includes a substrate and a pressure diaphragm formed upon the substrate. A sensor coil can be provided, comprising a capacitor and an inductor formed on the substrate and surrounded by the pressure diaphragm. The ferrite core is located proximate to the sensor coil, such that when the pressure diaphragm is exposed to a pressure, the diaphragm moves close to the inductor or the capacitor, thereby resulting in a change in the capacitor or the inductor and an indication of pressure. The capacitor can be implanted as an adjustable, trimmable or variable capacitor. The inductor may also be provided as an adjustable or variable inductor and can include the use of a variable capacitor and a PVDF based piezoelectric transducer. When the PVDF layer is under pressure, it can generate an electric field across the interdigital transducer and transmit a signal thereof through an antenna.

Owner:HONEYWELL INT INC

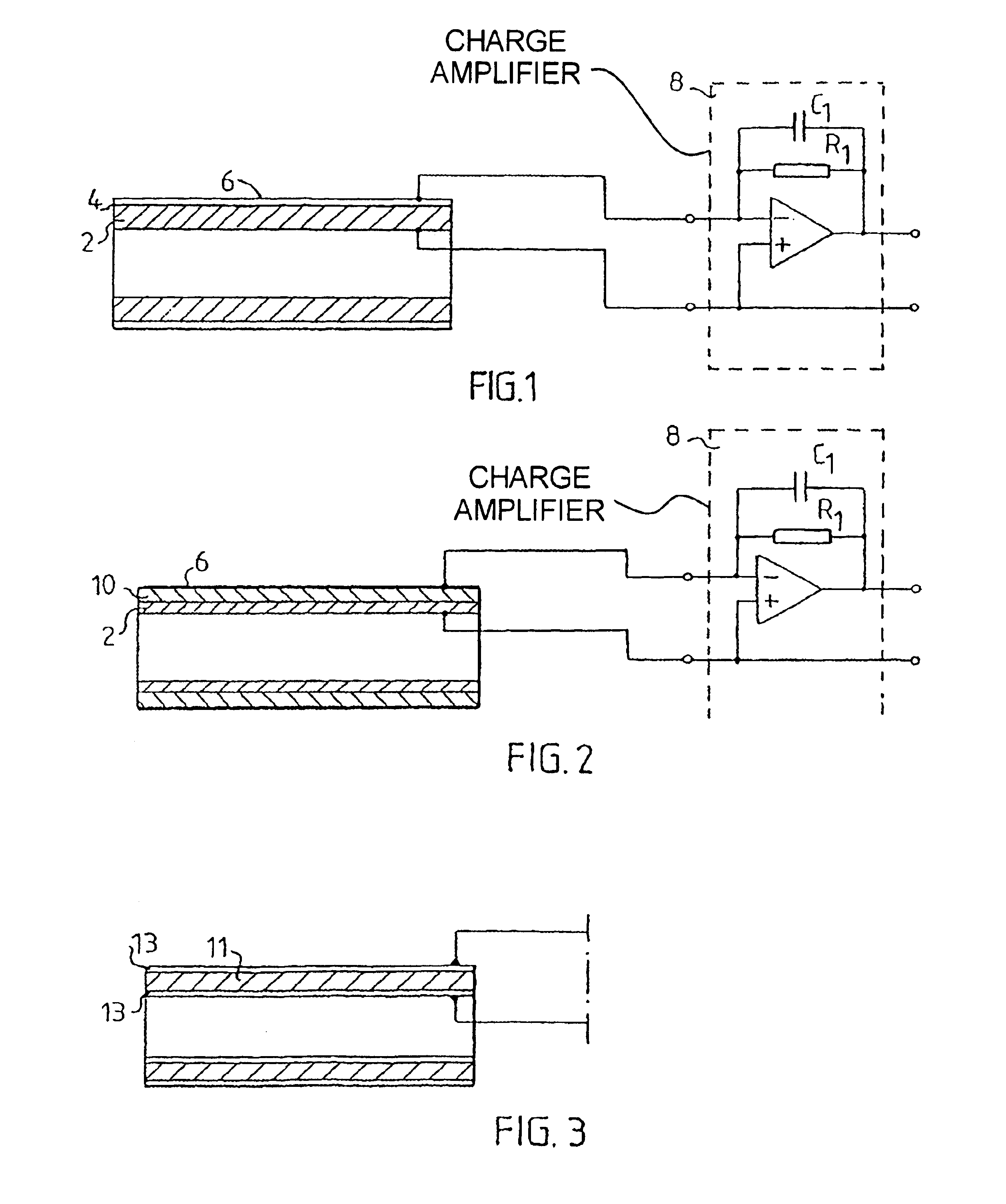

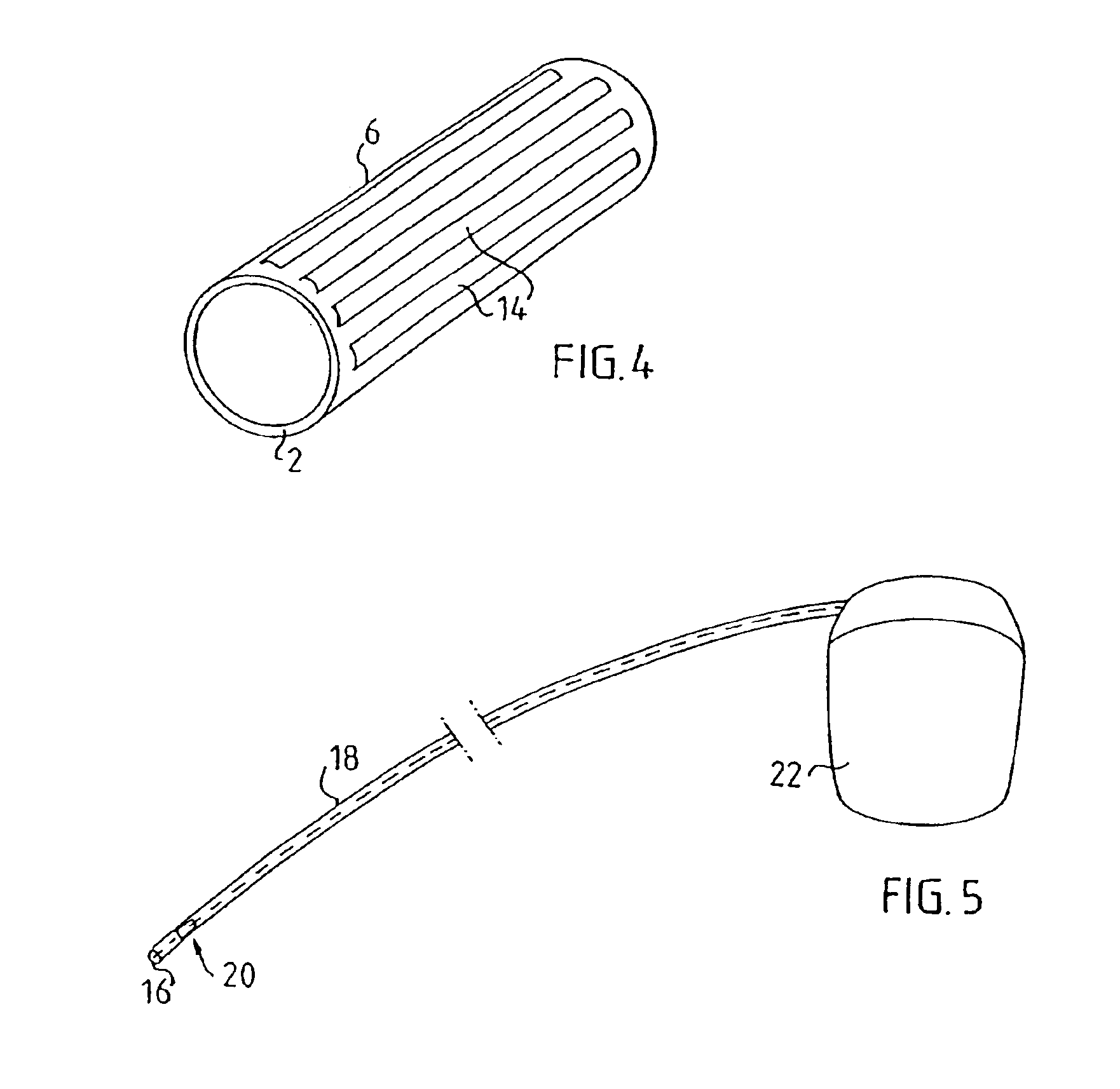

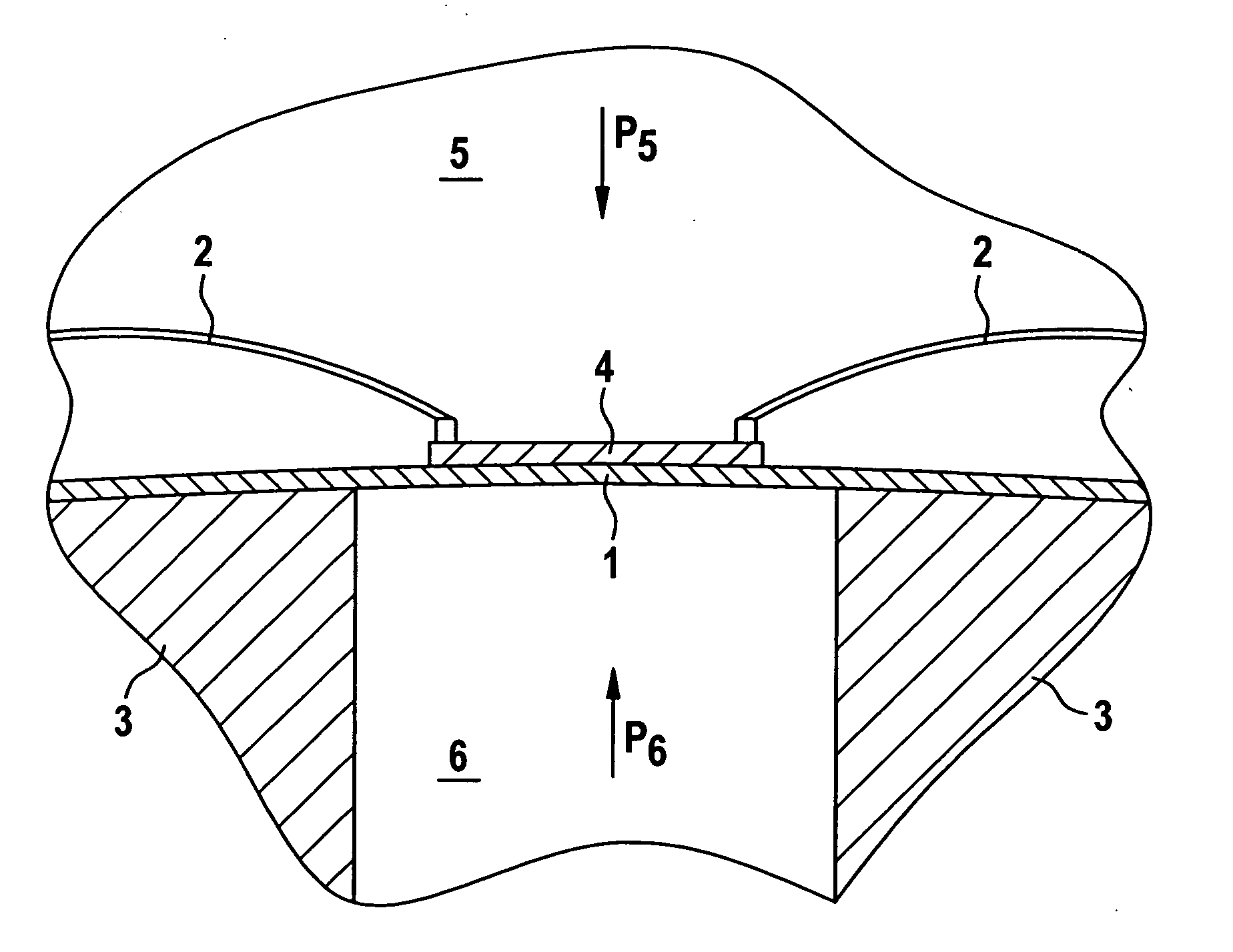

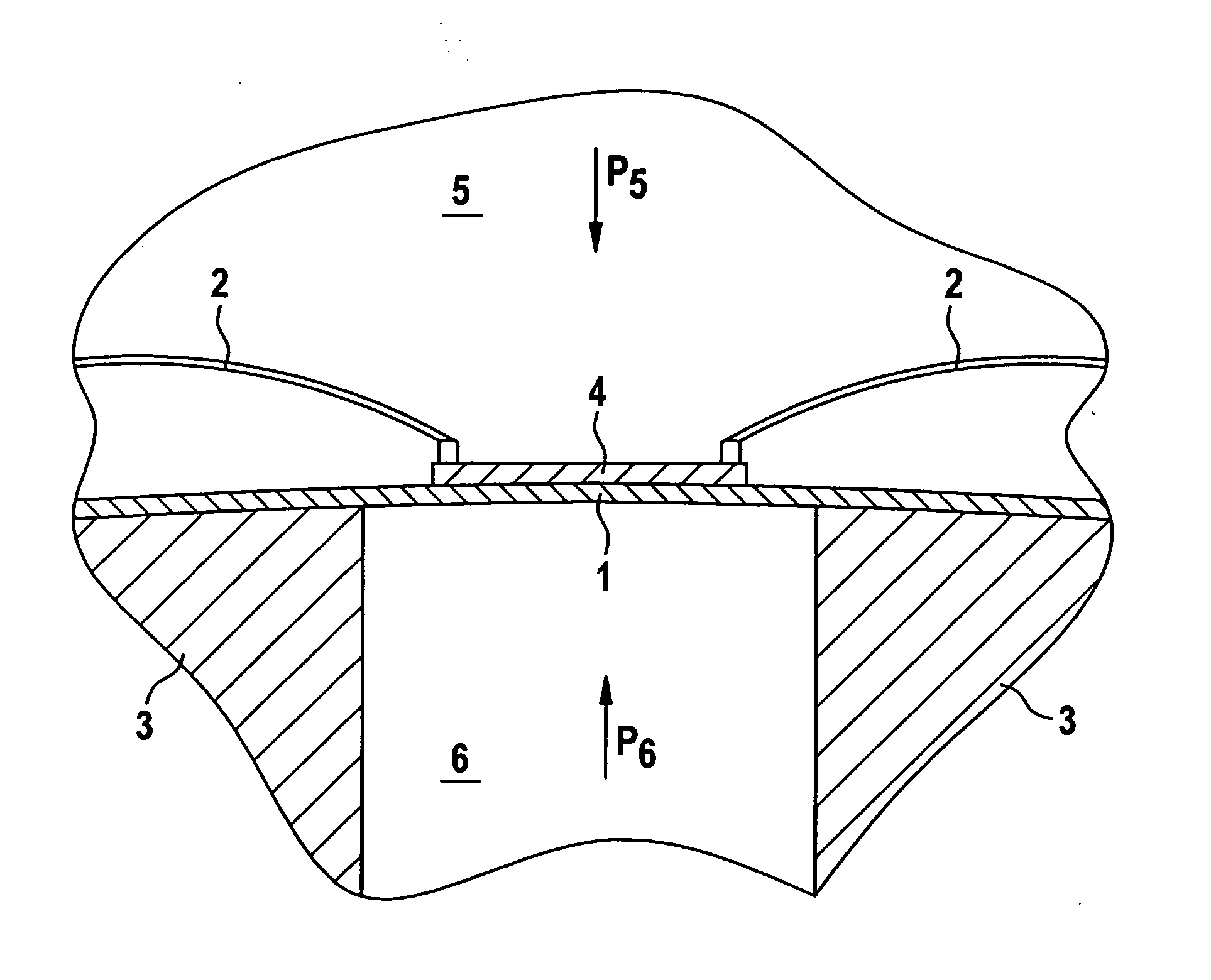

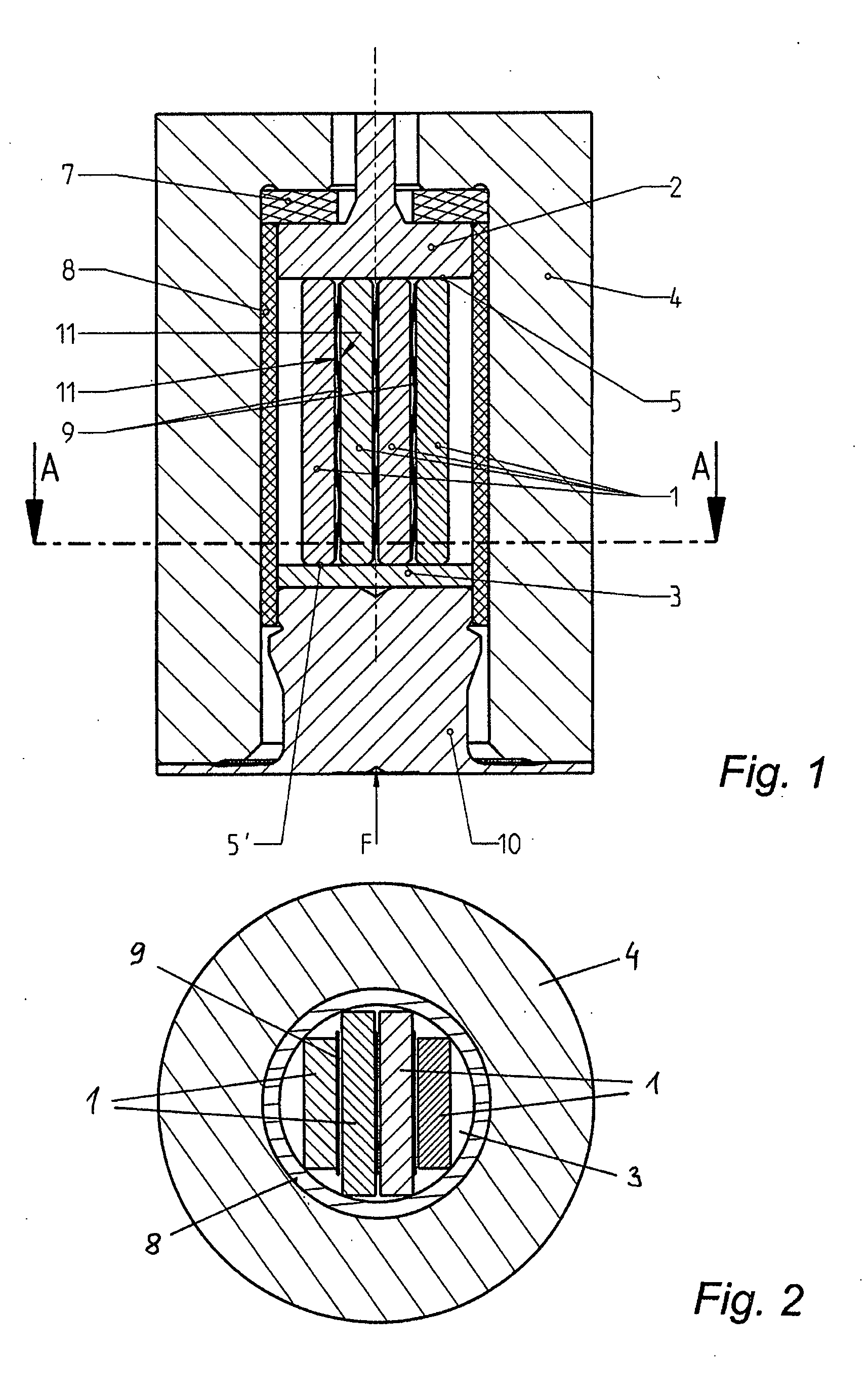

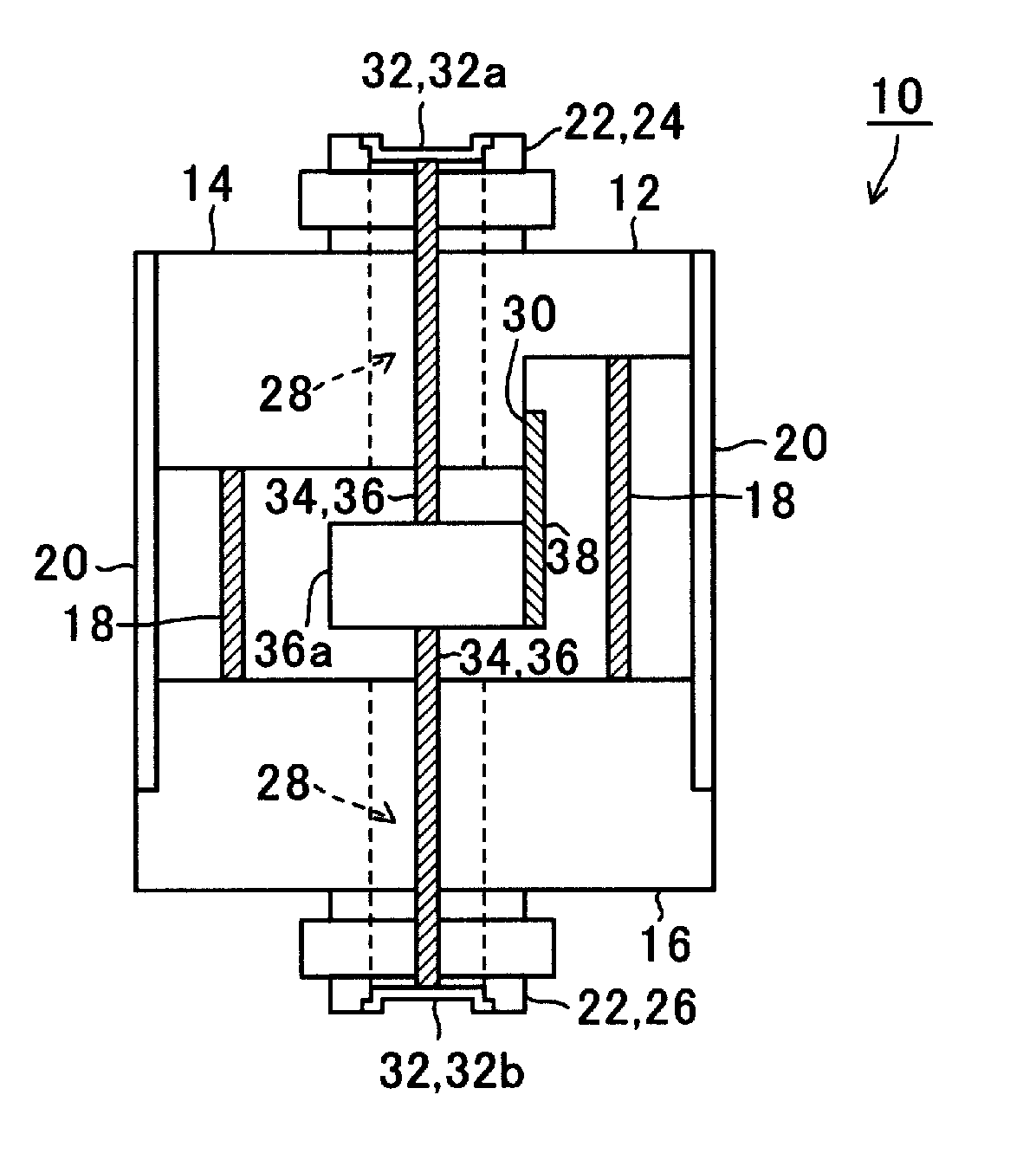

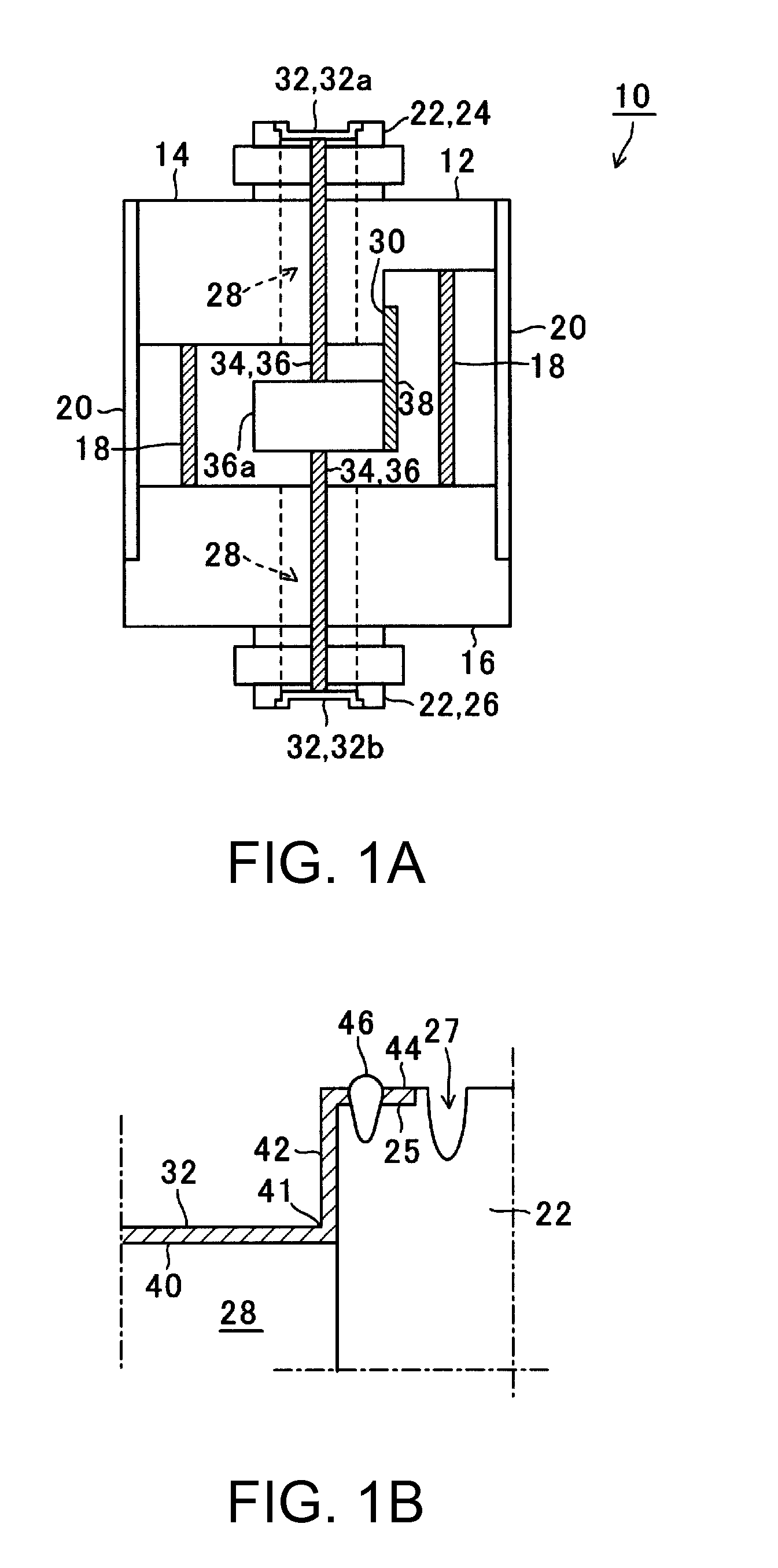

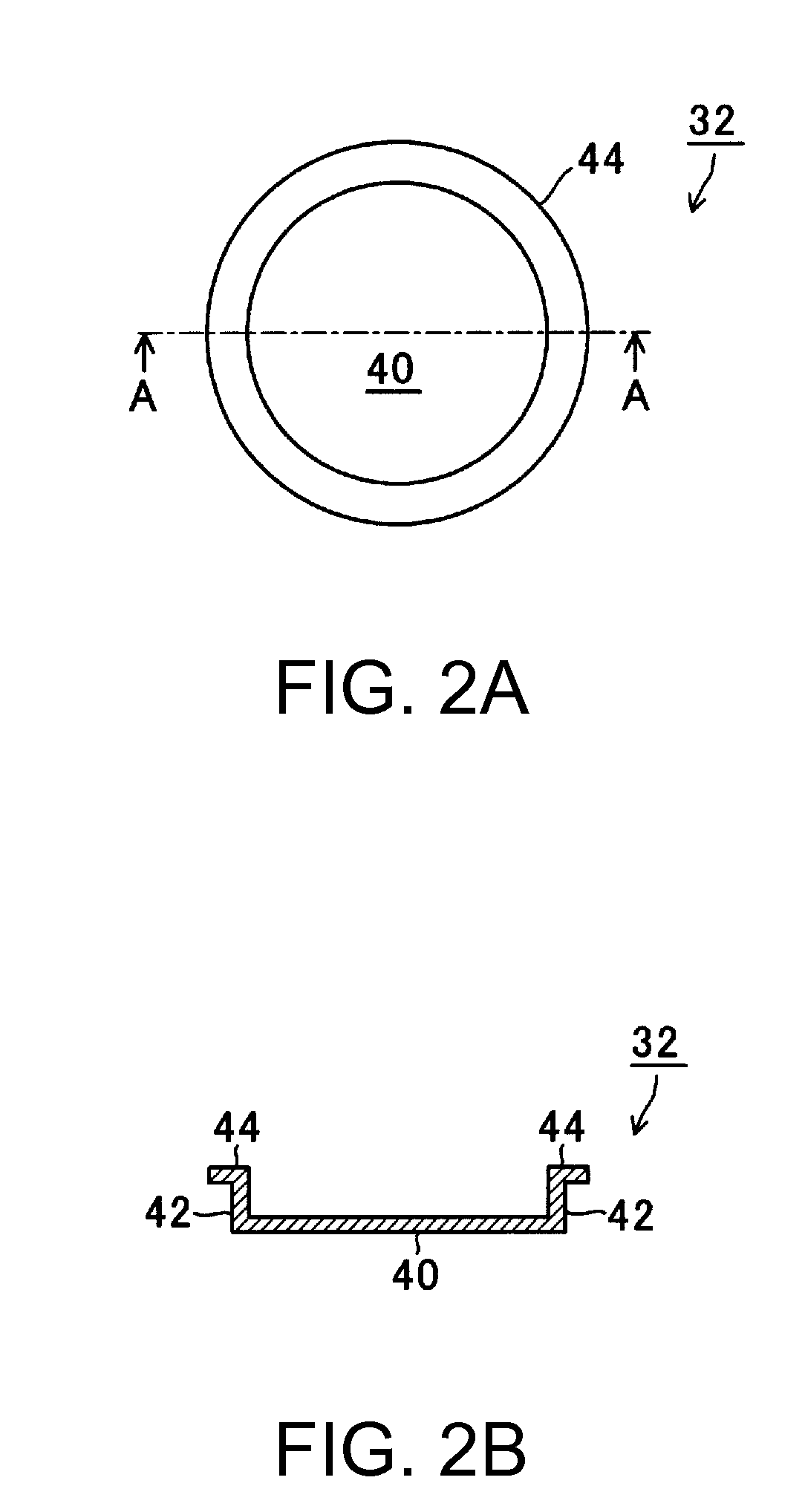

Piezoelectric sensor in a living organism for fluid pressure measurement

InactiveUS6886411B2Sensitive to pressure variationReliable measurement signalFluid pressure measurement using piezo-electric devicesFluid pressure measurement using ohmic-resistance variationBiological bodyElectricity

A fluid pressure sensor for a lead or catheter intended for placement in a living organism, such as a human heart, includes a rigid annular or tubular supporting structure and a piezoelectric element disposed on at least a portion of the outer surface thereof. The piezoelectric element delivers an electrical signal when subjected to a pressure variation, and exhibits circumferential sensitivity. The rigidity of the sensor is defined to satisfy predetermined criteria to ensure that the sensor, when sensing pressure transferred to the sensor through an on-growth of tissue on the sensor, which is at least 90% of the signal which the sensor would emit without the on-growth.

