Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60results about How to "Good strengthening effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicon carbide reinforced aluminum-based composite material and its preparation method

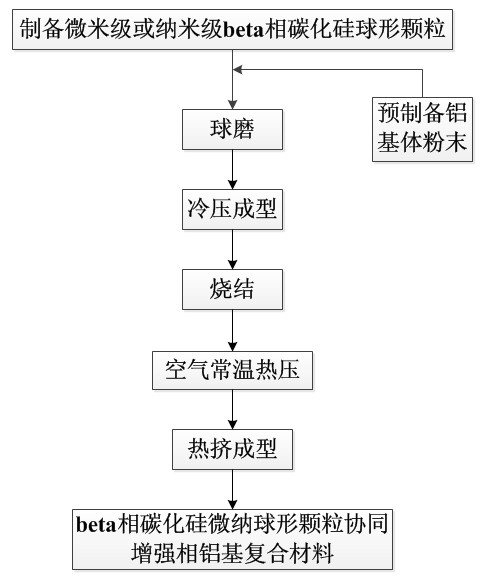

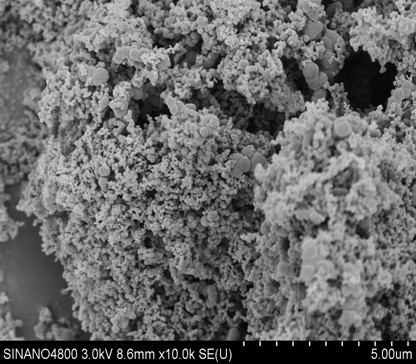

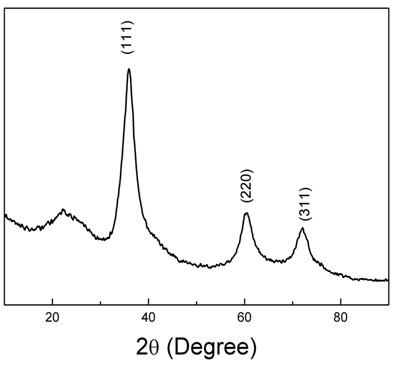

The invention relates to a silicon carbide reinforced aluminum-based composite material and its preparation method. The composite material is characterized by being composited by micron-scale and nano-scale beta-phase silicon carbide spherical particles and an aluminum substrate, with the beta-phase silicon carbide spherical particles distributed in the aluminum substrate to form a synergistic reinforced phase. The preparation method is summarized to be mainly composed of: pre-preparing beta-phase silicon carbide spherical particles, adding aluminum substrate powder and the beta-phase silicon carbide spherical particles accounting for 0-25wt% of the composite material into a ball mill for ball milling treatment, and conducting cold press molding, sintering, as well as air hot pressing sequentially, and finally carrying out hot extrusion molding to obtain a molded product of the composite material. Specifically, the particle size of the aluminum substrate powder is 1micrometer to 100micrometers. The technical scheme of the invention innovatively uses spherical particulate beta-phase silicon carbide and makes use of the synergistic reinforcement effect of the micron and nano-silicon carbide particles, substantially improves the strength, toughness, abrasion resistance and others of the aluminum-based composite material. The preparation process is simple, and the cost input is effectively reduced.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI +1

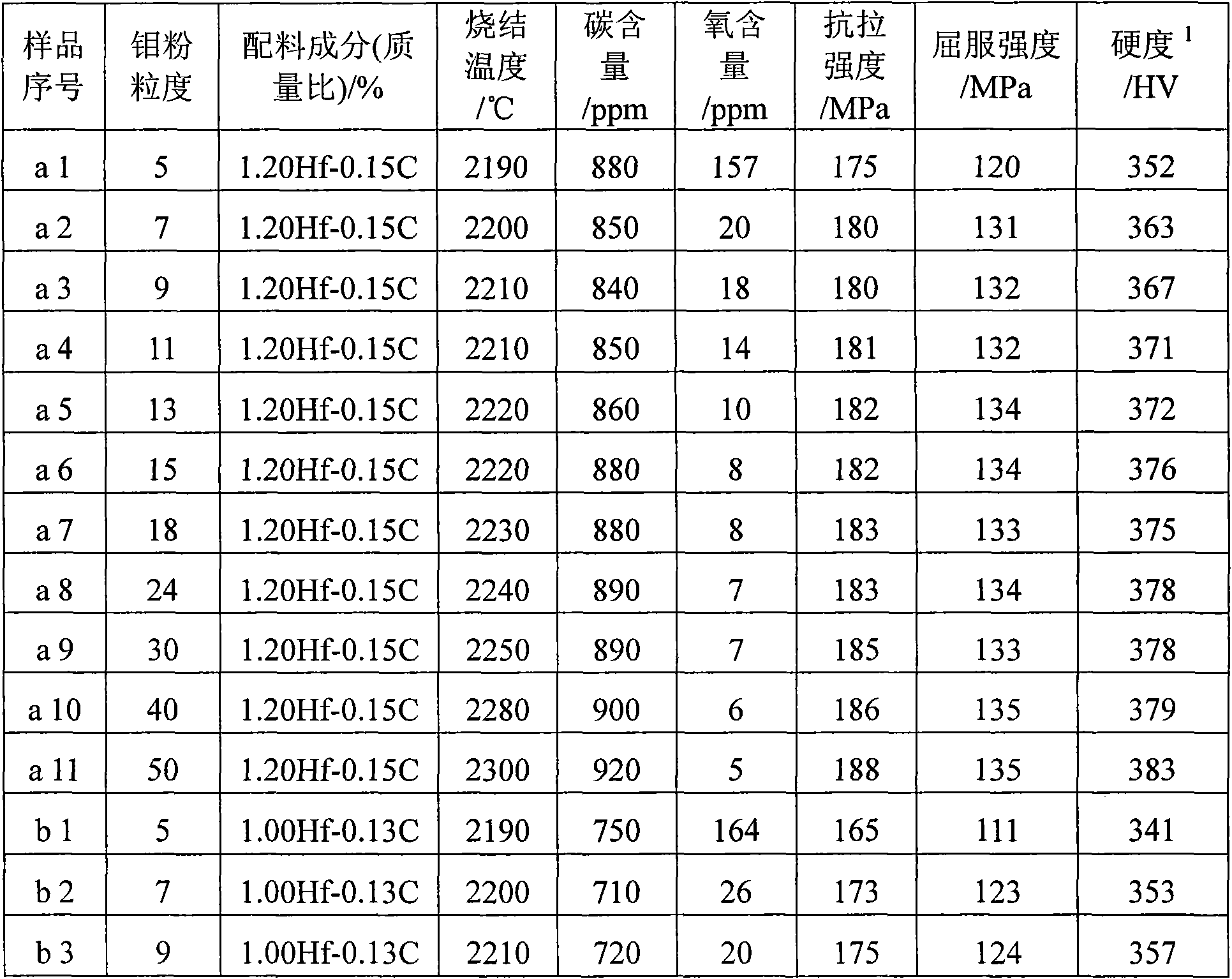

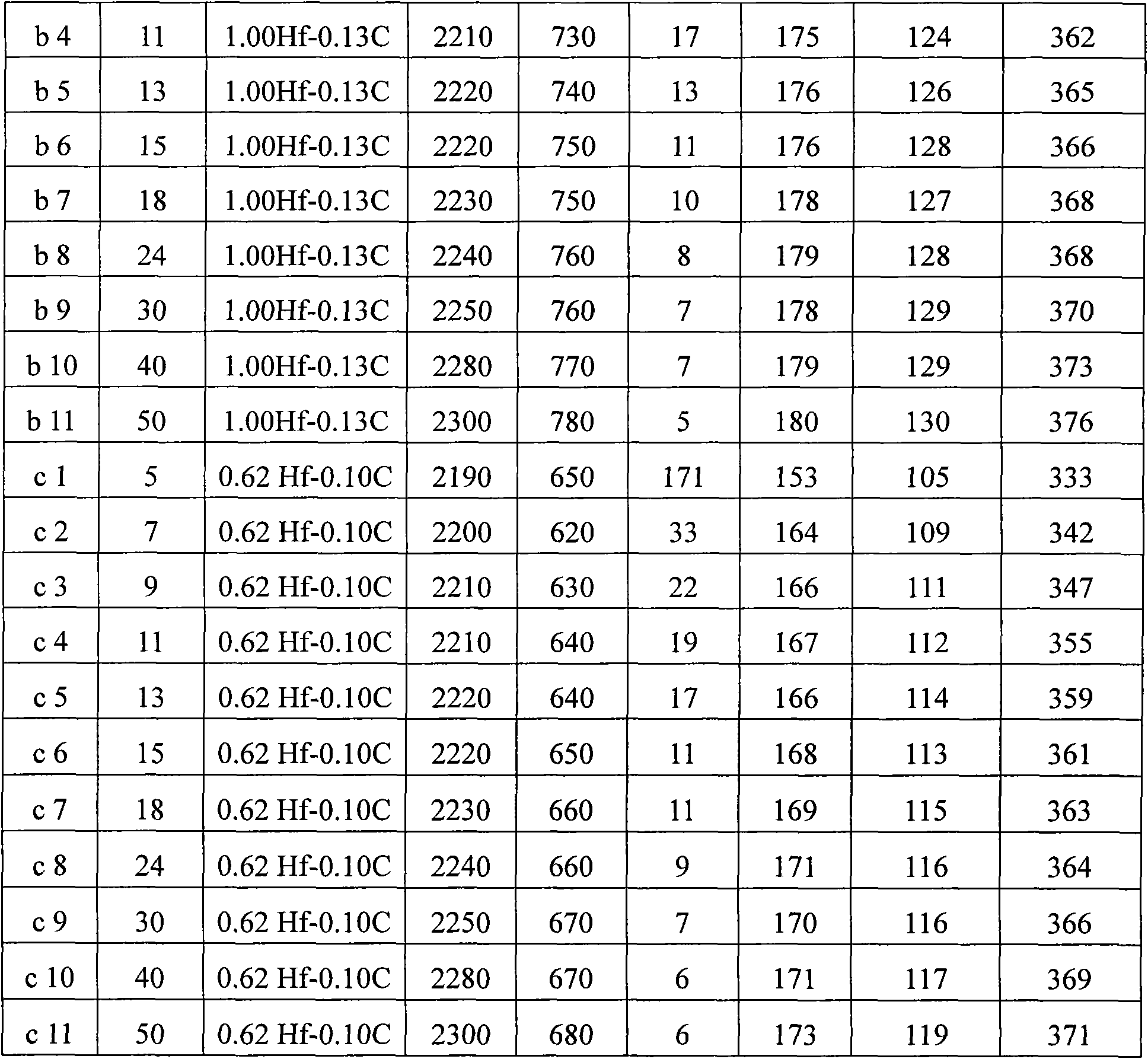

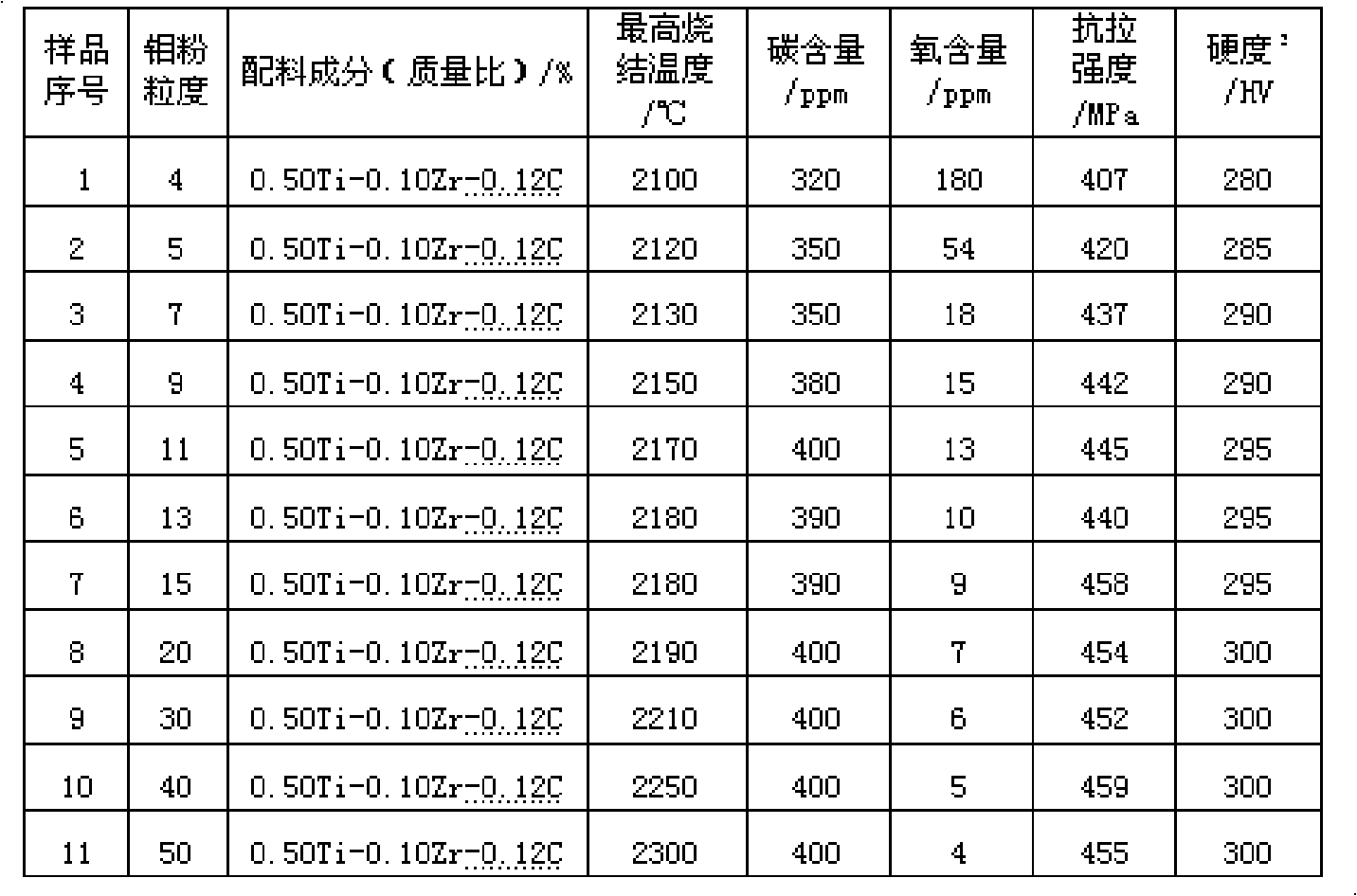

Preparation method of low-oxygen molybdenum alloy and application thereof

InactiveCN102041402AReduce oxygen contentOxygen content less impurityX-ray tube electrodesForging/hammering/pressing machinesMass ratioAlloy

The invention provides a preparation method of a low-oxygen molybdenum alloy. The method comprises the following steps: 1) selecting raw materials: uniformly mixing industrial molybdenum powder with Fisher particle size of 3-100 mum, powder containing strengthening elements with Fisher particle size of 3-10 mum, and carbon simple substance powder with Fisher particle size of 0.1-3 mum at certain mass ratio; 2) forming the raw materials: performing static pressing or mould pressing treatment on the mixed raw materials under pressure of 100-300 MPa to obtain formed blank; and 3) sintering the raw materials: sintering the formed blank in vacuum, hydrogen or inert gas environment at the high temperature of between 1,800 and 2,300 DEG C for 5-15 h to obtain the low-oxygen molybdenum alloy. Through the invention, the problem of high oxygen content of the molybdenum alloy prepared by powder metallurgy is solved. The low-oxygen molybdenum alloy prepared by the method can be used for preparing an X-ray tube rotating anode target, a composite target-based target, a high-temperature crucible, a hot-forging die and a high-temperature ceramic gasket.

