Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about How to "Composite process is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High barrier film and manufacturing method thereof

InactiveCN102837474AImprove barrier propertiesLow oxygen transmission rateSynthetic resin layered productsSurface layerLow oxygen

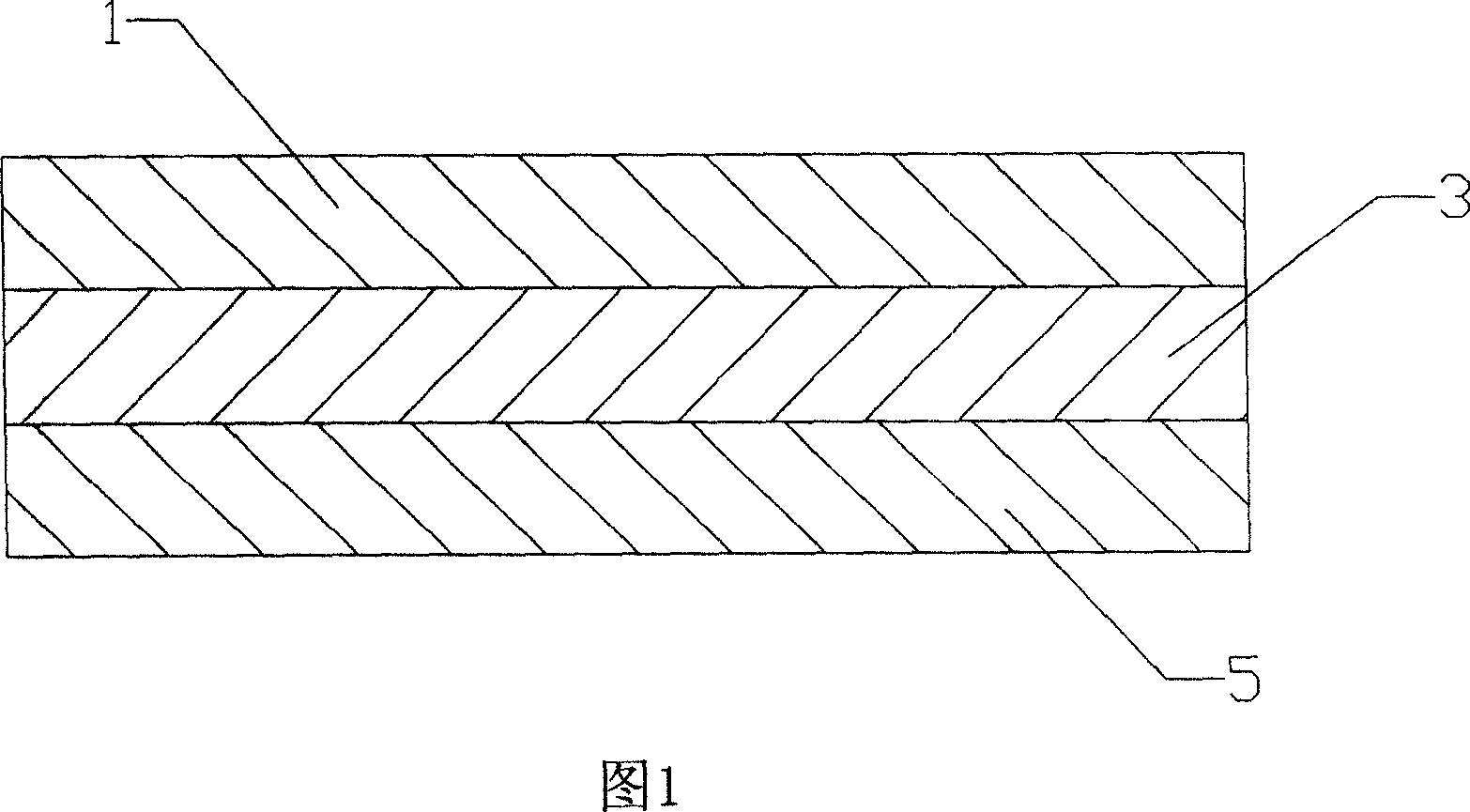

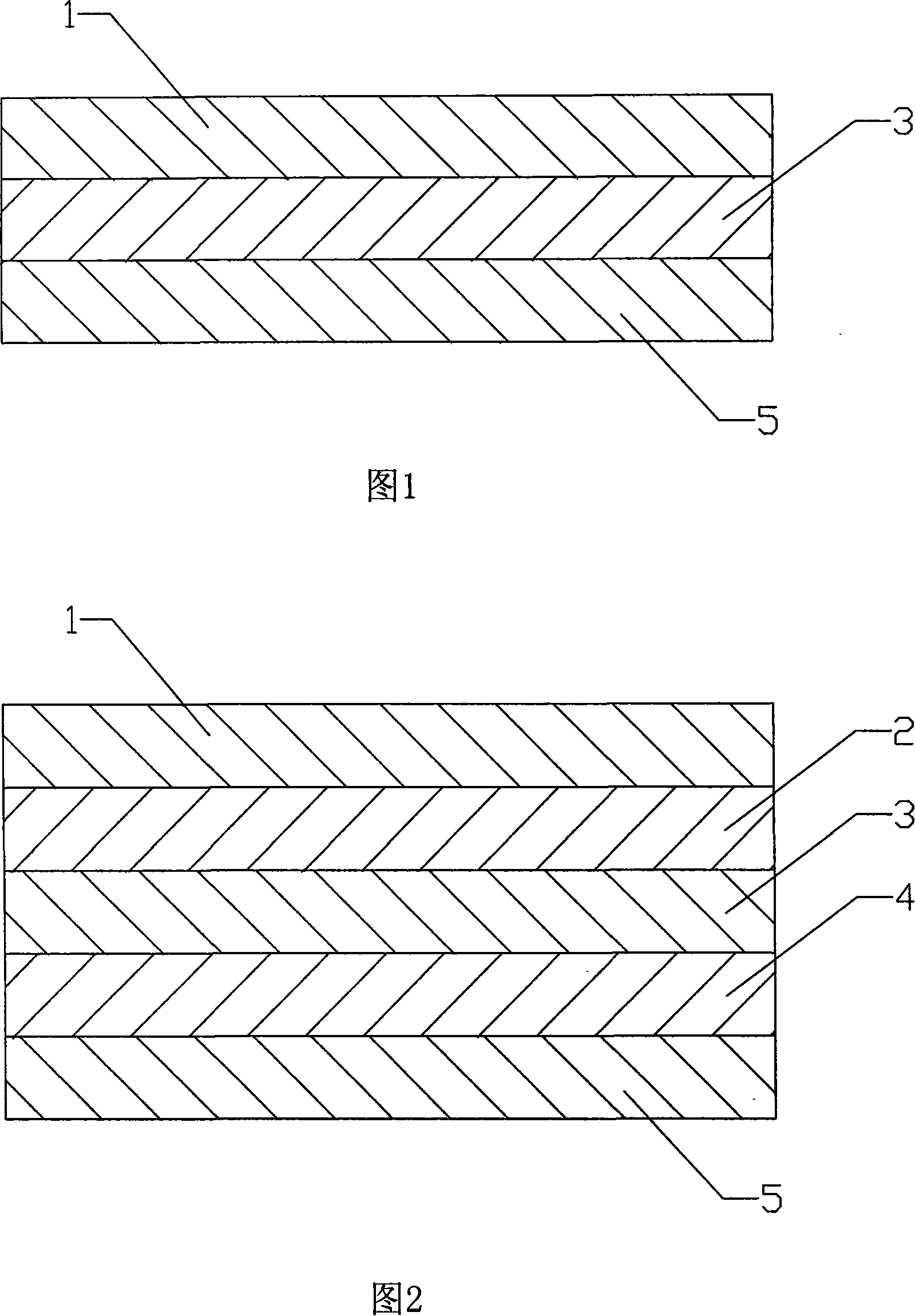

The invention provides a high barrier film and a manufacturing method thereof. The high barrier film is a three-layer structure composed of a first surface layer, a core layer, and a second surface layer. The first surface layer is composed of 0-0.3wt% of a slipping agent, 0-0.5wt% of an anti-block agent, 10-40 wt% of MXD6, and 59.2-90 wt% of PA6 chips; the core layer is composed of 60-95 wt% of MXD6, and 5-40 wt% of PA6 chips; and the second surface layer is composed of 0-0.3wt% of a slipping agent, 0-0.5wt% of an anti-block agent, 10-40 wt% of MXD6, and 59.2-90 wt% of PA6 chips. The high barrier film above has greatly improved barrier performance, and has the characteristics of excellent barrier property, low oxygen transmission rate of the film, and good transparency and flexibility.