Owner:ST JUDE MEDICAL

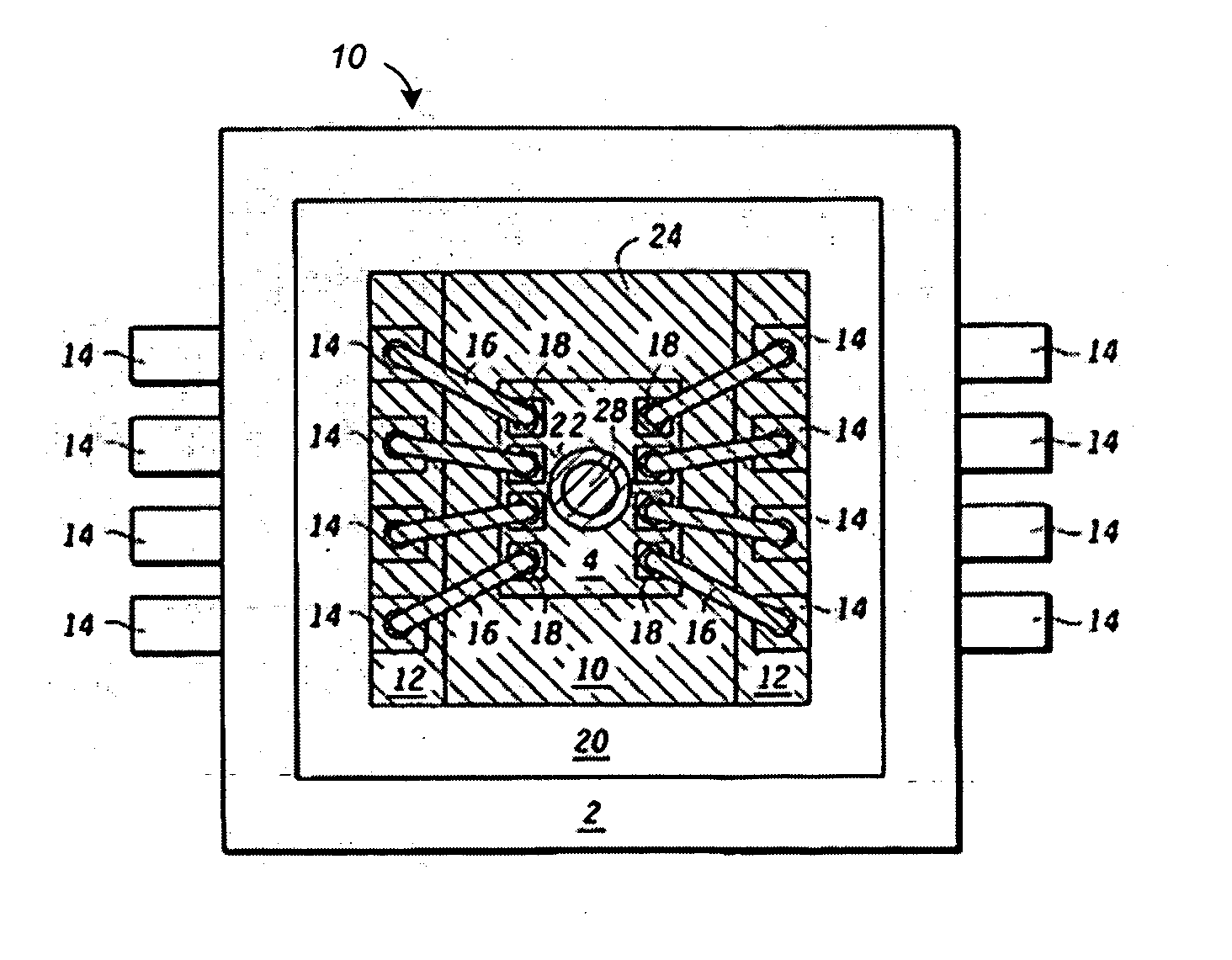

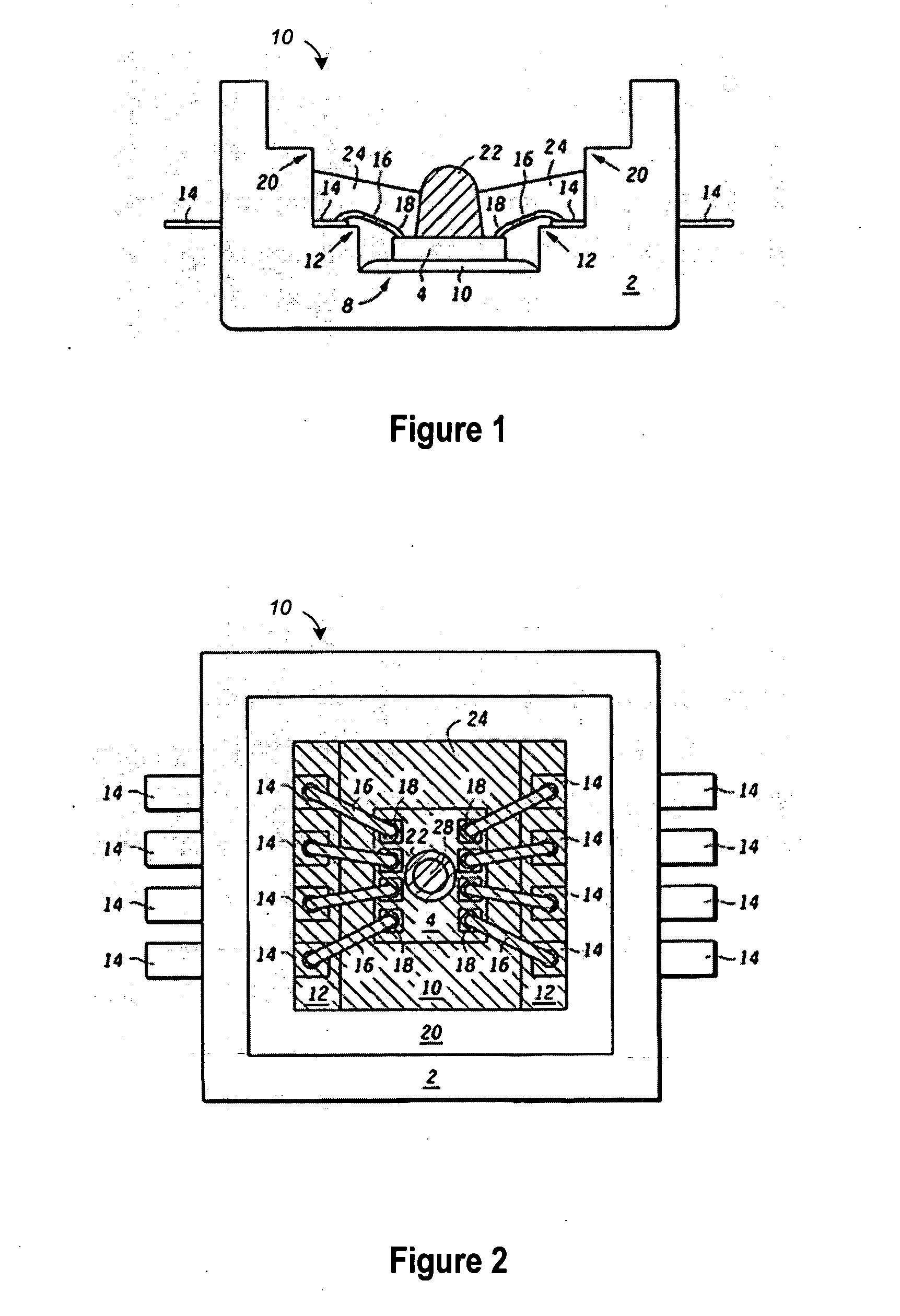

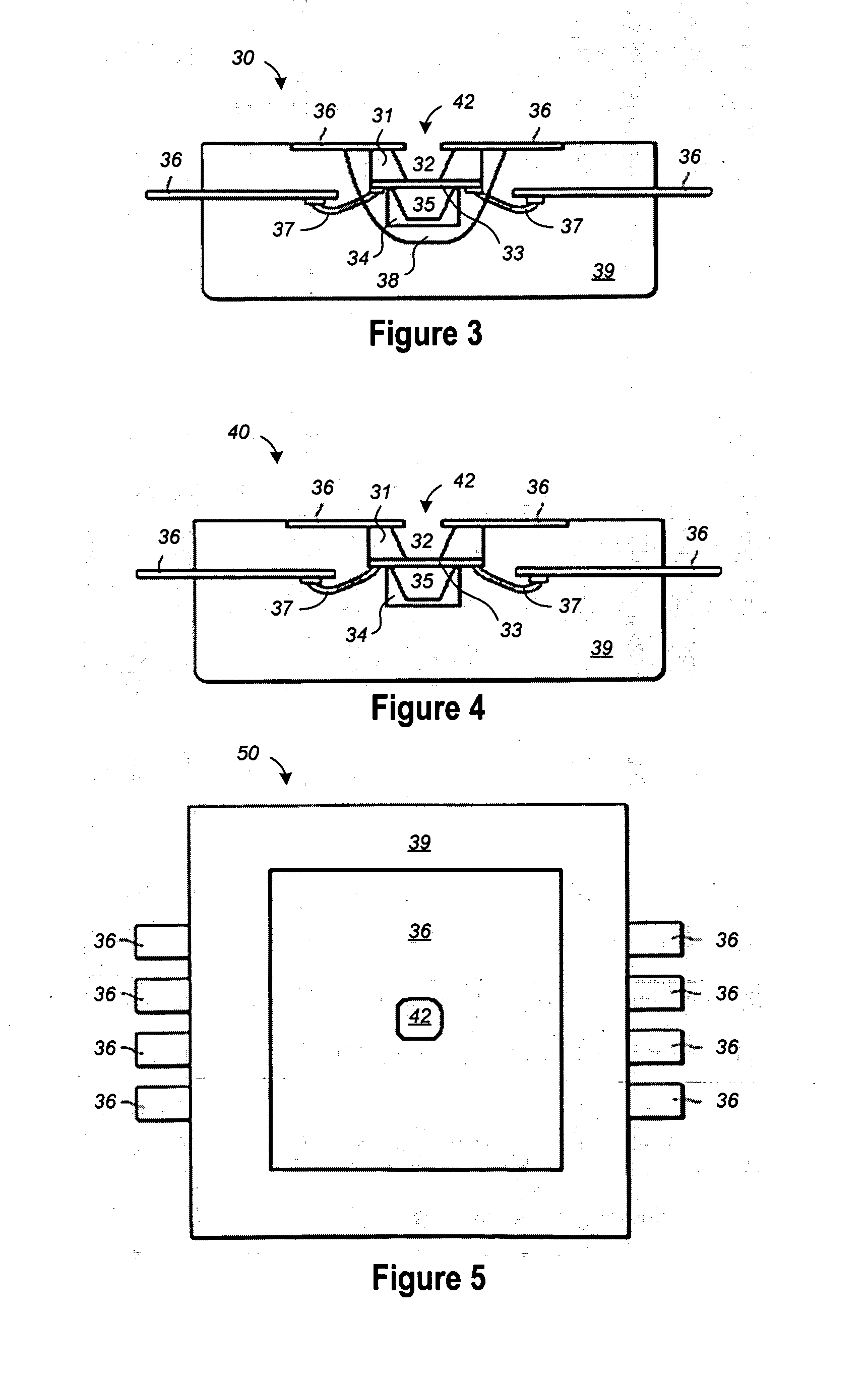

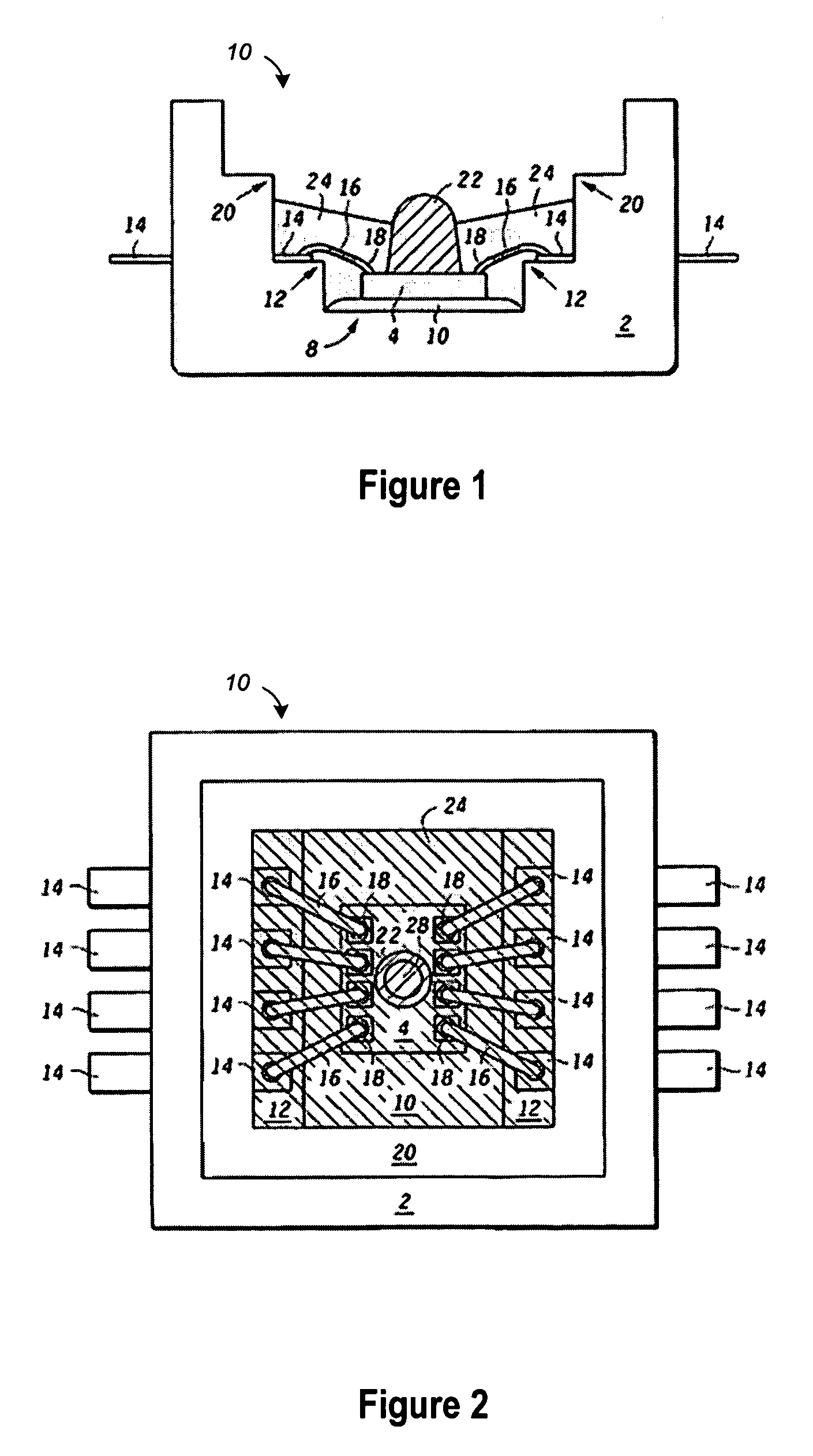

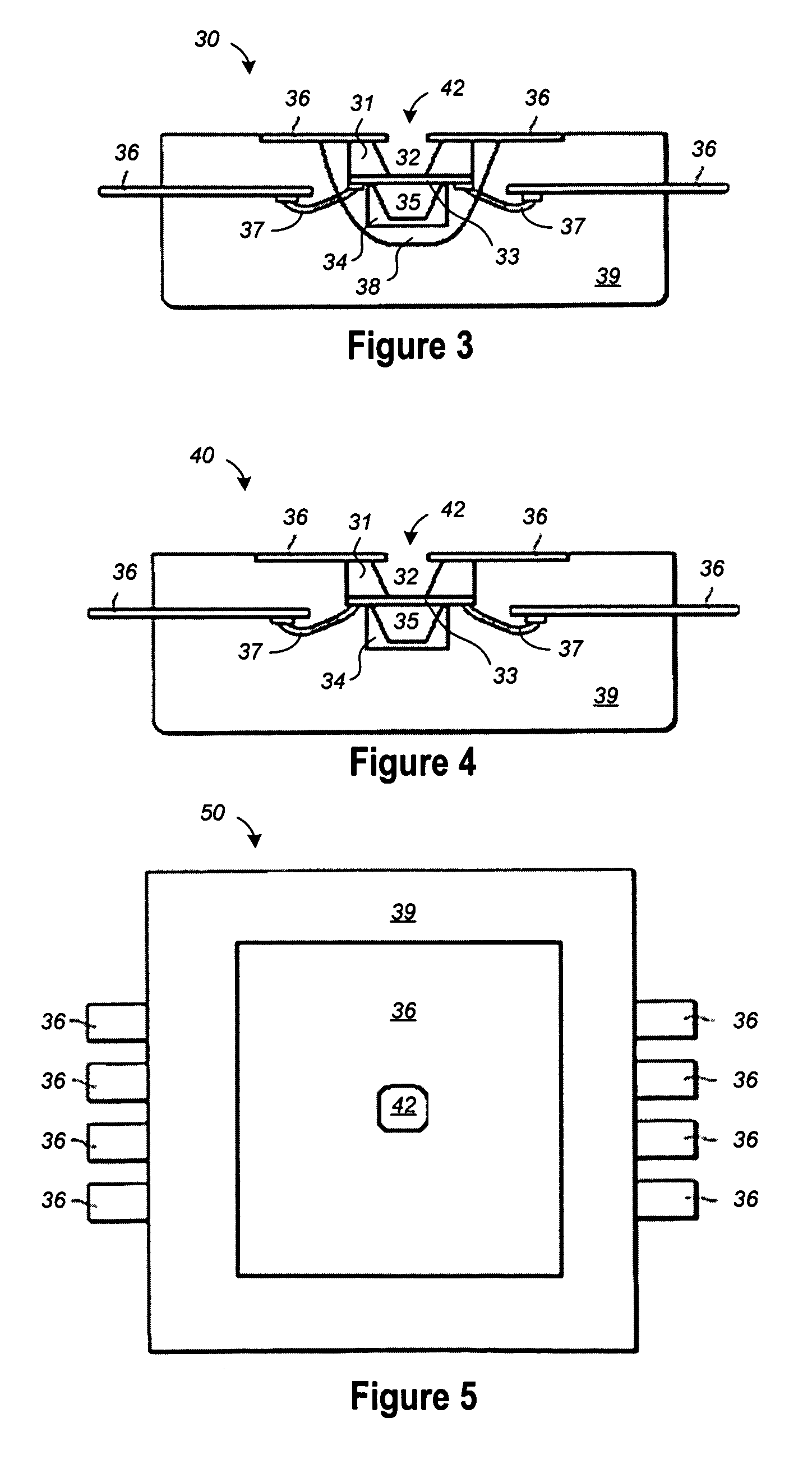

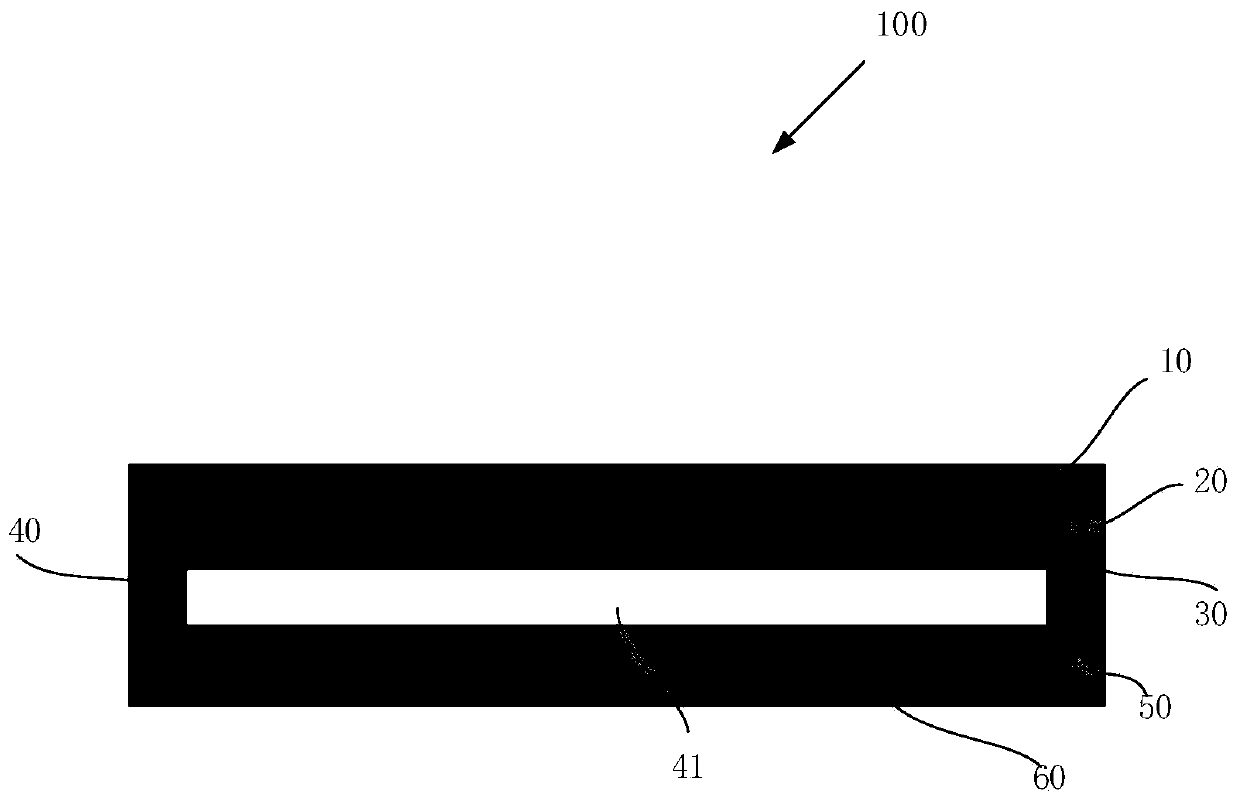

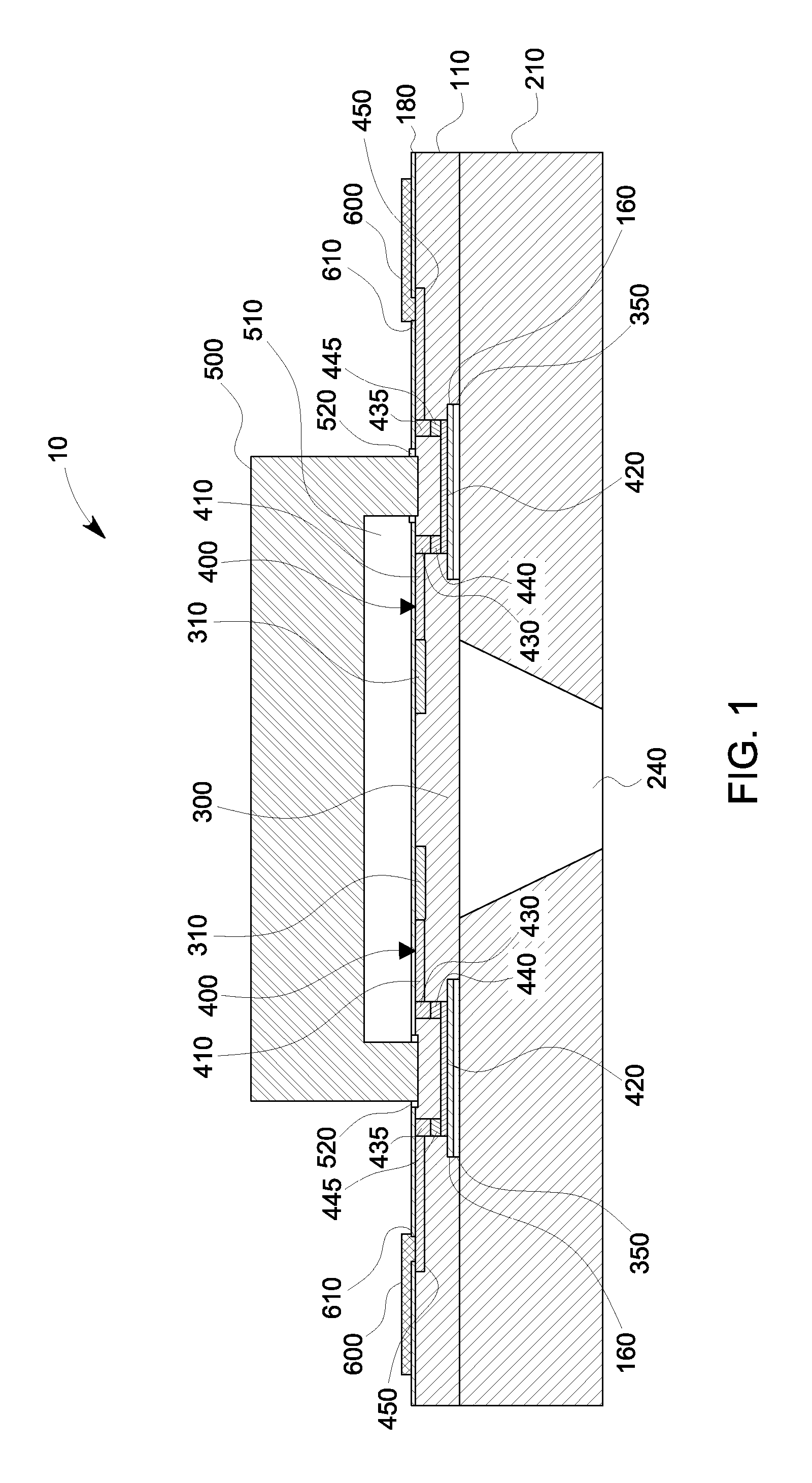

Exposed Pad Backside Pressure Sensor Package

InactiveUS20100199777A1Fluid pressure measurement using piezo-electric devicesInflated body pressure measurementTransducerEngineering

A method and apparatus are described for fabricating an exposed backside pressure sensor (30) which protects interior electrical components (37) formed on a topside surface of a pressure sensor transducer die (31) from corrosive particles using a protective gel layer (38) and molding compound (39), but which vents a piezoresistive transducer sensor diaphragm (33) formed on a backside of the pressure sensor transducer die (31) through a vent hole (42) formed in an exposed die flag (36), enabling the sensor diaphragm (33) to directly sense pressure variations without the influence of a protective gel.

Owner:NORTH STAR INNOVATIONS

Micromechanical high-pressure sensor

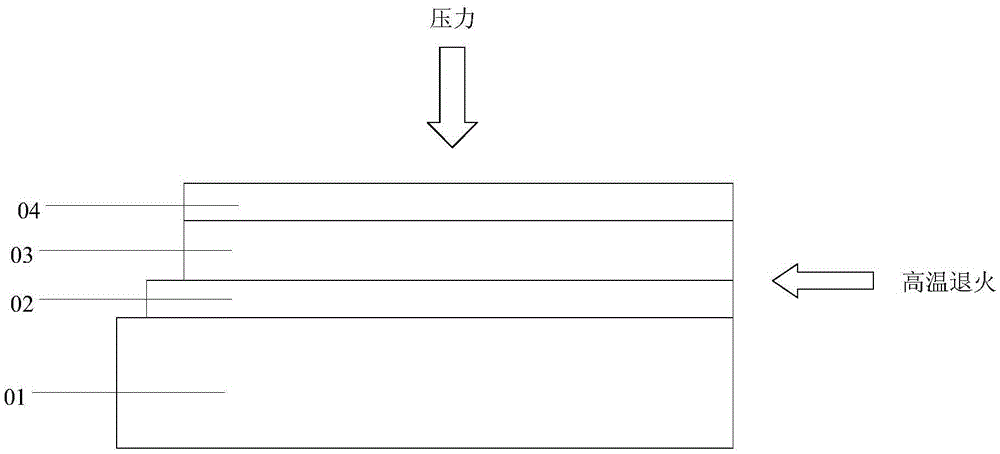

InactiveUS20050188769A1Accelerated agingReduce resistanceFluid pressure measurement using piezo-electric devicesFluid pressure measurement using elastically-deformable gaugesEngineeringHigh pressure

A micromechanical pressure sensor and a method for producing a micromechanical pressure sensor. This pressure sensor has at least one membrane and a measuring element situated on the membrane. A pressure applied at the membrane or a pressure differential applied at the different sides of the membrane results in deformation of the membrane. Simultaneous with the deformation of the membrane, the measuring element is subjected to elastic elongation and / or compression. In a piezo-sensitive component, such elastic elongation and / or compression generates a measured variable in the measuring element, which represents the applied pressure or the applied pressure differential at the membrane. It is provided in this context that the measuring element have at least partially a NiCr(Si) layer. Due to an at least partial crystallization in the production of the micromechanical pressure sensor, this NiCr(Si) layer has more advantageous piezoelectrical characteristics than an amorphous NiCr(Si) layer.

