Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62results about How to "Improve the distribution pattern" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

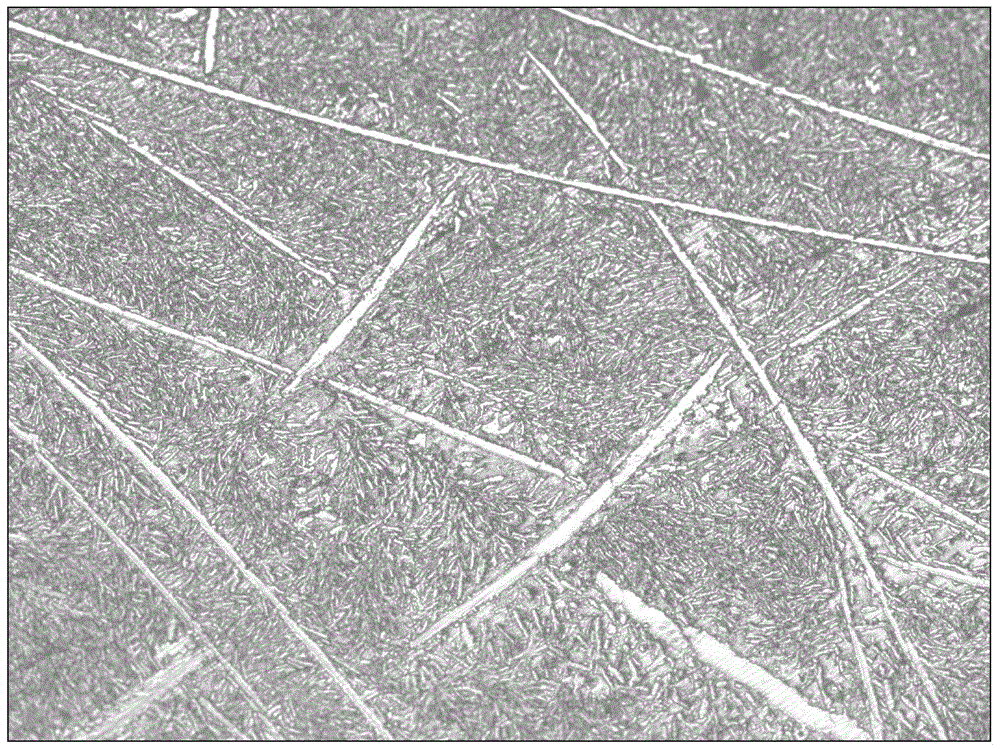

Iron-based Cr3C2 laser-cladding coating added with CeO2 and preparation method of coating

ActiveCN105112909AHigh hardnessImprove wear resistanceMetallic material coating processesAlloyHardness

The invention discloses an iron-based Cr3C2 laser-cladding coating added with CeO2 and a preparation method of the coating, and belongs to the technical field of surface modification. The coating is prepared by uniformly mixing the following components in percentage by mass for laser-cladding: 65-73% of iron-based self-fluxing alloy powder, 26.5-34% of Cr3C2 alloy powder and 0.5-1% of CeO2 powder. The preparation method comprises the following steps: powder preparation; uniform mixing and drying; preparation and post-treatment of the coating. Through adoption the technical scheme, the rigidity, abrasion resistance and high-temperature oxidation resistance of the coating can be improved; besides, the forming quality and cladding property of the coating can be remarkably improved to inhibit and eliminate bubbles and cracks.

Owner:ANHUI MA STEEL SURFACE TECH CO LTD

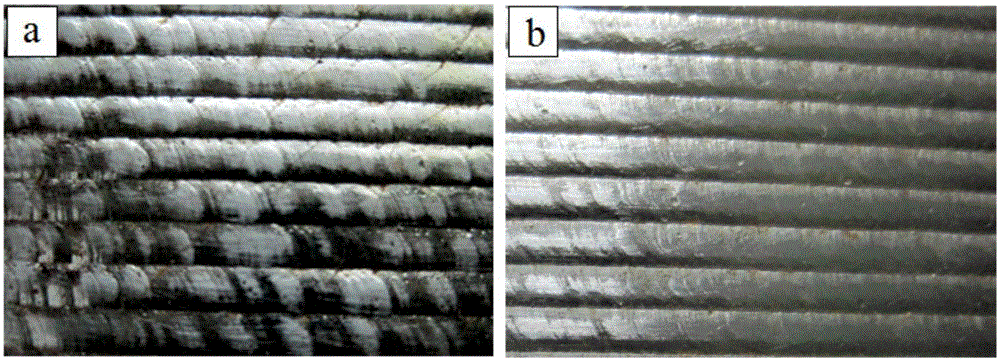

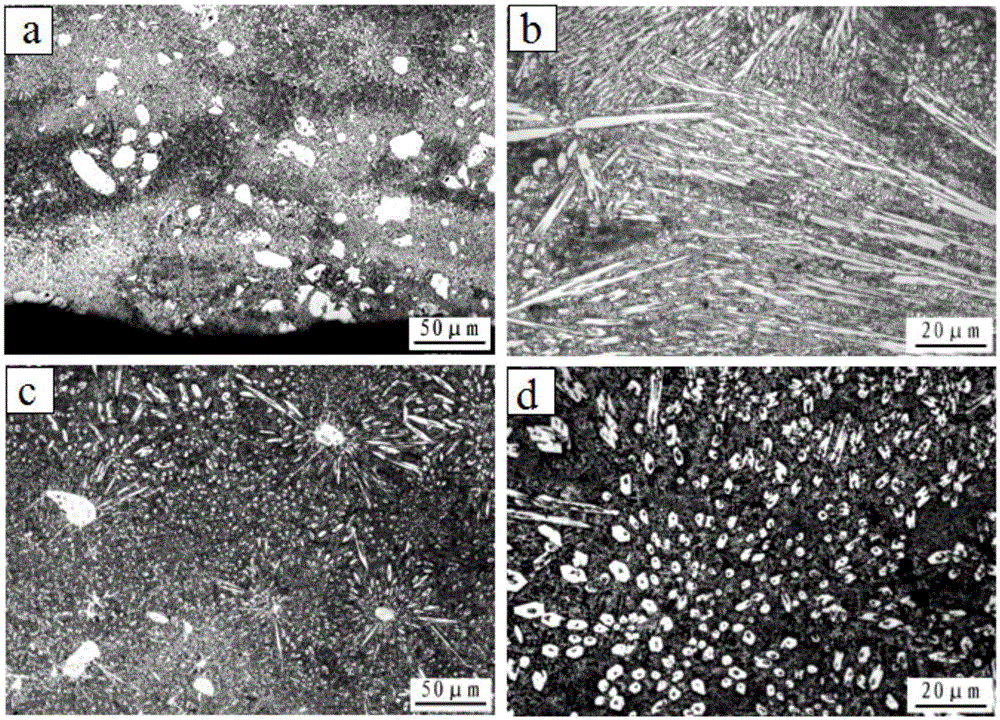

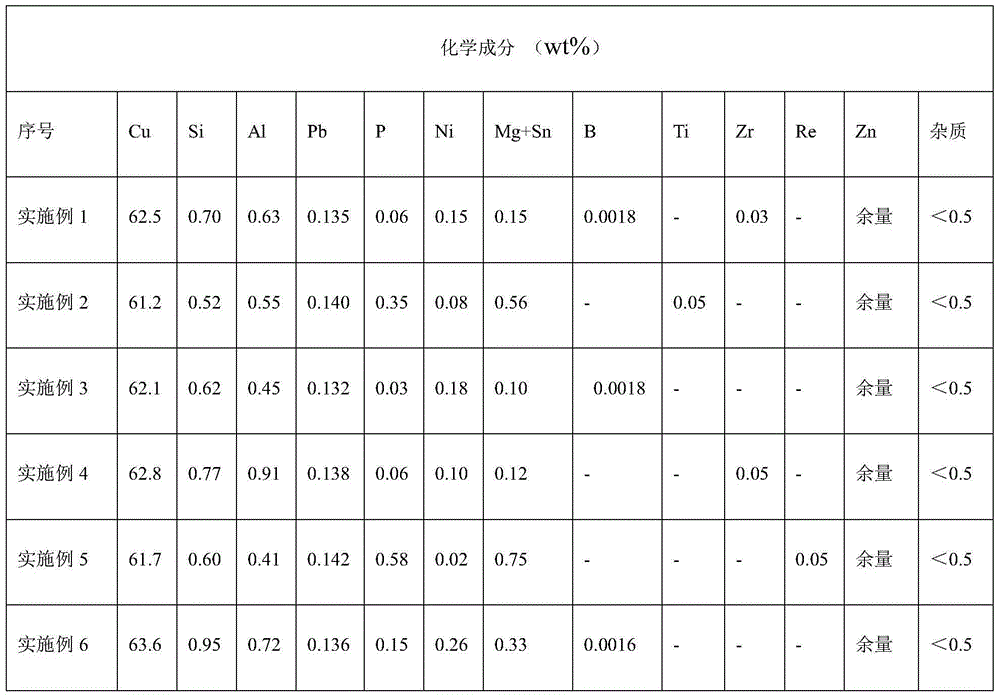

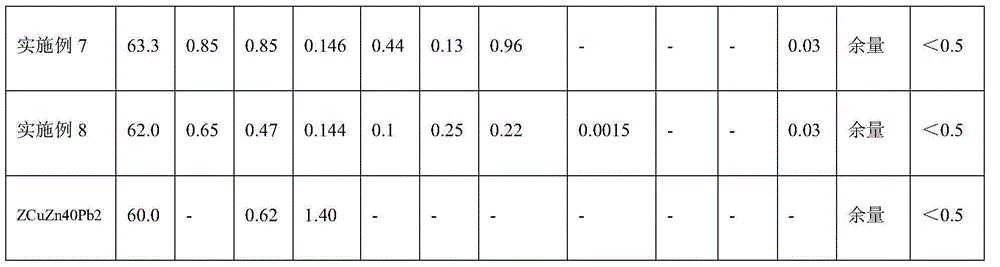

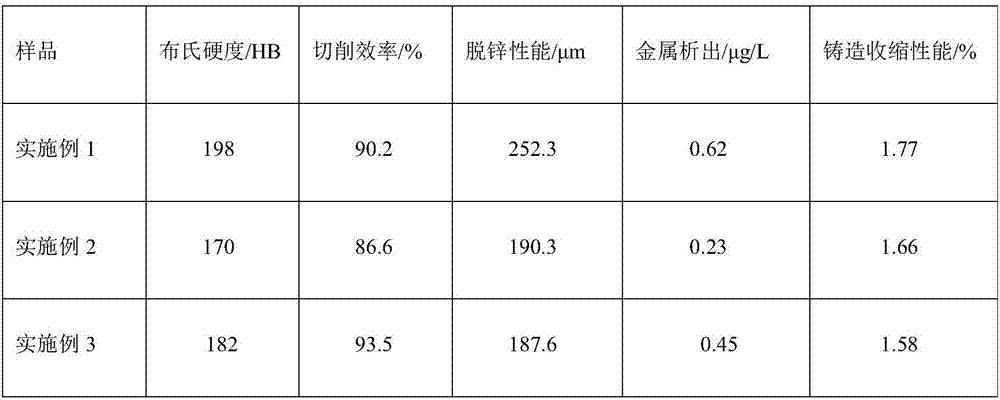

Phosphorus containing free-cutting silicon brass alloy and preparation method thereof

The invention discloses a phosphorus containing free-cutting silicon brass alloy. The phosphorus containing free-cutting silicon brass alloy is prepared from the following components: 61-64wt% of Cu, 0.5-1.0wt% of Si, 0.4-1.0wt% of Al, 0.01-0.6wt% of P, 0.1-0.15wt% of Pb, 0.01-0.3wt% of Ni, 0.1-1.0wt% of Mg+Sn, less than 0.08 wt% of at least one modificator, and the balance of Zn and impurities, wherein the modificator is B, Ti, Zr or Re, and the total weight percent of the impurities is not more than 0.5wt%. The invention further discloses a preparation method of the phosphorus containing free-cutting silicon brass alloy. The phosphorus containing free-cutting silicon brass alloy disclosed by the invention has excellent dezincification corrosion resistance, also has excellent casting performance and cutting performance, is relatively low in cost and is suitable for components of a drinking water system.

