A method of adding rare earth to improve the strength and toughness of boron-containing high-entropy alloys

A high-entropy alloy, strong toughness technology, applied in the field of alloys, can solve the problems of reducing solid solution strengthening effect and alloy toughness, and achieve the effect of promoting toughening effect, improving comprehensive mechanical properties, and widely used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

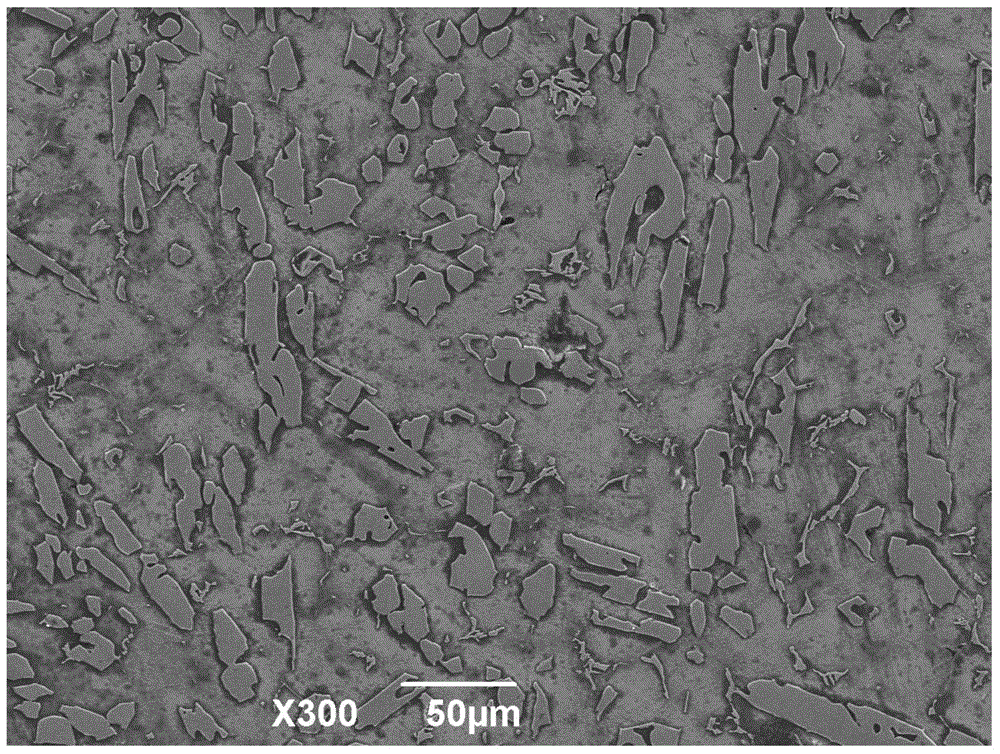

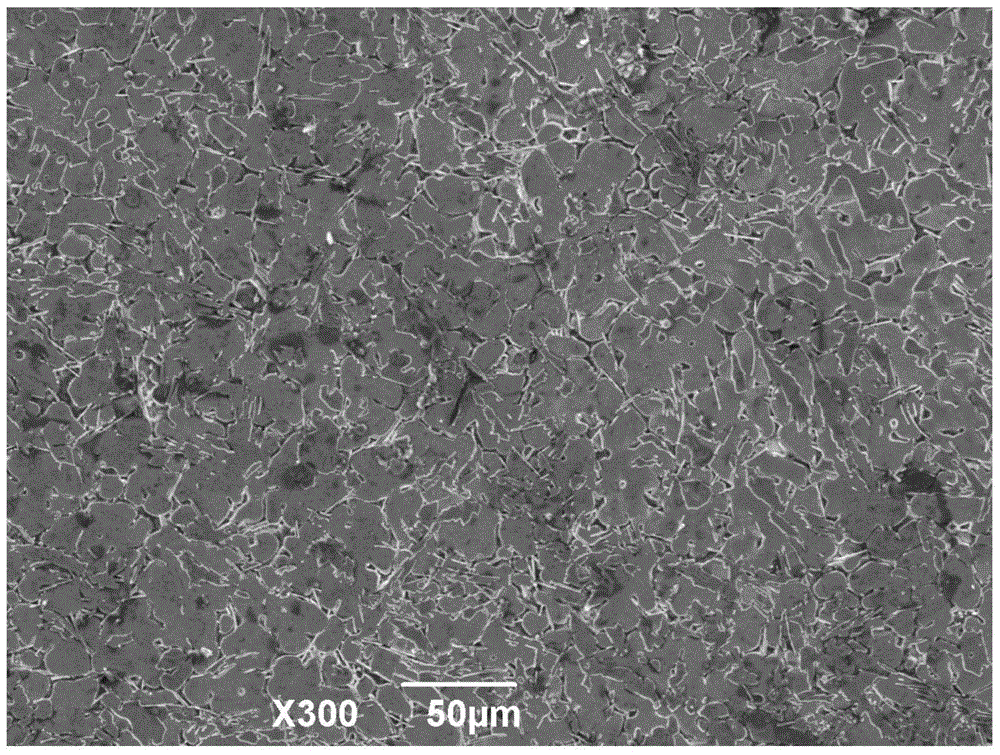

[0015] Fe, Co, Ni, Cr, Cu, Mn, Mo and other metal elements are taken, and different contents of small atomic boron elements and rare earth elements yttrium or cerium are added to the alloy, and the high-entropy alloy components are respectively labeled 1 to 3 groups A total of 9 components are used to compare the effects of the joint addition of boron and rare earth elements on the hardness and brittleness of high-entropy alloys. The component numbers are shown in Table 1. Put the prepared components of each group in the water-cooled copper mold of the vacuum electric arc furnace melting furnace, and then cover the furnace cover. First, the vacuum is pumped to about 0.01 atmospheric pressure, and then pure argon is injected, and then the pumping and restarting operations