Pressure sensor

A pressure sensor and pressure unit technology, used in the measurement of fluid pressure, instruments, and fluid pressure measurement through electromagnetic components, which can solve problems such as pressure measurement value errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Next, the pressure sensor of the present invention will be described in detail using the illustrated embodiments. However, unless otherwise specified, the constituent elements, types, combinations, shapes, and relative arrangements described in the embodiments are not intended to limit the scope of the present invention thereto, but are merely illustrative examples.

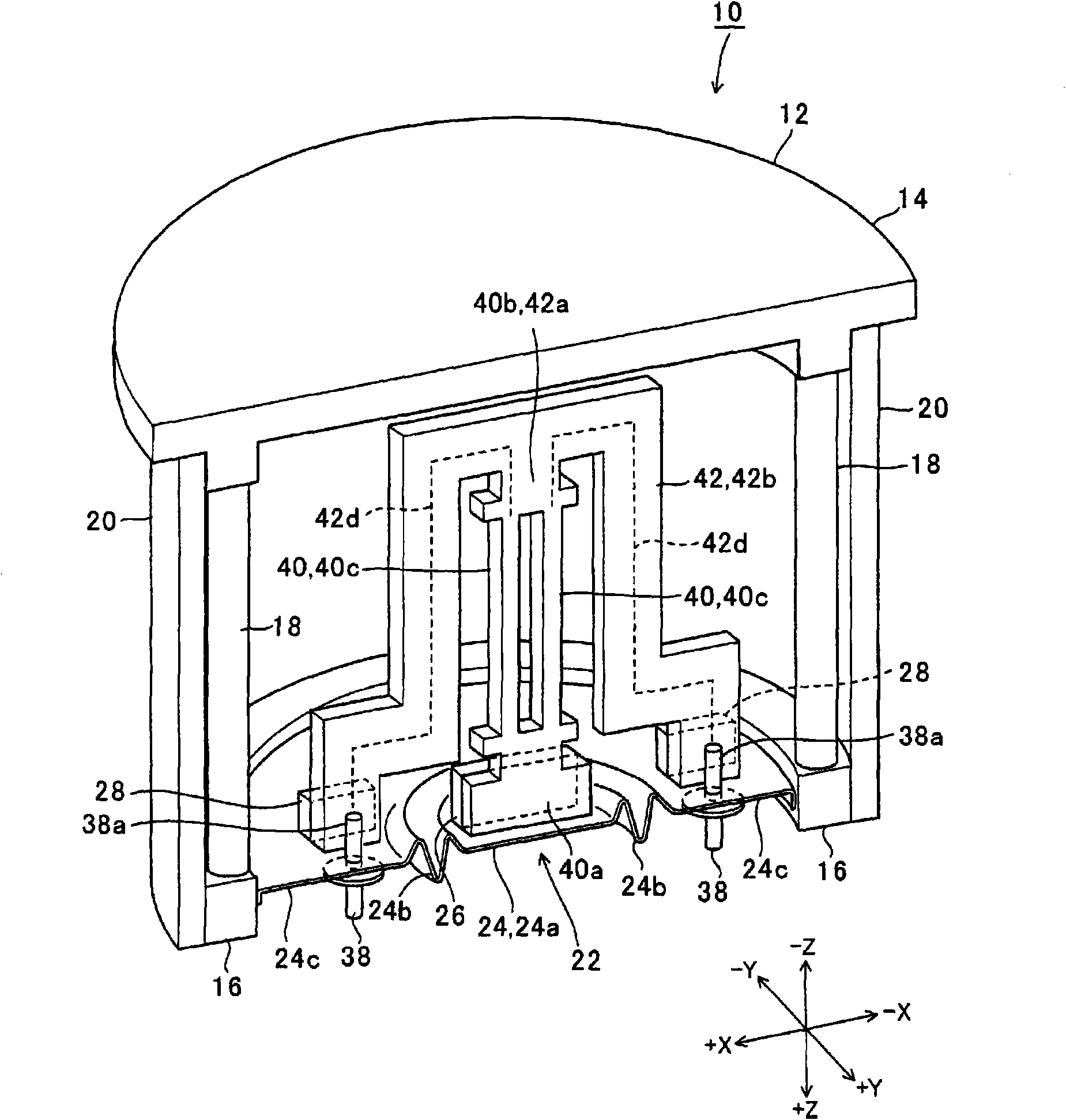

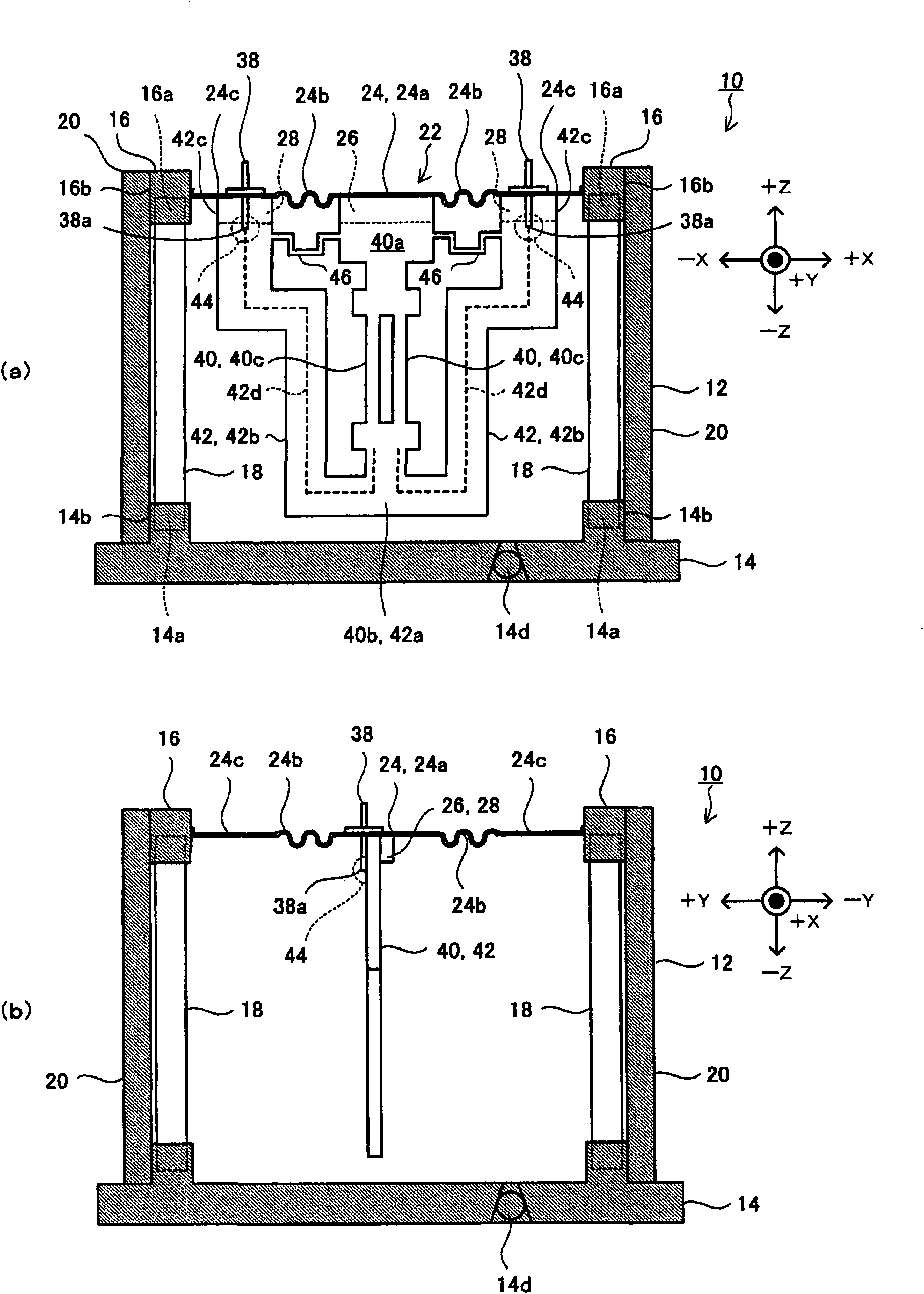

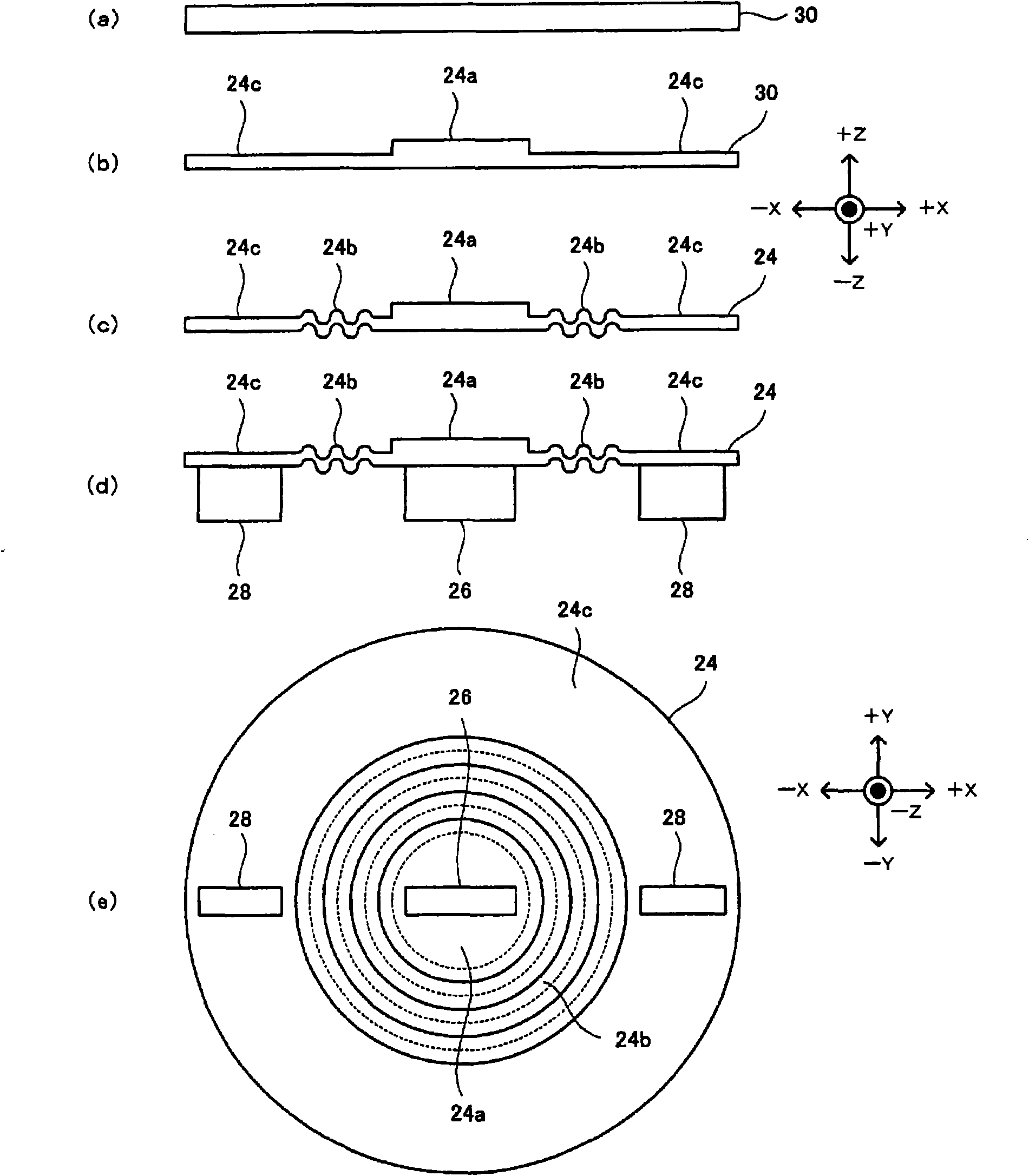

[0055] figure 1 (taking the XZ plane as a cross section) is a perspective view showing the pressure sensor of the first embodiment, figure 2 ( figure 2 (a) Taking the XZ plane as a section, figure 2 (b) YZ plane is a sectional view) shows a sectional view. in addition, figure 1 , 2 The shown ZYX forms a rectangular coordinate system, and the same applies to the drawings used hereinafter. The pressure sensor 10 of the first embodiment has a housing 12, a diaphragm 24 as a pressure receiving unit, a pressure sensitive element 40, a connecting member 42 as a connecting unit, and a reinforcing part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com