Owner:JOMOO KITCHEN & BATHROOM

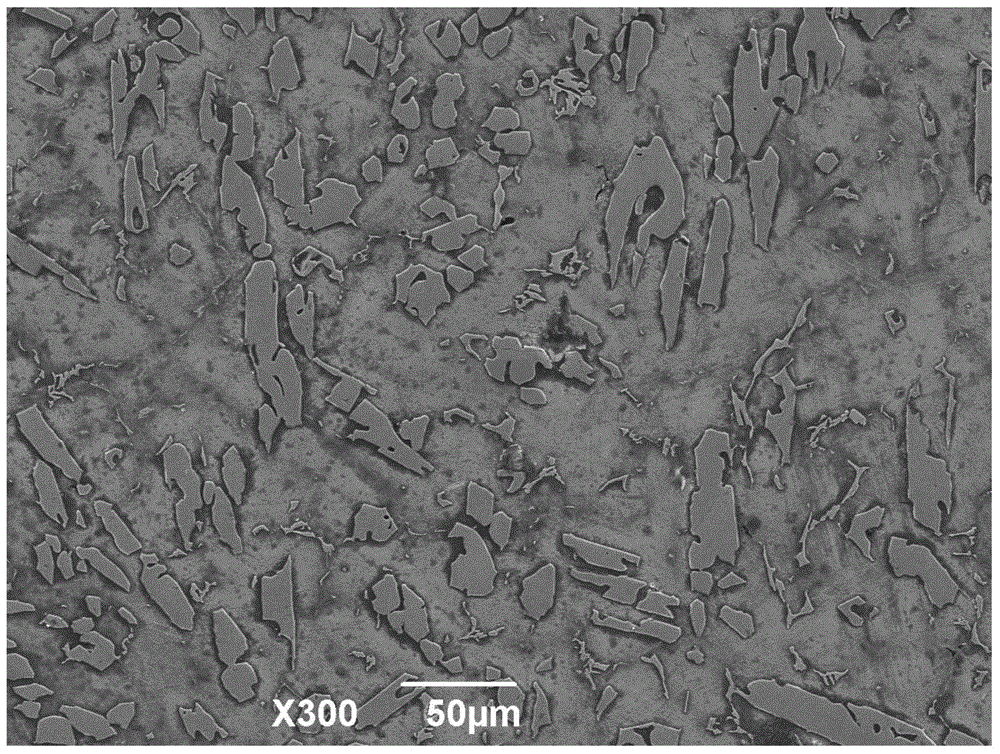

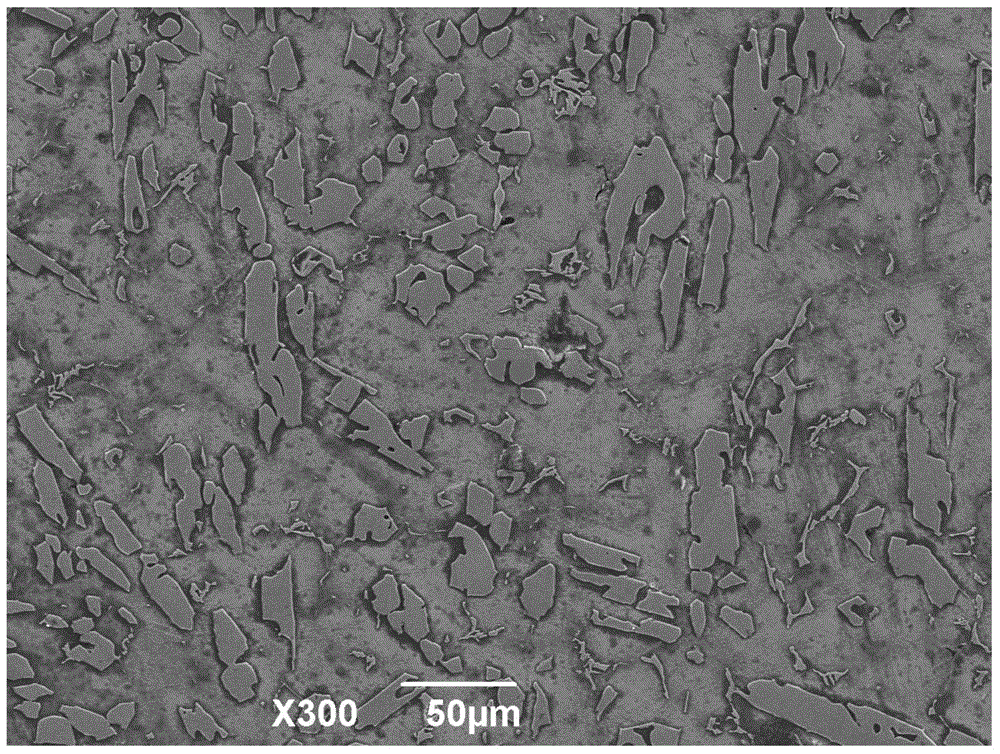

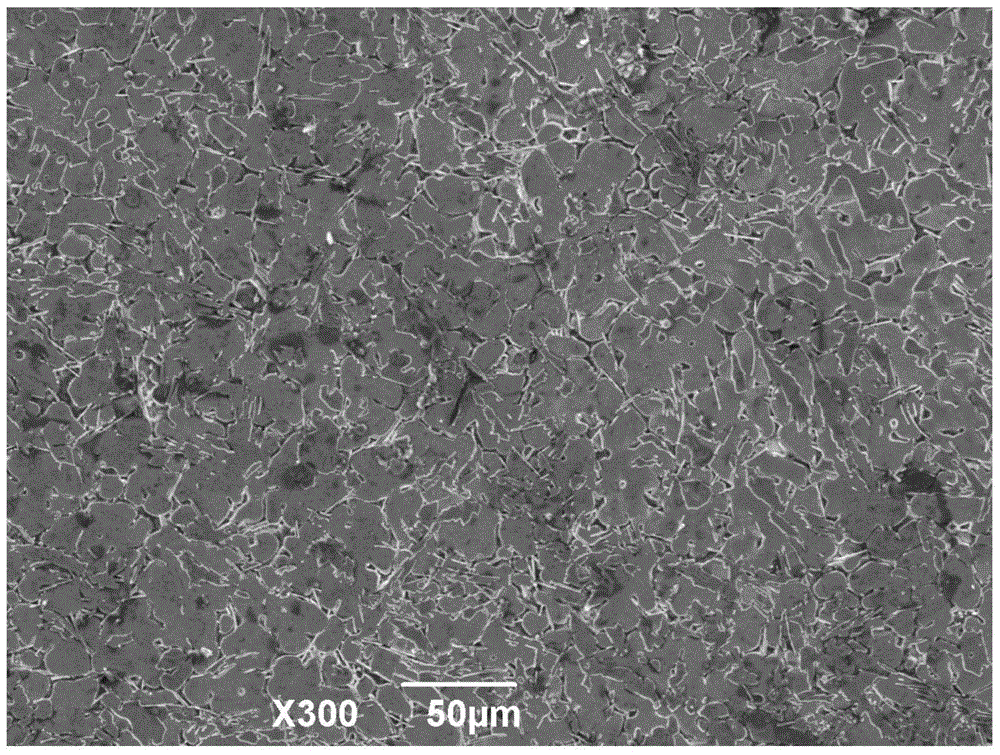

High vanadium high-wear-resistant alloy and its preparation method

The present invention relates to a high-vanadium high-wearability alloy, its composition contains: (wt%) C:2.0-3.2; Si:1.0-1.5; Cr: 7.0-12.0; Mn: 0.8-1.2; V: 8.0-15.0; S is less than or equal to 0.05; Mo:0.8-1.5; P is less than or equal to 0.07; and the rest is Fe and impurity, in its optimum scheme Re: 0.03-0.05 and Ti: 0-0.5 also can be added. Its preparation method includes the following steps: placing pig iron, waste steel, ferrochrome and ferromolybdenum into smelting furnace, heating and melting; placing ferrovanadium in the heating furnace, preheating to about 500 deg.C; heating molteniron to about, 500 deg.c in smelting furnace, deoxidizing inserted aluminium, adding ferrovanadium, ferrosilicium, ferromanganese, rare earth and ferrotitanium, heating to 1490-1520 deg.C, pouring temp. is 1400-1420 temp., then heating to 500-550 deg.c and tempering.

Owner:JIANGSU MACHINERY & ELECTRICAL RES INST

Manufacturing method of high-strength oxidable aluminum alloy plate strip

The invention discloses a manufacturing method of a high-strength oxidable aluminum alloy plate strip. The manufacturing method of the high-strength oxidable aluminum alloy plate strip comprises the following steps that (1) molten aluminum alloy is prepared, specifically, chemical elements are determined, and the aluminum alloy comprises, by mass, 0.6%-0.9% of Si, 0.1%-1.4% of Fe, 0.6%-0.9% of Cu, 0.2%-0.3% of Mn, 0.9%-1.1% of Mg, 0-0.05% of Cr, 0-0.05% of Zn, 0-0.05% of Ti, 0-0.05% of single impurities, 0-0.15% of blended impurities, and the balance Al; (2) casting is conducted; (3) hot rolling is conducted; (4) intermediate annealing is conducted; (5) cold rolling and finish rolling are conducted; and (6) continuous pull-correcting or predrawing is conducted. The aluminum alloy plate strip manufactured through the method has high strength, the tensile strength T.S(delta b / MPa) is equal to or higher than 350 MPa, the yield strength Y.S(delta 0.2 / MPa) is equal to or higher than 320 MPa, the extensibility (theta / %) is equal to or higher than 8%, and the surface hardness HV is equal to or higher than 120. The type of the aluminum alloy plate strip manufactured through the method is TY62-T651, the aluminum alloy plate strip is high in supporting strength and surface strength and oxidable when used for a side key of a mobile phone support, continuous punching can be achieved, and the production efficiency is high.