Owner:厦门长塑实业有限公司

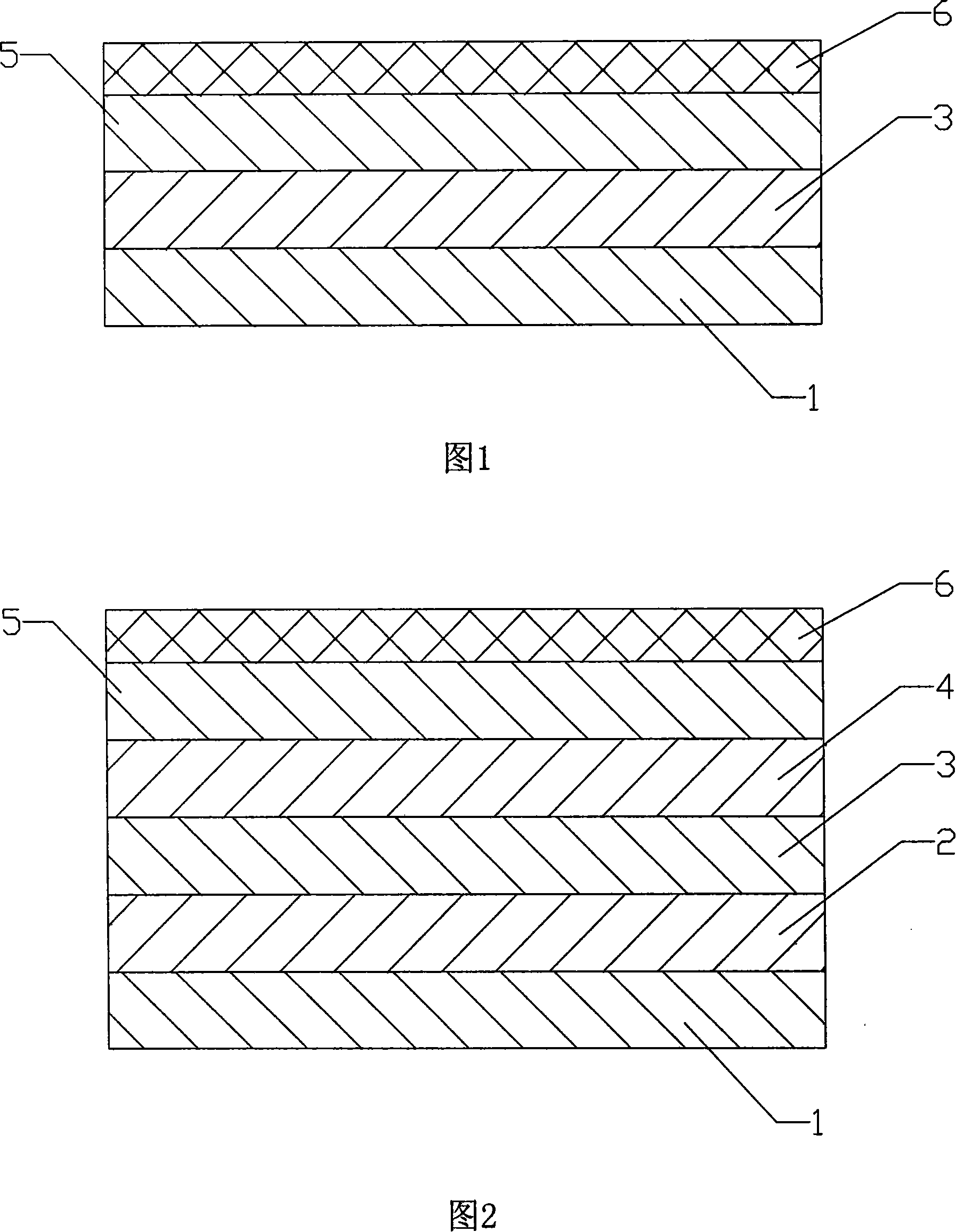

Paper plastic glue-free composite bidirectional stretching polypropylene film and its preparation method

ActiveCN101058247ASimple structureHigh heat sealing strengthSynthetic resin layered productsFlat articlesThick plateEngineering

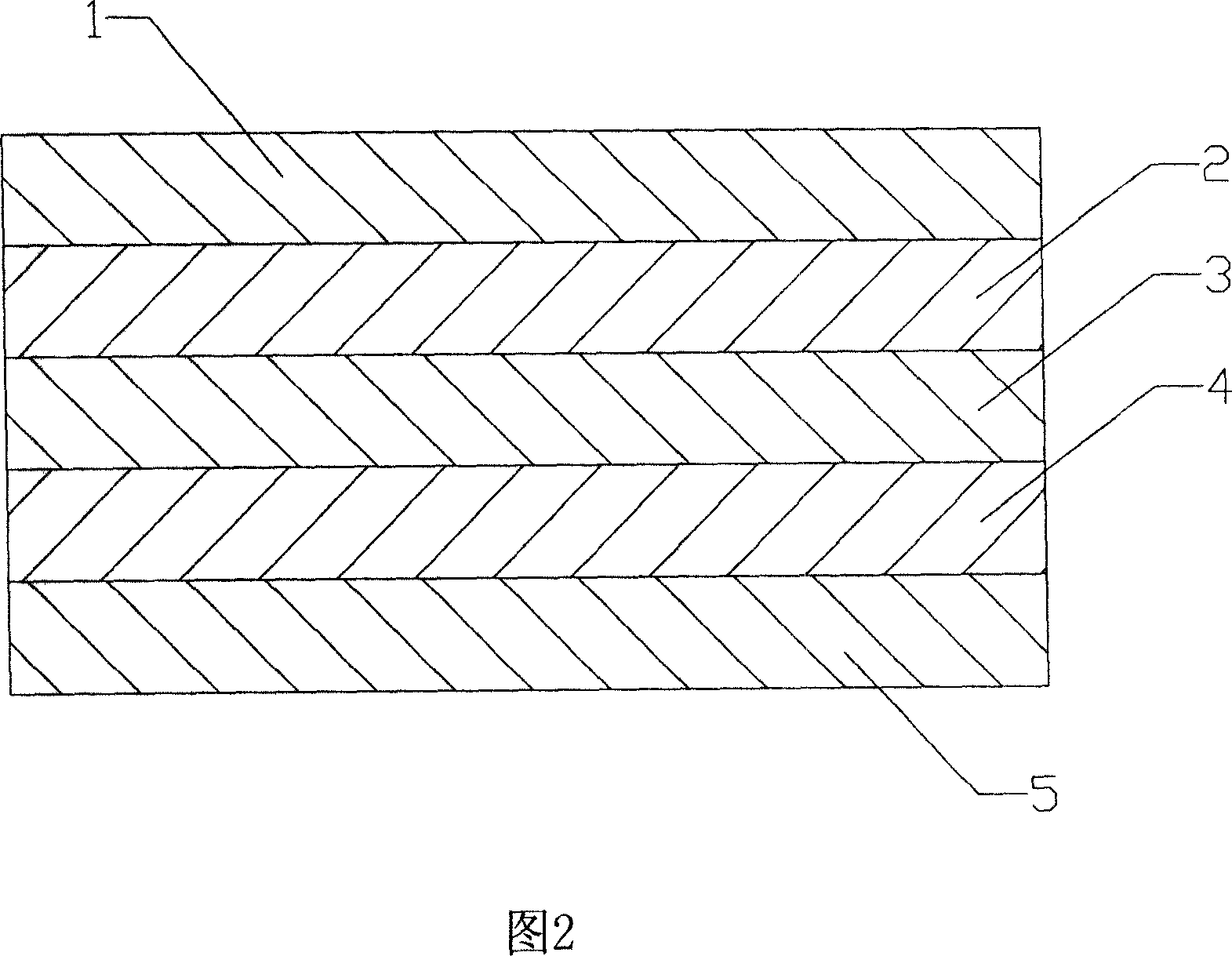

The invention relates to a paper plastic glue free compound bi-directional stretch polypropylene film, which has coextruded surfaced, core layer, functional layer being able to compound with paper, pre-print paper or thin film, with upper sub surface between the surface and core layer, and lower sub surface between the core layer and the functional layer. All of them are extruded through bi-directional stretch. It feeds formulated material into the extruder to melt, which is co-extruded into thick plates through slip cast, then the thick plates being stretched in both directions into thin film, which are processed through corona and flame into mother film, through effective treatment to get the final thin film product. It is simple in structure, strong in thermal sealing, high in stripping strength.

