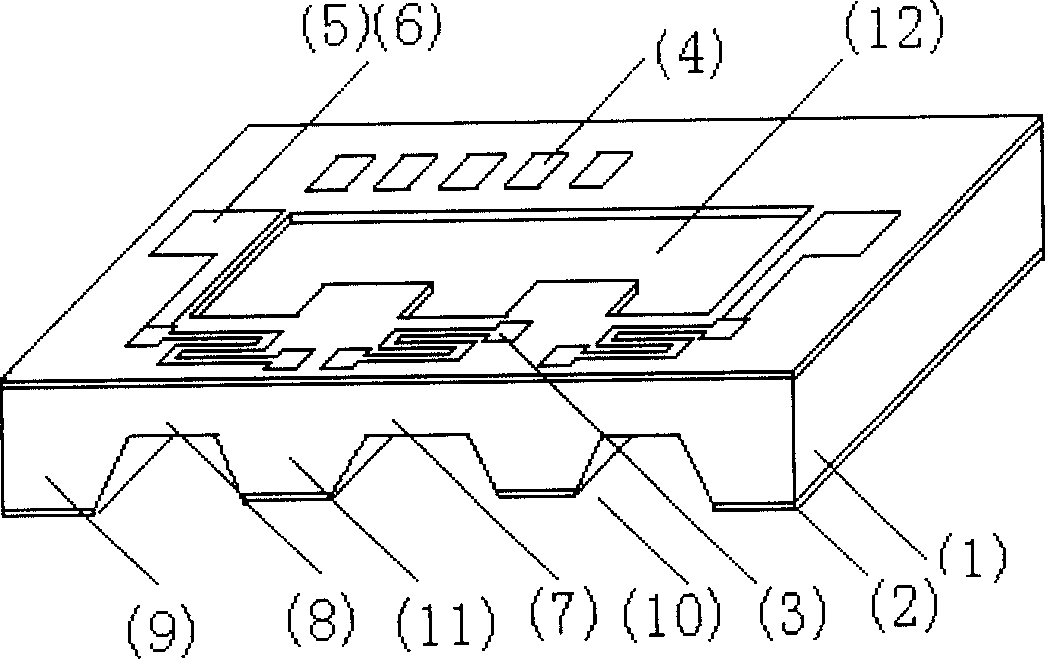

Monolithic silicon based SOI high-temperature low-drift pressure sensor

A pressure sensor and low-drift technology, applied in the field of sensing, can solve problems that cannot be solved, cannot be practical, and cannot be practically applied, and achieve the effects of precise design, improved anti-overload capability, and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

