Welded joint fatigue life prolonging method

A welded joint and fatigue technology, which is applied in the field of fatigue life extension of welded joints, can solve the problems of reducing stress level, reducing fatigue life, and local stress concentration on the surface of components, so as to improve fatigue performance and wear resistance, increase surface strength and hardness, Effect of improving fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

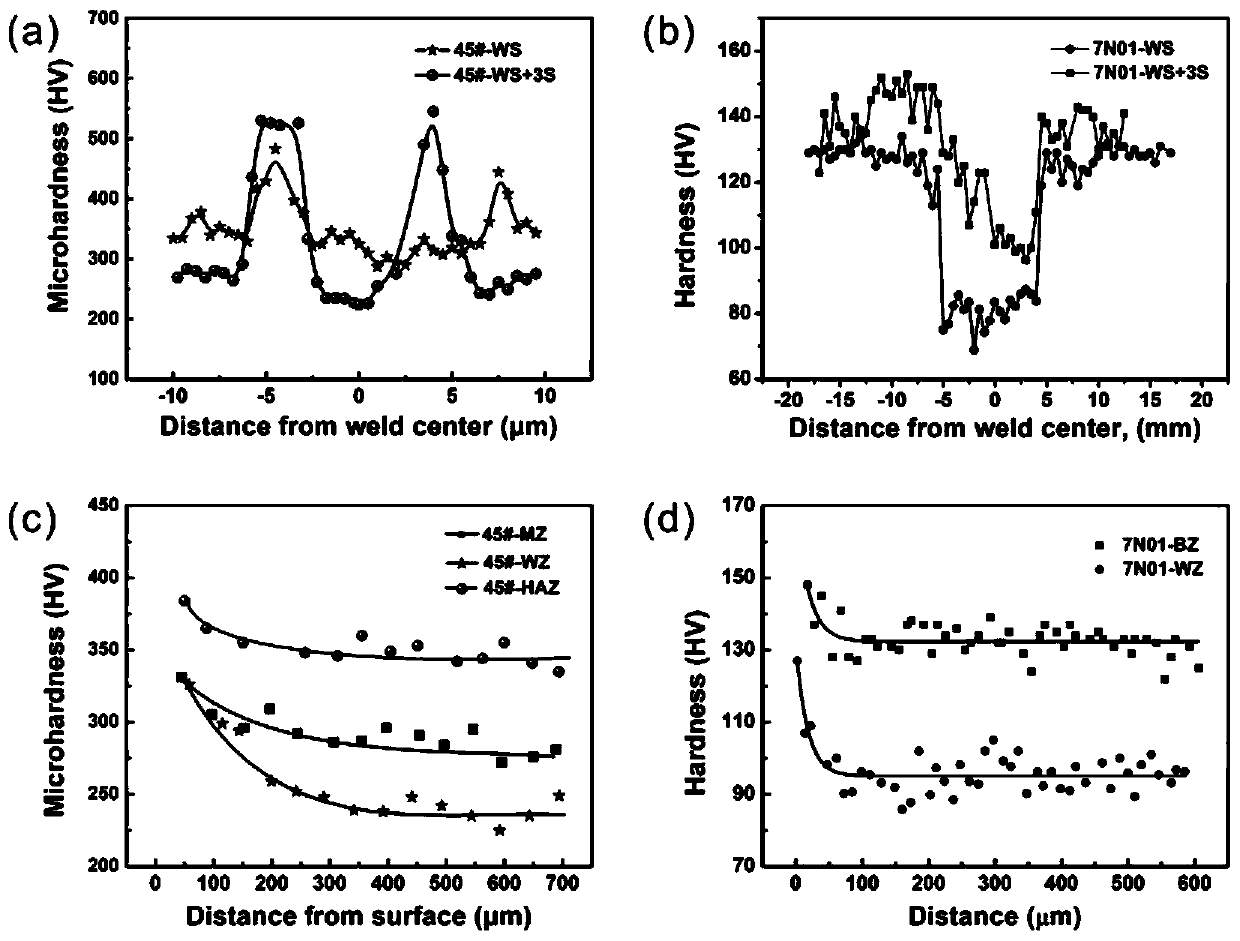

Embodiment 1

[0056] This embodiment is the surface spinning strengthening process of 45# steel welded joints. For the 45# steel (tensile strength 500MPa-1000MPa) of this embodiment, in order to ensure the input of the required compressive stress and shear stress for surface strengthening, it can simultaneously achieve For better surface finish, choose a tool with a double helix machining blade with a pitch value of 200mm, a tooth thickness of 1.5mm, a tooth width of 2mm, and a helical groove depth of 1.5mm.

[0057] The surface spinning process of the present embodiment is as follows:

[0058] Step 1: Work piece welding. Two 45# steel base metal plates were butt welded with ER-70S-6 low carbon steel welding wire, and the welding method was non-melting inert gas shielded welding (TIG).

[0059] Step 2: Spinning tool and workpiece clamping. Install the spinning tool on the bearing of the spinning machine, and clamp the workpiece on the worktable. The processed surface of the workpiece is p...

Embodiment 2

[0068] This embodiment is the surface spinning strengthening process of 7N01 aluminum alloy welded joints. For the aluminum alloy with high plasticity in this embodiment, in order to obtain a lower surface roughness, the pitch value of the double helix processing blade is 400mm. A tool with a tooth thickness of 0.3mm, a tooth width of 1.5mm, and a helical groove depth of 0.3mm.

[0069] The surface spinning process of the present embodiment is as follows:

[0070] Step 1: Work piece welding. Two 7N01 aluminum alloy base metal plates were butt welded with 5356 aluminum alloy welding wire, and the welding method was molten inert gas shielded welding (MIG).

[0071] Step 2: Spinning tool and workpiece clamping. Install the spinning tool on the bearing of the spinning machine, and clamp the workpiece on the worktable. The processed surface of the workpiece is parallel to the axis of the spinning tool.

[0072] Step 3: Calibrate the knife. The worktable and the spinning tool ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com