A silver tin/copper oxide compound electrical contact and preparation method

A technology of silver tin oxide and electric contacts, applied in contacts, circuits, electric switches, etc., can solve the problems of limited tin oxide content of products, high silver content of contact materials as a whole, and high production costs, so as to save precious metal silver , Physical properties and electrical properties are improved, and the uniformity of the structure is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

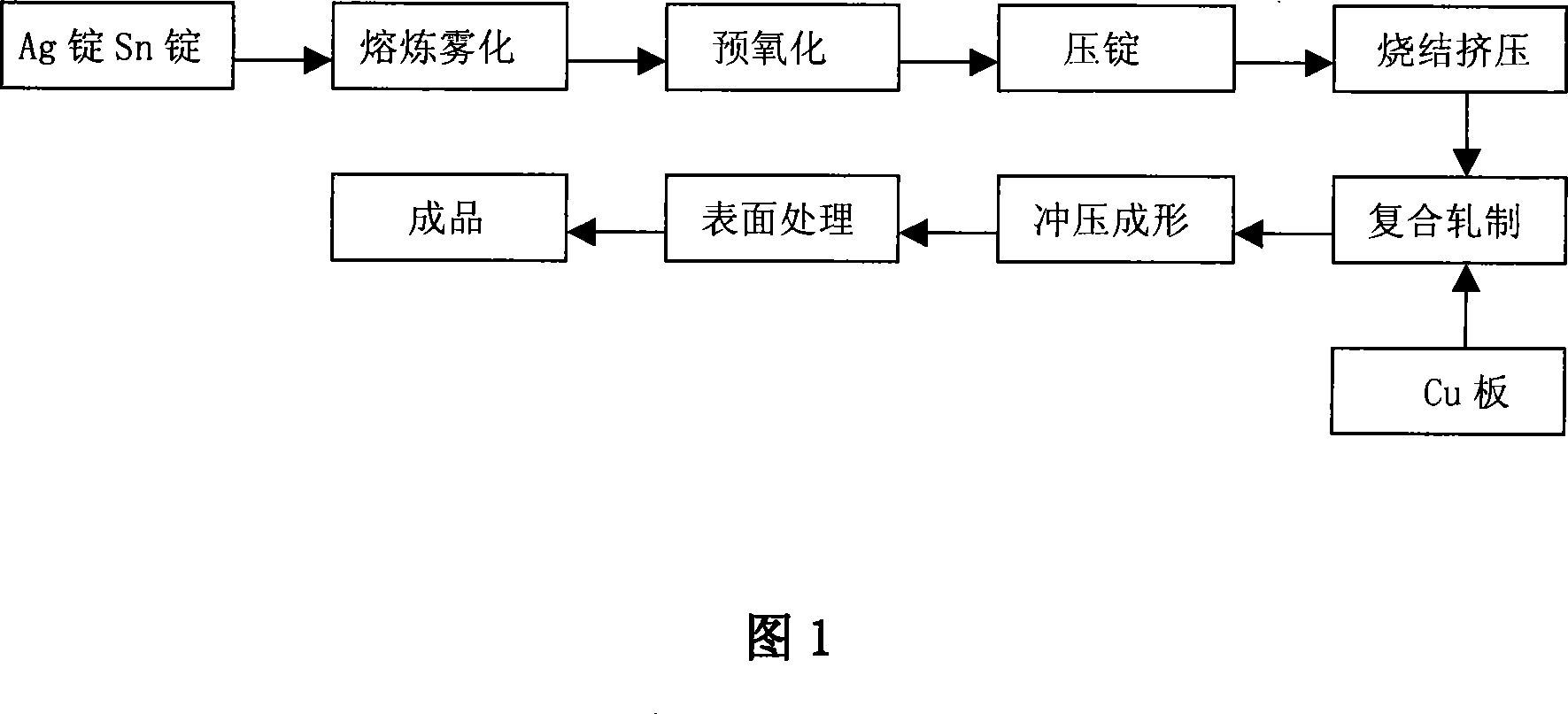

Embodiment 1

[0023] Embodiment 1: Ag ingot, Sn ingot and mixed rare earth in a ratio of 88:9.5:0.3 by weight, take 26.4Kg of Ag ingot, 2.85Kg of Sn ingot and 0.09Kg of mixed rare earth, place it in an intermediate frequency melting furnace and smelt it into a liquid state After that, the alloy is atomized with high-pressure water atomization equipment, and the atomized particle liquid is dried into alloy powder. 600℃, keep the oxygen pressure of 0.6MPa, take it out after oxidizing for 2 hours, adopt cold isostatic pressing process after testing meets the requirements, put it into a special pressure equipment with a pressure of 150MPa and process it into a billet, and then put it in the equipment with a temperature of 880℃ Sintered for 5h, extruded into a sheet, fixed with copper with Ф6mm copper rivets, under the protection of nitrogen atmosphere, the sintering temperature is 780 ℃, the sintering time is 1h, the composite rolling deformation is 71%, the silver after composite rolling The t...

Embodiment 2

[0025] Ag ingot, Sn ingot and mixed rare earth in a ratio of 92:6.3:0.3 by weight, take 27.6Kg of Ag ingot, 1.89Kg of Sn ingot and 0.09Kg of mixed rare earth, put it in an intermediate frequency melting furnace and smelt into a liquid state, then use high pressure The water atomization equipment is used to atomize the alloy. The atomized particle liquid is dried into alloy powder. After screening, the powder with a particle size of 100-300 mesh is charged into the internal oxidation furnace for oxidation. The temperature during oxidation is controlled at 580 ° C and maintained at 0.5 Oxygen pressure of MPa, take out after 2 hours of oxidation, adopt cold isostatic pressing process after testing and meet the requirements, put it into a special pressure equipment with a pressure of 150MPa and process it into a billet, and then sinter it in the equipment with a temperature of 850 ℃ for 5 hours. After being extruded into a sheet, fixed with copper with Ф5mm copper rivets, under the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com