Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

961results about How to "Improve the strengthening effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

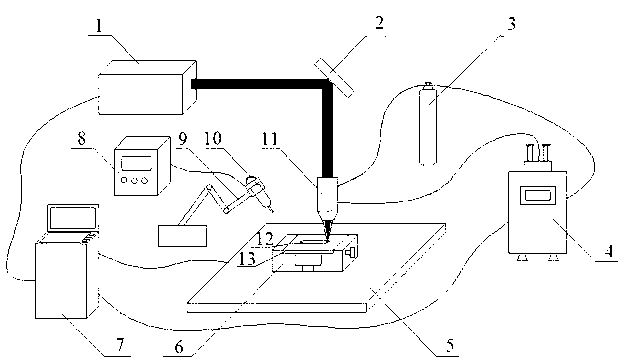

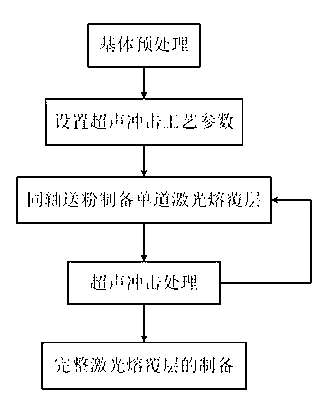

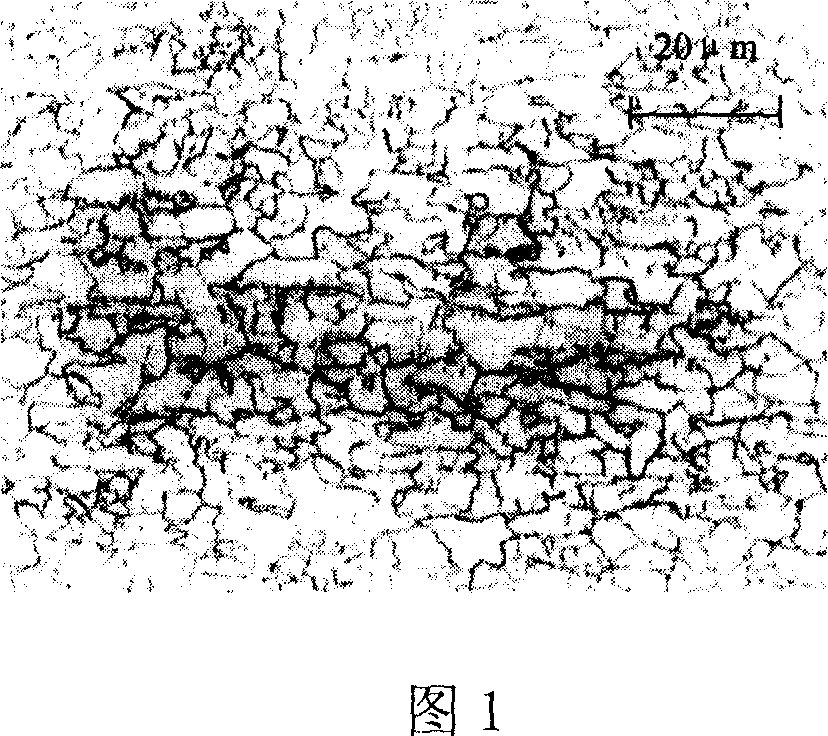

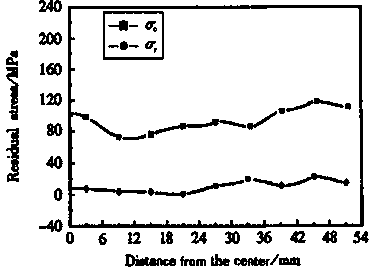

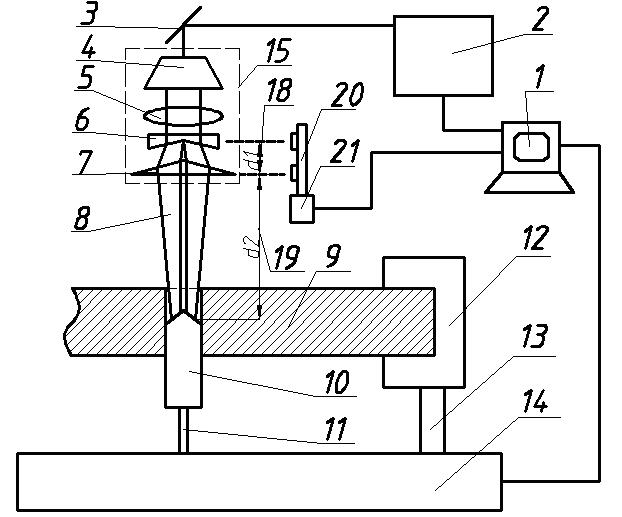

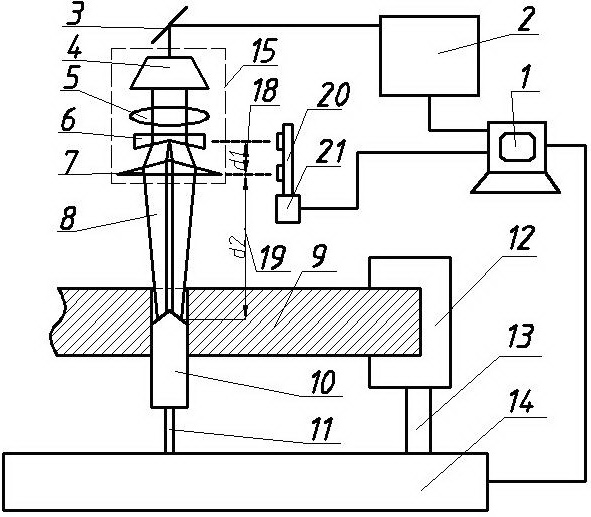

Device for strengthening laser cladding layer by ultrasonic impact and method thereof

ActiveCN103305828ARefining solidified tissueReduce residual stressLaser beam welding apparatusPressure inorganic powder coatingHigh densityOptoelectronics

The invention relates to a device for strengthening a laser cladding layer by ultrasonic impact and a method thereof. A conventional powder feeding type laser cladding method is used for preparing the laser cladding layer on the surface of a cladding base material; after one path of laser cladding is finished, the ultrasonic impact is used for playing effects on the laser cladding layer; when a plurality of paths and layers of laser cladding are carried out, the laser cladding and the ultrasonic impact are alternatively carried out. According to the device and the method disclosed by the invention, the laser cladding layer is obviously strengthened to refine tissues of the laser cladding layer and eliminate residual stress in the laser cladding layer; when the ultrasonic impact is used for playing the effect on the laser cladding layer, a plastic deformation layer with a certain depth is formed in the laser cladding layer; grains and crystal lattices in the plastic deformation layer are distorted to form high-density dislocation so that dendritic crystals in condensation tissues of the laser cladding layer are crushed and are dispersed into the laser cladding layer to form small crystal nucleuses which are uniformly distributed and refine the grains; meanwhile, the ultrasonic impact is used for planting pressing stress into the laser cladding layer to counteract pulling stress in the laser cladding layer and eliminate the residual stress in the laser cladding layer.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Steel plate for hot-rolled double-side enamel and method for producing same

InactiveCN1966753AIncrease productivityUniform compositionTemperature control deviceSheet steelChemical composition

The invention provides a kind of hot-rolled double-sided enamel-used nickelclad, the chemical components of which is: C 0.02%-0.06%, Si <=0.50%, Mn 0.15%-0.40, P <=0.15%, S <=0.006%, N<=0.003%, Ti 0.08%-0.20%, Als 0.005%-0.055%, Ti / C 2.2-5,unavoidable impurities and Fe as balance. The architecture of the nickelclad is ferrite with grain diameter = 2 mum-20 mum under hot rolling conditions, and TiC particles (diameter < 20nm is uniformly distinguished in the architecture. V 0.015%-0.060% and / or Cr 0.05%-0.20% can also be added. The production method of the clad is: producing unburnt earthenware with continuous cast method, heating to 1180-1260DEG C, descaling with high-handed water, rough rolling, finish rolling for 5-7 passes at 1100-960 DEG C and finally at 920DEG C-840DEG C, continuously cooling to 450- 630DEG C at a speed of >=30DEG C / S in 0-7S, and coiling. The nickelclad has the advantages of good performance and high strength, and can meet the requirement of large scaled engineering fembers.

Owner:ANGANG STEEL CO LTD

Low-alloy high-strength high-toughness steel plate and manufacturing method thereof

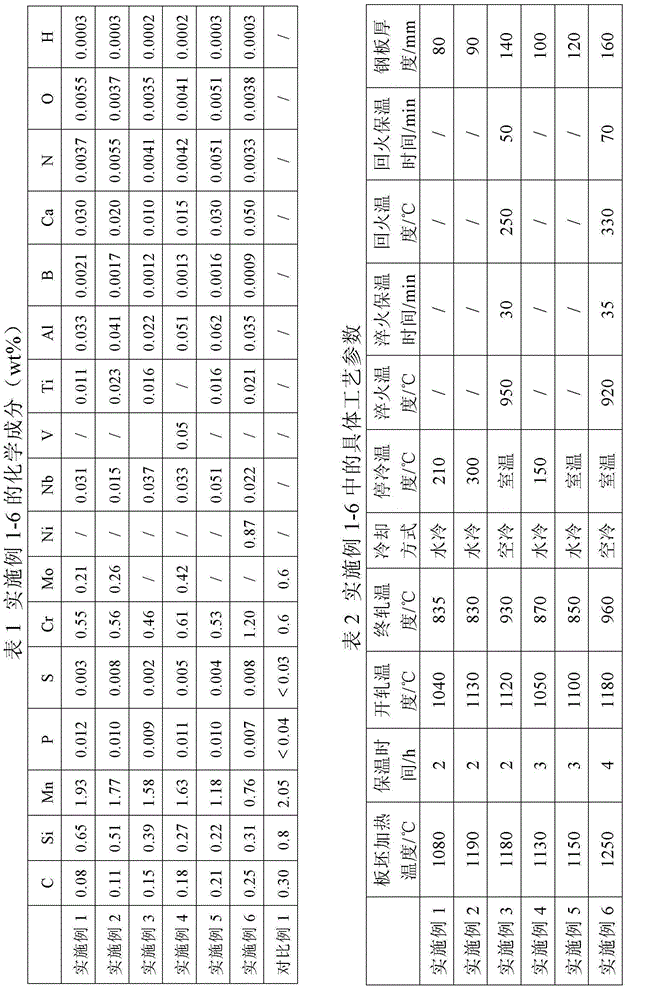

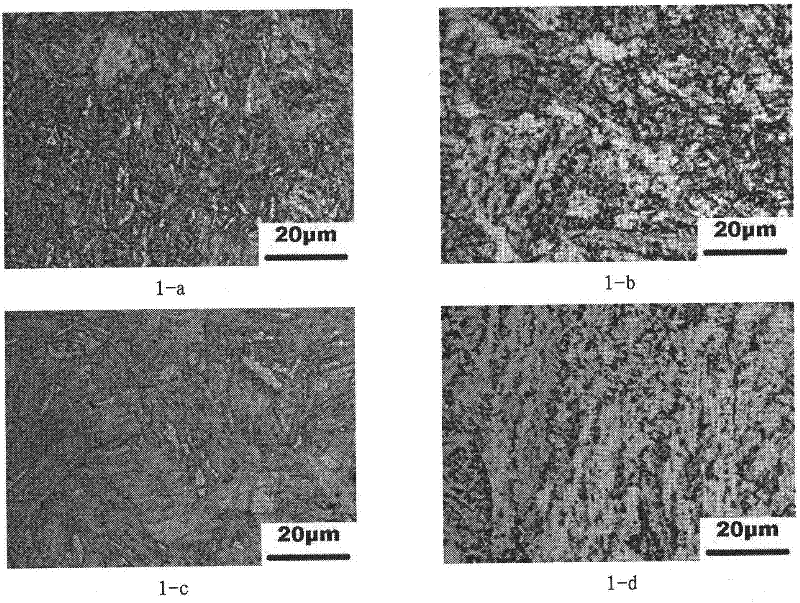

InactiveCN104480406AUniform compositionImprove surface qualityMetal rolling arrangementsAlloyHardness

The invention relates to a low-alloy high-strength high-toughness steel plate and a manufacturing method thereof. The low-alloy high-strength high-toughness steel plate comprises the following components in percentage by mass: 0.08-0.25% of C, 0.10-1.00% of Si, 0.50-2.00% of Mn, less than 0.020% of P, less than 0.010% of S, 0.10-2.00% of Cr, 0-1.00% of Mo, 0-2.00% of Ni, 0.010-0.080% of Nb, at most 0.10% of V, at most 0.060% of Ti, 0.0005-0.0040% of B, 0.010-0.080% of Al, 0.010-0.080% of Ca, at most 0.0080% of N, at most 0.0080% of O, at most 0.0004% of H, and the balance of Fe and inevitable impurities. 0.20%<=(Cr / 5+Mn / 6+50B)<=0.55%, 0.02%<=(Mo / 3+Ni / 5+2Nb)<=0.45%, and 0.01%<=(Al+Ti)<=0.13%. The Brinell Hardness of the steel plate is 390-460 HB, the yield strength is 900-1100 MPa, the tensile strength is 1100-1400 MPa, the elongation percentage is 11-15%, the -40 DEG C Charpy V-notch longitudinal impact work is greater than or equal to 40J, and the plate thickness can reach 100mm above. Thus, the steel plate implements matching of high strength, high hardness and high toughness, and has favorable machining properties.

Owner:BAOSHAN IRON & STEEL CO LTD

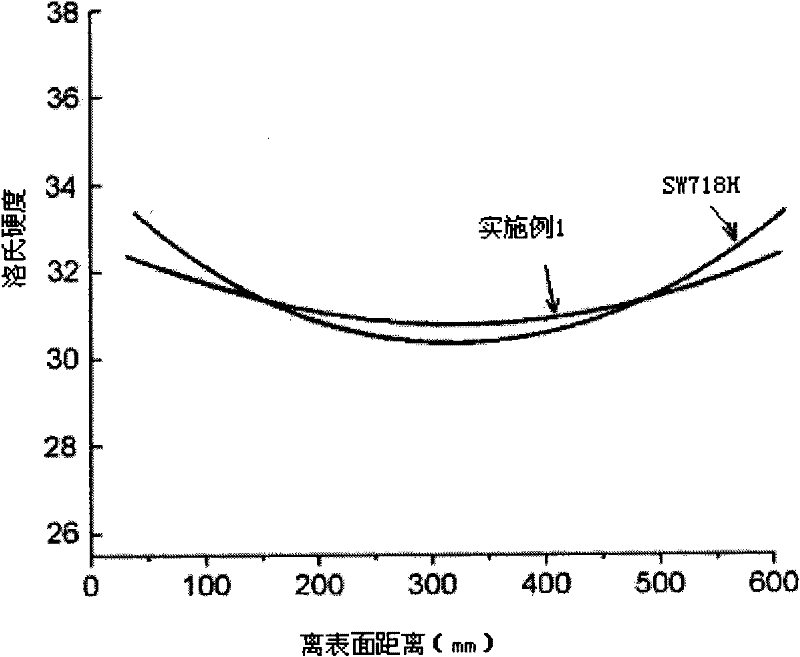

A kind of plastic mold steel and its manufacturing method

The invention discloses a plastic mold steel which comprises the following chemical components in percentage by weight: 0.25-0.29% of C, 1.30-1.50% of Mn, 0.40-0.60% of Si, 1.20-1.50% of Cr, 0.40-0.50% of Mo, 0.02-0.05% of Nb, less than or equal to 0.15% of Ni, less than or equal to 0.15% of Cu, less than or equal to 0.020% of P, less than or equal to 0.015% of S, less than or equal to 0.012% of N and the balance of iron and inevitable impurities. In the manufacture method of the plastic mold steel, a quenching and tempering heat treatment process is not used, and direct air cooling after forging is carried out, thus prehardened plastic mold steel with thickness above 600 mm and uniform hardness from core to surface is manufactured. According to the plastic mold steel disclosed by the invention, the limit that the existing non-quenched and tempered mold steel has thickness smaller than 400 mm is overcome, and the requirements of mold industries on low-cost high-quality large-sized prehardened plastic mold steel are reached.

