Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

113 results about "Atomic diffusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vacancy diffusion is a diffusion process whereby the random thermally-activated movement of atoms in a solid results in the net transport of atoms. For example, helium atoms inside a balloon can diffuse through the wall of the balloon and escape, resulting in the balloon slowly deflating. Other air molecules (e.g. oxygen, nitrogen) have lower mobilities and thus diffuse more slowly through the balloon wall. There is a concentration gradient in the balloon wall, because the balloon was initially filled with helium, and thus there is plenty of helium on the inside, but there is relatively little helium on the outside (helium is not a major component of air). The rate of transport is governed by the diffusivity and the concentration gradient.

Low-temperature doping processes for silicon wafer devices

InactiveUS20080000521A1Quality improvementImprove concentrationPolycrystalline material growthFinal product manufactureGas phaseSystem configuration

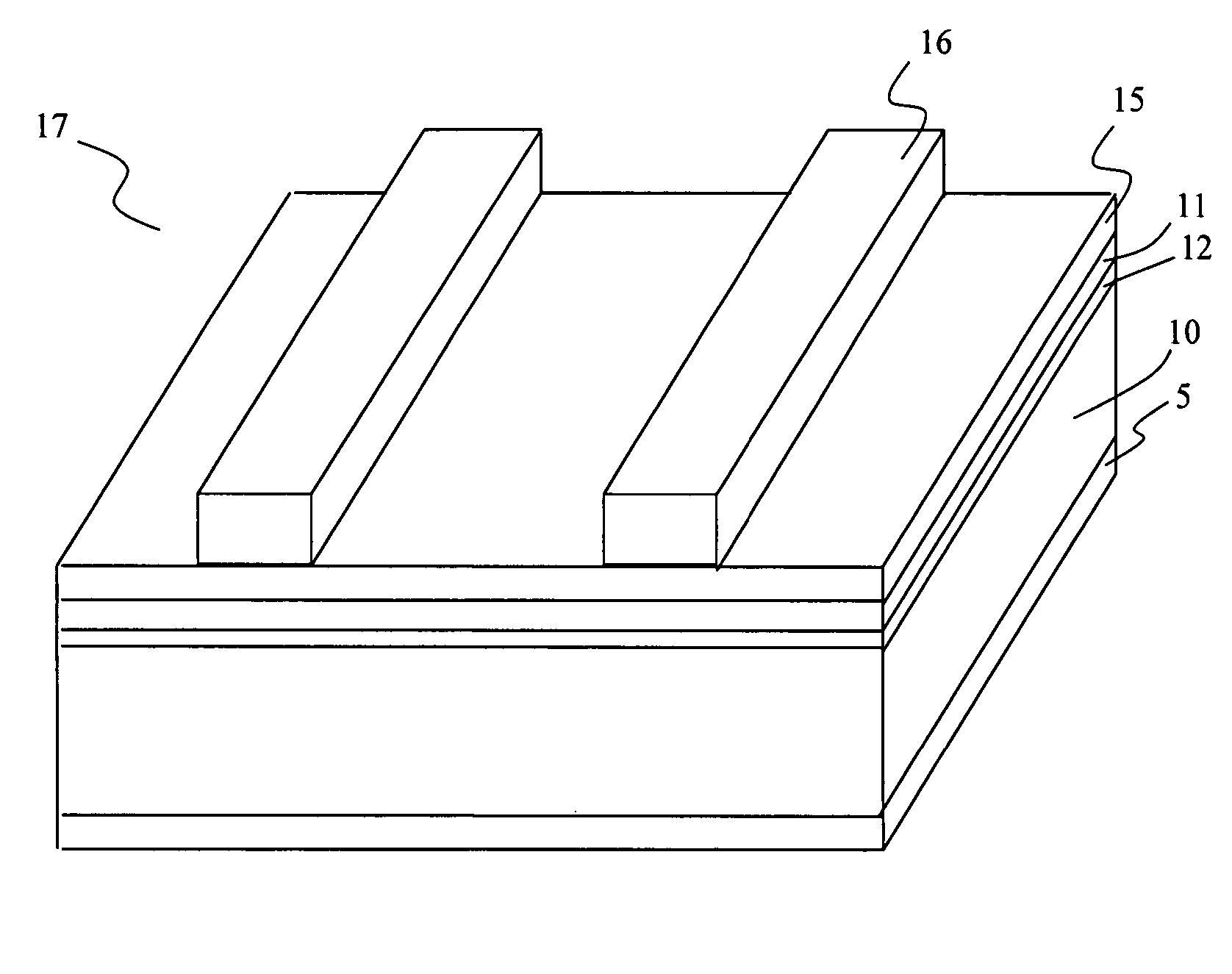

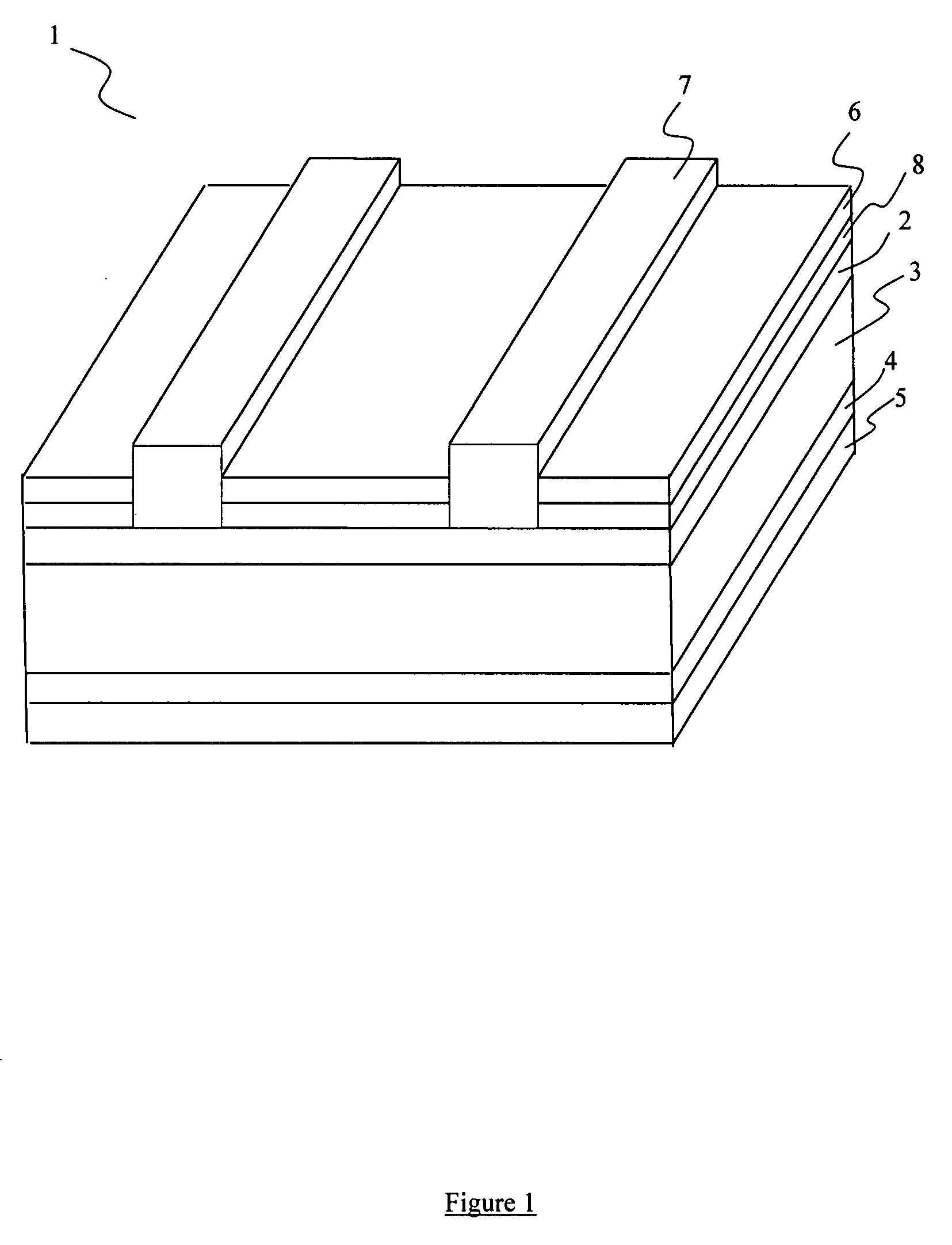

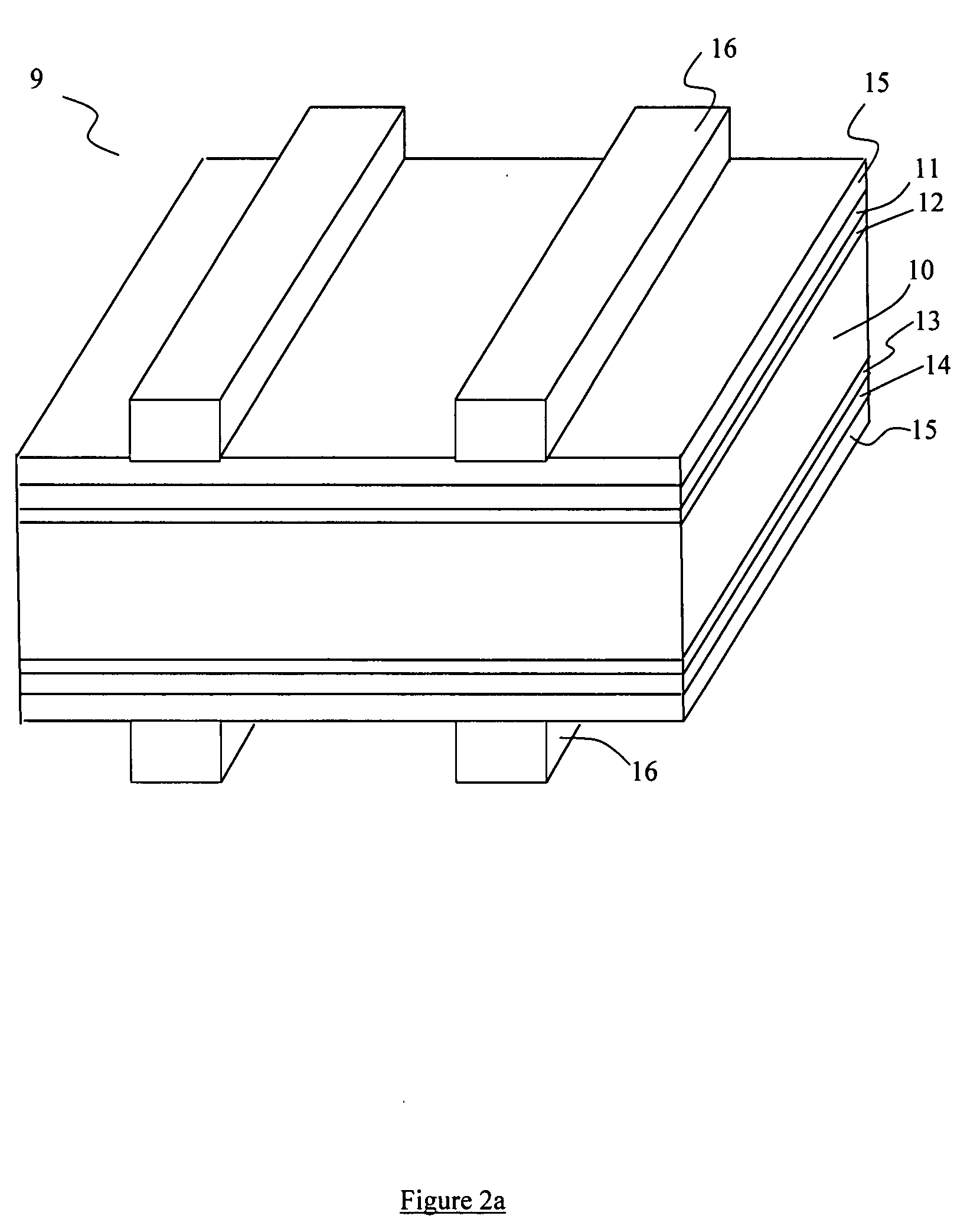

A low temperature method and system configuration for depositing a doped silicon layer on a silicon substrate of a selected grade. The silicon substrate for functioning as a light absorber and the doped silicon layer for functioning as an emitter. The method comprises the acts of: positioning the silicon substrate in a chamber suitable for chemical vapour deposition of the doped silicon layer on the silicon substrate, an external surface of the silicon substrate suitable for promoting crystalline film growth; using a plurality of process parameters for adjusting growth of the doped silicon layer, the plurality of process parameters including a first process parameter of a process temperature for inhibiting diffusion of dopant atoms into the external surface of the silicon substrate, and a second process parameter of a hydrogen dilution level for providing excess hydrogen atoms to affect a layer crystallinity of the atomic structure of the doped silicon layer; exposing the external surface of the silicon substrate in the chamber to a vapour at appropriate ambient chemical vapour deposition conditions, the vapour including silicon atoms, dopant atoms and the excess hydrogen atoms, the atoms for use in growing the doped silicon layer; and originating growth of the doped silicon layer on the external surface to form an interface between the doped silicon layer and the silicon substrate, such that the doped silicon layer includes first atomic structural regions having a higher quality of the layer crystallinity next to the interface with adjacent second atomic structural regions having a lower quality of the layer crystallinity with increasing concentrations of crystal defects for increasing thickness of the doped silicon layer from the interface. The resultant silicon substrate and doped layer (or thin film) can be used in solar cell manufacturing.

