Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

78 results about "Chromium atom" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chromate is an ion that contains one chromium atom (in its +6 oxidation state) and four oxide atoms. Its formula is CrO 4.

Process for the Preparation of 1,3,3,3-Tetrafluoropropene and/or 1,1,3,3,3-Pentafluoropropene

InactiveUS20090043138A1Preparation by dehalogenationPreparation by hydrogen halide split-offHydrogen fluoridePtru catalyst

A process for the manufacture of CF3CH═CHF and / or CF3CH═CF2 is disclosed. The process involves involves (a) reacting HF and at least one halopropene of the formula CX3CCI═CCIX (where each X is independently F or CI) to produce a product including both CF3CCI═CF2 and CF3CHCICF3; (b) reacting CF3CCI═CF2 and / or CF3CHCICF3 produced in (a) with hydrogen to produce a product including CF3CH2CHF2 and / or CF3CH2CF3; (c) dehydrofluorinating CF3CH2CHF2 and / or CF3CH2CF3 produced in (b) to produce a product comprising CF3CH═CHF and / or CF3CH═CF2; and (d) recovering CF3CH═CHF and / or CF3CH═CF2 from the product produced in (c). In (a), the CF3CCI═CF2 and CF3CHCICF3 are produced in the presence of a fluorination catalyst comprising at least one chromium-containing component selected from (i) a crystalline alpha-chromium oxide where at least 0.05 atom % of the chromium atoms in the alpha-chromium oxide lattice are replaced by divalent copper, and (ii) a chromium-containing composition of (i) which has been treated with a fluorinating agent.

Owner:EI DU PONT DE NEMOURS & CO

Ethylene polymers and method for producing the same

InactiveUS6646069B2Improve impact resistanceImprove balanceOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationChromium CompoundsCrack resistance

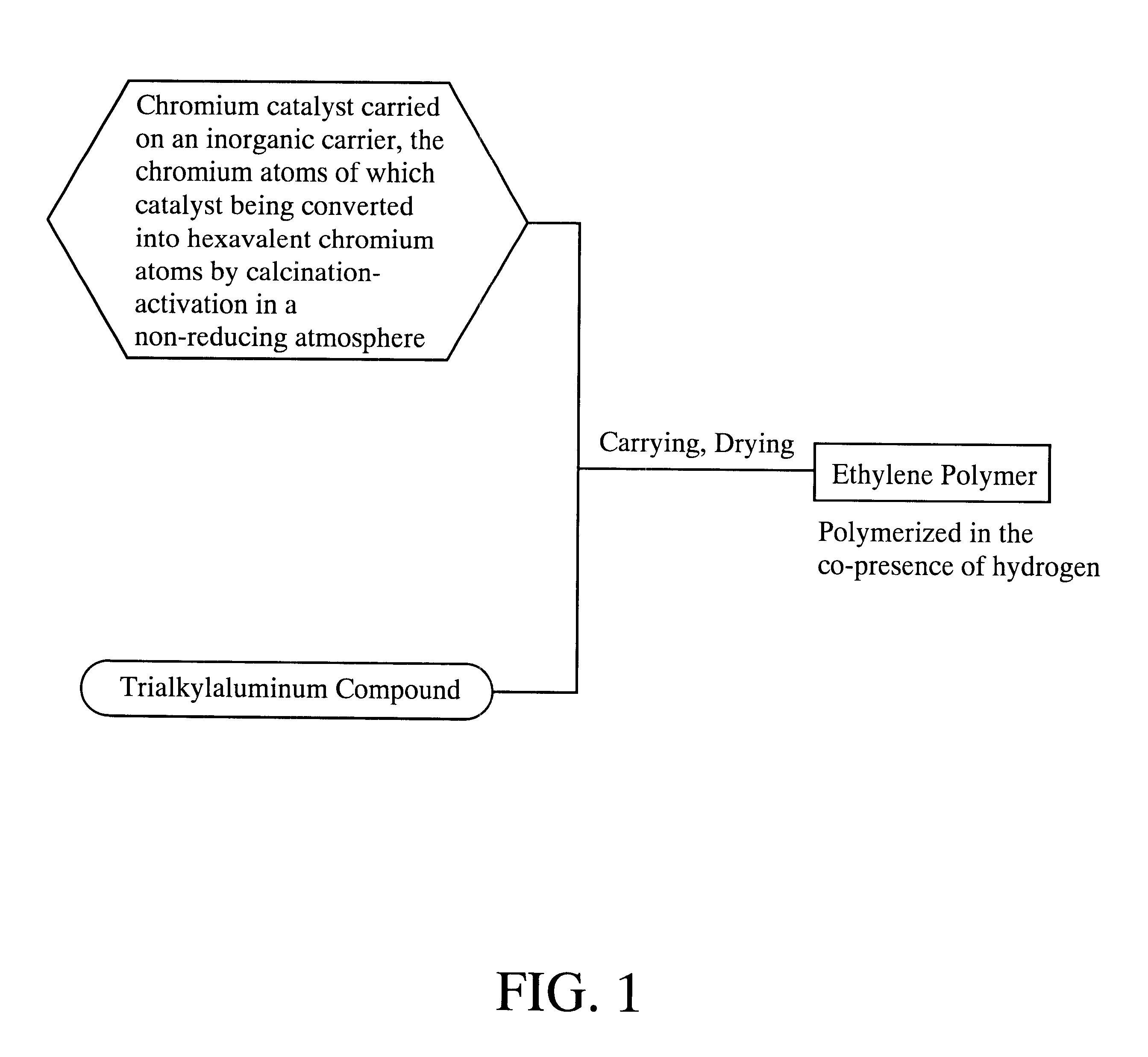

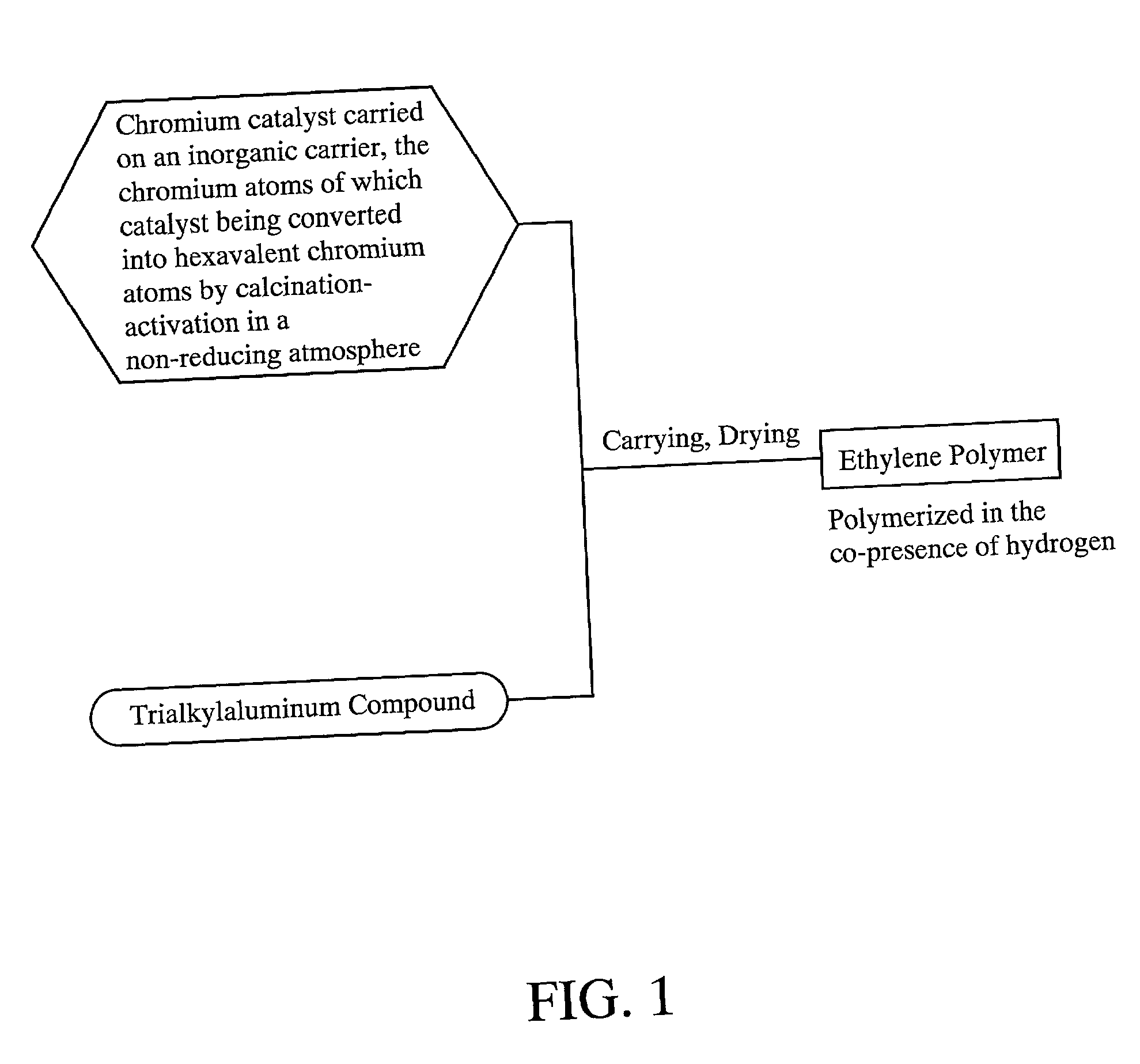

The invention relates to a method for producing an ethylene polymer, comprising performing polymerization of ethylene in co-presence of hydrogen using a trialkylaluminum compound-carried chromium catalyst, wherein the chromium catalyst is obtained by calcination-activating a chromium compound that is carried on an inorganic oxide carrier in a non-reducing atmosphere to convert chromium atoms in the chromium compound into hexavalent chromium atoms for at least a portion thereof, and treating with a trialkylaluminum compound in an inert hydrocarbon solvent to carry thereon and removing to dry the solvent so that the chromium atoms are not over-reduced by the trialkylaluminum compound, and to an ethylene polymer suitable for blow molded articles obtained by the production method. The ethylene polymer of the invention have improved environment stress crack resistance (ESCR) and impact resistance in a good balance and are suitable for molded blow articles, in particular large size blow molded articles.

Owner:JAPAN POLYOLEFINS CO LTD

Process for the preparation of 1,1,1,2,2-pentafluoroethane

InactiveUS7074973B2Preparation by halogen halide additionOrganic chemistry methodsCrystalline oxideHydrogen fluoride

A process for the preparation of pentafluoroethane is disclosed which involves contacting a mixture comprising hydrogen fluoride and at least one starting material selected from haloethanes of the formula CX3CHX2 and haloethanes of the formula CX2═CX2, where each X is independently selected from the group consisting of F and Cl (provided that no more than four of X are F), with a fluorination catalyst in a reaction zone to produce a product mixture comprising HF, HCl, pentafluoroethane, underfluorinated halogenated hydrocarbon intermediates and less than 0.2 mole percent chloropentafluoroethane based on the total moles of halogenated hydrocarbons in the product mixture. The process is characterized by the fluorination catalyst comprising (i) a crystalline cobalt-substituted alpha-chromium oxide where from about 0.05 atom % to about 6 atom % of the chromium atoms in the alpha-chromium oxide lattice are replaced by trivalent cobalt (Co+3) and / or (ii) a fluorinated crystalline oxide of (i).

Owner:EI DU PONT DE NEMOURS & CO

Ethylene polymers and method for producing the same

InactiveUS20020042482A1Improve impact resistanceImprove balanceOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationChromium CompoundsCrack resistance

The invention relates to a method for producing an ethylene polymer, comprising performing polymerization of ethylene in co-presence of hydrogen using a trialkylaluminum compound-carried chromium catalyst, wherein the chromium catalyst is obtained by calcination-activating a chromium compound that is carried on an inorganic oxide carrier in a non-reducing atmosphere to convert chromium atoms in the chromium compound into hexavalent chromium atoms for at least a portion thereof, and treating with a trialkylaluminum compound in an inert hydrocarbon solvent to carry thereon and removing to dry the solvent so that the chromium atoms are not over-reduced by the trialkylaluminum compound, and to an ethylene polymer suitable for blow molded articles obtained by the production method. The ethylene polymer of the invention have improved environment stress crack resistance (ESCR) and impact resistance in a good balance and are suitable for molded blow articles, in particular large size blow molded articles.

