Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

178 results about "Arc erosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

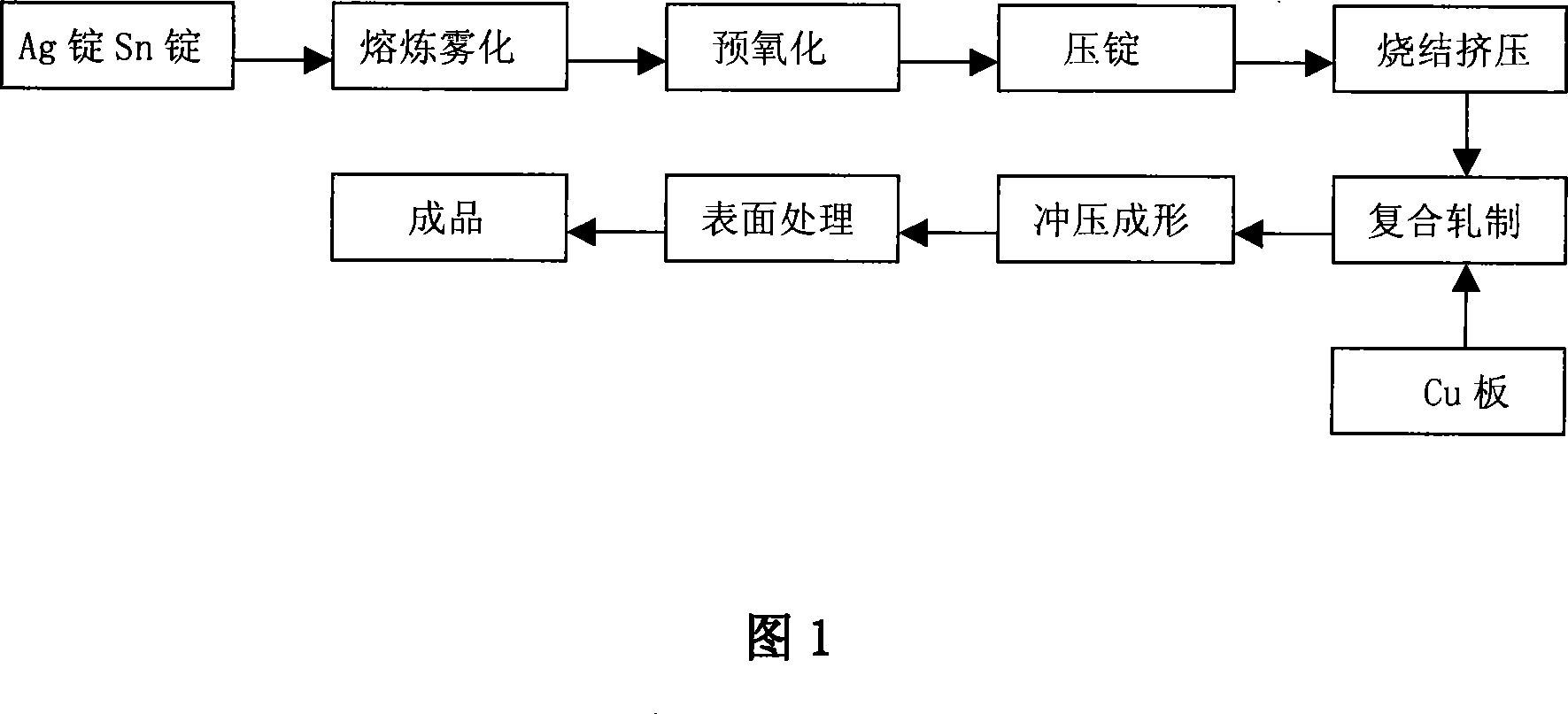

A silver tin/copper oxide compound electrical contact and preparation method

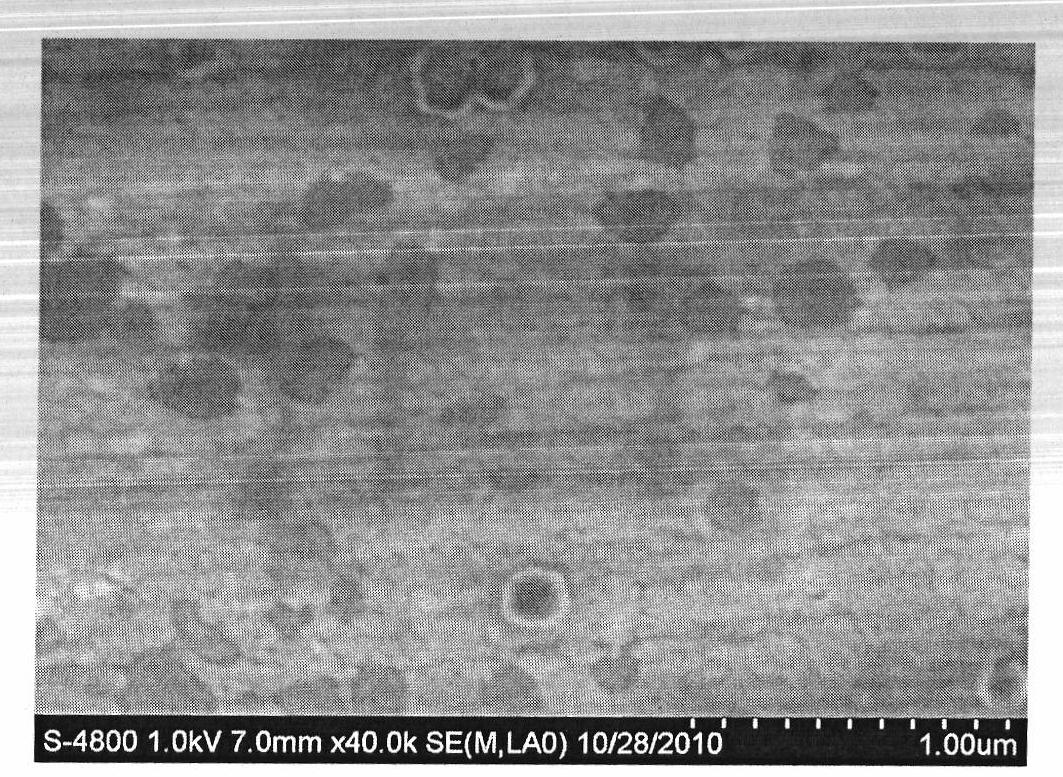

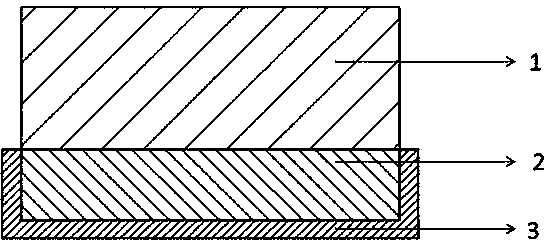

The invention relates to a silver tin oxide / copper compound electrical contact, a working layer of the electrical contact material is composed of silver, tin oxide and mixed rare earth oxide, the weight content of all the components is: 85 percent to 94 percent of Ag, 6 percent to 15 percent of SnO2 and 0.1 percent to 2.0 percent of mixed rare earth oxide, and a welding layer is T2 copper. The weight content of SnO2 is 8 to 12 percent preferentially. The mixed rare earth oxide is a mixture of cerium oxide, lanthanum oxide and yttrium oxide. The preparation method is that the silver and the tin are first mixed according to certain proportion and then are smelted in an intermediate frequency furnace, then high-pressure water atomization equipment is used for carrying out alloy atomization, powder is obtained by drying after the atomization, the powder is screened and arranged in an internal oxidation furnace to carry out the oxidation at certain temperature and oxygen pressure, then billet is obtained by the processing of isostatic cool pressing after the oxidation, after that, a plate is formed by carrying out the sintering and extruding, and finally the finished product is obtained by compound rolling with the copper. The electrical contact is characterized by high conductivity, even and exquisite texture, high bonding strength of the working layer and the welding layer, welding resistance and arc erosion resistance.

Owner:SHANGHAI LONGSUN ALLOY CO LTD

Metal oxide blended silver-tin dioxide electric contactor material and its preparing method

The present invention belongs to the preparation techonlogy of electric alloy material. The electric contactor material consists of Ag 85-90 wt%, SnO2 5-20 wt% and blended metal oxide 0.5-8 wt%. The blended metal oxide is ZrO2, ZnO, TiO2, MnO2, WO3 or Sb2O3. The electric contactor material is prepared through coating oxide through chemical plating with plating liquid with dispersant, mixing the coated pwoder and silver powder, pressing, sintering, hot extruding, cold drawing or cold rolling, and making rivet or punched product. The present invention has the features of homogeneous oxide dispersion, good fusion welding resistance, high arc corrosion resistance and less electric transfer. The production process is simple, practical, low in cost and suitable for large scale production.

Owner:TIANJIN UNIV

Processing method for manufacturing silver tungsten composite contact material

The invention discloses a processing method for manufacturing a silver tungsten composite contact material, which comprises the following steps: putting tungsten powder in a reaction vessel, adding water and a proper amount of reducing agents, slowly injecting a silver-ammonia complexing solution under stirring, cleaning silver tungsten coating powder to become neutral, drying the powder, performing uniform ball milling treatment by a high-energy bowl mill, performing distressing treatment of the silver tungsten powder, performing primary pressing and molding, performing presintering, infiltration sintering, and secondary pressing with the protection of reducing atmosphere to obtain the silver tungsten composite contact material. The invention has an advanced and simple process; the distribution of tungsten particles in a silver substrate is improved by a coating process based on a chemical plating principle; a high-energy bowl milling process is selected to allow the powder particlesto repeatedly generate cold welding and fractures, which causes atomic diffusion in the powder particles and improves the mechanical properties, physical properties, electrical properties, and the like of the material; a high temperature presintering process is adopted, which increases the material compactness, greatly optimizes the conductivity, reduces resistivity, and improves arc erosion resistance.

Owner:YANGZHOU LEYIN ALLOY TECH

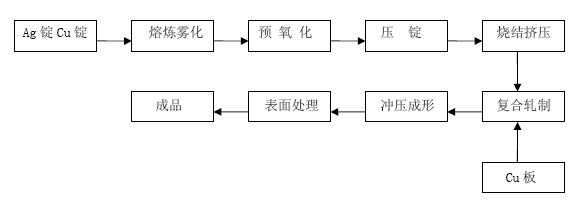

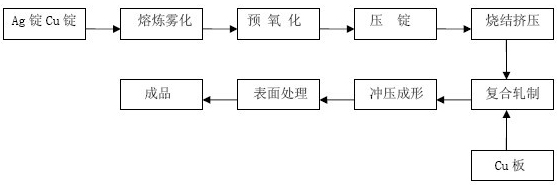

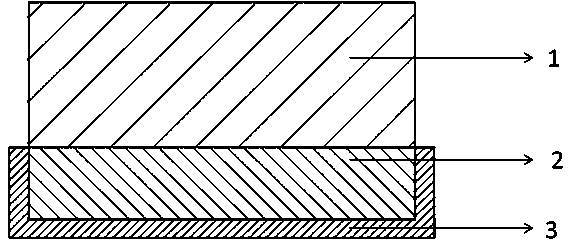

Silver copper oxide/copper composite electrical contact material and preparation process thereof

ActiveCN102054598AGuaranteed uniformityGrain refinementContactsMetal rolling arrangementsCopper oxideHigh pressure water

The invention discloses a silver copper oxide / copper composite electrical contact material and a preparation process thereof. The process comprises the following steps: mixing silver and copper according to certain proportions, and then, smelting the mixture in an intermediate frequency furnace; then, carrying out alloy atomization by using high pressure water atomizing equipment; baking after atomization to obtain powder; screening; putting the screened powder into an internal oxidization furnace for oxidizing at certain temperature and oxygen pressure; carrying out isostatic cool pressing after oxidization to form a billet; sintering and extruding to form a plate; and then, carrying out composite rolling with copper to obtain a finished product. Because the formula and process disclosed by the invention are reasonable, the produced electrical contact has the characteristics of high conductivity, uniform and fine tissue, high bonding strength between a working layer and a welding layer, fusion welding resistance, electrical arc erosion resistance and the like.

