Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

352 results about "Internal oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Internal oxidation, in corrosion of metals, is the process of formation of corrosion products (e.g. a metal oxide) within the metal bulk. In other words, the corrosion products are created away from the metal surface, and they are isolated from the surface.

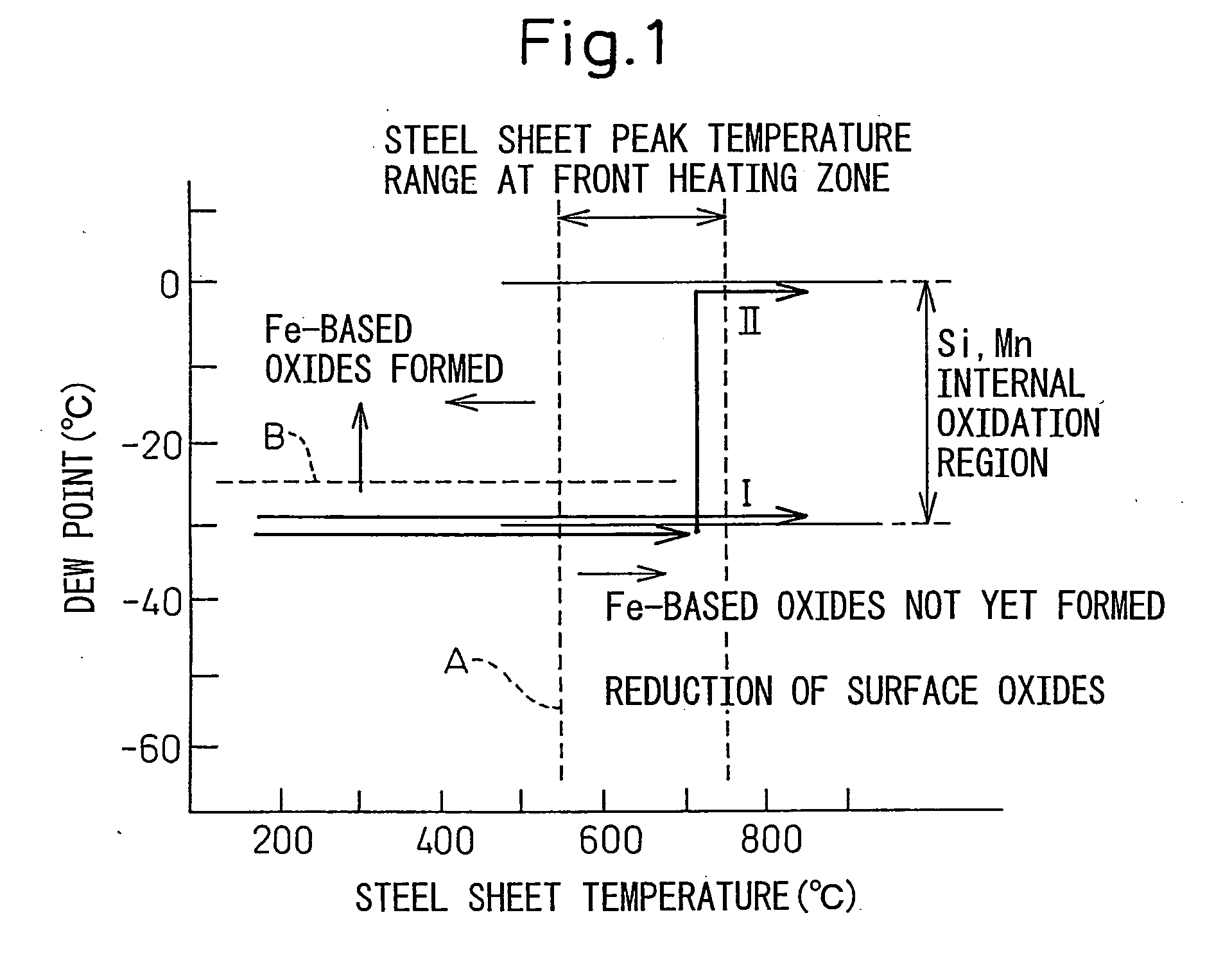

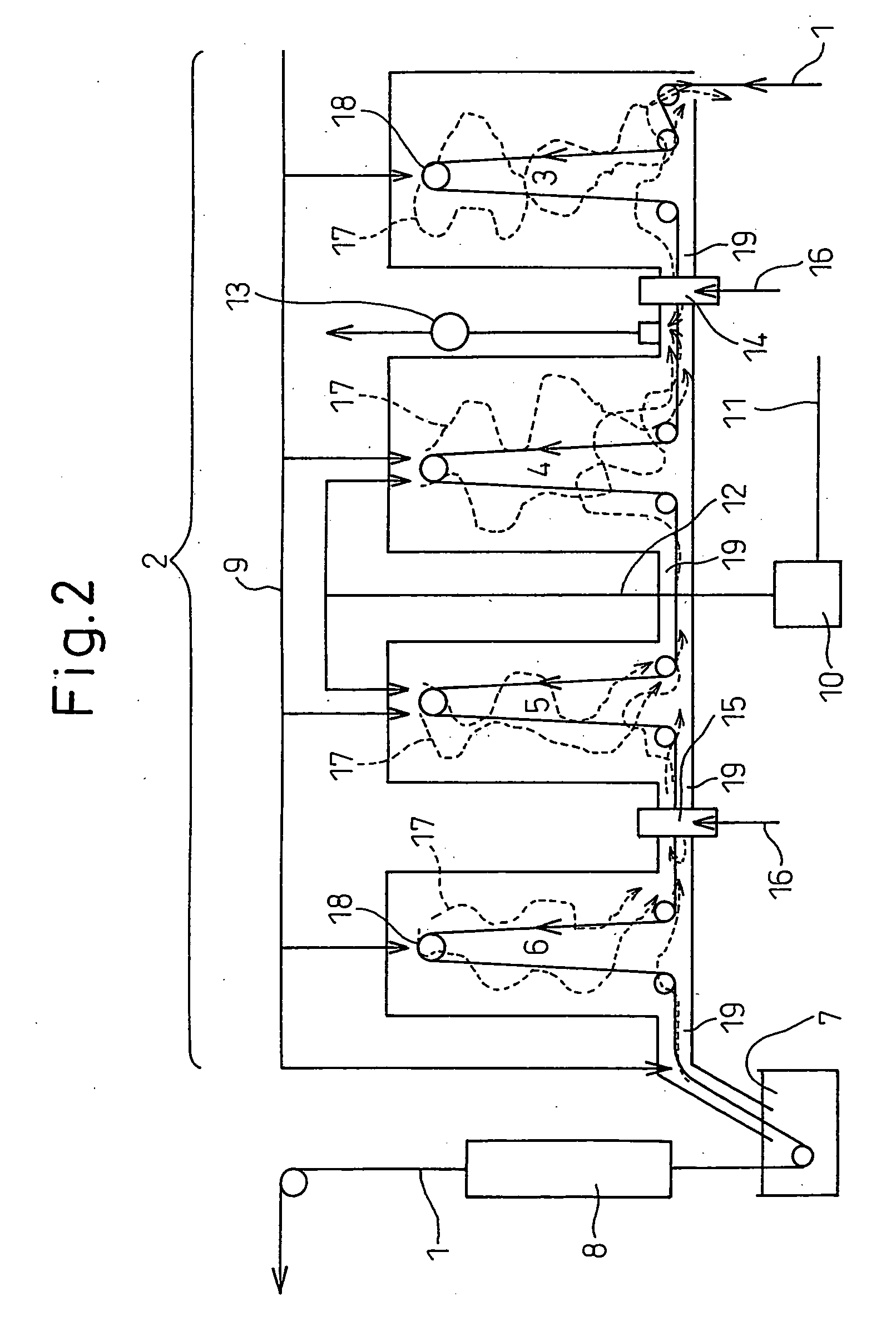

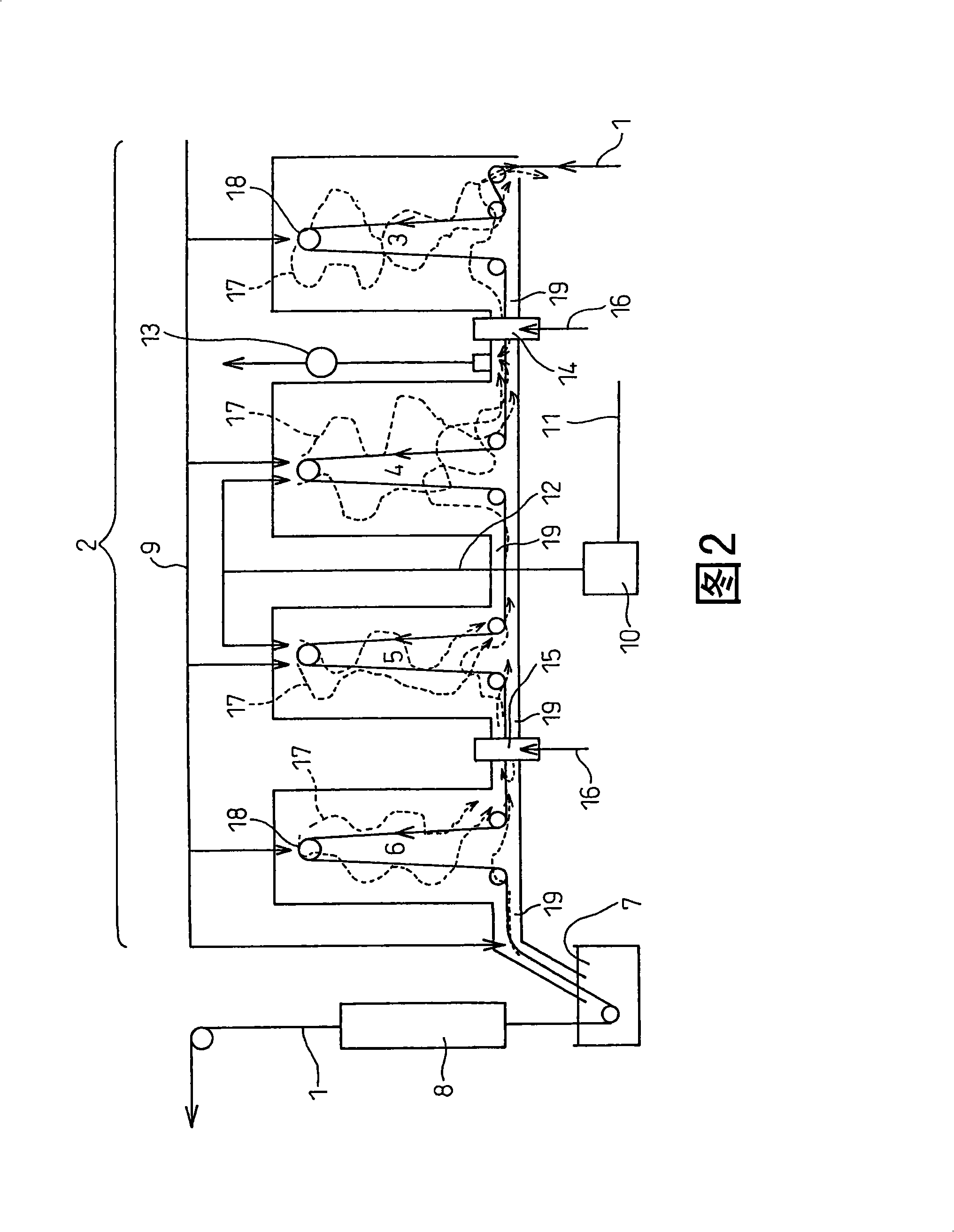

Continuous Annealing and Hot Dip Plating Method and Continuous Annealing and Hot Dip Plating System of Steel sheet Containing Si

InactiveUS20090123651A1Suppress surface concentrationImprove adhesionHot-dipping/immersion processesPretreated surfacesSheet steelHydrogen

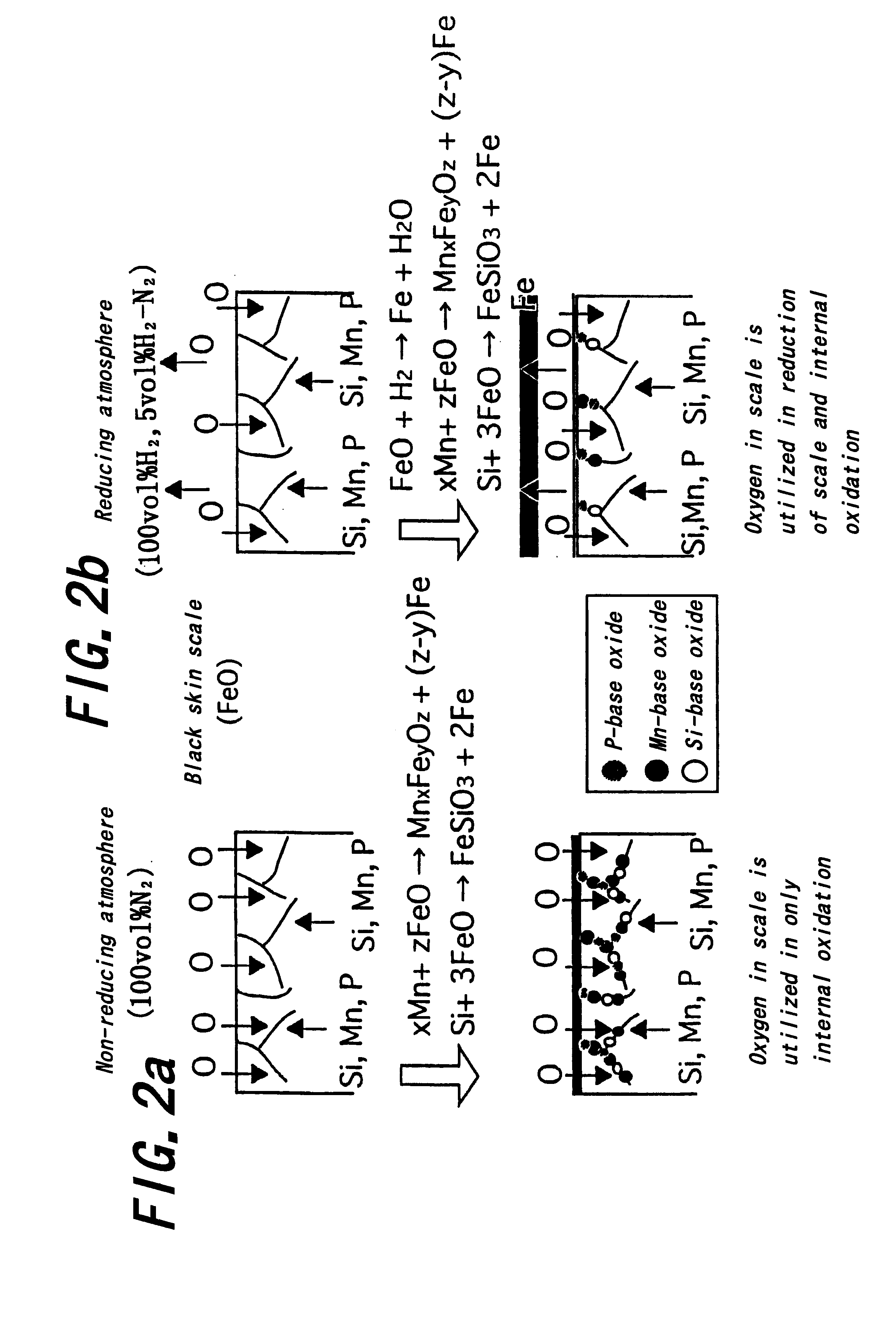

The present invention provides, in a hot dip plating system having an annealing furnace for hot dip plating steel sheet containing Si, a continuous annealing and hot dip plating method and system causing internal oxidation without causing surface oxidation of the Si in the steel and avoiding a drop in the plating ability of the steel sheet and retardation of alloying, that is, a continuous annealing and hot dip plating method using an annealing furnace having, in order, a front heating zone, rear heating zone, soaking zone, and cooling zone and a hot dip plating bath, comprising heating or soaking the steel sheet at a steel sheet temperature of a temperature range of at least 300° C. or more by indirect heating, making an atmosphere of the zones one comprised of hydrogen H: 1 to 10 vol % and a balance of nitrogen and unavoidable impurities, making a steel sheet peak temperature during heating at the front heating zone 550 to 750° C. and making the dew point less than −25° C., making dew points of the following rear heating zone and soaking zone −30° C. to 0° C., and making a dew point of the cooling zone less than −25° C.