Owner:JAPAN POLYOLEFINS CO LTD

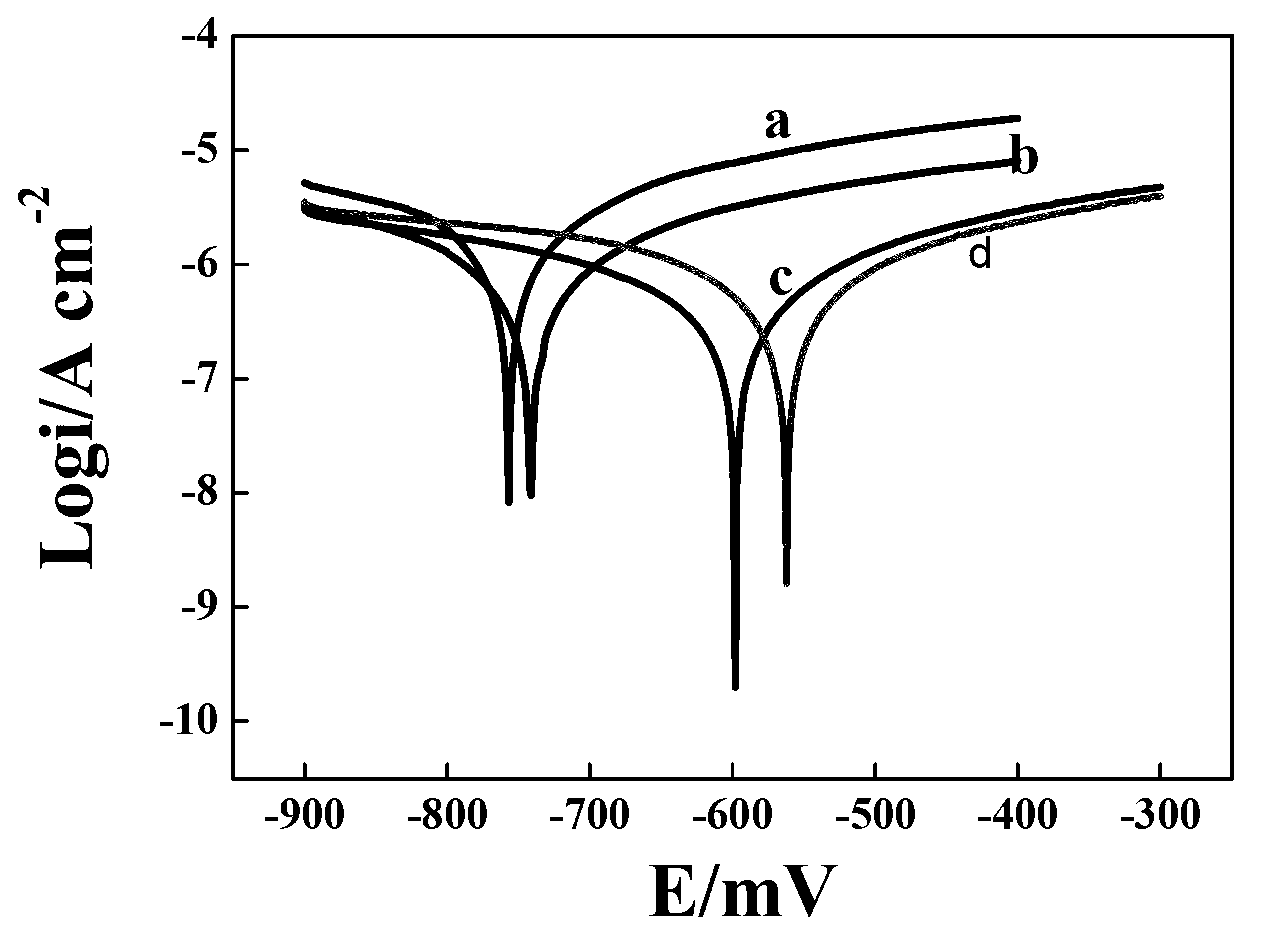

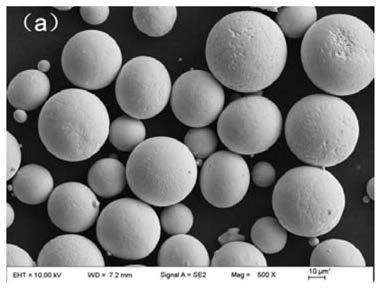

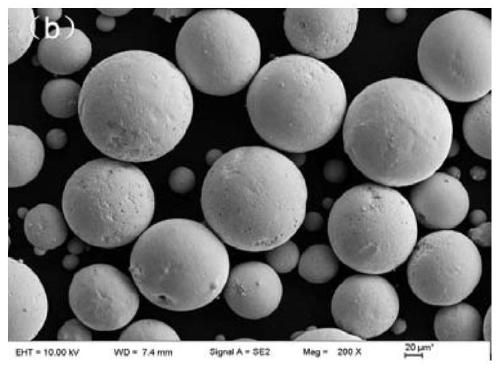

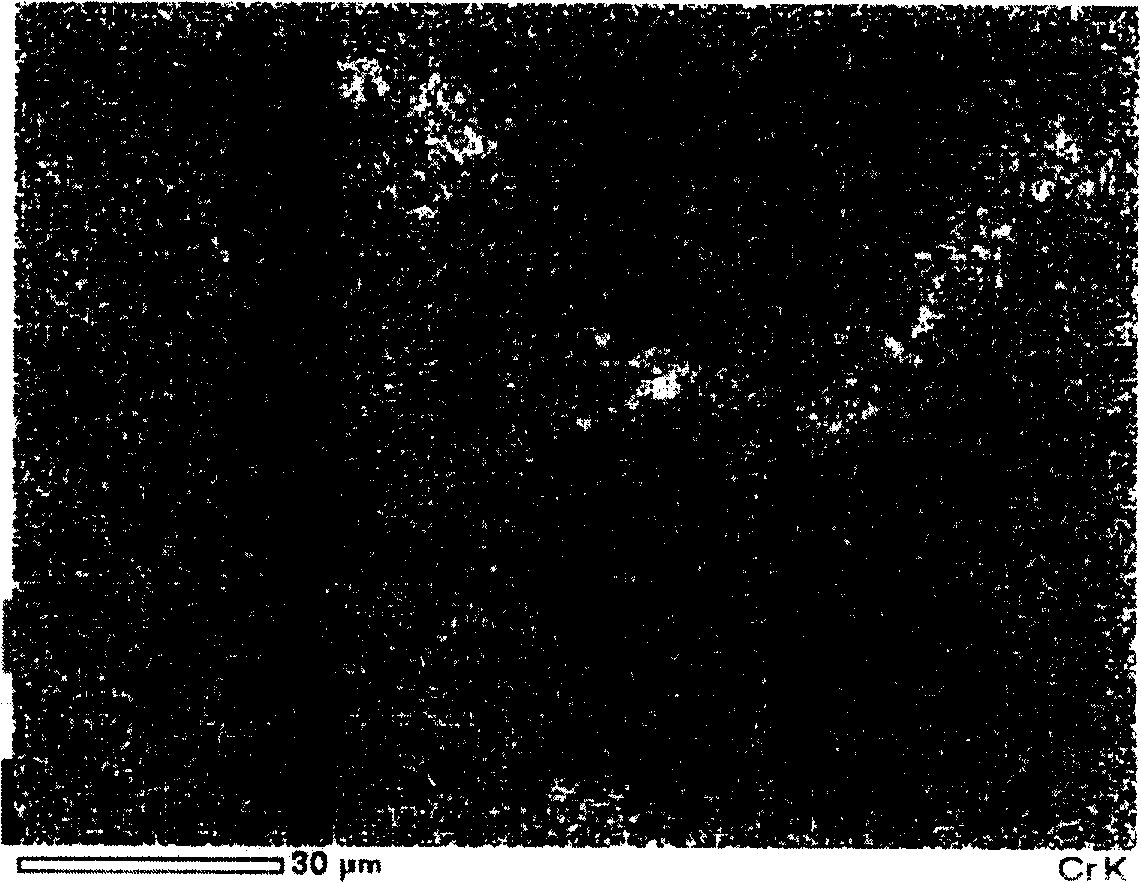

CoCrPt Base Sputtering Target and Production Process for the Same

InactiveUS20090308740A1Improve uniformityAvoid nodulesCellsElectric discharge tubesHigh concentrationSputtering

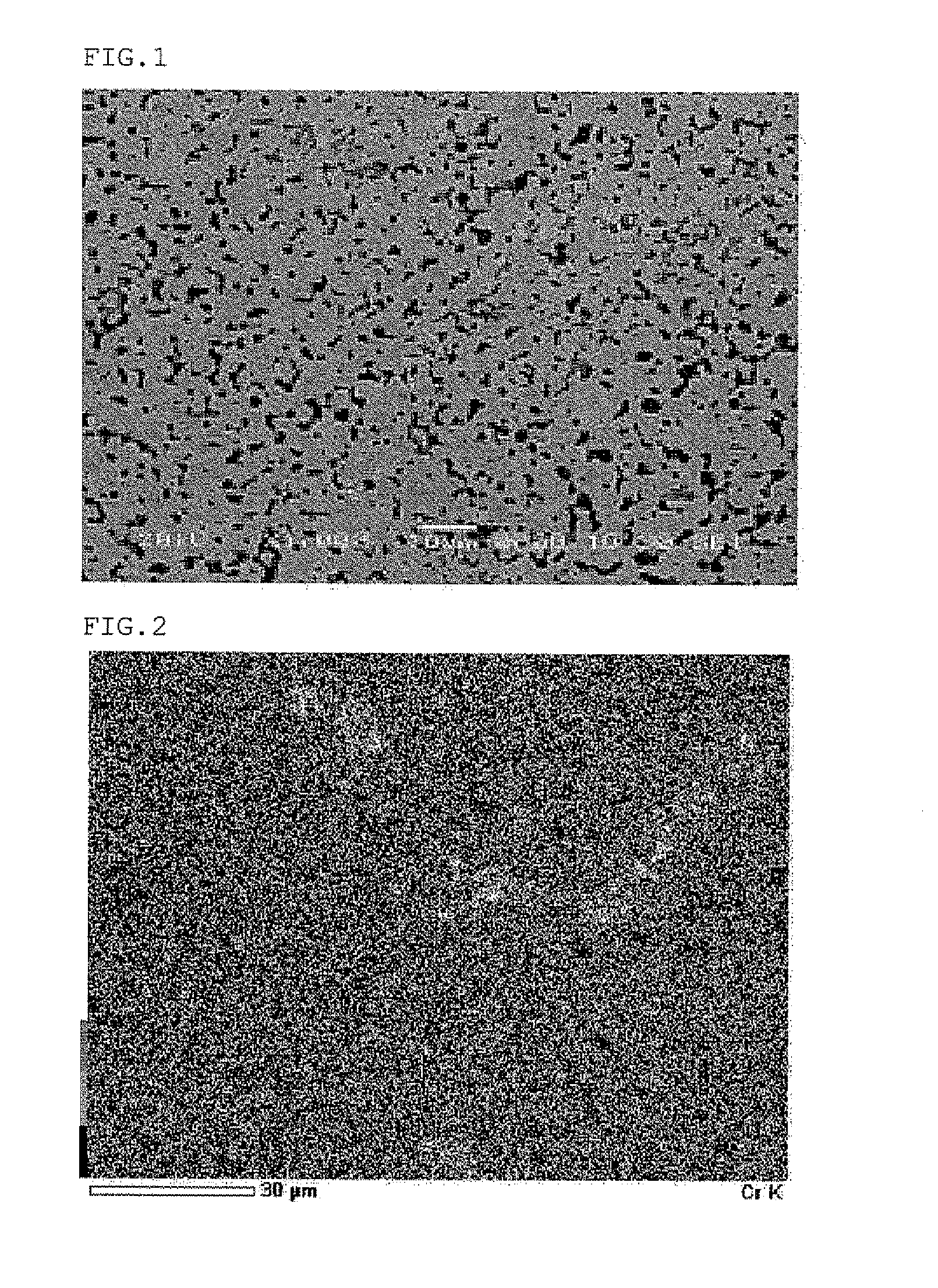

An object of the present invention is to provide a CoCrPt base sputtering target in which high chromium-containing particles containing a chromium atom at a high concentration unevenly distributed in the above sputtering target are reduced in a size and a production amount to thereby enhance a uniformity of the target and inhibit nodules or acing from being caused and which has the targeted composition ratio.The CoCrPt base sputtering target of the present invention is a sputtering target containing cobalt, chromium, ceramics and platinum, and it is characterized by that high chromium-containing particles containing a chromium atom at a high concentration which are unevenly distributed in the above sputtering target have a maximum full diameter of 40 μm or less.

Owner:MITSUI MINING & SMELTING CO LTD

Process for the preparation of 1,3,3,3-tetrafluoropropene and/or 2,3,3,3-tetrafluoropropene

InactiveUS7678949B2Preparation by dehalogenationPreparation by hydrogen halide split-off1,3,3,3-TetrafluoropropeneCopper

Owner:EI DU PONT DE NEMOURS & CO

Processes for the preparation of 2-chloro-1,1,1,2,3,3,3-heptafluoropropane, hexafluoropropene and 1,1,1,2,3,3,3-heptafluoropropane

InactiveUS7129383B2Preparation by dehalogenationPreparation by hydrogen halide split-offCrystalline oxideHalohydrocarbon