Owner:SIVOTHTHAMAN SIVA +1

Cold-rolled double-surface stainless steel composite plate having excellent comprehensive performances and manufacturing method

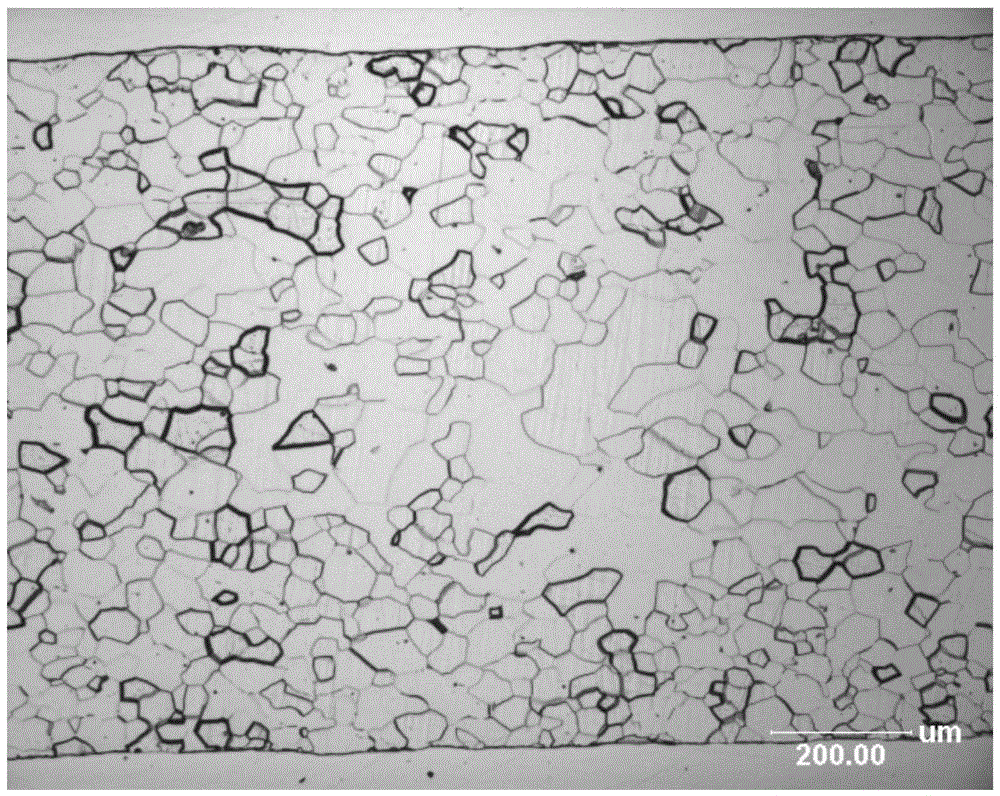

ActiveCN105296854AUniform tissueNo surface yield pattern defectsMetal rolling arrangementsRoom temperatureComposite plate

The invention discloses a cold-rolled double-surface stainless steel composite plate having excellent comprehensive performances and a manufacturing method. The composite plate comprises a basal plate and a compound plate, wherein the upper and lower surfaces of the basal plate are wholly and continuously coated with the compound plate; the basal plate and the compound plate are formed to the cold-rolled double-surface stainless steel composite plate through an atomic diffusion metallurgical bonding method, wherein the basal plate is ultralow carbon aluminum killed steel; and the compound plate is 304 type austenitic stainless steel. The prepared cold-rolled double-surface stainless steel composite plate is excellent in surface quality and uniform in base material structure of carbon steel, has the room-temperature elongation above 45%, is excellent in corrosion resistance and stable in material performance, has the use performance of pure stainless steel, can largely reduce the cost, can serve as a substitute good of 304 stainless steel, and is widely applied to decoration panels and fields with higher forming requirements.

Owner:BAOSTEEL DESHENG STAINLESS STEEL +1

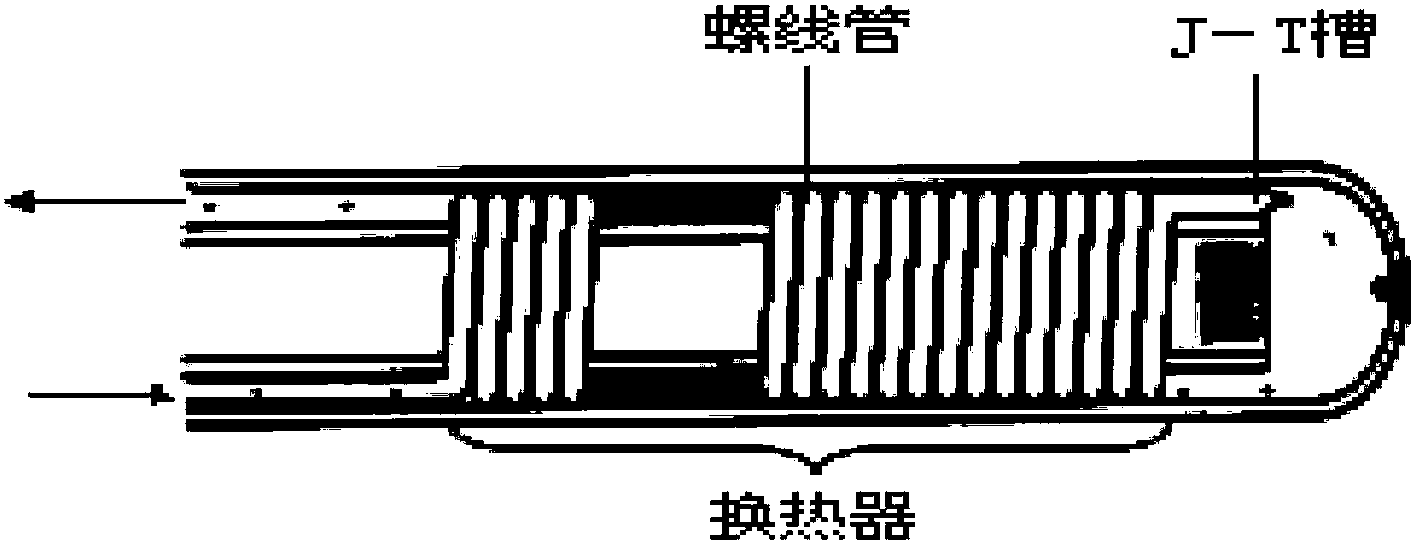

Refrigerator

InactiveCN103423911AImprove cooling effectImprove compactnessMechanical apparatusCompression machinesEngineeringHigh pressure

A refrigerator based on micro-channel regenerative heat exchange technology and Joule-Thomson effect is machined by the aid of atomic diffusion fusion welding technology and comprises an inlet-outlet portion, a regenerative heat exchange portion, a throttling portion and an evaporating cavity. The inlet-outlet portion is provided with an inlet and an outlet, the regenerative heat exchange portion comprises at least one high-temperature layer and at least one low-temperature layer which are pairwise adjacent, each layer is provided with at least one channel, high-temperature and high-pressure gas enters the channels of the high-temperature layers from the inlet, then enters the throttling portion and is cooled in a throttling manner once, and then the high-temperature and high-pressure gas flows to the evaporating cavity with a large space and accordingly is cooled in the throttling manner again. Owing to throttling and cooling, part of the gas is condensed into liquid, the rest gas is low-temperature and low-pressure gas, the liquid and the low-temperature and low-pressure gas are mixed together to form a low-temperature and low-pressure gas liquid mixture, the evaporating cavity keeps the low temperature by the aid of the low-temperature and low-pressure gas liquid mixture, a high-temperature device connected with the evaporating cavity is cooled by the evaporating cavity, and the gas in the evaporating cavity reflows into the channels of the low-temperature layers and is discharged from the outlet after exchanging heat with the high-temperature and high-pressure gas in the channels of the high-temperature layers adjacent to the low-temperature layers.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Processing method for manufacturing silver tungsten composite contact material

The invention discloses a processing method for manufacturing a silver tungsten composite contact material, which comprises the following steps: putting tungsten powder in a reaction vessel, adding water and a proper amount of reducing agents, slowly injecting a silver-ammonia complexing solution under stirring, cleaning silver tungsten coating powder to become neutral, drying the powder, performing uniform ball milling treatment by a high-energy bowl mill, performing distressing treatment of the silver tungsten powder, performing primary pressing and molding, performing presintering, infiltration sintering, and secondary pressing with the protection of reducing atmosphere to obtain the silver tungsten composite contact material. The invention has an advanced and simple process; the distribution of tungsten particles in a silver substrate is improved by a coating process based on a chemical plating principle; a high-energy bowl milling process is selected to allow the powder particlesto repeatedly generate cold welding and fractures, which causes atomic diffusion in the powder particles and improves the mechanical properties, physical properties, electrical properties, and the like of the material; a high temperature presintering process is adopted, which increases the material compactness, greatly optimizes the conductivity, reduces resistivity, and improves arc erosion resistance.

Owner:YANGZHOU LEYIN ALLOY TECH

Ndfeb permanent magnet material with high magnetic energy product and high coercivity and manufacturing method thereof

ActiveCN105957679ALow costSolve adhesionInorganic material magnetismSolid state diffusion coatingRare earthGraphite

The invention belongs to the technical field of permanent magnet materials, and claims a Ndfeb permanent magnet material with high magnetic energy product and high coercivity. Component of the Ndfeb permanent magnet material is RE1xRE2yFzBwMmHn, wherein RE1 is selected from one or more than two of Pr, Nd, Ho, Gd, La and Ce, RE2 is selected from one or two of Dy and Tb, B is selected from one or two of boron and carbon, M is selected from one or more than two of Al, Cu, Zr, Nb, Ga, Si, Mo and Ti, H is an oxygen element, the rest is F, and F is selected from one or more than two of transition elements Fe, Co and Ni; and a manufacturing method of the Ndfeb permanent magnet material is (1) sintering for preparing a blank, covering two sides of a base material with heavy rare earth plates, isolating the heavy rare earth plates from the base material with a molybdenum net, and placing the blank in a graphite material box after isolation; (2) performing deposition and diffusion under vacuum condition at high temperature; further performing solid-state atomic diffusion under vacuum condition at low temperature; (3) repeating the step (2) more than once.

