Preparation method of high-strength and high-conductivity copper alloy serving as contact line material of high-speed rail with speed per hour of above 400 km

A technology of copper alloy and alloy, which is applied in the field of preparation of Cu alloy, can solve the problems such as the inability to meet the minimum requirements of contact wire material properties, and achieve the effects of preventing spheroidization, reducing solid solubility, and high resistance to softening temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

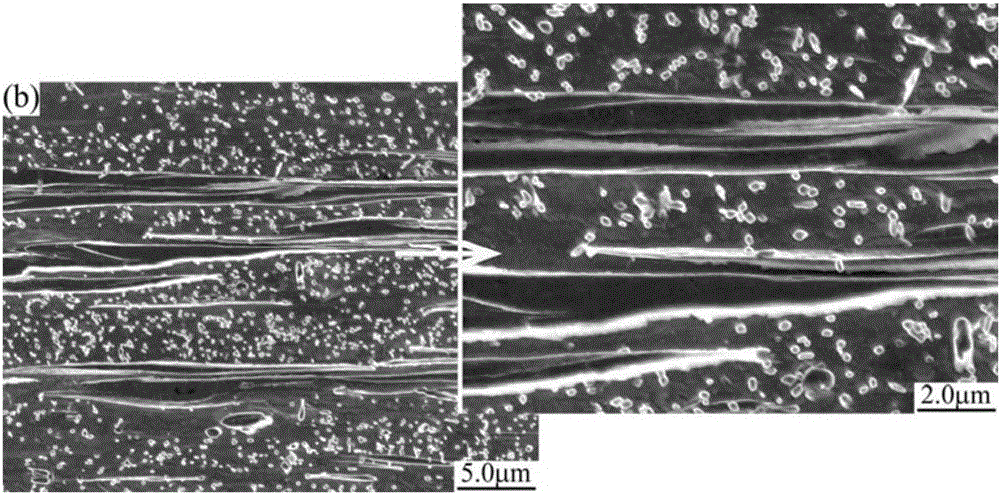

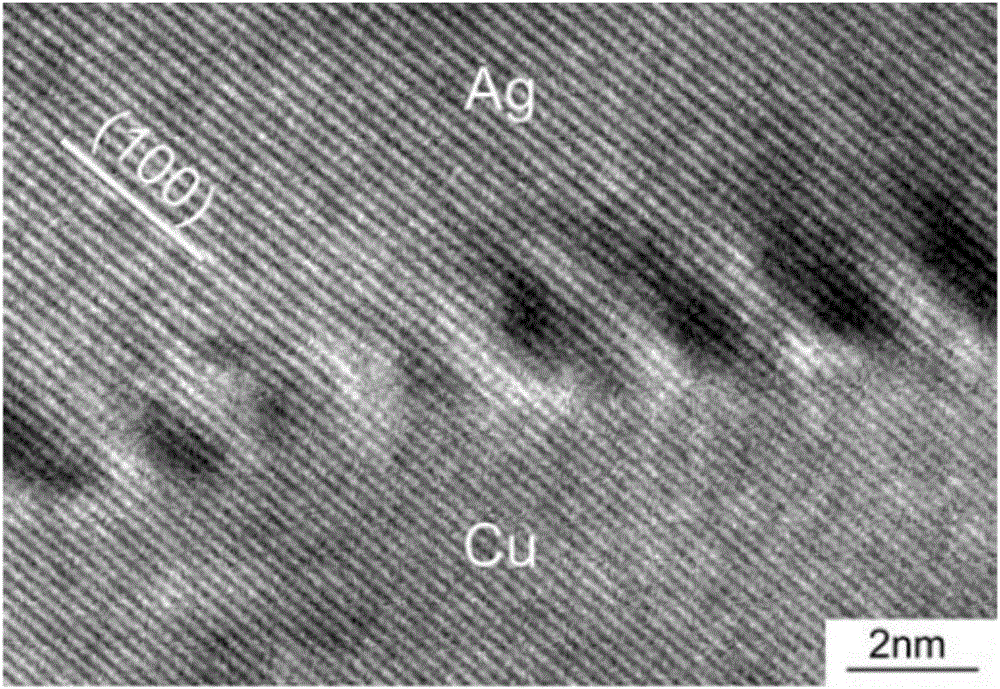

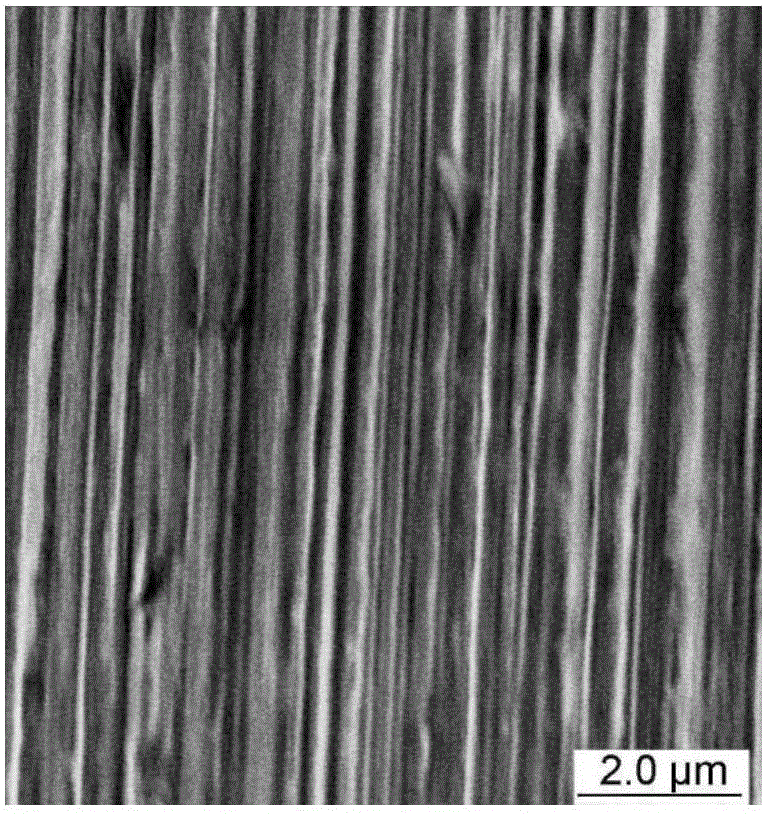

[0031]Using pure Cu, pure Ag, pure Cr, pure Zr and pure Si as raw materials, the vacuum melting furnace was used to heat up and melt and cast to obtain Cu-12%Ag-0.3%Cr-0.1%Zr-0.05%Si cast rods. Multi-pass drawing at room temperature makes the area shrinkage rate reach 80%. The obtained sample was annealed at 300 °C for 24 h, and then continued to be drawn at room temperature. At this stage, the area shrinkage rate was 50%. Finally, the sample was placed in liquid nitrogen for 24 h and then returned to room temperature at a rate of 10 °C / min to make the obtained alloy Contains a large number of fine Ag nanofibers and Cr, Zr, Si nanoparticles. The average diameter of nanofibers is 50 nm, the length is greater than 2000 nm, the distance between fibers is less than 1000 nm, and the interface between the fiber and the copper matrix is a semi-coherent interface, and there is a misfit dislocation for every 9 (111) atomic planes of Cu on the interface . The average diameter of Cr,...

Embodiment 2