Owner:EI DU PONT DE NEMOURS & CO

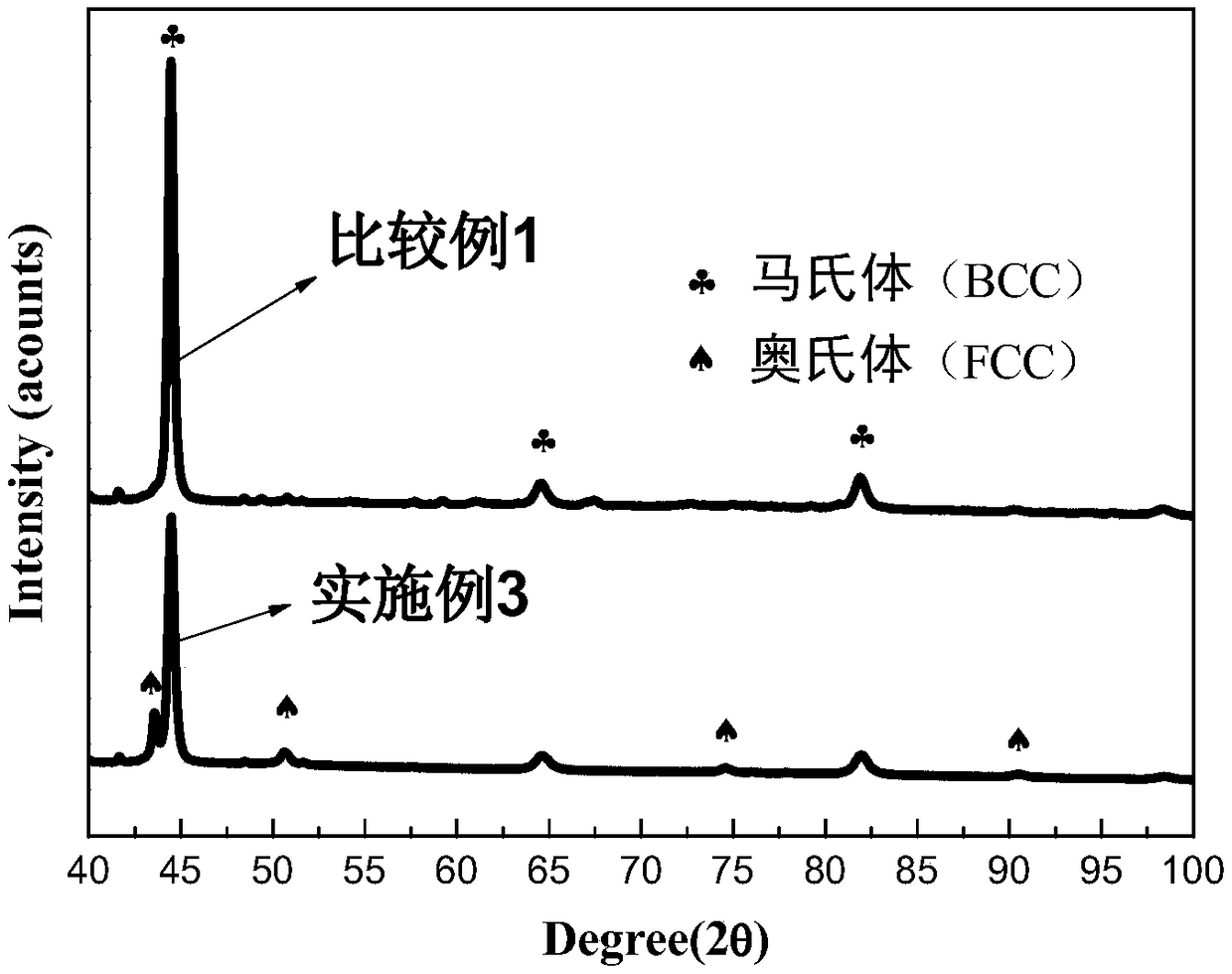

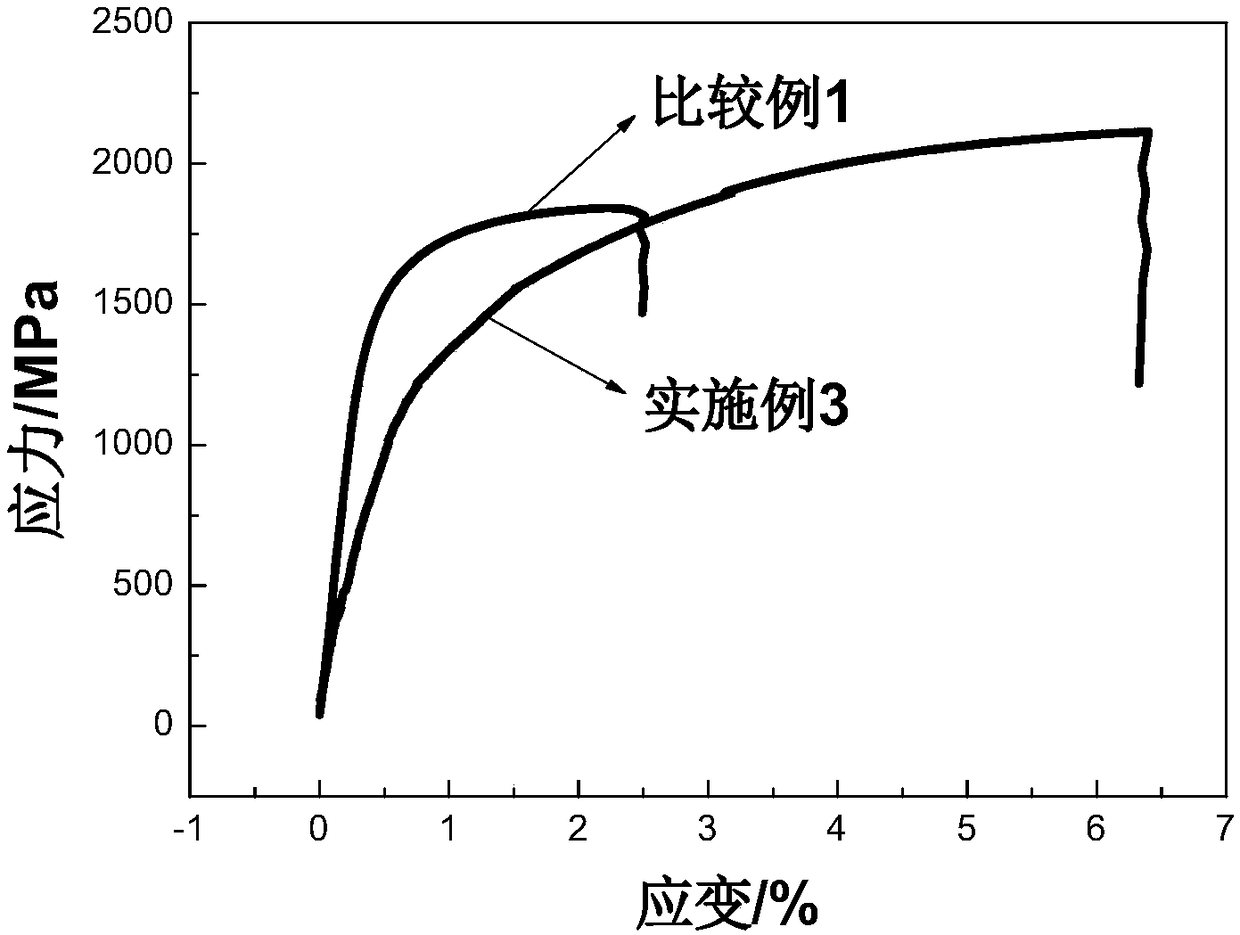

High-carbon high-chromium martensite stainless steel and preparation method thereof

The invention relates to high-carbon high-chromium martensite stainless steel and a preparation method thereof and belongs to the technical field of materials. The high-carbon high-chromium martensitestainless steel comprises the following chemical components in percentage by weight: 0.40-0.55% of C, 14.0-16.0% of Cr, 0.5-1.0% of Mo, 0.1-0.2% of V, less than or equal to 1.0% of Mn, less than or equal to 1.0% of Si, less than or equal to 0.30% of Ni, less than 0.05% of P, less than 0.005% of S, less than 0.004% of O, less than or equal to 0.1% of N and the balance ferrum. The preparation method of the high-carbon high-chromium martensite stainless steel comprises the following steps of proportioning, smelting, molding by casting, forging and hot working, and cold working and hot treating.By controlling the ratio of carbon and chromium atoms in a material within a certain range, the proportion of martensite and austenite is regulated after the hot treating process, the best match of strength and toughness of the material is obtained, and the high-carbon high-chromium martensite stainless steel shows a good corrosion-resisting property.

Owner:沈阳金锋特种刀具有限公司

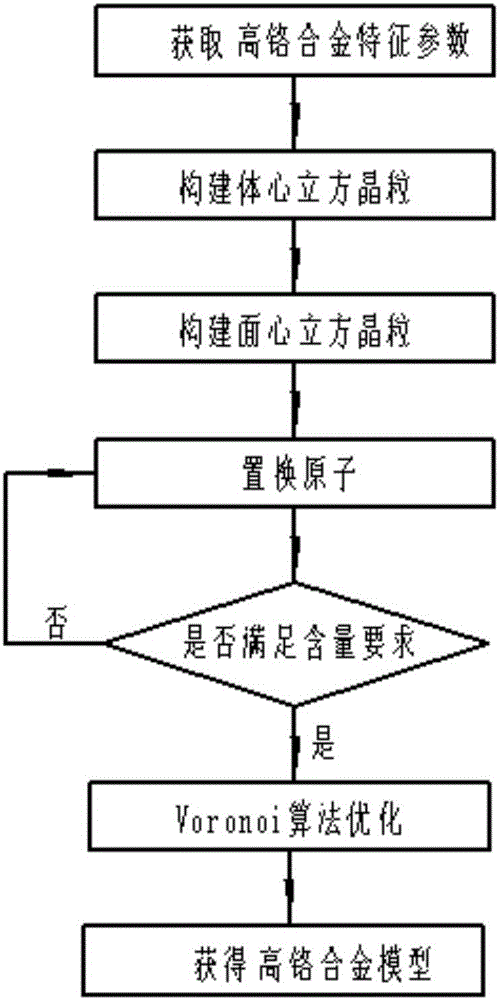

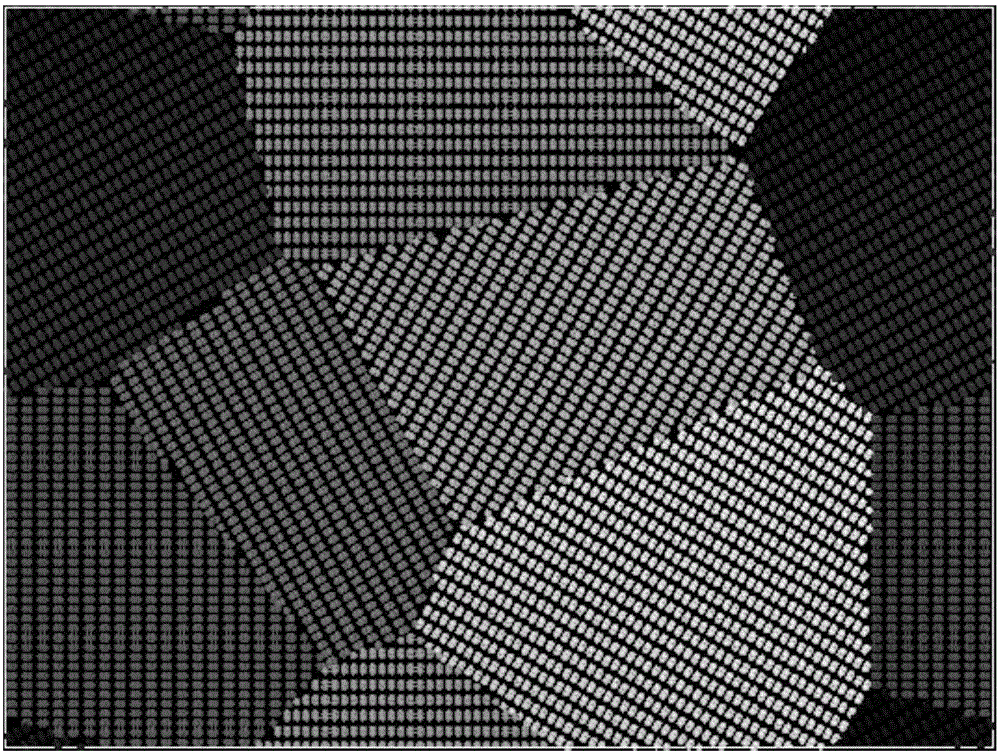

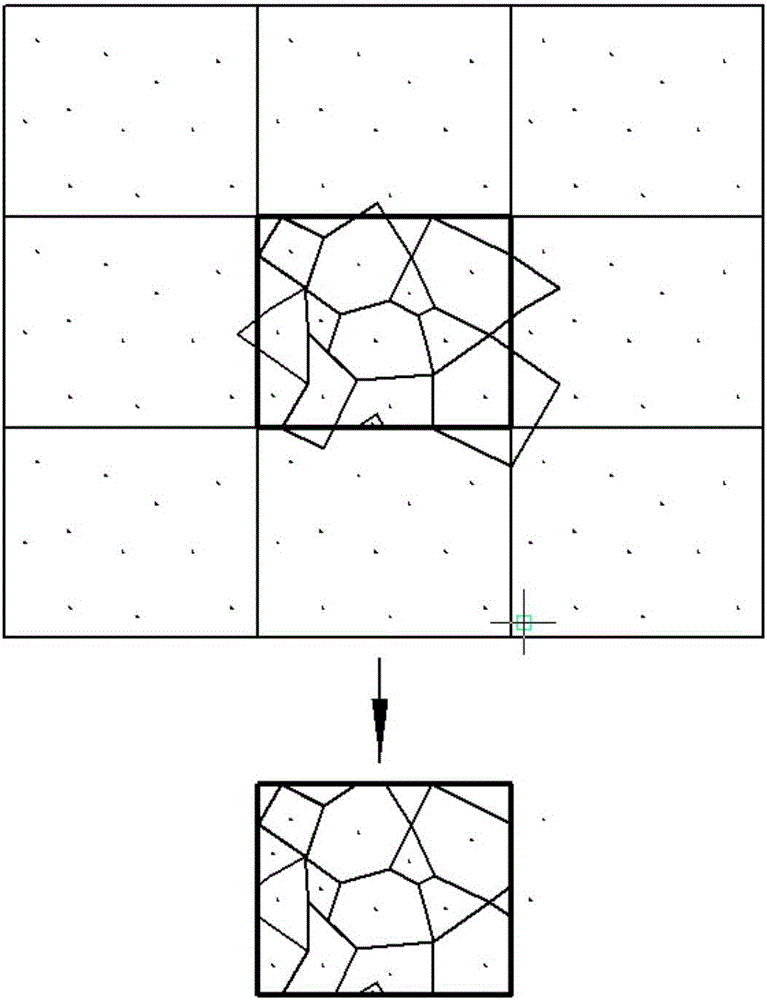

Casting high-chromium alloy modeling method based on molecular dynamics

InactiveCN105772689AGenerate content accuratelyAccurate generation methodCrystal structureFeature parameter

The invention relates to a casting high-chromium alloy modeling method based on molecular dynamics and belongs to the field of alloy material structural design. According to the modeling method, modeling of a composition structure of casting high-chromium alloy is conducted through molecular dynamic modeling software, firstly, characteristic parameters of the casting high-chromium alloy, an atomic model of a construction body-centered cubic crystal structure and an atomic model of a construction face-centered cubic crystal structure are obtained; then, by means of a substitution program, existing atoms in the models are substituted with the chromium atoms; the content of the substitution element is judged, and if the content requirement is not met, substitution continues till the chromium element meets the requirement in the alloy; finally, by means of the Voronoi algorithm, the constructed models are optimized till the content requirement of all elements in the alloy is met. The modeling method can accurately reflect microstructure components and the structure of the alloy, and has practical significance to property and machining method research of alloy.