Owner:宝武特种冶金有限公司

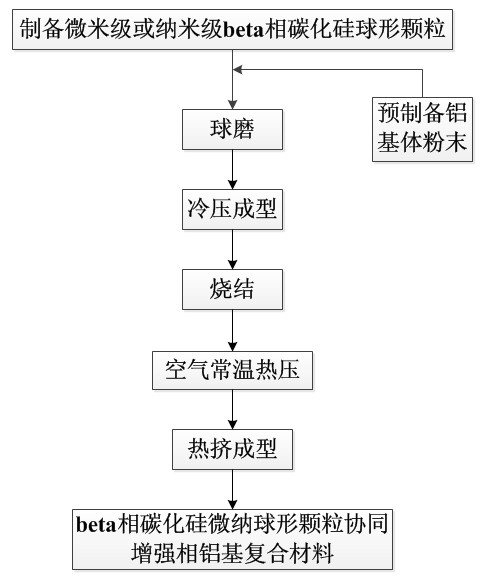

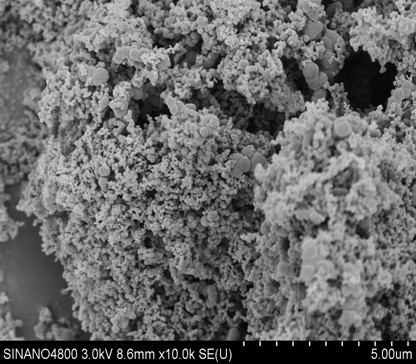

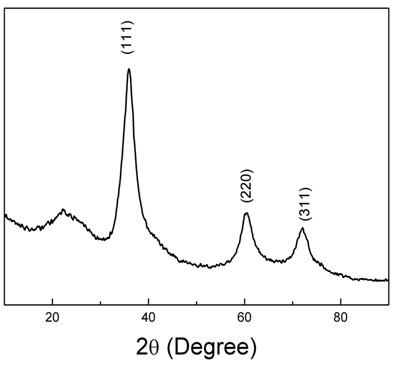

Silicon carbide reinforced aluminum-based composite material and its preparation method

The invention relates to a silicon carbide reinforced aluminum-based composite material and its preparation method. The composite material is characterized by being composited by micron-scale and nano-scale beta-phase silicon carbide spherical particles and an aluminum substrate, with the beta-phase silicon carbide spherical particles distributed in the aluminum substrate to form a synergistic reinforced phase. The preparation method is summarized to be mainly composed of: pre-preparing beta-phase silicon carbide spherical particles, adding aluminum substrate powder and the beta-phase silicon carbide spherical particles accounting for 0-25wt% of the composite material into a ball mill for ball milling treatment, and conducting cold press molding, sintering, as well as air hot pressing sequentially, and finally carrying out hot extrusion molding to obtain a molded product of the composite material. Specifically, the particle size of the aluminum substrate powder is 1micrometer to 100micrometers. The technical scheme of the invention innovatively uses spherical particulate beta-phase silicon carbide and makes use of the synergistic reinforcement effect of the micron and nano-silicon carbide particles, substantially improves the strength, toughness, abrasion resistance and others of the aluminum-based composite material. The preparation process is simple, and the cost input is effectively reduced.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI +1

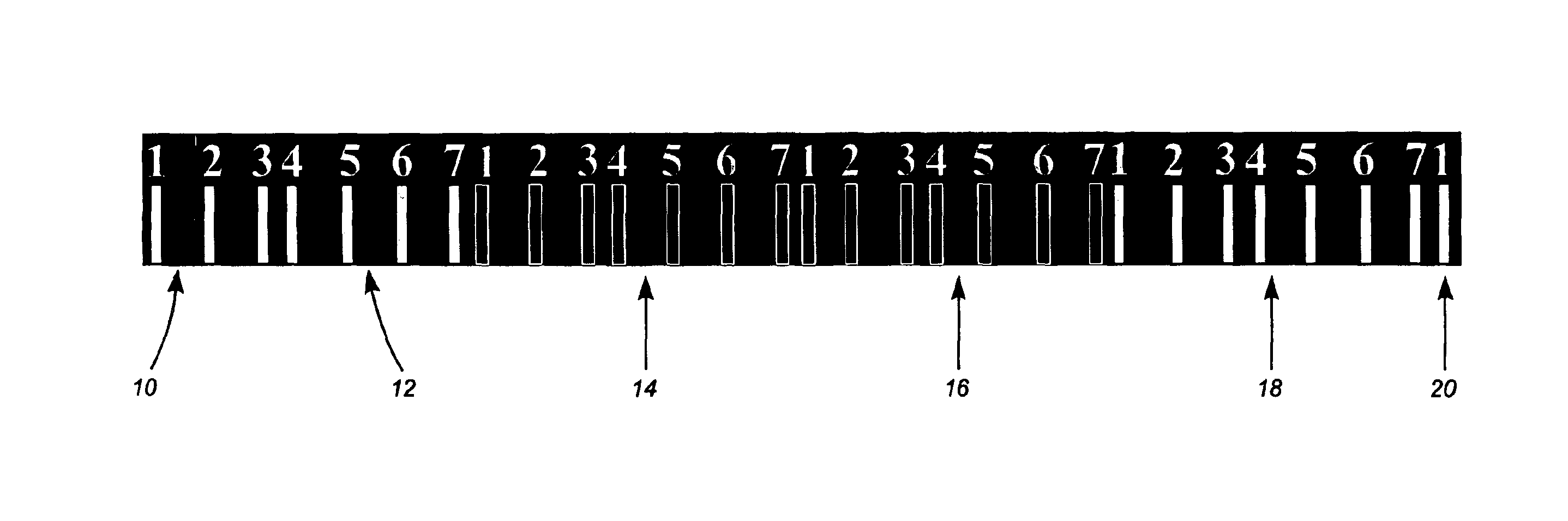

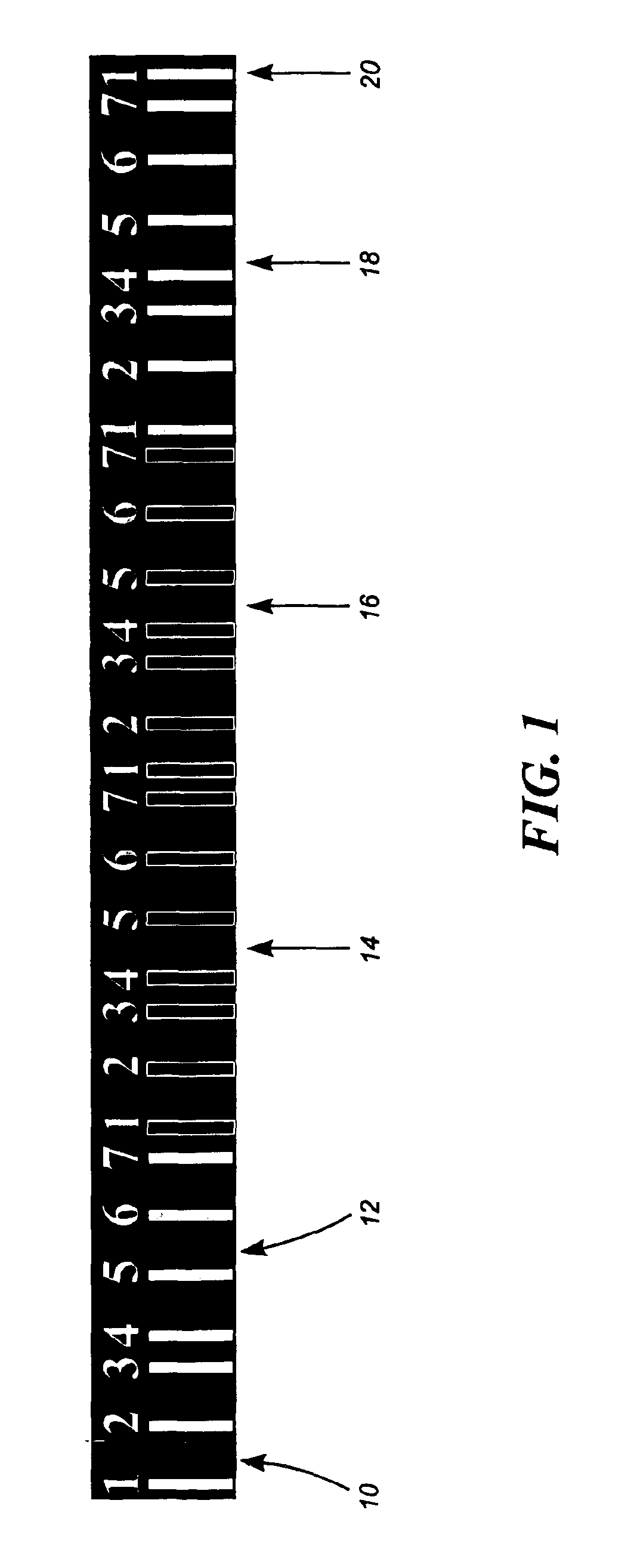

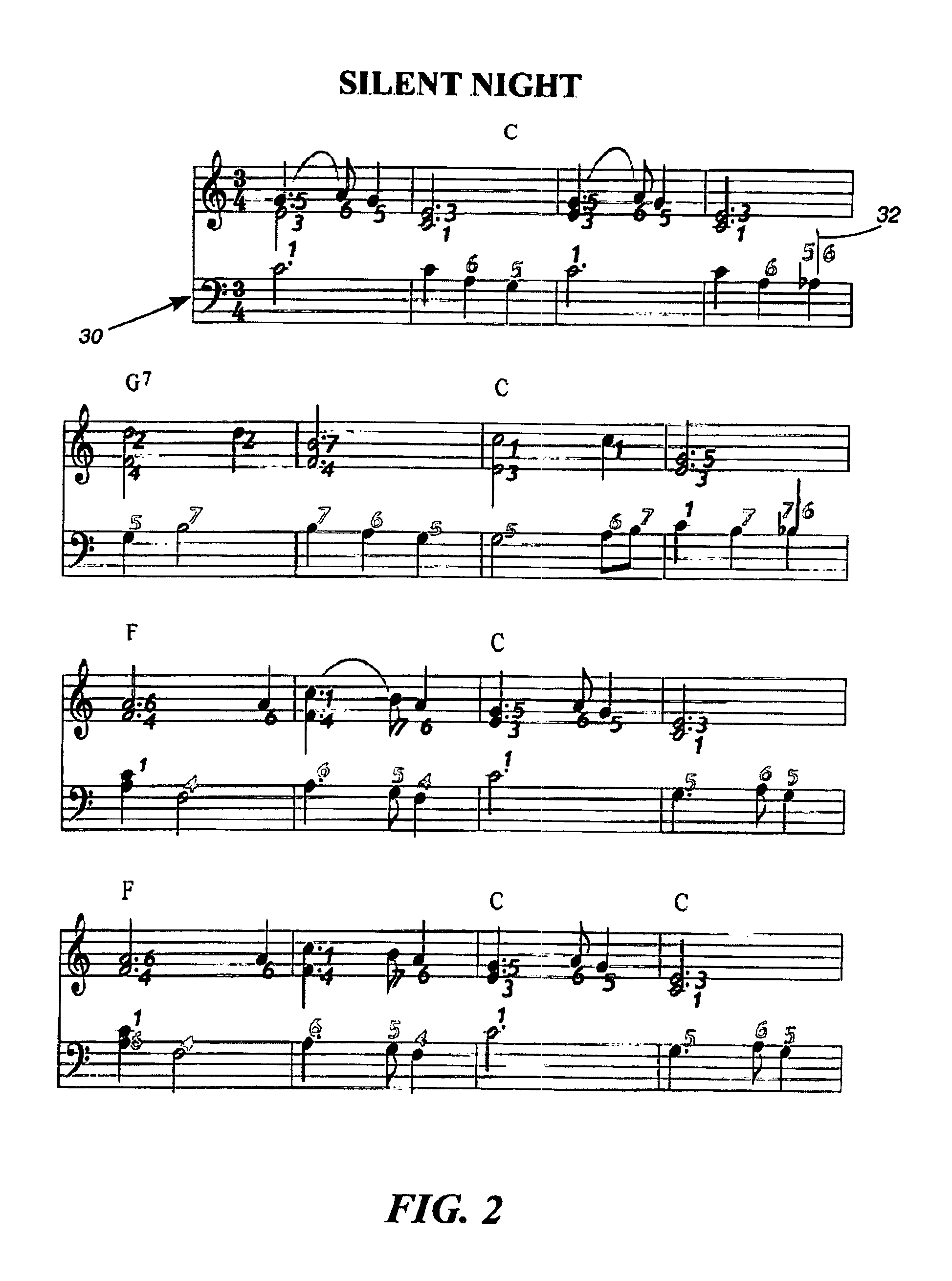

Teaching method and guides to teach piano

InactiveUS6881887B2Strengthen fingerDeveloping earElectrophonic musical instrumentsPercussion musical instrumentsPianoComputer science

A guide is disclosed with vertical numerically color coded lines on it. The guide can then be moved along the space between the keys and the fallboard of the piano, so that the keys can be played by anyone placing their fingers on the keys indicated by the lines on the guide.Sheet music is prepared with numbers and colors juxtaposed to the notes corresponding to the lines, so that the piano student will know which keys to stroke.

Owner:BERENS CHRISTOPHER P

Multi-element nitralloy material and preparation method and application thereof

The invention discloses a multi-element nitralloy material and a preparation method and application thereof and belongs to the technical field of alloy material development. The multi-element nitralloy material comprises 9-48% of V, 13-45% of Si, 0.05-9% of Mn, 3.3-14% of Fe, 15-30.5% of N, 0.01-5.0% of Cr, 0.06-2.0% of Al, 0-7.0% of Ti, 0-6.5% of B, 0-4.5% of Nb, 0-1.8% of C, 0-0.1% of P, and 0-0.1% of S. According to the multi-element nitralloy material and the preparation method and application thereof, the content of nitrogen in the alloy can be effectively controlled to be within a reasonable range according to different combining capacities of various elements and the nitrogen; meanwhile, the content of the nitrogen can be adjusted within a wider range according to requirements of practical purposes, and great convenience is provided for a molten steel microalloying reinforcing technique; safety and environmental friendliness are achieved in the preparation and using process, and no smoke or dust or odor is generated.

Owner:马鞍山中科冶金材料科技有限公司

New method for eliminating aluminium alloy workpiece residual stress

The invention provides a new method for eliminating aluminium alloy workpiece residual stress, mainly aims at defects existing in a conventional residual stress eliminating method that the cost is high, the operation is complex, the requirement is high, the workpiece mechanical property is reduced, the workpiece surface is damaged, and the use is limited, and achieves double effects of eliminating residual stress and refining crystal grains through the organic combination of subzero treatment, the uphill quenching technology and conventional heat treatment. The new method has the specific operating steps of solution treatment, subzero treatment, uphill quenching and aging treatment, and has the characteristics that the technology method is simple, the environment is protected, the operation cost is low, the effect is superior to that of the conventional residual stress eliminating method, the residual stress is eliminated, meanwhile, the workpiece comprehensive mechanical property can be improved, and industrialized scale production can be realized.

