Hall Ion Source excitation magnetron sputtering enhancement magnetism filtration multi-arc ion composite coating method

A multi-arc ion and composite coating technology, used in sputtering, ion implantation, vacuum evaporation, etc., can solve the problem of quality reduction, magnetron sputtering deposition rate, low film-base bonding strength, thin film, etc. problem, to achieve the effect of good bonding strength, significant strengthening effect, and high density bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

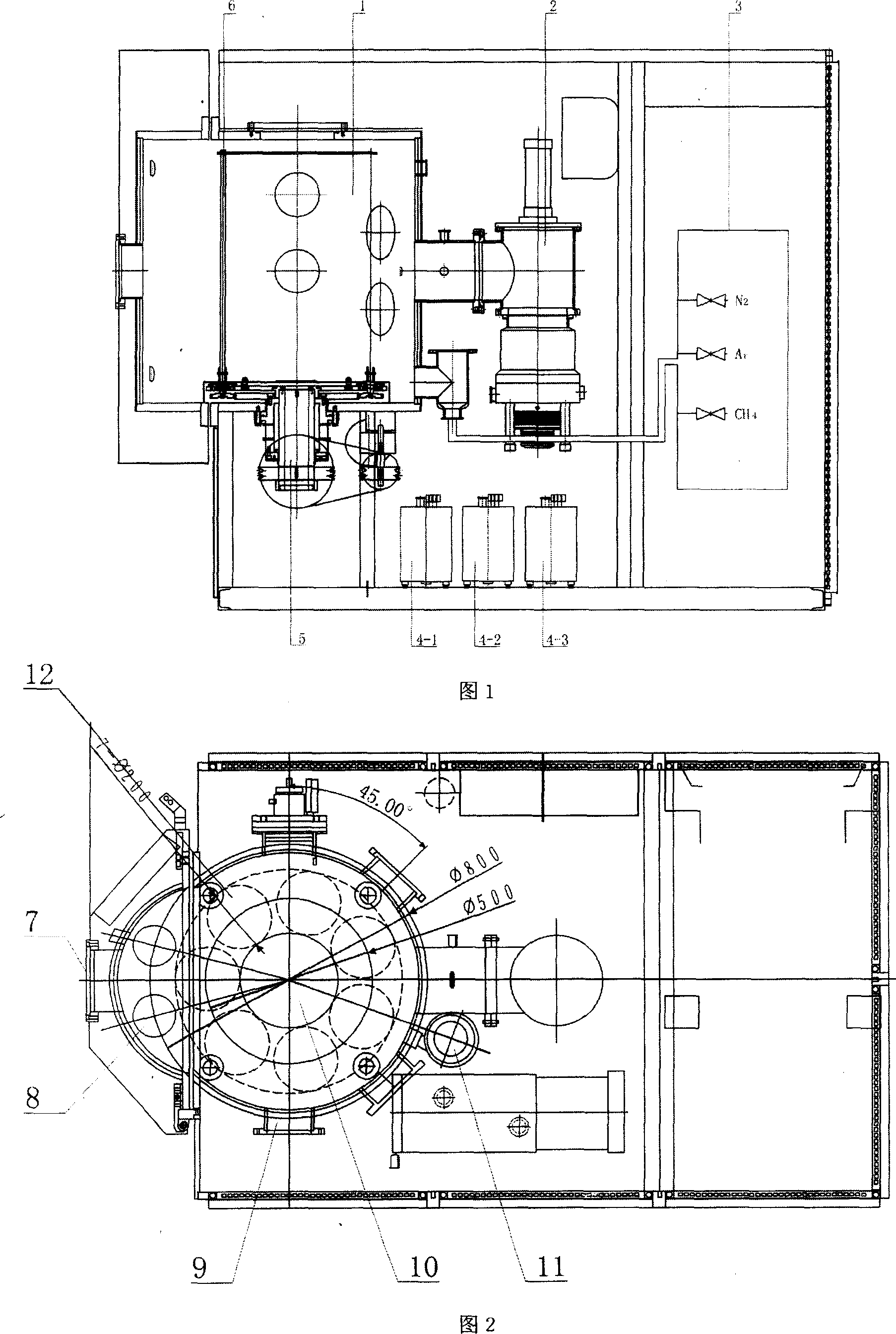

[0024] Embodiment 1: Preparation of TiN hard film

[0025] 1. Put the workpiece 12 to be processed into the furnace reaction chamber 1 of the Hall source excited magnetron sputtering enhanced magnetic filter multi-arc ion coating equipment, and turn on the vacuum system 2 to evacuate to 6.0×10 -3 Pa, turn on the heating system 6, heat to 250°C and keep it stable until the coating is finished

[0026] 2. After heating and keeping warm for 30 minutes, turn on the Ar in the gas supply system 3, keep the Ar flow rate at 100ml / min, gradually increase the bias voltage and stabilize it at 900V, and the duty cycle is 50%. The high-energy ions in the plasma field generated by the bias power supply system 4-3 in the equipment bombard the surface of the workpiece for 30 minutes, so that the surface 12 of the workpiece to be treated is cleaned and activated;

[0027] 3. After the argon ion bombardment, restart the fine pumping system in the vacuum system 2 and adjust the pressure to 6.0×...

Embodiment 2

[0030] Embodiment 2: Preparation of TiC hard film

[0031] 1. Put the workpiece 12 to be processed into the furnace reaction chamber 1 of the Hall source excited magnetron sputtering enhanced magnetic filter multi-arc ion coating equipment, and turn on the vacuum system 2 to evacuate to 6.0×10 -3 Pa, turn on the heating system 6, heat to 350°C and keep it stable until the coating is finished;

[0032] 2. After heating and keeping warm for 30 minutes, turn on the Ar in the gas supply system 3, keep the Ar flow rate at 80ml / min, gradually increase the bias voltage and stabilize it at 1200V, and the duty cycle is 30%. The high-energy ions in the plasma field generated by the bias power supply system 4-3 in the equipment bombard the surface of the workpiece for 50 minutes, so that the surface 12 of the workpiece to be treated is cleaned and activated;

[0033] 3. After the argon ion bombardment, restart the fine pumping system in the vacuum system 2 and adjust the pressure to 6.0...

Embodiment 3

[0036] Embodiment 3: prepare Ti (CN) hard film

[0037] 1. Put the workpiece 12 to be processed into the furnace reaction chamber 1 of the Hall source excited magnetron sputtering enhanced magnetic filter multi-arc ion coating equipment, and turn on the vacuum system 2 to evacuate to 6.0×10 -3 Pa, turn on the heating system 6, heat to 300°C and keep it stable until the coating is finished

[0038] 2. After heating and keeping warm for 30 minutes, turn on the Ar in the gas supply system 3, keep the Ar flow rate at 50ml / min, gradually increase the bias voltage and stabilize it at 1100V, and the duty cycle is 35%. The high-energy ions in the plasma field generated by the bias power supply system 4-3 in the equipment bombard the surface of the workpiece for 40 minutes, so that the surface 12 of the workpiece to be treated is cleaned and activated;

[0039] 3. After the argon ion bombardment, restart the fine pumping system in the vacuum system 2 and adjust the pressure to 6.0×10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com