Owner:ORIENT MAGNET TECH OMT

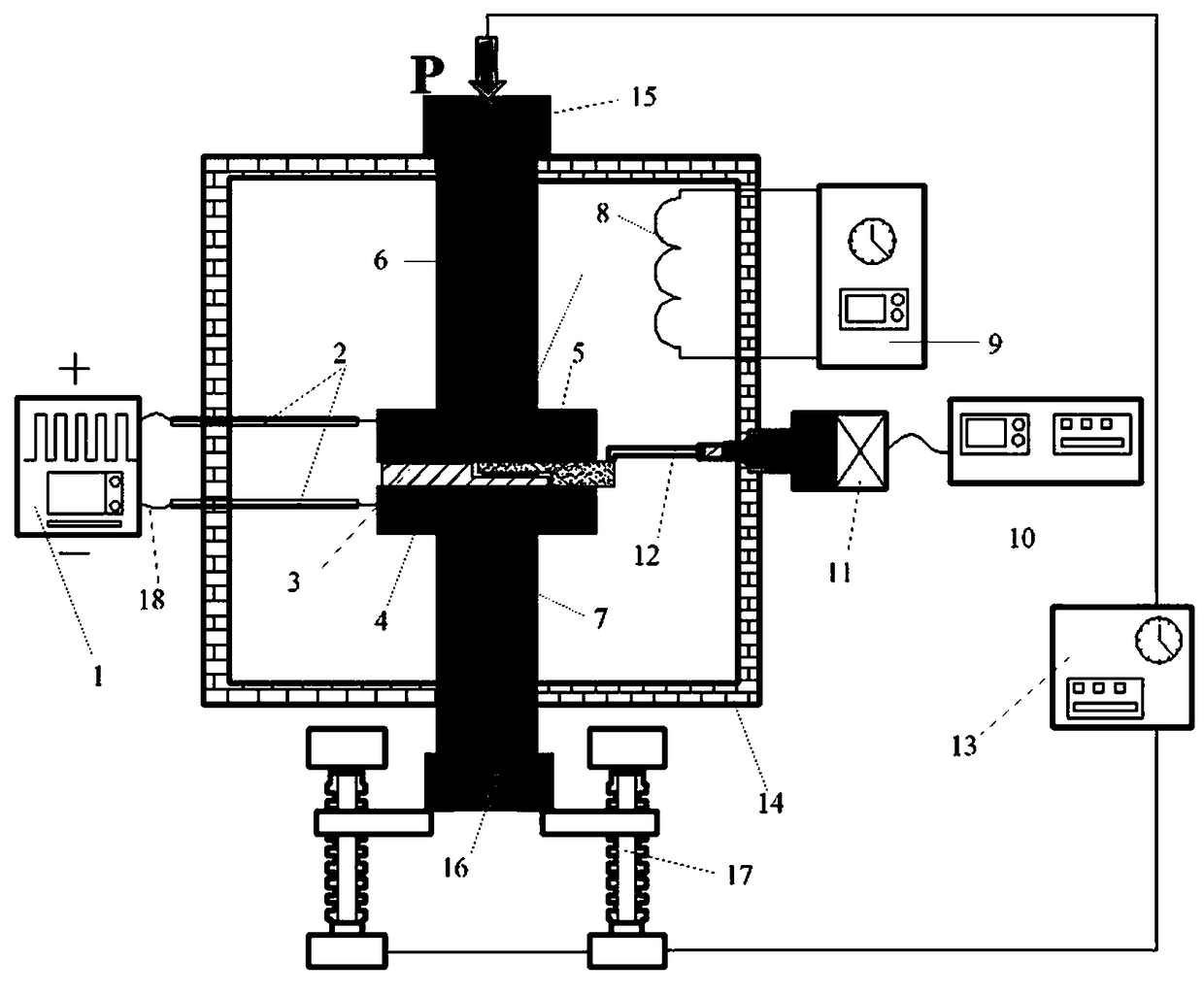

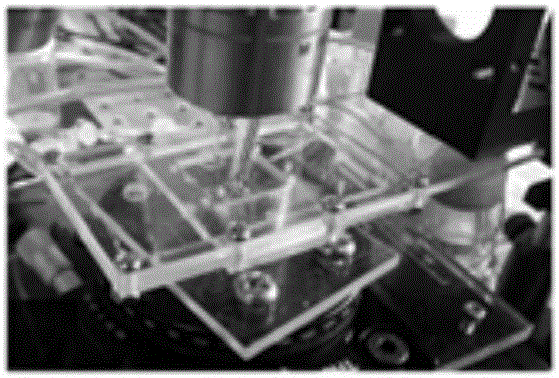

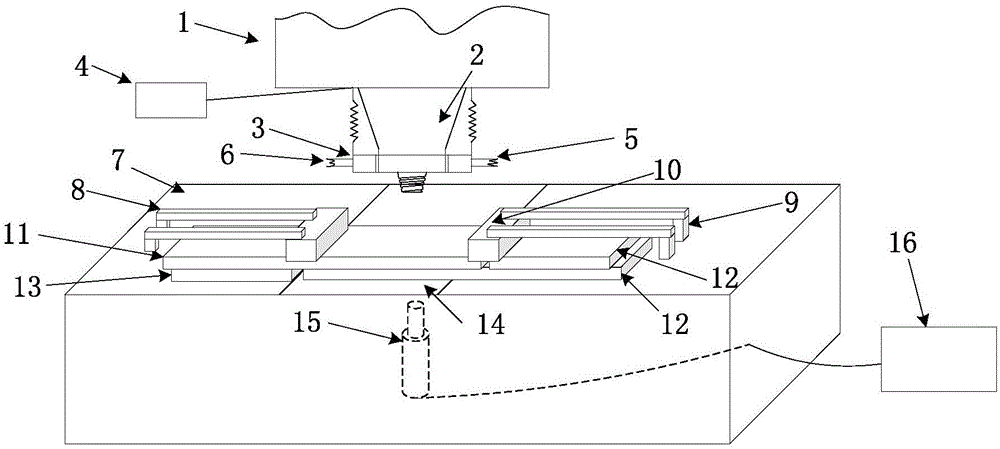

Synchronous bonding method for metal matrix composite material sintering assisted by pulsed electric field and ultrasonic field and device thereof

ActiveCN108890114ASevere thermal expansion effectChange growth characteristicsCharge treatment typeFurnace typesBond interfaceRadiant heat

The invention provides a synchronous bonding method for metal matrix composite material sintering assisted by pulsed electric field and an ultrasonic field and a device thereof. The invention discloses a method for connecting magnesium (or copper) matrix composite material with stainless steel while sintering, which is assisted by pulsed electric field and ultrasonic field, and a device for simultaneously sintering metal matrix composite material. The device of the method comprises an airtight heating furnace, a pulse current loading system, an ultrasonic load applying system, a pressure and lifting system, a sealed insulating pipe and other auxiliary devices. The remarkable advantage of the invention is that the sintering of the metal matrix composite material and the joining of the different materials are carried out simultaneously; Pulse current flowing through the experimental material induces interface resistance heat plasma spark heat sintering and bonding interface heating and cooling speed fast reducing external radiant heat reducing residual stress of the joint. Using the coupling function of pulsed electric field- ultrasonic field-pressure field, breaking the oxide film on the surface of reinforcing phase, sintering under atmospheric conditions, reducing the activation energy of atomic diffusion, promoting the interfacial metallurgical reaction, controlling the particle morphology and size, refining the interfacial grains and improving the quality stability of joints are conducive to the preparation of metal matrix composite / alloy joints with high comprehensive properties.

Owner:李纲

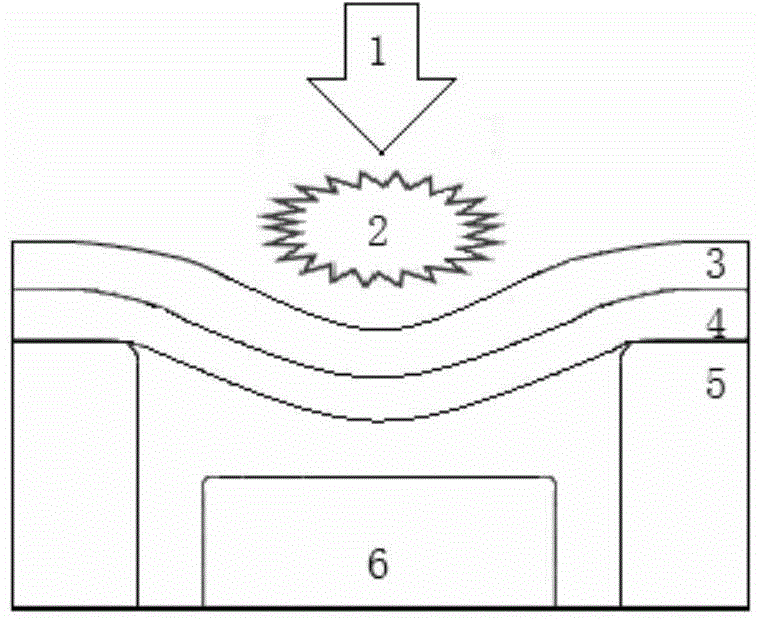

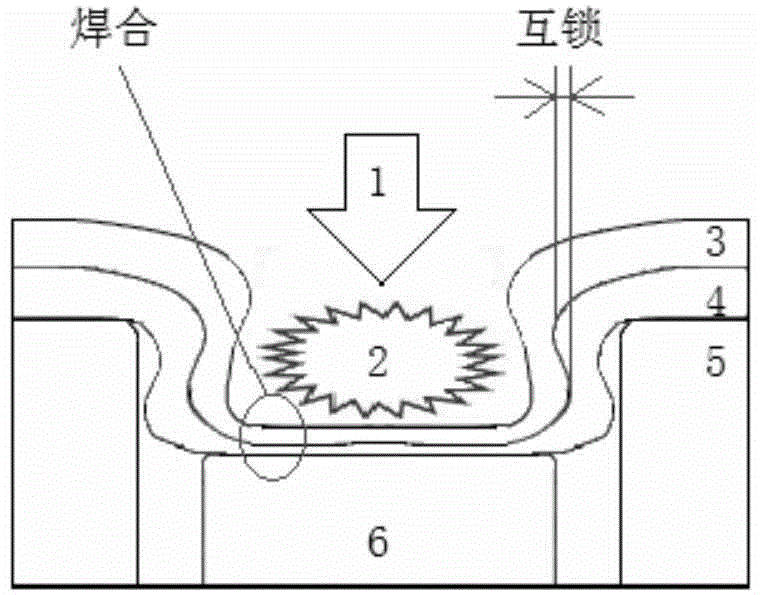

Pulse laser synchronous riveting and welding method and device of ultrathin plates

ActiveCN104816091ALow openness requirementsHigh strengthShaping toolsLaser beam welding apparatusEnergy absorptionShearing deformation

The invention relates to a pulse laser synchronous riveting and welding method and a device of ultrathin plates. An upper layer of plate and a lower layer of plate are stacked and positioned on a concave mold having mold holes; a bottom mold is arranged on the concave mold; a pulse laser beam is used for acting on the upper layer of plate or an energy absorbing layer coated on the surface of the upper layer of plate to form an explosive plasma; the lower layer of plate is collided by the upper layer of plate; the upper layer of plate and the lower layer of plate generate high-strain-rate plastic flow coupling; and under the restraint of the bottom mold, the upper layer of plate and the lower layer of plate are plasticized to form rivet button shapes so as to generate mechanical interlocking for riveting. In the plastic deformation process, the pressure stress exists on the contact interfaces of the upper layer of plate and the lower layer of plate, and the high-speed sliding and the shearing deformation are generated, so that the interfaces generate the melting and the atomic diffusion, and the upper layer of plate and the lower layer of plate are welded when colliding the bottom mold. The method and the device synchronously realize the riveting and the welding of the upper layer of plate and the lower layer of plate; and joints formed by the method and the device have higher connecting strength and fatigue resistance through the compounding effect characteristic of the mechanical bonding and the metallurgic bonding.

Owner:SHANDONG UNIV

Brazing clad material used for metal surface

ActiveCN104907725AWon't fall offReduce stressWelding/cutting media/materialsSoldering mediaEpoxyAtomic diffusion

The invention discloses a brazing clad material used for a metal surface, wherein the clad material is powder particles that is constituted of the follow components with weight percent; Ni tungsten carbide powder ( WC-10 Ni) is within 48 percent to 62 percent; Ni powder is within 7 percent to 11 percent; NiCrBSi alloyed powder (AWS BNi-2) is within 27 percent to 45 percent; binder occupies the rest percentage; the size of the Ni tungsten carbide powder particle is within 5 to 15 micro-meter; the size of the Ni powder particle is within 30 to 45 micro-meter; the NiCrBSi alloyed powder particle is within 25 to 35 micro-meter; and the degree of the metal bonding phase between Ni tungsten carbide powder particles is less or equal to 0.3 micro-meter. According to the invention, under the effect of the organic silicon resin binding material and the epoxy resin binding material, the component of the brazing material is uniform and has specific binding property; and the brazing clad material won't be fell off, thus facilitating to the atomic diffusion and the interface reaction during the high temperature connection process and improving the wetting ability of the clad material and the performance of the metal surface.

