Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Eliminate residual tensile stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laser welding method for metal sheets applied to ultra low temperature environment

ActiveCN102728950AAccelerate dislocation movementAccelerated particle diffusionLaser beam welding apparatusHigh energyMechanical property

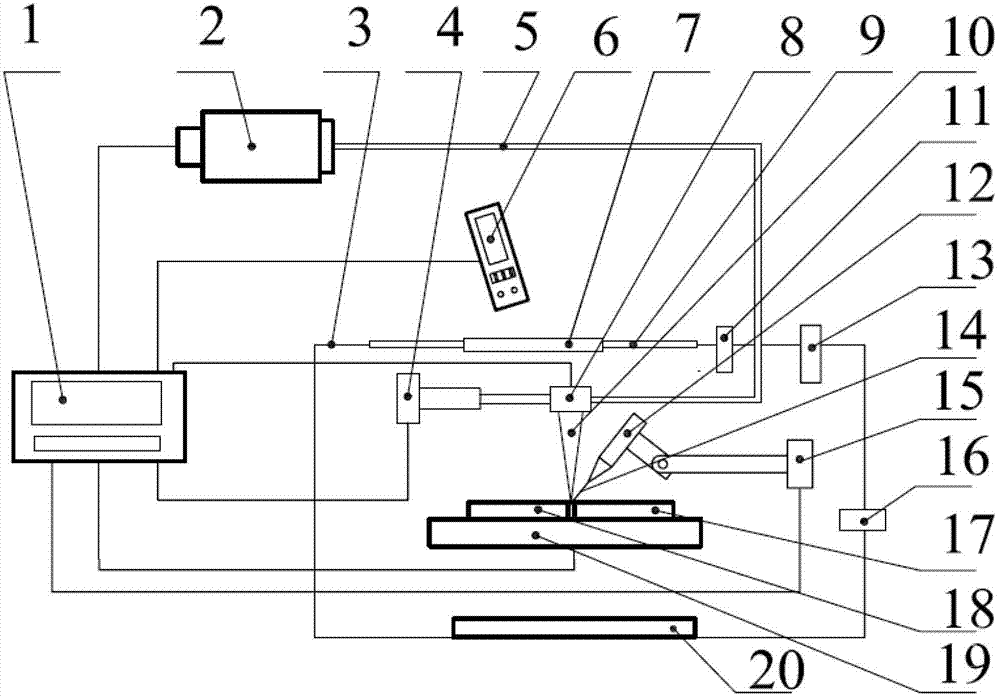

The invention discloses a laser welding method for metal sheets applied to an ultra low temperature environment. The method comprises the following steps of: integrally putting a metal sheet I and a metal sheet II in an inert gas environment, heating to the dynamic strain ageing temperatures of the metal sheet I and the metal sheet II, welding a filler wire in a seam zone by adopting fiber laser, putting the welded metal sheets in a liquid nitrogen environment, and emitting high-energy short pulse laser to carry out double-side laser impact on the metal sheets covered with an aluminum foil. The filler wire is welded for the metal sheets through laser at the dynamic strain ageing temperatures, so that the seam quality of a metal welding joint is greatly improved, and the seam zone is combined tightly with the metal sheets; and by laser impact strengthening treatment of the welding joint and the metal sheets in the same working environment at an ultra low temperature, ultra low temperature corrosion resistance and mechanical property of a metal welding member are remarkably improved.

Owner:ZHANGJIAGANG FURUI HEAVY EQUIP CO LTD

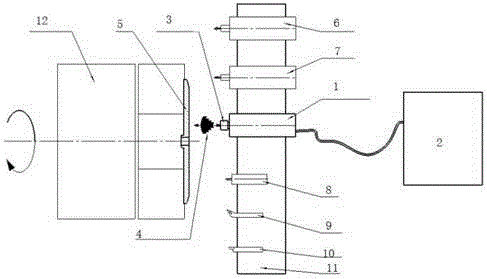

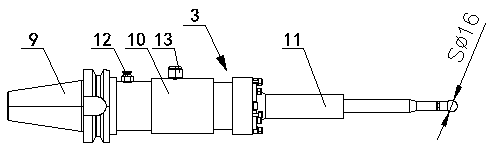

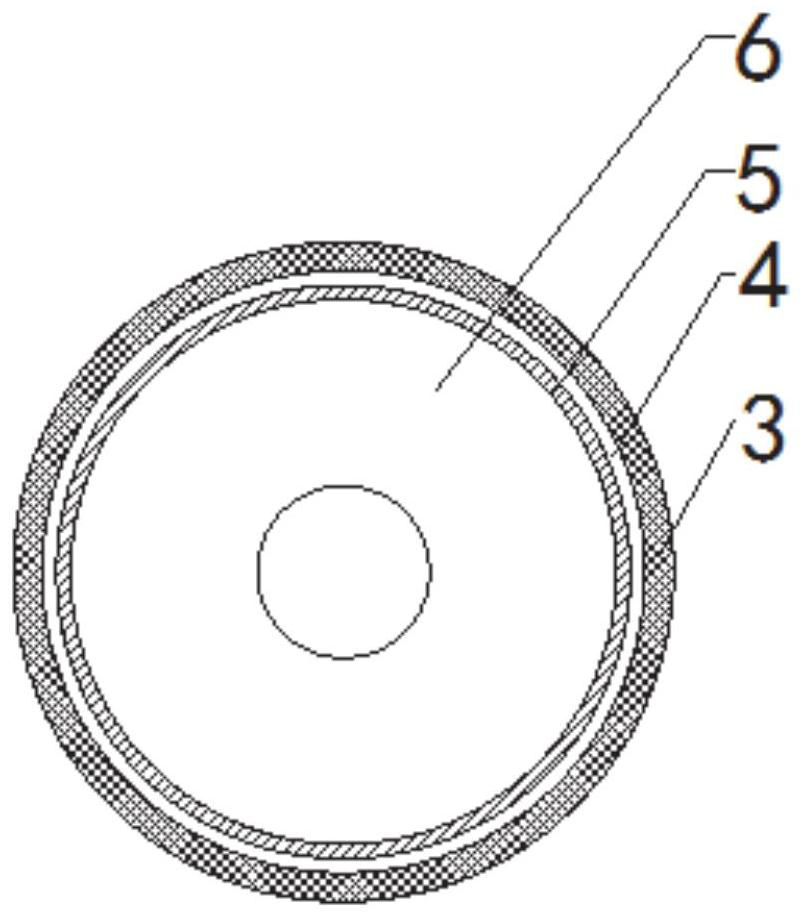

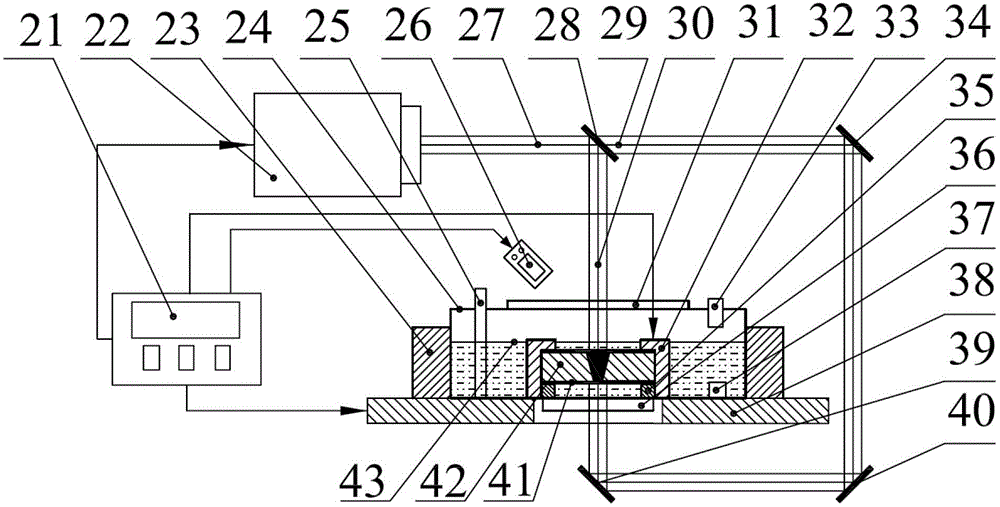

Method and device for forming micro-texture in composite mode on inner surface of cylinder sleeve through laser

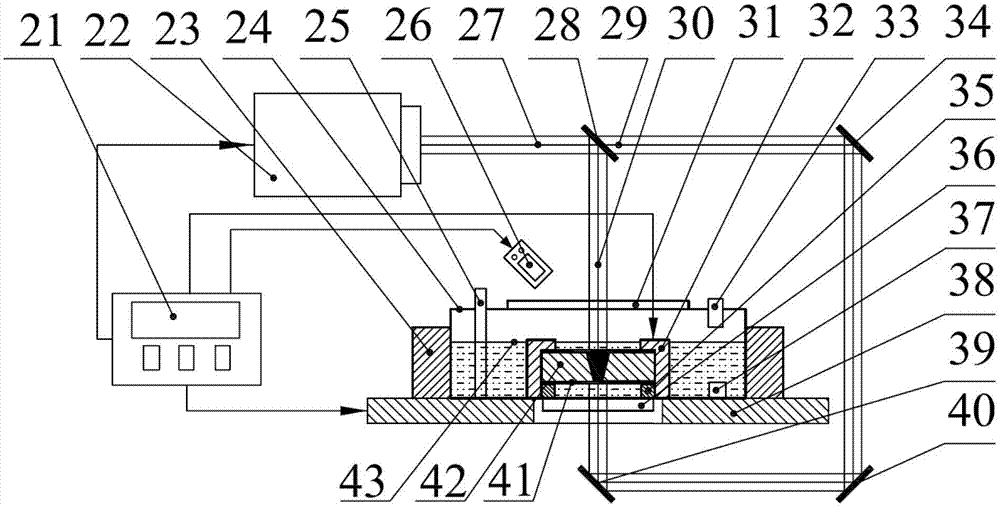

InactiveCN103111752AImprove mechanical propertiesImprove friction performanceLaser beam welding apparatusFriction reductionShock wave

The invention provides a method for forming micro-texture in a composite mode on the inner surface of a cylinder sleeve through laser. The method comprises the following steps: step (1), a femtosecond laser device is used for processing a needed microcosmic shape on the inner surface of the cylinder sleeve; and step (2), a nanosecond laser device is used for strengthening the area of the microcosmic shape processed in the step (1) through laser shock waves. Under the condition of dry friction, micro-concave surface texture can be used as a storage device for storing wear particles to reduce abrasive wear and furrows on the friction surface, and therefore the wear rate is lowered. The laser shock waves can eliminate residual tension after the micro-texture is formed on the inner surface of the cylinder sleeve, and therefore deep residual compressive stress is formed, grain refinement is enabled to be more uniform, the hardness, the abrasive resistance and the anti-fatigue performance of the cylinder sleeve are improved, and the service life of the cylinder sleeve is prolonged. The invention further provides a device for forming the micro-texture in the composite mode on the inner surface of the cylinder sleeve through the laser at the same time.

Owner:WENZHOU UNIVERSITY +1

Method for preparing composite brush plated deformation line diamond wire saw

InactiveCN102220623APlay a stirring roleReduce concentration polarizationElectrolytic coatingsMetal sawing toolsDiamond wire sawMegasonic cleaning

A method for preparing a composite brush plated deformation line diamond wire saw, comprising the following steps of: preparing materials, selecting diamond or surface metallized diamond and nonconductive free particles, ultrasonically washing, using distilled water to repeatedly wash and bake; taking a straight line metal wire with the diameter of 0.1-2 mm as a cathode and an electric brush plating pen as an anode, washing the metal wire, pre-brush plating the metal wire, and then washing with deionized water; electric brush plating an amorphous state plating layer, taking pre-brushed plated metal wire as a cathode and the electric brush plating pen as the anode, and electric brush plating the amorphous state plating layer to obtain the diamond wire saw; and deforming the diamond wire saw through a deformer, thermally processing to obtain a latter deformation line diamond wire saw. The preparation technology has a simple device, high production efficiency, and recycle use of plating solution; and the produced wire saw has few shortcoming, a good performance and a long service life.