Owner:WENZHOU LONGSUN ELECTRICAL ALLOY CO LTD

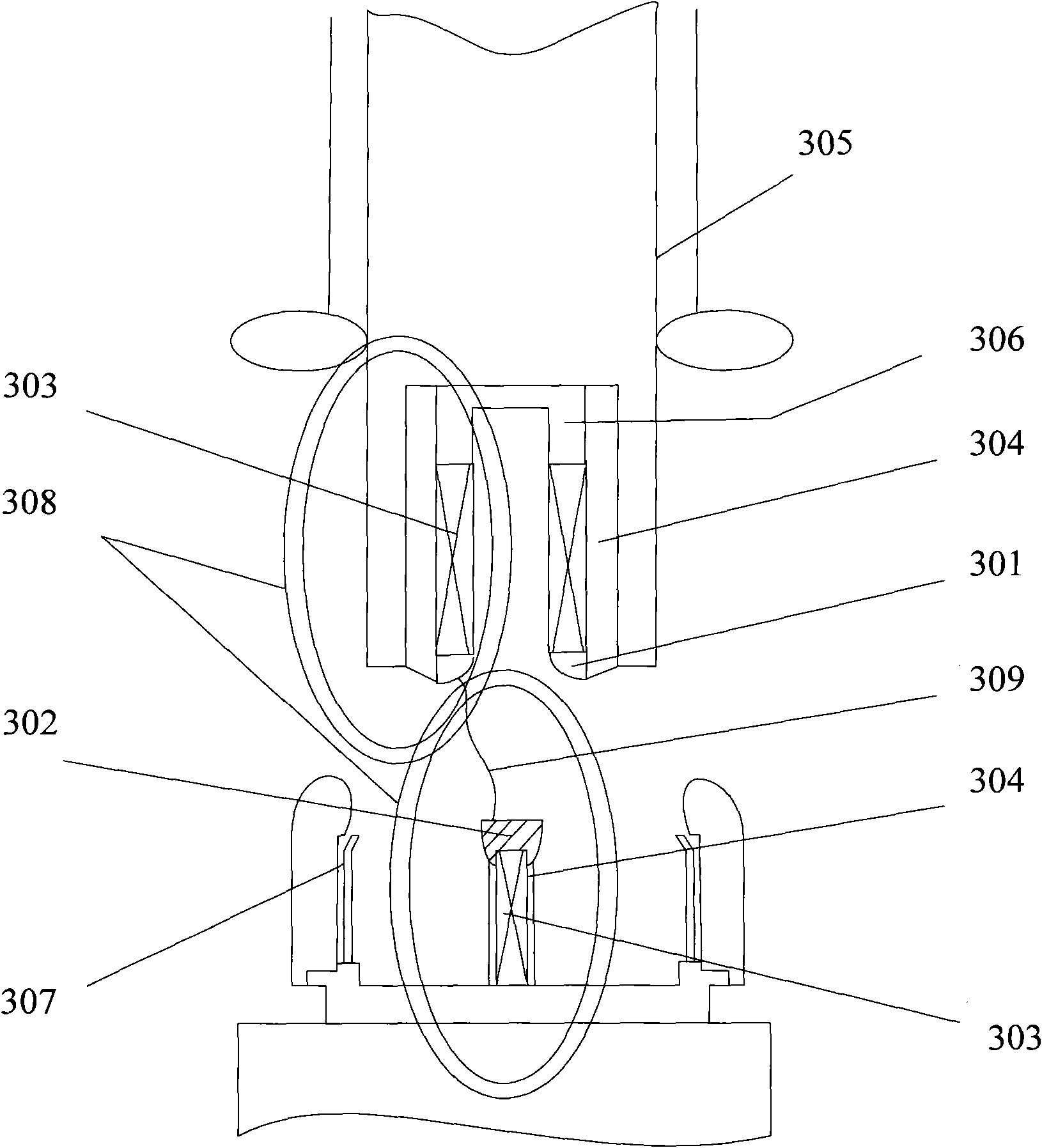

Device for measuring high-speed electrical sliding wear

InactiveCN101008596AEffective electrical wear test resultsUsing mechanical meansInvestigating abrasion/wear resistanceMeasurement deviceDevice form

This invention discloses one high speed slide electrical friction loss measurement device, which comprises electrical loss mechanic device, power control part, resistance box and test meter, wherein, the mechanic device forms loop circuit between copper disc and test materials through high speed rotation copper disc and slide electrical contact materials to make the test materials generate electrical arc erosion by relative motion to test for one load charge, one line or weight friction loss and rotation ring number; the power control part is to provide direct power to the mechanic device and the resistance box is to adjust interface friction mechanic device current size.

Owner:XIAN UNIV OF TECH

Method for preparing silver-based electrical contact material with fibrous structure

ActiveCN102002651AImproved arc erosion resistanceImprove conductivityContactsFusion weldingElectrical resistivity and conductivity

The invention discloses a method for preparing a silver-based electrical contact material with a fibrous structure, which comprises the following steps: 1, uniformly mixing reinforcing-phase material powder with substrate silver powder uniformly, and ball milling; 2, feeding the obtained mixed powder and substrate silver powder into a powder mixer for mixing powder; 3, performing isostatic cool pressing; 4, sintering; 5, performing hot pressing; and 6, performing hot extrusion and obtaining the silver-based electrical contact material. The method of the invention can prepare the sliver-based electrical contact material with an obvious fibrous structure regardless the processing deformation amount and the levels of the plasticity and ductility of a reinforcing phase; and in the method, theprocess is simple, it is convenient to operate, the cost is low, and special requirements on equipment are avoided. The fusion welding resistance, arc erosion resistance and conductivity of the material prepared by the method are all improved greatly, and the processing performance of the material is high.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

Silver tungsten carbide graphite contact material and preparation method thereof

InactiveCN101976615AImprove distributionImprove physical bond strengthContactsChemical platingHigh energy

The invention discloses a novel silver tungsten carbide graphite contact material and a preparation method thereof, which belong to the technical field of electric engineering material. The preparation method comprises the following steps of: putting tungsten carbide powder, graphite powder and tungsten into a reaction vessel; adding deionized water and 40% hydrazine hydrate into the reaction vessel; spraying 50-500 g / l silver ammonia complex solution into the reaction vessel at a flow rate of 5 to 500 ml / min with stirring at a rotating speed of 50 to 200 r / min to coat silver powder on the tungsten carbide graphite, the graphite powder and the tungsten particles; and performing high-energy ball milling, destressing, initial-pressing forming, sintering, re-pressing forming, annealing and re-pressing forming to obtain the contact material, wherein the weight percents of silver, tungsten carbide and graphite in the contact material are 72 to 85 percent, 13 to 24 percent and 2 to 5 percent respectively, and the weight of tungsten is 0.5 to 1.5 percent of the total weight of the silver, the tungsten carbide and the graphite. By using a coating process with a chemical plating principle,the invention improves the physical bonding strength between non-wetting materials, improves chemical properties and physical properties of the materials, greatly optimizes the conductivity and improves the arc erosion resistance.

Owner:YANGZHOU LEYIN ALLOY TECH

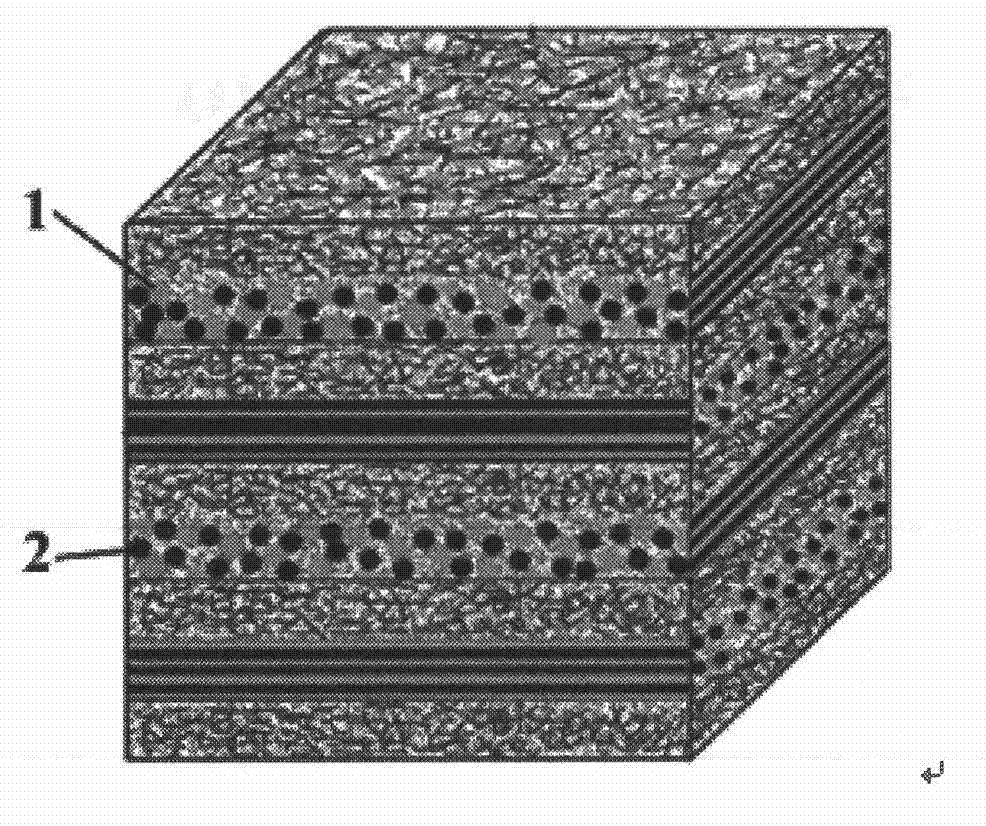

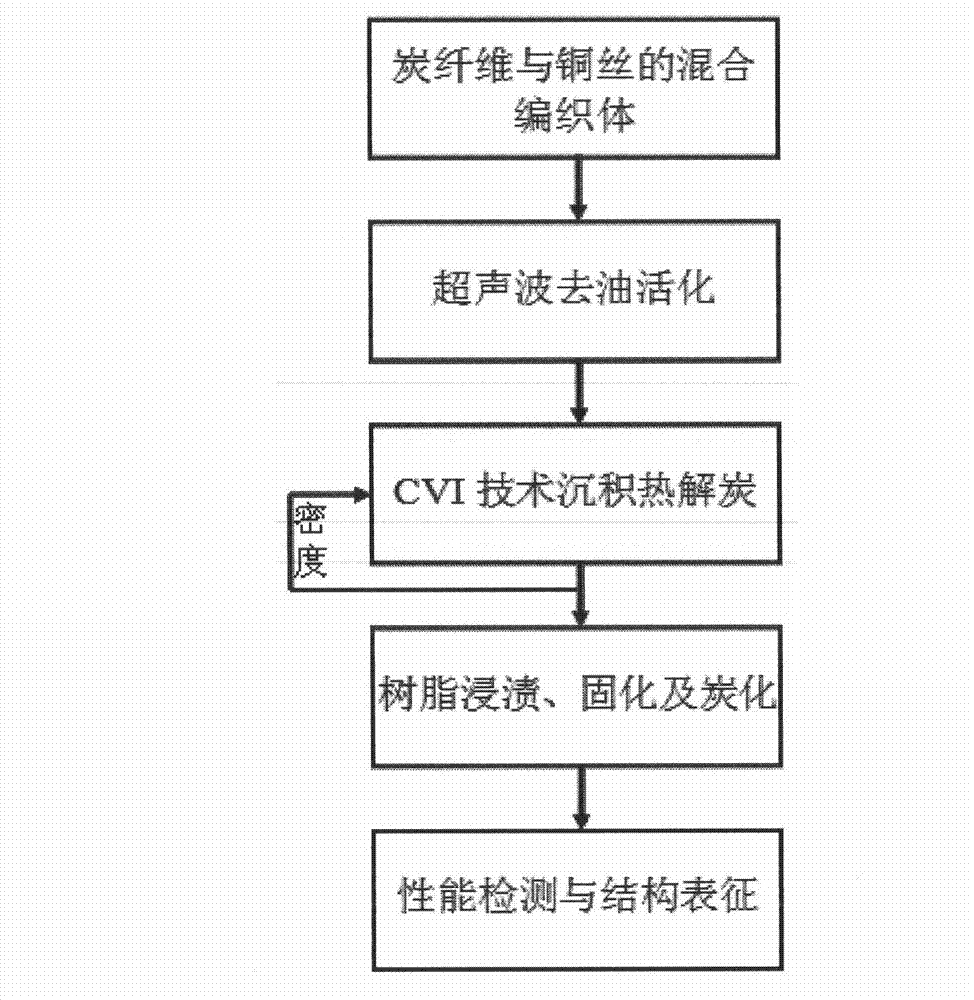

Composite material for pantograph slide plate and preparing method thereof

ActiveCN103192718AReduce performanceStrong reliabilityCarbon fibresUltrasonic/sonic fibre treatmentCarbon fibersCopper wire

The invention discloses a composite material for a pantograph slide plate and a preparing method thereof. A reinforced body of the composite material is a three-dimensional mixed fabric body formed by carbon fibers and copper wires. The preparing method of the composite material includes that the mixed fabric body is subjected to ultrasonic deoiling activation; propylene is adopted to serve as a precursor for pyrolytic carbon depositing, H2 is adopted to serve as diluents and furnace pressure regulation gases, and the mixed fabric body is placed into a chemical vapor deposition furnace for Chemical Vapor Infiltration (CVI) depositing; and a green body deposited with pyrolytic carbon is placed into a vacuum-pressure dipping tank, thermosetting resin is adopted to serve as impregnants, the high-pressure dipping process is used for processing, and finally the composite material is obtained after curing and carbonizing in sequence. The reinforced body of the composite material is the three-dimensional mixed fabric body formed by carbon fibers and copper wires, metallic coppers form a mutually connected network structure in the composite material, a low-resistance channel is provided for electron movement in the current-carrying state, the composite material has good mechanical performance and electric conduction performance, and abrasion resistance and arc erosion resistance of the composite material are improved due to the pyrolytic carbon.

Owner:HUNAN UNIV

Copper-based electric contact composite material and preparing method thereof

The invention discloses a copper-based electric contact composite material and a preparing method thereof, and belongs to the technical field of metal composite material preparing. The copper-based electric contact composite material comprises, by mass percentage, 10%-30% of chromium, 1%-5% of tungsten carbide and the balance copper. The copper-based electric contact composite material is high in compactness and even in structure and has high specific conductance and good anti-arc erosion performance. According to the preparing method, after chromium powder, tungsten carbide powder and copper powder are mixed, the spark plasma sintering technology is utilized for preparing a copper-chromium-tungsten carbide composite material. The obtained composite material has the high strength and high smelting point of chromium, good electrical conductivity and abrasion resistance of tungsten carbide and high electric conductivity and thermal conductivity of copper. The preparing method is controllable and environment-friendly, the technology is simple, cost is low, and the production period is short. The preparing of the electric contact composite material which has high anti-arc erosion performance, anti-welding capability, strength and electric conductivity performance is achieved, and the copper-based electric contact composite material is suitable for application and popularization.