Owner:XIAN GEMEI METAL MATERIAL

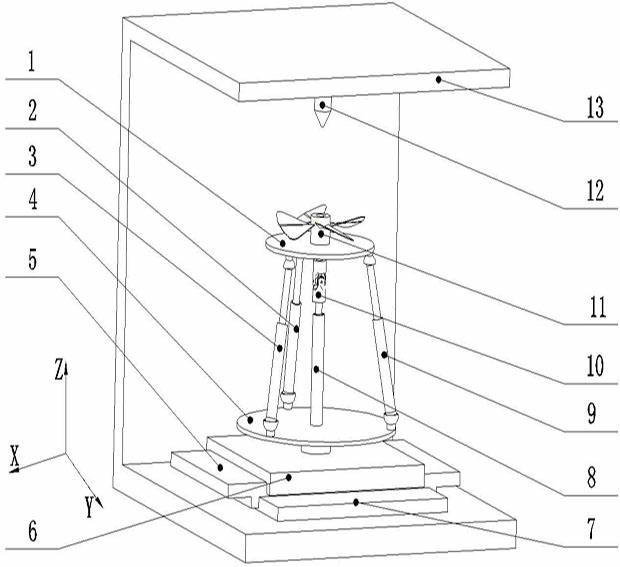

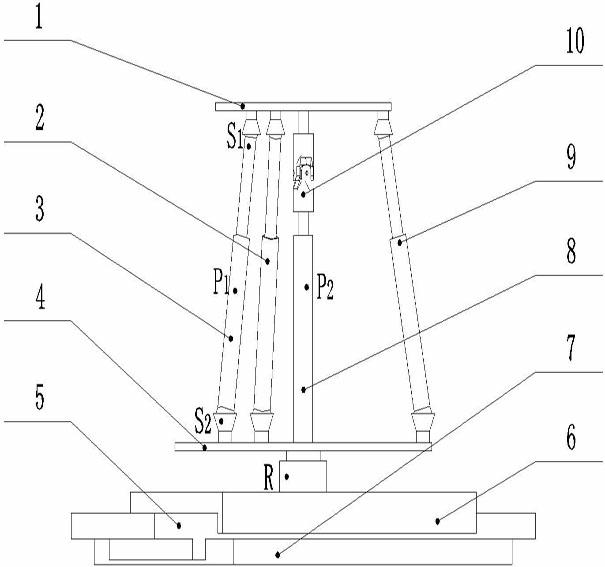

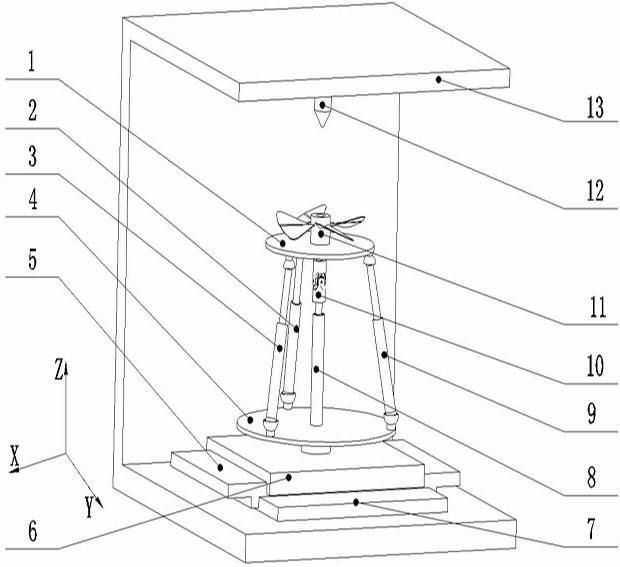

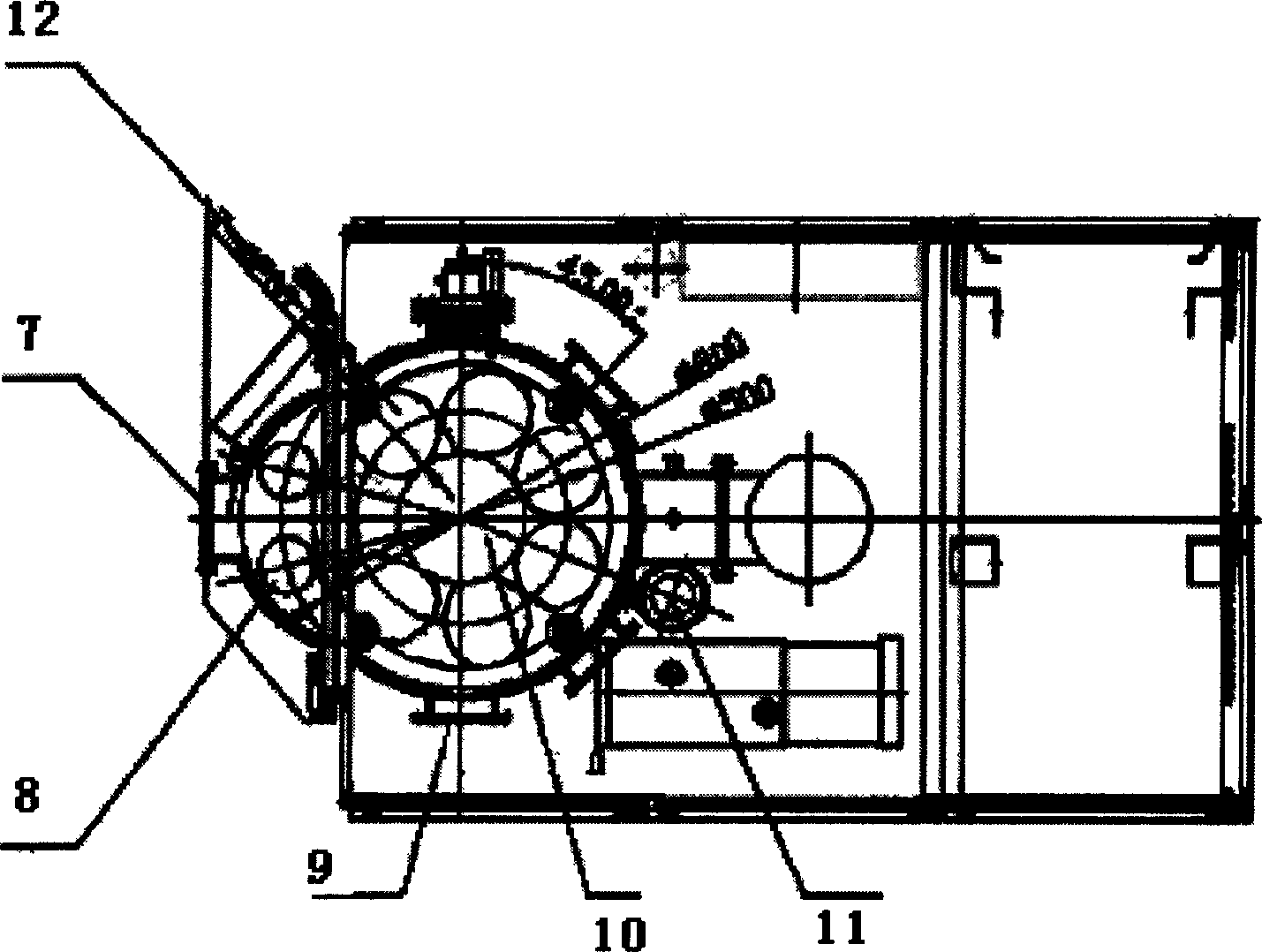

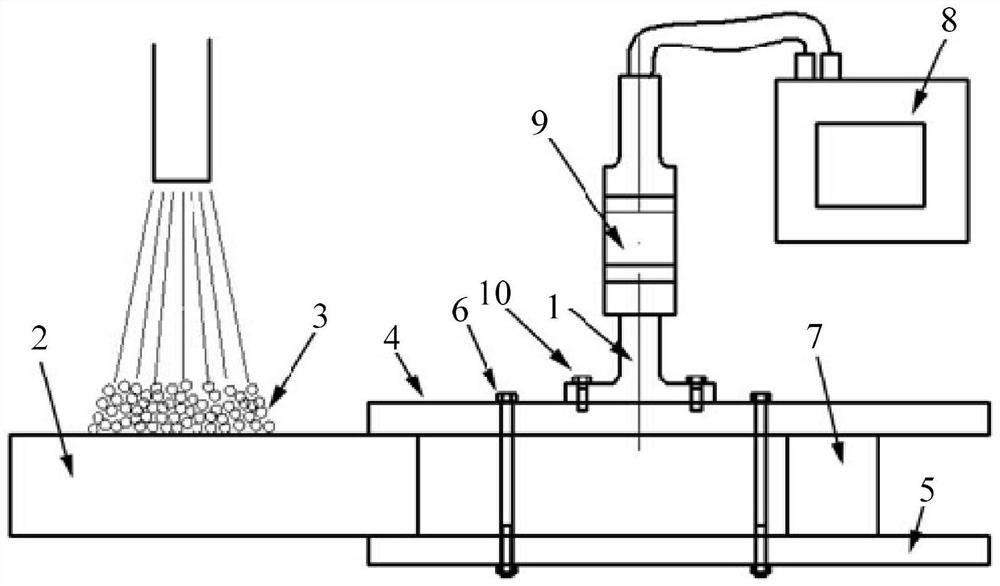

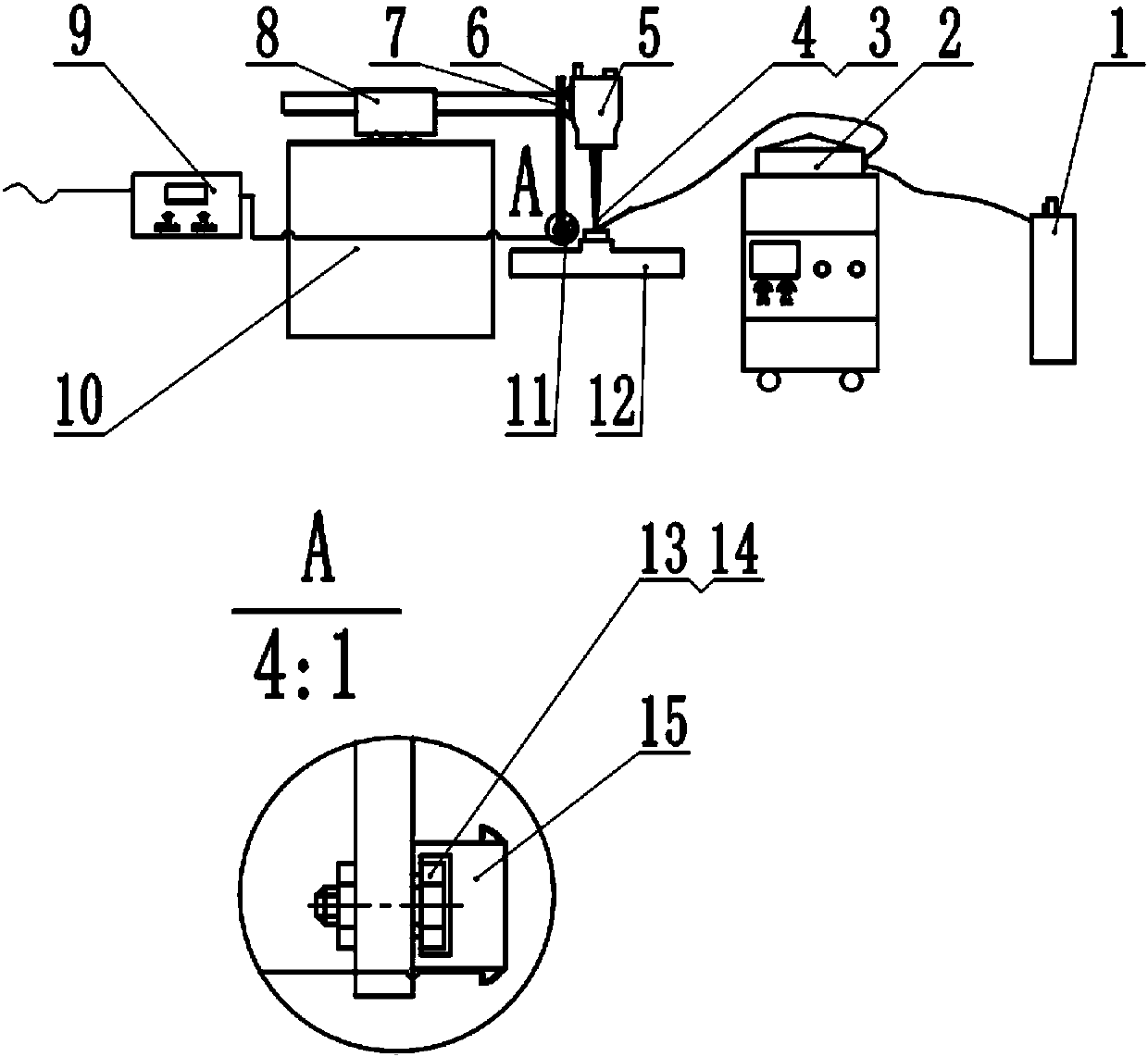

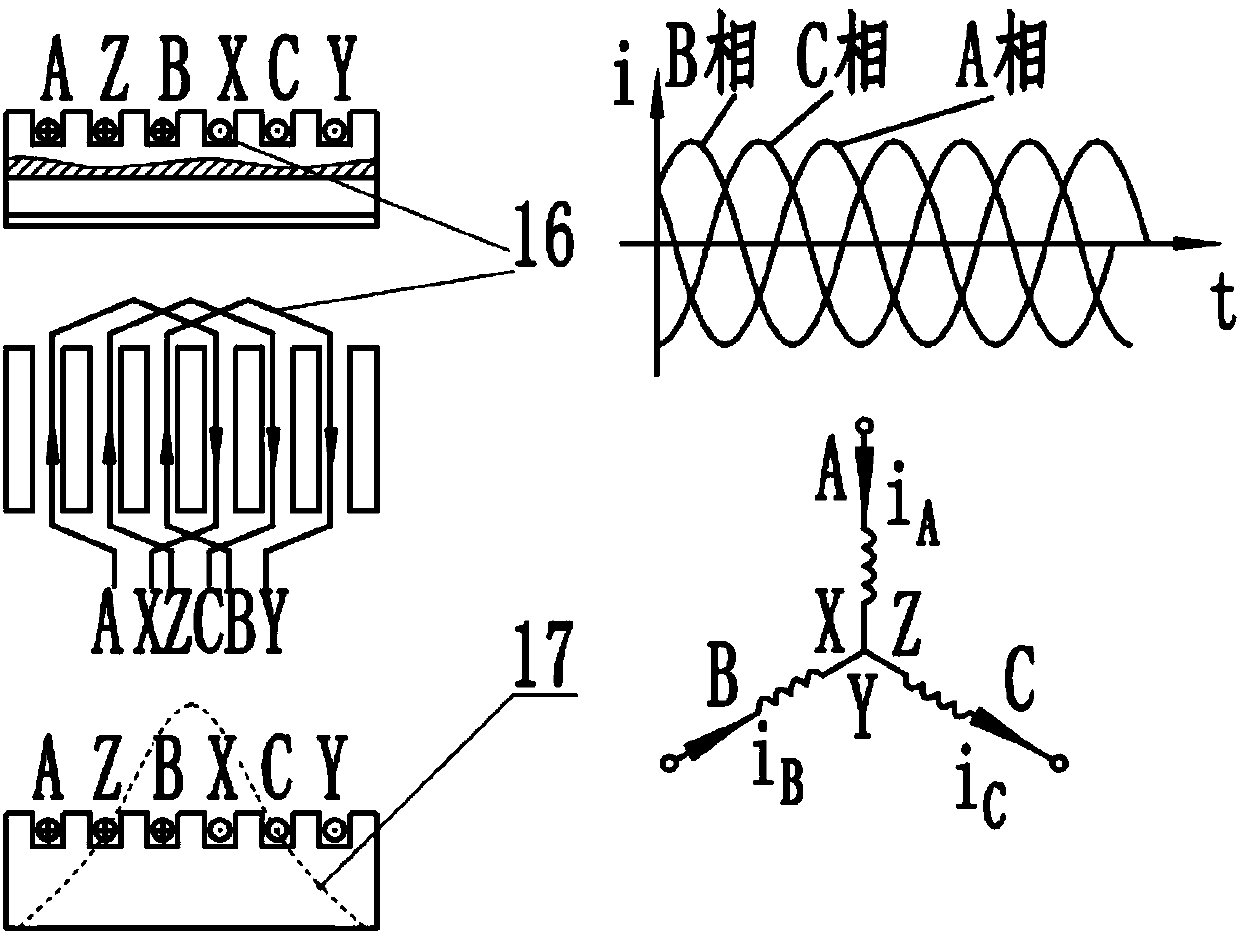

Parallel-series six-freedom-degree operating platform for adjusting position of curved workpiece

InactiveCN102350590ASolve the problems that the posture of the mechanism cannot be adjusted and cannot be automatically positionedSolve the problems that the attitude cannot be adjusted, and the automatic positioning cannot be performedLaser beam welding apparatusUniversal jointEngineering

The invention discloses a parallel-series six-freedom-degree operating platform for adjusting a position of a curved workpiece, which is applied to a laser strengthening process. A guide rail which is arranged along a y axis direction is arranged between a frame and a y axis moving platform; a guide rail which is arranged along an x axis direction is arranged between the y axis moving platform and an x axis moving platform; a central position on the upper surface of the x axis moving platform is connected to the central position at the bottom of a rotating platform along a z axis direction through a rotating pair; a moving platform is arranged on upper part of the rotating platform; four moving chains are in parallel connection between the rotating platform and the moving platform; moving pairs are arranged on the middle parts of first, second and fourth moving chains; two ends of the first, second and fourth moving chains are respectively connected to the rotating platform and the moving platform through spherical pairs; a lower end of a third moving chain is vertically and fixedly connected to the centre of the rotating platform along the z axis direction, a moving pair is arranged on the middle part of the third moving chain and an upper end of the third moving chain is connected to the moving platform through a universal joint; and the first, second and third moving chains are respectively connected to driving pieces, thereby being capable of realizing the free adjustment for the position and displacement of a large-scale irregular curved workpiece during the strengthening process.