Owner:无锡腾达海川新材料有限公司

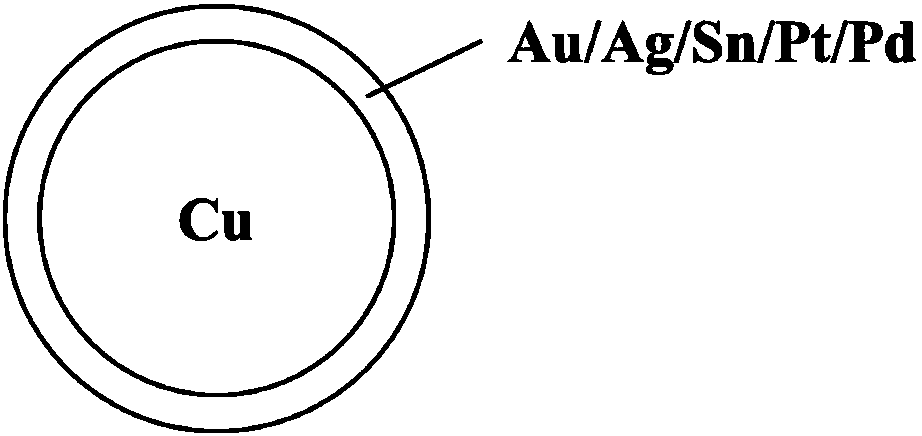

Nuclear shell structure nano-metal interconnection process

ActiveCN108237222AImprove antioxidant capacityImprove stabilityMaterial nanotechnologyTransportation and packagingEngineeringPt element

The invention provides a nuclear shell structure nano-metal interconnection process. The nuclear shell structure nano-metal interconnection process comprises the steps that (A), nuclear shell structure nano-particle interconnection materials are printed on a base plate, the nuclear shell structure nano-particle interconnection materials comprise nano-copper particles wrapped by a metal shell layer, and the metal is one or several kinds selected from gold, silver, tin, platinum and palladium; (B), a chip is covered on the surface of the nano-particle interconnection materials, and a whole device is obtained; (C), the whole device is sintered, and an interconnection device is obtained. According to the nuclear shell structure nano-metal interconnection process, the shell layer metal in the nano-copper particles wrapped by the metal shell layer is compact in form, uniform and controllable in size, prone to generate atomic diffusion at low temperature and is connected with the nuclear layer nano-copper particles together to form a three-dimensional interconnection system, the oxidation resistance and stability of nano copper are improved, the interconnection temperature and interconnection condition are further greatly lowered, by means of the nuclear shell structure nano-metal interconnection process, the chip can be interconnected with the base plate at low temperature without pressure, and connection and packaging of electronic devices are finished.

Owner:GUANGDONG UNIV OF TECH

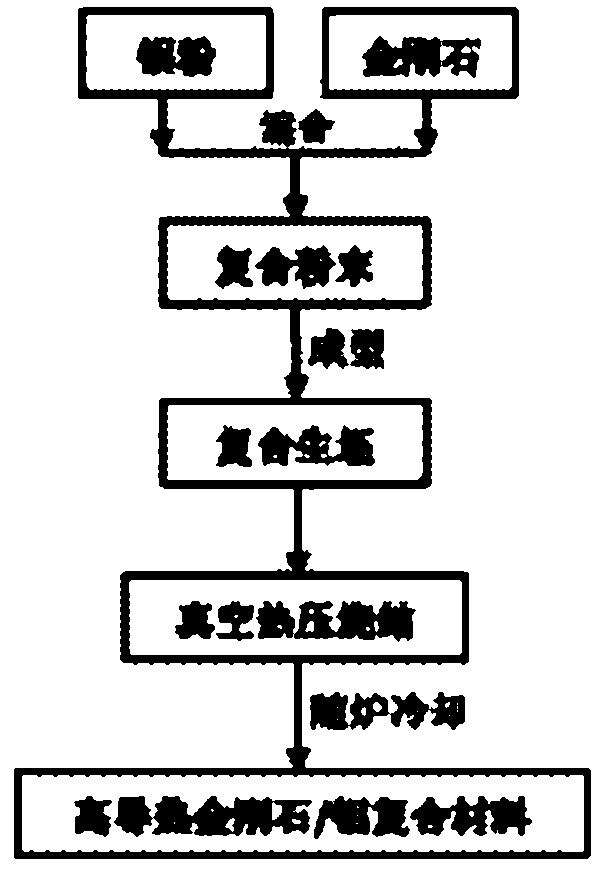

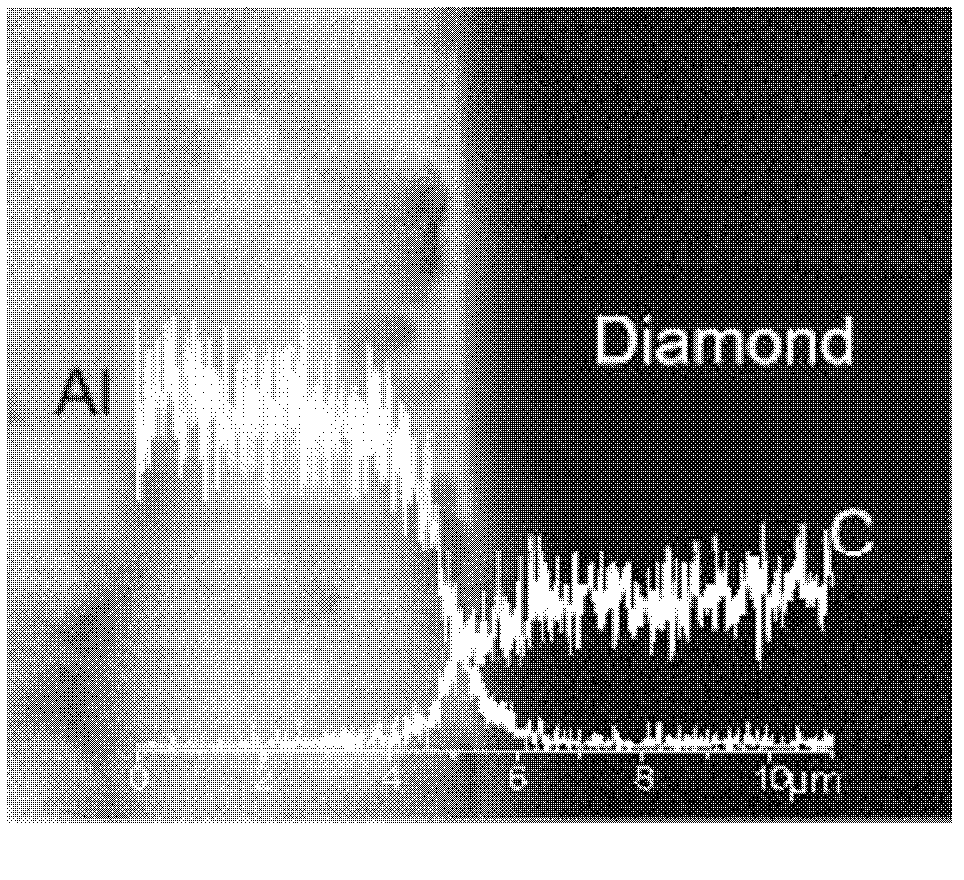

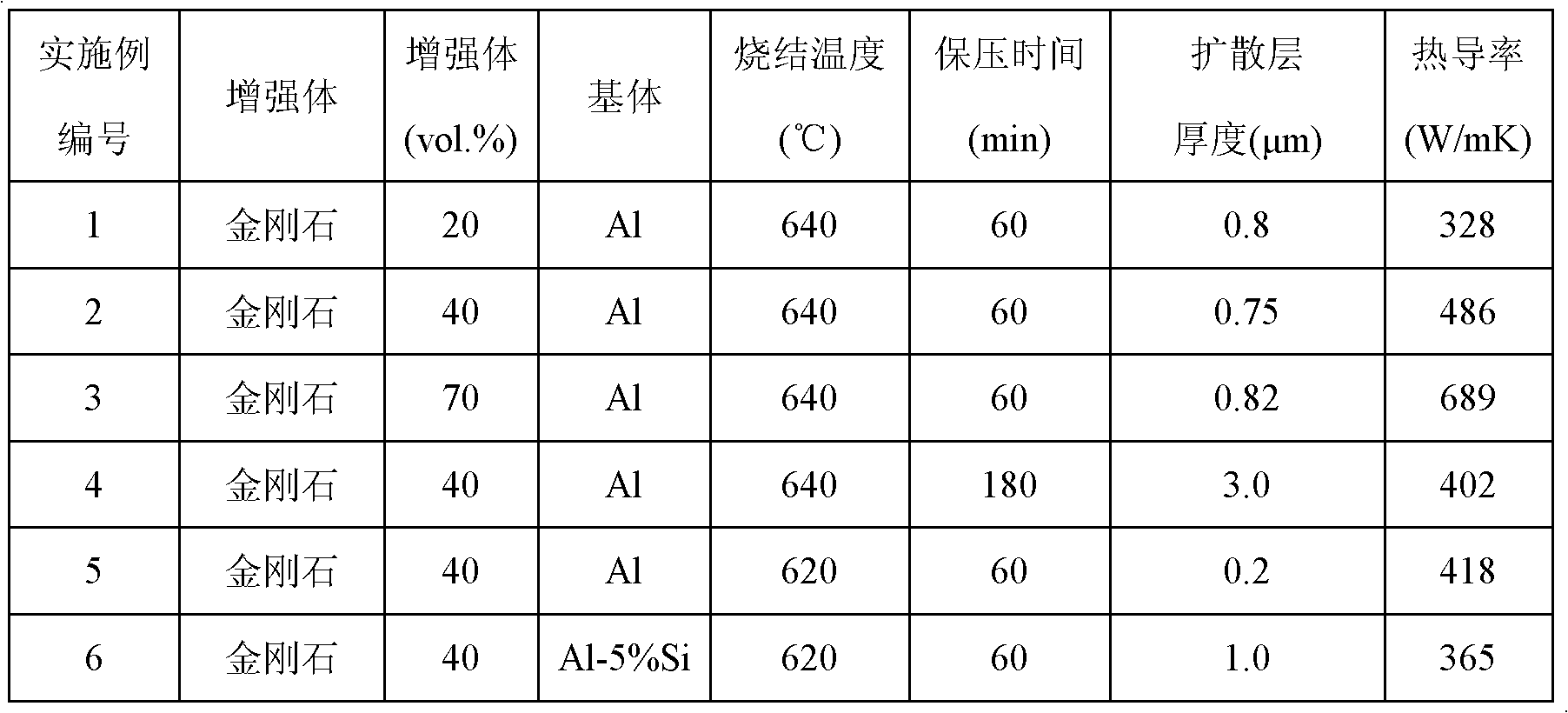

Method for preparing high conductivity diamond/aluminum composite material

ActiveCN102534331AEnhanced interface bindingHigh thermal conductivityMicrometerInterfacial thermal resistance

The invention discloses a method for preparing a high conductivity diamond / aluminum composite material. The method comprises the following steps of: uniformly mixing diamond and aluminum powder to obtain diamond / aluminum composite powder; performing cold pressing or cold isostatic pressing to obtain a diamond / aluminum powder compact; performing vacuum hot pressed sintering on the compact, and ensuring that an atomic diffusion layer with proper thickness is generated at a diamond / aluminum interface by controlling the sintering temperature and time; and cooling to obtain the high conductivity diamond / aluminum composite material. The atomic diffusion layer with the thickness of 0.01-5.0 micrometers is formed at the diamond / aluminum interface by controlling the temperature and time of the vacuum hot pressed sintering, so that good interface bond can be achieved, low interface thermal resistance can be achieved, and the high conductivity composite material is obtained. The method is simple and feasible, low in production cost and suitable for preparing large-size composite materials.

