Structure and method for packaging pressure sensor

A pressure sensor and packaging structure technology, applied in the measurement of the force of the piezoelectric device, fluid pressure measurement using the piezoelectric device, etc., can solve the problems of cumbersome steps, poor air tightness and reliability, and high production costs. Achieve the effect of simple process steps, high reliability and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

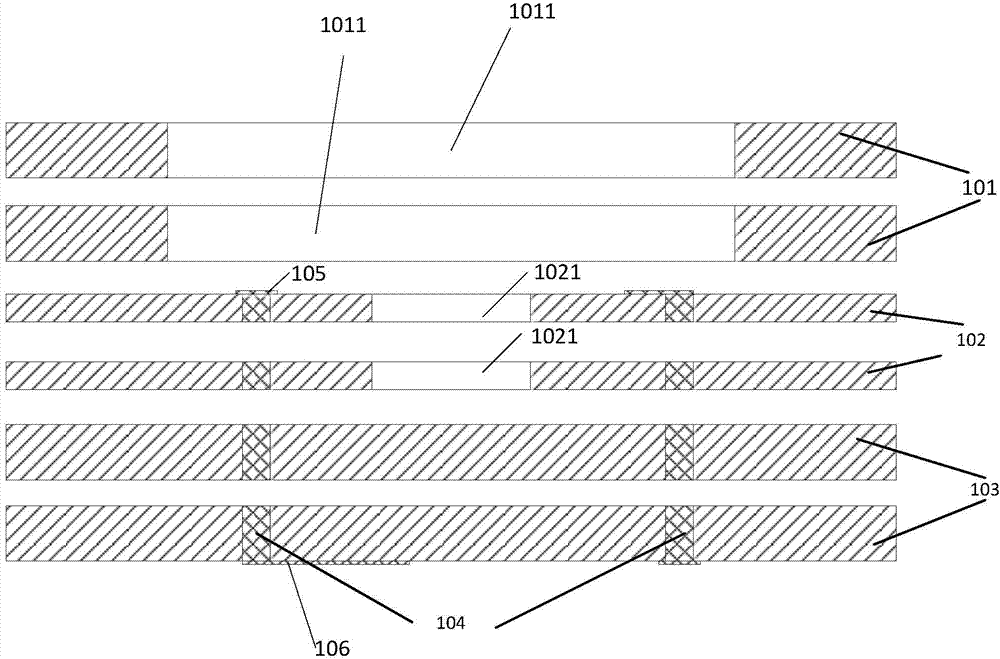

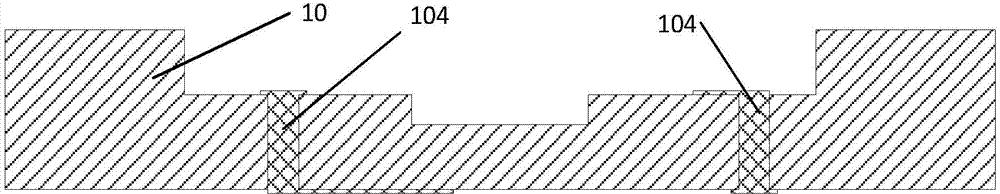

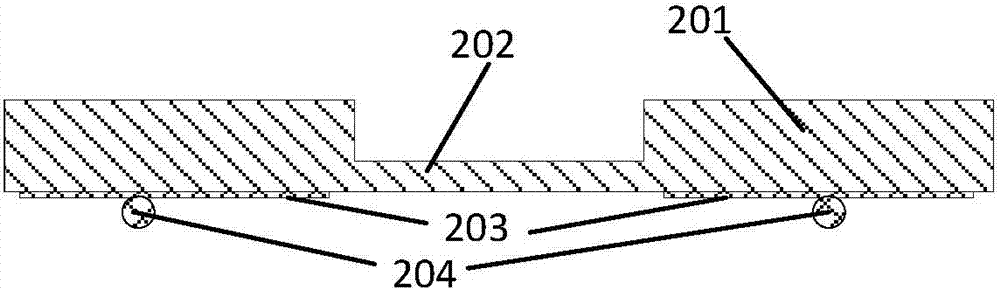

[0036] see figure 2 , 3 , 6 and 7, the embodiment of the present invention provides a packaging structure of a pressure sensor, including: an upper cover 40, a lower cover 10, a pressure sensor chip 201 with a vibrating membrane; the lower cover 10 is provided with a first The rectangular groove 1011 and the second rectangular groove 1021; the second rectangular groove 1021 is embedded in the bottom of the first rectangular groove 1011, so that the first rectangular groove 1011 and the second rectangular groove 1021 are connected to form a two-stage cavity structure The bottom of the first rectangular groove 1011 is provided with a through hole 104 through the lower cover plate 10; the upper and lower surfaces of the through hole 104 are connected with the pad 105 and the wiring layer 106; the pressure sensor chip bump 204 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com