Owner:昆山灿鑫精密电子科技有限公司

Fine-grain high-strength TiAl alloy including nano Y2O3 and preparation method thereof

ActiveCN106521238ASolve the problem of severe segregationIncrease profitMechanical heat treatmentYttrium

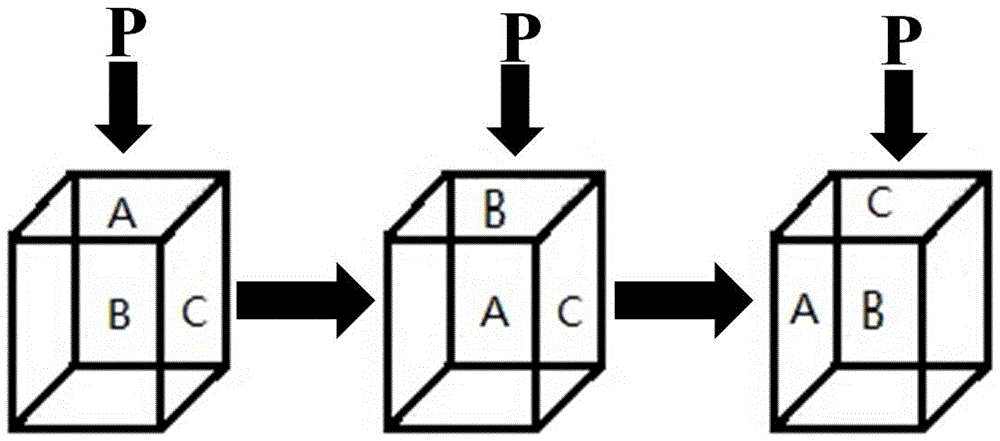

The invention discloses fine-grain high-strength TiAl alloy including nano Y2O3 and a preparation method thereof. In order to solve the problems that existing aluminum-yttrium intermediate alloy is added to cause Y-phase-rich uneven distribution, the dimensions differ greatly, and microscopic structure and mechanical property anisotropism is caused by an existing mechanical heat treatment technology, the method includes the specific steps that first, all the raw material components are weighed; second, an ingot casting is prepared by means of water-cooling copper crucible reaction kish smelting and fired mold precision casting; third, a blank is pretreated; and fourth, multi-directional forging is performed, and accordingly the fine-grain high-strength TiAl alloy can be obtained. The forging stock structure obtained through the method is uniform, crystal grains are small, and the excellent mechanical property can be achieved in three directions.

Owner:TAIYUAN UNIV OF TECH

Method for improving toughness of boracic high-entropy alloy by adding rare earth

ActiveCN104451351APromotes toughening effectImprove comprehensive mechanical propertiesRare-earth elementHigh entropy alloys

The invention discloses a method for improving the toughness of a boracic high-entropy alloy by adding rare earth, belonging to the technical field of alloy materials. According to the component design idea of the invention, a boron element with the mole fraction of 0.1-8% is added into a high-entropy alloy consisting of five or more than five elements, and meanwhile 0.1-4% of a rare earth element such as Y or Ce is added together. Due to addition of the rare earth elements, the gap solid solution reinforcement effect of the small atom boron element in the high-entropy alloy is improved, and the separation content, the morphology and the distribution of rigid boride hard phase are improved, so that the strength and the toughness of the boracic high-entropy alloy are synchronously improved.

Owner:江苏康柏斯机械科技有限公司

Manganese-contained free-cutting type silicon brass alloy as well as preparation method and application thereof

The invention discloses a manganese-contained free-cutting type silicon brass alloy. The alloy is composed of the following components, by weight percentage, 60.2-64.0wt% of Cu, 1.0-2.0wt% of Si, 0.2-1.0wt% of Al, 0.2-0.48wt% of Mn, 0.1-0.25 wt% of Pb, one or more of P, Mg and Sn, and the balance Zn and not greater than 0.5wt% of impurities, wherein the P accounts for 0.01-0.25wt%, the Mg accountsfor 0.01-0.25wt%, and the Sn accounts for 0.01-0.1wt%. The invention further discloses a preparation method for the alloy. The manganese-contained free-cutting type silicon brass alloy has the advantages of being excellent in dezincification corrosion resistance, good in casting property and cutting property, relatively low in cost and suitable for casting parts of a drinking water system, such as a faucet, a valve, a quick switch.

Owner:JOMOO KITCHEN & BATHROOM

Application of deep eutectic solvent in preparing metal doped carbon quantum dots and preparation method of metal doped carbon quantum dots

ActiveCN109825289AGood chemical stabilityImprove uniformityMaterial nanotechnologyNanoopticsSolventChemical stability

The invention relates to the technical field of carbon quantum dots, and particularly disclosesapplication of a deep eutectic solvent in preparing metal doped carbon quantum dots and a preparation method of the metal doped carbon quantum dots. The deep eutectic solvent is prepared from quaternary ammonium salt, an alcohol compoundand metal halide with a molar ratio of 1 to 2:2 to 5:1 for preparingthe metaldoped carbon quantum dots. The application improves a material utilization rate, improves a quantum dot synthesis yield, optimizes the distribution pattern of metal on the surface of carbonquantum, makes the obtained carbon quantum dots have good dispersibility, and has a good photoinduced charge transfer property, high chemical stability and high lightfastness.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Aluminum alloy band for jalousie and manufacturing method thereof

ActiveCN101144133AImprove the distribution patternSimple structureLight protection screensBase framesArc stabilityRare earth

The present invention discloses an aluminum alloy strip steel rolled stock used for a window blind and the production method thereof. The present invention is characterized in that the strip steel rolled stock includes the components and the weight mixing proportions of the material that iron is 0.26-0.34 percent, silicon is 0.05-0.15 percent, copper is 0.005-0.04 percent, manganese is 0.005-0.04 percent, chromium is 0.21-0.28 percent, magnesium is 2.20-2.48 percent, titanium is 0.025-0.045 percent, rare earth metal is 0.10-0.20 percent, and the residual is aluminum; the production method of the aluminum alloy strip used for the window blind comprises smelting, casting, head cutting and surface milling, homogenization annealing, hot rolling, intermediate annealing, cold rolling, intermediate annealing, cold rolling, draw bending and straightening, stabilizing treatment, and vertical cutting and strip separating. Compared with the prior art, the present invention has the remarkable advantages that the surface quality is good, the size accuracy is high, the shape of strip steel rolled stock is smooth, and the tensile strength, the product forming performance, and the arc stability better conform to the demand to the window blind.

Owner:JIANGSU ALCHA ALUMINUM CO LTD

Manufacturing method of high-strength aluminum alloy strip for supporting middle plate of mobile phone

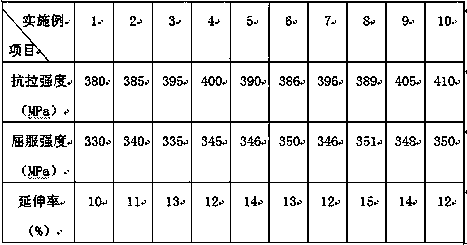

The invention discloses a manufacturing method of a high-strength aluminum alloy strip for a supporting middle plate of a mobile phone. The manufacturing method comprises the following steps: (1) preparing an aluminum alloy melt; (2) casting; (3) carrying out hot rolling, cold rolling and finish rolling. Components and microstructure of a cast ingot are controlled by virtue of a casting process, and by virtue of the optimized hot rolling, cold rolling and intermediate annealing process, the high-strength aluminum alloy strip for the supporting middle plate of the mobile phone is relatively high in strength and deformed microstructure and relatively high in tensile strength, yield strength and elongation percentage; the tensile strength is more than or equal to 380MPa, the yield strength is more than or equal to 330MPa, and the elongation percentage is more than or equal to 10 percent. By adopting the method, the elongation percentage of the aluminum alloy strip is increased, the punch forming performance is good, the process is simple and easy to realize, the punch yield is high, and no special special equipment is needed.

Owner:重庆市灿煜金属制品有限公司

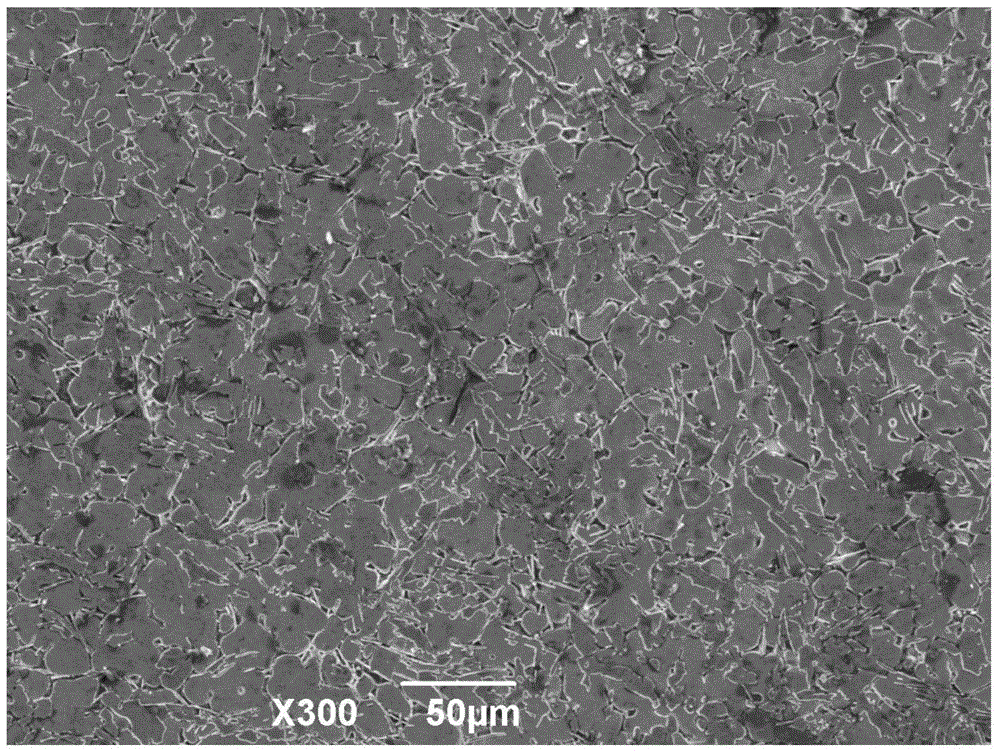

High-performance chrome-free high-boron cast iron composite material and preparation method thereof

The invention discloses a high-performance chrome-free high-boron cast iron composite material and a preparation method thereof, and belongs to the field of steel wear-resistant materials. Alloy comprises chemical components in percentage by weight as follows: 0.43%-0.58% of C, 1.1%-4.6% of B, 0.65%-0.9% of Si, 0.55%-1.1% of Mn, 0.02%-0.21% of Ce, 0.02%-0.05% of S, 0.04%-0.09% of P and the balance of Fe and unavoidable trace impurities, the hardness is 45 HRC-58 HRC, and the impact toughness is 10 J-20 J. The alloy is produced by an electric furnace, smelt, cast and used after thermal treatment; and the alloy doesn't contain chrome and is low in price, good in combination property, low in production cost, simple in process and high in operability.