Owner:SHANGHAI JIAO TONG UNIV

High-temperature Zr-based brazing filler metal for brazing of W-Cu alloy and stainless steel, as well as preparation method and welding method

InactiveCN104858570AEvenly meltedImprove wettingWelding/cutting media/materialsWelding/soldering/cutting articlesFiller metalMechanical property

The invention discloses high-temperature Zr-based brazing filler metal for brazing of W-Cu alloy and stainless steel, as well as a preparation method and a welding method. The high-temperature Zr-based brazing filler metal comprises the following elements by weight: 10 to 12 percent of V, 3.0 to 9.0 percent of Nb, 3.0 to 4.0 percent of Si, 8.0 to 16 percent of Cu, 9.0 to 12 percent of Ni, 11 to 14 percent of Cr, 3.0 to 5.0 percent of Sn, and the balance of Zr. The brazing temperature of the brazing filler metal is 1010 to 1090 DEG C and moderate, so that the brazing filler metal is uniformly melted; tinsel made of the brazing filler metal can accelerate atomic diffusion and interface reaction in a high-temperature connection process, so that the wetting and spreading capabilities of the brazing filler metal are improved, the residual stress in a joint is reduced, and the mechanical property of the joint is improved. Through the adoption of the preparation method of the brazing filler metal, the preparation of the brazing filler metal can be reproduced repeatedly, so as to facilitate popularization and application; through the adoption of the brazing technology provided by the invention, sample pieces are connected through vacuum brazing, wherein the sample pieces are in a vacuum atmosphere while being heated, so that problems such as oxidation and pollution are solved, the surface wetting and spreading capabilities are relatively high, convenience is brought for filling of a brazing seam, the strength of the joint is improved, and the obtained welded joint can be stable and reliable.

Owner:江门市新会区华科电器制品有限公司

Preparation method and preparation mold of amorphous alloy-copper laminated composite material

ActiveCN102848073AGood removal effectGuaranteed accuracyNon-electric welding apparatusRoom temperatureAtomic diffusion

The invention relates to a preparation method and preparation mold of an amorphous alloy-copper laminated composite material. The amorphous alloy is an amorphous alloy bar made of 41.25% of Zr, 13.75% of Ti, 12.5% of Cu, 10% of Ni and 22.5% of Be; and the copper is a red copper tube or a brass tube. The outer diameter of the bar is the same with the inner diameter of the copper tube. The preparation method comprises the following steps: under a room-temperature vacuum environment, removing oxide films on the surfaces of the amorphous alloy and the copper through the rubbing effect between the amorphous alloy and the copper; and then heating in vacuum to a temperature in the temperature range of a supercooled liquid region of the amorphous alloy, and keeping the temperature for a period of time to enable the amorphous alloy and the copper to be subjected to atomic diffusion, thus preparing the amorphous alloy-copper laminated composite material. The prepared amorphous alloy-copper laminated material has a tight connection interface between the amorphous alloy and the copper, and the interface is straight and level without any diffusion connection defect such as perforation and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

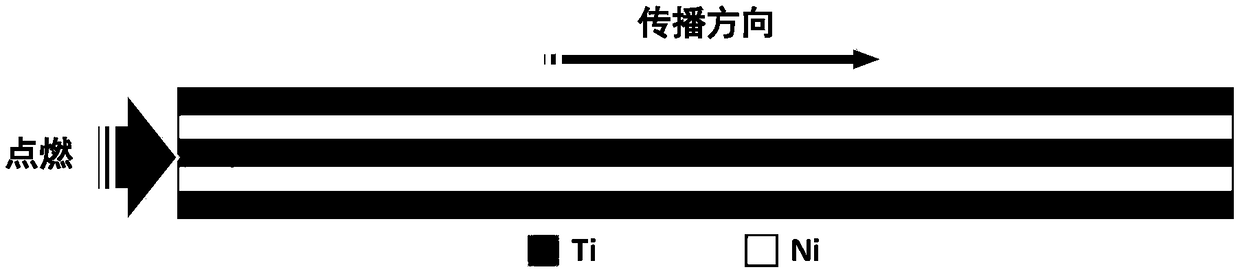

Molecular-dynamics simulation method of predicting diffusion coefficient of combustion process of nano-multilayer film

InactiveCN108491569APlay a guiding roleDesign optimisation/simulationSpecial data processing applicationsDiffusionMean square

The invention provides a molecular-dynamics simulation method of predicting a diffusion coefficient of a combustion process of a nano-multilayer film. The method comprises the following steps: 1) constructing a nano-multilayer-film molecular-dynamics simulation model, and exporting a configuration file; 2) completing a control file; 3) using a molecular-dynamics method to calculate and output mean-square-displacement (MSD) data of each component; 4), drawing the MSD data as a curve of MSD versus step length; 5) calculating a slope of the MSD versus time; and 6), obtaining the diffusion coefficient by solving according to Einstein's law. According to the method, solving is carried out for the diffusion coefficient of each component of the nano-multilayer film, the problem that real-time atomic diffusion behaviors of the self-propagating reaction combustion process of the nano-multilayer film cannot be tested and analyzed by experiment means is solved, difficulty of program compilation is significantly reduced, atomic behaviors and processes of nano-connection are more accurately understood, and a reference is provided for structure design of nano-multilayer films through study on diffusion coefficients and diffusion behaviors of the multilayer films of different atomic proportions under different temperatures.

Owner:BEIJING UNIV OF TECH

Tube fin brazing process and internal tube heating soldering machine for

InactiveCN101318245AUnchanged structureEasy to operateHeating appliancesMetal working apparatusCrystal structureEngineering

The invention discloses a tube fin brazing process and an in-tube heating brazing machine and is characterized in that a finned tubular pipe welding element well filled with solders is placed on a bracket and the surfaces of welding elements to be brazed are chemically cleaned; a rod type electric heating tube extends into the pipe to perform in-tube radiation heating to firstly moisten and apply the solders at the external wall of the pipe to fill the brazing gaps and then transfer the temperature to a finned folding edge by liquid solders; the metallurgical bonding is formed between the solders and the pipe as well as the folding edge by the atomic diffusion and solution. By adopting the in-tube heating brazing machine which consists of a machine stand, the bracket which is arranged at the front end of the machine stand and a heating tube holder arranged at the bracket, the tube fin brazing process and the in-tube heating brazing machine have the advantages of simple and convenient operation, minimal investment, no limitation to the geometric shapes of the brazed elements, no damage to the surfaces of the brazed elements and no change of the crystal structures in metals and solve the problems that the fins reach the brazing temperature before the pipes and the temperature is not easily controlled, and the brazing can not completely penetrate and fill the connection gaps and the brazing effect is bad, and the problems are caused by the traditional brazing heating ways.

Owner:AECC AERO SCI & TECH CO LTD

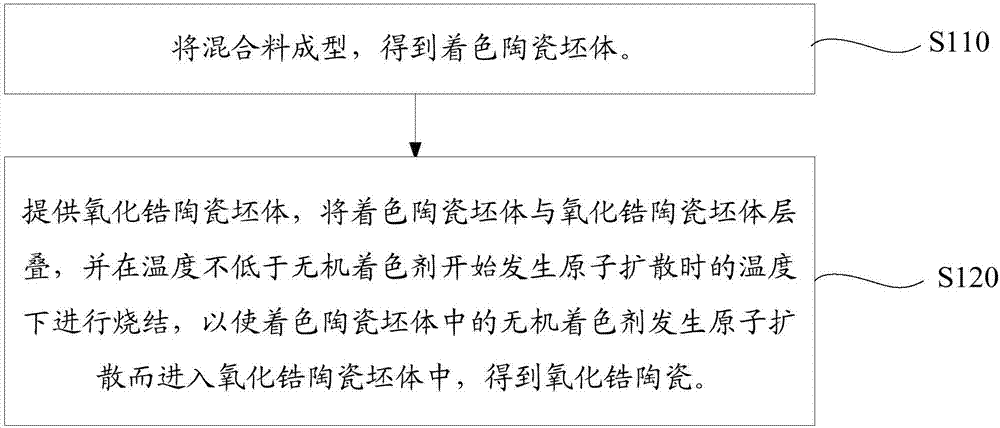

Zirconium-oxide ceramic, mobile phone backboard, preparing method of zirconia ceramic and preparing method of mobile phone backboard

The invention relates to a zirconium-oxide ceramic, a mobile phone backboard, a preparing method of the zirconium-oxide ceramic and a preparing method of the mobile phone backboard. The preparing method of the zirconium-oxide ceramic includes the following steps that mixed materials are formed, and a colored ceramic blank is obtained, wherein the mixed materials comprise zirconium oxide and an inorganic coloring agent, and the mass ratio of the zirconium oxide to the inorganic coloring agent is (80-90):(10-20); a zirconium-oxide ceramic blank is provided, the colored ceramic blank and the zirconium-oxide ceramic blank are stacked, the product is sintered under the condition that the temperature is higher than or equal to the temperature when the inorganic coloring agent is started to be subjected to atomic diffusion so that the inorganic coloring agent in the colored ceramic blank can be diffused to enter the zirconium-oxide ceramic blank, and the zirconium-oxide ceramic is obtained. By means of the preparing method of the zirconium-oxide ceramic, figures, characters, graphs and the like can be made on the zirconium-oxide ceramic, and the obtained zirconium-oxide ceramic also has the good wear-resistant performance.

Owner:DONGGUAN HUAJING POWDER METALLURGY

Preparation method of sponge-structured alloy ternary oxide layer-loaded hydrogen evolution electrode material

ActiveCN106222694ALarge specific surface areaGood chemical stabilityAnodisationElectrodesElectrolysisHydrogen

The invention provides a preparation method of a sponge-structured alloy ternary oxide layer-loaded hydrogen evolution electrode material. The preparation method specifically comprises the following preparation processes: a process of electrically depositing an organic solvent of a La-Y base layer of a sponge structure, a process of electrically depositing a Ni-Cu middle layer on the surface of the La-Y base layer, a process of electrically compositing and depositing Ni-Cu and RuO2 particles on the surface of the Ni-Cu middle layer, a process of performing atomic diffusion treatment, and a process of anodizing a sponge-structured Ni-Cu-La-Y alloy base body-loaded RuO2 layer. The novel hydrogen evolution electrode material prepared by the preparation method disclosed by the invention is high in chemical stability and electrocatalytic activity, has excellent low hydrogen evolution overpotential and high specific surface area, and can be applied to large-scale industrial production for preparing hydrogen by low-energy-consumption water electrolysis.

Owner:山东清大银光金属海绵新材料股份有限公司

Nickel-base superalloy alitizing method and product and nickel-base superalloy surface aluminum- chromium-silicon solid powder aluminizing agent

ActiveCN108468015AImprove organizationReduce processSolid state diffusion coatingSilicon alloyGrain boundary

The invention discloses a nickel-base superalloy alitizing method and product and a nickel-base superalloy surface aluminum-chromium-silicon solid powder aluminizing agent. The method comprises the steps that a discharge plasma sintering method is adopted, nickel-base alloy and the aluminizing agent are placed into a graphite die, the temperature is rapidly increased to 1000 DEG C, and heat insulation is carried out for 30 min in a discharge plasma furnace. The aluminizing agent is prepared from 1.5-2.5% of chromium powder, 79-80% of aluminum oxide and 18-18.5% of aluminum-silicon alloy powder. Atomic diffusion is accelerated through a temperature field, an electric field and a magnetic field of discharge plasma sintering, and an ideal aluminizing layer can be rapidly obtained. The discharge plasma sintering advantages are combined, grains are refined, a large number of grain boundaries are obtained, and the grain boundaries can achieve a reinforcing effect and also can provide a rapiddiffusion channel and improve diffusion efficiency. The product has the high temperature oxidation resistance and thermal corrosion resistance, and the thickness of an alitizing layer can be adjustedby changing the sintering temperature, heat insulation time and pulse current.