Owner:长沙和谦新材料科技有限公司

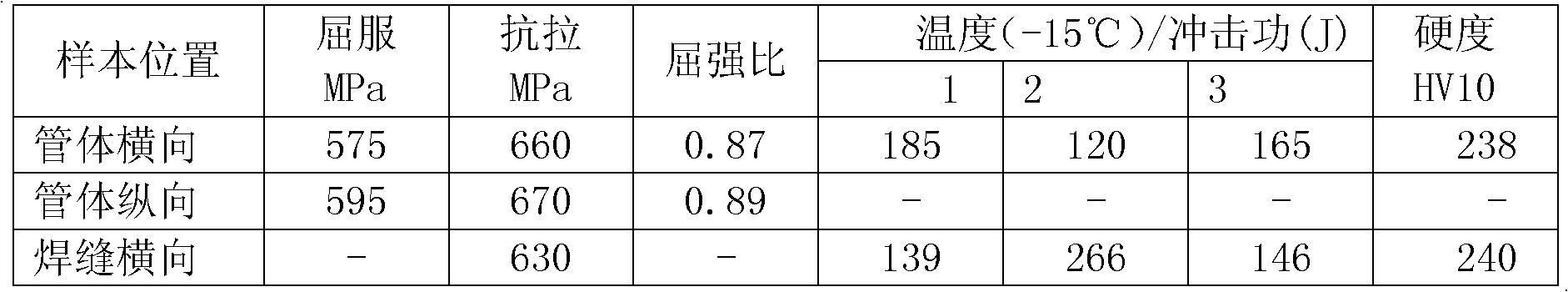

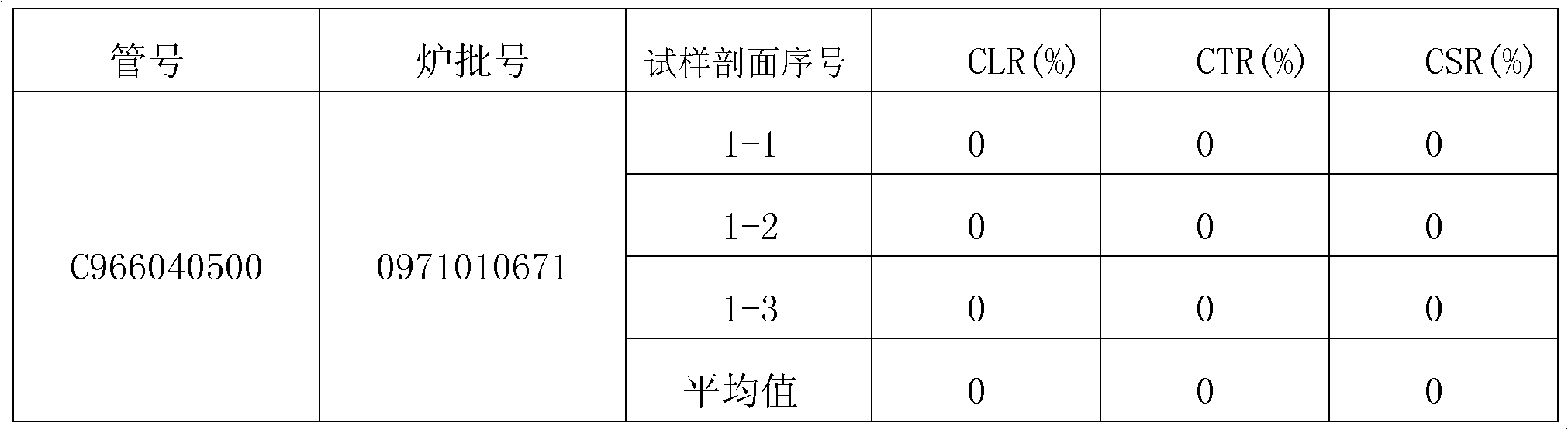

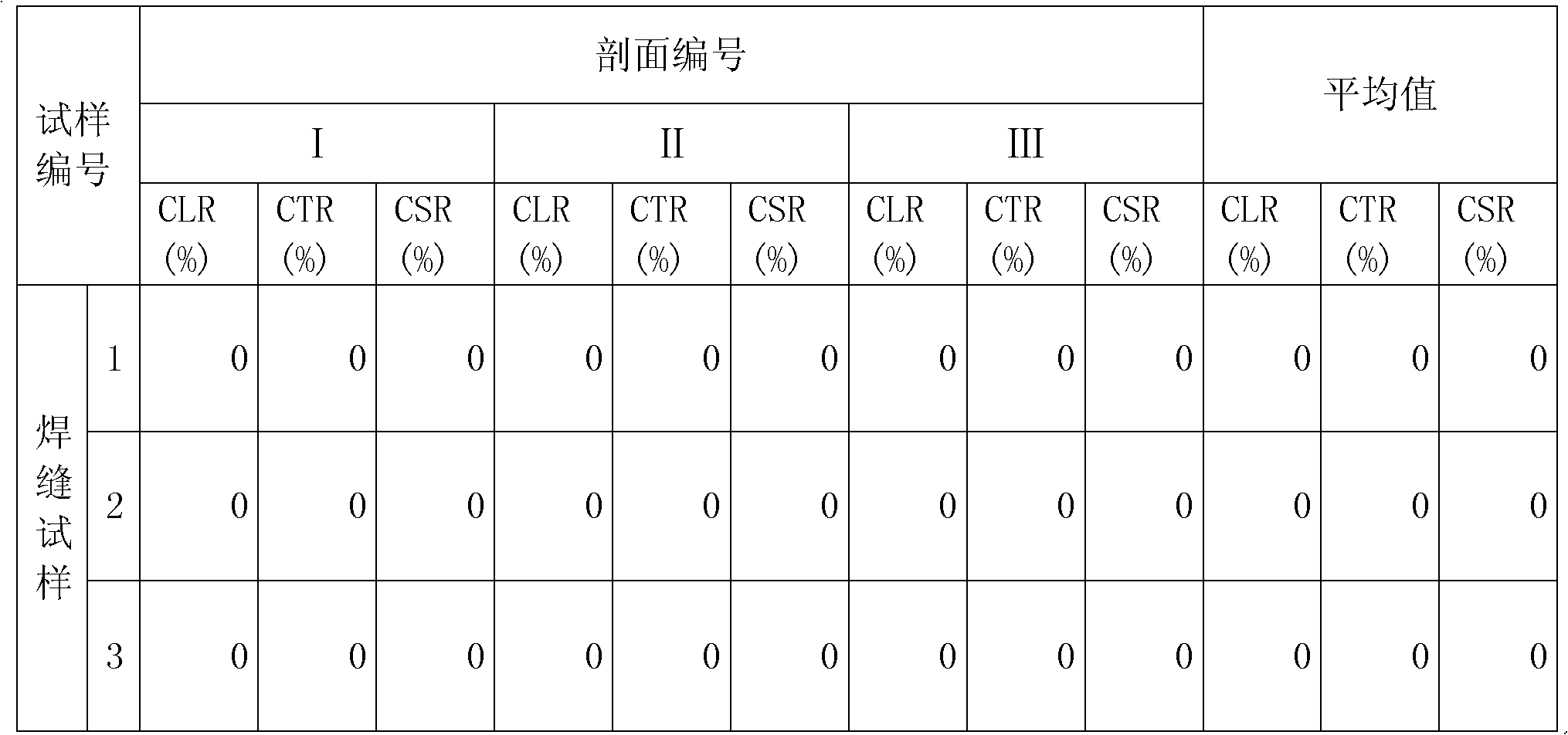

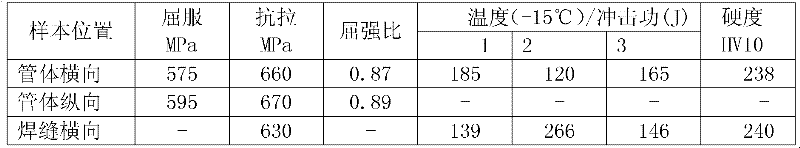

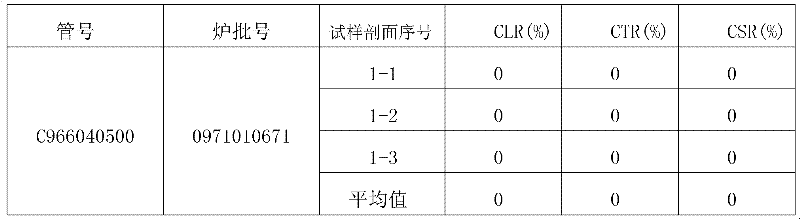

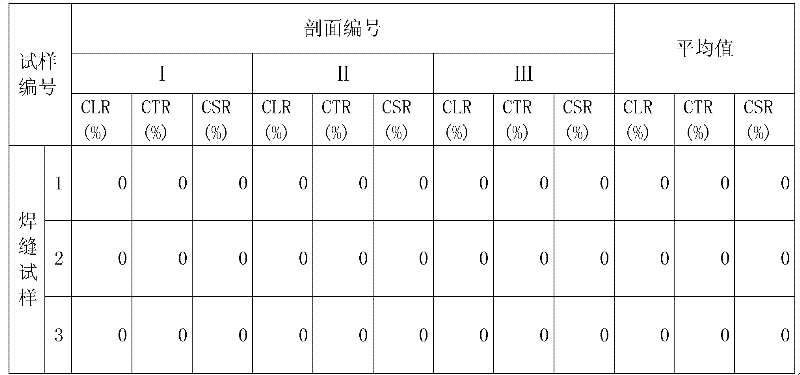

Method for manufacturing delivery steel pipe serving acid environment

InactiveCN102121081AGuaranteed corrosion resistanceFulfil requirementsHigh frequency current welding apparatusWelding/soldering/cutting articlesCrack resistanceIntermediate frequency

The invention discloses a method for manufacturing a delivery steel pipe serving an acid environment. The steel pipe comprises the following chemical components of raw materials in percentage by weight: less than or equal to 0.1 percent of C, less than or equal to 1.6 percent of Mn, less than or equal to 0.02 percent of P, less than or equal to 0.002 percent of S, less than or equal to 0.15 percent of Nb, V and Ti, less than or equal to 0.22 percent of Pcm, more than or equal to 1.5 percent of Ca / S and the balance of Fe. High frequency induction welding is adopted in welding of the steel pipe; the welding quality is improved in the welding process by increasing the welding extrusion quantity, controlling the open angle of seams and increasing welding protective gas; and on-line quenching and on-line tempering are performed in heat treatment of the seams by adopting six intermediate frequency heat treatment machines. By selection of raw material components and metallographic structures, completeness of a welding mechanism and improvement of the heat treatment process, the steel pipe has hydrogen induced cracking resistance and sulfide stress corrosion resistance and has high strength and high pressure resistance, the cost can be reduced, and the use of the steel pipe under the acid serving condition can be met.

Owner:CHINA NAT OFFSHORE OIL CORP +2

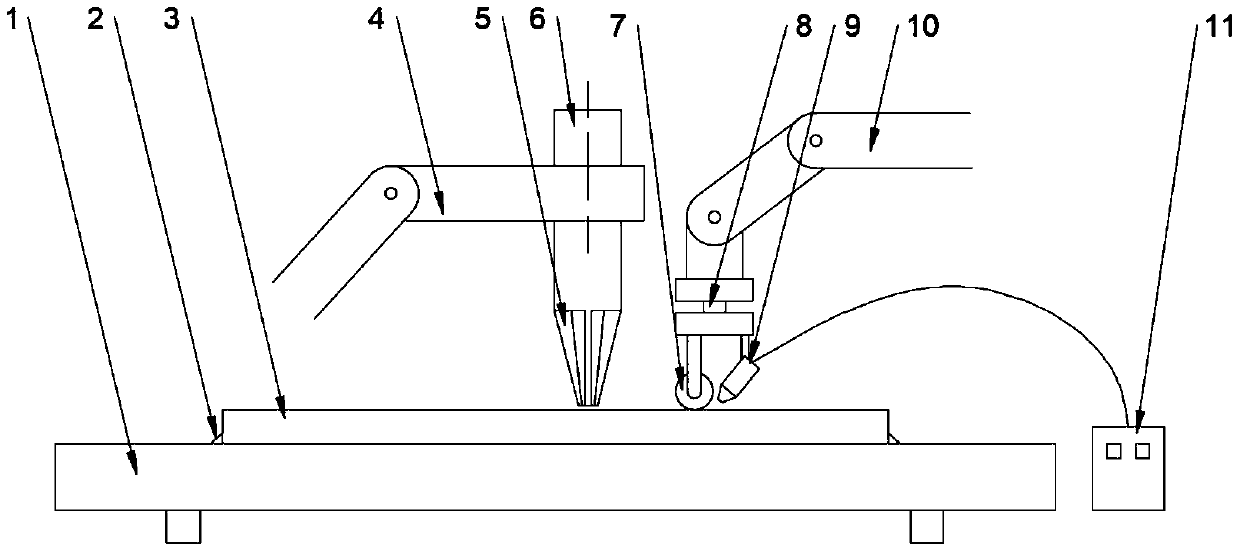

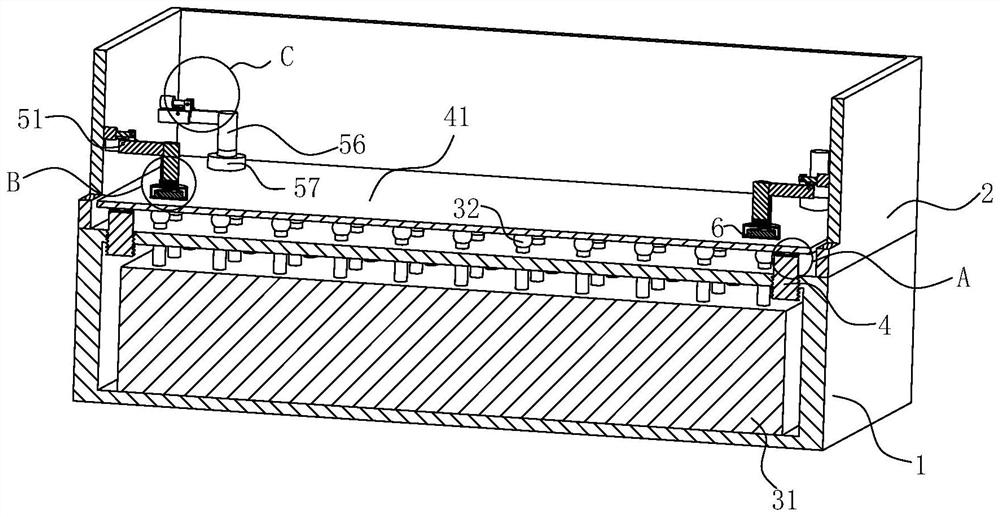

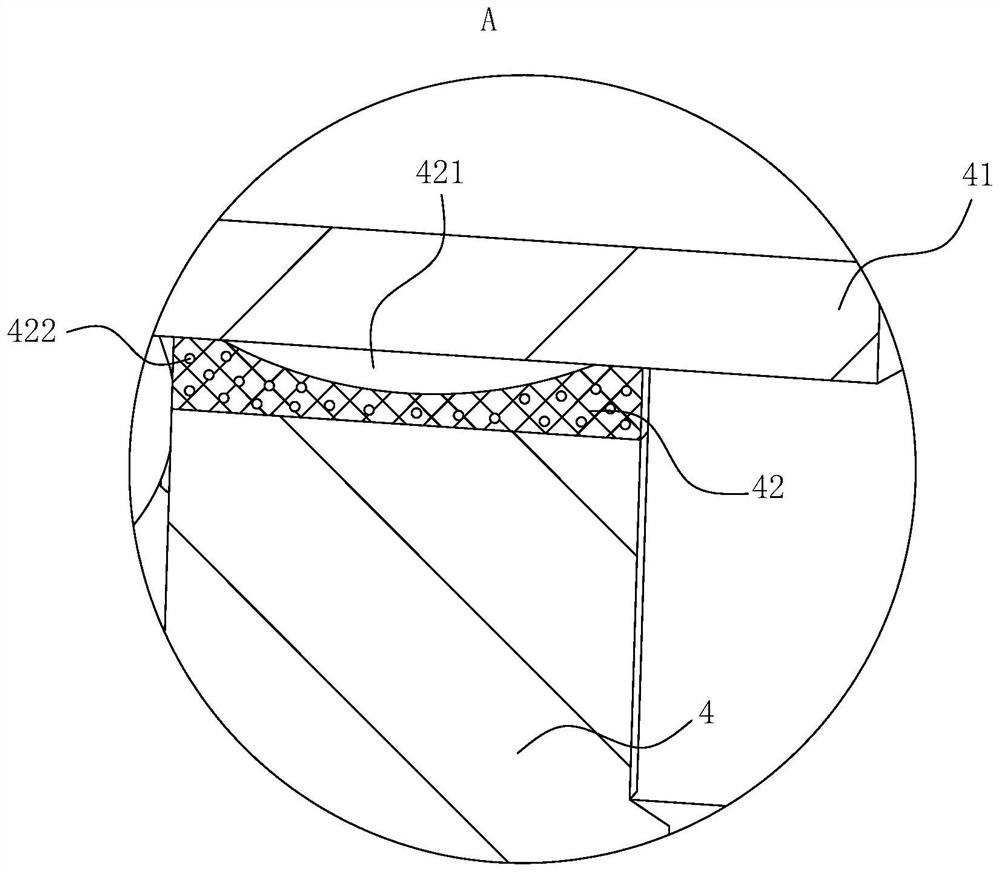

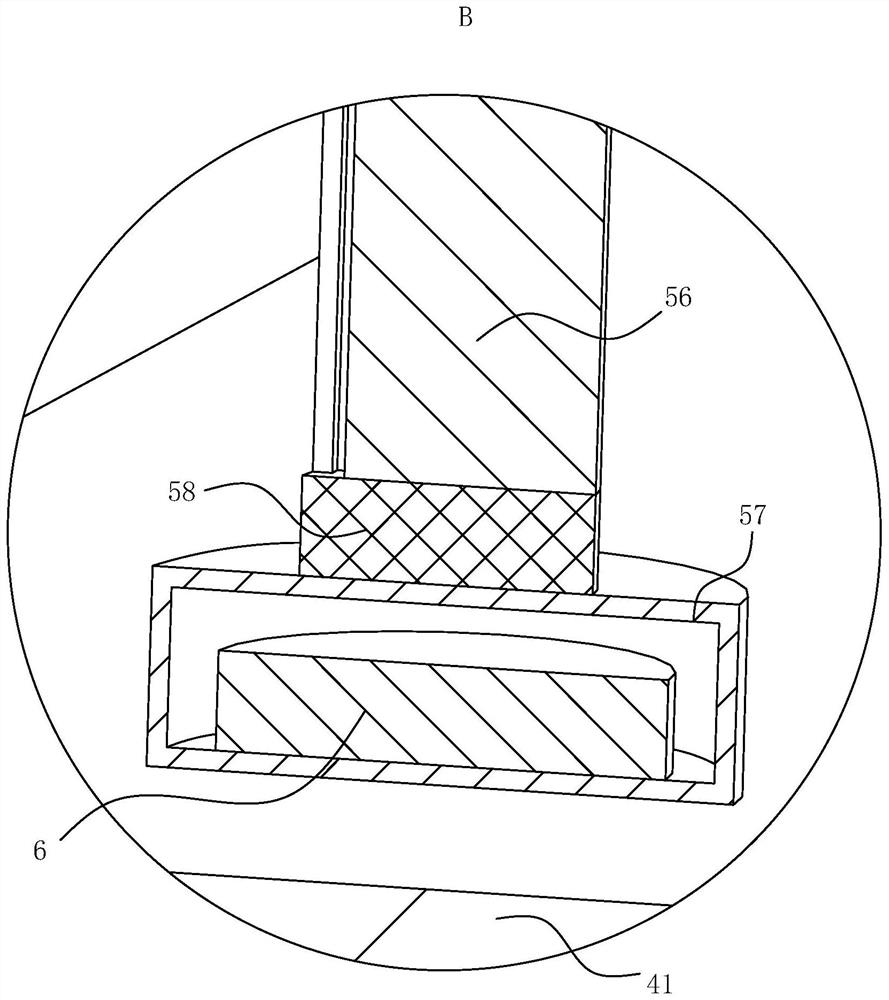

Micro rolling and ultrasonic-assisted laser cladding device

PendingCN110643996AEliminate residual tensile stressReduce residual tensile stressMetallic material coating processesLaser scanningEngineering

The invention relates to a micro rolling and ultrasonic-assisted laser cladding device, in particular to strengthening to the surface of a cladding layer. The device comprises a workbench, a fixed check block, a workpiece, a first mechanical arm, a synchronous powder feeder, a laser device, a micro roller, a rotating device, an amplitude-change pole, a second mechanical arm and an ultrasonic generator. During laser cladding, the micro rolling technology and the ultrasonic technology are used for assistance, and adverse effects left during pure laser scanning can be eliminated to the largest degree by means of the combination. By means of micro rolling, dendritic crystalline lenses generated during cooling of the cladding layer are ground through the micro roller, the crystal structure is refined, and air pores are effectively suppressed. By means of the ultrasonic technology, residual tension generated during temperature decrease of the cladding layer is eliminated, and cracks are effectively reduced. The micro rolling technology and the ultrasonic technology are applied to the laser cladding layer, and compactness, isotropy and other properties of the cladding layer are further improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for manufacturing pre-deformation line diamond line saw through powder metallurgy

InactiveCN102218537AImprove gripExtended service lifeMetal sawing toolsStone-like material working toolsBLENDER/MIXERPre deformation

The invention provides a method for manufacturing a pre-deformation line diamond line saw through powder metallurgy, comprising the following steps: basic line manufacturing: selecting metal wires, stranding at least two metal wires into a line, and deforming the stranded line by a deformer to obtain a pre-deformation base line; powder preparation: weighing metal powder, a binder and diamond by mass percent, and adding the mixture into a blender mixer to evenly mixing; line blank manufacturing: putting the base line and powder into a mould, and taking the pre-deformation base line as a center to prepare a line blank by using a forming technology; and line saw manufacturing: putting the line blank to a sintering furnace for sintering, and cooling with the furnace to obtain the line saw. The manufacturing method provided by the invention has the advantages of simple process, low cost and high production efficiency. The produced line saw has excellent performance, high strength, good flexibility, high hold to diamonds, stable cutting performance, good chip discharging performance and long service life, and is not easy to crack.