Owner:GUANGDONG DECRO PACKAGE FILMS +1

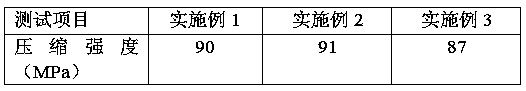

Carbon fibre wood electromagnetic shielding material and preparation method thereof

InactiveCN103214865AComposite process is simpleEasy to operateFunctional compositeIsocyanate compound

The invention relates to a carbon fibre wood electromagnetic shielding material and a preparation method thereof, belonging to the field of electromagnetic shielding materials. According to the invention, a carbon fibre reinforced wood functional composite material is formed by preparing glue mixed carbon fibre and glue mixed wood fibre according to the mass ratio of 3:7 to 1:1 through a hot-pressing mould process; the glue mixed carbon fibre is formed by mixing carbon fibre with isocyanate according to the mass ratio of 10:1; and the glue mixed wood fibre is formed by mixing wood fibre with urea-formaldehyde glue according to the mass ratio of 5:1. According to the invention, the functional wood composite material is prepared from carbon fibre as reinforcement and a wood fibre material (wood residue)through a simple and effective composite process; good electrical conductivity and electromagnetic shielding characteristics are given to the composite material while the mechanical property of the wood composite material is increased; furthermore, the wood optimization using purpose for recycling wastes is realized.

Owner:NORTHEAST FORESTRY UNIVERSITY +2

Paper plastic glue-free composite bidirectional stretching polypropylene film and its preparation method

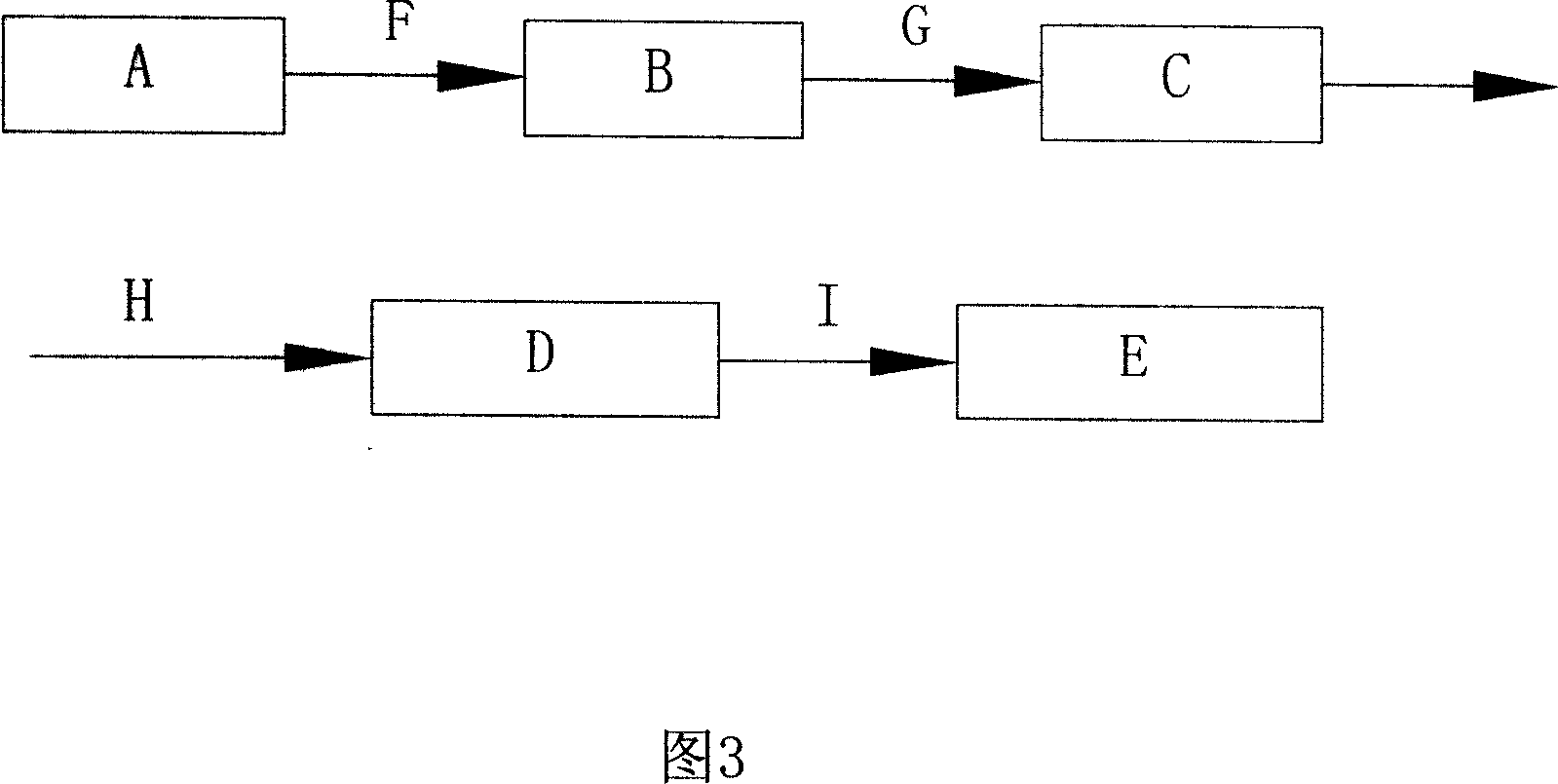

ActiveCN101148106AReduce gluing processComposite process is simpleSynthetic resin layered productsFlat articlesPolypropylenePolymer chemistry

The present invention discloses one kind of biaxially stretched polypropylene film for no-adhesive paper-plastic combination and its preparation process. The film includes one surface layer, one core layer, one functional layer for direct combination with paper material, one second upper layer between the surface layer and the core layer, and second lower surface layer between the core layer and the functional layer. The film is prepared through plasticizing the material to form melt in an extruder, conveying the melt in a pipeline, filtering in a filter, forming film in a mold head, corona treatment or flame treatment to form mother film, and cutting into the film product. The biaxially stretched polypropylene film with on-line leached layer for no-adhesive paper-plastic combination has low power consumption, environment friendship, high heat sealing strength and high stripping strength.

Owner:GUANGDONG DECRO PACKAGE FILMS +1

Easy-to-composite multi-layer composite mask and manufacturing method thereof

InactiveCN104585924AImprove filtering effectImprove comfortProtective garmentSpecial outerwear garmentsSurface layerBiochemical engineering

The invention relates to a protective article and particularly relates to an easy-to-composite multi-layer composite mask and a manufacturing process thereof. The mask comprises a mask body; the mask body consists of a surface layer, an intermediate layer and an inner layer; both the surface layer and the inner layer are non-woven fabric layers; the intermediate layer is an electrostatically-loaded and melt-blown filter material layer; a pure cotton fabric layer is arranged between the surface layer and the intermediate layer; outer edges of the surface layer, the electrostatically-loaded and melt-blown filter material layer and the inner layer are composited by hot melting; the surface layer, the pure cotton fabric layer, the electrostatically-loaded and melt-blown filter material layer, and the inner layer are welded ultrasonically. According to the mask disclosed by the invention, because the electrostatically-loaded and melt-blown filter material layer is adopted by the intermediate layer and the cotton fabric layer can be fused between the surface layer and the intermediate layer, the mask has good filtering effect, low resistance, nice comfort and strong air permeability and water absorption; meanwhile, the multiple layers of materials are composited through ultrasonic welding, so the stitching with threads is avoided and the composite process is simplified.

Owner:ZHEJIANG JIANDE CHAOMEI DAILY CHEM

Casting-penetrating method of Al2O3 particle surface reinforced steel-base composite material

The invention discloses a casting-penetrating method of a Al2O3 particle surface reinforced steel-base composite material. The method comprises five steps of proportioning, preparing Al2O3 precast blocks, roasting briquettes, fixing the precast blocks and smelting, casting and penetrating. In the composite material prepared by the method disclosed by the invention, the Al2O3 particles are embedded in the steel base perfectly; as the Al2O3 particles are mixed according to the particle sizes, the arrangement is relatively dense without clustering; and a steel substrate is filled around the Al2O3 particles in a metallurgical bonding state. The composite process provided by the invention is simple and has low cost, and is applicable to the surface recombination wear-resistant material in the working condition of low-stress abrasive corrosion wear.

Owner:JIANGSU GREENHUB TECH

Paper plastic glue-free composite on line repeated spraying bidirectional stretching polypropylene film and its preparation method

ActiveCN101148105ARealize paper-plastic composite without glueComposite process is simpleSynthetic resin layered productsSurface layerEngineering

The present invention discloses one kind of biaxially stretched polypropylene film with on-line leached layer for no-adhesive paper-plastic combination and its preparation process. The film includes one base film comprising one or two biaxially stretched upper surface layers, one core layer and one or two biaxially stretched lower surface layers, and one functional film layer for direct combination with paper material. The film is prepared through forming melt with the material in an extruder, flow casting the melt to form co-extruded thick sheet, biaxially stretching to form film, corona treatment or flame treatment to form mother film, ageing treatment and cutting into the film product. The biaxially stretched polypropylene film with on-line leached layer for no-adhesive paper-plastic combination has low power consumption, environment friendship, high heat sealing strength and high stripping strength.