Owner:葛鹏

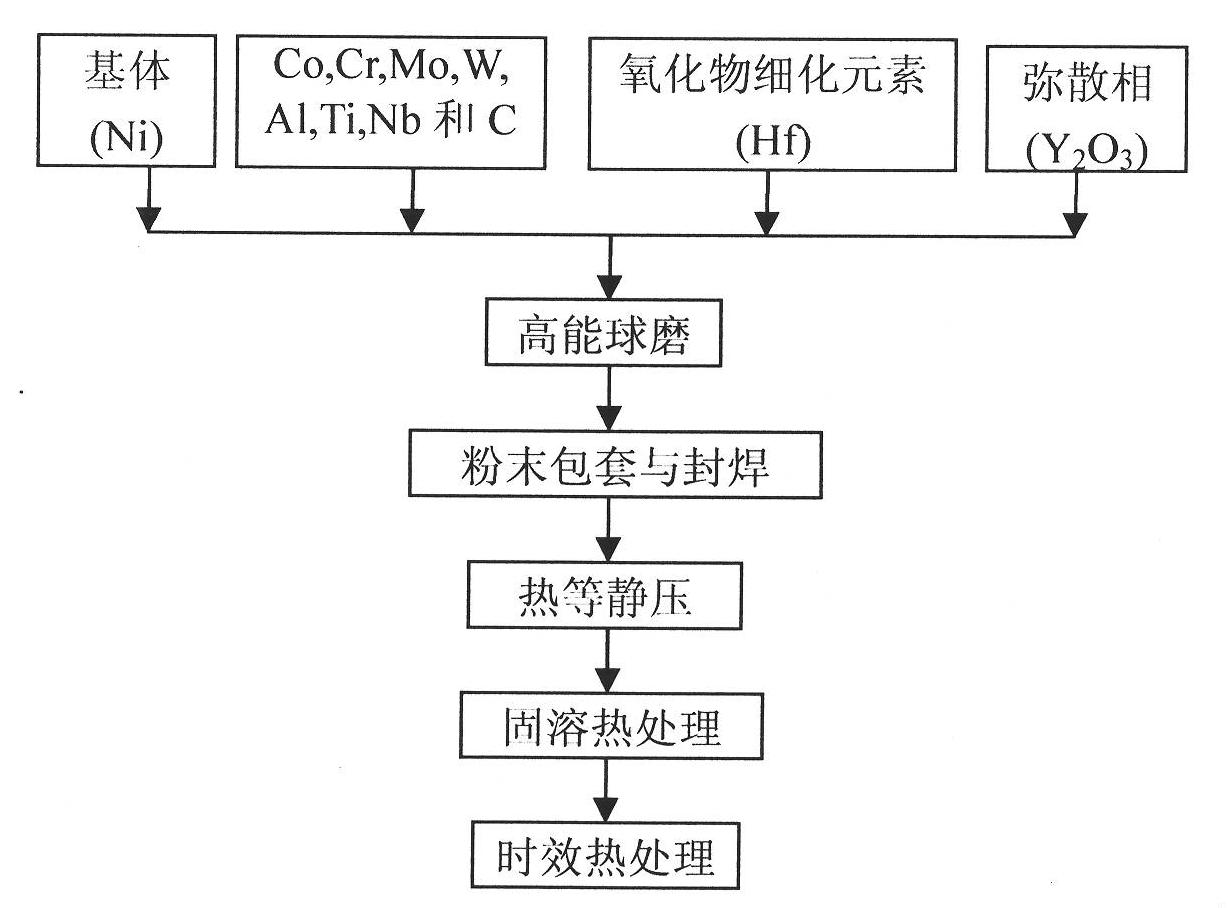

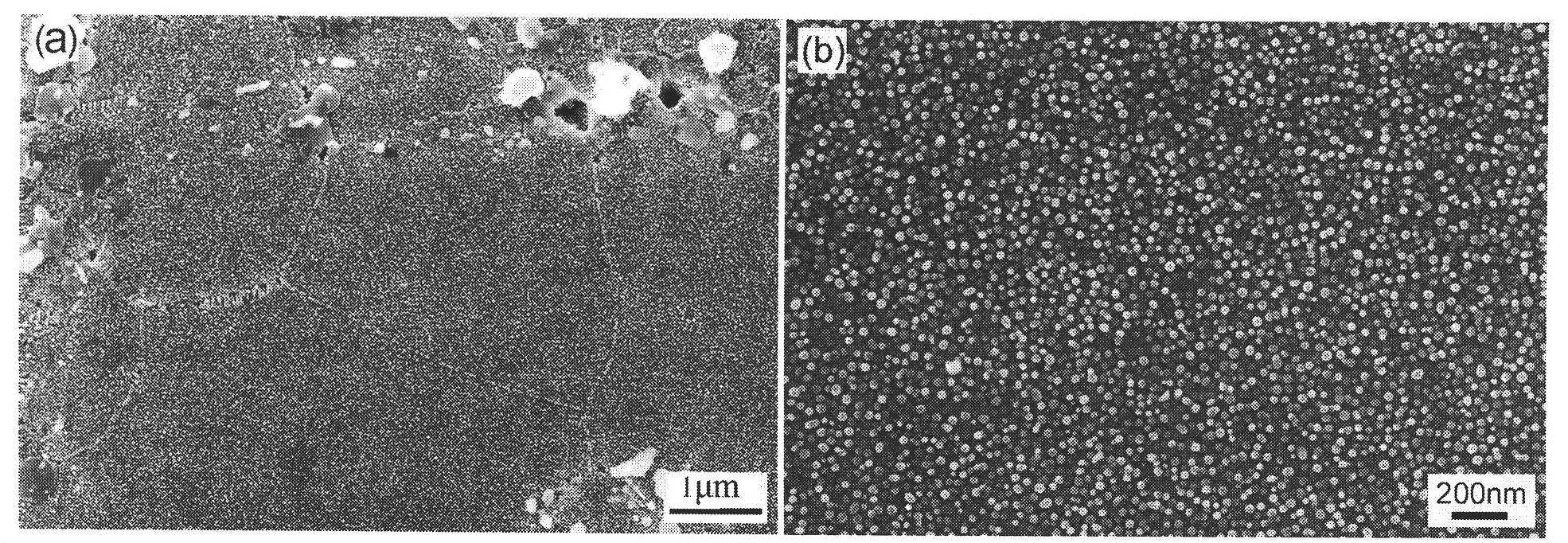

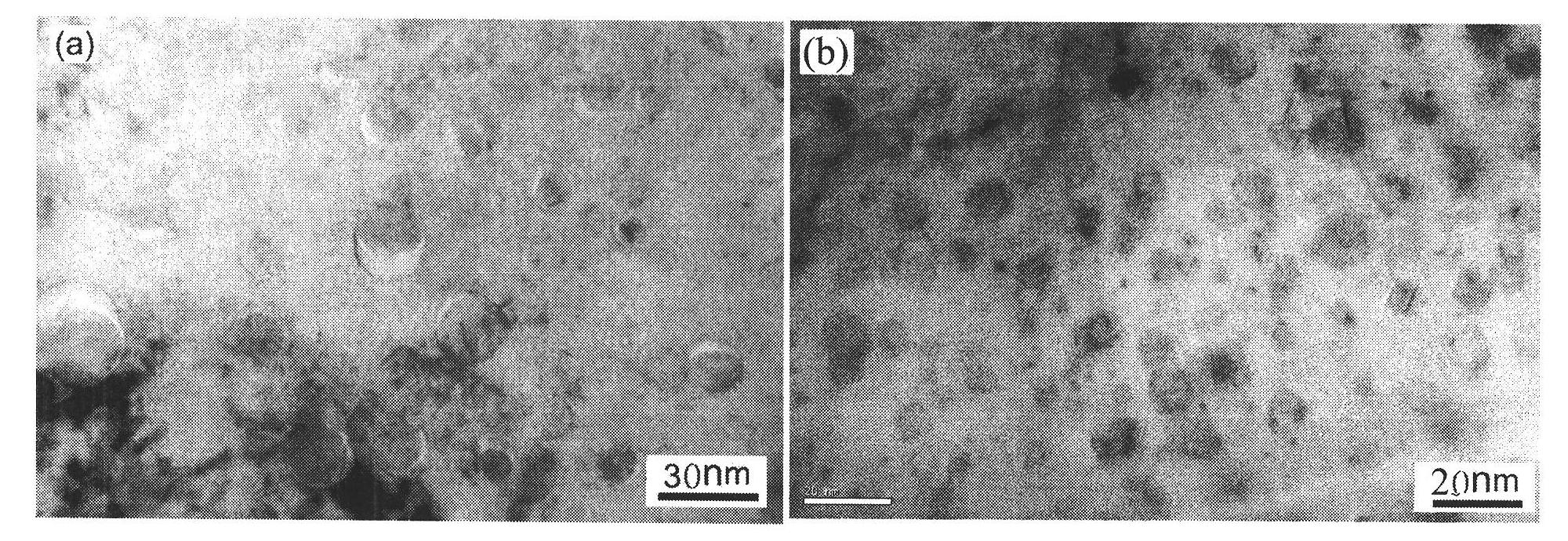

Mechanical alloying method for preparing strengthened dispersion alloy of nickel-based oxide

InactiveCN101948970AEnhancement effect is goodExert high temperature mechanical propertiesHigh energyBall mill

The invention discloses a mechanical alloying method for preparing strengthened dispersion alloy of nickel-based oxide, belonging to the field of metal matrix composite. The process flow of the method is as follows: uniformly pre-mixing FGH96 alloy element powder, oxide refined element (Hf) and oxide dispersed phase (Y2O3) the particle size of which is 20-30nm; uniformly dispersing nanometer Y2O3 particles in nickel matrix under high purity Ar atmosphere through high energy ball milling; coating the alloy powder after high energy ball milling with low carbon steel and performing hot isostatic pressing at 950-1200 DEG C; and performing solid solution heat treatment at 950-1200 DEG C and aging heat treatment at 600-900 DEG C on samples after hot isostatic pressing to obtain a final nanophase enhanced composite material. The advantages of the method are mainly reflected in that the components of FGH96 alloy are taken as basic components, and element Hf is added to form Y2Hf2O7 complex oxide to inhabit the formation of Y-Al-O complex oxide, so that the disperse phase is refined to 5-13nm. The volume percentage of gamma' phase after heat treatment can reach as high as 38-45%.

Owner:UNIV OF SCI & TECH BEIJING

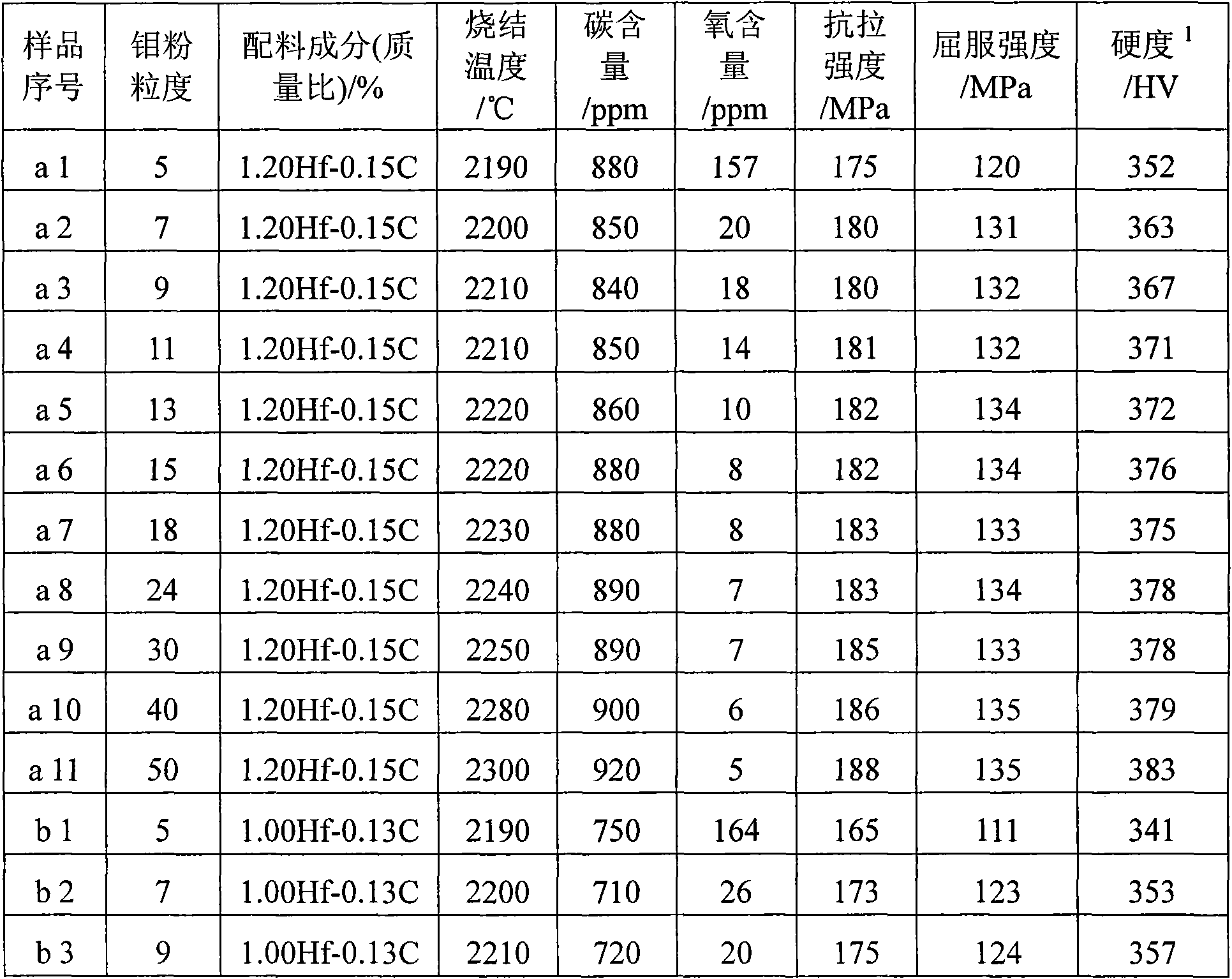

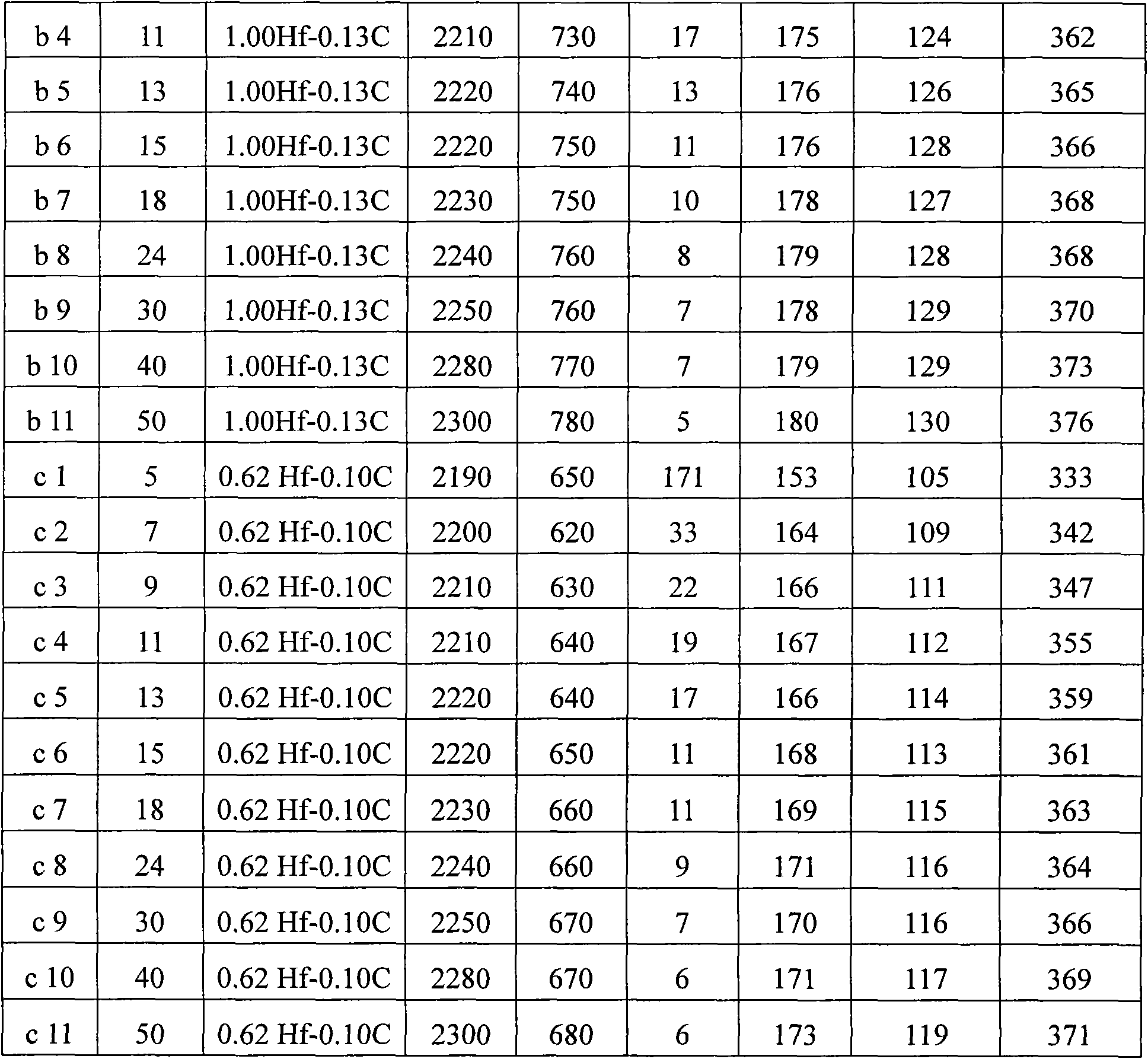

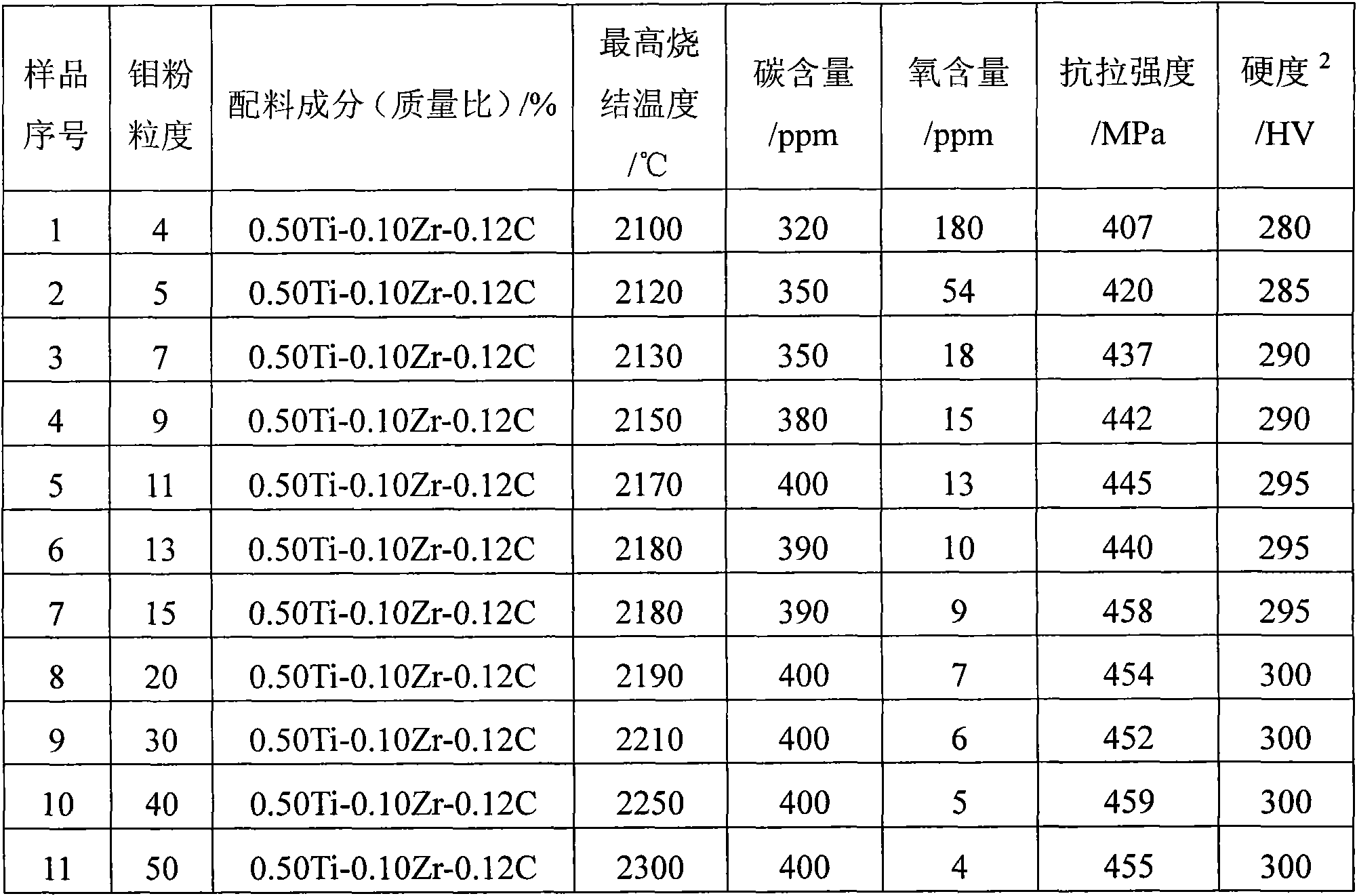

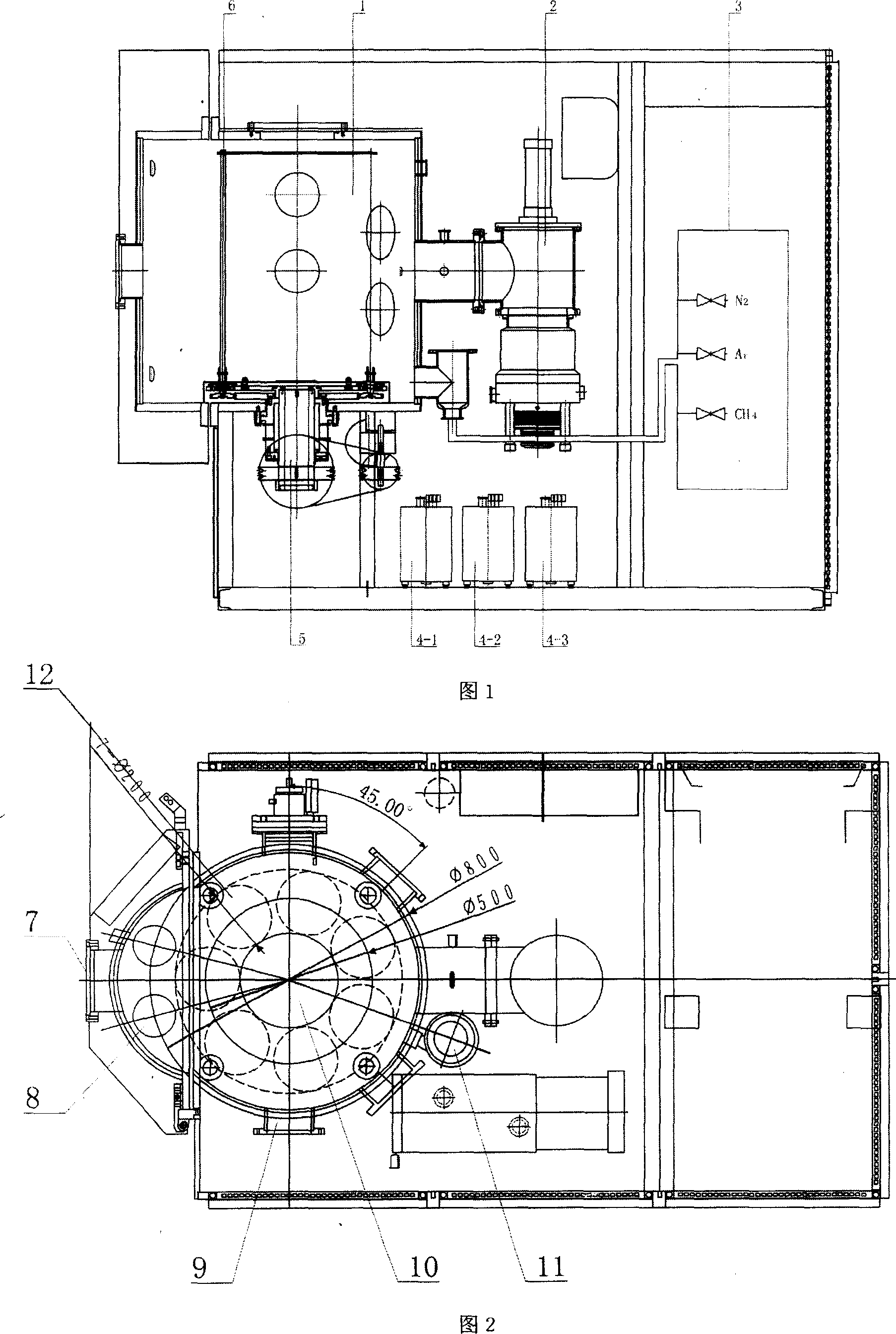

Preparation method of low-oxygen molybdenum alloy and application thereof

InactiveCN102041402AReduce oxygen contentOxygen content less impurityX-ray tube electrodesForging/hammering/pressing machinesMass ratioAlloy

The invention provides a preparation method of a low-oxygen molybdenum alloy. The method comprises the following steps: 1) selecting raw materials: uniformly mixing industrial molybdenum powder with Fisher particle size of 3-100 mum, powder containing strengthening elements with Fisher particle size of 3-10 mum, and carbon simple substance powder with Fisher particle size of 0.1-3 mum at certain mass ratio; 2) forming the raw materials: performing static pressing or mould pressing treatment on the mixed raw materials under pressure of 100-300 MPa to obtain formed blank; and 3) sintering the raw materials: sintering the formed blank in vacuum, hydrogen or inert gas environment at the high temperature of between 1,800 and 2,300 DEG C for 5-15 h to obtain the low-oxygen molybdenum alloy. Through the invention, the problem of high oxygen content of the molybdenum alloy prepared by powder metallurgy is solved. The low-oxygen molybdenum alloy prepared by the method can be used for preparing an X-ray tube rotating anode target, a composite target-based target, a high-temperature crucible, a hot-forging die and a high-temperature ceramic gasket.

