Method for enhancing strength of low-carbon and medium-carbon steel through nano carbide precipitation

A low-carbon steel, high-strength technology, applied in the field of metallurgy, can solve the problem that the strengthening effect is not very obvious, and achieve the effect of improving the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

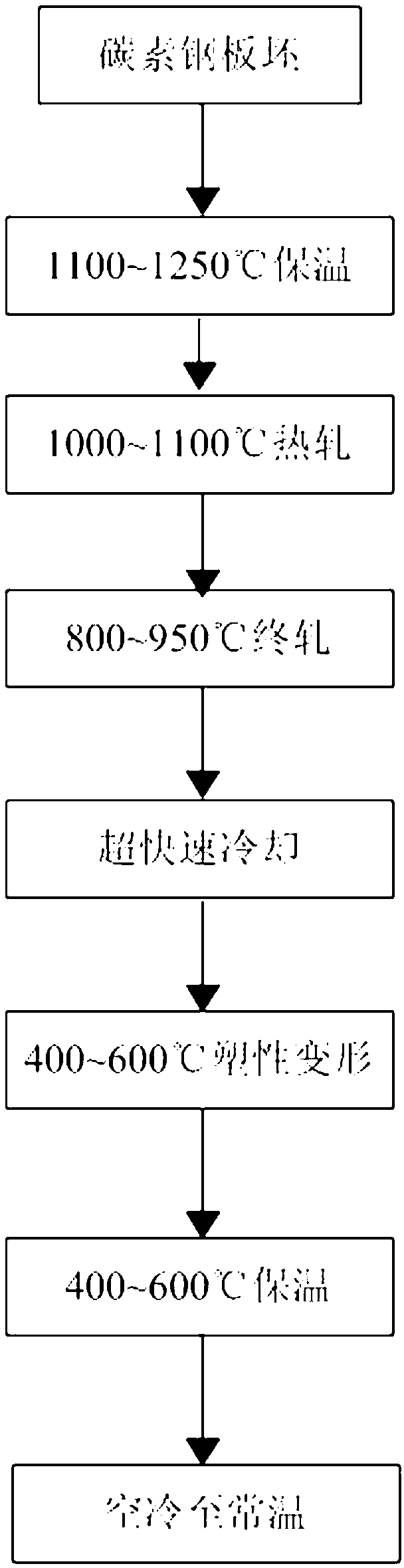

Method used

Image

Examples

Embodiment 1

[0026] The thickness of the carbon steel slab used is 70mm, and the composition is C 0.17%, Si 0.19%, Mn 0.7%, P 0.002%, S0.002% by weight percentage, and the balance is iron;

[0027] Heat the carbon steel slab to 1200°C and keep it warm for 1h;

[0028] The heated carbon steel slab is hot-rolled at 1100°C with a rolling mill, the cumulative reduction is 90%, and the final rolling temperature is 890°C to obtain a hot-rolled slab;

[0029] The hot-rolled slab is water-cooled to 500°C at a rate of 100-120°C / s by using an ultra-rapid cooling method;