Owner:GUANGDONG DECRO PACKAGE FILMS +1

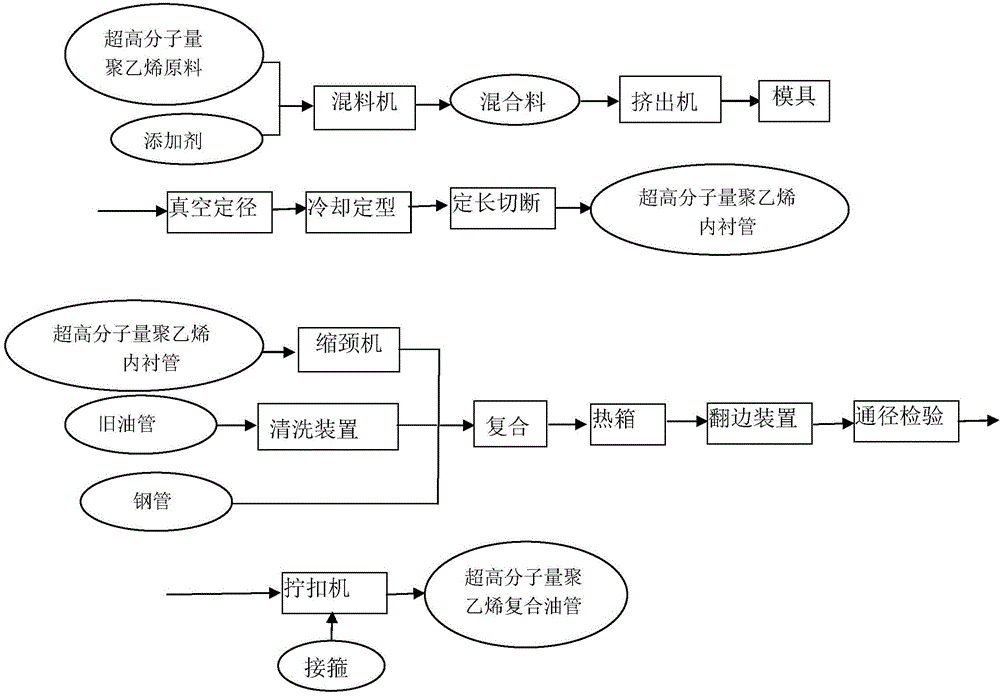

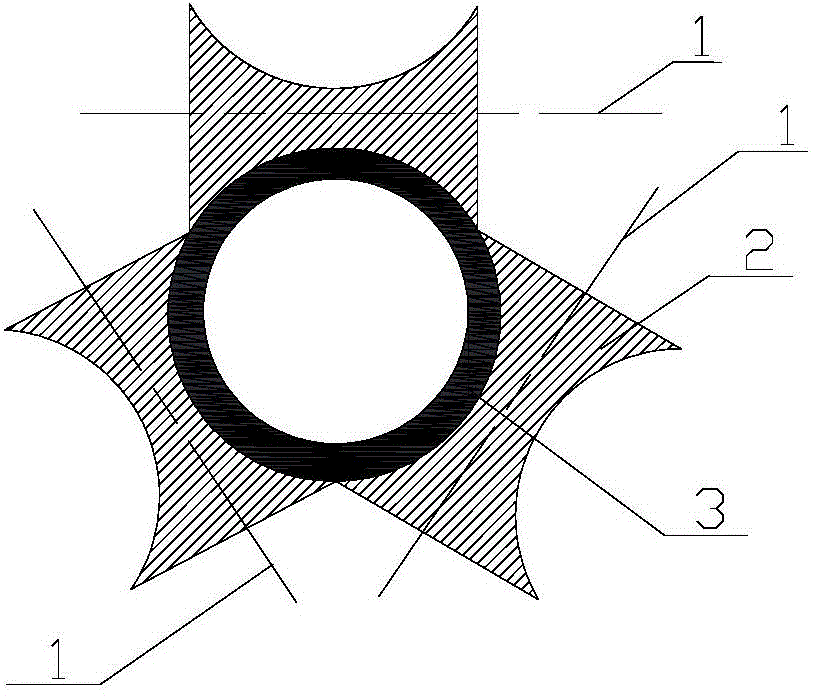

Production method and production system of ultrahigh molecular weight polyethylene compound oil pipe

ActiveCN103600503AImprove liquidityReduced wall thicknessTubular articlesTemperature resistanceWear resistance

The invention discloses a production method and a production system of an ultrahigh molecular weight polyethylene compound oil pipe. The method utilizes the memory property of the ultrahigh molecular weight polyethylene material and a special composite technology: conducting hole shrinkage treatment on an ultrahigh molecular weight polyethylene lining pipe with outer diameter larger than the inner diameter of a steel pipe, sheathing in the steel pipe, heating to restore inner diameter of the ultrahigh molecular weight polyethylene lining pipe, and forming the lining pipe with the steel pipe into an integral structure to reach a compactness and firmness without layering and stripping. By introducing additives, the invention greatly improves liquidity of the ultrahigh molecular weight polyethylene in order to produce the inner lining pipe with small wall thickness and reduce cost. The ultrahigh molecular weight polyethylene compound oil pipe provided by the invention comprehensively reserves specific superior performances of good memory property, high impact resistance, good temperature resistance, wear resistance, corrosion resistance, wax precipitation and fouling resistance of ultrahigh molecular weight polyethylene pipe. The invention also discloses a production system supporting the production method.