Owner:长沙和谦新材料科技有限公司

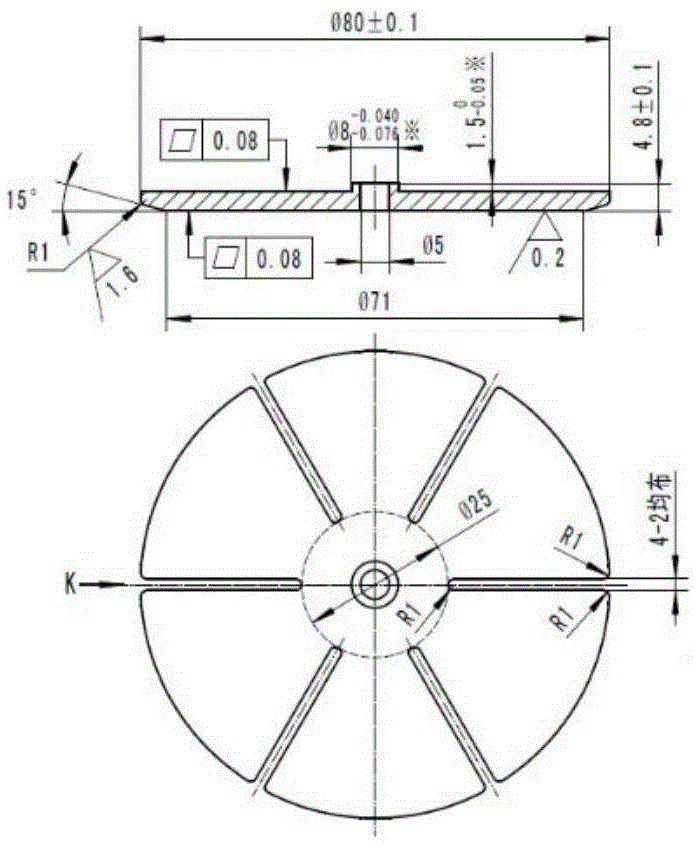

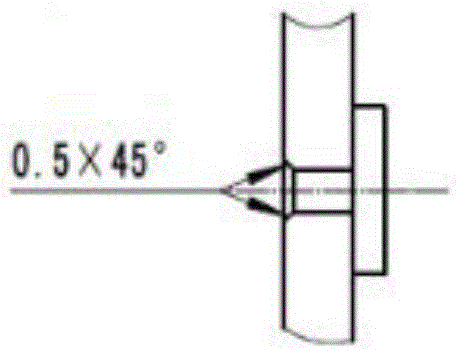

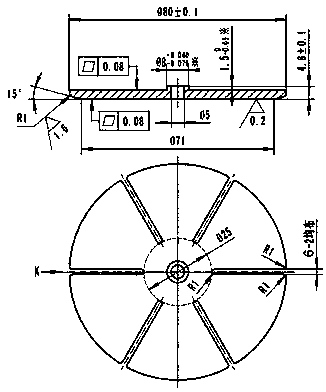

CuCr contact surface finishing equipment and method

The invention relates to CuCr contact surface finishing equipment and method. The equipment is a turning and milling composite machine tool additionally provided with a Hawking tool assembly directly installed on a machine tool row tool support plate of the turning and milling composite machine tool. The method comprises steps including blank preparation, turning I, turning II, Hawking finishing, milling of six grooves, cleaning and drying, turning III, appearance treatment, final inspection and vacuum packaging. Micro impact extrusion deformation is formed on contact surfaces under the combined action of high-frequency vibration impact energy and Hawking energy of Hawking metal machining equipment, so that the surface roughness of a CuCr contact material can be increased to Ra2.0 or below, the mirror effect can be realized, and the requirement of special use occasions of the CuCr contact material for working surface Ra2.0 or below is met.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

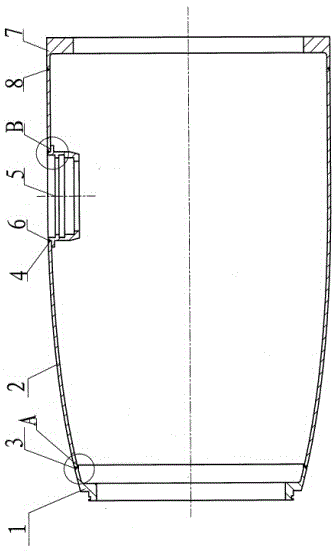

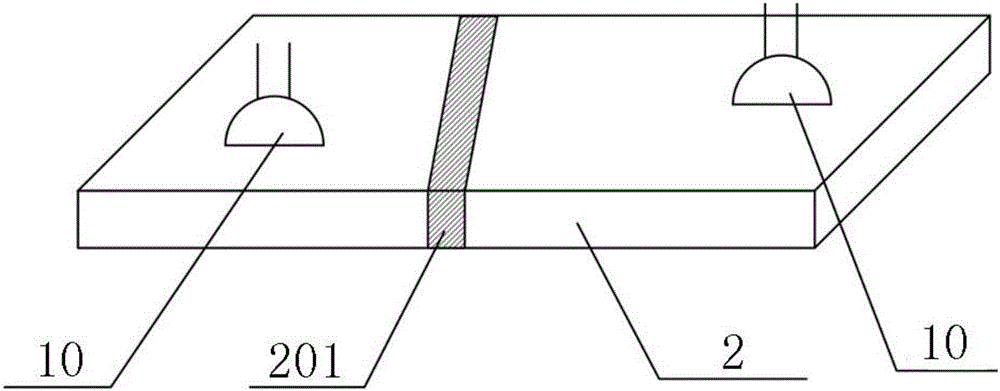

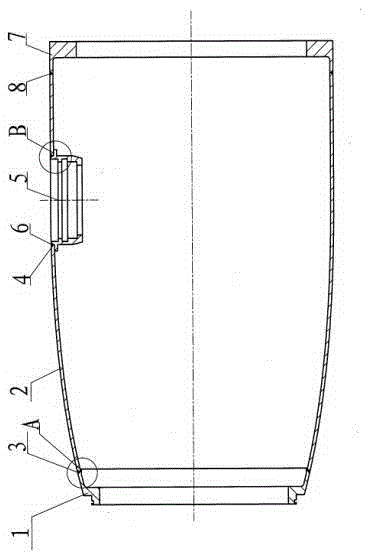

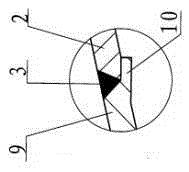

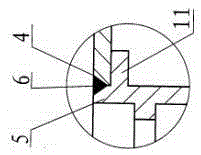

Destressing warhead-curve-shaped aluminum alloy thin-walled cylinder and machining process of destressing warhead-curve-shaped aluminum alloy thin-walled cylinder

ActiveCN104084771AImprove the qualified rate of flaw detectionImprove welding strengthCurve shapeWeld strength

The invention discloses a destressing warhead-curve-shaped aluminum alloy thin-walled cylinder and a machining process of the destressing warhead-curve-shaped aluminum alloy thin-walled cylinder. The destressing warhead-curve-shaped aluminum alloy thin-walled cylinder and the machining process solve the problems that an existing thin-walled cylinder is not thorough in destressing and the welding strength of weld joints can be easily lowered due to machining. The destressing warhead-curve-shaped aluminum alloy thin-walled cylinder comprises a warhead-curve-shaped thin-walled cylinder body (2), a front flange (1) and a rear flange (7). A front annular weld joint (3) in the perpendicular direction is arranged between an annular groove (10) of an annular cylinder body (9) arranged on the side face of the rear end of the front flange (1) and the front end of the warhead-curve-shaped thin-walled cylinder body (2). A hole base hole (4) is formed in the cylinder wall of the warhead-curve-shaped thin-walled cylinder body (2), and an positioning annular step (11) is arranged on the outer side wall of a hole base (5). The invention discloses an effective method for removing welding stress of the thin-walled cylinder. By means of the destressing warhead-curve-shaped aluminum alloy thin-walled cylinder and the machining process, surface residual tension of the thin-walled cylinder is effectively eliminated, the material structural strength is improved, and the fatigue life is prolonged.

Owner:SHANXI FENXI HEAVY IND

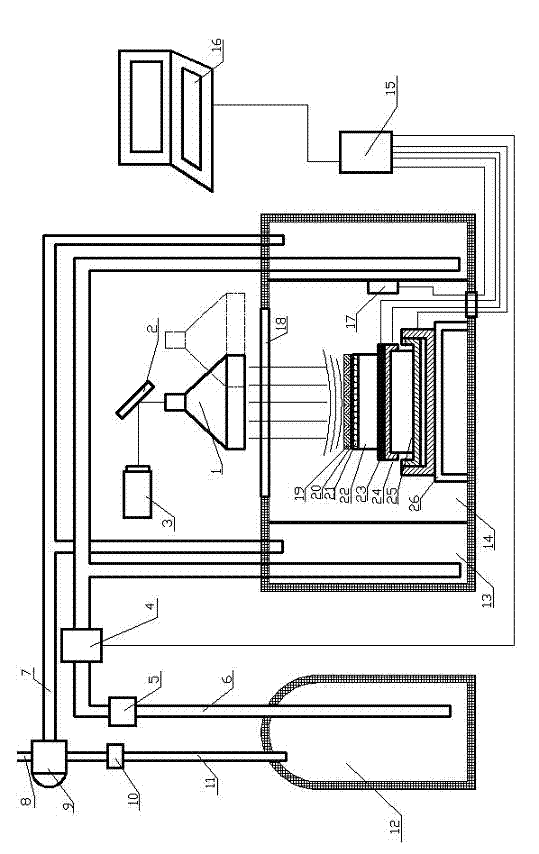

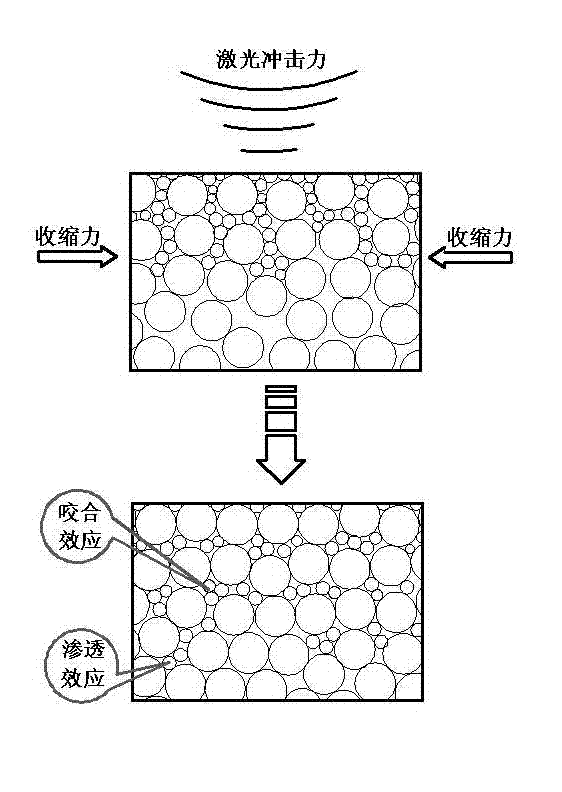

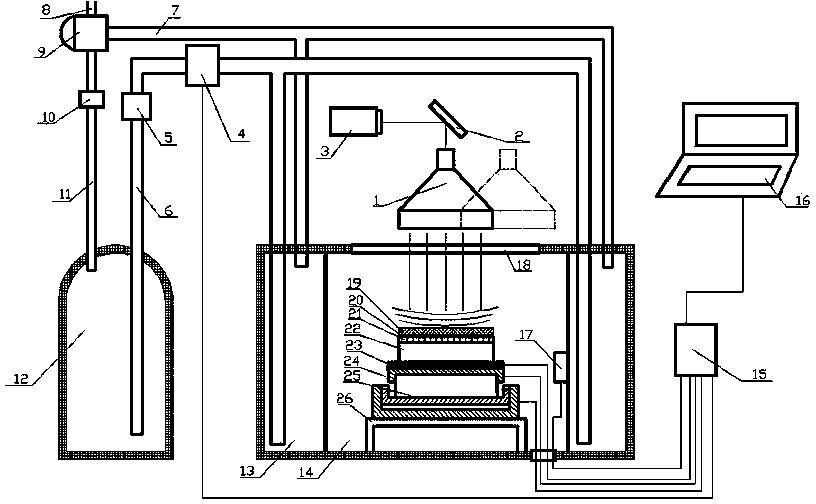

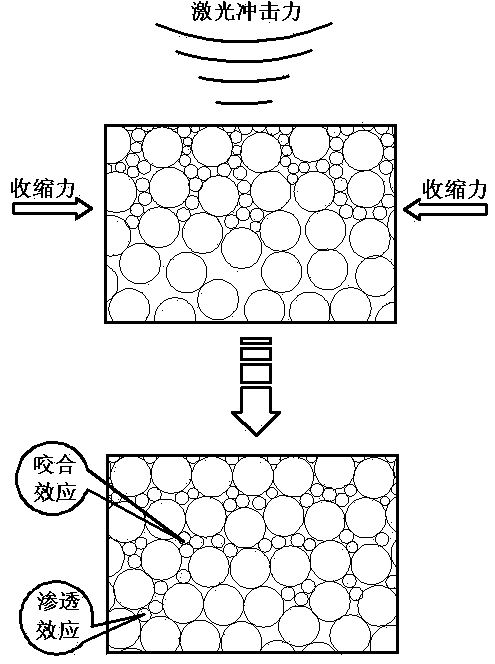

Method for obtaining high-adhesion nano coating and device thereof

ActiveCN102776506AEliminate residual tensile stressImprove adhesionPressure inorganic powder coatingOcclusion effectImpact system

The invention discloses a method for obtaining high-adhesion nano coating and a device thereof. The method comprises the following steps: impacting nano powder at 80-150 degrees centigrade by laser induction to obtain a nano coating, then, carrying out impacting treatment on the coating by laser induction at ultralow temperature by dint of ultralow temperature constant-high-pressure block and extrusion technology; and the device comprises a laser induction impacting system, a deep cooling treatment system, an auxiliary control system, an adjustable working platform, a heating platform and the like. According to the invention, the ultralow temperature constant-high-pressure block and extrusion technology is used; at the ultralow temperature, a base body is contracted sharply; the base body is prevented from outwardly extruding the coating by laser induction impact force; thus, the coating and the base body are contracted at constant high pressure; finally, coating atoms are combined with base body atoms more compactly; in addition, occlusion effect and penetration effect happen so as to fundamentally solve a difficult problem of poor adhesion of the coating and the base body.

Owner:SANMENXIA ZHONGYUAN PRECISION

Method for realizing stress corrosion resistance of stainless steel welding connector impacted by nanosecond-pulse laser

ActiveCN106834659ANo obvious mechanical forceFast processingFurnace typesHeat treatment furnacesWeld seamNanosecond pulse

The invention provides a method for realizing stress corrosion resistance of a stainless steel welding connector impacted by nanosecond-pulse laser. According to the method, a welding seam is impacted by adopting laser along an S shape, and an outer region of the welding seam is impacted along a direction parallel to the welding seam, so that pull stress of the welding connector is eliminated. By reasonably selecting power density, phase change does not occur and residual pull stress can be eliminated, so that a condition that the stress corrosion resistance performance of the welding connector is reduced is avoided. According to the method provided by the invention, the surface of a workpiece is impacted through the nanosecond-pulse laser, and no obvious mechanical force is used; a machining speed is rapid and automation is easy to realize; a complicated mold surface can be impacted.