Owner:HENAN UNIV OF SCI & TECH

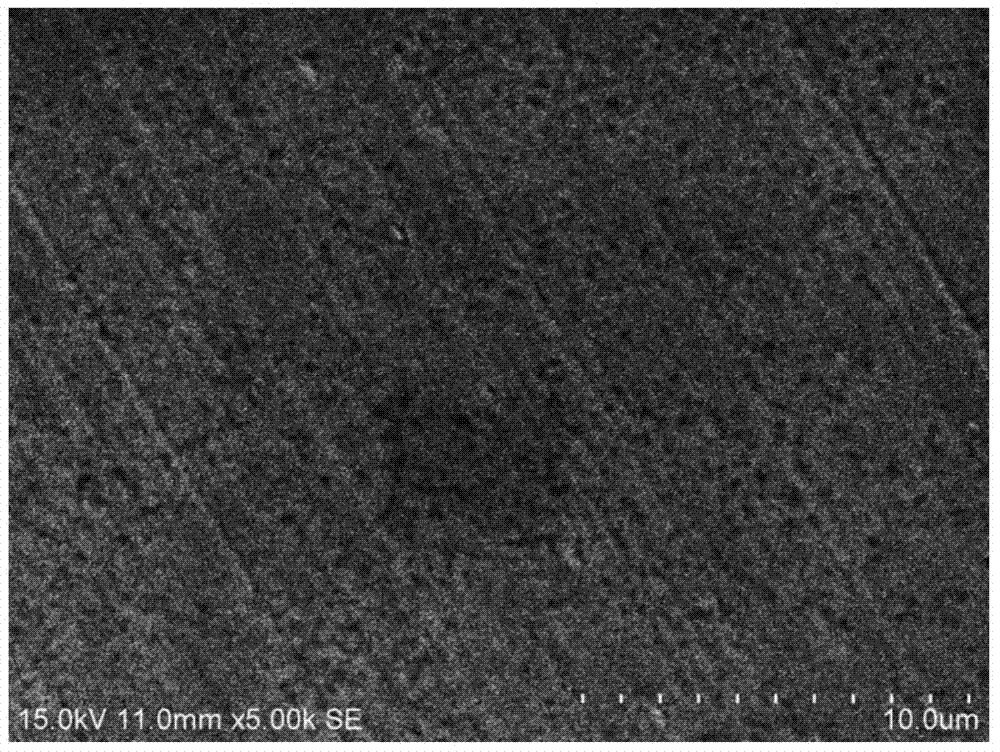

Silver-base electric contact head materials

InactiveCN1552926AImprove performanceReduce electrical erosion rateContact materialsElectricityWear resistant

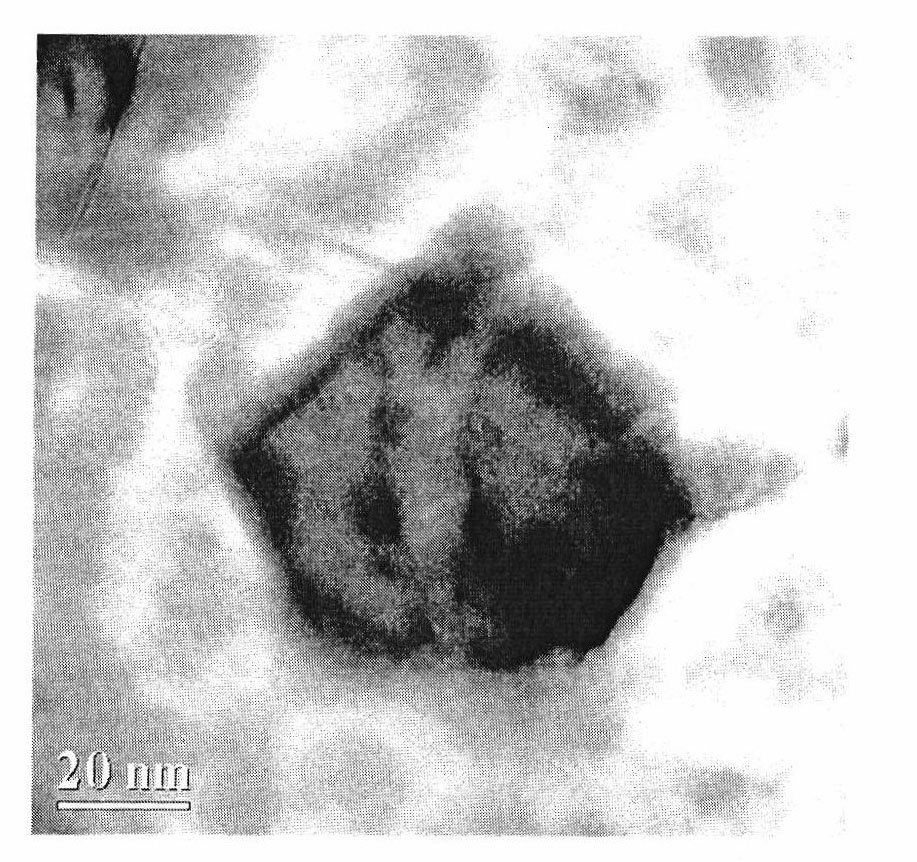

A durable wear-resistant and arc erosion-resistant silver based electric contact material consists of carbon material 0.5-20wt% and balanced of silver. One dimension nano carbon material replaces, partially or completely, graphite to be added into the silver based material to form one dimension nano carbon / silver composite material as electric contact material. It has higher electric and heat conductivities, higher strength and better self-lubrication, reduces losses by wear or arc erosion, and can replace graphite silver contact material completely.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

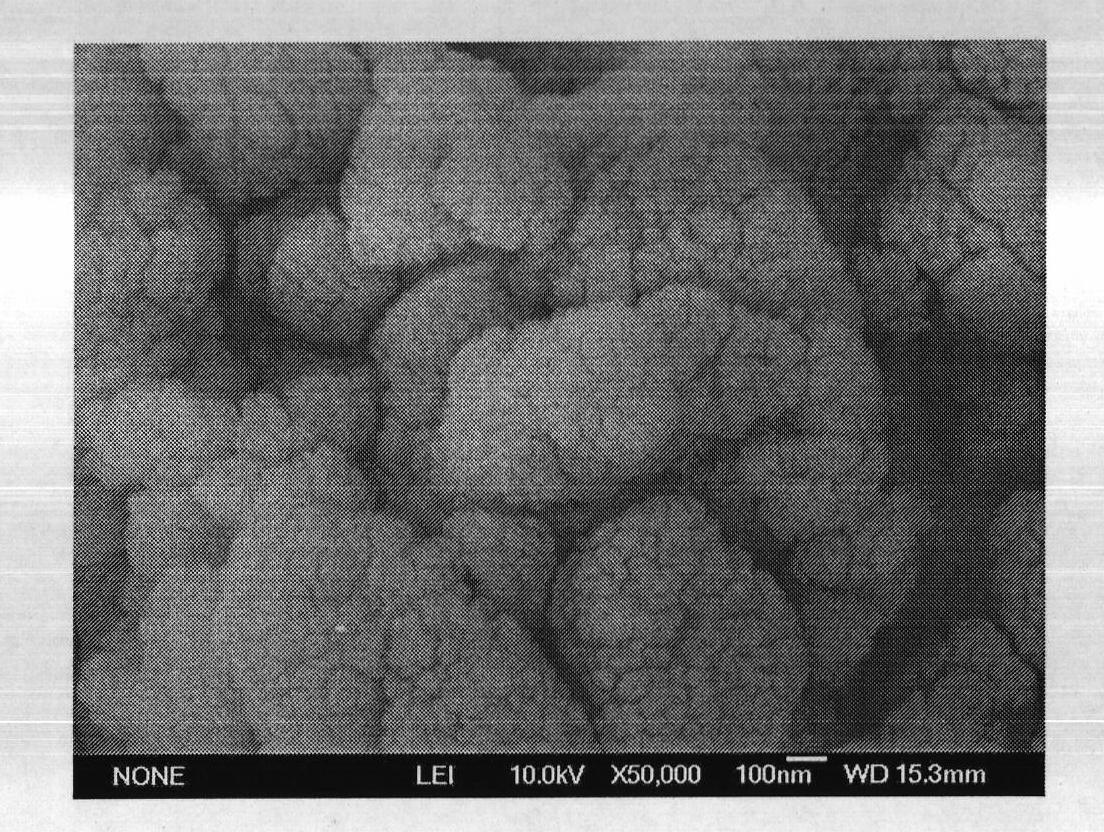

Method for preparing silver-tin oxide electrical contact material by virtue of sol-gel technique

ActiveCN104498914AFulfil requirementsEvenly dispersedLiquid/solution decomposition chemical coatingContactsVolumetric Mass DensityAmmonia

The invention relates to a method for preparing a silver-tin oxide electrical contact material by virtue of a sol-gel technique. The method comprises the following steps: with tin oxide powder and silver nitrate with the particle sizes from 20 nanometers to 100 microns as raw materials, firstly preparing silver nitrate into a water liquid with a certain concentration; adding a proper amount of glycine; adding tin oxide; adding a certain amount of glycol, and regulating the pH value with ammonia water, so as to obtain a stable suspension liquid; heating the suspension liquid to form gel; drying gel to form xerogel; calcining xerogel to obtain silver-tin oxide compound powder; and carrying out hot pressing on the compound powder to prepare a silver-tin oxide electrical contact material. The method can be used for preparing electrical contact materials with any particle size from 20 nanometers to 100 microns and can meet requirements of different circuit loads, and the silver bases of the electrical contact materials are strengthened by tin oxide particles; other addition components are easily added in a sol-gel process, the material loss is avoided, and the silver resource is saved; the temperature of the process for calcining xerogel into the compound powder is low, and the energy consumption is low; and tin oxide is uniformly dispersed in the silver base, so that the material is high in density and the rigidity and good in electrical conductivity, welding resistance and arc erosion resistance.

Owner:NORTHEASTERN UNIV

Silver-nickel composite electrical contact material with nickel distributed in net-shaped mode, and preparation method thereof

InactiveCN103996426ASmall sizeEasy to transformMetal/alloy conductorsCable/conductor manufactureElectricityAdhesive

The invention discloses a silver-nickel composite electrical contact material with nickel distributed in a net-shaped mode, and a preparation method of the silver-nickel composite electrical contact material, and belongs to the field of composite electrical contact materials. According to the silver-nickel composite electrical contact material with the nickel distributed in the net-shaped mode, the nickel is distributed in a silver base body in a continuous net-shaped mode. The silver-nickel composite electrical contact material is composed of, by mass, 50% to 98% of silver and 2% to 50% of nickel. The preparation method includes the steps of obtaining silver particles through a particle manufacturing method, annealing the silver particles, coating the surfaces of the silver particles with nickel powder through adhesives after weighing the material to obtain nickel-coated silver particle composite powder bodies, and obtaining the silver-nickel composite electrical contact material with the nickel distributed in the net-shaped mode through sintering and forming. In a silver-nickel composite material ingot blank, the pure silver areas are large and evenly distributed, the nickel is distributed in the continuous net-shaped mode, and the nickel is lengthened according to deformation of the silver base body after plastic working and distributed in the direction parallel to the pulling direction in a fibriform mode; the silver-nickel composite electrical contact material is high in conductivity, good in arc erosion resistance, easy to operate, short in technological procedure, low in energy consumption and suitable for industrial production, and raw materials can be easily obtained.