Owner:CENT SOUTH UNIV

AgCuTi active brazing filler metal and preparation method thereof

InactiveCN105537799AOvercome the shortcomings of single formSolve the mixed methodWelding/cutting media/materialsSoldering mediaProcess equipmentHigh energy

The invention discloses AgCuTi active brazing filler metal and a preparation method thereof. The AgCuTi active brazing filler metal is composed of, by mass, 60%-75% of Ag, 20%-35% of Cu and 1%-7% of Ti. In order to improve the dispersal uniformity of powder, main adopted measures are that AgCu28 powder, Cu powder and Ti powder of which the grain sizes are uniform (between 10 [mu]m and 30 [mu]m) are selected to be subjected to high energy ball milling (mechanical alloying) under the protection of Ar atmosphere. By means of a hot isostatic pressing process, the plastic processing performance is improved through a similar core-shell structure formed by atomic diffusion while the compactness of alloy ingots is improved. The defect of the simplex form of the AgCuTi active brazing filler metal in China is overcome, the problem that components of a single metal powder mixing method and a vacuum induction melting method are nonuniform is solved, and the competitiveness of Chinese active silver brazing filler metal in domestic and overseas markets is improved. Processing equipment required by the preparation method is simple and easy to operate, and large-batch preparation of active brazing filler metal alloy can be achieved quite easily.

Owner:KUNMING INST OF PRECIOUS METALS

Composite powder of stannic oxide Nano crystal with silver being covered

InactiveCN1539744AImprove plasticityLow resistivityLiquid/solution decomposition chemical coatingTin oxidesHardnessNanocrystal

A silver covered tin oxide nanocrystal is prepared through preparing nanocrystals of tin oxide (13 nm), coating a silver layer on the surface of each nonocrystal, and atomic diffusion. Its advantage is high performance is density, hardness, resistivity and electric conductivity.

Owner:SHANGHAI ELECTRICAL APPLIANCES RES INSTGROUP

Net-shape or near net-shape powder isostatic pressing process

A method of producing a net or near net-shape component from metal powder comprises producing an insert of accurate dimensions corresponding to the dimensions of a bore to be created in the finished component, the bore having a length of at least 750mm, supporting the insert within a mould cavity, filling the mould cavity with metal powder, subjecting the powder to isostatic pressing, and subsequently removing the material of the insert. The mould can be an independent mould that is removed after an initial step to bind the powder together into a pre-form, and the pre-form is then encapsulated in a suitable containment, such as a canister or a sprayed coating. The insert can be a metallic insert of a material, such as copper, that is subsequently removable by chemical etching. The insert can be coated with a material that is amenable to removal by etching, and to enable the insert to be extracted. A metallic insert can be coated with a material that provides a diffusion barrier to prevent the material of the insert from diffusing by atomic diffusion into the powder being consolidated during HIPing.

Owner:ADVANCED INTERACTIVE MATERIALS

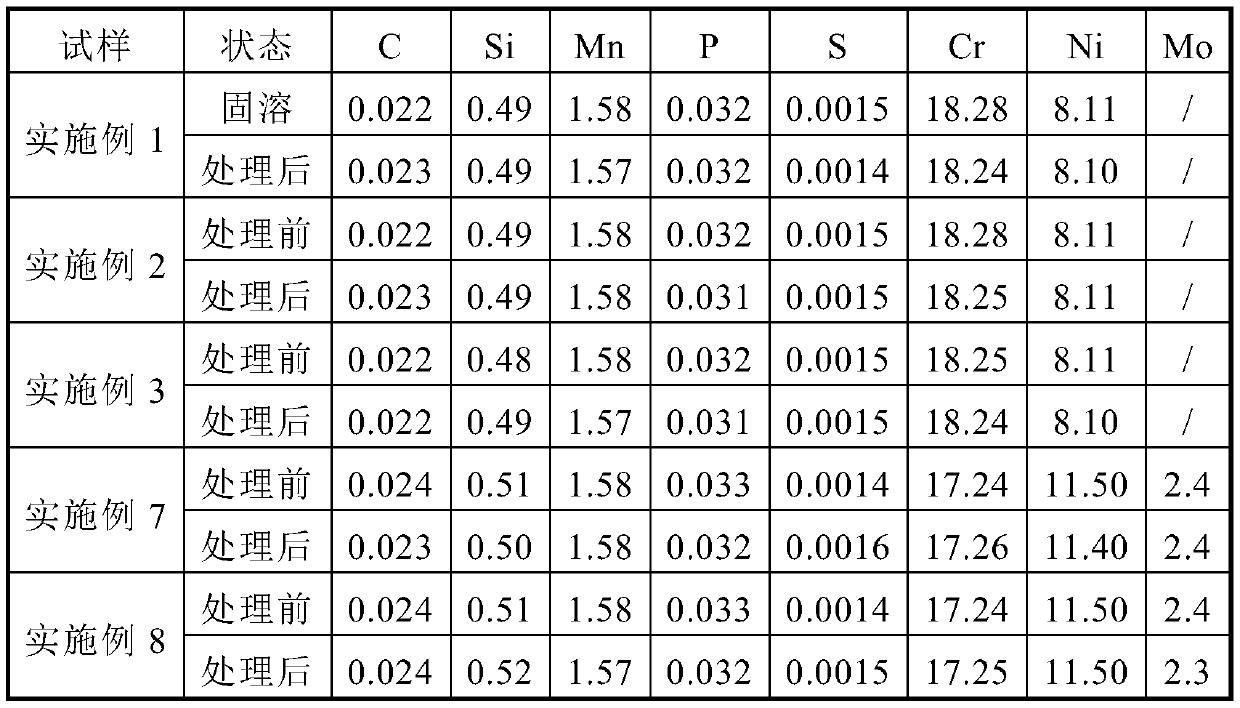

Method for improving intergranular corrosion resistance capacity of austenitic stainless steel

The invention provides a method for improving the intergranular corrosion resistance capacity of austenitic stainless steel. The method comprises the following steps that sensitization treatment is carried out, specifically, heating treatment and sensitization treatment are carried out on the austenitic stainless steel, so that chromium carbide is separated out between crystal particles, and the sensitized stainless steel is obtained; the sensitized stainless steel is continuously heated to 880 DEG C-950 DEG C through atomic diffusion treatment, and the stainless steel is subjected to heat preservation; and then the stainless steel is cooled to the room temperature. According to the method, the chromium carbide is separated out between the crystal particles of the austenitic stainless steel through sensitization treatment firstly, so that the content of chromium between the crystal particles is low; then chromium atoms in the austenitic stainless steel crystal particles are diffused tothe crystal boundary through atomic diffusion treatment, so that the intergranular barren chromium phenomenon is eliminated, and the intergranular corrosion resistance is achieved in a stable state;and the method has the advantages that the heating temperature is low, the fuel consumption is low, the thermal forming process does not need to avoid a sensitization region, the equipment requirementis low, normalizing treatment can be carried out with a carbon steel material at the same time, the cost is low, and chemical components of an austenitic stainless steel material do not need to be changed.

Owner:HENAN SHENZHOU PRECISION MFG CO LTD

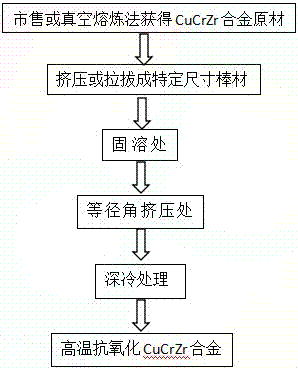

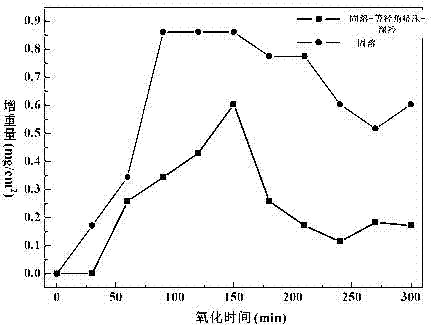

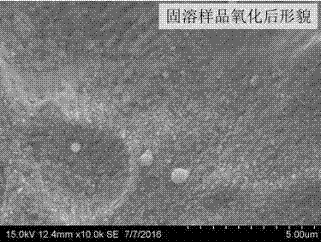

Method for in-situ enhancement of high-temperature oxidation resistance of Cu-Cr-Zr alloy

InactiveCN107502777AImprove high temperature oxidation resistanceSimple processSolution treatmentNanoparticle

The invention discloses a method for in-situ enhancement of high-temperature oxidation resistance of Cu-Cr-Zr alloy. The method is characterized in that equal channel angular pressing treatment is performed on the Cu-Cr-Zr alloy subjected to solution treatment, lots of dislocation defects in dispersed distribution are formed in the alloy material, the defects serve as nucleation points for precipitation of second-phase particles during follow-up subzero treatment, and dispersed distribution of precipitated phases is facilitated; during subzero treatment, thermodynamic conditions of the precipitation process are regulated and controlled to enable the dislocation defects to serve as the nucleation points, so that the nucleation activation energy is reduced; and during subzero treatment, dynamic conditions of the precipitation process are regulated and controlled to control the situations that the precipitation driving force under the subzero conditions is increased and the atomic diffusion transfer capability is reduced, and the Cu-Cr-Zr alloy with high-temperature oxidation resistance is obtained after subzero treatment. Compared with the prior art, through technological and parameter optimization, the precipitation behaviors of the precipitation phases are finely regulated and controlled, uniform and compact nano-particles are subjected to in-situ precipitation, and the high-temperature oxidation resistance of the Cu-Cr-Zr alloy is optimized for the first time.

Owner:临沂市科创材料有限公司

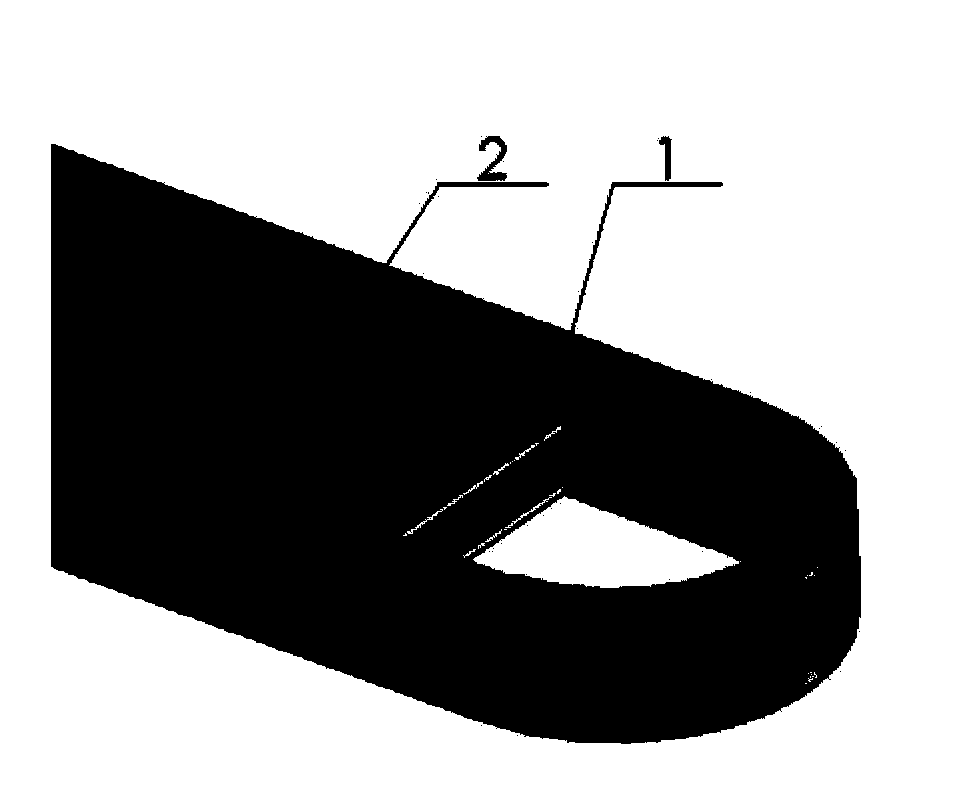

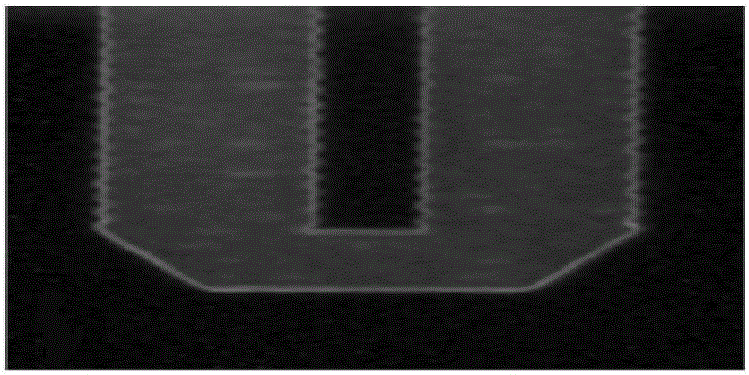

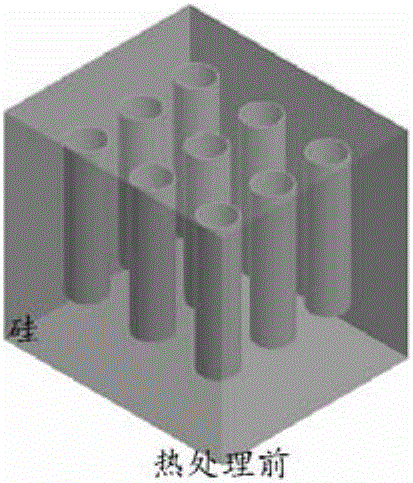

SON (Silicon on Nothing) deformation mechanism study method based on phase field model at high temperature