Owner:AIR FORCE UNIV PLA

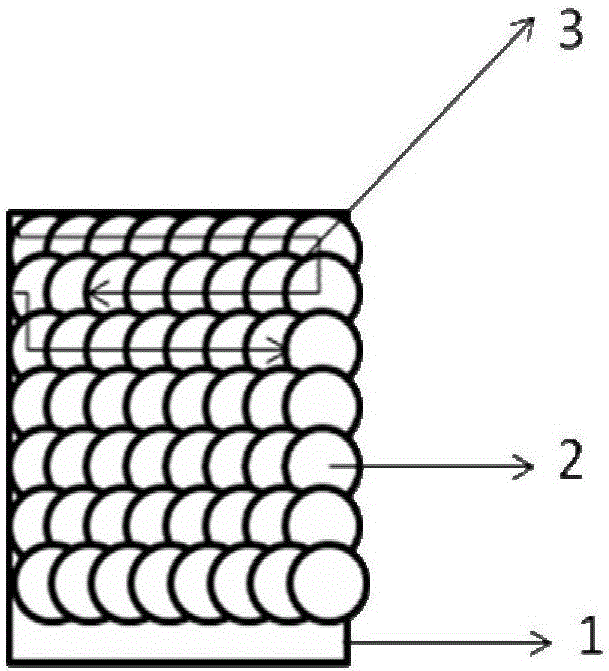

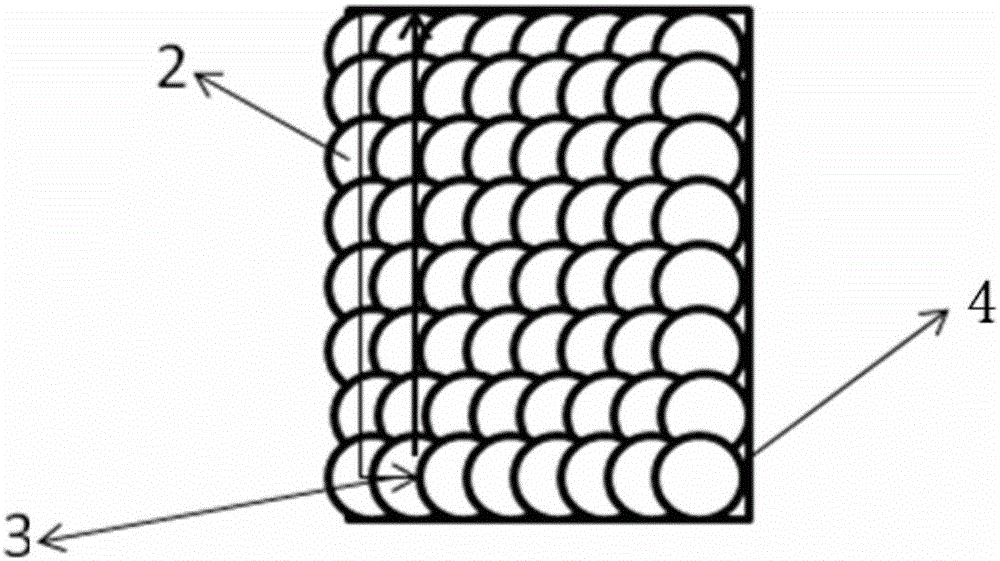

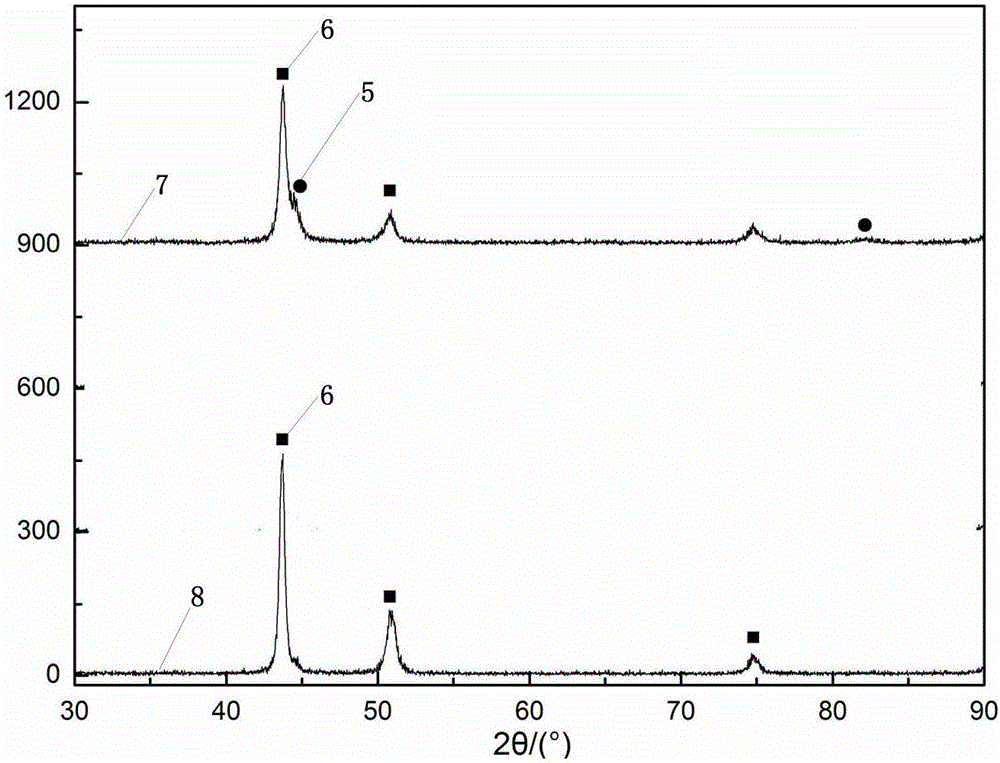

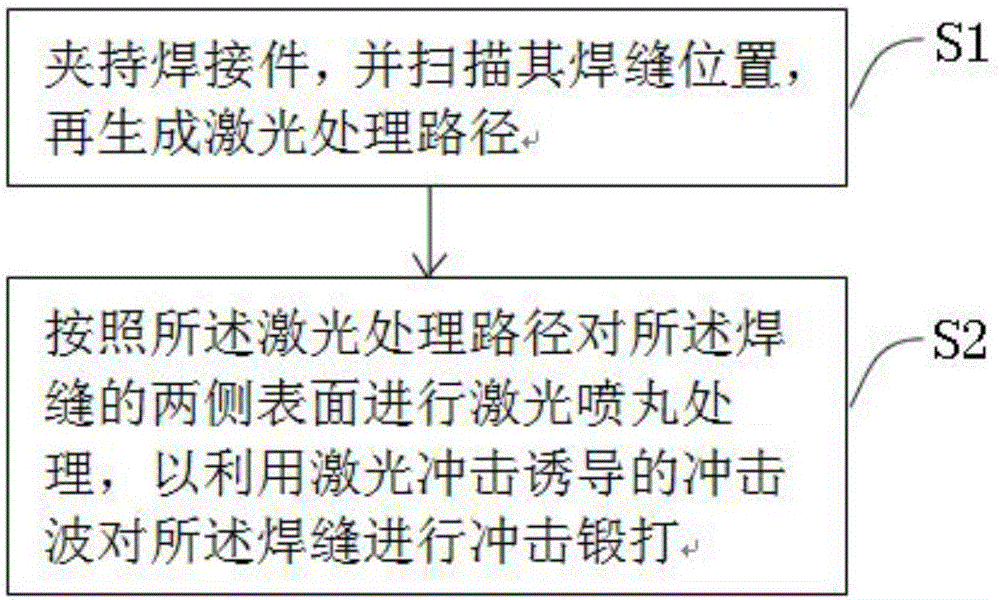

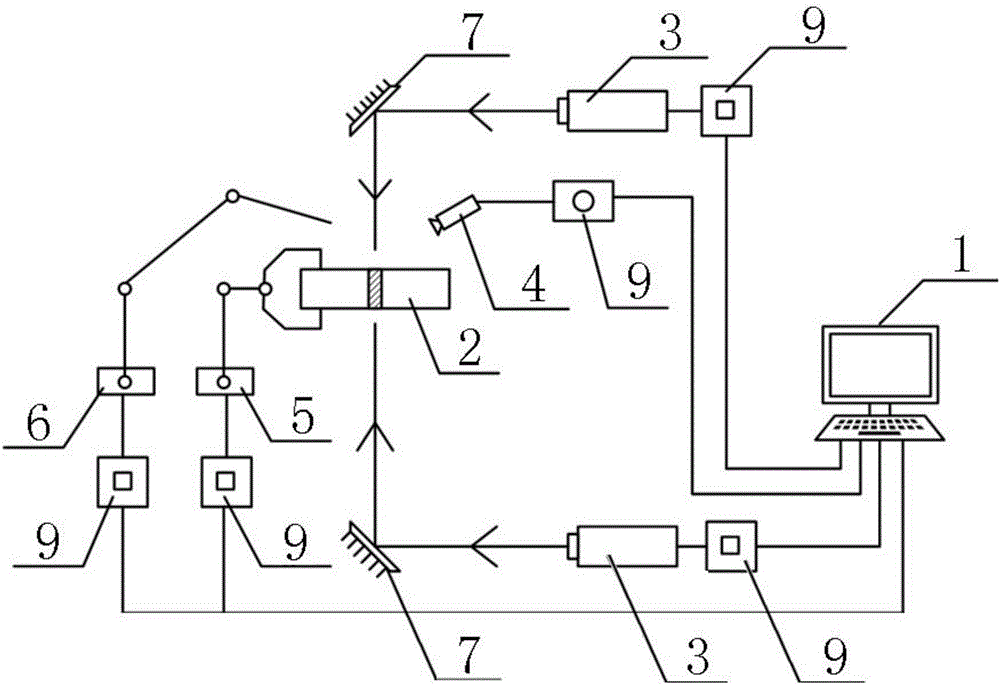

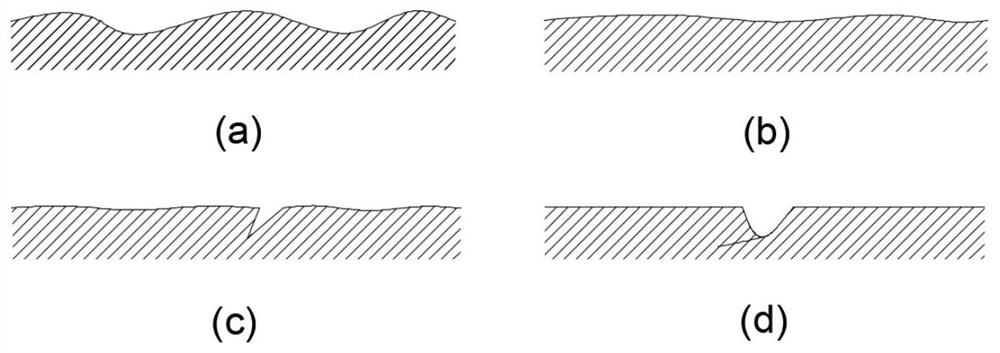

Laser peening weight-reducing method and device for riveting-altered-to-welding structure of metal thin-walled part

InactiveCN106826248AImprove processing efficiencyImprove processing qualityOther manufacturing equipments/toolsShock waveOptoelectronics

The invention discloses a laser peening weight-reducing method and device for the riveting-altered-to-welding structure of a metal thin-walled part. The method includes: clamping a welded part, and scanning a weld joint position to generate a laser processing path; performing laser peening on the surfaces on two sides of the weld joint according to the laser processing path. The laser peening weight-reducing method and device has the advantages that during the laser peening on the surfaces on two sides of the weld joint, shock waves induced by laser of certain power striking on the surface of the metal thin-walled part are used to perform the peening reinforcing on the surfaces of the weld joint, and accordingly the residual tension stress of the weld joint area is eliminated, the grains of the weld joint area are refined, dislocation density is increased, and weld joint strength is increased; the deformation of the welded part is partially corrected, the dimensional precision of the part is guaranteed; the weight of the metal thin-walled part in an aerospace device can be reduced, and the weld joint of the welded structure can be optimized to increase welding quality.

Owner:GUANGDONG UNIV OF TECH

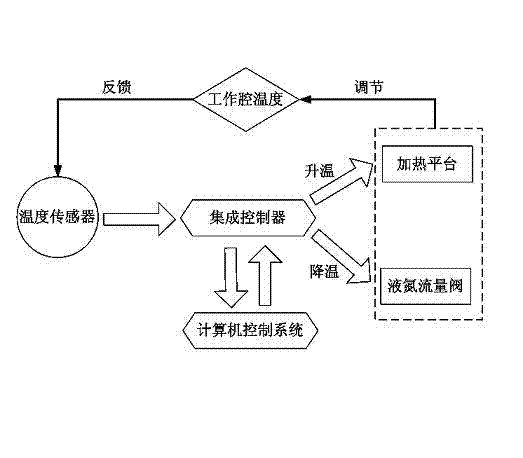

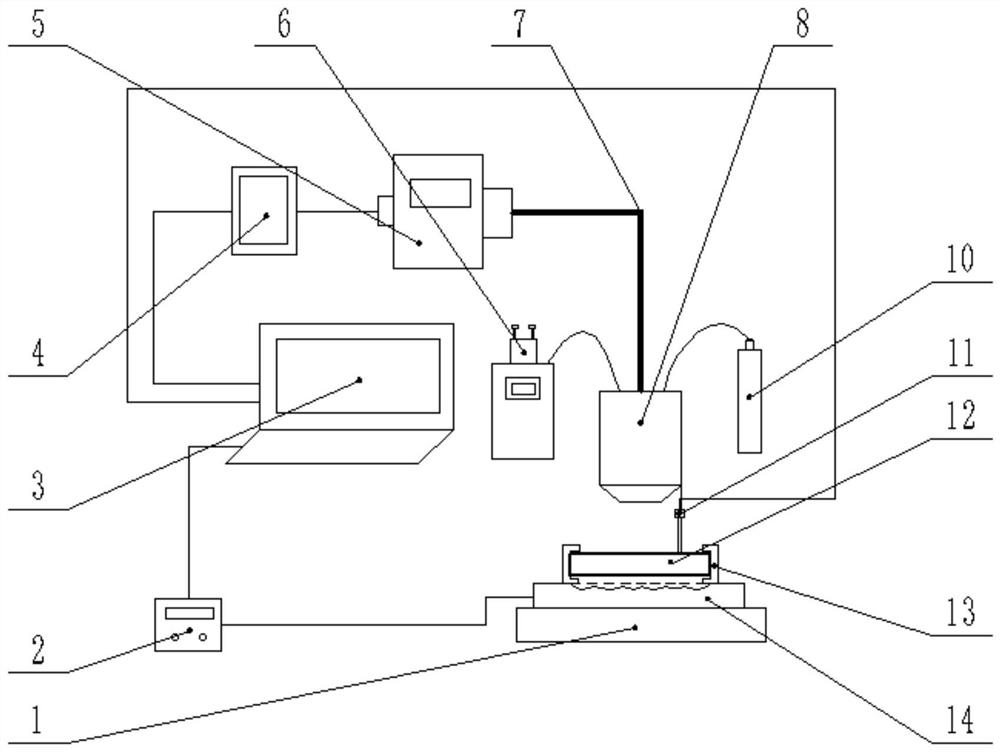

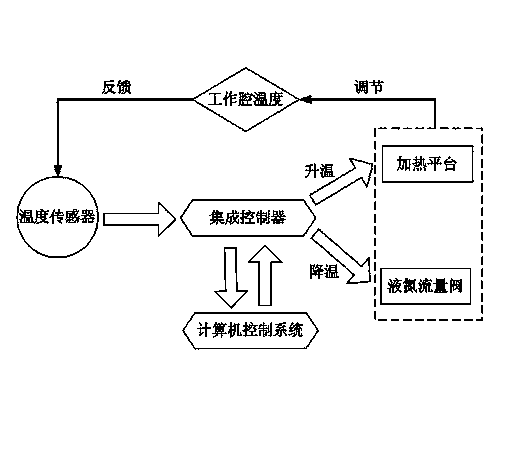

Laser cladding process and laser cladding repair processing system based on thermal aging treatment

PendingCN112760641ARealize dynamic temperature controlSmall temperature differenceMetallic material coating processesTemperature controlRoom temperature

The invention provides a laser cladding process based on thermal aging treatment. The laser cladding process comprises the following steps of (1) pretreating a cladding part and a flat sample; (2) clamping the flat sample, and arranging a heating device below a chuck clamp; (3) arranging a temperature sensor near a to-be-cladded area of the flat sample for detecting the cladding temperature; (4) carrying out a single-pass laser cladding test on the flat sample, and recording the temperature range achieved by the cladding surface under corresponding cladding process parameters; (5) clamping the cladding part on the chuck clamp, enabling a temperature control system to control the heating temperature of the heating device according to the recorded temperature range, performing dynamic temperature control on the cladding part, and maintaining the overall temperature of the cladding part within the temperature interval achieved by laser cladding; (6) setting the corresponding laser cladding process parameters, and carrying out laser cladding on the surface of the cladding part; and (7) after the cladding is finished, controlling to stop heating by the temperature control system, and slowly cooling to room temperature. According to the process, the generation of cladding cracks can be reduced, and the cladding quality and effect can be improved.

Owner:NANJING ZHONGKE RAYCHAM TECH

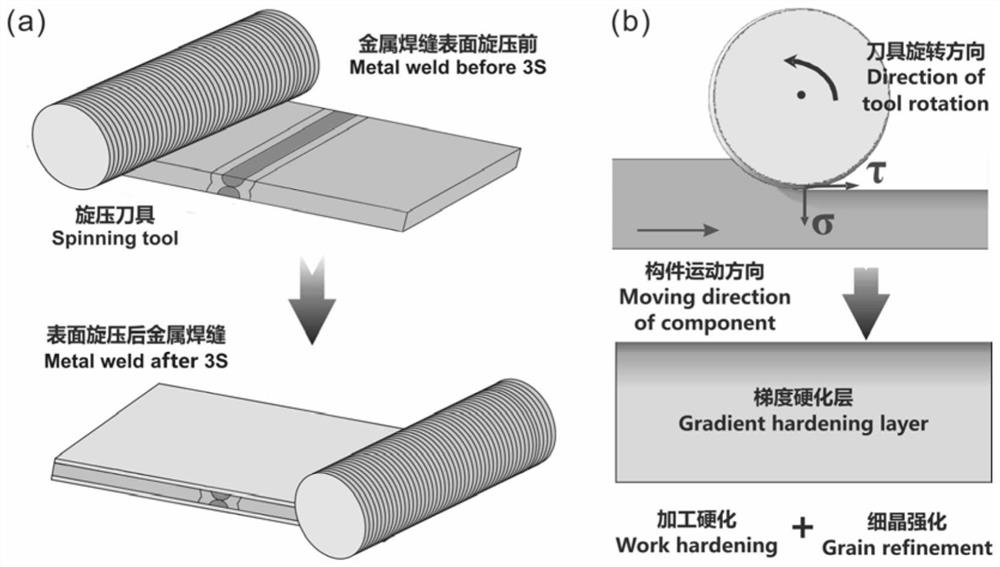

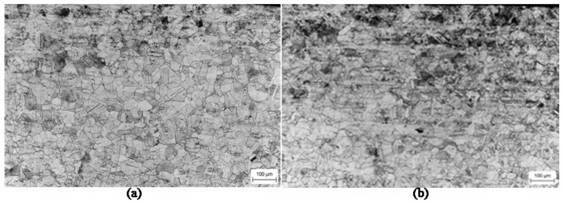

Welded joint fatigue life prolonging method

ActiveCN111069703AAchieving grain refinementAchieve refinementMachined surfaceStructural engineering

The invention discloses a welded joint fatigue life prolonging method and belongs to the technical field of surface strengthening processing for improving the fatigue property of a metal welding seam.According to the welded joint fatigue life prolonging method, the surface spinning strengthening technology is adopted to carry out surface strengthening processing on a welded joint so as to obtaina metal surface layer microstructure with hardness gradient, so that surface strengthening and hardening of the metal welded joint are realized; and in addition, the processing surface is smooth, so that the surface stress concentration level and the postwelding residual stress level of a welded component are lowered. When the metal welded component takes service under the action of cyclic load, afatigue crack can be restrained from generating on the surface of the welded joint after spinning processing to improve the fatigue property of the metal welded joint.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

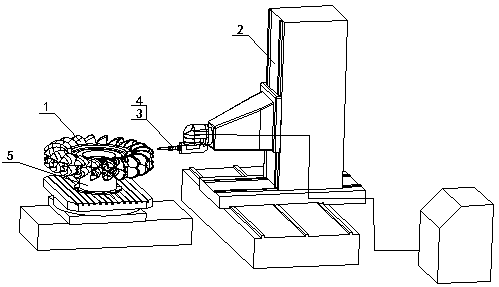

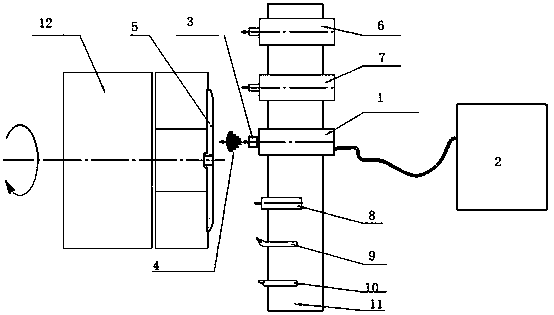

Surface recombination energy machining method for high-water-head impact type runner bucket

InactiveCN111168158AAchieving Fatigue-Resistant ManufacturingImprove fatigue resistanceNumerical controlCrazing

The invention discloses a surface recombination energy machining method for a high-water-head impact type runner bucket. The surface recombination energy machining method comprises the following stepsthat 1) clamping is conducted; 2) mounting is conducted; 3) the machining reference of a runner is determined; 4) a written machining program is executed by using a Hauck energy actuator A, and the surface of the runner bucket is machined; 5) a written machining program is executed by using a Hauck energy actuator B, and the root of the runner bucket is machined; and (6) after surface recombination energy machining of one bucket is completed through the step 4) and the step 5), indexing is conducted through a numerical control rotary workbench of a machining center, and machining of other water buckets one by one is achieved through the same steps. According to the surface recombination energy machining method for the high-water-head impact type runner bucket, anti-fatigue manufacturing of the root of the bucket is achieved, the anti-fatigue degree of the root of the bucket is improved, generation of fatigue cracks is reduced, mirror finishing of the inner side space molded surface ofthe bucket is achieved, a nano layer is directly machined on the inner side space molded surface of the bucket, residual tensile stress of the root of the bucket and a water cutting blade is eliminated, height-controllable pressure stress is preset, and the service life of the impact type runner is prolonged.