Owner:NORTHEASTERN UNIV +1

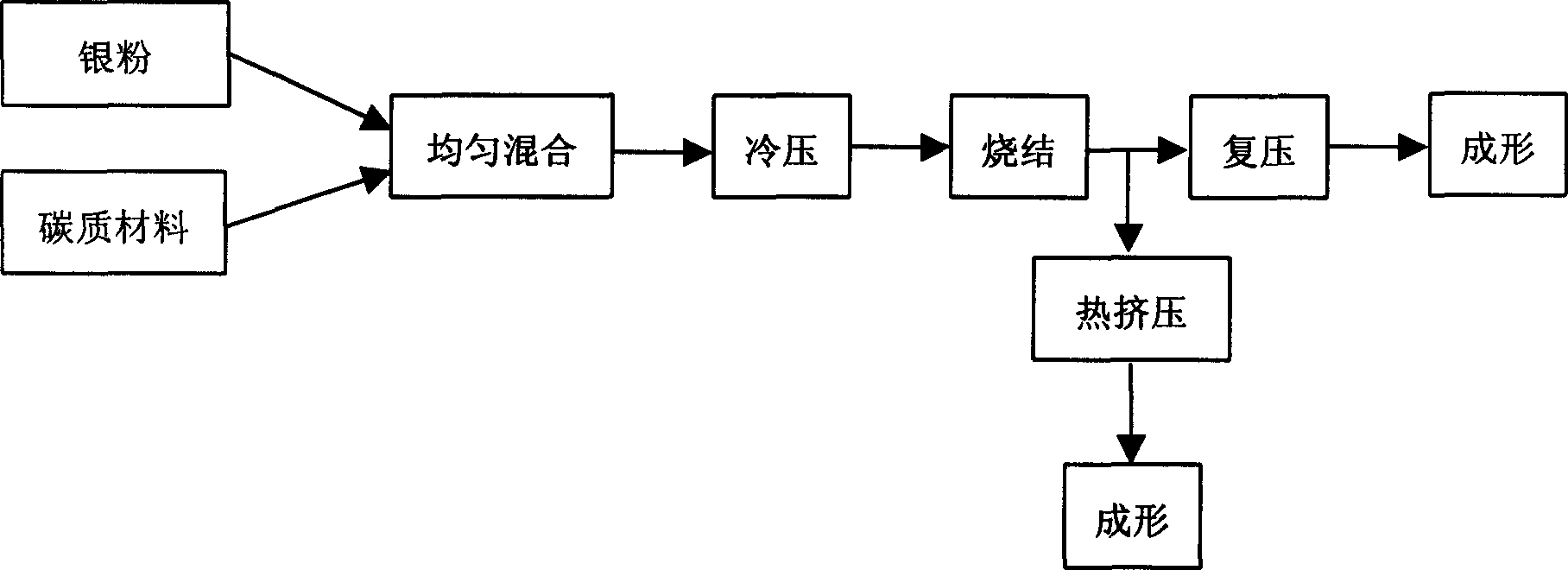

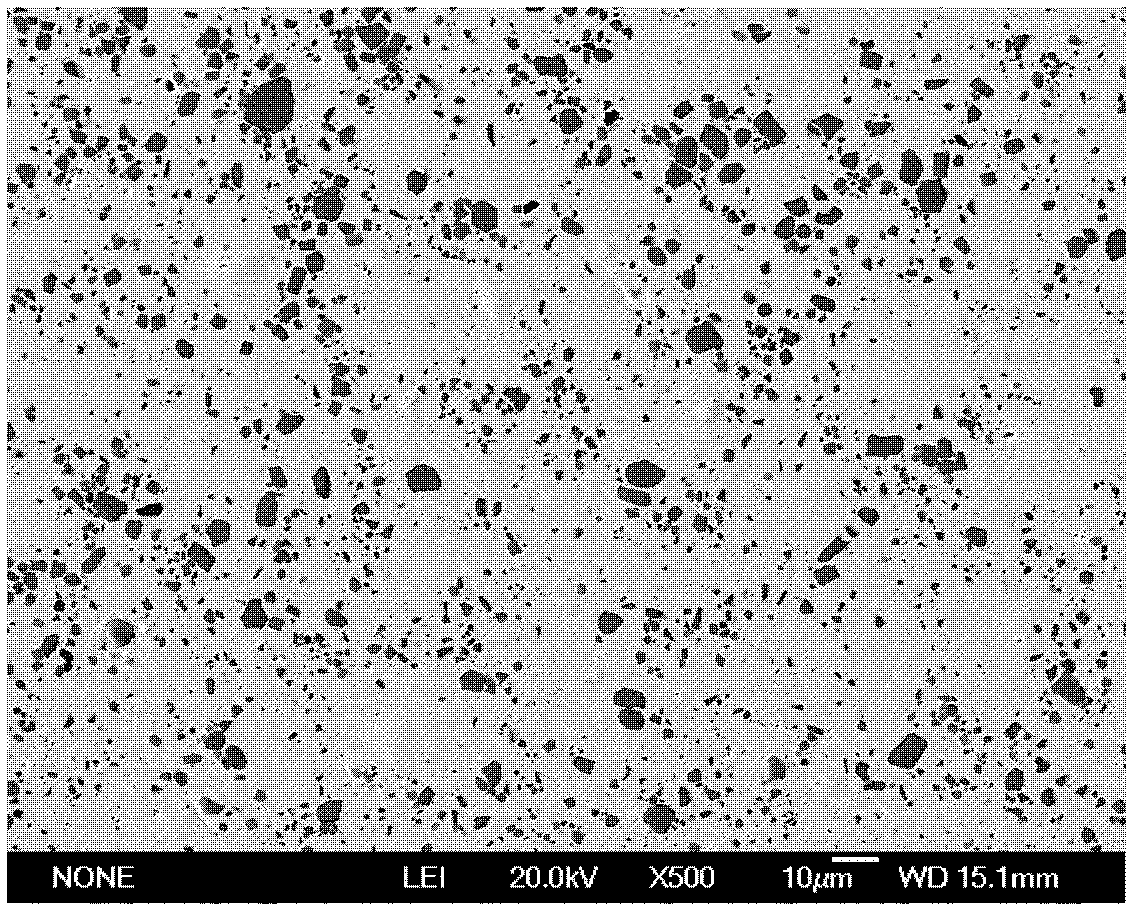

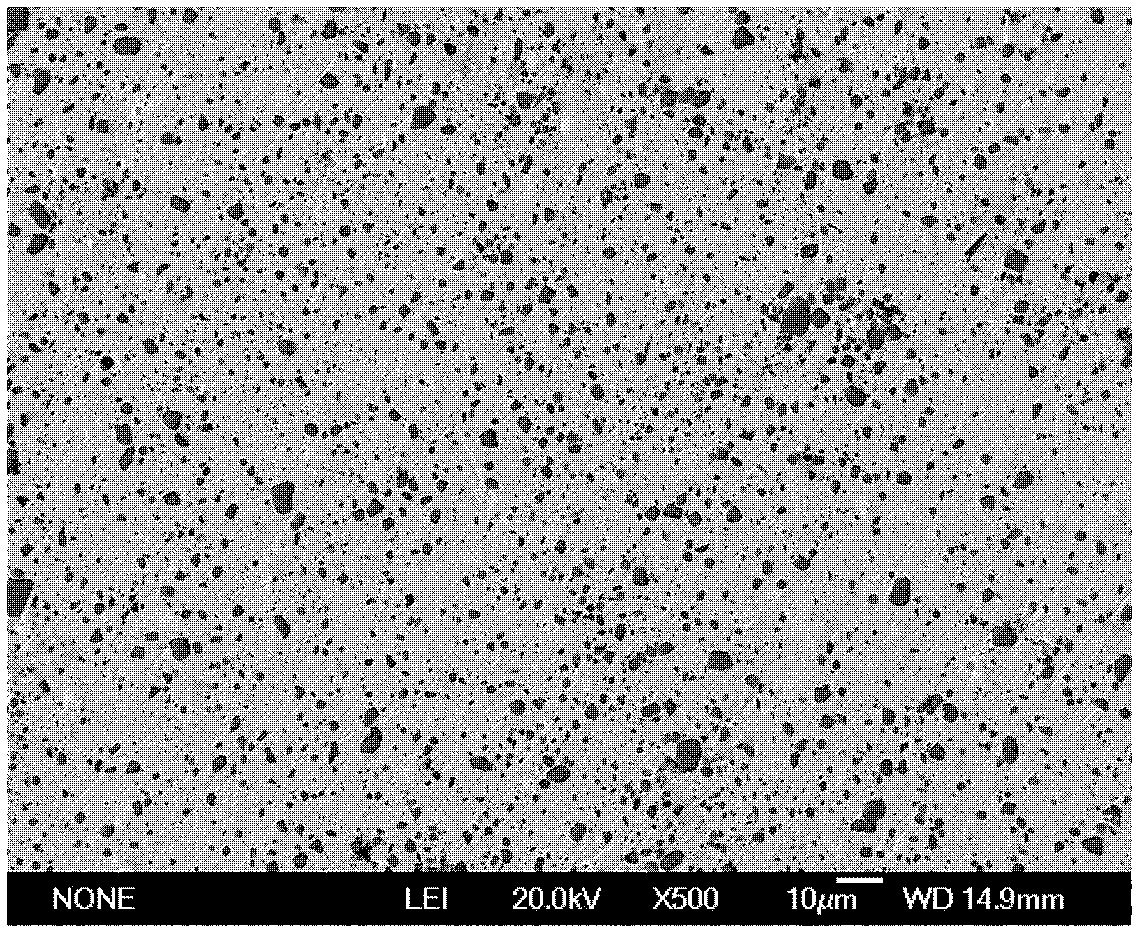

Method of preparing Ag- based oxide contact materials with directionally arranged reinforcing particles

ActiveUS20130266791A1Easy to processImprove performanceCeramic shaping apparatusAnimal housingHigh energyCompound (substance)

In the present invention, a method of preparing Ag-based oxide contact materials with directionally arranged reinforcing particles is disclosed, comprising steps of: a) preparing evenly dispersed composite powders by chemical co-precipitation method combining with roasting, b) granulating the composite powders by high energy ball milling, and sieving the powders, c) mixing the powders and Ag matrix in a powder mixing machine, d) cold isostatic pressing, e) sintering, f) hot-pressing, g) hot-extruding to obtain Ag-based oxide contact materials with directionally arranged reinforcing particles. This method can obtain particle reinforced Ag-based material with good electrical performance even when the reinforced (oxide) particles are very small. This method is simple, easy to operate, and does not require special equipment. The resistance to welding and arc erosion, electric conductivity and the processability of the material prepared through this present invention can be greatly improved.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

Preparation method of silver-based contact material containing graphene

InactiveCN105838914AEffective processing performanceImprove tissue uniformityElectric switchesInsulation layerHeat conducting

The invention discloses a preparation method of a silver-based contact material containing graphene. The silver-based contact material comprises silver oxide, tin oxide, nickel oxide, lanthanum oxide and silver-plated graphene, wherein the content of tin elements is 5-10 wt%, the content of nickel elements is 2-5 wt%, the content of lanthanum elements is 0.5-1 wt%, the content of the silver-plated graphene is 2.5-3.5 wt%, and the balance inevitable impurities, silver and oxygen. Through optimization selection of the ratios and process of the raw materials, the organization uniformity of the silver-based contact material prepared through the method is improved, and the electrical performance of the material is improved. SnO2 powder is prepared through a sol-gel process. Nano SnO2 is uniformly distributed and dispersed in silver base bodies. Contact resistance reduction caused by an insulation layer formed by enrichment of SnO2 can be avoided. The breaking effect of the oxide on the base bodies is reduced. The processing performance of the silver-based contact material can be effectively improved. The capability of welding resistance and electrical arc erosion resistance of the silver-based contact material are improved. The interface wettability between the graphene and metal is improved through the silver-plated grapheme, and the good interface bonding effect can be achieved, so that the electrical conductivity, the heat conducting property and electrical arc erosion resistance of the composite material are further improved, and the requirement for the performance of electrical contacts is met better.

Owner:SUZHOU SICHUANGYUANBO ELECTRONICS TECH CO LTD

Preparation method of tin oxide fiber reinforced silver-based electric contact alloy

InactiveCN105908108AImprove conductivityImproved arc erosion resistanceElectric switchesFiberElectrical resistance and conductance

The invention provides a preparation method of a tin oxide fiber reinforced silver-based electric contact alloy. The method specifically includes: firstly preparing a Sb element doped tin oxide precursor gel, adding the gel into a fiber forming agent to prepare a spinning solution, and conducting electrostatic spinning to obtain Sb element doped SnO2 fiber; then subjecting the fiber and silver powder to mechanical mixing, and carrying out pressing-sintering-extrusion on a silver-tin oxide fiber mixture by a traditional process, thus obtaining the tin oxide fiber reinforced silver-based electric contact alloy. The method provided by the invention improves the electroconductivity of tin oxide through effective doping of the Sb element, reduces the resistance of a contact alloy body, at the same time enables fibrous distribution of a second phase oxide and reinforcement of the oxide in a silver matrix, solves the problems of large contact resistance, high temperature rise and large oxide loss in traditional oxide particle reinforced silver-based electric contact materials during arc erosion, improves the arc erosion resistance of silver-based oxide electric contact alloy, and also expands the application scope of the silver-based oxide electric contact alloy.

Owner:XI'AN POLYTECHNIC UNIVERSITY

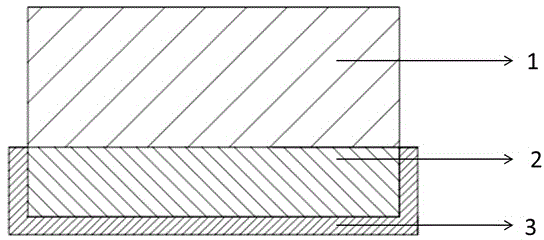

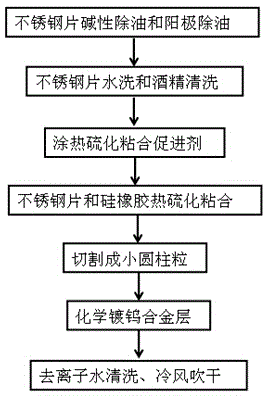

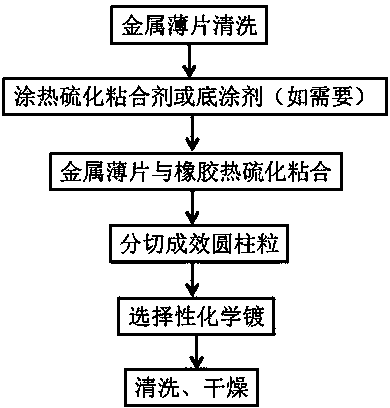

Plated switch contact and preparing method thereof

ActiveCN104112607AImproved arc erosion resistanceImprove reliabilityLiquid/solution decomposition chemical coatingContactsKey pressingVulcanization

The invention discloses a plated switch contact and a preparing method thereof. The switch contact is a combined body with a three-layer structure, the first layer is a hydrophobic rubber layer, the second layer is a sheet metal layer, the third layer is a plated layer, and a combination body of the first layer and the second layer is soaked in a chemical plating solution with a soluble gold compound and gold or gold alloy is selectively deposited on the surface of sheet metal in the combination body by a chemical deposit method to form the plated layer. According to the plated switch contact and the preparing method thereof, the prepared switch contact is suitable for heat vulcanization bonding and forming with rubber, and thereby, a rubber press key with the switch contact can be produced. The switch contact has the advantages that the resistance to atmospheric corrosion, contact chatter and arc erosion is good, the surface contact resistance is low, the service life is long, and the like.