are repeated 1~ Start smelting after 2 times. After each smelting and solidification is completed, the alloy in the copper mold is turned over and then arc-dissolved, and this is repeated several times until a...

Embodiment 2

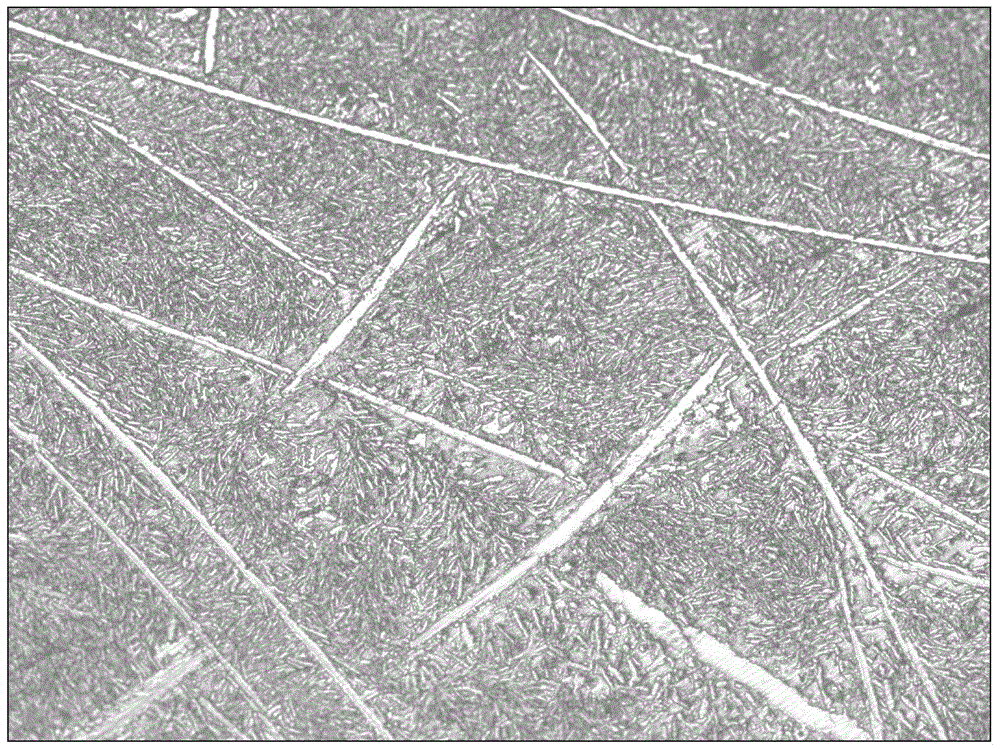

[0019] Fe, Co, Ni, Cr, Cu, Mn, Ti, Mo and other metal element powders are taken, and different contents of small atomic boron and rare earth element yttrium, cerium and other powders are added to the alloy, and the particle size of the powder is 50-300 μm. According to the composition shown in Table 2, the composition of the boron-containing high-entropy alloy coating was configured and labeled 4 to 6 groups, a total of 9 components were used to compare the effects of the combined addition of boron and rare earth elements on the hardness and brittleness of the laser cladding high-entropy alloy coating. Laser cladding process measures: firstly, the iron-based or nickel-based or cobalt-based substrate materials are pretreated for surface derusting, decontamination, preheating, etc.; then semiconductor or CO 2 The laser adopts the reverse synchronous or coaxial powder feeding method, cladding the configured high-entropy alloy powder numbered 4 to 6 groups; at the same time, the la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com