Owner:ROBERT BOSCH GMBH

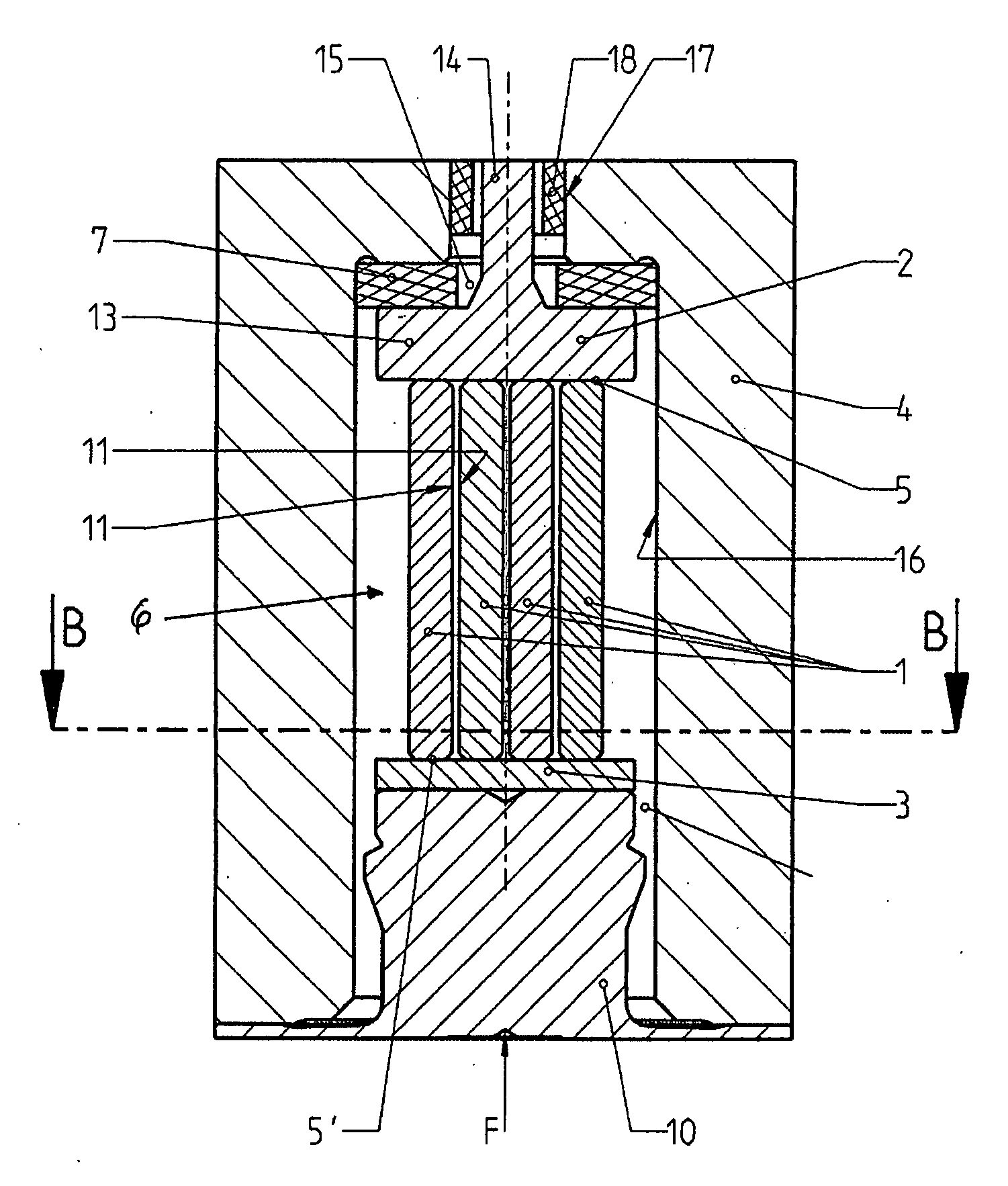

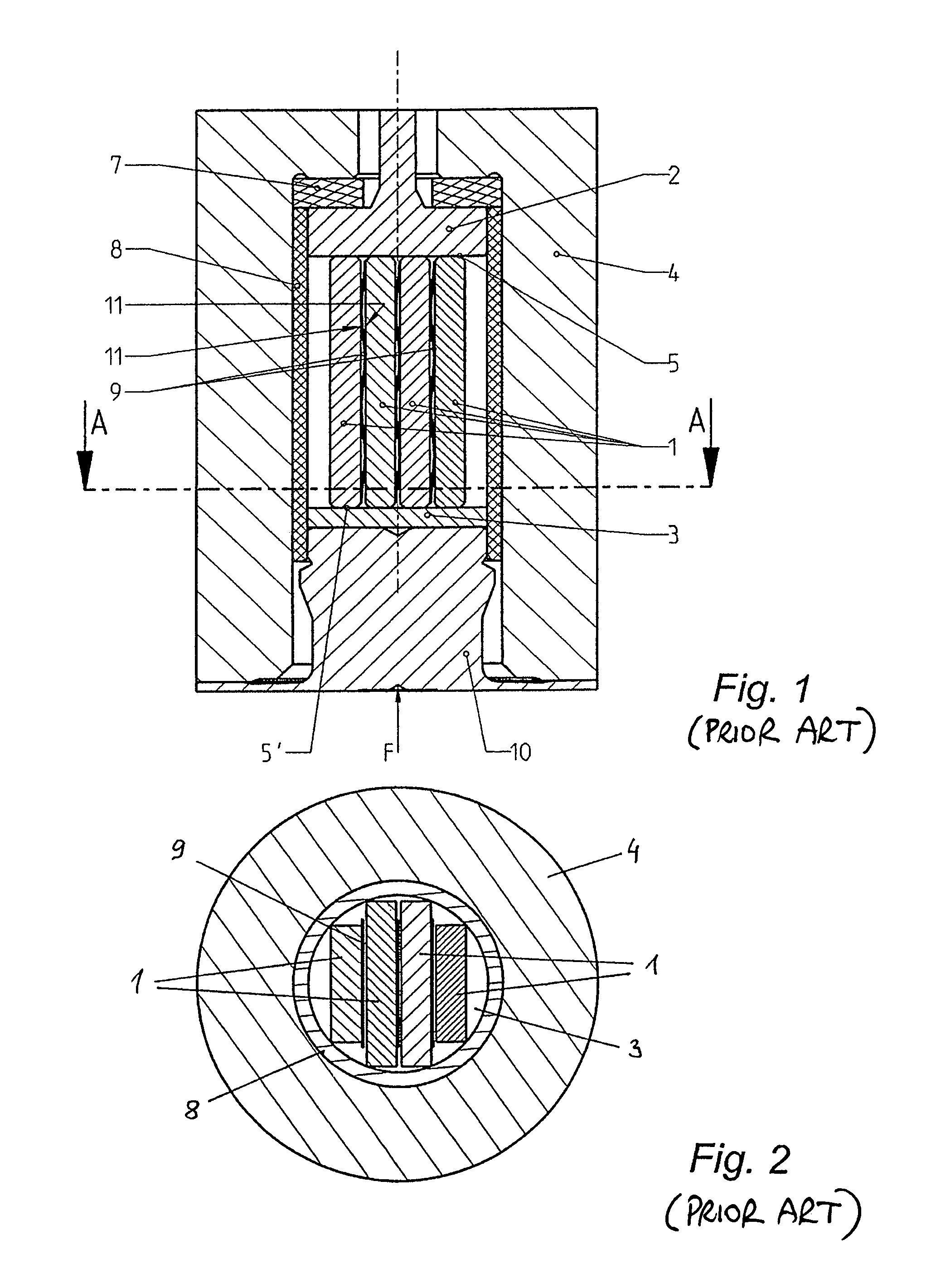

Piezoelectric sensor

InactiveUS20070277618A1Precise positioningAdequate insulation performanceFluid pressure measurement using piezo-electric devicesPiezoelectric/electrostriction/magnetostriction machinesSolderingAcoustics

A piezoelectric sensor, preferably a pressure sensor, comprising at least two piezoelectric measuring elements placed in a housing, which are clamped between a membrane on the pressured side of the housing and a pick-up electrode electrically insulated against the housing. The piezoelectric measuring elements are fixedly attached to the pick-up electrode by thermo-compression or soldering and together with said pick-up electrode form a compact measuring element stack, which will significantly simplify assembly of the piezoelectric sensor.

Owner:PIEZOCRYST ADVANCED SENSORICS

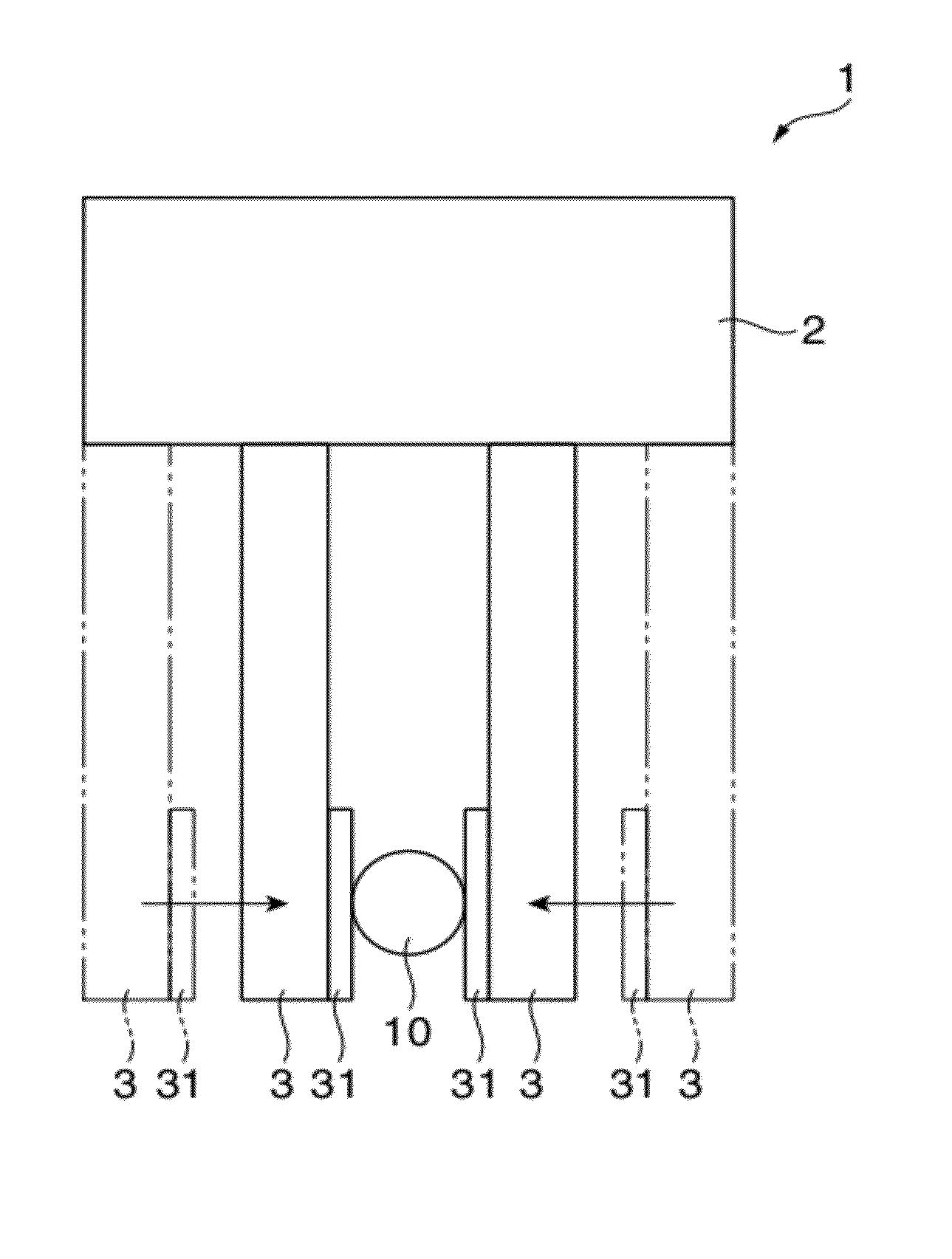

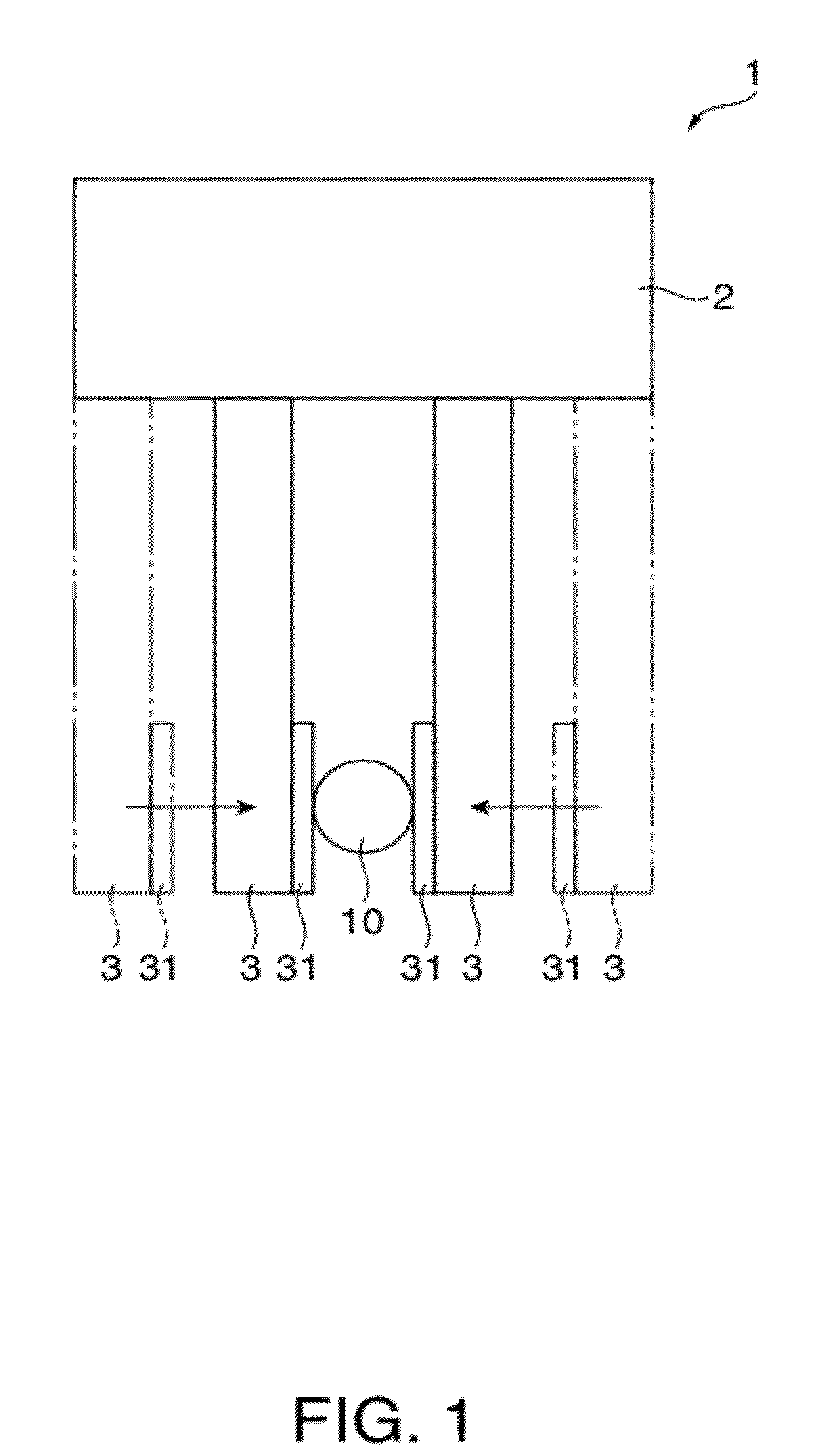

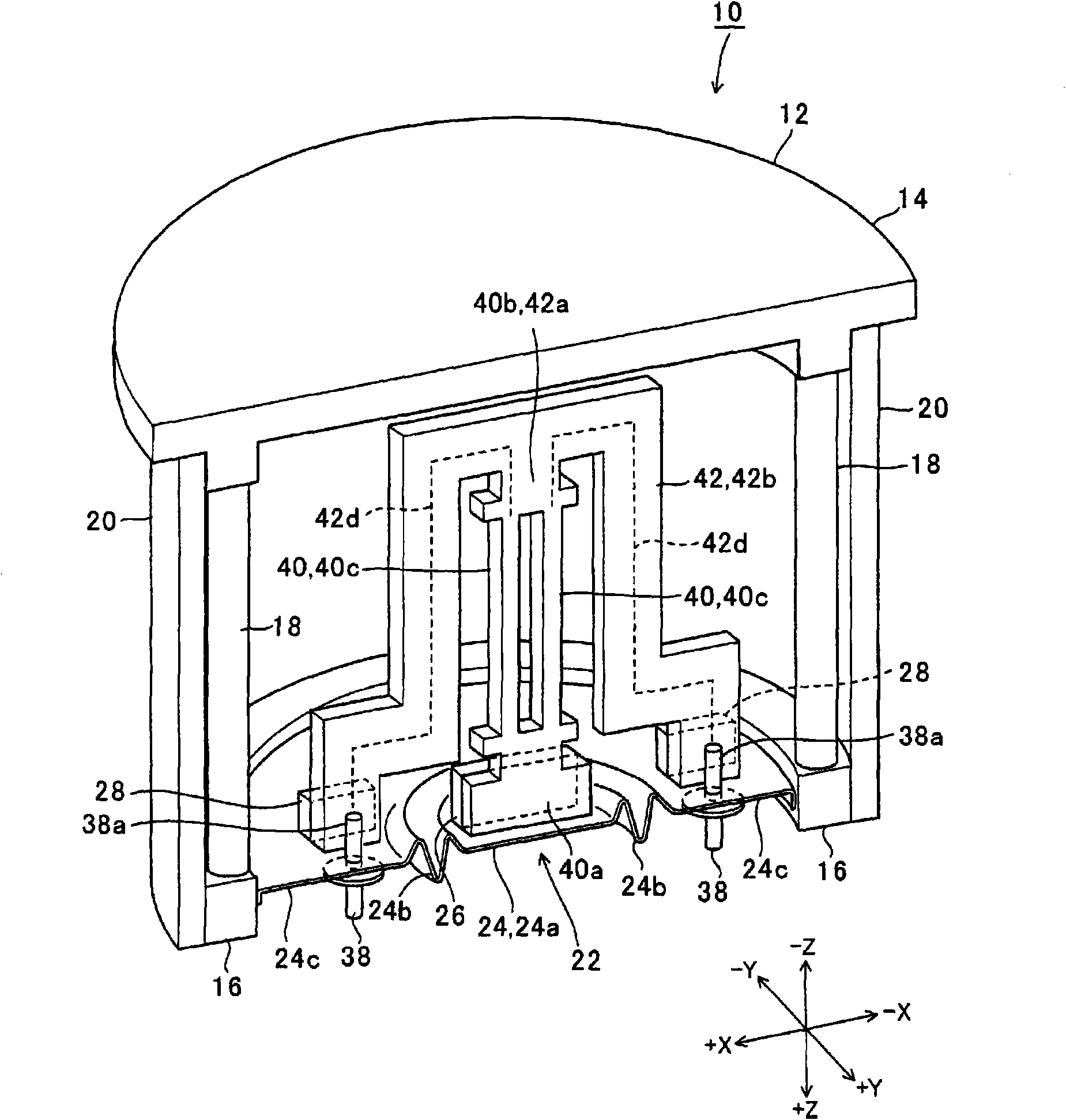

Pressure sensor, sensor array, method for manufacturing sensor array, and grasping apparatus

ActiveUS20120247217A1Increase driving speedPrecise grasping pressureFluid pressure measurement using piezo-electric devicesPiezoelectric/electrostrictive device manufacture/assemblySensor arraySilicone oil

A pressure sensor includes: a supporting body which has an opening; a pressure detecting portion which includes a supporting film provided on the supporting body and having a diaphragm portion closing the opening, and a piezoelectric body provided on the diaphragm portion and deflecting to output an electric signal; a frame body which has, on the pressure detecting portion, a cylindrical cavity along a film thickness direction of the supporting film, and is formed, in plan view when viewed from the film thickness direction of the supporting film, at a position where a cylindrical inner peripheral wall of the cavity overlaps with the opening, or outside of the opening; a sealing film which closes the frame body; and a silicone oil which is filled in an inner space formed of the cylindrical inner peripheral wall of the cavity, the sealing film, and the pressure detecting portion.

Owner:SEIKO EPSON CORP

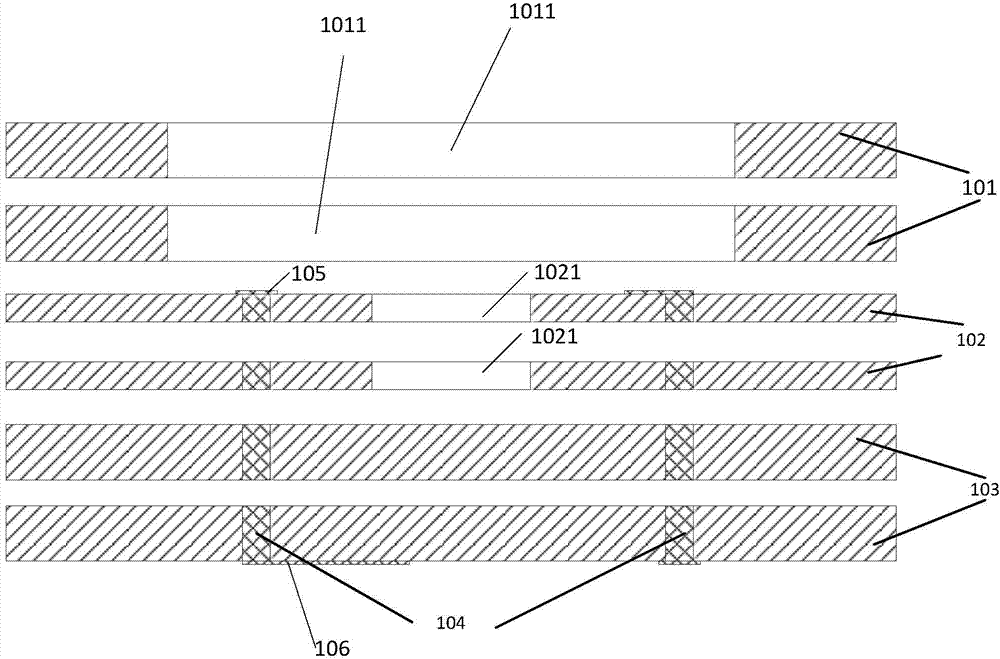

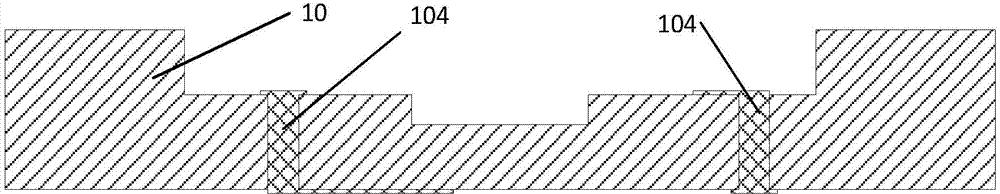

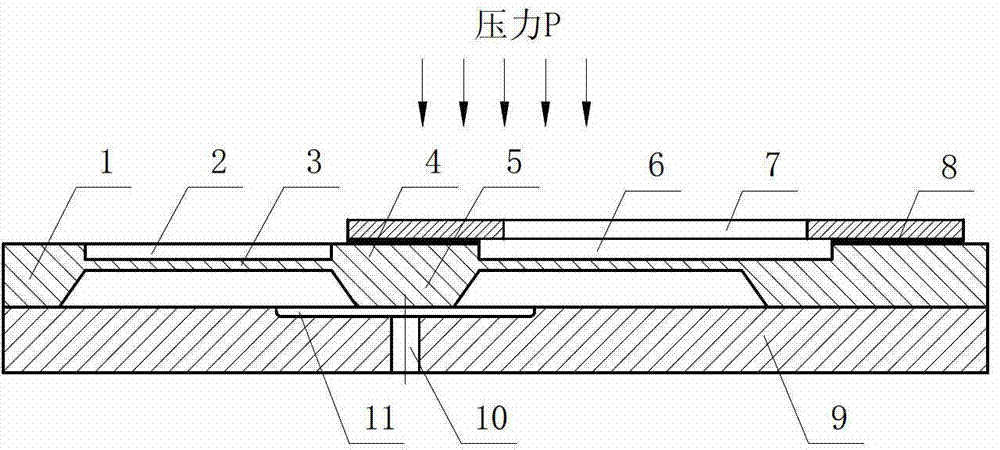

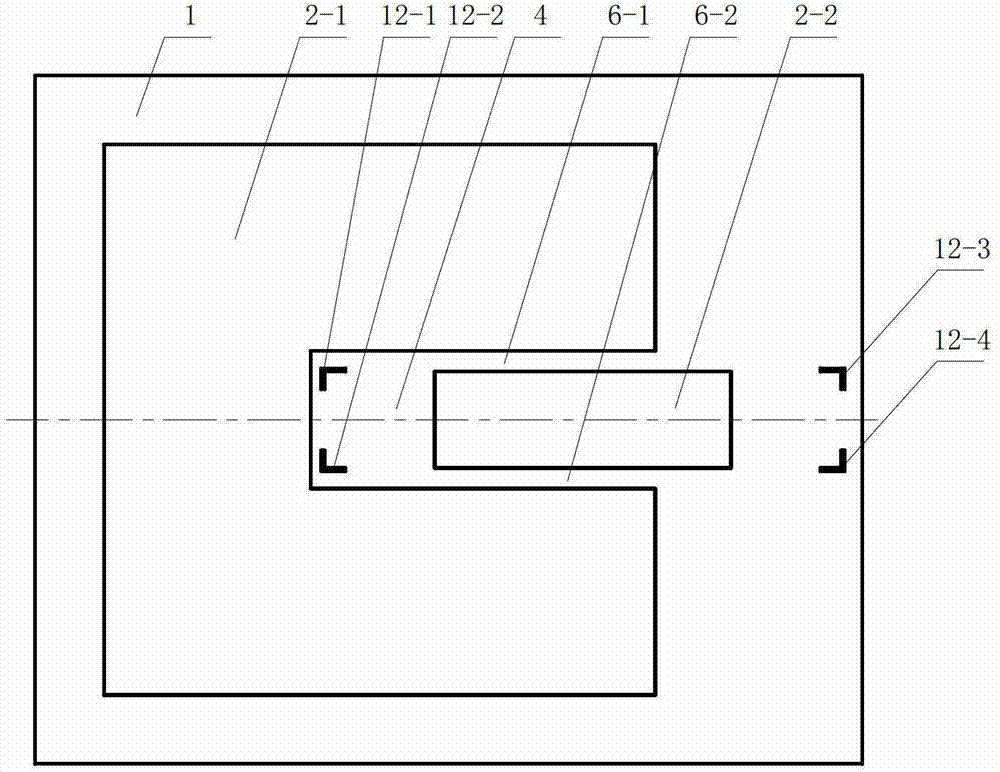

Structure and method for packaging pressure sensor

ActiveCN103487176AProtectImprove air tightnessFluid pressure measurement using piezo-electric devicesForce measurement using piezo-electric devicesHigh humidityEngineering

The invention discloses a structure and method for packaging a pressure sensor, and belongs to the technical field of microelectronic packaging. The structure for packaging the pressure sensor comprises an upper cover board, a lower cover board and a pressure sensor chip. The lower cover board is provided with a first rectangular groove and a second rectangular groove. The bottom of the first rectangular groove is embedded in the second rectangular groove so that the first rectangular groove and the second rectangular groove can be communicated to form a two-stage cavity structure. Through holes penetrating through the lower cover board are formed in the bottom of the first rectangular groove. The upper surfaces and the lower surfaces of the through holes are connected with a bonding pad and a wiring layer respectively. Protrusions of the pressure sensor chip are connected with the through holes of the lower cover board. The upper cover board is provided with a third rectangular groove. The pressure sensor chip is located inside a space formed by connecting the upper cover board and the lower cover board. The invention further discloses the method for packaging the pressure sensor. By means of the system and method for packaging the pressure sensor, the capacity for resisting a severe environment, stress uniformity, the reliability and the accuracy of the pressure sensor chip are improved, and application demands of special environments with high temperature, high humidity and the like can be met.

