Quartz girder resonant mode micro-pressure sensor chip with silicon substrate single island structure

A pressure sensor, vibrating micro technology, applied in the direction of fluid pressure measurement using piezoelectric devices, can solve the problems of difficult to process resonator structure, resonator excitation and detection difficulties, etc., to achieve no hysteresis, low cost, high resolution The effect of rate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

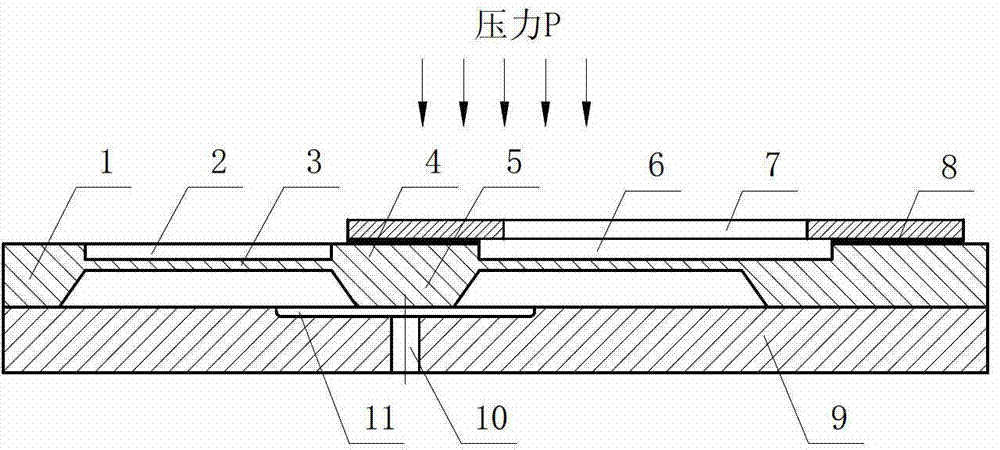

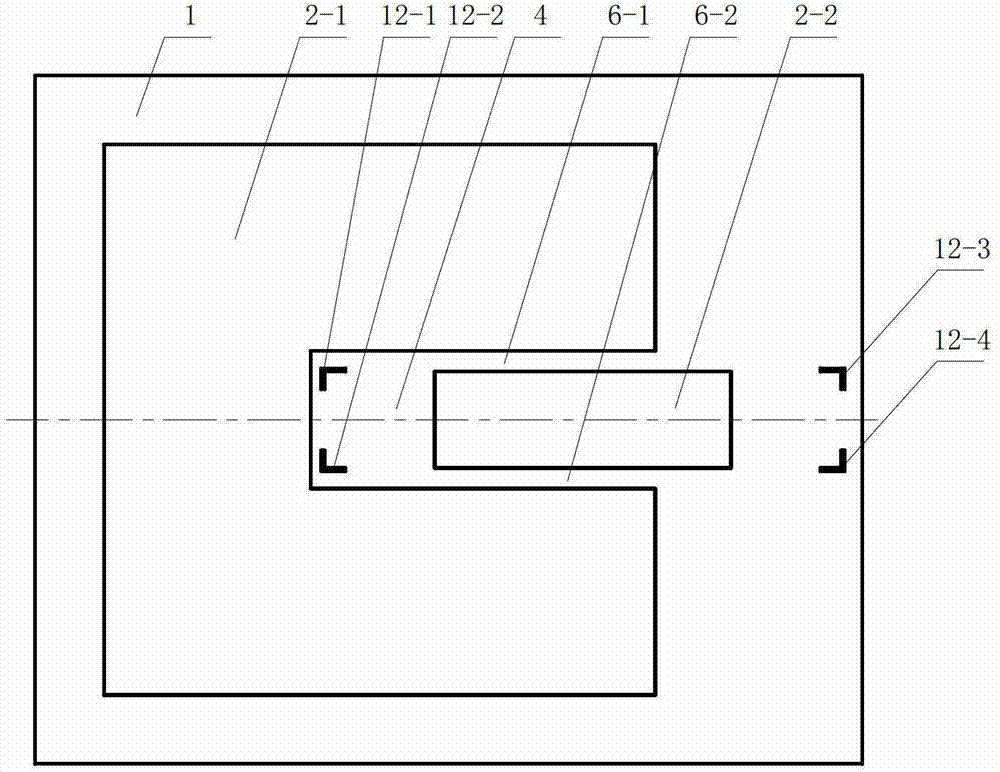

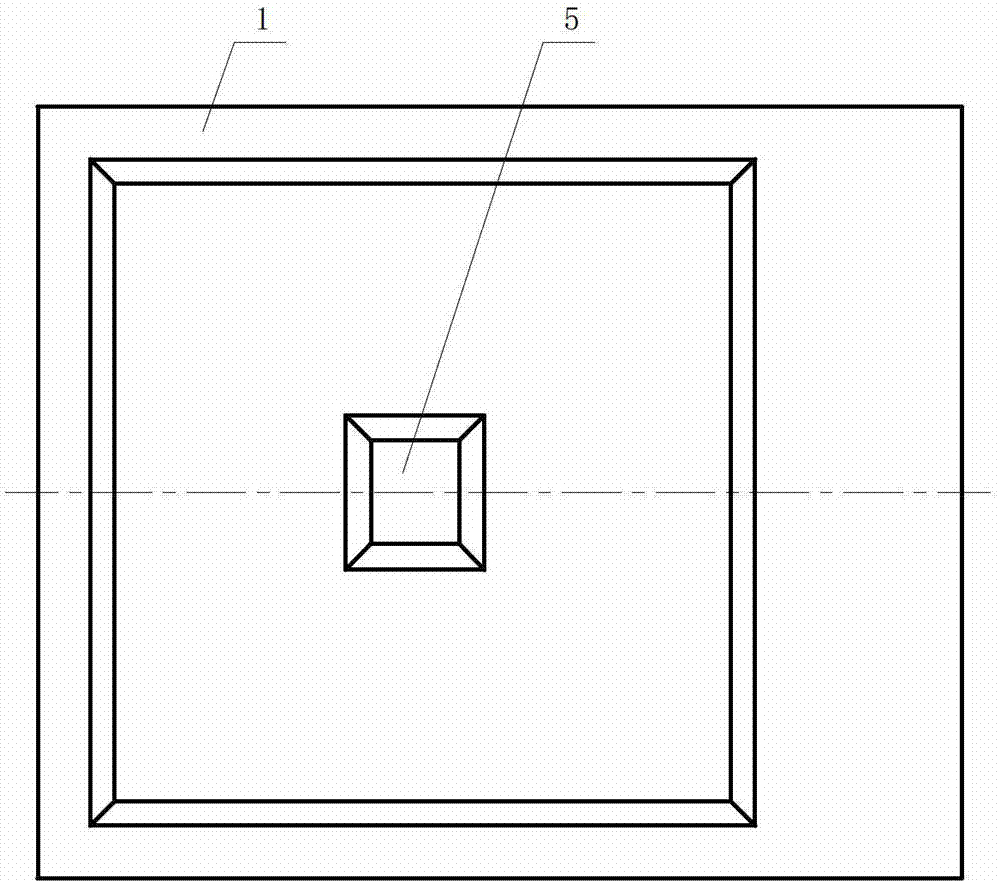

[0023] refer to figure 1 , a silicon-based single-island structure quartz beam resonant micro-pressure sensor chip, including a quartz beam 7, the quartz beam 7 is bonded on the front side of the silicon substrate 1 through a low-stress adhesive 8, and the four diagonal corners of the quartz beam 7 are respectively Align with the four alignment marks 12-1, 12-2, 12-3, 12-4 on the front side of the silicon substrate 1, the back side of the silicon substrate 1 is sealed with the glass substrate 9, and the front side of the glass substrate 9 is etched A groove 11 is formed, and a pressure hole 10 is processed in the center of the groove 11;

[0024] The front of the packaged chip communicates with the outside gas to be measured to sense the measured pressure, and the pressure hole 10 on the glass on the back of the chip communicates with the atmosphere to form a gauge pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Etching depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com