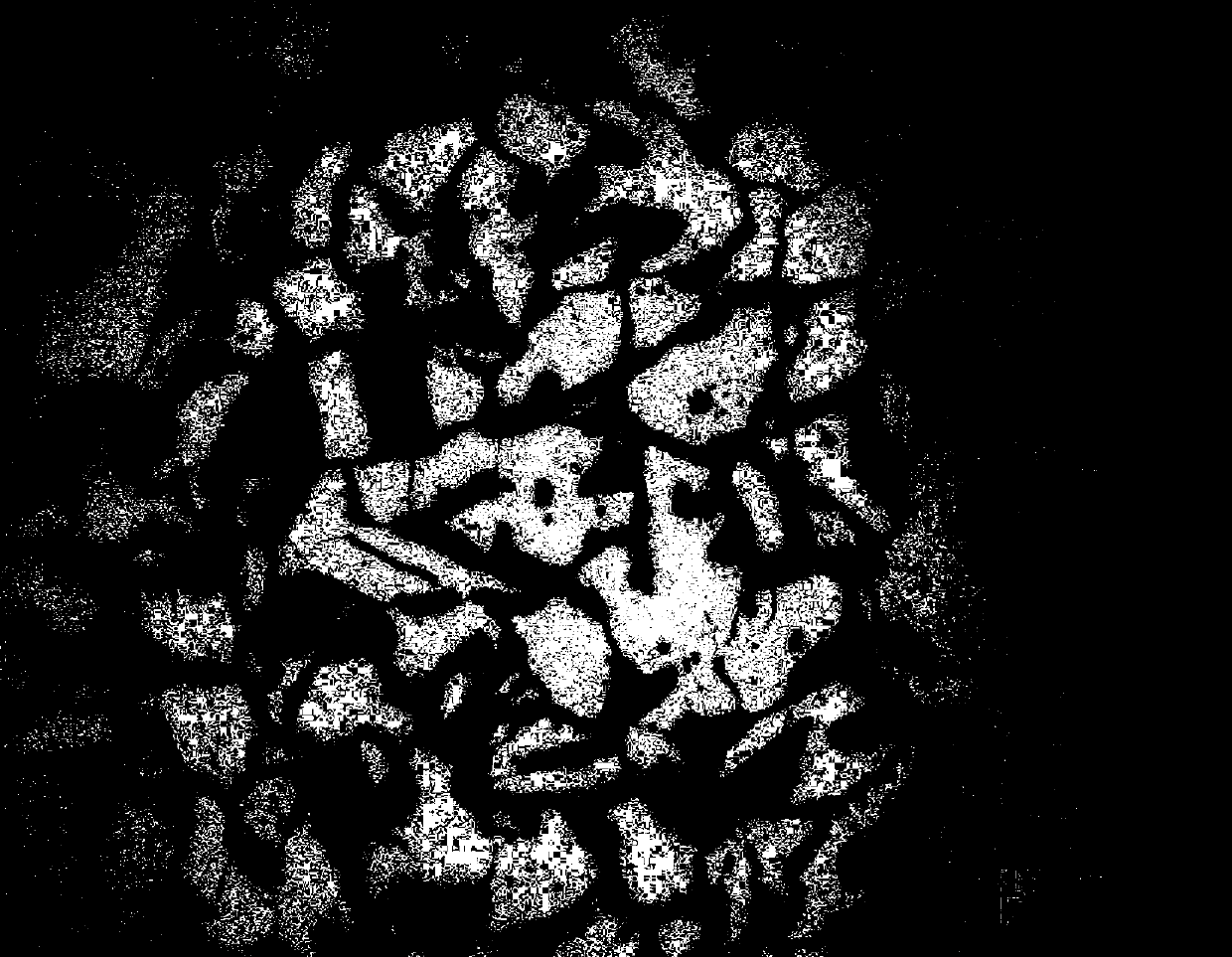

[0030] Using a rolling mill, the water-cooled hot-rolled slab is subjected to single-pass plastic deformation at 500°C, with a deformation of 7%, and then kept at 500°C for 60 minutes, and then air-cooled to room temperature to obtain high-strength carbon steel. Its structure is uniform lath bainite, and its morphology is as follows: Figure 4 As shown, the volume fraction of nano-cementite particles reaches 10%; nano-cementite p...

Embodiment 2

[0034] The thickness of the carbon steel slab used is 80mm, and the composition is C 0.19%, Si 0.3%, Mn 0.7%, P 0.002%, S0.004% by weight percentage, and the balance is iron;

[0035] Heat the carbon steel slab to 1200°C and keep it warm for 1h;

[0036] The heated carbon steel slab is hot-rolled at 1100°C with a rolling mill, the cumulative reduction is 90%, and the final rolling temperature is 890°C to obtain a hot-rolled slab;

[0037] The hot-rolled slab is water-cooled to 450°C at a rate of 100-120°C / s by means of ultra-rapid cooling;