Owner:CHONGQING WATER TURBINE WORKS

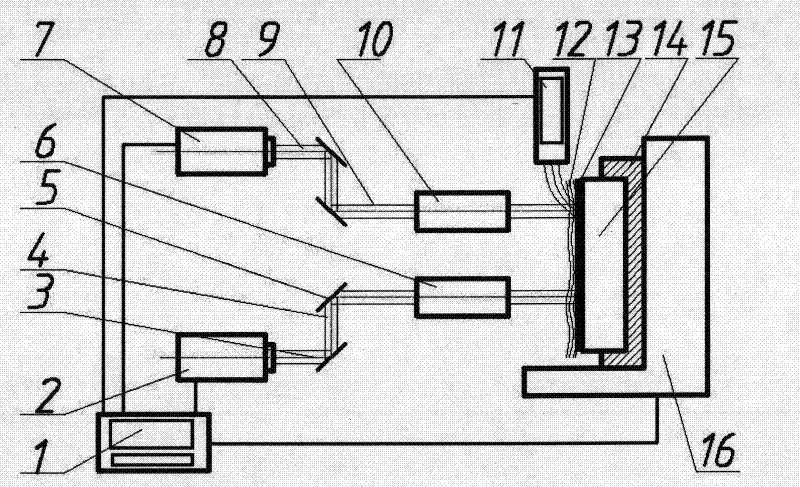

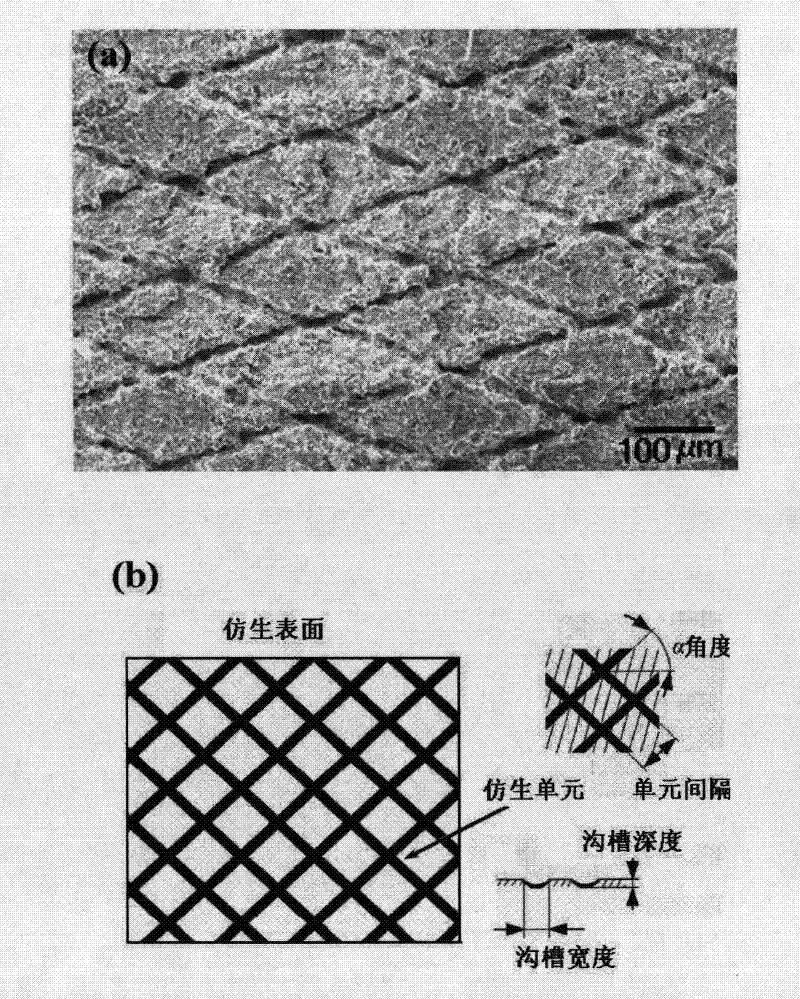

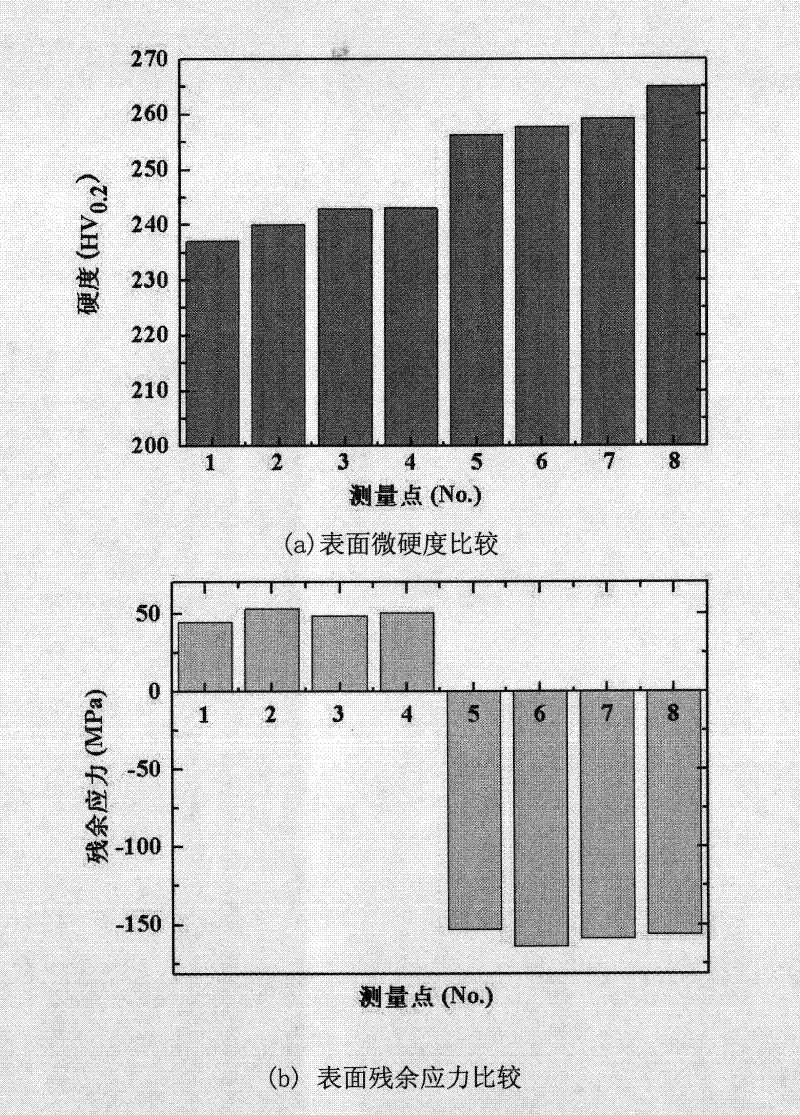

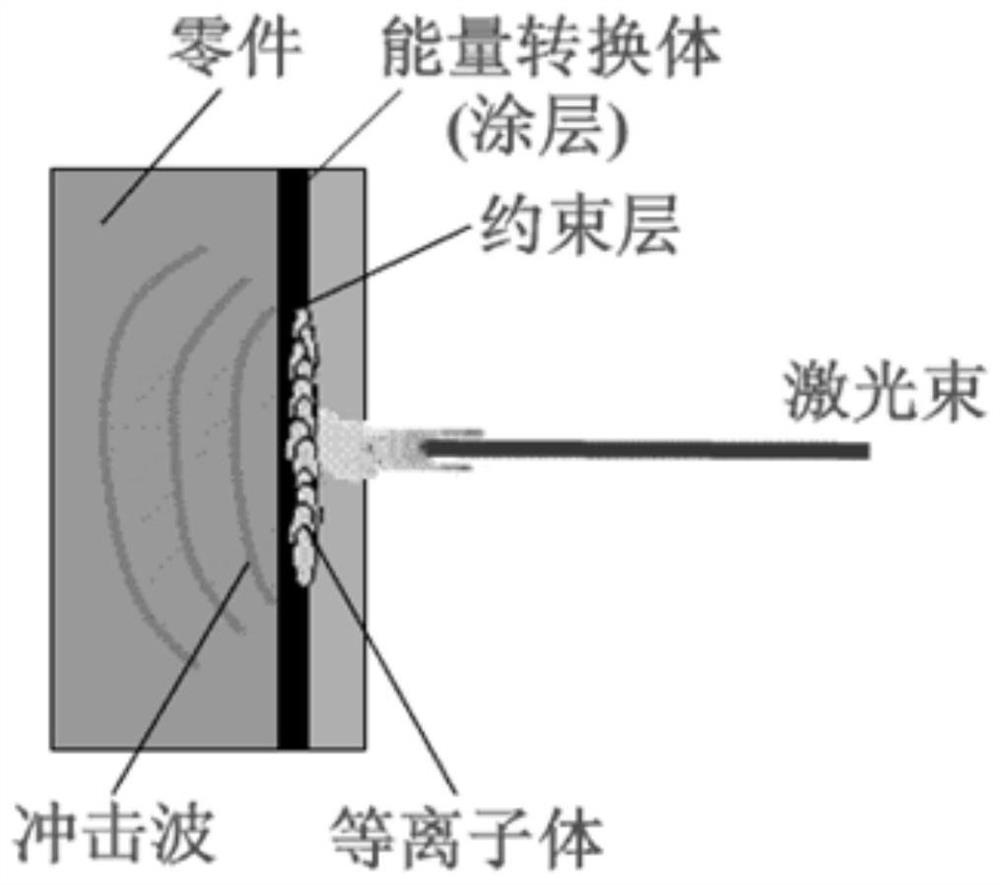

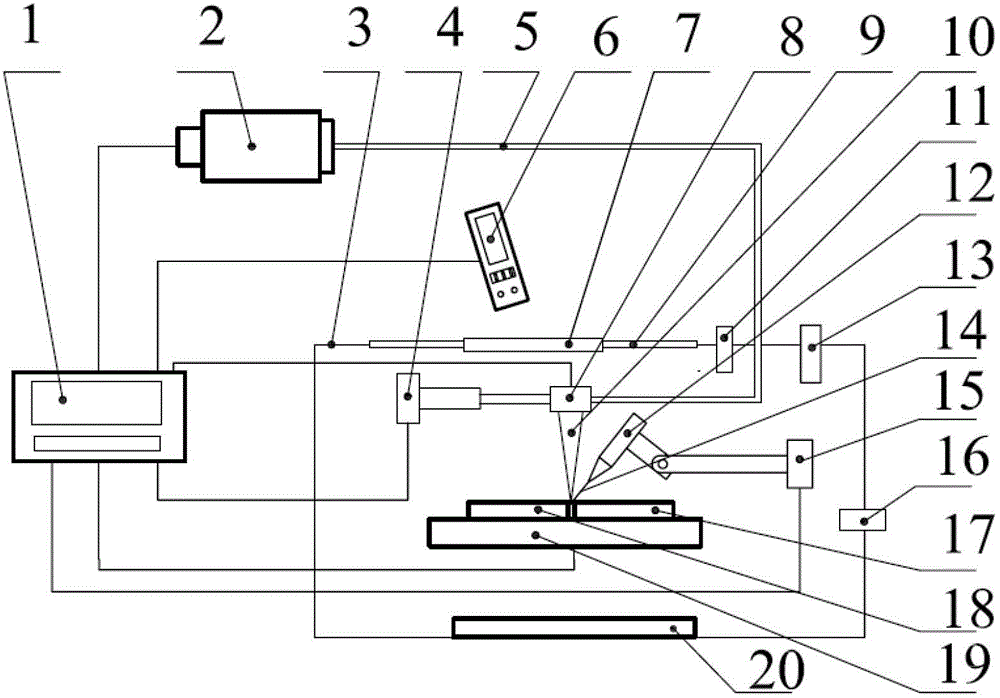

Method and device for compositely preparing surface-layer biomimetic structure by laser

InactiveCN101590569BNo wearSimple processLaser beam welding apparatusNanosecond laserLaser processing

The invention relates to the field of laser processing, in particular to a method and a device for compositely preparing a surface-layer biomimetic structure by mechanical effects based on laser carving and laser shock, which are particularly suitable for processing a biomimetic surface and a friction pair surface. The method is characterized by comprising the following steps: firstly preparing aregular micro geometrical appearance with certain density (space), width, depth, angle and shape on the surface of a workpiece by the laser carving technology; and then forcedly processing the micro geometrical appearance area by laser shock to process a microstructure which has the required shape and management mode and is optimally matched with the requirement of lubricating property on the surface of the workpiece. The device for the implementation method comprises a control device, a nanosecond laser generator, a laser beam I, a light guide tube I, a totally reflecting mirror I, a light spot adjusting device I, a fiber laser, a laser beam II, a light guide tube II, a totally reflecting mirror II, a light spot adjusting device II, an automatic spraying device, a restrain layer, an absorption layer, the workpiece, a workpiece fixture system and a five-axis working platform.

Owner:JIANGSU UNIV

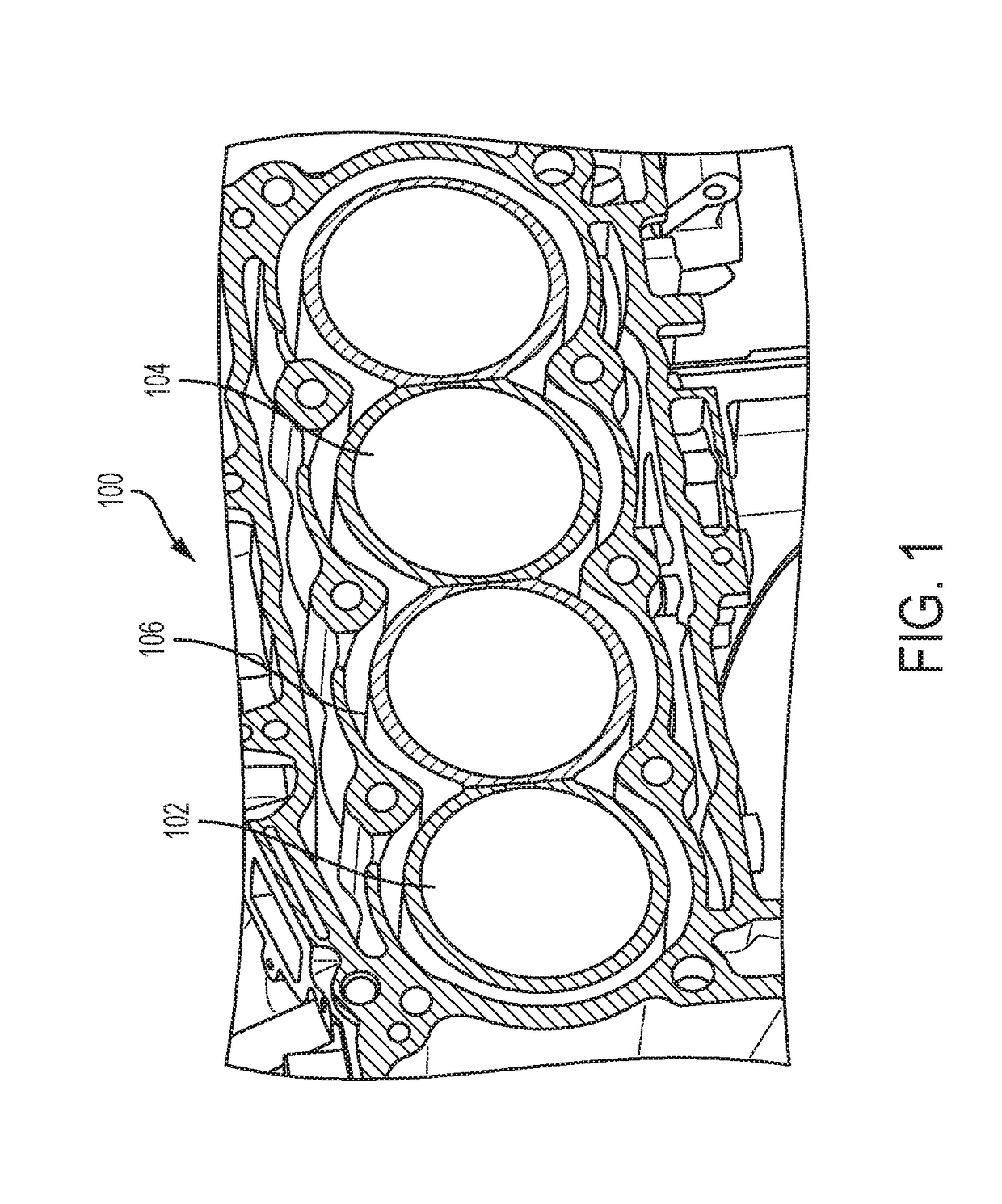

Method and system for processing an automotive engine block

ActiveUS20190032594A1Prevent intrusionReduce exposureCasingsCylinder headsThermal expansionEngineering

A method and system for processing an engine block that includes a cylinder liner. The engine block having a first material with different coefficient of thermal expansion than a second material forming the cylinder liner. The method includes providing an insulating barrier to the cylinder liner, and quenching the engine block. The insulating barrier provides a lower cooling rate to the second material forming the cylinder liner than a cooling rate for the first material forming the engine block during the quenching.