Owner:XIAN GEMEI METAL MATERIAL

Hall Ion Source excitation magnetron sputtering enhancement magnetism filtration multi-arc ion composite coating method

InactiveCN101058870AHigh hardnessImprove toughnessVacuum evaporation coatingSputtering coatingPower flowIon bombardment

The invention discloses a making method of magnetic control sputtering reinforced typed magnetic filter multihead ion composite coater excited by Hall source, which comprises the following steps: extracting into vacuum; heating; exciting ion; plating; improving the connecting strength; obtaining the entire and compact film system for industrial need.

Owner:西安宇杰表面工程有限公司

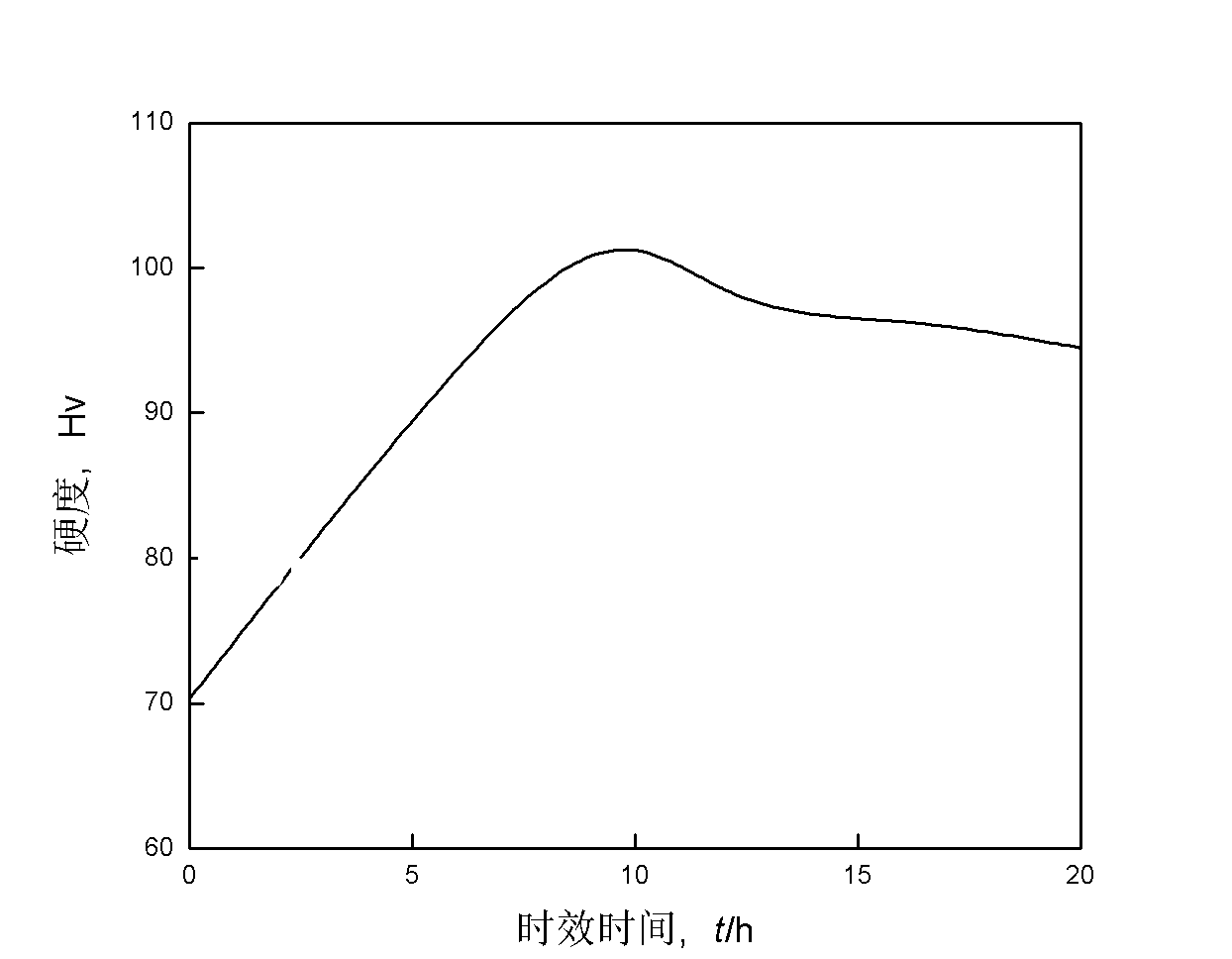

Heat treatment process of large-size high-tensile magnesium alloy extrusion

The invention relates to a heat treatment process of large-size high-tensile magnesium alloy extrusion. The magnesium alloy extrusion comprises the components in percent by weight of 6 to 13 percent of Gd, 2 to 6 percent of Y, 0.3 to 0.8 percent of Zr, and the balance of Mg and unremovable impurity elements. The heat treatment process comprises the steps of: homogenizing magnesium alloy ingots semicontinuously casted at a temperature of 445 to 455 DEG C for 5 h and at a temperature of / 535-545 DEG C for 15h; extruding and moulding the homogenized magnesium alloy ingots to obtain large-size extrusion boards and bars, and carrying out artificial aging treatment on the extrusion boards at a temperature of 200 to 220 DEG C for 20-64h. The strength of the magnesium alloy is greatly improved. The tensile strength of the extrusion boards subjected to artificial aging is more than 460Mpa, and the yield strength is more than 390Mpa. The tensile strength of the bars subjected to the artificial aging is more than 455Mpa, and the yield strength is more than 400Mpa.

Owner:CENT SOUTH UNIV

Submerged arc welding wire of high tensile pipeline steel

ActiveCN101905391AHigh yield strengthQuality improvementArc welding apparatusPipeline systemsCrack resistanceSheet steel

The invention discloses a submerged arc welding wire of a high tensile pipeline steel. The welding wire material comprises the following chemical components in percentage by weight: not more than 0.10 of C, not more than 0.6 of Si, 1.3-1.8 of Mn, 1.4-2.5 of Ni, 0.25-0.55 of Mo, not more than 0.12 of Ti, not more than 0.05 of V, not more than 0.35 of Cr, 0.0005-0.005 of B, not more than 0.015 of S, not more than 0.015 of P, and the balance of Fe and other inevitable impurities. The submerged arc welding wire of the high tensile pipeline steel provided by the invention has the yield strength of deposited metals of more than 690MPa and the tensile strength of more than 785Mpa, has attractive welding formation, high intensity, high flexibility and high crack resistance without defects of cracking, undercut and the like, and has favorable matching effect with X100 level pipeline steel plates, and meets the requirement on the welding of oil-gas transmission pipelines under the condition of higher pressure.