Owner:JIANGSU YINYU MOLD MATERIAL

Bundle-type catalyst for oxidation of methanol and its combined structure

InactiveCN106938195AChange the physical structureImprove the distribution patternCarbonyl compound preparation by oxidationMetal/metal-oxides/metal-hydroxide catalystsMaterial consumptionEngineering

The invention discloses a bundle-type catalyst for oxidation of methanol. The bundle-type catalyst comprises a stainless steel corrugated screen, an active catalyst and a flat screen. The active catalyst is uniformly distributed on the flat screen. The stainless steel corrugated screen is tiled and stacked and coats the active catalyst, then the edge of the stainless steel corrugated screen is enclosed, the stainless steel corrugated screen and the active catalyst are rolled to form the bundle-type catalyst through one end as an axle core. The physical structure of the catalyst is changed so that the distribution form and flowing way of the reaction materials are greatly improved, product quality is improved, impurities are reduced, material consumption and energy consumption are further reduced and solid foundation is laid for methanol oxidation industrial large-scale development and production.

Owner:KAIRUI ENVIRONMENTAL PROTECTION TECH

Manufacturing method of aluminous plate for PS plate substrate for printing

InactiveCN1693992AEasy to processSimple surface treatmentPrinting pre-treatmentPhotosensitive materials for photomechanical apparatusHigh intensityIngot

A manufacturing method of aluminum board used for the PS plate aluminum board used for printing. The steps of the method are: a. according to the weight proportions of Al: 98, Si: < 1.0, Fe: 0.3 - 1.0, Cu: 0.03, Zn: 0.03, Mg: 0.03, Ti: 0.05, mix the said alloy components and smelt them in the temperature condition of 720 - 800 Deg. C; b. found them into alloy cast ingot in the temperature condition of 690 - 750 Deg. C; c. make the cast ingot equably anneal in the temperature condition of 500 - 610 Deg. C; d. have hot roll in the temperature condition of 400 - 540 Deg. C; e. cold roll them from 9.0 mm to 0.7 mm; f. have 11 hours' middle anneal, 1 hour's heat preservation, then cold roll them to 0.15 mm. The advantages are light weight, high intensity, good water-proof performance, good hydrophilic performance and easy to have surface process.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Time-efficient reinforced aluminium alloy extrusion

The invention discloses a time-efficient reinforced aluminium alloy extrusion, which belongs to the field of a metal material. The aluminium alloy extrusion comprises components, by weight percentage: 0.75-0.90 of Mg, 0.5-0.6 of Si, 0.10-0.14 of Cu, 0.20-0.25 of Mn, 0-0.1 of Ti, 0-0.1 of Cr, 0.1-0.3 of Fe, and 0.20-0.28 of Zn, and is balanced with Al. According to the invention, alloy components are optimized; steps of melting and casting, homogenization, extrusion, thermal treatment, and surface treatment in production technology are optimized; and mechanical properties and the surface film quality are effectively improved.

Owner:ANHUI XIN FA ALUMINUM PROD

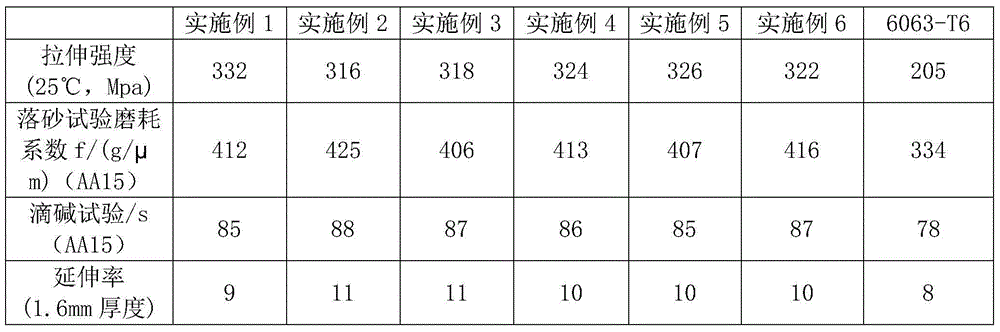

Method for manufacturing high-strength aluminum capable of being etched and used for mobile phone medium plate

The invention discloses a method for manufacturing high-strength aluminum capable of being etched and used for a mobile phone medium plate. The method comprises the following manufacturing steps of (1) molten aluminum alloy preparation; (2) casting; (3) hot rolling; (4) intermediate annealing; (5) cold rolling and finish rolling; and (6) continuous withdrawal and straightening. In the step (6), flattening withdrawal and straightening are added, the rear segment enters a tunnel furnace of 300 DEG C to be baked for 4-6 minutes to remove the stress, thus a high-strength aluminum alloy strip capable of being etched and used for the mobile phone medium plate keeps the balanced deformation texture and deformation structure, can be bent by 90 degrees but does not crack, and can be etched but doesnot deform. The strip has the high strength, the tensile strength T.S (sigma b / MPa) is larger than or equal to 360 MPa, the yield strength Y.S (sigma 0.2 / MPa) is larger than or equal to 300 MPa, theelongation (delta / %) is larger than or equal to 11%, and the surface hardness HV is larger than or equal to 95. The aluminum alloy strip manufactured through the method is used for the mobile phone medium plate and is high in strength, the high surface strength, the function of large-angle bending and the function of etching but not deforming are compatible, continuous stamping is met, and thus the production efficiency is high.

Owner:DONGGUAN CANYU METAL PROD CO LTD

Manufacturing method of high-strength mirror surface aluminum oxide suitable for mobile phone rear shell and frame integration and middle plate and frame integration

The invention discloses a manufacturing method of high-strength mirror surface aluminum oxide suitable for mobile phone rear shell and frame integration and middle plate and frame integration. The manufacturing method comprises the manufacturing steps of (1) molten aluminum alloy preparation, (2) casting, (3) hot rolling, (4) intermediate annealing, (5) cold rolling and finish rolling and (6) continuous stretching and straightening, wherein the cold rolling and finish rolling technique of the fifth step comprises the steps that the one-time downward-pressing amount reaches 60%, and a stretchedcrystal fractures again through the large downward-pressing amount; then the crystal is annealed at the high temperature, the elongated structure absorbs heat to be spherized, and then 30% of the downward-pressing amount is applied to enable the crystal material to be elongated; the balance deformation texture and the deformation structure are maintained while high strength is ensured, structurebank marks are reduced as much as possible, and thus the high mirror surface oxidation effect is obtained; and then, an A5252-HT high-strength mirror surface aluminum oxide alloy strip is obtained after continuous stretching and straightening in the sixth step, the crystal material grain sizes of the surface layers, the subsurface layers and the middle interlayer of the section structure of the A5252-HT high-strength mirror surface aluminum oxide alloy strip are increased gradually, the thickness of each surface layer is greater than 20 centimillimeters, and the great mirror surface effect isstill maintained even through three damaged parts on each surface layer are milled.

Owner:DONGGUAN CANYU METAL PROD CO LTD

High surface aluminium strip and its prodn. method

ActiveCN1834274AFine grain structureIncrease brightnessTemperature control deviceMetal rolling arrangementsSurface finishIngot

This invention provides a method for manufacturing high surface are aluminum strips. The aluminum strips are composed of (by weight parts) Al 100, Si less than 0.3, Fe 0.5-0.7, Cu 0.08-0.15, Zn 0.09-0.11 and Ti 0.01-0.05. The aluminum strips are manufactured by preparing the raw materials and mixing, smelting and casting into alloy ingots, homogenizing, hot-rolling, and cold-rolling to the thickness of the final products, shearing and annealing to form the final products. The aluminum strips in this invention are smooth and homogeneous in thickness, have high surface brightness, and can directly satisfy the requirements of high surface areas without any need for polishing.

Owner:NORTHEAST LIGHT ALLOY CO LTD

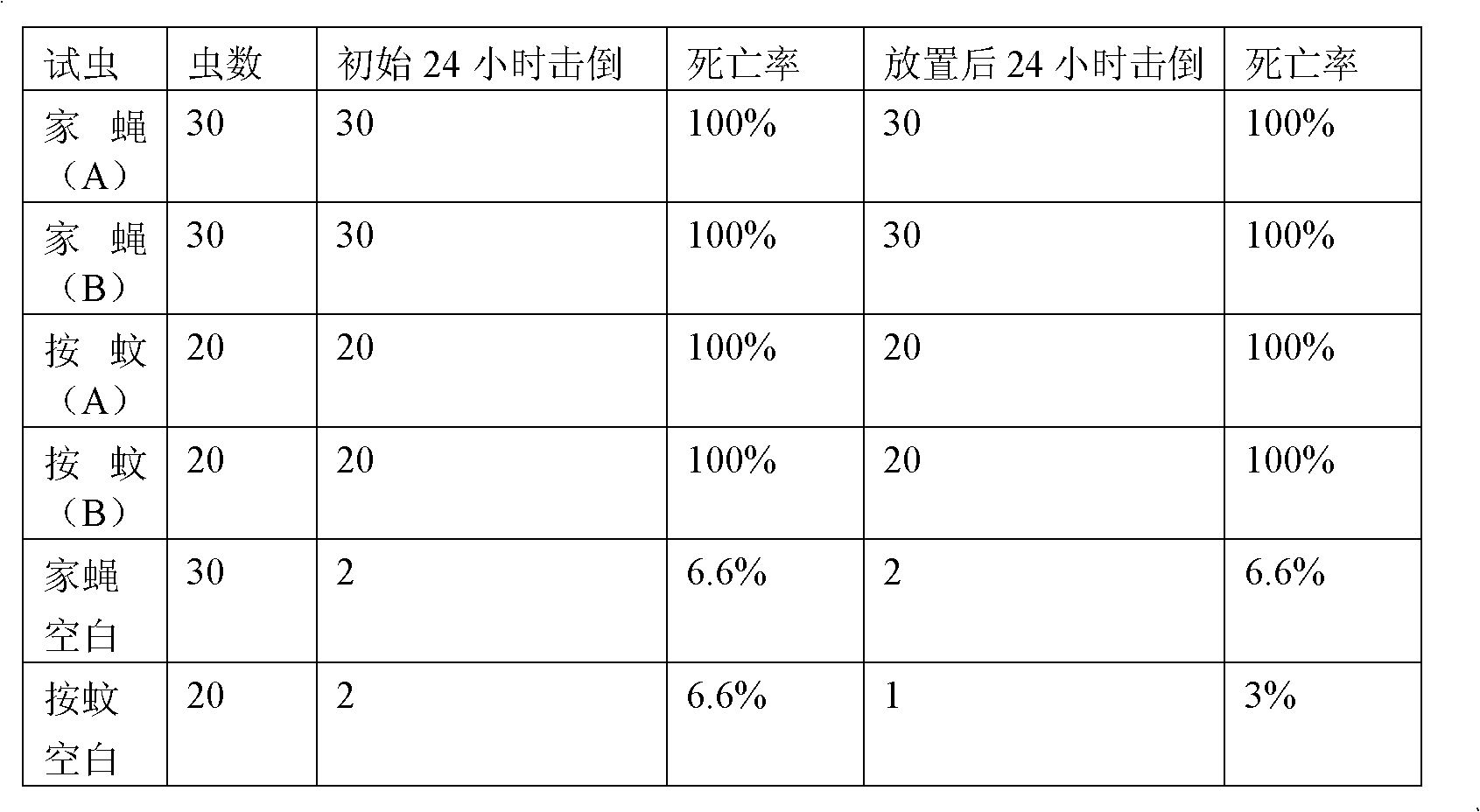

Method for preparing sustained-release insecticide microcapsule by using supercritical fluid technology

