Method for improving intergranular corrosion resistance capacity of austenitic stainless steel

A technology of austenitic stainless steel and intergranular corrosion, which is applied in the field of improving the resistance of austenitic stainless steel to intergranular corrosion, and can solve the problem of limited application range of austenitic stainless steel, high smelting cost, and reducing carbon content of austenitic stainless steel, etc. problem, to improve the resistance to intergranular corrosion, avoid grain growth, and achieve the effect of good resistance to intergranular corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

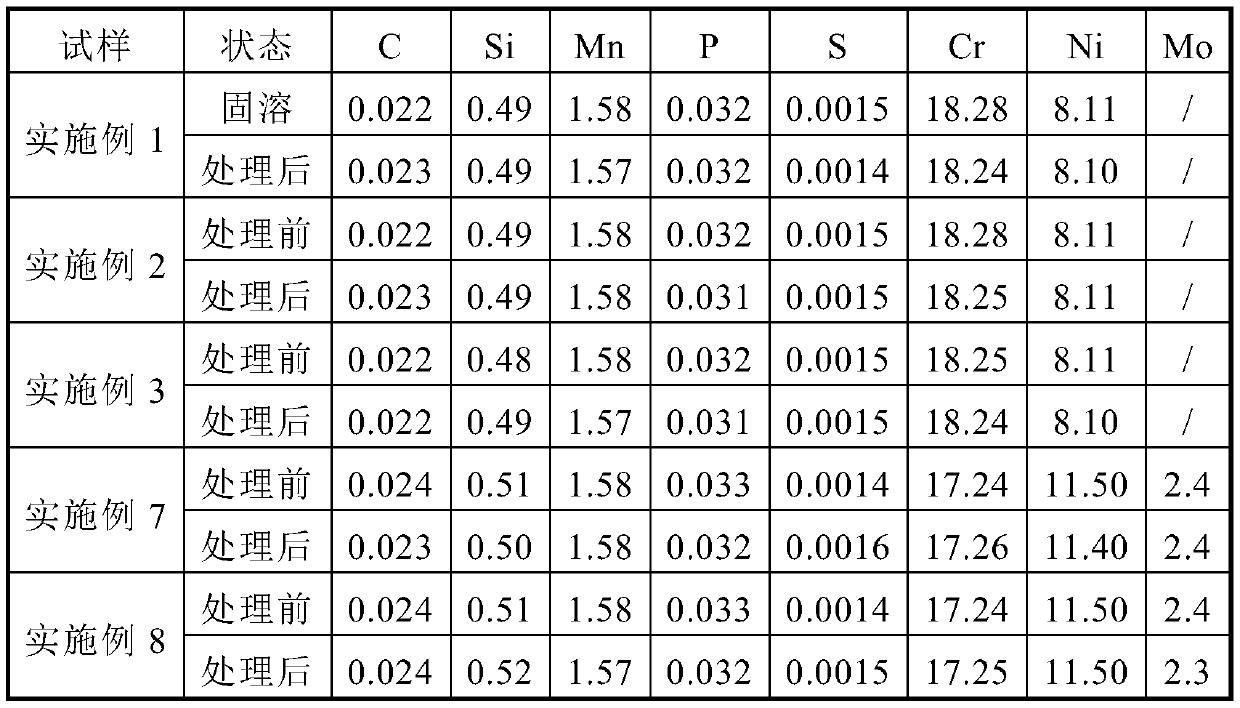

[0019] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

[0020] The embodiment of the present invention provides a method for improving the intergranular corrosion resistance of austenitic stainless steel, comprising the steps of:

[0021] Sensitization treatment uses stable element-free austenitic stainless steel with a size of 80mm×10mm×14mm as the raw material, heats the raw material to 600°C to 700°C, and keeps it warm for 2 to 5 hours for sensitization treatment to make chromium carbide Precipitate between the grains to obtain stainless steel after sensitization treatment; wherein, in this step, the main purpose of heating first, and then heat preservation treatment is to fully consume the free carbon between the grains, and form chromium carbide to precipitate between the grains;

[0022] Atomic diffusion treatment continues to heat the stainless steel after the sensitization treatment, h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com