Owner:YICHANG MONKEY KING WELDING WIRE

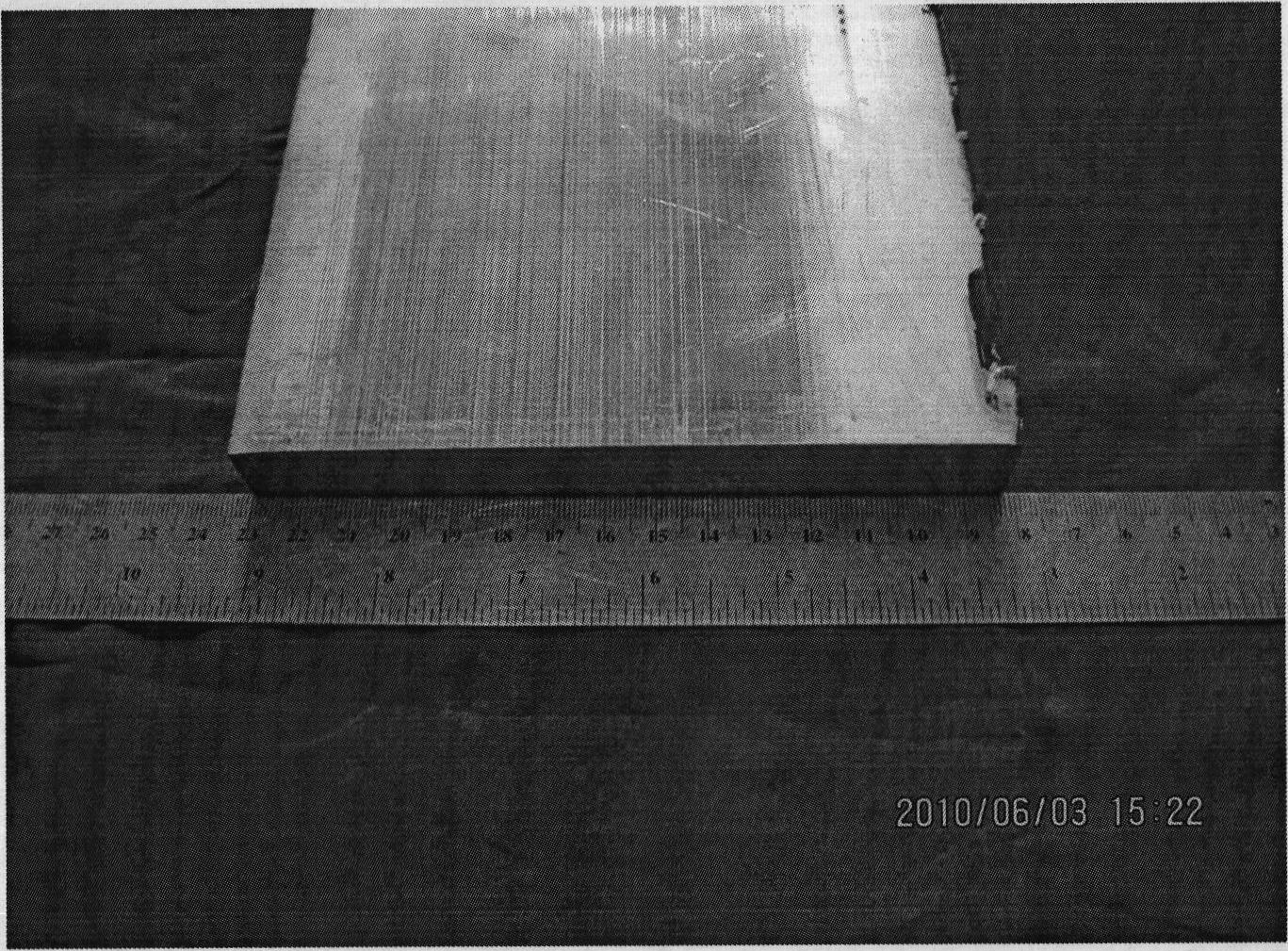

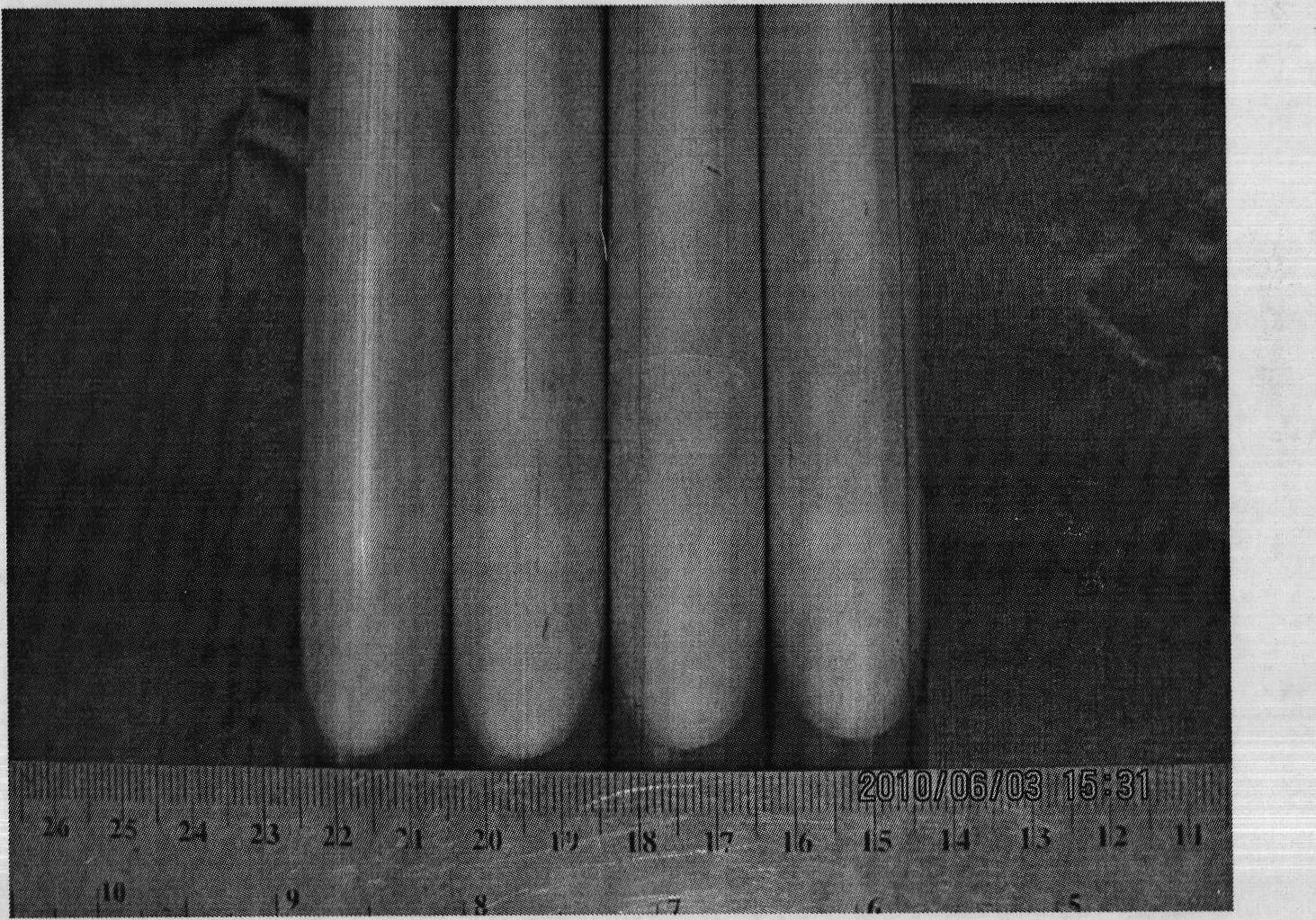

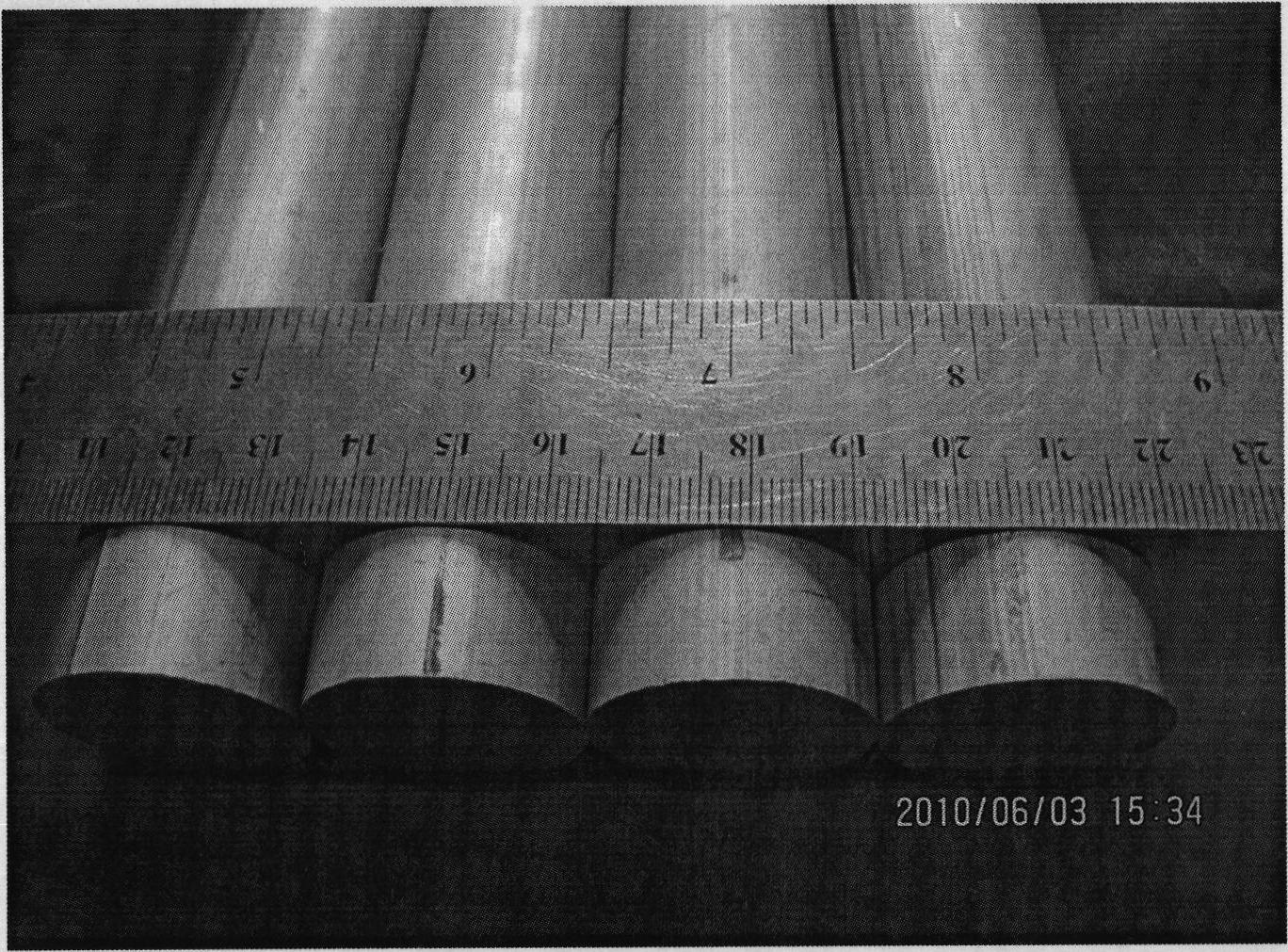

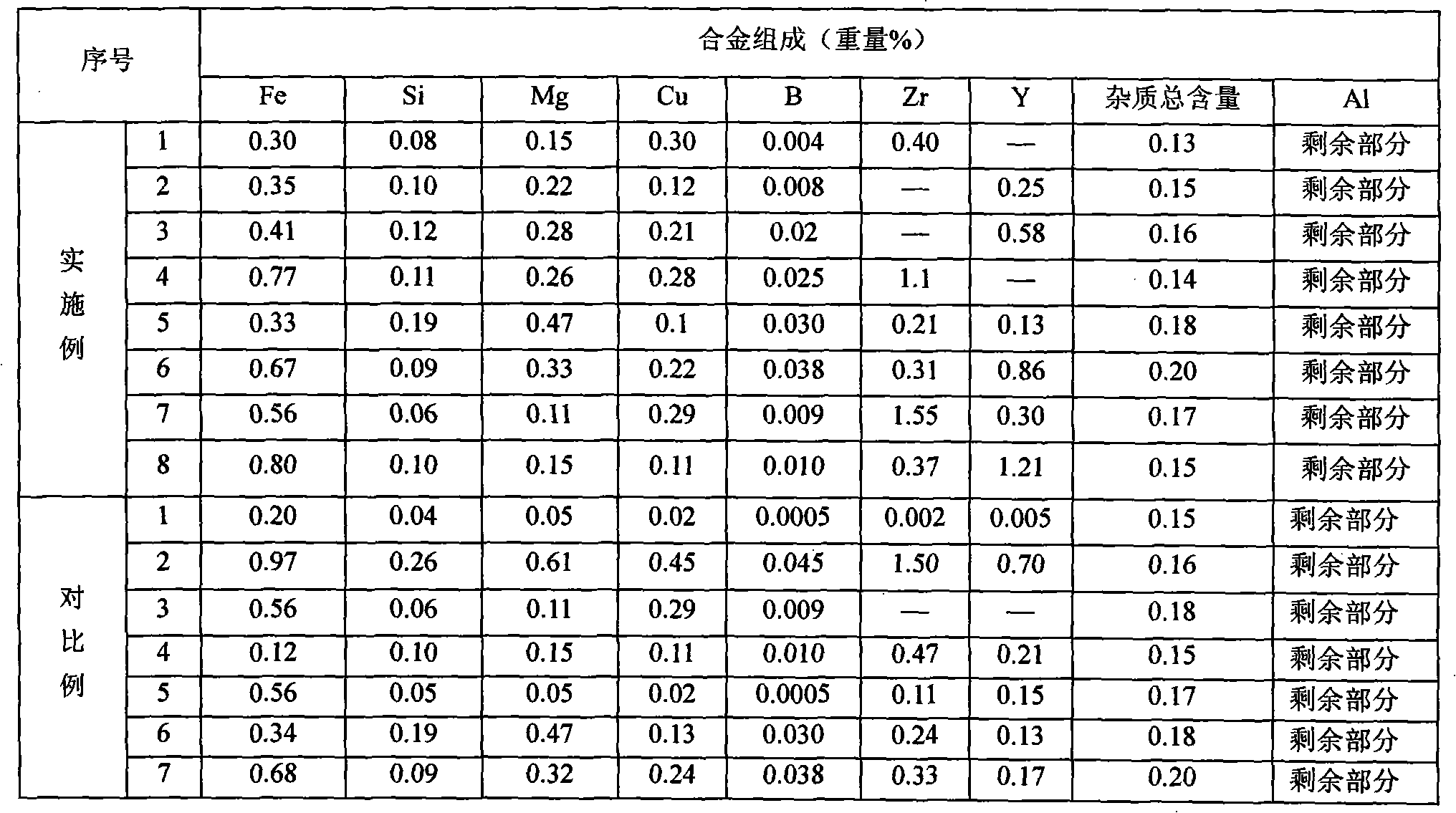

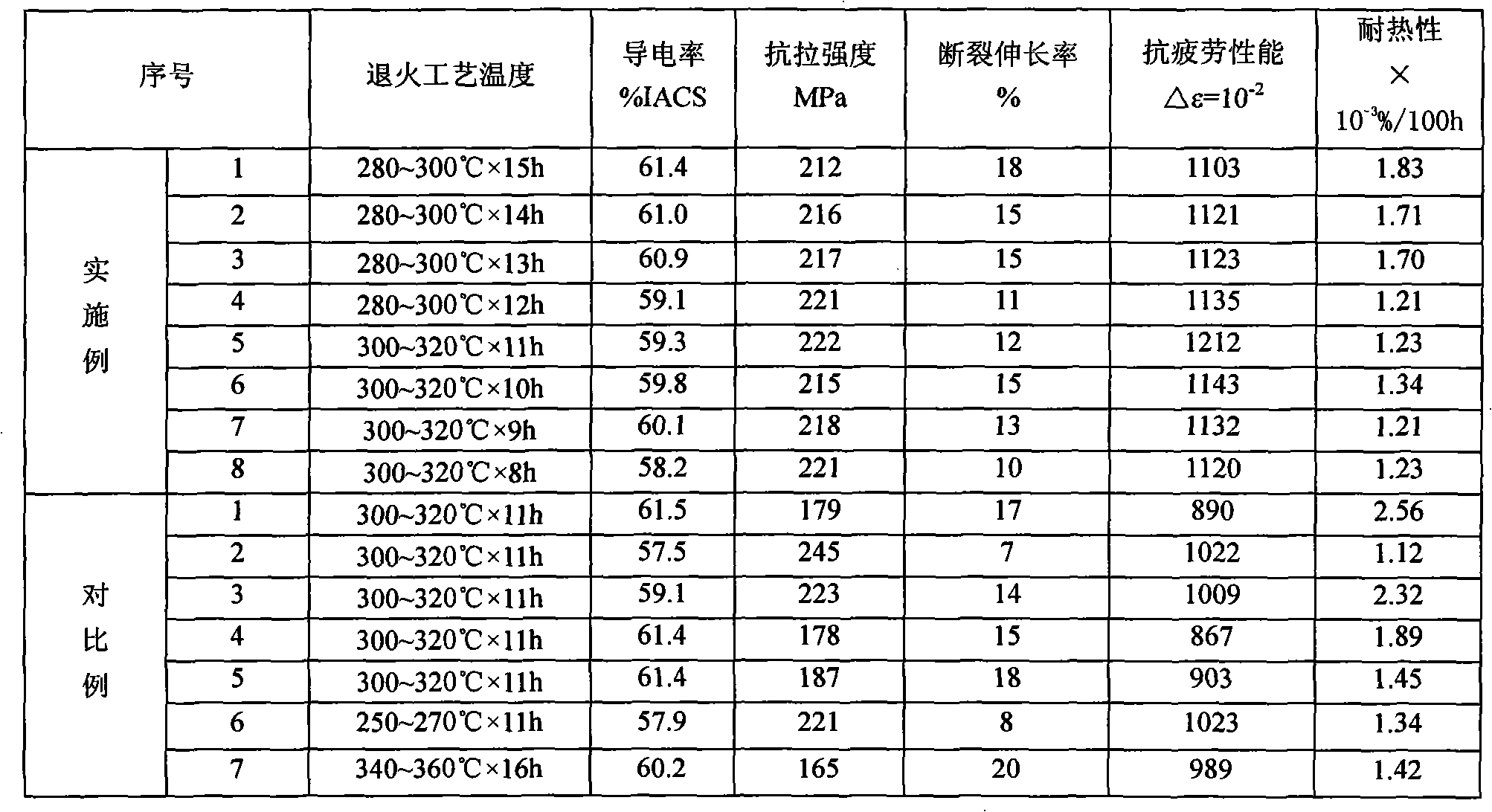

Aluminium alloy conductor for automotive wires and manufacturing method thereof

ActiveCN101923908AHigh tensile strengthImprove corrosion resistanceInsulated cablesMetal/alloy conductorsYttriumMagnesium

The invention discloses an aluminium alloy conductor for automotive wires, which has the advantages of high heat resistance, conductivity, tensile strength, extensibility and fatigue resistance, and a manufacturing method thereof. The alloy contains 0.3 to 0.8 weight percent of iron, 0.05 to 0.20 percent of silicon, 0.1 to 0.5 weight percent of magnesium, 0.1 to 0.3 weight percent of copper, 0.001 to 0.04 weight percent of boron, 0.001 to 0.04 weight percent of zirconium, 0.001 to 0.04 weight percent of yttrium, and the balance of aluminium and inevitable impurities, wherein one or two elements, except the aluminium and the inevitable impurities, account for 0.1 to 2.0 weight percent. The manufacturing method comprises the following steps of: adding the iron, silicon, magnesium, copper, boron, zirconium, yttrium and aluminium into a smelting furnace; smelting, and casting and rolling; performing intermediate annealing treatment; drawing into aluminium alloy filaments with the diameterof 0.5mm; and stranding into wire cores, and performing annealing treatment. The conductor prepared by the method has the tensile strength of 210MPa and above, the elongation at break of over 10 percent, the conductivity of over 58 percent, and excellent heat resistance and flexibility.

Owner:安徽中青欣意铝合金电缆有限公司

HRB500 hot-rolled belt rib antiseismic steel bar and preparation method thereof

The invention discloses an HRB500 hot-rolled belt rib antiseismic steel bar and a preparation method thereof. The steel comprises the following chemical components in percentage by weight: 0.17-0.25% of C, 0.4-0.8% of Si, 1.2-1.5% of Mn, at most 0.045% of P, at most 0.045% of S, 0.028-0.045% of V, 0.008-0.014% of N, and the balance of Fe and inevitable impurity elements. The preparation method comprises the following steps: molten iron desulfurization, converter smelting, argon blowing, continuous casting, square billet heating, rolling, controlled cooling after rolling, and cooling bed air cooling. The steel has the advantages of high strength, high toughness and low manufacturing cost. The preparation technique has the advantages of simple process and low production cost.

Owner:武汉钢铁有限公司

In-situ-synthesis particle-reinforced aluminum-base composite material and preparation method thereof

ActiveCN104264001AImprove fracture toughnessImprove fatigue resistanceMechanical propertyMaterials science

The invention discloses an in-situ-synthesis particle-reinforced aluminum-base composite material applicable to helicopter hub splints, which comprises the following components in percentage by mass: 0.38-0.42% of Si, 1.2-2.0% of Cu, 0.26-0.32% of Mn, 2.1-2.9% of Mg, 0.1-0.28% of Cr, 5.1-6.1% of Zn, 5-12% of TiB2 particle and 78.7-82.22% of Al. The invention also discloses a preparation method of the in-situ-synthesis particle-reinforced aluminum-base composite material. The TiB2 particle is synthesized in the aluminum-base composite material in situ, so that the strength and modulus elasticity of the aluminum-base composite material are obviously enhanced, and the fracture toughness and fatigue resistance of the aluminum-base composite material are also greatly enhanced; and the material has favorable plasticity, thereby further enhancing the comprehensive mechanical properties of the material. The preparation method has the advantages of simple technique and cheap raw materials, is suitable for large-scale industrial production, and has favorable popularization and application value.

Owner:KING STRONG MATERIAL ENG LTD +1

Oxide dispersion strengthened (ODS) steel preparing method and martensitic steel

The invention provides an oxide dispersion strengthened (ODS) steel preparing method and martensitic steel. The oxide dispersion strengthened steel preparing method includes the steps that iron oxides are added into a casting mould, a proper number of rare earth elements are added into a fully deoxidized molten steel, the mixture is rapidly cast into the casting mould, and the ODS steel is obtained through the reaction between the rare earth elements and the iron oxides. The martensitic steel is obtained by performing hot forging, hot rolling, hot machining and hot treatment on the ODS steel prepared through the method. The ODS steel prepared through the method is high in hardenability, the residual austenitic content is very low, and a full martensite structure can be obtained. W, V and Ta are strong carbide forming elements and have a remarkable strengthening effect, and the mechanical property is obviously higher than that of steel prepared through a traditional smelting technology. Meanwhile, the ductile-brittle transition temperature (DBTT) value is minus 80 DEG C and minus 90 DEG C, the good toughness of the traditional smelting technology is well inherited, and meanwhile good anti-radiation performance is achieved. By means of the ODS steel preparing method, the demands for preparing ODS steel in batches with stability, short process and low cost can be met.

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing high-strength high-toughness magnesium alloy plate strip

InactiveCN102127725AImprove ductilityImprove the strengthening effectThermal deformationHigh intensity

The invention relates to a method for preparing a high-strength high-toughness magnesium alloy plate strip by cold deformation and artificial ageing, comprising the following steps of: placing a magnesium alloy in a thermal deformation state or a solid solution magnesium alloy cooled by water quenching after temperature preservation at the temperature of 400-540 DEG C for 1-15 hours into liquid nitrogen to be subjected to subzero treatment and cold deformation, or directly carrying out cold deformation on the original magnesium alloy in the thermal deformation state or the solid solution state, wherein the deformation is controlled to be 5-20%; and finally preserving the temperature of 100-250 DEG C for 5-100 hours and then carrying out artificial ageing, thus the high-strength high-toughness magnesium alloy is obtained. The method provided by the invention is reasonable in design, the equipment requirement is simple, the operation is convenient, and the problems that the cost is high, a large magnesium alloy is difficult to prepare and large-scale application is difficult to realize in the traditional high-strength high-toughness magnesium alloy preparation process can be effectively solved; and magnesium alloy plate strips with excellent comprehensive mechanical properties such as strength, stretchability and the like, thus the method has a good industrial application prospect.

Owner:CENT SOUTH UNIV

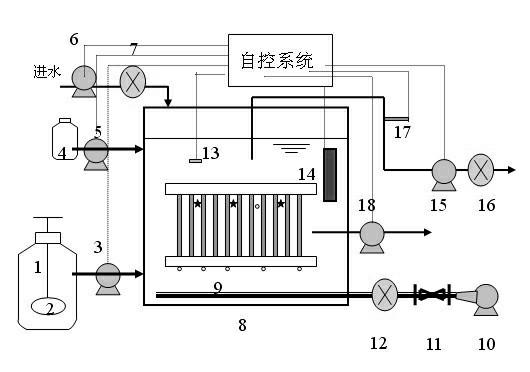

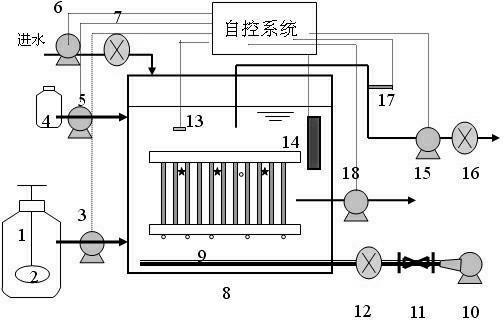

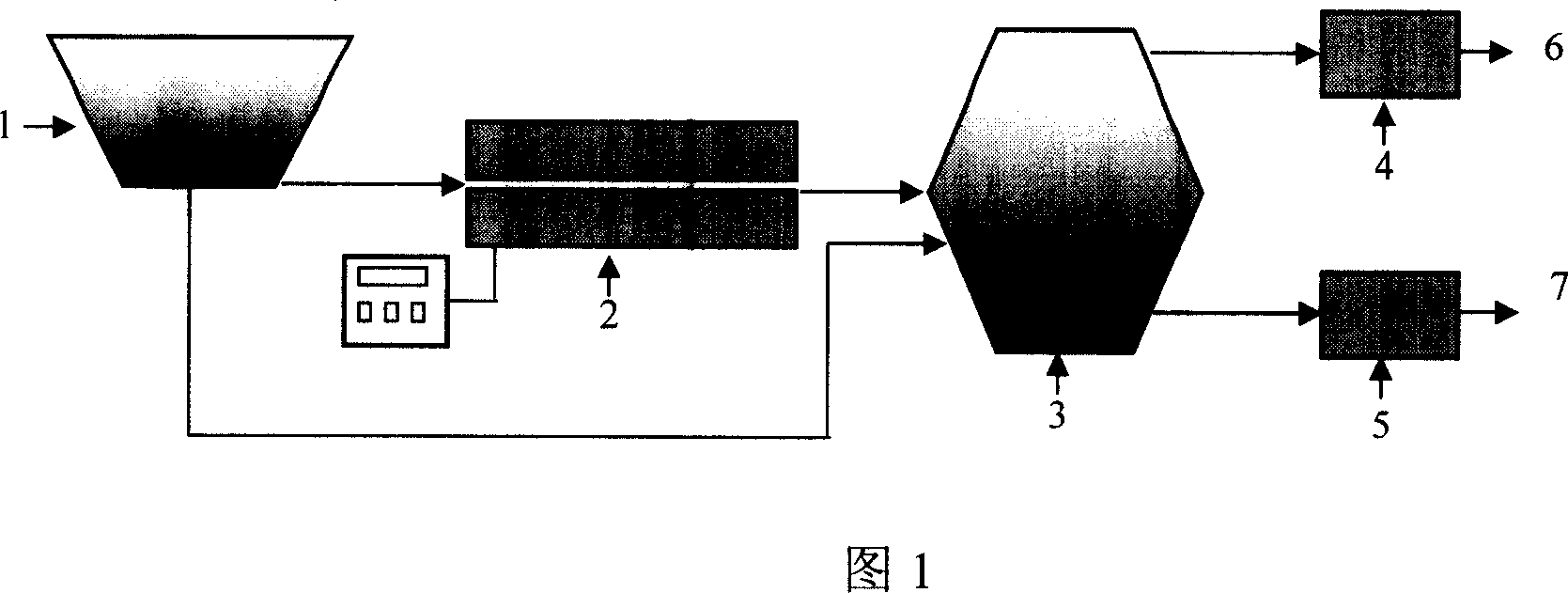

Nitrified sludge efficient enriching culture system based on membrane bioreactor and method

InactiveCN102674539AReduce the cost of trainingAvoid churnSustainable biological treatmentBiological water/sewage treatmentTrace elementLiquid storage tank

The invention relates to a nitrified sludge efficient enriching culture system based on a membrane bioreactor and a method. The system comprises an ammonia nitrogen and trace element storage tank, wherein a stirrer is arranged inside the ammonia nitrogen and trace element storage tank, the ammonia nitrogen and trace element storage tank is connected with the membrane bioreactor through a liquid conveying pump, a pH regulating liquid storage tank is also connected with the membrane bioreactor through the pH regulating liquid conveying pump, and a water inlet connected with a water inlet pump, a water outlet connected with a water outlet pump and a sludge discharge opening connected with the sludge discharge pump are respectively arranged on the membrane bioreactor. The system and the method provided by the invention have the basic characteristic that the membrane bioreactor system is used for realizing the semi-sealed enriching culture on the nitrified sludge. Compared with the fermentation culture of nitrobacterium agents, the system and the method provided by the invention have the advantages that the nitrobacterium culture cost is greatly reduced, the thorough separation of the nitrobacterium and the culture substrate is realized, and the unnecessary loss of the nitrobacterium in the culture process is effectively avoided.