The invention discloses a method for preparing a sustained-release insecticide microcapsule by using a supercritical fluid technology. A composition prepared with the method comprises ingredients, such as cellulose, attapulgite, essence, a betaine ampholytic surface active agent and the like. The method comprises the following steps of: compounding the above ingredients; and further evenly covering particles with a supercritical impact micro-granule wrapping method. With the method, the agglomeration tendency which easily appears when the common means are adopted is lightened so as to improvethe evenness of the microcapsule. Meanwhile, the method also has the universal advantages of the traditional supercritical wrapping method. The composition prepared with the method has a good insecticidal effect and an obvious sustained-release effect.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

Low hygroscopicity submerged-arc welding sintered flux and preparation method thereof

InactiveCN109454361ALow S contentImprove the ability to resist H2S corrosionArc welding apparatusWelding/cutting media/materialsSlagPolyvinyl alcohol

The invention relates to low hygroscopicity submerged-arc welding sintered flux and a preparation method thereof. The low hygroscopicity submerged-arc welding sintered flux is prepared from the following components in percent by weight: 13-28% of fluorite, 16-20% of bauxite, 20-28% of magnesite, 28-45% of marbles, 17-20% of wollastonite, 3-6% of rutile, 0.1-1.2% of zircon sand, 3-6% of polyvinyl alcohol, 1.2-3.6% of chrome green, 2-8% of sodium carbonate, 3-6% of metal nickel, 2-5% of manganese metal and 1-3% of rare earth oxides. By adjusting a flux slag system and improving the manufacturingprocess by means of a weld joint alloy transitional mode, the invention provides the low hygroscopicity submerged-arc welding sintered flux which is excellent in low temperature impact toughness.

Owner:DONGGUAN UNIV OF TECH

A method of adding rare earth to improve the strength and toughness of boron-containing high-entropy alloys

The invention discloses a method for improving the toughness of a boracic high-entropy alloy by adding rare earth, belonging to the technical field of alloy materials. According to the component design idea of the invention, a boron element with the mole fraction of 0.1-8% is added into a high-entropy alloy consisting of five or more than five elements, and meanwhile 0.1-4% of a rare earth element such as Y or Ce is added together. Due to addition of the rare earth elements, the gap solid solution reinforcement effect of the small atom boron element in the high-entropy alloy is improved, and the separation content, the morphology and the distribution of rigid boride hard phase are improved, so that the strength and the toughness of the boracic high-entropy alloy are synchronously improved.

Owner:江苏康柏斯机械科技有限公司

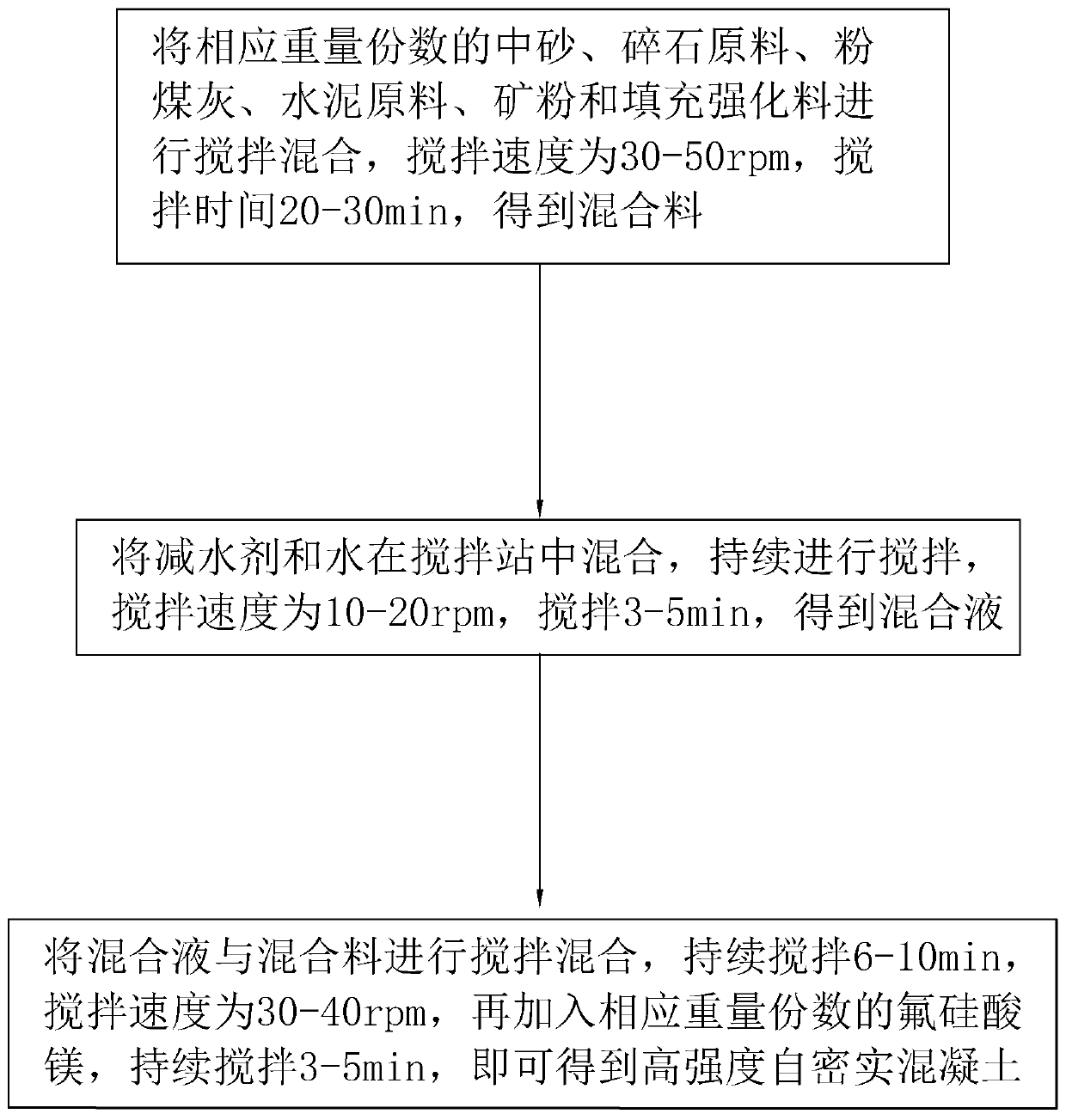

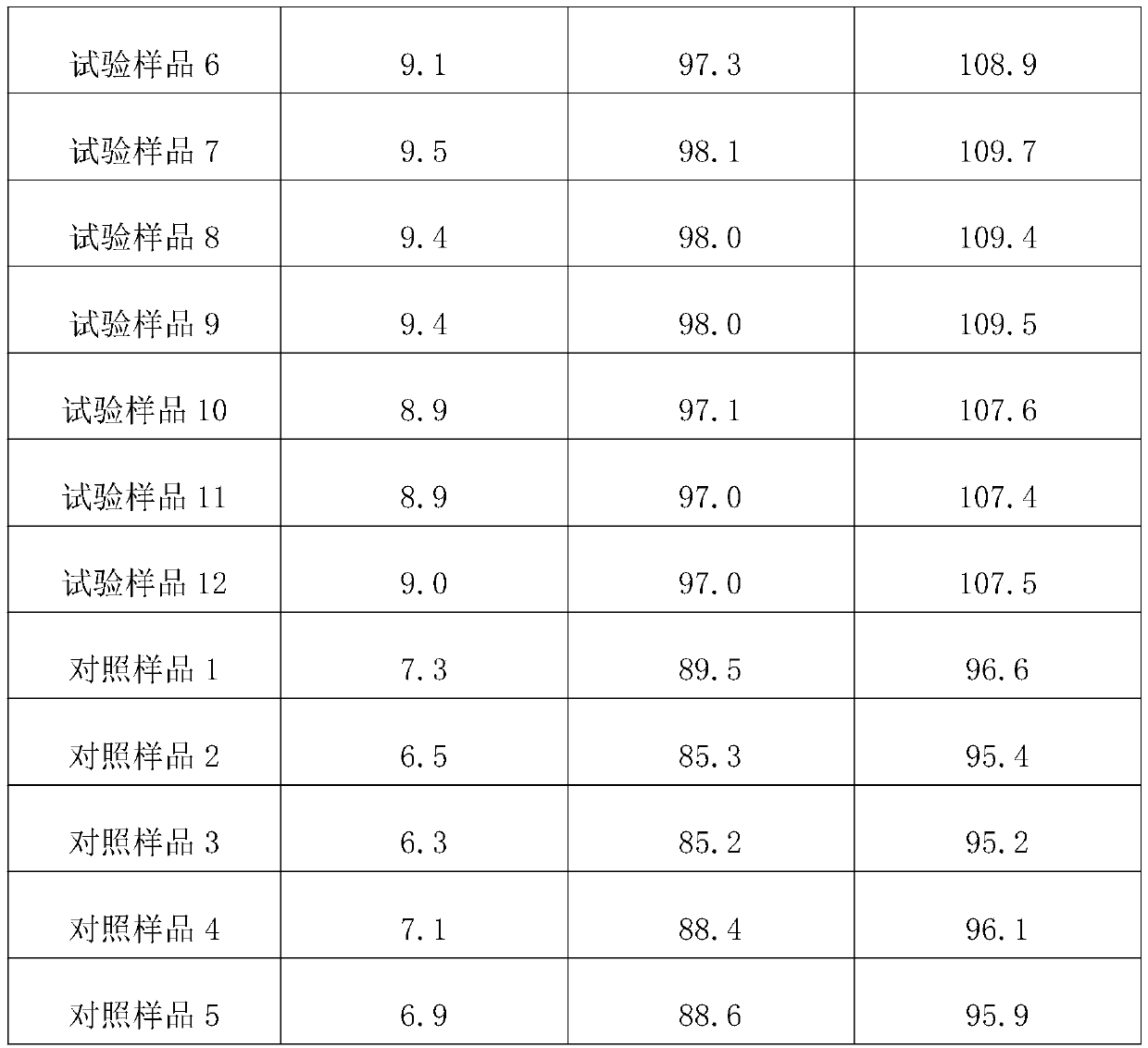

Industrial production process of high-strength self-compacting concrete

The invention discloses an industrial production process of high-strength self-compacting concrete, relates to the technical field of concrete production and processing, and solves the problem that the overall strength of the concrete is greatly reduced due to the fact that cement aggregates exist in a mixture and cannot be fully hydrated in the production process of the concrete. The industrial production process comprises the following steps: 1, preparing raw materials, 2, mixing the slurry, 3, preparing slurry, 4, preparing a mixed material, and step 5, discharging a finished product. According to the process, the mixed material obtained in the step 3 is heated to 50-60 DEG C in 5-10 seconds, then is subjected to heat preservation for 2-5 seconds, and finally is cooled to 20-30 DEG C in5-10 seconds along with continuous stirring to obtain the high-strength self-compacting concrete. In the application process, formation of cement aggregates can be avoided, the diffusion uniformity of cement particles is greatly improved, and the overall strength of concrete is improved.