Owner:DALIAN UNIV OF TECH

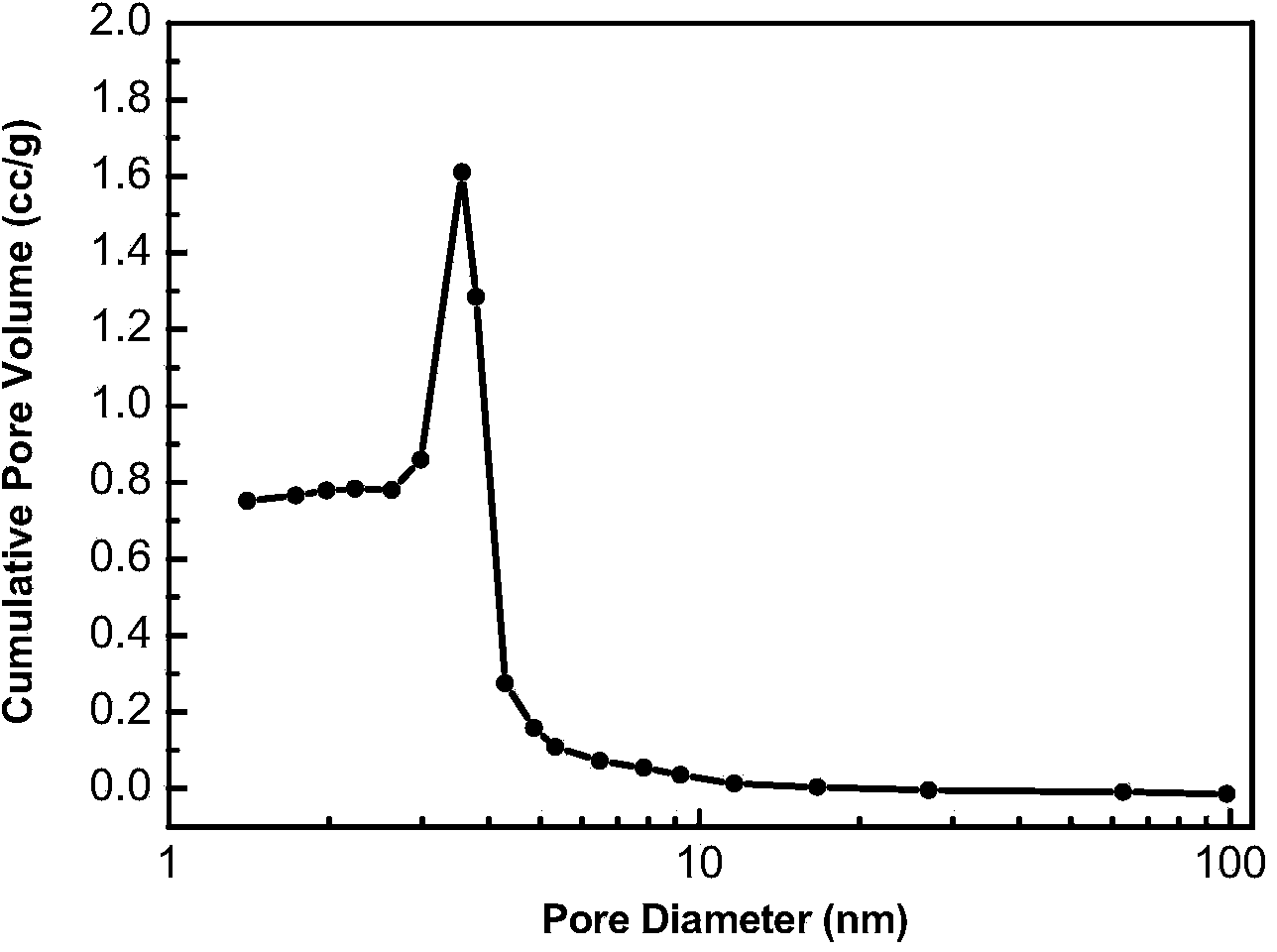

Preparation method of shape-controllable ordered layer porous chromium carbide skeleton carbon material for supercapacitor

ActiveCN103771392AShape controllable and diverseFast transferMaterial nanotechnologyHybrid capacitor electrodesCapacitanceChromium carbide

The invention discloses a preparation method of a shape-controllable ordered layer porous chromium carbide skeleton carbon material for a supercapacitor. In a preparation process, a chromium carbide precursor with a special shape is synthesized through template control, a chromium atom is removed by using an etching agent in situ to obtain a micropore, then orderly arranged meso pores with regular pore passages are obtained by removing a mesopore template to form porous carbon hierarchically combined by meso pore and micropores, wherein the shape of the chromium carbide framework carbon can be controlled through a template process, the relative content of the micropores and the meso pores can be adjusted through controlling a synthesis reaction condition and a raw material ratio, and thus the ordered layer porous chromium carbide skeleton carbon the pore structure and the pore diameter distribution of which are accurate and adjustable in atom-scale level and controllable in shape is obtained. According to the preparation method, a shape-controlled porous electrode material for a novel supercapacitor, which is high in specific capacitance, small in ion diffusion and transfer impedance, better in rate capability, excellent in cycle performance and controllable in shape can be obtained.

Owner:XIANGTAN UNIV

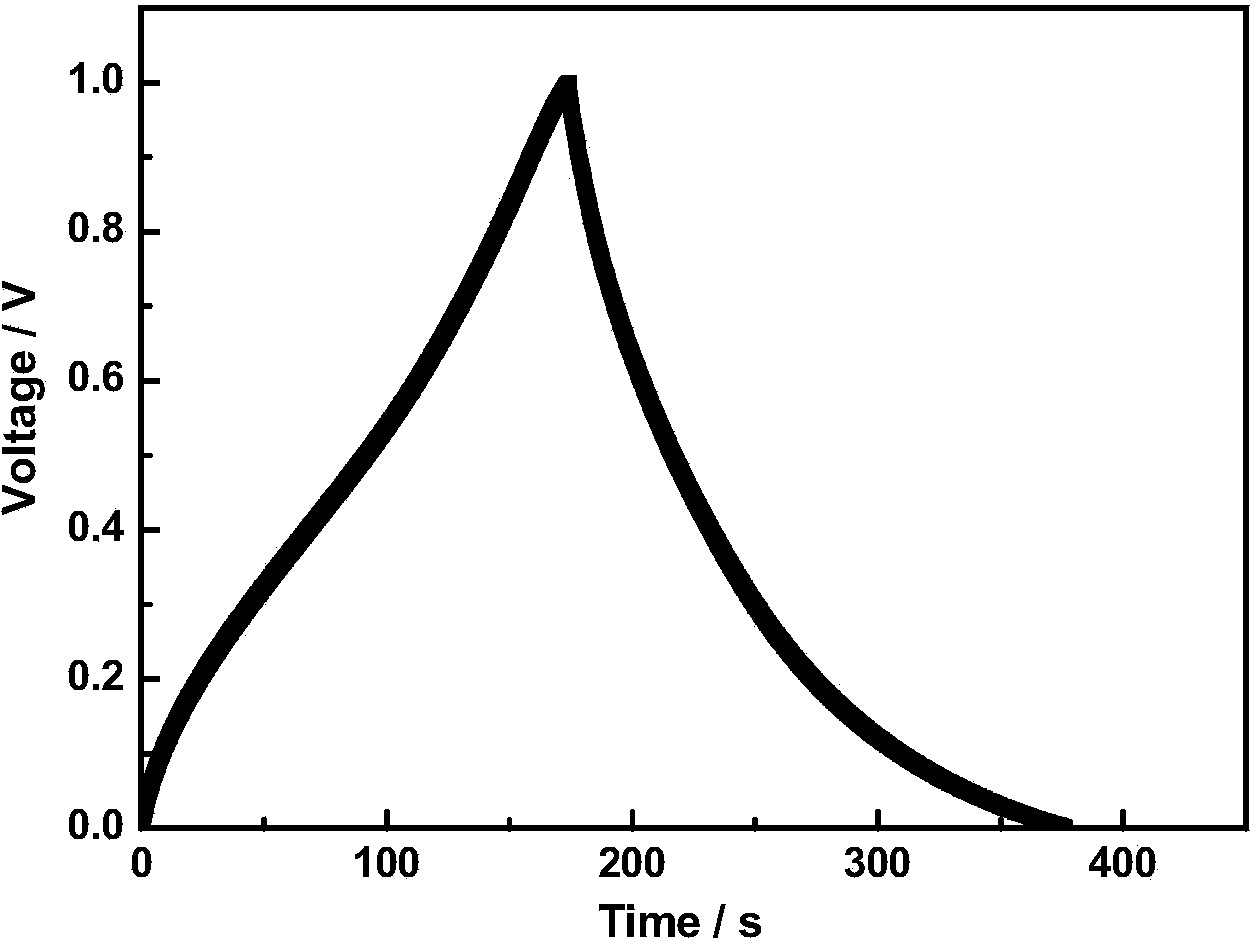

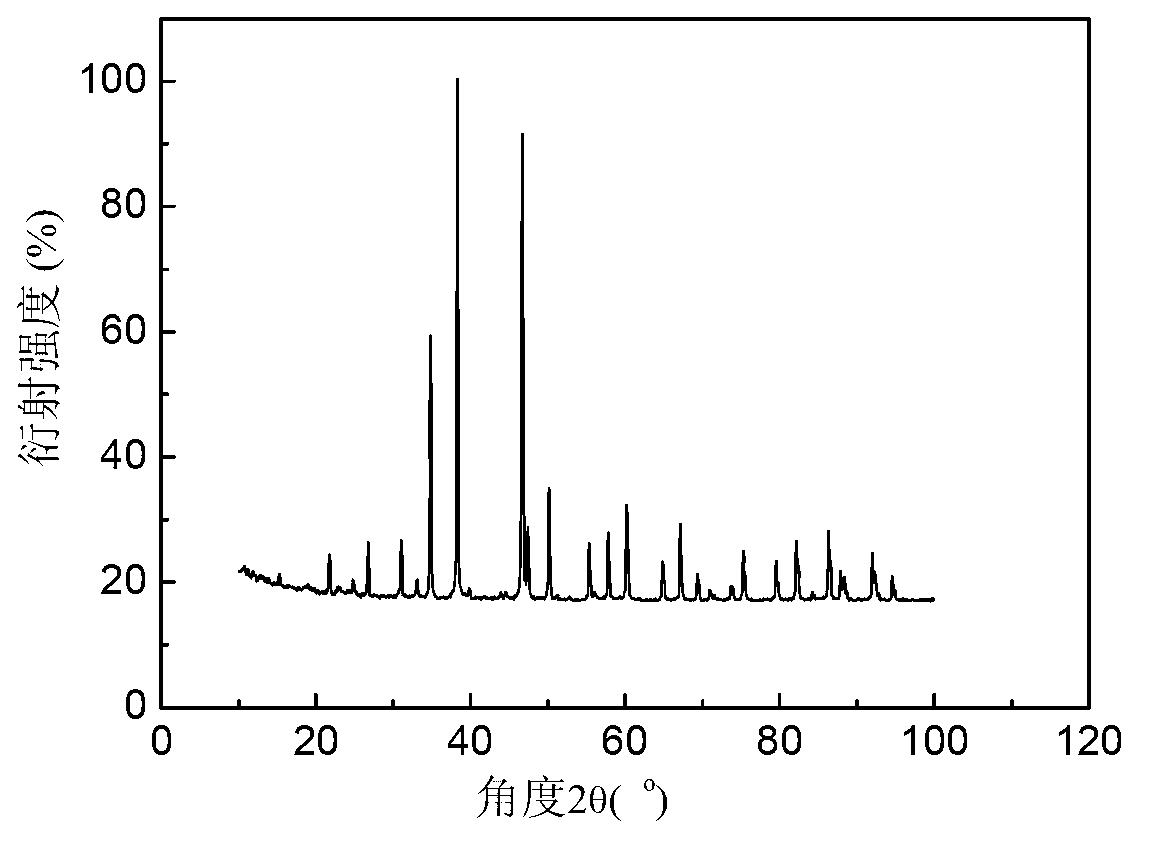

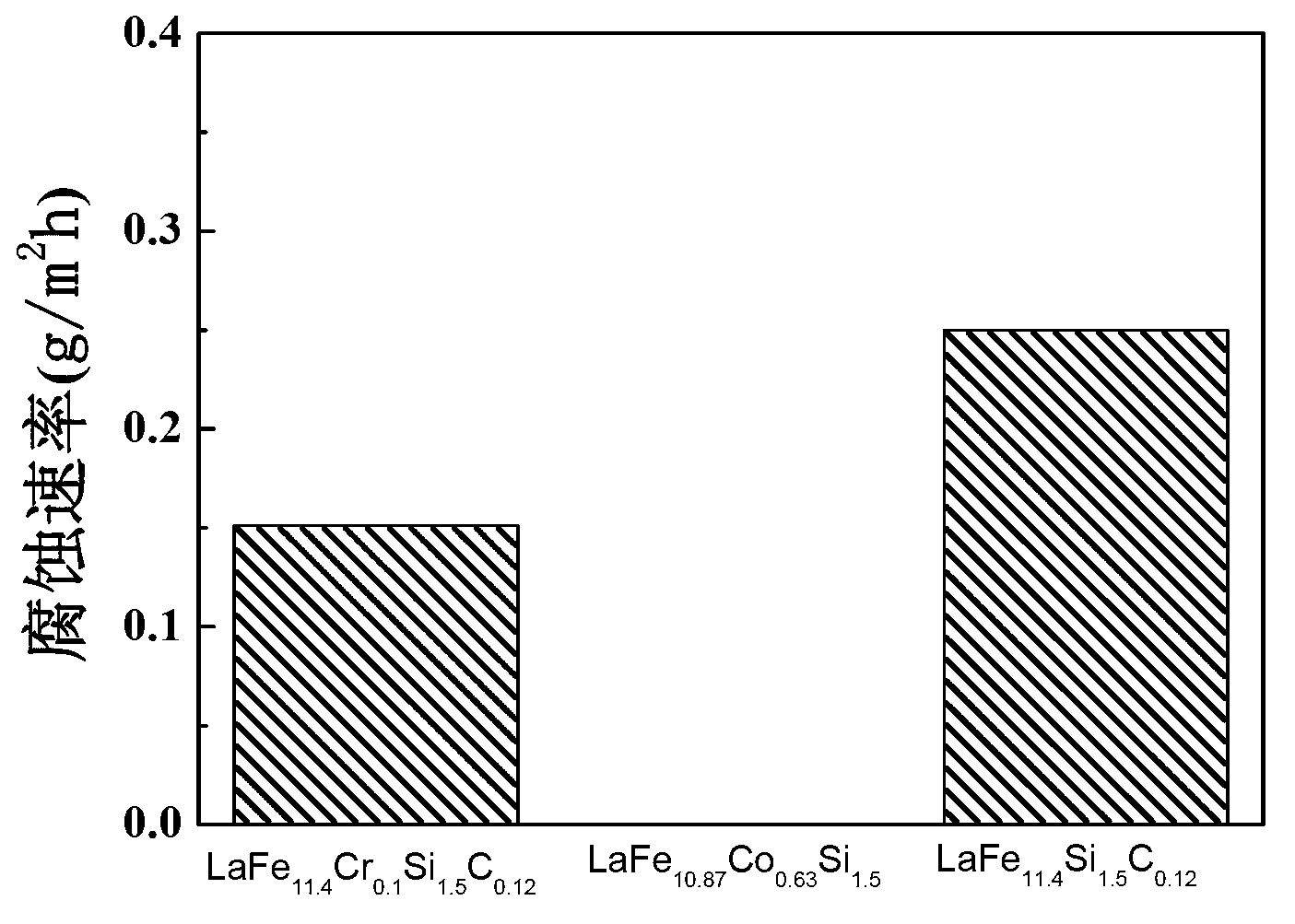

High corrosion resistance rare earth-iron chromium silicon carbon magnetocaloric material and preparation method thereof