Owner:NIPPON STEEL & SUMITOMO METAL CORP

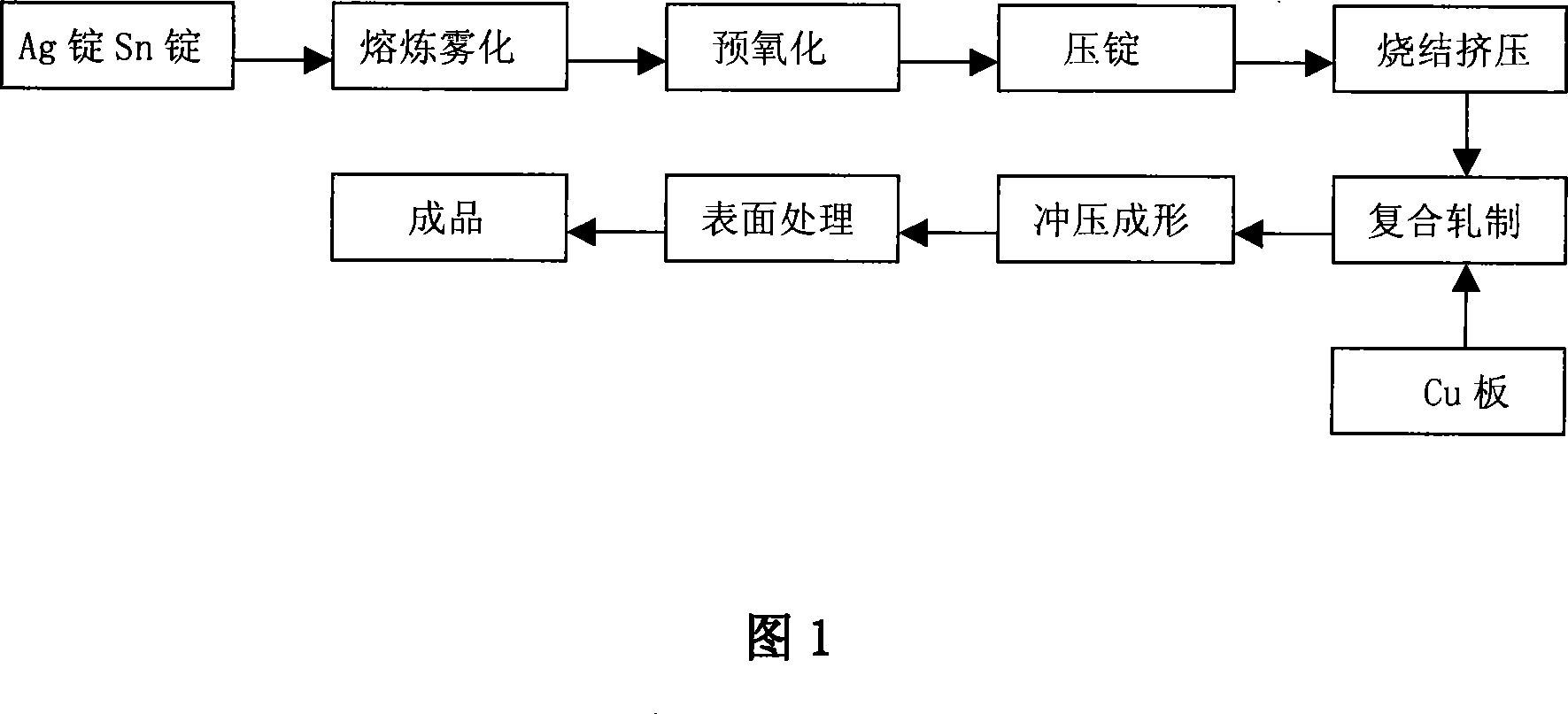

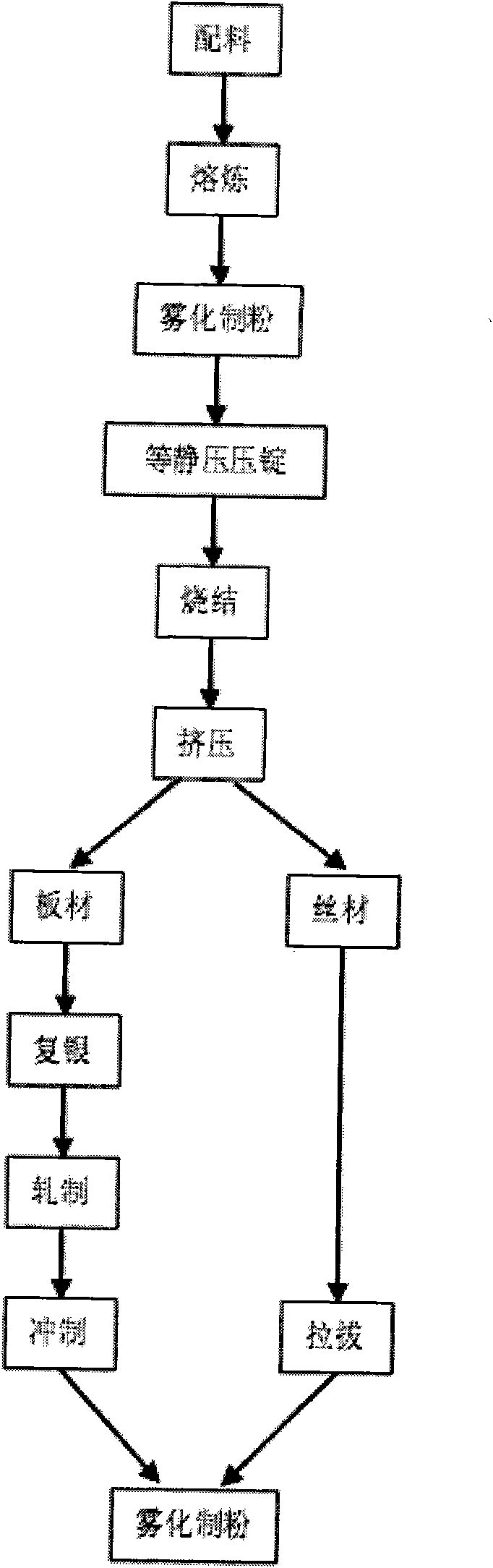

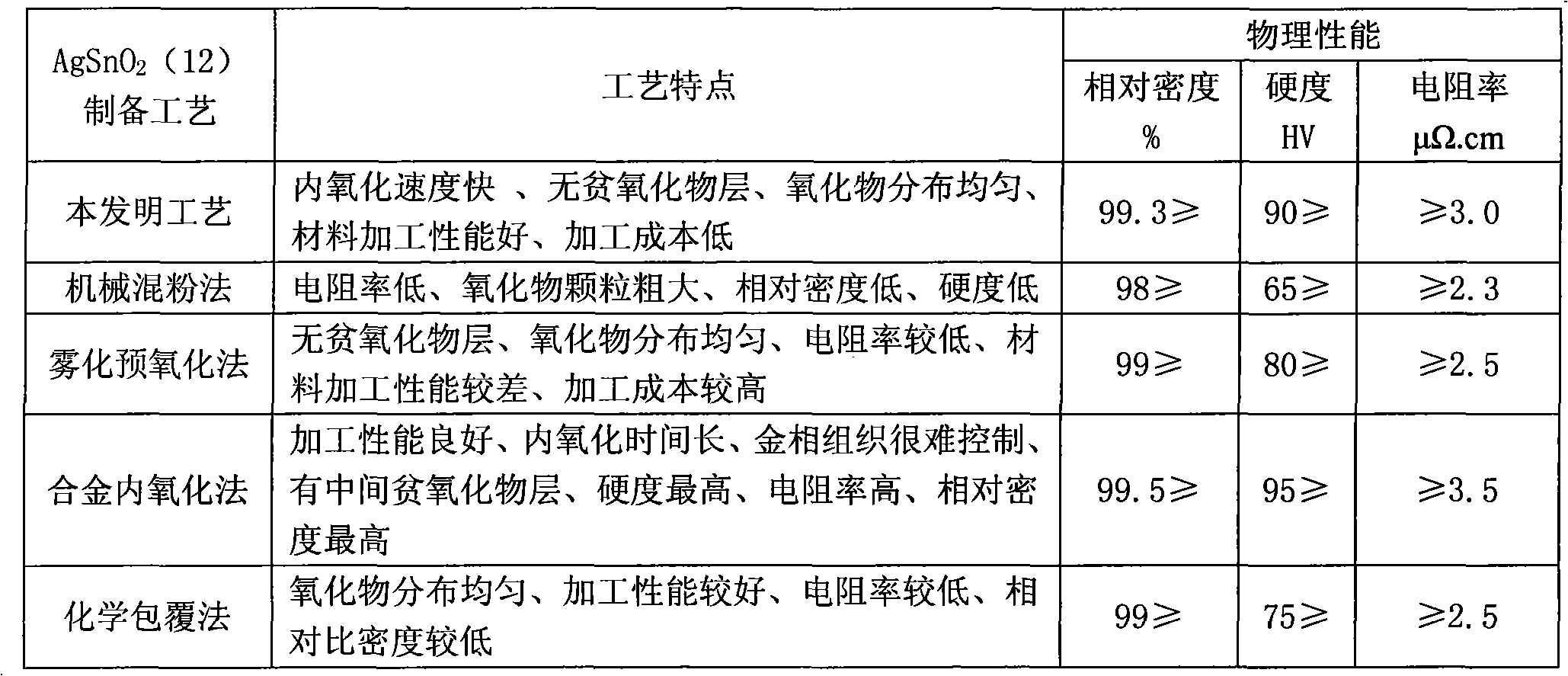

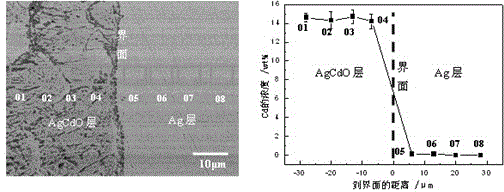

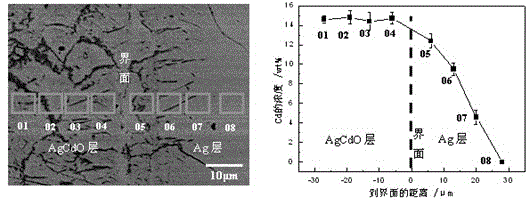

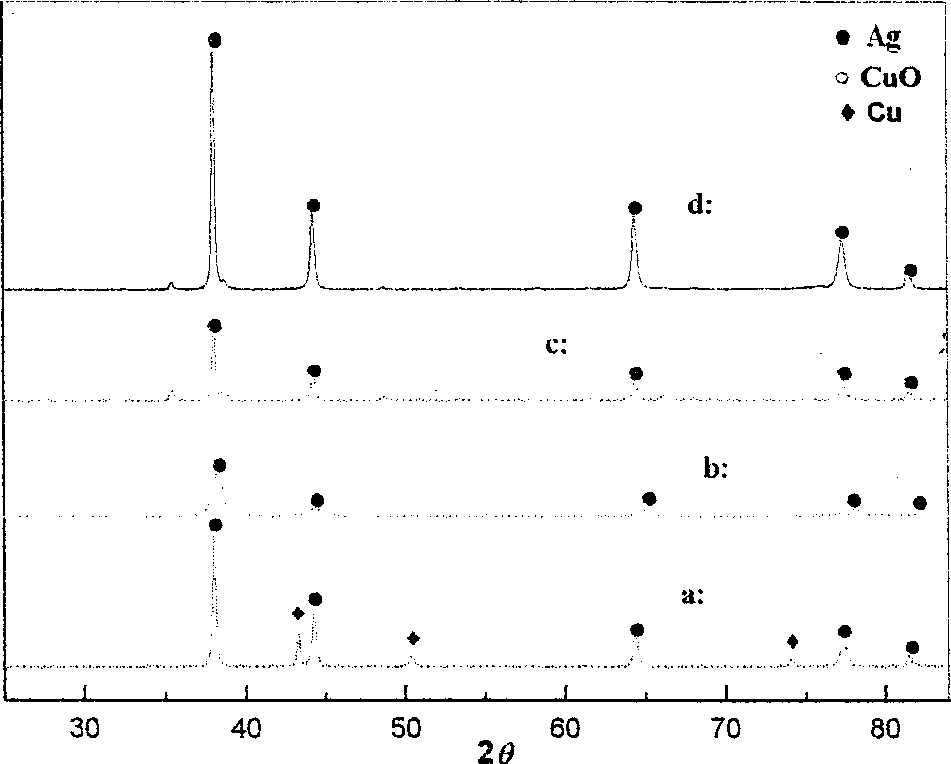

A silver tin/copper oxide compound electrical contact and preparation method

The invention relates to a silver tin oxide / copper compound electrical contact, a working layer of the electrical contact material is composed of silver, tin oxide and mixed rare earth oxide, the weight content of all the components is: 85 percent to 94 percent of Ag, 6 percent to 15 percent of SnO2 and 0.1 percent to 2.0 percent of mixed rare earth oxide, and a welding layer is T2 copper. The weight content of SnO2 is 8 to 12 percent preferentially. The mixed rare earth oxide is a mixture of cerium oxide, lanthanum oxide and yttrium oxide. The preparation method is that the silver and the tin are first mixed according to certain proportion and then are smelted in an intermediate frequency furnace, then high-pressure water atomization equipment is used for carrying out alloy atomization, powder is obtained by drying after the atomization, the powder is screened and arranged in an internal oxidation furnace to carry out the oxidation at certain temperature and oxygen pressure, then billet is obtained by the processing of isostatic cool pressing after the oxidation, after that, a plate is formed by carrying out the sintering and extruding, and finally the finished product is obtained by compound rolling with the copper. The electrical contact is characterized by high conductivity, even and exquisite texture, high bonding strength of the working layer and the welding layer, welding resistance and arc erosion resistance.