Owner:NAT CENT FOR ADVANCED PACKAGING

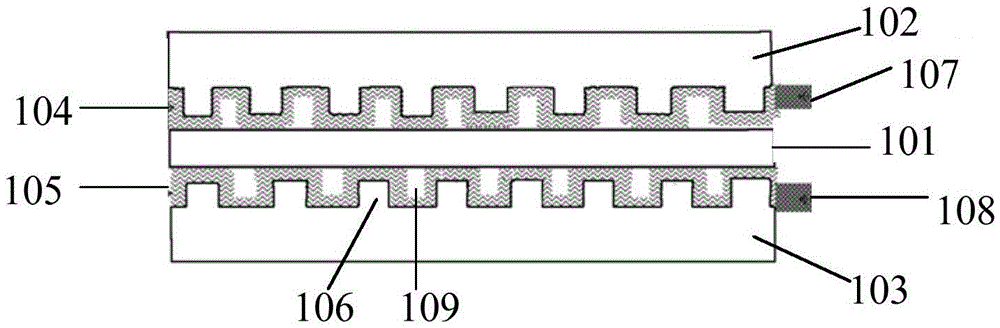

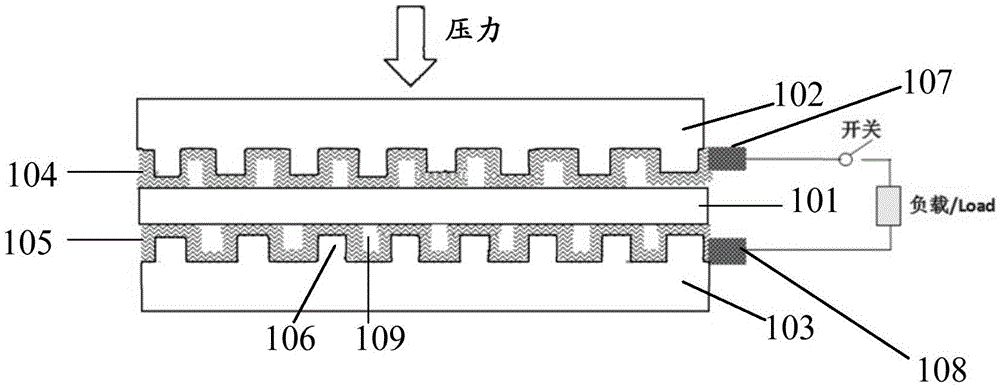

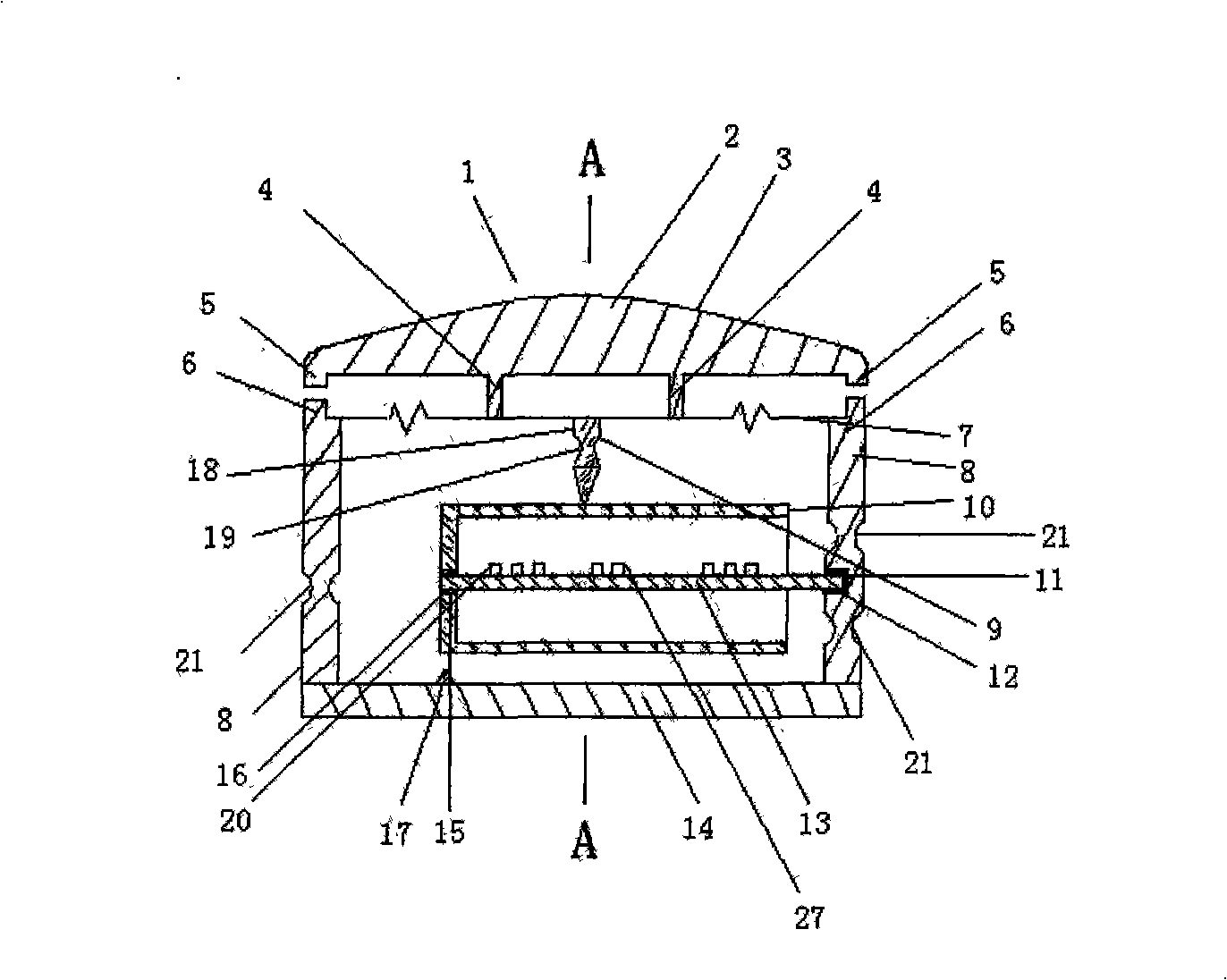

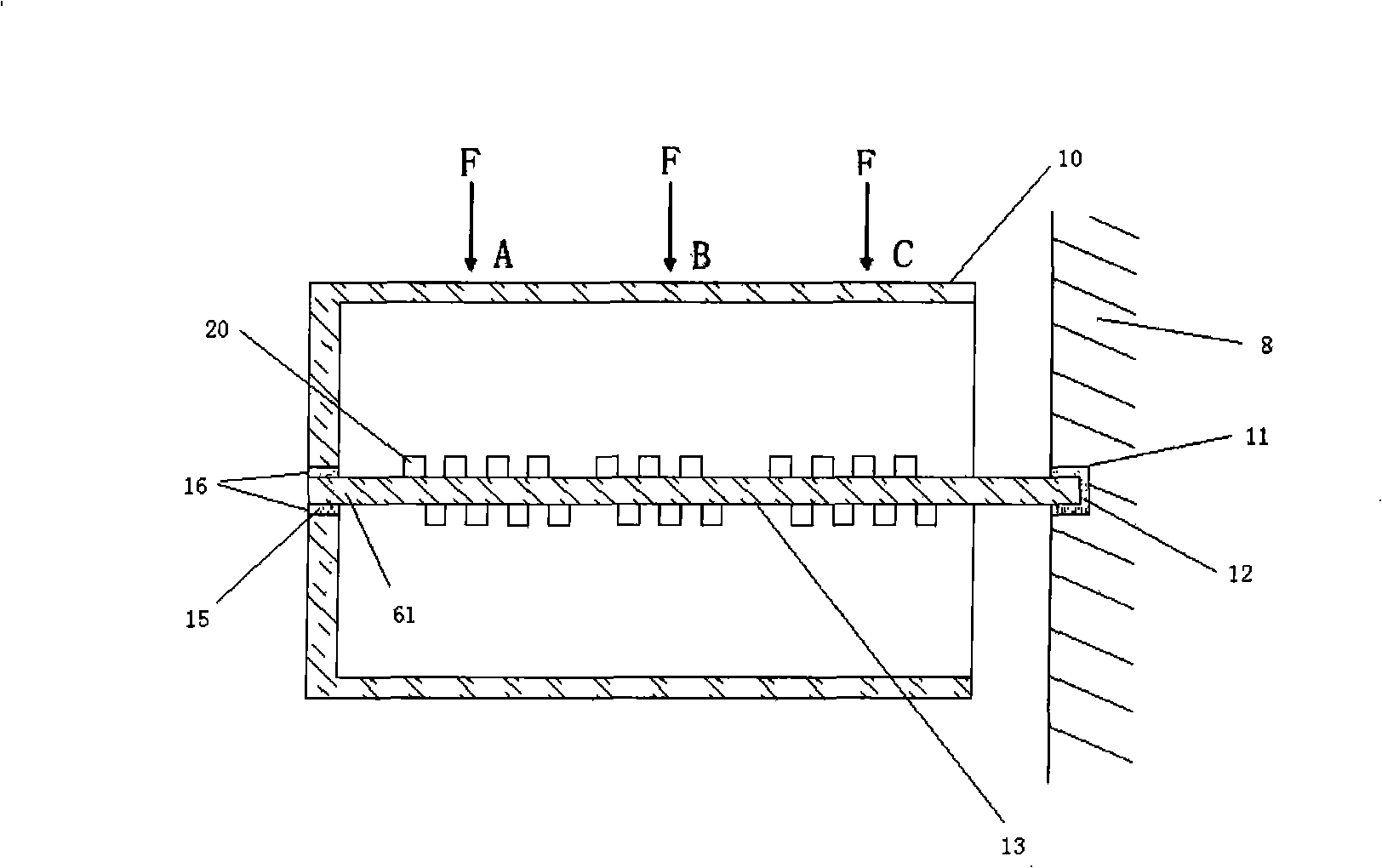

Pressure sensor based on friction power generation and pressure sensing system

ActiveCN104374498ASelf-poweredHigh precisionFluid pressure measurement using piezo-electric devicesForce measurement using piezo-electric devicesElectromagnetic interferenceEngineering

The invention discloses a pressure sensor based on friction power generation and a pressure sensing system. The pressure sensor based on friction power generation comprises a pressure bearing component, a first elastic base body, a first structural layer, a base and a second structural layer, wherein the first elastic base body is arranged on a first side surface of the pressure bearing component and is provided with a regular protruding structure, the first structural layer covers the first elastic base body and forms a corresponding structure matched with the protruding structure of the first elastic base body, and the second structural layer is arranged on a first side surface of the base. When pressure is acted on the pressure bearing component, the first elastic base body and the first structural layer deform so as to enable the contacting area of a friction interface to be increased along with the increase of pressure, and a corresponding relation between the contacting area and output signals is utilized to enable the output signals of a signal output end to represent the intensity of pressure. The pressure sensor based on friction power generation overcomes the defect that a traditional pressure sensor is easily interfered by static electricity and electromagnetism, and has the advantages of being high in accuracy, wide in measurement range and wide in application environment.

Owner:NEWNAGY TANGSHAN

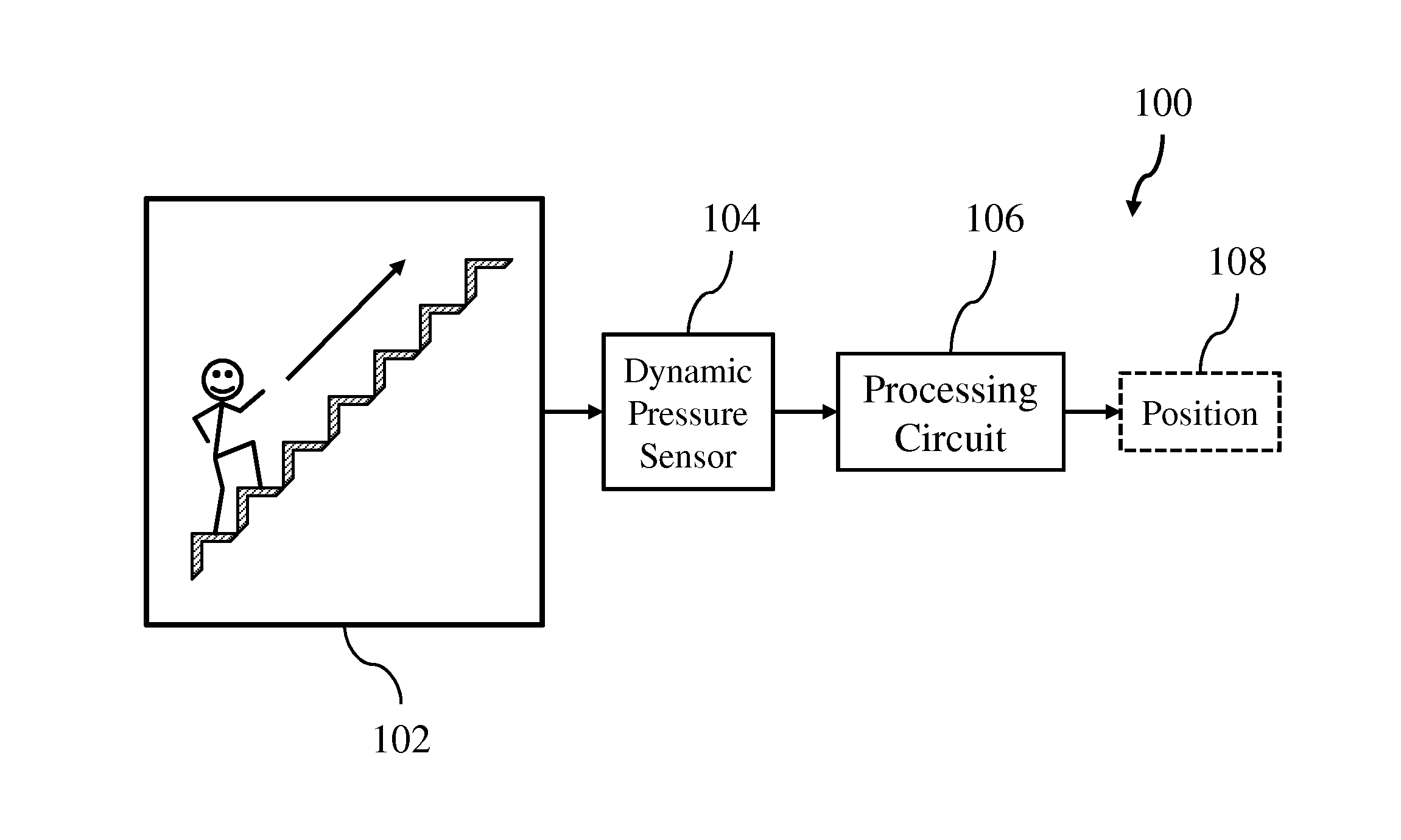

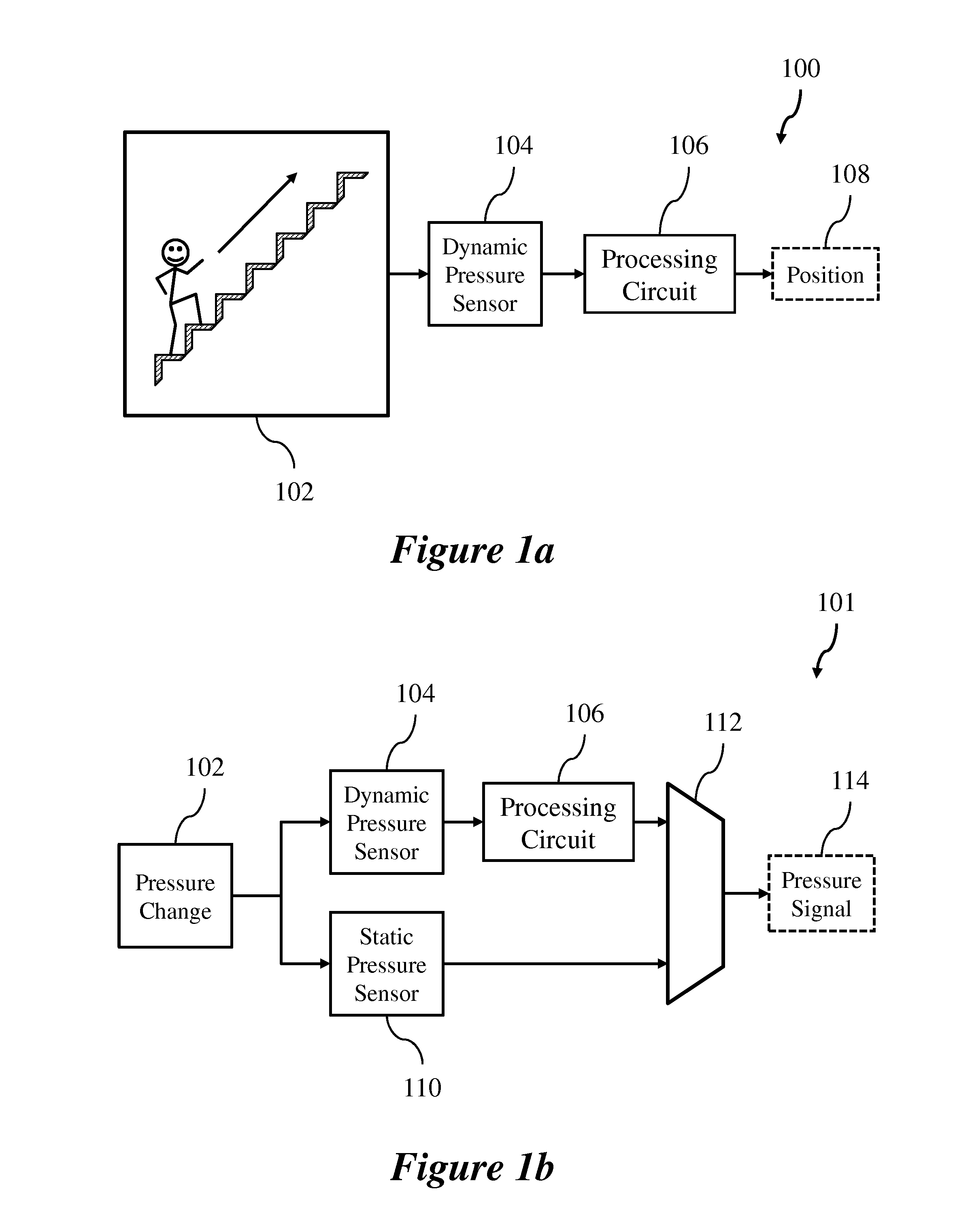

Dynamic Pressure Sensor

ActiveUS20150276529A1Fluid pressure measurement using piezo-electric devicesMicrophonesAmbient pressureEngineering

According to various embodiments, a dynamic pressure sensor includes a substrate, a reference volume formed in the substrate, a deflectable membrane sealing the reference volume, a deflection sensing element coupled to the membrane and configured to measure a deflection of the membrane, and a ventilation hole configured to equalize an absolute pressure inside the reference volume with an absolute ambient pressure outside the reference volume.

Owner:INFINEON TECH AG

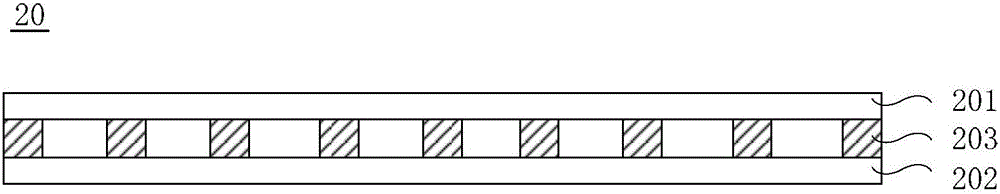

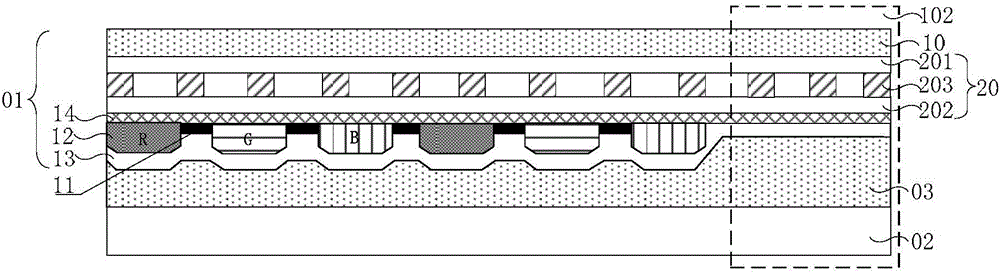

Display base plate, display device, pressure detection system and detection method thereof

ActiveCN105136378AEasy to detectEasy to carryFluid pressure measurement using piezo-electric devicesFluid pressure measurement using capacitance variationBiochemical engineeringPressure sense

The invention relates to a display base plate, a display device, a pressure detection system and a detection method thereof and relates to the field of display technology. Environment pressure test functions can be integrated in the display base plate, thereby improving convenience to carry objects when people go out. The display base plate comprises a substrate base plate and a pressure sensing structure which is arranged on the substrate base plate and used for testing environment pressure. The pressure sensing structure comprises oppositely arranged first and second pressure-sensitive electrodes, and multiple separately-arranged insulation support columns arranged between the first pressure-sensitive electrode and the second pressure-sensitive electrode. The first pressure-sensitive electrode contacts with the substrate base plate.

Owner:BOE TECH GRP CO LTD +1

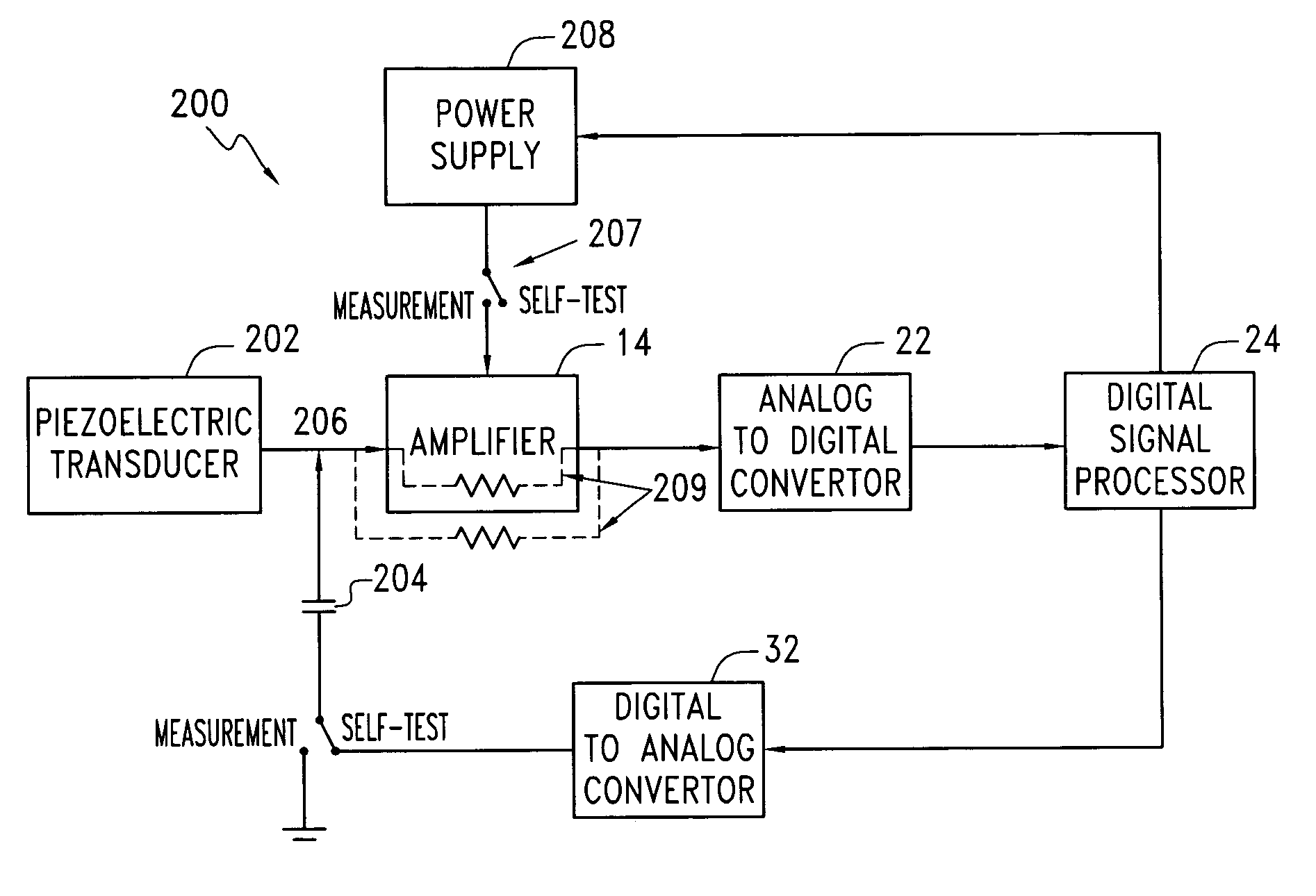

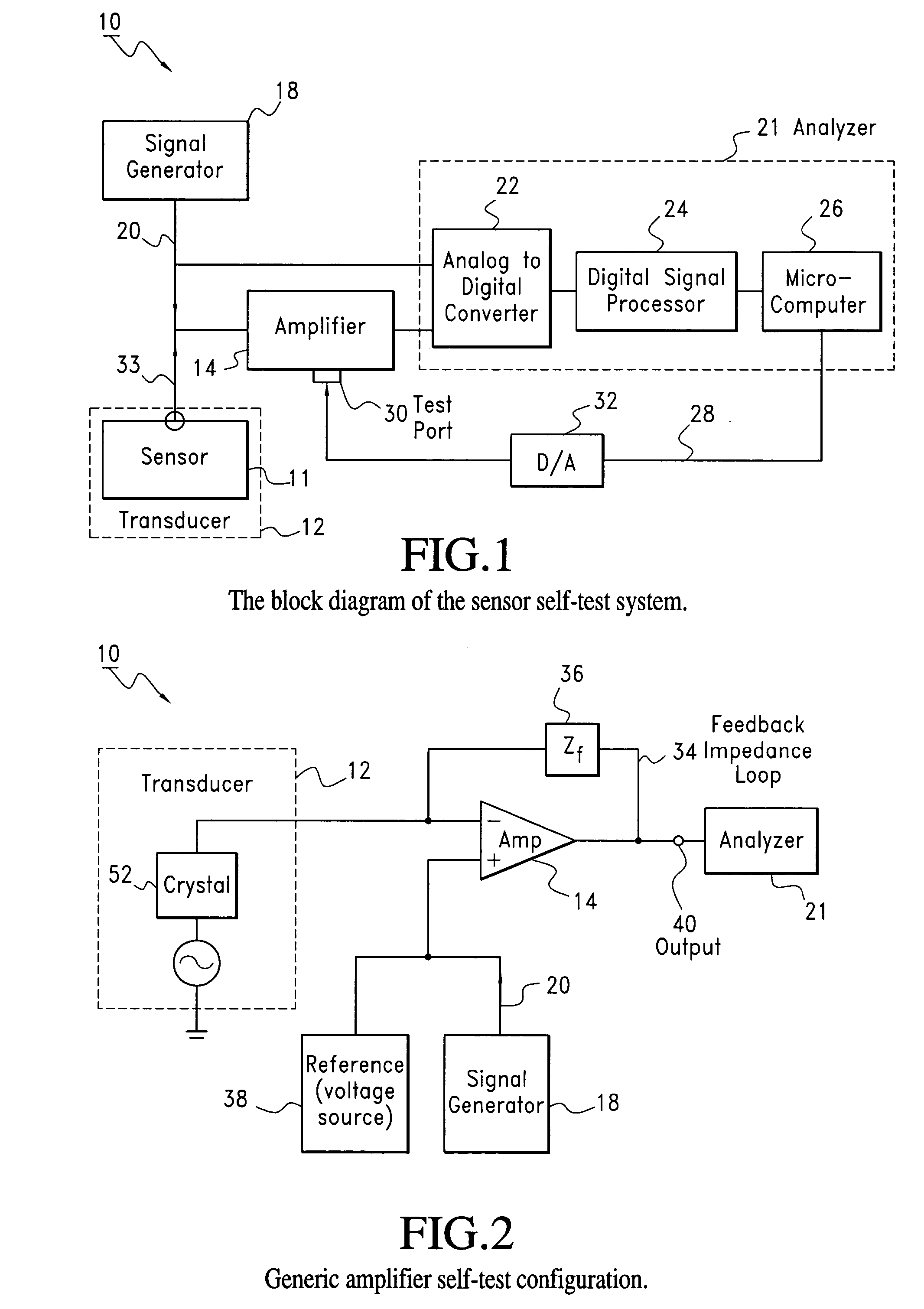

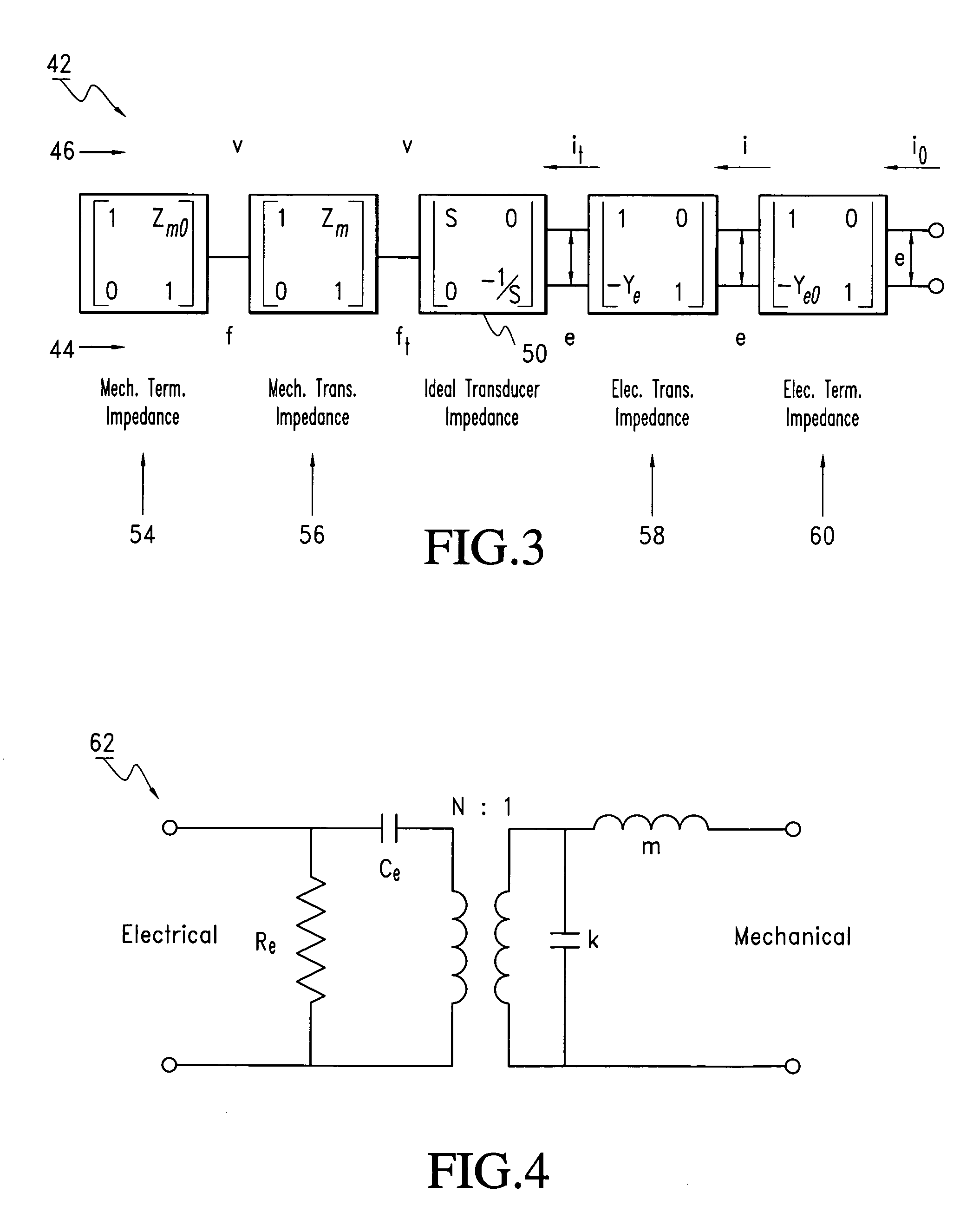

Transducer in-situ testing apparatus and method

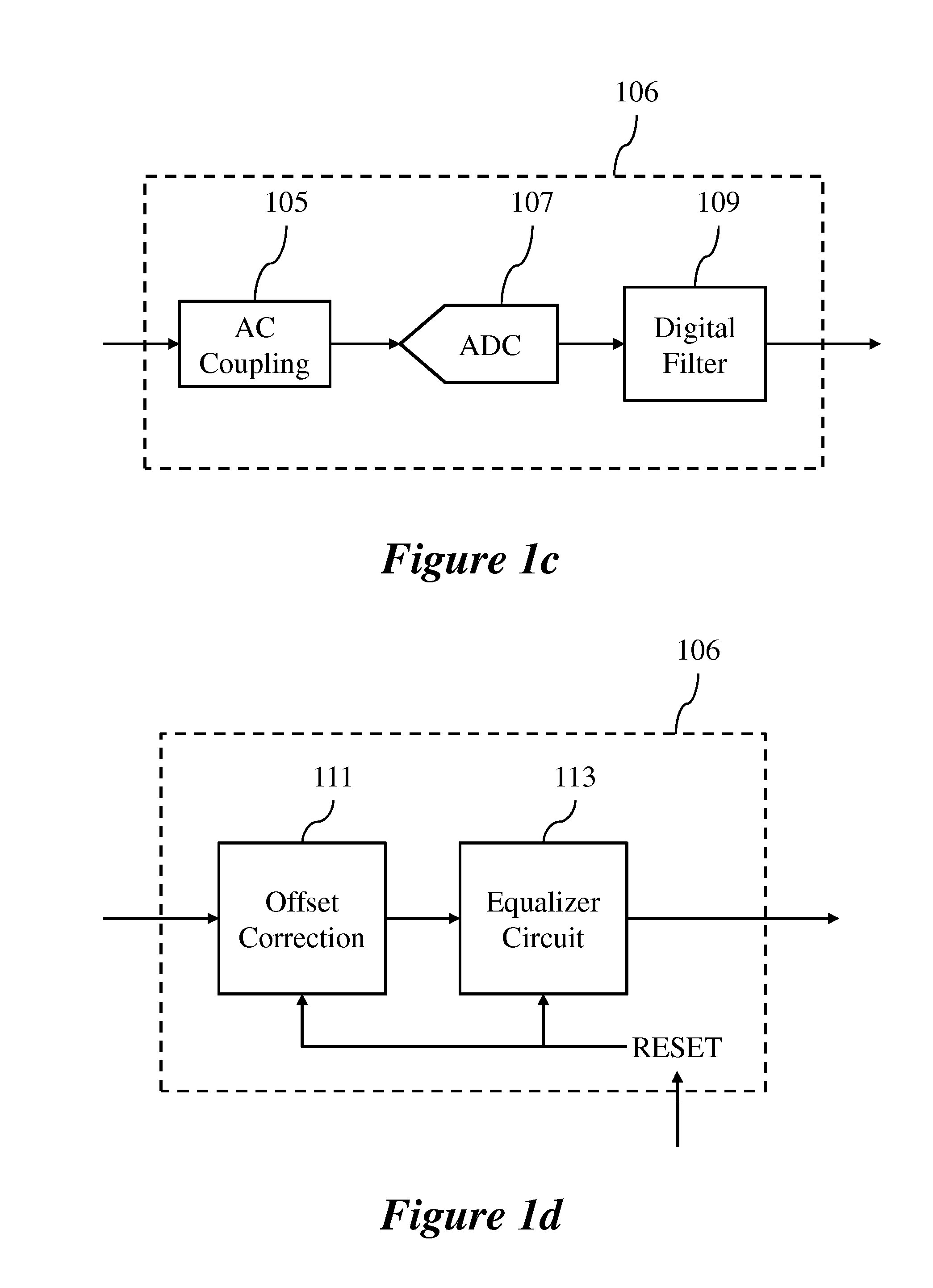

InactiveUS7042228B2Disabling amplifierFluid pressure measurement using piezo-electric devicesAcceleration measurement using interia forcesFrequency spectrumAudio power amplifier

The present invention is directed to an apparatus and method for a measurement system for the testing of transducers, and more particularly to the testing of piezoelectric transducers. The measurement system includes a transducer, a feedback amplifier coupled to the transducer and a signal processing circuit coupled to the output of the amplifier. The method of testing the transducer includes coupling the test signal to the transducer, disabling the amplifier, and measuring the response of the transducer to the test signal with the test processing circuit. The circuit itself used for performing this method includes a piezoelectric transducer, an amplifier, including a feed-back circuit coupled to the amplifier for amplifying the output of the transducer, a power source coupled to the amplifier, a signal source generating a test signal having a frequency spectrum at least overlapping the self resonant frequency of the transducer coupled to the transducer, and a switch coupled to the amplifier capable of disabling the amplifier.