Owner:王庆昭

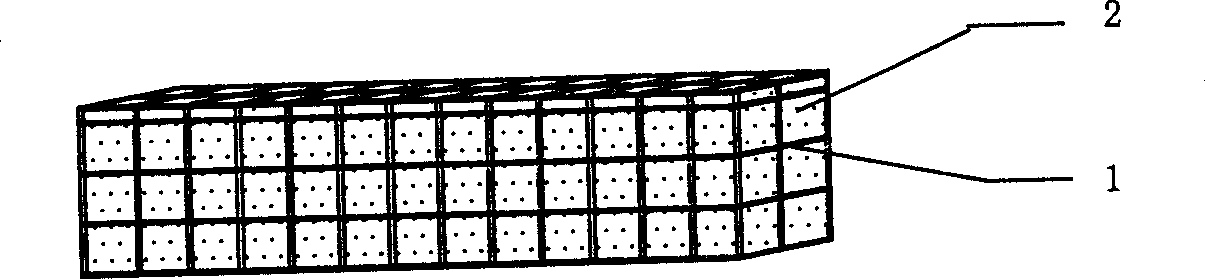

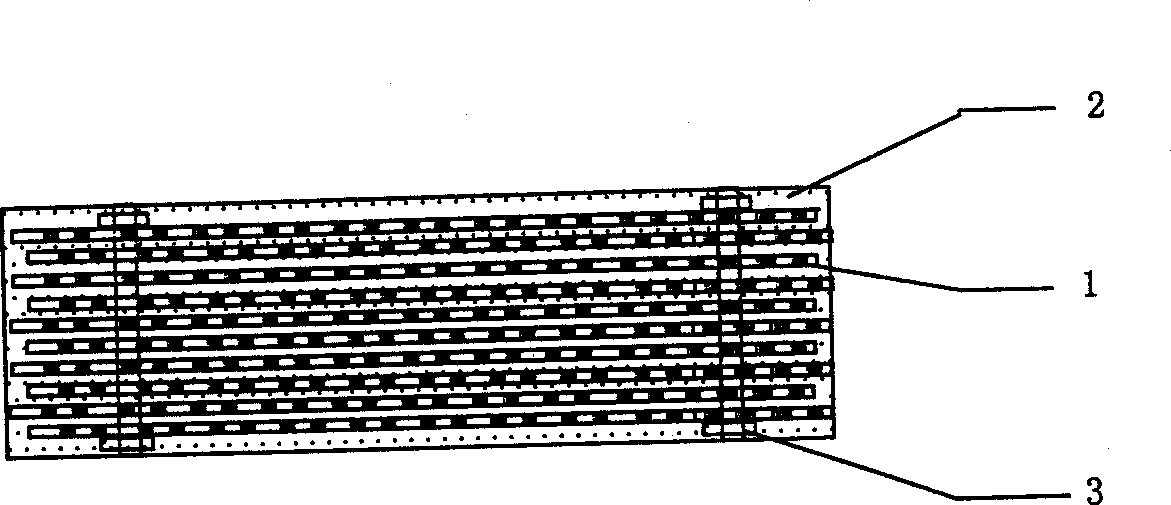

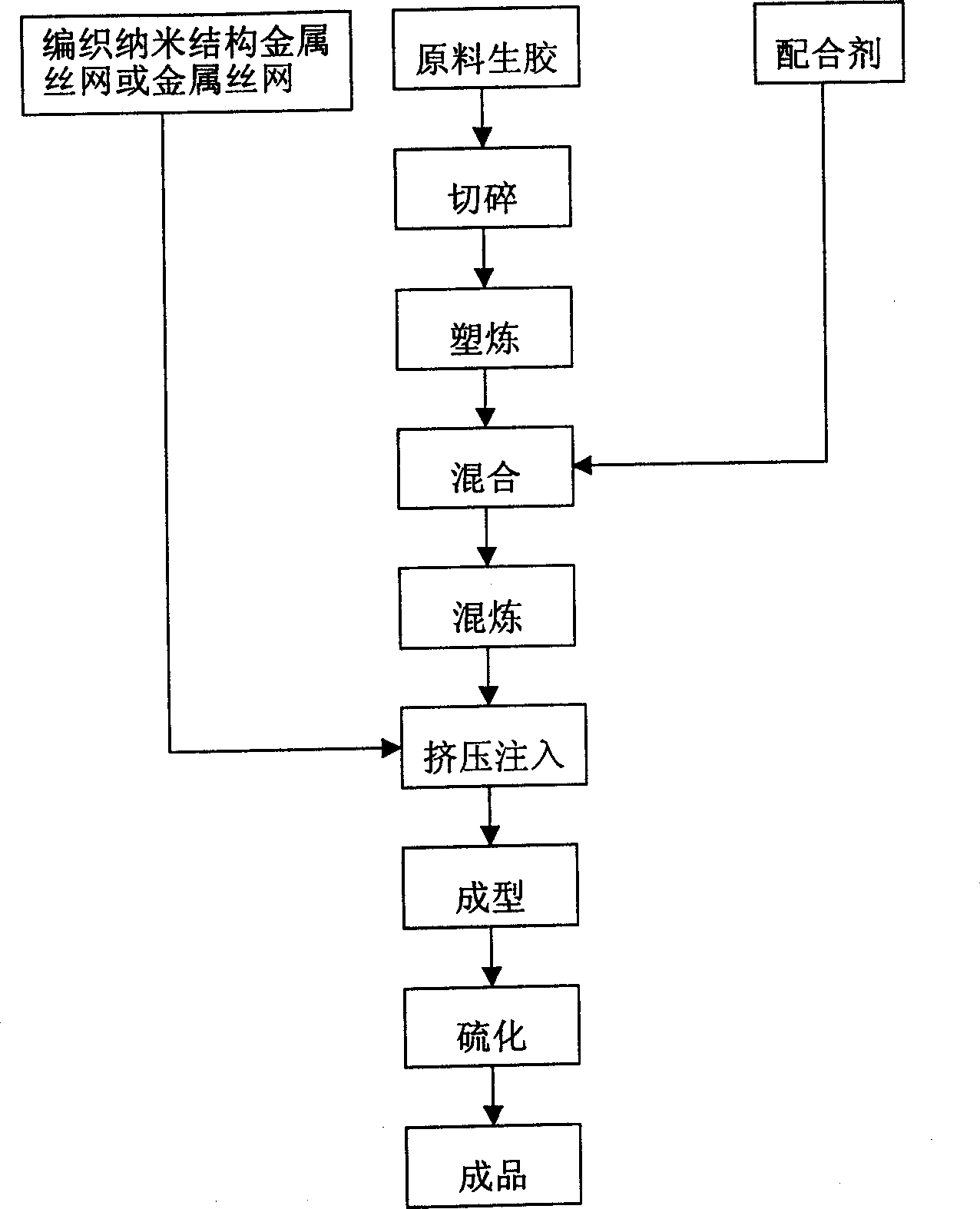

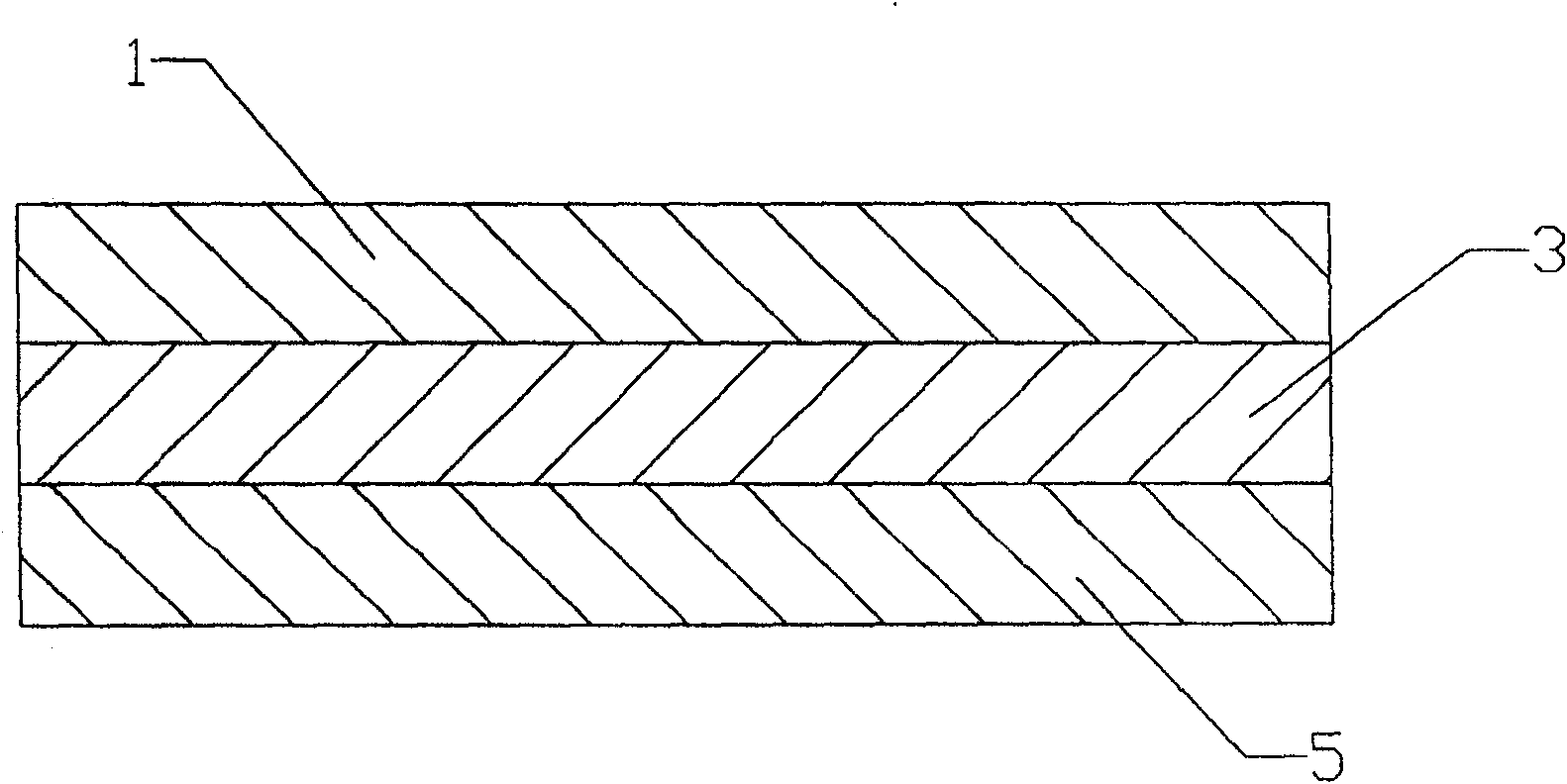

Composite lining with metal wire screen in nanometer structure and its production process

The present invention discloses a kind of nano structure wire gauze composite lining plate and its preparation process. Said lining plate is made up by using wire gauze and compounded filing materialthrough a compositive process. Said wire gauze can be integrally braided, also can be a multilayer structure pieced by using single-layer of wire gauze, said wire gauze can be placed in the interior of compounded filling material, then they are combined into a whole body. Said composite lining plate possesses high wear-resistance, water-resisting property, vibration-absorbing property and corrosion-resisting property, etc..