[0033] Using pure Cu, Cu-20%Nb master alloy, Cu-5%Cr master alloy, pure Zr and pure Si as raw materials, using a vacuum melting furnace to heat up and melt and cast to obtain Cu-12%Nb-1%Cr-0.2%Zr- 0.1% Si cast rod, multi-pass drawing of the cast rod at room temperature to make the area shrinkage rate reach 85%. Afterwards, the sample was annealed at 320 °C for 16 h, and the obtained sample was drawn again. At this stage, the area shrinkage rate was 30%. Finally, the sample was placed in liquid nitrogen for 100 h, and then the temperature was raised at 5 °C / min to return to room temperature. The resulting alloy contains a large number of fine Nb nanofibers and Cr, Zr, Si nanoparticles. The average diameter of the nanofibers is 100 nm, the length is greater than 1000 nm, and the distance between the fibers is less than 8000 nm, and the interface between the fiber and the copper matrix is a semi-coherent interface, and a misfit dislocation appears every 13 (111) atomic planes o...

Embodiment 3

[0035] Using pure Cu, pure Ag, Cu-15%Ta master alloy, and Cu-3%Cr master alloy as raw materials, the vacuum melting furnace is used to heat up and melt and cast to obtain Cu-6%Ag-6%Ta-0.1%Cr cast rods. The cast rod is drawn for multiple times at room temperature to make the area shrinkage rate reach 85%. Afterwards, the sample was annealed at 400°C for 8 hours, and the obtained sample was drawn again. At this stage, the area shrinkage rate was 40%. Finally, the sample was placed in liquid nitrogen for 1 hour, and then the temperature was raised at 2°C / min to return to room temperature, so that the obtained alloy Contains a large number of fine Ag and Ta nanofibers and Cr nanoparticles. The average diameter of the nanofibers is 100 nm, the length is greater than 1000 nm, the distance between the fibers is less than 1000 nm, and the interface between the fiber and the copper matrix is a semi-coherent interface, and there is a fault at every 9 Cu (111) atomic planes on the Cu / A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com