Owner:上海兆捷实业发展有限公司

Iron-based self-lubricating wear-resistant alloy

InactiveCN1276116CGood friction compatibilityReduce coefficient of frictionWear resistantPetrochemical

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Energy-containing eutectic solvent, application thereof, metal doped carbon quantum dots prepared from energy-containing eutectic solvent, and preparation method of metal doped carbon quantum dots

InactiveCN110550616AGood chemical propertiesThe hydrothermal reaction is smoothNanotechnologyNano-carbonDispersityAlcohol

The invention relates to the technical field of carbon quantum dots, and particularly discloses an energy-containing eutectic solvent, application thereof, metal doped carbon quantum dots prepared from the energy-containing eutectic solvent, and a preparation method of the metal doped carbon quantum dots. The energy-containing eutectic solvent is prepared from an alcohol compound, a nitroimidazoleenergy-containing compound and a transition metal soluble salt. The energy-containing eutectic solvent is used for preparing the metal doped carbon quantum dots. The metal doped carbon quantum dots are good in dispersity, and have good light-induced charge transfer performance, high chemical stability and high light resistance; and the preparation method is simple in process, easy to operate, high in raw material utilization rate, high in energy utilization rate, low in cost, low in toxicity and environmentally friendly.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Modificator for high-chromium alloy grinding balls and preparation method thereof

The invention discloses a modificator for high-chromium alloy grinding balls and a preparation method thereof, and relates to the technical field of wear-resistant material modificators. The chemicalcomponents of the modificator for high-chromium alloy grinding balls comprise, by weight percentage, 7-12% of Nb, 5-10% of Ti, 7-13% of Al, 3-8% of Sc, 5-10% of Ce, 15-20% of Si, 2-6% of B and the balance Fe. The preparation method includes the steps that pure aluminum is heated to be molten; then ferro-columbium alloy, ferro-titanium alloy, ferro-boron alloy, aluminum scandium alloy, ferro-ceriumalloy, pure silicon and pure iron are added, and heated to be molten; after all the components are molten, the melt is cast into a metal mold and cooled; and cast ingots are taken out, and the modificator is obtained. The modificator is used for modification of high-chromium alloy grinding balls, molten steel can be purified, grains and structures can be effectively refined, the form and distribution form of carbide are improved, the carbide is dispersed evenly, a substrate is reinforced, good toughness is achieved after heat treatment, abrasion resistance is good, and the service life is prolonged. Besides, on the basis of not affecting the performance of grinding balls, the contents of precious metal elements such as Mo, Ni and Cr are reduced, and the production cost is lowered.

Owner:TONGLING MINGCHENG FOUNDRY

Super-strength abrasion-resistant alloy and preparation method thereof

The invention discloses a super-strength abrasion-resistant alloy, and belongs to the technical field of abrasion-resistant alloys. The super-strength abrasion-resistant alloy is prepared from the components in percentage by weight: 0.25-0.60% of C, 0.001-0.005% of B, 1.8-2.2% of Cr, 0.25-0.35% of Nb, 0.5-0.8% of Si, 0.6-0.9% of Mn, 0.4-0.5% of Mo, 0.3-0.7% of Cu, 0.025-0.030% of N, 0.35-0.50% ofRe, less than 0.03% of S, less than 0.03% of P and the balance of Fe. Valuable elements such as chromium and molybdenum are not added to the prepared alloy, boron is taken as a main alloy element, anabrasion-resistant skeleton is obtained through high hardness boride and carbide containing boron relying on boron formed in steel to obtain high abrasion-resistant resistance. Trace amount of ceriumimproves the distribution morphology of a hard phase in a matrix, and further improves the properties of the alloy. An alloy preparation method has lower production process cost, the modification treatment technology has lower cost, and a modification treatment method is relatively simple.

Owner:四川泰铸耐磨材料有限公司

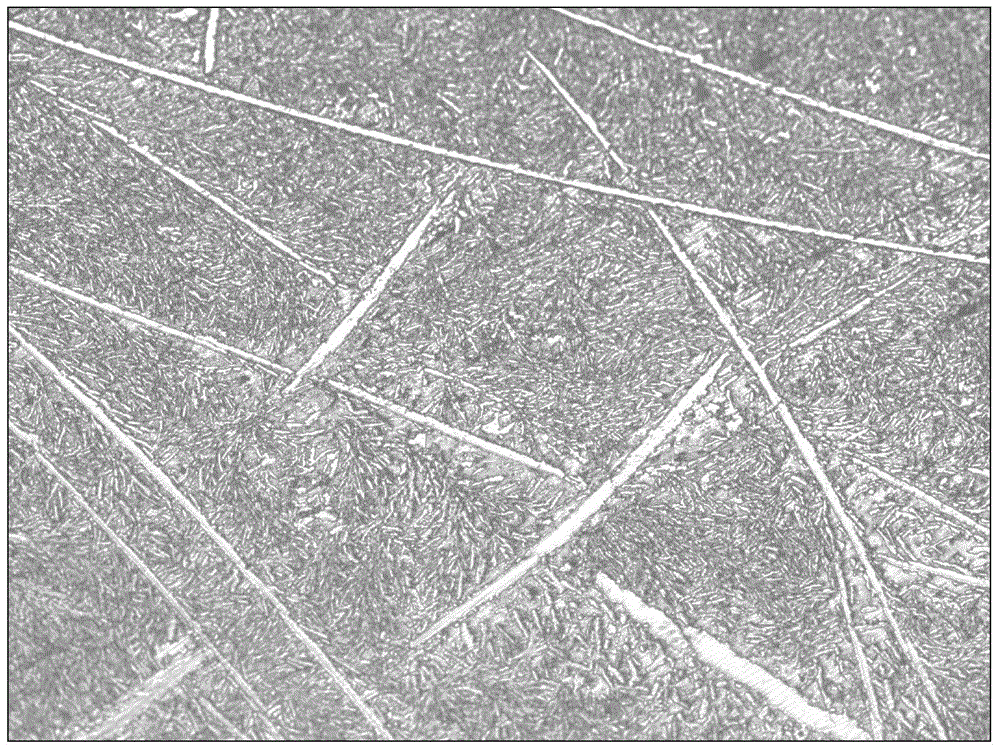

Medium carbon-rare earth alloy strengthening cast steel shot/grit and preparation technology thereof

ActiveCN106337154AGranularityIncrease productionFurnace typesHeat treatment furnacesNiobiumGrain structure

The invention provides medium carbon-rare earth alloy strengthening cast steel shot / grit and a preparation technology thereof, and belongs to the technical field of metal abrasives. The medium carbon-rare earth alloy strengthening cast steel shot / grit is characterized by being prepared from, by mass, 0.30%-0.85% of C, 0.30%-1.50% of Si, 0.30%-1.50% of Mn, 0.10%-0.15% of Re, 0.10%-0.90% of Cr, 0.01%-0.04% of Nb, smaller than or equal to 0.05% of P, smaller than or equal to 0.05% of S and the balance Fe. According to the medium carbon-rare earth alloy steel, by adding rare earth, molten steel is purified, and a grain structure of steel is refined; the strength, the hardness and the wear resistance are improved through chromium; niobium forms a carbide, and therefore the hardness and the wear resistance are improved; by means of alloy elements, the eutectoid temperature of the steel is increased, and diffusion of carbon is prevented. Accordingly, increase of the quenching temperature is beneficial for conversion from pearlite to austenite and diffusion of carbon. A metallographic structure is converted into tempered martensite and tempered troostite.

Owner:SHANDONG UNIV OF TECH +1

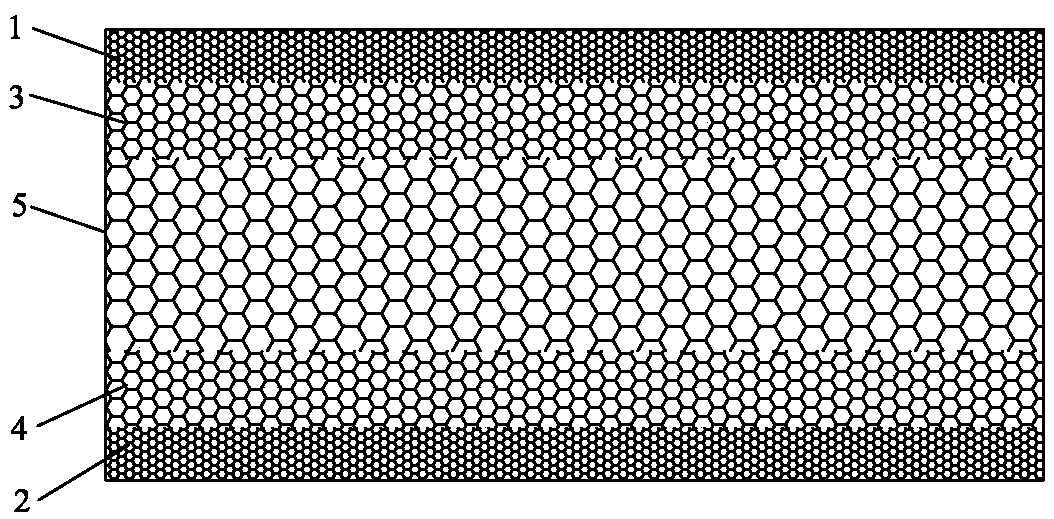

Method for manufacturing composite aluminum foil for car heat exchanger

ActiveCN100574972CImprove microstructureImprove the distribution patternRoll mill control devicesMetal rolling arrangementsPlate heat exchangerIngot

The invention discloses a metal material processing technology, in particular to a manufacturing method used for manufacturing an aluminum-alloy compound foil. The method includes the following steps: the aluminum liquid is cast into an ingot through melting, smelting, sediment-removing and stirring; the ingot is heated and rolled into an aluminum-ally plate; the aluminum-alloy plates of an upper and a lower claddings are washed and then are covered onto an upper surface and a lower surface of a cast plate of a core layer, then the alloy plates are welded into a whole; the welded alloy plates are heated and hot rolled into a blank, and the hot rolled blank is rolled into a foil material through a cold rolling mill; in the end the foil material is put into an annealing furnace for a medium annealing; after taken from the annealing furnace, the foil material is rolled, drawn and cut fine so as to make into the compound foil used for an automobile heat exchanger. The invention has the advantages that a microstructure of the compound foil and the distribution form and structure of a second-phase particle are enhanced so as to raise the structural capability of the compound foil; the optimized welding, hot rolling, cold rolling and medium annealing techniques lead to equal structure and conformed thickness and size of the claddings.