Owner:JIANGSU UNIV

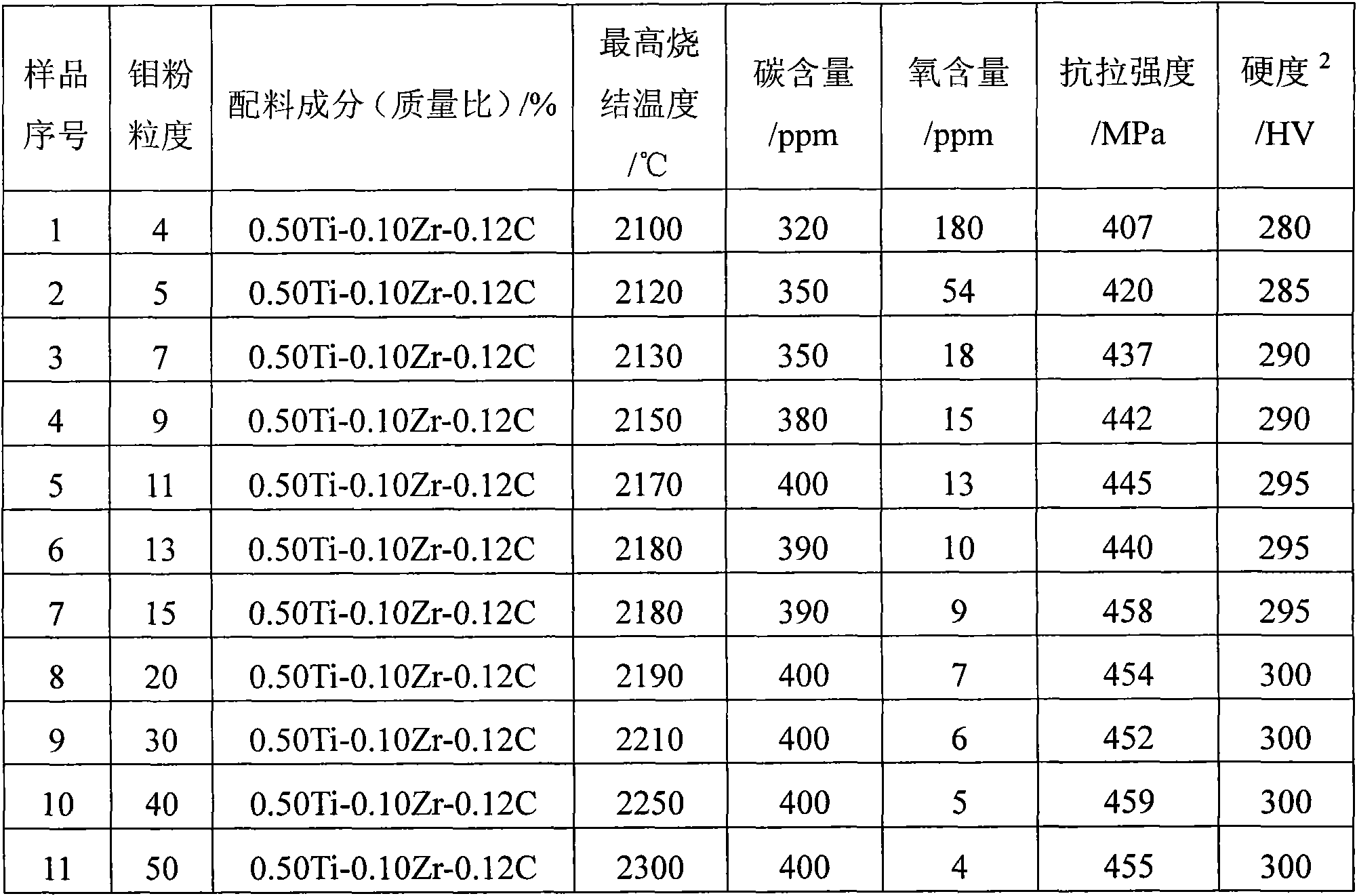

Method for preparing low-oxygen titanium-zirconium-molybdenum (TZM) alloy and application

ActiveCN102041404AReduce oxygen contentOxygen content less impurityX-ray tube electrodesForging/hammering/pressing machinesTitanium zirconiumAlloy

The invention provides a method for preparing a low-oxygen titanium-zirconium-molybdenum (TZM) alloy, which comprises the following steps of: 1) selecting raw materials, namely, uniformly mixing industrial molybdenum powder with the Fisher particle size of 4 to 50 mu m, powder containing titanium and zirconium and with the Fisher particle size of 3 to 10 mu m, and simple substance carbon powder with the Fisher particle size of 0.1 to 3 mu m according to a certain mass ratio; 2) shaping the raw materials, namely, treating the mixed raw materials under the pressure of 100 to 300 Mpa to obtain a shaped blank; and 3) sintering the raw materials, namely, sintering the shaped blank in the environment of vacuum, hydrogen or inert gas at the temperature of 1,800 to 2,300 DEG C for 5 to 15h to obtain the low-oxygen TZM alloy. The method solves the problem of high oxygen content of the TZM alloy prepared by a powder metallurgy method. The low-oxygen TZM alloy prepared by the method can be used for the preparation of a rotating anode of an X-ray tube, a composite target substrate, a high-temperature crucible, a hot-forging die and a high-temperature ceramic pad.

Owner:XIAN GEMEI METAL MATERIAL

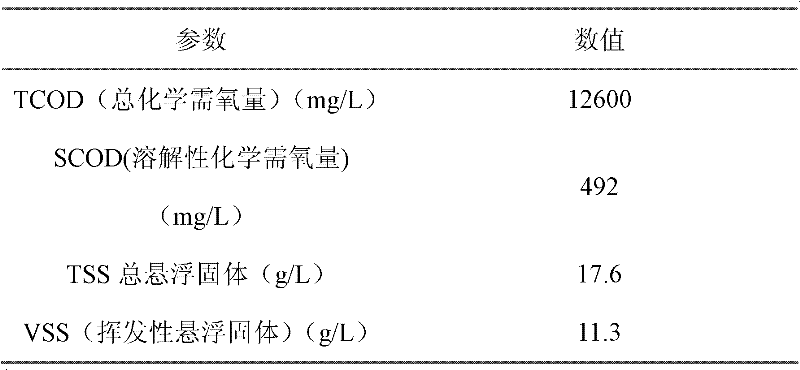

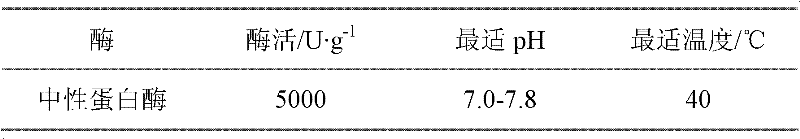

Method for strengthening electricity generating performance of MFC (micro-function circuit) by taking excess sludge as fuel and strengthening sludge reduction by enzyme

InactiveCN102569860AHigh removal rateImprove power generation performanceBiochemical fuel cellsBiological sludge treatmentNeutral proteaseSludge

The invention belongs to the filed of microbiological fuel cells, and provides a method for strengthening electricity generating performance of an MFC (Microbial Fuel Cell) by taking excess sludge as fuel and strengthening sludge reduction by enzyme. The method comprises the steps of adding 20mM of NaCl in the excess sludge for strengthening the electrical conductivity of solution, adding neutral protease and Alpha-amylase, and generating electricity by directly using electricity generating microorganisms in the excess sludge for one day so as to start the MFC and obtain higher electric energy, wherein the strengthening effect of the neutral protease and the Alpha-amylase on an SMFC (Sediment Microbial Fuel Cell) at 40 DEG C is the most obvious. Under a condition that the total concentration of the enzyme is not changed, the mass concentration ratio of the neutral protease and the Alpha-amylase is 2:3, at the moment, the power density is the largest (776mW*m-2), and the removal rates of TCOD (total chemical oxygen demand), TSS (total suspended solids) and VSS (volatile suspended solids) reach 87.29%, 91.75% and 95.01% respectively. The method is fast in starting, simple in process, convenient to operate, and low in cost, and can treat the excess sludge in an urban domestic sewage treatment plant.

Owner:HUNAN UNIV

Moderate-intensity anti-corrosion aluminium alloy material and aluminium alloy rod for cable

The invention discloses a moderate-intensity anti-corrosion aluminium alloy material and an aluminium alloy rod for a cable. The moderate-intensity anti-corrosion aluminium alloy material comprises the components of iron, silicon, magnesium, boron, copper, zinc, rare earth and the balance of aluminium; in a preparation process, an aluminium ingot, aluminum-boron alloy, aluminum-silicon alloy, aluminum-iron alloy, aluminum-rare earth alloy, aluminum-copper alloy, aluminum-zinc alloy and a magnesium alloy ingot are smelted to form alloy liquid, the alloy liquid is refined and stands by thermal insulation, component regulation is performed, then casting is performed to obtain a cast ingot, and homogenization treatment is performed on the cast ingot to obtain a homogenized cast ingot; the homogenized cast ingot is water-cooled, then hot rolling is performed, and the cast ingot is cooled to be below 100 DEG C to obtain hot rolling aluminum alloy; the hot rolling aluminum alloy is heated, kept warm and then cooled to room temperature, and precipitation heat treatment is performed to obtain the moderate-intensity anti-corrosion aluminium alloy material. The moderate-intensity anti-corrosion aluminium alloy material and the aluminium alloy rod for the cable are high in mechanical strength, good in corrosion resistance and excellent in comprehensive performance.

Owner:ANHUI ELECTRIC GRP SHARES

Metal surface nanometer powder permeating method based on laser induction shock waves

The invention relates to a metal surface nanometer powder permeating method based on laser induction shock waves. The method comprises the following steps that base materials are pretreated; a machining surface is covered with an absorbing layer; a base metal surface is covered with the absorbing layer; a restraining layer is exerted on the base metal surface; pre-impact life-extension treatment is carried out on the base metal surface on which the restraining layer is exerted; impact life extension is carried out on the base metal surface subjected to the impact life extension treatment; and base metal materials are subjected to aftertreatment. In the process of covering the machining surface with the absorbing layer, in a clean room, a thin plate is taken, and an opening with the needed size and shape is shorn out in the middle; the thin plate is attached to the surface of the absorbing layer, and the middle of the thin plate is evenly coated with nanometer particles; and the rest is removed thoroughly, and a particle coating layer with the thickness equal to that of the thin plate is formed on the surface of the absorbing layer. According to the metal surface nanometer powder permeating method, a crystal structure, orientation distribution and metal surface elementary components on the base metal surface are obviously changed, the hardness, the fatigue life, the abrasion resistance and the corrosion resistance of the metal surface are effectively improved, operation is simple, and cost is low.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

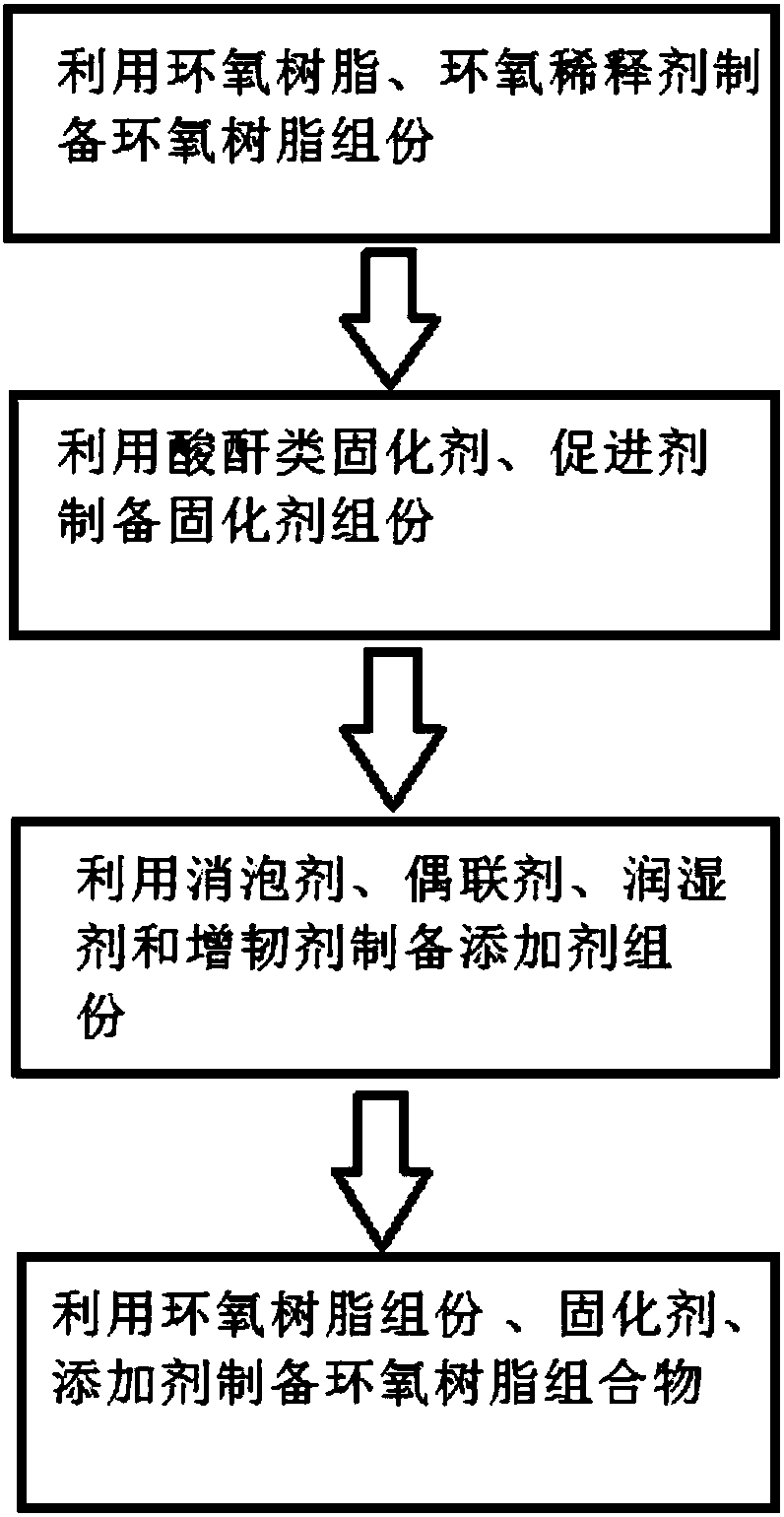

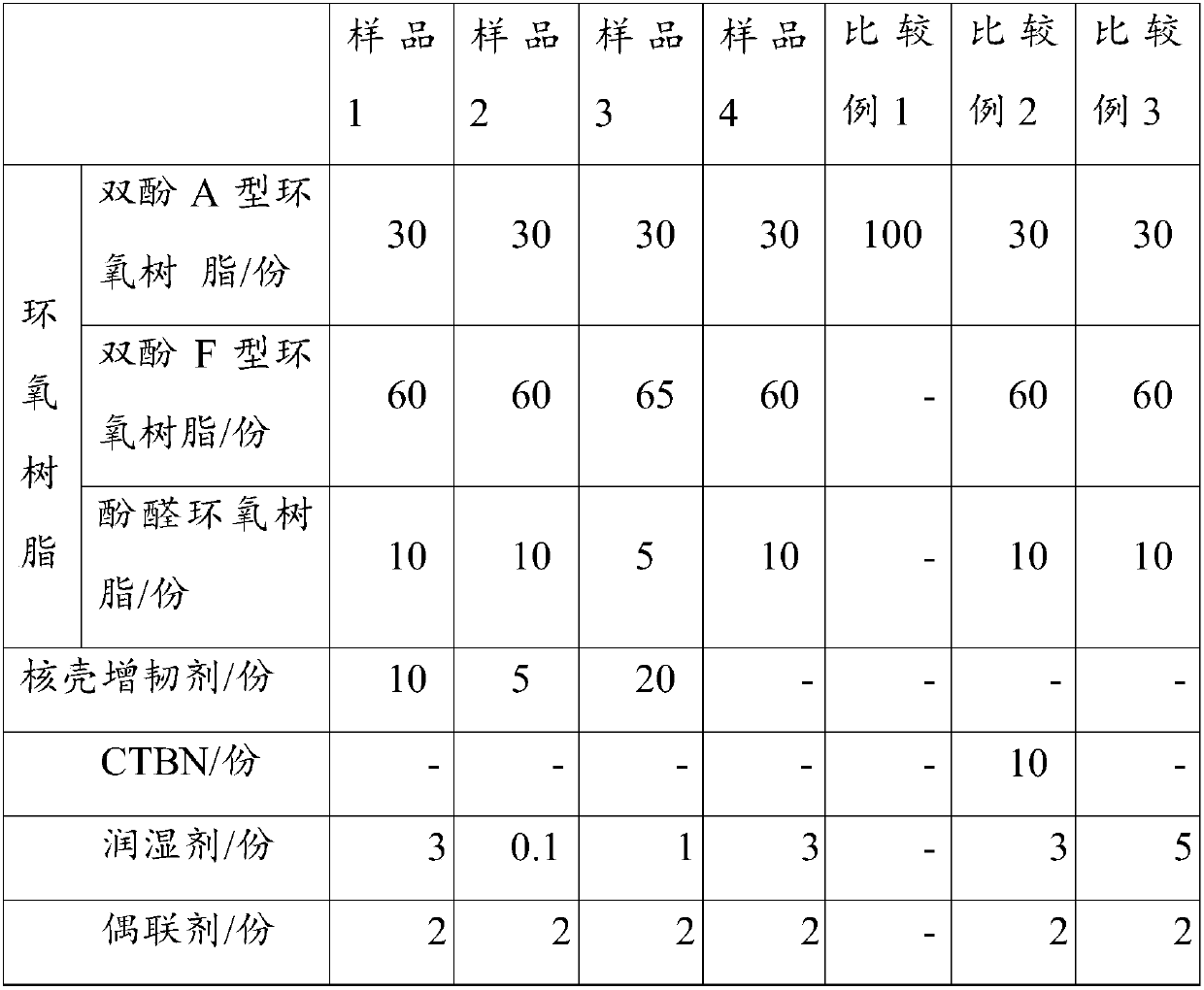

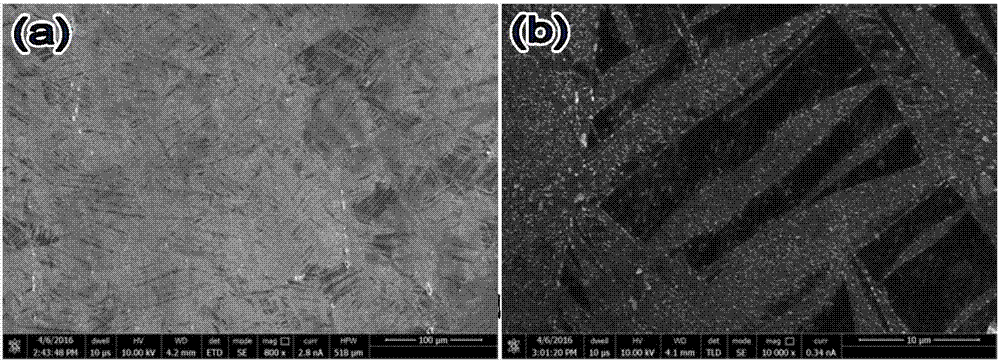

Epoxy resin composition used for fiber winding and preparation method of epoxy resin composition

The invention relates to the field of composite materials, and concretely relates to an epoxy resin composition used for fiber winding and a preparation method of the epoxy resin composition. The epoxy resin composition comprises an epoxy resin component, a curing agent component and an additive component which are in the weight ratio of 100:(80-120):(0.1-20); the epoxy resin component comprises the following materials in percentage by weight: 5-65% of epoxy resin and 10-20% of an epoxy diluent; the curing agent component comprises the following materials in percentage by weight: 90-99% of acid anhydride curing agents and 1-10% of an accelerator; the additive component comprises the following materials in percentage by weight: 0.1-3% of a defoaming agent, 2-5% of a coupling agent, 0.1-3% of a wetting agent, and 5-20% of a flexibilizer; and the flexibilizer comprises one or a mixture of more selected from glass microspheres, liquid carboxyl-terminated butadiene acrylonitrile rubber, carboxyl-terminated butadiene acrylonitrile rubber, core-shell rubber and polyurethane rubber. According to the invention, the epoxy resin composition prepared by the method has the advantages of havingexcellent toughness and strength and excellent bonding properties with fibers.