Owner:YANGTZE DELTA REGION INST OF TSINGHUA UNIV ZHEJIANG

Semi-solid die-casting aluminum alloy material and die-casting molding method using same

A semi-solid die-casting aluminum alloy material comprises 6%-9% of Si, 0-0.3% of Cu, 0.25%-0.55% of Mn, 0.2%-0.5% of Mg, 0.6%-1.2% of Fe, 0-0.15% of Ni, 0-0.15% of Zn, 0-0.15% of Pb, 0-0.05% of Sn, 0-0.2% of Ti, 0-0.15% of impurities, and the balance Al. The content of Si is controlled to be 6%-9% and the content of Fe is controlled to be 0.6%-1.2%, so that the good die-casting molding performance, corrosion resistance and demoulding effect are ensured; meanwhile, 0.25%-0.55% of Mn is added to form a MnAl6 compound, so that the harmful effect of iron is effectively weakened; also, Mn can hinder the recrystallization process of aluminum alloy, the recrystallization temperature is increased, and favorable conditions are provided for the semi-solid pulping process of alloy slurry; in addition, 0.2%-0.5% of Mg is contained properly so as to improve the tensile strength.

Owner:FUJIAN KINRUI HIGH TECH CO LTD

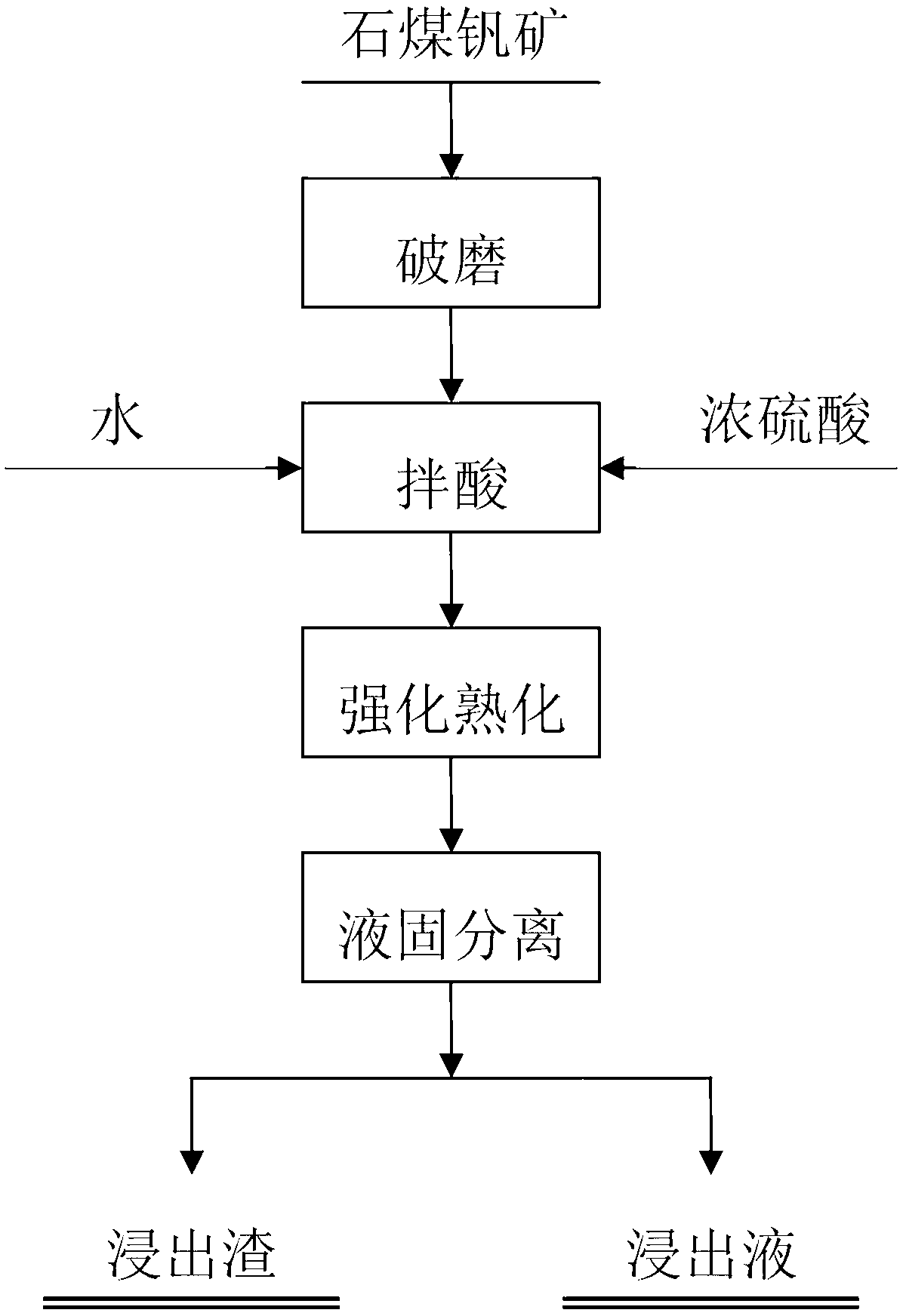

Method for curing and leaching reinforced stone coal navajoite concentrated acid

ActiveCN103290215AShort processReduce energy consumptionProcess efficiency improvementPhysical chemistryCoal

The invention discloses a method for curing and leaching reinforced stone coal navajoite concentrated acid. The method comprises the following steps of: crushing and grinding the stone coal navajoite; adding water and concentrated acid to the obtained mineral powder for uniformly stirring; curing the mixture at a high temperature, and controlling the moisture evaporation amount to be 30%-90% of the adding amount of the moisture during the high-temperature curing process; and leaching the obtained clinker under the normal temperature and the normal pressure, and obtaining a vanadium-containing leaching solution and leaching residue after the liquid-solid separation. The method for curing and leaching reinforced stone coal navajoite concentrated acid has the advantages of being simple in process flow, energy-saving and consumption-reducing, convenient to operate, green and environment-friendly, high in vanadium leaching rate, low in acid consumption and the like.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

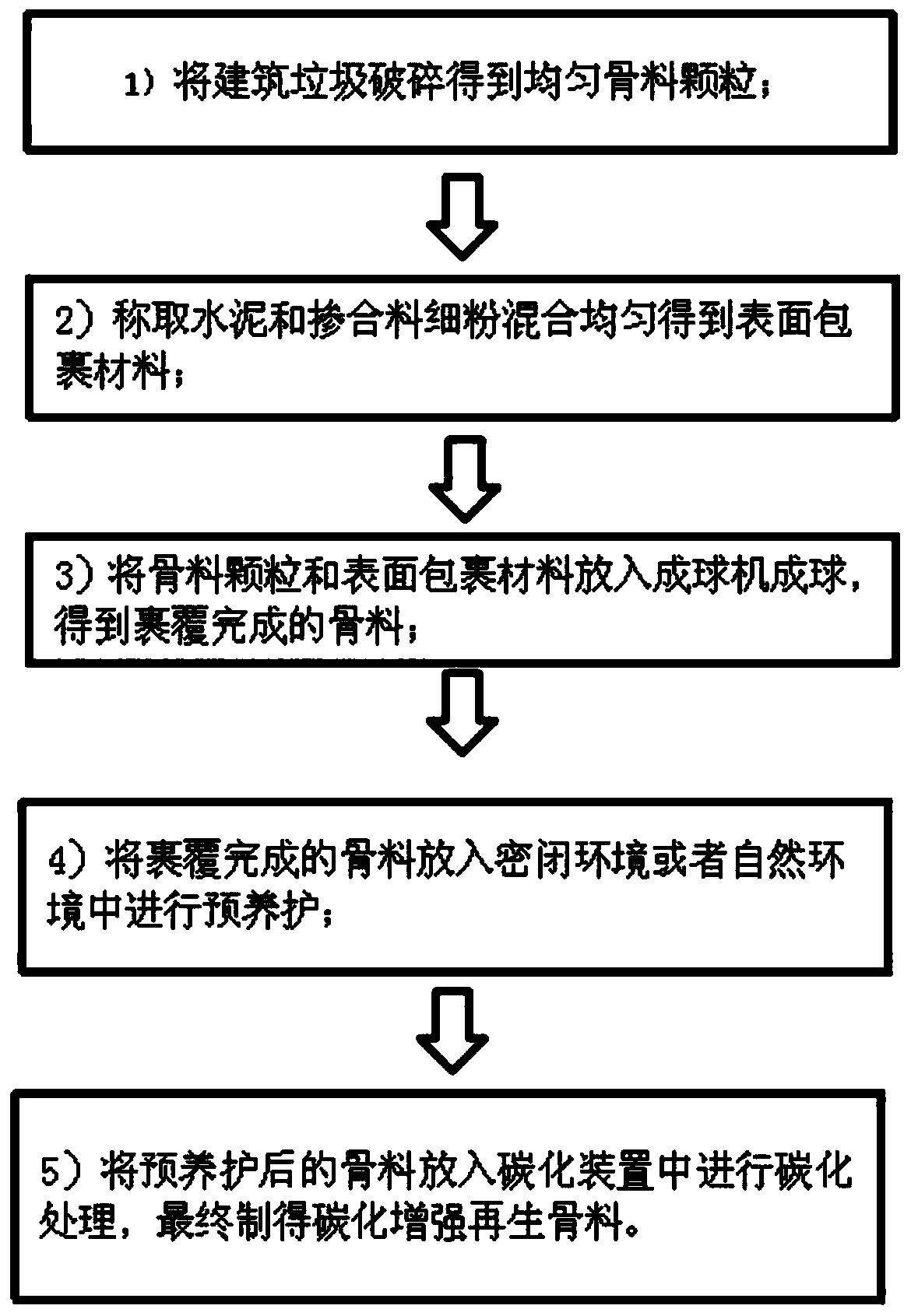

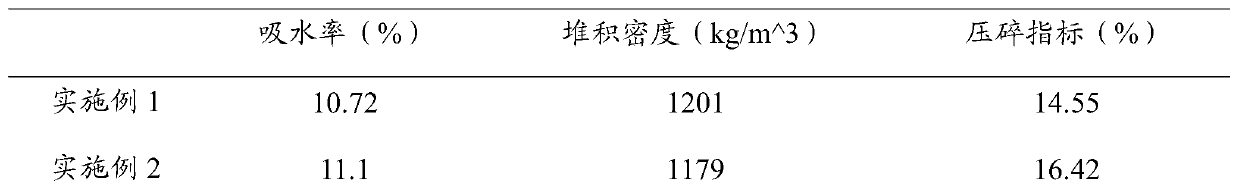

Carbonization reinforced regenerated aggregate, and preparation method and applications thereof

InactiveCN110357473ARealize resource utilizationPermanent storageSolid waste managementResource utilizationCarbonization

The invention discloses a carbonization reinforced regenerated aggregate, and a preparation method and applications thereof, and belongs to the technical field of building material. The preparation method comprises following steps: building garbage is crushed so as to obtain uniform aggregate particles; cement and admixture fine powder are weighted for uniform mixing so as to obtain a surface coated material; the prepared aggregate particles and the surface coated material are mixed, and are introduced into a granulator, water is sprayed uniformly for granulation so as to obtain a coated aggregate; the coated aggregate is introduced into a sealed environment or the natural environment for pre-curing; an aggregate obtained through pre-curing is introduced into a carbonization device for carbonization treatment so as to obtain the carbonization reinforced regenerated aggregate. The preparation method is adopted to prepare the light aggregate, so that aggregate light weight and high strength are achieved, aggregate cylinder compressive strength can be as high as 13.0MPa, and is higher than the using standard cylinder compressive strength 6.5MPa of common light aggregate. The production technology is simple; resource utilization of solid waste is realized; adsorption immobilization of carbon dioxide is realized; sintering is not needed; and low carbon emission and environment protection are realized.

Owner:NANJING UNIV OF TECH

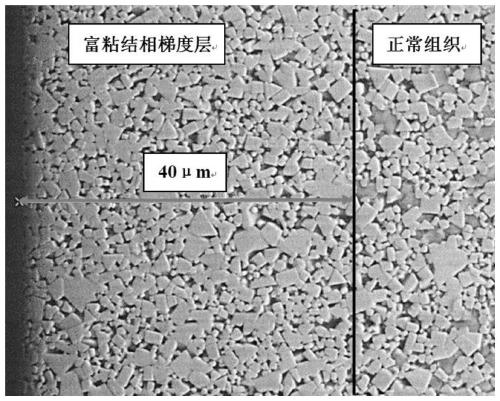

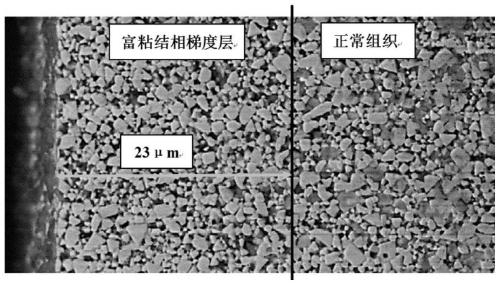

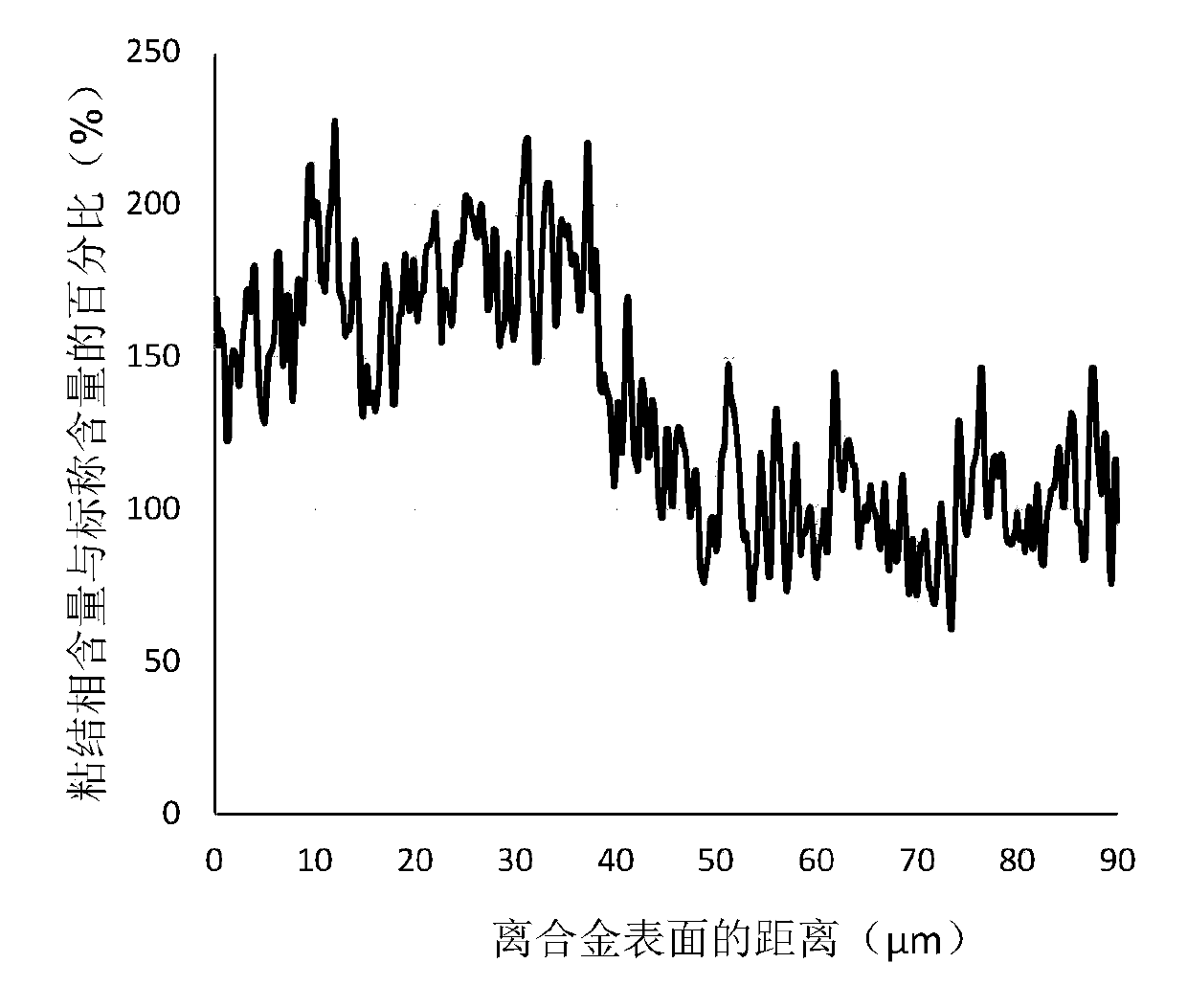

Hard alloy with surface-layer binding-phase-rich gradient structure and preparation method thereof

ActiveCN111378885ALow costImprove antioxidant capacityTurbinesOther manufacturing equipments/toolsMetallic materialsSS - Stainless steel

The invention discloses a hard alloy with a surface-layer binding-phase-rich gradient structure and a preparation method thereof. The hard alloy with the surface-layer binding-phase-rich gradient structure takes Ni3Al, Ru, Re and B strengthened metal as a binding phase, takes WC and cubic carbides such as TaC, NbC, TiC and TiCxNy or solid solutions thereof as a hard phase, wherein the cubic carbides account for 3-12% (in mass fraction) of the hard alloy, and TiCxNy content is 0.5-2.0%; and the binding phase accounts for 4.5-12.5% (in mass fraction) of the hard alloy, and the rest is WC. The preparation method comprises wet-grinding, drying and pelletizing, mould-pressing and forming as well as sintering. The hard alloy with the surface-layer binding-phase-rich gradient structure has excellent toughness, wear resistance and oxidization resistance, and is suitable for processing metal materials such as cast iron, alloy steel, stainless steel and high-temperature alloy.