Owner:OCEANA SENSOR TECH

Exposed pad backside pressure sensor package

InactiveUS7900521B2Fluid pressure measurement using piezo-electric devicesInflated body pressure measurementTransducerEngineering

A method and apparatus are described for fabricating an exposed backside pressure sensor (30) which protects interior electrical components (37) formed on a topside surface of a pressure sensor transducer die (31) from corrosive particles using a protective gel layer (38) and molding compound (39), but which vents a piezoresistive transducer sensor diaphragm (33) formed on a backside of the pressure sensor transducer die (31) through a vent hole (42) formed in an exposed die flag (36), enabling the sensor diaphragm (33) to directly sense pressure variations without the influence of a protective gel.

Owner:NORTH STAR INNOVATIONS

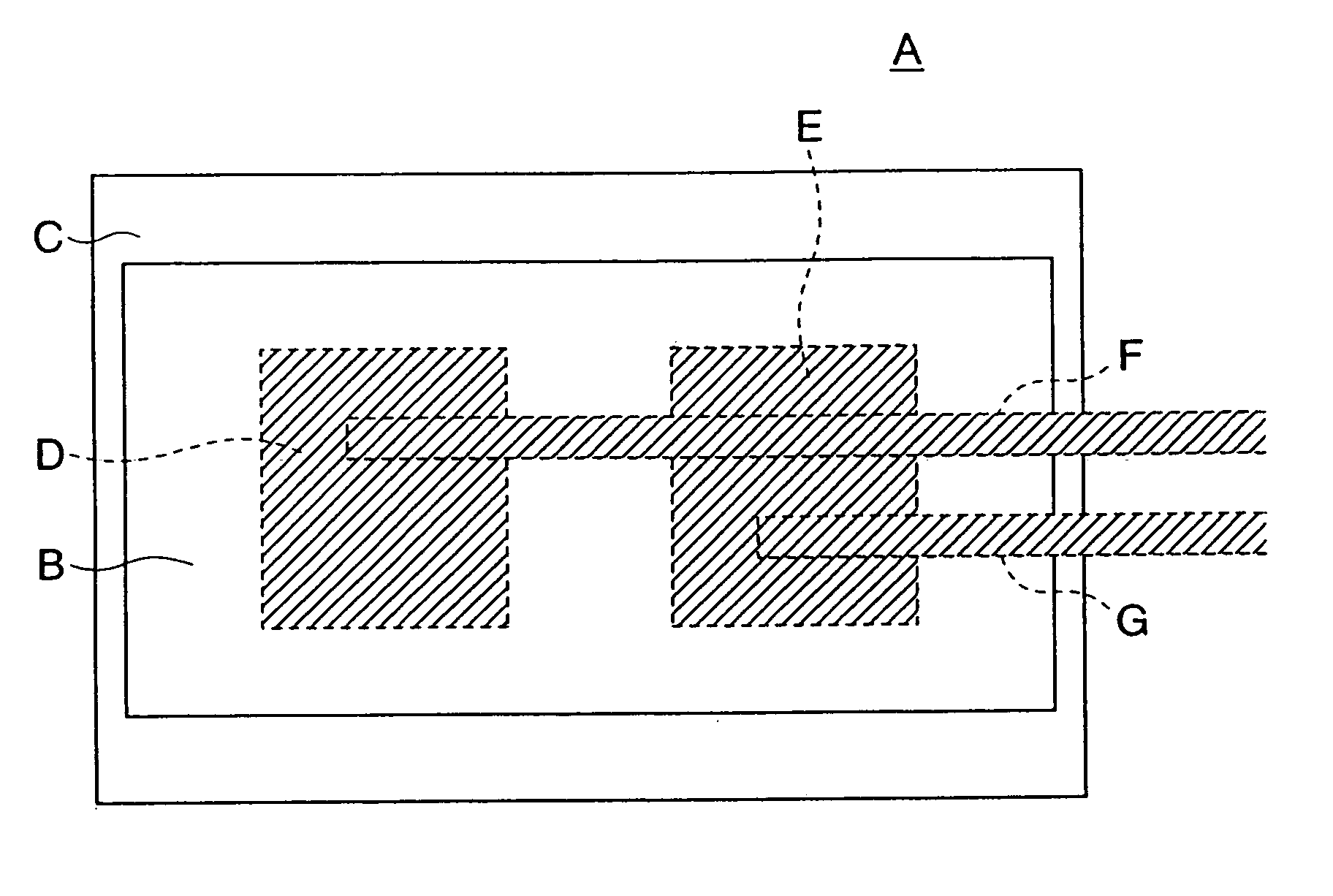

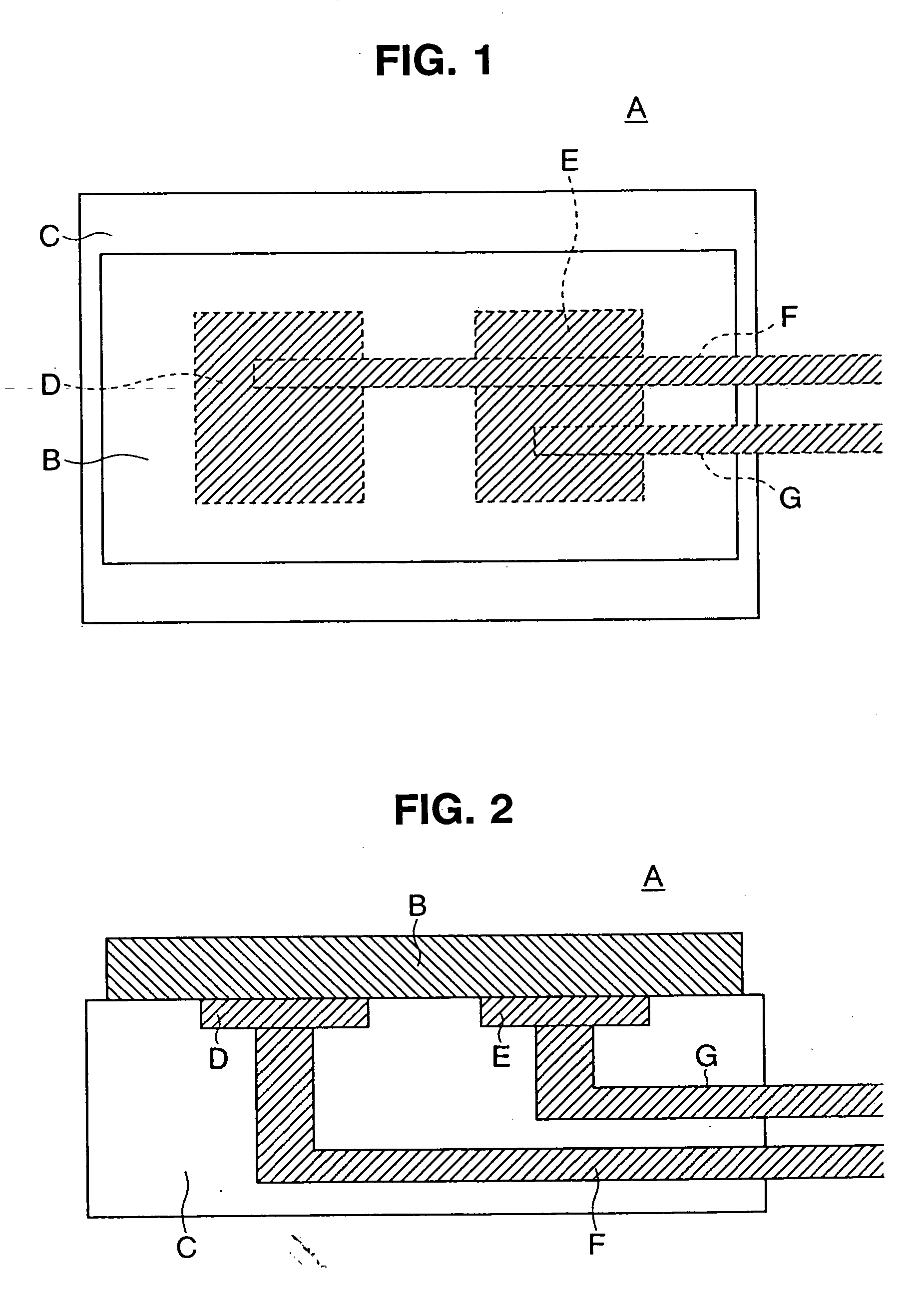

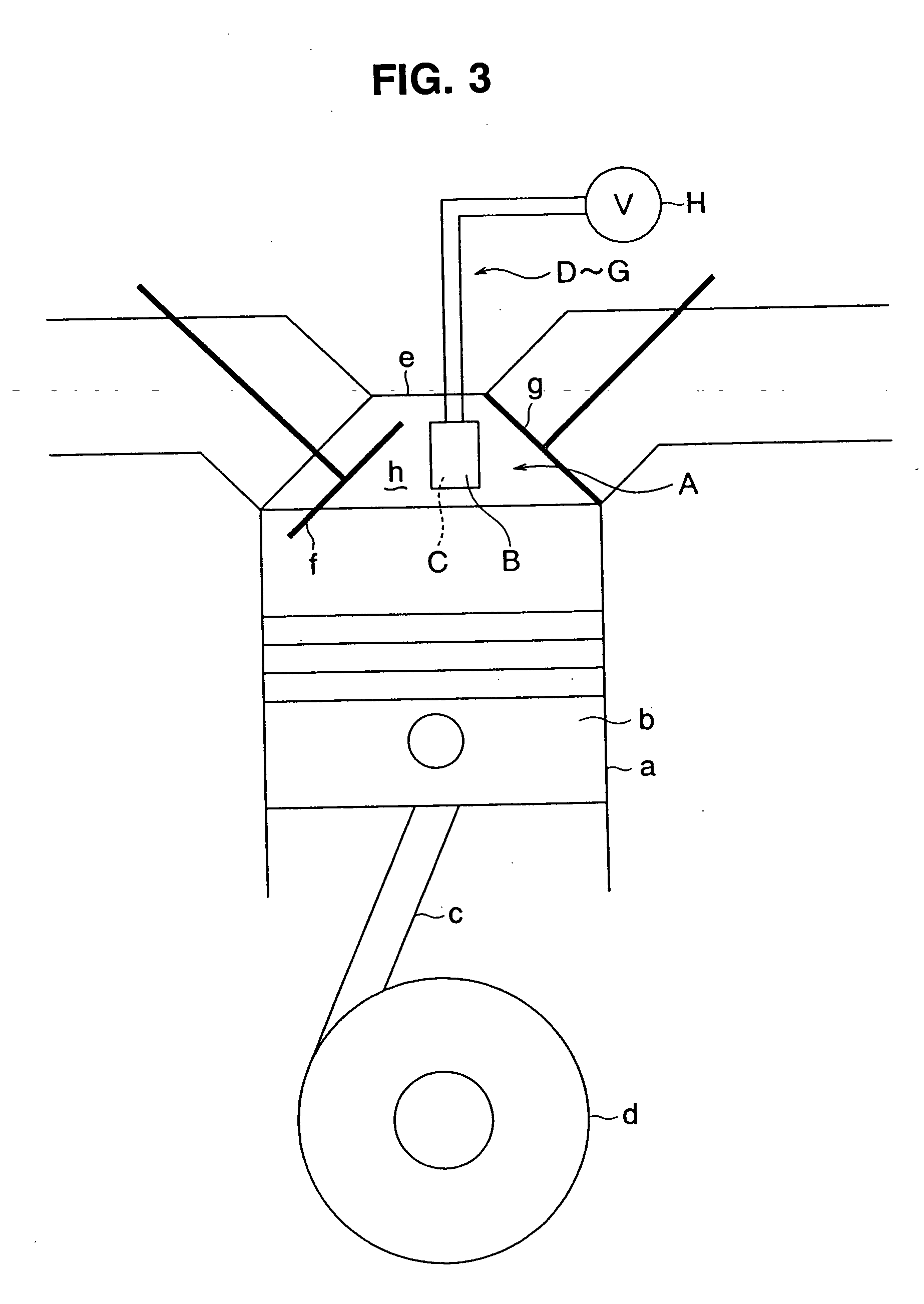

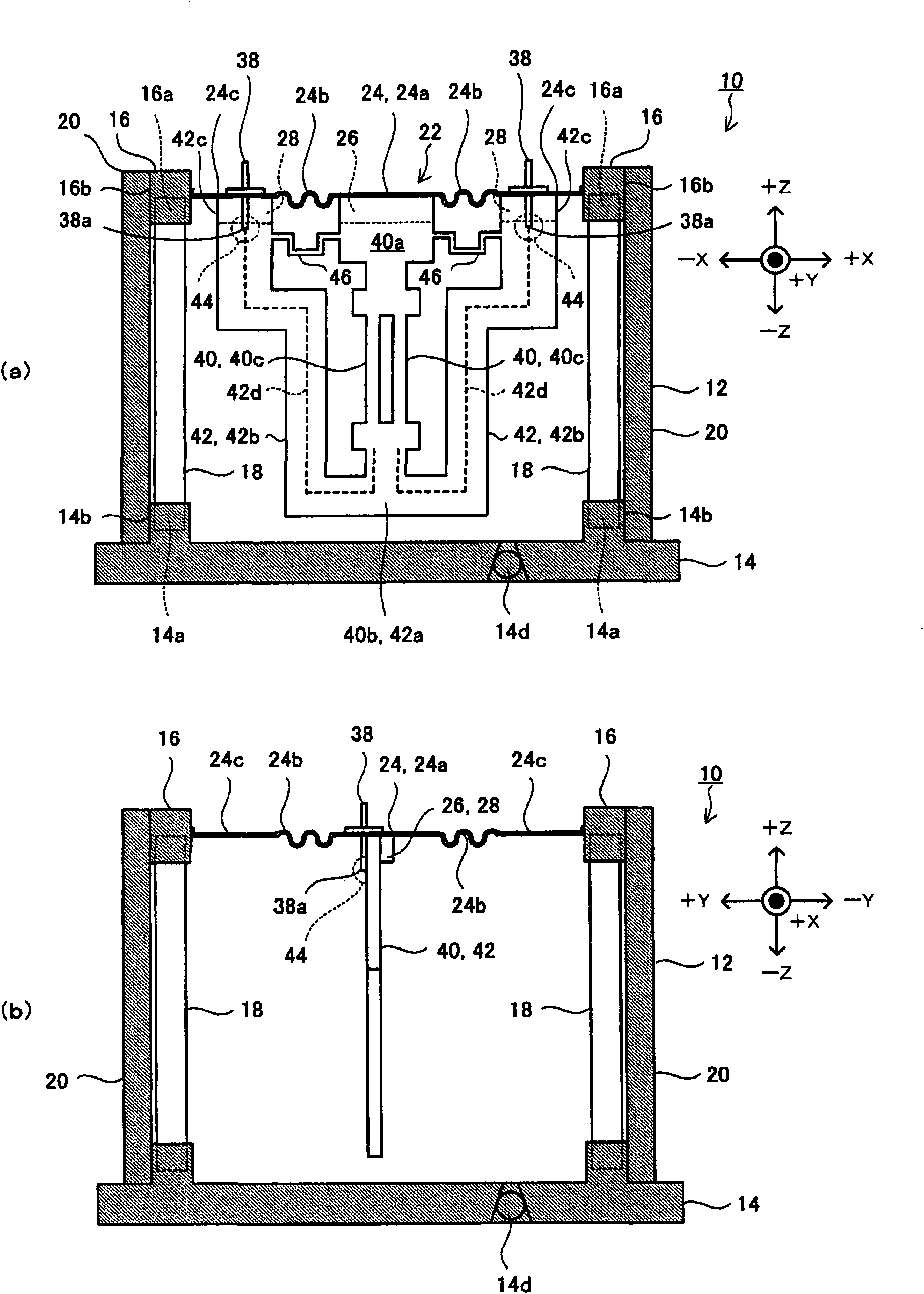

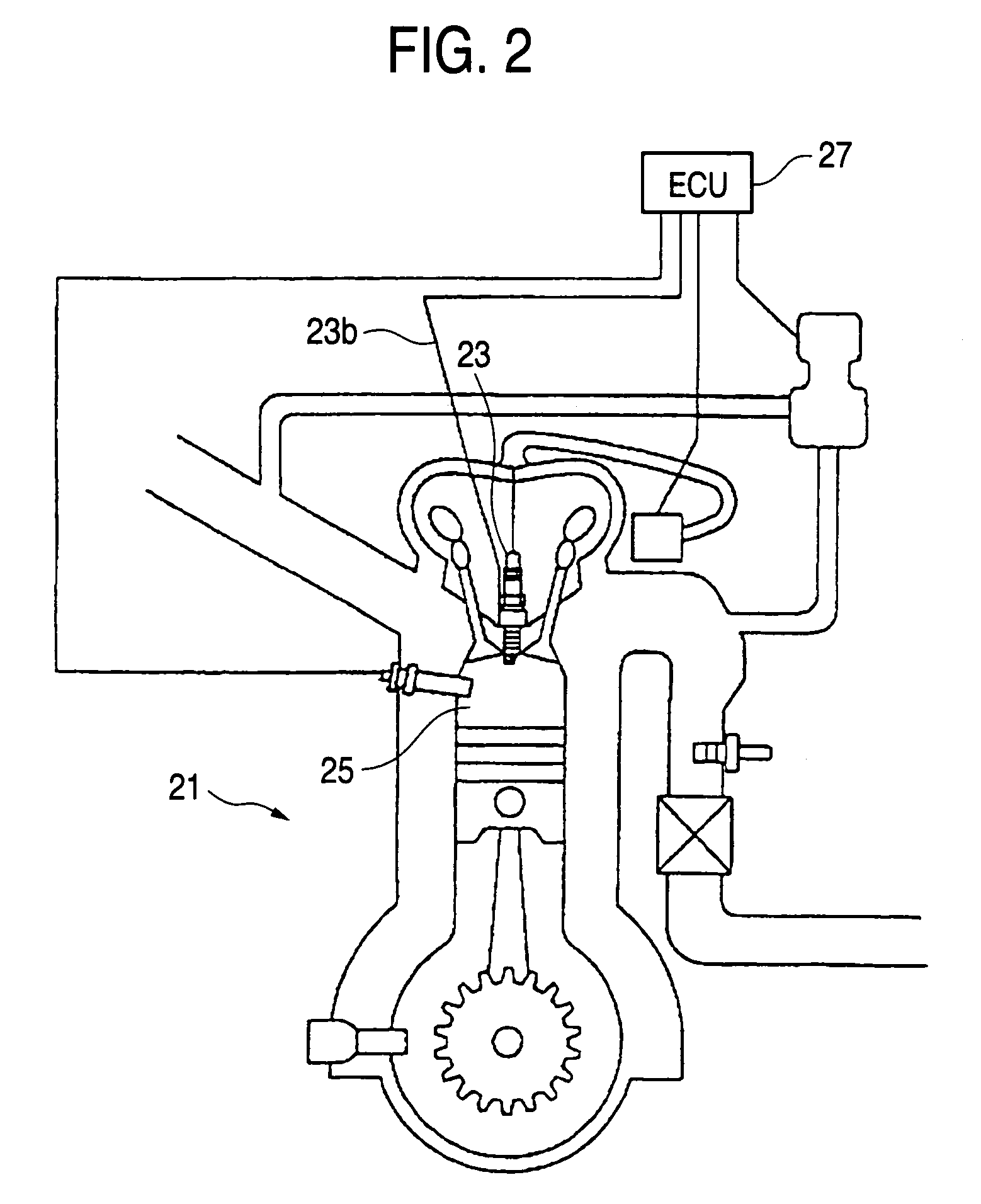

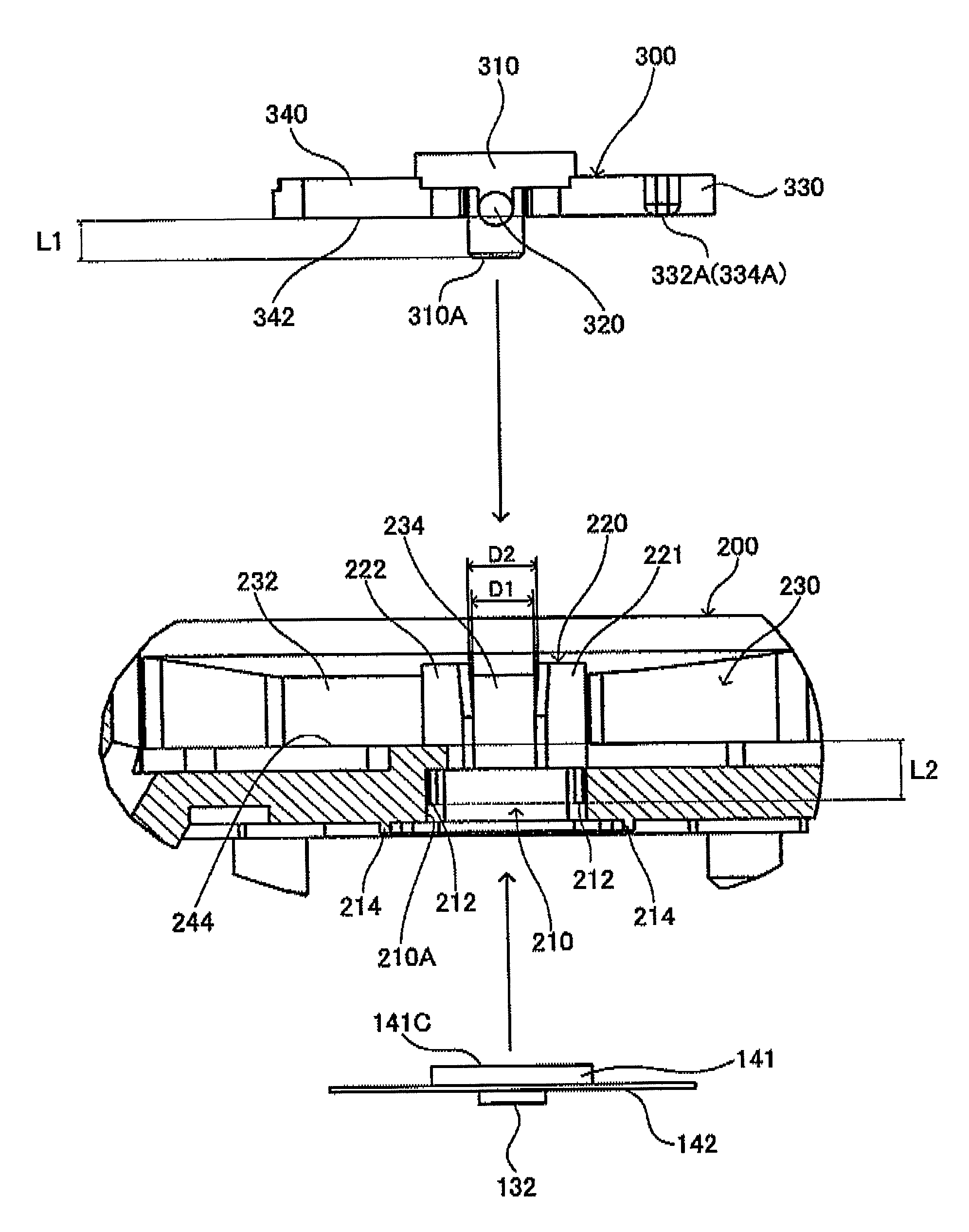

Pressure sensor, method of producing the sensor, and in-cylinder pressure detection structure of internal combustion engine

InactiveUS20050211214A1Slight cost-upSave on fuel costsFluid pressure measurement using piezo-electric devicesIncandescent ignitionElectricityCombustion chamber

In a pressure sensor A according to the presenting invention, a piezoelectric element B formed by a thin film of aluminium nitride is mounted on a base material C of an insulating material, and output electrodes D and E and output lead wires F and G which transmit a signal detected by the piezoelectric element B are mounted on the side of the base material C. The pressure sensor A is directly mounted on a cylinder head e of an internal combustion engine, or is mounted on the outer surface of a heater L which is secured at the free end of a glow plug K, whereby it is disposed to face a combustion chamber h. A combustion pressure or oscillations during the operation of the engine can be detected with a high sensitivity.