Owner:GM GLOBAL TECH OPERATIONS LLC

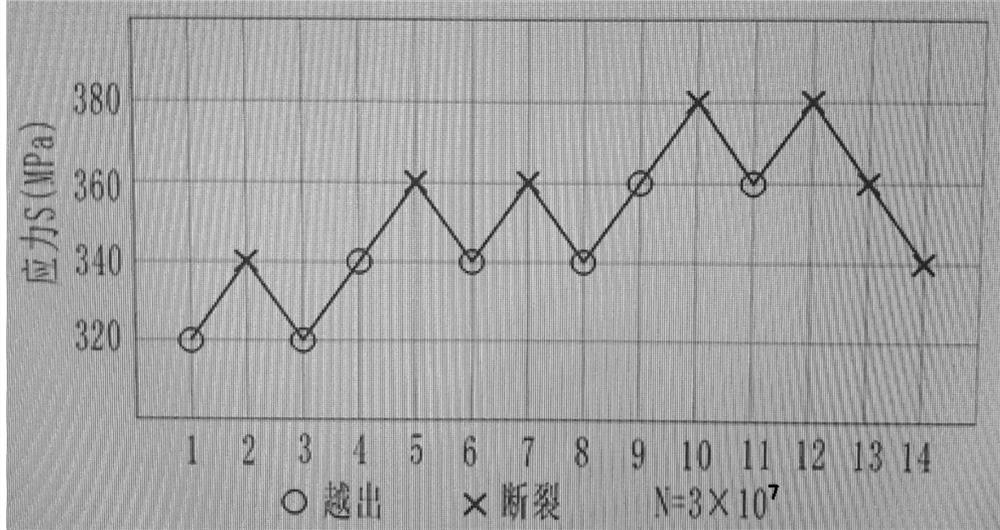

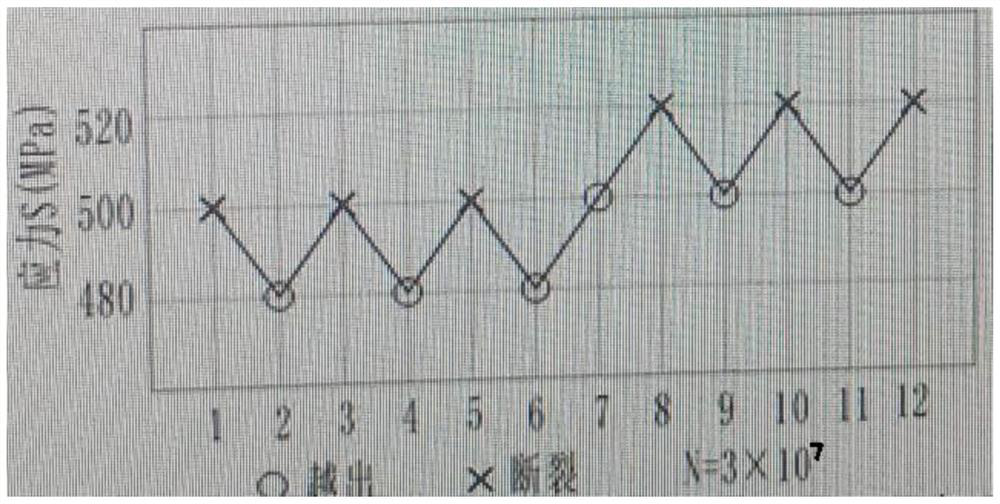

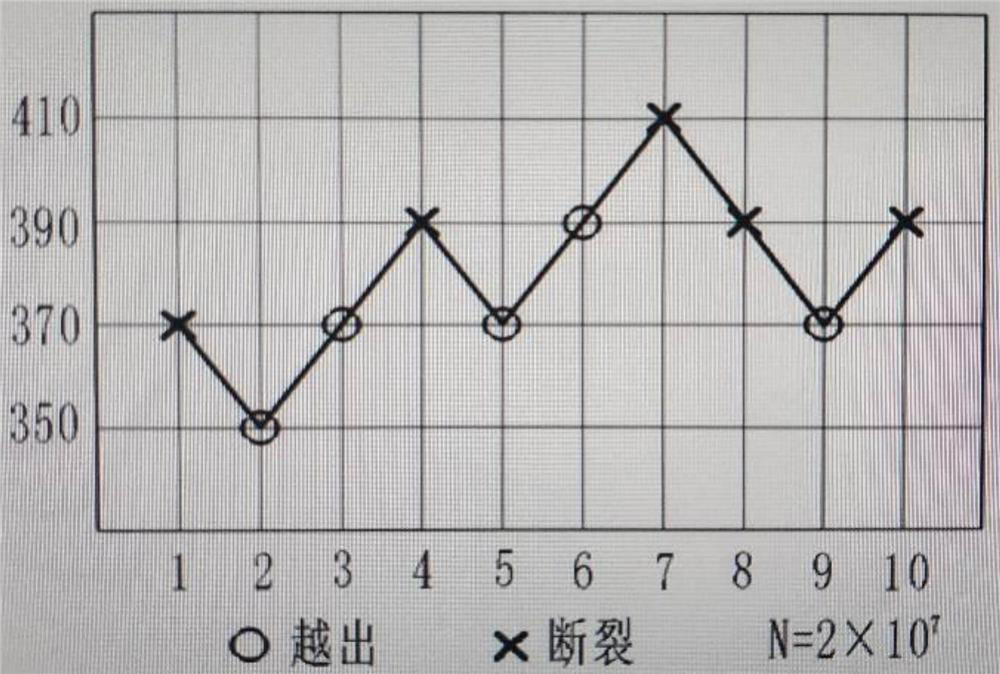

A method for prolonging fatigue life of welded joints

The invention discloses a method for prolonging fatigue life of welded joints, and belongs to the technical field of surface strengthening processing for improving the fatigue performance of metal welds. This method adopts surface spinning strengthening technology to carry out surface strengthening processing on welded joints to obtain metal surface structure with hardness gradient, realize surface strengthening and hardening of metal welded joints, and process smooth surface at the same time, which reduces the level of stress concentration and stress concentration on the surface of welded components. Post-weld residual stress levels. When metal welded components serve under cyclic loads, the initiation of fatigue cracks from the surface of welded joints can be inhibited after spinning, thereby improving the fatigue performance of metal welded joints.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Blade and preparation process thereof

ActiveCN113462872AIncrease compressive stressReduce surface roughness valuePump componentsFurnace typesStress reliefForge

The invention discloses a blade and a preparation process thereof. The preparation process comprises the following steps that primary vacuum stress relief annealing is carried out on a blade forge piece after a correction procedure of blade profile forming of a precision forging blade; the blade forge piece is machined; secondary vacuum stress relief annealing is carried out on the machined blade forge piece; and shot blasting and vibration finishing are carried out on the blade forge piece subjected to secondary vacuum stress relief annealing, and preparation is completed.

Owner:AECC AVIATION POWER CO LTD

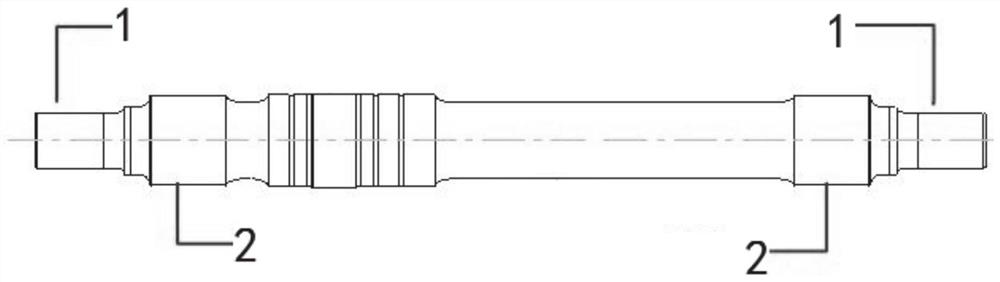

Axle remanufacturing method, remanufactured axle and system

ActiveCN112899678AQuality improvementExtended service lifeMetallic material coating processesStructural engineeringLaser

The invention discloses an axle remanufacturing method, a remanufactured axle and a system, solves the problems of surface residual stress and surface structure deterioration of the remanufactured axle, and has the beneficial effects of improving the product quality of the remanufactured axle and prolonging the service life of the remanufactured axle. The specific scheme is as follows: the axle remanufacturing method comprises the following steps: removing a scratch defect part of the axle; carrying out a plurality of layers of laser cladding on the removed to-be-repaired area of the axle to form a laser cladding layer; and after laser cladding of the axle is completed, quenching the to-be-repaired area of the axle, in the quenching process, heating the to-be-repaired area of the axle, carrying out heat preservation for set time so as to heat the area, within the set range from the laser cladding layer to the center of the axle, of the laser cladding layer, and after quenching is completed, tempering the to-be-repaired area of the axle.

Owner:CRRC QINGDAO SIFANG CO LTD

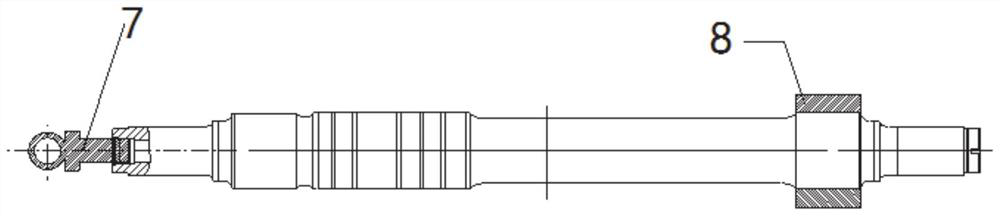

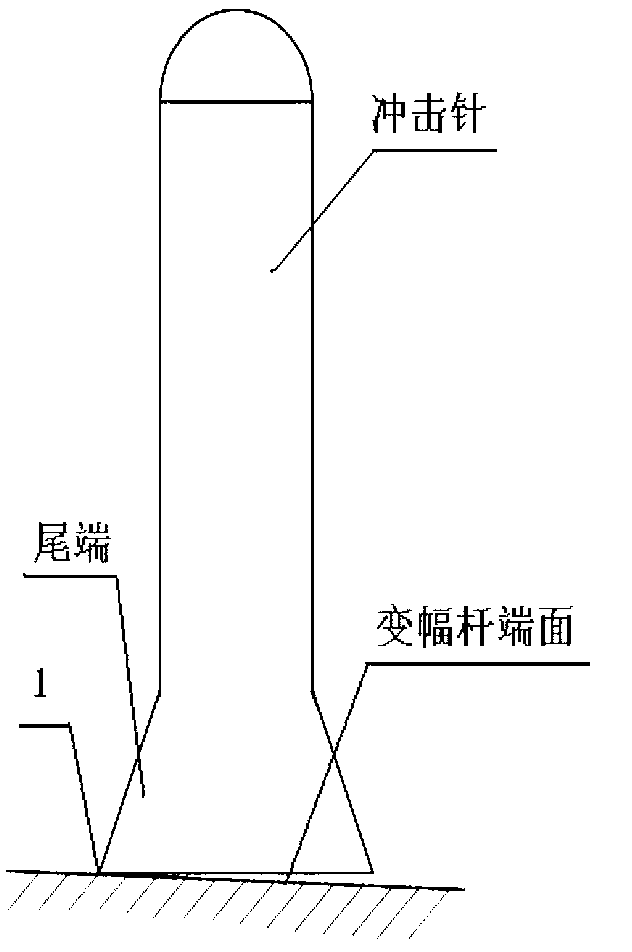

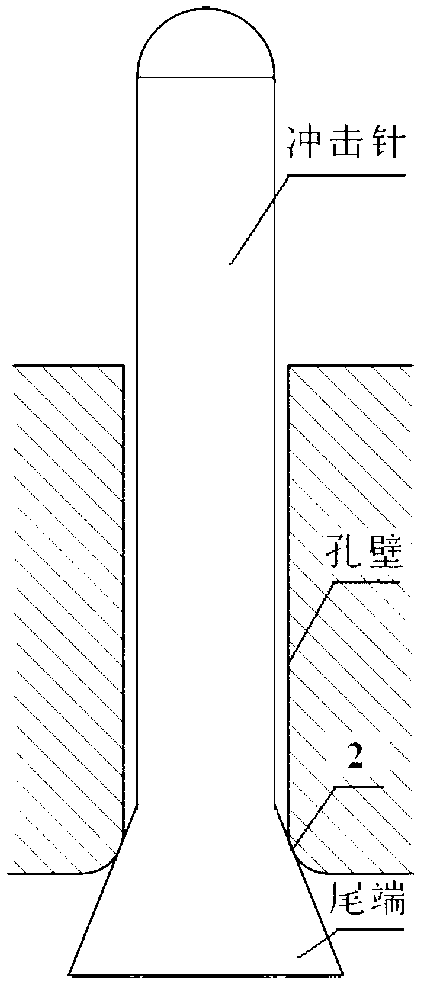

Stepped ultrasonic impact needle device and application thereof

The invention discloses a stepped ultrasonic impact needle device and the application thereof; an impact needle and a muzzle try to have rigid collision by changing the shape of the impact needle, so that the problem of the prior art that the speed of the impact needle is reduced caused by that quite great friction force is produced when the impact needle with a pin has collision with an impact needle base muzzle is solved. Meanwhile, the collision method of the impact needle and an extended head of the impact needle is changed, point contact replaces surface contact, so that the stress direction of a contact surface when in collision is consistent with the axial direction of the impact needle, the impact needle does not easily deviate, and the ultrasonic impact efficiency and stability can also be improved.

Owner:天津天东恒科技发展有限公司

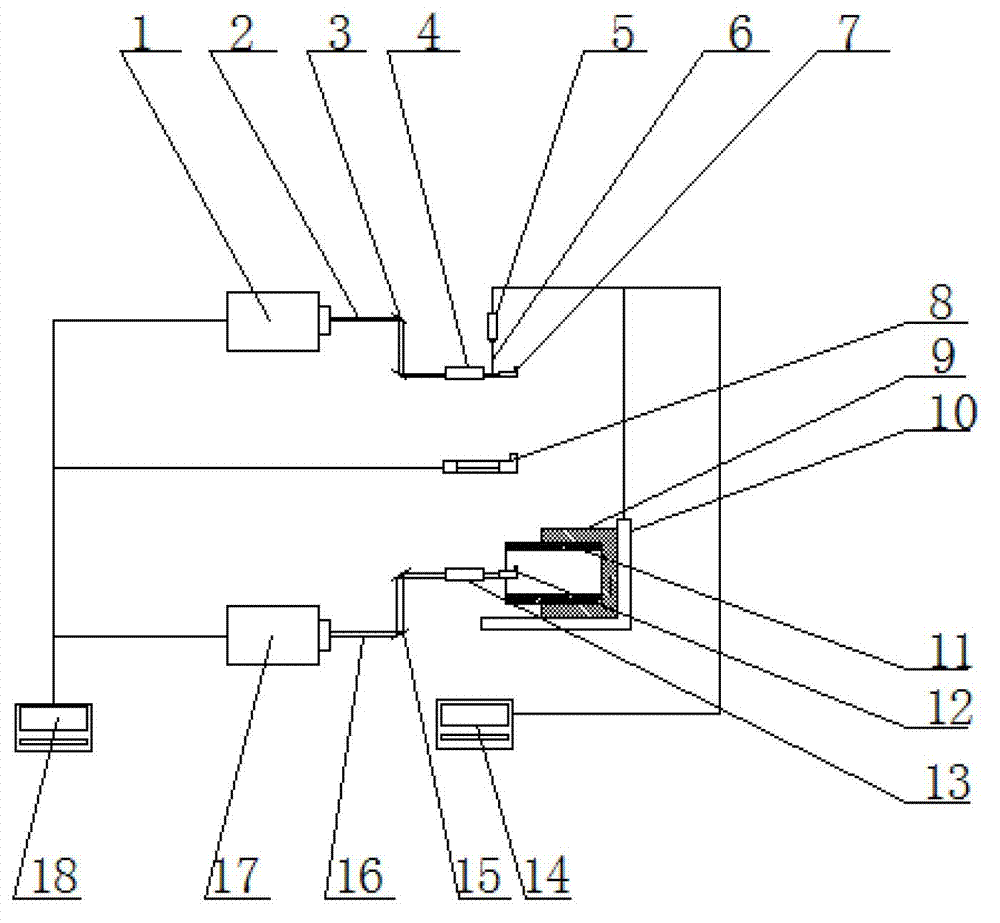

Method for repairing micro-contact fatigue damage of tooth surface and repairing device

ActiveCN113523708AImprove mechanical propertiesAddress process complexityProcess efficiency improvementLaser beam welding apparatusControl systemMonitoring system

The invention discloses a method for repairing micro-contact fatigue damage of a tooth surface and a repairing device. The method comprises the following steps that a to-be-repaired gear is fixed on a motion platform through a clamp; geometrical morphology characteristics of a to-be-repaired area are measured by using a three-dimensional morphology instrument, collected information is input to a comprehensive control and monitoring system, and material and mechanical characteristics of the to-be-repaired gear are compared through a database to determine optimal laser shock repair process parameters; the optimal process parameters are imported into a pulse laser generator, the laser generator emits laser according to the optimal process parameter scheme, and laser beams are exported through a light path regulation and control system and a light path system; meanwhile, a water restraint layer system controls a water nozzle to form a water restraint layer on the tooth surface; and the laser acts on the to-be-repaired area on the tooth surface, so that the gear generates the required reinforced repair effect, and the purpose of repairing the tooth surface damage is achieved. The problems that in a traditional repairing mode, the process is complex, roughness is high, abrasion resistance is poor, and the gear can be repaired only after obvious defects or faults occur to the gear are solved.