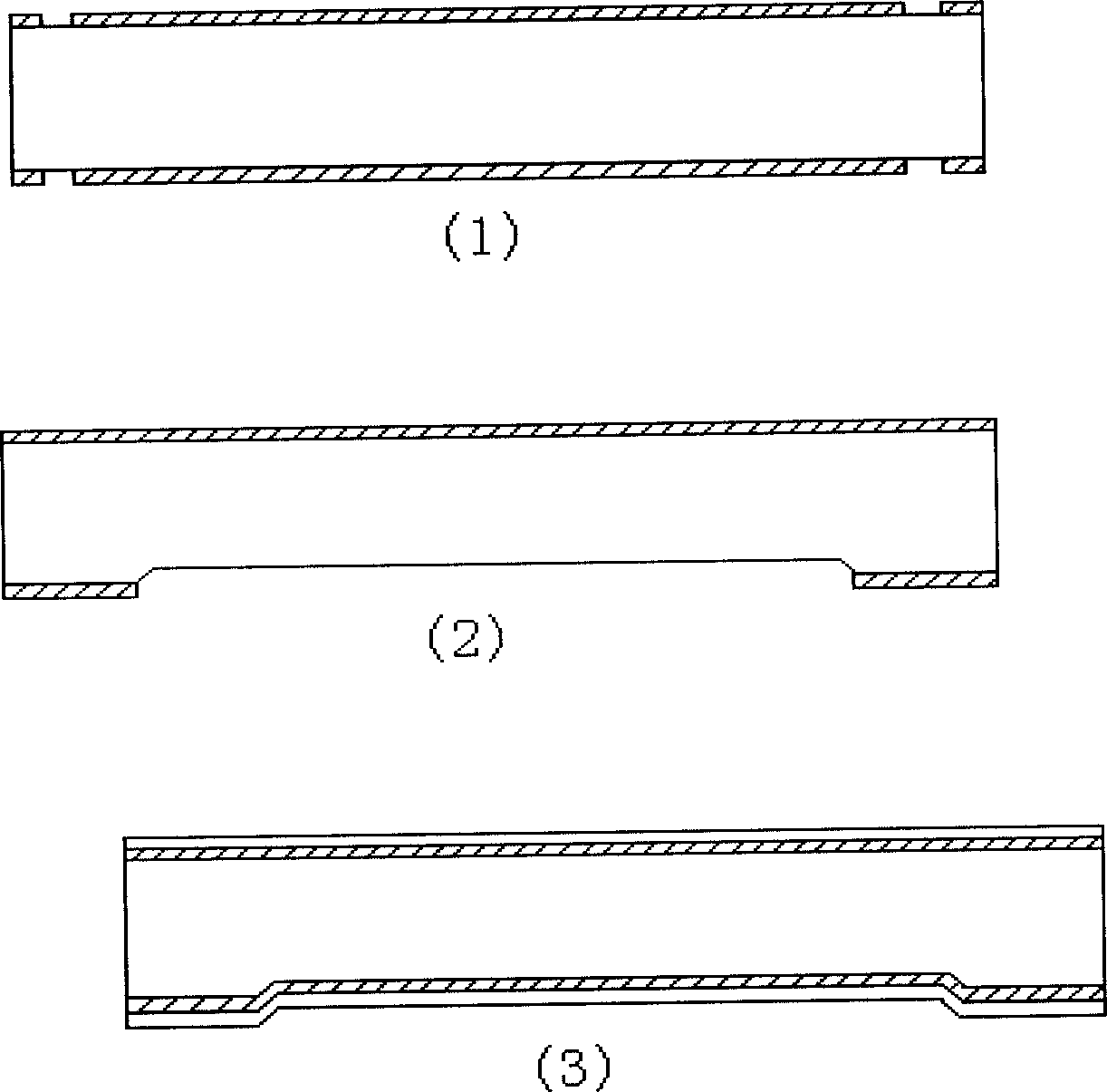

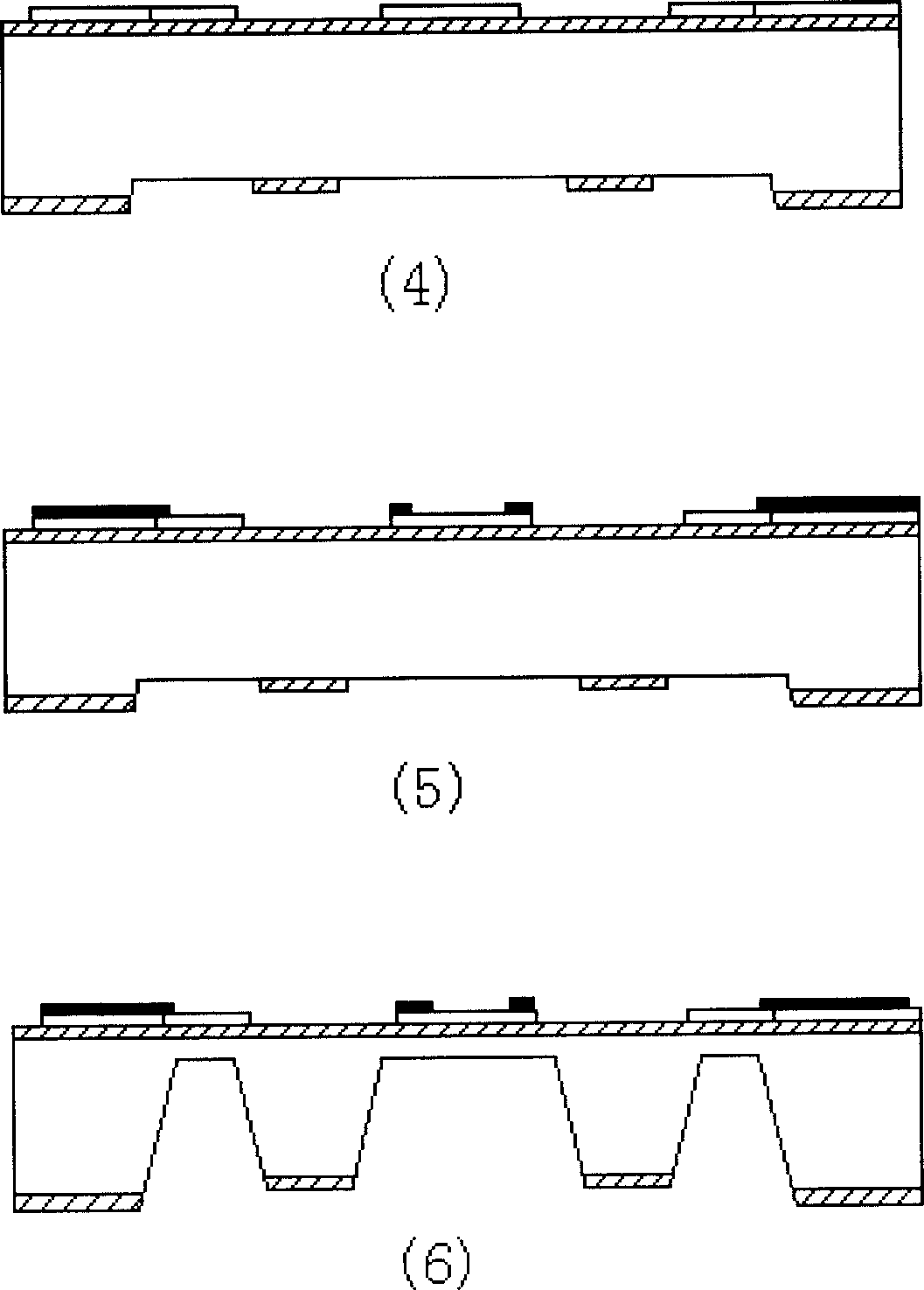

[0025] The invention adopts SOI material to form the Wheatstone bridge road working at high temperature.

[0026] The four bridge resistances of the Wheatstone bridge in a general diffused silicon piezoresistive pressure sensor use thermal diffusion or ion beam doping to form a P-type resistance region on an N-type (100) silicon single crystal, and the resistances depend on each other. The back-to-back P-N junction is electrically insulated. Since the reverse current of the P-N junction is a function of temperature, when the pressure sensor works at high temperature (>100°C), its reverse current will seriously affect the normal working state of the sensor. Therefore, such sensors cannot be used at high temperatures. The use of silicon insulating medium to isolate bridge resistance is currently a research hotspot in the world for high temperature sensors. In the past two years, people have successfully developed a variety of SOI materials, including polysilicon SOI, SIMOXSOI ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com