InactiveCN103060692AImprove corrosion resistanceReduce manufacturing costHeat-exchange elementsTap waterPhysical chemistry

The invention belongs to the technical field of magnetic refrigeration materials, and provides a high corrosion resistance rare earth-iron chromium silicon carbon magnetocaloric material, which comprises part of chromium atoms substituting for iron atoms as well as carbon atoms as interstitial atoms. After the high corrosion resistance rare earth-iron chromium silicon carbon magnetocaloric material is soaked in tap water of 25 DEG C for 12 hours, the corrosion rate is less than 0.2g / m<2>.h. The high corrosion resistance rare earth-iron chromium silicon carbon magnetocaloric material has two chemical molecular formulas, one is La1-xRx(Fe1-y-mCryMm)13-zSizCa, and the other is LaFeSi. The corrosion rate of the high corrosion resistance rare earth-iron chromium silicon carbon magnetocaloric material is less than half that of ordinary rare earth-iron silicon magnetocaloric material; and the high corrosion resistance rare earth-iron chromium silicon carbon magnetocaloric cast ingot has high magnetic entropy change value after short-time annealing, thus being used in magnetic refrigeration technology as a practical material.

Owner:UNIV OF SCI & TECH BEIJING

Process For The Preparation Of 1,1,1,3,3- Pentafluoropropane And 1,1,1,2,3- Pentafluoropropane

InactiveUS20090124836A1Preparation by dehalogenationPreparation by halogen halide additionHydrogen fluorideHydrogen

A process is disclosed for the manufacture of CF3CH2CHF2 and CF3CHFCH2F. The process involves (a) reacting hydrogen fluoride, chlorine, and at least one halopropene of the formula CX3CCI═CCIX (where each X is independently F or CI) to produce a product including both CF3CCI2CCIF2 and CF3CCIFCCI2F; (b) reacting CF3CCI2CCIF2 and CF3CCIFCCI2F produced in (a) with hydrogen to produce a product including both CF3CH2CHF2, and CF3CHFCH2F; and (c) recovering CF3CH2CHF2 and CF3CHFCH2F from the product produced in (b). In (a), the CF3CCI2CF3 and CF3CCIFCCIF2 are produced in the presence of a chlorofluorination catalyst including (i) a crystalline alpha-chromium oxide where at least 0.05 atom % of the chromium atoms in the alpha-chromium oxide lattice are replaced by divalent copper, and / or (ii) a chromium-containing composition of (i) which has been treated with a fluorinating agent.

Owner:EI DU PONT DE NEMOURS & CO

Process for producing 2-chloro-3,3,3-trifluoropropene

ActiveUS20140249336A1High yieldReduce catalytic activityPreparation by hydrogen halide split-offPreparation by halogen replacementHydrogen fluorideGas phase

This invention provides a process for producing 2-chloro-3,3,3-trifluoropropene, comprising: reacting anhydrous hydrogen fluoride with at least one chlorine-containing compound selected from the group consisting of chloropropanes and chloropropenes represented by specific formulas in a gas phase in the presence of a chromium atom-containing fluorination catalyst while heating, the reaction being carried out in the presence of molecular chlorine or with a water content in the reaction system of 300 ppm or less. This invention enables suppression of catalyst deterioration and efficient production of 2-chloro-3,3,3-trifluoropropene in a simple and economically advantageous manner on an industrial scale.

Owner:DAIKIN IND LTD

High-nickel eutectic high-entropy alloy powder for additive manufacturing and preparation method of high-nickel eutectic high-entropy alloy powder

PendingCN111519078AReduce inclusionsAvoid defectsMetallic material coating processesHigh entropy alloysBoron atom

The invention relates to a high-nickel eutectic high-entropy alloy powder for additive manufacturing and a preparation method of the high-nickel eutectic high-entropy alloy powder. The high-nickel eutectic high-entropy alloy powder mainly comprises aluminum, iron, chromium, cobalt, nickel, silicon and boron elements, wherein the mole ratio of aluminum atoms is 0.5-1.5, the mole ratio of iron atomsis 1.0-1.5, the mole ratio of chromium atoms is 0.8-1.5, the mole ratio of cobalt atoms is 0.5-1.0, the mole ratio of nickel atoms is 1.0-2.5, the mole ratio of silicon atoms is 0-0.05, and the moleratio of boron atoms is 0-0.05. The preparation method of the powder includes the following steps that 1, a high-entropy master alloy is prepared by using a vacuum induction smelting furnace; and 2, the high-entropy alloy powder is prepared by using a crucible-free induction melting atomization furnace. The high-entropy alloy powder prepared by the preparation method is spherical or nearly spherical to form a eutectic structure, so that burning loss of low-melting-point elements and component segregation of the multi-element alloy are reduced, and rapid and precise manufacture and remanufacturing repair of high-temperature-resistant special parts can be effectively achieved. The high-nickel eutectic high-entropy alloy powder avoids the problems of low strength or poor plasticity of a traditional single-phase high-entropy alloy material.

Owner:ZHEJIANG ASIA GENERAL SOLDERING & BRAZING MATERIAL

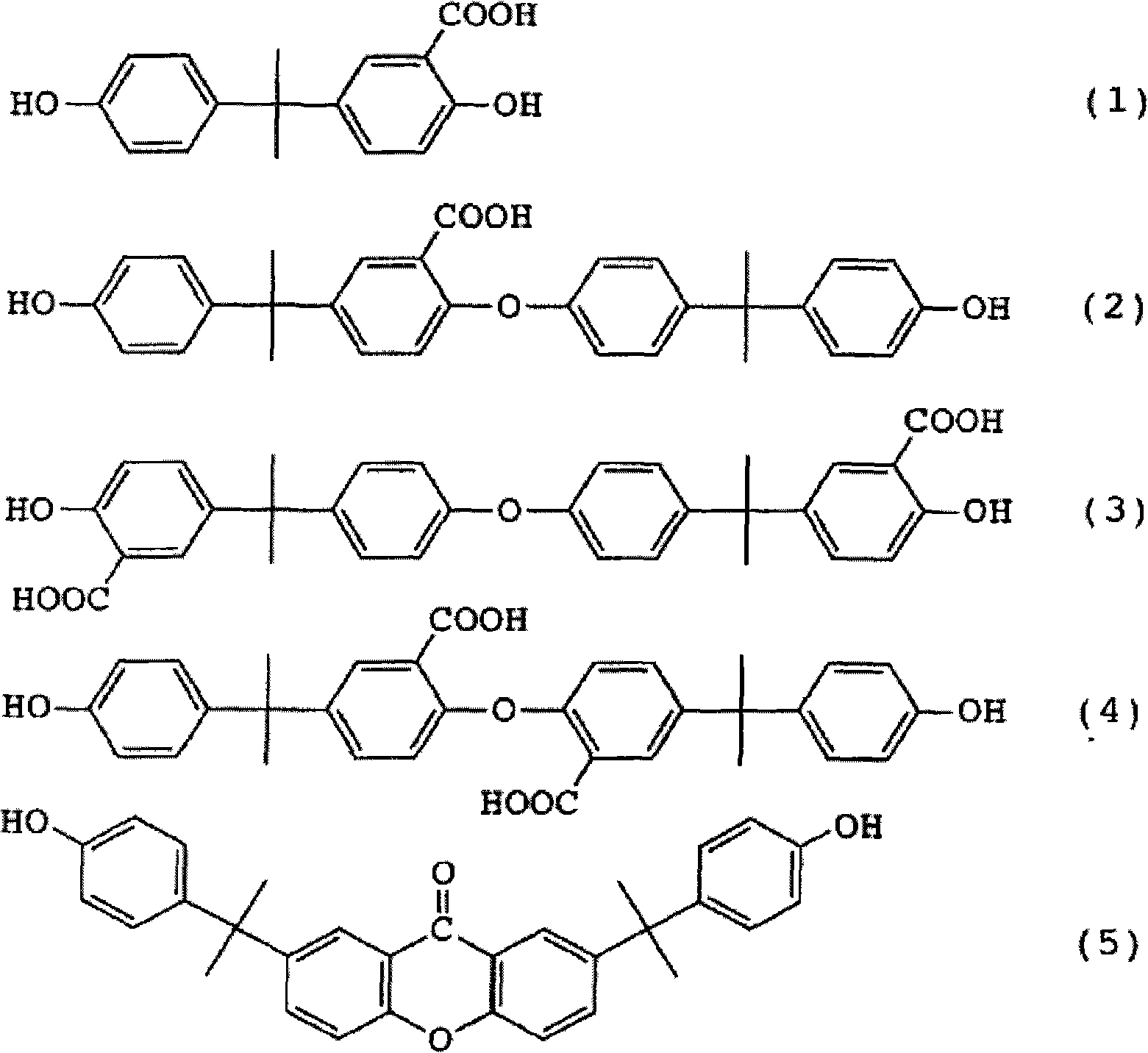

Charge control agent composition and toner utilizing the same

InactiveUS20090104554A1Excellent rising in electrostatic chargeHigh charge-imparting effectDevelopersPhotopigmentEngineering

The present invention provides a modified charge control agent composition exhibiting a high charge-imparting effect, and an electrostatic image developing toner containing such a charge control agent composition and having a high electrostatic charge amount and an environmental stability.A composition comprising a metal compound (A) of aromatic hydroxycarboxylic acid having an aromatic hydroxycarboxylic acid bonded with a metal atom selected from a zirconium atom, a calcium atom, an aluminum atom, a chromium atom, a boron atom and a zinc atom via at least any of ionic bond, covalent bond and coordinate bond; and at least one inorganic pigment (B), wherein the pigment (B) is contained in an amount of from 1 to 20 parts by mass in 100 parts by mass of the composition.

Owner:HODOGOYA CHEMICAL CO LTD

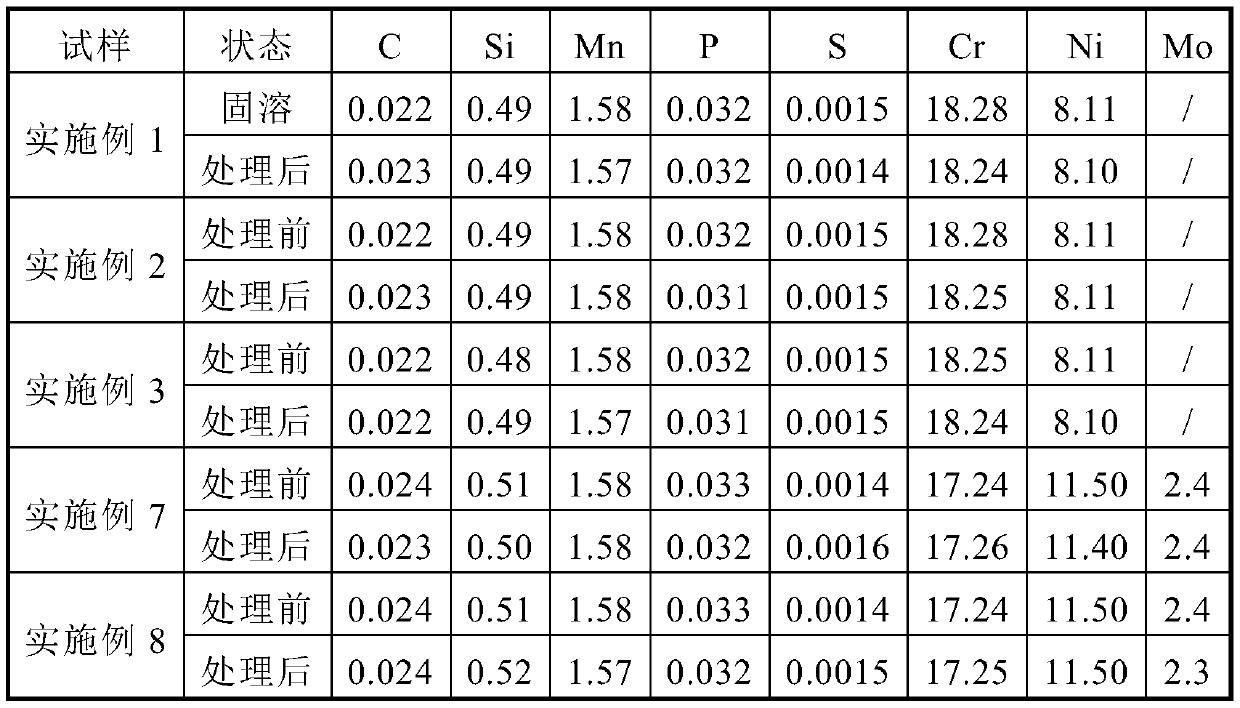

Method for improving intergranular corrosion resistance capacity of austenitic stainless steel

The invention provides a method for improving the intergranular corrosion resistance capacity of austenitic stainless steel. The method comprises the following steps that sensitization treatment is carried out, specifically, heating treatment and sensitization treatment are carried out on the austenitic stainless steel, so that chromium carbide is separated out between crystal particles, and the sensitized stainless steel is obtained; the sensitized stainless steel is continuously heated to 880 DEG C-950 DEG C through atomic diffusion treatment, and the stainless steel is subjected to heat preservation; and then the stainless steel is cooled to the room temperature. According to the method, the chromium carbide is separated out between the crystal particles of the austenitic stainless steel through sensitization treatment firstly, so that the content of chromium between the crystal particles is low; then chromium atoms in the austenitic stainless steel crystal particles are diffused tothe crystal boundary through atomic diffusion treatment, so that the intergranular barren chromium phenomenon is eliminated, and the intergranular corrosion resistance is achieved in a stable state;and the method has the advantages that the heating temperature is low, the fuel consumption is low, the thermal forming process does not need to avoid a sensitization region, the equipment requirementis low, normalizing treatment can be carried out with a carbon steel material at the same time, the cost is low, and chemical components of an austenitic stainless steel material do not need to be changed.