Owner:NANTONG MEMTECH TECH

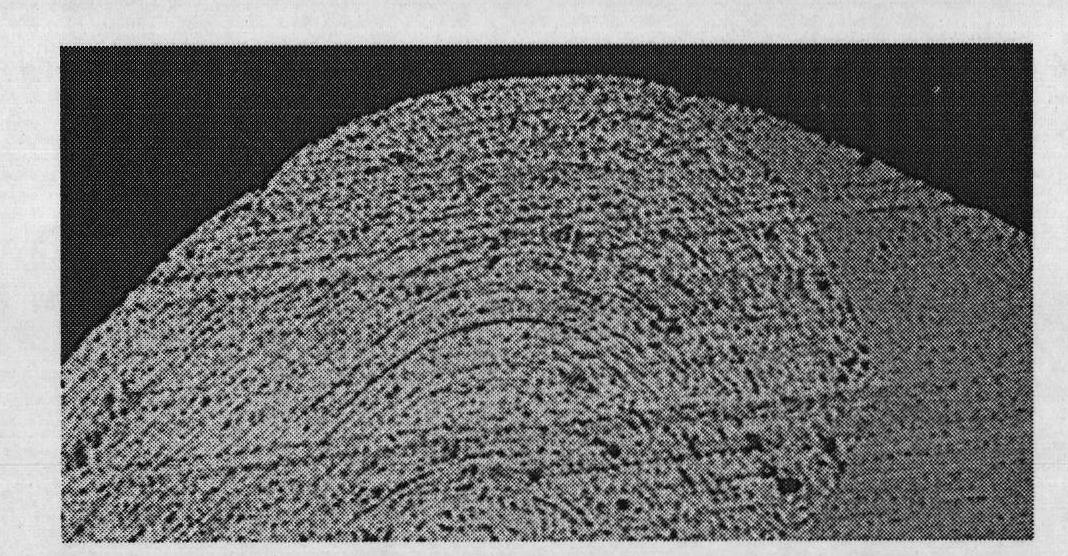

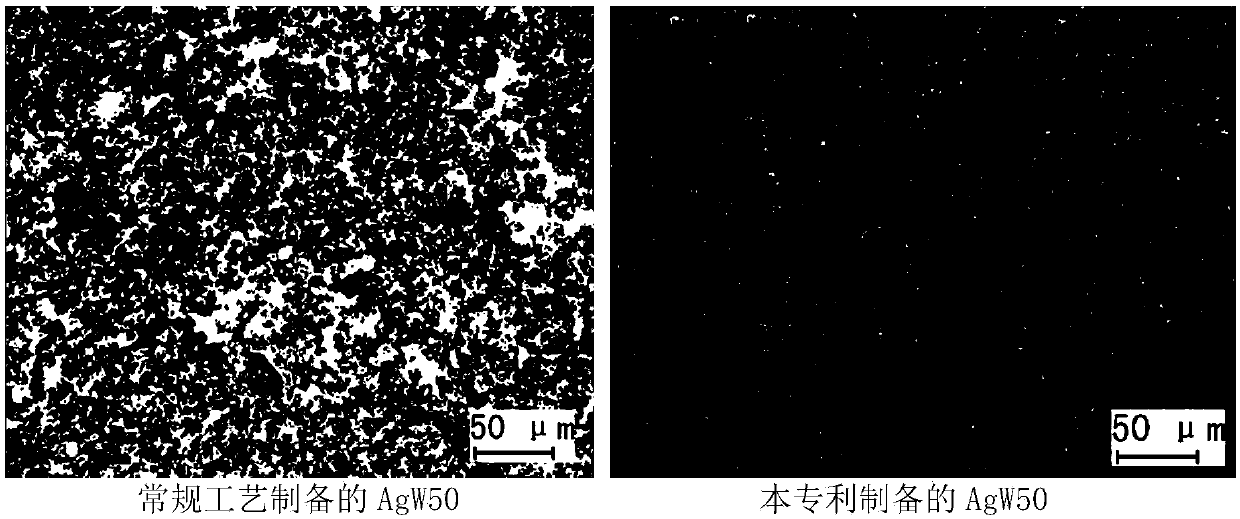

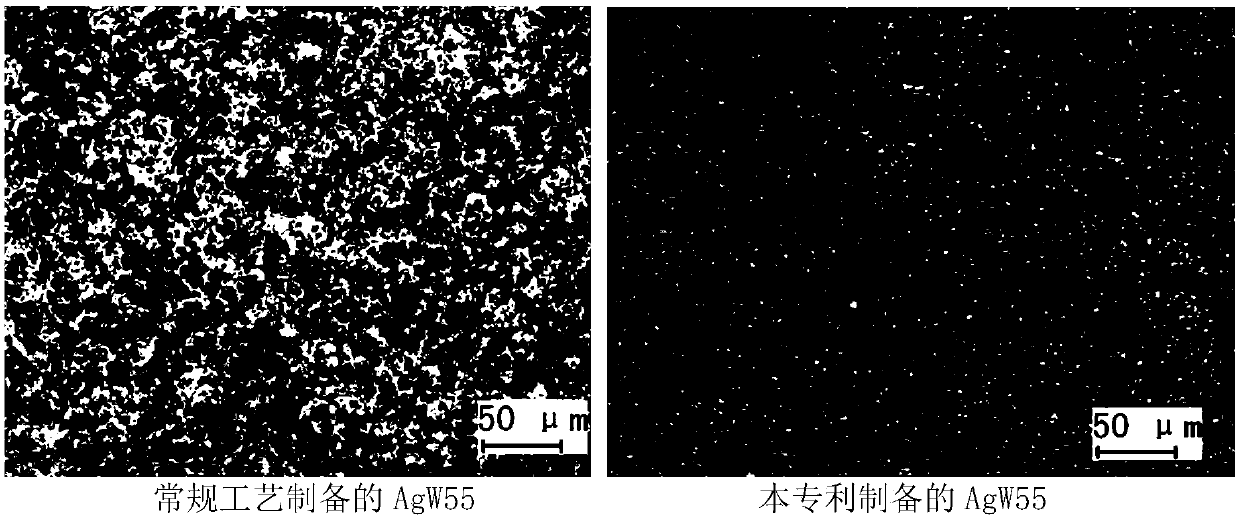

Preparation method of superfine high-diffusion silver-tungsten electric contact material

The invention discloses a preparation method of a superfine high-diffusion silver-tungsten electric contact material. Spherical foam tungsten powder and activating elements are premixed and then mixedwith a part of silver powder into framework powder, the framework powder is primarily pressed into a framework with certain porosity, vacuum sintering is conducted, then silvering is conducted, and compact superfine high-diffusion silver-tungsten alloy is obtained. According to the prepared high-uniformity silver-tungsten electric contact material, two phases of matrix silver and high-melting-point tungsten are fine in grain and are distributed in a mutually diffusing mode, components and shapes in all micro-area range of contact surfaces in the arc erosion process change slightly, and thus the high and reliable arc erosion resistance is achieved. The superfine high-diffusion silver-tungsten electric contact material is simple in process and suitable for mass production, and prepared products can be widely applied to circuit breakers and contactors.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

Micromotor commutator electric contact material for raising wear resistance and arc erosion resistance

The invention discloses a micromotor commutator electric contact material for raising wear resistance and arc erosion resistance. The material provided by the invention comprises the following components of: by weight, 1-8% of Cu, 0.1-0.5% of Ni, 0-5% of Zn, 0.5-2% of an oxide, and the balance being silver, wherein the oxide is any one selected from Al2O3, ZrO2, CeO2 and Cr2O3, and the granularity of the oxide needs to be controlled below 3 microns. Prepared by a powder metallurgic technique, the material has excellent wear resistance, arc resistance and welding resistance, can be used to effectively prevent short circuit caused by aggregation of abrasive dust in a groove of a commutator, and is suitable for manufacturing a micromotor commutator with large arc during the commutation stage.

Owner:CHONGQING CHUANYI AUTOMATION

Silver-based and titanium-carbide-based contact material and preparation method thereof

InactiveCN104051054AHigh melting pointImprove antioxidant capacityNon-metal conductorsCable/conductor manufactureTitanium carbideCobalt

The invention provides a silver-based and titanium-carbide-based contact material and a preparation method thereof. The silver-based and titanium-carbide-based contact material comprises, by weight, 3%-40% of titanium carbide and the balance silver, or comprises, by weight, 3%-40% of titanium carbide, 0.01%-5% of carbon and the balance silver, or comprises, by weight, 3%-40% of titanium carbide, 0.01%-4% of a mixture of one or several kinds of iron, cobalt and nickel and the balance silver, or comprises, by weight, 3%-40% of titanium carbide, 0.01%-5% of carbon, 0.01%-4% of a mixture of one or several kinds of iron, cobalt and nickel and the balance silver. A power metallurgic method and an infiltration method are adopted in the preparation method. The silver-based and titanium-carbide-based contact material has the advantages that welding resistance is good, arc erosion resistance is achieved, under the condition of long-time use, contact resistance between contacts is low, and contact temperature rising is low and stable.