Owner:NANTONG UNIVERSITY

Method for manufacturing delivery steel pipe serving acid environment

InactiveCN102121081BGuaranteed corrosion resistanceFulfil requirementsHigh frequency current welding apparatusWelding/soldering/cutting articlesCrack resistanceIntermediate frequency

The invention discloses a method for manufacturing a delivery steel pipe serving an acid environment. The steel pipe comprises the following chemical components of raw materials in percentage by weight: less than or equal to 0.1 percent of C, less than or equal to 1.6 percent of Mn, less than or equal to 0.02 percent of P, less than or equal to 0.002 percent of S, less than or equal to 0.15 percent of Nb, V and Ti, less than or equal to 0.22 percent of Pcm, more than or equal to 1.5 percent of Ca / S and the balance of Fe. High frequency induction welding is adopted in welding of the steel pipe; the welding quality is improved in the welding process by increasing the welding extrusion quantity, controlling the open angle of seams and increasing welding protective gas; and on-line quenching and on-line tempering are performed in heat treatment of the seams by adopting six intermediate frequency heat treatment machines. By selection of raw material components and metallographic structures, completeness of a welding mechanism and improvement of the heat treatment process, the steel pipe has hydrogen induced cracking resistance and sulfide stress corrosion resistance and has high strength and high pressure resistance, the cost can be reduced, and the use of the steel pipe under the acid serving condition can be met.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Welding bead residual stress eliminating device and method

PendingCN114107632AEliminate residual tensile stressReduce fatigueProcess efficiency improvementManufacturing engineeringMetallurgy

The invention belongs to the technical field of stress relief, and particularly relates to a weld bead residual stress relief device and method.The weld bead residual stress relief device comprises a supporting column, the supporting column is connected to the upper surface of a base through threads, and the supporting column is used for supporting a to-be-treated welding part; the impact unit is mounted on the base, and the impact unit is in contact with a to-be-treated welding part; the impact unit is used for generating an impact effect on the to-be-treated welding part to complete weld bead stress elimination; the pressing unit is installed on the inner wall of the shell, and the pressing unit is used for limiting movement of the to-be-treated welding part; the device is simple in structure, residual stress in a plurality of welding beads on the same welding piece can be eliminated at the same time, and therefore the situation that the fatigue performance of the welding piece is reduced and the service life is shortened due to the residual stress of the welding beads is avoided.

Owner:李军

A kind of cucr contact surface finish processing equipment and processing method thereof

The invention relates to CuCr contact surface finishing equipment and method. The equipment is a turning and milling composite machine tool additionally provided with a Hawking tool assembly directly installed on a machine tool row tool support plate of the turning and milling composite machine tool. The method comprises steps including blank preparation, turning I, turning II, Hawking finishing, milling of six grooves, cleaning and drying, turning III, appearance treatment, final inspection and vacuum packaging. Micro impact extrusion deformation is formed on contact surfaces under the combined action of high-frequency vibration impact energy and Hawking energy of Hawking metal machining equipment, so that the surface roughness of a CuCr contact material can be increased to Ra2.0 or below, the mirror effect can be realized, and the requirement of special use occasions of the CuCr contact material for working surface Ra2.0 or below is met.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

Method for obtaining high-adhesion nano coating and device thereof

ActiveCN102776506BEliminate residual tensile stressImprove adhesionPressure inorganic powder coatingControl systemEngineering

The invention discloses a method for obtaining high-adhesion nano coating and a device thereof. The method comprises the following steps: impacting nano powder at 80-150 degrees centigrade by laser induction to obtain a nano coating, then, carrying out impacting treatment on the coating by laser induction at ultralow temperature by dint of ultralow temperature constant-high-pressure block and extrusion technology; and the device comprises a laser induction impacting system, a deep cooling treatment system, an auxiliary control system, an adjustable working platform, a heating platform and the like. According to the invention, the ultralow temperature constant-high-pressure block and extrusion technology is used; at the ultralow temperature, a base body is contracted sharply; the base body is prevented from outwardly extruding the coating by laser induction impact force; thus, the coating and the base body are contracted at constant high pressure; finally, coating atoms are combined with base body atoms more compactly; in addition, occlusion effect and penetration effect happen so as to fundamentally solve a difficult problem of poor adhesion of the coating and the base body.

Owner:SANMENXIA ZHONGYUAN PRECISION

Method of Stress Corrosion Resistance of Stainless Steel Welded Joints by Nanosecond Pulse Laser Shock

ActiveCN106834659BReduced stress corrosion resistanceAccelerated corrosionFurnace typesHeat treatment furnacesNanosecond pulseWeld seam

The invention provides a method for realizing stress corrosion resistance of a stainless steel welding connector impacted by nanosecond-pulse laser. According to the method, a welding seam is impacted by adopting laser along an S shape, and an outer region of the welding seam is impacted along a direction parallel to the welding seam, so that pull stress of the welding connector is eliminated. By reasonably selecting power density, phase change does not occur and residual pull stress can be eliminated, so that a condition that the stress corrosion resistance performance of the welding connector is reduced is avoided. According to the method provided by the invention, the surface of a workpiece is impacted through the nanosecond-pulse laser, and no obvious mechanical force is used; a machining speed is rapid and automation is easy to realize; a complicated mold surface can be impacted.

Owner:AIR FORCE UNIV PLA

Laser welding method for metal sheets applied to ultra low temperature environment

ActiveCN102728950BAccelerate dislocation movementAccelerated particle diffusionLaser beam welding apparatusHigh energyMechanical property

The invention discloses a laser welding method for metal sheets applied to an ultra low temperature environment. The method comprises the following steps of: integrally putting a metal sheet I and a metal sheet II in an inert gas environment, heating to the dynamic strain ageing temperatures of the metal sheet I and the metal sheet II, welding a filler wire in a seam zone by adopting fiber laser, putting the welded metal sheets in a liquid nitrogen environment, and emitting high-energy short pulse laser to carry out double-side laser impact on the metal sheets covered with an aluminum foil. The filler wire is welded for the metal sheets through laser at the dynamic strain ageing temperatures, so that the seam quality of a metal welding joint is greatly improved, and the seam zone is combined tightly with the metal sheets; and by laser impact strengthening treatment of the welding joint and the metal sheets in the same working environment at an ultra low temperature, ultra low temperature corrosion resistance and mechanical property of a metal welding member are remarkably improved.

Owner:ZHANGJIAGANG FURUI HEAVY EQUIP CO LTD

Processing Technology of Curved Aluminum Alloy Thin-wall Cylinder for Stress Relief Projectile

ActiveCN104084771BImprove the qualified rate of flaw detectionImprove welding strengthCurve shapeWeld strength

The invention discloses an aluminum alloy thin-walled cylinder with a curved shape of a stress-relief warhead and a processing technology thereof, which solves the problems of incomplete stress-relief and easy reduction of welding seam welding strength of the existing thin-walled cylinder. It includes a warhead curved thin-walled cylinder (2), a front flange (1) and a rear flange (7), and an annular cylinder (9) arranged on the rear end side of the front flange (1). Between the annular groove (10) and the front end of the warhead curved thin-walled cylinder (2), there is a vertical front annular welding seam (3), and on the cylinder wall of the warhead curved thin-walled cylinder (2), there is a The socket hole (4) is provided with a positioning annular step (11) on the outer wall of the hole socket (5), and discloses an effective method for removing welding stress of a thin-walled cylinder. The invention effectively eliminates the residual tensile stress on the surface of the thin-walled cylinder, and improves the structural strength and fatigue life of the material.

Owner:SHANXI FENXI HEAVY IND

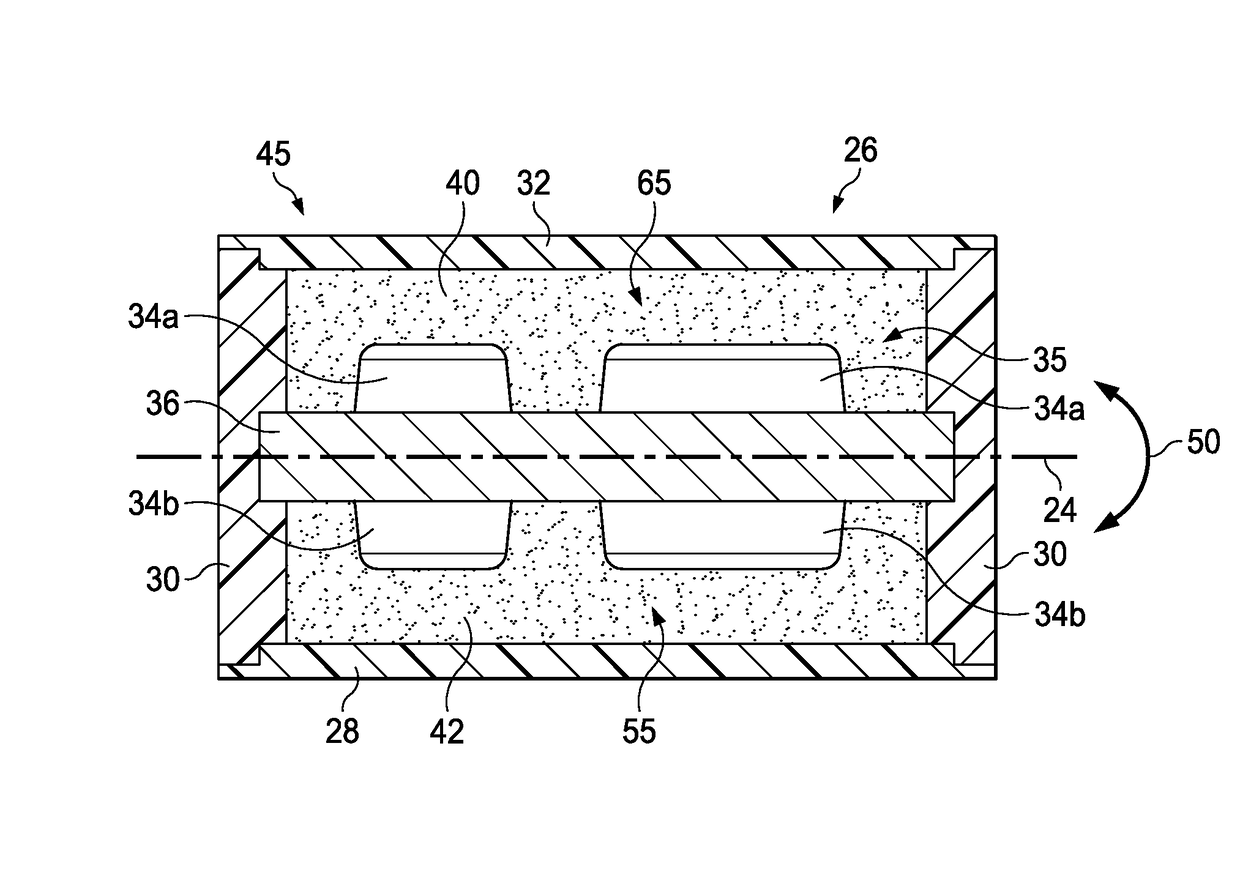

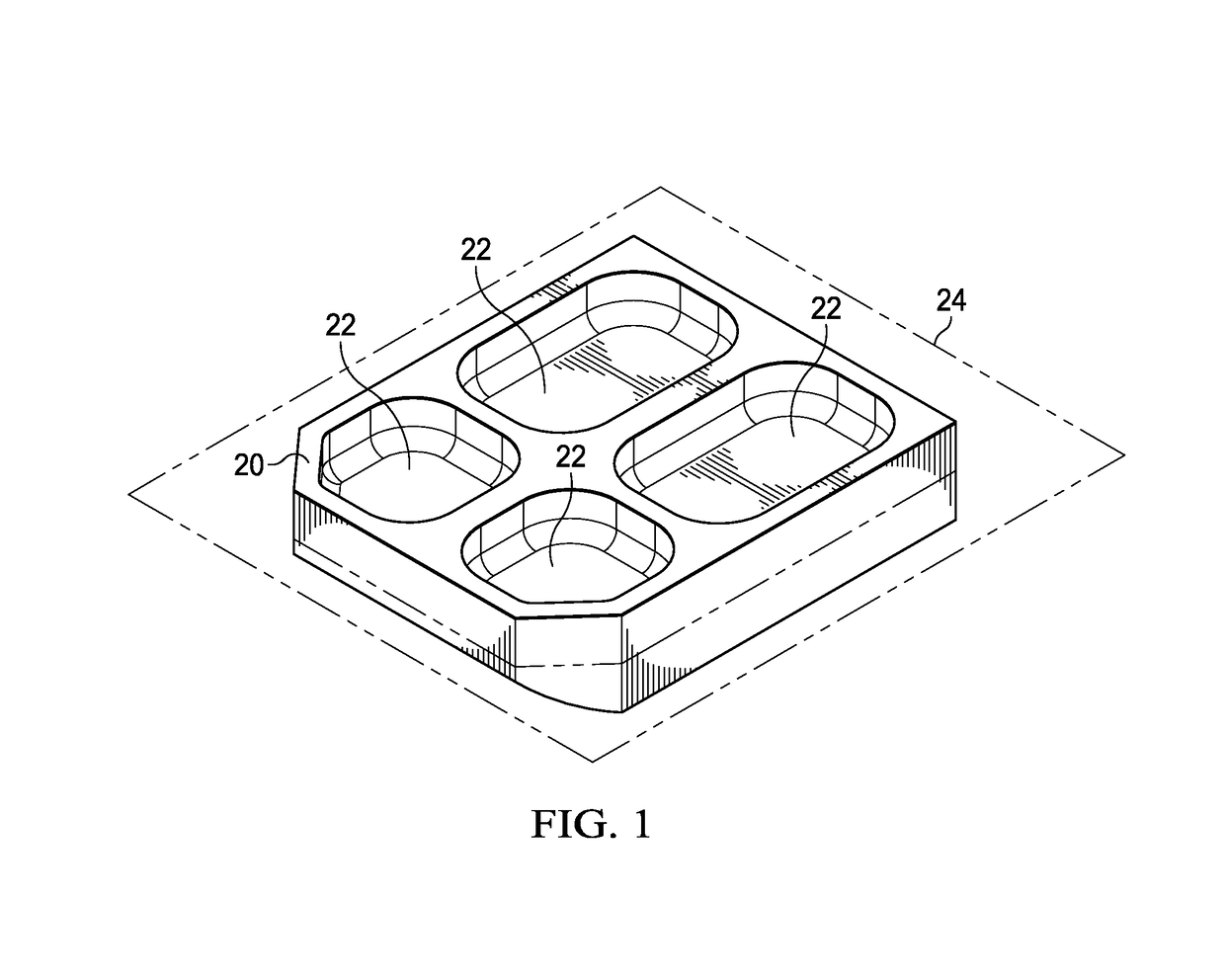

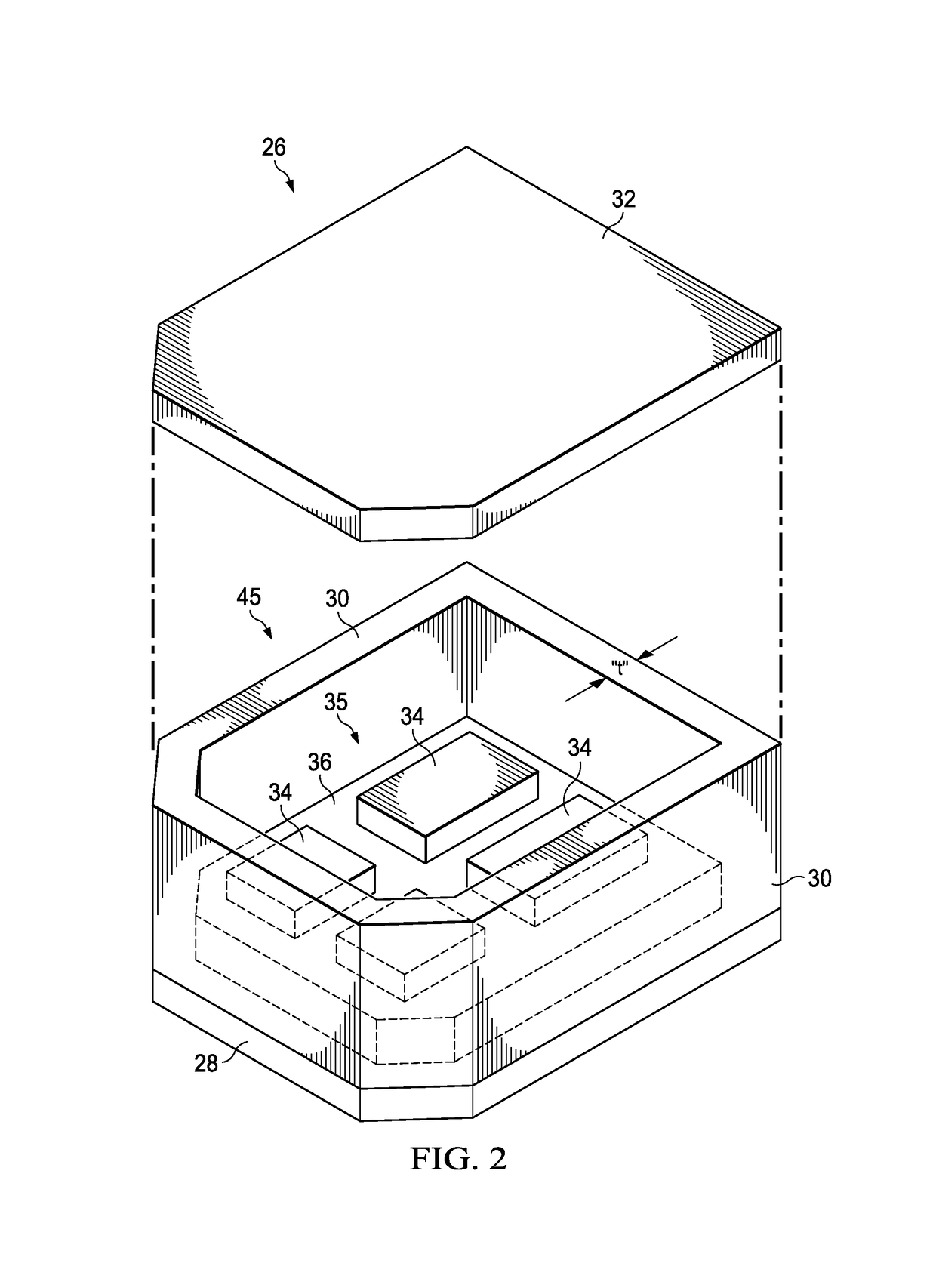

Crack-free fabrication of near net shape powder-based metallic parts

ActiveUS10046392B2Eliminate residual tensile stressAvoid bendingShaping pressCrack freeSoft materials

Crack-free powder-based, near net shaped parts are fabricated using a die assembly and cold isostatic pressing. Soft materials are introduced on both sides of die components in order to balance compression loads applied to the die component, and thereby avoid deformation of the die component.