Owner:BOSCH AUTOMOTIVE SYST CORP

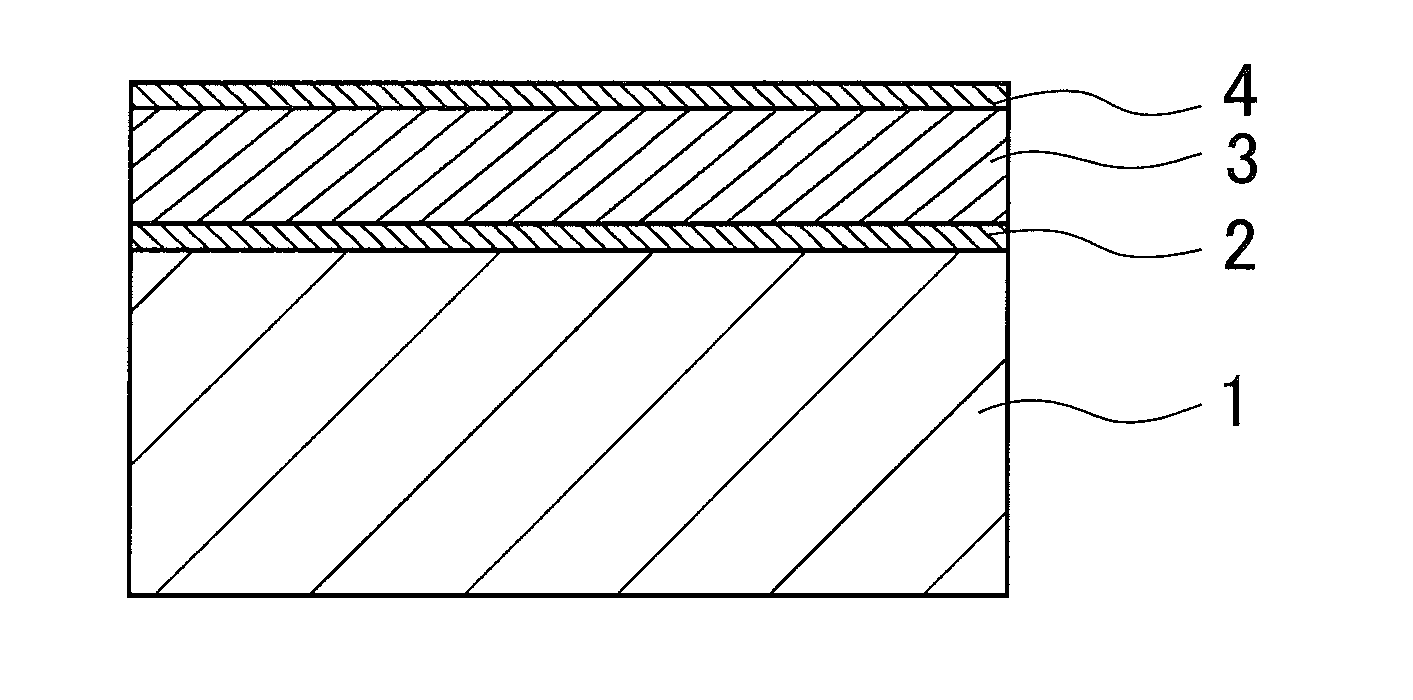

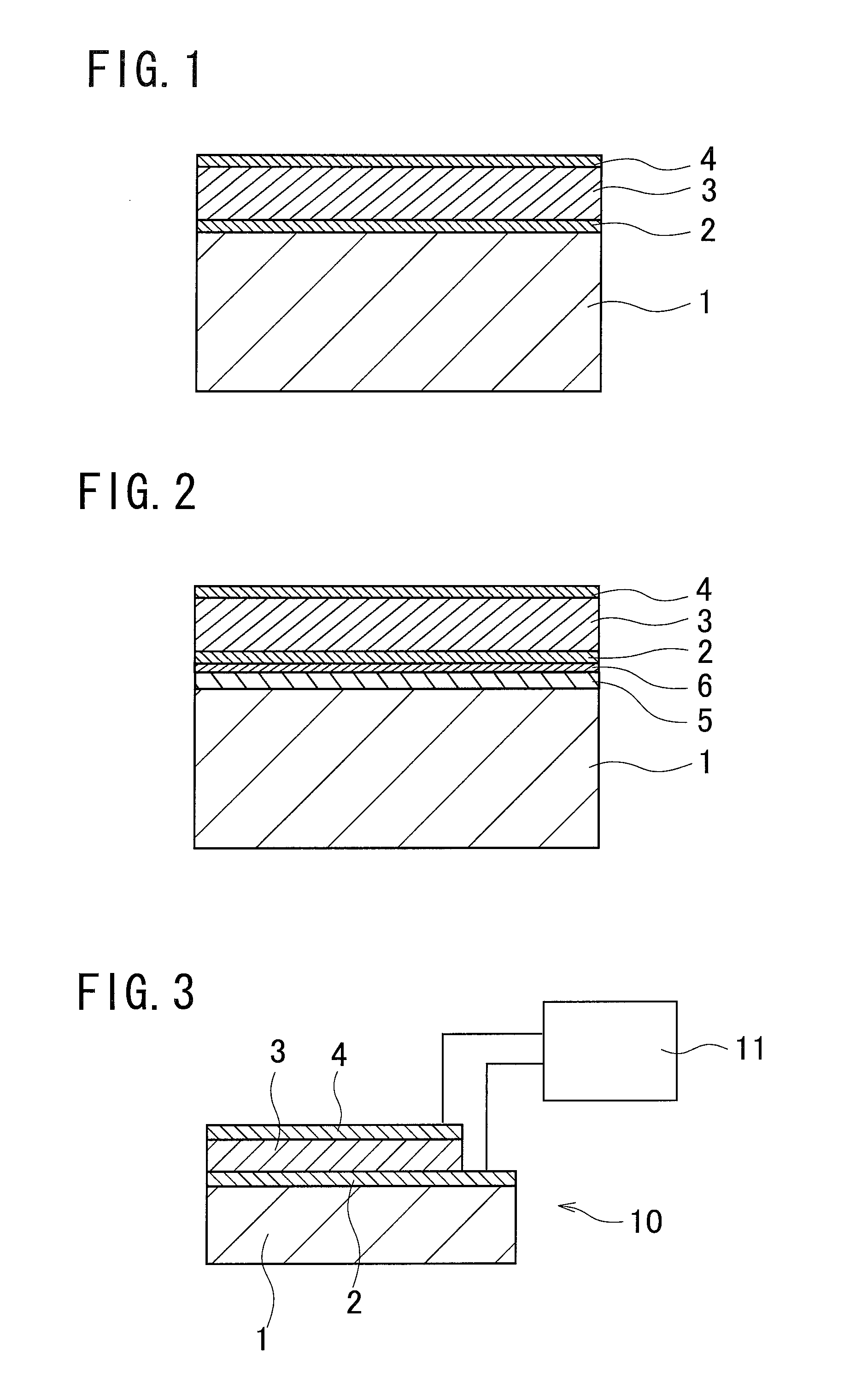

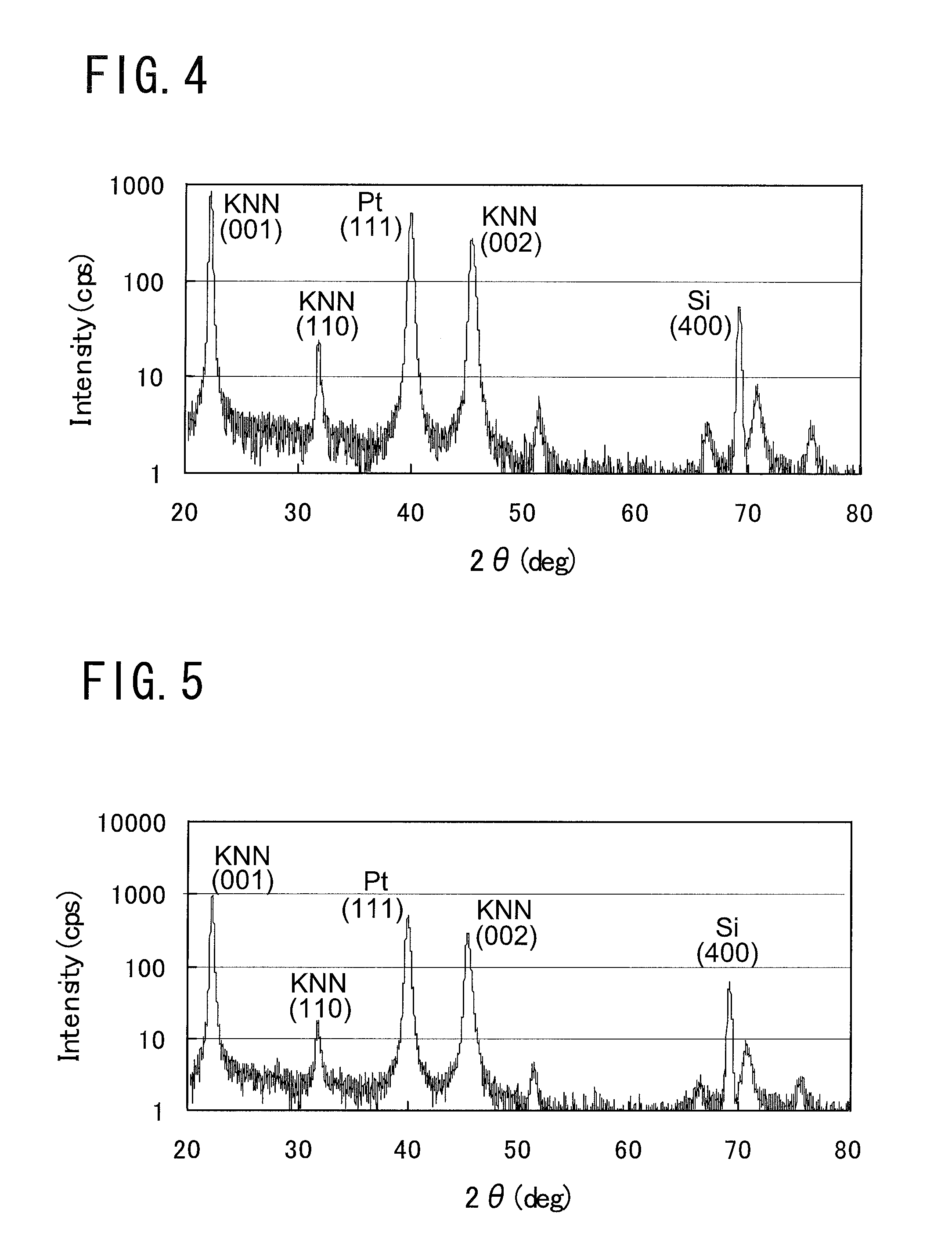

Piezoelectric thin film element and piezoelectric thin film device

ActiveUS20110121690A1Fluid pressure measurement using piezo-electric devicesAcceleration measurement using interia forcesOptoelectronicsMaterials science

To provide a piezoelectric thin film element comprising: a piezoelectric thin film on a substrate, having an alkali-niobium oxide-based perovskite structure expressed by a composition formula (K1-xNax)yNbO3, wherein composition ratios x, y of the piezoelectric thin film expressed by (K1-xNax)yNbO3 are in a range of 0.4≦x≦0.7 and 0.7≦y≦0.94.

Owner:SUMITOMO CHEM CO LTD

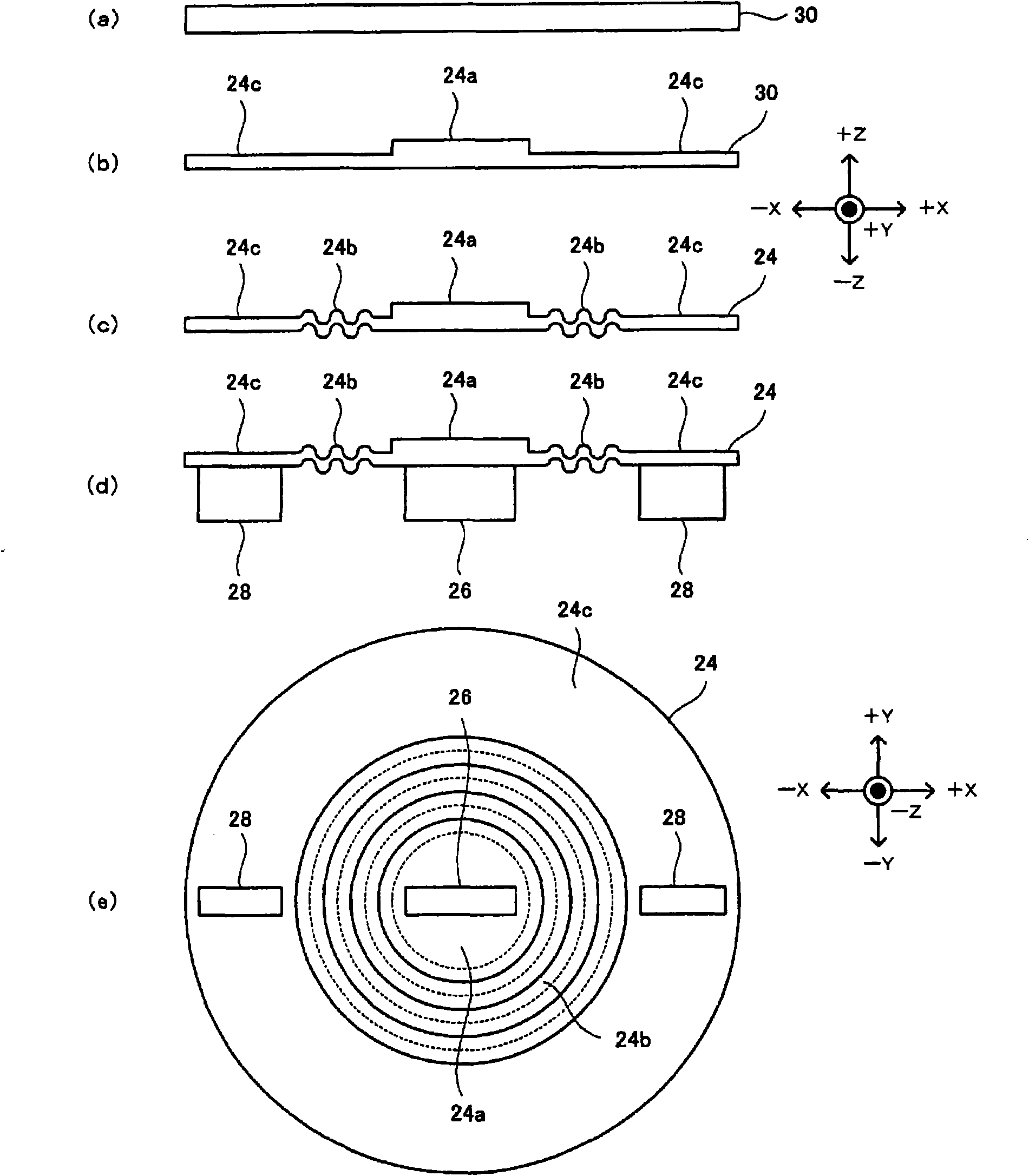

Diaphragm for pressure sensor and pressure sensor

InactiveUS20090308168A1Less occurrenceLess susceptibilityFluid pressure measurement using piezo-electric devicesFluid pressure measurement using elastically-deformable gaugesEngineeringDiaphragm seal

A diaphragm for a pressure sensor includes: a central section serving as a diaphragm body, the central section including: an external surface deformed upon receipt of an external pressure; and an internal surface transmitting a force to a pressure sensitive element inside a housing of the pressure sensor; a peripheral section that is an exterior of the central section and welded to an outer circumference of a pressure input orifice that is provided to the housing; and a step wall provided between the central section and the peripheral section. The central section and the peripheral section are integrally and concentrically provided. The diaphragm seals the pressure input orifice.

Owner:SEIKO EPSON CORP

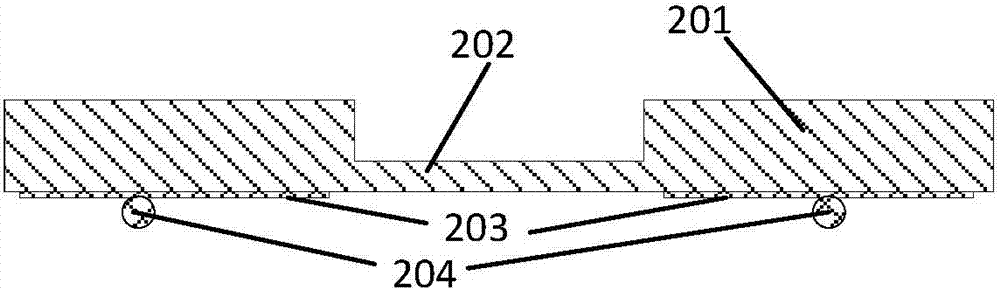

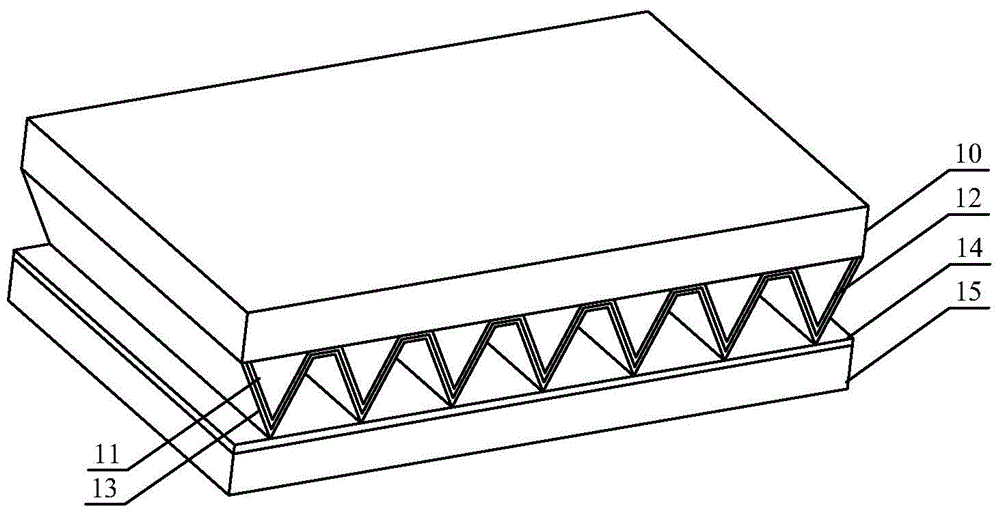

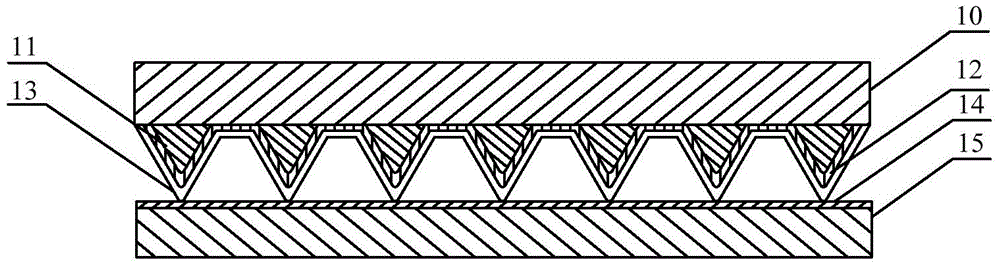

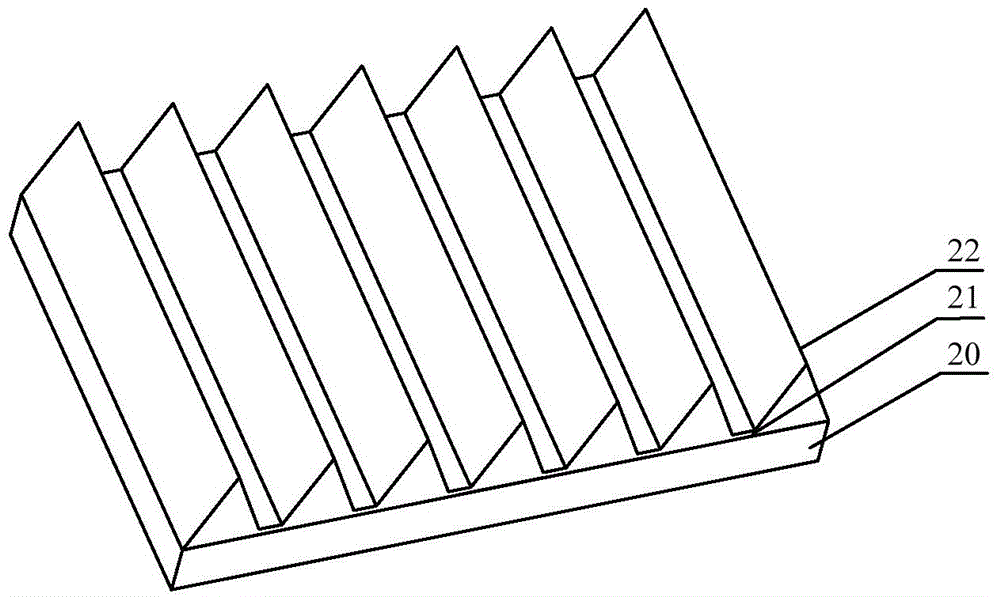

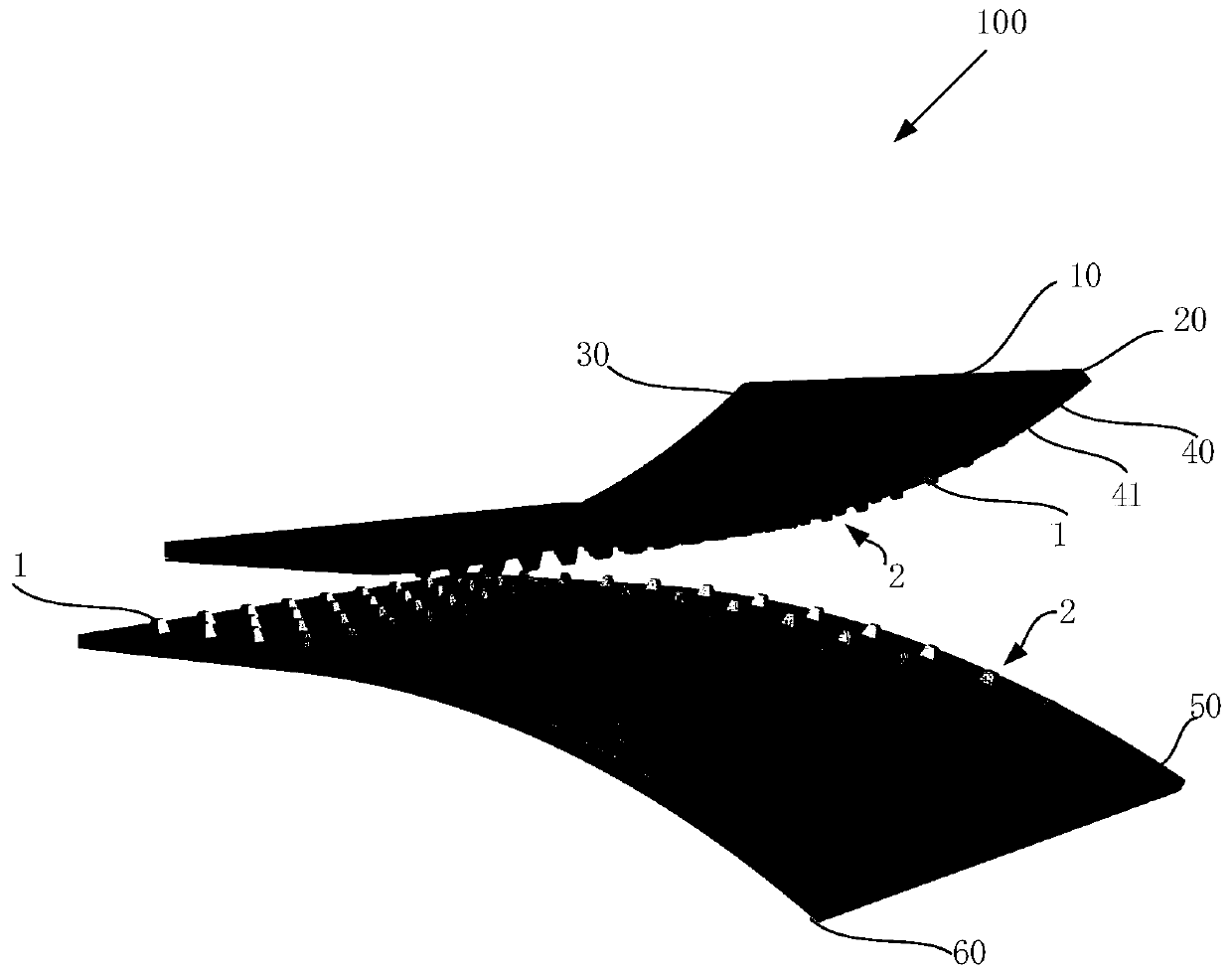

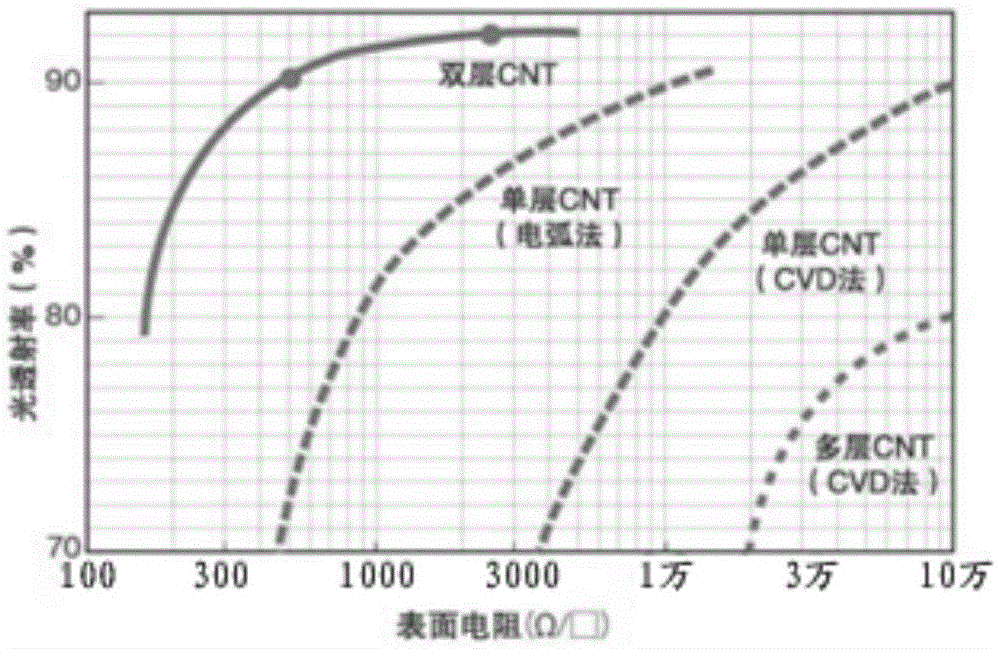

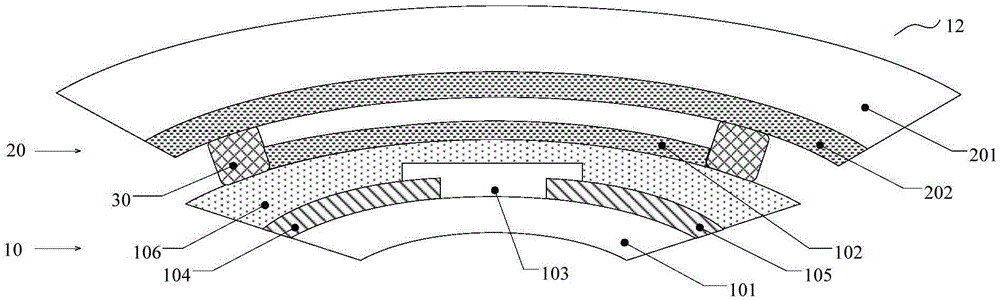

Flexible wearable sensor and corresponding wearable device and preparation method thereof

InactiveCN109738095AImprove output performanceHigh acquisition sensitivityFluid pressure measurement using piezo-electric devicesForce measurement using piezo-electric devicesEngineeringMechanical engineering

The invention provides a flexible wearable sensor and a corresponding wearable device and preparation method thereof, wherein the flexible wearable sensor is small in size and high in flexible degreeand output capacity. The flexible wearable sensor comprises a first electrode layer, a piezoelectric layer, a second electrode layer, an interval layer, a friction layer and a third electrode layer which are arranged in sequence; a flexible mixed material at least constituted by a piezoelectric material and silicone rubber is contained in the piezoelectric layer, and the piezoelectric layer can generate a piezoelectric signal after being subjected to polarization treatment; a flexible mixed material at least constituted by silicone rubber is contained in the friction layer, a plurality of protrusion parts formed by a plurality of protrusion structures which are configured in an arrayed mode are formed on the opposite areas in the inner surface of the piezoelectric layer and the inner surface of the friction layer correspondingly, and the two inner surfaces are oppositely arranged; the outer surface and the inner surface of the piezoelectric layer are covered with the first electrode layer and the second electrode layer correspondingly; and the interval layer is provided with hollow parts opposite to the protrusion parts on the inner surface of the piezoelectric layer, and the outersurface of the friction layer is covered with the third electrode layer.

Owner:ZHONGBEI UNIV

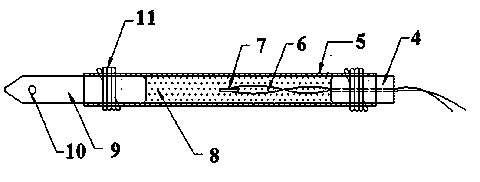

Water shooting pressure measurement sensor

InactiveCN102032969AOvercoming the problem of short circuit damageImprove resistance to damageFluid pressure measurement using piezo-electric devicesMeasurement of explosion forceEpoxyEngineering

The invention discloses a water shooting pressure measurement sensor. The sensor mainly comprises a piezocrystal assembly and an amplifying circuit, wherein the amplifying circuit is arranged in a shell; the piezocrystal assembly is connected with the amplifying circuit through a connecting lead; the amplifying circuit is connected with a signal output cable; the piezocrystal assembly is coated in sound-transparent silicone rubber by an epoxy resin; a graphite layer is coated on the external surface of the sound-transparent silicone rubber; the amplifying circuit is coated by an insulated tape and is packaged in the shell by elastic silicone rubber; one end of the shell is connected with a top cap; the output cable passes through the top cap to be connected with the amplifying circuit; and a screw for fixing the signal output cable is arranged on the shell. The sensor has a simple structure, cannot be easily shot and damaged by explosive products, and can be used for measuring water shooting pressure in a complex environment; and the output cable is reliably connected.

Owner:XIAN MODERN CHEM RES INST

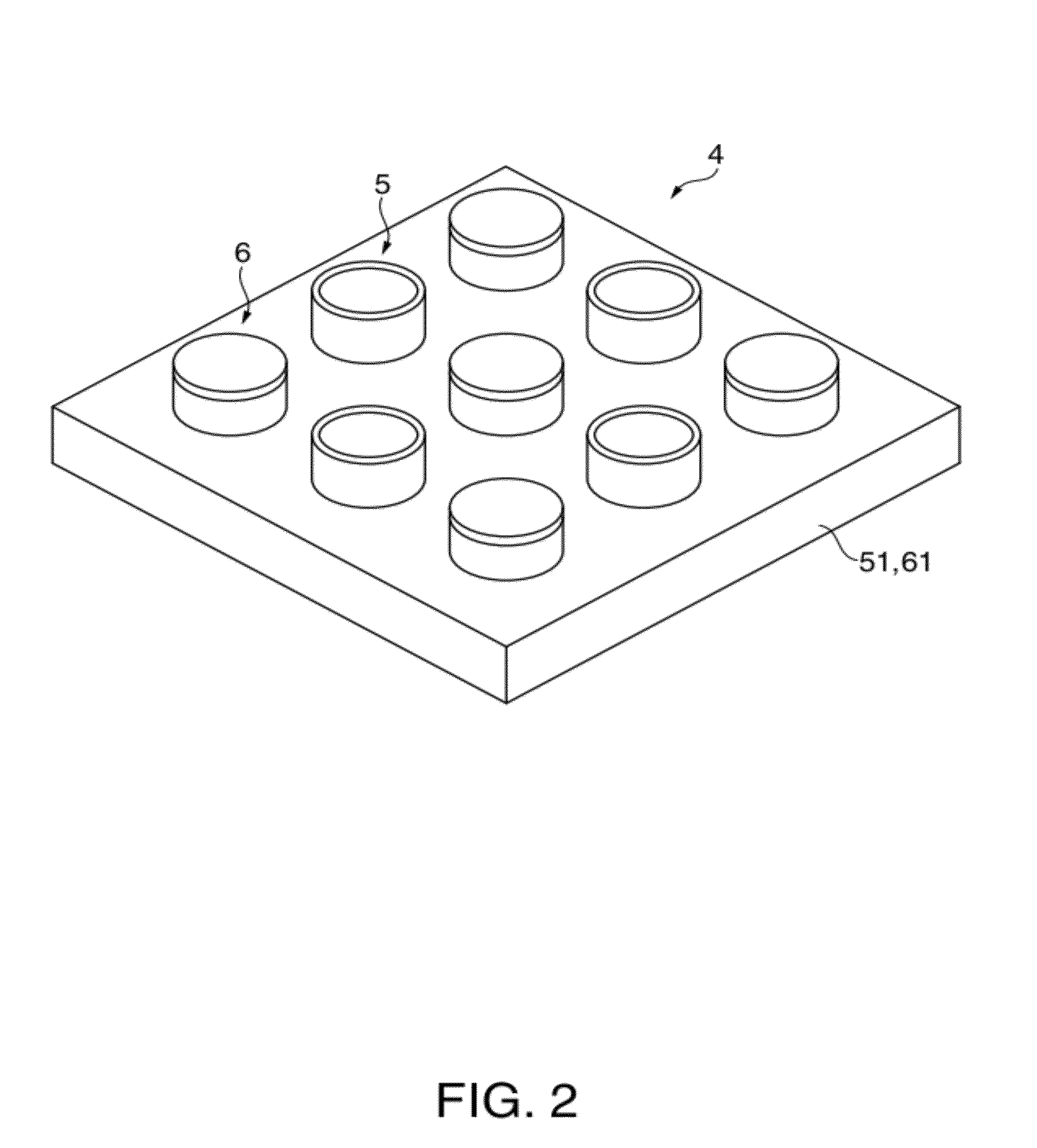

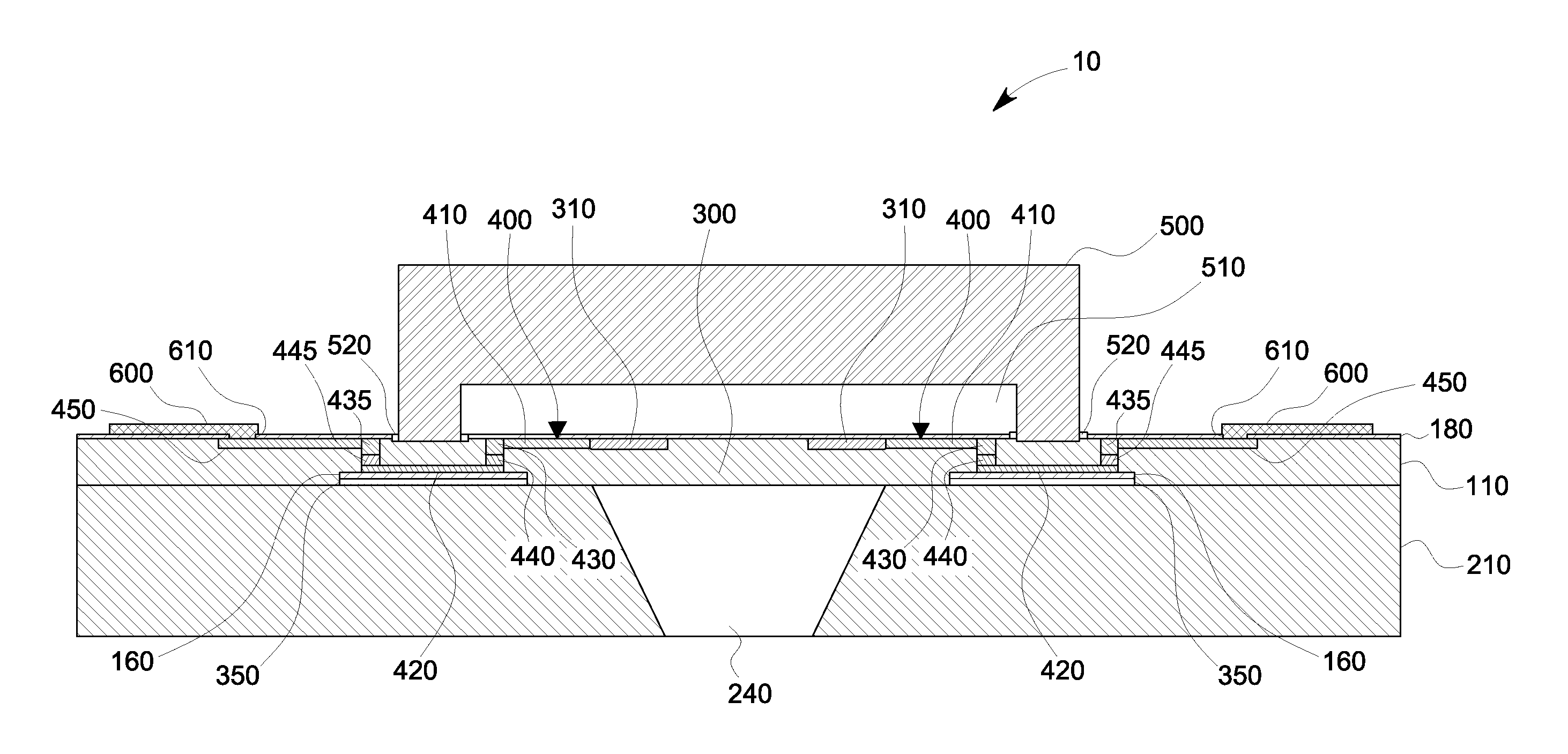

Piezoelectric element, manufacturing method thereof, and piezoelectric sensor

ActiveCN105651429AHigh sensitivityRelieve pressureFluid pressure measurement using piezo-electric devicesForce measurement using piezo-electric devicesOptoelectronicsPiezoelectric sensor

Embodiments of the present invention relates to a piezoelectric element, a manufacturing method thereof, and a piezoelectric sensor. The piezoelectric element comprises a piezoelectric member, a first substrate, a second substrate, a first electrode layer and a second electrode layer, wherein the first substrate and the second substrate are respectively arranged on the two sides of the piezoelectric member. The first electrode layer is arranged between the first substrate and the piezoelectric member, and the second electrode layer is arranged between the second substrate and the piezoelectric member. The surface of the first substrate and / or the surface of the second substrate layer, positioned closer to the piezoelectric member, are / is provided with lug bosses. According to the technical scheme of the invention, the sensitivity of the piezoelectric element is improved.