Owner:SHANGHAI LONGSUN ALLOY CO LTD

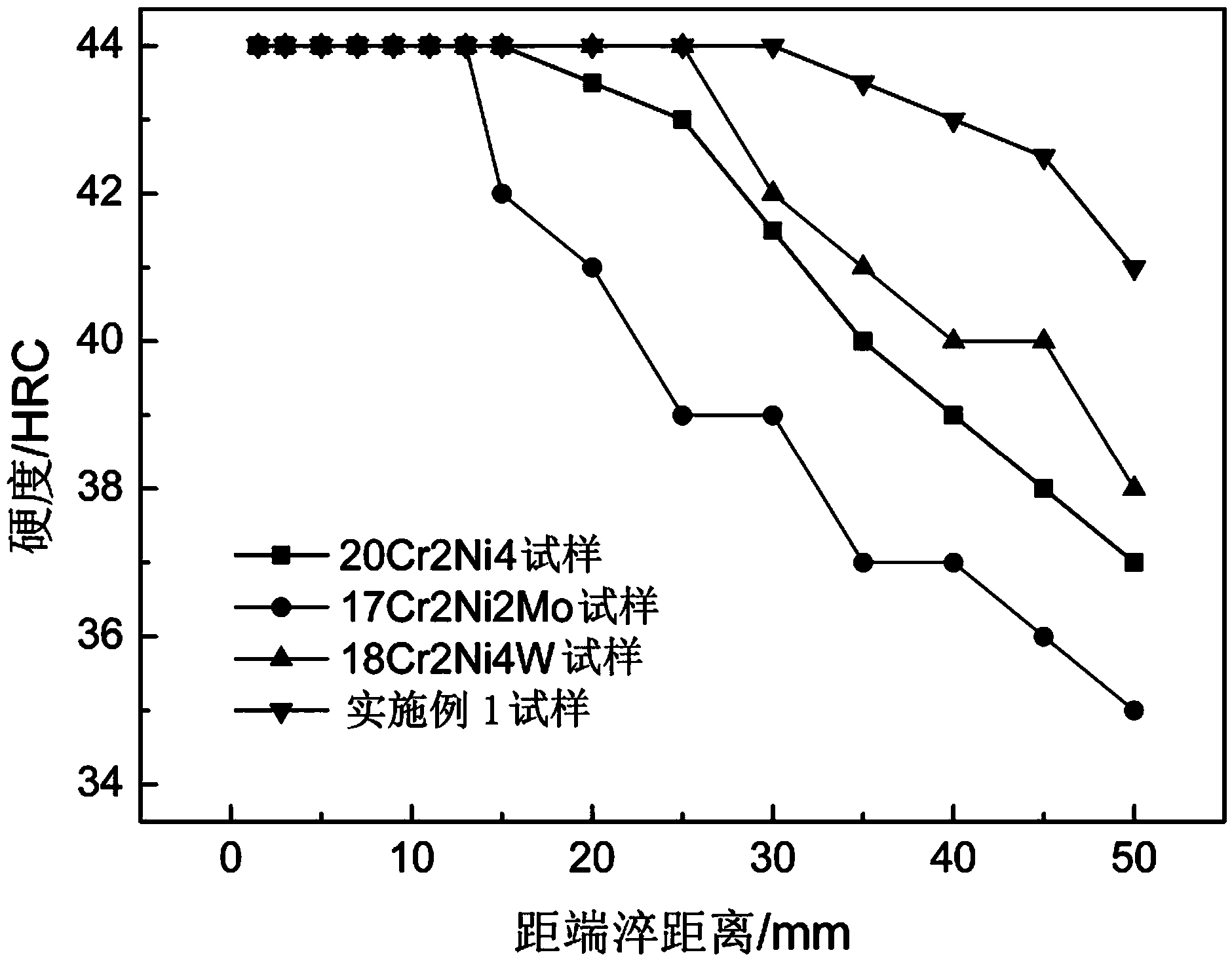

Carburizing alloy steel, and preparation method and application thereof

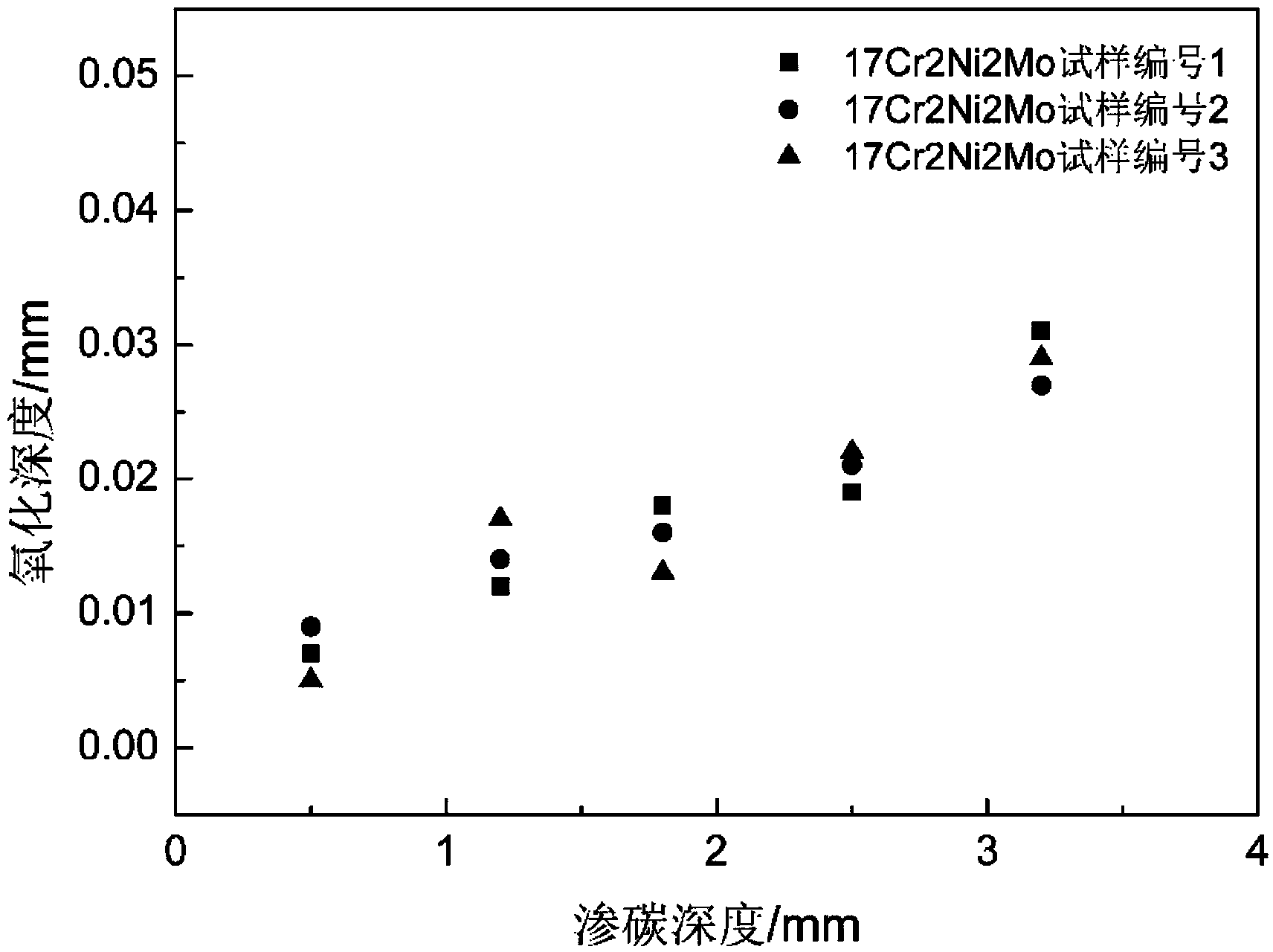

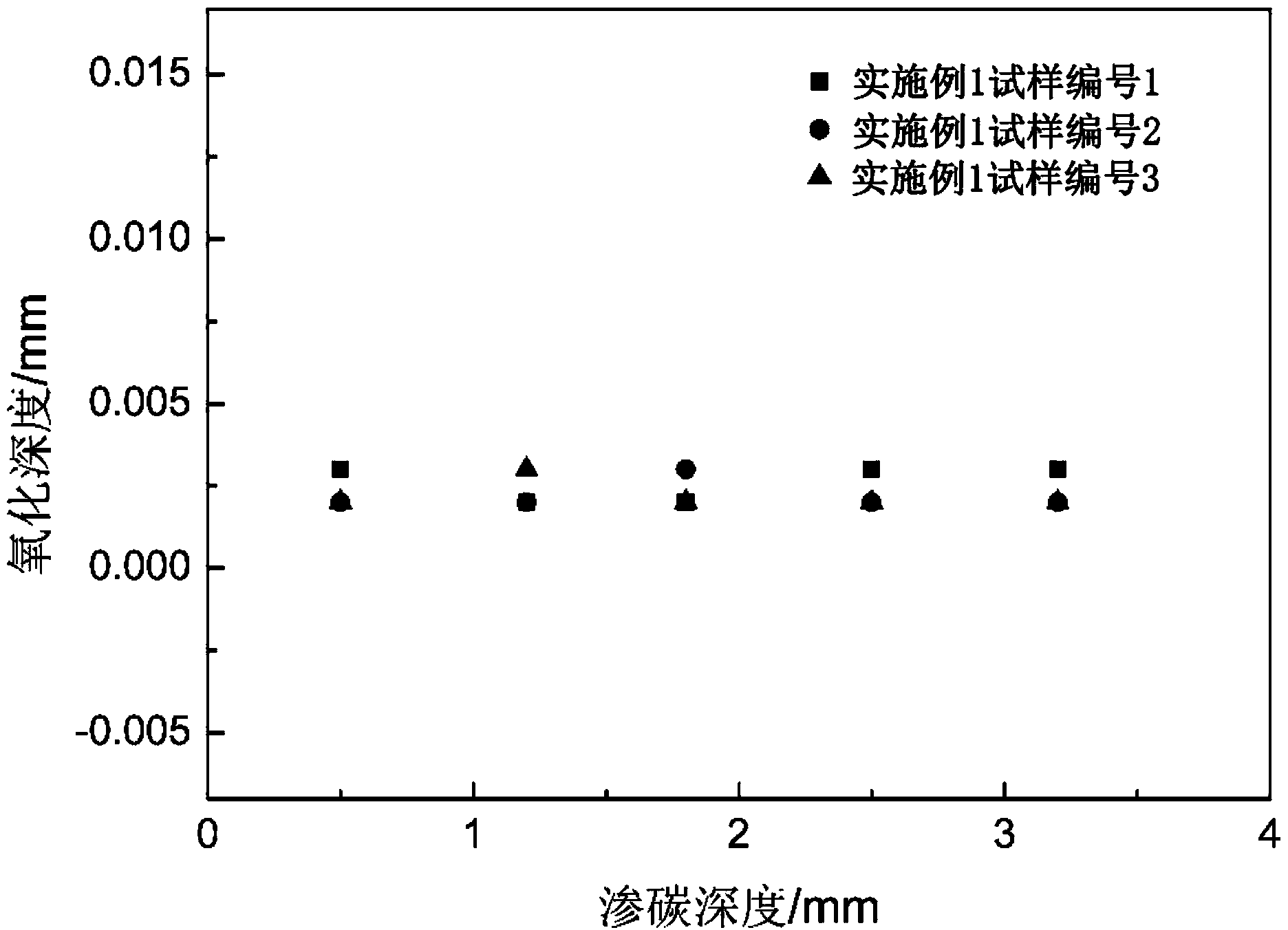

The invention relates to carburizing alloy steel, and a preparation method thereof. The alloy of the carburizing alloy steel comprises, by mass, 0.15%-0.25% of C, less than or equal to 0.30% of Si, 0.30%-1.20% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, 0.30%-1.50% of Cr, 2.80%-3.80% of Ni, 0.30%-1.00% of Mo, 0.01%-0.08% of Al, at least one selected from 0.05%-0.15% of V and 0.025-0.10% of Nb, and the balance being Fe and inevitable impurities. A mass percentage of V, Nb and Al meets an equation of V+Nb+Al <= 0.30%. The carburizing alloy steel provided by the invention has good anti-fatigue performance, excellent comprehensive properties, good hardenability, high yield ratio, extremely small internal oxidation and the characteristic of resisting grain growth at a high temperature, and is suitable for manufacturing heavy-duty gears.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

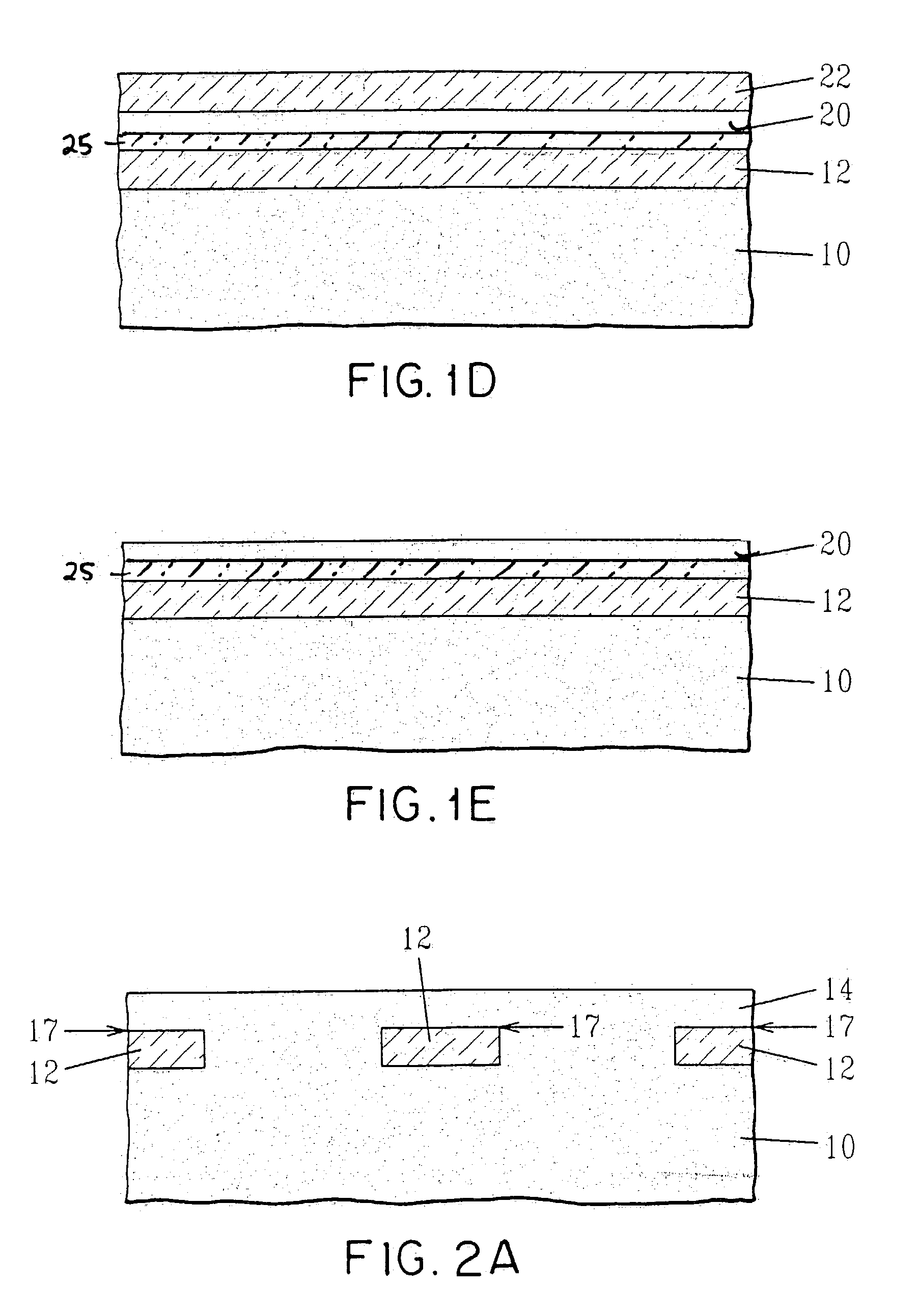

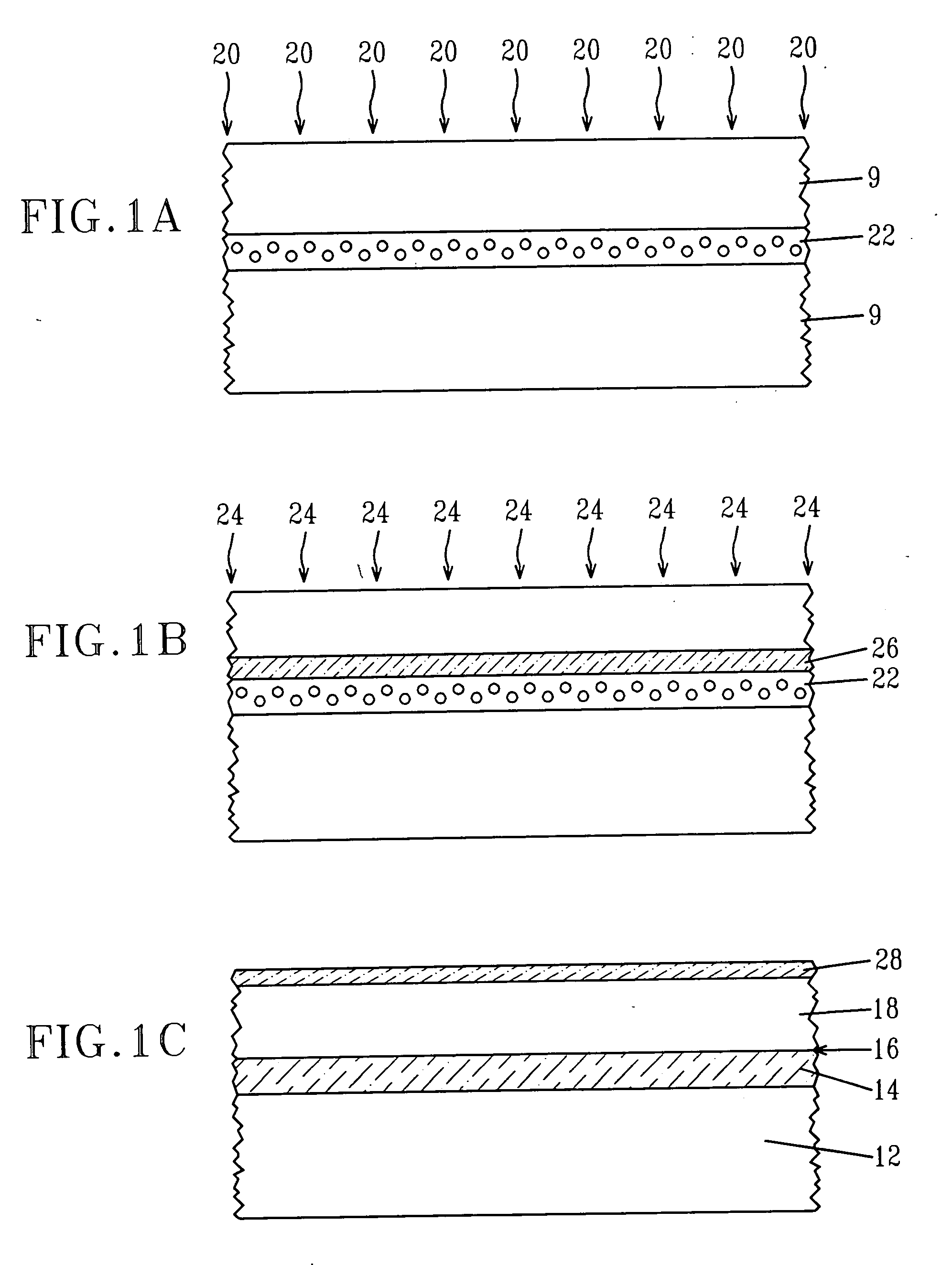

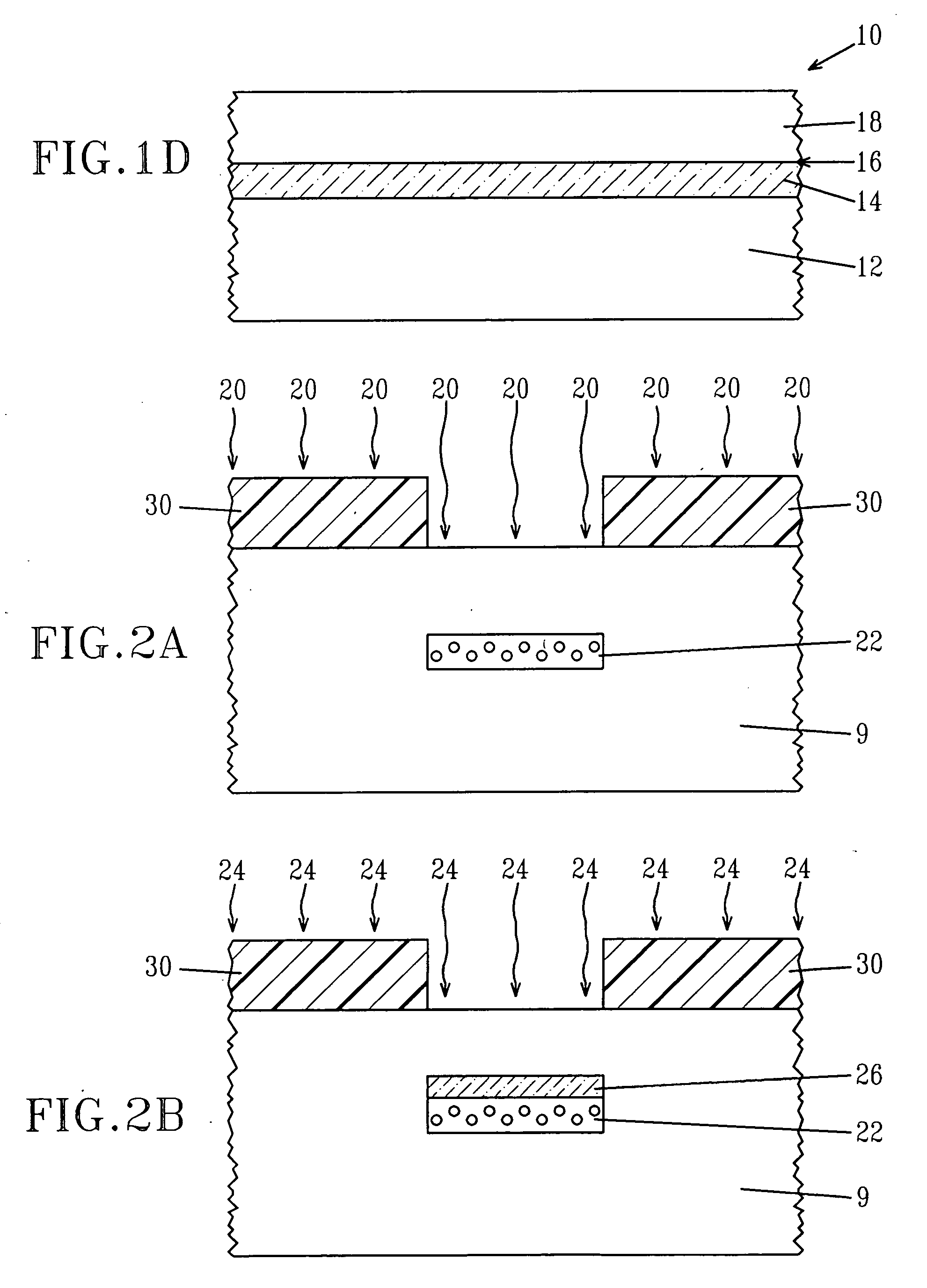

Defect reduction by oxidation of silicon

A method of fabricating high-quality, substantially relaxed SiGe-on-insulator substrate materials which may be used as a template for strained Si is described. A silicon-on-insulator substrate with a very thin top Si layer is used as a template for compressively strained SiGe growth. Upon relaxation of the SiGe layer at a sufficient temperature, the nature of the dislocation motion is such that the strain-relieving defects move downward into the thin Si layer when the buried oxide behaves semi-viscously. The thin Si layer is consumed by oxidation of the buried oxide / thin Si interface. This can be accomplished by using internal oxidation at high temperatures. In this way the role of the original thin Si layer is to act as a sacrificial defect sink during relaxation of the SiGe alloy that can later be consumed using internal oxidation.