Owner:HENAN SHENZHOU PRECISION MFG CO LTD

Monatomic catalyst and application thereof

PendingCN112156802AIncrease confusionIncrease entropyElectrolysis componentsCatalyst activation/preparationPtru catalystPhysical chemistry

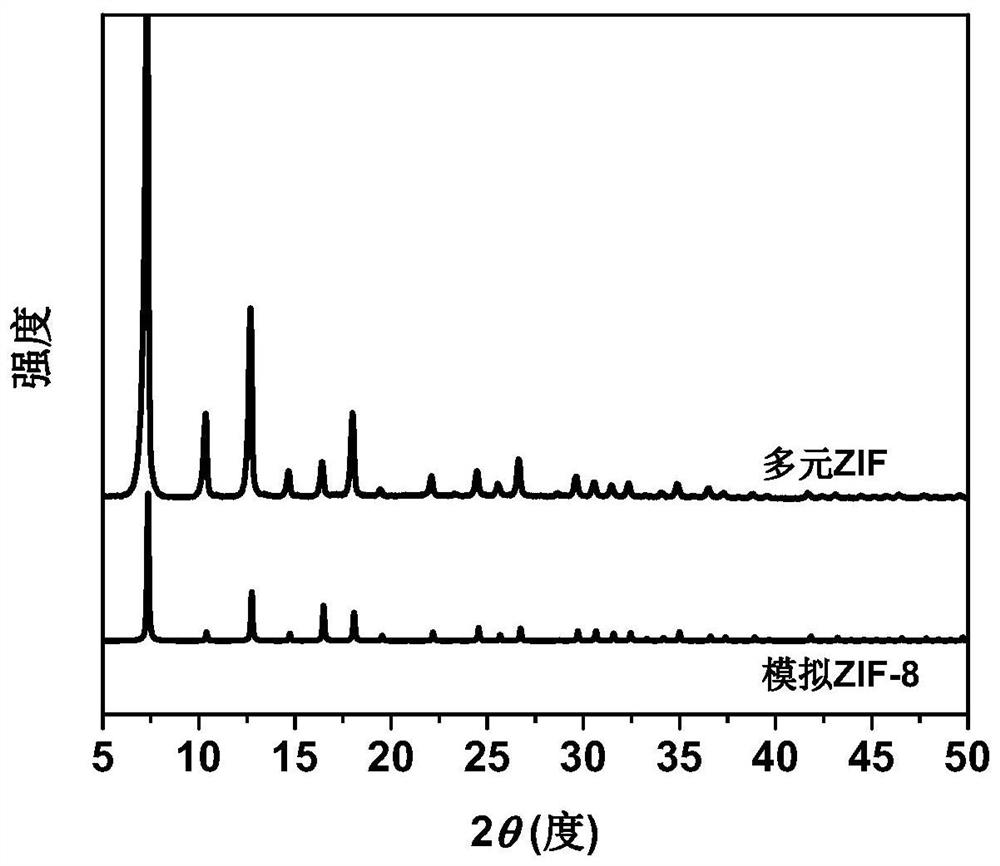

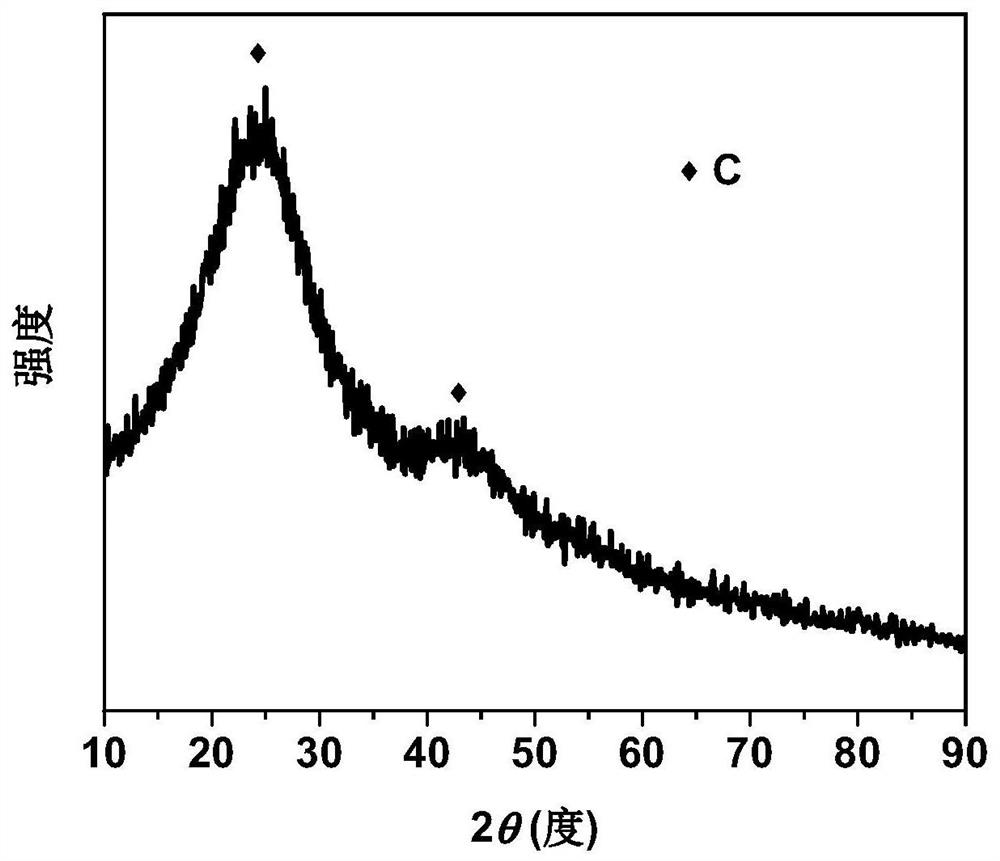

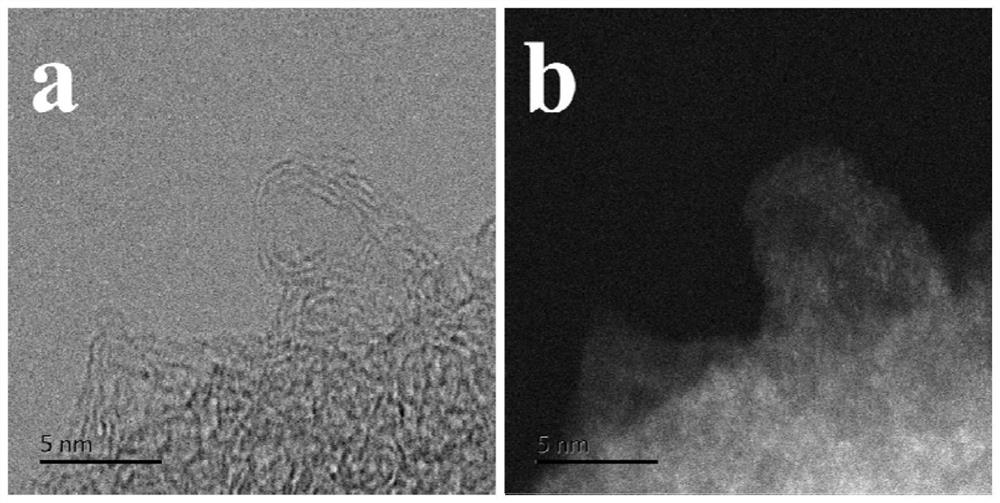

The invention relates to the technical field of catalyst preparation, in particular to a monatomic catalyst and application thereof. The monatomic catalyst is a nitrogen-doped carbon skeleton loaded with metal atoms, wherein the metal atoms comprise at least five of chromium atoms, manganese atoms, iron atoms, cobalt atoms, nickel atoms, copper atoms, zinc atoms and cadmium atoms; a nitrogen-dopedcarbon skeleton is composed of carbon atoms and nitrogen atoms. The at least five monatomic sites are disorderly distributed on the MOF-derived nitrogen-doped carbon skeleton, so that the disorder degree of the system is increased, and the entropy of the system is increased From the perspective of thermodynamics, the high-entropy monatomic catalyst provided by the invention is more beneficial toimproving the overall structural stability of the system.

Owner:SUZHOU ADVANCED MATERIALS CO LTD

Process for the preparation of 1,1,1,3,3-pentafluoropropane and 1,1,1,2,3-pentafluoropropane

InactiveUS7659435B2Preparation by dehalogenationPreparation by halogen halide additionPtru catalystCarbon Chloride

A process is disclosed for the manufacture of CF3CH2CHF2 and CF3CHFCH2F. The process involves (a) reacting hydrogen fluoride, chlorine, and at least one halopropene of the formula CX3CCl═CClX (where each X is independently F or Cl) to produce a product including both CF3CCl2CClF2 and CF3CClFCCl2F; (b) reacting CF3CCl2CClF2 and CF3CClFCCl2F produced in (a) with hydrogen to produce a product including both CF3CH2CHF2, and CF3CHFCH2F; and (c) recovering CF3CH2CHF2 and CF3CHFCH2F from the product produced in (b). In (a), the CF3CCl2CF3 and CF3CClFCClF2 are produced in the presence of a chlorofluorination catalyst including (i) a crystalline alpha-chromium oxide where at least 0.05 atom % of the chromium atoms in the alpha-chromium oxide lattice are replaced by divalent copper, and / or (ii) a chromium-containing composition of (i) which has been treated with a fluorinating agent.