Owner:SUBARU CORP +1

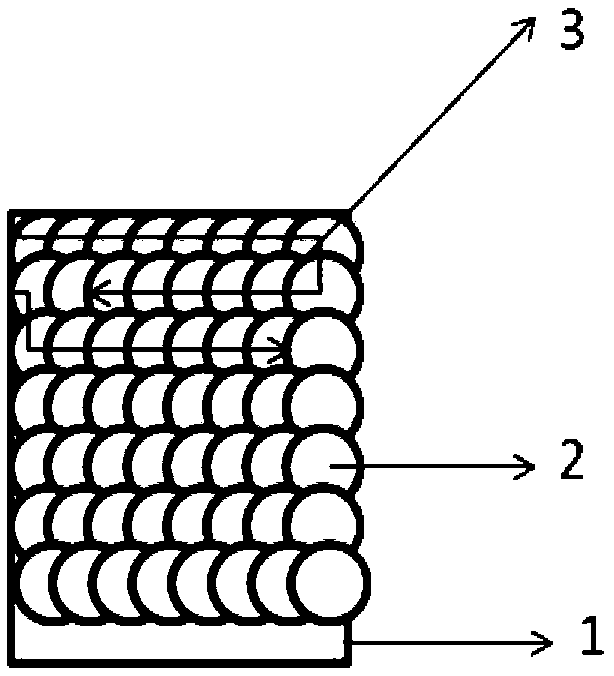

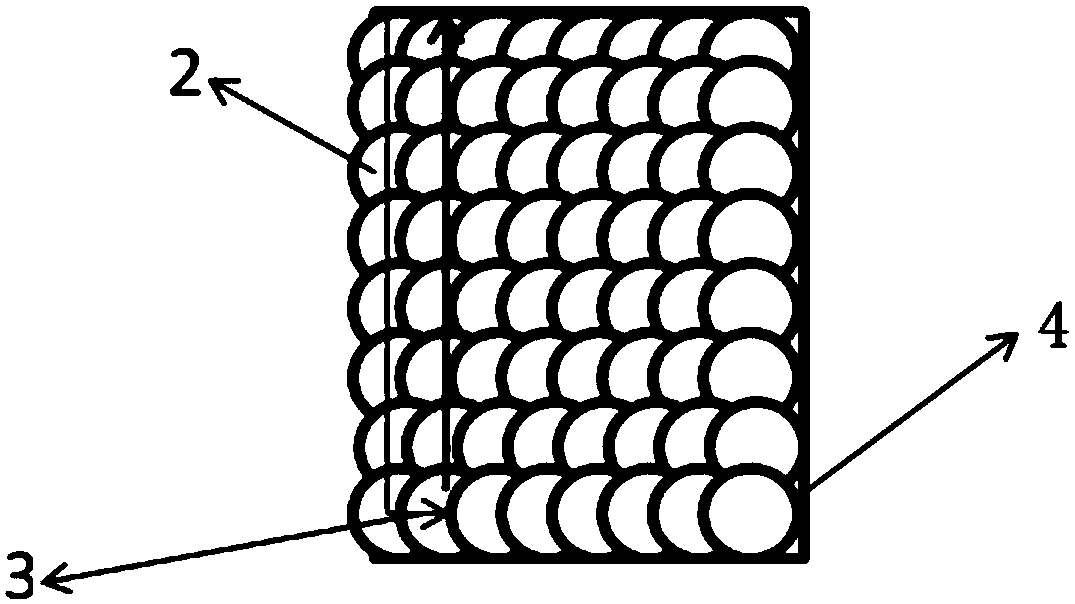

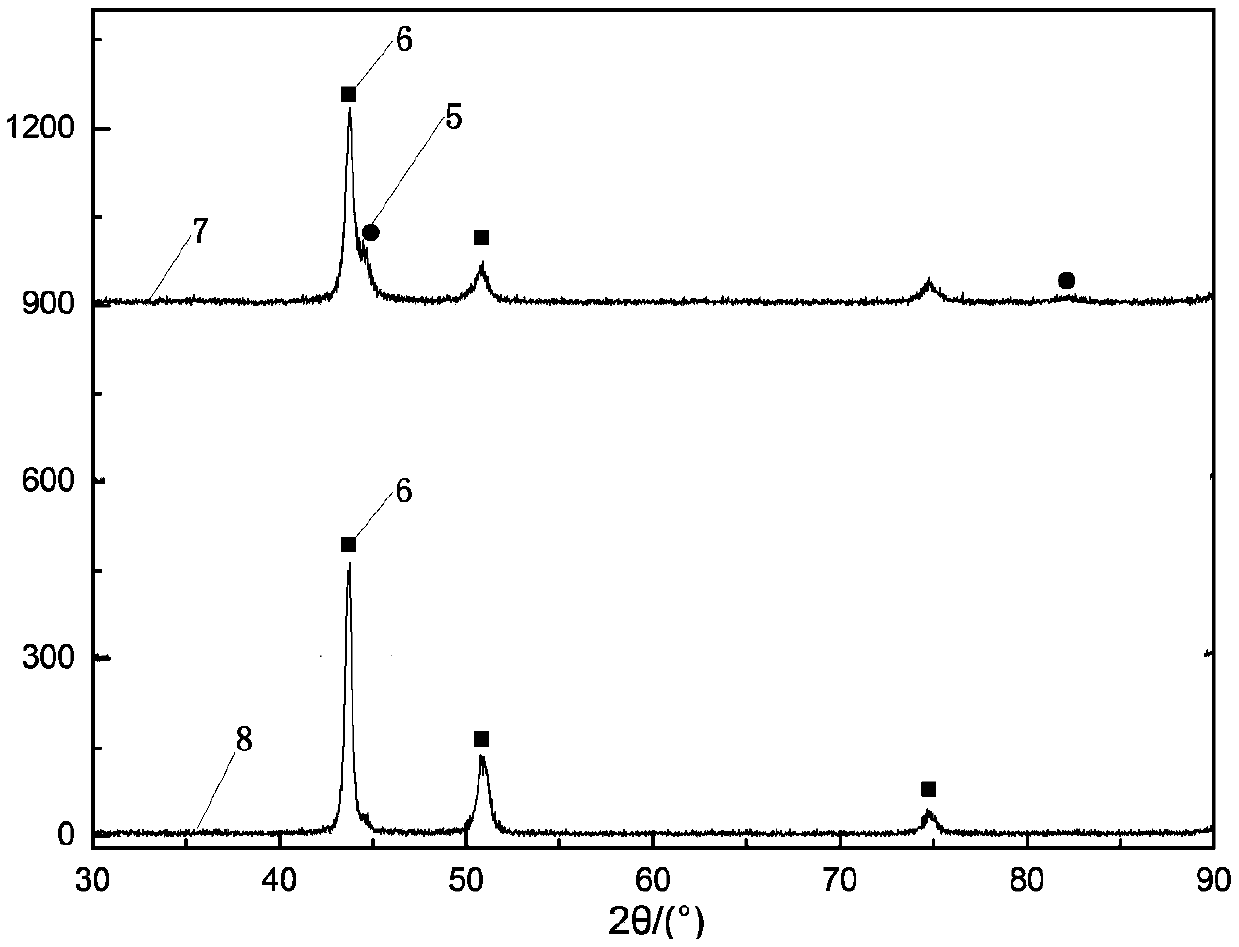

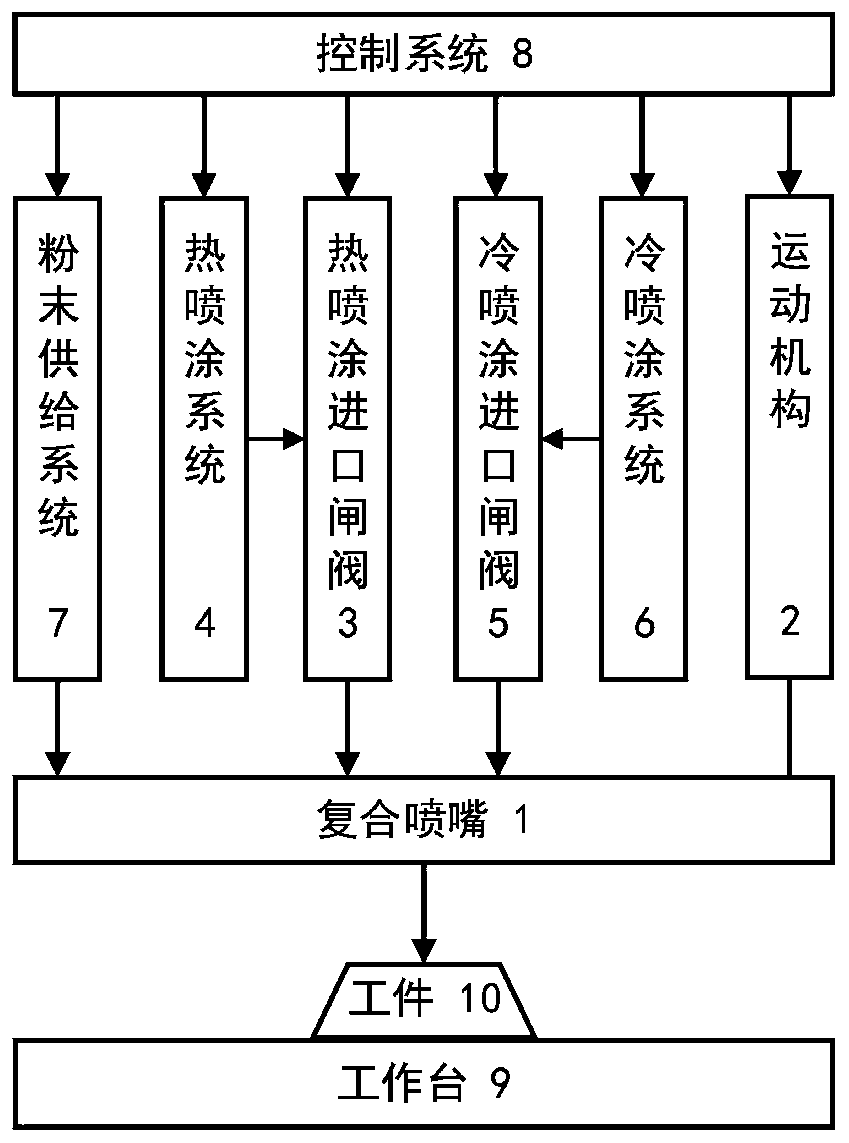

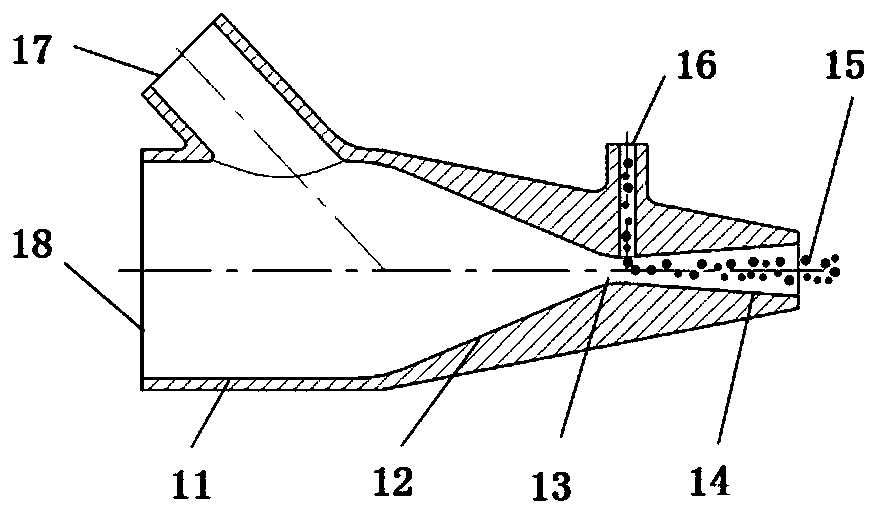

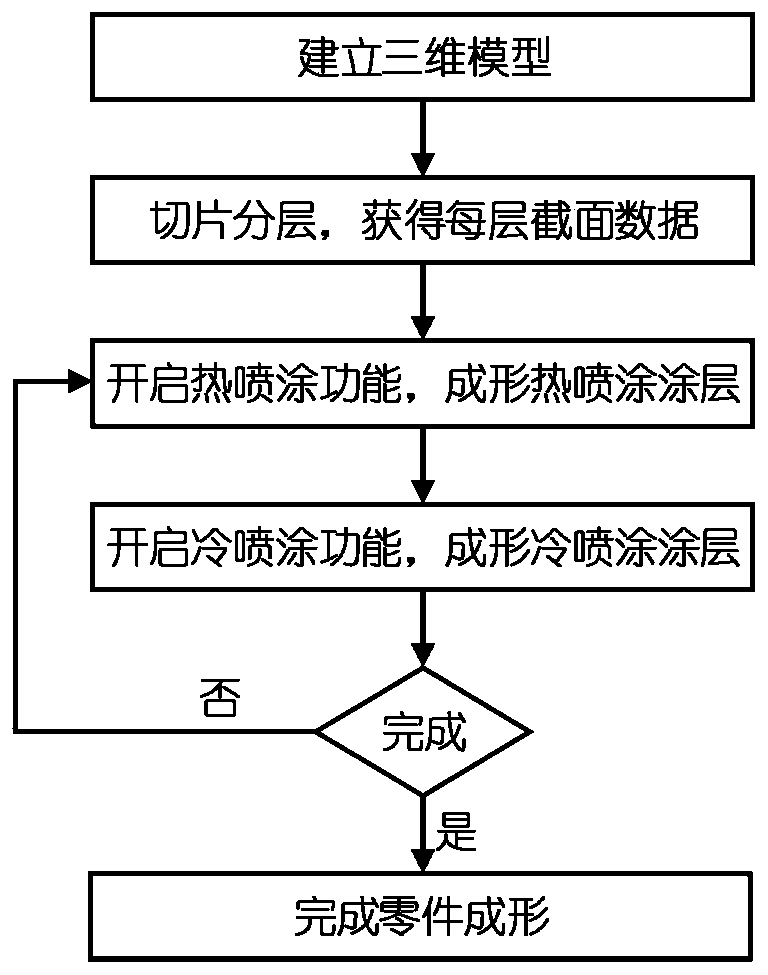

A high density and low residual stress parts additive manufacturing equipment and method

ActiveCN108500275BEliminate residual tensile stressEliminate compressive stressAdditive manufacturing apparatusHigh densityThermal spraying

The invention discloses a high-density low-residual-stress part additive manufacturing device and method. The device comprises a composite nozzle arranged above a workbench, the composite nozzle is installed on a movement mechanism, a heat spray energy inlet of the composite nozzle is connected with a heat spray system through a heat spray inlet gate valve, a cold spray gas inlet of the compositenozzle is connected with a cold spray system through a cold spray inlet gate valve, a powder inlet of the composite nozzle is connected with a powder supply system, control input of the movement mechanism, the heat spray system, the heat spray inlet gate valve, the cold spray system, the cold spray inlet gate valve and the powder supply system is connected with a control system, and opening or closing or movement is controlled by the control system. A workpiece is obtained on the surface of a substrate of the workbench, manufacturing is completed through hot spray and cold spray alternately, three-dimensional forming of the part can be achieved, residual stress is low, the structure is more compact, and the performance is better.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com