Owner:JIANGSU ALCHA ALUMINUM CO LTD

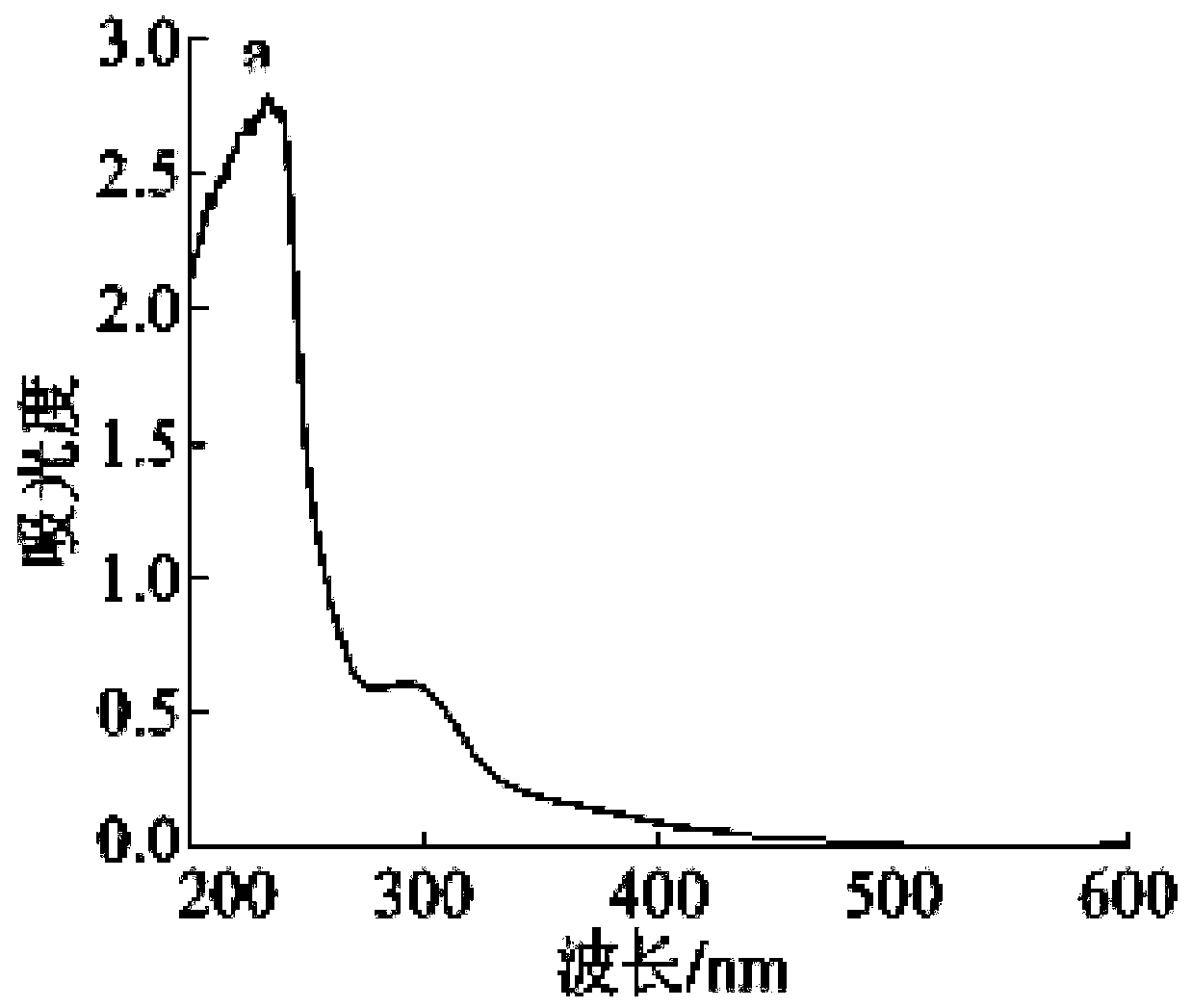

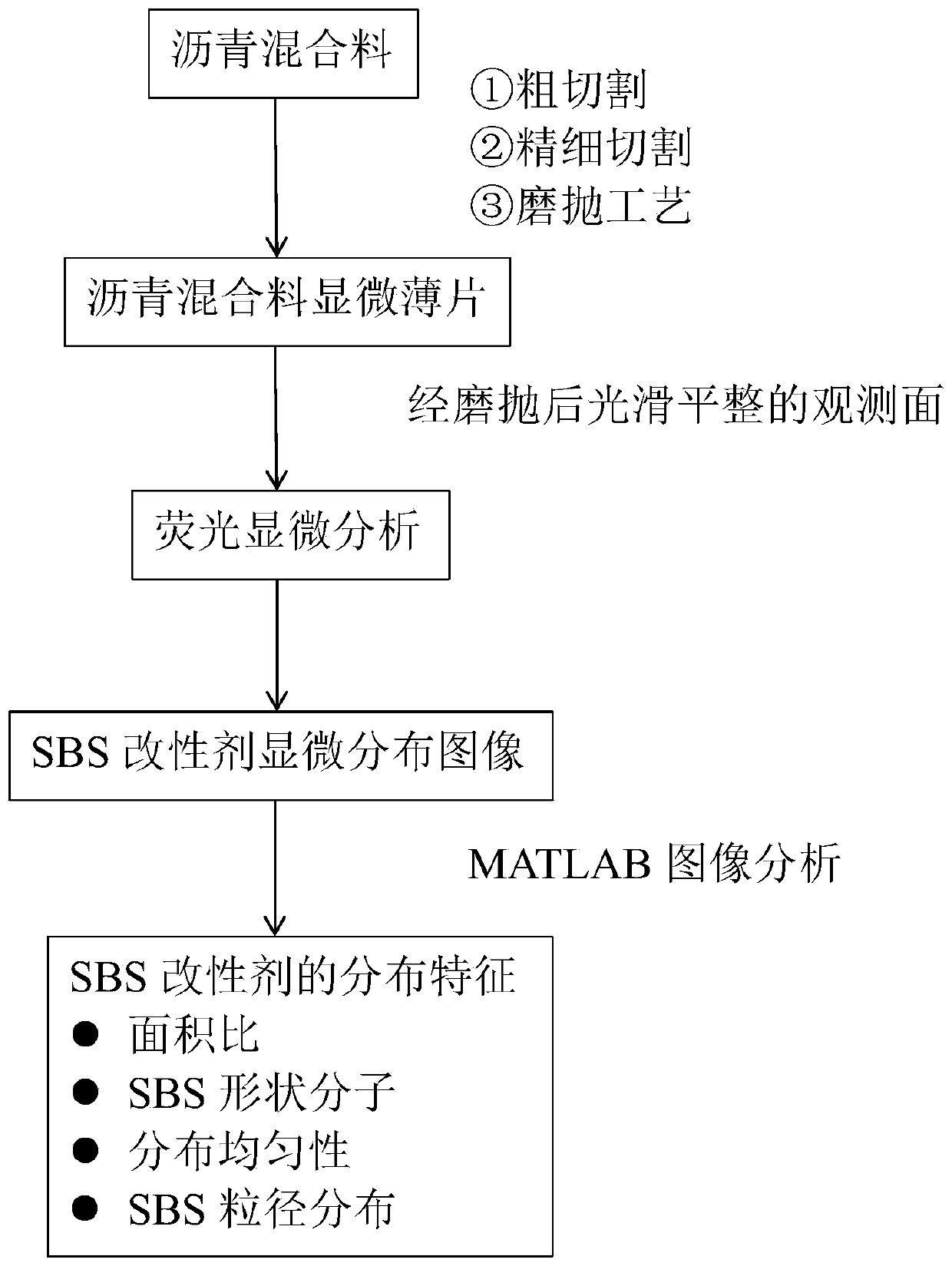

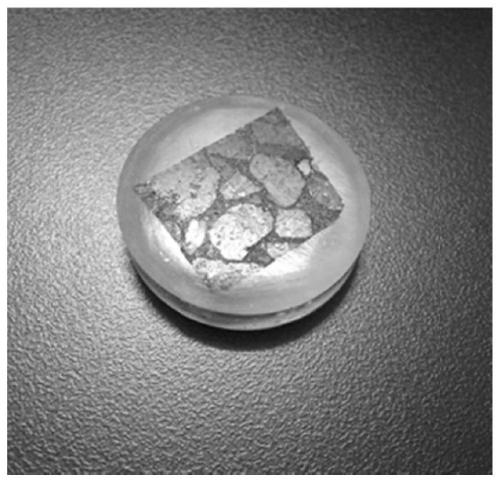

Method for analyzing distribution form of SBS modifier in asphalt mixture

InactiveCN111307767AIntuitively reflect the distribution shapeNo damage to internal structurePreparing sample for investigationFluorescence/phosphorescenceFluorescenceImage segmentation

The invention discloses a method for analyzing the distribution form of an SBS modifier in an asphalt mixture, which belongs to the field of road pavement materials and processing and preparation of the road pavement materials. The method comprises the steps of preparing an SBS modified asphalt mixture microsection; observing the mixture slice sample by using a fluorescence-polarization microscope; carrying out qualitative and quantitative analysis on the mixture slice image; determining an image segmentation threshold of an SBS phase and an asphalt phase through image RGB (three primary colors) value analysis; and distinguishing the SBS modifier and other phases in the mixture, and analyzing the distribution form of the SBS modifier in the asphalt mixture according to the area ratio, shape factor, distribution uniformity, particle size and the like of the SBS in the image. The method provided by the invention is simple, convenient and feasible, can represent the distribution form of the SBS modifier in the mixture under the condition of not destroying the inherent aggregate inlay structure of the mixture, and provides a new method for analyzing the damage behavior of the SBS asphalt mixture in the service process.

Owner:WUHAN UNIV OF TECH

SAL8090 aluminum-lithium alloy TIG (Tungsten Inert Gas)/MIG (Metal-Inert Gas) solder wire and preparation method thereof

ActiveCN102145441AEasy to oxidizeSolve surface roughnessWelding/cutting media/materialsSoldering mediaLithiumWire rod

The invention discloses an SAL8090 aluminum-lithium alloy TIG (Tungsten Inert Gas) / MIG (Metal-Inert Gas) solder wire and a preparation method thereof. Raw materials used in preparation comprise the following components in percentage by weight: 2.5-3.5% of Li, 0.5-1.5% of Mg, 1.0-2.0% of Cu, 0.1-0.25% of Zr, 0.1-0.2% of Sr and the balance of Al. The preparation method of the SAL8090 aluminum-lithium alloy TIG / MIG solder wire comprises the following steps of: a. smelting the mixed raw materials in a vacuum induction furnace, and then casting under the protection of argon gas; b. continuously squeezing to prepare an alloy steel wire rod; and c. carrying out rough, moderate and fine wire drawing operation on the alloy steel wire rod, and then scraping and cleaning to obtain the solder wire. The aluminum-lithium alloy TIG / MIG solder wire prepared by using the method disclosed by the invention has low burning rate and good mechanical property and is not easy to fracture.