Owner:GLOBALFOUNDRIES INC

Preparation method for silver tin oxide electrical contact material

The invention discloses a preparation method for a silver tin oxide electrical contact material, which comprises the following steps: by taking a silver ingot, a tin ingot, an indium ingot and an additive ingot as raw materials, atomizing the raw materials to prepare a silver tin alloy powder; ingoting, sintering, extruding and drawing / rolling the silver tin alloy powder to prepare a wire material or a sheet plate or a belt material; and finally, carrying out internal oxidation to prepare the silver tin oxide electrical contact material. The preparation method for the silver tin oxide electrical contact material has the characteristics of uniform and stable contact material components, no conventional internally oxidized central lean oxidation zone, high density, high hardness and the like. The preparation method for the silver tin oxide electrical contact material has a simple process and is suitable for mass production. A prepared silver tin oxide product can be widely used for relays and contactors.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

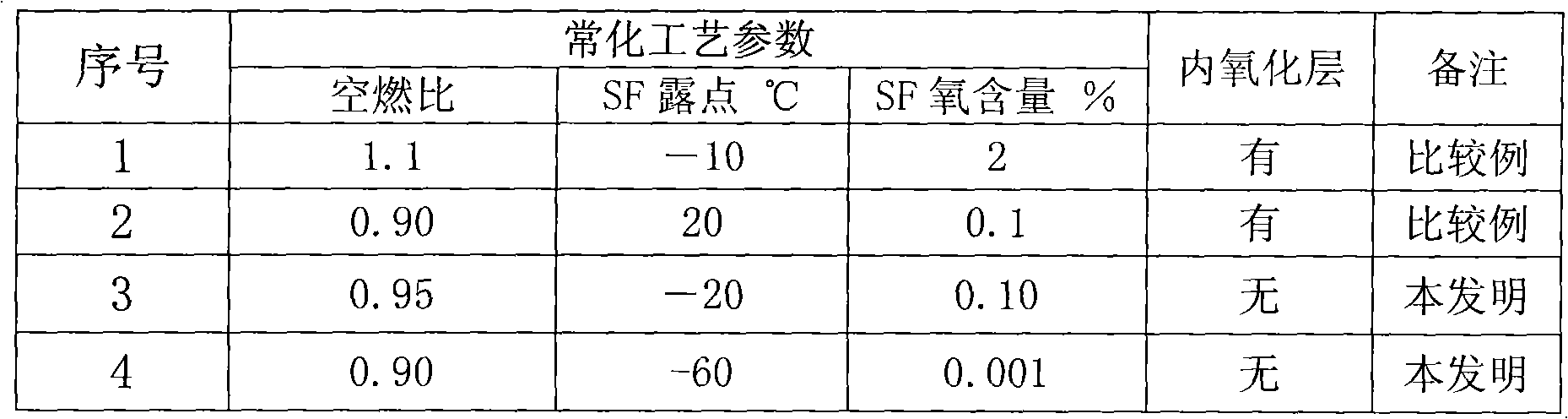

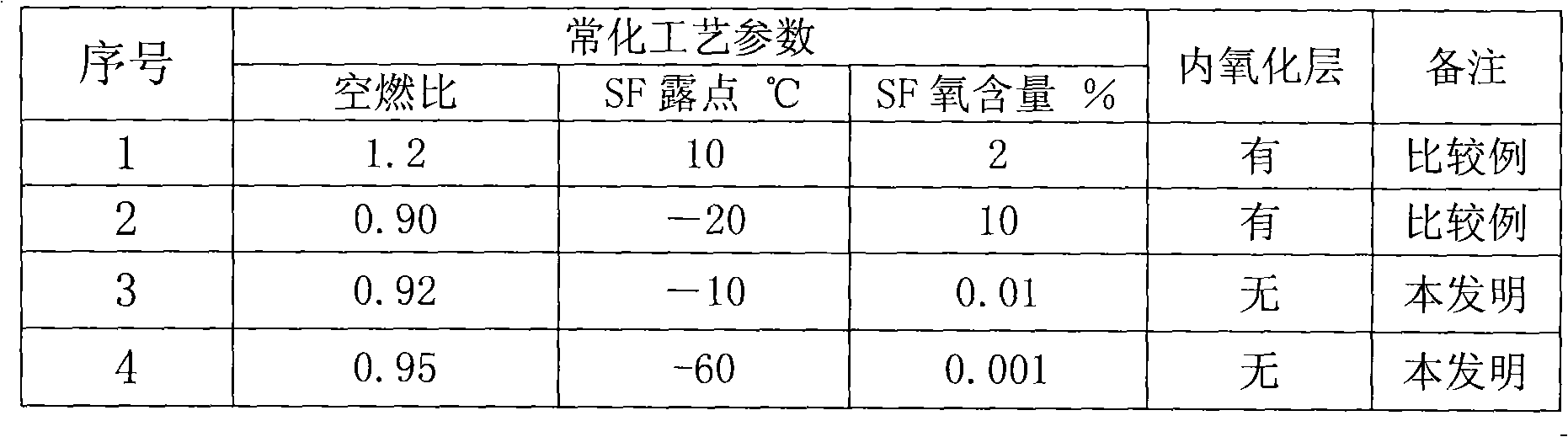

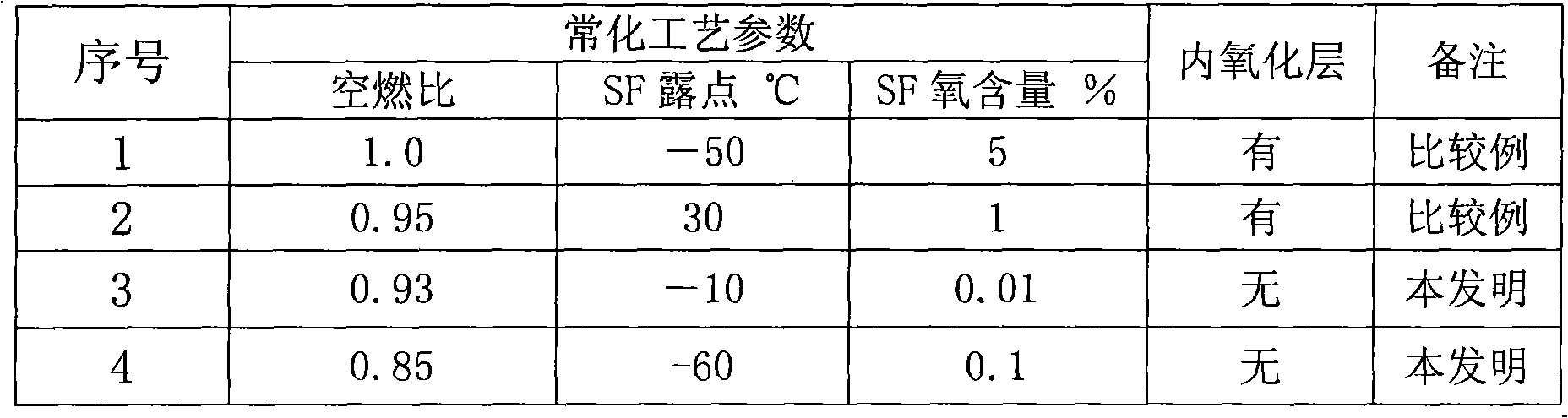

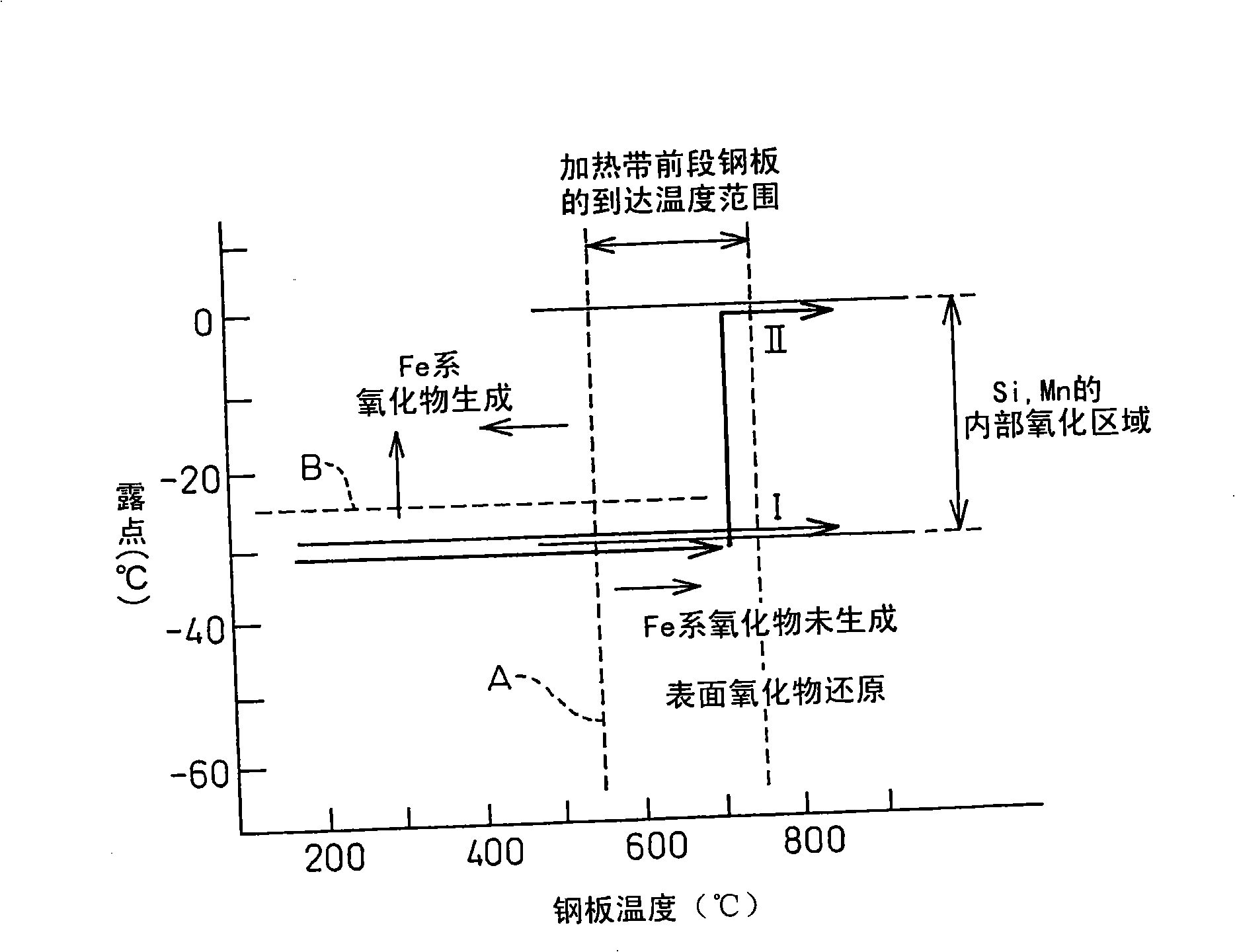

Method for preventing internal oxidation layer in normalization treatment of electrical hot-rolled strip steel

ActiveCN101812571AAvoid cleanupImprove efficiencyFurnace typesHeat treatment furnacesSteel platesDew point

The invention relates to a treatment method of hot-rolled steel plates, in particular a method for preventing an internal oxidation layer from generating in the non-oriented normalization treatment of electrical hot-rolled strip steel. The normalization treatment comprises a preheating section, a non-oxidation heating section, an even heating section and a cooling section, wherein the non-oxidation heating section adopts direct fire heating and has an air-fuel ratio coefficient of 0.85-0.95. An even heating furnace adopts electric heating or radiation tub heating in the atmosphere of N2 under the condition that in-furnace dew point is 65-10 DEG C below zero and oxygen content is not more than 0.1 percent. The invention reduces and eliminates the internal oxidation layer generated during the normalization of a hot-rolled strip steel during controlling the normalization process, radically eliminates furnace roller nodulation generated in final anneal, avoids subsequent furnace roller nodulation cleaning work, improves the efficiency and decreases the cost.

Owner:BAOSHAN IRON & STEEL CO LTD

Method of continous annealing/hot-dipping of steel sheet containing silicon and apparatus for continuous annealing/hot-dipping

ActiveCN101287854ASuppressor enrichmentAvoid generatingHot-dipping/immersion processesFurnace typesSheet steelHydrogen

A method of continuous annealing / hot-dipping using a hot-dipping apparatus having an annealing furnace in which a silicon-containing steel sheet is hot-dipped. In this method, the silicon contained in the steel is caused to undergo internal oxidation without undergoing surface oxidation to thereby avoid a decrease in deposit adhesion to the steel and a delay in galvannealing. Also provided is the apparatus for use in this method. The method of continuous annealing / hot-dipping employs an annealing furnace having a former heating zone, latter heating zone, heat retention zone, and cooling zone in this order and a hot-dipping bath. It comprises conducting annealing under the following conditions. In regions where the steel sheet has a temperature of at least 300 DEG C, the steel sheet is heated or kept hot by means of indirect heating. The atmosphere inside the furnace in each zone is an atmosphere consisting of 1-10 vol.% hydrogen and, as the remainder, nitrogen and unavoidable impurities. In the former heating zone, the steel is heated to a maximum temperature of 550-750 DEG C and the atmosphere is regulated so as to have a dew point lower than -25 DEG C. In the subsequent latter heating zone and heat retention zone, the dew point is regulated to from -30 DEG C to 0 DEG C. In the cooling zone, the dew point is regulated to below -25 DEG C.

Owner:NIPPON STEEL CORP

Preparation method of high-oxide content flake-like contact material

The invention relates to a preparation method of a high-oxide content flake-like contact material. The preparation method is suitable for two types of materials comprising a silver-cadmium oxide alloy material and a silver-tin oxide-indium oxide material. The silver-cadmium oxide alloy material comprises, by weight, 75-82% of silver, 15-22% of cadmium oxide, 0-5.5% of copper oxide, 0.1-0.3% of nickel oxide and a trace amount of other oxides. The silver-tin oxide-indium oxide material comprises, by weight, 78-85% of silver, 11-17% of tin oxide, 3-8% of nickel oxide, 0.05-0.25% of nickel oxide and a trace amount of other oxides. The preparation method comprises melting, extrusion, compound silver hot rolling, cold rolling, punching, high-temperature diffusion annealing, internal oxidation treatment and aftertreatment. The prepared high-oxide content flake-like contact material has high oxide content and high compound silver interface bonding strength, has simple production processes and is suitable for large batch production.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

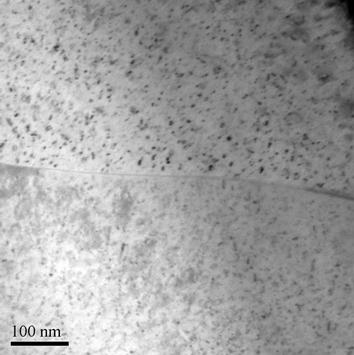

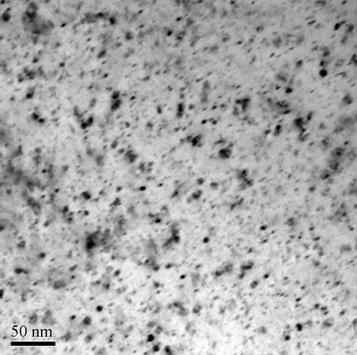

Preparation method of siluer metal oxide electric contact material

InactiveCN1477219ALower internal oxidation temperatureReduce manufacturing costContact materialsHigh energyMaterials processing

The preparation method of silver metal oxide electric contact material is characterized by that it adopts high-energy ball-grinding process to prepare silver-containing alloyed or intermetallic compound or obviously-fined powder, then utilizes the processes of internal oxidation and forming treatment so as to obtain the invented electric contact. It utilizes the control of partial pressure and temp. of oxygen in the course of internal oxidation of can obtain dispersed distribution of nano-grade or micrometer-grade metal oxide in silver base body. There is a self-formed interface between the oxide and silver base body.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

High-strength high-conduction strengthened dispersion copper alloy and preparation method thereof

InactiveCN101121974AImprove conductivityHigh strengthRoll mill control devicesMetal rolling arrangementsWire cuttingHardness

The invention discloses a high strength and high conductivity dispersion strengthened copper alloy. 0.10 to 0.30wtpercent Al is added into an alloy-based material. The technology of the invention cosists of (1)Melting of alloy; (2) Hot rolling or cold rolling (wire cutting)of alloy for preparing thin sheets; (3)Internal oxidation of alloy sheet; (4)Heat pressing and hot extrusion of alloy sheet with internal oxidation; (5)Processing of alloy. Wherein, the thickness of the alloy thin sheet is 0.3 to 2.0mm; and the method for internal oxidation is embedding with the standard of (850DEG C -950DEG C) * (3-15) h; and the temperature of heat pressing and hot extrusion is 900DEG C-950DEG C. The invention adopts a Cu-Al alloy internal oxidation thin sheet, and the micro-hardness and the conductivity of the alloy with the process of heat pressing reaches 120 HV and 78percent IACS respectively; and the tensile strength reaches 260MPa. The micro-hardness and the conductivity of the alloy with the process of hot extrusion reach 135 HV and 85percent IACS respectively; and the tensile strength reaches 450MPa. The softening temperature of the alloy reaches above 900DEG C.

Owner:LUOYANG INST OF SCI & TECH

Method for producing oriented silicon steel with excellent underlying quality

ActiveCN103695620AReduce or eliminate point-like exposed gold defectsDefect reduction or eliminationMoistureHeating temperature

The invention discloses a method for producing oriented silicon steel with excellent underlying quality. The method comprises the following steps: heating a continuous casting billet; hot rolling; rolling by adopting a one-time cold rolling method or a two-time cold rolling method comprising middle complete decarburization and annealing; coating an annealing parting agent, wherein the moisture content is 2-4%; annealing at a high temperature and carrying out oxidative annealing treatment in a pure nitrogen atmosphere or an atmosphere of nitrogen and argon which are mixed in any ratio before the first heating temperature reaches 800 DEG C; stretching, leveling, annealing and applying an insulating coating. According to the method, an outer oxidation layer is formed to limit the development of internal oxidation by controlling the oxygen content of a decarbonized and annealed steel plate and the moisture content in the parting agent, and carrying out oxidative annealing treatment at a high-temperature annealing stage and / or after decarburization and nitriding treatment or in the cooling stage in the decarburization and nitriding treatment, or / and after middle complete decarburization and annealing or in the cooling state of the middle complete decarburization and annealing, and / or in recovery annealing. Thus, the targets of reducing or removing dot gold defects of the oriented silicon steel and improving the underlying quality of the product are reached.