Owner:BOE TECH GRP CO LTD

Monolithic silicon based SOI high-temperature low-drift pressure sensor

InactiveCN1731115AThere will be no leakageCorrectly designedFluid pressure measurement using piezo-electric devicesSolid-state devicesElectrical resistance and conductanceSingle chip

The invention relates to a single chip silicon SOI high temperature low drift pressure sensor in the field of sensitive sensing technology. Wherein the four voltage-sensitive resistances which form the Wheatstone bridge adopt SOI material; it adopts the interval compensation and the outer compensation technology of partial interval resistance of the SOI resistance network to make the zero point temperature drift below 1X10-6Vs / íµ; it adopts girder-film-island structure to improve the sensibility and linearity of the sensor; it adopts polysilicon with thick boron and the aluminum lead wire covered the lead wire surface to form the interval lead wire of the sensor; it adopts thick boron automatically end technology to make high sensibility high temperature low drift pressure sensor.

Owner:SHANGHAI SAISU SENSOR TECH

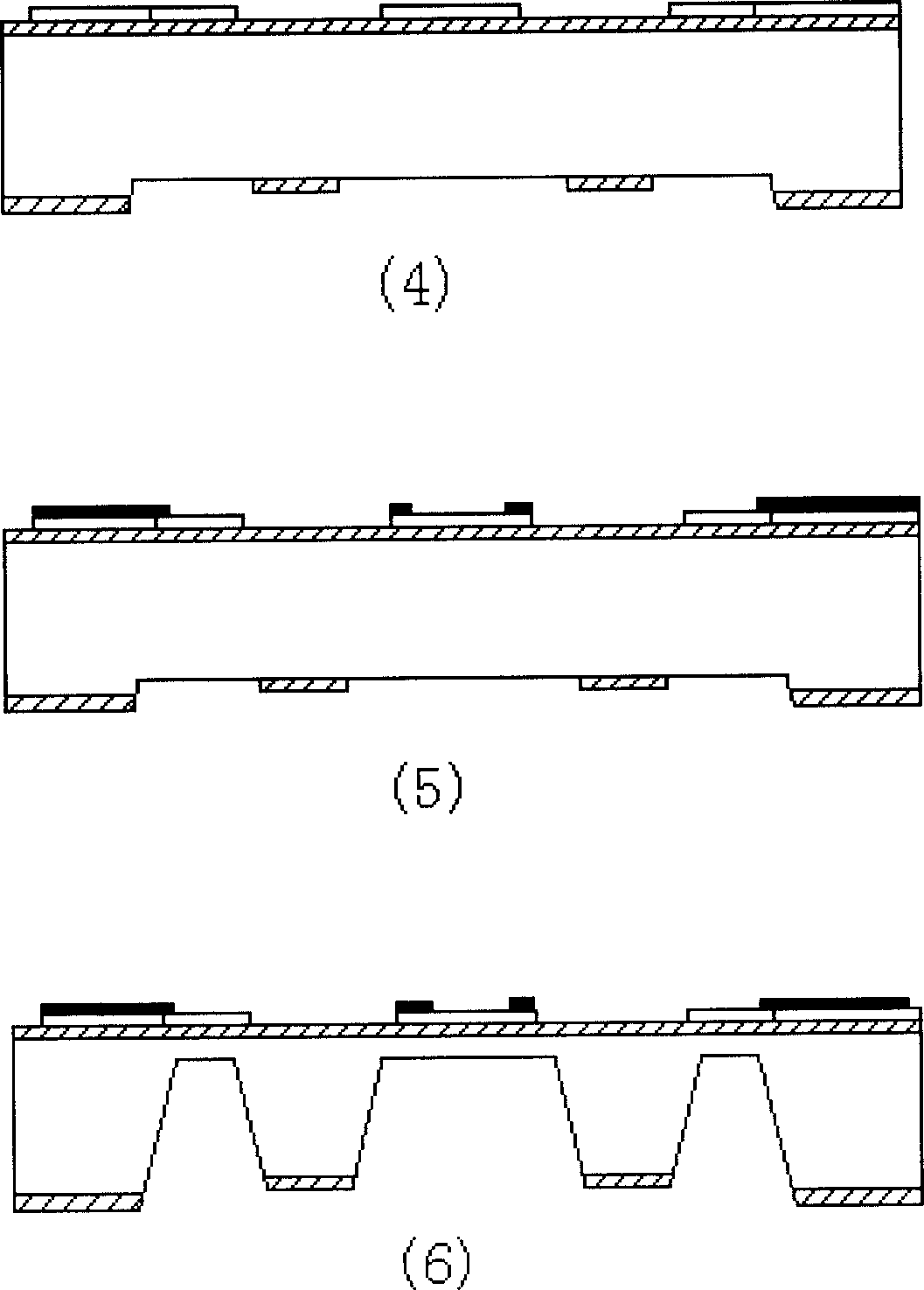

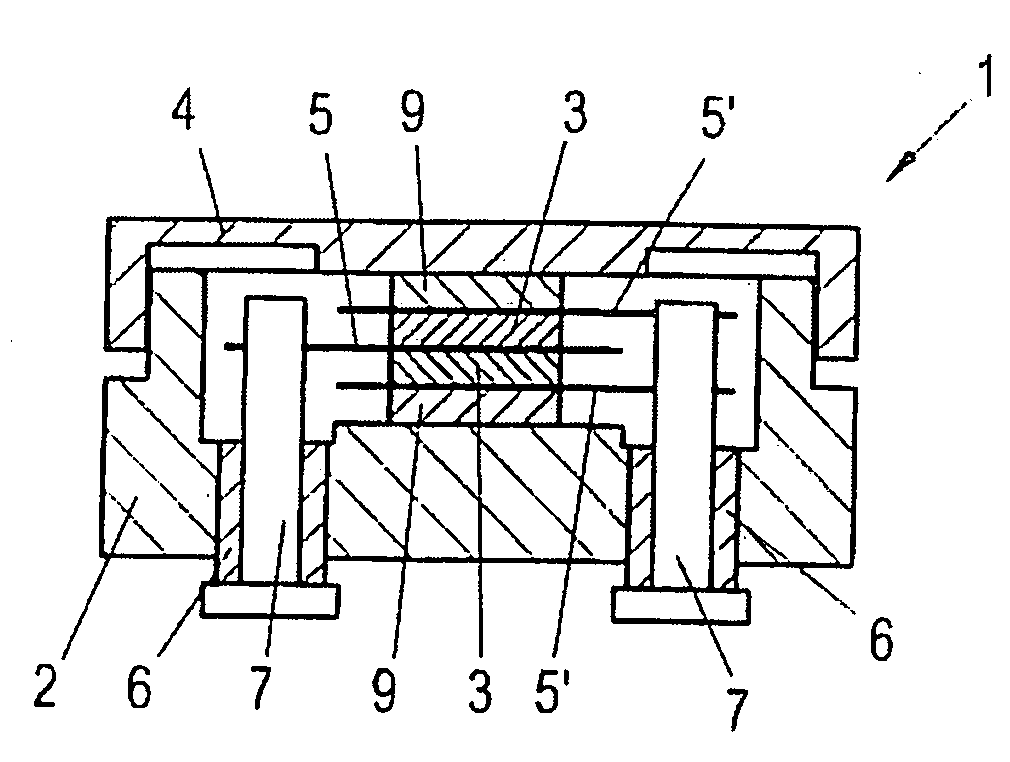

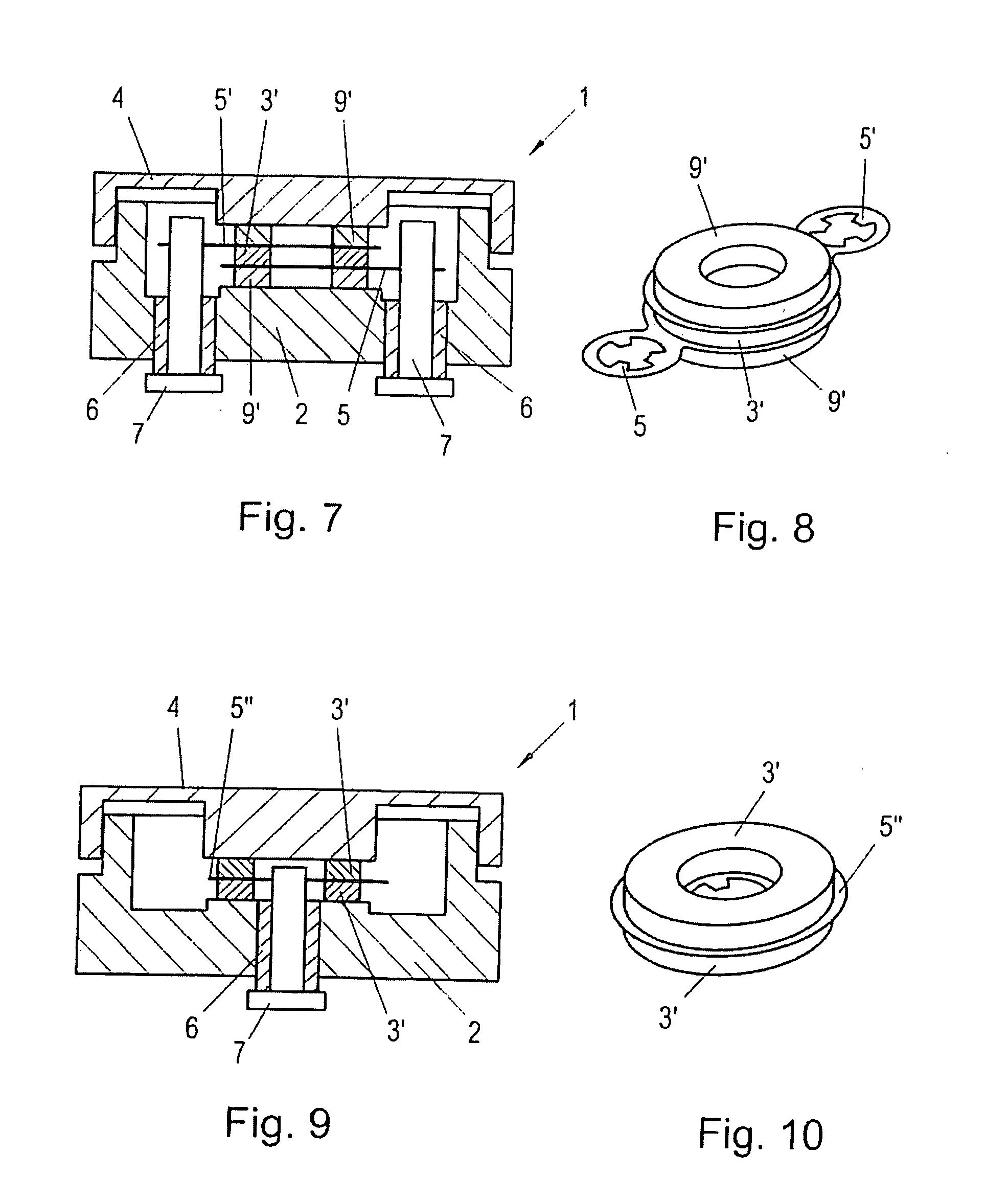

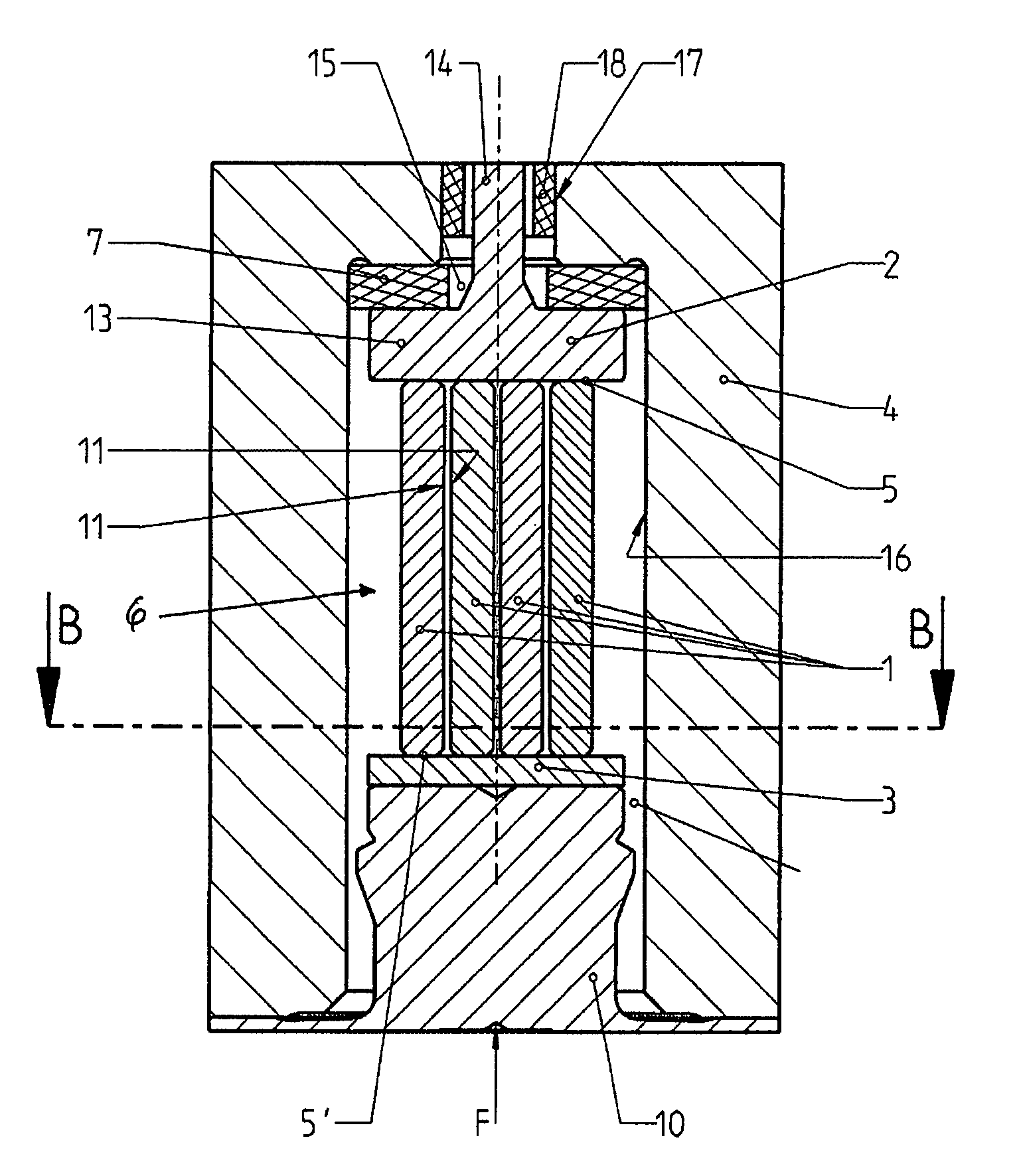

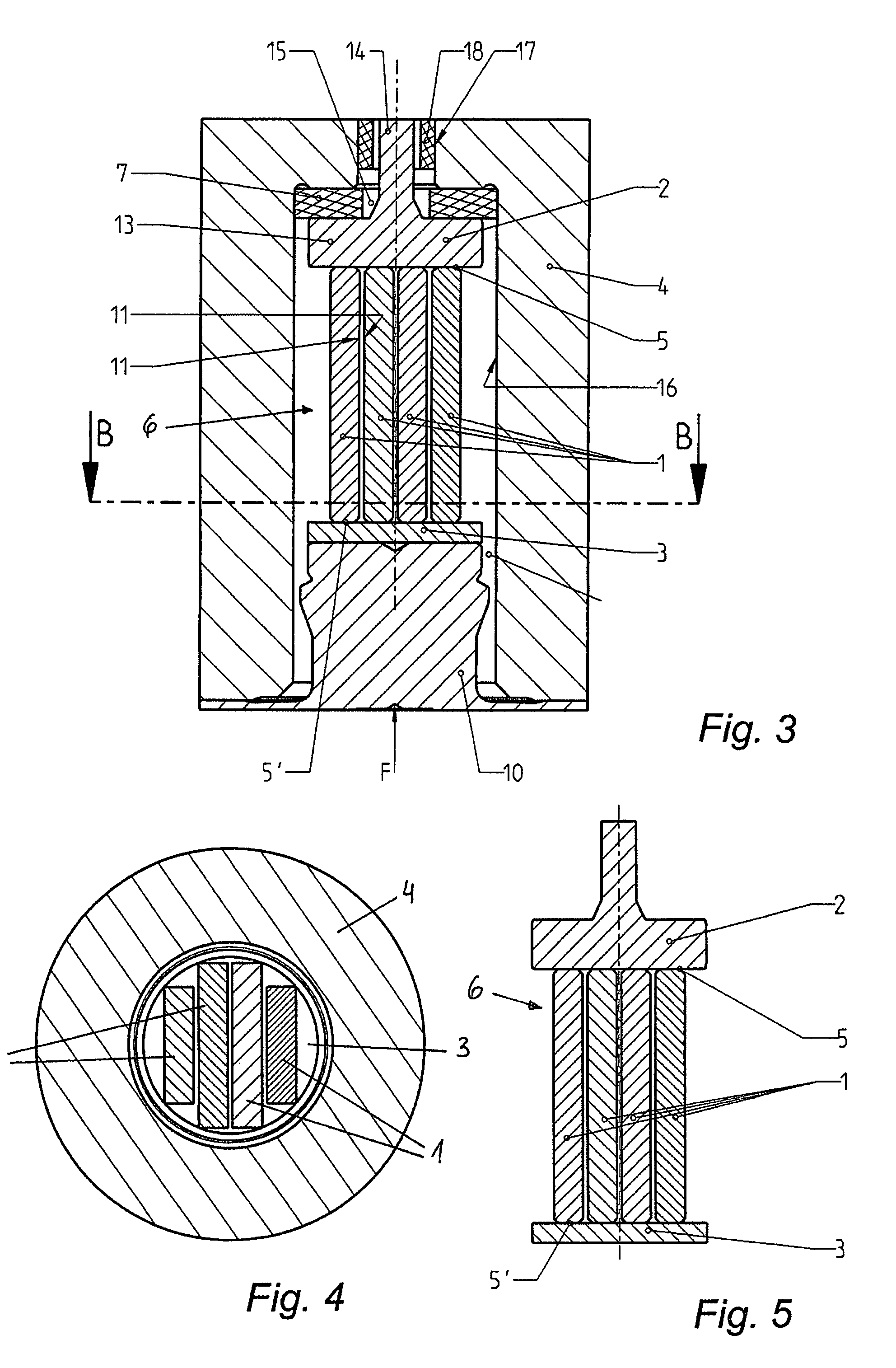

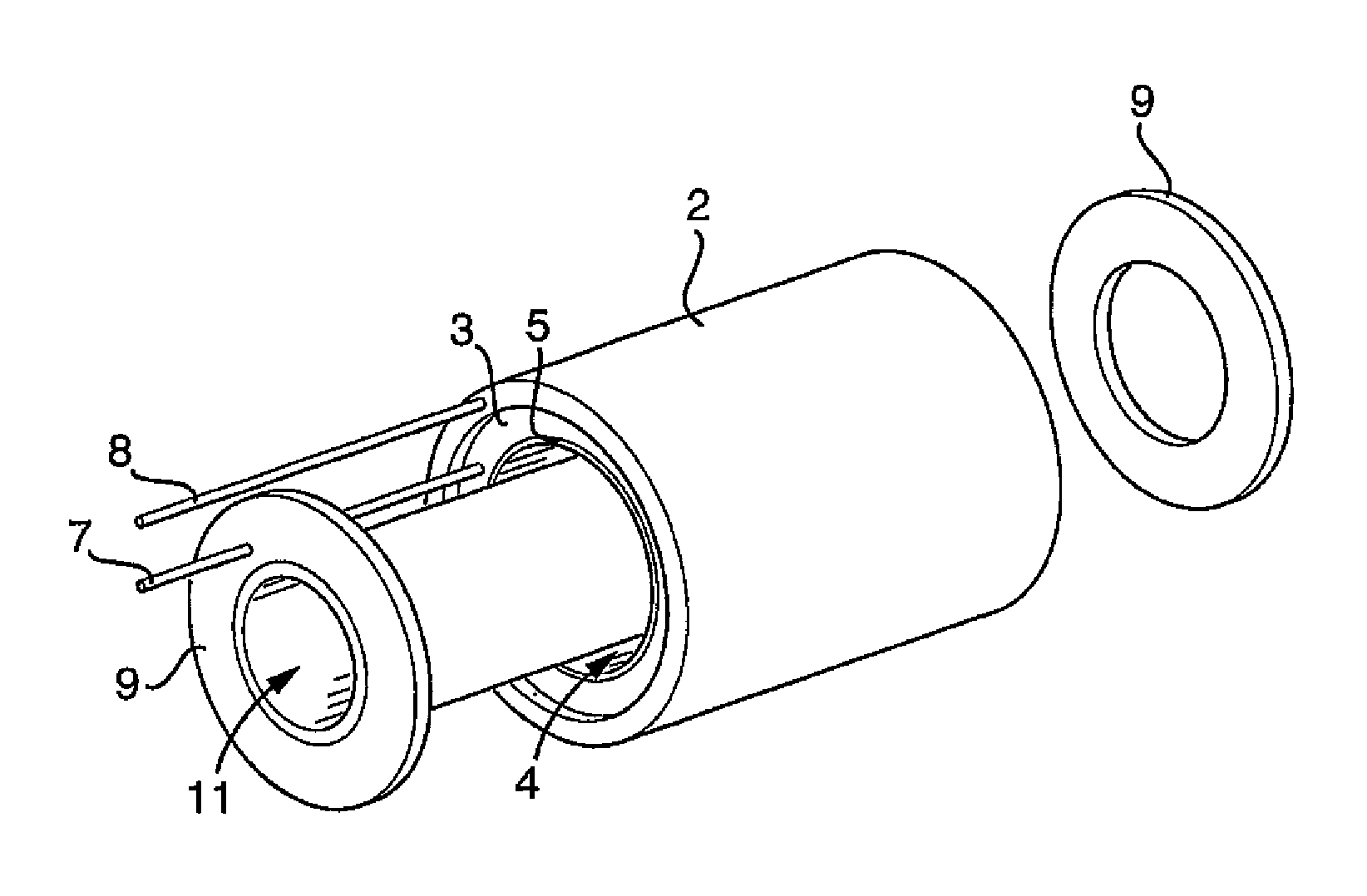

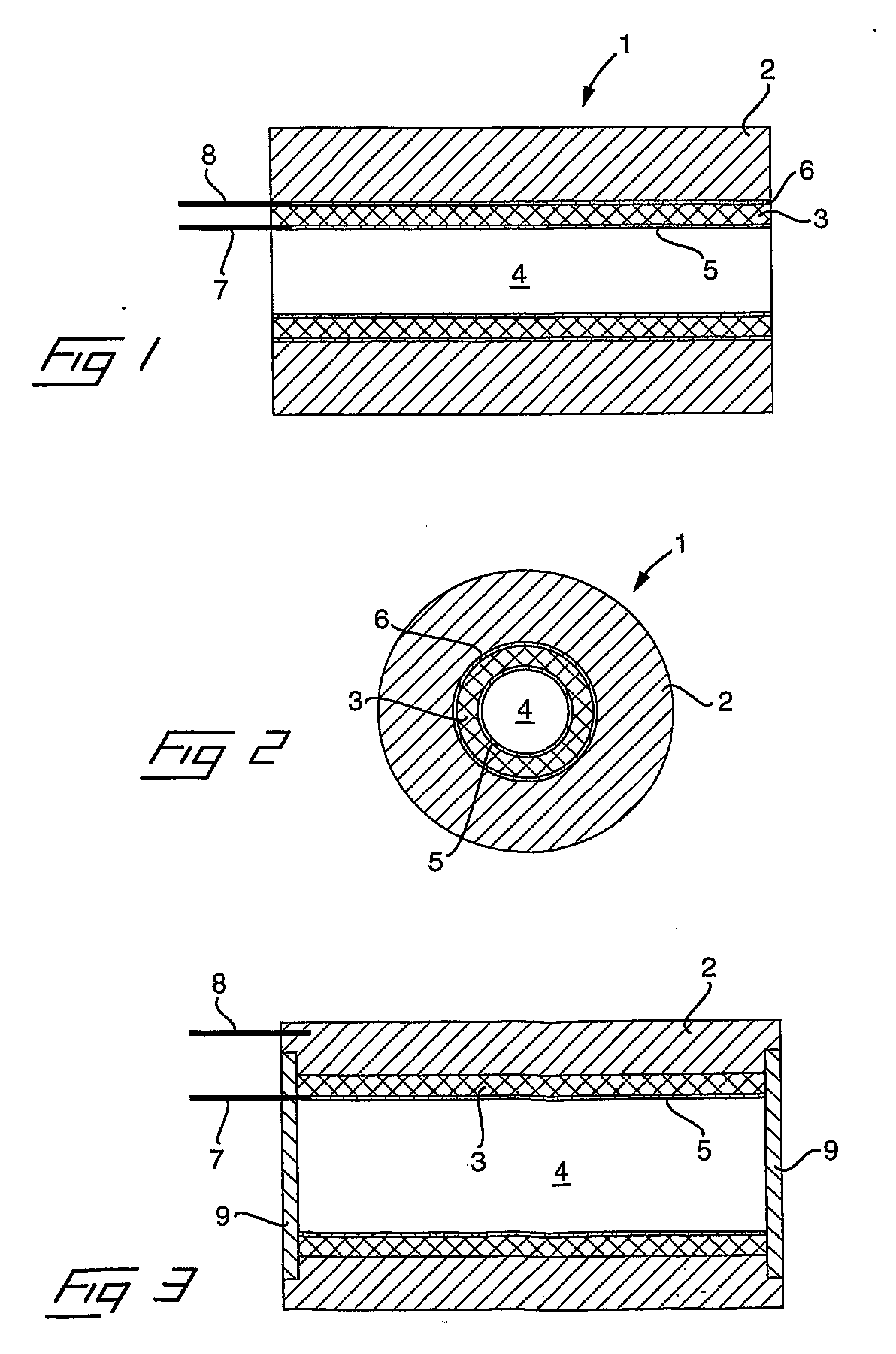

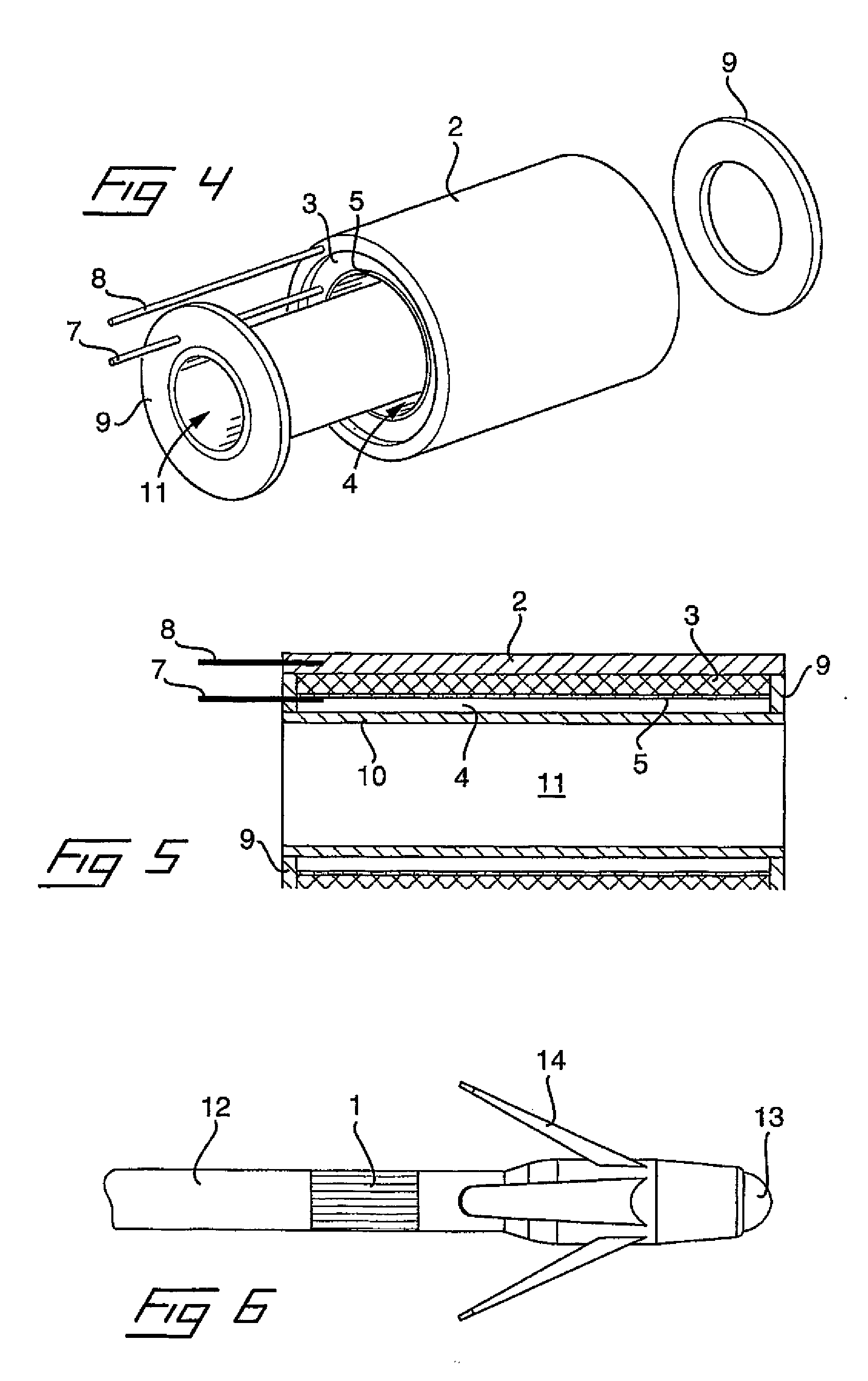

Piezoelectric pressure transducer

ActiveUS20100058875A1Simple and thus cost-effective designThe process is simple and accurateFluid pressure measurement using piezo-electric devicesNon-mechanically variable capacitorsTransducerEngineering

To render possible a high-quality, yet cost-effective provision suitable for mass production of a piezoelectric pressure transducer (1) with at least one piezoelectric measuring element (3, 3′, 3″) arranged on a housing base part (2), which measuring element is connected on the opposite side to a diaphragm (4), the measuring element (3, 3′, 3″) is fixed on an electrode sheet (5, 5′, 5″, 5″′) or directly on the base part 2 or the diaphragm 4, wherein the electrode sheet (5, 5′, 5″, 5″′) wraps conductively and positively as well as in a manner fixing the layers around a contact pin (7) insulated with respect to the base part (2) and projecting outwards.