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Polyaniline/MnO2 compound modified three-dimensional graphene composite material, preparation method and application of composite material

InactiveCN103854875ASave raw materialsComposite process is simpleHybrid capacitor electrodesElectric capacityAniline

The invention discloses a polyaniline / MnO2 compound modified three-dimensional graphene composite material, a preparation method and application of the composite material. The preparation method comprises the following steps: dissolving manganese salt and an aniline monomer into dilute sulphuric acid solution with the concentration being 0.1-0.5mol / L, adding three-dimensional graphene serving as a working electrode, a saturated calomel electrode serving as a reference electrode and a platinum electrode serving as a counter electrode into the solution, performing electrochemical deposition by utilizing cyclic voltammetry, forming a compound from the polyaniline and MnO2 and depositing the compound in the three-dimensional graphene so as to obtain the polyaniline / MnO2 compound modified three-dimensional graphene composite material. The invention has the obvious characteristics that (1) raw materials are cheap, the compounding process is simple and convenient, the preparation cost is low and large-scale production is facilitated; (2) the ratio of the components of the component material can be controlled by controlling the scanning parameters of cyclic voltammetry and the amount of reactants; (3) the composite material has high specific electric capacity and stable electrochemical performance.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Gelatinized starch adhesive and preparation method thereof

InactiveCN103555223AComposite process is simpleGood adhesionNon-macromolecular adhesive additivesStarch adhesivesSimple compoundAdhesive

The invention relates to a gelatinized starch adhesive and a preparation method thereof. The gelatinized starch adhesive is mainly composed of starch, nickel sulfate, sodium hydroxide, sodium hypochlorite, sodium thiosulfate, borax, tributyl phosphate and water. The gelatinized starch adhesive has the characteristics of low price, simple compound process, strong adhesion, good fluidity, no toxic or odor and fast drying.

Owner:张家港市敬业包装有限公司

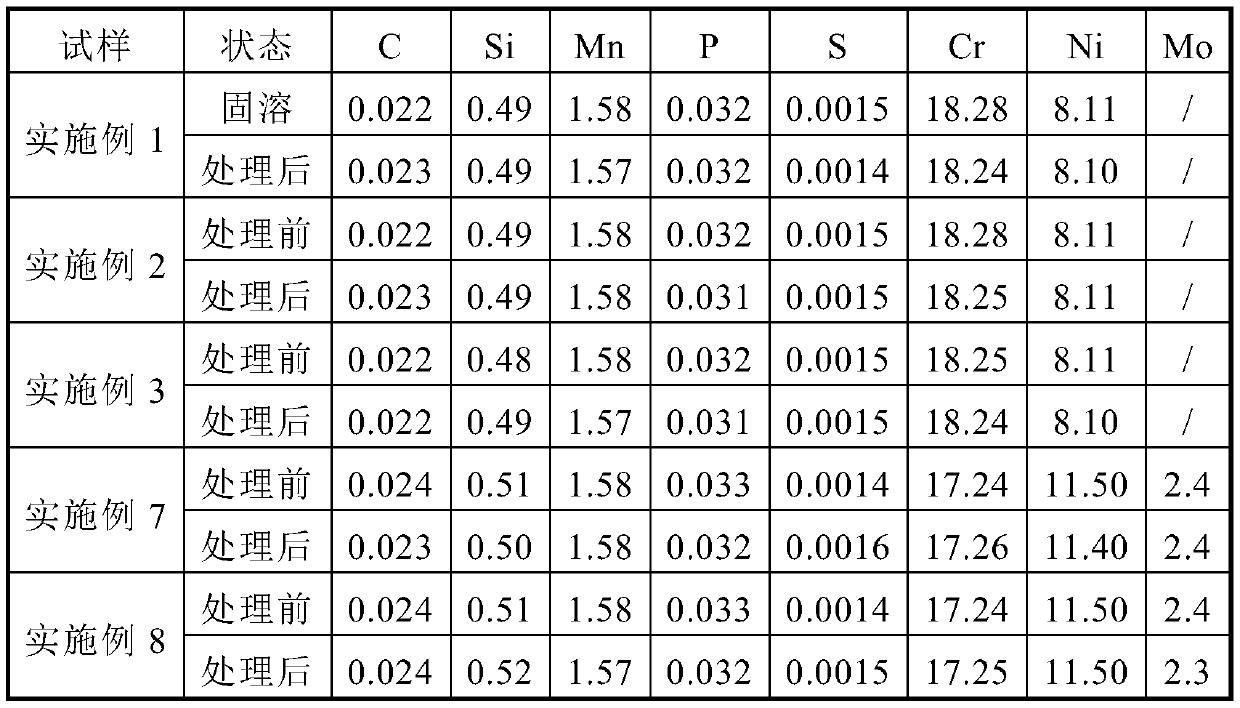

Method for improving intergranular corrosion resistance capacity of austenitic stainless steel

The invention provides a method for improving the intergranular corrosion resistance capacity of austenitic stainless steel. The method comprises the following steps that sensitization treatment is carried out, specifically, heating treatment and sensitization treatment are carried out on the austenitic stainless steel, so that chromium carbide is separated out between crystal particles, and the sensitized stainless steel is obtained; the sensitized stainless steel is continuously heated to 880 DEG C-950 DEG C through atomic diffusion treatment, and the stainless steel is subjected to heat preservation; and then the stainless steel is cooled to the room temperature. According to the method, the chromium carbide is separated out between the crystal particles of the austenitic stainless steel through sensitization treatment firstly, so that the content of chromium between the crystal particles is low; then chromium atoms in the austenitic stainless steel crystal particles are diffused tothe crystal boundary through atomic diffusion treatment, so that the intergranular barren chromium phenomenon is eliminated, and the intergranular corrosion resistance is achieved in a stable state;and the method has the advantages that the heating temperature is low, the fuel consumption is low, the thermal forming process does not need to avoid a sensitization region, the equipment requirementis low, normalizing treatment can be carried out with a carbon steel material at the same time, the cost is low, and chemical components of an austenitic stainless steel material do not need to be changed.

Owner:HENAN SHENZHOU PRECISION MFG CO LTD

Three-layer composite two-sided knitted fabric and production process thereof

ActiveCN106218055AComposite process is simpleIncrease elasticitySynthetic resin layered productsCellulosic plastic layered productsMaterials preparationEngineering

The invention belongs to the technical field of garment fabrics, and particularly relates a three-layer composite two-sided knitted fabric and a production process thereof. The three-layer composite two-sided knitted fabric and the production process solve the problems of high plate hardness, low elasticity and the like in the prior art. The production process of the three-layer composite two-sided knitted fabric comprises the following steps of A, material preparation and B, compounding. The three-layer composite two-sided knitted fabric is processed and formed by the production process. The three-layer composite two-sided knitted fabric and the production process have the advantages that the process is simple; the elasticity, the bulkiness and the softness of the product can be greatly improved.

Owner:CPL NEW MATERIAL TECH CO LTD

Paper plastic glue-free composite bidirectional stretching polypropylene film and its preparation method

ActiveCN100566994CSimple structureHigh heat sealing strengthSynthetic resin layered productsFlat articlesSurface layerComposite film

Owner:GUANGDONG DECRO PACKAGE FILMS +1

Composite waterproof moisture permeable fabric and preparation method thereof

ActiveCN109435358AGood waterproof and moisture permeable functionImprove waterproof performanceSynthetic resin layered productsLaminationMicro nanoHigh concentration

The invention discloses a composite waterproof moisture permeable fabric and a preparation method thereof, and belongs to the field of textile finishing. Spinning solution with different concentrationgradients is adopted, low-concentration spinning solution is pushed out of a solution storage pipe before other high-concentration spinning solution, hydrophobic material micro-nano liquid drops notforming fibers are firstly prepared on a traditional fabric and then pushed out along with the high-concentration spinning solution, hydrophobic materials can form fibers and can be collected on the traditional fabric, and the previous hydrophobic material micro-nano liquid drops function as adhesives and combines the traditional fabric together with electrostatic spinning nano-fibers to obtain the composite waterproof moisture permeable fabric. A compound technology is simplified, time and material cost are saved, and the problem of fabric thickness and performance non-uniformity caused by the adhesion process is avoided.

Owner:BOSIDENG DOWN WEAR

Paper plastic glue-free composite bidirectional stretching polypropylene film and preparation method thereof

ActiveCN100534787CHigh heat sealing strengthHigh peel strengthSynthetic resin layered productsFlat articlesSurface layerAdhesive

The invention discloses a biaxially stretched polypropylene film for paper-plastic composite without glue and a preparation method thereof. Material, pre-printed paper material or another film heat-compressed functional layer containing this layer, the upper surface layer is provided between the surface layer and the core layer, and the next surface layer is provided between the core layer and the functional layer. The preparation method of the present invention is: feeding the selected raw materials into the extruder to be plasticized into a melt, the melt is transported through a pipeline, filtered through a filter, distributed to a die head for co-extrusion through a flow channel, and then can be respectively processed according to the flat film method Or processed into a film by the bubble tube method, the film is corona treated or flame treated into a master roll, the master roll is subjected to aging treatment, and finally cut into film products. The biaxially stretched polypropylene film of the present invention can realize glue-free compounding of paper and plastic, save energy, and is environmentally friendly and hygienic. At the same time, the product also has the advantages of high heat-sealing strength and high peeling strength, which is beneficial to manufacture and promotion.