Owner:武汉钢铁有限公司

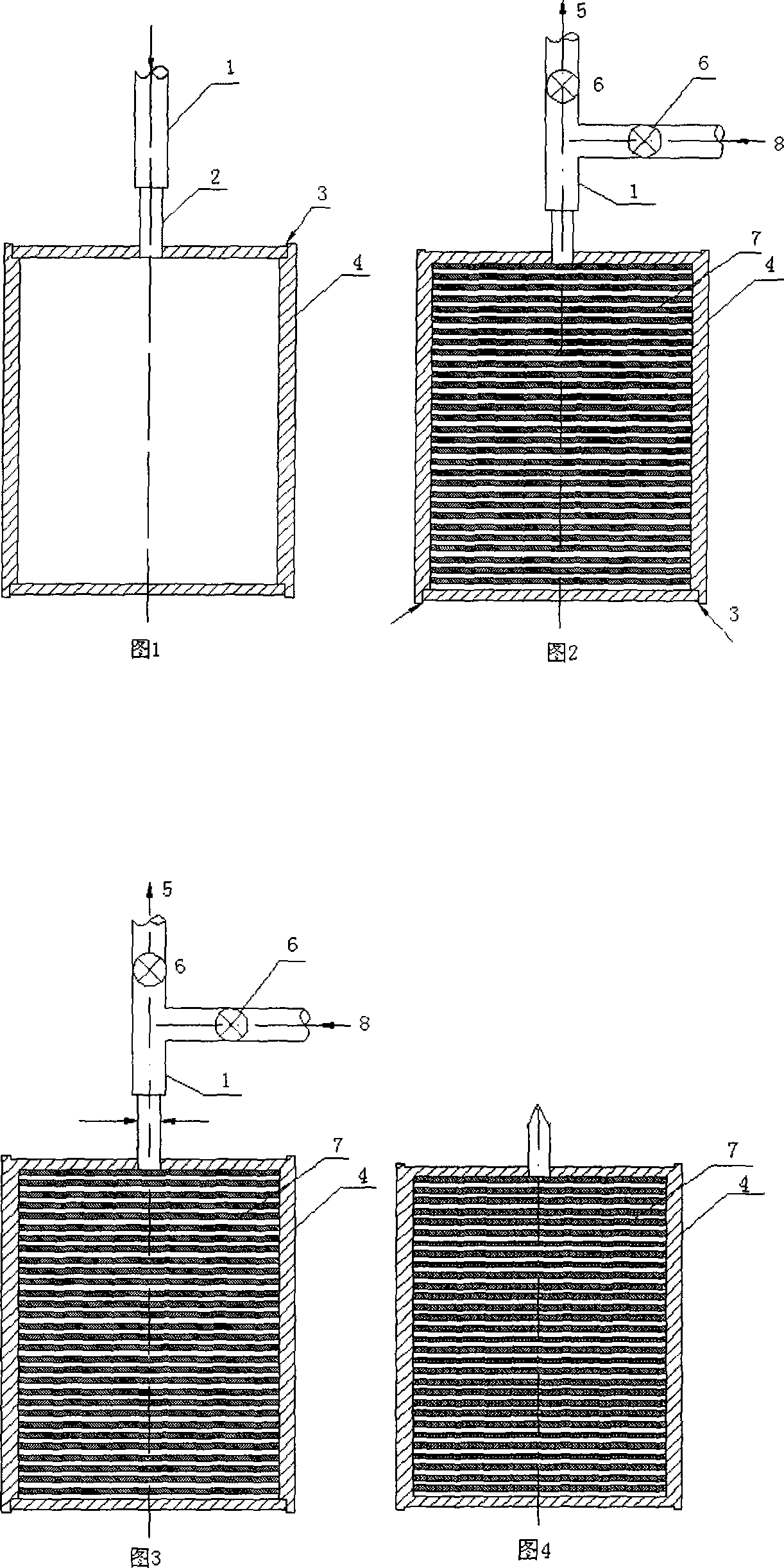

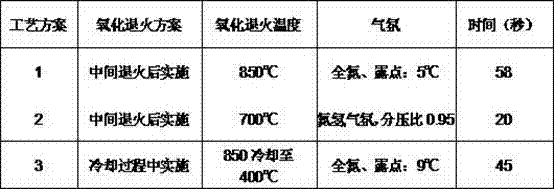

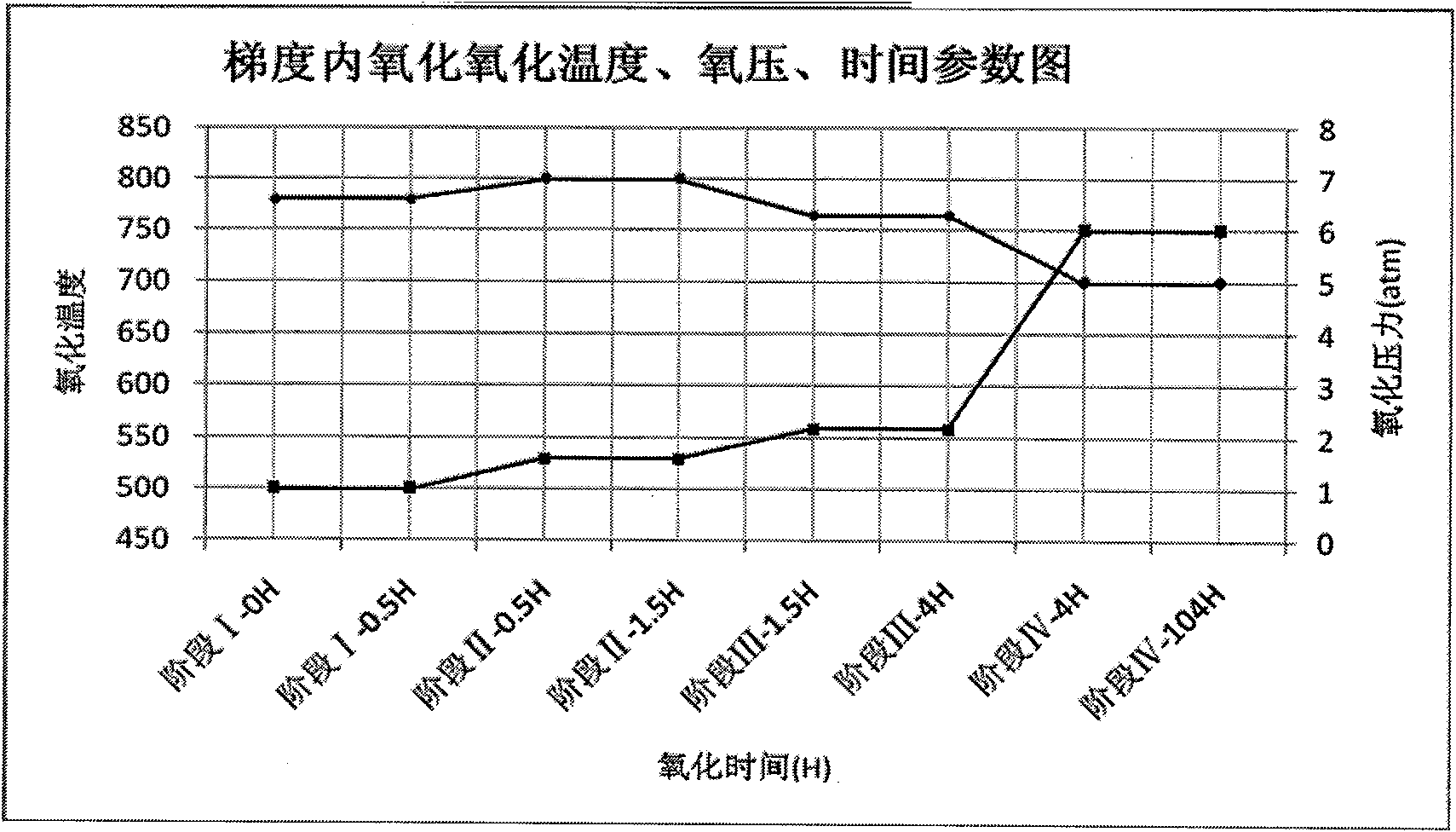

Method for preparing sliver-tin oxide and indium oxide electrical contact material by gradient internal oxidation method and material thereof

The invention discloses a method for preparing a sliver-tin oxide and indium oxide electrical contact material by a gradient internal oxidation method and a material thereof. The method comprises the following steps of smelting alloy, performing lathe machining, extruding and drawing, performing the gradient internal oxidation of alloy, cutting and rolling the alloy, sintering for forming, extruding and drawing wires or rolling again and manufacturing a finished product, wherein in the process of alloy smelting, 6 to 12 weight percent of Sn ingot or stannum oxide SnO2, 3 to 6 weight percent of In ingot or indium oxide, 0 to 1 weight percent of one or more of Cu, Bi, Sb, Te, Co, Ni and W which serve as alloy elements or oxides thereof and 82 to 91 weight percent of silver are smelted to form a silver stannum and indium alloy ingot in an intermediate frequency furnace. In the process, the control over process parameters of the gradient internal oxidation is taken as the key technology, wherein oxidation temperature, oxygen pressure and heat preservation time in each stage are used as a key control point; and the process has high production efficiency and short period, and a fine silver layer is not generated on the surface of a silver stannum and indium alloy material in the internal oxidation process.

Owner:NINGBO HANBO PRECIOUS METAL ALLOY

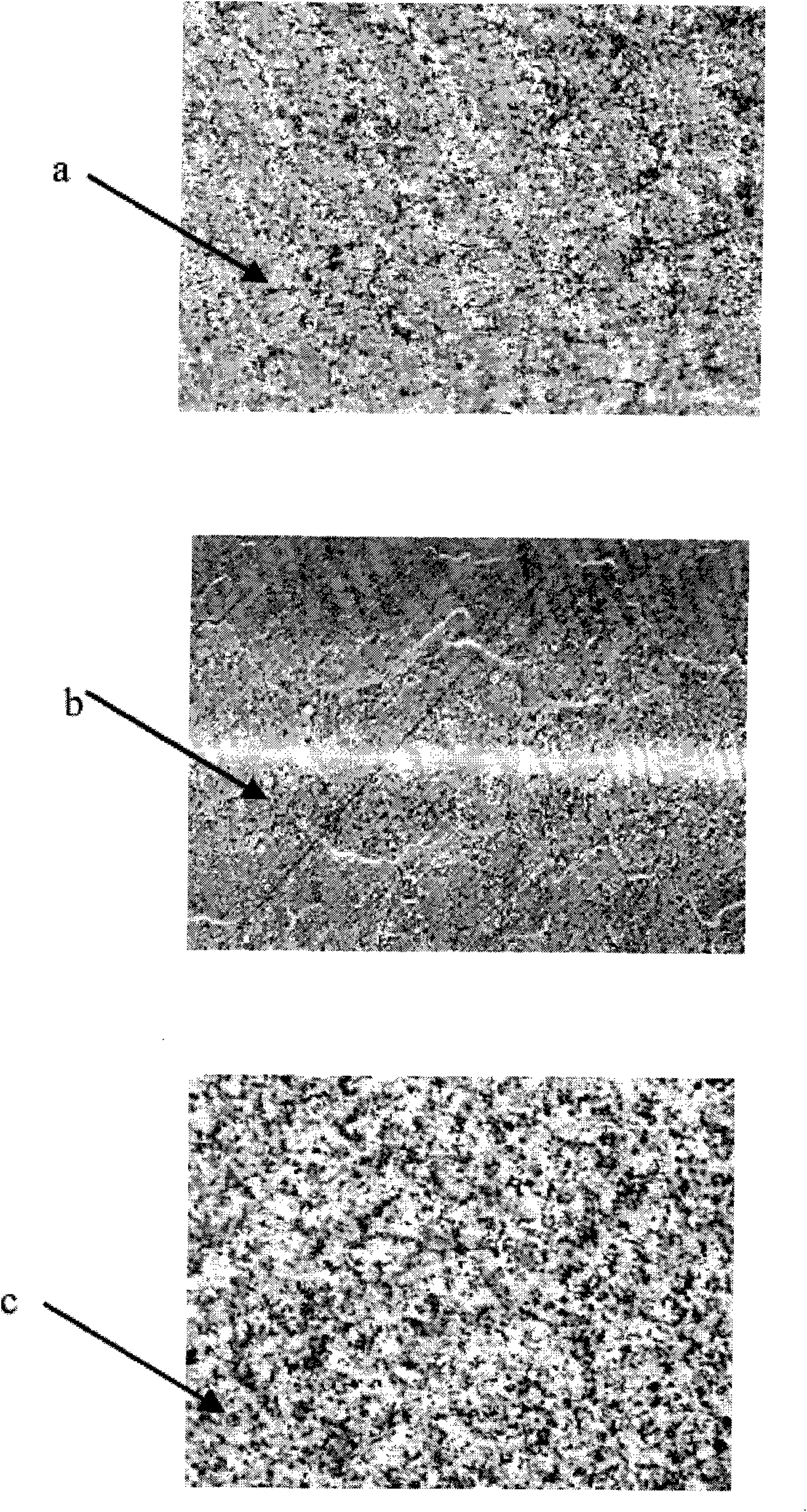

Sliver stannic oxide electrical contact material and preparation method thereof

The invention discloses a sliver stannic oxide electrical contact material and a preparation method thereof. In the electrical contact material, the oxide content of tin is 6-12wt%, the total oxide content of an additive is 0.44-3.19wt%, and silver accounts for the balance. The additive is one or more of bismuth, copper, zinc and nickel, preferably the bismuth and the copper. The preparation method comprises the following steps of: smelting and pouring raw materials into alloy round ingot; extruding the alloy round ingots into alloy wires; after the wire is drawn, breaking the wire into wire sections; cleaning and drying; carrying out internal oxidation for 20-50h at the temperature of 650-820 DEG C under the oxidation pressure of 0.2-0.7MPa for 20-50h; pressing the material subjected to internal oxidation into a round ingot; and extruding the round ingot into wires or plates or strips. The electrical contact material has even tissue, high oxidation rate and density, low resistivity; and moreover, the material preparation technology is simple with low production cost and no pollutant is generated in the production process.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

Copper alloy contact wire and method of producing the same

InactiveCN101178957AImprove wear resistanceImprove fatigue resistanceSingle bars/rods/wires/strips conductorsContact cablesReduction treatmentInternal oxidation

The invention provides copper alloy contact lines and a preparation method thereof, wherein, the method includes the following steps: (1) preparing master alloy powders of Cu-AI, in which 0.21-0.53wt% is the content of AI, and the rest is copper; (2) using the master alloy powders of Cu-AI obtained from step (1) to prepare an oxygen source of Al2O3-Cu2O, in which the weight ratio of Cu and AI keeps unchanged; (3) mixing the master alloy powders of Cu-AI obtained from step (1) and the oxygen source of Al2O3-Cu2O obtained in step (2), wherein, the weight ratio of the oxygen source of Al2O3-Cu2O in the mixture is 10-25wt%; (4) carrying out internal oxidation and reduction treatment for the mixture obtained in step (3), so as to obtain alloy powders of Cu-Al2O3, in which the content of Al2 O3 is 0.4-1.0wt%; (5) suppressing the alloy powders of Cu-Al2O3 obtained in step (4) into billets and then carrying out sintering treatment; (6) molding the suppressed and sintered billets obtained in step (5) into bars; (7) making the bars obtained in step (6) into contact lines with required section size by drawing. The copper alloy contact lines prepared by the method present good conductivity, high mechanical strength and softening temperature, good performance of friction and abrasion resistance.

Owner:DATANG LUOYANG SHOUYANGSHAN POWER PLANT

Dispersed copper composite material and preparation method thereof

The invention discloses a dispersed copper composite material and a preparation method thereof, belonging to the technical field of dispersed copper processing. The dispersed copper composite material is composed of the following components in percentage by mass: 0.24-3.74% of Al2O3, 0.03-1.27% of Y2O3 and the balance of Cu and unavoidable impurities. The dispersed copper composite material is prepared from Cu2O powder and Cu-Al-Y alloy powder through the steps of mixing, pressing, sintering and internal oxidation, extruding and forging; the composite material has the high strength of 500Pa or above and the high conductivity of 80% IACS or above and overcomes the defect that the high strength and high conductivity of other composite materials cannot simultaneously exist; and meanwhile the composite material is favorable in softening resistance, high in high-temperature strength and good in plasticity, and the softening temperature is 800 DEG C or higher.

Owner:HENAN UNIV OF SCI & TECH

Preparation method for particle reinforced copper-TiC high-intensity high-conductivity spot-welding electrode

The invention relates to a preparation method for a particle reinforced copper-TiC high-intensity high-conductivity spot-welding electrode. The preparation method adopts the following components in percentage by mass: a low-solid solution Cu-Al alloy with aluminium content of not more than 0.50wt%; TiC powder with the particle size of less than 10mm and the content of 5.7wt% to 19.22wt% of the total mass; an oxidant with the content of 2.5 wt% to 5wt% of the mass of Cu-Al powder; and the balance of Cu. The preparation process of the preparation method comprises the following steps of: mixing the oxidant, the TiC powder and the Cu-Al alloy powder; carrying out internal oxidation; and carrying out cold (hot) extrusion (rolling) deformation, wherein the oxidant is industrial Cu2O, the sintering and the internal oxidation are synchronously carried out, the sintering temperature is 900 to 1,000 DEG C and the internal oxidation time is 2 to 6h. The dispersion copper spot-welding electrode prepared by the process method disclosed by the invention not only has a high wear resistance, a high intensity, a high conductivity and a high softening resistance temperature, but also has the advantages of short internal oxidation time, low cost and high efficiency.

