Novel treatment method for nano precipitation strengthened CoCrNi-based high-entropy alloy

A high-entropy alloy and precipitation strengthening technology, applied in the field of high-entropy alloys, can solve the problems of limited alloy performance improvement, poor economy, complex process, etc., and achieve the effects of increased yield strength, significant strengthening effect, and improved tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

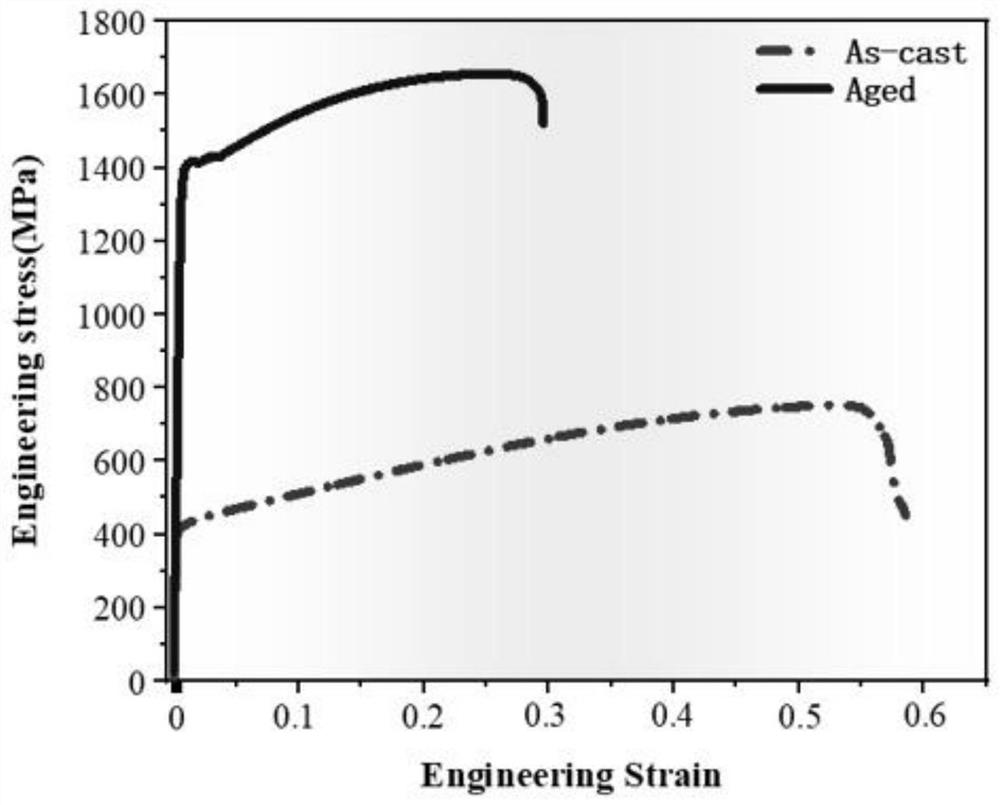

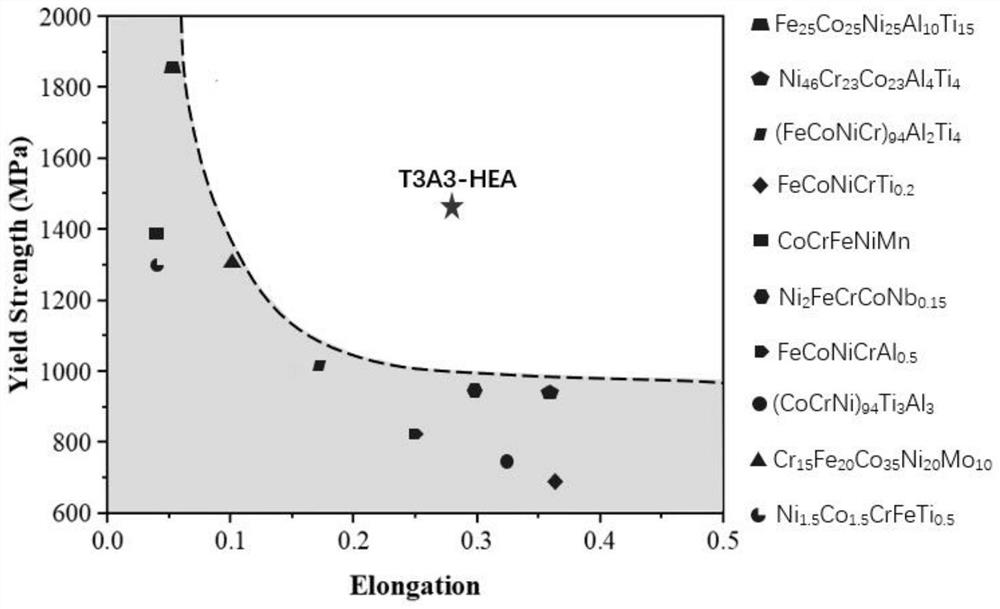

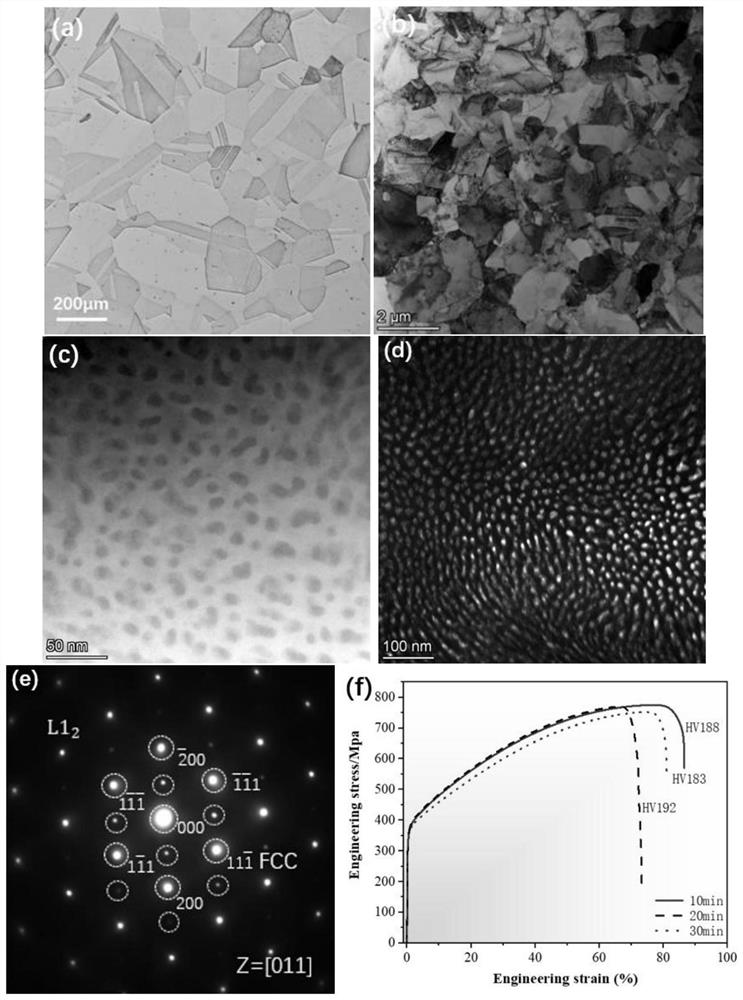

Embodiment 1

[0029] A treatment method for a novel nano-precipitation strengthened CoCrNi-based high-entropy alloy, comprising the following steps: casting Co 37 Cr 20 Ni 37 Ti 3 Al 3 For high-entropy alloys, put them into a 1200°C muffle furnace for homogenization annealing for 2 hours, put the annealed sample into cold water for quenching treatment; then carry out rolling at room temperature to reduce the thickness by 50%; put the thinned sample into a 1200°C muffle furnace Recrystallization treatment was carried out for 10 minutes, and the recrystallized sample was quenched in cold water; rolled again at room temperature to reduce the thickness by 80%, and finally put the sample in a muffle furnace at 700°C for aging treatment for 16 hours, took out the aged sample and put it in cold water Water quenching and cooling can strengthen Co 37 Cr 20 Ni 37 Ti 3 Al 3 High entropy alloy (T3A3-HEA).

Embodiment 2

[0031] Same as Example 1, except that the recrystallization treatment was performed for 20 minutes.

Embodiment 3

[0033] Same as Example 1, except that the recrystallization treatment was 30 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com