ActiveCN105956249AObserve molding changesEffective Dynamic Deformation ProcessSpecial data processing applicationsStudy methodsAtomic diffusion

The invention discloses an SON (Silicon on Nothing) deformation mechanism study method based on a phase field model at a high temperature. The method comprises the following steps of 1, putting a sample, i.e., an SON material at a certain temperature so that the sample becomes soft, and then making the sample into a U-shaped cylindrical hole shape; 2, putting the SON material into a high-temperature environment to be processed for several minutes for obtaining the SON form change state in different time periods; and 3, building a system model of the SON at the high temperature. According to the method, the SON deformation mechanism at the high temperature is studied by the method of integrating the experiment study and the simulation model for the first time. The SON forming process is controlled by using the high-temperature atomic diffusion motion; through the simulation model, the SON forming change can be more directly observed; and thus, a novel idea for processing the SON is provided.

Owner:嘉兴华吉环保科技有限公司

Metalized materials for Si3N4 ceramic surface and preparation method as well as brazing technique

ActiveCN105057919AEvenly heatedReduce stress concentrationNon-macromolecular adhesive additivesEster polymer adhesivesInterfacial reactionAdhesive

The invention discloses metalized materials for Si3N4 ceramic surface and a preparation method as well as brazing technique. Silver-based materials are of powder particles, which are prepared from the following components in percentage by weight: 20 to 25 percent of Cu, 3 to 5 percent of Ti, 2 to 3 percent of Ni, 0.1 to 0.3 percent of Ce, 0.2 to 0.3 percent of Sc, 0.5 to 0.6 percent of Re, and the balance of Ag; a particle size of the Ag, the Cu, the Ti and the Ni is 40 mu. m to 55 mu. m, the particle size of the Ce, Sc and Re is 15 mu. m to 25 mu. m. The silver-based materials provided by the invention are of flexible fibrous metal cloth materials, which are prepared by the pressure roller under the effect of a special adhesive; the composition of Ag-base alloy materials are uniform and the Ag-base alloy materials have a certain adhesive property; the Ag-base alloy materials are conductive to the local binding of ceramic parts in various complex parts, can ensure that the metalized materials for the Si3N4 ceramic surface do not fall off and the distribution of the surface metal is uniform under the condition of brazing, are conductive to the atomic diffusion and the interfacial reaction in a brazed connection process, can improve the wettability of the metalized materials for a surface, and are conductive to a good connection between the ceramic and a metal.

Owner:JIANGSU UNIV OF SCI & TECH

Casting technique of imbedding type composite hammerhead

The invention discloses a casting technique of an imbedding type composite hammerhead, which is the technique for bonding a wear resistant material with a substrate during the solidification of a cast by using the heat of molten metal; the production technique of the hammerhead comprises the following steps: pre-forming a hammer handle, polishing to remove surface impurities, smoothening corner angles, coating protective agent, covering a hammer end evanescent mode, putting into a mould cavity and then filling with sands for moulding; taking out the hammer end evanescent mode after the sands are compact, setting a feeding riser runner on the top of the hammer end, wherein the evanescent modes are adopted in the hammer end, sprue base and ingate, and wood former moulds are adopted in riser, riser neck and sprue; arranging the whole sand mould 3-8J into an induction coil before composting, pre-heating the hammer handle by electromagnetic induction heating principle, starting to cast molten metal when the hammer handle reaches a needed temperature, heating while casting, stopping heating after the mould cavity of the hammer end is full, keeping on casting until the whole riser is full; the technique has the following beneficial effects: (1), by utilizing the in-mould induction heating in the hammer handle, the heating efficiency is high; (2), the atomic diffusion energy is improved; (3) the metal atoms exchanging rate of molten metal and solid surface layer is enhanced; and (4), the location accuracy and size precision of workpiece are guaranteed, the production efficiency is improved, and the working condition is improved.

Owner:QINGDAO TIANHENG MACHINERY

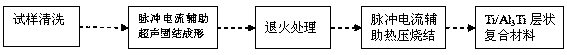

Preparation method of Ti/Al3Ti layered composite material

The invention provides a preparation method of a Ti / Al3Ti layered composite material. The preparation method is characterized by comprising the following steps that S1, a sample is cleaned; S2, pulsecurrent auxiliary ultrasonic consolidation forming is carried out; S3, annealing treatment is carried out; and S4, pulse current auxiliary hot-pressing sintering is carried out. According to the preparation method, the atomic diffusion in the ultrasonic consolidation process can be promoted, the Ti / Al interface bonding quality is improved, the follow-up in-situ reaction test is facilitated, Ti / Alcan be activated through the instantaneous high energy, the reaction efficiency is improved, the crack defect is overcome, and then the Ti / Al3Ti layered composite material with high density and good bonding quality is obtained.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Stirring friction spot welder and stirring friction spot welding method

ActiveCN106624344AImprove mechanical propertiesAvoid Secondary Hook DefectsNon-electric welding apparatusUltrasonic vibrationSpot welding

The invention relates to a stirring friction spot welder. A static shaft shoulder is driven to move up and down by an independent motor; a cooling medium channel is arranged at the bottom of the static shaft shoulder; the cooling medium channel is closed by a bottom cap which is made from a high heat conductivity sheet metal. When the stirring friction spot welder is used for performing stirring friction spot welding, the motor can apply pressure to a workpiece in a manner of driving the static shaft shoulder to move downward and the cooling medium can cool the surface of a welding area; an ultrasonic generator arranged on the lower part of the workpiece is utilized to vibrate the workpiece surface; a stirring head is rotated and is downward penetrated through an upper plate; after the stirring head is downward penetrated through the upper plate, the stirring head is remained for a period of time and then is pulled back; after the cooling medium is continuously applied for a period of time, the static shaft shoulder is retracted and is out of contact with the workpiece; the ultrasonic vibration is kept for a period of time and then is stopped. The stirring friction spot welder has the beneficial effects that the welding area is free from secondary hooked defect and deformation, the material flow at the bottom of the welding core is enhanced, the atomic diffusion behavior is improved, the residual stress is reduced and the mechanical property of the joint is excellent.

Owner:SHENYANG AEROSPACE UNIVERSITY

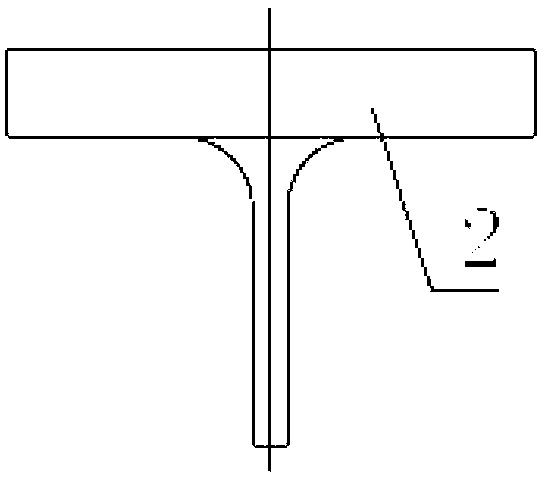

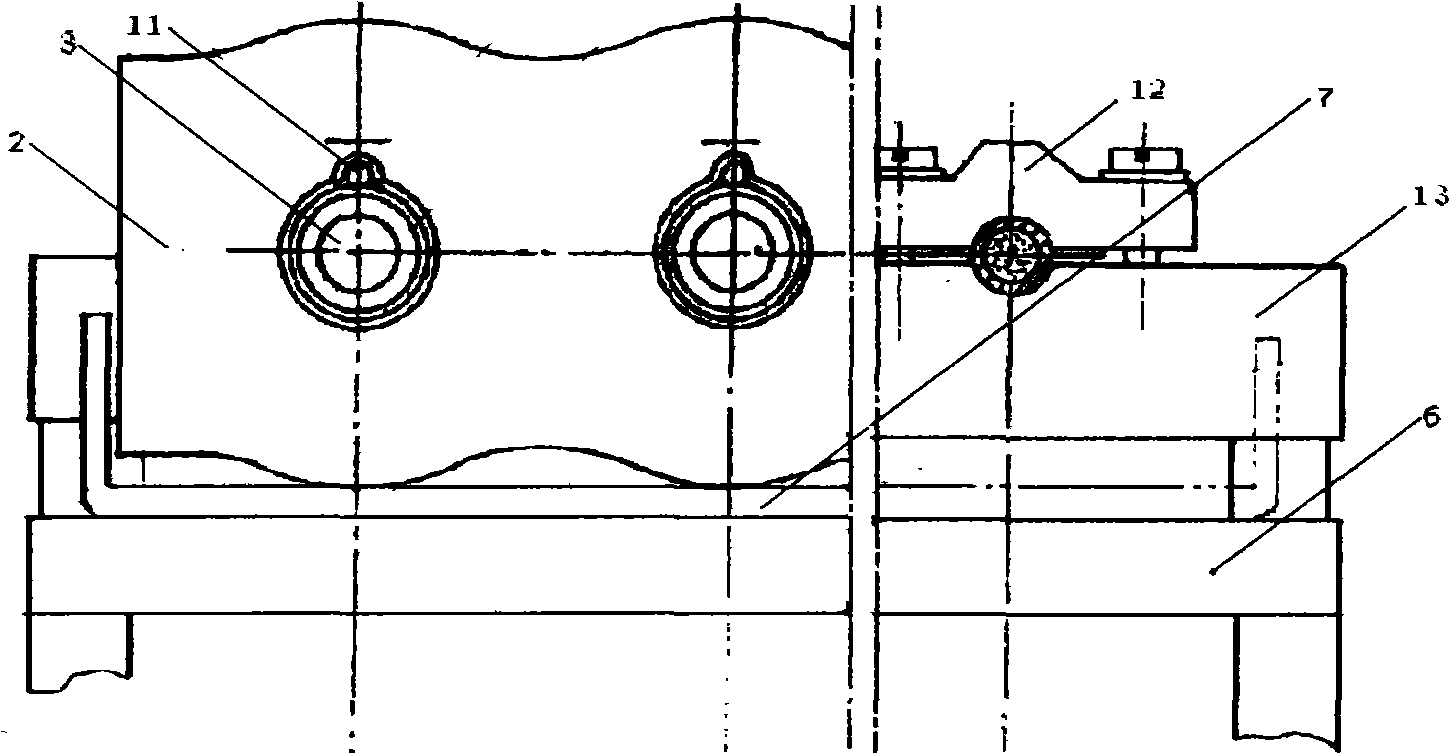

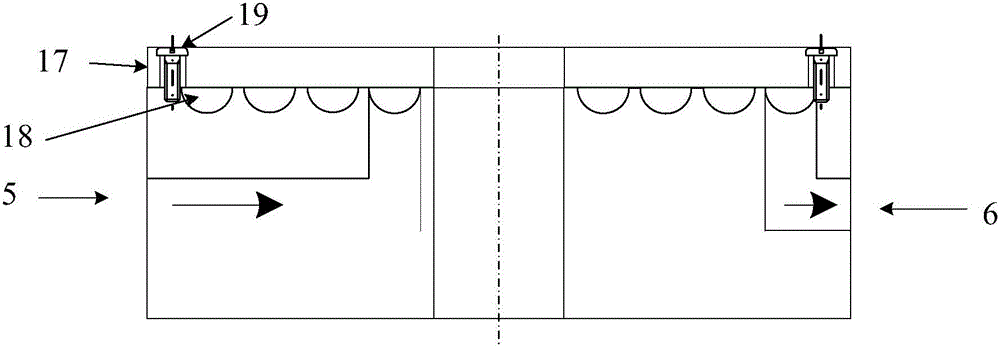

Multi-path micro-hole heat exchanger

InactiveCN104833245AHigh heat transfer area densityImprove heat transfer efficiencyStationary plate conduit assembliesPlate heat exchangerEngineering

The invention provides a multi-path micro-hole heat exchanger. A heat medium inlet collector and a heat medium outlet collector of the multi-path micro-hole heat exchanger are located on the two opposite sides of a main part respectively. A heat medium runner extends in the straight line direction. A cold medium inlet collector and a cold medium outlet collector are located at the two opposite corners of the main part respectively. A cold medium runner extends to the edge of a cold medium plate sheet in the direction perpendicular to the hot medium runner from the cold medium inlet collector and then rotates and extends to the other edge of the cold medium plate sheet in the direction perpendicular to the heat medium runner, and the cold medium runner moves forwards in a detouring mode to be communicated with the cold medium outlet collector. The multi-path micro-hole heat exchanger has a large heat exchanging area, meanwhile, the mode that a multi-path runner and a single-path runner are combined is adopted, and efficient heat exchanging capability is guaranteed; on the structure, the photoelectrochemistry etching technology and the atomic diffusion technology are adopted for machining and manufacturing, the high-temperature and high-pressure resisting capability of a heat exchanging core is guaranteed, and the structure form is simple.