Owner:HENAN UNIV OF SCI & TECH

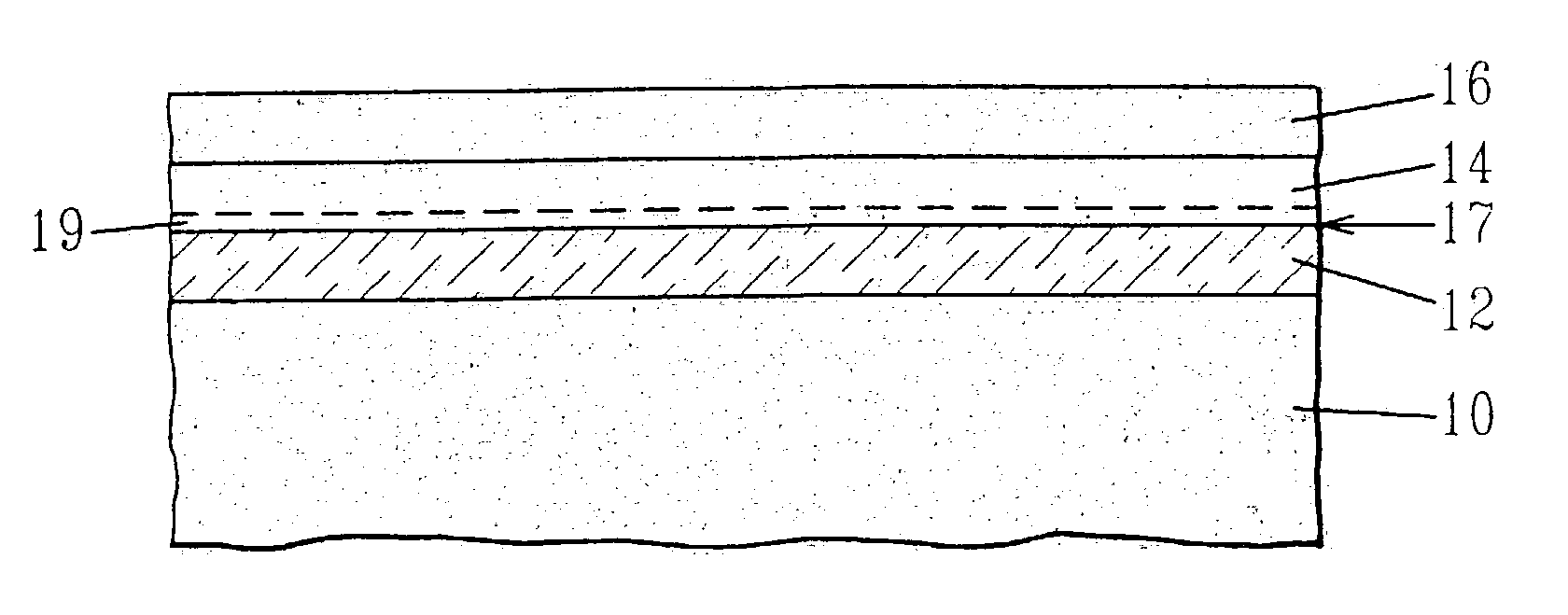

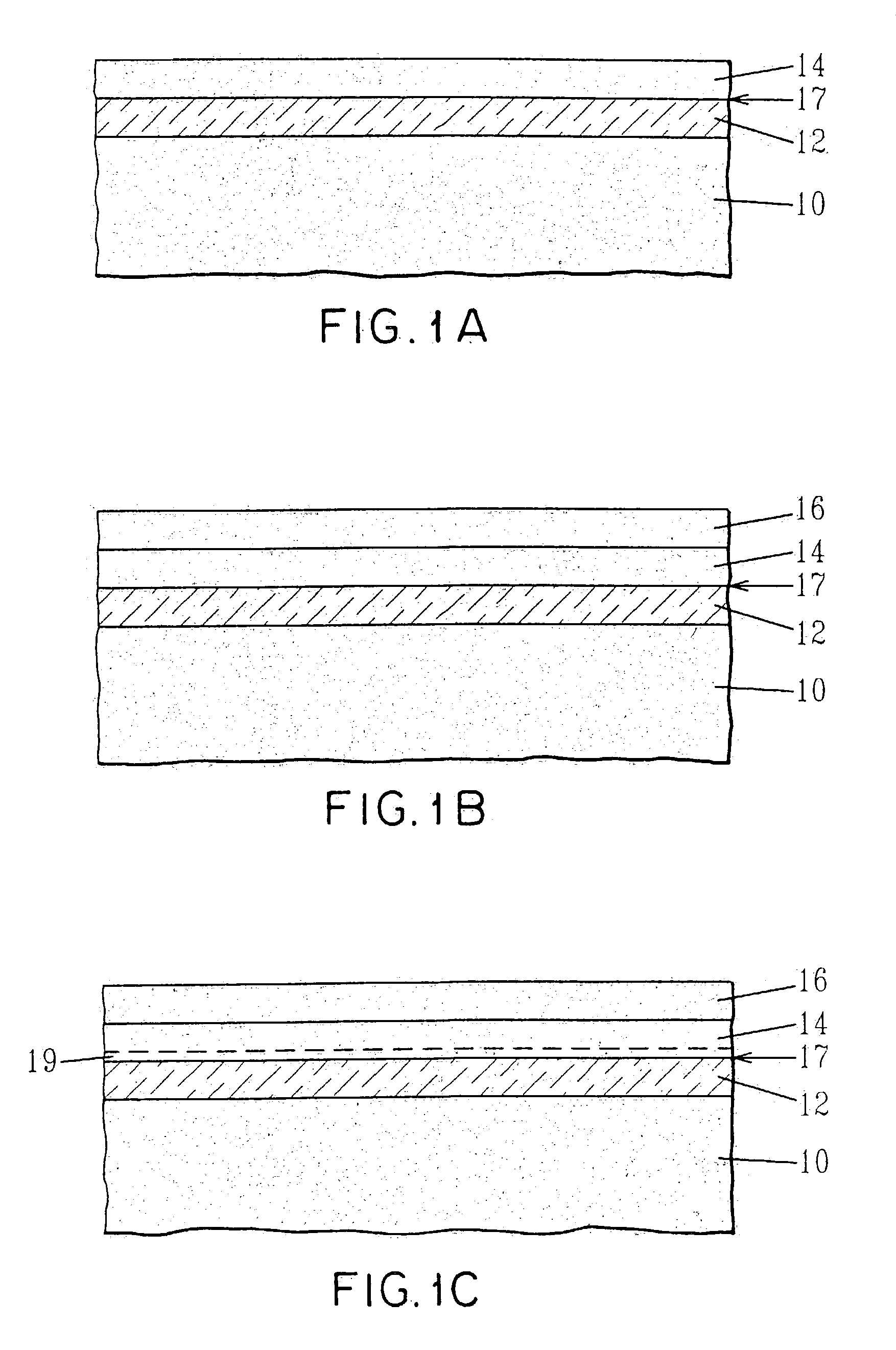

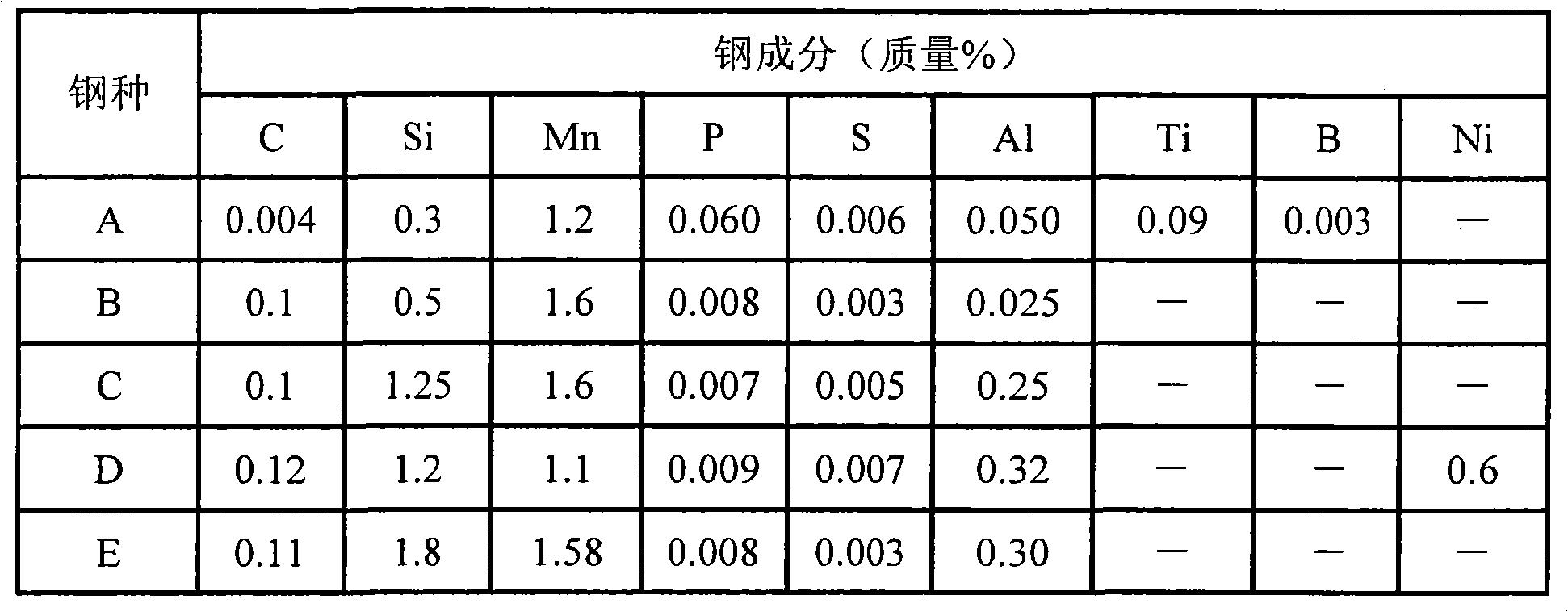

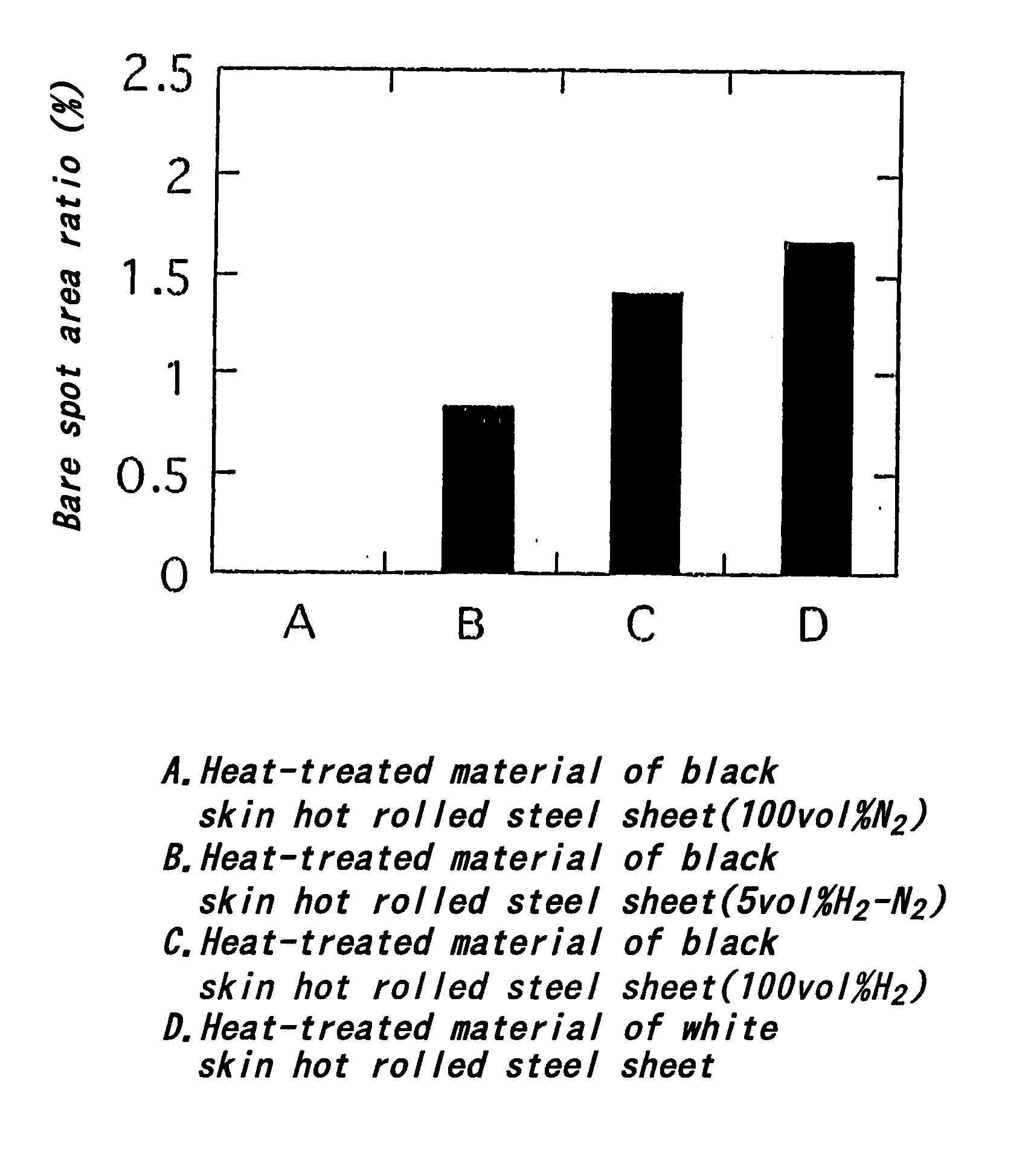

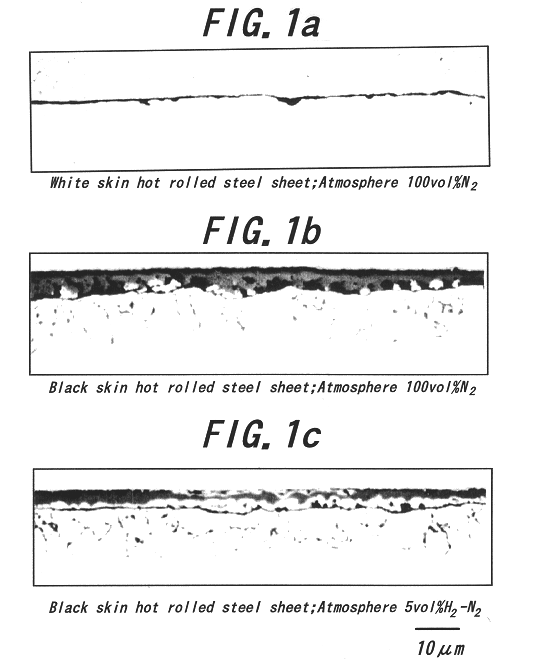

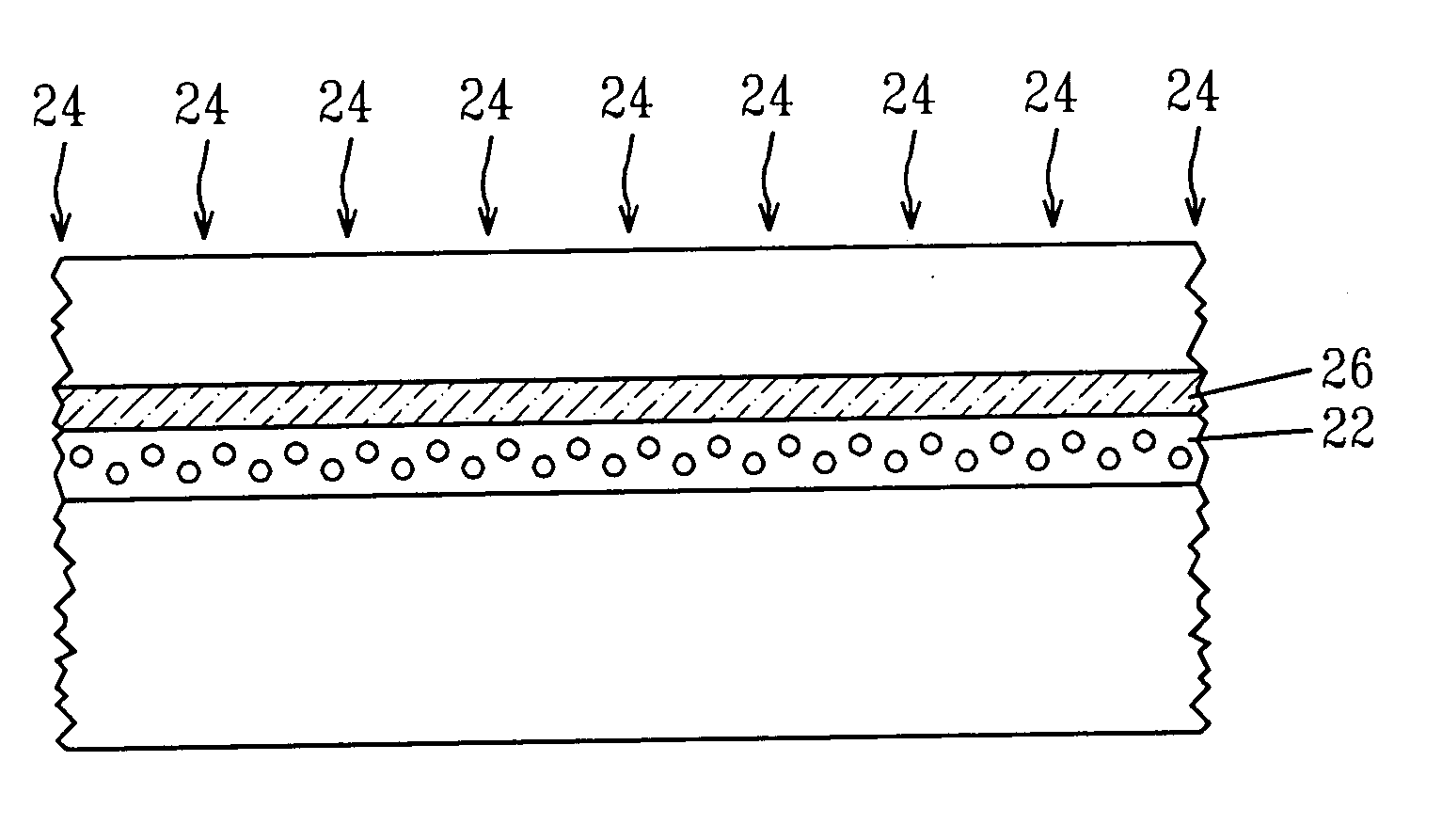

Methods of producing steel sheet, hot-dip steel and alloyed hot-dip steel sheet

InactiveUS6398884B1Easy to solveExcellent hot-dipping property propertyHot-dipping/immersion processesSheet steelSurface layer

This invention can form a sufficiently internal oxide layer in a surface layer portion of an iron matrix of a steel sheet by hot rolling a base steel and subjecting to a heat treatment at a temperature range of 650-950° C. in an atmosphere substantially not causing reduction while being adhered with a black skin scale irrespectively of a chemical steel composition or production history, or even when a radiation type heating of a radial tube or the like is used in a recrystallization annealing before a hot dipping treatment, and hence excellent hot-dipping property and conversion treating property can be given to a steel sheet for hot dipping.