Owner:哈尔滨东大高新材料股份有限公司

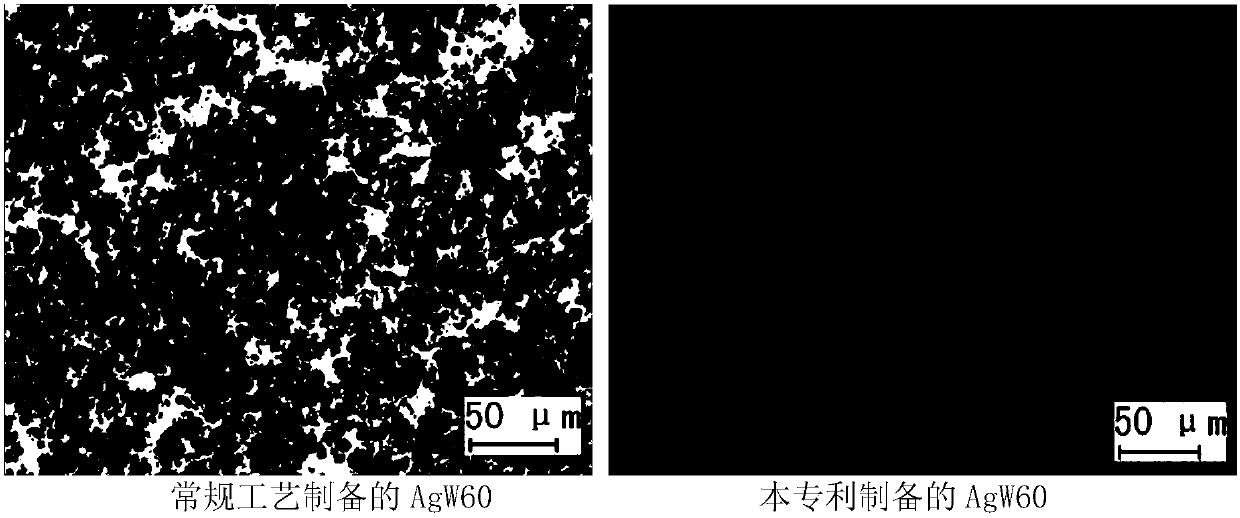

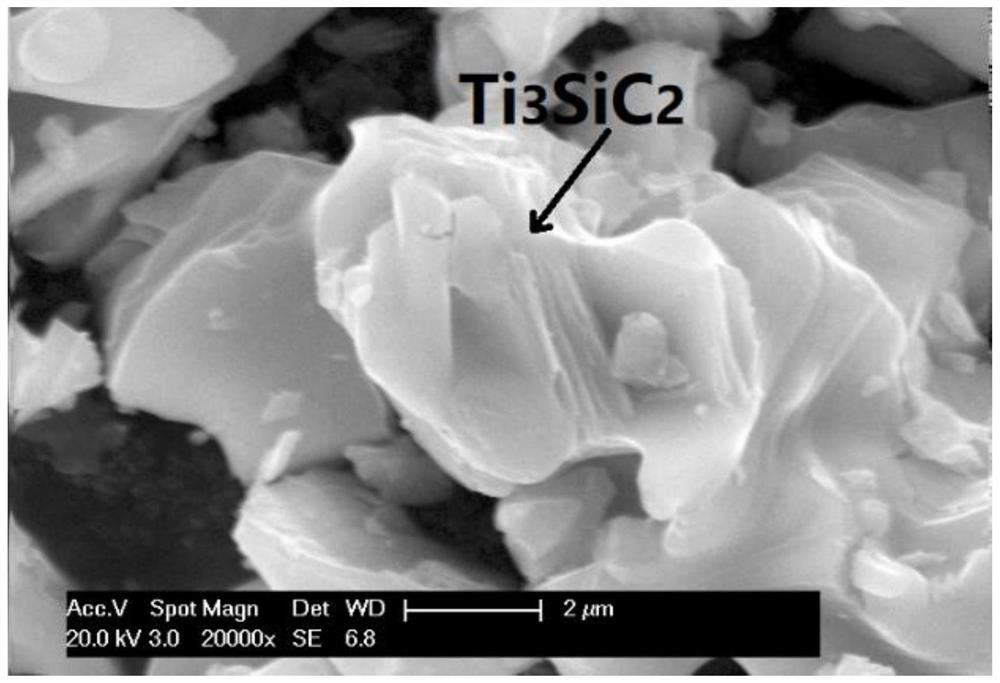

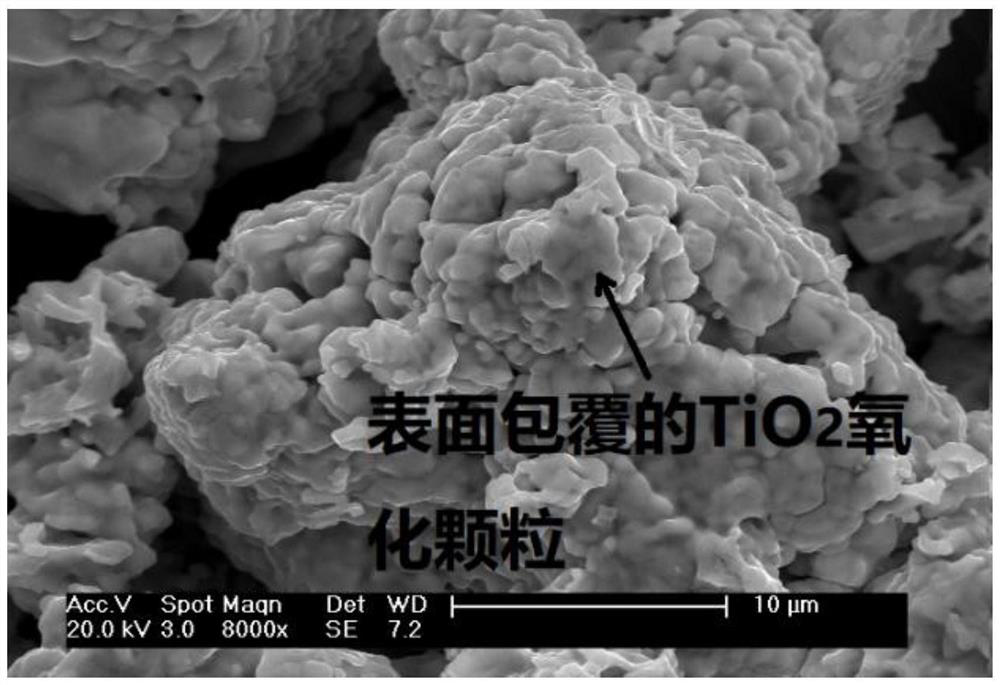

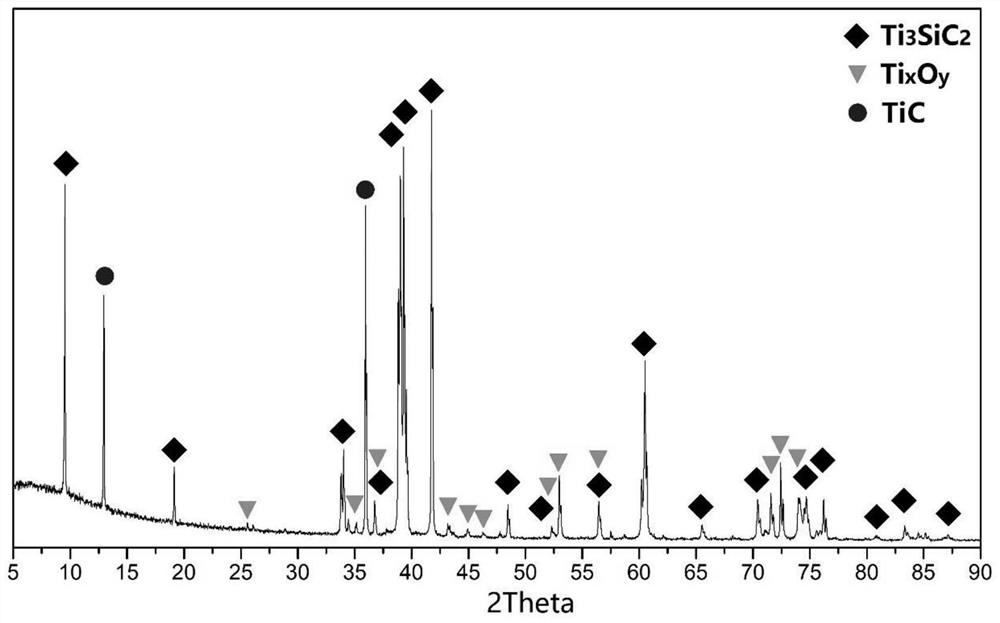

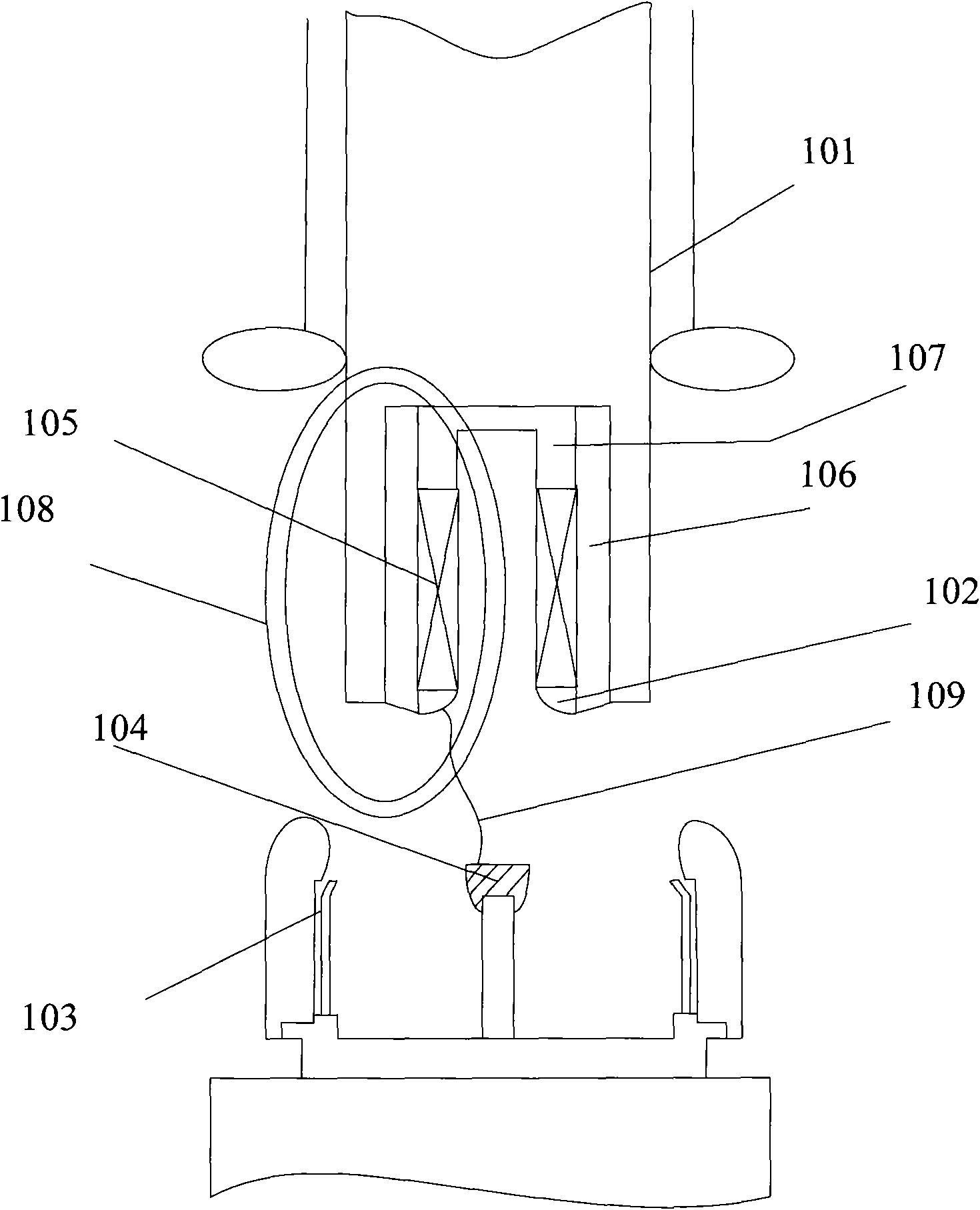

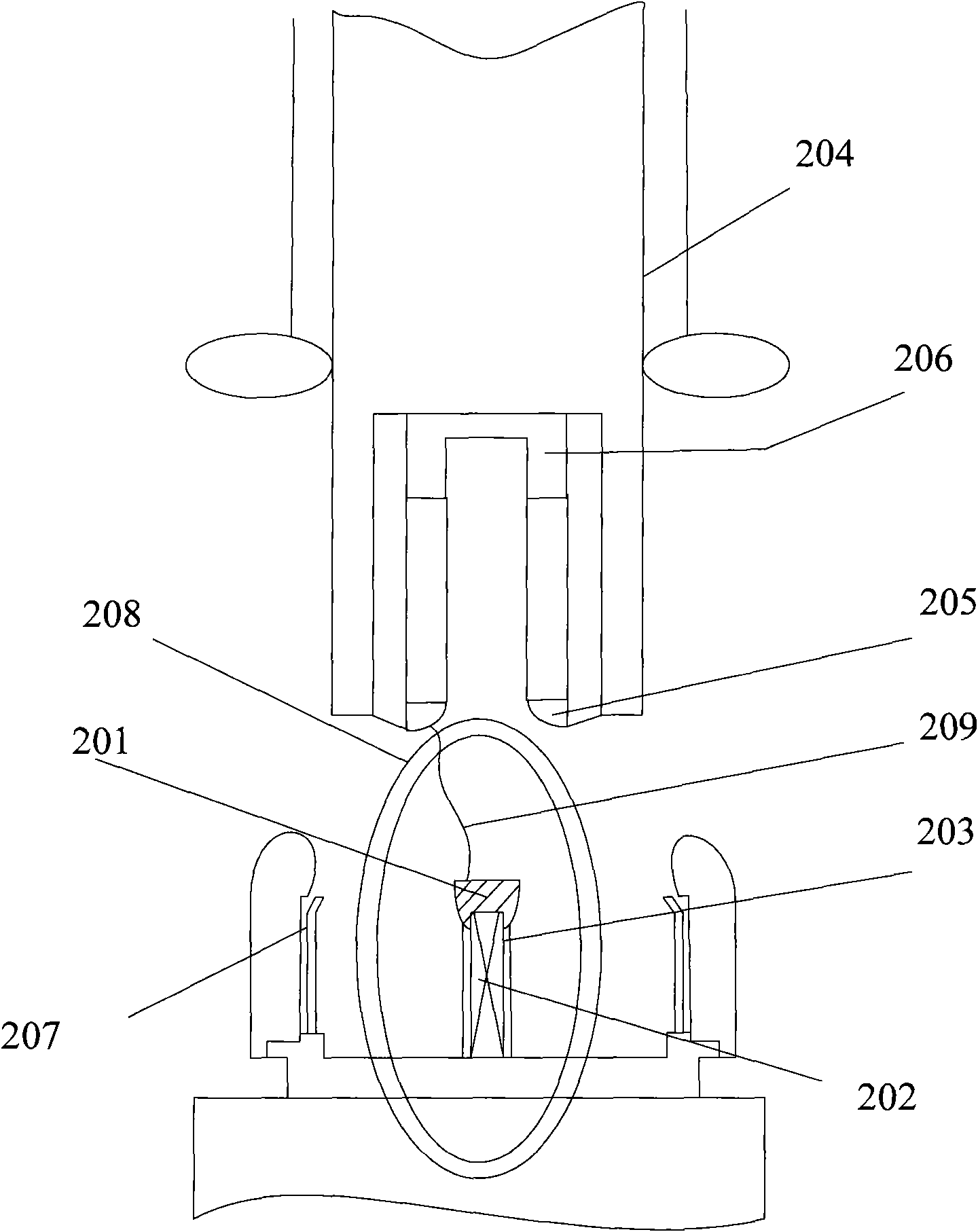

MAX@MOm/AOn electrical contact reinforced phase material, composite electrical contact material and preparation method

The invention discloses an MAX@MOm / AOn electrical contact reinforced phase material, a composite electrical contact material and a preparation method. The material is MAX@MOm / AOn with a core-shell structure, the inner core of the MAX@MOm / AOn is a three-dimensional material MAX phase, and the outer shell of the MAX@MOm / AOn is oxide particles MOm, AOn or a composite oxide layer MOm / AOn correspondingto the material of the inner core MAX phase. The Ag / MAX@MOm / AOn composite electrical contact material prepared by adopting the MAX@MOm / AOn prepared by the invention as a reinforcing phase is used forpreparing the Ag / MAX@MOm / AOn composite electrical contact material, the composite material is excellent in electrical conductivity, moderate in hardness and good in processability, can be processed into various electrical contact shapes according to actual application requirements, is excellent in arc erosion resistance and remarkable in silver-saving effect, and the content of a reinforcing phase MAX@MOm / AOn in an Ag matrix accounts for 40 wt% of the composite material at most. The preparation process is simple, good in practicability and suitable for large-scale production, is suitable forlow-voltage switch equipment such as contactors, circuit breakers and relays, and brings social and economic values.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Isolating switch

InactiveCN101587787AReduce arc ablationIncreased ability to switch currentHigh-tension/heavy-dress switchesAir-break switchesEngineeringMagnetic field

The invention embodiment discloses an isolation switch, comprising a movable contact and a stationary contact. An arc-extinguishing device is installed on the movable contact and / or the stationary contact. The isolation switch introduces the arcing current generated between the contacts into a coil in the process of converting the current by turning on / off the bus. The coil forms a magnetic field. The electric arc can be extinguished stably, driven by a magnetic field force, thus reducing the arc erosion degree of the contact, effectively improving the ability of the isolation switch for converting the current by turning on / off the bus.