Owner:九江金鹭硬质合金有限公司

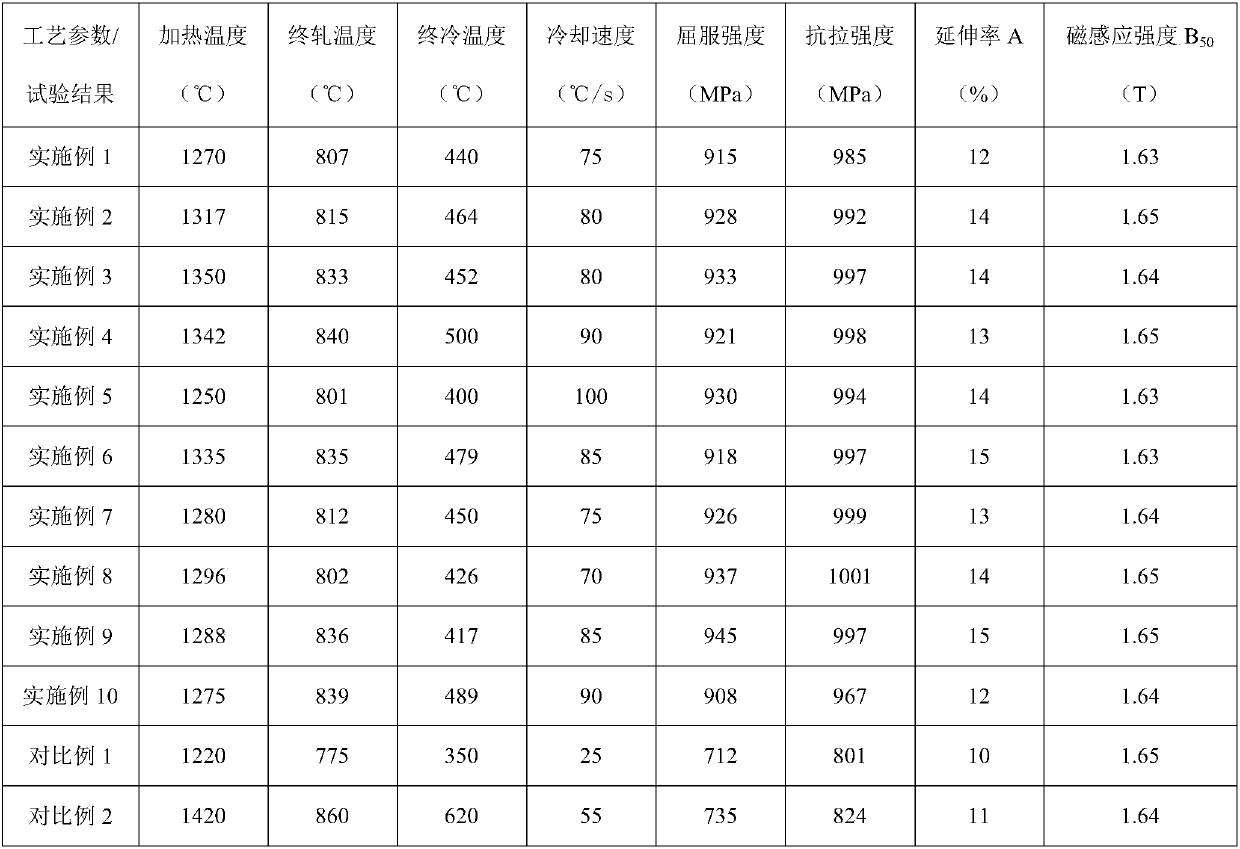

Super high strength magnet yoke steel and manufacturing method thereof

The invention discloses super high strength magnet yoke steel. The super high strength magnet yoke steel comprises, by weight percentage, 0.10-0.15% of C, smaller than or equal to 0.15% of Si, 1.85-2.00% of Mn, smaller than or equal to 0.015% of P, smaller than or equal to 0.010% of S, 0.20-0.30% of Ti, 0.05-0.07% of Nb, 0.35-0.55% of Mo, 0.001-0.003% of B, 0.02-0.10% of Als, smaller than or equalto 0.010% of N and the balance Fe and inevitable impurities. According to the super high strength magnet yoke steel, in order to further improve strength and effectively break through the extreme strength 700 MPa of steel of a ferritic structure, in a structure reinforcing manner, by adding a proper amount of bainite to form elements, in cooperation with a super fast cooling process, a bainite structure is obtained, and the super high strength magnet yoke steel is obtained.

Owner:武汉钢铁有限公司

Supersonic wave reinforcement sludge anaerobic digestion gas production method

InactiveCN101012096AGood strengthening effectReduce energy consumptionWaste based fuelBiological sludge treatmentSolubilityCavitation

The invention discloses a manufacturing method through hypersonic reinforced sludge anaerobic digestive method, which is characterized by the following: condensing sludge; breaking cell wall structure through extreme condition of cavitation effect; increasing sobule organic material; pumping sludge through sludge pump after a while; digesting under anaerobic condition; purifying methane; making digestive sludge into sludge dehydrating system to obtain dried sludge to do terminal disposal.

Owner:TSINGHUA UNIV

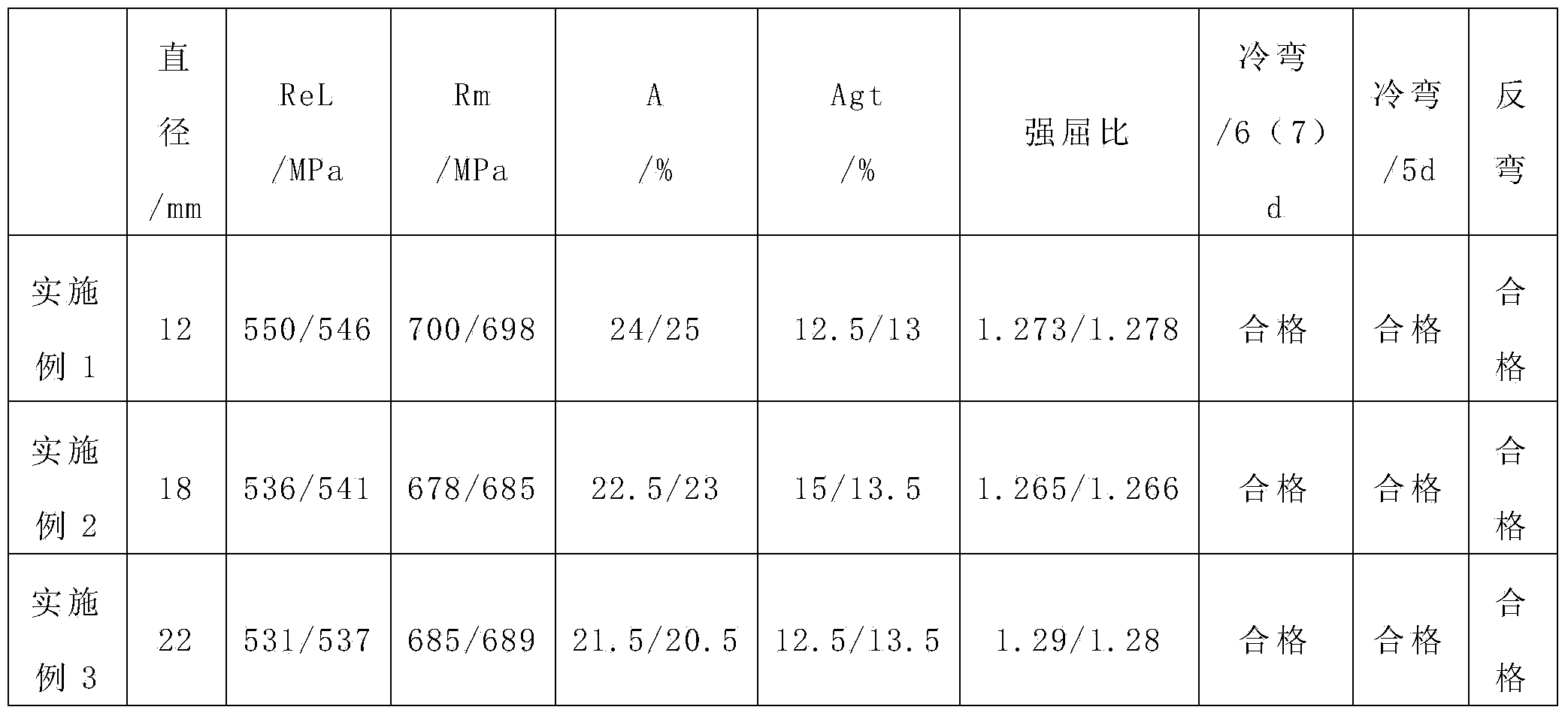

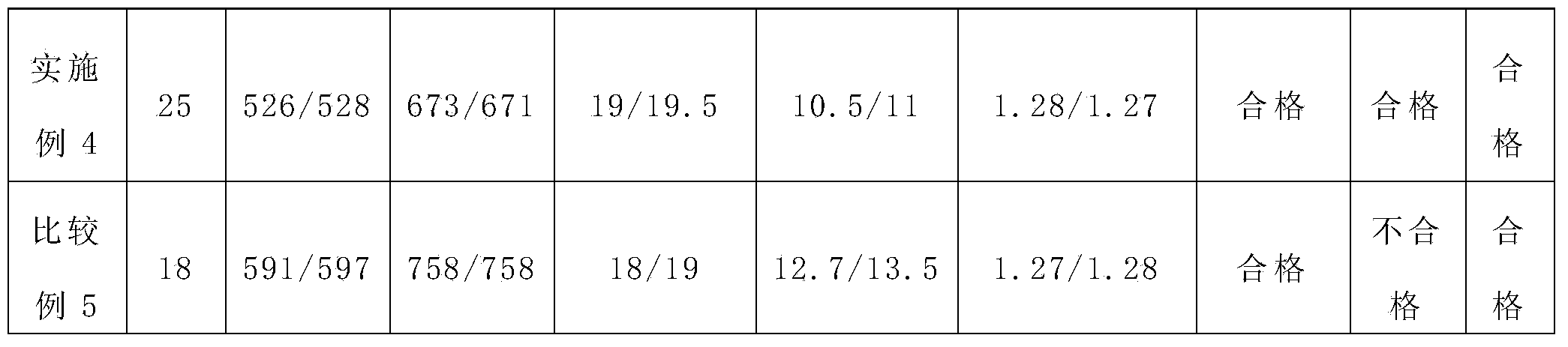

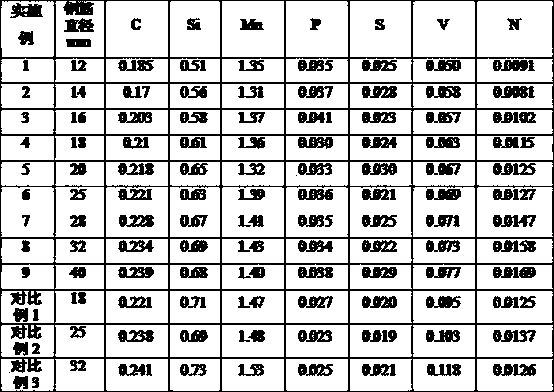

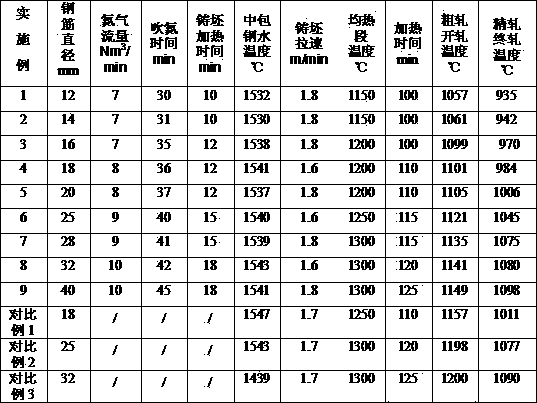

Hot-rolled ribbed steel bar having strength-to-yield ratio of 1.25 or more, and production method thereof

A hot-rolled ribbed steel bar having a strength-to-yield ratio of 1.25 or more comprises 0.17-0.25wt% of C, 0.4-0.8wt% of Si, 1.2-1.5wt% of Mn, 0.045wt% or less of P, 0.045wt% or less of S, 0.05-0.08wt% of V, 0.006-0.018wt% of N, and the balance of Fe and impurity elements, and has a specification diameter of 12-40mm. A production method of the hot-rolled ribbed steel bar comprises the following steps: desulfurizing molten iron; carrying out top-bottom blowing of a converter; carrying out component fine-adjustment at an argon station, and blowing in nitrogen; refining an LF furnace, and blowing nitrogen into the LF furnace; continuously casting; carrying out stacking cooling; heating casted blanks; carrying out rough rolling and finish rolling; and naturally cooling to room temperature. Nitrogen is blown to realize greatly reduced cost, greatly reduced vanadium alloy consumption, increased V (C,N) amount and dispersity with the increase of the content of N in steel, substantial reinforcement effect and stable mechanical performances on the premise that mechanical performances comprising a hot-rolled yield strength of above 530MPa, a strength-to-yield ratio of 1.25-1.30, an A value of 18% or more and an Agt value of 10 or more are guaranteed.

Owner:武汉钢铁有限公司

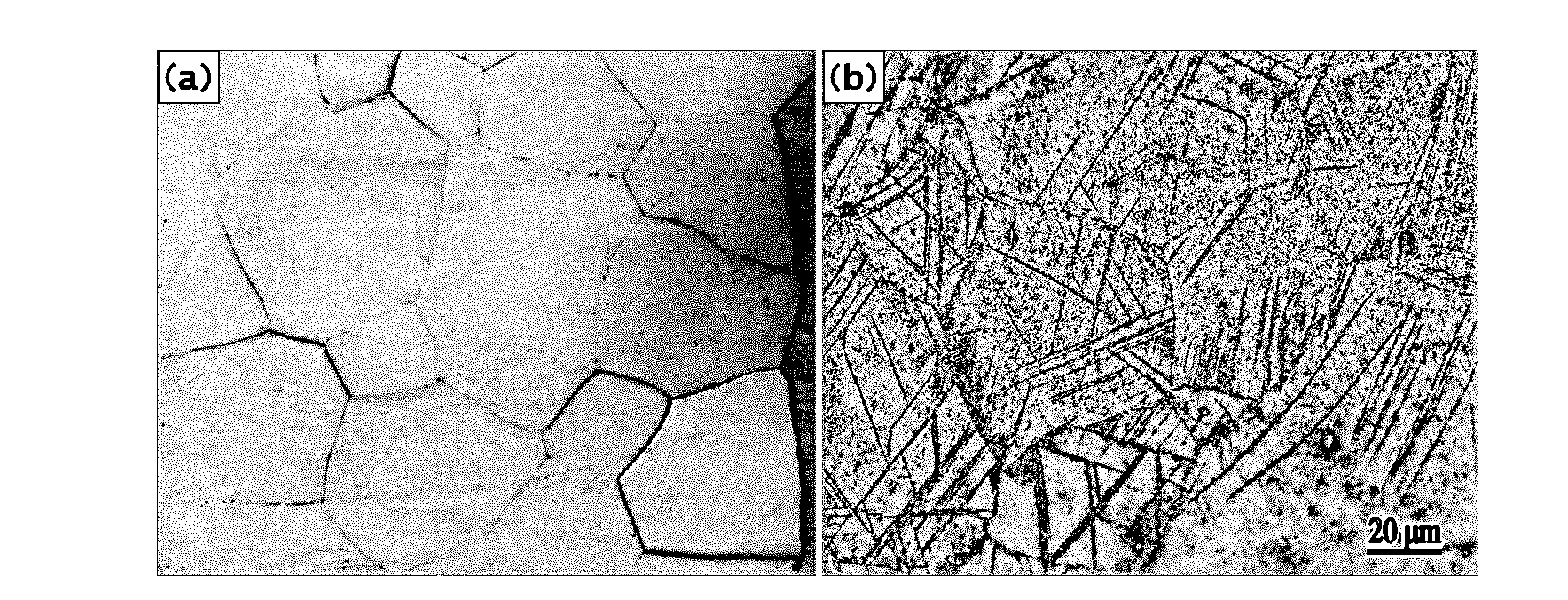

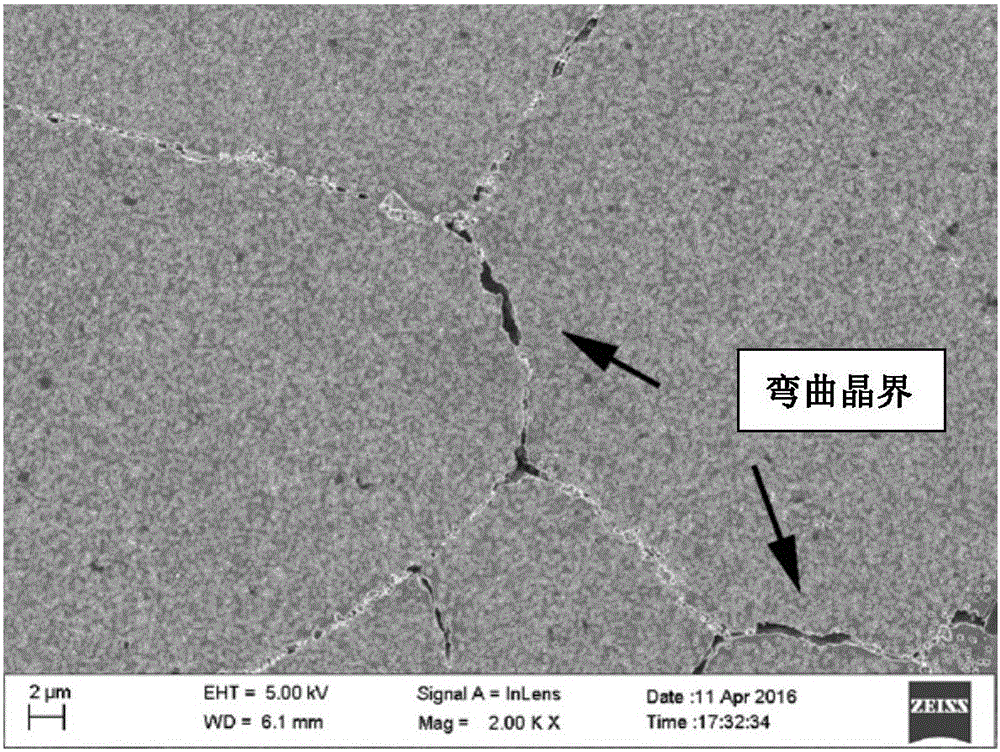

Heat treatment technology for improving high-temperature tensile ductility of Ni-Fe-Cr based deformation high-temperature alloy