Owner:EI DU PONT DE NEMOURS & CO

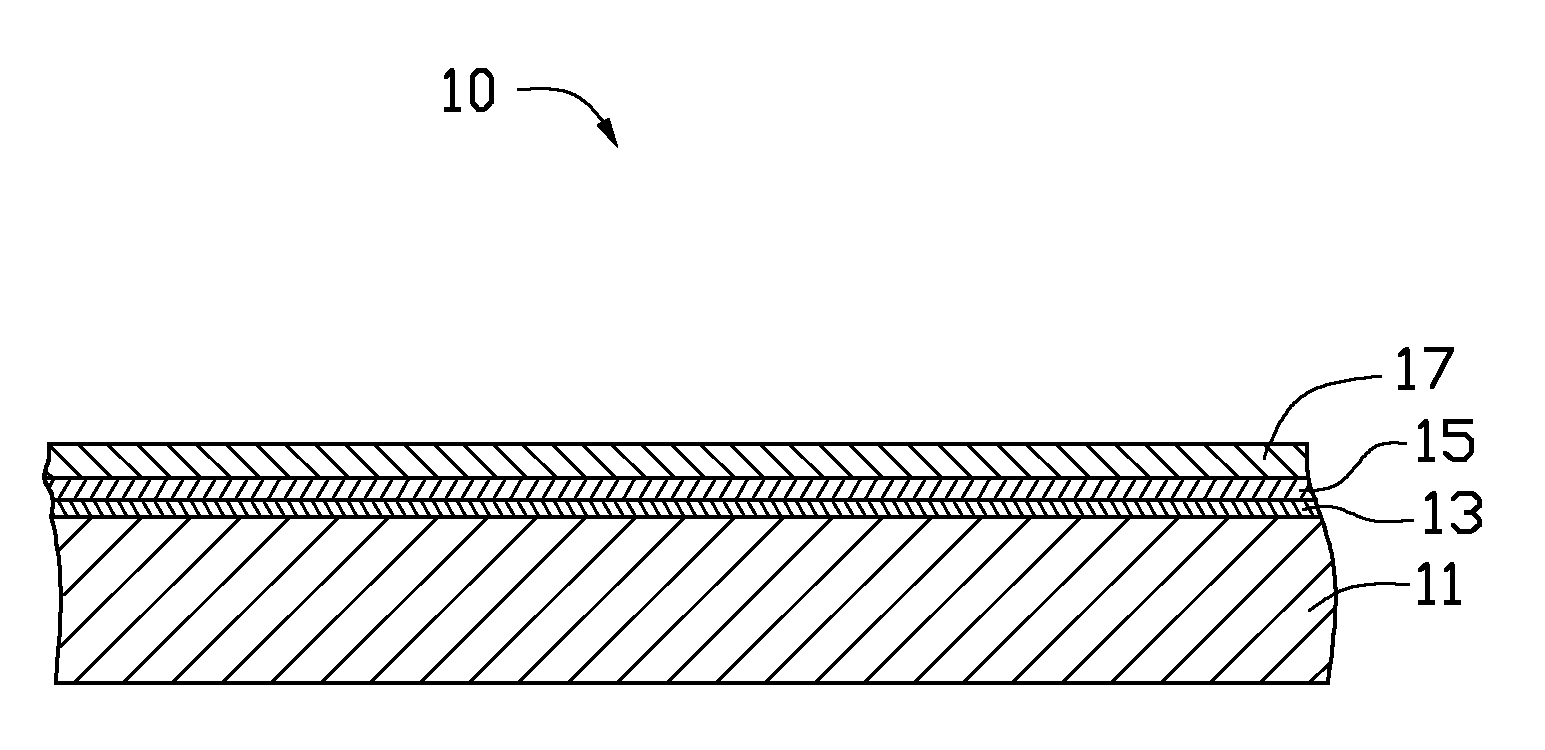

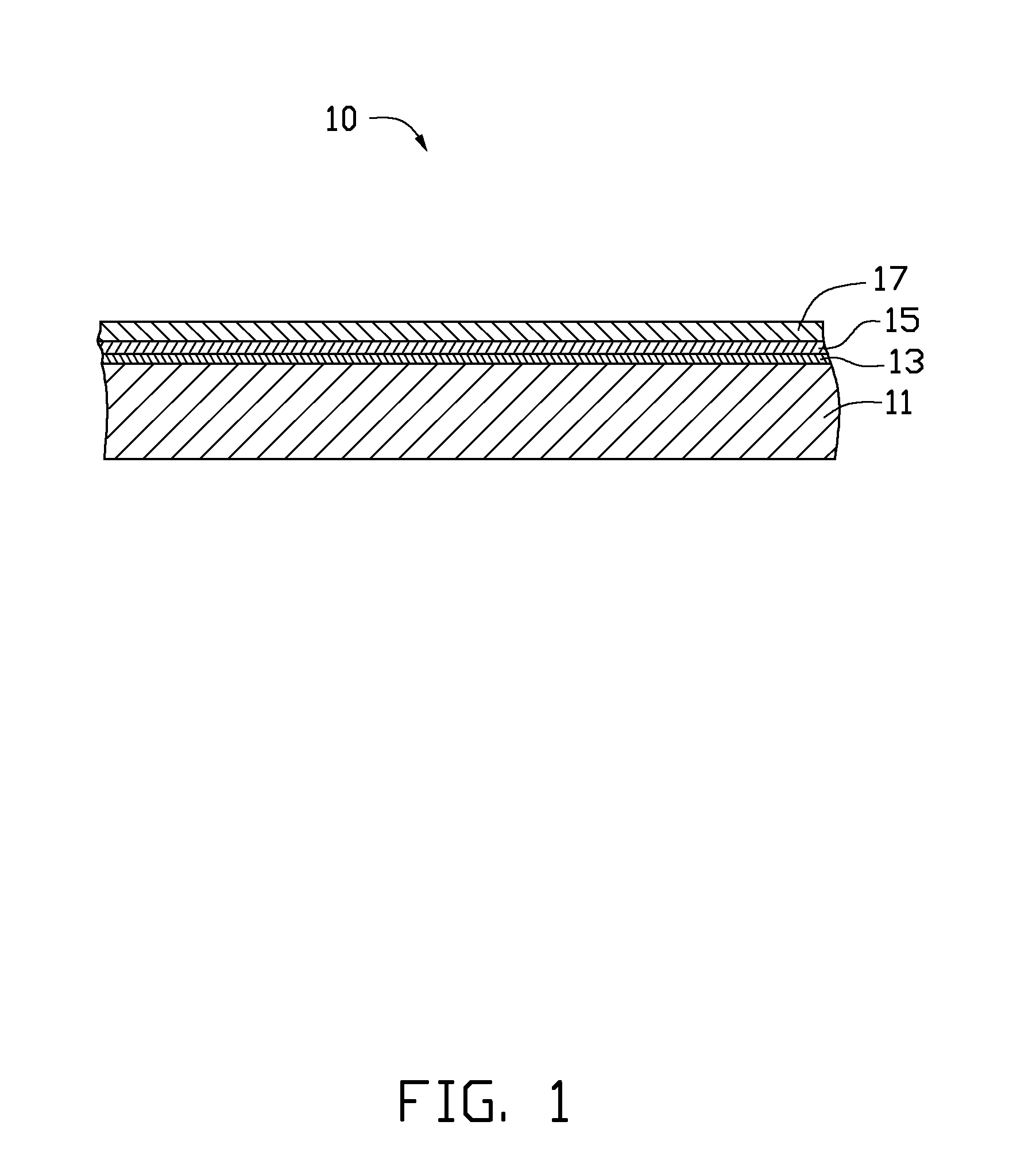

Coated article

A coated article includes a substrate and a color layer formed on the substrate. The color layer is a chromium-aluminum-silicon layer containing chromium atoms, aluminum atoms and silicon atoms. The color layer has an L* value between about 25 to about 28, an a* value between about −1 to about −6, and a b* value between about −5 to about −9 in the CIE L*a*b* (CIE LAB) color space. A method for making the coated article is also described.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD +1

Process for the preparation of 1,1,3,3,3-pentafluoropropene and 1,2,3,3,3-pentafluoropropene

InactiveUS8017817B2Preparation by dehalogenationPreparation by hydrogen halide split-offCopperChemistry

A process for the manufacture of CF3CH═CF2 and CF3CF═CHF is disclosed. The process involves (a) reacting HF and chlorine and at least one halopropene of the formula CX3CCI═CCIX (where each X is independently F or Cl) to produce a product including both CF3CCI2CF3 and CF3CCIFCCIF2; (b) reacting CF3CCI2CF3 and CF3CCIFCCIF2 produced in (a) with hydrogen to produce a product including both CF3CH2CF3 and CF3CHFCHF2; (c) dehydrofluorinating CF3CH2CF3 and CF3CHFCHF2 produced in (b) to produce a product including both CF3CH═CF2 and CF3CF═CHF; and (d) recovering CF3CH═CF2 and CF3CF═CHF from the product produced in (c). In (a), both CF3CCI2CF3 and CF3CCIFCCIF2 are produced in the presence of a chlorofluorination catalyst consisting of (i) compositions comprising a crystalline alpha-chromium oxide where at least 0.05 atom % of the chromium atoms in the alpha-chromium oxide lattice are replaced by copper, and (H) compositions of (i) which have been treated with a fluorinating agent.

Owner:EI DU PONT DE NEMOURS & CO

High-temperature resistant seamless austenitic stainless steel pipe and preparation method thereof

The invention relates to a high-temperature resistant seamless austenitic stainless steel pipe and a preparation method thereof. The pipe comprises the following elements in percentage by weight: not more than 0.12% of C, not more than 1.5% of Mn, not more than 0.2% of Cu, 1.70 to 2.10% of Si, not more than 0.035% of P, not more than 0.005% of S, 23 to 26% of Cr, 18 to 22% of Ni, and the balance being Fe. The preparation method comprises the following steps: (a) hot rolling and punching; (b) first acid washing and inspection; (c) lubricating; (d) cold drawing and cold rolling; (e) second acid washing; (f) heat treatment; (g) third acid washing and inspection. The contents of chromium and nickel of the provided pipe are high, and the sizes of the chromium atom and nickel atom are different from that of iron atom, so the lattice is deformed by the chromium and nickel, at the same time the tissue is enhanced, and thus the steel pipe has a high recrystallization temperature. Furthermore, the silicon is added to properly enhance the mechanical performance and antioxidant property of steel.

Owner:SUZHOU GOLDEN WAY STEEL TUBE

Process for the preparation of 1,3,3,3-tetrafluoropropene and/or 1,1,3,3,3-pentafluoropropene

InactiveUS7663007B2Preparation by dehalogenationPreparation by hydrogen halide split-off1,3,3,3-TetrafluoropropeneCopper

A process for the manufacture of CF3CH═CHF and / or CF3CH═CF2 is disclosed. The process involves (a) reacting HF and at least one halopropene of the formula CX3CCI═CCIX (where each X is independently F or CI) to produce a product including both CF3CCI═CF2 and CF3CHCICF3; (b) reacting CF3CCI═CF2 and / or CF3CHCICF3 produced in (a) with hydrogen to produce a product including CF3CH2CHF2 and / or CF3CH2CF3; (c) dehydrofluorinating CF3CH2CHF2 and / or CF3CH2CF3 produced in (b) to produce a product comprising CF3CH═CHF and / or CF3CH═CF2; and (d) recovering CF3CH═CHF and / or CF3CH═CF2 from the product produced in (c). In (a), the CF3CCI═CF2 and CF3CHCICF3 are produced in the presence of a fluorination catalyst comprising at least one chromium-containing component selected from (i) a crystalline alpha-chromium oxide where at least 0.05 atom % of the chromium atoms in the alpha-chromium oxide lattice are replaced by divalent copper, and (ii) a chromium-containing composition of (i) which has been treated with a fluorinating agent.

Owner:EI DU PONT DE NEMOURS & CO

Processes for the preparation of 2-chloro-1,1,1,2,3,3,3-heptafluoropropane, hexafluoropropene and 1,1,1,2,3,3,3-heptafluoropropane

InactiveUS20050222471A1Preparation by dehalogenationPreparation by hydrogen halide split-offCrystalline oxideGas phase

A process for the preparation of 2-chloro-1,1,1,3,3,3-heptafluoropropane is disclosed which involves (a) contacting a mixture comprising hydrogen fluoride, chlorine, and at least one starting material selected from the group consisting of halopropenes of the formula CX3CCl═CX2 and halopropanes of the formula the CX3CClYCX3, wherein each X is independently F or Cl, and Y is H, Cl or F (provided that the number of X and Y which are F totals no more than six) with a chlorofluorination catalyst in a reaction zone to produce a product mixture comprising CF3CClFCF3, HCl, HF, and underfluorinated halogenated hydrocarbon intermediates. The process is characterized by said chlorofluorination catalyst comprising at least one chromium-containing component selected from (i) a crystalline alpha-chromium oxide where at least 0.05 atom % of the chromium atoms in the alpha-chromium oxide lattice are replaced by nickel, trivalent cobalt or both nickel and trivalent cobalt, provided that no more than 2 atom % of the chromium atoms in the alpha-chromium oxide lattice are replaced by nickel and that the total amount of chromium atoms in the alpha-chromium oxide lattice that are replaced by nickel and trivalent cobalt is no more than 6 atom %, and (ii) a fluorinated crystalline oxide of (i). Also disclosed is a process for the manufacture of a mixture of HFC-227ea and hexafluoropropene by reacting a starting mixture comprising CFC-217ba and hydrogen in the vapor phase at an elevated temperature, optionally in the presence of a hydrogenation catalyst. This process involves preparing the CFC-217ba by the process described above.