Owner:PIEZOCRYST ADVANCED SENSORICS

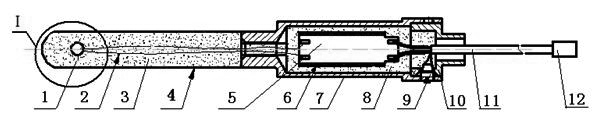

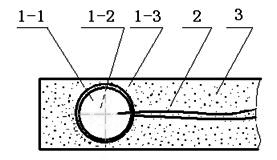

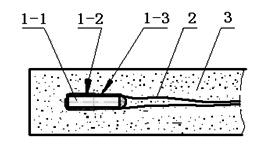

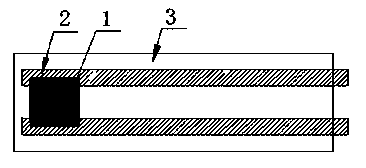

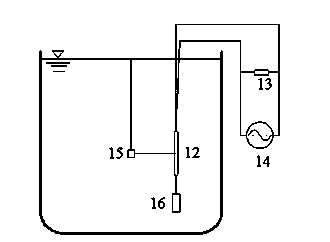

Piezoelectric film type underwater explosion pressure sensor and measuring method thereof

InactiveCN103674383ALow costEliminate measurement errorsFluid pressure measurement using piezo-electric devicesMeasurement of explosion forceMeasuring equipmentSilicone oil

The invention belongs to the field of underwater explosion measuring equipment, and particularly relates to a piezoelectric film type sensor used for underwater explosion pressure measurement and a measuring method thereof. According to the sensor, a sandwich type piezoelectric film pressure gage is placed in a hose filled with silicone oil, the two ends of the hose are sealed through plastic plugs, an extension leading wire is led out from a thin through hole of the upper plastic plug, and a flexible fine wire is wound on the outer wall face of the hose. The measuring method includes the steps that (1) the sensor is hung in the same horizontal line with an underwater explosion explosive cylinder through a counter weight, a resistor is connected to the sensor in parallel, a piezoelectric film and the resistor form a powered loop through an extension electrode leading wire, and an oscilloscope is arranged on the loop; (2) after explosives are ignited, voltage signals at the two ends of the resistor are recorded; (3) the quantity of electric charges of the piezoelectric film is obtained through calculation according to the voltage signals, and an explosive shock wave pressure numerical value is acquired through conversion. The piezoelectric film type sensor can be used for directly measuring the pressure change rate of underwater explosion, and is wide in pressure measuring range, convenient to process and low in cost.

Owner:UNIV OF SCI & TECH OF CHINA

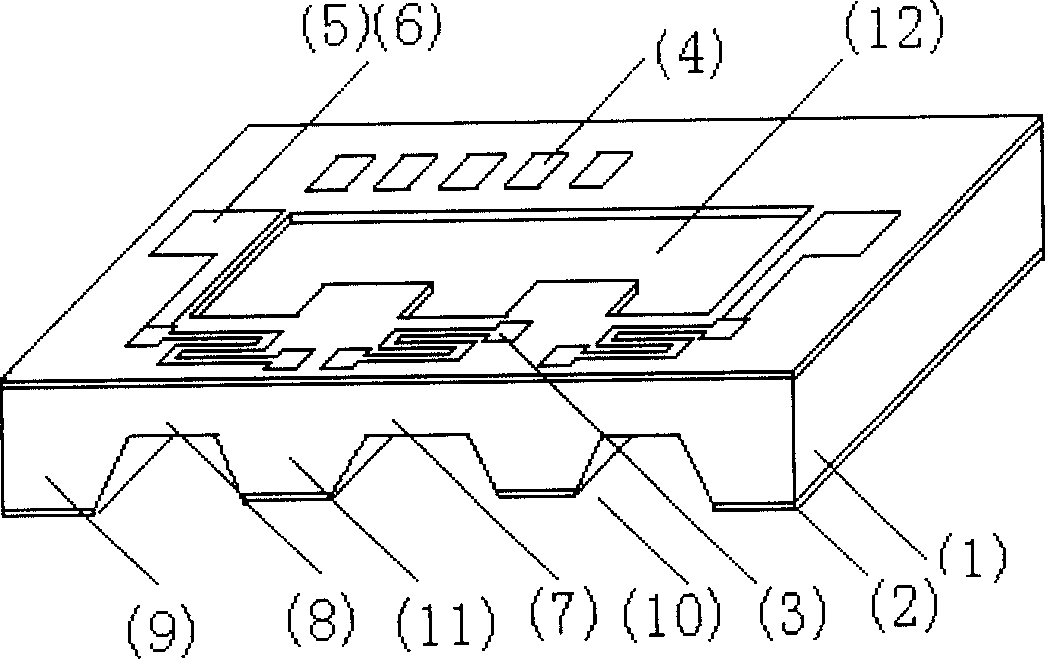

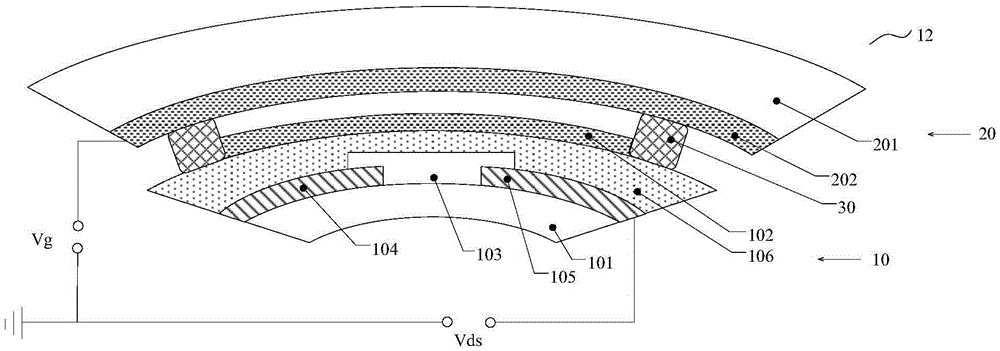

Thin film transistor sensor and fabrication method thereof

ActiveCN105552132ATransistorFluid pressure measurement using piezo-electric devicesEngineeringActive layer

The invention relates to a thin film transistor sensor and a fabrication method thereof. The thin film transistor sensor comprises a first substrate and a second substrate, wherein the first substrate and the second substrate are opposite to each other, the first substrate comprises a first flexible substrate and a first grid arranged on the inner side of the first flexible substrate, the second substrate comprises a second flexible substrate and a second grid arranged on the inner side of the second flexible substrate, at least parts of the second grid and the first gird are in opposite, the second grid and the second grid are isolated from each other when the thin film transistor sensor is in a non-working state, an active layer, a source and a drain are further arranged on the first flexible substrate, the active layer is opposite to the first grid, the source and the drain are electrically connected with the active layer. In the thin film transistor sensor, spatial point contact changes of the first grid and the second grid of a flexible thin film transistor are utilized to realize the switching function of the thin film transistor, and thus, the effect of the sensor is achieved.

Owner:BOE TECH GRP CO LTD

Method for fabricating a sensor

InactiveUS7998777B1Fluid pressure measurement using piezo-electric devicesFluid pressure measurement using ohmic-resistance variationEngineeringElectrical and Electronics engineering

A method for fabricating a sensor is disclosed that in one embodiment bonds a first device wafer to an etched second device wafer to create a suspended structure, the flexure of which is determined by an embedded sensing element that is in electrical communication with an outer surface of the sensor through an interconnect embedded in a device layer of the first device wafer. In one embodiment the suspended structure is enclosed by a cap and the sensor is configured to measure absolute pressure.

Owner:AMPHENOL THERMOMETRICS

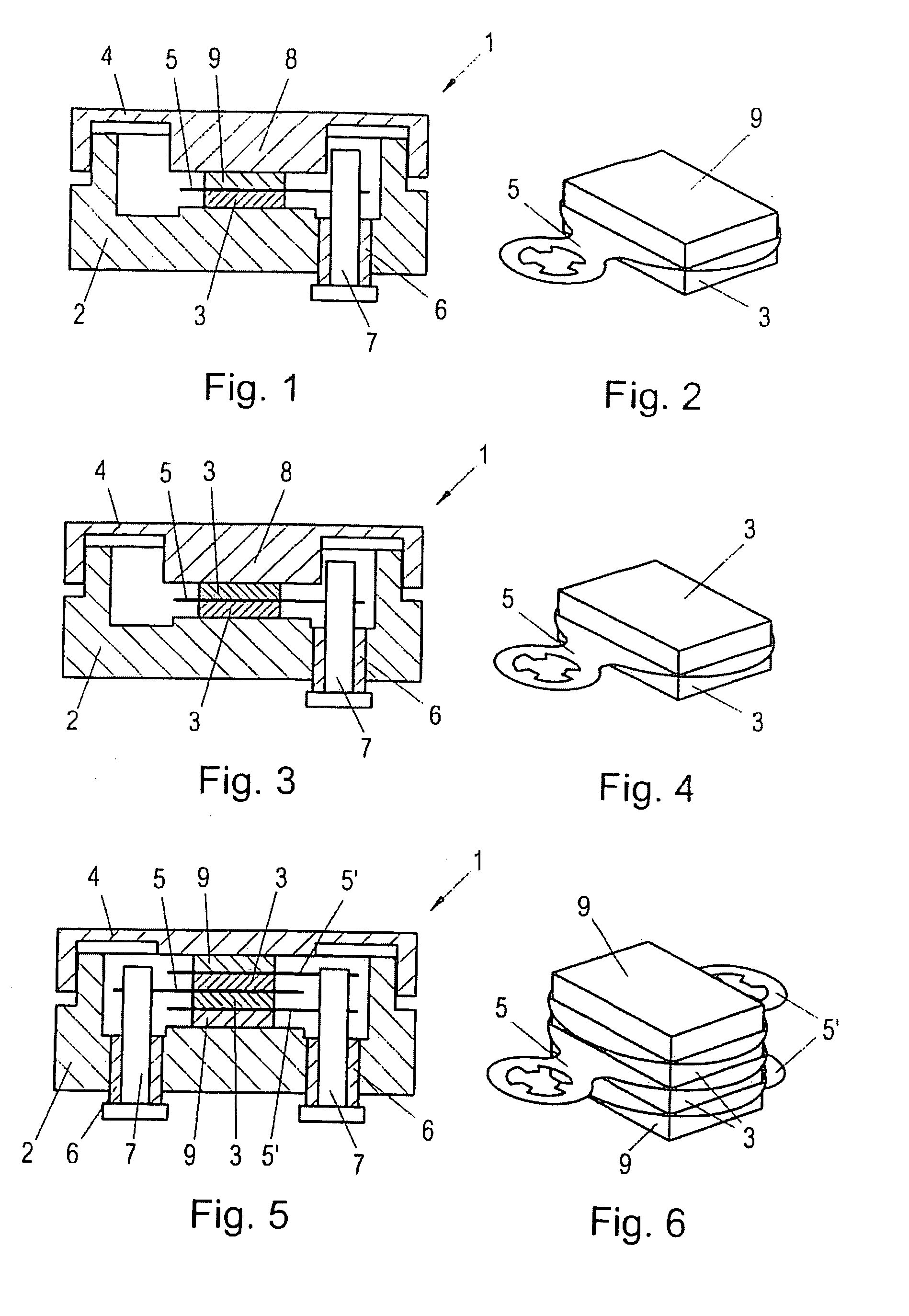

Piezoelectric sensor

InactiveUS7603906B2Precise positioningAdequate insulation performanceFluid pressure measurement using piezo-electric devicesForce measurement using piezo-electric devicesSolderingAcoustics

Owner:PIEZOCRYST ADVANCED SENSORICS

Sonic surface wave pressure sensor using composite mold

ActiveCN101354302AImprove long-term stabilityReduce oxidationFluid pressure measurement using piezo-electric devicesForce measurement using piezo-electric devicesOvervoltageSurface acoustic wave

The invention relates to a surface acoustic wave pressure sensor adopting a compound die, which pertains to the technical field of sensors and comprises a mushroom pressurization cap, a hard-core ball shell pressure guiding metal diaphragm, a metal force guiding column, an overvoltage protective device, a metal shell side wall, a force guiding ejector disk, a force guiding cylinder, a quartz cantilever beam sensitive element, a bottom case and an overvoltage protective device, wherein, the hard-core ball shell pressure guiding metal diaphragm, the metal shell side wall and the bottom case form an air-tight container; the upper surface of the hard-core ball shell pressure guiding metal diaphragm is connected with the mushroom pressurization cap by the metal force guiding column, while the lower surface thereof is fixed with the force guiding ejector disk rigidly connected with the force guiding cylinder; the interior of the force guiding cylinder is provided with the quartz cantilever beam sensitive element; one end of the quartz cantilever beam sensitive element is connected with a blind hole end surface of the force guiding cylinder by glass powder, while the other end thereof is connected with a blind hole of the metal shell side wall by utilizing glass powder. The flexibility of the invention is 15 times higher than the conventional surface wave sensor, and the surface acoustic wave pressure sensor of the invention is suitable for the wireless monitoring of the tire pressure of carts.

Owner:SHANGHAI JIAO TONG UNIV

Pressure sensor

InactiveCN101634598AFluid pressure measurement using piezo-electric devicesFluid pressure measurement using elastically-deformable gaugesPressure senseEngineering

The invention provides a pressor sensor for reducing error of pressure measurements. The pressure sensor includes: a housing; a pressure receiver which seals an opening of the housing and transmits pressure from outside the housing to the inside of the housing; and a pressure sensing element having a pressure sensing portion and a pair of base portions which are respectively coupled to both ends of the pressure sensing portion. In the pressure sensor, a force detecting direction is set to be a detection axis, a line connecting the pair of base portions and a displacement direction of the pressure receiver are arranged in parallel, one of the base portions is coupled to a central region, which is displaced by the pressure, of the pressure receiver, and the other of the base portions is coupled to a marginal region, which is at a fixing side, of the pressure receiver through a connecting member.

Owner:SEIKO EPSON CORP

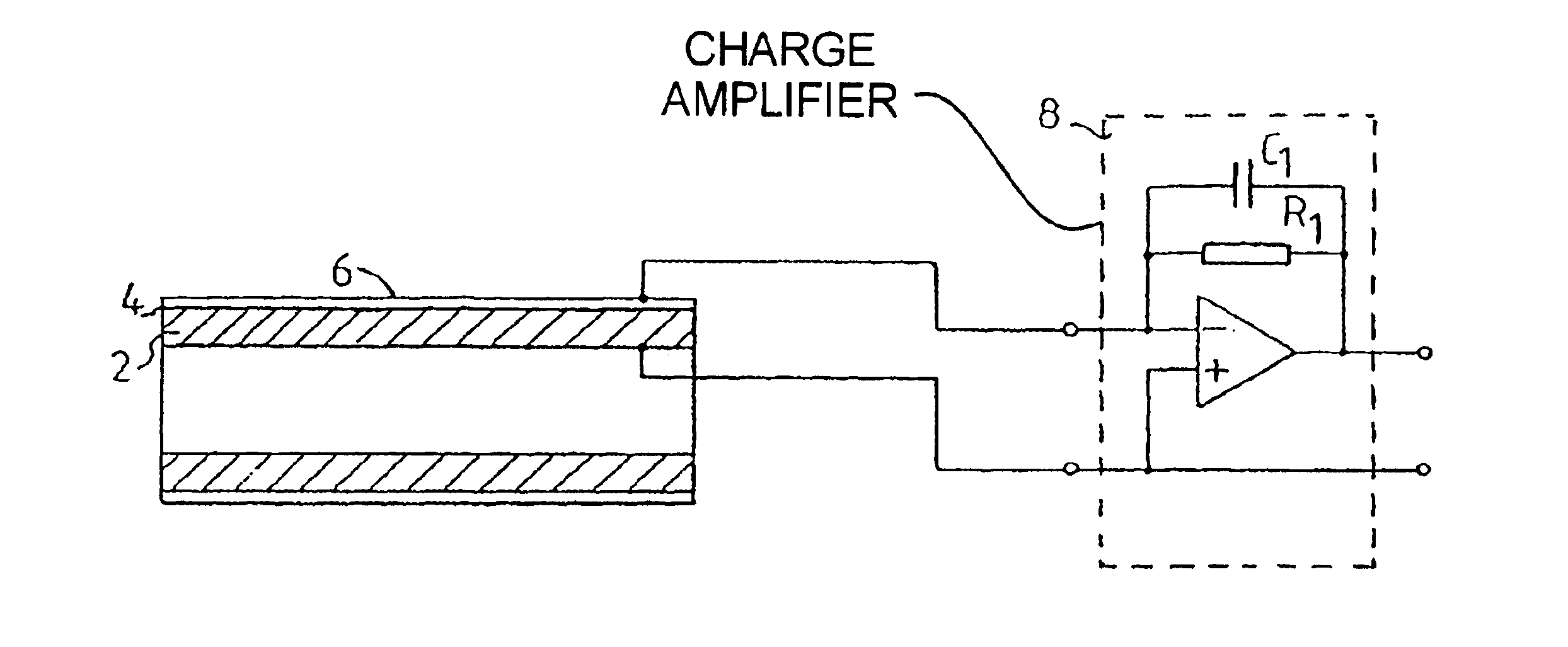

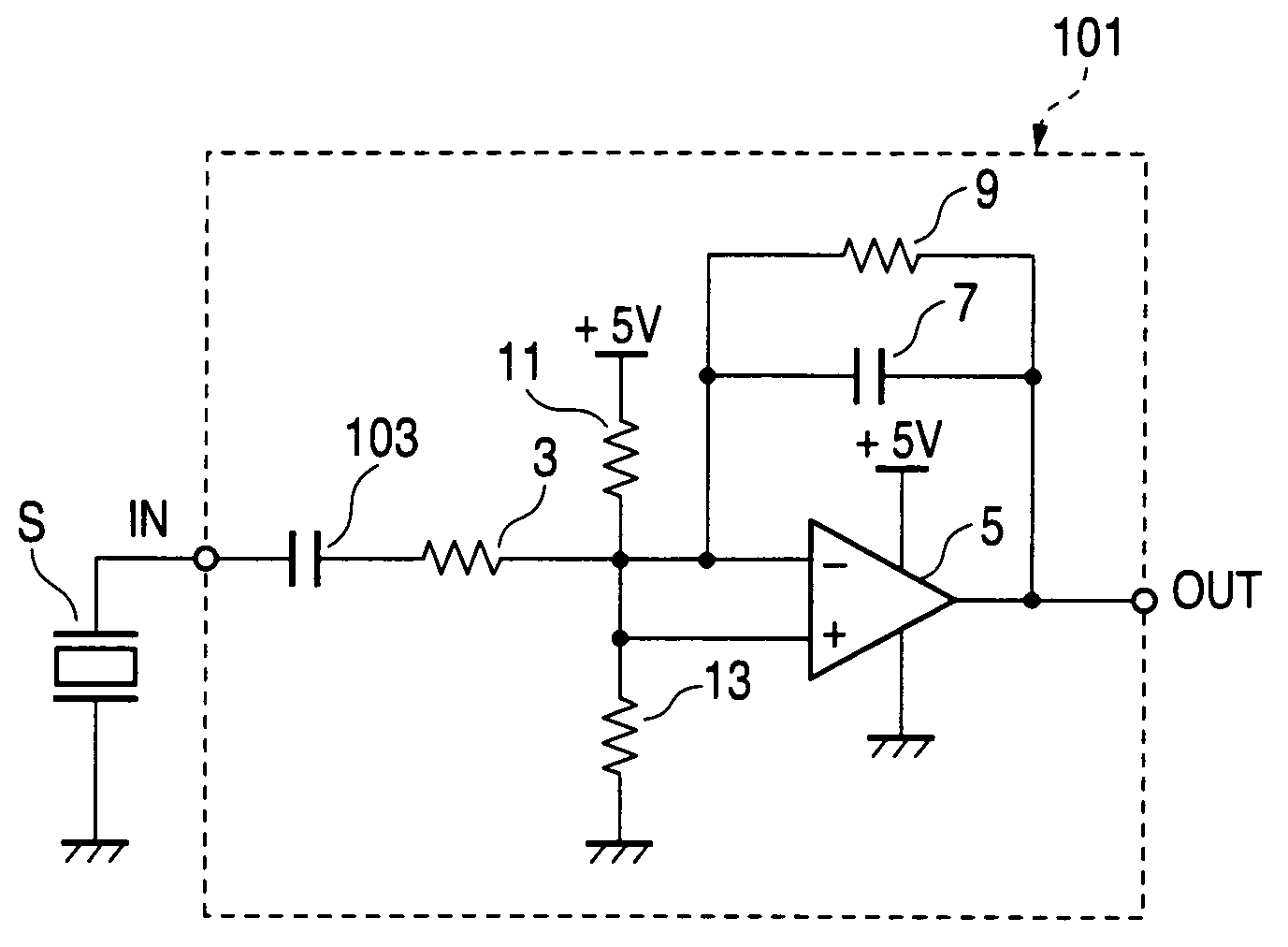

Charge amplifier for piezoelectric pressure sensor

InactiveUS7042288B2Efficient processPressure resistanceFluid pressure measurement using piezo-electric devicesMachines/enginesElectricityAudio power amplifier

An object of the present invention is to provide a charge amplifier which can be operated at low cost so that electric charge generated in a piezoelectric pressure sensor having one end grounded is converted into a voltage signal.In the charge amplifier (1) according to an embodiment of the present invention, a plus side power source input terminal of an operational amplifier (5) is connected to a plus power source (+5 V) while a minus side power source input terminal of the operational amplifier (5) is grounded, so that the operational amplifier (5) is supplied with a single power source. Further, an offset voltage lower than the plus power source voltage but higher than the ground potential is applied to a non-inverted input terminal of the operational amplifier (5). Accordingly, change of pressure in both positive and negative directions can be converted into a voltage signal with the offset voltage as its center though the operational amplifier (5) is driven by a single power source. That is, cost can be suppressed because a double power source is not required.

Owner:NGK SPARK PLUG CO LTD

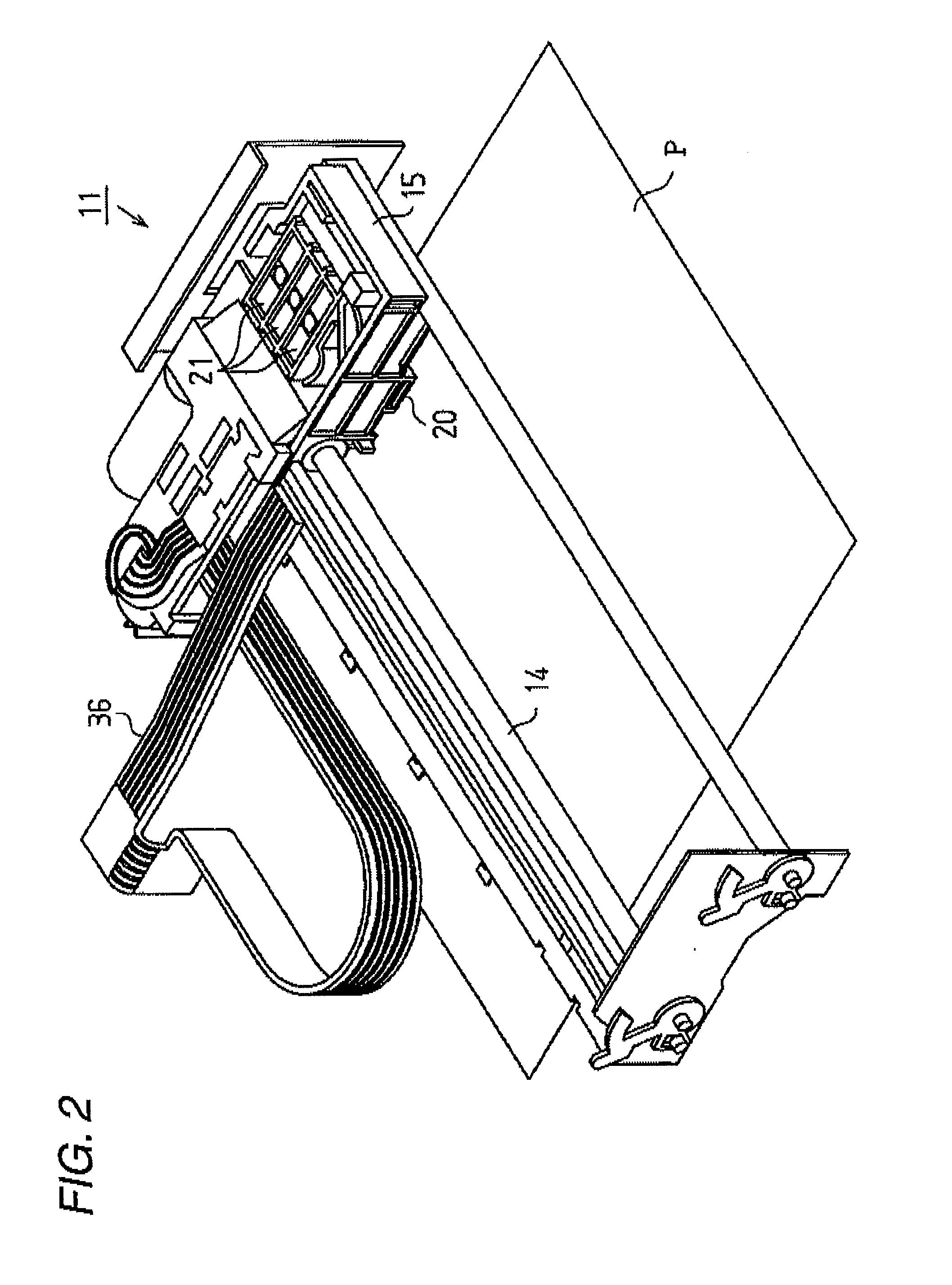

Liquid detecting device, liquid container, and liquid refilling method

InactiveUS20080148859A1Reliable fillingFluid pressure measurement using piezo-electric devicesPrintingLiquid pressure

A liquid container includes; a liquid containing portion for containing liquid therein; a unit case, including a liquid inlet communicating with the liquid containing portion, a liquid outlet for supplying the liquid outside, a flexible diaphragm that covers an upper opening of the unit case and that is displaceable depending on liquid pressure between the liquid inlet and the liquid outlet; a movable member attached to the flexible diaphragm and that has a pair of shafts formed to protrude from opposite sides of the movable member: a sensor assembly attached to a bottom opening formed in a bottom plate of the unit case and used for detecting that the liquid in the liquid containing portion is exhausted to a predetermined amount; and a pair of shaft receiving portions that is provided on the unit case for receiving the pair of the shafts to fix the movable member in a predetermined position in an initial state where the liquid has not flowed from the liquid inlet to the detection portion.

Owner:SEIKO EPSON CORP

Quartz girder resonant mode micro-pressure sensor chip with silicon substrate single island structure

ActiveCN103115720AHigh precisionHigh resolutionFluid pressure measurement using piezo-electric devicesClosed loop feedbackDifferential pressure

A quartz girder resonant mode micro-pressure sensor chip with a silicon substrate single island structure comprises a quartz girder which is bonded on the front of the silicon substrate through low stress adhesive glue. Four opposite angles of the quartz girder are directed at four alignment markers on the front of the silicon substrate. The back of the silicon substrate is connected with a glass substrate in a sealing mode. The front of the glass substrate corrodes a groove. A pressure hole is formed at the center of the groove. The pressure hole is communicated with the atmosphere to form a gauge pressure sensor, or is communicated with the other tested atmosphere to form a differential pressure type sensor. The back of the silicon substrate corrodes the groove to form a silicon island. The quartz girder is driven to self-oscillate with an inverse piezoelectric effect of the quartz and when vibration frequency is equal to the inherent frequency of the quartz girder, resonance oscillation occurs. Resonant frequency is tested under a closed-loop feedback control system. Variable quantity of the resonant frequency represents the size of air pressure to be tested, and therefore the measurement of the outside air to be measured can be realized. The quartz girder resonant mode micro-pressure sensor chip with the silicon substrate single island structure has the advantages of being high in sensitivity, high in accuracy and high in resolution ratio.

Owner:陕西麟德惯性电气有限公司

Piezoelectric sensor, a method for manufacturing a piezoelectric sensor and a medical implantable lead comprising such a piezoelectric sensor

InactiveUS20100010600A1Improve protectionImprove shielding effectFluid pressure measurement using piezo-electric devicesPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric sensorMaterials science

In a piezoelectric sensor, a method for the manufacture thereof, and an implantable lead embodying such a piezoelectric sensor, a layer of piezoelectric material, having aligned, polarized dipoles, is applied to a tubular supporting substrate, the layer of piezoelectric material having at least one electrode at an outer surface thereof and at least one electrode at an inner surface thereof. The piezoelectric material is applied on the inner circumference of the tubular supporting substrate.

Owner:ST JUDE MEDICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com