Owner:WELLS ADVANCED MATERIALS SHANGHAI

Preparation method for electrodeposition of Ni-Co/SiC nanocomposite coatings under three-electrode system

ActiveCN109097812AEffective protectionEconomic protectionElectrolytic coatingsNanocomposite coatingHardness

The invention discloses a preparation method for electrodeposition of Ni-Co / SiC nanocomposite coatings under a three-electrode system. The preparation method includes the following steps of (1) preparation of nano-particle SiC dispersion liquid; (2) preparation of modified electroplating liquid; and (3) preparation of the Ni-Co / SiC nanocomposite coatings. Under the three-electrode system, nano-SiCparticles are co-deposited with base metal through an electrochemical method to prepare the Ni-Co / SiC nanocomposite coatings. The preparation method has convenient sampling, easy process operation, low cost, large hardness, abrasion resistance and corrosion resistance, and is a high precision surface enhancement technology. The prepared deposited Ni-Co / SiC nanocomposite coatings have wide application prospects in surface material protection.

Owner:CENT SOUTH UNIV

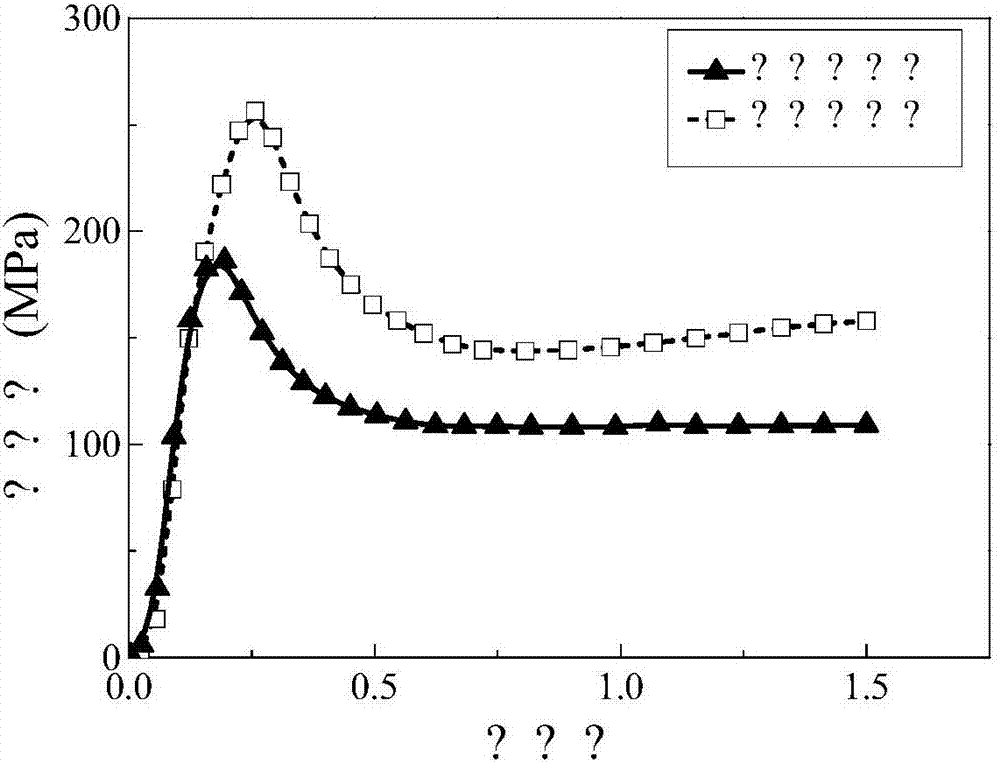

Method for improving Mg-Al-Zn magnesium alloy thermoforming and service performance

InactiveCN107119246AImprove mechanical propertiesExcellent thermoforming propertiesCrystal twinningPre deformation

The invention provides a method for improving Mg-Al-Zn magnesium alloy thermoforming and service performance. The method comprises the steps that Mg-Al-Zn magnesium alloy is subjected to pre-deformation treatment at 25 DEG C to 300 DEG C, twin crystal or low-angle crystal boundaries are introduced, and then aging treatment is conducted. According to the deformation heat treatment method, precipitation of a continuous precipitation phase of the Mg-Al-Zn magnesium alloy can be effectively promoted, and alloy tissue with a uniform, small and dispersively distributed precipitation phase is obtained finally; and alloy strength and plasticity are synchronously improved, and thermoforming performance and service performance of the alloy are improved. The method for improving the Mg-Al-Zn magnesium alloy thermoforming and service performance is reasonable in design, simple in equipment requirement, convenient to operate, low in cost and high in efficiency, distribution of the precipitation phase of the Mg-Al-Zn magnesium alloy is reasonably controlled, the thermoforming performance and service performance of the alloy are improved, and the method has a good industrial application prospect.

Owner:CENT SOUTH UNIV

High-intensity high-damping deforming magnesium alloy with rear earth yttrium

The invention discloses a high-intensity high-damping deforming magnesium alloy with rear earth yttrium, which is characterized by comprising the following components by weight percent: 2.9-3.1 percent of Al, 0.9-1.1 percent of Zn, 0.5-2 percent of Y, 0.29-0.31 percent of Mn and the rest of Mg and unavoidable impurities. The high-intensity high-damping deforming magnesium alloy with rear earth yttrium can greatly increase the mechanical property and the damping performance of the high-intensity AZ series deforming magnesium alloy, successfully solve the conflict of the mechanical property andthe damping performance of the magnesium alloy and satisfy the actual requirements for a high-intensity high-damping light-weight material in the fields of very high-speed trains, automobiles, aerospace, national defense war industry, and the like, moreover, the magnesium alloy material has lower cost, and a technical device is the normal universal device with strong portability and easy operation.

Owner:CHONGQING UNIV

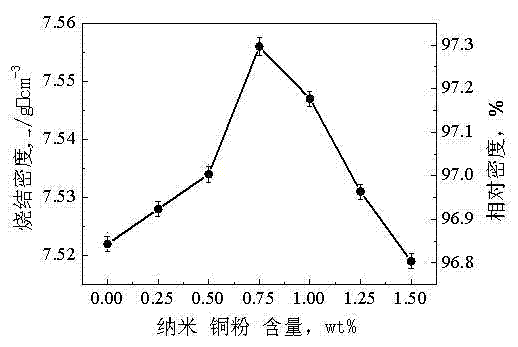

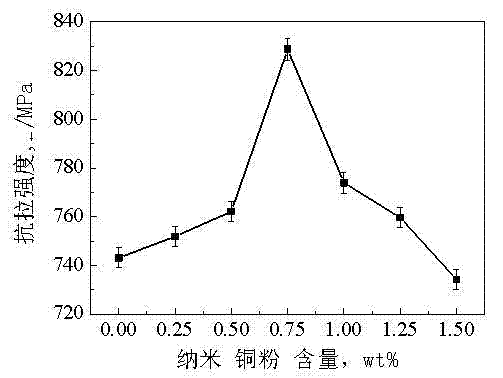

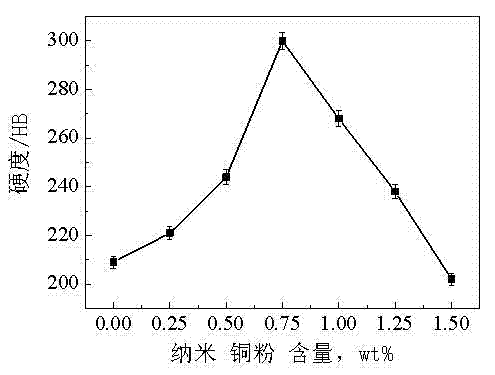

Method of improving performance of iron-based powder metallurgy parts prepared by high velocity compaction

InactiveCN102773481AExacerbate cold weldingImprove mechanical propertiesPowder mixtureMechanical property

A method of improving performance of iron-based powder metallurgy parts prepared by high velocity compaction belongs to the technical field of powder metallurgy. An optimization method that nanometer copper powder is used for replacing partial copper powder in iron-based mixed powder is adopted. The nanometer copper powder, the copper powder and iron powder are prepared in a glove box filled with high-purity argon according to a certain mass fraction, and fed into a charging barrel. The charging barrel is sealed, and put into a centrifugal drum machine to carry out mixing for a certain period of time, so that a uniform iron-based powder mixture is obtained. Zinc stearate acetone suspension is used as a die wall lubricant, and the iron-based parts are prepared by the high velocity compaction. The parts are sintered for a certain period of time under the protective atmosphere of hydrogen at the temperature of 1150-1280DEG C, so as to obtain iron-based products with high mechanical properties. According to the invention, the nanometer metal powder is combined with an advanced high velocity compaction technology, the iron-based powder metallurgy parts with high mechanical properties are successfully prepared, and the method has the advantages that the preparation process is simple, the cost is low, the production efficiency is high, the part density and the mechanical property are stable, the part sintering size precision is high, and the like.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method for graphene-enhanced copper-niobium multi-core composite wire

ActiveCN106448799AHigh strengthImprove ductilityConductive materialMetal/alloy conductorsReduction treatmentAlcohol

The invention provides a preparation method for a graphene-enhanced copper-niobium multi-core composite wire. The preparation method comprises the following steps: firstly, uniformly mixing graphene powder, niobium powder and copper powder to obtain mixed powder; secondly, adding a tackifier and the mixed powder into alcohol ketone mixed solution, stirring uniformly, drying to obtain a powder material, and then performing thermal reduction treatment on the powder material to obtain graphene-enhanced copper-niobium composite powder; thirdly, filling a pipe with graphene-coated copper-niobium composite powder to obtain a piped composite body; fourthly, drawing to obtain a single-core composite wire; fifthly, performing primary compounding moulding to prepare a 19-core composite wire; sixthly, performing secondary compounding moulding to prepare a 192-core composite wire; seventhly, performing tertiary compounding moulding to obtain the graphene-enhanced copper-niobium multi-core composite wire. The wire prepared by the preparation method has the characteristics of high strength, high extensibility, high conductivity and the like of the graphene, and the obstacle that the performance of a Cu / Nb material prepared by a conventional process cannot be further improved is overcome.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