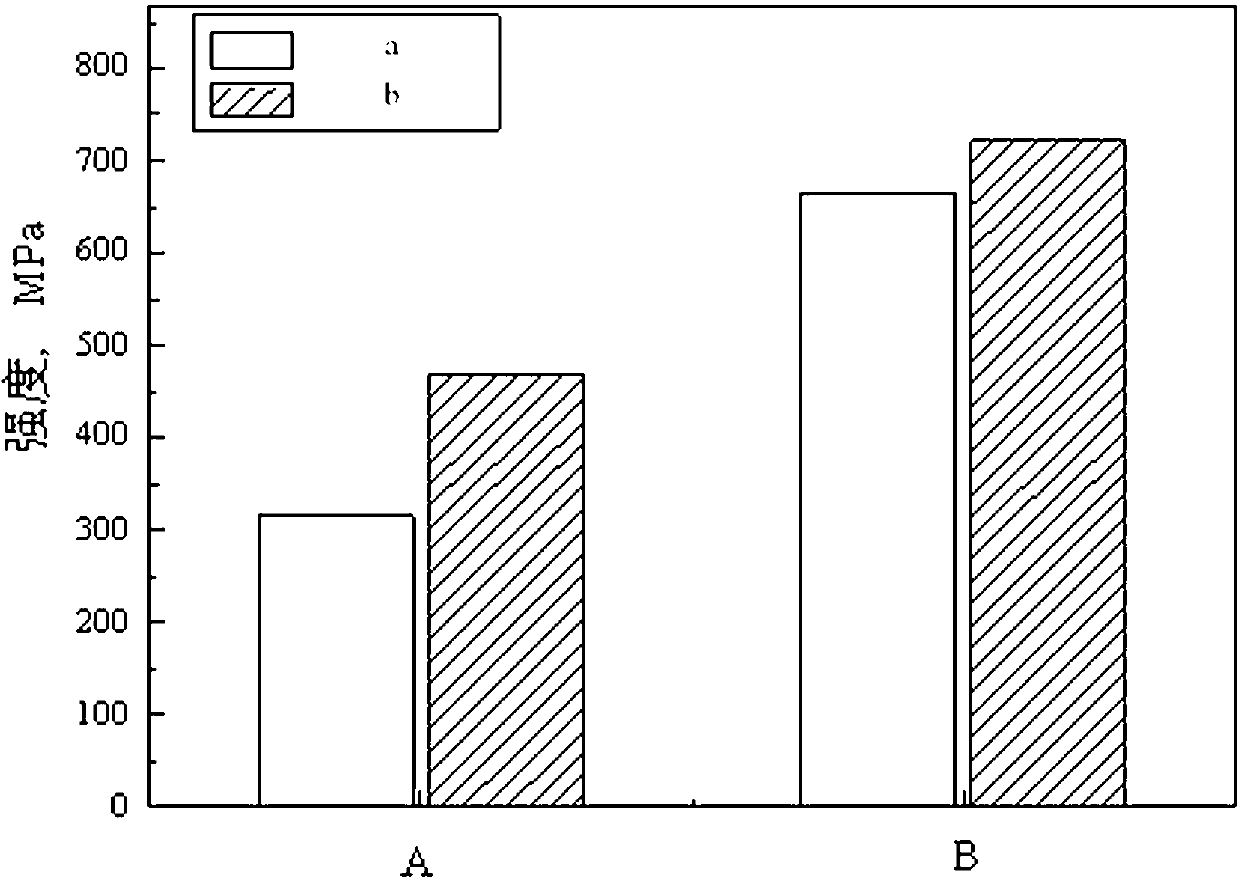

[0038]Using a rolling mill, the water-cooled hot-rolled slab is subjected to single-pass plastic deformation at 450°C, with a deformation of 6%, and then kept at 500°C for 20 minutes, and then air-cooled to room temperature to obtain high-strength carbon steel. Its structure is bainite, and dispersed nano-scale cementite particles are precipitated in the structure of the material, with a particle size of 5-30nm; the yield strength of high...

Embodiment 3

[0040] The thickness of the carbon steel slab used is 40mm, and the composition is C 0.15%, Si 0.23%, Mn 0.7%, P 0.003%, S0.002% by weight percentage, and the balance is iron;

[0041] Heat the carbon steel slab to 1200°C and keep it warm for 1h;

[0042] The heated carbon steel slab is hot-rolled at 1100°C with a rolling mill, the cumulative reduction is 90%, and the final rolling temperature is 880°C to obtain a hot-rolled slab;

[0043] Using ultra-rapid cooling method, the hot-rolled slab is water-cooled to 600°C at a speed of 150-200°C / s;

[0044] Using a rolling mill, the water-cooled hot-rolled slab is subjected to single-pass plastic deformation at 600°C, with a deformation of 7%, and then kept at 600°C for 20 minutes, and then air-cooled to room temperature to obtain high-strength carbon steel. It is mainly a degenerated pearlite structure, in which dispersed nano-scale cementite particles are precipitated, and the particle size of the cementite particles is 5-50nm; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com