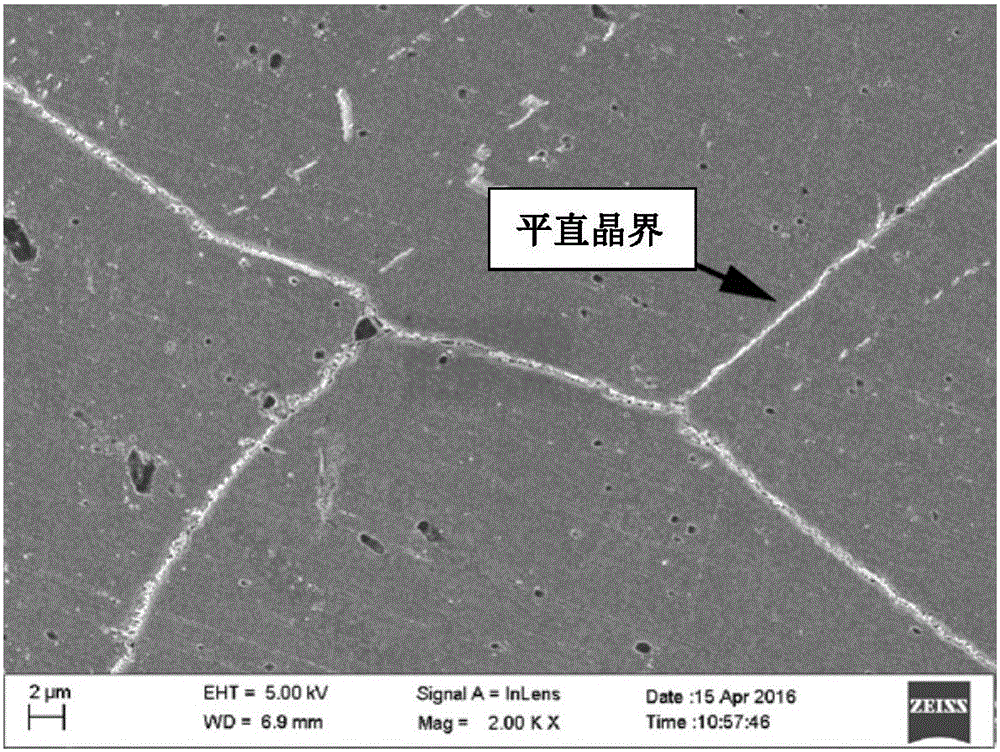

ActiveCN106834990AImprove grain boundary strengthImprove tensile plasticitySolution treatmentCarbide

The invention discloses a heat treatment technology for improving high-temperature tensile ductility of Ni-Fe-Cr based deformation high-temperature alloy. The technology includes the steps that heat preservation lasts for 0.5-2h within the temperature range of 1050-1200 DEG C for performing solution treatment; the temperature is lowered to 20-150 DEG C below a gamma' phase precipitation temperature from the solution temperature at the speed of 0.1-20 DEG C / min, and air cooling is conducted to an indoor temperature after heat preservation lasts for 0.5-4h; and heat preservation is performed for 4-30h at the temperature 150-350 DEG C below the gamma' phase precipitation temperature, and air cooling is conducted again to the indoor temperature. According to the heat treatment technology, the method with high-temperature solution, slow cooling and low-temperature aging combined is adopted, the grain size of an obtained alloy structure is moderate, a bent sawtooth crystal boundary is formed among grains, and M23C6-type carbide is evenly distributed on the crystal boundary; and the crystal boundary has a good reinforcement effect under the high-temperature condition, and the high-temperature tensile ductility of the alloy is high.

Owner:HUANENG POWER INT INC +1

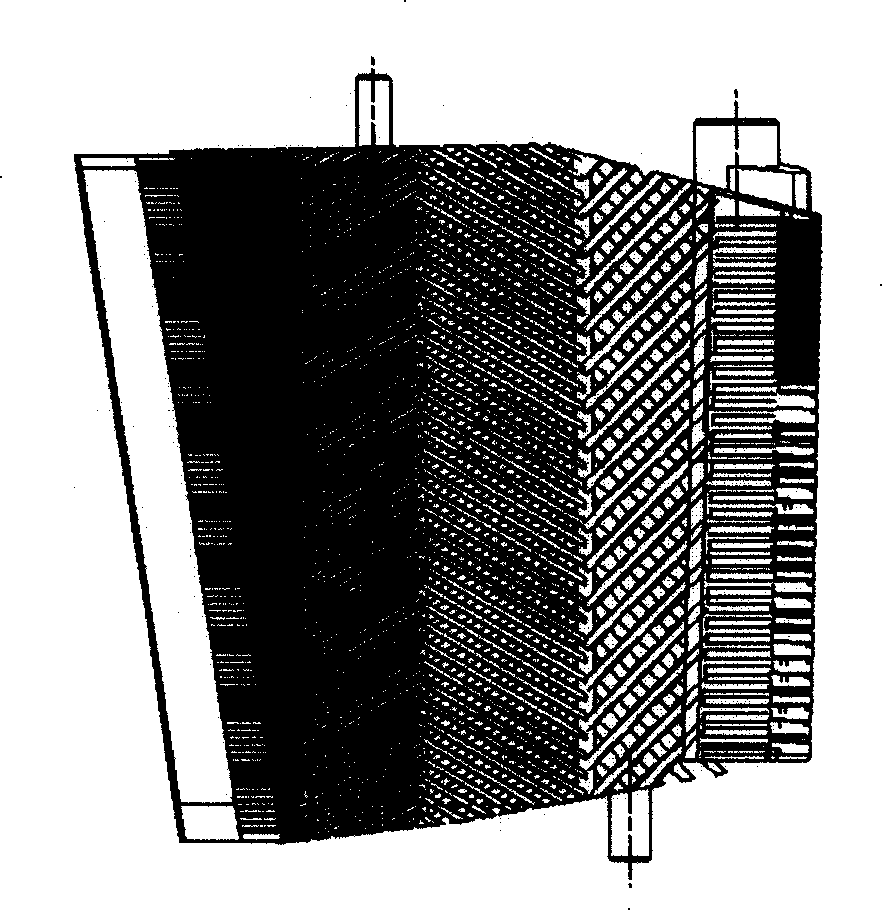

Casting method for heavy combustion engine II-stage diverter blade

InactiveCN101168184AQuick removalFix cracks or deformationFoundry mouldsFoundry coresEngineeringSystems design

A molding method of II level diverter fins of a R0110 heavy combustion engine utilizes roof pouring style molding scheme, which is characterized in that the insulating blanket thickness of the outer portion of the fin shape casing is thickened from top to bottom, from 10+-2mm to 40+-5mm, simultaneously the bottom of the fin shape casing is covered with a layer of iron bolus at a thickness of 20-30mm, a roof pouring style dead system utilizes a huge dead head, the volume of the dead head is 500 to 600cm3, and the height of the dead head is 110-120mm, the molding temperature is controlled at 1405-1480 DEG C and the molding time is 6-8 seconds. Through the design change of a prior guiding fin dead system and the improvement of a prior craft, the invention is capable of producing casts with fine and close organizations.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

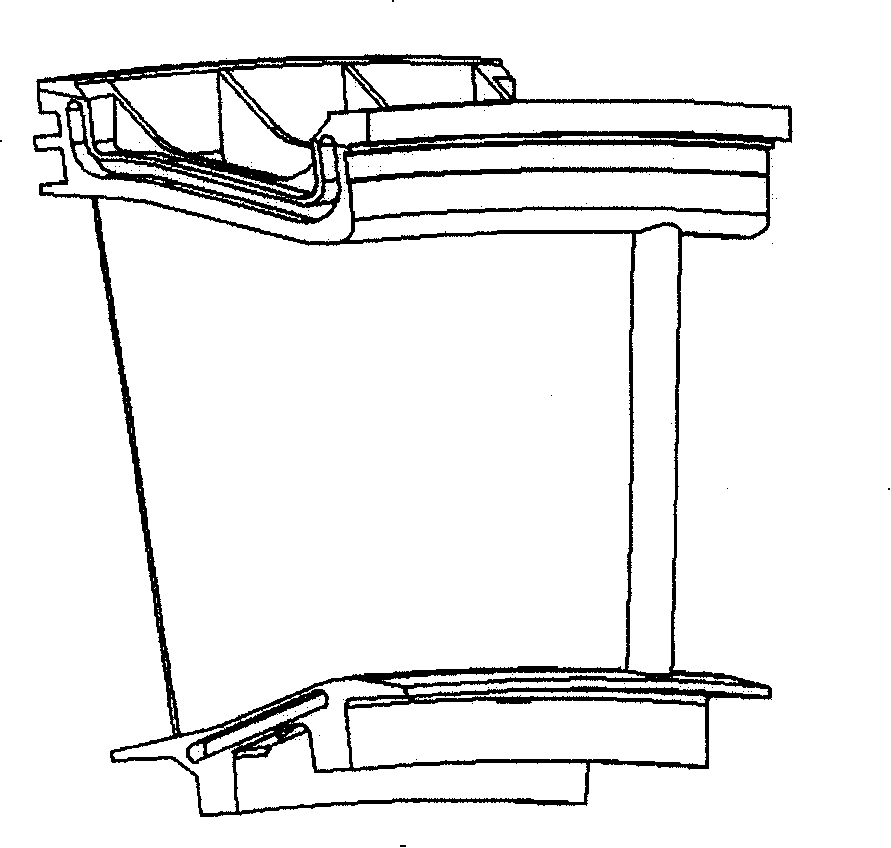

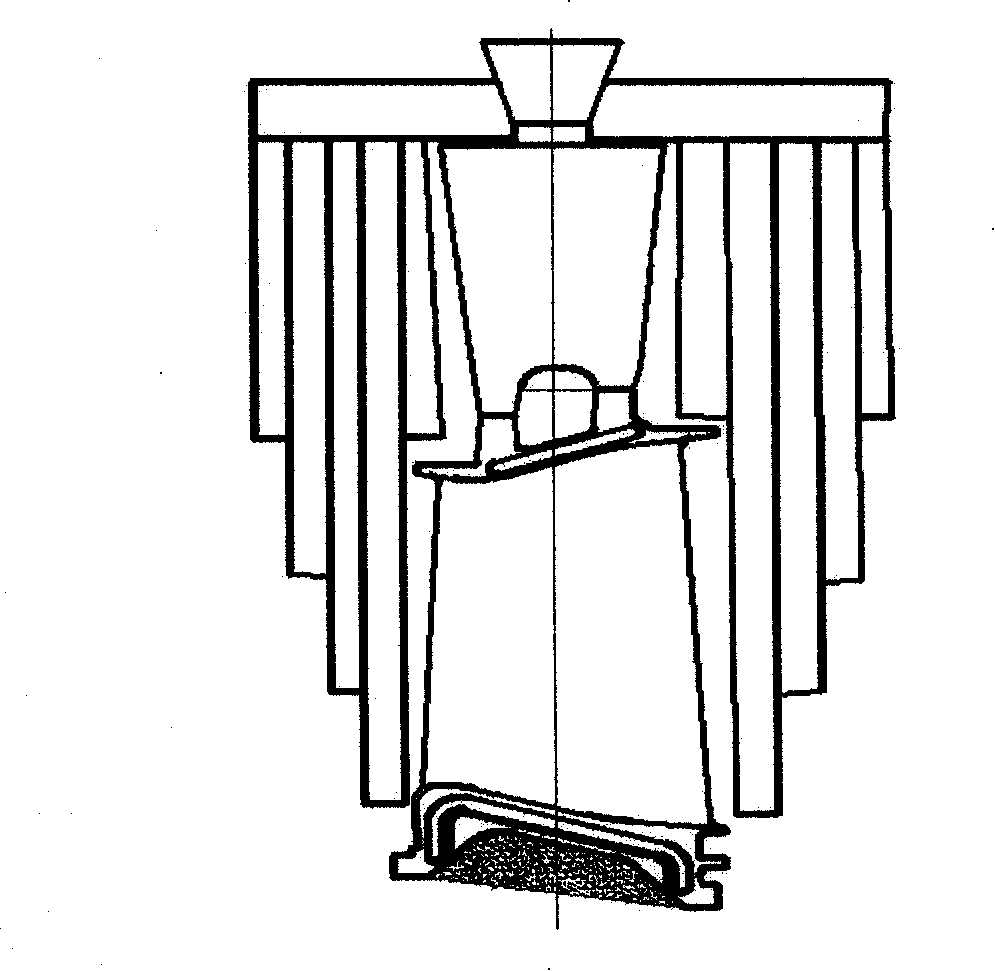

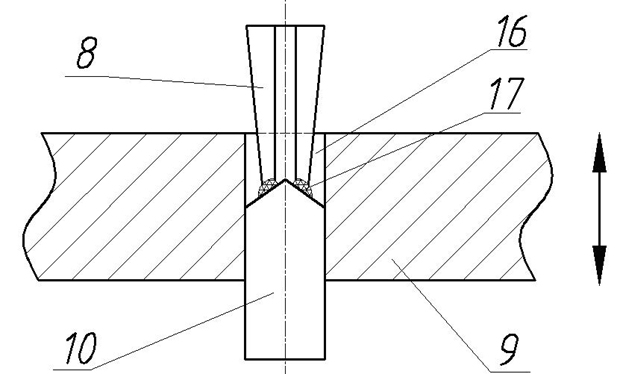

Method and device for strengthening fastening hole by shocking with ring laser

InactiveCN102061362ANot easy to damageConvenient for continuous operationFurnace typesHeat treatment furnacesShock waveManufacturing technology

The invention discloses a method and device for strengthening a fastening hole by shocking with ring laser, relating to the technical field of machining and manufacturing of fastening holes. In the invention, the head part of an energy absorbing rod (10) is a conical surface; high power pulse laser outputs ring laser pulse (8) through a spot adjusting device (15); the ring laser pulse (8) accommodates the tip of the conical head surface of the energy absorbing rod (10) in a hollow part of a laser beam; and the ring laser pulse (8) acts on the conical head surface of the energy absorbing rod (10) to induce a plasma (17) to explode so as to generate shock waves acted on the inner wall of the fastening hole, and thereby the fastening hole is strengthened. The method and the device are suitable for strengthening the fastening hole with a small diameter; the hollow part of the ring laser pulse (8) keeps away from the tip of the conical surface of the energy absorbing rod (10) so that the energy absorbing rod (10) is difficult to be damaged, which is favorable for continuous operation, and the strengthening effect is good.

Owner:JIANGSU UNIV

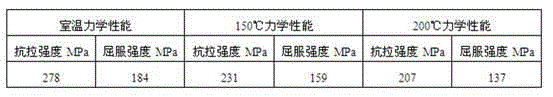

Low-cost multi-component heat-resistant magnesium alloy and preparation method of magnesium alloy

InactiveCN104694805AImprove plasticityImprove high temperature performanceHeat resistanceRoom temperature

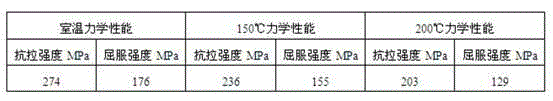

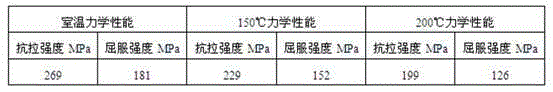

The invention provides a low-cost multi-component heat-resistant magnesium alloy and a preparation method of the magnesium alloy. The low-cost multi-component heat-resistant magnesium alloy comprises the following components in percentage by weight: 4.2-6.7% of Al, 0.5-1.2% of Zn, 0.7-0.9% of Sr, 0.2-0.8% of Ca, 1.1-1.5% of Sn, 0.8-1.3% of Sb, 0.05-0.4% of Mn, 0.2-0.6% of Bi, 0.4-0.9% of Si and the balance of Mg. According to the low-cost multi-component heat-resistant magnesium alloy, a right amount of low-cost alloy elements such as Sr, Ca, Sn, Sb, Mn, Bi and Si are introduced; the high-temperature performance of the magnesium alloy can be remarkable improved; the application range of the magnesium alloy can be expanded; the magnesium alloy is low in cost, simple in smelting and heat treatment process and uniform in microscopic structure; the mechanical performance and the heat resistance of the alloy can be remarkably improved; after the alloy is solidified and aged, the maximum room-temperature tensile strength reaches 278MPa; the maximum tensile strength at 150 DEG C reaches 236MPa; the maximum tensile strength at 200 DEG C reaches 207MPa.

Owner:HENAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com