Owner:LANZHOU WEITE WELDING MATERIAL FURANCE BURDEN

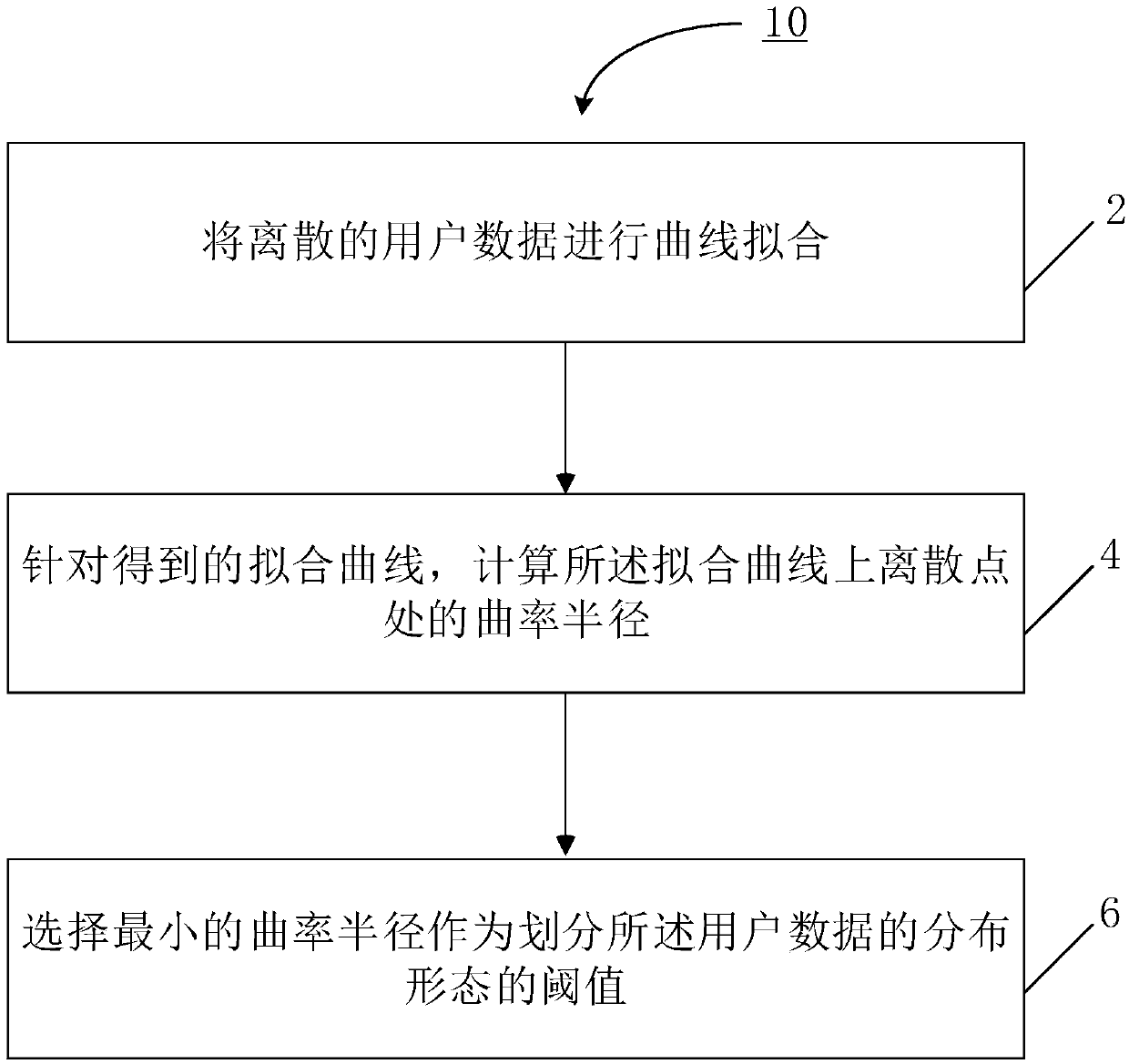

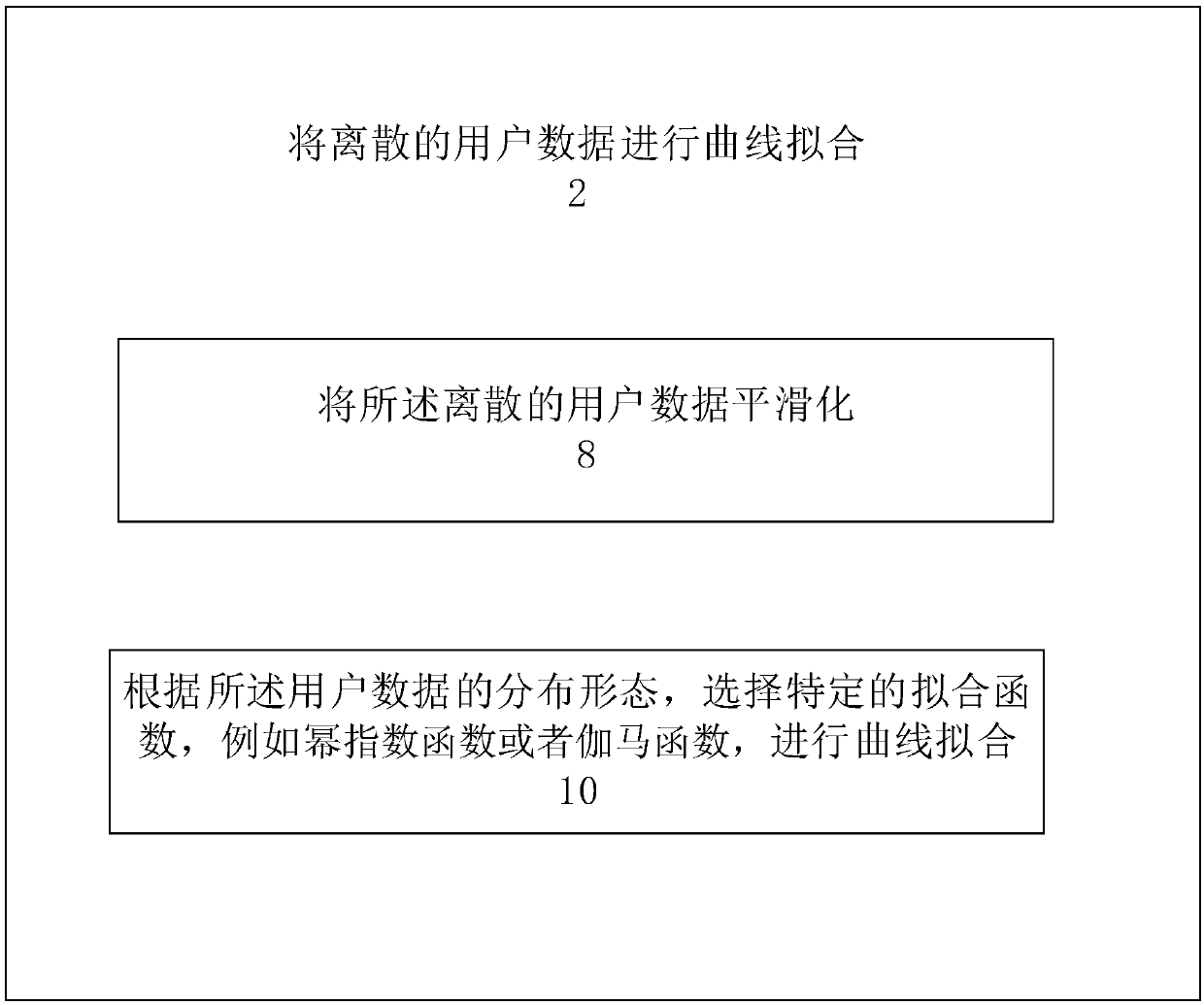

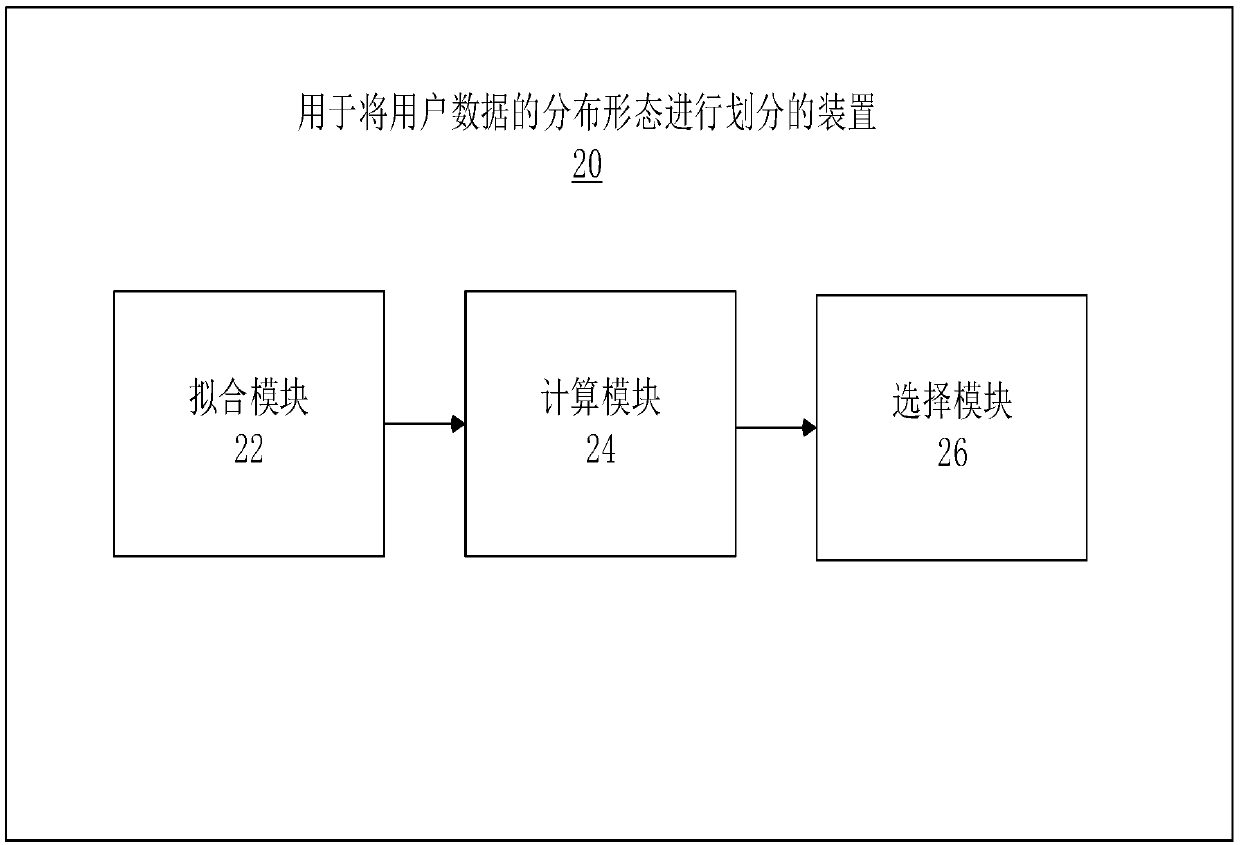

Method and device for dividing distribution form of user data

PendingCN111104559AImprove the distribution patternEasy to cutOther databases retrievalPersonalizationTheoretical computer science

The invention provides a method and a device for dividing a distribution form of user data, computer equipment and a computer readable storage medium. The method for dividing the distribution form ofthe user data can comprise the following steps: carrying out curve fitting on discrete user data; for the obtained fitting curve, the curvature radius of discrete points on the fitting curve is calculated; and selecting the minimum curvature radius as a threshold value for dividing the distribution form of the user data. Therefore, threshold division of the head and the tail of the user data of the distribution form of the user data can be conveniently carried out. By means of the method and the device, segmentation of the Internet target user can be facilitated, and the method and the devicecan be applied to the fields of information intelligent recommendation, precision marketing and delivery, personalized analysis and deep understanding of the user and the like.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com