Owner:KAWASAKI STEEL CORP

Binder, preparation method of binder and application of binder used as metallurgical pellet binder

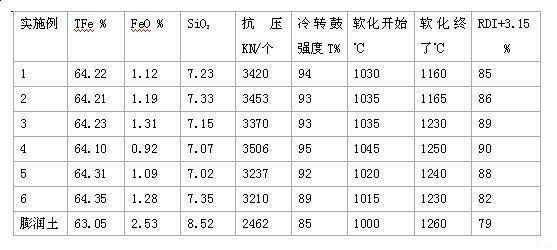

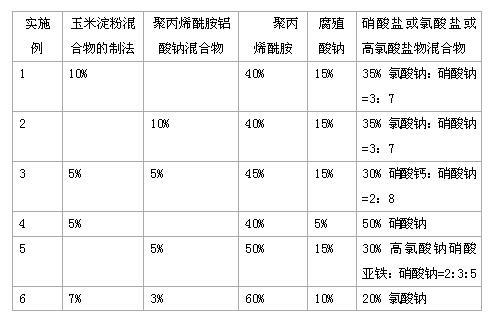

The invention relates to a binder, a preparation method of the binder and an application of the binder used as the metallurgical pellet binder, belonging to the technical field of the production of sintered pellets of the ferrous metallurgy. The technical scheme of the invention is as follows: the binder consists of the following one or two components: the mixture of polyacrylamide, sodium humate and nitrate or chlorate or perchlorate, corn starch mixture and the mixture of polyacrylamide and sodium aluminate. The preparation method comprises the following steps: adding the binder in fine iron powder for pelletizing of which 200-mesh passing rate is no less than 70% to mix evenly and pelletizing, wherein the dosage of the binder is 0.2-0.5% of fine iron powder. The invention has the beneficial effects: the binder has some properties of bentonite such as hygroscopicity and lubricity, the binder does not contain silicon, aluminum, phosphorus and sulfur, the pelletizing dosage of the binder is small, the burning loss is high, the high temperature burning loss of the binder is up to 60%-90%; and the pelletizing process mainly adopts lamellar packing growth, the agglomeration growth is reduced, the internal oxidation of the pellets in the chain grate can be promoted.

Owner:张家口佳一昌科技发展有限公司

Preparation process of silver tin oxide electric contact material

InactiveCN100999789AEasy to oxidizeImprove bindingContact materialsInternal oxidationMaterials science

The preparation process of silver-tin oxide electric contact material features the material comprising 150 mesh SnO2 powder in 2-12 wt% and 50-1000 mesh AgSn alloy powder with Sn content of 1-5 wt% for the rest. The preparation process includes no-air ball milling or forced mixing the said material to obtain compound powder, and forming before or after internal oxidation to produce the electric contact material. Thus process has powder metallurgy and internal oxidation and the prepared silver-tin oxide electric contact material has excellent electric performance and mechanical performance.

Owner:沈阳金纳新材料股份有限公司

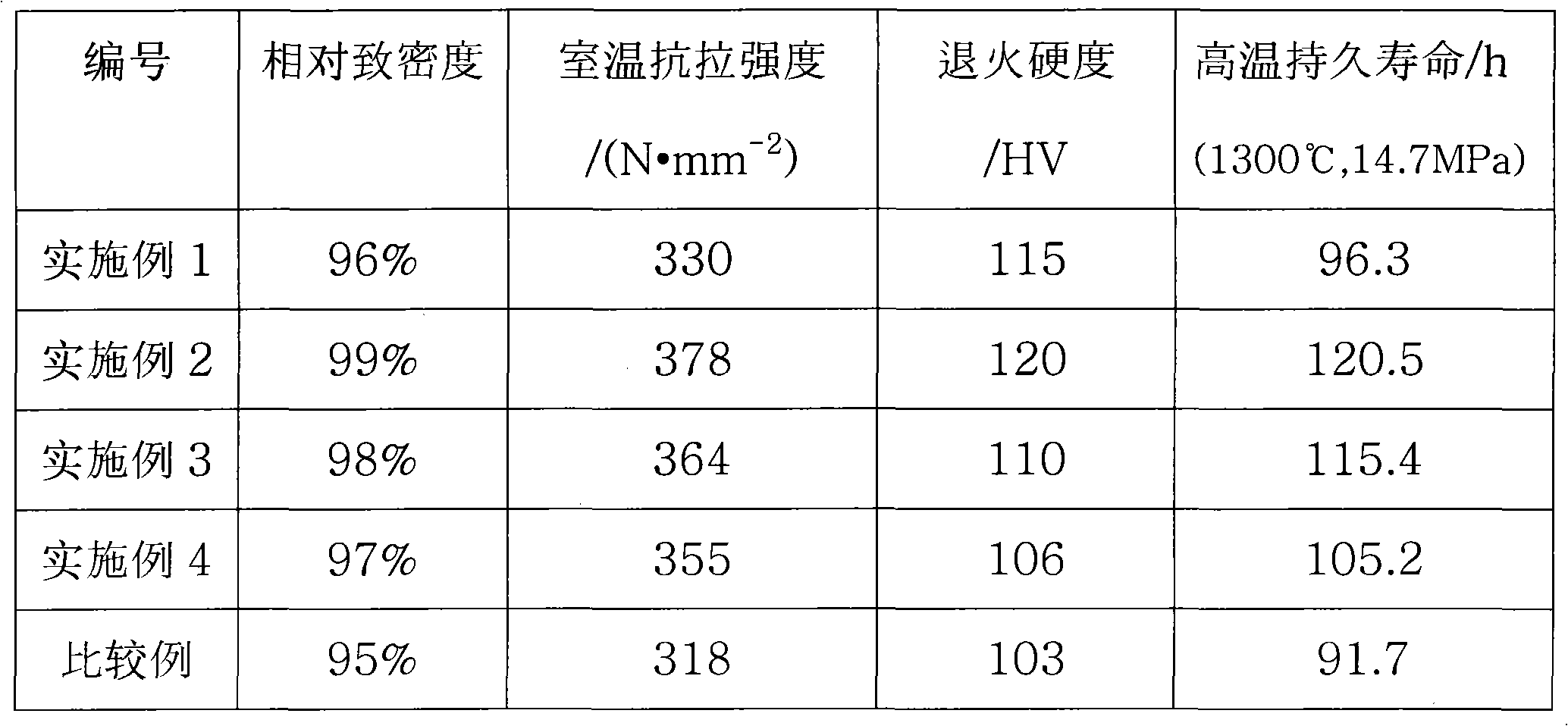

Method of preparing lamination dispersion strengthening platinum-base composite material

The invention relates to the field of preparing layered composite material by vacuum pressure sintering, particularly to a method of preparing lamination dispersion strengthening platinum-base composite material by vacuum pressure sintering. The obtained composite material has the characteristics of high relative density and few defects at the lamination interface. The method comprises the following steps: vacuum melting, rolling, internal oxidation and preparation of composite ingots by clipping. Then the ingots are heated to the temperature of 1000-1500 DEG C. at a vacuum degree of 10<-2>-10<-3>Pa and are cooled to room temperature in the furnace after being pressurized to 10-50MPa with dwell time 10-90 minutes. Products with a relative density of greater than 95% can be obtained by the pressure molding of composite ingots in the above vacuum environment. By adopting the method provided by the invention, the generation probability of air bubbles at the interface is reduced and interface jointing strength is increased. Meanwhile, the anti-creeping property of dispersion strengthening platinum-base composite material at high temperature is also improved. The present invention solves the problems of low interface jointing strength, more defects at the lamination interface, long technological process and high cost of products prepared by traditional hot pressing method, thus is applicable to the preparation of dispersion strengthening platinum-base composite material of high relative density and few defects at the lamination interface.

Owner:SINO PLATINUM METALS CO LTD

Preparation method of silver tin oxide electric contact material

ActiveCN104269296AImprove the distribution patternReduce aggregationTransportation and packagingMetal-working apparatusElectricityDistribution pattern

The invention relates to a preparation method of a silver tin oxide electric contact material. According to the method, atomized silver tin powder is processed through internal oxidation and then is mixed with tin oxide powder and additives, and the mixture is manufactured into the silver tin oxide electric contact material with the needed specifications through working procedures such as sintering, pressing, wiredrawing and the like. Compared with a traditional electric contact material, the silver tin oxide electric contact material prepared with the method has the characteristics of a power internal oxidation and power mixing method, the rigidity and the plasticity of the silver tin oxide material are enhanced, it is guaranteed that the material has good forming performance, the distribution pattern of the tin oxide can also be improved, the frequency of the phenomenon that tin oxide gathers can be reduced, the homogeneity of a structure is improved, the temperature rise of the contact material is reduced, and the service life of the contact material can be prolonged easily.

Owner:CHONGQING CHUANYI AUTOMATION

Preparation method of silver-metallic oxide electrical contact material

InactiveCN101609755AImprove organizationIncrease productivityContact materialsMolybdeum compoundsAdditive ingredientInternal oxidation

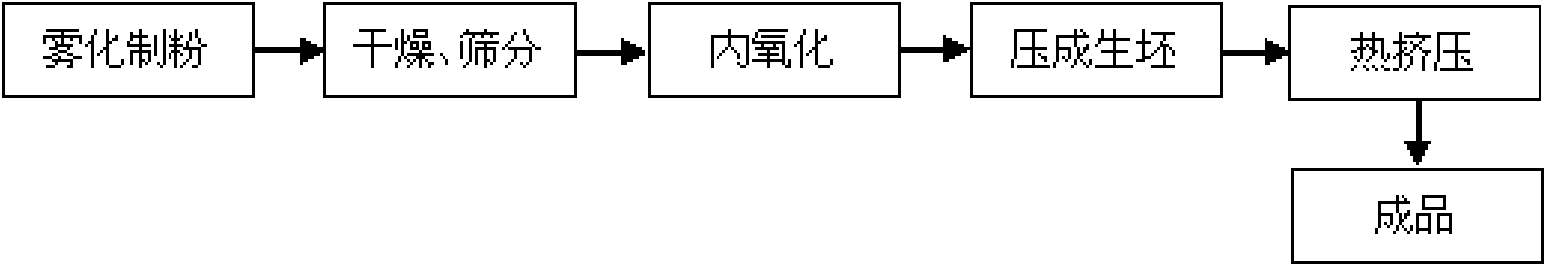

The invention discloses a preparation method of a silver-metallic oxide electrical contact material, which comprises the following steps of: firstly preparing Ag-Me alloy powder with uniform ingredient 3 and fine granularity by a gas atomization method, then conducting internal oxidation on the powder to generate composite Ag-MeO powder, die-pressing the composite Ag-MeO powder into blanks, and adopting a powder hot extrusion technique to prepare the electrical contact material. The preparation method is characterized by low temperature of internal oxidation, short time and simple technique, solves the problem that the Ag-MeO material is difficult to process, reduces the production cost, improves the structure of the contact material and improves the comprehensive performance thereof simultaneously.

Owner:CENT SOUTH UNIV

High electrical quality buried oxide in simox

InactiveUS20050170570A1Improve power qualityInferior electrical qualitySemiconductor/solid-state device manufacturingOxygen ionsRoom temperature

A SIMOX (separation by implanted oxygen) process is provided that forms a silicon-on-insulator (SOI) substrate having a buried oxide with improved electrical properties. The process implements at least one of the following processing steps into SIMOX: (I) lowering of the oxygen ion dose in the base oxygen ion implant step; (II) off-setting the implant energy of the room temperature (RT) implant step to a value that is about 5 to about 20% lower than the base ion implant step; and (III) creating a soak cycle, i.e., pre-annealing step, prior to the internal oxidation anneal which allows dissolution of Si and SiOx precipitates in the oxygen implanted region. The temperature and time of the soak cycle as well as the base implant dose are critical in determining the final BOX quality.

Owner:GLOBALFOUNDRIES INC

Method for preparing TiAl-based composite material sheet material

InactiveCN101497082AImprove tissue uniformityNo internal oxidationFurnace typesHeat treatment process controlAluminum matrix compositesInternal oxidation

The invention provides a method for preparing a TiAl-based composite material plate, and relates to a method for preparing the composite material plate. The method solves the problems that TiAl-based alloy prepared by the prior process has poor uniformity and compactness in texture and serious internal oxidation phenomenon, and only block body TiAl-based composite material can be prepared by a composite strengthening and toughening method. The method of the invention comprises the following steps that: firstly, aluminum-based composite material plates and pure tatinium plates are alternately laminated and subjected to hot pressing and hot rolling to prepare a multilayer composite plate; and secondly, the multilayer composite plate is subjected to heat treatment to prepare the TiAl-based composite material plate. The TiAl-based composite material plate obtained by the method has good uniformity and compactness in texture, and has no internal oxidation; and compared with the block body TiAl-based composite material, the plate type TiAl-based composite material has convenient use and wide application field.

Owner:HARBIN INST OF TECH

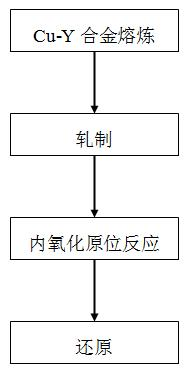

Dispersion strengthening copper-based composite material and preparation method thereof

The invention relates to a dispersion strengthening copper-based composite material and a preparation method thereof. The dispersion strengthening copper-based composite material and the preparation method thereof are characterized in that A dispersion strengthening phase is yttrium oxide, and the content of yttrium oxide in copper is 1-2.5 percent by weight, and the preparation method comprises the processes of alloy smelting, rolling, internal oxidation, reduction and the like. The preparation method has the advantages of short process and low production cost. The tensile strength of the product is greater than 550 MPa, the conductivity exceeds 90 percent IACS (international annealed copper standard), and the softening temperature is higher than 900 DEG C. The dispersion strengthening copper-based composite material has higher mechanical property, excellent electrical conductivity and high-temperature softening resistance. The Y2O3 granulate dispersion strengthening copper-based composite material prepared in the invention can be applied to computer integrated circuit lead frames, resistance welding electrodes for automobile industry, linings of crystallizers of continuous casting machines for metallurgical industry, equipment and carrier rockets, electric car and electric power train aerial conductor and the like, and the character of service and the service life can be obviously improved.

Owner:NANCHANG UNIV

Preparation process of rare-earth copper alloy material for preparing integral dispersion copper

The invention belongs to the technical field of alloy material. The proposed rare earth Cu-Al alloy materials used for preparing integral dispersion copper mainly comprise Cu, Al and rare earth additive RE; wherein, the contents of each component are: 0.10wt percent to 1.00wt percent of Al; 0.05wt percent to 0.50 wt percent of RE and the rest is Cu; the rare earth additive RE relates to Y or Ce or mixed rare earth element (Ce +Y); the mixed rare earth element (Ce +Y) adopts pure rare earth to weigh and carry out mixing; the mixture ratio thereof is: wt percent of Ce: wt percent of Y is equal to 1:1; the preparation technique of the rare earth Cu-alloy material includes the smelting of the alloy; the thermal processing of the alloy; the solid dissolving of the alloy; the cold processing and shaping after the solid dissolving; wherein, the processing temperature of the solid dissolving of the alloy is 900 to 950 DEG C; water quenching is carried out after preserving the temperature for 2 to 4h; then thermal squeezing or hot rolling process is carried out for 4h to 8h under the temperature of 850 to 950 DEG C. The dispersion copper prepared by the invention has the characteristics of high intensity, high conductance, high anti-softening temperature; the preparation method thereof has the advantages of short internal oxidation time, low cost and high efficiency.