Owner:GUANGDONG DECRO PACKAGE FILMS +1

Preparation method of ceramic curtain wall and foamed ceramic composite material

ActiveCN107337429AAchieve the purpose of reuseIncrease profitCeramic materials productionCeramicwareCeramic compositeEnergy consumption

The invention discloses a preparation method of a ceramic curtain wall and foamed ceramic composite material. The method comprises the steps that PVA is added into a foamed ceramic mixture and a ceramic curtain wall mixture for granulation, a foamed ceramic granulation material and a ceramic curtain wall granulation material are obtained respectively, the foamed ceramic granulation material and the ceramic curtain wall granulation material are subjected to semi-dry pressing molding to obtain a foamed ceramic body and a ceramic curtain wall body, the foamed ceramic body and the ceramic curtain wall are dried, the dried foamed ceramic body is placed on the top face of the dried ceramic curtain wall body, the combination faces of the foamed ceramic body and the ceramic curtain wall body is smooth and flat, and sufficient contact is performed to obtain a composite body; then, the composite body is kept at the temperature of 120 DEG C for 12 h, the temperature is increased to 1,100-1,150 DEG C for foaming, after foaming is finished, the temperature is decreased to 600 DEG C, heat preservation is performed for 4 h, and after furnace cooling is performed, the ceramic curtain wall and foamed ceramic composite material is obtained. By adopting the foamed ceramic and ceramic curtain sintering method, the compound technology is simple, the energy consumption can be greatly lowered, and the cost is lowered.

Owner:SHAANXI UNIV OF SCI & TECH

Phase change coating and preparation method and application thereof

InactiveCN107905028ALow priceLarge latent heat of phase changeCoatings with pigmentsCoatingsParaffin waxAdhesive

The invention belongs to the field of phase change materials, and specifically discloses a phase change paint, a preparation method and application thereof. The phase change coating comprises paraffin wax and montmorillonite composite phase change material, filler, adhesive, dispersant, water repellent, thickener and water, and the paraffin wax and montmorillonite composite phase change material is composed of paraffin wax and montmorillonite Composite montmorillonite. The phase change paint has the advantages of large phase change latent heat, good temperature regulation and energy storage effect, and low price. Applying the paint to the wallpaper of home decoration can not only regulate temperature and store energy, but also have the function of moisture resistance.

Owner:FOSHAN GAOMING DISTRICT MINGCHENG TOWN NEW ENERGYNEW MATERIAL IND TECH INNOVATION CENT

Paper plastic glue-free composite off line repeated spraying bidirectional stretching polypropylene film and its preparation method

ActiveCN101148104AImprove performanceRealize paper-plastic composite without glueSynthetic resin layered productsCoatingsSurface layerEngineering

The present invention discloses one kind of biaxially stretched polypropylene film with off-line leached layer for no-adhesive paper-plastic combination and its preparation process. The film includes one base film comprising one or two biaxially stretched upper surface layers, one core layer and one or two biaxially stretched lower surface layers, and one functional film layer for direct combination with paper material. The film is prepared through preparing the base film by means of one co-extruding and biaxially stretching process and compounding functional melt in an off-line film leaching device onto the base film to form the functional film layer. The biaxially stretched polypropylene film with off-line leached layer for no-adhesive paper-plastic combination has simple structure, high heat sealing strength and high stripping strength.

Owner:GUANGDONG DECRO PACKAGE FILMS +1

Intermediate alloy for titanium/carbon steel bimetal compounding and compounding process

InactiveCN110936680AImprove adaptabilityWide range of ingredientsLamination ancillary operationsLaminationHigh entropy alloysTitanium

The invention discloses an intermediate alloy for titanium / carbon steel bimetal compounding and a compounding process. A composite material is formed by compounding titanium, carbon steel and the intermediate alloy; wherein the intermediate alloy is a high-entropy alloy, the high-entropy alloy is composed of the following five metal elements in atomic percent: 5-35% of Ga, 5-35% of Cu, 5-35% of Zn, 5-35% of Mn and 5-35% of Fe, and the high-entropy alloy is prepared by adopting a mechanical alloying method. The preparation method of the intermediate alloy is simple, the compounding temperatureis low, the adaptability is wide, and the metallurgical bonding strength of the obtained titanium / carbon steel bimetal composite material is high.

Owner:NANJING TECH UNIV

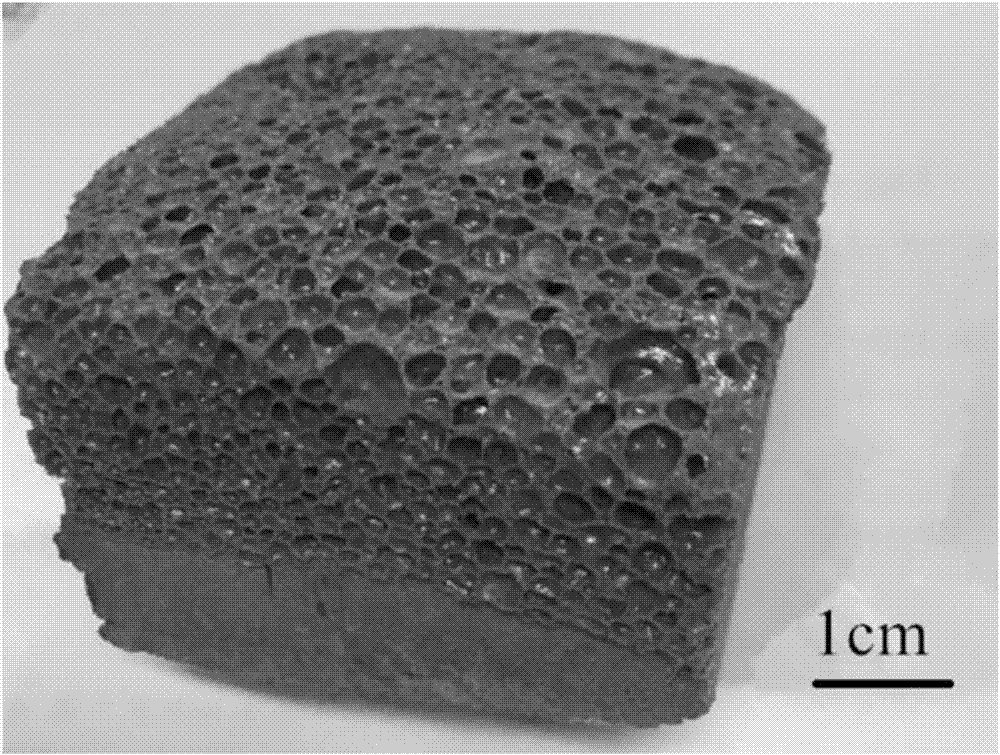

Multi-scale ceramic/metal composite abrasion-resistant material and preparation method thereof

ActiveCN102357652BSave resourcesRealize energy savingGearingCylindersComposite constructionSocial benefits

The invention relates to a preparation technology of a high-performance and abrasion-resistant material, in particular to a multi-scale ceramic / metal composite abrasion-resistant material and a preparation method thereof. The resource-saving high-performance and abrasion-resistant material is obtained by using a high-performance foamed ceramic / metal double continuous phase composite material as an abrasion-resistant matrix, using a high-toughness metal as a constraint framework and using a casting method. The abrasion-resistant material has multi-scale composite structural characteristics, the abrasion-resistant unit is compounded in micron and millimeter scales, and the abrasion-resistant unit and the constraint framework are compounded in a centimeter scale. The structure can well realize reasonable matching of high abrasion resistance and high strength and toughness of the material, the abrasion resistance and the impact toughness of the material are respectively over 7 times and 10 times those of high-chromium cast iron, and meanwhile, scarce alloy elements (Cr, Ni, Mo and the like) are not used. The material is applied to large engineering equipment of crushing, excavating, transporting and the like, is excellent in abrasion resistance, low in cost and convenient to use, greatly prolongs the service life, greatly improves the production efficiency, and has good social benefit and economic benefit.

Owner:LIAONING ZHUOYI NEW MATERIAL

Water-retention tree-planting material and preparation method thereof

The invention relates to a water-retaining tree-planting material and a preparation method thereof. The water-retaining tree-planting material is composed of two layers of plant fiber substrates and a water-retaining layer between the two layers of substrates. The preparation method of the water-retaining tree-planting material comprises the following steps: smearing an adhesive on one side of the substrate, spreading the water-retaining agent flatly, and then pressurizing and compounding the two layers of substrates to obtain the water-retaining tree-planting material. The water-retaining tree-planting material of the invention is green and environment-friendly, simple to manufacture, convenient to use, wide in application range, superior in market prospect, good in use effect and stable in performance.