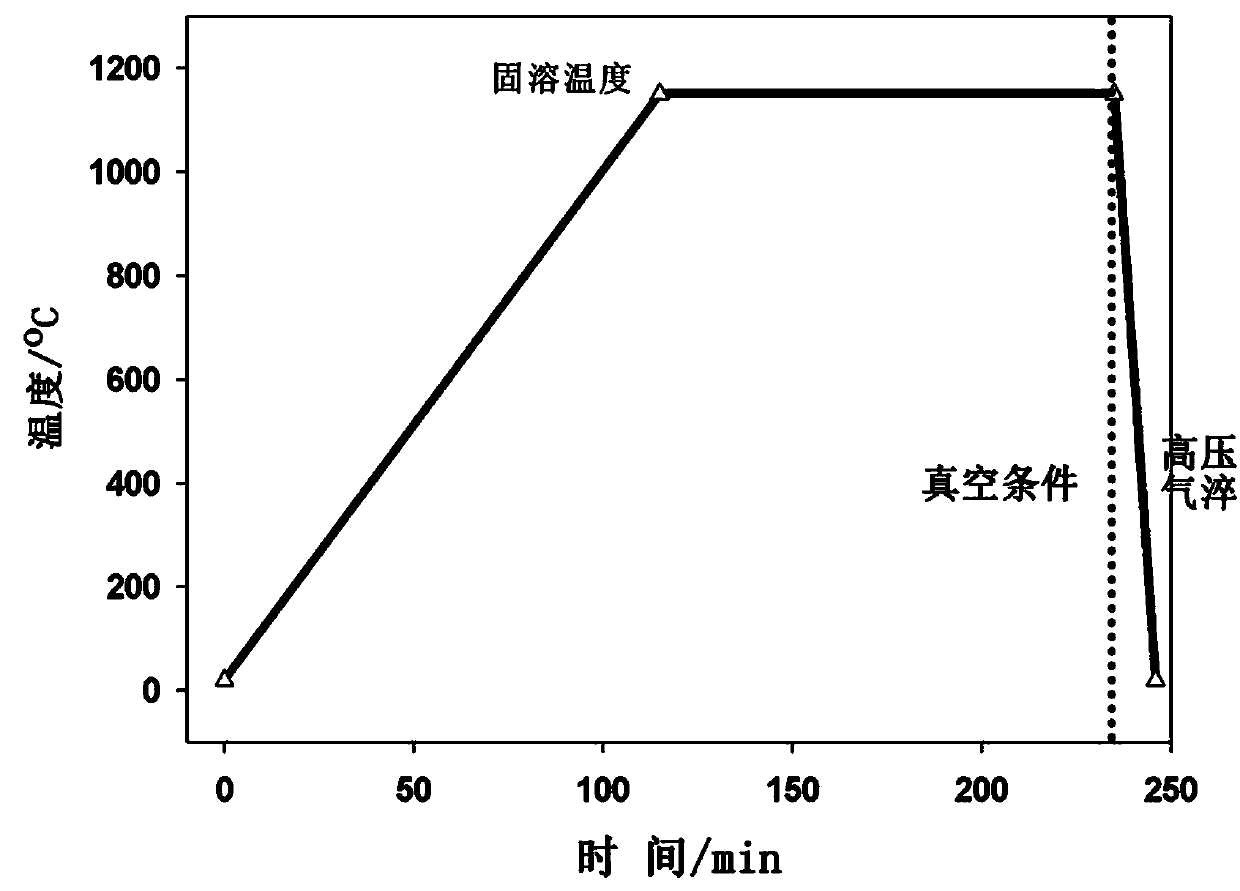

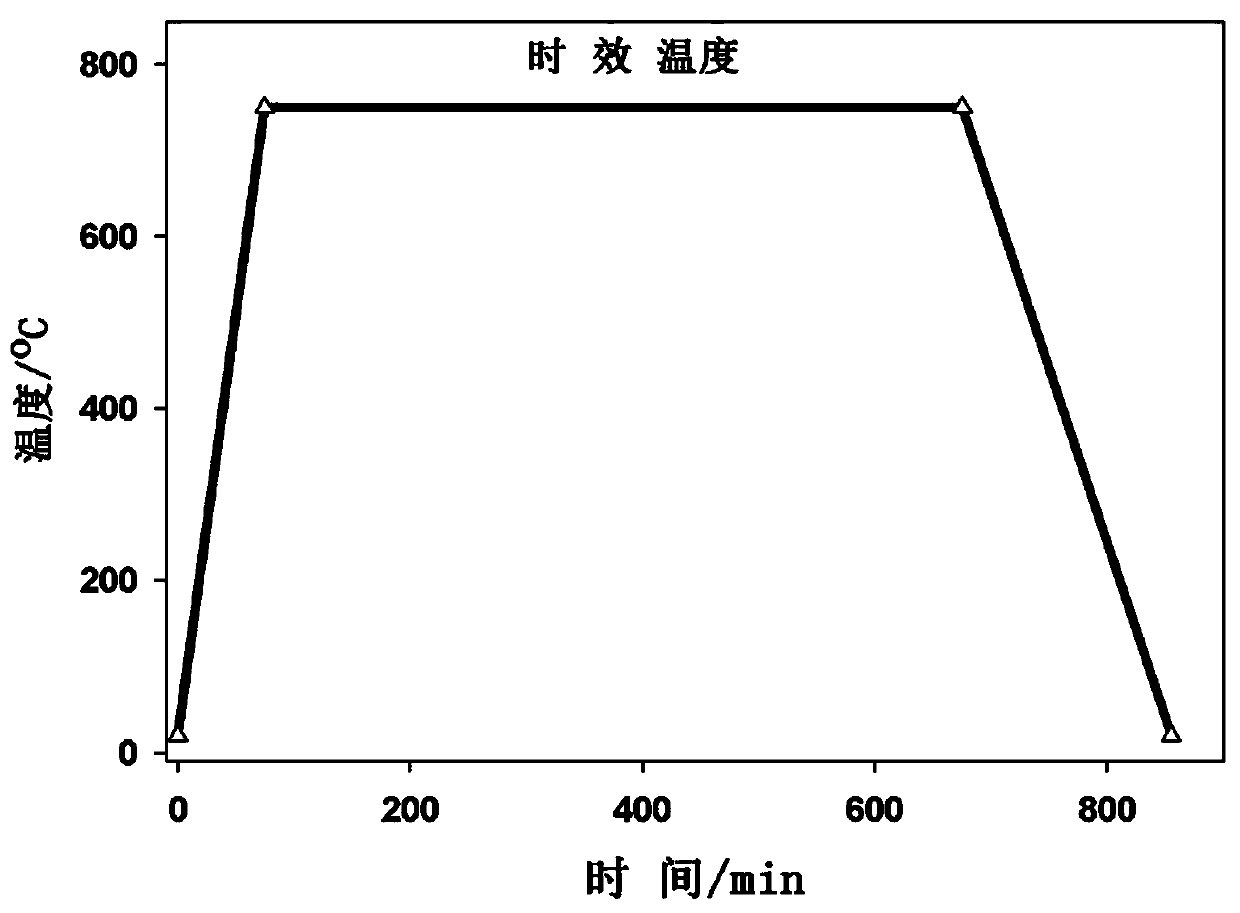

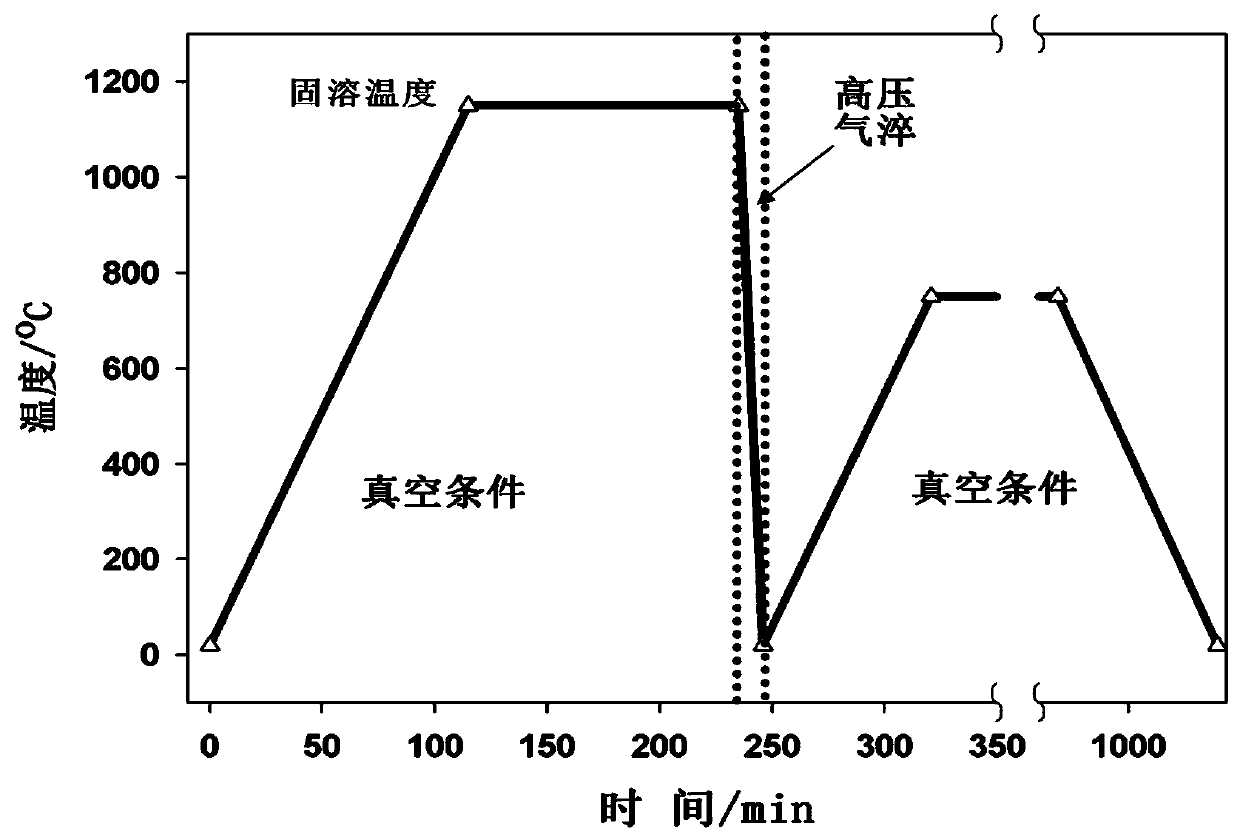

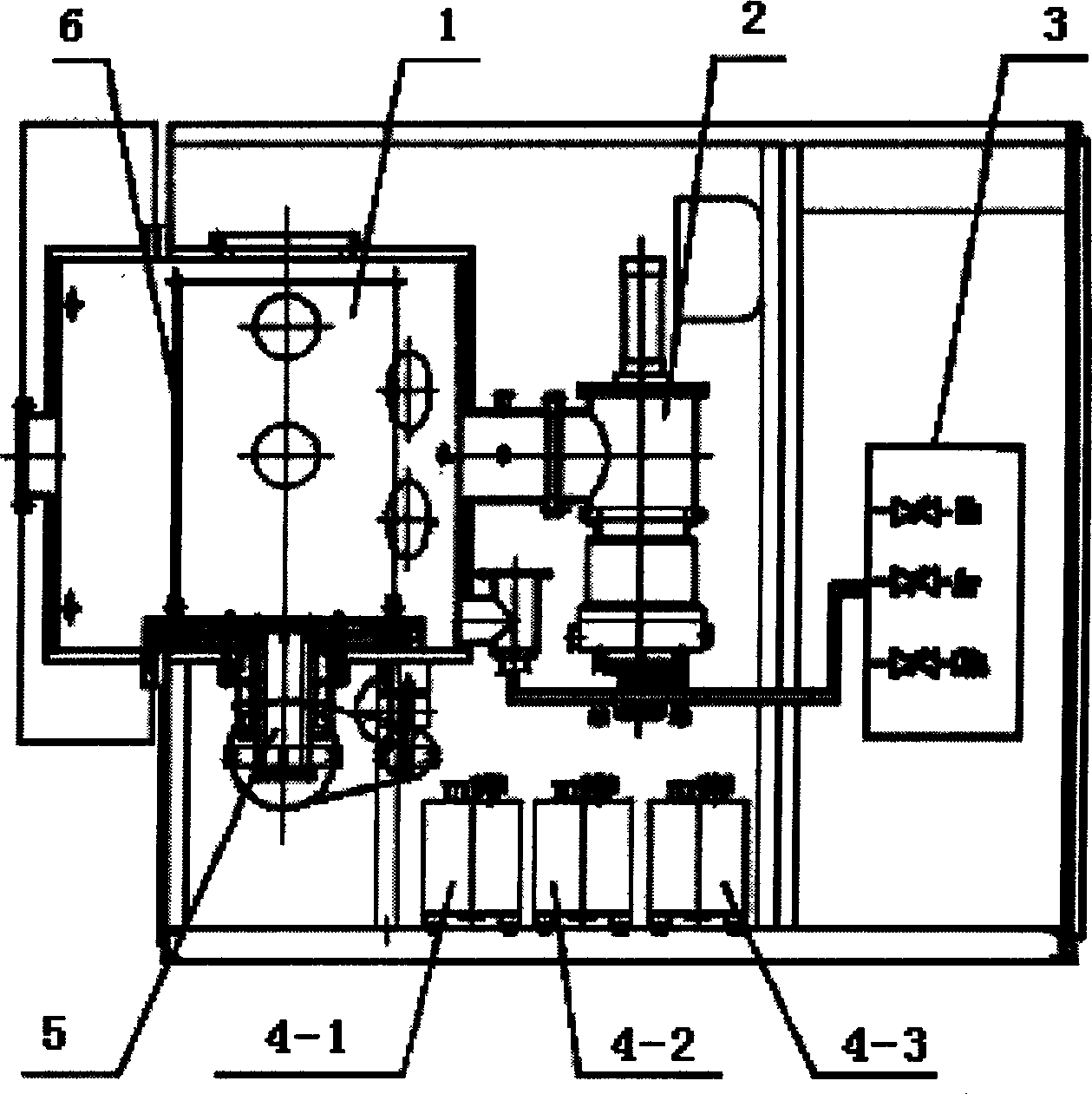

Heat treatment method of WC-Co-Ni3Al hard alloy

The invention discloses a heat treatment method of a WC-Co-Ni3Al hard alloy. The heat treatment method sequentially comprises the following steps: heating the WC-Co-Ni3Al hard alloy to a solid solution temperature of 1000-1300 DEG C under a vacuum condition of lower than 1 Pa at a speed of not less than 10 DEG C / min, and then, preserving the temperature for 10-120 minutes to carry out a solid solution treatment; introducing high pressure N2 or Ar after the temperature maintaining treatment, and cooling the hard alloy to the room temperature at a cooling speed of not less than 100 DEG C / min; heating the hard alloy to 600-900 DEG C under a vacuum condition of lower than 1 Pa at a speed of not less than 10 DEG C / min, preserving the temperature for not less than 10 h to carry out an aging treatment; and then, slowly cooling the hard alloy to the room temperature to obtain the WC-Co-Ni3Al hard alloy with obviously increased gamma'(Ni3Al) phase precipitation amount; compared with an alloy without heat treatment, the precipitation amount of the gamma' phase in the heat treated alloy disclosed by the invention is obviously increased, the strengthening effect is more obvious, the bending strength of the alloy is further improved, obviously, and meanwhile, stress generated in an early stage gas quenching rapid cooling process can be eliminated; moreover, the heat treatment method is simple in process, simple and convenient to operate, efficient and environment-friendly.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Method for enhancing high strength cast aluminum alloys by large volume fraction of quasi-crystal

This invention discloses a method for producing high-strength Al alloy reinforced with high-volume-percentage crystalloid. The method utilizes crystalloid alloy Al15-Mg44-Zn41 or Mg40-Zn60-Y10 as the reinforcing alloy, and cast Al102 or Al60-Mg40 alloy as the matrix. The method controls the pre-crystallization morphologies of the two alloys by liquid quenching. When the crystalloid melt temperature is reduced to 5-25 deg.C below its phase transition point, and the matrix temperature is 10-30 deg.C below crystalloid melt temperature, high-volume-percentage crystalloid is introduced into the matrix melt. During the co-melting process, the temperature difference ensures precipitated crystalloid is not re-molten, thus can realize reinforcement of high-volume-percentage crystalloid micro- or nano-particles to Al alloy matrix. During the re-melting process, the crystalloid particles are not molten. The method is a-effect reinforcement method.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

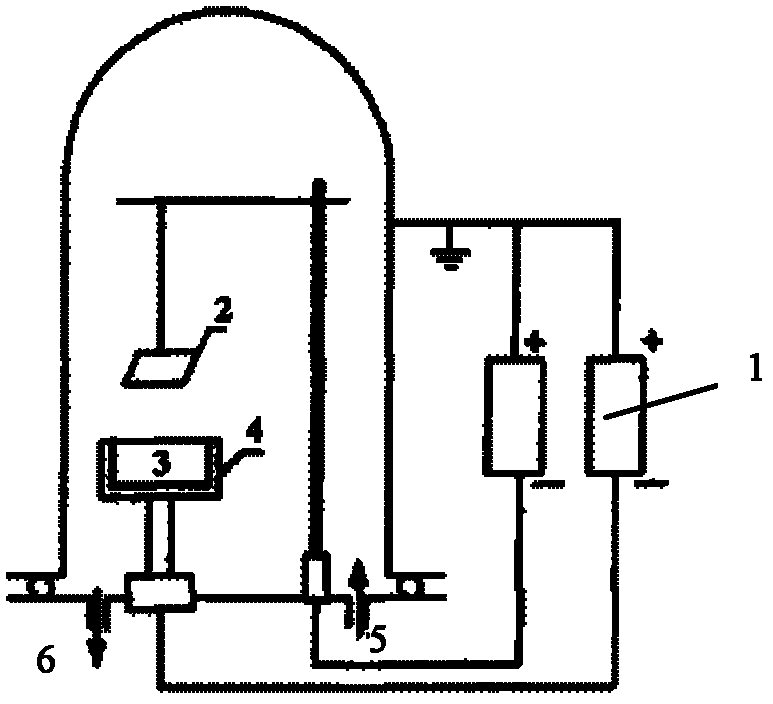

Hall ion source actuated magnetron sputtering enhancing type multi-arc ion plating film method

InactiveCN1664161AHigh bonding strengthIncrease ionization rateVacuum evaporation coatingSputtering coatingIntermediate frequencyAlternating current

The invention discloses a method of enhanced multi-arc ion film plating through the Hall source driving magnetron sputtering, which is used for preparing the rigid film materials including TiN, TiC, (Ti, Si)N, (Ti, Si)C, (Ti, Si)CN, Ti(CN), (Ti, Al)N. The method comprises the following steps: treating the surface of the workpiece in the device, heating it to 300-350 Deg.c, charging the working gas Ar and N2 in the air pressure 1-2x10-1Pa, wherein the voltage is provided by the direct current power and intermediate-frequency alternating-current power of the device, and the high inonization reacting gas ion is provided by the Hall source of the device, then the hard electron and the molecular gas collide and generate the glow discharge, and form the ion with chemical activity which reacts with the free radical in the workpiece surface and deposit the film, the depositing speed is 2.0-4.0 per hour; charging the protective atmosphere to the furnace and cooling, then can get the film in the workpiece surface.

Owner:XI AN JIAOTONG UNIV

Overhead heat-resistance aluminum alloy conductor material and preparation method thereof

InactiveCN106893899ARaise the recrystallization temperatureAdd lessConductive materialMetal/alloy conductorsCeriumTemperature resistance

The invention discloses an overhead heat-resistance aluminum alloy conductor material and a preparation method thereof, and relates to the technical field of aluminum alloy conductor materials. The overhead heat-resistance aluminum alloy conductor material comprises the following elements in percentage by mass: 0.10-0.45% of zirconium, 0.01-0.10% of yttrium, 0.01-0.10% of scandium, 0.3-1.0% of lanthanum and cerium, 0.05-0.18% of iron, silicon not more than 0.05%, nickel not more than 0.05, magnesium not more than 0.02, zinc not more than 0.04, boron not more than 0.01, and the balance of aluminum and inevitable impurities. The preparation method comprises the following steps: foundry returns, aluminum ingots and Al-Fe intermediate alloy blanks are put in a smelting furnace, are heated for melting, and are transferred into an insulation furnace; then, Al-Zr, Al-Sc, Al-Y and Al-RE intermediate alloys are added for refining and deslagging to prepare fine alloy melts; a continuous casting and continuous rolling process is adopted to firstly pour the fine alloy melts as aluminum alloy castings; and the aluminum alloy castings are leaded into a rolling mill to roll aluminum alloy rods with needed specifications. The aluminum alloy conductor material is high in electric conductivity and excellent in high-temperature resistance; and the preparation method needs no heat treatment, saves the energy consumption, and reduces the production cost.

Owner:河北欣意电缆有限公司

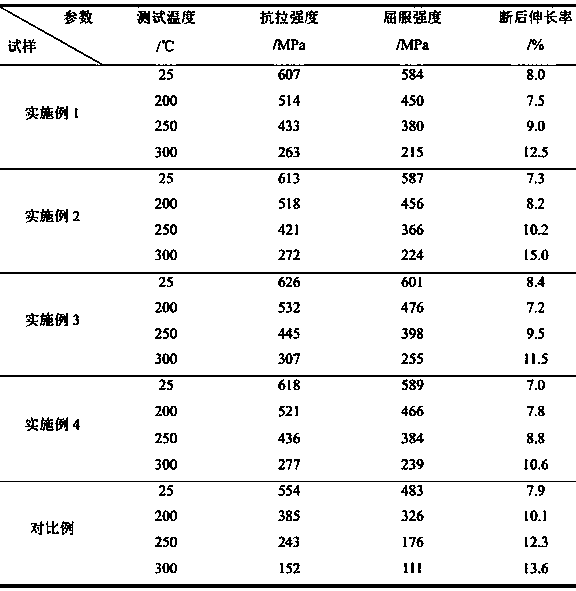

Ultrahigh-strength and heat-resistant aluminum alloy and preparation method thereof

ActiveCN109898000AInhibit growthSuppress coarseningFurnace typesHeat treatment furnacesYttriumScandium

The invention provides an ultrahigh-strength and heat-resistant aluminum alloy and a preparation method, and the alloy aims at overcoming the defects of an existing heat-resistant aluminum alloy. Theultrahigh-strength and heat-resistant aluminum alloy comprises the following components in percentage by mass: 5.9-7.2% of copper, 0.60-1.50% of silver, 0.6-0.9% of magnesium, 0.1-0.5% of chromium, 0.1-0.5% of molybdenum, 0.09-0.3% of zirconium, 0.07-0.12% of scandium and / or 0.07-0.12% of erbium and / or 0.07-0.12% of yttrium, and the balance aluminum, wherein the mass ratio of copper to magnesiumis 7-10. According to the ultrahigh-strength and heat-resistant aluminum alloy, the separating out of a strengthening phase in the alloy and the distribution are controlled by means of microalloying,deforming, thermal treatment and the like based on the abovementioned mixing ratio of the alloy, so that the density of the strengthening phase in the alloy is improved, and the alloy remains a largeamount of fine dispersed strengthening phases under high temperature, and as a result, the alloy strength and heat resistance are improved.

Owner:郑州轻研合金科技有限公司

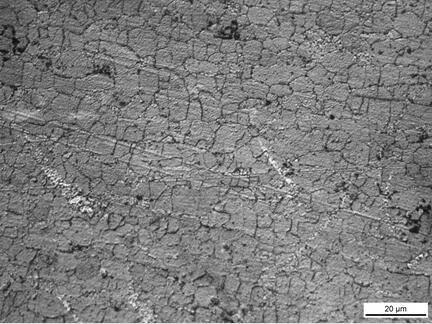

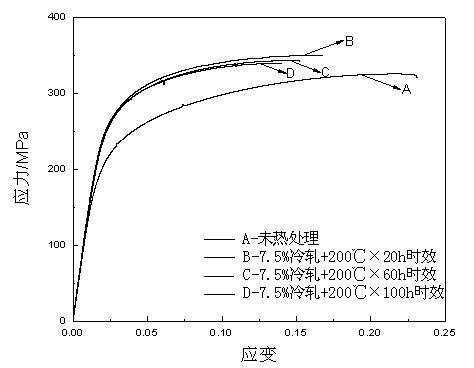

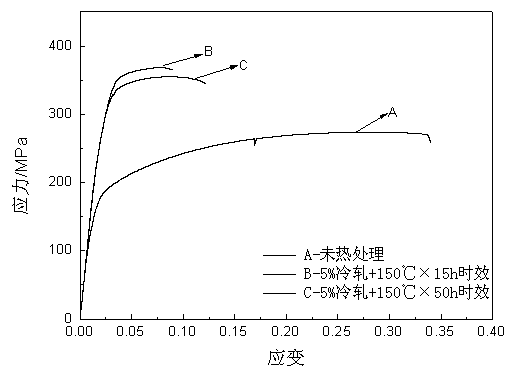

Thermal treatment process for improving deformed magnesium alloy strength

The invention provides a thermal treatment process for improving deformed magnesium alloy strength, which is used for achieving the purpose of remarkably improving the magnesium alloy strength through small-deformation cold rolling and different-time artificial ageing. The thermal treatment process specifically comprises the following steps of: (1), carrying out cold rolling on magnesium alloy under the room temperature, wherein the cold-rolling deformation is 5%-7.5%; and (2), heating up the cold-rolled and pre-deformed magnesium alloy to 150 DEG C to 200 DEG C for ageing, preserving the heat for 15 hours to 100 hours, and cooling in the air to the room temperature. The thermal treatment process can be used for remarkably improving the strength of the magnesium alloy. Moreover, relative to the normal ageing process, the thermal treatment process further can be used for remarkably improving the aging velocity of the magnesium alloy. Besides, the used process equipment is normal common equipment which is easy to operate, lower in cost and easy to industrialize.