Owner:LICE SCI & TECH SHANGHAI

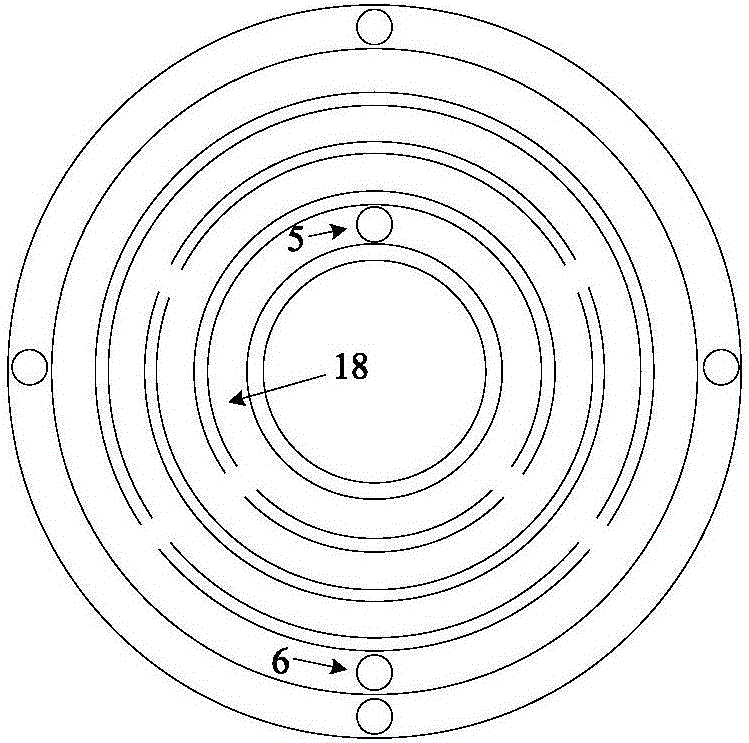

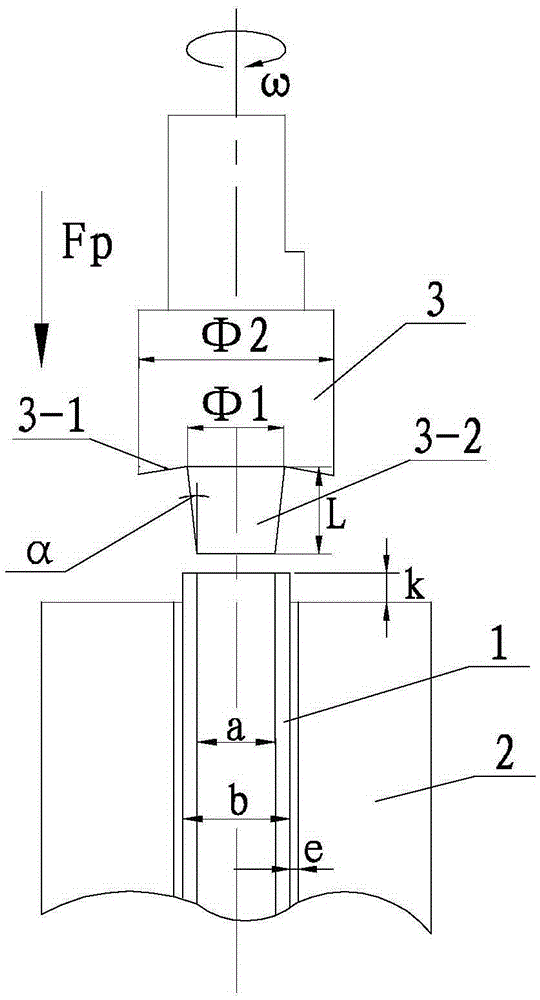

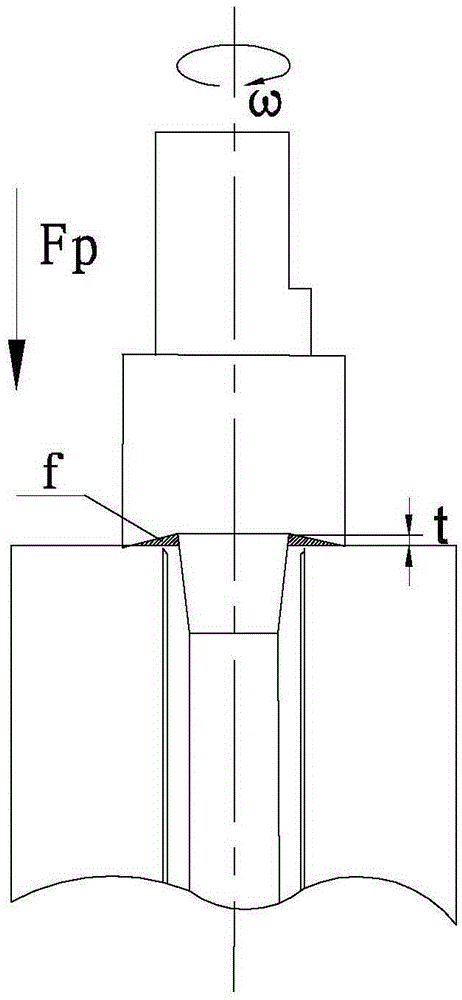

Solid-phase diffusion bonding method for integrated expanded jointing and welding of tube sheet structure

ActiveCN105414740AGuaranteed tightnessImprove mechanical propertiesNon-electric welding apparatusSurface oxidationEngineering

The invention discloses a solid-phase diffusion bonding method for integrated expanded jointing and welding of a tube sheet structure, and aims to solve the problems that a high-temperature joint loosens and crevice corrosion occurs when a tube and a tube plate of a heat exchanger are connected according to an expanded jointing method, a fusion welding method as well as a method integrating the expanded jointing method and the fusion welding method. The solid-phase diffusion bonding method comprises the following steps; (1) surface oxidation films on materials in to-be-welded areas of the tube and the tube plate are removed by polishing at first, and then the surfaces of the tube and the tube plate are scrubbed by adopting an organic solvent or a cleaning agent; (2) when the tube and the tube plate are clamped together, the interval between the outer wall of the tube and an inner hole in the tube plate is e, and the length of the upper end, extending out of the upper end surface of the tube plate, of the tube is k; (3) a high-speed rotating friction head is inserted into an inner hole in the tube at a certain press-in speed, so that the tube is subjected to friction between the friction head and the tube plate, heat is generated due to the friction, and then the tube gradually reaches a thermoplastic state when being deformed to generate heat; when a shaft shoulder of the friction head is pressed in the upper surface of the tube plate at a depth of t, the friction head keeps rotating at a high speed and remains for 5 seconds, and then is lifted at a constant speed, so as to realize atomic diffusion between the tube plate and the tube as well as metallurgical bonding. The solid-phase diffusion bonding method is applicable to tube plate welding.

Owner:HARBIN INST OF TECH

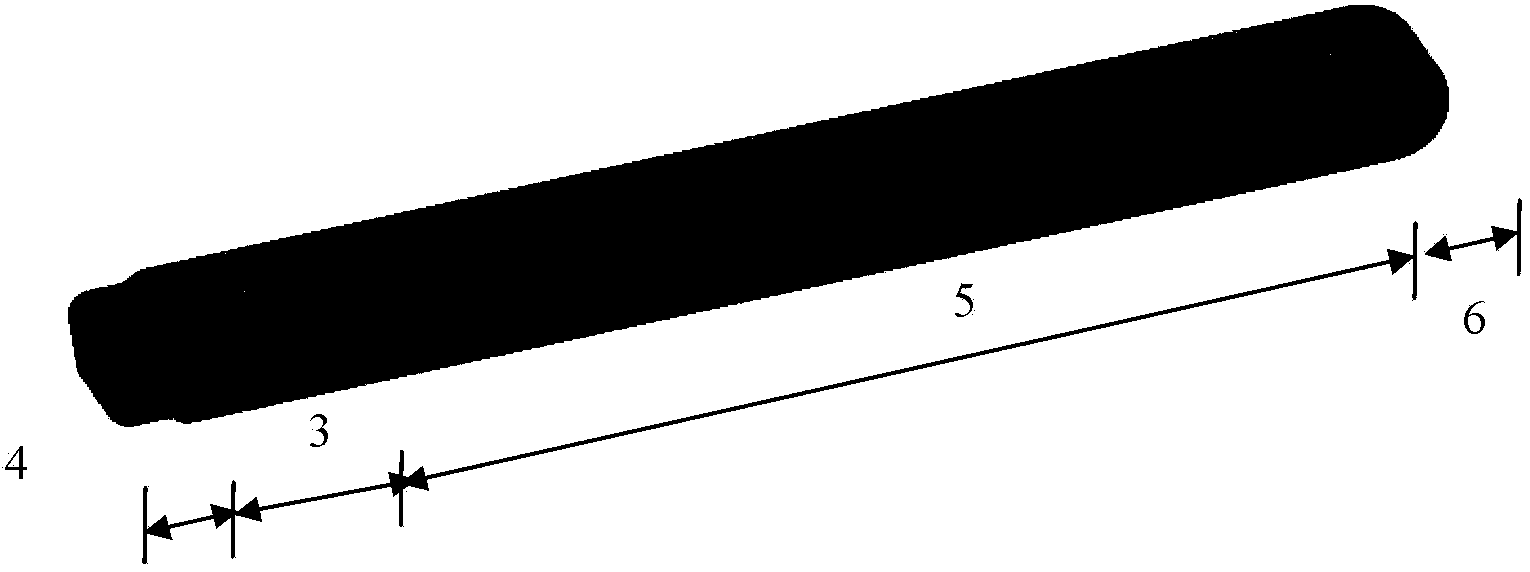

Hollow fan blade and manufacturing method thereof

ActiveCN103089317AIntegrity guaranteedReduce weightBlade accessoriesMachines/enginesTitanium alloyAtomic diffusion

The invention provides a hollow fan blade which comprises an upper wallboard, a lower wallboard and an inner cavity. The inner cavity is defined by the upper wallboard and the lower wallboard through atomic diffusion connection, internally comprises a plurality of titanium alloy springs and is internally filled with damping materials, two ends of each spring are connected to the upper wallboard and the lower wallboard respectively through atomic diffusion, at least one of the upper wallboard and the lower wallboard is provided with a plurality of grooves, and ends of the springs are positioned in the grooves respectively. The invention further provides a manufacturing method of the hollow fan blade. The hollow fan blade has damping and impact energy absorption effects, and is lighter, and simpler in process.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com