Pulse electric field-traveling wave magnetic field composite method for reducing cracks of cladding layer

A technology of traveling wave magnetic field and pulsed electric field, which is applied in the field of material surface modification, can solve the problems of not considering the cladding speed of laser cladding and the short existence time of molten pool, and achieve the increase of pore rising and escape time and the number of crystal nuclei Increase, the effect of particle charging ability enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

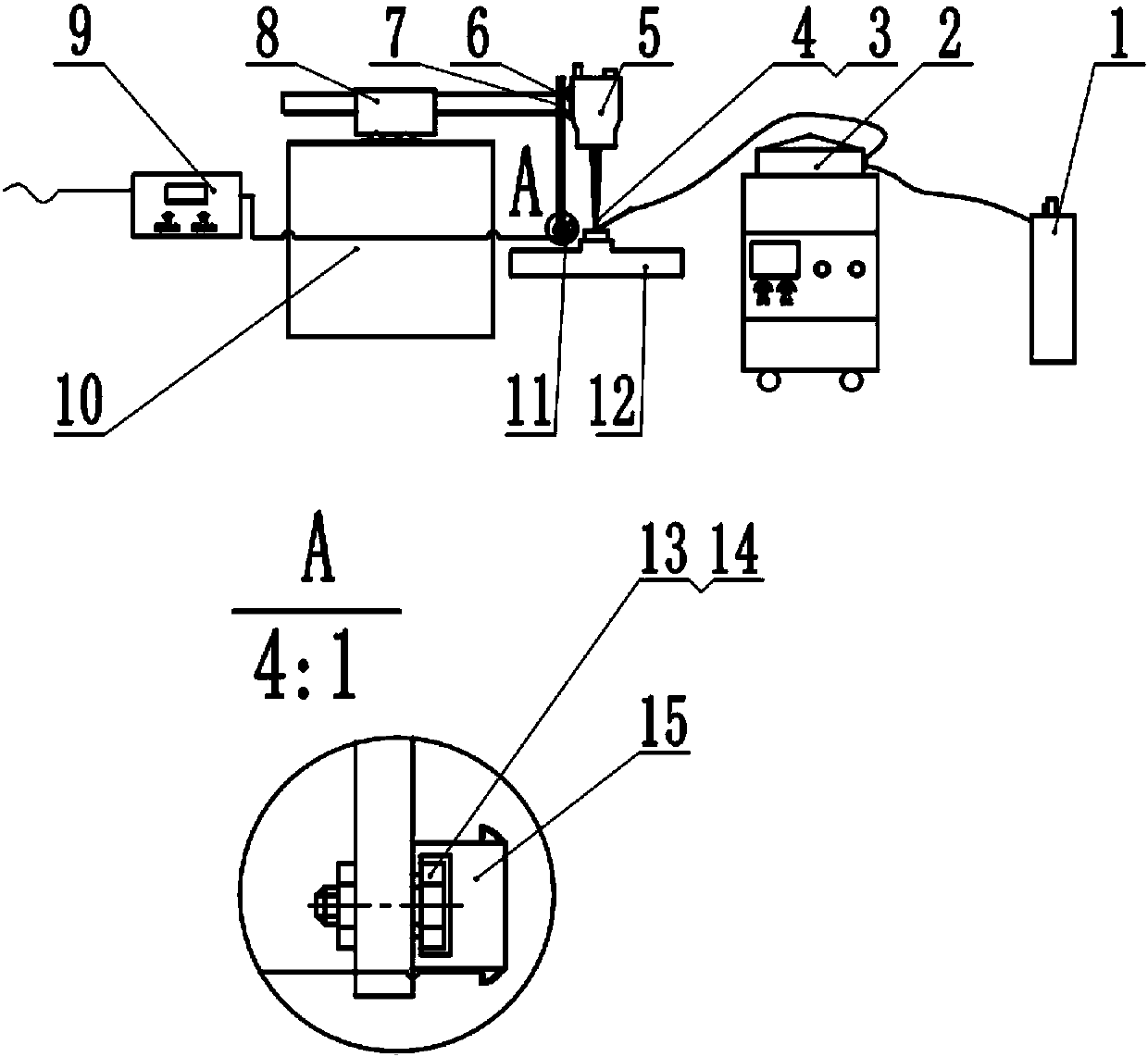

[0029] 1. Fix Q235 (chemical composition percentage Wt%: 0.5Mn, 0.3Si, 0.2C, 0.05S, 0.045P, Fe balance) substrate plate with a size of 100mm*20mm*20mm (length*width*height) Place it on the workbench, fine-tune the relative position of the electrode substrate and the numerical control device, so that the focus of the laser beam is located at the center of the rectangular through hole. Adjust the position of the connecting lug so that the distance between the two electrode rollers is d 1 25mm, adjust the position of the fastening nut on the electrode column, so that the electrode roller is pressed against the upper surface of the substrate;