Owner:CHONGQING UNIV

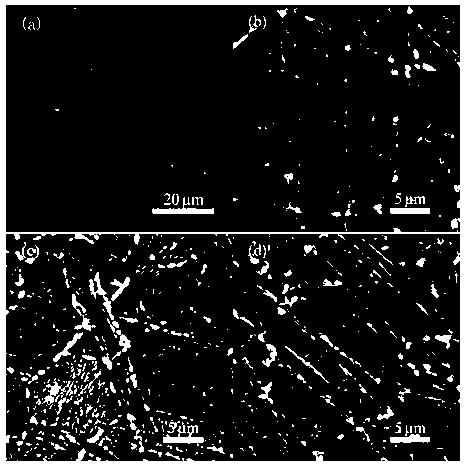

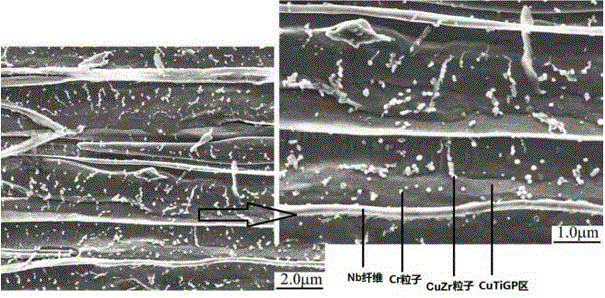

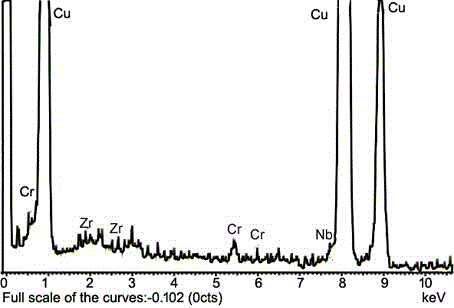

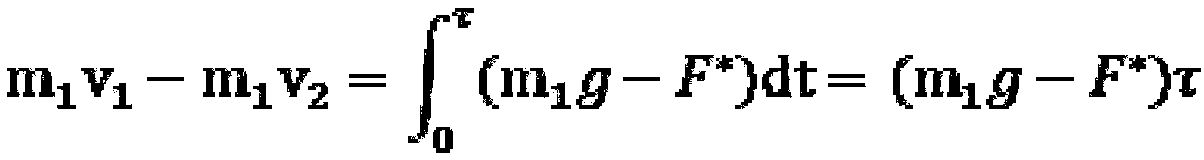

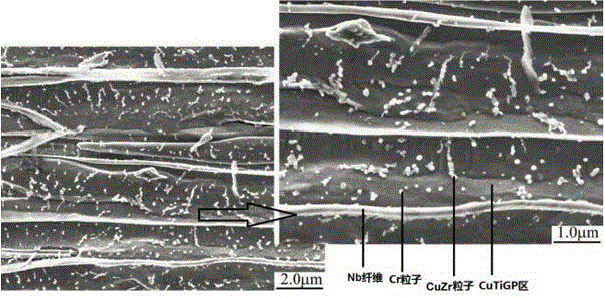

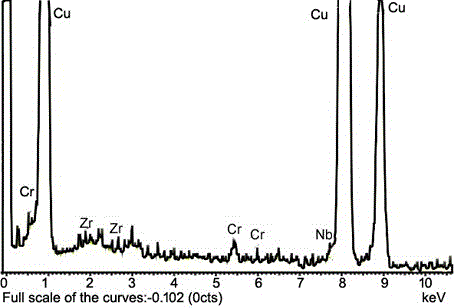

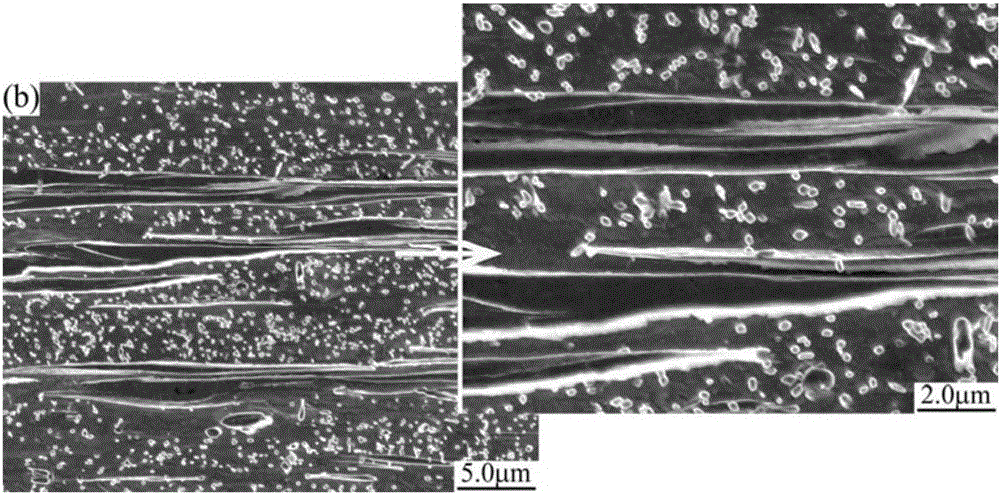

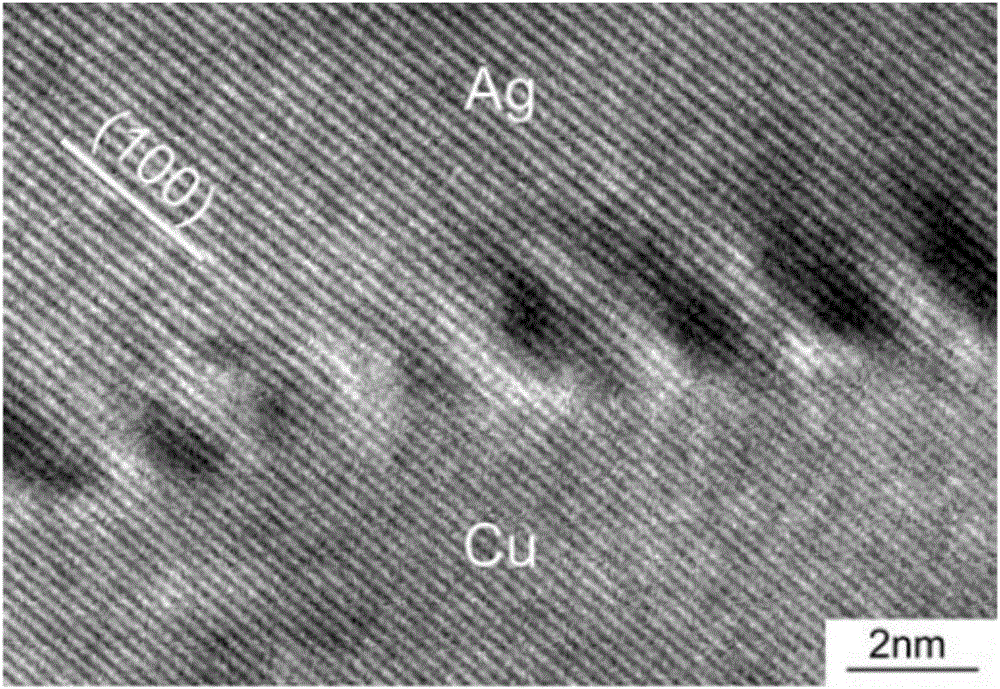

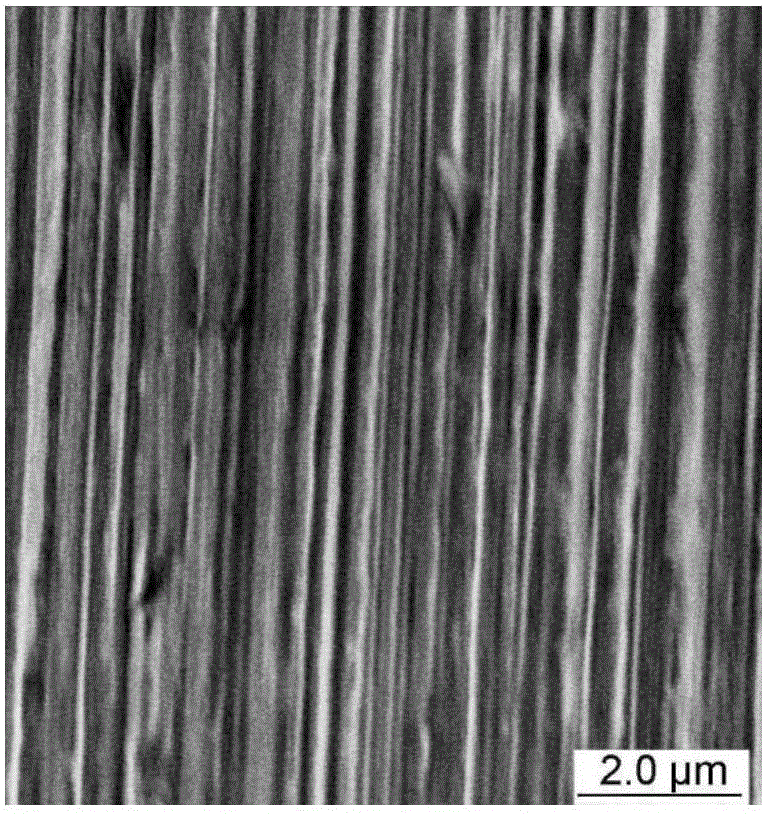

Super-strong high-conductivity copper alloy used as material for contact lines of high speed railways with speed per hour being 400 km or above

Disclosed is super-strong high-conductivity copper alloy used as a material for contact lines of high speed railways with the speed per hour being 400 km or above. The copper alloy comprises, by weight, 3-20% of niobium, 0.01-1% of chromium, 0.01-0.5% of zirconium, 0.01-0.2% of titanium, and the balance copper. The copper alloy is in a long bar or line form, wherein niobium in the form of nanofibers and solid solution atoms is distributed in a copper substrate, most of the niobium nanofibers are arranged in the copper substrate approximately in parallel, and the axial direction of the fibers is roughly parallel to the axial direction of the copper alloy bar or line. Chromium in the form of nano-particles and solid solution atoms is distributed around the niobium nanofibers and in the copper substrate, zirconium in the form of copper-zirconium compound nano-particles and solid solution atoms is distributed around the niobium nanofibers and in the copper substrate, and titanium in the form of a copper-titanium GP zone and solid solution atoms is distributed in the copper substrate. The total quantity of the niobium, chromium and zirconium solid solution atoms in the copper alloy is smaller than 0.2%. Part of the chromium nano-particles and the copper-zirconium compound nano-particles are pinned in the phase interface of the niobium nanofibers and the copper substrate.

