A kind of cucr contact surface finish processing equipment and processing method thereof

A technology of finishing processing and equipment, which is applied in the field of metal surface processing, can solve the problems of no CuCr contact material, etc., achieve the effects of shortening the processing and manufacturing cycle, improving surface strengthening and dimensional stability, and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

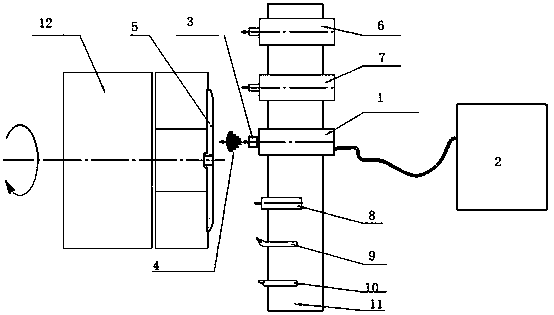

[0033] refer to figure 1 , a CuCr contact surface finish processing equipment, the equipment is a turn-milling compound machine tool equipped with a Hawker tool assembly 1, and the Hawker tool assembly 1 is directly installed on the machine tool pallet of the turn-mill compound machine tool On 11, the Hawk energy cutter assembly 1 is connected with an energy generation control device 2, which provides the Hawk energy energy transmission to the Hawk energy tool assembly 1, and is converted into high-frequency vibration impact energy and energy by the Hawk energy tool assembly 1. The compound energy 4 of the Hawk energy, the Hawk energy cutter assembly 1 has the Hawk energy cutter head 3 for smoothing the surface of the CuCr contact 5; The compound milling machine tool includes a first powered tool 6 , a second powered tool 7 , a drill 8 , a first turning tool 9 and a second turning tool 10 , which are respectively arranged on the tool pallet 11 of the machine tool.

[0034] re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com