Owner:EI DU PONT DE NEMOURS & CO

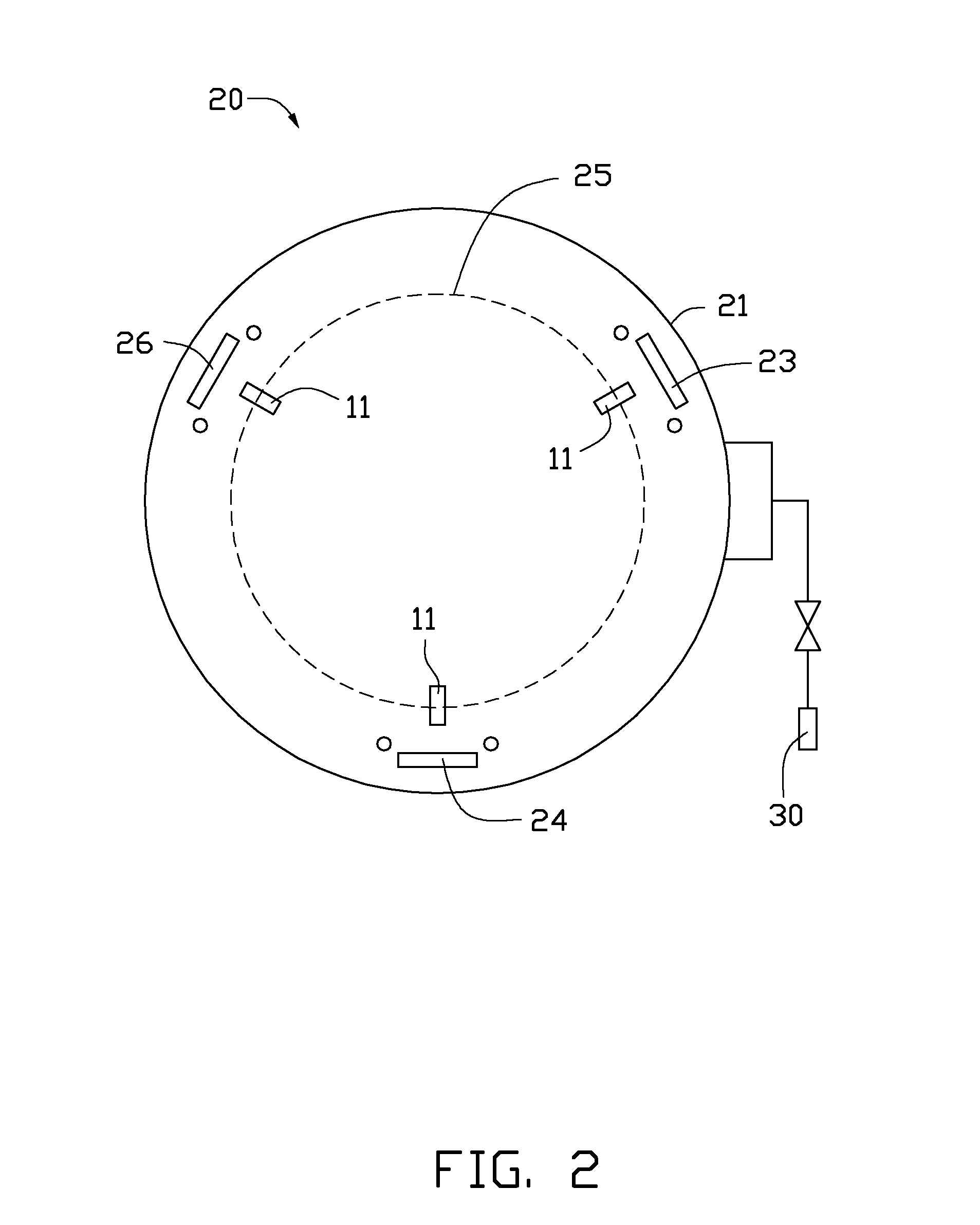

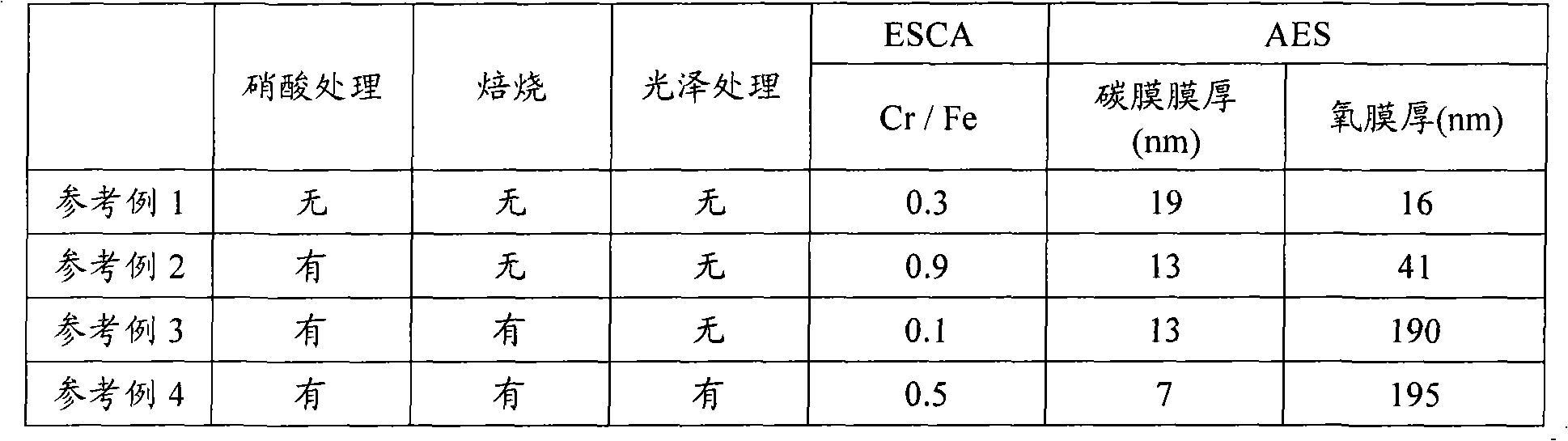

Process for production of aromatic polycarbonate resin

Disclosed is a process for producing an aromatic polycarbonate resin, which can prevent the deterioration of a product during the retention of the product in a filter, and which produces contaminants or phenol compounds in reduced amounts. In the production of a purified aromatic polycarbonate resin by treating a molten aromatic polycarbonate resin by using a polymer filter, the polymer filter to be used is a filter in which the ratio of the chromium atom concentration to the iron atom concentration (Cr / Fr ratio) on its outermost surface is 1.5 or more as measured by X-ray photoelectron spectroscopy. In one preferred embodiment, the polymer filter to be used is a filter having a carbon film as the outermost surface thereof and an oxide coating film, wherein the carbon film has a thickness of 10 nm or less and the oxide film has a depth-wise thickness of 100 nm or more both as measured by Auger electron spectroscopy.

Owner:MITSUBISHI RAYON CO LTD

CoCrPt-based sputtering target and method for production thereof

InactiveCN101495667AReduce in quantityImprove uniformityElectric discharge tubesVacuum evaporation coatingPlatinumLongest Diameter

Disclosed is a CoCrPt-based sputtering target which is reduced in the size and the quantity of a high-chromium particle having a high chromium atom content unevenly distributed in the sputtering target and therefore has increased target homogeneity, which is reduced in the formation of nodule or arcing, and which has a desired chemical composition. The CoCrPt-based sputtering target comprises cobalt, chromium, a ceramic material and platinum, wherein a high-chromium particle which has a high chromium atom content and is unevenly distributed in the sputtering target has a longest diameter of 40 [mu]m or less.

Owner:MITSUI MINING & SMELTING CO LTD

Reinforcing method for high-strength tire bead steel wire material and preparation method for tire bead steel wires

The invention provides a reinforcing method for high-strength tire bead steel wire material. According to the reinforcing method, on the condition of not changing the tensile strength and the carbon equivalent (Ceq) of the material, the content of carbon atoms is lowered to 0.74-0.78 wt% from 0.80-0.84 wt%, and the content of chromium atoms is increased to 0.20-0.30 wt% from 0.008 wt%. Thus, by lowering the content of carbon in raw material and adding chromium capable of refining pearlite lamellas, on the condition of the same carbon equivalent, the work hardening rate is increased, cementite dissolution in the cold-drawing process is restrained, and the twisting and layering problem of tire bead steel wires with the dependent variable epsilon being greater than or equal to 2.3 but smaller than or equal to 3.0 is solved; the mechanical property and the torsion property of the tire bead steel wires made of the material are improved, the cold-drawing limit is improved, the intermediate heat treatment process can be eliminated for partial thin-size and high-strength tire bead steel wires, and the production cost of the steel wires is greatly lowered.

Owner:JIANGSU XINGDA STEEL TYPE CORD

Process for the Preparation of 1,1,1,3,3-Penta-Fluoropropane and/or 1,1,1,3,3,3-Hexafluoropropane

InactiveUS20090137853A1Preparation by dehalogenationPreparation by hydrogen halide split-off1,1,1,3,3,3-HexafluoropropaneCopper

A process for the manufacture of CF3CH2CHF2 and / or CF3CH2CF3 is disclosed. The process involves (a) reacting HF and at least one halopropene of the formula CX3CCI═CCIX (where each X is independently F or Cl) to produce a product including both CF3CCI═CF2 and CF3CHCICF3; (b) reacting CF3CCI═CF2 and / or CF3CHCICF3 produced in (a) with hydrogen to produce a product including CF3CH2CHF2 and / or CF3CH2CF3; and (c) recovering CF3CH2CHF2 and / or CF3CH2CF3 from the product produced in (b). In (a), the CF3CCI═CF2 and CF3CHCICF3 are produced in the presence of a fluorination catalyst comprising at least one chromium-containing component selected from (i) a crystalline alpha-chromium oxide where at least 0.05 atom % of the chromium atoms in the alpha-chromium oxide lattice are replaced by divalent copper, and (ii) a chromium-containing composition of (i) which has been treated with a fluorinating agent.

Owner:EI DU PONT DE NEMOURS & CO

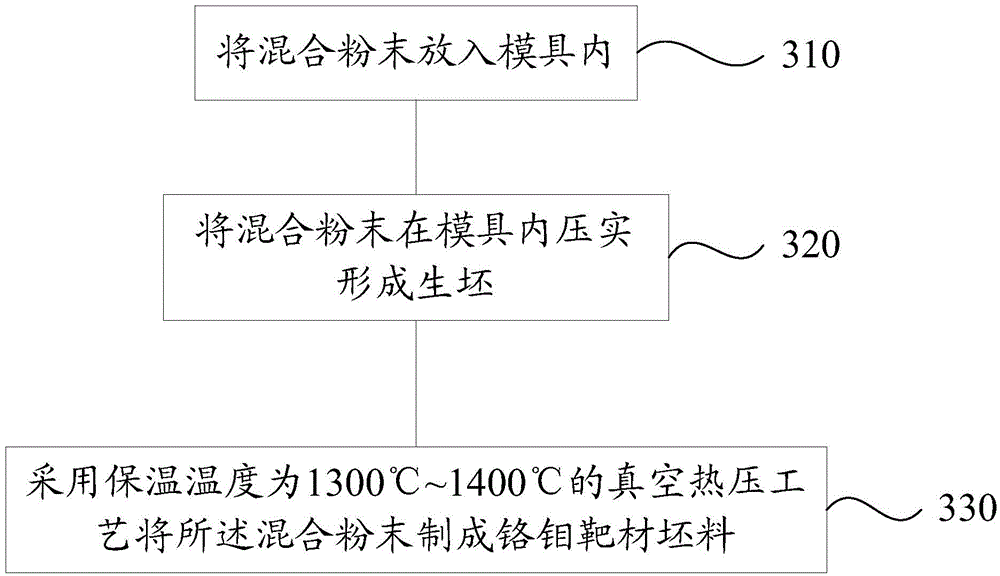

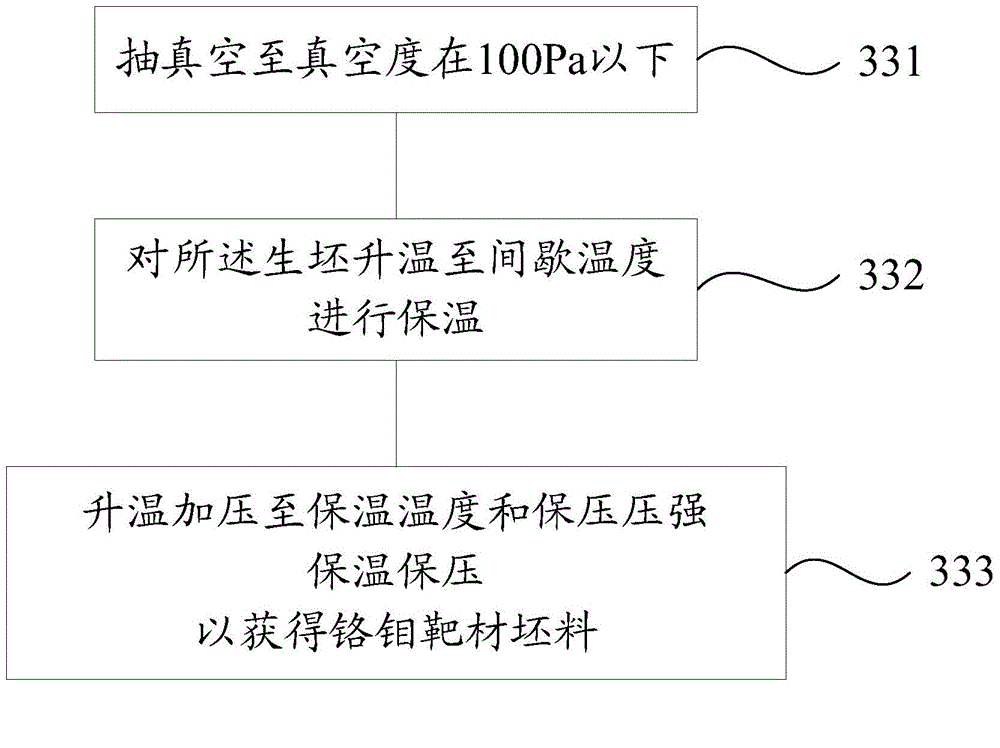

Manufacturing method for chromium-molybdenum target

InactiveCN106141190AImprove compactnessHigh strengthVacuum evaporation coatingSputtering coatingSputteringHigh density

A manufacturing method for a chromium-molybdenum target comprises the steps that chromium powder and molybdenum powder are provided; the chromium powder and the molybdenum powder are mixed, and mixed powder is formed; the mixed powder is manufactured into a chromium-molybdenum target blank through the vacuum hot-pressing technology in which the heat preservation temperature ranges from 1,300 DEG C to 1,400 DEG C; and the chromium-molybdenum target blank is manufactured into the chromium-molybdenum target. According to the manufacturing method, the chromium powder and the molybdenum powder which are mixed are manufactured into the chromium-molybdenum target through the vacuum hot-pressing technology, diffusion of chromium atoms and molybdenum atoms is facilitated at the heat preservation temperature ranging from 1,300 DEG C to 1,400 DEG C, and therefore the void ratio in the manufactured chromium-molybdenum target can be effectively reduced, and the density and strength of the target are improved. Thus, the high-density chromium-molybdenum target with the density larger than or equal to 99% can be obtained through the manufacturing method, a microstructure of the obtained chromium-molybdenum target is uniform, and the requirements of magnetron sputtering for the purity and density of the target can be met.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

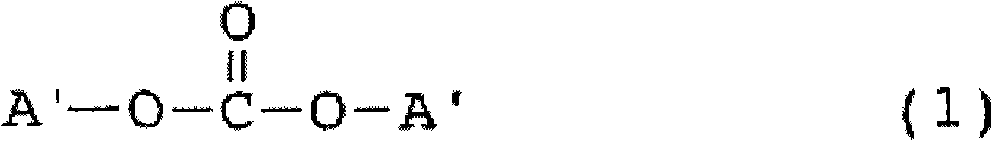

Ethylene polymer, catalyst for producing thereof and method for producing thereof

ActiveUS20050288459A1Improve creep resistanceSilicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsPolymer scienceCalcination

A method for producing an ethylene polymer which comprises continuously polymerizing ethylene alone or copolymerizing ethylene and a C3-C8 α-olefin by multistage polymerization in a plurality of polymerization reactors connected in series in the presence of a chromium catalyst having at least a part of chromium atoms converted to hexavalent chromium carried on an inorganic oxide carrier by calcination-activating in a non-reducing atmosphere, wherein an organoaluminum compound of the formula (1): (R1)xAl(OR2)y(OSiR3R4R5)z (1) (in the above formula, R1 and R2 may be the same or different, each represents a C1-C18 alkyl group or a C6-C18 aryl group, R3, R4 and R5 may be the same or different, each represents a C1-C18 alkyl group or a C6-C18 aryl group, R1, OR2 and OSiR3R4R5 respectively may be the same or different when each has a plurality of kinds, and x, y and z are respectively 0≦x≦3, 0≦y<3, 0≦z<3, and x+y+z=3) is introduced at least one or all of the polymerization reactors.

Owner:JAPAN POLYETHTYLENE

Method for producing fluorine-containing olefin

ActiveUS20160052841A1High selectivityModerate starting material conversionPreparation by halogen replacementHydrogen fluorideFluorine containing

The present invention provides a method for producing a fluorine-containing olefin, the method comprising reacting a chlorine-containing compound represented by a specific formula with anhydrous hydrogen fluoride in the presence of a chromium atom-containing fluorination catalyst, the reaction being carried out at a temperature within the range of 200 to 350° C. in the presence of 0.0001 to 0.03 mol of molecular chlorine per mol of the chlorine-containing compound. The present invention is capable of achieving the effect of suppressing catalyst deterioration, maintaining the starting material conversion and the target product selectivity within excellent ranges, and reducing adverse effects caused by the use of a large amount of non-condensable gas.

Owner:DAIKIN IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com