Owner:ZHEJIANG UNIV

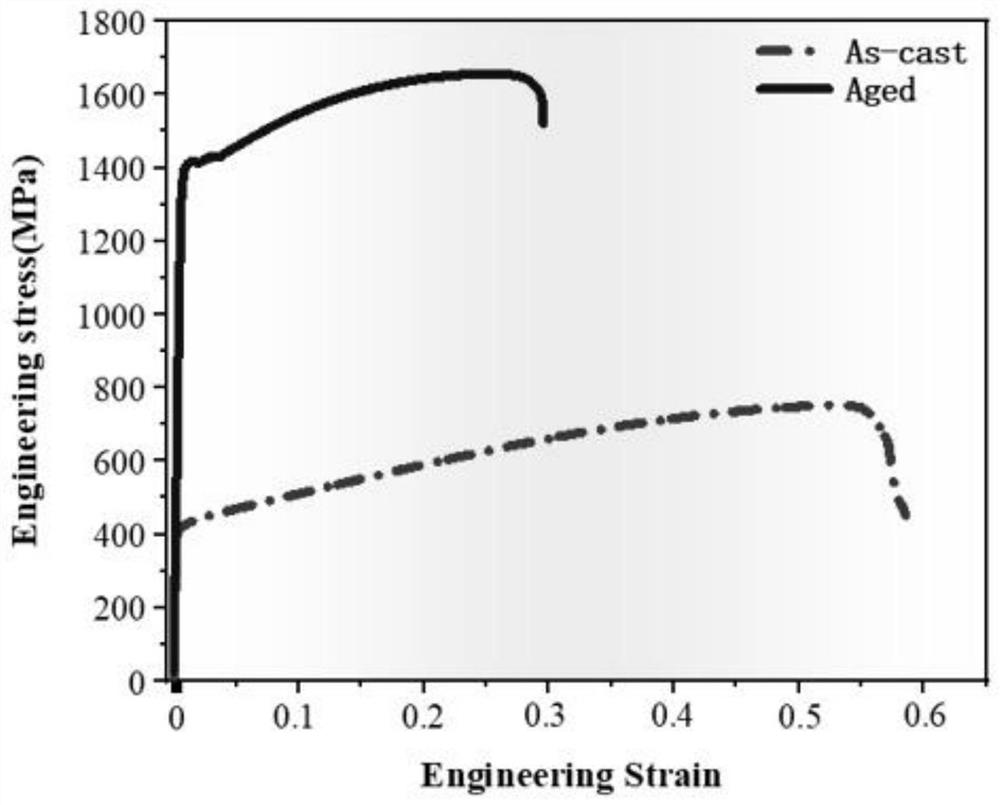

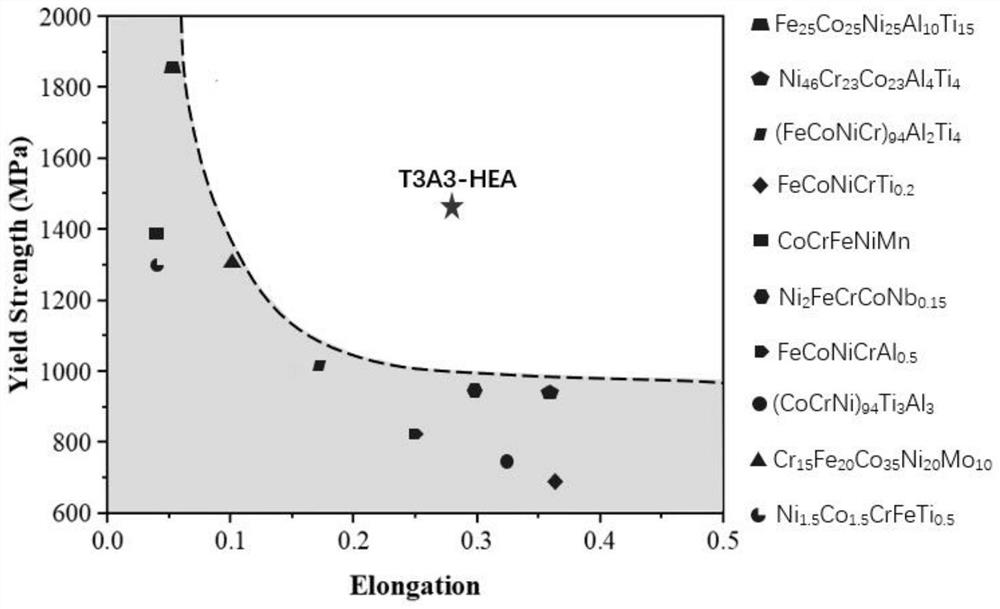

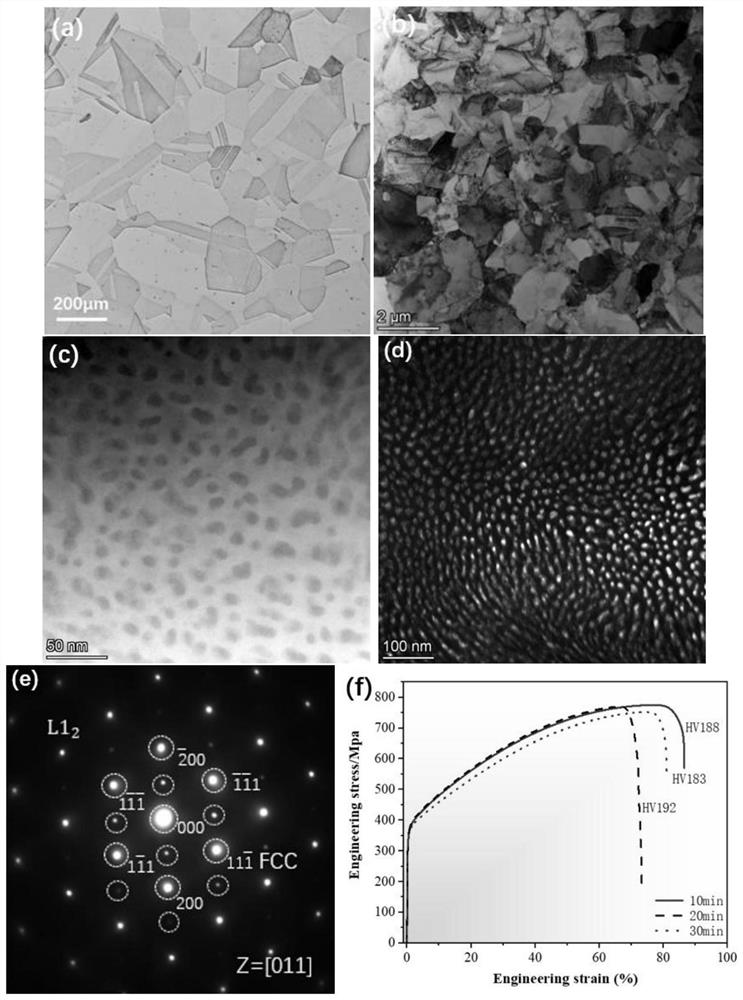

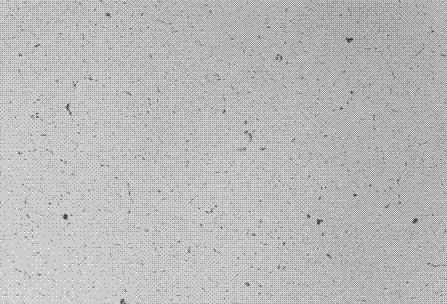

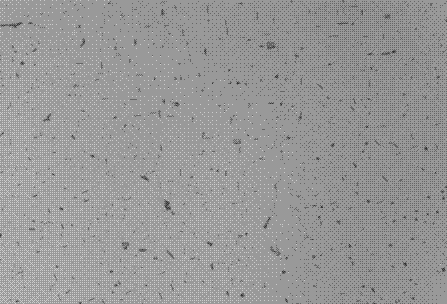

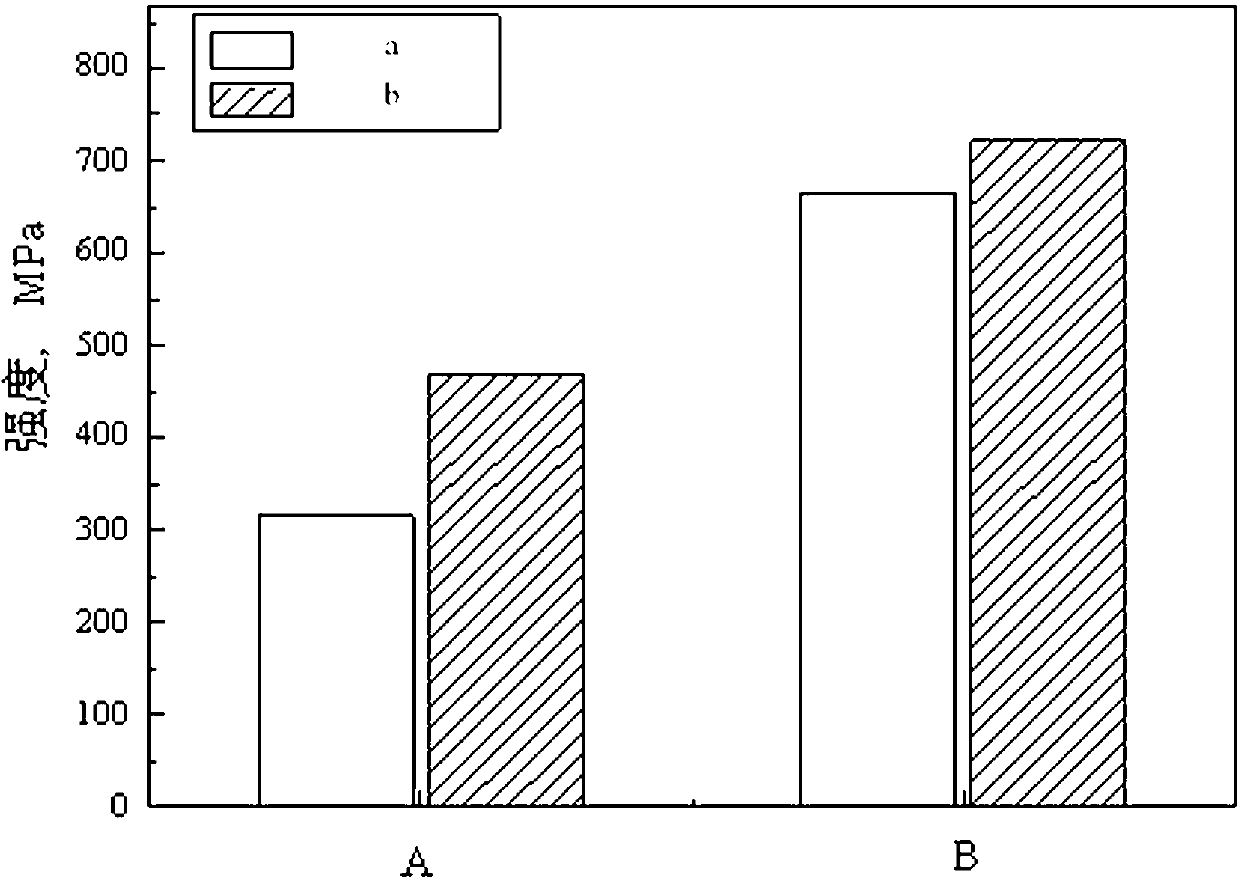

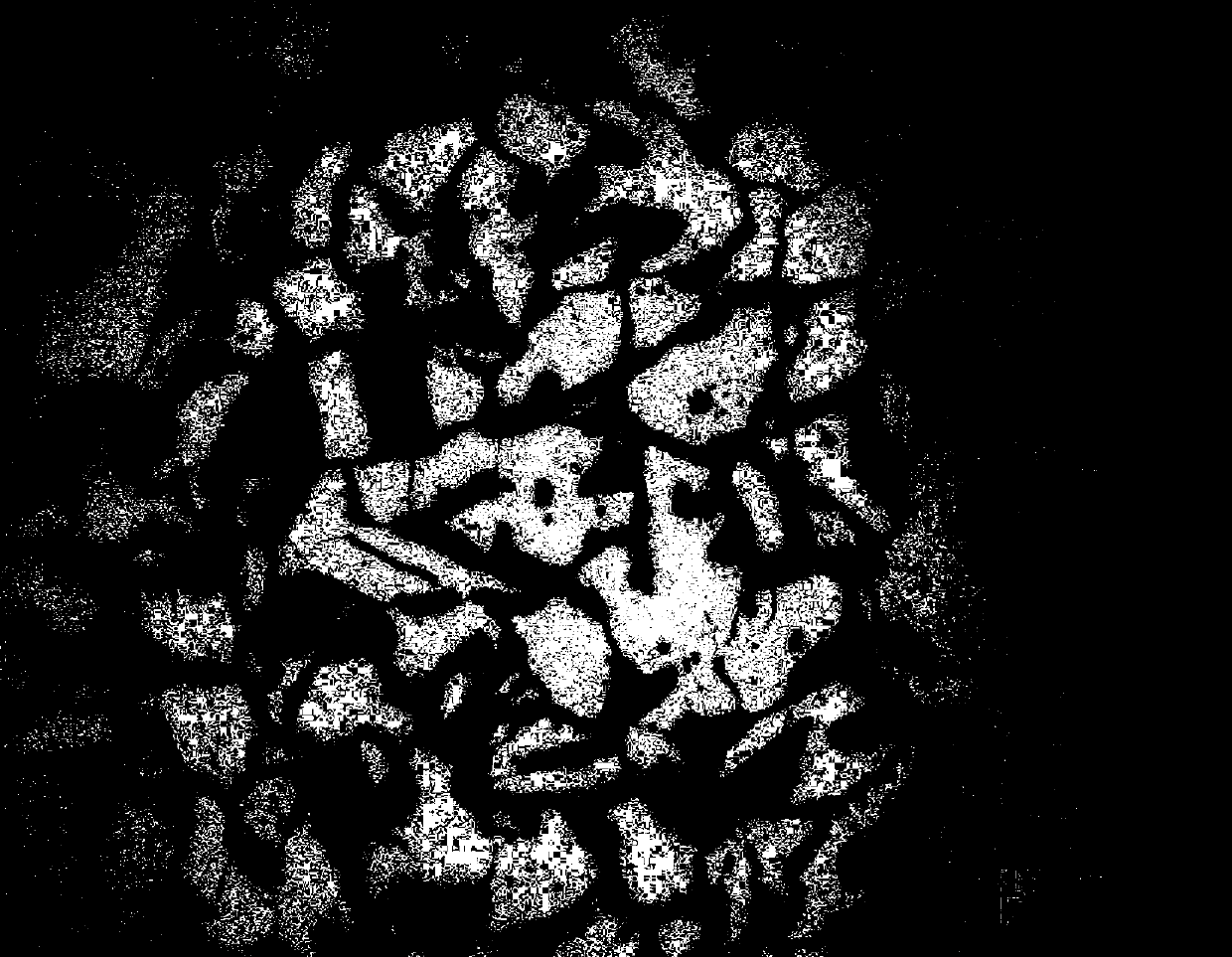

Novel treatment method for nano precipitation strengthened CoCrNi-based high-entropy alloy

ActiveCN113430343AGood strengthening effectHigh yield strengthMetal rolling arrangementsMechanical heat treatmentMachining deformation

The invention discloses a novel treatment method for a nano precipitation strengthened CoCrNi-based high-entropy alloy, and relates to the technical field of high-entropy alloys. The novel treatment method comprises the following steps that after an as-cast CoCrNi-based high-entropy alloy is subjected to homogenizing annealing for 1.5-3 h at the temperature being 1150-1250 DEG C, first-time machining deformation thinning is conducted till the thickness is 30-60% of that of the as-cast alloy, then recrystallization treatment is conducted for 8-15 min at the temperature being 1150-1250 DEG C, second-time machining deformation thinning is conducted till the thickness is 70-85% of that of the alloy subjected to first-time machining deformation, then aging treatment is conducted for 12-20 h at the temperature being 650-850 DEG C, and the strengthened CoCrNi-based high-entropy alloy is obtained. The room temperature rolling process is adopted twice in the mechanical heat treatment process of the CoCrNi-based high-entropy alloy, compared with an existing process, the strengthening effect is remarkable, the yield strength is improved by 400 MPa or above, and the maximum tensile strength is improved by 300 MPa or above.

Owner:SHAANXI UNIV OF SCI & TECH

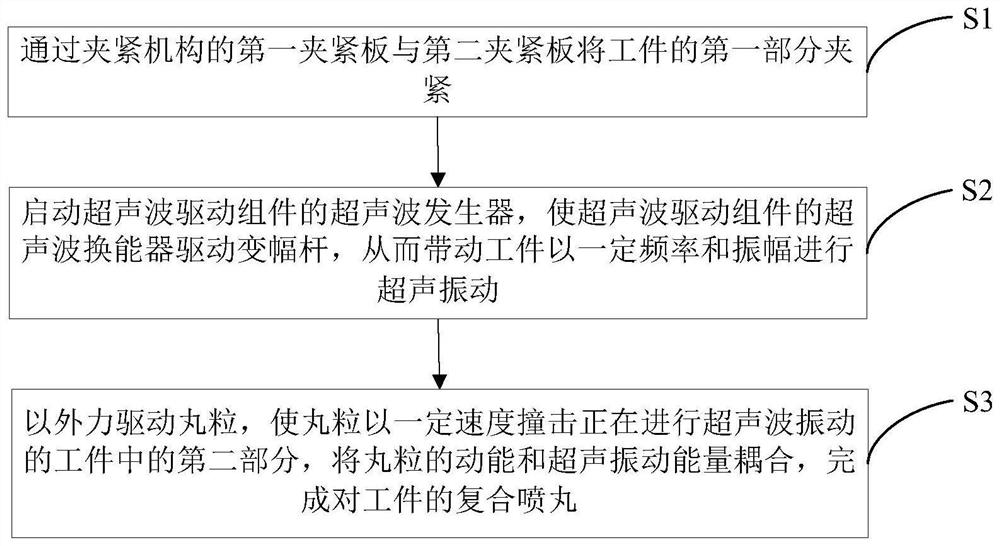

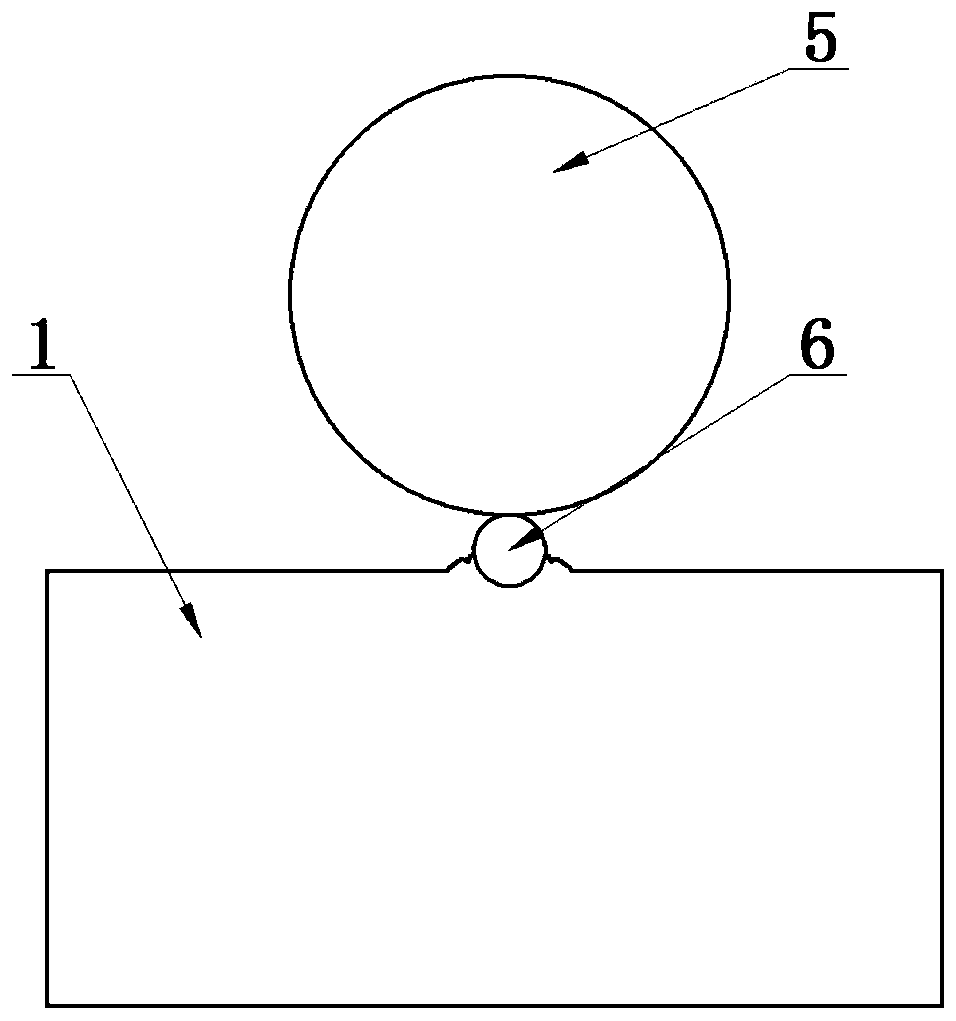

Composite shot blasting device and method utilizing pellet kinetic energy and ultrasonic vibration

ActiveCN111941288AReduce frictionAvoid collisionAbrasive machine appurtenancesAbrasive blasting machinesEngineeringUltrasonic vibration

The invention discloses a composite shot blasting device and method utilizing pellet kinetic energy and ultrasonic vibration. The device comprises an ultrasonic driving assembly, an amplitude-change pole and a clamping mechanism, wherein the clamping mechanism is used for clamping one part of a workpiece, the ultrasonic driving assembly is connected with the amplitude-change pole, the amplitude-change pole is fixedly connected with the clamping mechanism, and the ultrasonic driving assembly is used for driving the amplitude-change pole so as to drive the workpiece to perform ultrasonic vibration; and when the workpiece is subjected to ultrasonic vibration, pellets are driven by an external force to impact other parts of the workpiece except for the part clamped by the clamping mechanism. According to the device, the pellets with certain kinetic energy can impact the workpiece in ultrasonic vibration, the kinetic energy of the pellets and ultrasonic vibration energy are compounded, thesurface of a material is strengthened, the shot blasting strengthening effect is improved, a special sealing bin for placing the workpiece and the pellets for common ultrasonic shot blasting is not needed, and broken pellets can be cleaned up and separated in time, so that the cost is reduced, the working efficiency is improved, and the strengthening effect is enhanced.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of hot die-casting die surface coating

ActiveCN106399952AIncrease working temperatureMeet wear resistanceVacuum evaporation coatingSputtering coatingAbrasive blastingOxidation resistant

The invention relates to a preparation method of a hot die-casting die surface coating. The preparation method of the hot die-casting die surface coating comprises the following steps: blasting sand on the surface of a hot die-casting die, washing the surface of the hot die-casting die, then putting the hot die-casting die into an electric arc ion plating device, taking a rectangular Ti target as a Ti source of a bottom layer, mounting the rectangular Ti target on the left inner wall of a furnace body, controlling the evaporation rate of the rectangular Ti target through current of a rectangular Ti target electric arc power supply and preparing a Ti bottom layer on the surface of the hot die-casting die; then taking a circular CrAl target as Cr and Al element sources for preparing a CrAlN coating, wherein the atomic component ratio of the Cr to Al is expressed as Cr / Al and is 70 to 30, and controlling the evaporation rate of the CrAl target through current of a circular CrAl target electric arc power supply; taking high-purity N2 as reaction gas, ionizing the N2 and combining N2 with Cr and Al elements, and depositing N2 and the Cr and Al elements on the Ti bottom layer to form the CrAlN coating. The oxidation resistance temperature of the prepared CrAlN coating reaches 1100 DEG C; the hardness of the CrAlN coating reaches Hv3000; the requirements of abrasion resistance, fatigue resistance and oxidation resistance of the hot die-casting die can be well met; the CrAlN coating is suitable for strengthening the surface of the hot die-casting die under severe service conditions such as high temperature, high speed and heavy load and the like.