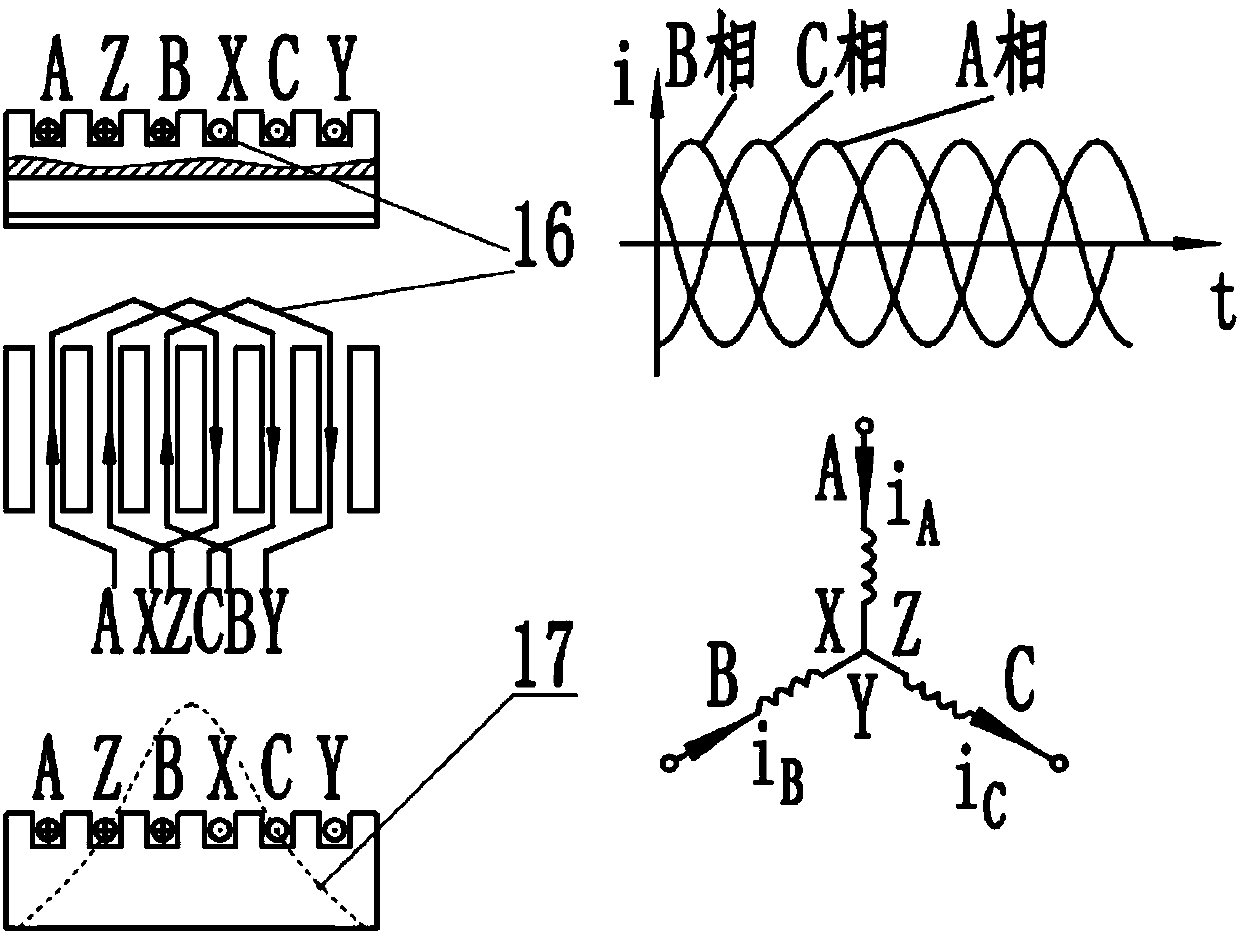

[0030] 2. Turn on the positive and negative pulse electric field power switch, so that the amplitude of the positive and negative pulse current passing through the workpiece is ±5kA, and the period T is 0.008s. After the positive and negative pulse current output by the electric field device is stable, turn on the traveling wave magnetic fi...

Embodiment 2

[0033] Method is all identical with embodiment 1, only embodiment 1 the 1st walking wave magnetic field power source control device makes each phase energization frequency be 80Hz, each phase energization current i A (or i B i C ) for 3A.

Embodiment 3

[0035] The method is the same as that of Example 1, only the second step of Example 1 makes the amplitude of the positive and negative pulse current passing through the workpiece be ±8kA, the period T is 0.008s, and the traveling wave magnetic field power supply control device makes the energization frequency of each phase be 80Hz, and each phase is connected electric current i A (or i B i C ) for 3A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com