Owner:HENAN PINGGAO ELECTRIC +1

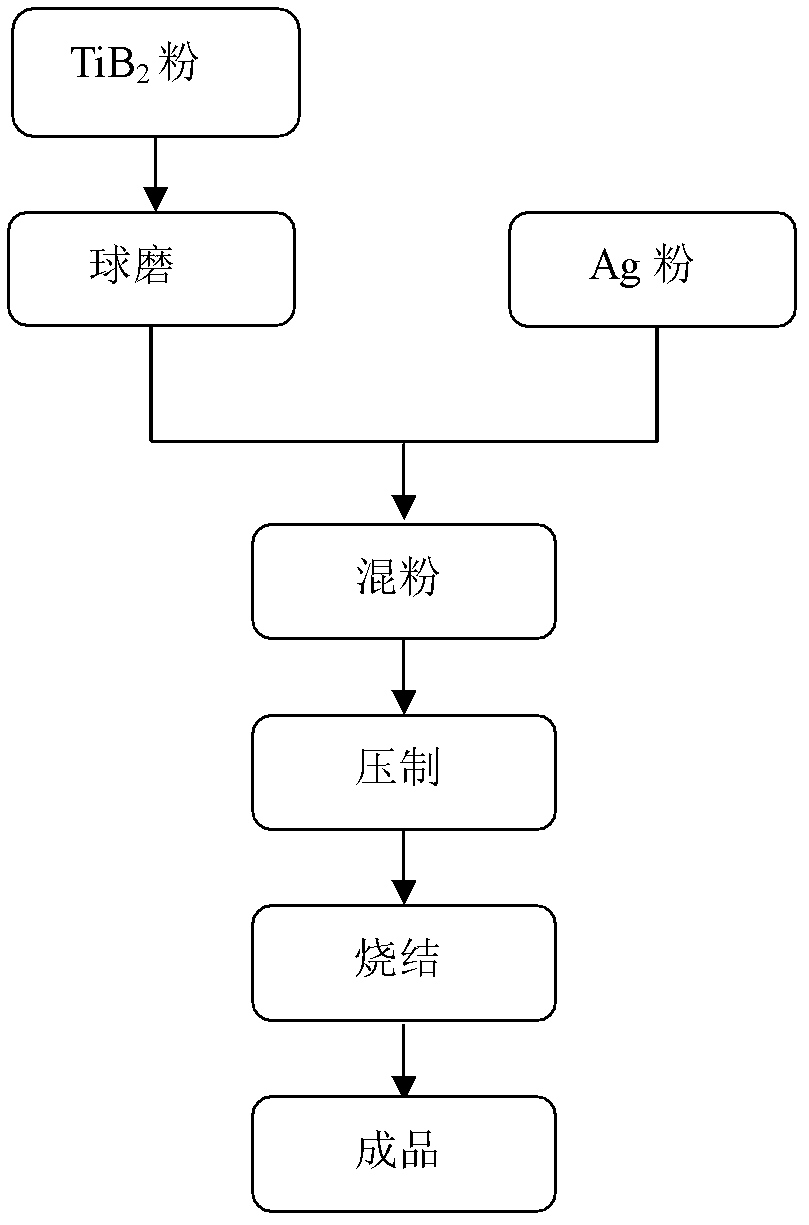

Method for preparing AgTiB2 contact material

The invention discloses a method for preparing a AgTiB2 contact material, which comprises: ball-milling TiB2 powder, and mixing the TiB2 powder and Ag powder, wherein the high-purity Ag powder and TiB2 powder are used as the raw materials; and pressing the mixed powder by a press, sintering the pressed blanks under vacuum, and obtaining the AgTiB2 contact material. Compared with the conventional powder metallurgy technology, the preparation method disclosed by the invention can obviously improve the compactness and hardness of the AgTiB2 contact material, thereby improving arc erosion resistance.

Owner:XIAN UNIV OF TECH

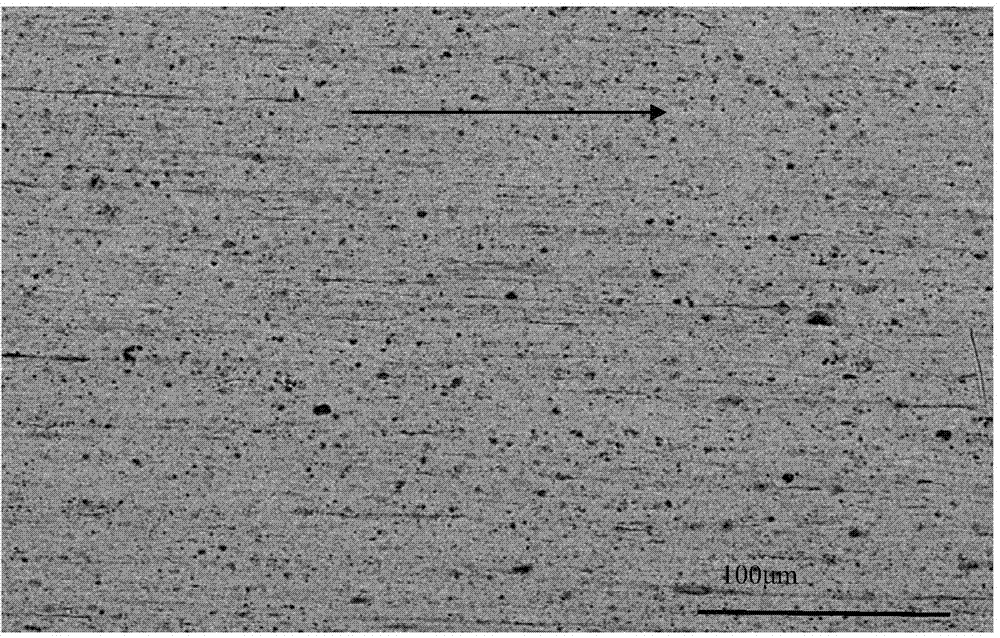

Method of Preparing Silver-Based Oxide Electrical Contact Materials with Fiber-like Arrangement

ActiveUS20130266468A1High to erosionIncrease resistanceMetal/alloy conductorsContactsFiberMetal alloy

A method of preparing silver-based oxide electrical contact materials with fiber-like arrangement, includes the following steps of: (1) uniformly mixing the silver-metal alloy powders and graphite powders and then ball-milling; (2) internally oxidizing the ball-milled powders; (3) sieving; (4) placing the sieved powders and the matrix powders into the powder mixer for mixing; (5) cold-isostatically pressing; (6) sintering; (7) hot-pressing; and (8) hot-extruding, thereby obtaining the silver-based oxide electrical contact material with fiber-like arrangement. The method of the present invention can obtain the silver-based oxide electrical contact material having neat fiber-like arrangement with no specific requirement on processing deformation, plasticity and ductility of the reinforcing phase. The production process in this method is simple and is easy to operate. Besides, there is no particular requirement on the equipment. The method greatly improves the performance of contact materials in aspects of resistance to welding and arc erosion, conductivity, and processing performance

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

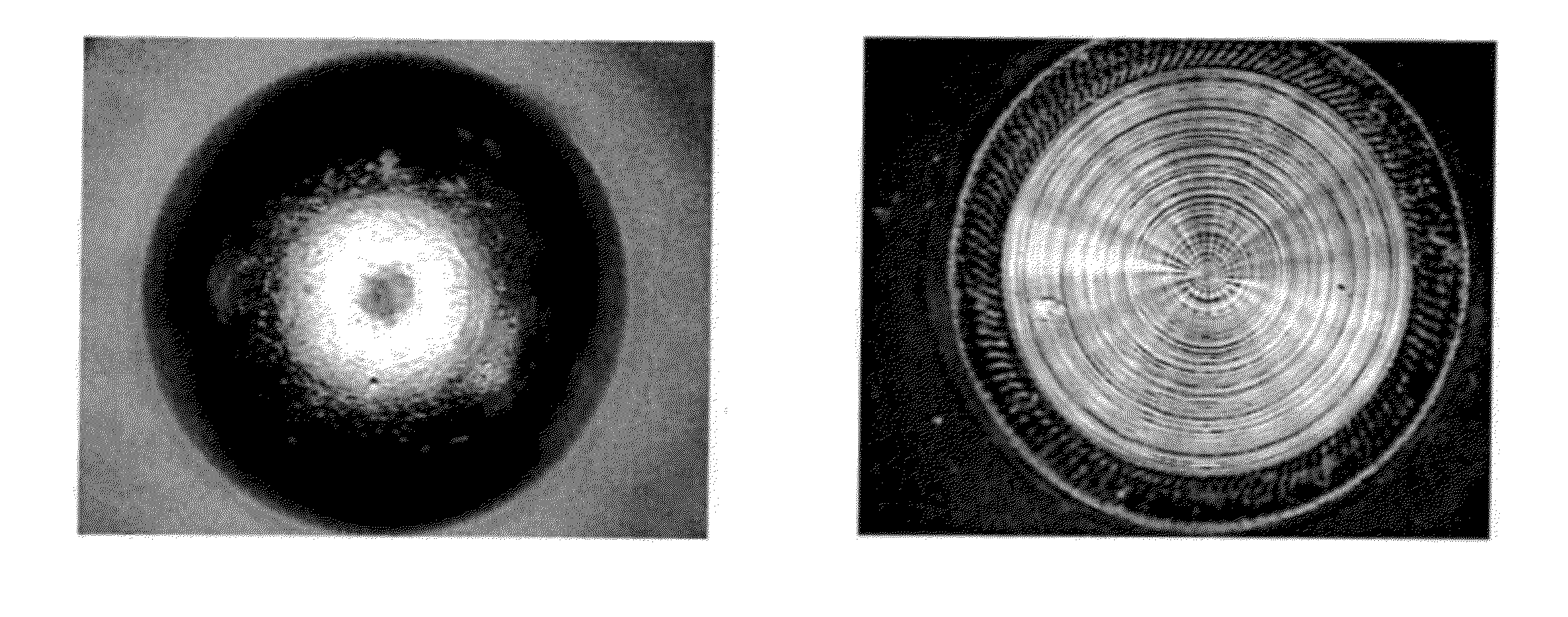

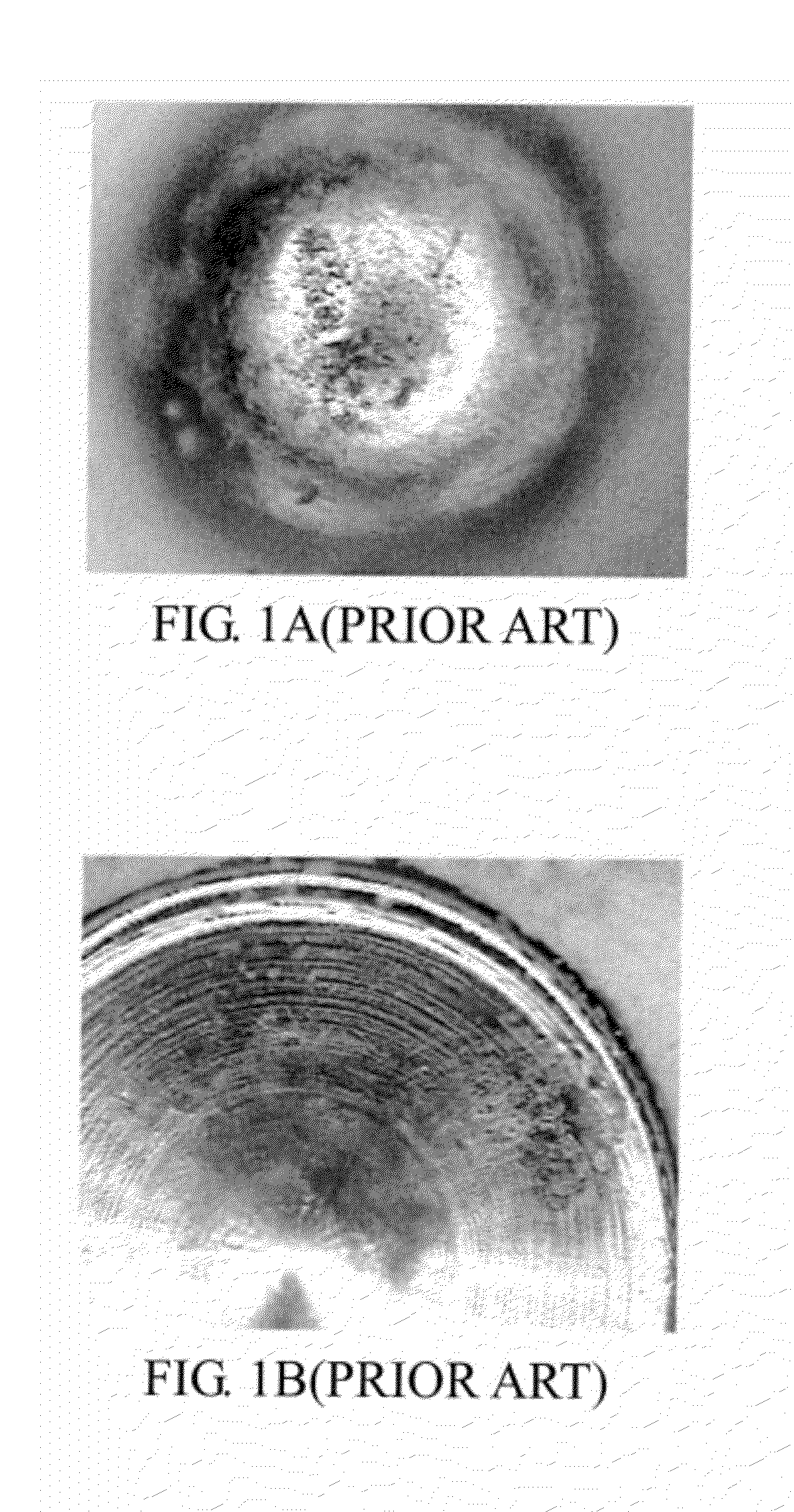

Switch contact comprising molybdenum alloy coating and production method thereof

ActiveCN104103432AImprove conductivityReduce contact resistanceLiquid/solution decomposition chemical coatingContactsVulcanizationGram

The invention discloses a switch contact comprising a molybdenum alloy coating and a production method thereof. The switch contact comprises three layers of structures; the first layer is a hydrophobic rubber layer; the second layer is a sheet metal layer; the third layer is a molybdenum alloy chemical sediment layer; a plating solution adopted in the chemical sediment layer comprises 20 to 125 grams per liter of soluble molybdenum compounds; the molybdenum alloy coating is selectively deposited on the metal surface when the chemical deposition is performed on layered composites of the hydrophobic rubber layer and the sheet metal layer through the plating solution. According to the switch contact comprising the molybdenum alloy coating and the production method thereof, the switch contact is good in metal color, low in contact resistance, high in switching arc erosion resistance, long in service life and suitable for hot vulcanization bonding and forming with rubber.