Owner:XIAN HAOYUAN COATING TECH

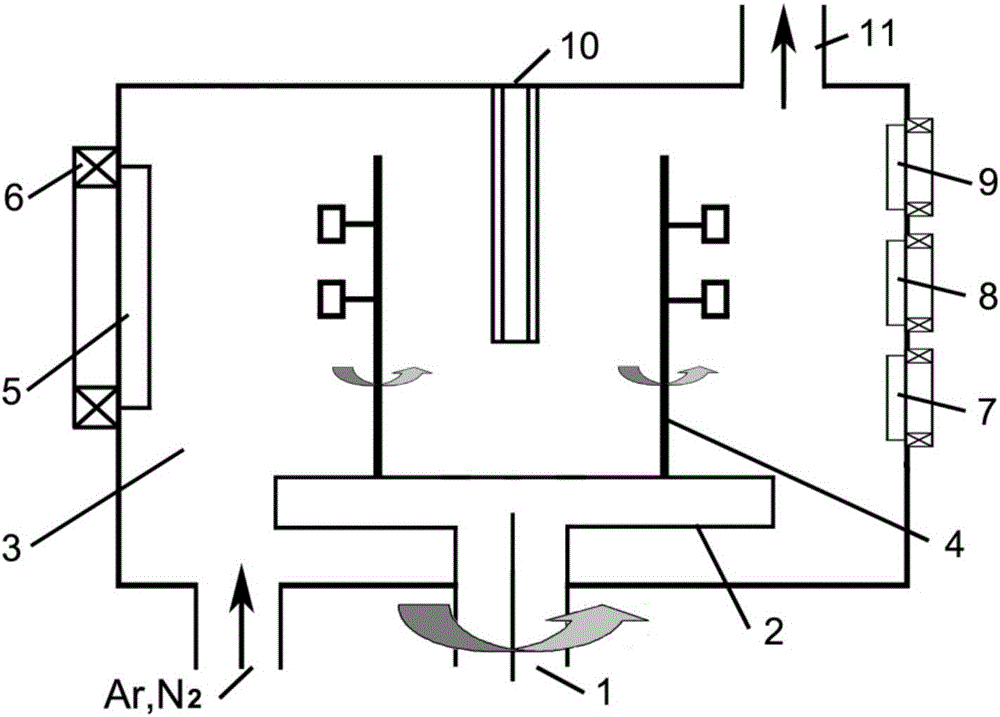

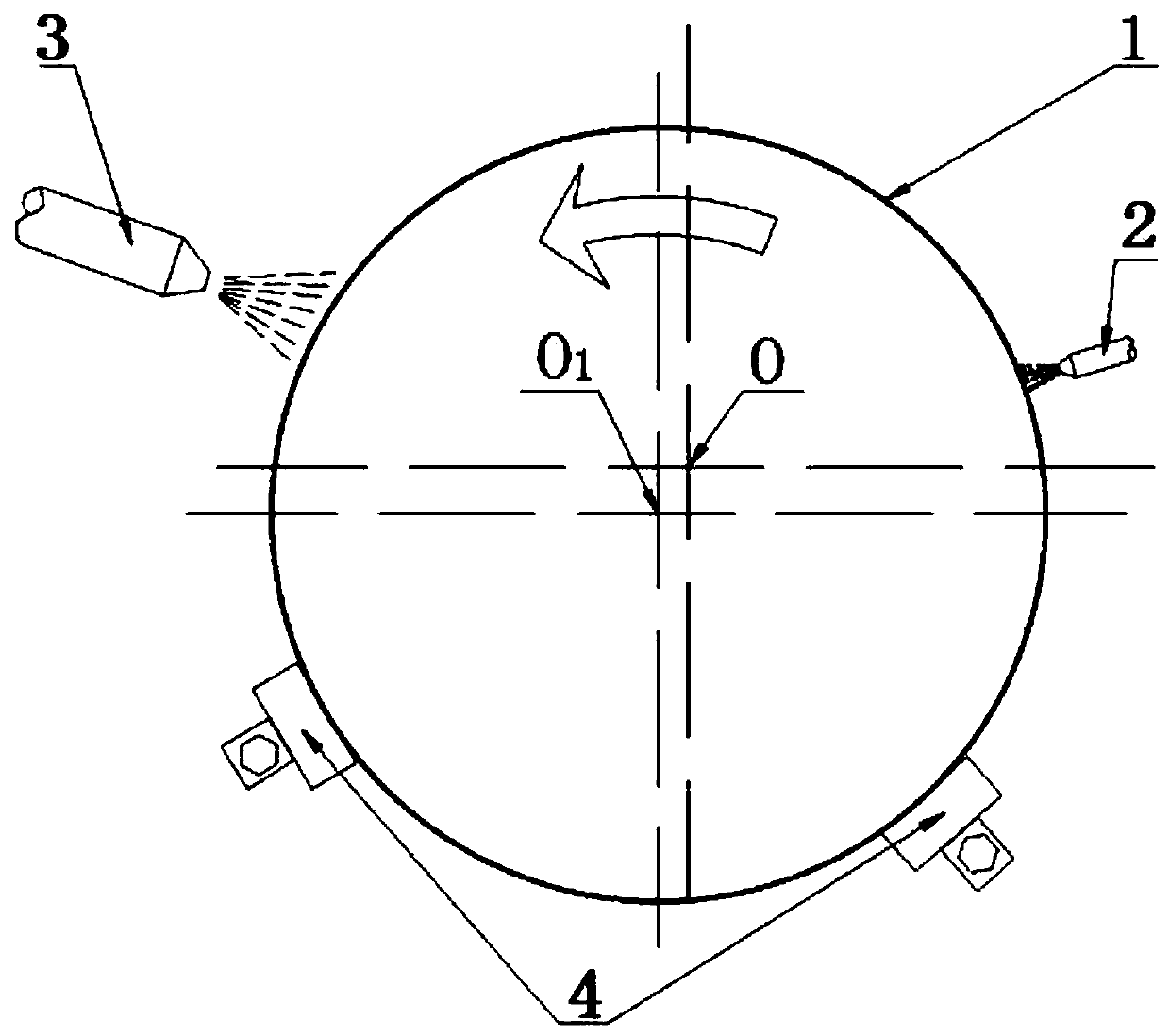

Coated type metal workpiece surface strengthening grinding processing method and device

ActiveCN110640635AAdhesion is stable and uniformThe effect of uniform strengthening processingAbrasive blasting machinesMachined surfaceSurface oxidation

The invention discloses a coated type metal workpiece surface strengthening grinding processing method and device. The processing method comprises the following steps that (1), a to-be-processed workpiece is clamped on an electromagnetic centerless clamp, and a high-speed nozzle and a coating head are aligned to the processing surface of the workpiece; (2), a rotary driving mechanism is started, so that the electromagnetic centerless clamp drives the to-be-processed workpiece to rotate; (3), a mixing and coating device is started, grinding powder and a grinding liquid are mixed, and a mixed grinding material is coated on the surface of the workpiece through the coating head, and the grinding liquid adheres the grinding powder to the surface of the workpiece; and (4), a high-pressure spraying device is started, steel balls are sprayed to the surface of the workpiece at high speed, the steel ball with the high-speed directly impacts the grinding powder, the surface of the workpiece is subjected to strong impact through the grinding powder, and the surface of the workpiece forms a reinforced grinding layer. According to the method, not only the enhanced grinding processing effect canbe ensured to be more uniform, but also the situation that the grinding material is diffused in the working environment to cause pollution is avoided, and meanwhile, the surface oxidation of the workpiece is avoided.

Owner:GUANGZHOU UNIVERSITY

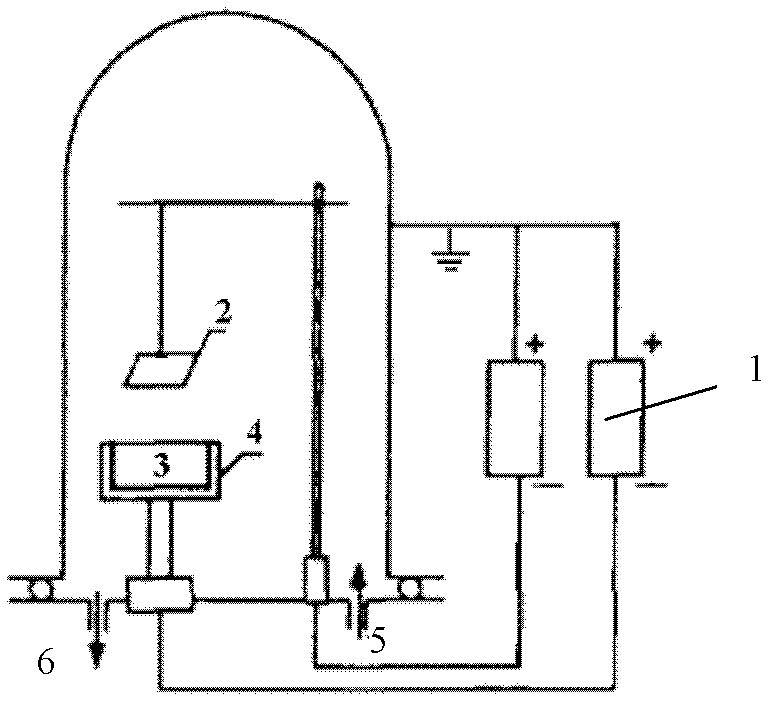

Preparation method of super-strong high-conductivity copper alloy serving as contact line material of high-speed railway with speed per hour being above 400 kilometers

Provided is a preparation method of a super-strong high-conductivity copper alloy serving as a contact line material of a high-speed railway with the speed per hour being above 400 kilometers. The copper alloy comprises, by weight, 3-20% of niobium, 0.01-1% of chromium, 0.01-0.5% of zirconium, 0.01-0.2% of titanium, and the balance copper. The preparation method comprises the steps that (1) simple substances and / or an intermediate alloy serve / serves as raw materials, the materials are fed according to the needed matching ratio, the materials are fused in a vacuum induction melting furnace and rapidly casted into a water-cooling copper mould, and the cooling speed is greater than 20 DEG C / s; (2) an ingot casting obtained in the step (1) is subjected to multi-pass drawing at a room temperature, deformation of a single pass of drawing is smaller than 0.3, and finally deformation of drawing above 3.5 is achieved; (3) a copper alloy bar or wire molded through drawing is annealed at 375-575 DEG C for 1-100 hours; (4) the annealed copper alloy is subjected to drawing at the room temperature again, deformation of a single pass of drawing ranges from 0.1 to 0.2, and deformation of drawing is 0.5-1.0; and (5) the copper alloy is put into liquid nitrogen to be subjected to freezing treatment for 12-72 hours, then the temperature is slowly increased to the room temperature, the temperature increasing rate is smaller than 10 DEG C / min, and the copper alloy is obtained.

Owner:ZHEJIANG UNIV

Method for diffusing and plating aluminum on surface of titanium-aluminium intermetallic compound

InactiveCN102586724AEnsure effectivenessEnsure persistenceSolid state diffusion coatingAlcladOxidation resistant

The invention relates to a method for diffusing and plating aluminum on the surface of a titanium-aluminium intermetallic compound, comprising the following steps of: placing a pure aluminium product in a conductive crucible to form a diffusing-plating source electrode, and then placing the crucible into a vacuum chamber, placing a titanium-aluminium intermetallic compound workpiece above the crucible and filling argon into the vacuum chamber, applying direct current negative voltage to smelt an aluminium product in the source electrode and keeping a discharging and sputtering state, and then, applying negative voltage to the titanium-aluminium intermetallic compound workpiece to raise the temperature of the workpiece to 700-1200 DEG C, keeping the temperature for 0.5-8 hours to complete diffusing and plating operation. The surface of a diffused and plated workpiece is provided with a high-temperature antioxidant protective layer with a settled layer and a diffusion layer, and 3-10mu m compact Al on the outer layer can give alloy to have sufficient oxidation resistance, and a 50-200mu m of diffusion layer below the settled layer can preventing Al atoms of the settled layer from diffusing rapidly to a matrix when in long-time high-temperature service and enhance the bonding force of the functional settled layer and the matrix.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Preparation method of high-strength and high-conductivity copper alloy serving as contact line material of high-speed rail with speed per hour of above 400 km

The invention discloses a preparation method of a high-strength and high-conductivity copper alloy serving as a contact line material of a high-speed rail with speed per hour of above 400 km. Components of the alloy alloy accord with a form of CuXY, wherein X is at least one of Ag, Nb and Ta; and Y is at least one of Cr, Zr and Si. The method comprises the following steps: a simple substance and / or raw materials of an intermediate alloy are fed in a vacuum smelting furnace according to a designed alloy component ratio for heating, melting and casting in a mold to obtain an ingot; the ingot is drawn by multiple times at room temperature to deform as a bar or a line; the section shrinkage of a sample reaches above 80%; then, the bar or the line is annealed; the alloy is drawn again; in the phase, the section shrinkage of the sample is within 50%; then, the liquid nitrogen freeze treatment is performed for the obtained alloy, so that remained X or Y solid soluble atoms in a copper matrix are continuously separated out; and then, the copper alloy is obtained through slowly heating to reach the room temperature.

Owner:ZHEJIANG UNIV

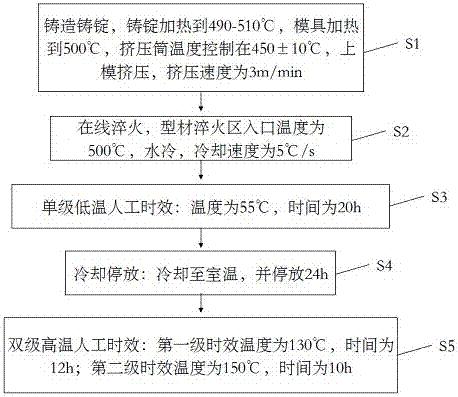

Preparation method of Al-Mg-Si alloy profile for high speed motor car

InactiveCN107164710AMeet the requirementsImprove mechanical propertiesSingle stageUltimate tensile strength

The invention discloses a preparation method of Al-Mg-Si alloy profile for a high speed motor car, and relates to the technical field of aluminum alloy preparation. A single-stage aging technology commonly adopted in present industrial production is adjusted from the original extrusion-online quenching-single-stage high temperature artificial aging to extrusion-online quenching-single-stage low temperature artificial aging-cooling and placing-double-stage high temperature artificial aging, matching with specific alloy components, through third-stage aging treatment, a second phase is more tiny and uniform after growing up, and accordingly the mechanical property of a T5 state of alloy is improved, the strength of the alloy reaches to or slightly higher than a common T6 state, and therefore the using requirement of the high speed motor car is met.

Owner:广西南南铝加工有限公司

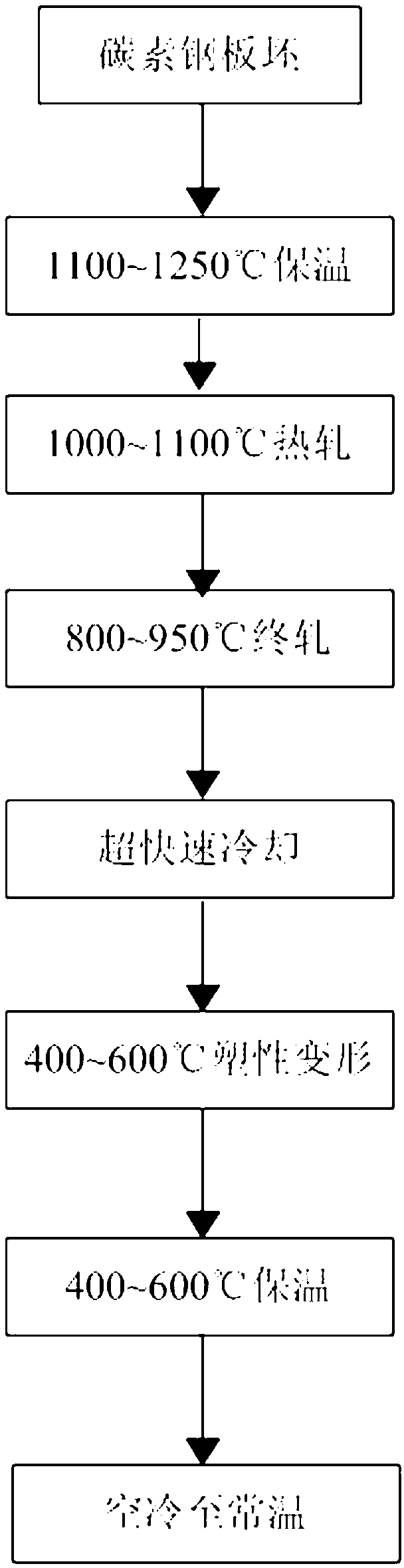

Method for enhancing strength of low-carbon and medium-carbon steel through nano carbide precipitation

The invention discloses a method for enhancing the strength of low-carbon and medium-carbon steel through nano carbide precipitation, belonging to the technical field of metallurgy. The method comprises the following steps of: (1) heating a carbon steel plate blank to 1100-1250 DEG C, and preserving the heat for 1-2 hours; (2) carrying out hot rolling at the temperature of 1000-1100 DEG C to obtain a hot rolled plate blank, wherein the accumulated reduction amount is 70-95%; (3) carrying out water cooling on the hot-rolled plate blank to 400-600 DEG C at the speed of 100-200 DEG C / s in a super rapid cooling way; (4) carrying out plastic deformation at the temperature of 400-600 DEG C, then, preserving the heat of 400-600 DEG C for 10-120 minutes, and then, carrying out air cooling to the room temperature, wherein the deformation amount is 2-10%. The method has the advantages that the traditional laminated structure of a pearlite in a common carbon steel tissue is changed through changing a process on the premise that no any microalloy elements are added, the nano carbide precipitation is realized, a uniform dispersed distribution effect is formed in the whole tissue, a remarkable enhancing effect is achieved, and the requirement for the strength of part of microalloy steel is met or exceeded.

Owner:NORTHEASTERN UNIV

Pulse electric field-traveling wave magnetic field composite method for reducing cracks of cladding layer

PendingCN110527999AImprove chargeabilityImprove flushing effectMetallic material coating processesNumerical controlElectromagnetic shielding

The invention discloses a pulse electric field-traveling wave magnetic field composite method for reducing the cracks of a cladding layer. The devices used in the method comprise a laser cladding numerical control device, a traveling wave magnetic field device and a positive and negative pulsed electric field device. During the cladding process, a traveling wave magnetic field is applied to a molten pool, so that the charged quantity of the non-magnetic particles and the charged particles in the molten pool is increased under the action of impressed current, the liquid metal particles are remarkably enhanced in Lorentz force in an external follow-up traveling wave magnetic field, the stirring effect on a molten pool is enhanced, the effects of fluid scouring, crushing and the like on dendrites are increased, the grain size is reduced, the fine grain strengthening effect is obvious, the defects, such as air holes, inclusions, component segregation, etc., are reduced, and the crack generation probability of a cladding layer is reduced. The composite device effectively solves the problems that the non-magnetic and charged particles are subjected to small Lorentz force in an electromagnetic field, and the electromagnetic stirring effect of the magnetic field on the molten pool is small.

Owner:魏永强

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com