Owner:杭州卓瑞低温科技有限公司

Glass fiber reinforced plastic composite material and composite process

A glass fiber reinforced plastic composite material is formed by composition of organic FRP (fiber reinforced plastic), FRIM and interface materials. A rectangular box of the organic FRP is coated on the surface of the FRIM, resin is painted and the interface materials are laid between the rectangular box and the FRIM, and the interface materials are alumina hollow spheres with a diameter of 3-5mm. The glass fiber reinforced plastic composite material is light in weight, good in intensity, high-temperature resistant, heat insulating, water-tolerant, simple in process, high in production efficiency, low in manufacturing cost and suitable for being used as fireproof boards and fireproof doors.

Owner:ZUNYI CITY GUI KE TECH

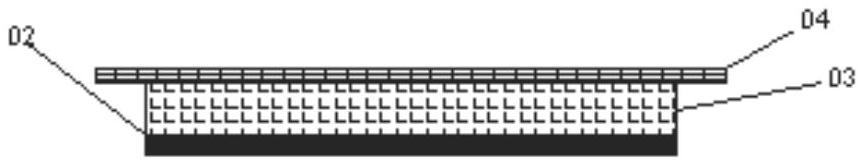

Polyamide-aluminum cold-stamping formed medicine packaging composite film

InactiveCN103240935AImprove water absorptionGood hygroscopicityFlexible coversWrappersComposite filmWater vapor

The invention discloses a polyamide-aluminum cold-stamping formed medicine packaging composite film. The composite film is characterized by sequentially comprising a polyamide layer, an aluminum foil layer and a heat seal coating layer, wherein a composite adhesive layer is arranged between the polyamide layer and the aluminum foil layer. Most of conventional packaging films adopt a twice dry-type compounding technology, so that in a cold stamping process, an aluminum foil layer is easy to break; and in a wet or strong-light environment, medicines are prone to oxidative deterioration because of a delamination phenomenon. The composite film is higher in isolation property to water steam, oxygen and light rays; the polyamide layer is made from PA6, is high in water absorption property and wet absorption property and can be recycled; and the heat seal coating layer is made of a double-component adhesive, has a non-drying property and a hot smelting property, and is high in bonding strength and suitable for packaging of health protection foods, medicines and other products with high requirements on high density and wet resistance.

Owner:SICHUAN HUILI IND

Lithium ion capacitor negative electrode pre-lithiation method, composite negative electrode and lithium ion capacitor

ActiveCN112151283AEasy accessAvoid gatheringHybrid capacitor electrodesDouble layer capacitorsElectrolytic agentPhysical chemistry

The invention provides a lithium ion capacitor negative electrode pre-lithiation method, a composite negative electrode and a lithium ion capacitor. The lithium ion capacitor negative electrode pre-lithiation method comprises steps of 1, preparing a lithium ion capacitor negative electrode and a through hole lithium film with a supporting layer; 2, superposing the through-hole lithium film with the supporting layer with the negative electrode in a manner that one side of the through-hole lithium film is in contact with the surface of the negative electrode, and transferring the through-hole lithium film to the surface of the negative electrode through pressure compounding; and 3, separating the supporting layer, and collecting the negative electrode attached with the lithium film to obtainthe composite negative electrode of the lithium ion capacitor. 4, stacking or winding the composite negative electrode, the positive electrode and the diaphragm together according to the structure ofthe composite negative electrode, the diaphragm and the positive electrode; and 5, injecting an electrolyte, packaging, and carrying out pre-lithiation to obtain the lithium ion capacitor with the pre-lithiated negative electrode.

Owner:CHINA ENERGY LITHIUM

Production method of ultra-high molecular weight polyethylene composite oil pipe

ActiveCN103600503BImprove liquidityReduced wall thicknessTubular articlesTemperature resistanceWear resistance

The invention discloses a production method and a production system of an ultrahigh molecular weight polyethylene compound oil pipe. The method utilizes the memory property of the ultrahigh molecular weight polyethylene material and a special composite technology: conducting hole shrinkage treatment on an ultrahigh molecular weight polyethylene lining pipe with outer diameter larger than the inner diameter of a steel pipe, sheathing in the steel pipe, heating to restore inner diameter of the ultrahigh molecular weight polyethylene lining pipe, and forming the lining pipe with the steel pipe into an integral structure to reach a compactness and firmness without layering and stripping. By introducing additives, the invention greatly improves liquidity of the ultrahigh molecular weight polyethylene in order to produce the inner lining pipe with small wall thickness and reduce cost. The ultrahigh molecular weight polyethylene compound oil pipe provided by the invention comprehensively reserves specific superior performances of good memory property, high impact resistance, good temperature resistance, wear resistance, corrosion resistance, wax precipitation and fouling resistance of ultrahigh molecular weight polyethylene pipe. The invention also discloses a production system supporting the production method.

Owner:王庆昭

Web-like spider silk packed hydrogel high-thermal-conductivity insulating elastomer thermal interface material and preparation method thereof

ActiveCN110498937AImprove thermal conductivityEnhanced network structureHeat-exchange elementsSpider ProteinsElectronic component

The invention discloses a web-like spider silk packed hydrogel high-thermal-conductivity insulating elastomer thermal interface material and a preparation method thereof. The preparation method of thehigh-thermal-conductivity insulating elastomer thermal interface material comprises the following steps: pouring a uniform mixed solution of hydroxyethyl cellulose and acrylic acid into a heterogeneous system of a monomer radical polymerization initiator suspension having multilayered web-like spider silk stack, and performing a reaction in a high-temperature environment to prepare the elastomerthermal interface material. The method provided by the invention has a simple process; the obtained web-like spider silk-packed hydrogel high-thermal-conductivity insulating elastomer thermal interface material has excellent thermal conductivity, flexibility and insulation properties, and has more advantages in application to electronic components and heat sinks.

Owner:上海叠泰材料科技有限公司

A kind of electromagnetic shielding foam composite material and preparation method based on graphene oxide and polymer

ActiveCN106243379BComposite process is simpleContent requirements are lowPolymer scienceElectromagnetic shielding

The invention relates to a graphene oxide and polymer based electromagnetic shielding foam composite material and a preparation method thereof. Flexible polymer foams are selected and are immersed in a graphene oxide aqueous dispersion, then the immersed polymer foams are dried and reduced, and a layer of three-dimensional continuous graphene film structure is formed between a foam skeleton and a skeleton. The graphene film between the skeletons is conducive to improving the electromagnetic wave reflecting surface and beneficial to electromagnetic wave absorption. Through compounding and reduction of the polymer foams and graphene oxide, compounding of flexible polymer foams and graphene with high electromagnetic shielding properties can be realized, the three-dimensional continuous network structure of the polymer foams and graphene guarantees maximization of mechanical and electromagnetic shielding properties, under 80% compressive strain, the obtained foam composite material is compressed repeatedly for 1000 times, the recovery rate is greater than or equal to 95%, and the electromagnetic shielding effectiveness is greater than or equal to 40dB. The method provided by the invention has a simple compounding process, and can realize large-scale production.

Owner:TIANJIN UNIV

Method for manufacturing inner covered stainless steel compound steel pipe

InactiveCN101670383BOvercoming the problems that reduce the corrosion resistance of stainless steelOvercome the problem of anti-corrosion performanceFurnace typesHeat treatment process controlSolution treatmentInterference fit

Owner:大连合生科技开发有限公司

Interpenetrating network hydrogel material with high thermal conductivity and high elasticity, and preparation method thereof

The invention discloses an interpenetrating network hydrogel material with a high thermal conductivity and a high elasticity, and a preparation method thereof. The preparation method comprises the following steps: hydroxyethyl cellulose is taken, and is dissolved in a graphene oxide / ammonium persulfate suspension, stirring is performed until uniformity, an appropriate amount of acrylic acid is added, then the obtained mixed solution is rapidly poured into a mold, the mold is placed in a constant temperature oven, the mixed solution is reacted for a period of reaction, and the obtained hydrogelin the mold is taken out, and is washed with deionized water to remove unreacted monomers and impurities in order to obtain the hydrogel containing a small amount of graphene oxide. The method of theinvention has a simple process, the obtained hydrogel has good compression resistance and good thermal conductivity, and the high thermal conductivity can be achieved by adding only a small amount ofthe graphene oxide; and compared with other thermal conducting media, the interpenetrating network hydrogel material of the invention has the excellent characteristics of good compressive strength, reusability, no oil permeation, low viscosity, and easiness in disassembling.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com