Owner:NANTONG MEMTECH TECH

Electrical contact material of silver matrix capable of resisting arc erosion and containing no cadmium-composite

ActiveUS20120132869A1High hardnessImproved arc erosion resistanceContact with seperate bridge contactLegendsAmpereCadmium Cation

In an electric contact material of silver matrix capable of resisting arc erosion and containing no cadmium-composite, an Ag—(SnO2+In2O3) composite containing 9˜11% of (SnO2+In2O3) or an Ag—Cu oxide, composite containing 15˜25% of Cu oxide is used. The electrical contact material has a contact resistance of 5˜60 milliohms (mohm) and an arc erosion resistance capability up to 2*103˜10*103 times provided that the Vickers hardness (Hv) of the material is 100˜150, the measured current is 1˜5 amperes, and the measured voltage is 10˜20 volts. Two electrical contacts maintain an arc erosion resisting capability at the condition of a low contact resistance when the electrical contact material is formed on a surface of a metal substrate of an electric connector.

Owner:C C P CONTACT PROBES

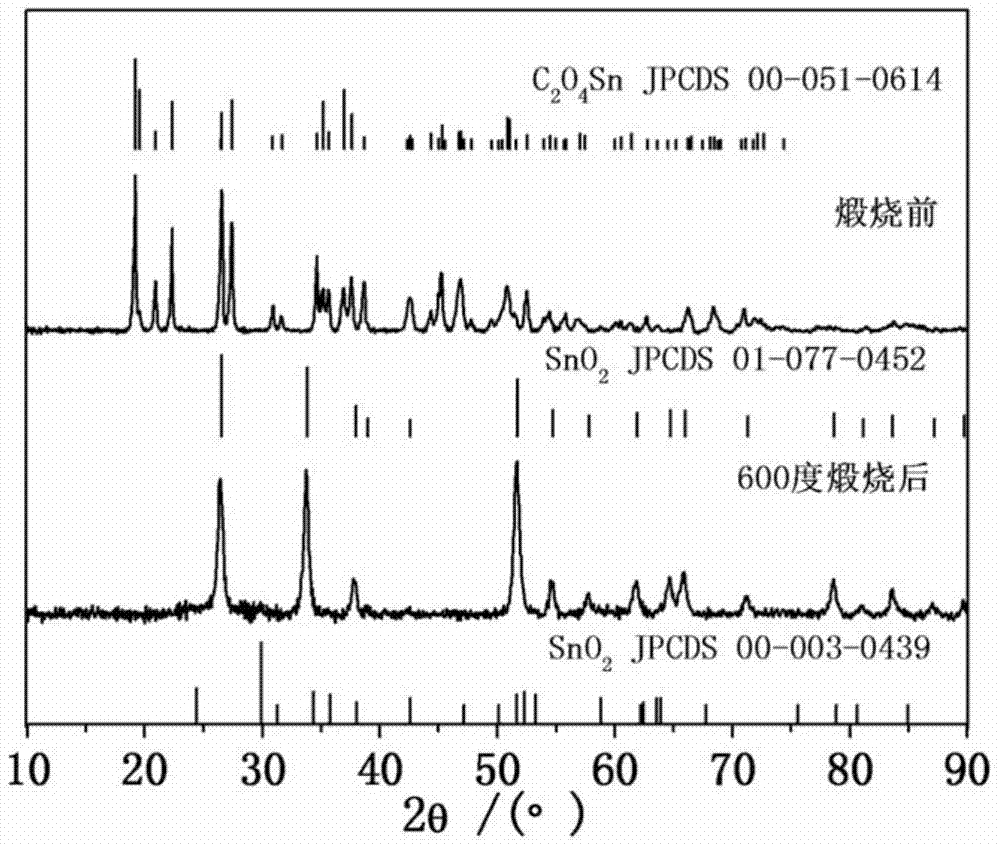

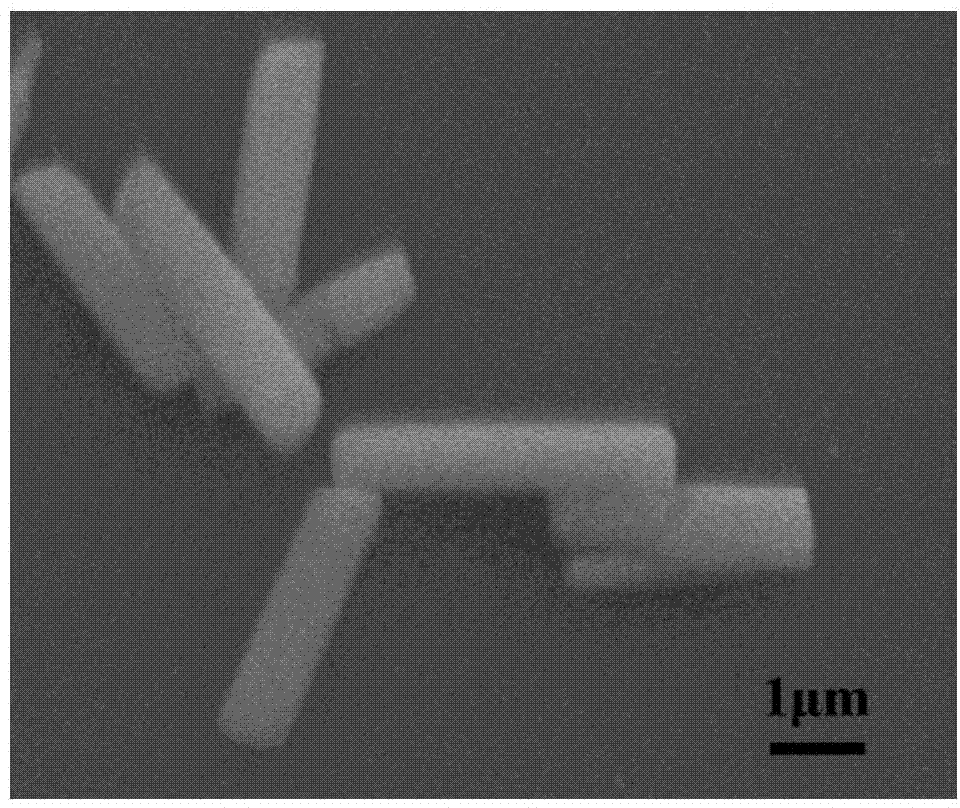

Preparation method of rod-shaped tin oxide-reinforced silver-based electric contact material

ActiveCN104505287AHigh yieldHigh purityTransportation and packagingMetal-working apparatusElectric contactRaw material

The invention provides a preparation method of a rod-shaped tin oxide-reinforced silver-based electric contact material. The preparation method comprises the following steps: (1), preparing a stannous salt solution with certain concentration and an oxalic acid solution with certain concentration; (2), taking a certain amount of stannous salt solution and oxalic acid solution according to the molar ratio of stannous salt to oxalic acid, and mixing to react for certain time; (3), separating out reaction precipitates by centrifugation, and drying the reaction precipitates to obtain a stannous oxalate precursor; (4) incinerating the stannous oxalate precursor to obtain putty powder; (5), preparing silver-coated tin oxide compound power by taking the putty powder and silver nitrate as raw materials according to a chemical coating method; (6) hot-pressing the compound powder into a blank; (7), hot-extruding the blank into a rod; and (8) drawing the rod into a wire material. According to the method, the rod-shaped putty powder is high in yield and high in purity, and the process is simple; the rod-shaped tin oxide is distributed in a electric contact wire material in an oriented manner along the drawing direction; the prepared electric contact material is high in rigidity and has favorable electric conductivity, welding resistance and arc erosion resistance.

Owner:NORTHEASTERN UNIV +1

Preparation method for copper-based electric contact material with graphene

InactiveCN105719854AEffective processing performanceImprove tissue uniformityContactsCopper platingLanthanoid Series Elements

The invention discloses a preparation method for a copper-based electric contact material with graphene. The copper-based electric contact material comprises copper, tin oxides, dysprosium oxides, lanthanum oxides and copper-plated graphene, wherein the content of the tin element is 5-10 wt%, the content of the dysprosium element is 0.2-0.5 wt%, the content of the lanthanum element is 0.5-1wt%, the content of the copper-plated graphene is 1.5-2.5 wt% and the balance comprises unavoidable impurities, and the balance elements are copper and oxygen. According to the copper-based electric contact material prepared by the preparation method, by optimally selecting the proportion of raw materials and technology, the material is enhanced in texture uniformity and improved in electrical property, particularly the rigidity and wear-resisting property of the material are improved by doping rare earth elements, and the interface wettability between the graphene and the metal is improved by the copper-plated graphene, thus the acquisition of the good interface bonding is facilitated, the electrical conductivity, heat-conducting property and anti-arc erosion performance of the composite material are further improved, and the performance requirement of the electric contact can be better met.

Owner:SUZHOU SICHUANGYUANBO ELECTRONICS TECH CO LTD

Silver-boron nitride-cerium switch apparatus contact material and preparation method thereof

InactiveCN102031409ASimple preparation processGood arc corrosion resistanceContactsElectricityLiquid state

The invention discloses a silver-ceramic series electric contact material and a preparation method thereof. The material consists of 1 to 15 weight percent of boron nitride (BN), 0.5 weight percent of cerium (Ce) and the balance of silver (Ag). The silver-boron nitride-cerium contact material prepared by the method is second-phase boron nitride (BN) particles which are dispersed and distributed in a silver matrix to reinforce the contact material, and the addition of the cerium improves wettability of liquid-state silver on the boron nitride to prevent the second-phase particles from clustering and more compactly combine the silver with the boron nitride. Experimental results of electric life after 2 hundred thousand times of action at direct current of 12V and lamp load of 8*21W+5*5W (impact current of 33A and steady current of 16A) can show that the pitting of a contact is not serious, and the contact material is not obviously transferred and the material has the advantages of high arc erosion resistance, material transfer resistance and comprehensive performance.

Owner:HEBEI UNIV OF TECH

CuCr alloy contact material and preparation method thereof

The invention discloses a CuCr alloy contact material and a preparation method thereof. The method comprises the following steps: (1) depositing a Cu membrane on an autorotating substrate by virtue of physical vapor deposition; (2) starting the deposition of a Cr component, keeping the relative deposition rate of the Cr component increasing in a terraced shape, and depositing a CuCr alloy membrane a on the Cu membrane, wherein the relative deposition rate of the Cr component is the ratio of the deposition rate of the Cr component to that of a Cu component, the deposition rate of the Cr component is the mass of Cr deposited on per unit area of the substrate in unit time, and the deposition rate of the Cu component is the mass of Cu deposited on per unit area of the substrate in unit time; (3) keeping the relative deposition rate of the Cr component unchanged, continuously depositing a CuCr alloy membrane b on the CuCr alloy membrane a and annealing in situ under a vacuum condition, thus obtaining the CuCr alloy contact material. According to the invention, the CuCr alloy contact material which is high in strength, high in electric conduction and high in arc erosion resistance is prepared by utilizing a physical vapor deposition method; and simultaneously, the preparation method disclosed by the invention can be used for saving energy and reducing raw material consumption.

Owner:CHINA CREC RAILWAY ELECTRIFICATION BUREAU GRP +1

Switch contact with refractory metal alloy coating layer and preparation method thereof

ActiveCN104112608ALiquid/solution decomposition chemical coatingContactsElectrical resistance and conductanceVulcanization

The invention discloses a switch contact with a refractory metal alloy coating layer and a preparation method thereof. A contact part is in a three-layer structure, the first layer is a hydrophobic rubber layer, the second layer is a sheet metal layer, and the third layer is a chemically deposited layer of a refractory metal alloy. A plating solution used for chemical deposition contains a soluble tungsten compound, a soluble molybdenum compound and the like. When a layered complex of the hydrophobic rubber layer and the sheet metal layer performs chemical deposition by the aid of the plating solution, the refractory metal alloy coating layer is selectively deposited on metal surfaces. The prepared switch contact has the advantages that the metal luster and color is good, the contact resistance and the costs are low, the resistance to switching arc erosion is high, the service life is long, and the switch contact is suitable for heat vulcanization bonding and forming with rubber.

Owner:NANTONG MEMTECH TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com