Owner:HENAN UNIV OF SCI & TECH

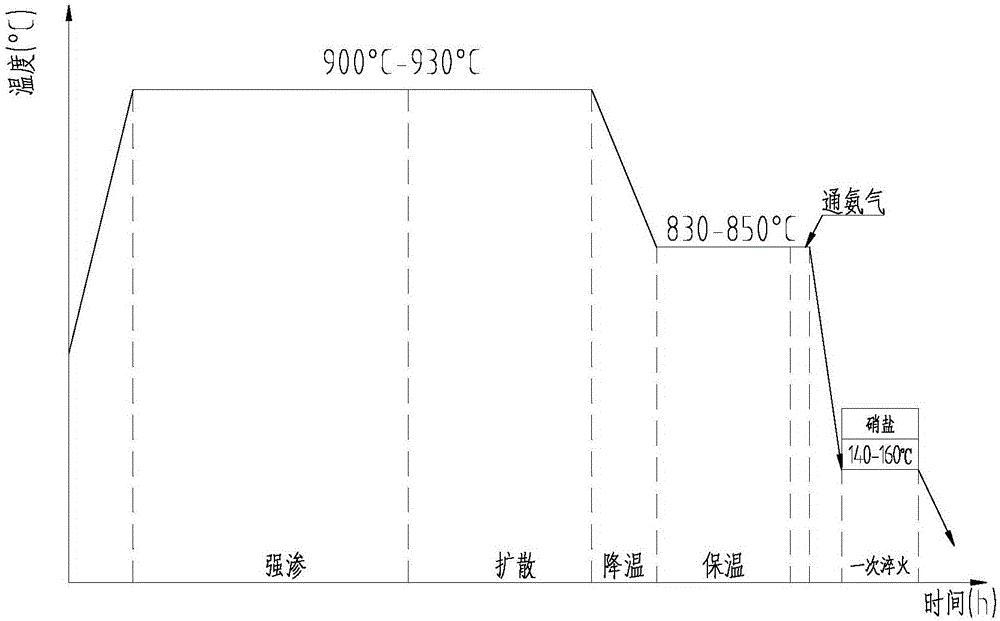

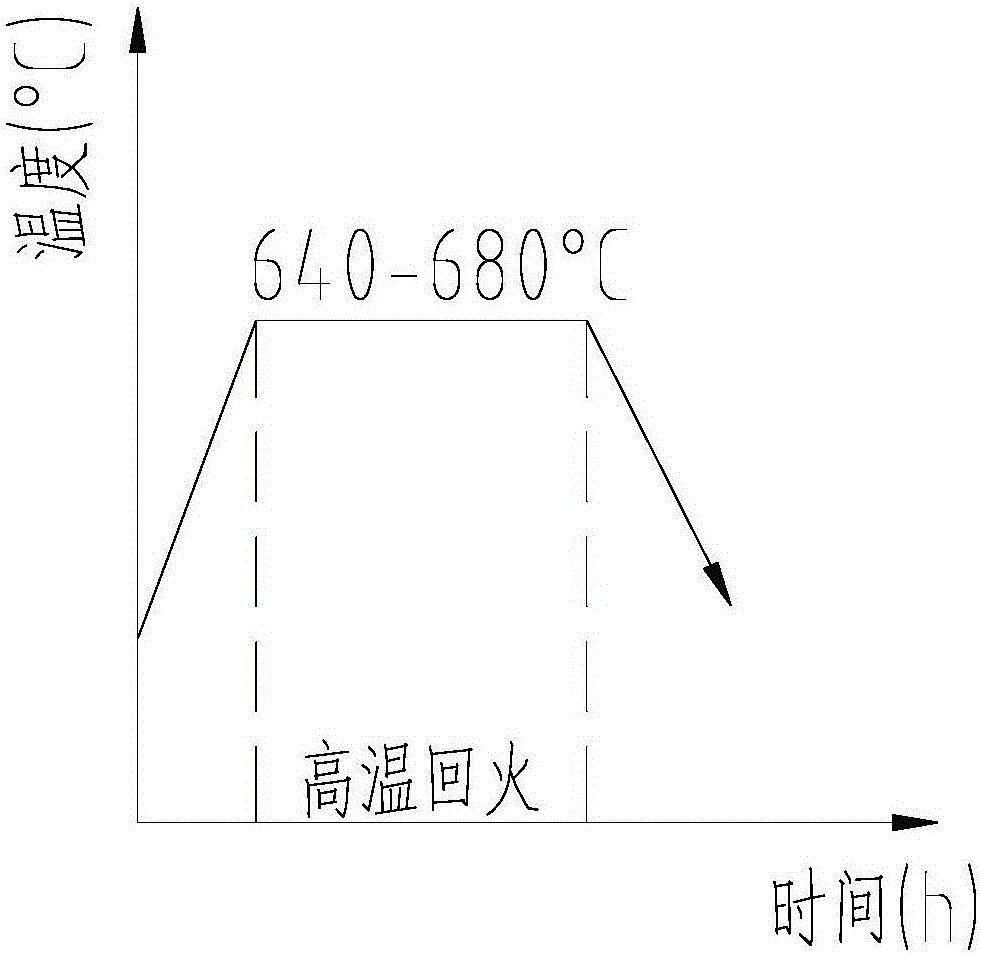

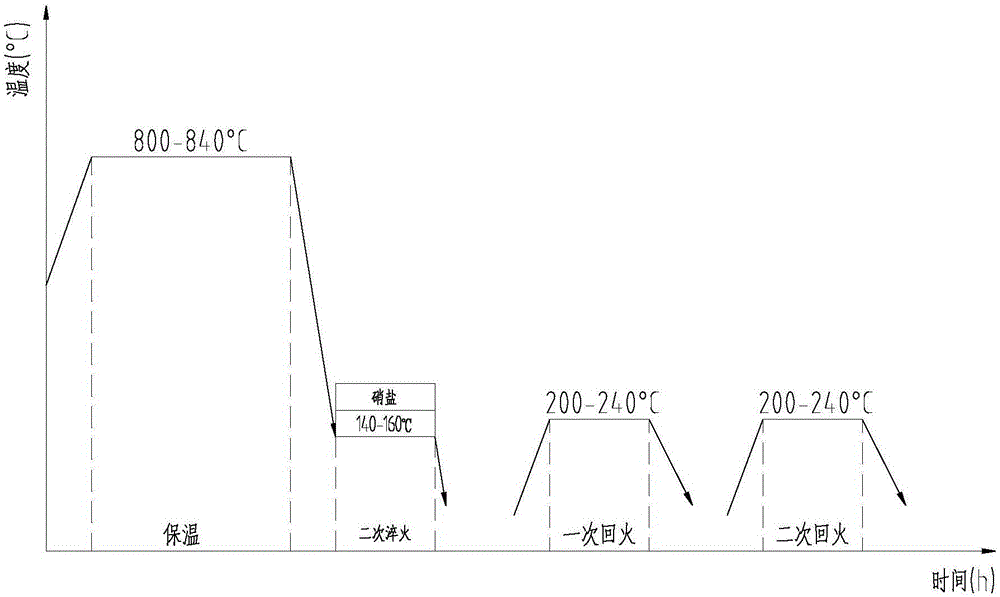

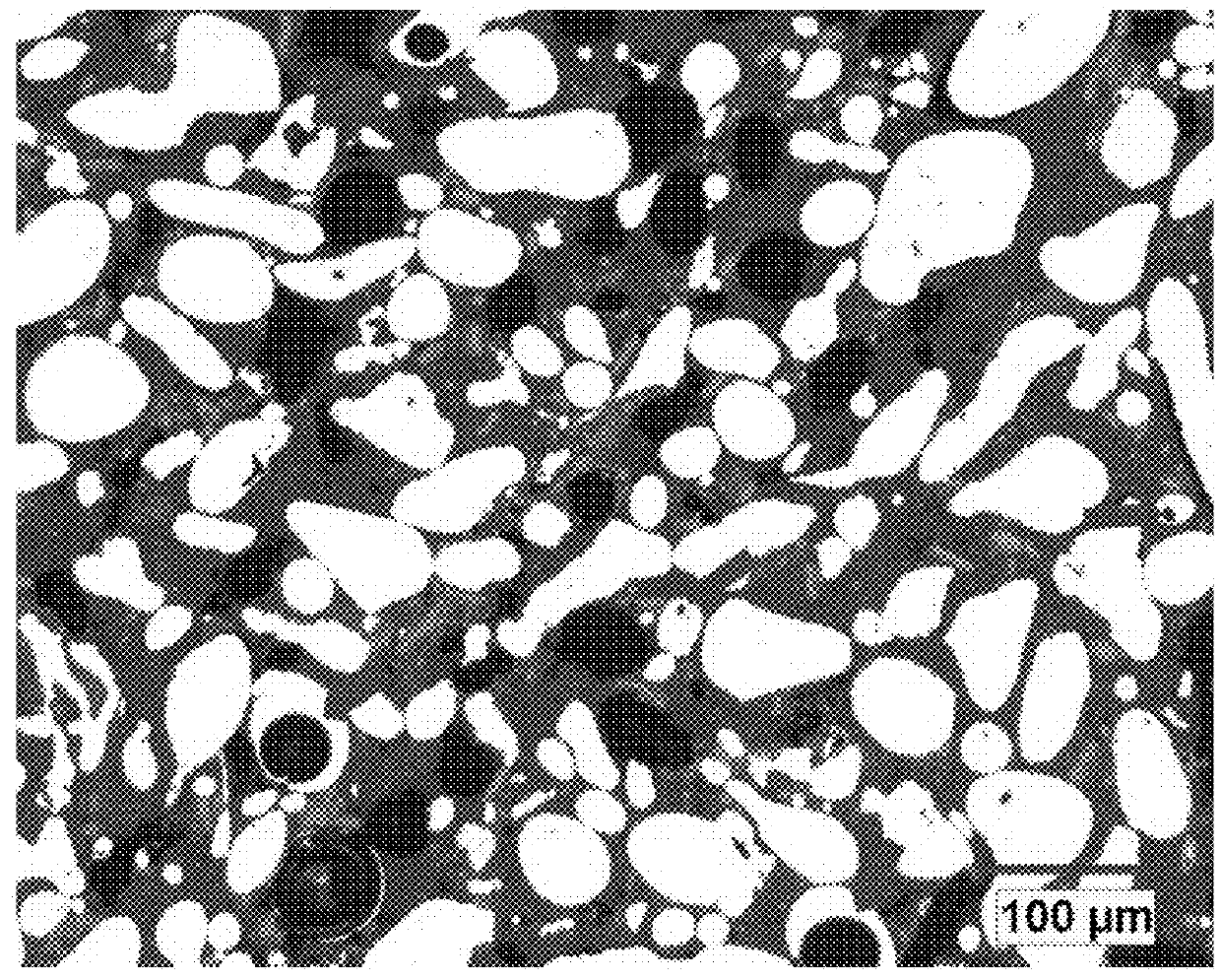

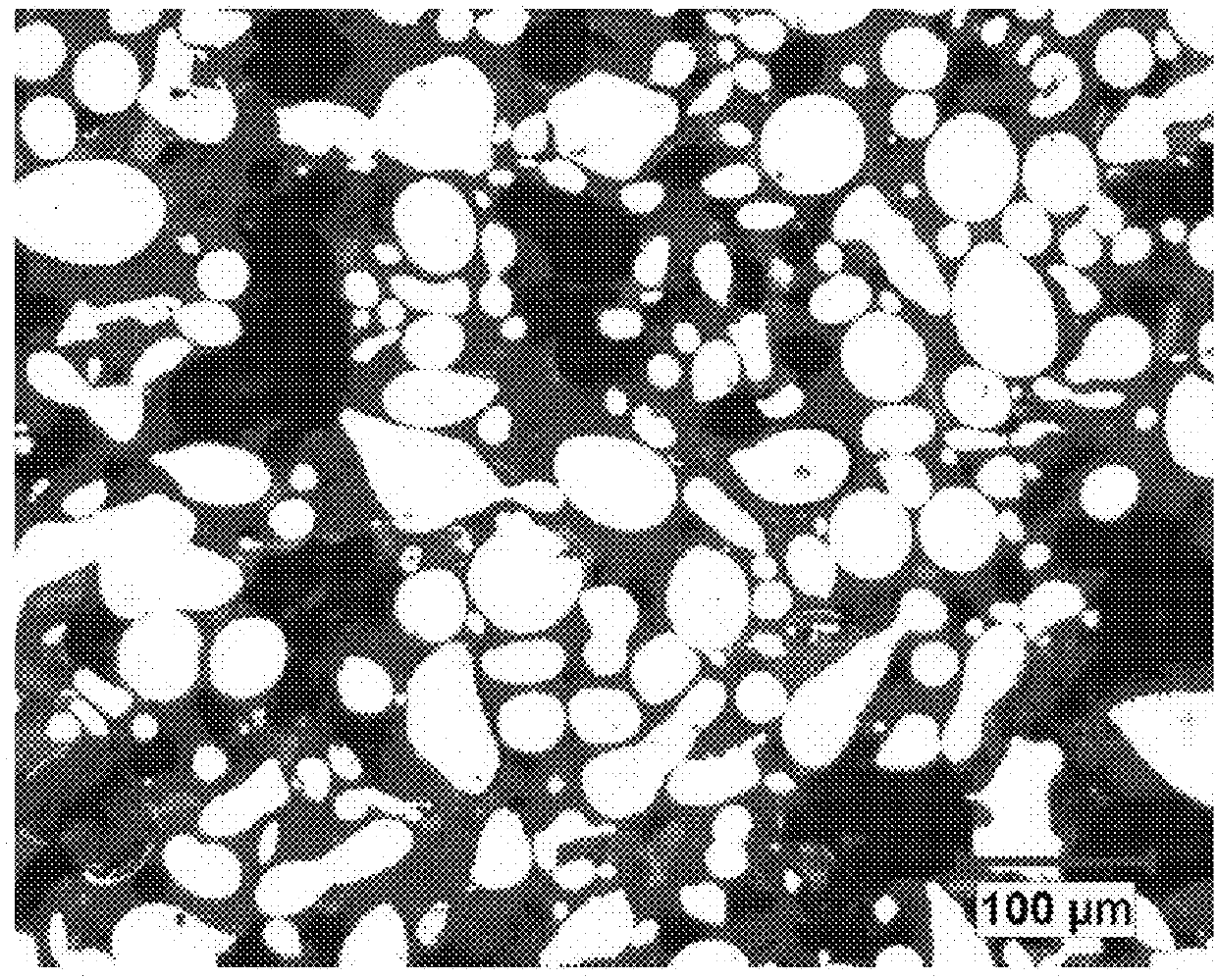

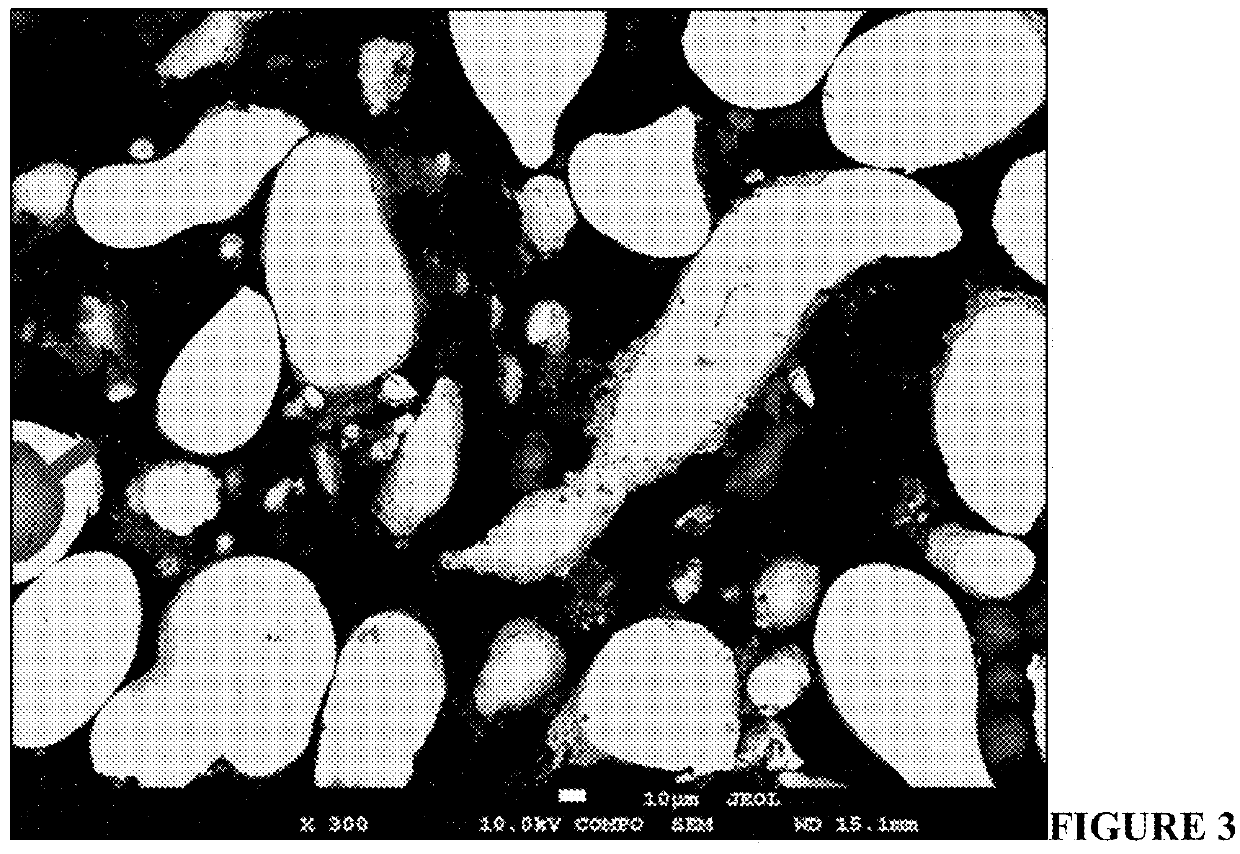

Process method for controlling non-martensite depth of carburized workpiece

ActiveCN106222606AImprove mechanical propertiesImprove stabilitySolid state diffusion coatingCarbon potentialSurface layer

The invention discloses a process method for controlling the non-martensite depth of a carburized workpiece. The process method comprises the steps of carburizing, ammonia introducing, primary quenching, high-temperature tempering, secondary quenching and low-temperature tempering for two times. According to the process method for controlling the non-martensite depth of the carburized workpiece, the carbon potential during carburizing is improved, and the proportion of the strong carburizing stage in the total carburizing time is increased, so that the internal oxidation depth in the carburizing atmosphere is decreased; in addition, a certain amount of ammonia is introduced in the final stage of carburizing and heat preservation, N atoms permeate into the surface of the workpiece, the hardenability of a workpiece carburized layer is improved, and hence formation of a non-martensite structure is effectively prevented; and meanwhile, after carburizing is conducted, the high-temperature tempering process is added between the two times of quenching processes, and the subsequent two times of low-temperature tempering processes are conducted, so that the content of surface layer residual austenite is effectively decreased, and the situation that the residual austenite does not meet the technical requirement is avoided.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Preparation technique for high-strength high conductivity integral dispersion copper spot-welding electrode

The invention provides a preparation technique method for a high intensity and high conductive integral dispersing copper spot welding electrode which adopts Cu-Al alloy with low solid solubility or rare-earth copper alloy with low solid solubility; the content of aluminum is not more than 1.00wt percent; the adding amount of the rare-earth is not higher than 0.50wt percent; the rest is Cu. The preparation technique method includes: mixing an oxidizer and a loading agent; embedding; internal oxidation; cold (hot) extrusion (rolling) deformation; wherein, the oxidizer is industrial Cu2O; the loading agent is industrial Al2O3; the oxidizer and the loading agent are mixed and the Cu-Al alloy or the rare-earth copper alloy stick or plate is embedded; the mixing proportion of the oxidizer and the loading agent is (40-60) percent:(60 to 40) percent; sintering and the internal oxidation are carried out synchronously; the sintering temperature is 900 to 1000 DEG C; the internal oxidation time is 4 to 20 hours. The dispersing copper spot welding electrode prepared by the technique method of the invention not only has the advantages of high intensity, high conductive property and high anti-intenerating temperature, but also has the advantages of short internal oxidation time, low cost and high efficiency.

Owner:HENAN UNIV OF SCI & TECH

Treatment of melt for atomization technology

InactiveUS20180104745A1Easy to manufactureTransportation and packagingMetal-working apparatusRe introductionSulfur

An improved method of manufacturing a powder metal material by water, gas, plasma, or rotating disk atomization is provided. The method includes adding at least one additive to a melted metal material before or during the atomization process. The at least one additive forms a protective gas atmosphere surrounding the melted metal material which is at least three times greater than the volume of melt to be treated. The protective atmosphere prevents introduction or re-introduction of contaminants, such as sulfur (S) and oxygen (O2), into the material. The atomized particles produced include at least one of the following advantages: median circularity of at least 0.60, median roundness of at least 0.60, less internal pores, less internal oxides, and an increased sphericity of the microstructural phases and / or constituents.

Owner:FEDERAL MOGUL MOTORPARTS LLC +1

Alloy steel for gear wheel and preparation method thereof

InactiveCN101191181AInternal oxidation tendencyHigh contact fatigue strengthPortable liftingFurnace typesGear wheelManganese

The invention discloses an alloy steel for gears. The weight percentage of the chemical compositions is that: carbon of 0.16 to 0.19 percent; silicon of less than or equal to 0.12 percent; manganese of 0.50 to 0.60 percent; chromium of 1.75 to 1.90 percent; nickel of 1.75 to 1.90 percent; phosphorus of less than or equal to 0.020 percent; sulfur of less than or equal to 0.015; copper of less than or equal to 0.20 percent; aluminum of 0.015 to 0.040 percent; molybdenum of 0.15 to 0.35 percent; tin of less than or equal to 0.020 percent; [oxygen] of less than or equal to 0.002 percent; [nitrogen] of 0.006 to 0.018 percent; [hydrogen] of less than or equal to 0.00015; stibium of less than or equal to 0.008 percent; titanium of less than or equal to 0.01 percent; calcium of less than or equal to 0.0020 percent; and the remainder is iron. The preparation method comprises hydrogen diffusion annealing procedures. The invention is made a carbonization treatment for 16 hours under the same carbonization condition, so the invention has small internal oxidation inclination; the invention has high contact fatigue strength and bending fatigue strength, and is suitable for the gears with the modulus of more than 10.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com